Page 1

Acer Altos G900

User’s guide

Page 2

Copyright © 2003 Acer Incorporated

All Rights Reserved.

Acer Altos G900

User’s guide

January 2003

Changes may be made periodically to the information in this publication without obligation

to notify any person of such revision or changes. Such changes will be incorporated in new

editions of this manual or supplementary documents and publications. This company makes

no representations or warranties, either expressed or implied, with respect to the contents

hereof and specifically disclaims the implied warranties of merchantability or fitness for a

particular purpose.

Record the model number, serial number, purchase date, and place of purchase information in

the space provided below. The serial number and model number are recorded on the label

affixed to your server. All correspondense concerning your unit should include the serial

number, model number, and purchase information.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form or by any means, electronic, mechanical, photocopy, recording, or otherwise,

without the prior written permission of Acer Incorporated.

Model Number : _________________________________

Serial Number: ___________________________________

Purchase Date: ___________________________________

Place of Purchase: ________________________________

Acer and the Acer logo are registered trademarks of Acer Inc. Other company’s product

names or trademarks are used herein for identification purposes only and belong to their

respective companies.

Page 3

iii

Notices

FCC notice

This device has been tested and found to comply with the limits for a Class A

digital device pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This device generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this device does cause harmful interference to radio or television

reception, which can be determined by turning the device off and on, the user

is encouraged to try to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the device and receiver

• Connect the device into an outlet on a circuit different from that to which

the receiver is connected

• Consult the dealer or an experienced radio/television technician for help

Notice: Shield cables

All connections to other computing devices must be made using shielded cables

to maintain compliance with FCC regulations.

Notice: Peripheral devices

Only peripherals (input/output devices, terminals, printers, etc.) certified to

comply with the Class A limits may be attached to this equipment. Operation

with noncertified peripherals is likely to result in interference to radio and TV

reception.

Caution! Changes or modifications not expressly approved by

the manufacturer could void the user’s authority, which is granted

by the Federal Communications Commission, to operate this

computer.

Page 4

iv

Use conditions

This part complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference,

and (2) this device must accept any interference received, including interference

that may cause undesired operation.

Notice: Canadian users

This Class A digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Remarque à l’intention des utilisateurs canadiens

Cet appareil numérique de la classe A respected toutes les exigences du

Règlement sur le matériel brouilleur du Canada

.

Laser compliance statement

The CD-ROM drive in this computer is a laser product. The CD-ROM drive’s

classification label (shown below) is located on the drive.

CLASS 1 LASER PRODUCT

CAUTION: INVISIBLE LASER RADIATION WHEN OPEN. AVOID EXPOSURE TO

BEAM.

Page 5

Important safety information

Only a technically qualified person shall access, integrate, configure, and service

this product.

Intended application uses

This product was evaluated as an Information Technology Equipment (ITE),

which may be installed in offices, schools, computer rooms, and similar

commercial type locations. The suitability of this product for other Product

Categories and Environments (such as medical, industrial, alarm systems, and

test equipment), other than as an ITE application, may require further

evaluation.

Checking the power cords

Warning! To avoid electrical shock, do not attempt to

modify or use the supplied AC power cord(s), if they are

not the exact type required.

If a power cord(s) supplied is not compatible with the AC wall outlet in your

region, get one that meets the following criteria:

• The power cord must be properly rated for the AC voltage in your region.

• The power cord plug cap must have an electrical current rating that is at

least 125% of the electrical current rating of the product.

• The power cord plug cap that plugs into the wall socket-outlet must have a

grounding-type male plug designed for use in your region.

• The power cord must have safety certifications for your region, and shall

be marked with the certification markings.

• The power cord plug cap that plugs into the AC receptacle on the power

supply must be an IEC 320, sheet C13, type female connector.

• In Europe, the power cord must be less than 4.5 meters (14.76 feet) long,

and it must be flexible <HAR> (harmonized) or VDE certified cordage to

comply with the chassis' safety certifications.

• The power supply cord(s) is the main disconnect device to AC power. The

socket outlet(s) shall be near the equipment and shall be readily accessible

for disconnection.

v

Page 6

vi

Multiple power cords

Warning! To avoid electrical shock, disconnect all AC power cords before

accessing inside the system.

Earth grounded socket-outlets

Warning! To avoid electrical shock, the system power cord(s) must be plugged

into socket-outlet(s) that is provided with a suitable earth ground.

Precautionary reminders

• Over current protection

The system is designed to operate on a 20A AC voltage source that is

provided with 20A over current protection. If the AC source for the rack

exceeds 20A over current protection, each system must be provided with

20A or less over current supplemental protection. The supplementary over

current protection must have the appropriate regional safety certifications

for the over current application.

• Power supply modules

Power supply modules have double-pole/neutral fusing.

• Ventilation considerations

The equipment rack must provide sufficient airflow to the front of the

system to maintain proper cooling. The rack selected and the ventilation

provided must be suitable to the environment in which the system will be

used.

•Fans

To avoid injury do not touch moving fan blades.

• Cooling and airflow

For proper cooling and airflow, always install all access covers before

turning on the system. Operating the system for longer than five minutes

without the covers in place can cause overheating and damage to system

components.

• Temperature limits

The operating temperature of the system, when installed in the rack, must

not go below 10°C (50°F) or rise above 35°C (95°F). Extreme fluctuations in

temperature may cause a variety of problems in system, and safety limits

may be broken.

• Lifting and Moving

Do not attempt to lift or move the server by the handles on the power

supplies.

Page 7

Equipment rack precautions

Follow the rack manufacturer's safety and installation instructions for proper

rack installation.

The following additional rack safety installation measures shall be considered:

• Anchor the equipment rack

The equipment rack must be anchored to an unmovable suitable support

to prevent the rack from falling over when one or more systems are fully

extended out of the rack assembly. You must also consider the weight of

any other devices installed in the rack assembly. The equipment rack must

be installed according to the manufacturer's instructions.

• Main AC power disconnect

You are responsible for installing an AC power disconnect for the entire

rack unit. This main disconnect must be readily accessible, and it must be

labeled as controlling power to the entire unit, not just to the system(s).

• Grounding the rack installation

To avoid the potential for an electrical shock hazard, the rack assembly

itself must be suitably earth grounded, according to your local regional

electrical codes. This typically will require the rack to have its own separate

earth ground. We recommend you consult your local approved electrician.

vii

Page 8

viii

Important safety instructions

Read these instructions carefully. Save these instructions for future reference.

1 Follow all warnings and instructions marked on the product.

2 Unplug this product from the wall outlet before cleaning. Do not use

liquid cleaners or aerosol cleaners. Use a damp cloth for cleaning.

3 Do not use this product near water.

4 Do not place this product on an unstable cart, stand, or table. The product

may fall, causing serious damage to the product.

5 Slots and openings in the cabinet and the back or bottom are provided for

ventilation; to ensure reliable operation of the product and to protect it

from overheating, these openings must not be blocked or covered. The

openings should never be blocked by placing the product on a bed, sofa,

rug, or other similar surface. This product should never be placed near or

over a radiator or heat register, or in a built-in installation unless proper

ventilation is provided.

6 This product should be operated from the type of power indicated on the

marking label. If you are not sure of the type of power available, consult

your dealer or local power company.

7 Do not allow anything to rest on the power cord. Do not locate this

product where persons will walk on the cord.

8 If an extension cord is used with this product, make sure that the total

ampere rating of the equipment plugged into the extension cord does not

exceed the extension cord ampere rating. Also, make sure that the total

rating of all products plugged into the wall outlet does not exceed the fuse

rating.

9 Never push objects of any kind into this product through cabinet slots as

they may touch dangerous voltage points or short out parts that could

result in a fire or electric shock. Never spill liquid of any kind on the

product.

10 Do not attempt to service this product yourself, as opening or removing

covers may expose you to dangerous voltage points or other risks. Refer all

servicing to qualified service personnel.

11 Unplug this product from the wall outlet and refer servicing to qualified

service personnel under the following conditions:

a When the power cord or plug is damaged or frayed

b If liquid has been spilled into the product

c If the product has been exposed to rain or water

Page 9

d If the product does not operate normally when the operating

instructions are followed. Adjust only those controls that are covered

by the operating instructions since improper adjustment of other

controls may result in damage and will often require extensive work

by a qualified technician to restore the product to normal condition.

e If the product has been dropped or the cabinet has been damaged

f If the product exhibits a distinct change in performance, indicating a

need for service.

12 Replace the battery with the same type as the product's battery we

recommend. Use of another battery may present a risk of fire or explosion.

Refer battery replacement to a qualified serviceman.

13 Warning! Batteries may explode if not handled properly. Do not

disassemble or dispose of them in fire. Keep them away from children and

dispose of used batteries promptly. Dispose of used batteries according to

manufacturer's instructions.

14 Use only the proper type of power supply cord set (provided in your

accessories box) for this unit. It should be a detachable type: UL listed/CSA

certified, type SPT-2, rated 7A 125V minimum, VDE approved or its

equivalent. Maximum length is 15 feet (4.6 meters).

