Page 1

CRT Monitor

Service Guide

Diamond View Model

1995SL

November 2000

Distributed by

Mitsubishi Electric Australia Pty. Ltd.

A.B.N. 58 001 215 792

348 Victoria Road

RYDALMERE NSW 2116

Australia

Telephone 1300 651 808

Page 2

Copyright

Copyright ã 1996 by the Company. All rights reserved. No part of this publication may be

reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language or

computer language, in any form or by any means, electronic, mechanical, magnetic, optical,

chemical, manual or otherwise, without the prior written permission of the Company.

Disclaimer

The Company makes no representations or warranties, either expressed or implied, with respect to

the contents hereof and specifically disclaims any warranties, merchantability or fitness for any

particular purpose. Further, the Company reserves the right to reserve this publication and to make

changes from time to time in the contents hereof without obligation of the Company to notify any

person of such revision or changes.

ii

Page 3

Section

Diamond View CRT Monitor

1995SL

Manual Contents

1. Engineering Specifications

2. Circuit Operation Theory

3. Alignment procedure

4. Trouble Shooting

5. Parts List

6. Schematic Diagrams

7. Assembly

iii

Page 4

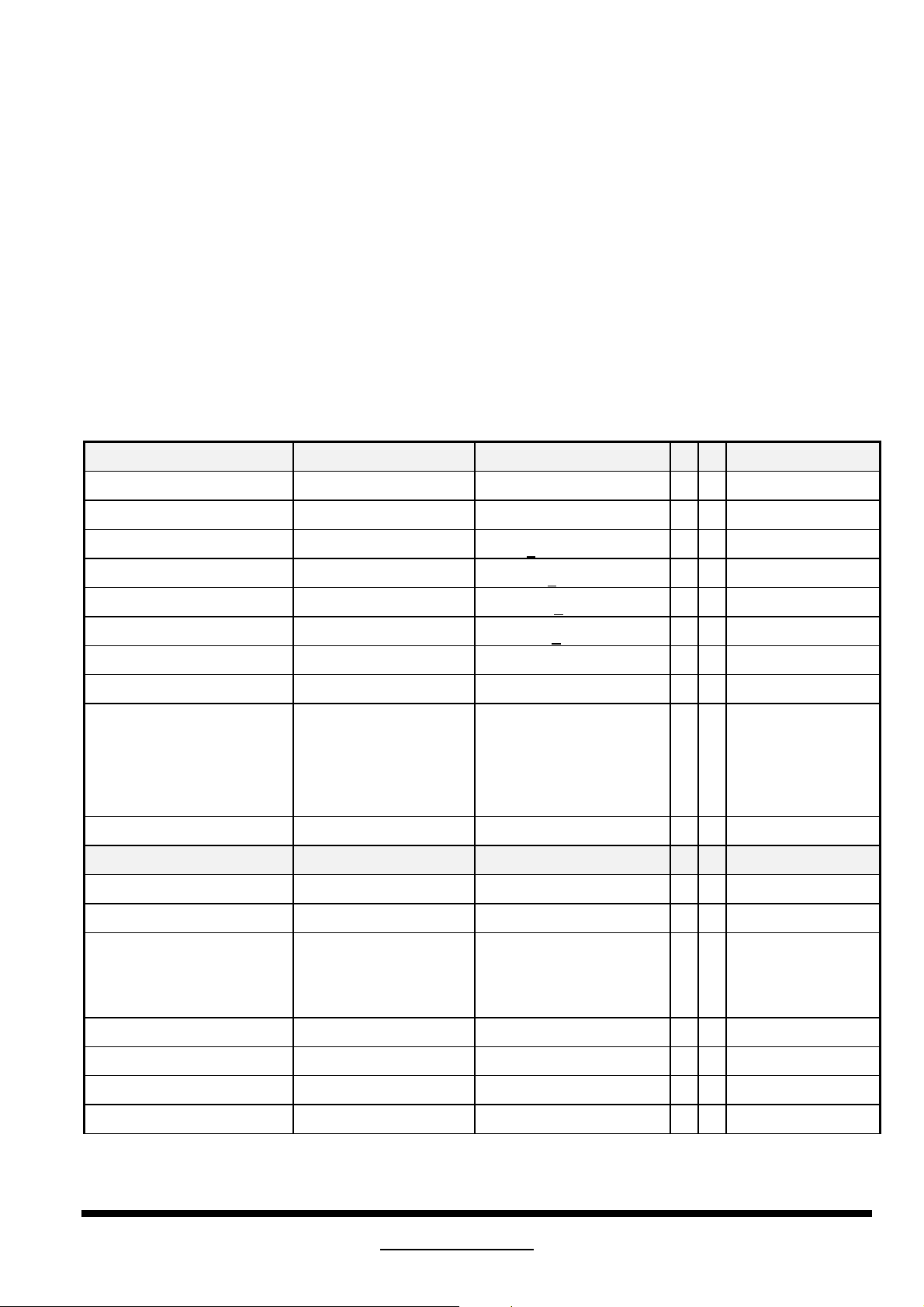

1995SL CRT Monitor Service Guide

Chapter 1 Engineering Specification

Table of Contents

0. Introduction :.....................................................................................................................................3

1. ELECTRICAL CHARACTERISTICS ................................................................................................3

1.1 Power Supply.......................................................................................................................3

1.2 Signal Interface....................................................................................................................3

1.3 Scan Range.........................................................................................................................4

1.4 Video Performance..............................................................................................................4

1.5 Timings ................................................................................................................................4

2.ENVIRONMENT & RELIABILITY ......................................................................................................5

3.CRT CHARACTERISTICS ................................................................................................................5

4.FRONT OF SCREEN ........................................................................................................................6

4.1 Geometry.............................................................................................................................6

4.2 Sharpness Crispness...........................................................................................................6

4.3 Light Quality.........................................................................................................................6

4.4 Image Stability .....................................................................................................................7

5. USER CONTROLS...........................................................................................................................8

5.1 Basic....................................................................................................................................8

5.2 Advanced.............................................................................................................................8

6. MECHANICAL CHARACTERISTICS...............................................................................................8

6.1 Dimension............................................................................................................................8

6.2 Weight..................................................................................................................................9

6.3 Plastic ..................................................................................................................................9

6.4 Carton..................................................................................................................................9

7. Pallet & Shipment.............................................................................................................................10

7.1 Dimension............................................................................................................................10

7.2 Shipping Container ..............................................................................................................10

7.3 Air Transport Container .......................................................................................................11

8. CERTIFICATION..............................................................................................................................11

9. Appendix...........................................................................................................................................12

Table 1 - DDC Table..................................................................................................................12

Table 2 - CRT Blemish & Scratch Spec ....................................................................................21

Table 3 - OSD Menu..................................................................................................................21

Table 4- Geometry Fig...............................................................................................................22

Fig.1 Linearity Measurements

Fig.2 General Pincushion Measurements

Fig.3 Trapezoid Measurements

................................................................................22

................................................................23

.................................................................................24

1

Page 5

1995SL CRT Monitor Service Guide

Table of Contents

Chapter 1 Engineering Specification

Fig.4 Picture Distortion & Phase Measurements

Fig.5 TCO 99 Pincushion Measurements

Fig.6 TCO 99 Barreling Measurements

Table 5 - TCO 99 Spec..............................................................................................................28

A. Ecology

B. CRT Display

.....................................................................................................................28

.............................................................................................................29

................................................................26

...................................................................27

.................................................25

2

Page 6

1995SL CRT Monitor Service Guide

Chapter 1 Engineering Specification

0. Introduction :

The subject model is designed for a value line 19” color monitor. It has the following figures :

0.26mm dot pitch , short length CRT, 176MHz video bandwidth ,1600X1200 max resolution.

Low radiation TCO99 standard,

ISO 14000 certificated green design. (Refer Table 5)

Optional items : E2000 USB.

1. ELECTRICAL CHARACTERISTICS

1.1 Power Supply

Voltage Universal input full range 90~264VAC /47~63Hz

Input Current 90 ~ 264VAC 4.0 Arms

Power consumption On < 120 W max

DPMS Standby < 15 W

Suspend < 5W

Off < 5 W

Inrush Current 220VAC/50Hz 50 Amp peak

Leakage Current 264 VAC/50Hz < 3.5mA

Hi-Pot 1. 1500VAC, 100mA, 1

sec

2. Ground test : 30A,

1sec

Power cord Length : 1800 mm Color : Flint Gray

1.2 Signal Interface

Pin assignment 5V on Pin 9

Condition Spec

w/o damage

< 0.1 ohm

Condition

Spec

OK

N.A

9

9

9

LED : Green

9

LED : Amber

9

LED : Amber Blink

9

LED : Amber Blink

9

Cold start

9

9

(in-line test)

9

KC-003

OK

N.A

9

Remark

(in-lab test)

Remark

Video input Level / Impedance 700mV / 75 Ohm

Sync input Level TTL-Positive/Negative

Impedance 50 Ohm on H-sync cable 9

Signal Cable D-Sub 1.5mm +/- 20mm

BNC

Color Flint Gray

9

9

9

9

9

0.7μs<H-sync width<25%

of H period 2s<V-sync

width< 400μs

3

Page 7

1995SL CRT Monitor Service Guide

Chapter 1 Engineering Specification

1.3 Scan Range

Horizontal 30 ~ 95 KHz

Vertical 50~ 160 Hz

1.4 Video Performance

Dot Rate 176 MHz

Max. Resolution 1600 x 1200

Rise time/Fall time 6ns

Video Ringing 10% max

Sag 5% max

Bandwidth -3db 176 MHz

DDC Version DDC1/2B

EDID Ver 1 ,Rev 2

1.5 Timings

Preset mode No. : 9 User mode No. : 20

Condition Spec

Spec

OK

N.A

9

9

OK: Positive performance

N. A.

: Not applicable for this set

OK

N.A

9

9

9

9

9

9

9

see table 1

9

Remark

Remark

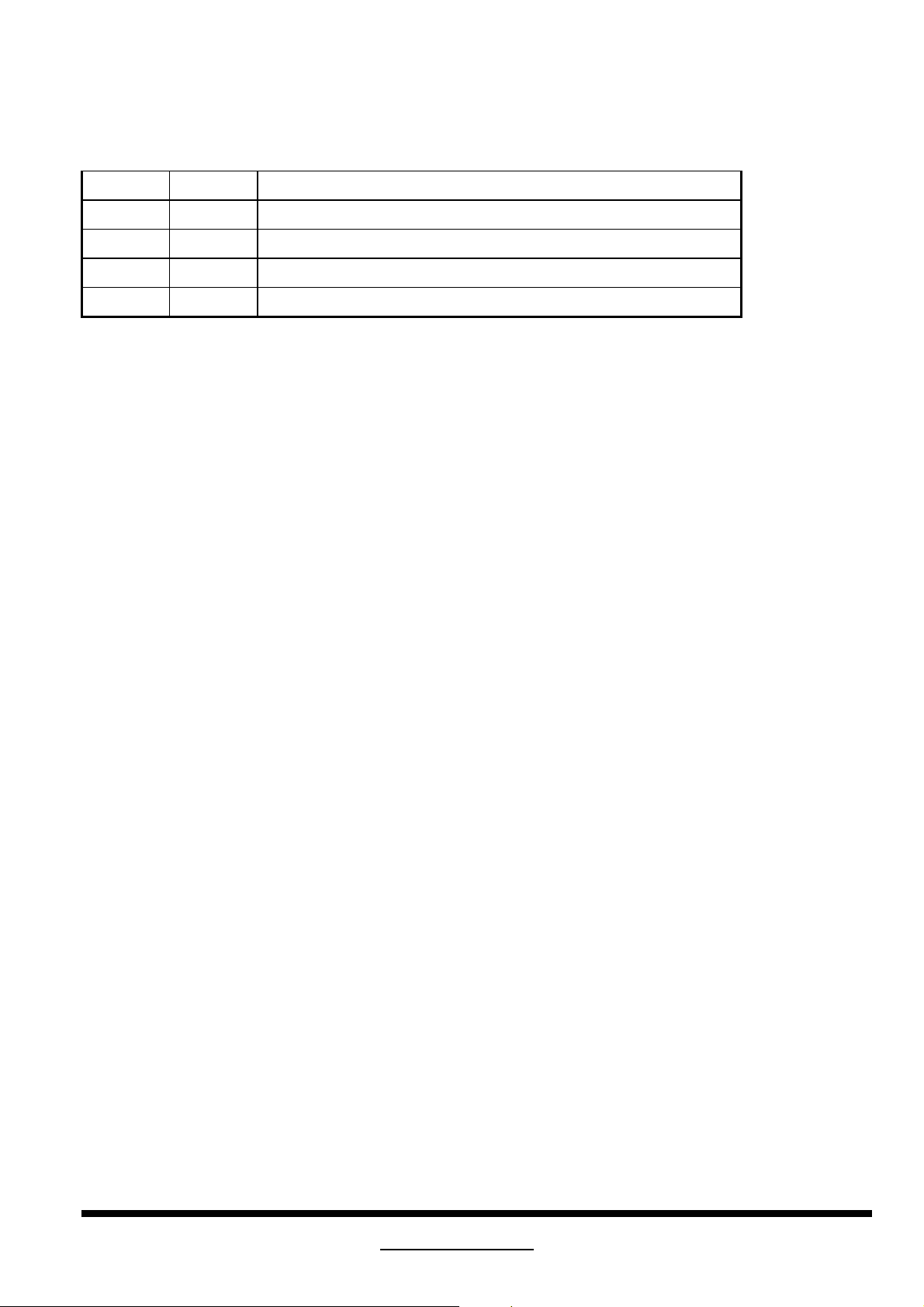

Preset

VGA400 640x400 31.47KHz/70Hz

VGA480 640x480 31.47KHz/59.94Hz

6448A 640X480 37.5KHz/75Hz

6448B 640X480 43.269KHz/85Hz

SVGA4 800x600 46.88KHz/75Hz

SVGA3 800x600 48.09KHz/72.01Hz

SVGA5 800x600 53.67KHz/85Hz

Apple 16”

UVGA2 1024x768 56.476KHz/70.069Hz

UVGA7 1024x768 60.023KHz/75.029Hz

Super MAC 19 1024x768 60.24KHz/75Hz 9

UVGA8 1024x768 68.68KHz/85Hz

WS2 1280x1024 64.317KHz/60.392Hz

WS7 1280x1024 79.98KHz/75Hz

WS8 1280x1024 91.15KHz/85Hz

Resolution Fh (KHz) / Fv (Hz)

832x624 49.71KHz/74.533Hz

OK

N.A

9

9

9

9

9

9

9

9

9

9

9

9

9

9

Sync polarity H/V

-/+

-/-

+/+

+/+

+/+

+/+

+/+

+/+

VESA1600 1600x1200 93.75KHz/75Hz

VESA 1600X1200 81.25KHz/65Hz

9

9

+/+

4

Page 8

1995SL CRT Monitor Service Guide

2.ENVIRONMENT & RELIABILITY

Chapter 1 Engineering Specification

Condition Spec

Operation Temp./Humidity

Non- Operation Temp./Humi.

Altitude Operating condition 0~3048m (10,000ft)

Non-operating condition 0~12,192m (40,000ft)

Vibration Package, Non-Operating 5~26.6Hz/0.6G

50~500 Hz/1.5G

Un-package, Non-

Operating

Drop (With packing) PKG. 18.2~27.2 Kg Drop Height 61 cm

Electrostatic Discharge

Acoustical Noise < 40 dB/A

Power Line Transient

IEC801-2 standard Contact:8KV, Air:15KV

IEC801-4,IEC1000-4-4 Coupling clamp 0 ~ 4KV

IEC1000-4-5 (Surge)

IEC1000-4-12 (100KHz

+5 ~ +40℃/ 20~90% R.H.

-20~ +60℃/ 10~90% R.H.

