Page 1

AW1000 Series

User Guide

AW170 F1/ AW170d F1/ AW170q F1

Page 2

Copyright © 2009. All Rights Reserved.

Acer AW1000 Series

User Guide

Acer AW1000 - AW170 F1/AW170d F1/ AW170q F1

Model Number :

Serial Number:

Purchase Date:

Place of Purchase:

Page 3

Information for your safety and comfort

Visit http://registration.acer.com and discover the benefits of being an Acer

customer.

Safety instructions

Read these instructions carefully. Keep this document for future reference.

Follow all warnings and instructions marked on the product.

Turning the product off before cleaning

Unplug this product from the wall outlet before cleaning. Do not use liquid

cleaners or aerosol cleaners. Use a damp cloth for cleaning.

CAUTION for plug as disconnecting device

Observe the following guidelines when connecting and disconnecting power to

the power supply unit:

• Install the power supply unit before connecting the power cord to the AC

power outlet.

• Unplug the power cord before removing the power supply unit from the

computer.

• If the system has multiple sources of power, disconnect power from the

system by unplugging all power cords from the power supplies.

iii

CAUTION for accessibility

Be sure that the power outlet you plug the power cord into is easily accessible

and located as close to the equipment operator as possible. When you need to

disconnect power to the equipment, be sure to unplug the power cord from the

electrical outlet.

Warnings

• Do not use this product near water.

• Do not place this product on an unstable cart, stand or table. If the product

falls, it could be seriously damaged.

Page 4

iv

• Slots and openings are provided for ventilation to ensure reliable

operation of the product and to protect it from overheating. These

openings must not be blocked or covered. The openings should never be

blocked by placing the product on a bed, sofa, rug or other similar surface.

This product should never be placed near or over a radiator or heat

register, or in a built-in installation unless proper ventilation is provided.

• Never push objects of any kind into this product through cabinet slots as

they may touch dangerous voltage points or short-out parts that could

result in a fire or electric shock. Never spill liquid of any kind onto or into

the product.

• To avoid damage of internal components and to prevent battery leakage,

do not place the product on a vibrating surface.

• Never use it under sporting, exercising, or any vibrating environment

which will probably cause unexpected short current or damage rotor

devices, HDD, Optical drive, and even exposure risk from lithium battery

pack.

• This product is not suitable for use with visual display workplace devices

according to B2 of the German Ordinance for Work with Visual Display

Units.

Using electrical power

• This product should be operated from the type of power indicated on the

marking label. If you are not sure of the type of power available, consult

your dealer or local power company.

• Do not allow anything to rest on the power cord. Do not locate this

product where people will walk on the cord.

• If an extension cord is used with this product, make sure that the total

ampere rating of the equipment plugged into the extension cord does not

exceed the extension cord ampere rating. Also, make sure that the total

rating of all products plugged into the wall outlet does not exceed the fuse

rating.

• Do not overload a power outlet, strip or receptacle by plugging in too

many devices. The overall system load must not exceed 80% of the branch

circuit rating. If power strips are used, the load should not exceed 80% of

the power strip's input rating.

• This product's power supply is equipped with a three-wire grounded plug.

The plug only fits in a grounded power outlet. Make sure the power outlet

is properly grounded before inserting the power supply plug. Do not insert

the plug into a non-grounded power outlet. Contact your electrician for

details.

Warning! The grounding pin is a safety feature. Using a power outlet that is

not properly grounded may result in electric shock and/or injury.

Page 5

Note: The grounding pin also provides good protection from unexpected

noise produced by other nearby electrical devices that may interfere with

the performance of this product.

• Use the product only with the supplied power supply cord set. If you need

to replace the power cord set, make sure that the new power cord meets

the following requirements: detachable type, UL listed/CSA certified, VDE

approved or its equivalent, 4.6 meters (15 feet) maximum length.

Product servicing

Do not attempt to service this product yourself, as opening or removing covers

may expose you to dangerous voltage points or other risks. Refer all servicing to

qualified service personnel.

Unplug this product from the wall outlet and refer servicing to qualified service

personnel when:

• the power cord or plug is damaged, cut or frayed

• liquid was spilled into the product

• the product was exposed to rain or water

• the product has been dropped or the case has been damaged

• the product exhibits a distinct change in performance, indicating a need

for service

• the product does not operate normally after following the operating

instructions

v

Note: Adjust only those controls that are covered by the operating

instructions, since improper adjustment of other controls may result in

damage and will often require extensive work by a qualified technician to

restore the product to normal condition.

CAUTION: Danger of explosion if battery is incorrectly replaced. Replace only

with the same or equivalent type recommended by the manufacturer. Dispose

of used batteries according to the manufacturer’s instructions.

Page 6

vi

Additional safety information

Your device and its enhancements may contain small parts. Keep them out of

the reach of small children.

Disposal instructions

Do not throw this electronic device into the trash when discarding.

To minimize pollution and ensure utmost protection of the global

environment, please recycle. For more information on the Waste

from Electrical and Electronics Equipment (WEEE) regulations, visit

http://www.acer-group.com/public/Sustainability/sustainability01.htm.

Mercury advisory

For projectors or electronic products containing an LCD/CRT monitor

or display: Lamp(s) inside this product contain mercury and must be

recycled or disposed of according to local, state or federal laws. For

more information, contact the Electronic Industries Alliance at www.eiae.org.

For lamp-specific disposal information, check www.lamprecycle.org.

Tips and information for comfortable use

Computer users may complain of eyestrain and headaches after prolonged use.

Users are also at risk of physical injury after long hours of working in front of a

computer. Long work periods, bad posture, poor work habits, stress,

inadequate working conditions, personal health and other factors greatly

increase the risk of physical injury.

Incorrect computer usage may lead to carpal tunnel syndrome, tendonitis,

tenosynovitis or other musculoskeletal disorders. The following symptoms may

appear in the hands, wrists, arms, shoulders, neck or back:

• numbness, or a burning or tingling sensation

• aching, soreness or tenderness

• pain, swelling or throbbing

• stiffness or tightness

• coldness or weakness

If you have these symptoms, or any other recurring or persistent discomfort

and/or pain related to computer use, consult a physician immediately and

inform your company's health and safety department.

The following section provides tips for more comfortable computer use.

Page 7

vii

Finding your comfort zone

Find your comfort zone by adjusting the viewing angle of the monitor, using a

footrest, or raising your sitting height to achieve maximum comfort. Observe

the following tips:

• refrain from staying too long in one fixed posture

• avoid slouching forward and/or leaning backward

• stand up and walk around regularly to remove the strain on your leg

muscles

• take short rests to relax your neck and shoulders

• avoid tensing your muscles or shrugging your shoulders

• install the external display, keyboard and mouse properly and within

comfortable reach

• if you view your monitor more than your documents, place the display at

the center of your desk to minimize neck strain

Taking care of your vision

Long viewing hours, wearing incorrect glasses or contact lenses, glare, excessive

room lighting, poorly focused screens, very small typefaces and low-contrast

displays could stress your eyes. The following sections provide suggestions on

how to reduce eyestrain.

Eyes

• Rest your eyes frequently.

• Give your eyes regular breaks by looking away from the monitor and

focusing on a distant point.

• Blink frequently to keep your eyes from drying out.

Display

• Keep your display clean.

• Keep your head at a higher level than the top edge of the display so your

eyes point downward when looking at the middle of the display.

• Adjust the display brightness and/or contrast to a comfortable level for

enhanced text readability and graphics clarity.

• Eliminate glare and reflections by:

• placing your display in such a way that the side faces the window or

any light source

• minimizing room light by using drapes, shades or blinds

• using a task light

• changing the display's viewing angle

Page 8

viii

• using a glare-reduction filter

• using a display visor, such as a piece of cardboard extended from the

display's top front edge

• Avoid adjusting your display to an awkward viewing angle.

• Avoid looking at bright light sources, such as open windows, for extended

periods of time.

Developing good work habits

Develop the following work habits to make your computer use more relaxing

and productive:

• Take short breaks regularly and often.

• Perform some stretching exercises.

• Breathe fresh air as often as possible.

• Exercise regularly and maintain a healthy body.

Warning! We do not recommend using the computer on a couch or bed. If

this is unavoidable, work for only short periods, take breaks regularly, and

do some stretching exercises.

Page 9

Regulations and safety notices

FCC notice

This device has been tested and found to comply with the limits for a Class A

digital device pursuant to Part 15 of the FCC rules. These limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This device generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this device does cause harmful interference to radio or television

reception, which can be determined by turning the device off and on, the

user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the device and receiver.

• Connect the device into an outlet on a circuit different from that to which

the receiver is connected.

• Consult the dealer or an experienced radio/television technician for help.

Notice: Shielded cables

All connections to other computing devices must be made using shielded cables

to maintain compliance with FCC regulations. In compliance with FCC

regulations, use shielded cables to connect to other computing devices. A duallink cable is recommended for DVI output.

ix

Notice: Peripheral devices

Only peripherals (input/output devices, terminals, printers, etc.) certified to

comply with the Class A limits may be attached to this equipment. Operation

with non-certified peripherals is likely to result in interference to radio and TV

reception.

Caution

Changes or modifications not expressly approved by the manufacturer could

void the user's authority, which is granted by the Federal Communications

Commission, to operate this computer.

Page 10

x

Operation conditions

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference,

and (2) this device must accept any interference received, including interference

that may cause undesired operation.

Notice: Canadian users

This Class A digital apparatus complies with Canadian ICES-003.

Remarque à l'intention des utilisateurs canadiens

Cet appareil numérique de la classe B est conforme a la norme NMB-003 du

Canada.

Compliant with Russian regulatory certification

Notice for Australia

For safety reasons, only connect headsets with a telecommunications

compliance label. This includes customer equipment previously labelled

permitted or certified.

Notice for New Zealand

1 The grant of a Telepermit for any item of terminal equipment indicates

only that Telecom has accepted that the item complies with minimum

conditions for connection to its network. It indicates no endorsement of

the product by Telecom, nor does it provide any sort of warranty. Above

all, it provides no assurance that any item will work correctly in all respects

with another item of Telepermitted equipment of a different make or

model, nor does it imply that any product is compatible with all of

Telecom's network services.

2 This equipment is not capable, under all operating conditions, of correct

operation at the higher speeds for which it is designed. Telecom will accept

no responsibility should difficulties arise in such circumstances.

3 Some parameters required for compliance with Telecom's Telepermit

requirements are dependent on the equipment (PC) associated with this

device. The associated equipment shall be set to operate within the

following limits for compliance with Telecom's Specifications:

a There shall be no more than 10 call attempts to the same number

within any 30 minute period for any single manual call initiation, and

b The equipment shall go on-hook for a period of not less than 30

seconds between the end of one attempt and the beginning of the

next call attempt.

Page 11

4 Some parameters required for compliance with Telecom's Telepermit

requirements are dependent on the equipment (PC) associated with this

device. In order to operate within the limits for compliance with Telecom's

specifications, the associated equipment shall be set to ensure that

automatic calls to different numbers are spaced such that there is not less

than 5 seconds between the end of one call attempt and the beginning

of another.