ix

Page 10

x

Page 11

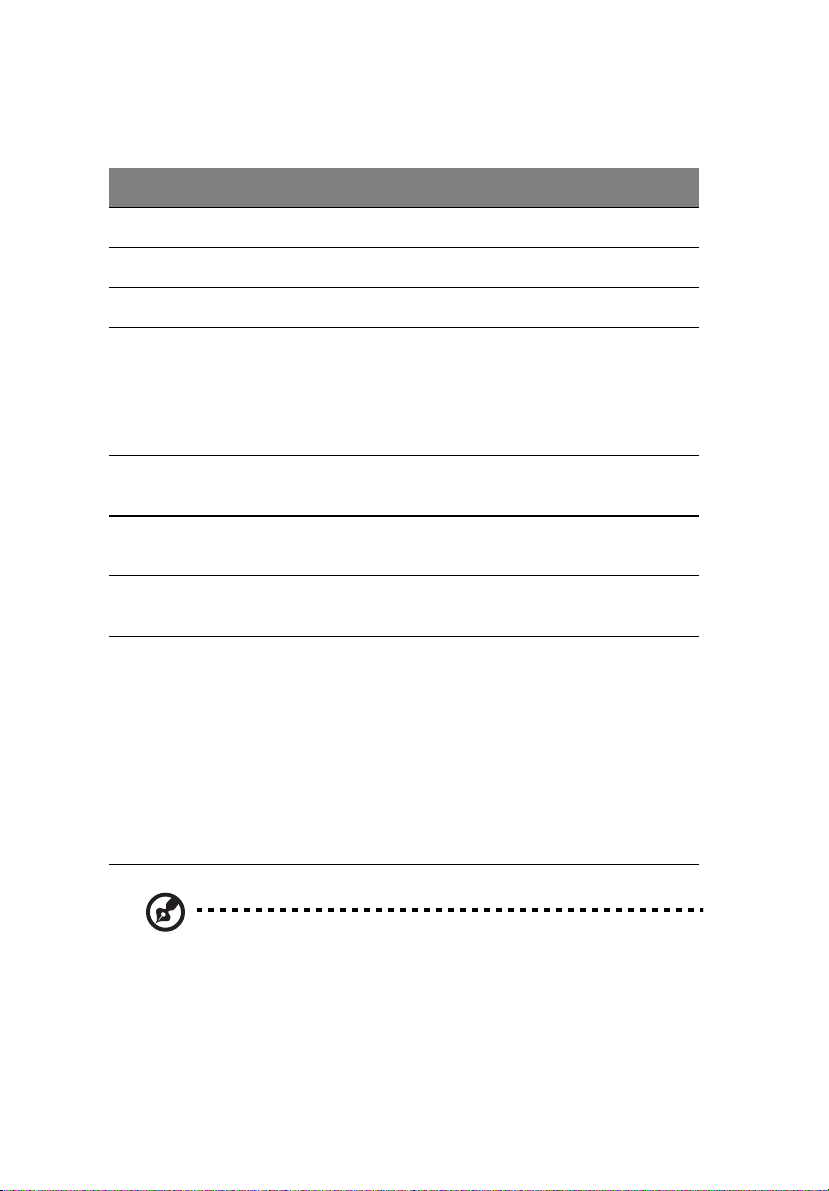

Notices iii

FCC notice iii

Laser compliance statement iv

Important safety information v

Intended application uses v

Checking the power cords v

Precautionary reminders vi

Equipment rack precautions vii

Important safety instructions viii

1 System tour 1

Features overview 3

Altos G900 physical specifications 4

External and internal structure 5

Access covers 5

Main chassis components 6

Electronics bay components 7

Front control panel 8

Rear panel 10

Peripheral device bay 12

Server board set features 13

Mainboard layout 13

System cables 19

System features 22

Processors 22

Memory 22

SCSI controller 22

Onboard video 23

Network interface controllers 23

Hot-swap hard drive bays 24

Power supply 25

System fan 25

ACPI 26

Contents

2 System setup 27

Getting started 29

Checking for damage to the packaging 29

Selecting a site 29

Checking the package contents 30

Setting up your system 32

Setup reminders 32

Pre-setup safety steps 32

Page 12

xii

Hardware setup 33

Turning on the server and running the Power-On

Self Test (POST) 34

Software setup 36

Network teaming features 37

3 Hardware configuration 39

Installation precautions 41

ESD precautions 41

Preinstallation instructions 42

Post-installation instructions 42

Tools and supplies needed 43

System access panels 44

Before removing the access panels 44

Rear access panel 44

Front access panel 45

Front subchassis and rear

electronics bay 47

Opening the front subchassis and rear

electronics bay 47

Removing the front subchassis and rear

electronics bay 48

Closing the front subchassis and rear

electronics bay 50

Accessing the system boards 51

Access cover to the system boards 51

Memory board 52

53

53

53

Processor board 54

Mainboard 55

Memory 60

DIMM sequence 60

Processors 63

Processor sequence 63

PCI add-in boards 67

PCI add-in board locations 67

Operating system support for hot-plug

add-in boards 68

Checking the status indicators for a hot-plug

add-in board 68

Installing and removing a hot-plug PCI

Page 13

add-in board 69

Installing and removing a PCI add-in board in

a non-hot-plug slot 72

Hot-swap SCSI drives 75

Checking a hot-swap SCSI drive status indicator 75

Installing and removing a hot-swap drive

in a carrier 76

Removing and installing hot-swap disk drives 78

DC power supplies 81

Checking the power supply LED status indicators 81

Removing and installing a power supply module 82

Cooling system fans 85

Checking a fan status indicator 85

Removing and installing a fan module 86

Backup battery 87

Replacing the battery 87

Front panel board 89

Installing the front panel board 89

Diskette drive 91

Replacing the diskette drive 91

5.25-inch peripheral drives 94

Preliminary considerations 94

Removing and installing a 5.25-inch

peripheral drive 95

Hot-swap drive bays 98

Removing and installing a hot-swap drive bay 98

Power distribution board 101

Replacing the power distribution board 101

Fan distribution board 103

Replacing the fan distribution board 103

Foam fan baffle 105

Removing and installing the foam fan baffle 105

Hot-plug indicator board 107

Replacing the hot-plug indicator board 107

4 BIOS setup 109

BIOS setup 111

Recording BIOS settings 111

Clearing CMOS memory 111

Using BIOS setup 112

Main 114

Primary IDE Master/Slave 116

Processor Settings 118

Page 14

xiv

Advanced 119

Memory Configuration 121

PCI Configuration 122

I/O Device Configuration 129

Advanced Chipset Control 131

Security 132

Server 136

System Management 138

Console Redirection 139

Boot 140

Exit 141

Appendix A: System rack installation 143

System rack installation 145

Rack-mount kit contents 145

Tools and supplies needed 146

Equipment rack precautions 146

Rack conversion procedures 148

Removing the bottom panel 148

Removing the left panel 149

Removing the original tower bezel 150

Removing the feet 151

Installing the rack bezel 152

Installing the bushings on the chassis 153

Installing the handles and rails 154

Appendix B: System management 159

Software and utilities 161

Integrated hardware system management 162

Baseboard management controller 162

Field replaceable units and sensor data records 163

System event log 163

Platform event management 164

Emergency management port 165

System Setup Utility 166

Creating SSU diskettes 166

Running the SSU 167

Working with the GUI 168

Customizing the SSU interface 168

Setting boot device priority 169

Setting passwords and security options 169

Viewing the system event log 171

Viewing FRU information 172

Page 15

Viewing Sensor Data Records 173

Updating system firmware and BIOS 174

Saving and restoring the system configuration 174

Alerting for platform events 175

Managing the server remotely 179

Exiting the SSU 182

FRU/SDR load utility 183

When to run the FRU/SDR load utility 183

Running the FRU/SDR load utility 183

SCSISelect 186

Running SCSISelect 186

Software updates 187

Software update packages 188

Individual updates 189

Appendix C: Equipment log and configuration worksheets

193

Equipment log 195

Calculating power consumption 196

Calculating DC power usage 196

Calculating the total combined power used

by the system 198

xv

Appendix D: Troubleshooting 199

Troubleshooting 201

Resetting the system 201

Initial system startup 201

Running new application software 202

After the system has been running correctly 203

Monitoring POST 203

Verifying proper operation of key system lights 204

Confirming loading of an operating system 204

Frequently asked questions (FAQs) 205

Appendix E: Codes and error messages 211

Standard BIOS post codes 213

Recovery BIOS POST codes 219

BMC beep codes 221

POST error messages and codes 222

Index 227

Page 16

xvi

Page 17

1 System tour

Page 18

This chapter gives you a tour of the system’s

internal and external components, as well as

a discussion of its many features.

Page 19

Features overview

The Acer Altos G900 four-way performance server model utilizes a PCI

bus based mainboard built on an ATX form factor. It supports up to

four processors from the Intel

For expandability, the mainboard supports eight full length PCI slots

(4 PCI-X hot plug, 2 PCI-X non-hot plug, 2 PCI non-hot plug). An

impressive 24 GB maximum system memory is achieved through 12

DIMM sockets utilizing DDR-266 (Double Data Rate) modules.

Media drives include one 3.5-inch floppy drive, a CD-ROM drive, plus

two 5.25-inch peripheral bays. The system also supports up to ten

1-inch hot-swap Ultra 320 SCSI hard drives providing an additional

1460 GB of storage space.

For connectivity, the mainboard provides two external USB (Universal

Serial Bus) ports and one internal header providing one additional USB

port, PS/2 interface for both mouse and keyboard, one VGA/monitor

port, one external serial port and one internal serial port header, one

parallel port with Extended Capabilities Port (ECP)/Enhanced Parallel

Port (EPP) support, and for networking, two NIC ports (RJ-45).

Power supply is provided by the three hot-swap power supply modules

in a 2+1 redundant configuration (third module optional).

®

Xeon™ processor family.

3

In terms of serviceability, the system features front access to hot-swap

hard disk drives, rear access to hot-swap power supplies, and side

access to hot-plug PCI boards and hot-swap fans. Serviceable items are

color coded throughout and detailed configuration labels are located

on the system’s side panel. Fault indicators and system UID (Unit ID)

light are also available.

Manageability features include compliance to both IPMI 1.5 and WfM

2.0 standard, extensive system sensors and monitoring, as well as

function for remote management and diagnostics via the serial or LAN

port. External chassis management is done via ICMB.

Page 20

4

1 System tour

Altos G900 physical specifications

Specification Rack-mount orientation Tower orientation

Height 12.25 inches (311 mm) (7U) 18.09 inches (459 mm)

Width Fits 19-inch rack 12.24 inches (311 mm)

Depth 25.25 inches (641 mm) 25.25 inches (641 mm)

Weight

Minimum

configuration

Maximum

configuration

90 pounds (41 kg)

119 pounds (57 kg)

96 pounds (44 kg)

125 pounds (57 kg)

Required front

clearance

Required rear

clearance

Required side

clearance

Power

requirements

Voltage (110)

Voltage (220)

Frequency

Note: Amperage values indicated on this section is based on

total system power, with two or three power supply modules

installed. For detailed information on calculating power

consumption for specific server configurations, see page 196.