5~100/0.015g2/Hz

Common:2KV,Differential:1KV

Common:3KV,Differential:1KV

OK

N.A

9

Non-condensing

9

Non-condensing

9

Without packing

9

With packing

9

26.6~50Hz/1.5G

9

9

100~200/-6db/oct

9

9

9

9

9

9

Remark

200~0.038g2/Hz

0.5~8KV tip table no

blanking

ringwave)

MTBF Demonstration 90% confidence level > 200,000 Hrs

MTBF Prediction

MIL-217F

> 40,000 Hrs

CRT Life 78% degradation > 10000 Hrs

9

Excluding the CRT

9

9

3.CRT CHARACTERISTICS

Spec

CRT Vender Philips Shadow mask

Technology FST

Coating Anti-glare/Anti-

OK

N.A

9

9

9

static/Anti-reflection

Dot pitch 0. 26m m

Phosphor P22

Light transmittance 52.3%

Viewable size >18”

Deflection angle 95 deg

9

9

9

9

9

Remark

Blemishes and scratches

1 trio missing,as approval

see table 2

5

Page 9

1995SL CRT Monitor Service Guide

4.FRONT OF SCREEN

Chapter 1 Engineering Specification

sheet

4.1 Geometry

Magnetic Environment Northern Hemisphere H = 0 + 0.05

V = +0.45 +

0.05

Southern Hemisphere H = 0 + 0.05

V = -0.45 +

0.05

Equatorial H = 0 + 0.05

V = 0 +

0.05

Size Hor. 360 + 4 mm

Ver. 270 + 4 mm

Centering Hor. & Ver. |A-B|,|C-D|< 4 mm

Geometric Distortion

Top/Bottom Barrel/pincushion

Side Barrel/pincushion

< 1.35 mm

1.8 mm

<

Hor./Ver. Trapezoid < 3.0mm

Tilt < 1.2 mm

Orthogonal < 2 mm

S-curve < 0.5 mm within 40mm

OK

N.A

9

9

9

9

9

9

9

9

9

9

9

9

Remark

Linearity Hor. & Ver. < 5 %

4.2 Sharpness

Crispness

“

Focus

Mis-convergence Center < 0.15 mm

Moire Over 18Ft-L no visible moire

Swing not permitted

Reverse character(white

background and black

characters) /20 Ft-L at ful l-white

Jitter DIN 66234 T2 < 0.1mm

4.3 Light Quality

Condition Spec

White Balance Full white center

(Brit. cut-off & Cont.

max.)

Purity W,R,G,B

X max-X min & Y max-Y min

e,w,m” at cut-off and

1280*1024@85Hz

resolution

A <

0.3mm ,B< 0.4mm

x = 0.283 +

y = 0.297 +

0.010

0.010

< 0.015

9

(Xmax-Xmin)/( Xmax+Xmin)*100

OK

N.A

9

9

9

9

9

OK

N.A

9

@ SVGA1280x1024

9

Remark

The distance of watch is

30cm from eyes t o screen

”

”

Remark

79.98KHz75Hz

“

6

Page 10

MEA 1995SL CRT Monitor Service Guide

Chapter 1 Engineering Specification

Color Tracking

Max Brightness with ABL

Max Brightness no ABL

Brightness Uniformit y

Brightness cut off

Full white pattern

3” Block

Full white pattern

Raster light O/P Bright./Cont. Max. 0.5 ~ 1.5Ft-L

Contrast ratio Max/Min 5:1

4.4 Image Stability

H/V regulation < 1 mm per side at cut-

x, y (nominal) + 0.015

30Ft-L(Cut-off)

40Ft-L (Cut-off )

70% (center to corner)

>

9

9

9

9

9

9

OK

N.A

9

Remark

“

“

“

“

“

“

off

Flicker No flicker

Ringing

No visible DY Hor. Video ringing

9

9

7

Page 11

1995SL CRT Monitor Service Guide

5. USER CONTROLS

Chapter 1 Engineering Specification

5.1 Basic

Power Switch

Contrast

Brightness

H Size

H Position

V Size

V Position

Barrel/Pincushion

Parallelogram

Trapezoid

5.2 Advanced

OSD position

Color Gain

Corner

Function Spec

Function Spec

OK

N.A

9

9

9

9

9

9

9

9

9

9

OK

N.A

9

See Table 3

9

9

Remark

Remark

Pin-balance

Tilt

Color Temp. C1~C5

9300K,6500K,5500K,7100K,1150

0K

Manual Degauss

Recall

Languages 5 languages

Mis-Convergence adj.

Moire adj.

D-sub/BNC switch

9

9

9

9

9

9

9

9

9

6. MECHANICAL CHARACTERISTICS

6.1 Dimension

Spec

Bezel opening 324x 243 mm

Monitor w/o Stand W x H x D mm 455x 406.5 x 416 mm

OK

N.A

9

9

Remark

Monitor w Stand W x H x D mm 455x 476.5 x 416 mm

9

8

Page 12

1995SL CRT Monitor Service Guide

Chapter 1 Engineering Specification

Carton Box W x H x D mm 575 x 522 x 536 mm

Tilt and Swivel range Tilt : -5/+15 deg r ee

9

9

Swivel:- 45/ +45 degrees

6.2 Weight

Spec

Monitor (Net) 19 Kg

Monitor w

23 Kg

OK

N.A

9

9

Remark

packaging(Gross)

6.3 Plastic

Flammability UL 94-5V

Heat deflection To

UV stability

Resin PC+ABS

Texture RE-6625

Color Light Gray

6.4 Carton

Spec

75 ℃mini

Delta E<1.5 after 300Hr Xted

test

Spec

OK

N.A

9

9

9

9

9

9

OK

N.A

Remark

Remark

Color Kraft

Material A B Flute

Compression strength 610 KGF

Burst Strength 23 KGF/cm 2

Stacked quantity 5 Layers(max)

9

9

9

9

9

9

Page 13

1995SL CRT Monitor Service Guide

Chapter 1 Engineering Specification

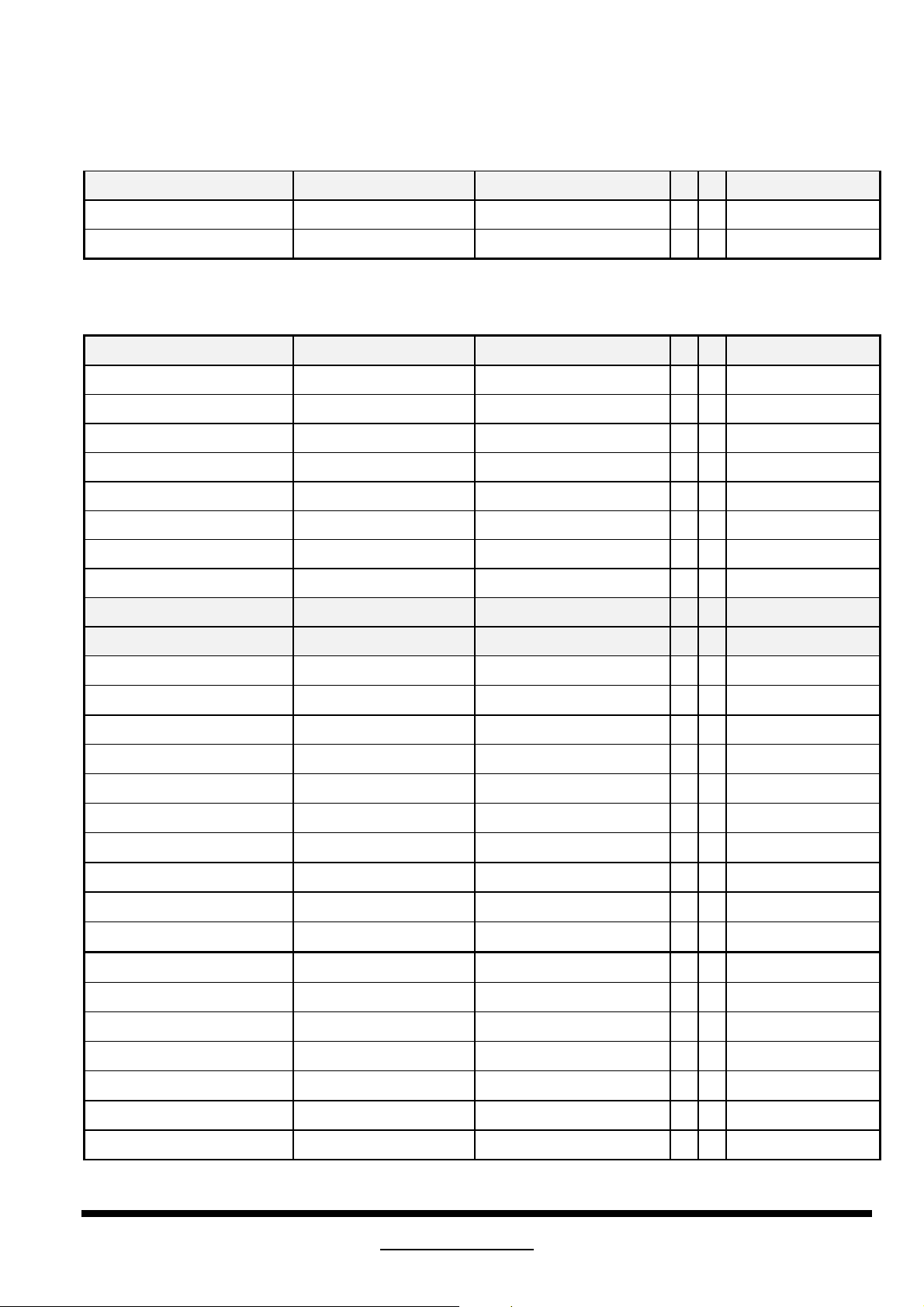

7. Pallet & Shipment

7.1 Dimension

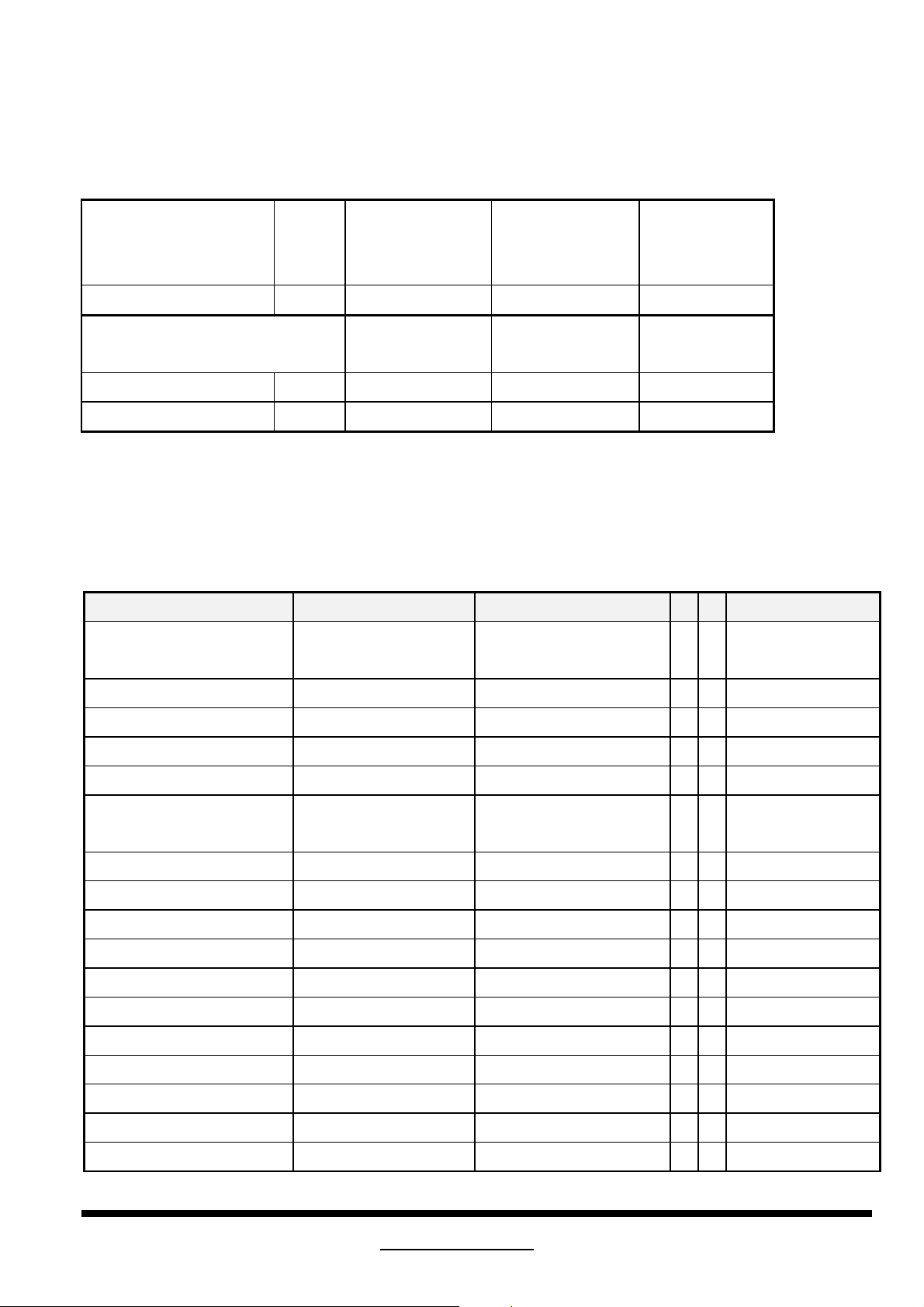

Transport Type Pallet A Pallet B Pallet C

Shipping Pallet Length 1150

Dimension(mm) Width 1072

Height 130

Air Transport Pallet Length 1072

Dimension(mm) Width 1150

Height 130

x

x

x

x

x

x

X

X

X

X

X

X

7.2 Shipping Container

Stowing Type Quantity of

products (sets)

(Every container) (Every Pallet) (Every Container)

20' 160 Pallet A: 16 Pallet A: 10

With pallet 40' 352 Pallet A: 16 Pallet A: 22

Quantity of Products

(sets)

Pallet B:

x Pallet B: x

Quantity of pallet

(sets)

Pallet B: X Pallet B: X

20' 160 X X

X X

Without pallet 40' 352 X X

X X

10

Page 14

1995SL CRT Monitor Service Guide

7.3 Air Transport Container

Chapter 1 Engineering Specification

Container Type Quantity of products

(sets)

(Every container)

Container

3048 * 2286 * 2438

Pallet B: 8 Pallet B: 2

80

Quantity of Products

(sets)

(Every Pallet)

Pallet A: 16 Pallet A: 4

Quantity of pallet

(sets)

(Every Container)