5 This equipment shall not be set up to make automatic calls to Telecom's

111 Emergency Service.

6 This device is equipped with pulse dialing while the Telecom standard is

DTMF tone dialing. There is no guarantee that Telecom lines will always

continue to support pulse dialing.

7 Use of pulse dialing, when this equipment is connected to the same line as

other equipment, may give rise to bell tinkle or noise and may also cause a

false answer condition. Should such problems occur, the user should NOT

contact the telecom Fault Service.

8 This equipment may not provide for the effective hand-over of a call to

another device connected to the same line.

9 Under power failure conditions this appliance may not operate. Please

ensure that a separate telephone, not dependent on local power, is

available for emergency use.

Notice: BSMI

xi

Laser compliance statement

The CD or DVD drive used with this computer is a laser product.

The CD or DVD drive's classification label (shown below) is located on the drive.

CLASS 1 LASER PRODUCT

CAUTION: INVISIBLE LASER RADIATION WHEN OPEN. AVOID EXPOSURE

TO BEAM.

Appareil à laser de classe 1

Attention : Radiation laser visible et invisible en cas d’ouverture. Éviter toute

exposition aux rayons.

Laserprodukt der Klasse 1

Achtung: Beim Öffnen werden unsichtbare Laserstrahlen freigelegt. Setzen Sie

sich diesen Strahlen nicht aus.

Page 12

xii

Prodotto laser di classe 1

Attenzione: Radiazioni laser invisibili in caso d’apertura. Evitare l’esposizione ai

raggi.

Producto láser de Clase 1

Precaución: Cuando está abierta, hay radiación láser. Evite una exposición al haz

de luz.

Produto Laser de Classe 1

Precaução: Radiação laser invisível quando aberto. Evite exposição ao feixe.

Laserproduct klasse 1

Voorzichtig: Onzichtbare laserstraling indien geopend. Voorkom blootstelling

aan straal.

Digital audio output statement

The optical connector contains no laser or light emitting diode (LED) more than

Class I.

Radio device regulatory notice

Note: Below regulatory information is for models with wireless LAN and/or

Bluetooth only.

General

This product complies with the radio frequency and safety standards of any

country or region in which it has been approved for wireless use. Depending on

configurations, this product may or may not contain wireless radio devices (such

as wireless LAN and/or Bluetooth modules). Below information is for products

with such devices.

Declaration of Conformity for EU countries

Hereby, Acer, declares that this system is in compliance with the essential

requirements and other relevant provisions of Directive 1999/5/EC.

List of applicable countries

This device must be used in strict accordance with the regulations and

constraints in the country of use. For further information, please contact local

office in the country of use. Please see

http://ec.europa.eu/enterprise/rtte/implem.htm for the latest country list.

Page 13

Information for your safety and comfort iii

Regulations and safety notices ix

1 System tour 1

System notes 2

System power 2

SATA backplane, drives and RAID 2

External and internal structure 3

Front panel 3

Rear panel 5

Internal components 7

Mainboard 8

2 System setup 15

Setting up the system 16

Pre-installation requirements 16

Connecting peripherals 17

Turning on the system 18

Power-on problems 19

Configuring the system OS 20

Turning off the system 21

3 System upgrades 23

Installation precautions 24

ESD precautions 24

Pre-installation instructions 25

Post-installation instructions 25

Configuring the storage devices 26

Accessing the drive bays 26

Hard disk drive configuration guidelines 26

Installing and removing the power supply 30

Power supply failure 31

Opening the server 33

Removing the top cover 33

Installing the top cover 34

Removing and installing the air duct 34

Replacing a system fan 35

Replacing the processor and heatsink 37

Removing the heatsink 37

Installing a heatsink 39

Upgrading the processor 41

Upgrading the system memory 44

xiii

Page 14

xiv

System memory interface 44

Installing an expansion card 52

Installing a PCI add-on card 52

4 System BIOS 53

Introduction 54

The BIOS setup utility 54

Changing configuration data 55

Main setup 55

System Overview 55

Advanced Settings 56

Boot Features 56

Power configuration 57

Processor & Clock Options 57

Advanced Chipset Control 60

Security Settings 71

System Management Settings 72

Product Information 72

IP Address 73

Remote Access Configuration 73

Event Log Configuration 74

Boot 74

Boot Device Priority 75

Hard Disk Drives 75

Removable Drives 75

CD/DVD Drive 76

Retry Boot Devices 76

Exit Options 76

5 System troubleshooting 79

Resetting the system 80

Initial system startup problems 80

Initial troubleshooting checklist 81

Hardware diagnostic testing 82

Checking the boot-up status 82

Verifying the condition of the storage devices 83

Confirming loading of the operating system 83

Specific problems and corrective actions 84

Appendix A Server management tools 89

Server management overview 90

RAID configuration utilities 91

Page 15

Intel onboard SATA RAID Creation 91

Adaptec onboard SATA RAID Creation 92

Appendix B Rack mount configuration 95

Rack installation information 96

System rack installation 98

Vertical mounting hole pattern 99

Installing the system into the rack 100

Appendix C: Acer Smart Console 105

Using Acer Smart Console 106

Software requirements 106

Accessing Acer Smart Console 107

Acer Smart Console user interface 108

System Information 108

Server Health 109

Configuration 111

Remote Control 121

Launch SOL 123

Virtual Media 124

Maintenance 126

KVM function description 127

Exit 133

xv

Index 147

Page 16

xvi

Page 17

1 System tour

Page 18

2

1 System tour

System notes

The AW1000 is a unique 1U server system with twin-mainboard

configuration. With two nodes incorporated into a single chassis, there

are several points you should keep in mind when working with this

server.

The server has an integrated dual-port Gigabit Ethernet which

supports Intel I/O Acceleration Technology (IOAT), iSCSI boot, Virtual

Machine Device Queues (VMDq) and PCI-SIG SR-IOV implementation.

Each node can be installed with one or two CPUs, different memory

capacities, different number and capacities of HDDs.

System power

A single power supply is used to provide the power for both

mainboards. Each mainboard however, can be shut down

independently of the other using the power button on its own control

panel.

Although they share a common power supply, the I2C signals used for

monitoring the power supply are received by the primary mainboard

only. (When viewed from the front of the chassis, the mainboard on

the left is referred to as the primary board and the mainboard on the

right as the secondary.)

SATA backplane, drives and RAID

The system supports up to eight 2.5-inch hot-plug hard disk drives or

four hard disk drives per server node. The SATA backplane works as a

single backplane divided into two sections. This means that while a

single power connector is used and functions such as overheating

apply to both sections together, each pair of SATA drives is logically

connected to its own mainboard. Consequently, RAID setup is limited

to a two-drive scheme (RAID cannot be spread across all eight drives).

Page 19

External and internal structure

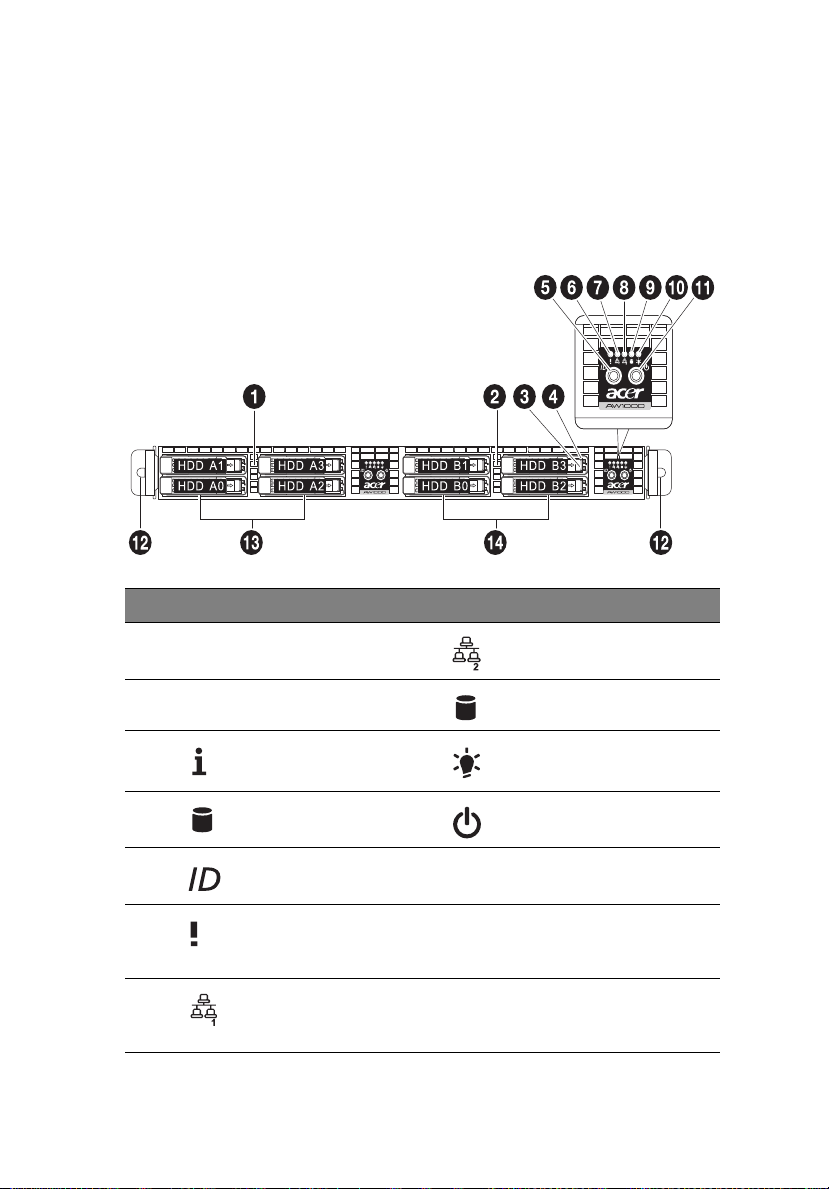

Front panel

The illustration below shows the system front panel.