3 inches (76 mm),

inlet airflow <35 °C (95 °F)

4.5 inches (114 mm),

no airflow restriction

0 inch (0 mm) 0 inch (0 mm)

90 Vrms min, 132 Vrms

max, 9 Arms

180 Vrms min, 264 Vrms

max, 4.5 Arms

47 Hz min, 63 Hz max

12 inches (305 mm)

9 inches (229 mm)

90 Vrms min, 132 Vrms

max, 9 Arms

180 Vrms min, 264 Vrms

max, 4.5 Arms

47 Hz min, 63 Hz max

Page 21

External and internal structure

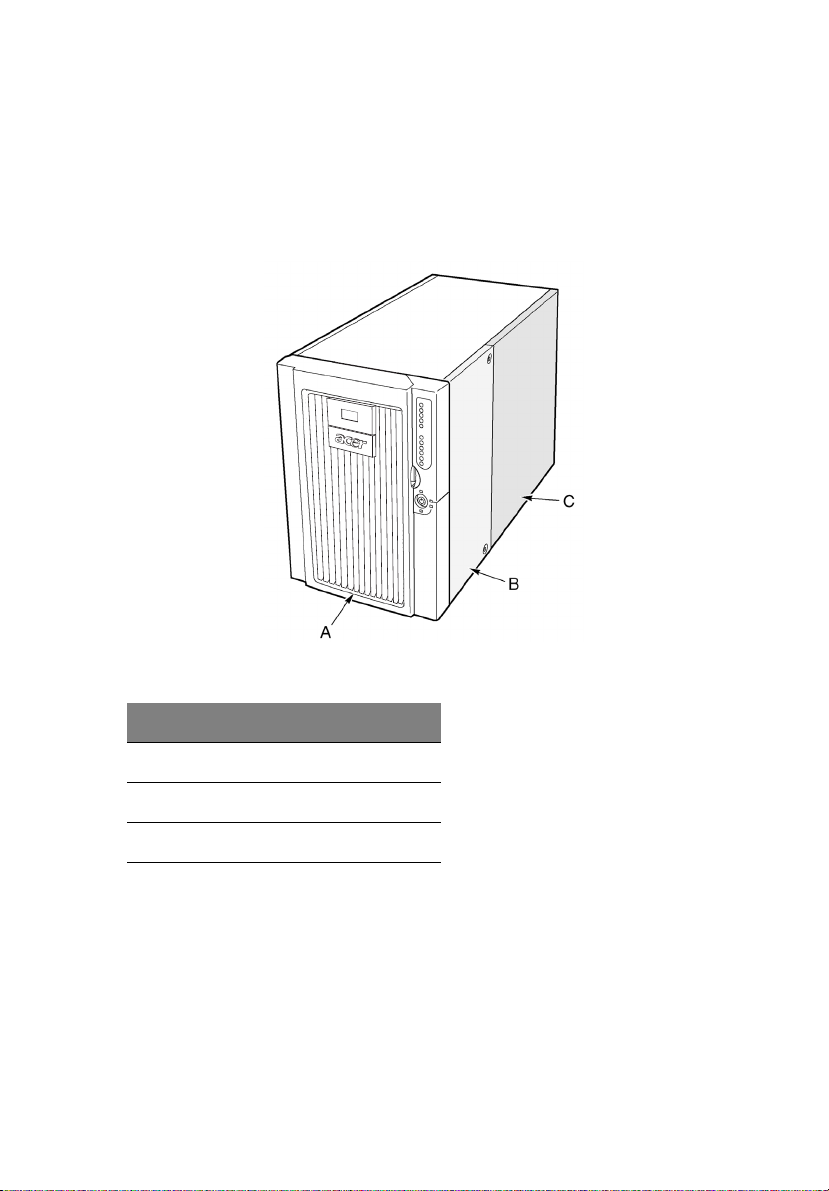

Access covers

The figure below shows the system’s access panels

5

Label Description

A Bezel

B Front access panel

C Rear access panel

Figure 1 - Access covers

Page 22

6

1 System tour

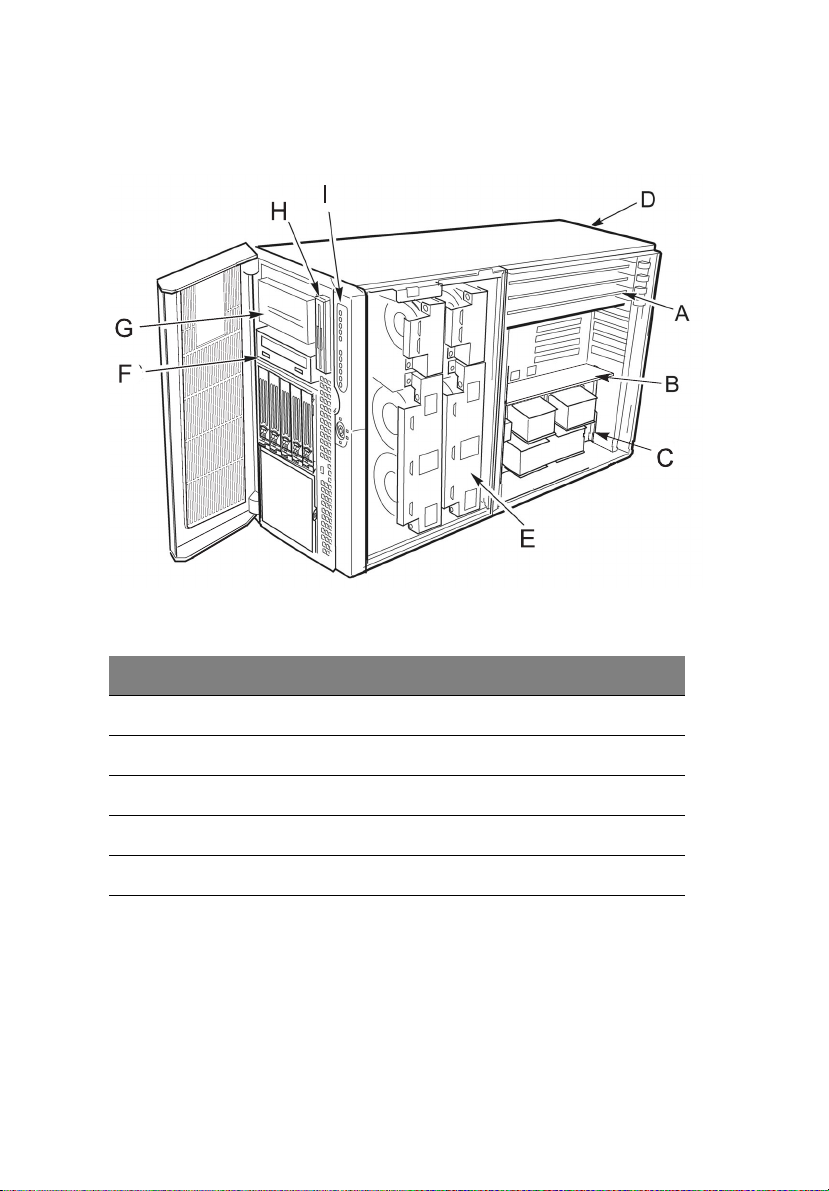

Main chassis components

The figure below shows the chassis with the access panels removed.

Figure 2 - Main chassis components

Label Description Label Description

A Hot-plug PCI add-in cards F CD-ROM drive

B Memory board G 5.25-inch peripheral bay

C Electronics bay H 3.5-inch diskette

D Power supply bay I Front control panel

EFan bay

Page 23

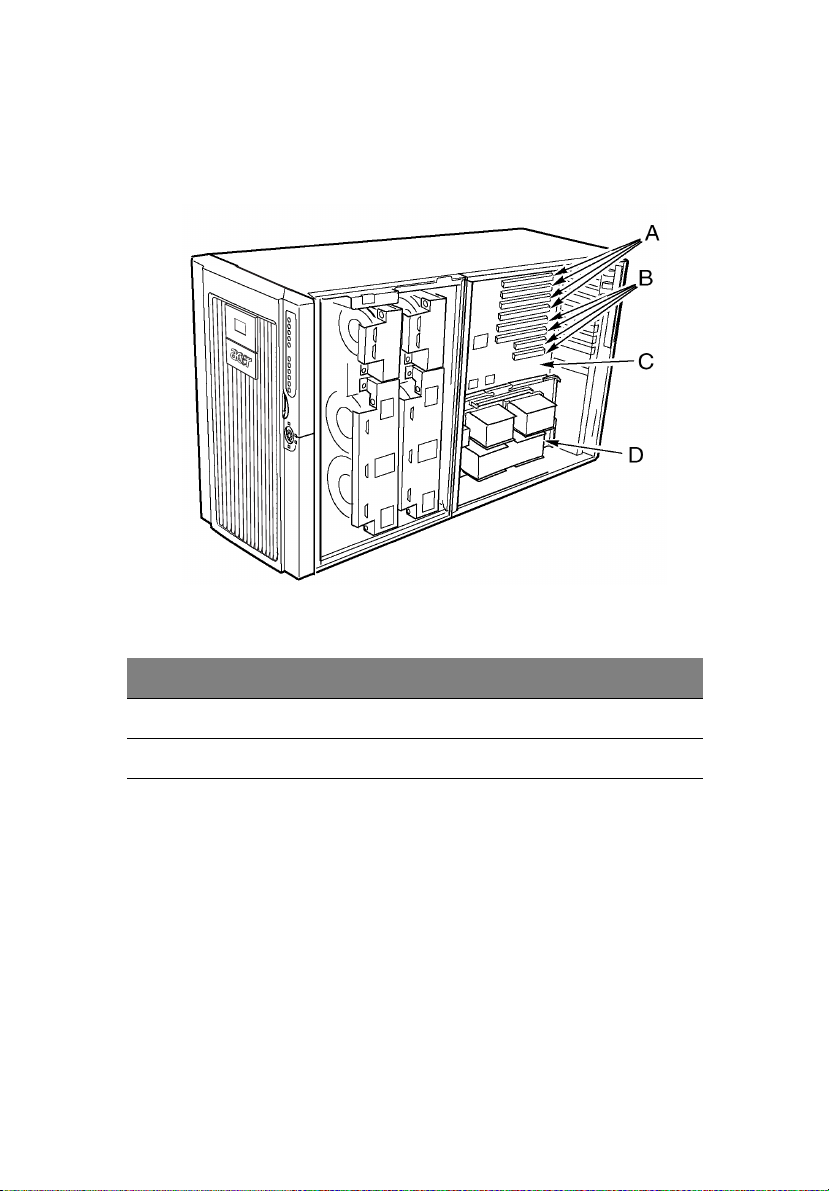

Electronics bay components

The figure below shows the electronics bay with the access cover and

memory board removed.