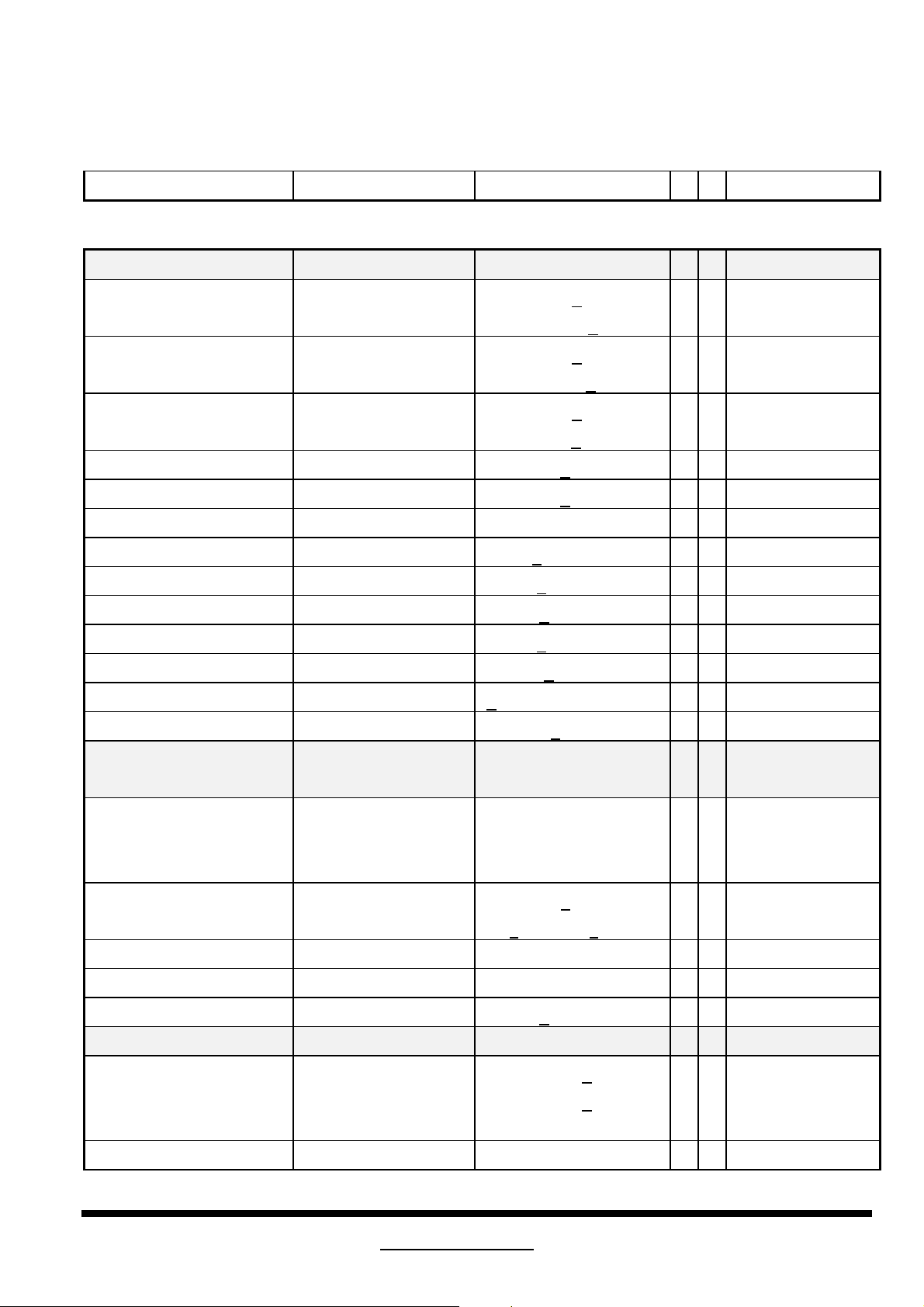

8. CERTIFICATION

Condition Spec

Environment Green design Doc. 715-C49

OK

N.A

9

ISO14000

Remark

Requirement

Blue Angel German Standard

E-2000 Switzerland

NUTEK Swedish Standard

EPA USA Standard

EN61000-3-2

9

9

Option

9

9

9

Harmonics

TCO92/95

TCO99

PC-Monitor Microsoft Windows PC98/99

DPMS VESA

DDC 1/2B Version 3.0

USB Internal

Safety UL (USA) UL 1950 3rd edition

CSA (Canada) C22.2 No. 950-M95

DNSF EN60950

IEC950 +A1+A2+A3+A4

9

9

9

9

9

9

Option

9

9

9

9

EN60950 +A1+A2+A3+A4

9

11

Page 15

1995SL CRT Monitor Service Guide

Chapter 1 Engineering Specification

73/23/EEC

CB (Nordics)

TUV/GS EN60950

CCIB (China)

EIAJ/JEIDA (Japan)

NOM (Mexico)

IAA (Korea)

EMC CE Mark 89/336/EEC

FCC (USA) Class B

EN55022 Class B

CISPR 22 Class B

VCCI (Japan) Class B

BCIQ (Taiwan)

C-Tick (Australia) AS3548

RRL (Korean)

X- Ray Requirement DHHS (21 CFR) USA X- Ray Standard

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

DNHW

PTB German X- Ray standard

MPRII

MPRIII

Ergonomics ZH1/618 German ergonomic

ISO 9241-3 -7 & 8

9

9

9

9

9

9

9. Appendix

Table 1 - DDC Table

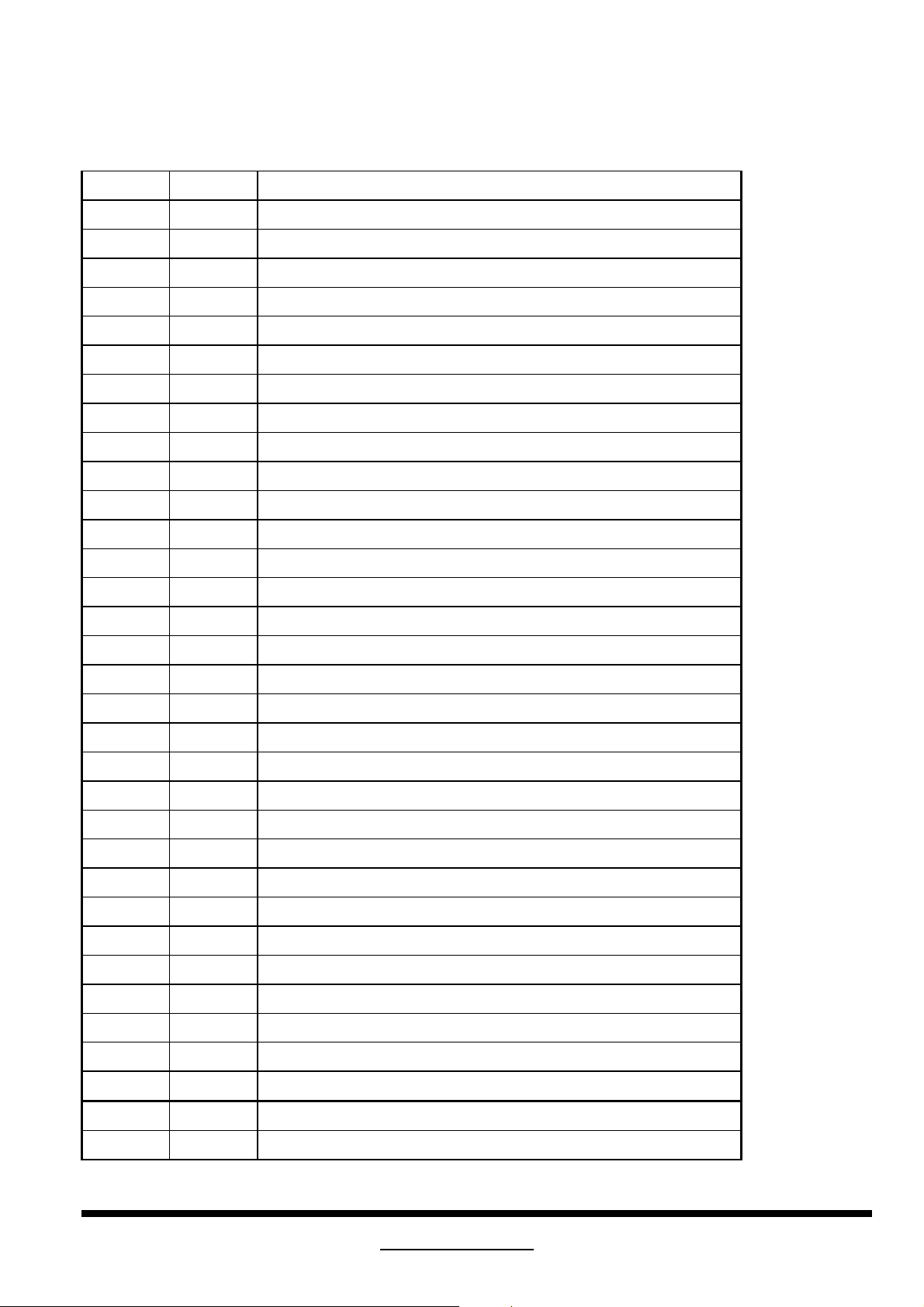

DDC1/2B Table

Address Data Description

00 00

01 FF

02 FF

12

Page 16

1995SL CRT Monitor Service Guide

03 FF Header

04 FF

05 FF

06 FF

07 00

08 06 ID Manufacturer Name = MEA

09 09

0A 03 ID Product Code = 1995SL

0B 99 (Vender Assigned code)

0C 00 ID Serial Number

0D 00

0E 00

Chapter 1 Engineering Specification

0F 00

10 * Week of Manufacture (0-53),use 0 if n/a

11 * Year of Manufacture (year - 1990)

12 01 EDID version

13 03 Revision

14 6C Video Input Define

15 24 Max. H. Image Size 360 (cm)

16 1B Max. V. Image Size 270 (cm)

17 A9 (gamma*100) - 100 , gamma = 2.75 (Data in Note 3)

18 EA DPMS

19 2C Red Green Bits Rx1Rx0Rxy1Ry0Gx1Gx0Gy1Gy0

1A 24 Blue White Bits Bx1Bx0By1By0Wx1Wx0Wy1Wy0

1B A0 Red x bit9-2

1C 56 Red y bit9-2 (Data in Note 3)