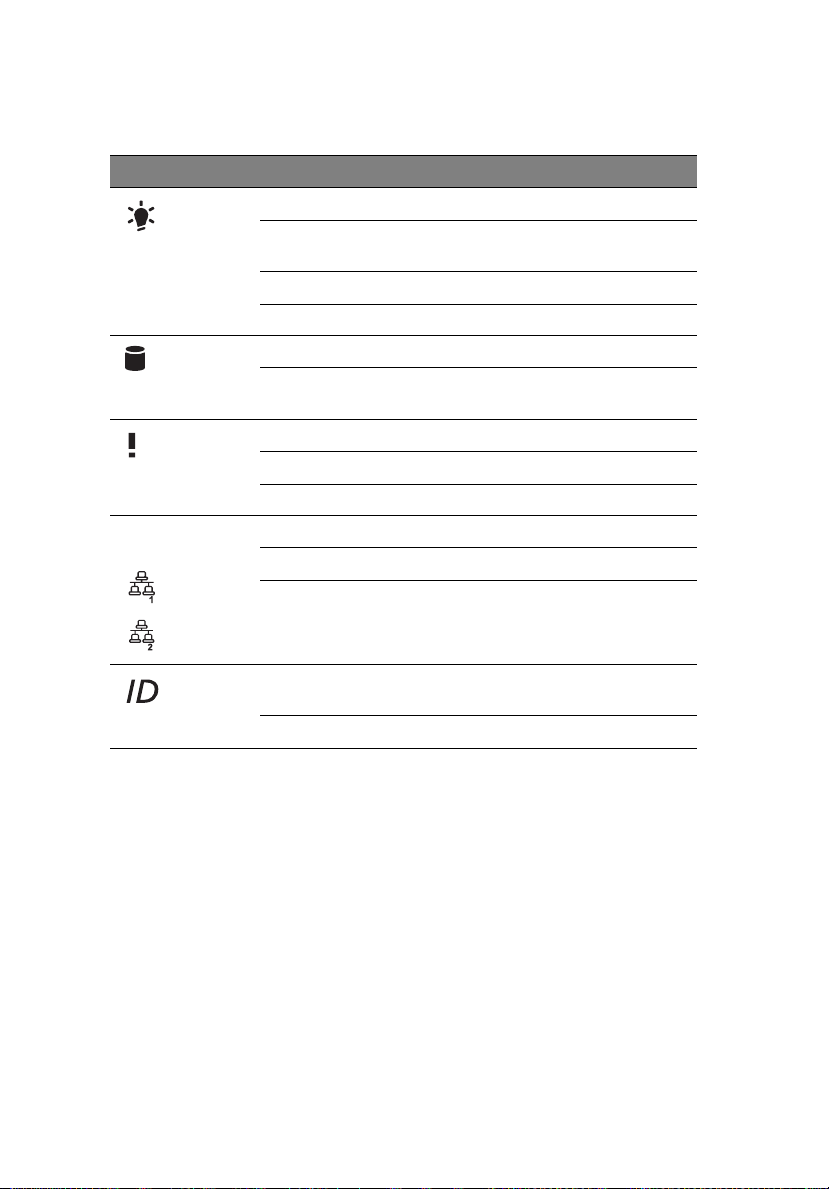

No. Icon Component No. Icon Component

1 Server node A 8 LAN2 activity indicator

3

2 Server node B 9 HDD activity indicator

3 Hot-plug HDD

status indicator

4 Hot-plug HDD

activity indicator

5 System ID button/

indicator

6 Status/fault

indicator

7 LAN1 activity

indicator

10 Power indicator

11 Power button

12 Rack handles

13 Four 2.5-inch hot-plug

drive bays (A0 to A3)

controlled by server node A

14 Four 2.5-inch hot-plug

drive bays (B0 to B3)

controlled by server node B

Page 20

4

Front panel LED indicator status

LED indicator LED color LED state Status

Power

indicator

HDD activity

indicator

Status/fault

indicator

LAN activity

indicator

LAN1,

LAN2)

Green On S0: Power ON

Green Blinking (1 Hz at

50% duty cycle)

N/A Off S4

N/A Off S5

Amber Blinking HDD Access

N/A Off No access and No HDD

Red On Overheat

Red Flashing 1 Hz Fan fail

Red Off Normal

Green On LAN Link / No Access

Green Blinking LAN Access

N/A Off Disconnect / Idle

1 System tour

S1: Sleep

fault

System ID

indicator

Blue On System ID button

pressed

Blue Blinking IPMI-activated system ID

Page 21

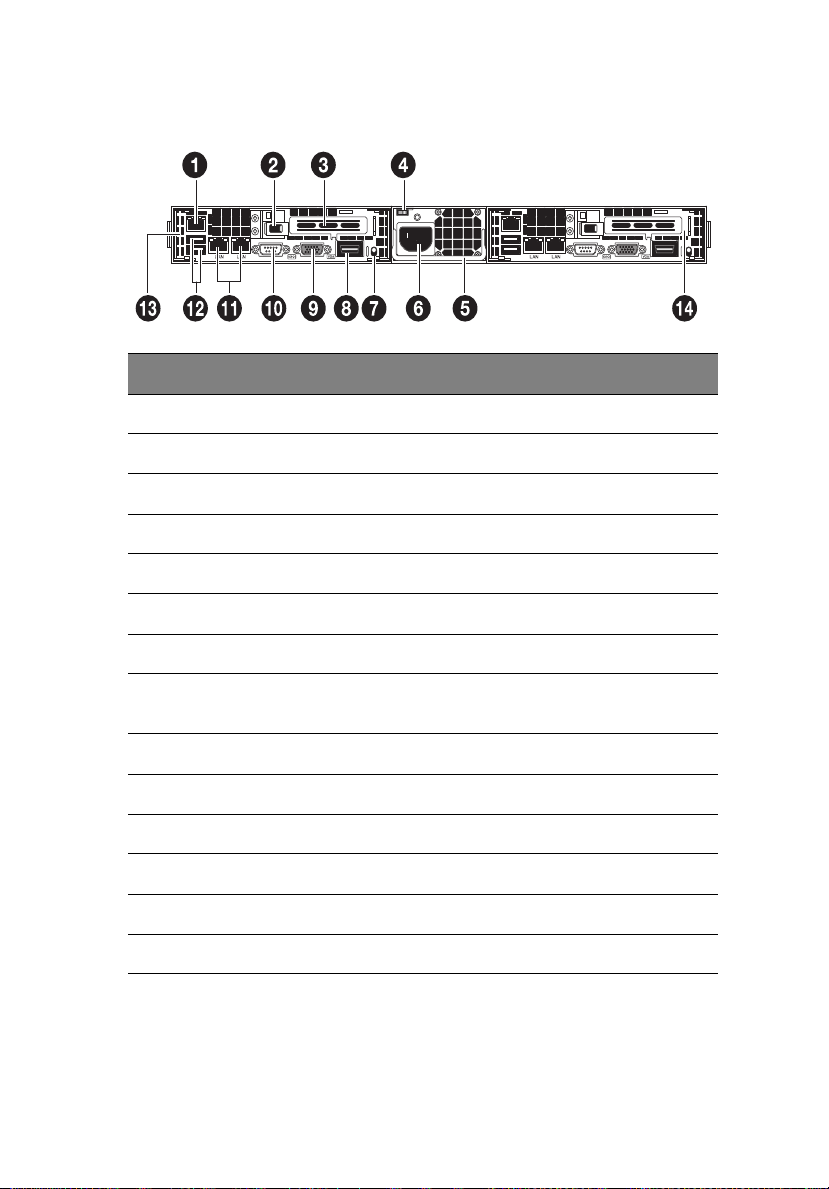

Rear panel

No. Component

1 Server management port (RJ-45) (10/100 Mbps)

2 PCI card locking tab

3 Low-profile PCI expansion slot

4 Power supply module release latch

5 Power supply module handle

6 Power socket

5

7 System ID switch

8 InfiniBand port QSFP connector (only available for AW170d F1 and

AW170q F1)