Figure 3 - Electronics bay components

7

Label Description Label Description

A Hot-plug PCI slots C Mainboard

B Non-hot-plug PCI slots D Processor board

Page 24

8

1 System tour

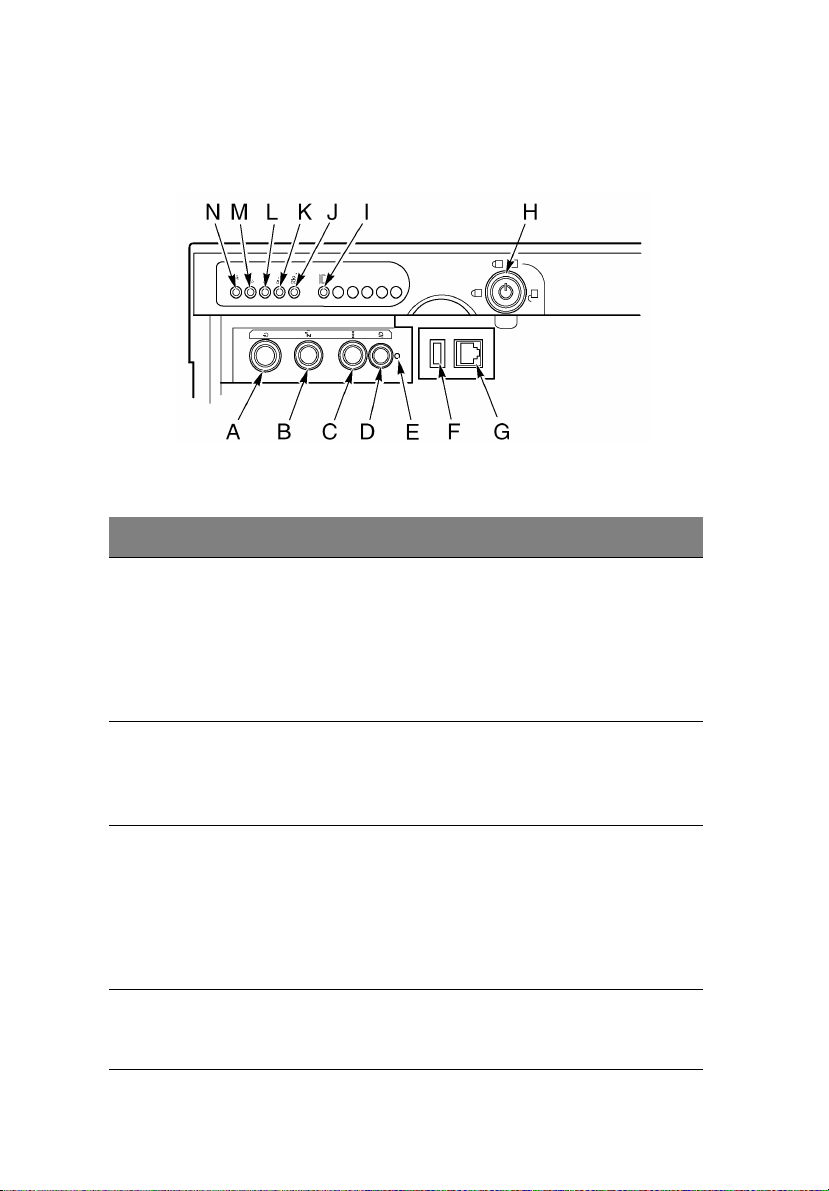

Front control panel

The figure below describes the features of the front control panel.

Figure 4 - Front control panel

Label Description Operation

A Power button To turn power on, press the power button

momentarily. If the system is in sleep state,

pressing the power button momentarily brings

the system out of the sleep state.

To turn power off, press and hold the power

button for more than four seconds. This

overrides ACPI mode.

B Sleep button To put a system supporting ACPI into sleep

mode (S1), press the sleep button momentarily.

To wake a system from sleep mode, press the

sleep button momentarily.

C Reset button To reset the system, press the reset button

momentarily.

To clear CMOS, press and hold the reset button

for at least four seconds, and then press the

power button. Release both the reset and

power buttons at the same time. The system

will power on and the CMOS will be reset.

D Chassis ID

button

Illuminates LEDs on both the front and rear of

the chassis, simplifying identification of the

chassis in a rack from the rear.

Page 25

Label Description Operation

E NMI switch Causes a non-maskable interrupt. Located

behind the bezel door.

F USB connector USB port 3. Located behind the bezel door.

9

G Serial port

connector

H Lock Locks the bezel and front access cover.

I Chassis ID LED Blue indicates chassis ID is active.

J LAN2 LED Green indicates LAN2 activity.

K LAN1 LED Green indicates LAN1 activity.

L Hard drive

activity LED

M Fault LED Red indicates any system fault condition.

N Main power

LED

Serial port B. Located behind the bezel door.

Green indicates system hard drive activity.

Solid green indicates the presence of DC power

in the server.

Flashing green indicates that the system is in

ACPI sleep mode.

Page 26

10

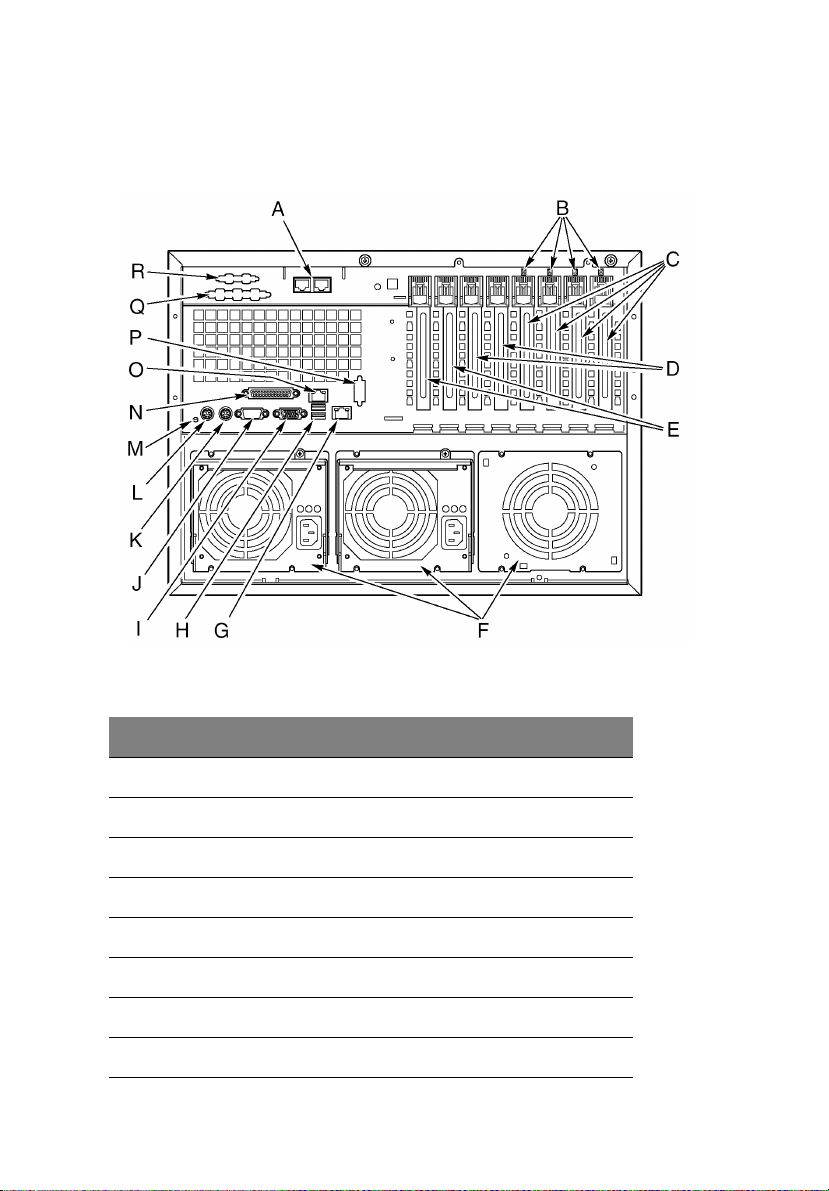

Rear panel

The figure below describes the features of the rear panel.

1 System tour

Figure 5 - Rear panel

Label Description

A Optional ICMB ports 1 (left) and 2 (right)

B Hot-plug PCI LEDs

C Hot-plug 64-bit, 100 MHz PCI-X add-in card slots

D Non-hot-plug 64-bit, 100 MHz PCI-X add-in card slots

E Non-hot-plug 32-bit, 33 MHz PCI add-in card slots

F Power supply bays

G LAN2 Gbit RJ-45 connector

H USB ports 0 (upper) and 1 (lower)

Page 27

Label Description

IVideo connector

J Serial port A

K PS/2-compatible mouse port

L PS/2-compatible keyboard port

M Chassis ID LED

N IEEE 1284 Enhanced Parallel Port

O LAN1 100/10 RJ-45 connector

P Knockout for optional serial port B

Q Knockout for optional SCSI connector

R Knockout for optional VHDCI SCSI connector

11

Page 28

12

1 System tour

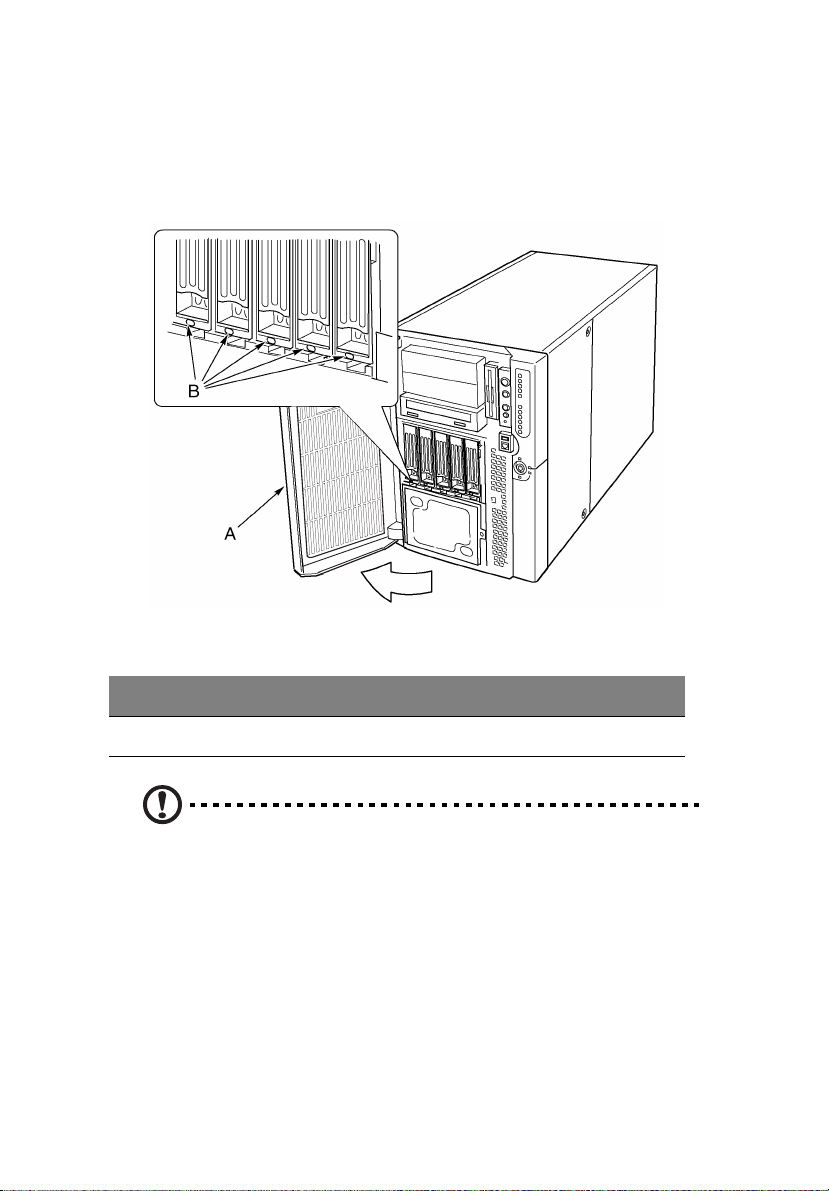

Peripheral device bay

Opening the right bezel door provides access to the peripheral bay.