1D 47 Green x bit9-2

1E 9A Green y bits9-2

1F 26 Blue x bit9-2

20 12 Blue y bit9-2

21 48 White x bit9-2

22 4C White y bit9-2

Address Data Description

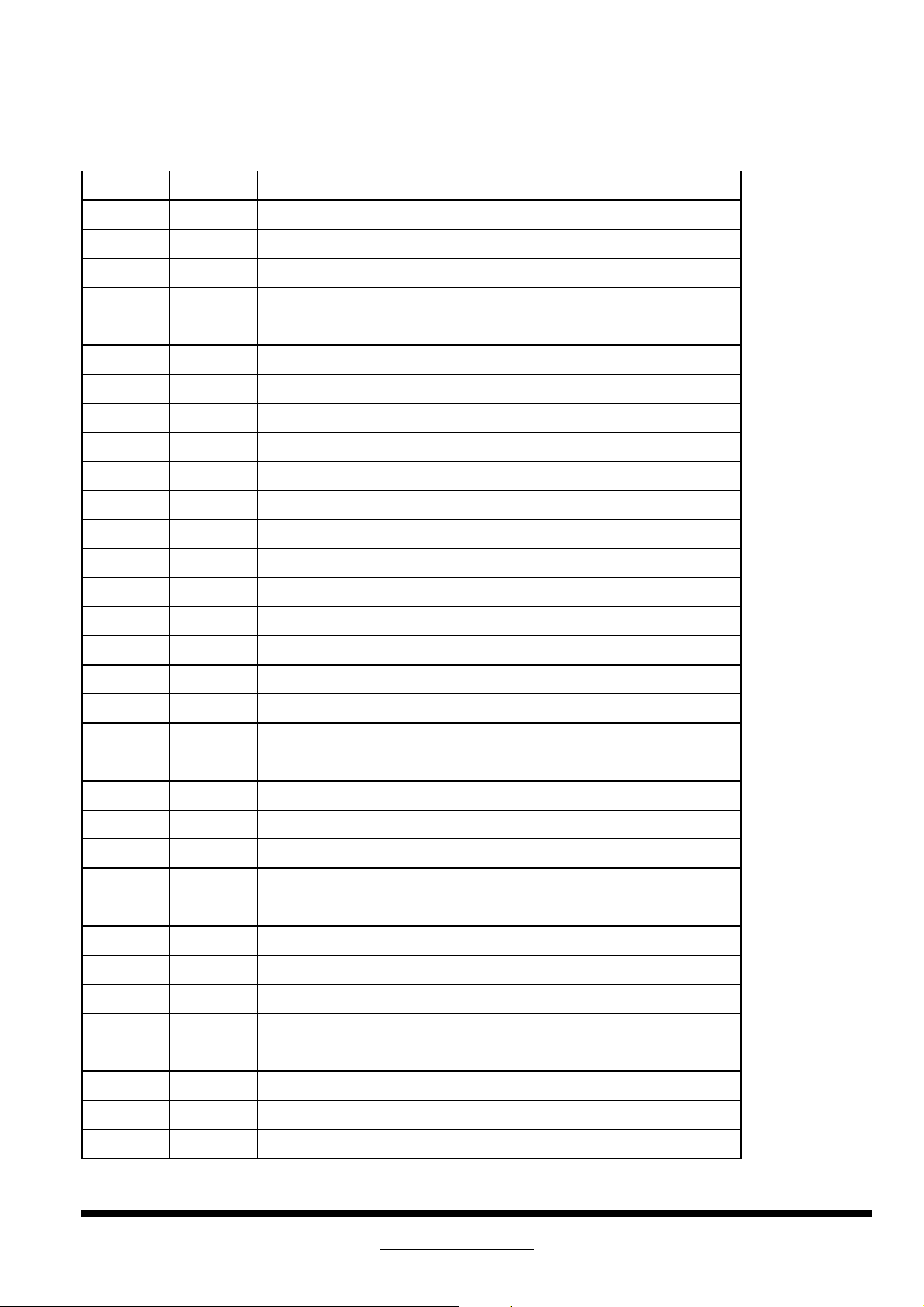

23 AF Established Timing I

13

Page 17

1995SL CRT Monitor Service Guide

24 CF Established Timing II

25 00 Established Timing III

26 A9 Standard Timing Identification

27 45 #1 1600x1200 / 65Hz

28 45 #2 800x600 / 85Hz

29 59

2A 61 #3 1024x768 / 85Hz

2B 59

2C 01

2D 01

2E 01

2F 01

Chapter 1 Engineering Specification

30 01 #6

31 01

32 01 #7

33 01

34 01 #8

35 01

36 86 Detailed Timing Description # 1

37 3D WS8 1280x1024 91.15k/85Hz

38 00

39 C0

3A 51

3B 00

3C 30

3D 40

3E 40

3F A0

40 13

41 00

42 68

43 0E

44 11

45 00

14

Page 18

1995SL CRT Monitor Service Guide

Chapter 1 Engineering Specification

46 00

47 00

Address Data Description

48 00 Detailed Timing Description # 2

49 00

4A 00

4B FC Monitor Name

4C 00 MEA 1995SL

4D 41

4E 43

4F 45

50 52

51 20

52 47 G

53 39 9

54 39 9

55 31 1

56 0A

57 20

58 20

59 20

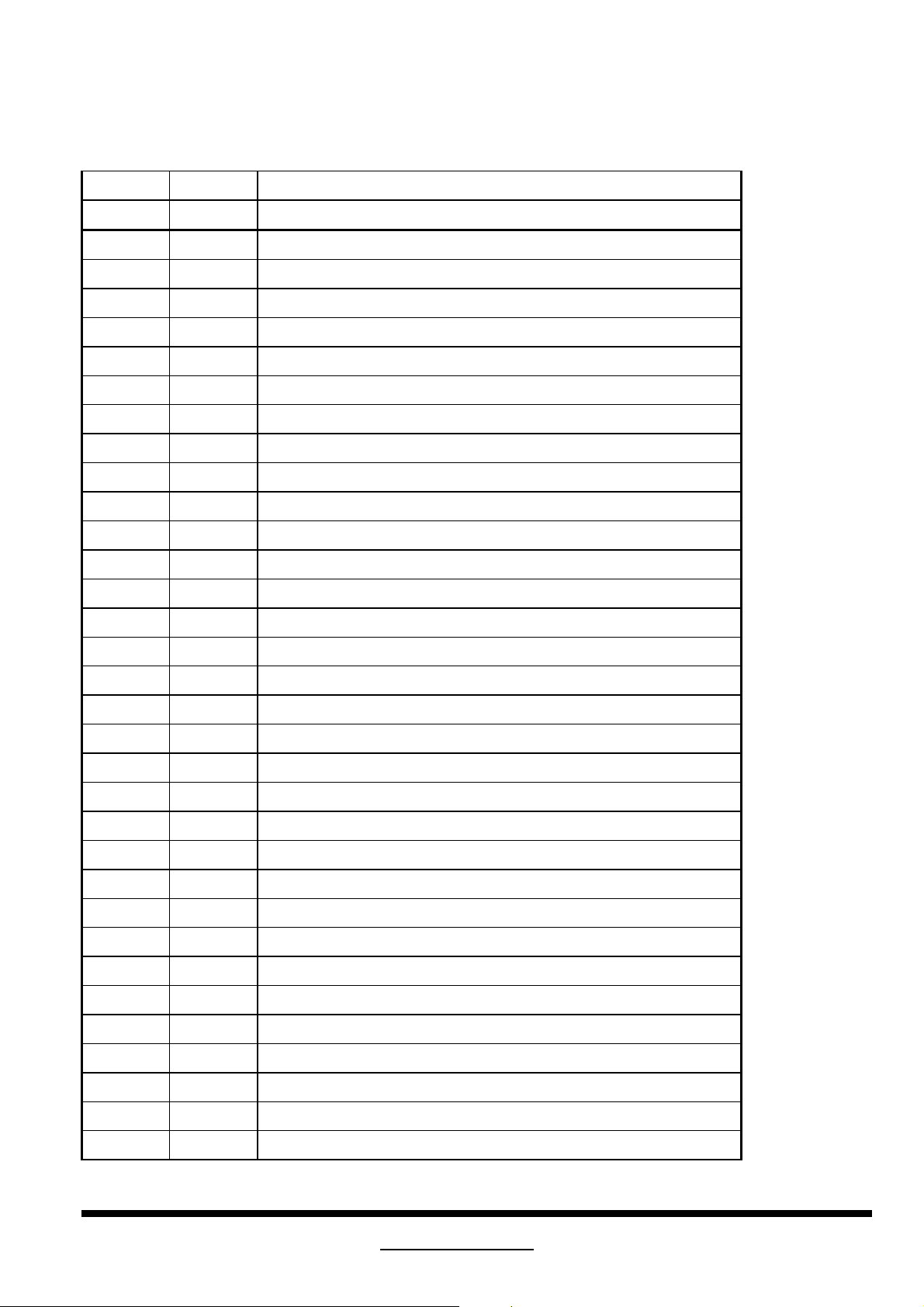

5A 00 Detailed Timing Description # 3

5B 00

5C 00

5D FD Range Limit: Vertical refresh rate 50Hz~160Hz

5E 00 Horizontal frequency 30KHz~95KHz

5F 32

60 A0

61 1E

62 5F

63 11

64 00

65 0A

66 20

15

Page 19

1995SL CRT Monitor Service Guide

67 20

68 20

69 20

6A 20

6B 20

Chapter 1 Engineering Specification

16

Page 20

1995SL CRT Monitor Service Guide

Chapter 1 Engineering Specification

Address Data Description

6C 00 Detailed Timing Description # 4

6D 00

6E 00

6F FF Serial number.

70 00 PS: Example :

71 32 Monitor serial number in description from 71 to 75 is 23456

72 33 ASCII data string in descriptor until 0A end.

73 34 20 is mean Null string.

74 35

75 36

76 0A

77 20

78 20

79 20

7A 20

7B 20

7C 20

7D 20

7E 00 Extension Flag

7F * Check sum

Serial number format : MEA

Bar code ID of model name : 7C

17

Page 21

1995SL CRT Monitor Service Guide

Chapter 1 Engineering Specification

Note 1

Bit Description

7 Analog / Digital Input : Defines usage of the rest if the byte as "analog input" or digital

input". Analog=0, Digital=1 . If input is described as analog, the following definitions apply to

bits 6-0.

6:5 Signal Level Standard (6:5) : Refer to the following bit definitions. Identified by the level of

reference white volts above blank, followed by the level of the sync tips in volts below

blank.

Bit 6

Bit 5 Operation

0 0 0.700V/0.300V (1.000V p-p)

0 1 0.714V/0.286V (1.000V p-p)

1 0 1.000V/0.400V (1.400V p-p)

1 1 0.700V/0.000V (0.700V P-P)

4 Setup: If set, the display is set to expect a blank-to-black setup or pedestal per the

appropriate signal level standard.

3:0 Sync Inputs (See Bit Operation below)

3 Separate Sync

2 Composite Sync (on H Sync line)

1 Sync on Green Video

0 Serration of the V.Sync Pulse is required when composite sync or sync-on-

green video is used

18

Page 22

1995SL CRT Monitor Service Guide

Note 2

Bit 7 Stand-by

Bit 6 Suspend

Bit 5 Active off

Bit 4-3 Display Type

0,0 - Monochrome/gray scale display

0,1 - RGB color display

1,0 - Non-RGB multicolor display (example:RGY)

1,1 - Undefined.

Bit 2-0 Reserved. Set at 00h until defined.

Chapter 1 Engineering Specification

Note 3

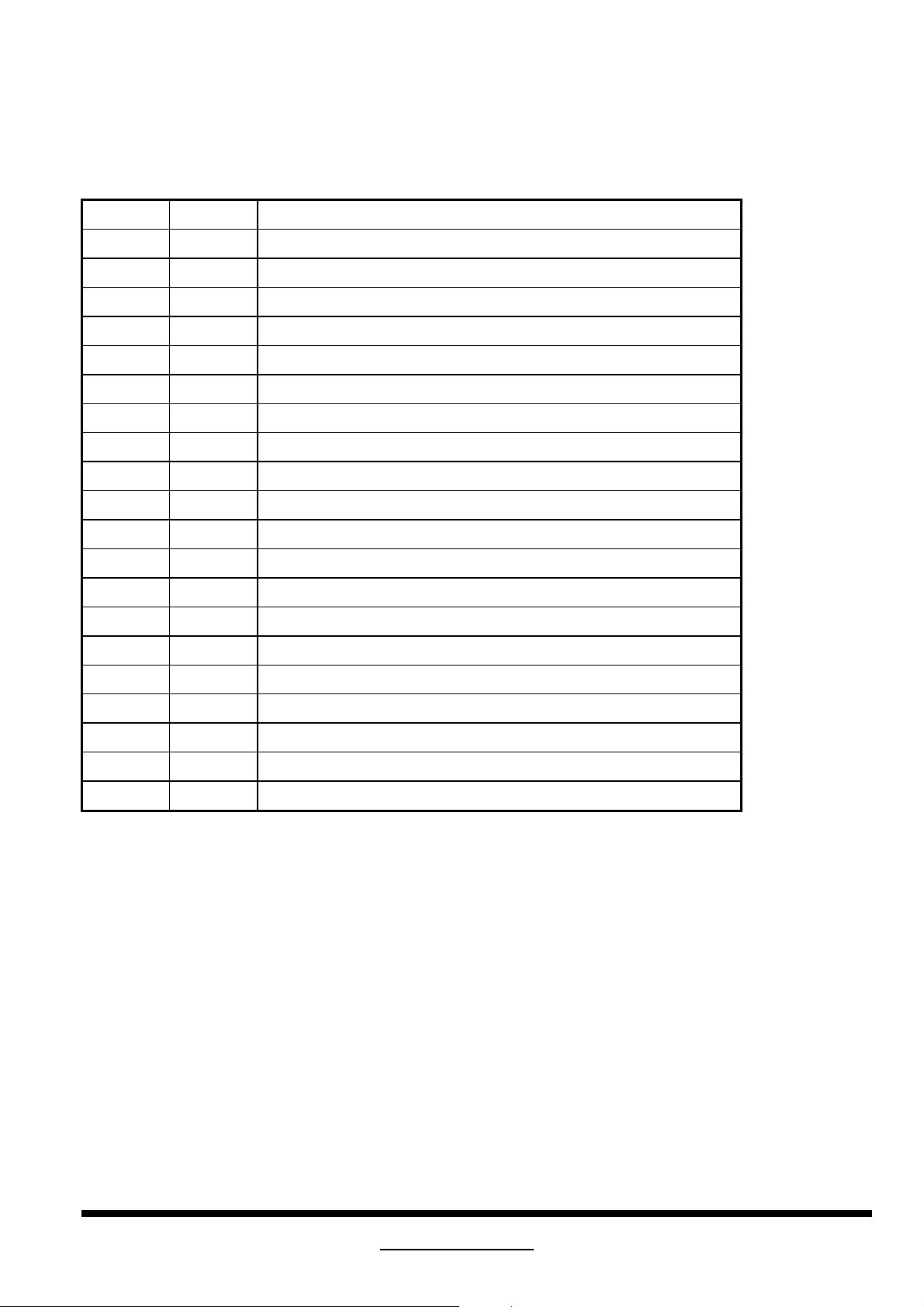

CRT Vender Red (x/y) Green (x/y) Blue (x/y) Gamma

Philip 0.615/0.350 0..290/0.610 0.155/0.065 2.75

Hitachi 0.625/0.333 0.285/0.605 0.150/0.065 2.76

Matsushita 0.535/0.350 0.285/0.605 0.152/0.068 2.90

CRT vender 17 19 1A 1B 1C 1D 1E 1F 20 21 22

Philips AF 64 A4 9D 59 4A 9C 27 10 48 4C

Hitachi B0 0F 64 A0 57 48 9A 26 10 48 4C

Matsushita BE DF D4 88 55 48 9A 26 11 48 4C

19

Page 23

1995SL CRT Monitor Service Guide

Note 4

Byte 1 bit Established Timings 1 Source

7 640*400 @ 70Hz (720x400) (VGA, MEA)

6 720*400 @ 88Hz (XGA2, MEA)

5 640*480 @ 60Hz (VGA, MEA)

4 640*480 @ 67Hz (Mac II, Apple)

3 640*480 @ 72Hz (VESA)

2 640*480 @ 75Hz (VESA)

1 800*600 @ 56Hz (VESA)

0 800*600 @ 60Hz (VESA)

Byte 2 bit Established Timings II

7 800*600 @ 72Hz (VESA)

Chapter 1 Engineering Specification

6 800*600 @ 75Hz (VESA)

5 832*624 @ 75Hz (Mac II, Apple)

4 1024*768 @ 87Hz (interlaced) (MEA)

3 1024*768 @ 60Hz (VESA)

2 1024*768 @ 70Hz (VESA)

1 1024*768 @ 75HZ (VESA)

0 1280*1024 @ 75HZ (VESA)

Byte 3 bit Manufacturer's Timings Manufacturer's Specified Timing

7 1152*870 @ 75Hz (Mac II, Apple)

6 Reserved

5 Reserved

4 Reserved

3 Reserved

2 Reserved

1 Reserved

0 Reserved

20

Page 24

1995SL CRT Monitor Service Guide

Chapter 1 Engineering Specification

Table 2 - CRT Blemish & Scratch Spec

The following criteria is applied to high-contrast blemishes.

Blemishes

Zone A Zone B

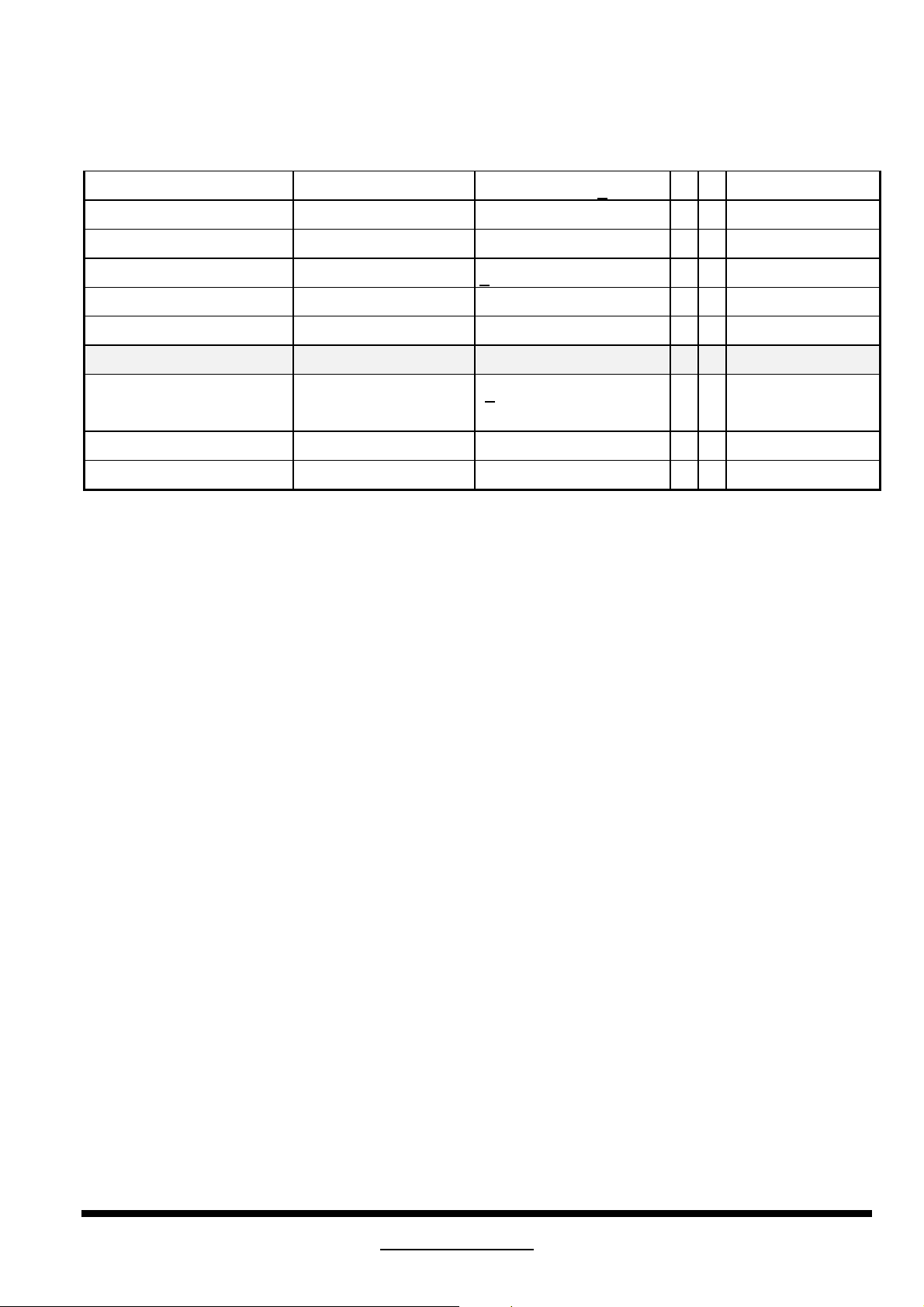

A 1 trio 0 1 1 --- --B (1) 0 0 0 --- ---

C (2) 1 2 2 --- 50

(3) 1 2 2 --- 20

D 1 dot

Red 5 4

Blue 5 4

(1) 3 or more consecutive same color phosphor dots.

(2) 2 consecutive same color phosphor dots.

(3) 2 consecutive different color phosphor dots.