9 Monitor port

10 Serial port (COM 1)

11 Gigabit LAN ports (10/100/1000 Mbps)

12 USB 2.0 ports

13 Server node B

14 Server node A

Page 22

6

1 System tour

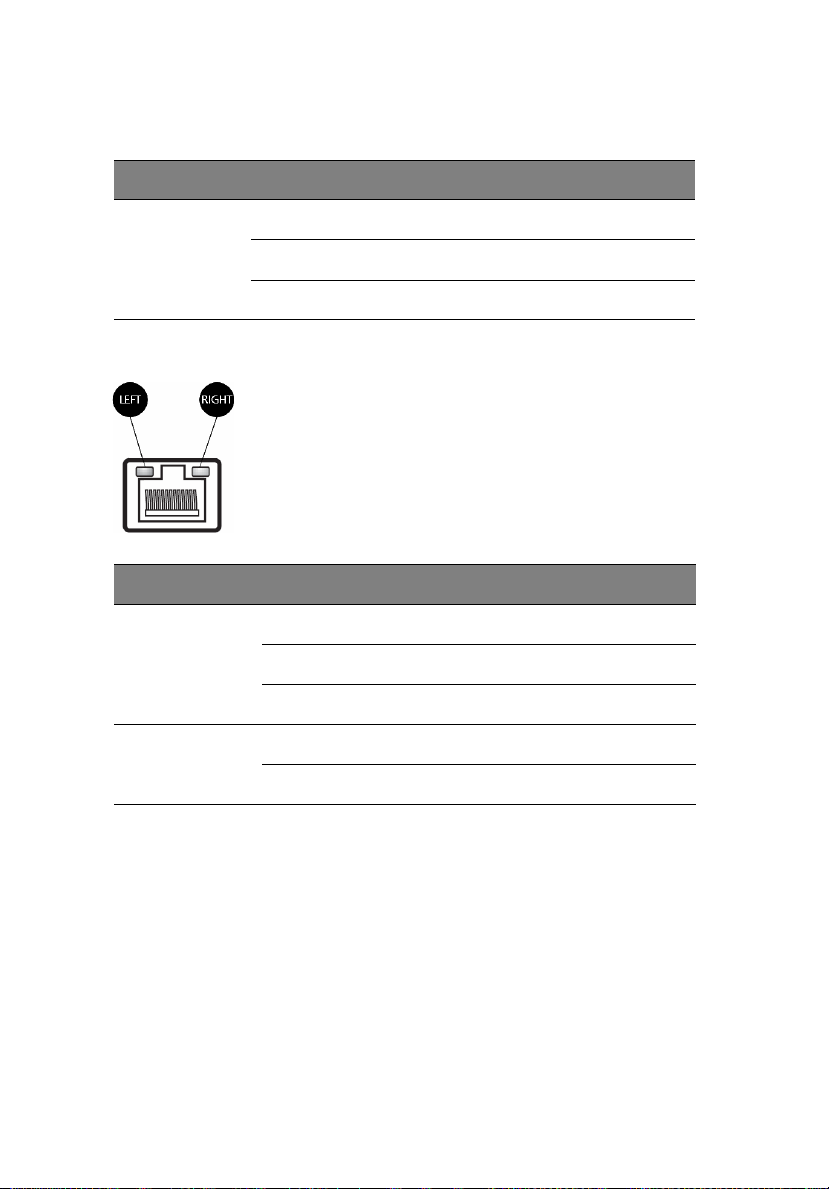

Rear panel LED indicator status

LED indicator LED color LED state Status

System ID LED N/A Off Normal

Blue On System ID button pressed

Blue Blinking IPMI-activated system ID

LAN port LED indicators

LED indicator LED color LED state Status

RJ45 LED (Left) N/A Off No connection or 10 Mbps

Green On 100 Mbps

Amber On 1000 Mbps

RJ45 LED (Right) Yellow On Active connection

Yellow Blinking Transmit/Receive activity

Page 23

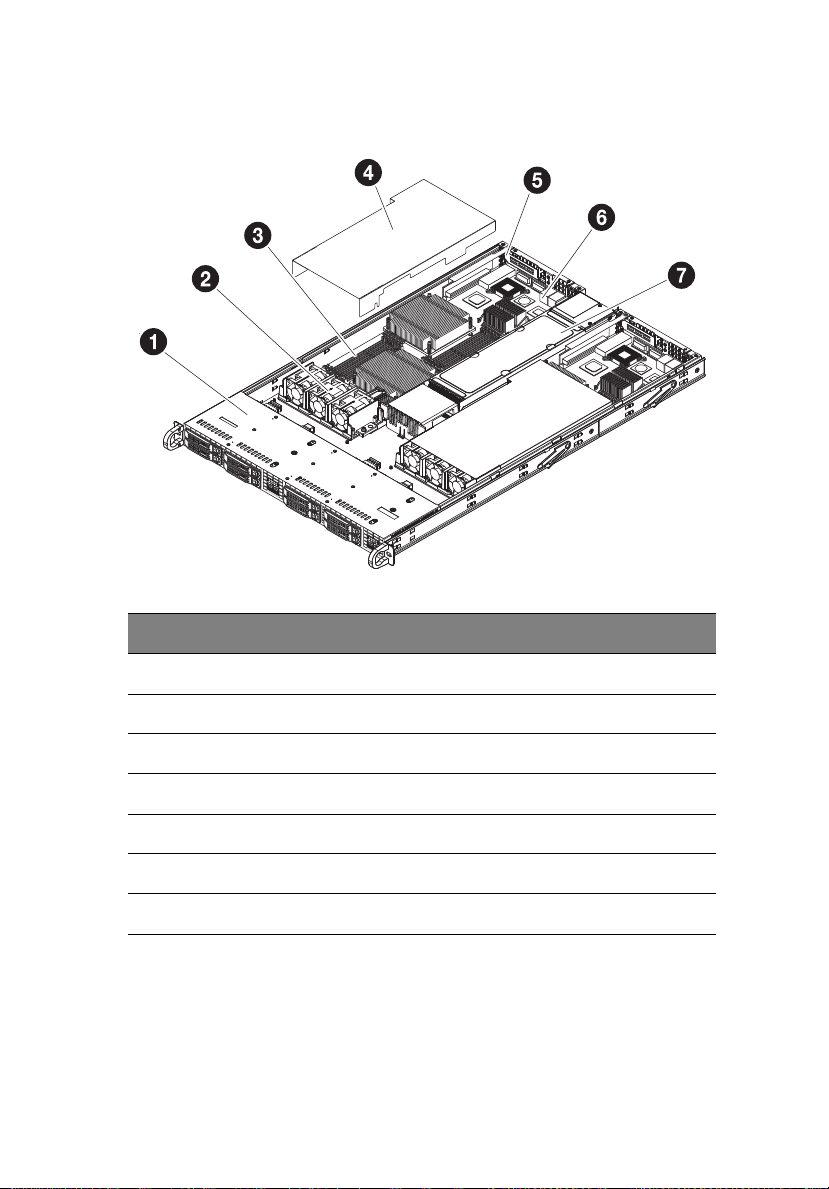

Internal components

No. Component

7

1 Hard disk drives

2 System fan modules

3 Memory modules

4 Air duct

5 PCI riser board bracket assembly

6 Mainboard

7 Power supply module

Page 24

8

1 System tour

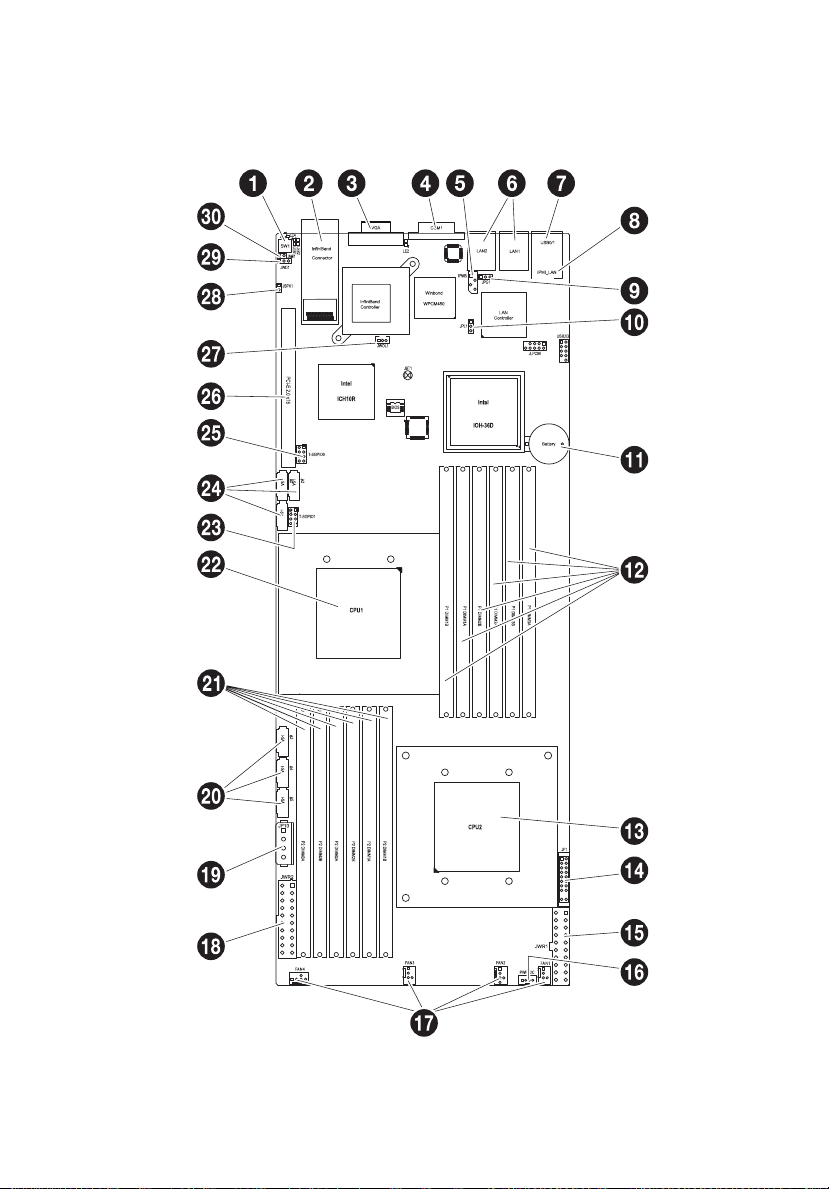

Mainboard

Both the AW170d F1 and AW170q F1 models include an InfiniBand

port at DDR (dual data rate) and QDR (quad data rate) speeds,

respectively. InfiniBand is a scalable serial communications link

intended for connecting processors with high-speed peripherals.

(InfiniBand requires a QSFP connector.)

Model Variations

AW170 F1 AW170d F1 AW170q F1

InfiniBand Connector No Yes Yes

DDR InfiniBand No Yes No

QDR InfiniBand No No Yes

Page 25

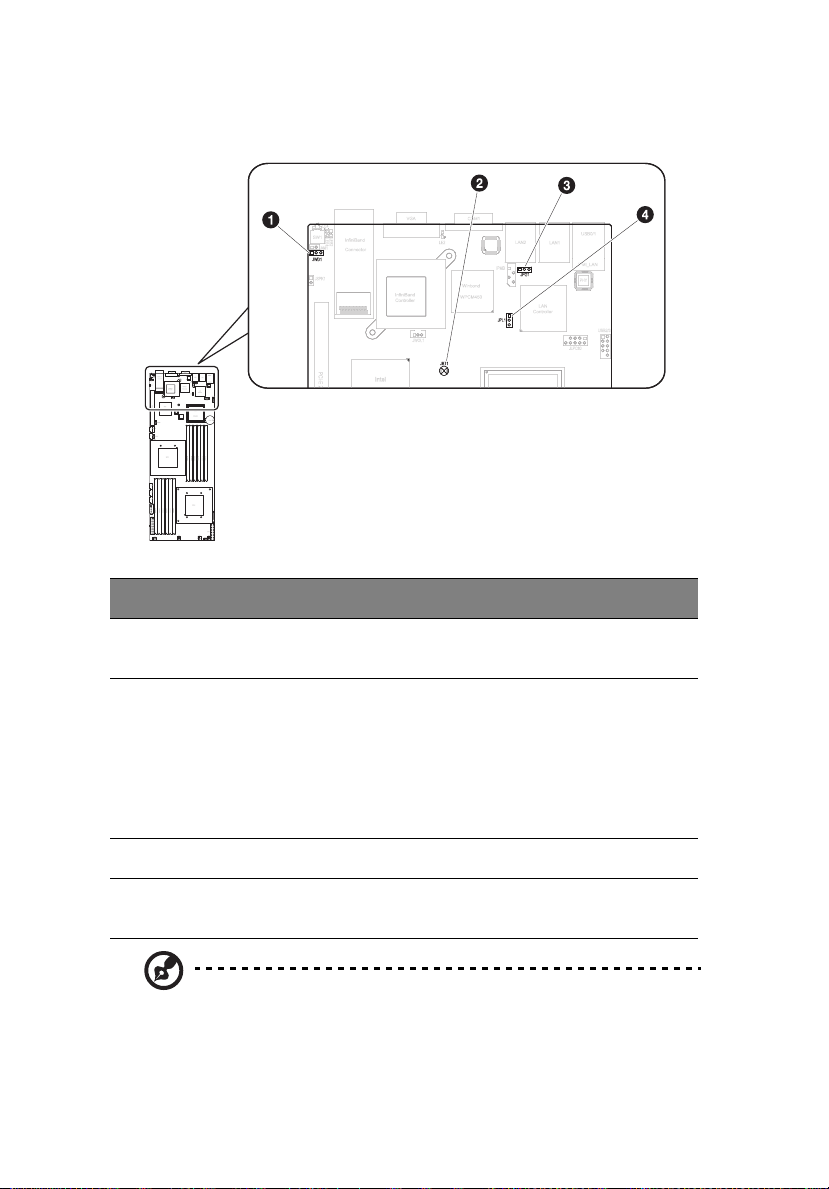

The mainboard becomes accessible once you open the system. It should

look like the figure shown below.

9

Page 26

10

No. Connector Description

1SW1 System ID switch

2 InfiniBand InfiniBand connector QSFP connector (only

available for AW170d F1 and AW170qF1).

