Page 1

Altos S700 Series

User’s Guide

Page 2

Copyright © 2002 Acer Incorporated

All Rights Reserved.

Altos S700 Series

User’s Guide

Changes may be made periodically to the information in this publication without obligation

to notify any person of such revision or changes. Such changes will be incorporated in new

editions of this manual or supplementary documents and publications. This company makes

no representations or warranties, either expressed or implied, with respect to the contents

hereof and specifically disclaims the implied warranties of merchantability or fitness for a

particular purpose.

Record the model number, serial number, purchase date, and place of purchase information in

the space provided below. The serial number and model number are recorded on the label

affixed to your computer. All correspondense concerning your unit should include the serial

number, model number, and purchase information.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form or by any means, electronic, mechanical, photocopy, recording, or otherwise,

without the prior written permission of Acer Incorporated.

Model Number : _________________________________

Serial Number: ___________________________________

Purchase Date: ___________________________________

Place of Purchase: ________________________________

Acer and the Acer logo are registered trademarks of Acer Inc. Other company’s product

names or trademarks are used herein for identification purposes only and belong to their

respective companies.

Page 3

Preface vii

Audience vii

Conventions Used In This User Guide vii

European Community Statement xv

Introduction 3

Features 4

Disk Drive Carrier 4

Power Supplies 4

Cooling System 5

I/O Option Modules 6

Safety Statements 13

Unpacking and Initial Setup 15

Installing the System in an Equipment Rack 16

Ambient Temperature 16

Air Flow 16

Mechanical Loading 16

Electrical Considerations 18

Circuit Overloading 18

Setting Fibre Channel Loop Speed (2Gb or 1Gb) 19

2Gb Operation 19

1Gb Operation 19

Split Fibre Channel Loop Operation (Quad Loop) 21

Setting Up Split Loop Operation 21

Removing Split Loop Operation 21

Configuration Rules 23

Supported Host Bus Adapters 24

Supported Cables 25

Copper Cables 25

Optical Cables 26

Setting the Enclosure ID 29

Configurations 32

JBOD Configurations 33

Dual FC Loop Configuration 33

Quad Loop Configuration 35

Connecting a Power Source 37

Connecting an AC Power Source 37

Disk Drive Spin Up Sequence 38

Altos S700 Series RAID Controller Introduction 41

RAID Controller Circuit Boards 43

Controller Circuit Board 43

I/O Circuit Board 43

RS232 Serial Port 44

RAID Controller Location 45

Contents

Page 4

RAID Controller Status LEDs 46

RAID Controller Configurations 47

Setting the Enclosure ID 48

Configurations 51

Single RAID Controller Configuration 51

Dual RAID Controller Configuration 54

Connecting a Power Source 57

Connecting an AC Power Source 57

Disk Drive Spin Up Sequence 58

Overview 61

LS Module 62

LS Module Features 62

Altos S700 Enclosure LEDs 63

Disk Drive LEDs 65

Power Supply LEDs 67

Advanced Cooling Module (ACM) LEDs 68

RAID Controller LEDs 69

Location of the Components 73

Installing and Removing a Disk Drive Carrier 74

Installing a Disk Drive Carrier 74

Removing a Disk Drive Carrier 74

Installing and Removing an LS Module 76

Installing an LS Module 76

Removing an LS Module 76

Installing and Removing a Power Supply 78

Installing a Power Supply 78

Removing a Power Supply 78

Installing and Removing an Advanced Cooling Module 79

Installing an Advanced Cooling Module 79

Removing an Advanced Cooling Module 79

Installing and Removing an I/O Module/RAID Controller 80

Installing an I/O Module/RAID Controller 80

Removing an I/O Module/RAID Controller 80

Caution: 82

Warning 88

Technical Specifications 90

Host Interface 90

Disk Drive Interface 90

System 90

Redundant, Hot Swappable Components 90

Physical Dimensions 90

Warranty 91

Monitoring 91

Failure Notification 91

Contentsiv

Page 5

Disk Drives 92

Power Supply 92

Temperature 92

Humidity 92

Altitude 92

Operational Shock 93

Operational Vibration 93

Regulatory Agency Compliance 93

Equipment and parts necessary for upgrade 103

Upgrading from JBOD to RAID 103

Installing the Battery Backup Unit 104

v

Page 6

Contentsvi

Page 7

vii

Preface

This Installation Guide describes the installation and operation of the

Altos S700 Series. The following products are covered: AS.S7001.001,

AS.S7001.002, AS.S7001.003, AS.S7001.004, AS.S7001.005,

AS.S7001.006.

Audience

This Installation Guide is intended for use by the person installing and

operating the Altos S700 Series. This Installation Guide describes the

operation of the Altos S700 Series only. For details relating to the host

system, refer to the documentation supplied with the host system.

Conventions Used In This User Guide

The following conventions are used throughout this Installation Guide.

A NOTE gives general information, such as helpful tips and

references to related information.

A CAUTION means take care. There is a risk of causing damage to

the equipment or losing data.

A WARNING means beware. There is a risk of electric shock

or personal injury. Before working on the enclosure be

aware of the hazards that exist.