Green 4 2

Allowable No. of Blemishes Allowable

Minimum

Separation

Zone

A

Zone

B

Total

(Zones A & B )

10

50

20

Table 3 - OSD Menu

Please refer to Release 001-C01

21

Page 25

1995SL CRT Monitor Service Guide

X5

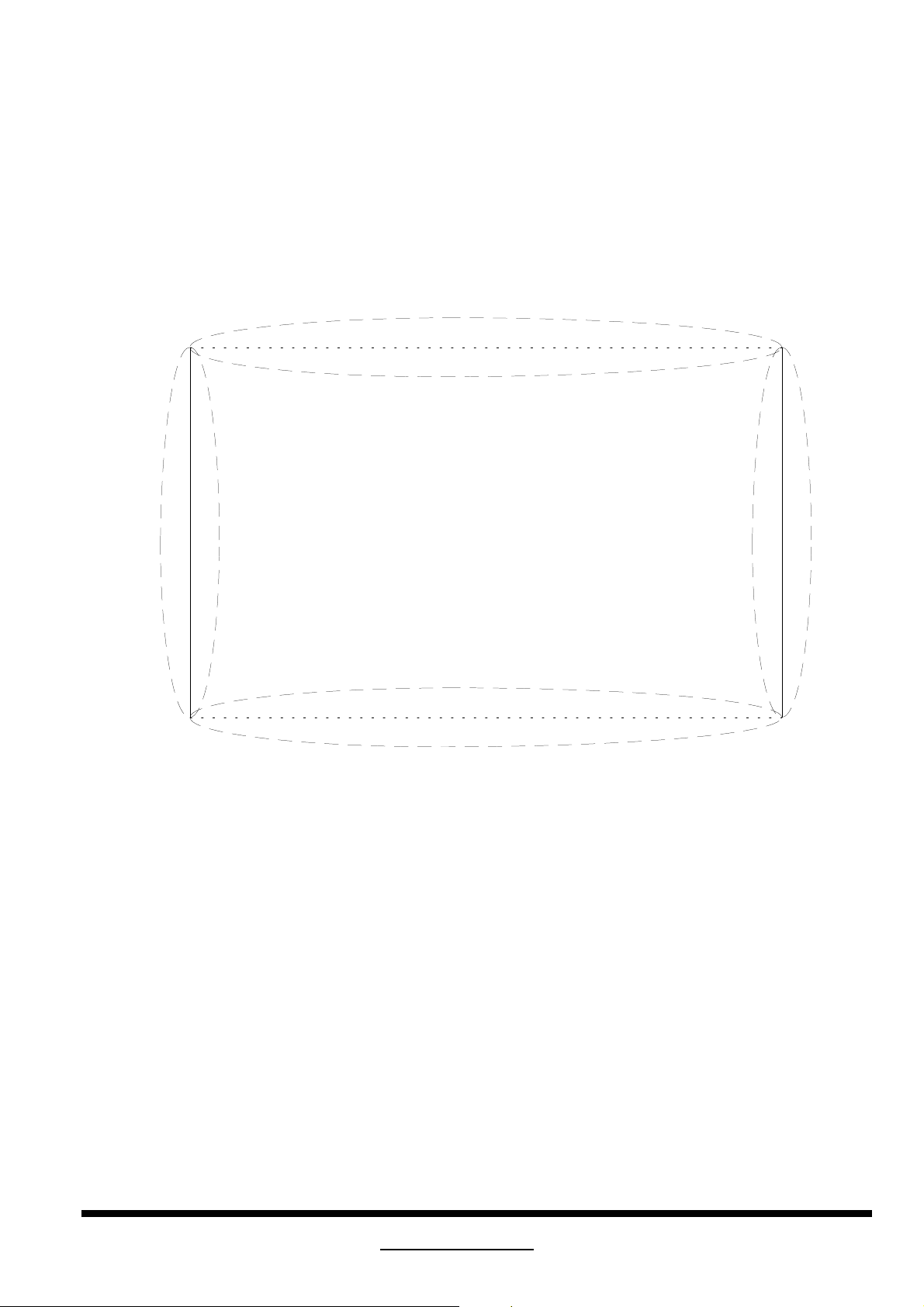

Table 4- Geometry Fig.

Fig.1 Linearity Measurements

X1 X2 X3 X4 X6 X7 X8 X9 X10X11 ~ X18

Y0

+ + + + + + + + + + + +

Y1

+ + + + + + + + + + + +

Y2

+ + + + + + + + + + + +

Y3

+ + + + + + + + + + + +

Y4

+ + + + + + + + + + + +

Y5

+ + + + + + + + + + + +

Y6

+ + + + + + + + + + + +

Y7

+ + + + + + + + + + + +

Y8

+ + + + + + + + + + + +

Y9

+ + + + + + + + + + + +

Y10

+ + + + + + + + + + + +

Y11

+ + + + + + + + + + + +

Y12

+ + + + + + + + + + + +

Y13

Chapter 1 Engineering Specification

Xmax - Xmin

------------------- X 100% < 5%

Xmax + Xmin

Ymax - Ymin

------------------- X 100% < 5%

Ymax + Ymin

22

Page 26

1995SL CRT Monitor Service Guide

Q

Fig.2 General Pincushion Measurements

Chapter 1 Engineering Specification

Amm

a1

P

Bmm b1

a2

S

b2

R

A, B represented as display area width and height

Top/Bottom Pincushion = (a1 or a2)

Side Pincushion = (b1 or b2)

Substituted A by (PS + QR)/2

B by (PQ + RS )/2

23

Page 27

1995SL CRT Monitor Service Guide

Fig.3 Trapezoid Measurements

2.5

Chapter 1 Engineering Specification

2.5

2.5

A

B

2.5

2.5

D

C

2.5

2.5

2.5

* Each of the 4 corners of picture shall fall within the relevant area (F) illustrated up (hatched)

* ABCD is the picture outlines.

24

Page 28

1995SL CRT Monitor Service Guide

Fig.4 Picture Distortion & Phase Measurements

H1

Chapter 1 Engineering Specification

A

V1

a1

orthogoal

D1

C D

b2

b1

D2

Tilt

a2

B

PeakTotal

H2

V2

]21|

HH

+−HH

02.0

≤

)21(5.0

]21|

VV

+−VV

02.0

≤

)21(5.0

]21|

DD

+−DD

03.0

≤

)21(5.0

25

Page 29

1995SL CRT Monitor Service Guide

G

Fig.5 TCO 99 Pincushion Measurements

AC

x

x1

∆

∆

Chapter 1 Engineering Specification

y1

B

y

∆

x2

Æ Linearity (TCO99) = x1/x or y1/y

Æ

[AC+EG]/2, [AG+CE]/2 represented as display area width and height

Æ

Top/Bottom Pincushion = y1 or y2

Æ

Side Pincushion = x1 or x2

∆

y2

E

26

Page 30

1995SL CRT Monitor Service Guide

Fig.6 TCO 99 Barreling Measurements

AC

x1

∆

x

∆

Chapter 1 Engineering Specification

y1

y

∆

x2

∆

y2

[AC+EG]/2, [AG+CE]/2 represented as display area width and height

Top/Bottom Pincushion = y1 or y2

Side Pincushion = x1 or x2

Linearity (TCO99) = x1/x or y1/y

EG

27

Page 31

1995SL CRT Monitor Service Guide

Chapter 1 Engineering Specification

Table 5 - TCO 99 Spec

A. Ecology

1 General Criteria

1.1 Manufacturing Processes

1.1.1 Ozone Depleting Substances:

* PCB and any Process shall not use any ozone depleting substance

1.1.2 Chlorinated Solvent:

* PCB and any Process shall not use any Chlorinated Solvent substance

1.2 Environmental Hazards

1.2.1 Mercury and Cadmium in Electronic Components:

*

1.2.2 Flame Retardants in Plastic Components:

*

1.3 Preparation for Recycling:

1.3.1 Labelling of Plastic:

*

1.3.2 Variety of Plastic:

*

1.3.3 Painting of Plastic:

*

*

* All paints, lacquers, vanishes or colour additives used shall be declared by the type and mount.

1.3.4 Metallization of Plastic Housing:

*The plastic housing shall have neither internal nor external metallization.

None of electronic components

Plastic > 25g

Plastic > 25g

Plastic >100g

Plastic > 25g

Mould decoration

shall not contain retardants of organically bound

shall be labelled in accordance with

shall be made from the

shall not be having

(IMD) is not allowed

contain any mercury or cadmium.

ISO11469

same type of plastic material

paint weight >1% of plastic weight

.

.

Chloride or Bromide.

.

28

Page 32

1995SL CRT Monitor Service Guide

B. CRT Display

Part 1: Visual Ergonomic - Legibility

1.3 Linearity: *

1.4 Orthogonality:

* H/V:

1.5.1: Display Luminance: *

1.5.2 Luminance Uniformity: *

1.5.3 Luminance Contrast: *

1.6 Front Frame Reflectance:

* Diffuse reflectance:

* Gloss

1.7.1: Color Temperature Variations:

* Δu'v': <+- 0.01 of White

* 9300

* 7500

* 6500

* 5000

* and actual measured

<= 1%

<= 2%,

<= 30%

o

8500-10250

K:

o

6980-8100

K:

o

6100-6950

K:

o

4700-5350

K:

, (See Fig.5 & Fig.6)

Diagonal:

>=100cd/m

< 1.5:1

> 3:1

> 20%

gloss unit

o

K

o

K

o

K

o

K

Pre-set of Lower CCT should not exceed Higher CCT

<= 3%

2

(80% Loading)

(test at 5% of corner and center)

Chapter 1 Engineering Specification

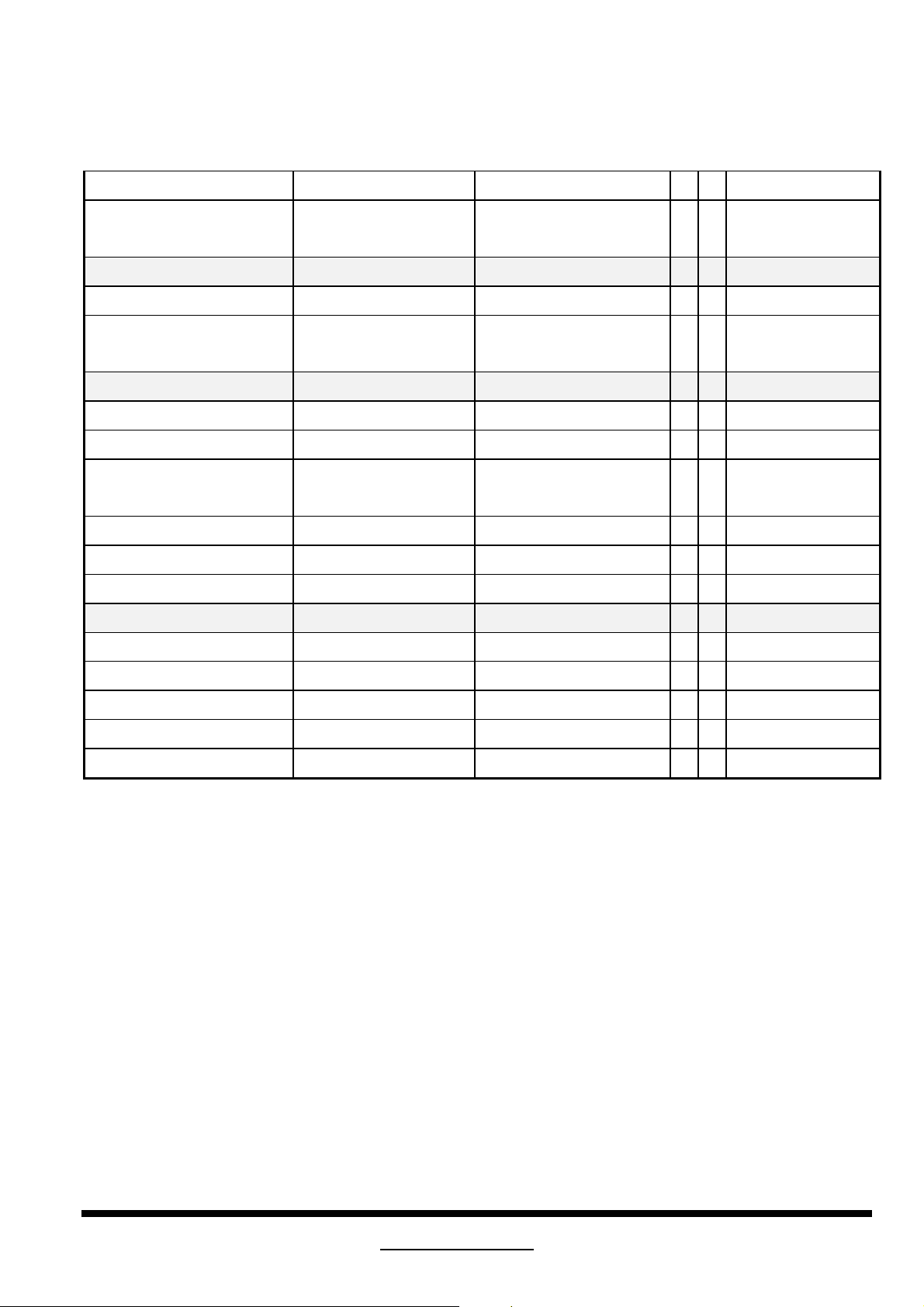

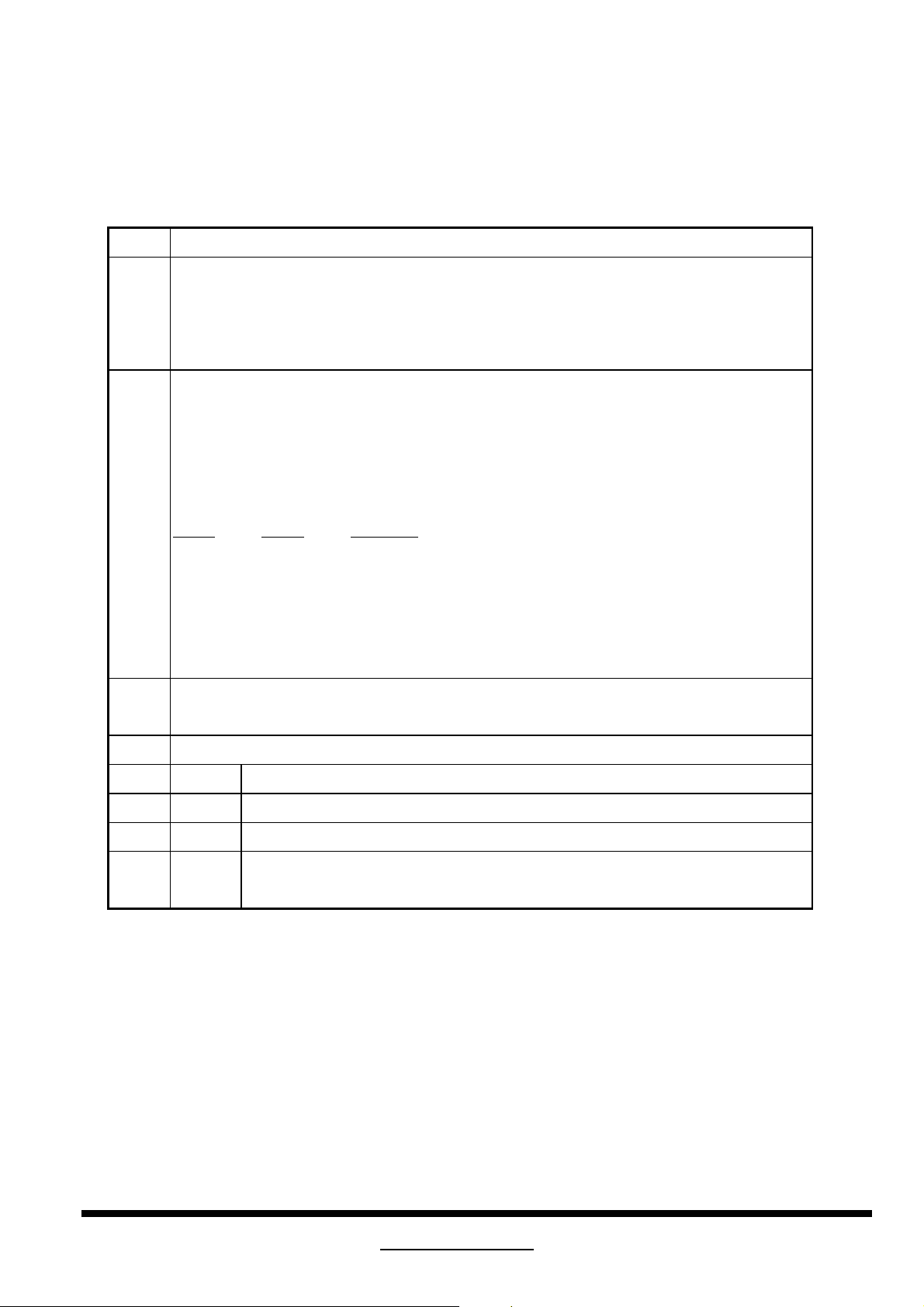

CCT (oK) x,y u’v’

9300 0.283, 0.297 0.189, 0.446

7100 0.304, 0.320 0.195, 0.462

6500 0.313, 0.329 0.198, 0.496

5500 0.333, 0.348 0.204, 0.481

11500 0.272, 0.283 0.186, 0.435

1.7.2: Color Uniformity and Characteristics:

* Δu'v':

<= 0.01

(between any two point of display area (White Color))

Reference White Color Spec. in TCO’99

1976 CIE u’v’ from 1931 CIE x,y

u’= 4x/(-2x+12y+3) v’= 9y/(-2x+12y+3)

29

Page 33

1995SL CRT Monitor Service Guide

Part 2: External Alternate Magnetic Fields:

2.1: External Alternating Magnetic Fields: *

Part 3: Emission and Energy Saving

3.1 X-Ray : *

3.2 Electrostatic Potential: *

3.3 Electric Field (AC):

*

*

Note:

3.4 Magnetic Field (AC):

*

*

Note:

3.5 Energy Saving:

* 1st stage: <15W (recover time: 3 sec.)