3 VGA Video port

4 COM1 COM1 serial port

5 IPMB IPMB header (for an IPMI card)

6 LAN1/2 Gigabit Ethernet (RJ45) ports

1 System tour

7 USB0/1,

USB 2/3

8 IPMI LAN Dedicated IPMI LAN port

9 JPG1 VGA Enable/Disable

10 JPL1 LAN1/2 Enable/Disable

11 BATTERY CMOS battery

12 P1 DIMM1B,

13 CPU2 Processor 2 socket

14 JF1 Front panel connector

15 JWR1 12 V 20-pin power connectors

16

17 FAN 1-4 System/CPU fan headers

18 JWR2 12 V 20-pin power connectors

P1 DIMM1A,

P1 DIMM2B,

P1 DIMM2A,

P1 DIMM3B,

P1 DIMM3A,

2

C Power supply SMBus I2C header

PWR I

Universal Serial Bus (USB) ports 0/1, 2/3

DDR3 sockets for processor 1

Page 27

No. Connector Description

19 JP10 Onboard 4-pin power connector

11

20 SATA3 -

SATA5

21 P2 DIMM1B,

P2 DIMM1A,

P2 DIMM2B,

P2 DIMM2A,

P2 DIMM3B,

P2 DIMM3A,

22 CPU1 Processor 1 socket

23 T-SGPIO1 Serial General Purpose Input/Output headers

24 SATA0 -

SATA2

25 T-SGPIO0 Serial General Purpose Input/Output headers

26 PCI-E 2.0 x16 Low-profile PCI-E riser slot

27 JWOL1 Wake-On-LAN header

28 JPSK1 Internal speaker/buzzer header

29 JWD1 Watch Dog Enable/Disable/Reset

30 JNMI1 NMI (Non-Masked Interrupt) header

SATA ports

DDR3 sockets for processor 2

SATA ports

Page 28

12

Mainboard jumper settings

No. Jumper Description Default Setting

1 System tour

1 JWD1 Enable/Disable/

Reset Watch Dog

2 JBT1 Clear CMOS Instead of pins, this jumper consists of

3 JPG1 Enable/Disable VGA Pins 1-2 (Enabled)

4 JPL1 Enable/Disable

LAN1/2

Note: Jumpers not indicated are for test purposes only.

Pins 1-2 (Reset).

contact pads to prevent accidental

clearing of the CMOS contents. To

clear CMOS, disconnect the power

and short the CMOS pads with a

metal object such as a small

screwdriver.

Pins 1-2 (Enabled)

Page 29

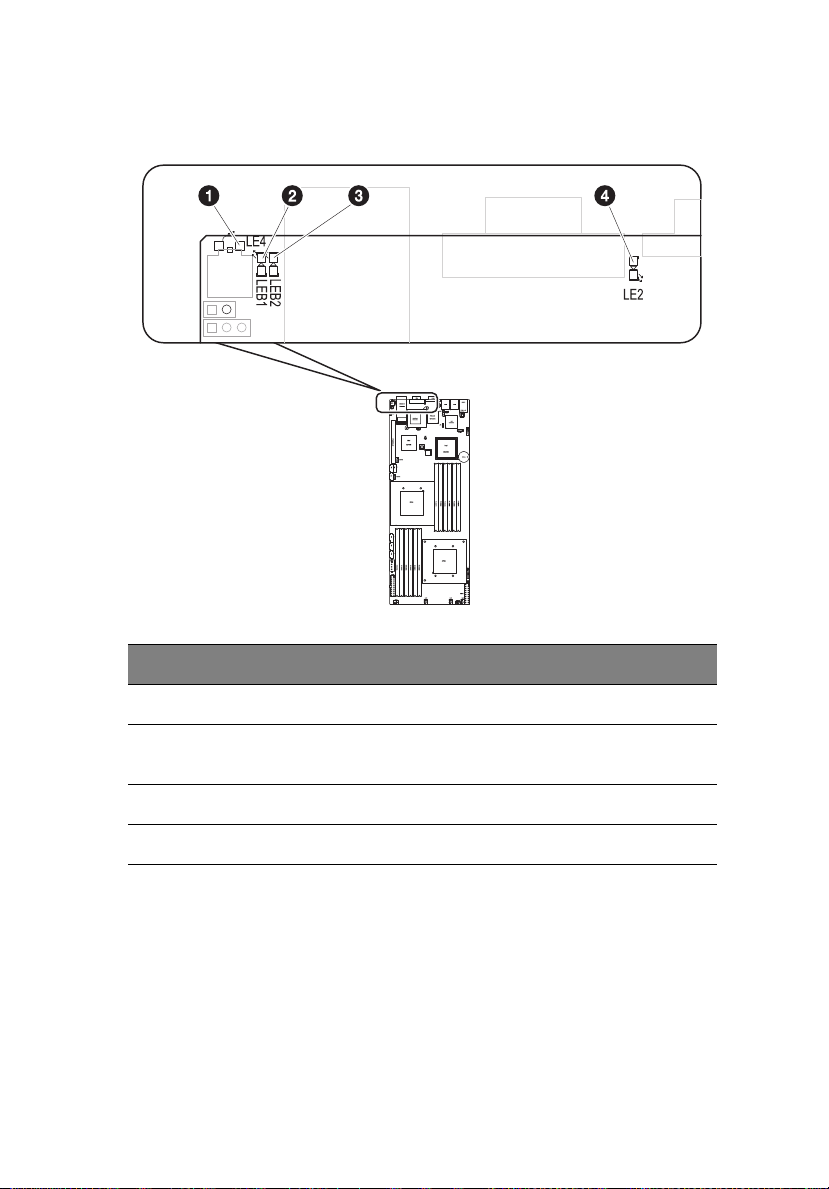

Mainboard LEDs

13

No. LED Description

1 LE4 System ID LED indicator (rear)

2 LEB1 InfiniBand link LED indicator (only available for

3 LEB2 BMC activity LED indicator

4 LE2 Onboard standby PWR warning LED Indicator

AW170d F1 and AW170q F1)

Page 30

14

1 System tour

Page 31

2 System

setup

Page 32

16

2 System setup

Setting up the system

Pre-installation requirements

Selecting a site

Before unpacking and installing the system, select a suitable site for

the system for maximum efficiency. Consider the following factors

when choosing a site for the system:

• Near a grounded power outlet.

• Clean and dust-free.

• Stable surface free from vibration.

• Well-ventilated and away from sources of heat.

• Protected from electromagnetic fields produced by electrical

devices such as air conditioners, radio and TV transmitters, etc.

Package contents

Ensure you have the following items:

• Acer AW1000 system.

• Acer AW1000 accessory box.

If any of the above items is damaged or missing, contact your dealer

immediately.

Save the boxes and packing materials for future use.

Page 33

Connecting peripherals

Caution! The server operates on 100-127/200-240 VAC only. Do

not connect the system to an incorrect voltage source.

Refer to the illustration below for specific connection instructions on

the peripherals you want to connect to the system.

17

Note: Consult the operating system manual for information on

how to configure the network setup.

Page 34

18

2 System setup

Turning on the system

After making sure that you have properly set up the system and

connected all the required cables, you can now power on the system.

To power on the system:

After plugging in the power cord, press the power button for each

node. Each node can be powered on or powered off independently.

You can turn on each node at any sequence.

The system starts up and displays a welcome message on the monitor.

After that, a series of POST messages appears. The POST messages

indicate if the system is running well or not.

Note: If the system does not turn on or boot after pressing the

power button(s), go to the next section for the possible causes of

the boot failure.

Aside from the POST messages, you can determine if the system is in

good condition by checking if the following occurred.

• The power indicator on the front panel lights up green.

• The Num Lock, Caps Lock, and Scroll Lock indicators on the

keyboard light up.

Page 35

Power-on problems

If the system does not boot after you have applied power, check the

following factors that might have caused the boot failure.

• The external power cord may be loosely connected.

Check the power cord connection from the power source to the

power supply module AC input connector on the rear panel. Make

sure that the power cord is properly connected to the power

source and to the AC input connector.

• No power comes from the grounded power outlet.

Have an electrician check your power outlet.

• Loose or improperly connected internal power cables.

Check the internal cable connections. If you are not confident to

perform this step, ask a qualified technician to assist you.

Warning! Make sure all power cords are disconnected from the

electrical outlet before performing this task.

Note: If you have gone through the preceding actions and the

system still fails to boot, ask your dealer or a qualified technician

for assistance.

19

Page 36

20

2 System setup

Configuring the system OS

Acer Smart Setup assists you to conveniently install your choice of

operating system.

Note: To purchase the Acer Smart Setup software, contact your

local Acer representative.

To start using Acer Smart Setup, follow the steps below.

1 Locate the Acer Smart Setup included in the system package.

2 Connect an external DVD drive to your system. Press the Stop/Eject

button on the DVD drive to eject the disc tray.

3 When the disc tray slides open, insert the DVD containing Acer

Smart Setup with the label or title side of the disc facing upward.

Note: When handling the disc, hold it by the edges to avoid

smudges or fingerprints.

4 Gently press the disc down to make sure that it is properly

inserted.

Caution! While pressing the disc, be careful not to bend the disc

tray. Make sure that the disc is properly inserted before closing

the disc tray. Improper insertion may damage both the disc and

the CD-ROM drive.

5 Gently press the drive Stop/Eject button again to close the disc

tray.

6 On the Acer Smart Setup setup window, select OS Installation.

7 Follow all onscreen instructions.

For more information, refer to the Acer Smart Setup Help file.

Note: The Windows or Linux OS disc is needed when you install

the OS with the Acer Smart Setup.

Page 37

21

Turning off the system

There are two ways to turn off the server — via software or via

hardware. The software procedure below applies to a system running

the Windows operating system. For further operating system

shutdown procedures, refer to the related user documentation.

To turn off the system via software:

1 Press <Ctrl> + <Alt> + <Delete> on the attached keyboard or click

Start on the Windows taskbar.

2 Select Shut Down.

3 Select Shut down from the drop-down window then click on OK.

To turn off the system via hardware:

If you cannot shut down the server using the software, press and hold

the power button for at least four seconds. Quickly pressing the button

may put the server in a Suspend mode only.

Page 38

22

2 System setup

Page 39

3 System

upgrades

Page 40

24

3 System upgrades

Installation precautions

Before you install any server component, we recommend that you read

the following sections. These sections contain important ESD

precautions along with pre-installation and post-installation

instructions.

ESD precautions

Electrostatic discharge (ESD) can damage the processor, disk drives,

expansion boards, mainboards, memory modules and other server

components. Always observe the following precautions before you

install a server component:

• Do not remove a component from its protective packaging until

you are ready to install it.

• Do not touch the component pins, leads, or circuitry.

• Components with a Printed Circuit Board (PCB) assembly should

always be laid with the assembly-side down.

• Wear a wrist grounding strap and attach it to a metal part of the

server before handling components. If a wrist strap is not

available, maintain contact with the server throughout any

procedure requiring ESD protection.

• Keep the work area free of nonconductive materials, such as

ordinary plastic assembly aids and foam packing.

Page 41

Pre-installation instructions

Perform the steps below before you open the server or before you

remove or replace any component:

Warning! Failure to properly turn off the server before you start

installing components may cause serious damage. Do not attempt

the procedures described in the following sections unless you are

a qualified service technician.