The peripheral bay consists of four bays for removable media:

Figure 6 - Peripheral device bay

Label Description Label Description

A Front bezel door B LED status indicators

Caution! It is not recommended to install a hard disk drive in the

5.25-inch bay, because of potential cooling and electromagnetic

interference (EMI) constraints.

Page 29

Server board set features

The server board set for Altos G900 consists of a mainboard, memory

board, and processor board.

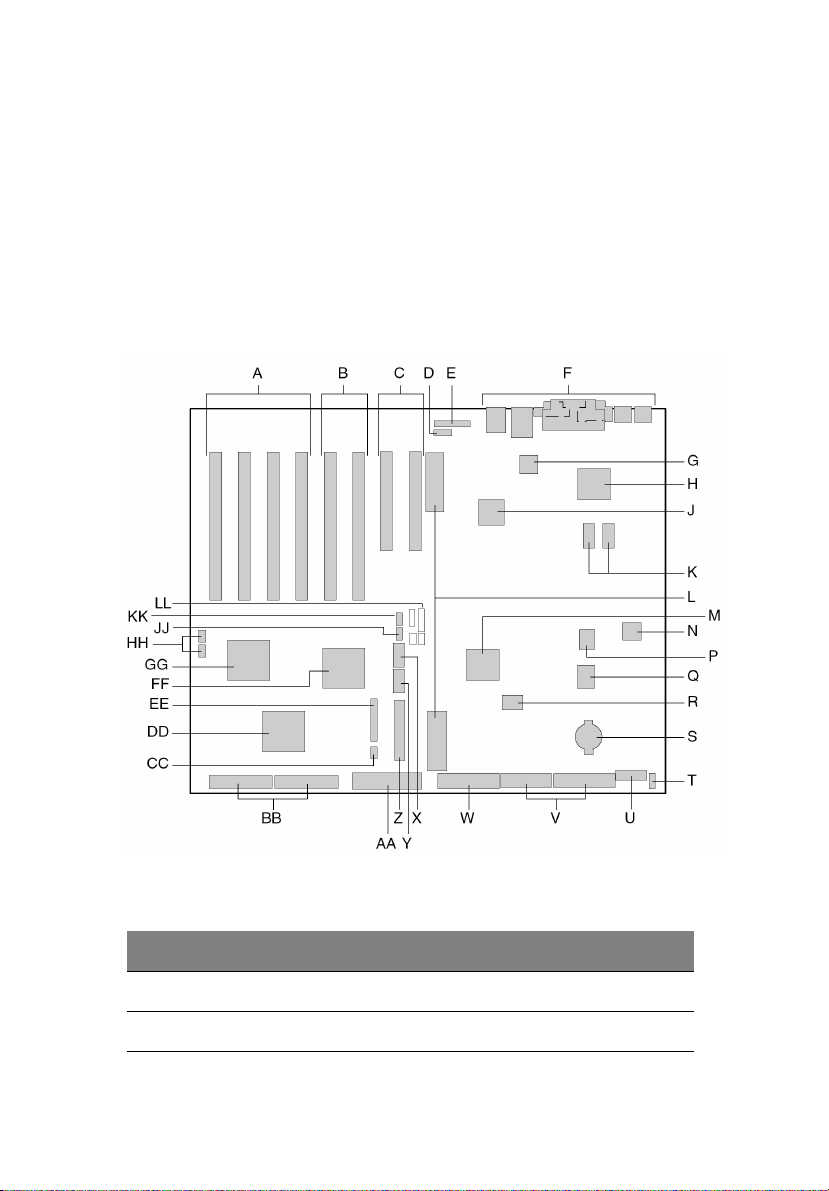

Mainboard layout

Below illustration identifies the connectors and major components on

the Altos G900 mainboard.

13

Figure 7 - Mainboard layout

Label Description

A 64-bit, 100-MHz, hot-plug PCI-X slots

B 64-bit, 100-MHz, non-hot-plug PCI-X slots

Page 30

14

Label Description

C 32 bit, 33-MHz, non-hot-plug PCI slots

D Intelligent Chassis Management Bus (ICMB) connector (P24)

E Hot-plug indicator board (HPIB) connector (P23)

F Back panel I/O connectors

1 System tour

G

®

Intel

82550 Ethernet controller

H ATI Rage XL 2D/3D graphics accelerator

J

®

Intel

82544 Ethernet controller

K Video RAM (VRAM) (4 MB total)

L Processor board connectors (P21 and P22)

M ServerWorks south bridge controller (CSB5)

N BMC component

P BIOS Flash component

Q PC87417 Super I/O controller

R BMC Flash component

S Battery

T Reserved

U power control connector (P35)

V power connector (P32)

W Floppy disk drive connector (P25)

X Serial port B connector (P17)

Y USB port 3 header (P18)

Z Front panel header (P19)

Page 31

Label Description

AA IDE connector (P13)

BB SCSI LVD connectors (P4 and P7)

CC Intelligent Platform Management Bus (IPMB) connector (P12)

DD Adaptec 7902 SCSI controller

EE Fan connector (P11)

FF ServerWorks PCI-X bus bridge controller (CIOB30)

GG ServerWorks PCI-X bus bridge controller (CIOB30)

HH RAID LED connectors (P1 and P2)

JJ Hot-swap backplane (HSBP) connector (P16)

KK Secondary HSBP connector (P15)

LL Jumpers

Mainboard jumpers

15

Jumpers on the mainboard are organized into three groups:

• Boot block jumpers (JP3)

• Main jumpers (JP4, JP5, and JP6)

• Serial port B jumpers (JP25).

Page 32

16

1 System tour

The figure below identifies the jumper blocks and pin numbers. The

function of each pair of pins is described in the sections that follow.

Figure 8 - Mainboard jumpers

Boot block jumpers

The boot block jumpers are used when updating the BIOS or BMC

firmware in the unusual event that the boot block area needs to be

updated. These jumpers are not used for routine firmware updates.

Use the boot block jumpers only when the instructions with a firmware

update specifically say to do so. When you do need to enable either of

these features, use one of the spares from JP4 pins 1 and 2 or JP25 pins

7 and 8. The table below identifies the function of each pin pair on

JP3.

Page 33

17

Jumper

block

JP3 1-8 Reserved.

Pins Jumper name - effect when shorted

9-10 BMC Boot Block Write Enable - Allows the BMC boot

block to be overwritten when updating the BMC

firmware.

11-12 BIOS Boot Block Write Enable - Allows the BIOS boot

block to be overwritten when updating the BIOS.

Main jumpers

Below table identifies the function of each pin pair on the main

jumper blocks (JP4, JP5, and JP6). The FRB3 Timer Disable jumper and

the BMC Force Update jumper are special purpose jumpers that you

should use only when instructed to do so. When you do need to

enable any of these features, use one of the spares from JP4 pins 1 and

2 or JP25 pins 7 and 8.

Jumper

block

Pin Jumper name - effect when shorted

1-2 Spare

3-4 BIOS Recovery - System will attempt to recover the

BIOS at the next boot.

5-6 Reserved

JP4

JP5 1-2 FRB3 Timer Disable - Disables fault resilient boot timer

JP6 1-2 BMC Force Update - Lets a system with corrupted BMC

7-8 Reserved

9-10 Password Clear - User and administrator passwords

are cleared at the next boot.

11-12 CMOS Clear - CMOS settings are cleared at the next

boot.

3.

firmware boot for an update.

Page 34

18

1 System tour

Serial port B jumpers

The table identifies the function of each pin pair on the serial port B

jumper block (JP25). By default, the serial port B connector is an RJ-45,

which has only eight pins and doesn't provide separate DCD and DSR

signals. The serial port B jumpers let you configure the DSR and DCD

signals passed from the port connector to the inputs of the UART. The

default configuration has jumpers installed on pins 1 and 2 and on pins

3 and 4.

Caution! Never install jumpers on pins 3 and 4 and on pins 5 and

6 at the same time. This would cause both the DCD and DSR

signals from the connector to drive the DCD input on the UART,

resulting in signal contention.

Jumper

block

JP25 1-2 DSR to DSR - DSR from connector is passed to DSR

Pin Jumper name - effect when shorted

input on UART (RJ-45 & DB9).

3-4 DSR to DCD - DSR from connector is passed to DCD

input on UART (RJ-45 only).

5-6 DCD to DCD - DCD from connector is passed to DCD

input on UART (DB9 only).

7-8 Spare.

Page 35

19

System cables

This section shows the correct routing of cables from the mainboard to

the front subchassis

Caution! To avoid possible damage to the cables or internal

components, the cables must be routed as shown in the following

illustrations.

Figure 9 shows the routing of cables from the mainboard to the front

subchassis components.

Figure 9 - Cables to the subchassis

Label Description Label Description

A Fan distribution board cable D IDE peripheral cable

B Front panel board cable E Diskette drive cable

Page 36

20

Label Description Label Description

C SCSI hard drive cable F Serial port B cables

1 System tour

Figure 10 shows the routing of ribbon cables through the cable clamp.

Additional cables are routed behind these ribbon cables as shown in

Figure 11.

Figure 10 - Front cables in the cable clamp

Label Description Label Description

A Diskette drive cable C Front panel board cable

B IDE peripheral cable D Cable clamp

Page 37

Finally, Figure 11 shows the routing of the cables at the back of the

cable clamp, behind the ribbon cables.

21

Figure 11 - Rear cables in the cable clamp

Label Description

A Front panel cable

B Serial port B cable

C Hot-swap back plane cable

DCable clamp

E Fan distribution board cable

Page 38

22

1 System tour

System features

The Altos G900 is a powerful server system loaded with a host of new

and innovative features. The system offers a new standard for flexible

productivity ideal for general business applications, email, web service,

file clustering and print services.

Processors

The Altos G900 server accommodates one to four processors from the

®

Xeon™ processor family.

Intel

Memory

The memory board contains twelve 184-pin DIMM slots each

supporting 72-bit ECC (64-bit main memory plus ECC) registered PC-266

Double Data Rate (DDR) DIMMs. Memory is partitioned in three banks.