2nd stage: <5W

* Single stage: <5W (recover time: <3 sec.)

* Monitor

(recover time < 3sec)

Part 4. Acoustic Noise:

4.1 Acoustic Noise (VDUs with fan):

*

*

< 0.5 mR/Hr

Band I < 10V/m (100cd/m

Band II< 1V/m (100cd/m

Shielded Power Cord is not acceptable

Band I < 200 nT (100cd/m

Band II< 25 nT (100cd/m

Shielded Power Cord is not acceptable

with USB Hub

Operating: < 5.5 B

Idle: < 4.8 B

(bels)

<+-0.5KV

: same as above or

(bels)

2,

, “+” Pattern)

2,

, “+” Pattern)

2,

, “+” Pattern)

2,

, “+” Pattern)

< 0.1 mm

(500 mm Viewing Distance; 80Hz, 200nT.)

single stage < 15W

Chapter 1 Engineering Specification

30

Page 34

1995SL CRT Monitor Service Guide

Chapter 2 Circuit Operation Theory

Table of Contents

1995SL System Block Diagram.............................................................................................................3

Switching Power Supply Operation Theory...........................................................................................4

1. General Specification...............................................................................................................4

2. Block Diagram .........................................................................................................................4

3. Circuit Operation Theorem ......................................................................................................5

3.1 RFI FILTER...............................................................................................................5

3.2 Rectifier and filter......................................................................................................5

3.3 switching Element and isolation transformer............................................................6

3.4 Output Rectifier and filter..........................................................................................6

3.5 Control circuit............................................................................................................7

3.6 Feedback circuit........................................................................................................8

3.7 DEGAUSS CIRCUIT.................................................................................................8

3.8 power saving control.................................................................................................8

MEA 1995SL MICROCONTROLLER CIRCUIT OPERATION THEORY..........................................9

1. Introduction..............................................................................................................................9

2. Block diagram..........................................................................................................................9

3.MCU and the peripheral circuit operation theory ......................................................................10

3-1.MCU function............................................................................................................10

3-2.How to detect mode timing.......................................................................................10

3-3.What are the valid key functions for user.................................................................10

3-4.How to memorize the timing and adjusted data .......................................................11

3-5.How to display the OSD menu..................................................................................11

3-6.How to execute the auto alignment function.............................................................11

Deflection Circuit....................................................................................................................................12

[ 1995SL Autosync Deflection Controller Circuit ]........................................................................14

[ Vertical Deflection ]....................................................................................................................14

[ G1 and Spot-killer ]....................................................................................................................15

[ Tilt Circuit ].................................................................................................................................16

[ Horizontal Size Modulation Circuit ]...........................................................................................16

< H-size and East-west PWM generator > .....................................................................16

< H-size Output Circuit >.................................................................................................17

< Top Ringing Elimination Circuit >.................................................................................17

< H-driver Circuit >..........................................................................................................17

< Cs Control Circuit >......................................................................................................18

< H-linearity Control Circuit >..........................................................................................18

[ High Voltage Processing Circuit ] ..............................................................................................19

1

Page 35

1995SL CRT Monitor Service Guide

Table of Contents

Chapter 2 Circuit Operation Theory

[ ABL Circuit ]...............................................................................................................................19

[ Dynamic Focus Circuit ].............................................................................................................19

Video Output Circuit...............................................................................................................................20

[ Design Specification ] ................................................................................................................20

[ CRT Specification ]....................................................................................................................20

[ Block Diagram ] .........................................................................................................................20

[ Circuit Descriptions ]..................................................................................................................21

Preamplifier.....................................................................................................................21

CRT Driver (LM2435) .....................................................................................................22

DC Restoration ...............................................................................................................23

2

Page 36

1995SL CRT Monitor Service Guide

1995SL System Block Diagram

Chapter 2 Circuit Operation Theory

VGA

signal

source

RS-232

Interface

Yoke

1

Video Amplifier

6

2

3

4

Micro-controller

&

DDC

7

Horizontal & Vertical

Deflection Circuit

9

10

11

12 13

14

19"

CRT

HV

90 - 264 VAC

HV Generation

8

5

Switching

Power Supply

&

Power Saving

3

Page 37

1995SL CRT Monitor Service Guide

Chapter 2 Circuit Operation Theory

Switching Power Supply Operation Theory

1. General Specification

Input Voltage : 90~264VAC (FULL RANGE)

Input Frequency : 47~63Hz

Output Requirement: Output MAX. Load Current

+6.5V 0.7 A

+16.5V 0.8 A

+85V 0.15A

+200V 0.37A

2. Block Diagram

DEGAUSS

CIRCUIT

AC

INPUT

RFI

FILTER

RECTIFIER

&

FILTER

SWITCHING

ELEMENT

ISOLATION

TRANSFOR

-MER

FEEDBACK

CONTROL

CIRCUIT

OUTPUT

RECTIFIER

AND FILTER

OUTPUT

POWER

SAVING

4

Page 38

1995SL CRT Monitor Service Guide

3. Circuit Operation Theorem

3.1 RFI FILTER

Chapter 2 Circuit Operation Theory

L

N

FG

R601

430K

1/2W

L602

3

12

C601

4

0.47U

250V

(X)

C602

2200P

250V

(Y)

C603

2200P

250V

(Y)

L603

L604

This circuit designed to inhibit electric and magnetic interference for meet FCC, VDE, VCCI standard

requirements.

3.2 Rectifier and filter

L

~

~

BD601

1

+

+

C612

330U

400V

(EL)

DC OUTPUT

3

4

AC INPUT

-

2

N

When power switch is turn on, the AC voltage is Rectifier and filter by BD601 , C612. The DC output voltage will

be 1.4*(ac input)

5

Page 39

1995SL CRT Monitor Service Guide

Chapter 2 Circuit Operation Theory

3.3 switching Element and isolation transformer

T601

L608

C614

220P

1KV

ZD650

(OPEN)

(D)

R619

1K

2W

6

1

8

9

R604

82K

3W

D608

RGP10J

R608

22K

L607

(BEAD)

R611

1K

L609

(BEAD)

Q602

FS14SM-12

C616

220P

1KV

R607

0.15

2W

C613

0.01U

1KV

(D)

RGP10J

L606

(BEAD)

D606

RGP10J

D607

(BEAD)

In a flyback converter operated in the discontinuous mode, the energy stored in the flyback transformer

(actually an inductor) must be zero at the beginning and end of each switching period . During the "ON" time,

energy taken from the input is stored in the transformer when the switching transistor turn-off, this stored energy

is all delivered to the output.

3.4 Output Rectifier and filter

The structure of each output is illustrated as below

T601

D1 L1

11

12

10

(SHORT)

16

(SHORT)

13

FR701

(SHORT)

FR702

15

18

FR704

+

C1

+

C2

since the transformer T601 acts as a storing energy inductance, diode D1 and capacitor C1 are to produce a dc

output and additional L1, C2 to suppress high-frequency switching spikes.

6

Page 40

1995SL CRT Monitor Service Guide

3.5 Control circuit

C625

50V (D)

330P

8

R613

33K

C615

1000P

50V

(PE)

R614

100K

+

C617

10U

50V

(EL)

D612

1N4148

D613

1N4148

4

C618

0.01U

50V

(D)

Chapter 2 Circuit Operation Theory

R607

0.15

2W

76

VCC OUT

VREF

IC601

UC3842

R/C

C619

0.047U

50V

(D)

R615

47K

IC603

MCR100-3 24V

A

R616

56K

R620

10K

ISSEN

GK

3

GNDFBCOMP

521

ZD602

R622

1K

C627

+

10U

50V

(EL)

+6.5VA

R611

1K

C620

820P

50V

(D)

R738

82

1/2W

4 1

The current mode control IC UC3842 is used in the switching power supply which function of each pin described

as follows.

pin 1 : Error amplifier output pin 5 : Ground

pin 2 : Error amplifier reverse input pin 6 : Output

pin 3 : Current sense pin 7 : VCC

pin 4 : OSC sawtooth pin 8 : Reference Voltage:5V

When power is initially applied to the circuit, capacitor C607 charges through R624, R623, Q601, D609. When

the voltage across C607 reaches a level of 16V, IC601 is turn-on the +5Vdc will be set up at pin8 then R613,

C615 generate a fixed frequency sawtooth wave to pin4, at this time MOSFET will be drived by pin6 with square

wave the pulse width of square wave is decided by pin2 , pin3 is current feedback control, It will to sense

MOSFET current. The D613, D612, R614, C617 are soft start components to avoid the duty too large when

power starts up.

7

Page 41

1995SL CRT Monitor Service Guide

2

5

Chapter 2 Circuit Operation Theory

3.6 Feedback circuit

This power supply adopt feedback circuit of +190V. It used IC701 for voltage regulation and IC602 for primarysecondary isolation, The output voltage differential signal will be detected and sensed to the pin2 of UC3842 for

comparison then the duty cycle of MOSFET will be decided to control the output voltage.

R617

1K

3.7 DEGAUSS CIRCUIT

LLLL

2

This circuit has the function of auto degaussing and manual degaussing. When power supply is switched ON it

is auto degaussing stage. When user make the selection of the manual degaussing function in OSD, the

degaussing current will flow through coil to degauss the screen of monitor.

TR602 is a PTCR to control degaussing coil current .

3.8 power saving control

Mode H-sync V-sync LED Power Rating

Normal Normal Normal Green

Stand-by None Normal Orange

Suspend Normal None Orange Flash

Off None None Orange Flash

When the H-sync is none ,the power supply +16.5V output will be cut-off. The power input will be under 15W.

When the V-sync is none, the power supply +6.5V and+16.5V output will be cut-off. The power input will be

under 5W.

When both of the H-sync and V-sync are none, the power supply +6.5V and +16.5V output will be cut-off. The

power input will be under 5W.

342

TR602

9 OHM

CN602

2P

(OPEN)

1

1

RL601

R603

3W

R720

82

1/2W

IC602

TLP721F

+6.5VA

43

+6.5VA

+190V

R730

200K

1/2W

1%

220K

C714

0.1U

50V

(MONO)

R718

470

VR701

500

R717

2.4K

1%

R719

K

R

IC701

TL431

A

D781

1N4148

R787

330

R784

220

1/2W

Q78

H94

D740

1N4148

1

2

Q740

56

H945

NNNN

R741

2.2K

+12V

R740

(OPEN)

DEGAUSS

+

C740

47U

25V

(EL)

100﹪

≦

15W

≦

5W

≦

5W

8

Page 42

1995SL CRT Monitor Service Guide

y

g

Chapter 2 Circuit Operation Theory

MEA 1995SL MICROCONTROLLER CIRCUIT OPERATION THEORY

1. Introduction

This model, 1995SL, will support powerful O SD function to help end user fine adjustment. The

Microcontroller circuit of the 1995SL can determine what mode it is by detecting the frequency of

horizontal and vertical synchronous and the polarity of horizontal synchronous, and provide DC

voltages to control the picture and save the adjus ted value into the EEPRO M by using the O SD,

"On Screen Display control", that means the user c an get any information of the picture display or

adjust it and save the status values into the EEPROM by choosing and pressing the proper key

according to the indication of the OSD.

2. Block diagram

The major parts of 1995SL Microcontroller circuit are MCU, EEPROM, and OSD IC. The circuit block

diagram is shown as below.

MCU

(MTV212)

Hsync

Vsync

H-polarity

EEPROM

Preset mode

User saved mode

Reset circuit

12MHz Crystal

Control Panel

4 ke

Left,Ri

circuit

s

ht,Enter,Ex

Detecting the

input signals

of H,Vsync &

H-polarity.

Searching for

the same saved

mode timing

with the input

signals and

get the data.

PWM

output

Degaussing

Blanking

SC0 – SC4

OSD IC

Display OSD

and output

PWM to video

circuit

To deflection

circuit

Checking if th e

valid key be pressed

and do key function.

(UART) External

adjustment

function

PC

RS232

auto alignment

program

9

Page 43

1995SL CRT Monitor Service Guide

Chapter 2 Circuit Operation Theory

3.MCU and the peripheral circuit operation theory:

3-1.MCU function

The MCU is MTV212, it is an 87C51 with PW M output controlled mic rocontroller, after power

on, the reset circuit output a "High" to "Low" signal(>40mS) and the 12MHz crystal oscillated

circuit working , the MCU begin to manages the following functions,

(1) To detect mode and output proper SC0 ~ SC5 to deflection circuit.

(2) To check if there is the same saved mode in the EEPROM and get the data to tr ans f er into

DC voltages by PWM output and RC filter circuits to control the picture, color, contrast and

brightness.

(3) To check if there is the valid key be pressed and do the key function.

(4) To memorize mode timings and any adjustable parameters of the picture into EEPROM.

(5) To output data to OSD IC for making an "on screen display control" menu.

(6) The inner registers and PWM output of MCU can be controlled by the external PC

alignment program.

3-2.How to detect mode timing

Only when the mode timing input is stable, we can adjust the picture and check the horizontal

and vertical sync frequency by the OSD menu, and the mode timing input mean the horizontal

sync signal and the vertical sync signal.

(1) The vertical sync frequency measurement:

We use the base timer, it can generate a count during a f ix ed time, this fixed time is 12/12MHz

and we call it "Time_base", so when the first vertical sync generated, we enable the base timer,

and the next vertical sync generated, we disable the base tim er, and we only need to calculate

how many counts are during a vertical sync period. The formula is

Vertical sync frequency

= FV

= 1 / Vertical sync period

= 1 / [ Counters * (Time_base)]

==> Vertical sync frequency = 1000000 / Counts

(2) The horizontal sync frequency measurement:

We use the event counter for calculating how m any counts are during a long fixed time,

because the vertical sync period is longer than the horizontal sync period, we can enable the

event counter when the first vertical sync generated and disable the event counter when the

next vertical sync generated, this time, we can get the horizontal sync counts during a vertical

sync period.

The formula is Horizontal sync frequency

= FH

= Horizontal sync counts / Vertical sync period

==> Horizontal sync frequency

= Horizontal sync Counts / Vertical sync period

3-3.What are the valid key functions for user

There are four k eys on 1995SL control panel. They are "Left," "Right," "Enter," and "Exit." "Enter" for

entering sub-menu of main menu, "Exit" for esc aping to main menu from sub-menu or leaving O SD menu,

and "Left," "Right" for adjusting the bar value.

Except the OSD basic key functions, the user can only press "Right" for brightness adjustment, or "Left"

for contrast adjustment.

10

Page 44

1995SL CRT Monitor Service Guide

u

Chapter 2 Circuit Operation Theory

3-4.How to memorize the timing and adjusted data

The EEPROM of 1995SL is 24C08, it has 1024 bytes memory size and comm unicates with

MCU by two wires of I2C bus, one wire is "SCL," the other is "SDA".