1 Turn off the system and all the peripherals connected to it.

2 Unplug all cables from the power outlets.

3 Disconnect all telecommunication cables from their ports.

4 Place the system unit on a flat, stable surface.

5 Open the system according to the instructions on page 33.

6 Follow the ESD precautions described in this section when

handling a server component.

Post-installation instructions

Perform the steps below after installing a server component.

1 See to it that all components are installed according to the

described step-by-step instructions.

2 Reinstall all components or cable that have been previously

removed.

3 Reinstall the top cover.

4 Reconnect the necessary cables.

5 Turn on the system.

25

Page 42

26

3 System upgrades

Configuring the storage devices

The system supports up to eight 2.5-inch hot-plug SATA hard disk

drives. An external optical drive can also be added to the server.

Accessing the drive bays

Since SATA drives have hot-plug capability, you do not need to access

the inside of the chassis or power down the system to install or replace

SATA drives. Proceed to the next step for instructions.

Note: The operating system you use must have RAID support to

enable the hot-plug capability of the SATA drives.

Caution! When working around the SATA backplane, do not

touch the backplane with any metal objects and make sure no

cables touch the backplane. Also, regardless of how many SATA

drives are installed, all eight drive carriers must remain in the

chassis to maintain proper airflow.

Hard disk drive configuration guidelines

Observe these guidelines when replacing or installing a hard disk drive.

• Use only qualified SATA HDDs. To purchase SATA HDD, contact

your local representative.

• Before removing a hard disk drive, make sure to back up all

important system files.

• Check hard disk drive status by checking the status LED indicators

on the HDD carrier.

Page 43

27

Node A control panel

(primary mainboard)

Node B control panel

(secondary mainboard)

• The hard disk drive carriers must be installed in the following

order:

Bay no. Description

Node A, HDD A0 to A3 Four 2.5-inch hot-plug drive bays controlled by

Node B, HDD B0 to B3 Four 2.5-inch hot-plug drive bays controlled by

node A

node B

Determining drive status

Each HDD carrier features two status LED indicators (see page 3) to

display the hard drive status. If you are replacing a failed HDD,

determine which drive has failed by checking the status LED indicators.

Hot-plug HDD carrier LED indicators

Description

HDD present no access Off Off

HDD access Blink Off

Green Red

Page 44

28

Removing a hard disk drive with carrier

1 Observe the ESD precautions described on page 24.

2 Remove the carrier with failed HDD.

(1) Unlock the HDD carrier latch.

(2) Slide the HDD carrier latch to release the lever.

(3) Pull the lever and slide the carrier out from the chassis.

3 System upgrades

3 Observe the post-installation instructions described on page 25.

Page 45

29

Installing a hard disk drive with carrier

1 Slide the HDD carrier all the way into the drive bay.

2 Close the HDD carrier lever and push the HDD carrier until it locks

into place.

3 Lock the HDD carrier.

4 Observe the post-installation instructions described on page 25.

Page 46

30

3 System upgrades

Installing and removing the power supply

WARNING! To reduce the risk of personal injury or damage to

the equipment, the installation of power supply modules

should be referred to individuals who are qualified to service

server systems and are trained to deal with equipment capable

of generating hazardous energy levels.

WARNING! To reduce the risk of personal injury from hot

surfaces, observe the thermal labels on each power supply

module. You can also consider wearing protective gloves.

WARNING! To reduce the risk of personal injury from electric

shock hazards, do not open the power supply modules. There

are no serviceable parts inside the module.

Caution! Electrostatic discharge can damage electronic

components. Make sure that you are properly grounded before

handling a power supply module.

Caution! Due to chassis airflow disruption, a power supply bay

should never be vacant for more than two minutes when the

server is powered on. Exceeding five minutes might cause the

system to exceed the maximum acceptable temperature and

possibly damage the system components.

Caution! Before removing or replacing the power supply, you

must first take the server out of service, turn off all peripheral

devices connected to the system, turn off the system by

pressing the power button, and unplug the AC power cord

from the system or wall outlet.

The server has a single 1000-/1200-watt power supply capable of

operating at 100 to 140/180 to 240 input volts.

Page 47

Power supply failure

If the power supply unit fails, the system will shut down and you will

need to replace the power supply unit. Replacement units can be

ordered directly from your local representative.

Replacing the power supply

Press all main power buttons on the front of the chassis and then

unplug the AC power cord to completely remove power from the

system before removing the power supply.

1 Remove the AC power cord from the power supply.

2 Remove the power supply module.

(1) Press the power supply release (1) latch to release the failed

power supply module from the chassis.

(2) Use the handle (2) to pull the power supply module out of the

server.

31

3 Install a new power supply module of the exact same model.

Page 48

32

3 System upgrades

4 Push the new power supply module into the power bay until it

clicks into place.

5 Plug the AC power cord back into the module and power up the

server by pushing the power on buttons for all nodes.

Page 49

Opening the server

Caution! Before you proceed, make sure that you have turned off

the system and all peripherals connected to it. Read the “Preinstallation instructions” on page 25.

You need to open the server before you can install additional

components or access the system’s internal components. Refer to the

following sections for instructions.

Removing the top cover

Note: Observe the ESD precautions and pre-installation

instructions described on page 24.

1 Remove the four screws securing the cover to the chassis.

2 Slide the cover toward the rear of the chassis.

3 Lift the cover off the chassis.

33

4 Put the top cover aside for reinstallation later.

Page 50

34

3 System upgrades

Installing the top cover

1 Perform the pre-installation instructions described on page 24.

2 Install the top cover.

(1) Place the top cover with the chassis so that the tabs on the

cover align with the slots on the chassis.

(2) Slide the top cover toward the front of the chassis until it is

fully closed.

3 Replace the four screws on the top cover.

Removing and installing the air duct

Caution! Always operate your server with the air duct installed to

ensure reliable and continued operation.

You need to remove the air duct to perform the following procedures:

• Removing and installing a processor

• Removing and installing a memory module

Removing the air duct

1 Perform the pre-installation instructions described on page 24.

2 Lift the air duct from the chassis.

Page 51

Installing the air duct

1 Perform the pre-installation instructions described on page 24.

2 Place the air duct on the chassis so that the tabs on the air duct

align with the slots on the chassis.

Caution! Do not pinch or unplug cables that may be near or under

the air duct.

35

Replacing a system fan

Each mainboard has its own set of three high-performance fans (for a

total of six in the chassis) to provide the cooling for the system. Fan

speed may be controlled by a setting in BIOS (see Chapter 4).

To replace a fan module

1 Perform the pre-installation instructions described on page 25.

Warning! The system fan becomes very hot when the system is on.

Allow it to cool off first before handling.

2 Remove the top chassis cover while the system is still running to

determine which of the fans has failed.

3 Remove the fan module.

Page 52

36

(1) Disconnect the fan cable.

(2) Pull up the fan module and detach it from the chassis.

4 Install the new fan module.

(1) Insert the new fan module into the chassis.

3 System upgrades

(2) Connect the fan cable.

5 Observe the post-installation instructions described on page 25.

Page 53

Replacing the processor and heatsink

Notes:

• Always connect the power cord last and always remove it before

adding, removing or changing any hardware components. Make

sure that you install the processor into the CPU socket before you

install the CPU heatsink.

• If you buy a CPU separately, make sure that you use an Intelcertified multidirectional heatsink and fan only.

• Make sure to install the mainboard into the chassis before you

install the CPU heatsinks.

• When receiving a mainboard without a processor pre-installed,

make sure that the plastic CPU socket cap is in place and none of

the socket pins is bent; otherwise, contact your retailer

immediately.

Removing the heatsink

Warning! We do not recommend that the CPU or the heatsink be

removed. However, if you do need to uninstall the heatsink,

please follow the instructions below to prevent damage to the

CPU or the CPU socket.

37

1 Remove power from the system and unplug the AC power cord

from the power supply.

Page 54

38

3 System upgrades

2 Using a screwdriver, loosen the heatsink screws from the

mainboard.

3 Lift the heat sink away from the processor.

4 Lay down the heat sink in an upright position — with the thermal

patch facing upward. Do not let the thermal patch touch the work

surface.

Page 55

Installing a heatsink

Caution! The heat sink has a thermal interface material (TIM) on

the underside. Use caution so that you do not damage the TIM. If

a protective film is installed on the TIM, remove it.

1 Remove power from the system and unplug the AC power cord

from the power supply.

2 Do not apply any thermal grease to the heatsink or the CPU die;

the required amount has already been applied.

3 Place the heatsink on top of the CPU so that the four mounting

holes are aligned with those on the (preinstalled) heatsink

retention mechanism.

39

4 Screw in two diagonal screws (i.e. the #1 and the #2 screws) until

just snug. Do not fully tighten the screws or you may damage the

CPU.)

Page 56

40

3 System upgrades

5 Add the two remaining screws then finish the installation by fully

tightening all four screws.

Page 57

41

Upgrading the processor

Processor configuration guidelines

Each server node supports two LGA 1366 processor sockets supporting

dual-core or quad-core Intel Xeon processors. The supplied processors

may be upgraded or additional processors installed.

Observe the following guidelines when replacing or installing a

processor.

• Processor 1 socket must always be populated. If no processor is

installed in this socket, the system will fail to boot.

• Before removing a processor, make sure to back up all important

system files.

• When installing a second processor, make sure it has same

stepping and frequency specifications as the default processor.

• Handle the processor and the heat sink carefully. Damage to either

may prevent the system from functioning properly.

Replacing the processor

Warning! The processor becomes very hot when the system is on.

Allow it to cool off first before handling.

1 Remove the heatsink (see “Removing the heatsink” on page 37).

2 Release then lift the load lever.

3 Open the retention plate to expose the socket body.

Page 58

42

3 System upgrades

(3) Grasp the installed processor by its edges and lift it out of its

socket.

(4) Store the old processor inside an anti-static bag.

4 Remove the new processor from its protective packaging.

5 Install the new processor.

(1) Hold the processor by its edges. Make sure the alignment tabs

on the socket fit the two notch located on the edge of the

processor. The pins are keyed in such a way that you cannot

install the processor in the wrong orientation without

bending the pins.

(2) Insert the new processor in the socket.

(3) Close the retention plate.

Page 59

(4) Engage the load lever back into place.

6 Apply the thermal interface material.

(1) Use an alcohol pad to wipe off the old thermal grease from

both the heat sink and the processor socket retention plate.

(2) Apply a thin layer of an approved thermal interface material

before installing the heat sink.

Make sure that only a very thin layer is applied so that both

contact surfaces are still visible.

7 Install the heatsink (see “Installing a heatsink” on page 39).

8 Observe the post-installation instructions described on page 25.

9 Repeat the steps above to replace the second processor.

43

Page 60

44

3 System upgrades

Upgrading the system memory

System memory interface

Each processor has three memory channels (1, 2 and 3 ) and each

channel has two slots - A (PxDIMM1A, 2A, 3A in blue) and B

(PxDIMM1B, 2B, 3B in black). So, the system has a total of twelve

memory slots. The memory slots support DDR3-1333 registered/

unbuffered ECC memory modules.