You may install a minimum of 512 MB (128 MB x 4) or as much as

24 GB.

• Minimum configuration: Four 128-MB DIMMs, for a total of

512 MB

• Maximum configuration: Twelve 2-GB stacked DIMMs for a total

of 24 GB

The controller automatically detects, sizes, and initializes the memory

array, depending on the type, size, and speed of the installed DIMMs,

and reports memory size and allocation to the server via configuration

registers.

SCSI controller

The mainboard includes an embedded Adaptec® 7902 SCSI controller,

which contains two independent SCSI channels. You can disable the

SCSI controller in BIOS setup. Both channels support 16-bit SE or LVD

SCSI operations at the following speeds:

• Ultra320 (320/MB/sec)

• Ultra160 (160 MB/sec)

• Ultra2 (80 MB/sec)

• Ultra Wide SE (40 MB/sec)

Page 39

23

The mainboard provides active terminators, termination voltage,

resettable fuses, and protection diodes for both SCSI channels. You can

disable the onboard terminators in BIOS setup.

Onboard video

The mainboard incorporates an ATI RAGE XL PCI graphics accelerator

with 4 MB of video SDRAM that supports all standard IBM VGA modes.

The embedded SVGA video subsystem supports:

• Pixel resolutions up to 1600 x 1200 under 2D and 1024 x 768 under

3D

• CRT and LCD monitors up to 100 Hz vertical refresh rate

The mainboard supports disabling of the onboard video through BIOS

setup or when a plug-in video card is installed in any of the PCI slots.

Network interface controllers

Note: To ensure EMC product regulation compliance, the system

must be used with shielded LAN cables.

The mainboard includes two network interface controllers (NICs):

•Intel

®

82550 NIC that supports 10Base-T and 100Base-TX networks

The 82550 controller supports the following features:

• 32-bit PCI, CardBus master interface

• Integrated IEEE 802.3 10Base-T and 100Base-TX compatible

PHY

• IEEE 820.3u auto-negotiation support

• Chained memory structure similar to the 82559, 82558, 82557

and 82596

• Full duplex support at both 10 Mbps and 100 Mbps operation

• Low power +3.3 V device

• IP checksum off-loading

NIC 1 can be used as both a network interface and server

management interface.

Page 40

24

1 System tour

•Intel

®

82544 NIC that supports 10Base-T, 100Base-TX networks,

and 1000BASE-T networks

The 82544 controller supports the following features:

• Direct 32/64-bit, 33/66-MHz interface to the PCI bus

• Integrated IEEE 802.3 1000BASE-T, 100BASE-TX, and 10BASE-T

• Integrated third-generation MAC and proven IEEE 803.3ab

compatible PHY

• Full duplex support for 10-Mbps, 100-Mbps, and 1000 Mpbs

operation

• Descriptor ring management architecture optimized to deliver

both high performance and PCI/PCI-X bus efficiency

• Low power +3.3 V device

• IP and TCP/UDP checksum off-loading

Hot-swap hard drive bays

The server comes with one hot-swap hard drive cage installed. A

second bay is available as an accessory. The hard drive bays each

support up to five 3.5-inch by 1.0-inch Ultra320 SCSI hard drives. The

hard drive bays also support SCSI hard drive technologies, such as

Ultra160 and Ultra2, that are slower than the Ultra320 SCSI technology.

®

Each hard drive is connected to an Adaptec

backplane. The backplane provides 80-pin SCA-2 connectors for each

hard drive and accepts 15,000 RPM and slower SCSI hard drives that

consume up to 20 watts of power.

Ultra320 SCSI hot-swap

Opening the bezel door provides access to the hard drives. To allow

hot swapping, each hard drive mounts in a hard drive carrier. When a

hard drive is removed from the system, both the carrier and the hard

drive are removed.

Caution! Because all hard drives have different cooling, power,

and vibration characteristics, specific hard drive types has been

validated to be compatible with the Altos G900 system.

Page 41

25

Power supply

The power supply bay comes with two 600-W power supply modules

and can accommodate a third module for redundancy. The modules

connect through the power distribution board (PDB) and auto-sense

input voltage. The power redundant (2+1) configuration allows you to

hot-swap a failed power supply without interrupting normal system

operation.

Warning! The power supply in this product contains no

user-serviceable parts. There may be more than one power

supply in this product. Refer servicing only to qualified

personnel.

System fan

Caution! All access covers must be on the system for proper

cooling.

To ensure that all components remain within specification under all

system environmental conditions, do not exceed five minutes for hot

swapping of fans or power supplies.

The server comes with four fan modules. Air enters through the bezel,

passes through the fan bay and electronics bay, and exhausts through

the rear of the chassis. The power supply modules and hot-swap hard

drive bays also come with their own fans which draw air through those

components and through the peripheral bays.

Under normal system conditions, the fans run at a slower, quieter

speed. If a fan failure is sensed, a fan is not detected, or ambient

temperature exceeds a certain limit, the fan speed is set to high.

LEDs indicate if individual fans are inoperative or not present. Under

the same fan failure conditions, the general system fault LED on the

front panel is lit.

Page 42

26

1 System tour

ACPI

The server supports the Advanced Configuration and Power Interface

(ACPI) standard as defined by the ACPI 1.0b and PC97 specifications.

An ACPI-aware operating system can put the system into a state where

the hard drives spin down, the system fans stop, and all processing is

halted. However, the power supply will still be on and the processors

will still be dissipating some power, so the power supply fans will still

run.

The server supports sleep states s0, s1, s4, and s5:

• s0: Normal running state.

• s1: Processor sleep state - No context will be lost in this state and

the processor caches will maintain coherency.

• s4: Hibernate or Save to Disk - The memory and machine state are

saved to disk. Pressing the power button or other wakeup event

will restore the system state from the disk and resume normal

operation. This assumes that no hardware changes have been

made to the system while it was off.

• s5: Soft off - Only the RTC section of the CSB and the BMC are

running in this state. No context is saved by the operating system

or hardware.

Caution! The system is off only when the AC power cord is

disconnected.

Page 43

2 System setup

Page 44

This chapter describes the system setup procedures

— both for hardware and software aspects.

Page 45

Getting started

Checking for damage to the packaging

Inspect the packaging container for evidence of mishandling during

transit. If the packaging container is damaged, photograph it for

reference. Save the packaging container and packing materials in the

event you need to package the server for reshipment.

Selecting a site

Before unpacking and installing the system, select a suitable site for

the system for maximum efficiency. Consider the following factors

when choosing a site for the system:

• Near a properly grounded, three-pronged power outlet

Note:

In the United States and Canada: a NEMA 6-15R outlet for 100120 V and for 200-240 V.

In other geographic areas: a properly grounded outlet in

accordance with the local electrical authorities and electrical code

of the region.

29

• Clean and dust-free

• Stable surface free from vibration

• Well-ventilated and away from sources of heat, with the

ventilation openings on the server kept free of obstructions

• Secluded from strong electromagnetic fields and noise caused by

electrical devices such as elevators, copy machines, air

conditioners, large fans, large electric motors, radio and TV

transmitters, and high-frequency security devices.

• Maximum ambient air temperature should not exceed 35°C

(95°F).

• Access space provided so the server power cords can be unplugged

from the power supply or the wall outlet; this is the only way to

remove AC power from the server.

Page 46

30

• Clearance provided for cooling and airflow.

Note: Surge suppressor recommended: In geographic regions

that are susceptible to electrical storms, it is strongly

recommended that you plug the server into a surge suppressor.

2 System setup

Checking the package contents

Remove the server from the packaging container and, using the list

below, check that all parts and accessories are included. Inspect the

server and accessories for damage. If any of the contents appear

damaged, file a damage claim with the carrier immediately.

The Altos G900 system comes with the following parts installed:

• System components

• Altos G900 mainboard

• Altos G900 processor board

• Altos G900 memory board

• Fan distribution board

• Front panel board

• Hot plug indicator board

• Power distribution board

• Two 600-W power supplies

• Six fan modules

• 3.5-inch floppy drive

• 5.25-inch CD-ROM drive

• 1-inch hard disk drive bay

• Bezel and feet for tower

• Three sets (six rails) 5.25-inch peripheral rails and screws

• Two North American power cords

• System accessory box

Page 47

31

• System keys (provided inside the system accessory box)

• Additional parts or components depending on specific system

configuration.

• System documentation

• Acer Altos G900 User’s guide (with system binder)

• Acer EasyBUILD

TM

v5.1 CD - contains product documentation,

device drivers, and software utilities, includes three discs:

• Management CD

•System CD

• Resource CD

If any of the above items are damaged or missing, contact your dealer

immediately.

Save the boxes and packing materials for future use

Page 48

32

2 System setup

Setting up your system

Setup reminders

• Do not attempt to modify or use the supplied AC power cord if it is

not the exact type required. A product with more than one power

supply will have a separate AC power cord for each supply.

• The power button on the system does not turn off system AC

power. To remove AC power from the system, you must unplug

each AC power cord from the wall outlet or power supply. The

power cord(s) is considered the disconnect device to the main (AC)

power. The socket outlet that the system plugs into shall be

installed near the equipment and shall be easily accessible.

Pre-setup safety steps

Whenever you remove the chassis panels to access the inside of the

system, follow these steps:

1 Turn off all peripheral devices connected to the system.

2 Turn off the system by pressing the power button.

3 Unplug all AC power cords from the system or from wall outlets.

4 Label and disconnect all cables connected to I/O connectors or

ports on the back of the system.

5 Provide some electrostatic discharge (ESD) protection by wearing

an antistatic wrist strap attached to chassis ground of the system—

any unpainted metal surface—when handling components.

6 Do not operate the system with the chassis panels removed.

After you have completed the six steps above, you can remove the

chassis panels. To do this:

1 Unlock and remove the padlock from the back of the system if a

padlock has been installed.

2 Remove and save all screws from the panels.

3 Remove the panels.

For proper cooling and airflow, always reinstall the chassis panels

before turning on the system. Operating the system without the these

panels in place can damage system parts. To install the chassis panels:

Page 49

33

1 Check first to make sure you have not left loose tools or parts

inside the system.

2 Check that cables, add-in boards, and other components are

properly installed.

3 Attach the panels to the chassis with the screws removed earlier,

and tighten them firmly.

4 Insert and lock the padlock to the system to prevent unauthorized

access inside the system.

5 Connect all external cables and the AC power cord(s) to the

system.

Hardware setup

The server is shipped without processors, memory, or hard drives. To

install the memory, processors, hard drives, and other options, follow

the steps shown below.