The MCU send clock and data to EEPROM to do "Write" function and send clock and

receive data from EEPROM to do "Read" function by these two wires.

We define three parts of storage area. One is for the storage of the factory preset data,

another is for saving user adjus ted data, the other is f or c ommon settings area where s tored the

data of the OSD color temperature settings, contrast and brightness value .

3-5.How to display the OSD menu

The OSD IC of 1995SL is AP3114 which is developed by vender, it receives the data of the

OSD fonts and attribute what we want to display on the screen from the MCU by 2 wires of

communication, and ex ports OSD window data and PW M volume to the VIDEO c ircuit, the bloc k

diagram is shown as below,

MCU(MTV212)

MCU(MTV112)

(1)Send data to

RAM for OSD

fonts or attribute.

(2)Send data to

Control registers

for PWM ouput

or OSD window

control.

SDA

SCL

OSD IC (MC141542)

Shift receiving

register and decoder.

Control

registers

RAM

Fonts

generator

PWM

output

Output to

the VIDEO circ

ROUT

GOUT

BOUT

FBKGC

VSYNC

HSYNC

(H-BLANK,HBNK)

VCO circuit

3-6.How to execute the auto alignment function

The MCU MTV212 supports the UART function, it has 2 I/O serious ports, one is the receiver, the other is

the transmitter, they are connected with an interface to PC and PC can execute alignment program by

RS232 communication to send the formatted data to the MCU for adjusting any adjustable parameters of

the picture and saving the adjusted values into EEPROM. By this way, we can get the products with the

same quality and reduce the manufacturing time.

11

Page 45

1995SL CRT Monitor Service Guide

Deflection Circuit

HUNLOCK

H/H+V

Sync.

Input

VOUT1

VOUT2

Vertical Output

(IC202--TDA8351)

Chapter 2 Circuit Operation Theory

G1 & Spot Killer

(Q201,Q202,Q203)

Vertical

Deflection

Yoke

G1

To Video

ABL

(Q382)

To

Video

V Sync.

Input

From

Micro-Controller

I2C control input

BSENS

AutoSync

Deflection

Controller

(IC201-TDA4856)

FOCUS

XRAY

BDRV

BOP

BIN

AFC

HDRV

EW

DRV

HV Feedback

X-Ray

Protection

HV

Generation

Driver

(Q320,323)

V-Focus.

Parabola

(Q324)

Sawtooth wave

Generation

(IC203)

AFC

Extract

(C316,C317)

H-DRIVER

(Q301)

H-Size

PWM

Converter

(Q317)

HV

Output

Circuit

With FBT

(T303)

V-Focus

Parabola

H-Fly Back Pulse

H Output

Circuit

(Q302)

Dynamic

Focus

Mixer

( T304)

H-Focus

Parabola

Horizontal

Deflection

Yoke

HV

26KV

G2

G5-1

G5-2

H-blank

To

Video

12

Page 46

1995SL CRT Monitor Service Guide

Chapter 2 Circuit Operation Theory

TDA4856 is a high performance and efficient solution for auto-sync monitors. Shown as fig. , all functions

are controllable by I2C bus.

TDA4856 provides synchronization processing, horizontal and vertical synchronization with fill auto-sync

capability, a TV/VCR mode and very short settling time after mode changes. External power components are

given a great deal of protection. The IC generates the drive waveforms for DC-couple vertical boosters such as

TDA486X and TDA8351.

TDA4856 provides extended functions e.g. as a flexible B+ controller, an extensive set of geometry control

facilities and a combined output for horizontal and vertical focus signals.

13

Page 47

5SL CRT Monitor Service Guide

Chapter 2 Circuit Operation Theory

[ 1995SL Autosync Deflection Controller Circuit ]

The auto-sync deflection control circuit is shown as fig. R214 and R215 are known as RHBUF and RHREF

which determine fmax and fmin of the horizontal oscillator. For 98e, free-run mode is 28.5KHz and the

frequency range is from 31KHz to 86KHz.

[ Vertical Deflection ]

TDA8351 vertical deflection booster is proper for TDA4856 auto-sync deflection IC. This vertical output circuit is

shown in fig. This vertical driver IC circuit is a bridge configuration. TDA4856 differential output signals VOUT1

and VOUT2 are connected to TDA8351 pin1 and pin2 via DC-couple. The vertical coil is connected between the

output amplifier pin4 and pin7, which are driven in opposite phase. TDA8351 can output current 2.8Ap-p

maximum to drive VDY. It can be calculated by:

IR226*R226 = Icoil*R228

So it will be easy to control Icoil by R226 and R228. R229 is used for thermal compensation for Vsize.

VO(GUARD) at pin8 is used for vertical blanking of the picture tube screen. It is inverted by Q201 to get a 40Vp-

14

Page 48

1995SL CRT Monitor Service Guide

Chapter 2 Circuit Operation Theory

p negative pulse and sent to G1 grid to cancel the vertical retrace line of the raster.

[ G1 and Spot-killer ]

When the monitor power turns off, horizontal and vertical deflection will stop quickly, but the light output still

remains on screen and turns into a light spot at the center screen to destroy the monitor. So monitors need

spot-killer circuits to cut off the light output as fast as possible. Mode changing also needs the blanking function.

G1 voltage level is determined by BRITE from the micro-controller DC control voltage. Users can adjust

brightness from the front panel directly.

When the monitor turns off, Q203 will be cut off and G1 will fall down to -190V quickly and prevents the light spot

from destroying the tube.

15

Page 49

1995SL CRT Monitor Service Guide

Chapter 2 Circuit Operation Theory

[ Tilt Circuit ]

Q204 generates a 12V PWM and the buffer (Q205 and Q206) outputs 0~11VDC to get positive and negative coil

current for tilt.

[ Horizontal Size Modulation Circuit ]

< H-size and East-west PWM generator >

Q207 and Q208 constitute a saw-toothed waveform (IC203 pin2)generator. It takes the PWM from HDRV via

the driver transistor Q301. Q210 acts as a thermal compensation. VR201 preset H-size to assure over-scan at

every preset mode. IC203 pin3 consists of HSIZE (via R257) and East-west waveform (via R203, from IC201

pin11). Then the comparator IC203 takes signals of pin2 and pin3 to generate a control-size PWM.

16

Page 50

1995SL CRT Monitor Service Guide

< H-size Output Circuit >

Chapter 2 Circuit Operation Theory

H-output circuit has a positive collect pulse up to 1200V

Q314 acts as a PWM converter for B+ to accept PWM waveform and vary on/off duty.

< Top Ringing Elimina tion Circuit >

L304, R331 and C321 are used to eliminate the ringing at the top of the screen.

< H-driver Circuit >

HDRV signal coming from IC201 pin7 is drived by Q301. T301 is the driver transformer, Q302 the horizontal

output transistor, D303 the damping diode and C305 the tuning capacitor. T301 offers adequate base current of

Q302 from low frequency mode to high frequency mode.

17

Page 51

1995SL CRT Monitor Service Guide

< Cs Control Circuit >

Chapter 2 Circuit Operation Theory

The monitor needs several Cs capacitors to obtain good linearity picture from 31K to 86KHz modes. Cs

capacitors include C309 ~ C313. They are switched by IC301 and switch control signals are sent from uC IC801.

The switching truth table is as follows:

< H-linearity Control Circuit >

The monitor use a special linearity coil to get good linearity picture from 31KHz to 86KHz modes. T302 pin3 and

pin4 are control side of linearity. The control signals which comes from uC IC801 are vary by different modes.

R308 and D306 are used to eliminate ringing bar caused by the linearity coil.

18

Page 52

1995SL CRT Monitor Service Guide

Chapter 2 Circuit Operation Theory

[ High Voltage Processing Circuit ]

The high voltage circuit uses two MOSFETs (Q320 and Q323) to drive FBT to generate HV up to 26KV. HVDRV

and BDRV both are from IC201 but are opposite waveforms. HV-FB is the feedback signal for HV compensation

to adjust the duties of HVDRV and BDRV.

[ ABL Circuit ]

When the loading of video increases, the current through R383 increases. And the base voltage of Q382

decreases. So the voltage of ABL to the video board decreases to keep the light output from going up.

[ Dynamic Focus Circuit ]

The monitor uses double focus CRT and it needs vertical and horizontal parabolic focus signals to input to CRT

G3 and G5 grids.

The vertical parabolic signal from IC201 pin32 is amplified by Q324 to obtain about 150Vpp at the collector of

Q324.

The horizontal parabolic signal is taken from Cs capacitors and amplified by T304 to reach about 350Vpp signal

at pin1 of T401 to combine with vertical parabolic signal and get into FBT focus pack.

19

Page 53

1995SL CRT Monitor Service Guide

Chapter 2 Circuit Operation Theory

Video Output Circuit

[ Design Specification ]

Input :

D-sub connector

Sync type :

Separate Sync (H-sync & V-sync)

Pixel rate = 150 MHz

Light output @ 3” block pattern = 35 F.L. min [brightness at cut-off and contrast max]

@ full white pattern = 28 F.L. min [brightness at cut-off and contrast max]

[ CRT Specification ]

Heater voltage = 6.3V

Heater current = 300 mA typical

Cathode spot cut-off voltage = 110V

Max to min cut-off ratio = 1.20

[ Block Diagram ]

R,G,B Drive

Contrast (ABL)

D-Sub Input

M101

R

G

B

H

V

R,G,B

H,V

(to Main BD)

Preamplifier

CRT Driver

IC101

LM1279

R,G,B

IC102

LM2435

R,G,B Bias

Fig. 1 Block Diagram of 7298e Video

R,G,B output

DC Restoration

Q121,Q122

Q141,Q142

Q161,Q162

19"

CPT

Tube

20

Page 54

1995SL CRT Monitor Service Guide

[ Circuit Descriptions ]

Preamplifier

Chapter 2 Circuit Operation Theory

IC101 (LM1279) is a high bandwidth preamplifier with OSD mixer.

CONTRAST voltage controls the gain of three guns simultaneously. R, G, B DRIVE voltages control the gains of

these three guns individually to approach the white balance of CRT.

CLAMP signal is used to active low to pull the LM1279 outputs below 0.2V during non-display period.

21

Page 55

1995SL CRT Monitor Service Guide

CRT Driver (LM2435)

Chapter 2 Circuit Operation Theory

IC102 (LM2435) contains three wide-bandwidth cascode amplifiers. The parasitic capacitance and

inductance between IC102 outputs and cathodes will also influence the frequency response of IC102.

The diodes and series resistors between cathodes and IC102 output pins are used to protect IC102 during

the tube arcing.

22

Page 56

1995SL CRT Monitor Service Guide

DC Restoration

Chapter 2 Circuit Operation Theory

The amplified video signals are AC couple to cathodes. So a DC restoration circuit is needed to fix their DC

levels. By adjusting R,G,B bias voltages. The raster can be set to specific color temperature.

The control ranges at Q122/Q142/ Q162 emitters are about 80V ~ 53V. Because the blanking pulse at

IC102 output is about 10V, the control range of DC level at cathodes is about 70V ~ 43V.

23

Page 57

1995SL CRT Monitor Service Guide

Table of Contents

Chapter 3 Alignment Procedure

Preparation for alignment : .......................................................................................................................2

1. B﹢Adjustment...................................................................................................................................... 3

2. HV Adjustment......................................................................................................................................3

3. H-center Adjustment :........................................................................................................................... 3

4. H-size preset :.......................................................................................................................................3

5. Factory setting mode adjustment ......................................................................................................... 3

6. Focus adjustment .................................................................................................................................4

7. Convergence adjustment......................................................................................................................4

8. Color Temperature auto alignment....................................................................................................... 4

9. Clear all of user mode data .................................................................................................................. 5

10. Geometry Specification...................................................................................................................... 5

11. Power Saving Function Check............................................................................................................5

12. Eyelet & Touch up ..............................................................................................................................7

13. Wire dressing:..................................................................................................................................... 9

1

Page 58

1995SL CRT Monitor Service Guide

Preparation for alignment :

(I) Setup unit and keep it warm up

(II) Signal mode

Mode Frequency (H/V) Display

1 31.47K / 70 (-/+) 640 * 400 (VGA400)

2 37.50K / 75 (-/-) 640 * 480 (6448A)

3 43.27K / 85 (-/-) 640 * 480 (6448B)

4 46.87K / 75 (+/+) 800 * 600 (SVGA4)

5 53.67K / 85 (+/+) 800 * 600 (SVGA5)

6 60.02K / 75 (+/+) 1024 * 768 (UVGA7)

7 68.68K / 85 (+/+) 1024 * 768 (UVGA8)

8 79.98K / 75 (+/+) 1280 * 1024 (WS7)

9 91.15K / 85 (+/+) 1280 * 1024 (WS8)

10 93.75K / 75 (+/+) 1600 * 1200 (1612E)

at least 30 minutes

Chapter 3 Alignment Procedure

2

Page 59

1995SL CRT Monitor Service Guide

Chapter 3 Alignment Procedure

1. B

a. Input mode

b. Set brightness and contrast in OSD to maximal value.

c. Adjust main board

2. HV Adjustment

a. Input mode

b. Adjust

or 26

3. H-center Adjustment :

a. Input mode

Adjustment

﹢﹢﹢﹢

91K (1280x1024)

VR701

91K (1280x1024)

VR301

±±±±

b. If raster center is near the center of the screen Î plug the CON3 Wire into NONE.

If raster center is near the right side of the screen Î plug the CON3 Wire into LEFT.

If raster center is near the left side of the screen Î plug the CON3 W ire into RIGHT.

to let anode voltage be

0.1KV(for Philips CRT).

91K (1280x1024)

with cross-hatch Pattern.

to main

200V

with cross-hatch pattern.

with raster pattern.

±±±±

0.5V.

±±±±

27

0.1KV (for Hitachi & Samsung CRT)

4. H-size preset :

a. Input mode

b. Use OSD to adjust H-size maximum at factory mode.

c. Adjust

5. Factory setting mode adjustment

1.

H-phase : Set picture to the center of screen

2.

H-Size : Set picture to

3.

V-center : Set picture to the center of screen

4.

V-size : Set picture to

5.

Tilt : L e t tilt ±0.5mm between edge to edge

6.

Pincushion : Set picture to a real rectangular

7.

Unbalance : Set picture to a real rectangular

8.

Trapezoid : Set picture to rectangular or balance of top and bottom

9.

Parallelogram : Set picture to rectangular or balance of top and bottom

10.

Top Corner : Set the line of top corner to a straight line

11.

Bottom Corner: Set the line of bottom corner to a straight line

37.5K (640x480)

VR201

to make H-size

with H-size limit pattern.

just overscreen.

±±±±

350

262

2

mm

±±±±

2

mm

3

Page 60

1995SL CRT Monitor Service Guide

Chapter 3 Alignment Procedure

6. Focus adjustment

a. Input mode

b. Adjust V(F2) Focus VR of FBT to make vertical line between center

and corner area of CRT clear.

c. Adjust H(F1) to make horizontal line between center and corner area

of CRT clear.

d. Repeat step b and c to get the best focus.

e. Check focus at input mode 91K (1280x1024) with reverse text-5x7 pattern.

7. Convergence adjustment

a. Input mode

b. Adjust VRs of Yoke and 4-pole , 6-pole to meet specification.

91K (1280x1024)

91K (1280x1024)

with green cross-hatch pattern.

with cross-hatch patterns.