The folllowing illustration shows the processor 1 memory slots (1) and

processor 2 memory slots (2).

Independent mode

• For all memory modes, slot A in each channel should be populated

first and then slot B. If slot A is empty, then slot B cannot be used.

• For a single-processor server configuration, install the processor in

CPU1 socket and the memory modules in slots P1DIMM 1A to

P1DIMM 3B.

• If there is a processor installed in the

enable the slots P2DIMM 1A to P2DIMM 3B.

• It is recommended to install the DIMM modules in the following

sequence:

For single processor

• Populate slot 1A first, followed by slots 2A, 3A,1B, 2B and 3B.

• The memory slots for processor 2 are not available.

CPU2 socket, the system will

Page 61

For dual processors

• Populate DIMM slots 1A of each CPU first, followed by slots

2A, 3A,1B, 2B and 3B.

• Install DIMM modules of the same type, size and manufacturer in

the same colored DIMM slots.

Memory population for independent mode

Single processor configuration

Single processor

Processor 1 P1DIMM slots

Channel 1 Channel 2 Channel 3

Configuration 1B 1A 2B 2A 3B 3A

A X

B XX

C XXX

D XXXX

E XXXXXX

Dual processor configuration

Dual processors

Processor 1 P1DIMM slots Processor 2 P2DIMM slots

Channel 1 Channel 2 Channel 3 Channel 1 Channel 2 Channel 3

Configuration 1B 1A 2B 2A 3B 3A 1B 1A 2B 2A 3B 3A

A XX

B XXX

C XX XX

D XXXXXX

E XXXX XXXX

F XXXXXXXXX

G XXXXXXXXXXXX

45

Notes: 1. Place DIMMs in “X” location.

2. DIMM population must correspond to the above tables.

3. DIMM modules support 1 GB, 2 GB, 4 GB and 8 GB

DIMMS.

4. The size of each DIMM must be the same across the

configuration.

5. Do not mix UDIMMs with RDIMMs.

Page 62

46

3 System upgrades

Mirroring mode

• For mirroring mode, the memory contains a primary image and a

copy of the primary image. Therefore, the effective size of

memory is reduced by at least one-half.

• Channels 3 has no function and cannot be populated in this mode.

• Follow the population rules described in independent mode.

• DIMM modules installed in channels 1 and 2 must be identical —

1A and 2A should be the same type, size and manufacturer.

1B and 2B memory should be the same type, size and

manufacturer. However, it is not necessary for slot A to have the

same memory module as slot B within a channel.

• The same rule applies to processor 2.

Memory population for mirroring mode

Single processor configuration

Single processor

Processor 1 P1DIMM slots

Channel 1 Channel 2 Channel 3

Configuration 1B 1A 2B 2A 3B 3A

A X X NA NA

B XXXXNANA

Dual processor configuration

Dual processors

Processor 1 P1DIMM slots Processor 2 P2DIMM slots

Channel 1 Channel 2 Channel 3 Channel 1 Channel 2 Channel 3

Configuration1B1A2B2A3B3A1B1A2B2A3B3A

A X X NA NA NA NA

B X X NA NA X X NA NA

C XXXXNANA X XNANA

D XXXXNANAXXXXNANA

Notes: 1. Place DIMMs in “X” location.

2. DIMM population must correspond to the above tables.

3. DIMM modules support 1 GB, 2 GB, 4 GB and 8 GB

DIMMS.

4. The size of each DIMM must be the same across the

configuration.

5. Do not mix UDIMMs with RDIMMs.

Page 63

47

Lockstep mode

• In Lockstep Channel Mode, each memory access is a 128-bit data

access that spans Channel 1 and Channel 2. This is done to support

SDDC for DRAM devices with 8-bit wide data ports. The same

address is used on both channels such that an address error on any

channel is detectable by ECC. Lockstep Channel mode is the only

RAS mode that supports x8 SDDC.

• Channel 3 has no function and cannot be populated in this mode.

• Follow the population rules described in independent mode.

• DIMM modules installed in channels 1 and 2 must be identical —

1A and 2A should be the same type, size and manufacturer.

1B and 2B memory should be the same type, size and

manufacturer. However, it is not necessary for slot A to have the

same memory module as slot B within a channel.

• The same rule applies to processor 2.

Memory population for lockstep mode

Single processor configuration

Single processor

Processor 1 P1DIMM slots

Channel 1 Channel 2 Channel 3

Configuration 1B 1A 2B 2A 3B 3A

A X X NA NA

B XXXXNANA

Dual processor configuration

Dual processors

Processor 1 P1DIMM slots Processor 2 P2DIMM slots

Channel 1 Channel 2 Channel 3 Channel 1 Channel 2 Channel 3

Configuration1B1A2B2A3B3A1B1A2B2A3B3A

A X X NA NA NA NA

B X X NA NA X X NA NA

C XXXXNANA X XNANA

D XXXXNANAXXXXNANA

Notes: 1. Place DIMMs in “X” location.

2. DIMM population must correspond to the above tables.

3. DIMM modules support 1 GB, 2 GB, 4 GB and 8 GB

DIMMS.

4. The size of each DIMM must be the same across the

Page 64

48

3 System upgrades

configuration.

5. Do not mix UDIMMs with RDIMMs.

Sparing mode (only supported on Intel Xeon

Processor 5600 Series CPUs )

• In this mode, if the system detects degrading memory and did not

crash, the data in the failed channel will be copied to the spare

channel. The failed channel is then isolated and the spare channel

becomes active. However, any uncorrectable error that happens

before the isolation will still cause the system to stop normal

operation.

• Channel 3 is the spare channel. Therefore, the effective size will be

reduced by one-third.

• Follow the population rules described in the independent mode.

• Sparing mode requires that all three channels use identical DIMMs.

1A, 2A and 3A should be the same type, size and manufacturer,

likewise for 1B, 2B and 3B. The same rule applies to processor 2.

• Intel® Xeon® Processor 5500 Series CPUs do NOT support the

memory sparing mode.

Memory population for sparing mode

Single processor configuration

Single processor

Processor 1 P1DIMM slots

Channel 1 Channel 2 Channel 3

Configuration 1B 1A 2B 2A 3B 3A

A XXX

B XXXXXX

Dual processor configuration

Dual processors

Processor 1 P1DIMM slots Processor 2 P2DIMM slots

Channel 1 Channel 2 Channel 3 Channel 1 Channel 2 Channel 3

Configuration 1B 1A 2B 2A 3B 3A 1B 1A 2B 2A 3B 3A

A XXX

B XXXXXX

C XXXXXXXXX

D XXXXXXXXXXXX

Page 65

49

Density

Rank

Bit organization

Speed

Notes: 1. Place DIMMs in “X” location.

2. DIMM population must correspond to the above tables.

3. DIMM modules support 1 GB, 2 GB, 4 GB and 8 GB

DIMMS.

4. The size of each DIMM must be the same across the

configuration.

5. Do not mix UDIMMs with RDIMMs.

Memory identification

Generally, there are some memory information printed on the label of

the DIMM module. Different vendors may have different formats but

the convention is usually like this:

Item Description

Density 1GB, 2 GB, 4 GB, 8 GB.

Rank 1R = Single Rank

Bit

Organization

Speed PC3 - 6400 => DDR3- 800

Intel® Xeon® Processor 5500 Series CPUs support DIMM organized by

1GB or 2GB DRAM chips.

2R = Dual Rank

4R = Quad Rank

Note: If quad rank DIMM is used, a maximum of only two DIMMs per

channel can be supported.

This platform supports x4 and x8.

Note: It is not recommend to mix DIMMs with different bit

organizations in one system.

PC3 - 8500 => DDR3- 1066

PC3 - 10600 => DDR3- 1333

PC3 - 12800 => DDR3- 1600

Page 66

50

3 System upgrades

Installing a memory module

Warning! Memory of the identical size, speed and organization

must be installed in the same colored DIMM slots.

1 Locate the DIMM slot on the mainboard.

2 Install the memory module.

a Align then insert the DIMM into the socket.

b Push the DIMM to the socket until the retaining clips snap

inward.

Note: The DIMM slot is slotted to ensure proper installation. If you

insert a DIMM but it does not fit easily into the socket, you may

have inserted it incorrectly. Reverse the orientation of the DIMM

and insert it again.

3 Observe the post-installation instructions described on page 25.

4 Reconfigure the system memory. See “To reconfigure the system

memory” section on page 51 for more information.

Page 67

Removing a memory module

Important: Before removing any DIMM from the mainboard,

make sure to create a backup file of all important data.

1 Remove the memory module.

a Press the holding clips on both sides of the DIMM slot outward

to release the DIMM.

b Gently pull the DIMM upward to remove it from the DIMM

slot.

51

2 If you intend to install a new memory module, refer to the

previous section.

To reconfigure the system memory:

The system automatically detects the amount of memory installed. Run

the BIOS setup to view the new value for total system memory and

make a note of it.

Page 68

52

3 System upgrades

Installing an expansion card

Your server has two preinstalled riser cards designed specifically for use

in the 1U rackmount chassis. These riser cards allow two low-profile PCI

Express x16 cards to fit inside the chassis.

Installing a PCI add-on card

A riser card has already been preinstalled into each mainboard.

Perform the following steps to add a PCI add-on card:

1 Open the locking tab on the PCI slot shield.

2 Remove the PCI slot shield.

3 Insert the add-on card into the PCI slot.

4 Secure the add-on card with the locking tab.

Page 69

4 System

BIOS

Page 70

54

4 System BIOS

Introduction

This chapter describes the BIOS Setup Utility for your server. The AMI

ROM BIOS is stored in a Flash EEPROM and can be easily updated.

This chapter describes the basic navigation of the BIOS Setup Utility

setup screens.

The BIOS setup utility

To enter the BIOS Setup Utility, press the <F2> key while the system is

booting up.

Each main BIOS menu option is described in this manual. The Main

BIOS setup menu screen has two main frames. The left frame displays

all the options that can be configured. Grayed-out options cannot be

configured. Options in blue can be configured by you.

The right frame displays the key legend. Above the key legend is an

area reserved for a text message. When an option is selected in the left

frame, it is highlighted in white. Often a text message will accompany

it.

Note: the BIOS has default text messages built in. Acer retains the

option to include, omit or change any of these text messages.

The BIOS setup utility uses a key-based navigation system called

hotkeys. Most of the BIOS setup utility hotkeys can be used at any time

Page 71

55

during the setup navigation process. These keys include <F1>, <F10>,

<Enter>, <Esc> and arrow keys.

Changing configuration data

The configuration data that determines the system parameters may be

changed by entering the BIOS setup utility. This setup utility can be

accessed by pressing <F2> at the appropriate time during system boot.