1 Removing the system access panels:

a Removing the rear access panel - see page 44

b Removing the access cover to the system boards - see page 51

2 Removing the memory and processor boards:

a Removing the memory board - see page 52

b Removing the processor board - see page 54

3 Installing memory and processors:

a Installing the DIMMs on the memory board - see page 60

b Installing the processors on the processor board - see page 64

4 If you are installing an ICMB board - follow the instructions that

came with the ICMB board kit.

5 Installing the processor and memory boards:

a Installing the processor board - see page 54

b Installing the memory board - see page 52

6 Installing PCI add-in cards - see page 67

7 Installing hard disk drives - see page 78

8 Installing an additional power supply or additional peripherals -

see page 84, page 96, and any additional documentation that

came with the peripherals.

Page 50

34

9 Reinstalling the system access panels:

a Installing the access cover to the system boards - see page 52

b Installing the rear access panel - see page 45

You have completed the hardware setup. The remainder of this

section discusses software setup and configuration. Refer to page 36.

2 System setup

Turning on the server and running the Power-On Self Test (POST)

Each time you start the server, the Power-On Self Test (POST) runs

automatically. POST is stored in flash memory.

To start the server, do the following:

Note: To access certain features, such as BIOS setup, you must

press specific keys at specific times during POST. To familiarize

yourself with this procedure, read the following instructions

completely before actually performing them. For a summary of

hot keys active during POST, see page 35.

1 Make sure all external devices, such as a monitor, keyboard, and

mouse, are connected.

2 If a drive protection card or diskette is present in the diskette

drive, remove it.

3 Plug the video monitor power cord into the power source or wall

outlet. Turn on the video monitor.

4 Plug the AC power cords into the power connectors on the back of

the chassis and into the power source or wall outlet.

5 If the server does not turn on when you plug it into the AC outlet,

press the on/off power button on the front panel.

6 Verify that the main power LED on the front panel is lit.

After a few seconds, POST begins and a splash screen is displayed

(if the splash screen is disabled in BIOS setup, a diagnostics screen

is displayed). POST discovers, configures, and tests the processors,

memory, keyboard, and most installed peripheral devices. The

length of time needed to complete POST depends on the amount

of memory installed and the number of option boards installed.

Page 51

35

7 Shortly after the splash screen is displayed, POST displays the

message "Press <F2> to enter Setup…" at the bottom of the

screen. At this point, you can press any of the keys identified with

an asterisk (*) on the following table, or you can do nothing and

wait until the server boots from the CD-ROM.

If you enter BIOS setup, the service partition, or the Adaptec

®

SCSISelect utility, when you exit those features, the server might

reboot.

8 After POST completes, the system beeps once and then searches all

boot devices in the order defined by the boot priority settings in

the BIOS. The system finds, loads, and runs the limited operating

system on the System CD.

If there is no device with a bootable operating system, the boot

process continues, the system beeps once, and the following

message is displayed:

Operating system not found

If you have a device with a bootable operating system but see this

message anyway, reboot and use BIOS setup to make sure your

boot device settings are correct.

Hot keys for POST

The table below lists the hot keys you can use during POST to access

setup utilities and alter the normal POST execution.

Items marked with an asterisk (*): Press any of these keys when the

prompt "Press <F2> to enter Setup…" is displayed

To do this: Press these keys:

Abort memory test during POST. Space

Press while BIOS is updating

memory size on screen.

Resume after a POST error is

displayed. (The system pauses after

displaying an error.)

Enter BIOS setup during POST. F2 *

Boot to the service partition. F4 *

F1

.

Page 52

36

To d o t h is : Press these keys:

2 System setup

Boot from a network using Preboot

Execution Environment (PXE).

Remove the splash screen to view

the diagnostic messages during

POST and display a menu for

selecting the boot device.

Enter the Adaptec SCSISelect utility

during POST.

F12 *

ESC *

Using BIOS setup, you can enable

the Boot-Time Diagnostic Screen, in

which case POST does not display

the splash screen. If you use the

displayed menu to change the boot

device, the change affects the

current boot only.

Ctrl+A *

Software setup

Installing the service partition (recommended)

When you are setting up your server system, you can install a service

partition on your hard drive. To create a service partition, follow the

related instructions that appears when installing the system OS using

the System CD. The service partition, in conjunction with Acer Server

Management Enterprise (ASMe), provides emergency remote

management and remote server setup. The service partition lets you

remotely access a local partition on the server and identify and

diagnose server health issues by using either a modem or network

connection. The service partition uses approximately 30 to 40 MB of

hard disk space.

Installing the operating system

The System CD contains a limited operating system with enough

functionality to boot the server and to copy and use the utilities and

other files from the CD. This limited operating system is not intended

to be used to run applications. To run your server and applications,

you must install the operating system of your choice on the server.

Follow the installation instructions that came with the operating

system.

Page 53

37

Network teaming features

NIC connector and status LEDs

The NICs drive LEDs on the network interface connectors that indicate

link connection and activity on the LAN and 10- or 100-Mbps

operation. The green LED indicates network connection when on and

TX/RX activity when blinking. The yellow LED indicates 100-Mbps

operation when lit.

Note: Using both onboard NICs in a team does not allow the use

of NIC 1 for server management access. To support both network

teaming features and server management features, a third NIC

must be added and teamed to NIC 2.

The network controller provides several options for increasing

throughput and fault tolerance when running Windows, NetWare, or

Linux:

• Adapter Fault Tolerance (AFT)

Provides automatic redundancy for your adapter. If the primary

adapter fails, the secondary takes over. AFT works with any hub or

switch.

• Adaptive Load Balancing (ALB)

Creates a team of two to eight adapters to increase transmission

throughput and includes AFT. Works with any 10Base-TX or

100Base-TX switch.

®

• Fast EtherChannel (FEC) or Intel

Creates a team of up to eight adapters to increase transmission

and reception throughput and includes AFT. Requires a FECenabled switch.

Link Aggregation

To set up an option, read the instructions in the Windows or NetWare

readme files.

Page 54

38

2 System setup

Considerations

Windows NT versions prior to 4.0 do not support Adapter Teaming

options.

Adapter Teaming options require NT 4.0 with Service Pack 4.0 or later

(or Service Pack 3.0 and the Windows Hot Fix).

In Windows NT, teaming options cannot be implemented on adapters

that have been configured for VLANs. NetWare can support teaming

options and VLANs on the same adapters.

Adapter Fault Tolerance

Adapter Fault Tolerance (AFT) is a simple, effective, and fail-safe

approach to increase the reliability of server connections. AFT gives

you the ability to set up link recovery to the server adapter in case of a

cable, port, or network interface card failure. By assigning two server

adapters as a team, AFT enables you to maintain uninterrupted

network performance.

AFT is implemented with two server adapters: a primary adapter and a

backup, or secondary, adapter. During normal operation, the backup

will have transmit disabled. If the link to the primary adapter fails, the

link to the backup adapter automatically takes over.

Adaptive Load Balancing

Adaptive Load Balancing (ALB) is a simple and efficient way to increase

your server's transmit throughput. With ALB you group server

adapters in teams to provide an increased transmit rate (up to 8 Gbps)

using a maximum of eight adapters. The ALB software continuously

analyzes transmit loading on each adapter and balances the rate across

the adapters as needed. Adapter teams configured for ALB also

provide the benefits of AFT. Receive rates remain at 100 Mbps or

1 Gbps depending on the primary adapter's capability.

To use ALB, you must have two to eight server adapters installed in

your server and linked to the same network switch.

Page 55

3 Hardware

configuration

Page 56

This chapter describes detailed procedures for

system hardware setup.

Page 57

41

Installation precautions

Before you install any system component, we recommend that you

read the following sections. These sections contain important ESD

precautions along with preinstallation and post-installation

instructions.

ESD precautions

When installing or removing system components, perform such

procedures only at an electrostatic discharge (ESD) workstation,

because the server components can be extremely sensitive to ESD. If no

such station is available, you can reduce the risk of ESD damage by

doing the following:

• Do not remove a component from its protective packaging until

you are ready to install it.

• Touch the metal on the server chassis before touching the server

components.

• Wear a wrist grounding strap and attach it to a metal part of the

server before handling components.

• If a wrist strap is not available, maintain contact with the metal

chassis throughout any procedure requiring ESD protection to

dissipate the static charge while handling the components.

• Avoid moving around unnecessarily.

• Hold the server components (especially boards) only by the edges.

• Place the server components on a grounded, static-free surface.

Use a conductive foam pad if available but not the component

wrapper.

• Do not slide the components over any surface.

Page 58

42

3 Hardware configuration

Preinstallation instructions

Always observe the following before you install any component:

1 Turn off your system and all the peripherals connected to it.

2 Unplug all cables from the power outlets.

3 Open your system according to the instructions on page 44.

4 Follow the ESD precautions described in this chapter when

handling a server component.

5 Remove any expansion board(s) or peripheral(s) that block access

to the DIMM socket or other component connector.

Warning! Failure to properly turn off the server before you

start installing components may cause serious damage.

Do not attempt the procedures described in the following

sections unless you are a qualified service technician.

Post-installation instructions

Observe the following after installing a server component:

1 See to it that all components are installed according to the

described step-by-step instructions.

2 Check to make sure you have not left loose tools or parts inside the

system.

3 Reinstall any expansion board(s), peripheral(s), board cover(s) that

you have previously removed.

4 Reinstall the chassis panels

5 Insert and lock the padlock to the system to prevent unauthorized

access to the inside of the system.

6 Connect all external cables and the AC power cord(s) to the

system.

7 Turn on the system.

Page 59

43

Tools and supplies needed

You will need the following items in installing the system components:

• Phillips screwdriver

• Small flat-bladed screwdriver

• Extraction tool for processor heat sink clips

• Antistatic wrist strap and conductive foam pad (recommended)

• Pen or pencil

• Equipment log (for a sample sheet, refer to page 195)

As you integrate new components into the system, record the

model and serial number of the server system, all installed options,

and any other pertinent information specific to the server system.

You will need this information when running the SSU.

Page 60

44

3 Hardware configuration

System access panels

This section discusses the procedures in:

• Removing and replacing the rear access panel

• Removing and replacing the front access panel

Before removing the access panels

To avoid personal injury or property damage, the following safety instructions

apply whenever accessing inside the product:

1 Turn off all peripheral devices connected to this product.

2 Turn off the system by pressing the power button on the front of

the product.

3 Disconnect the AC power by unplugging all AC power cords from

the system or wall outlet.

4 Disconnect all cables and telecommunication lines that are

connected to the system.

5 Retain all screws or other fasteners when removing the access

panel(s). Upon completion of accessing inside the product,

refasten access panels with original screws or fasteners.

6 Do not access inside power supply. There are no serviceable parts

in the power supply. Return to manufacturer for servicing.