8. Color Temperature auto alignment

[Input mode : 91K/ 85 Hz, WS8]

i) Equipment

a. PC + QUANTUM DATA/CHROMA card

b. RS232 BOX

c. COLOR ANALYZER (CA100)

d. RS232 CABLE (9P) connect RS232 BOX to PC(COM1)

e. CA100 CABLE to PC(COM2)

g. ADJUST PROGRAM for G991

ii) Alignment procedure

a. Press "SPACE BAR " to get raster pattern and set contrast and brightness to

maximum position, adjust the G2 VR such that the max. color of R.G.B color bar on

the monitor is in the mark region.

b. Press "SPACE BAR" to do auto color temperature adjustment and color tracking

c. Press "SPACE BAR" to get 3"-block and finish the adjustment

For TCO99 Color Temperature Alignment:

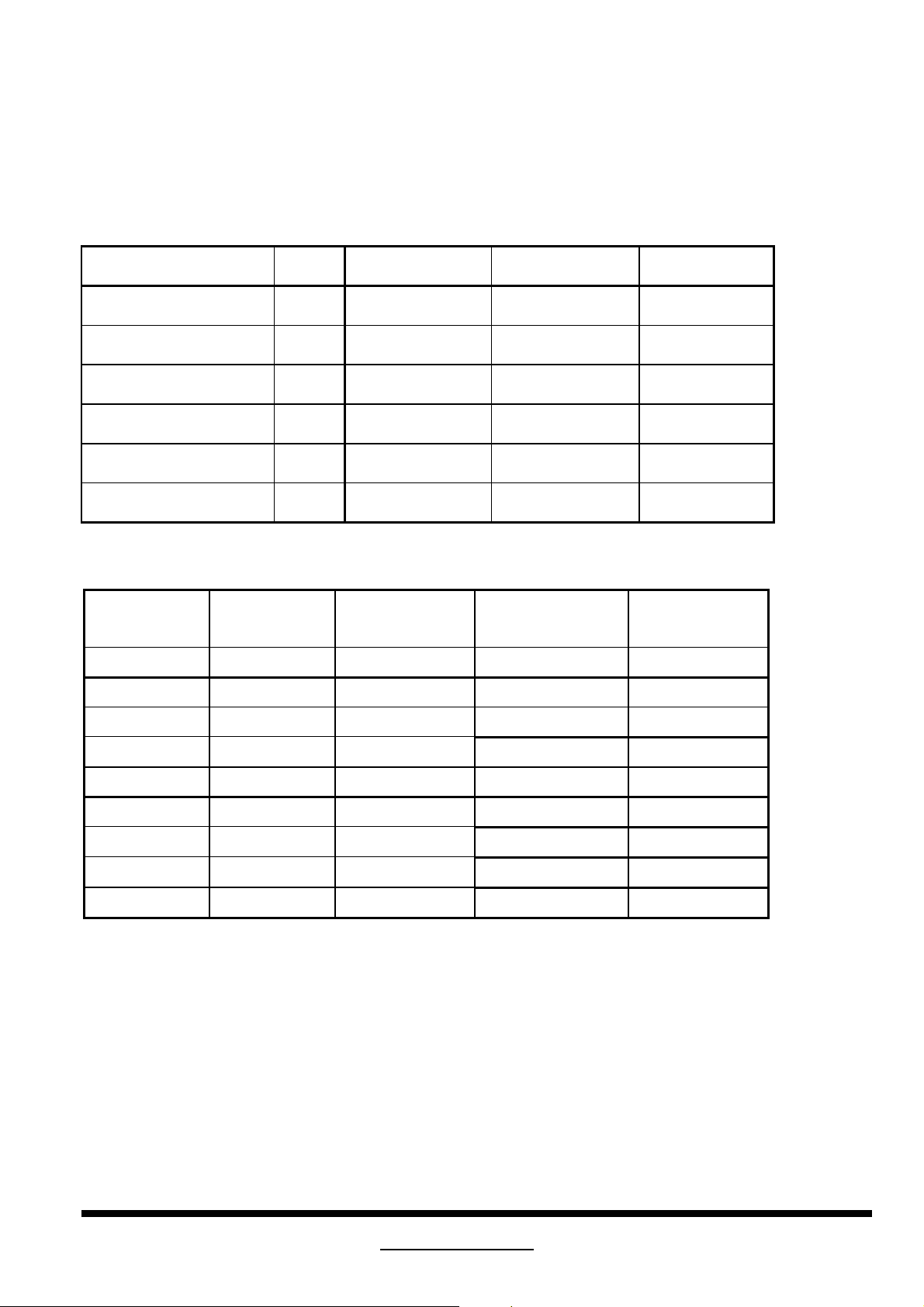

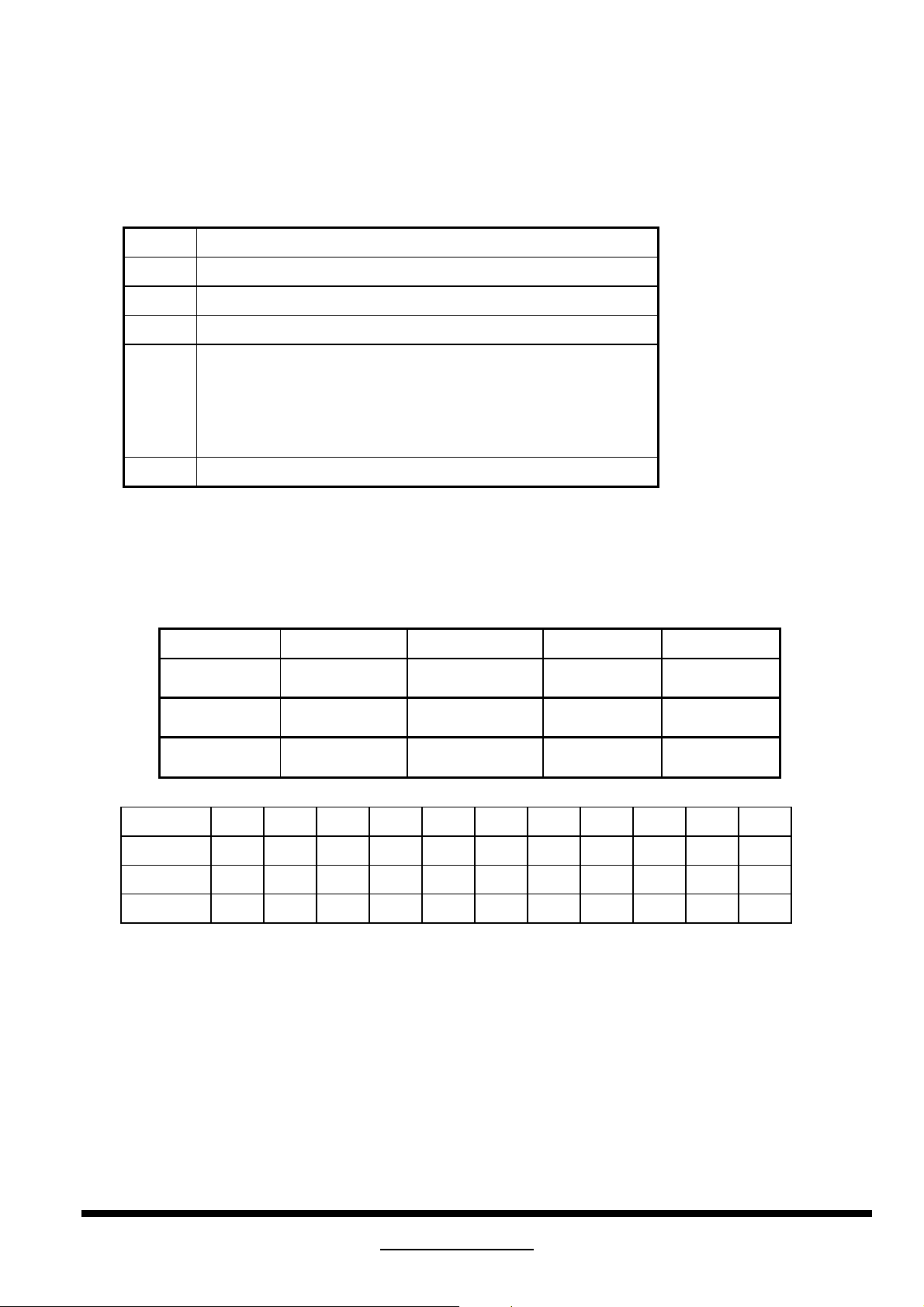

Item Descriptions x y u’ v’

C1 9300K

C2 6500K

For MPRII Color Temperature Alignment:

Item Descriptions X y

C1 9300K

C2 6500K

283 ± 5 297 ± 5

313 ± 5 329 ± 5

281 ± 5 311 ± 5

313 ± 5 329 ± 5

0.189 0.446

0.198 0.468

4

Page 61

1995SL CRT Monitor Service Guide

Chapter 3 Alignment Procedure

9. Clear all of user mode data

After finishing all factory setting , select “Reset to default “at MENU 1 then press enter.

10. Geometry Specification

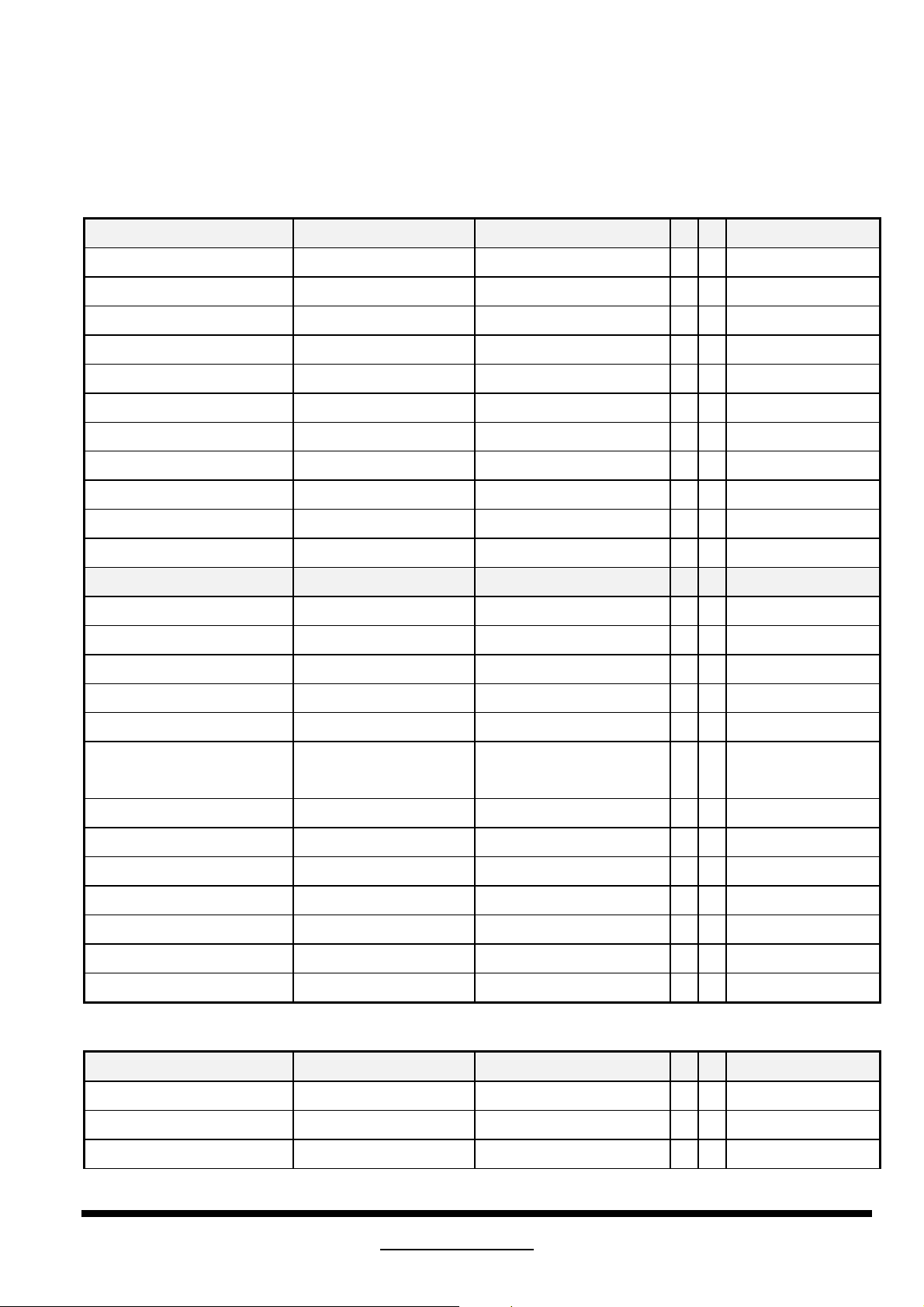

ITEM DESCRIPTION SPECIFICATION

1 HORI SIZE

2 VERT SIZE

3 SIDE PIN

4 TOP/BOTTOM PIN

5 SIDE BARREL

6 TOP/BOTTOM BARREL

7 TRAPEZOID

8 VIDEO OFFSET

9 PARALLELOGRAM

350±4 mm

262±4 mm

≦

1.8 mm

≦

1.35 mm

≦

1.8 mm

≦

1.35 mm

≦

3.0 mm

≦

4.0 mm

≦

3.5 mm

11. Power Saving Function Check

a. Input mode 31KHz (VGA400 640 X 400) with full-white pattern.

b. Press both contrast and brightness keys to maximum position.

[Standby Mode]

c. Remove the

The picture will disappear, and the LED indicator is

should be less than

horizontal sync

15W

signal from input, the unit will go into "

amber

.

Standby

. The power consumption

[Suspend Mode]

d. Remove

The picture will disappear, and the LED indicator is

vertical sync

signal from the input, the unit will go into "

amber (blinking)

Suspend

. The power

consumption should be less than 5W.

[Off Mode]

e. Remove

both syncs

from input, the unit will go into "

The picture will disappear, and the LED indicator is

Off

" mode.

amber (blinking)

. The power

consumption should be less than 5W in this case.

f. Input H-sync and V-sync signals in case c, d and e, the unit will recover to normal

state, and the LED indicator is green.

[Override Mode]

" mode.

" mode.

5

Page 62

1995SL CRT Monitor Service Guide

Chapter 3 Alignment Procedure

g. Disconnect the signal cable from input ,then power on , the unit will go into

"Override" mode. The OSD windows will show “no signal”, and the LED indicator is

green. The power consumption is normal.

h. Re-connect the signal cable in case g, the unit will recover to normal state, and the

LED indicator is green.

6

Page 63

1995SL CRT Monitor Service Guide

Chapter 3 Alignment Procedure

12. Eyelet & Touch up

Eyelet: IC301, Q317 headsink , H & V dy , T303 FBT , C612 , Q602

7

Page 64

1995SL CRT Monitor Service Guide

Touch up : T303 FBT , TR602

Chapter 3 Alignment Procedure

8

Page 65

1995SL CRT Monitor Service Guide

13. Wire dressing:

Right side

Chapter 3 Alignment Procedure

Top side

9

Page 66

1995SL CRT Monitor Service Guide

Back side

Right side Braid wire

Chapter 3 Alignment Procedure

10

Page 67

1995SL CRT Monitor Service Guide

Left side FBT schielding & braid wire

Chapter 3 Alignment Procedure

Top view FBT wire core

11

Page 68

1995SL CRT Monitor Service Guide

Ac GND wire & PCB GND wire

Chapter 3 Alignment Procedure

12

Page 69

1995SL CRT Monitor Service Guide

Chapter 4 Trouble Shooting

Table of Contents

0. Introduction..............................................................................................................................2

1. System trouble category.......................................................................................................... 2

2. Trouble shooting for short circuit............................................................................................. 3

3. Trouble shooting for bad geometry.......................................................................................... 4

4.Trouble shooting for no picture................................................................................................. 5

5. Trouble Shooting for bad video................................................................................................ 6

6. Power supply........................................................................................................................... 8

7. Check MCU and OSD for no video output............................................................................... 9

8. Check OSD,MCU for no OSD window .................................................................................... 10

9. Dis-assembly........................................................................................................................... 11

1

Page 70

1995SL CRT Monitor Service Guide

Chapter 4 Trouble Shooting

0. Introduction