Starting the setup utility normally, the only visible Power-On Self-Test

(POST) routine is the memory test. As the memory is being tested, press

the <F2> key to enter the BIOS setup utility main menu. From the main

menu, you can access the other setup screens. A BIOS identification

string is displayed at the left bottom corner of the screen below the

copyright message.

Warning! Do not upgrade the BIOS unless your system has a BIOSrelated issue. Flashing the wrong BIOS can cause irreparable

damage to the system. In no event shall Acer be liable for direct,

indirect, special, incidental, or consequential damages arising

from a BIOS update. If you have to update the BIOS, do not shut

down or reset the system while the BIOS is updating. This is to

avoid possible boot failure.

Main setup

When you first enter the BIOS setup utility, you will enter the main

setup screen. You can always return to the main setup screen by

selecting the main tab on the top of the screen. The main BIOS setup

screen is shown below.

System Overview

System Time/System Date

Use this option to change the system time and date. Highlight System

Time or System Date using the arrow keys. Enter new values using the

keyboard. Press the <Tab> key or the arrow keys to move between

fields. The date must be entered in MM/DD/YY format. The time is

Page 72

56

entered in HH:MM:SS format. (Note: The time is in the 24-hour format.

For example, 5:30 P.M. appears as 17:30:00.)

BIOS Build Ver: This item displays the BIOS revision used in your system.

BIOS Build Date: This item displays the date this BIOS was completed.

4 System BIOS

Processor

The BIOS will automatically display the status of the processor used in

your system and indicate the CPU type used.

Speed: This item displays the speed of the CPU detected by the BIOS.

Physical Count: This item displays the number of processors installed in

your system as detected by the BIOS.

Logical Count: This item displays the number of CPU cores installed in

your system as detected by the BIOS.

System Memory

This displays the size of memory available in the system as detected by

the BIOS.

Advanced Settings

Use the arrow keys to select Boot Setup and press <Enter> to access the

submenu items:

Boot Features

Quick Boot: Skip certain tests during POST to reduce the time needed

for system boot.

Quiet Boot: Allows the bootup screen options to be modified between

POST messages or the OEM logo. Select Disabled to display the POST

messages. Select Enabled to display the OEM logo instead of the

normal POST messages.

AddOn ROM Display Mode: Sets the display mode for Option ROM.

Bootup Num-Lock: Selects the Power-on state for Numlock key.

Page 73

57

Wait For 'F1' If Error: Forces the system to wait until the <F1> key is

pressed if an error occurs.

Hit F2 Message Display: Displays "Press <F2> to run Setup" during

POST.

Interrupt 19 Capture: Interrupt 19 is the software interrupt that

handles the boot disk function. When this item is set to Enabled, the

ROM BIOS of the host adaptors will capture Interrupt 19 at boot and

allow the drives that are attached to these host adaptors to function as

bootable disks. If this item is set to Disabled, the ROM BIOS of the host

adaptors will not capture Interrupt 19, and the drives attached to these

adaptors will not function as bootable devices.

Power configuration

Power Button Function: If set to Instant_Off, the system will power off

immediately when you press the power button. If set to

4_Second_Override, the system will power off when you press the

power button for four seconds or longer.

Restore on AC Power Loss: Use this feature to set the power state after

a power outage. Select Power-Off for the system power to remain off

after a power loss. Select Power-On for the system power to be turned

on after a power loss. Select Last State to allow the system to resume

its last state before a power loss.

Watch Dog Timer: If enabled, the Watch Dog Timer will allow the

system to reboot when it is inactive for more than five minutes.

Processor & Clock Options

This submenu displays the status of the processor as detected by the

BIOS, including items such as the processor manufacturer, type,

frequency, Base Clock (BCLK), CPUID, Microcode Revision, Cache L1/L2/

Page 74

58

4 System BIOS

L3, Ratio Status, and Ratio Actual Value. The submenu also allows you

to configure the processor and clock settings.

Ratio CMOS Setting: This option allows you to set the ratio between

the CPU core clock and the FSB frequency.The default setting depends

on the type of CPU installed on the motherboard. The default setting

for the CPU installed in your motherboard is [18]. Press "+" or "-" on

your keyboard to change this value.

Note: if an invalid ratio is entered, the BIOS will restore the setting

to the previous state.

C1E Support: Select Enabled to use the feature of Enhanced Halt State.

C1E significantly reduces the CPU's power consumption by reducing

the CPU's clock cycle and voltage during a Halt State.

Important: The following feature is only available if supported by

the processor and/or operating system.

Hardware Prefetcher: If set to Enabled, the hardware prefetcher will

prefetch streams of data and instructions from the main memory to

the L2 cache in the forward or backward manner to improve CPU

performance.

Important: The following feature is only available if supported by

the processor and/or operating system.

Page 75

59

Adjacent Cache Line Prefetch: The CPU fetches the cache line for 64

bytes if this option is set to Disabled. The CPU fetches both cache lines

for 128 bytes as comprised if Enabled.

MPS and ACPI MADT Ordering: Allows you to configure the MPS

(Multi-Processor Specifi cations) and ACPI settings for your

motherboard. Select Modern Ordering if Windows XP or newer is used.

Select Legacy Ordering if Windows 2000 or earlier is used.

Important: The following feature is only available if supported by

the processor and/or operating system.

Intel Virtualization Technology: Select Enabled to use Virtualization

Technology to allow one platform to run multiple operating systems

and applications in independent partitions, creating multiple virtual

systems in one physical computer.

Important: The following feature is only available if supported by

the processor and/or operating system.

Execute-Disable Bit Capability: Set to Enabled to enable the Execute

Disable Bit which will allow the processor to designate areas in the

system memory where an application code can execute and where it

cannot, thus preventing a worm or a virus from flooding illegal codes

to overwhelm the processor or damage the system during an attack.

Important: The following feature is only available if supported by

the processor and/or operating system.

Simultaneous Multi-Threading: Set to Enabled to use simultaneous

multi-threading technology, which will result in increased CPU

performance.

Active Processor Cores: Set to Enabled to use a processor's second core

and beyond. The options are All, 1 and 2.

Intel EIST Technology: EIST (Enhanced Intel SpeedStep Technology)

allows the system to automatically adjust processor voltage and core

frequency in an effort to reduce power consumption and heat

dissipation. Please refer to Intel’s web site for detailed information.

The options are Disable (Disable GV3) and Enable (Enable GV3).

Page 76

60

Intel TurboMode Technology: Select Enabled to use the Turbo Mode to

boost system performance.

Intel C-STATE Tech: If Enabled, C-State is set by the system

automatically to either C2, C3 or C4.

C-State package limit setting: If set to Auto, the BIOS will automatically

set the limit on the C-State package register.

C1 Auto Demotion: When Enabled, the CPU will conditionally demote

C3, C6 or C7 requests to C1 based on un-core auto-demote

information.

C3 Auto Demotion: When Enabled, the CPU will conditionally demote

C6 or C7 requests to C3 based on un-core auto-demote information.

Clock Spread Spectrum: Select Enable to use the feature of Clock

Spectrum, which will allow the BIOS to monitor and attempt to reduce

the level of Electromagnetic Interference caused by the components

whenever needed.

4 System BIOS

Advanced Chipset Control

The items included in the Advanced Settings submenu are listed below:

CPU Bridge configuration

QPI Links Speed: This feature selects QPI data transfer speed.

Page 77

61

Important: The following feature is only available when QPI Links

Speed is set to Full Speed.

QPI Frequency: This selects the desired QPI frequency.

QPI L0s and L1: This enables the QPI power state to low power. L0s and

L1 are automatically selected by the motherboard.

Memory Frequency: This feature enables you to force a DDR3

frequency slower than what the system has detected.

Memory Frequency: Allows you to force a DDR3 memory module to

run at a frequency other than what the system has detected.

Memory Mode: Set the memory mode.

• Independent - All DIMMs are available to the operating system.

• Channel Mirror - The motherboard maintains two identical copies

of all data in memory for redundancy.

• Lockstep - The motherboard uses two areas of memory to run the

same set of operations in parallel.

Demand Scrubbing: A memory error-correction scheme where the

processor writes corrected data back into the memory block from

where it was read by the processor.

Patrol Scrubbing: A memory error-correction scheme that works in the

background looking for and correcting resident errors.

Bank Interleave: Allows you to set the interleave scheme for a memory

bank.

Throttling - Closed Loop/Throttling - Open Loop: Throttling improves

reliability and reduces power in the processor by automatic voltage

control during processor idle states. If Enabled, the following items will

appear:

• Hysteresis Temperature (For Closed Loop only) - Temperature

Hysteresis is the temperature lag (in degrees Celsius) after the set

DIMM temperature threshold is reached before Closed Loop

Throttling begins.

• Guardband Temperature (For the Closed Loop only) - This is the

temperature which applies to the DIMM temperature threshold.

Steps are in 0.5 °C increments. The default is [006]. Press "+" or "-"

on your keyboard to change this value.

Page 78

62

• Inlet Temperature - This is the temperature detected at the chassis

inlet. Steps are in 0.5 °C increments. The default is [070]. Press "+"

or "-" on your keyboard to change this value.

• Temperature Rise - This is the temperature rise to the DIMM

thermal zone. Steps are in 0.5 °C increments. The default is [020].

Press "+" or "-" on your keyboard to change this value.

• Air Flow - This is the air flow speed to the DIMM modules. Each

step is one mm/sec. The default is [1500]. Press "+" or "-" on your

keyboard to change this value.

• Altitude - This feature defines how many meters above or below

sea level the system is located.

• DIMM Pitch - This is the physical space between each DIMM

module. Each step is 1/1000 of an inch. The default is [400]. Press

"+" or "-" on your keyboard to change this value.

4 System BIOS

NorthBridge configuration

This feature allows you to configure the settings for the Intel

NorthBridge chip.

Intel I/OAT: Significantly reduces CPU overhead by leveraging CPU

architectural improvements, freeing resources for other tasks.

DCA Technology: Uses Intel's DCA (Direct Cache Access) Technology to

enhance data transfer effi ciency.

DCA Prefetch Delay: Used with TOE components to prefetch data in

order to shorten execution cycles and maximize data processing effi

ciency. Prefetching too frequently can saturate the cache directory and

Page 79

63

delay necessary cache accesses. This feature reduces or increases the

frequency the system prefetches data.

Intel VT-d: Select Enabled to enable Intel Virtualization Technology

support for Direct I/O VT-d by reporting the I/O device assignments to

VMM through the DMAR ACPI Tables. This feature offers fullyprotected I/O resource-sharing across the Intel platforms, providing

you with greater reliability, security and availability in networking and

data-sharing.

Active State Power-Management: Uses power management for signal

transactions between the PCI Express L0 and L1 Links. Select Enabled to

configure PCI Express L0 and L1 Link power states.

IOH PCIE Max Payload Size: Some add-on cards perform faster with the

coalesce feature, which limits the payload size to 128 MB. Others

perform better with a payload size of 256 MB, which inhibits the

coalesce feature. Please refer to your add-on card user guide for the

desired setting.

South Bridge configuration