Rear access panel

The rear access panel provides access to the electronics bay, which

contains the PCI add-in cards and the server board set, and to the

power supply bay.

To remove the rear access panel

1 Release the captive screws located on the rear edge of the panel.

2 While lightly pressing the panel against the chassis, slide it toward

the rear of the chassis.

Page 61

3 Lift the panel away from the chassis.

Figure 12 - Removing the rear access panel

To install the rear access panel

Note: Before installing the rear access panel, check that you have

not left any tool or loose parts inside the system.

45

1 Position the panel on the chassis so that the panel tabs align with

the chassis slots.

2 While lightly pressing the panel against the chassis, slide it toward

the front of the chassis until the panel tabs fully engage the chassis

slots.

3 Attach the panel to the chassis with the captive fasteners located

on the rear edge of the panel.

Front access panel

The front access panel provides access to the hot-swap fans, to devices

in the peripherals bay, and to the hot-swap drive bay.

Page 62

46

3 Hardware configuration

To remove the front access panel

1 Remove the rear access panel (refer to page 44).

2 Release the two captive panel screws (Figure 13, A).

3 Lift the rear edge of the panel slightly and slide it toward the rear

of the chassis.

4 Lift the panel up and off of the chassis.

Figure 13 - Removing the front access panel

To install the front access panel

Note: Before installing the front access panel, check that you

have not left tools or loose parts inside the system.

1 Position the panel on the chassis so that the panel tabs align with

the chassis slots.

2 While lightly pressing the panel against the chassis, slide it toward

the front of the chassis until the panel tabs fully engage the chassis

slots.

3 Attach the panel to the chassis with the captive screws.

4 Reinstall the rear access panel (refer to page 45).

Page 63

Front subchassis and rear electronics bay

The server chassis consists of three parts, which include the following:

• Main chassis

• Front subchassis (sometimes called the C-tilt)

• Rear electronics bay

Both the front subchassis and the rear electronics bay swing open.

Additionally, you can completely remove them to gain access to the

server’s internal components. You can more easily open and remove

the front subchassis and electronics bay if the system is laying on its

side (rack-mount orientation).

Opening the front subchassis and rear electronics bay

The front subchassis must be opened slightly to allow the rear

electronics bay to open because the front subchassis overlaps the rear

electronics bay.

47

To open the front subchassis and rear electronics bay

1 Remove the front and rear access covers (refer to page 46 and

page 44).

2 To open the front subchassis, grasp the edge of the bezel and

swing the front subchassis out until the spring clip at the top of

the subchassis just springs open.

3 To open the rear electronics bay:

a Disconnect all cables attached to the mainboard.

b Grasp the inside edge of the electronics bay and swing the

electronics bay out from the main chassis.

Page 64

48

Figure 14 - Opening the front subchassis and rear electronics bay

Label Description

3 Hardware configuration

A Front subchassis latch

B Mainboard cables

C Rear electronics bay

Removing the front subchassis and rear electronics bay

To remove the front subchassis

1 Disconnect all cables attached to the power distribution board and

to the mainboard.

2 With the front subchassis open, lift it straight up and clear of the

main chassis.

Page 65

49

To remove the electronics bay

With the electronics bay open, pull it up and toward the front of the

chassis, lifting it clear.

Installing the front subchassis and rear

electronics bay

To install the front subchassis

1 With the front subchassis tilted open about 30°, align the notch in

the subchassis with the hinge pins on the main chassis.

2 Lower the subchassis straight down until the hinge pins engage

the notches.

3 Connect all cables from the front subchassis to the power

distribution board and to the mainboard.

To install the electronics bay

1 With the electronics bay tilted open about 30°, align the pins on

the electronics bay with the notches in the main chassis .

2 Lower the electronics bay until the pins engage the notches and

slide it back and down.

Figure 15 - Installing the front subchassis and rear electronics bay

Page 66

50

3 Hardware configuration

Closing the front subchassis and rear electronics bay

Caution! Before you close the front subchassis or electronics bay,

make sure no cables are pinched or otherwise obstructing the

front subchassis and rear electronics bay. Excessive cable stress or

chafing can cause cables to disconnect and connector pins to bend

or break the cable insulation.

To close the front subchassis and rear electronics bay

1 To close the rear electronics bay:

a Grasp the inside edge of the electronics bay and swing the

electronics bay into the main chassis.

b Connect all cables to the mainboard.

2 To close the front subchassis:

a Grasp the edge of the front subchassis.

b Depress and hold the spring clip (Figure 16, B) and swing the

front subchassis all the way into the main chassis.

Figure 16 - Closing the front subchassis and rear electronics bay

Page 67

51

Accessing the system boards

This section discusses the procedures in:

• Removing and installing the access cover to the system boards

• Removing and installing the memory board

• Removing and installing the processor board

• Removing and installing the mainboard

Caution! A microprocessor and heat sink may be hot if the

system has been running. Also, there may be sharp pins and edges

on some board and chassis parts. Contact should be made with

care. Consider wearing protective gloves.

Access cover to the system boards

To remove the access cover to the system boards

1 Remove the rear access panel (refer to page 44).

2 Loosen the two captive screws located at the front of the access

cover to the system boards.

3 Lift the end of the cover where the screws are located and remove

the cover.

Figure 17 - Removing the access cover to the system boards

Page 68

52

3 Hardware configuration

To install the access cover to the system boards

1 Orient the access cover with the captive screws toward the front of

the server.

2 Insert the tabs on the rear of the cover into the slots at the rear of

the chassis.

3 Press down gently and tighten the captive screws at the front of

the cover.

Memory board

To remove the memory board

1 Grasp the bracket on the top edge of the memory board and pull

straight up until the board disengages from the connector on the

processor board.

2 Lift the memory board out of the chassis.

Figure 18 - Removing the memory board

Page 69

53

To install the memory board

1 Holding the bracket on the top edge of the memory board, insert

the board into the guides at both ends of the electronics bay.

2 Align the memory board with the connector on the processor

board and press down on the bracket until the board is fully

inserted into the connector.

Figure 19 - Installing the memory board

P

Page 70

54

3 Hardware configuration

Processor board

To remove the processor board

1 Rotate the handles on the processor board until they are fully

open.

2 Using the handles, tilt the processor board up and remove it from

the chassis.

Figure 20 - Removing the processor board

To install the processor board

1 Insert the tabs on the processor board into the slots on the

mainboard bracket (Figure 21, A).

2 With the handles in the open position, lower the processor board

until it rests on the mainboard bracket.

3 Close and press down on the handles until the processor board is

fully engaged with the sockets on the mainboard.

Page 71

Figure 21 - Installing the processor board

Mainboard

55

To remove the mainboard

1 Remove all external cables from the mainboard I/O ports at the

back of the chassis.

2 Label and disconnect all internal cables connected to the PCI

add-in boards.

3 Remove all PCI add-in boards (refer to page 71 and 74).

4 Plastic curtains run the length of the electronics bay separating the

PCI add-in cards. Remove the curtains as follows:

a Release one end of the curtain from the front retention

mechanism. Lift the free end high enough to clear the chassis.

b From outside of the rear of the chassis, push down on the

other end of the curtain and pull the free end out of the

chassis.

5 Label and remove all internal cables attached to connectors on the

board.

Page 72

56

3 Hardware configuration

For a diagram showing labeled connectors, refer to “Mainboard

layout” on page 13.

6 Remove all cables from the cable retention clip on the front of the

electronics bay.

7 A plastic retention mechanism for the PCI add-in cards is fastened

to the front of the electronics bay by three clips (Figure 22, A).

Release each clip by pressing down on the tab and remove the

retention mechanism.

8 Remove the plastic protective overlay covering the PCI area of the

mainboard as follows:

a Unscrew the captive screw holding the overlay in place

(Figure 22, D).

b Near the middle of the mainboard, lift the edge of the overlay

until it is clear of the connectors on the board (Figure 22, B).

c Slide the overlay toward the front of the electronics bay and

unhook it from the two tabs (Figure 22, C).

d Remove the overlay.

Figure 22 - Removing the front retention mechanism

Page 73

Label Description Label Description

57

A Tabs (3) on retention

mechanism

B Protective overlay D Overlay screw

C Overlay tab (1 of 2)

9 Remove the six screws, the plastic overlay, and the two processor

board mounting brackets that attach the mainboard to the

electronics bay (Figure 23, A).

10 Lifting the board slightly, slide the mainboard toward the front of

the chassis until the I/O ports clear the chassis.

11 At one side of the chassis, the board is inserted into slots in a foam

panel (Figure 23, B). Lift up on the opposite end of the board and

pull the edge of the board out of the slots in the foam panel.

12 Lift the mainboard out of the electronics bay and place it

component-side up on a nonconductive, static-free surface (or in

an antistatic bag).

Figure 23 - Mainboard mounting

Page 74

58

3 Hardware configuration

To install the mainboard

1 With the rear of the electronics bay closest to you and the

mainboard oriented so that the I/O connectors line up with the

cutout in the back left of the chassis (Figure 23), lower the right

end of the mainboard into the electronics bay and slip the board

edge into the slots of the foam panel (Figure 23, B).

2 Lower the other end of the mainboard to the floor of the

electronics bay and slide it toward the back of the chassis until:

a The I/O connectors fit all of the way into the I/O connector

openings.

b The six mounting holes on the mainboard (Figure 23, B) are

aligned with their corresponding threaded standoffs in the

floor of the electronics bay.

3 Install the processor board mounting brackets and processor-side

plastic overlay as follows:

a Align the processor board mounting bracket for the center of

the mainboard with the three mounting holes. Insert a screw

through each of the holes and partially thread the screws into

the standoffs.

b Align the other mounting bracket along the edge of the

board. Align the plastic overlay with the bracket and the two

plastic studs. Insert a screw through each of the holes in the

overlay and mounting bracket and partially thread the screws

into the standoffs.

c Adjust the board position as needed and tighten the six

screws.

4 Install the plastic protective overlay covering the PCI area of the

board as follows:

a At the side of the electronics bay where the edge of the

mainboard is inserted into the foam, place the two slots in the

overlay over the hooked tabs (Figure 22, C on page 56).

b Slide the overlay toward the rear of the chassis to hook the

tabs in the slots.

c Carefully fit the overlay around the mainboard connectors

and down against the board.

d Tighten the captive screw that holds the overlay in place.

5 Install the front retention mechanism for the PCI add-in cards on

the front wall of the electronics bay (Figure 22 on page 56).

Page 75

6 Connect all internal cables to the mainboard.

To make sure you route the cables correctly, refer to “Front panel

board” on page 89. If the cables are not routed correctly, you

won't be able to close the front subchassis.

7 Install the PCI add-in board curtains as follows:

a At the back of the electronics bay, slide the end of a curtain