Page 8

viii

Notices

FCC notice

This device has been tested and found to comply with the limits for a Class B

digital device pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This device generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this device does cause harmful interference to radio or television

reception, which can be determined by turning the device off and on, the user

is encouraged to try to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the device and receiver

• Connect the device into an outlet on a circuit different from that to which

the receiver is connected

• Consult the dealer or an experienced radio/television technician for help

Notice: Shield cables

All connections to other computing devices must be made using shielded cables

to maintain compliance with FCC regulations.

Notice: Peripheral devices

Only peripherals (input/output devices, terminals, printers, etc.) certified to

comply with the Class B limits may be attached to this equipment. Operation

with noncertified peripherals is likely to result in interference to radio and TV

reception.

Caution! Changes or modifications not expressly approved by

the manufacturer could void the user’s authority, which is granted

by the Federal Communications Commission, to operate this

computer.

Page 9

Use conditions

This part complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference,

and (2) this device must accept any interference received, including interference

that may cause undesired operation.

Notice: Canadian users

This Class B digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Remarque à l’intention des utilisateurs canadiens

Cet appareil numérique de la classe B respected toutes les exigences du

Règlement sur le matériel brouilleur du Canada

.

ix

Page 10

x

Important safety information

Only a technically qualified person shall access, integrate, configure, and service

this product.

Intended application uses

This product was evaluated as Information Technology Equipment (ITE), which

may be installed in offices, schools, computer rooms, and similar commercial

type locations. The suitability of this product for other Product Categories and

Environments (such as medical, industrial, alarm systems, and test equipment),

other than an ITE application, may require further evaluation.

Checking the power cords

Warning! To avoid electrical shock, do not attempt to

modify or use the supplied AC power cord(s), if they are

not the exact type required.

If a power cord(s) supplied is not compatible with the AC wall outlet in your

region, get one that meets the following criteria:

• The power cord must be properly rated for the AC voltage in your region.

• The power cord plug cap must have an electrical current rating that is at

least 125% of the electrical current rating of the product.

• The power cord plug cap that plugs into the wall socket-outlet must have a

grounding-type male plug designed for use in your region.

• The power cord must have safety certifications for your region, and shall

be marked with the certification markings.

• The power cord plug cap that plugs into the AC receptacle on the power

supply must be an IEC 320, sheet C13, type female connector.

• In Europe, the power cord must be less than 4.5 meters (14.76 feet) long,

and it must be flexible <HAR> (harmonized) or VDE certified cordage to

comply with the chassis' safety certifications.

• The power supply cord(s) is the main disconnect device to AC power. The

socket outlet(s) shall be near the equipment and shall be readily accessible

for disconnection.

Page 11

Multiple power cords

Warning! To avoid electrical shock, disconnect all AC power cords before

accessing inside the system.

Earth grounded socket-outlets

Warning! To avoid electrical shock, the system power cord(s) must be plugged

into socket-outlet(s) that is provided with a suitable earth ground.

Precautionary reminders

• Over current protection

The system is designed to operate on a 20A AC voltage source that is

provided with 20A over current protection. If the AC source for the rack

exceeds 20A over current protection, each system must be provided with

20A or less over current supplemental protection. The supplementary over

current protection must have the appropriate regional safety certifications

for the over current application.

• Power supply modules

Power supply modules have double-pole/neutral fusing.

• Ventilation considerations

The equipment rack must provide sufficient airflow to the front of the

system to maintain proper cooling. The rack selected and the ventilation

provided must be suitable to the environment in which the system will be

used.

•Fans

To avoid injury do not touch moving fan blades.

• Cooling and airflow

For proper cooling and airflow, always install all access covers before

turning on the system. Operating the system for longer than five minutes

without the covers in place can cause overheating and damage to system

components.

• Temperature limits

• The operating temperature of the system, when installed in the rack, must

not go below 10 °C (50 °F) or rise above 35 °C (95 °F). Extreme fluctuations

in temperature may cause a variety of problems in system, and safety limits

may be broken.

• Lifting and Moving

Do not attempt to lift or move the server by the handles on the power

supplies.

xi

Page 12

xii

Equipment rack precautions

Follow the rack manufacturer's safety and installation instructions for proper

rack installation.

The following additional rack safety installation measures shall be considered:

• Anchor the equipment rack

The equipment rack must be anchored to an unmovable suitable support

to prevent the rack from falling over when one or more systems are fully

extended out of the rack assembly. You must also consider the weight of

any other devices installed in the rack assembly. The equipment rack must

be installed according to the manufacturer's instructions.

• Main AC power disconnect

You are responsible for installing an AC power disconnect for the entire

rack unit. This main disconnect must be readily accessible, and it must be

labeled as controlling power to the entire unit, not just to the system(s).

• Grounding the rack installation

To avoid the potential for an electrical shock hazard, the rack assembly

itself must be suitably earth grounded, according to your local regional

electrical codes. This typically will require the rack to have its own separate

earth ground. We recommend you consult your local approved electrician.

Page 13

xiii

Important safety instructions

Read these instructions carefully. Save these instructions for future reference.

1 Follow all warnings and instructions marked on the product.

2 Unplug this product from the wall outlet before cleaning. Do not use

liquid cleaners or aerosol cleaners. Use a damp cloth for cleaning.

3 Do not use this product near water.

4 Do not place this product on an unstable cart, stand, or table. The product

may fall, causing serious damage to the product.

5 Slots and openings in the cabinet and the back or bottom are provided for

ventilation; to ensure reliable operation of the product and to protect it

from overheating, these openings must not be blocked or covered. The

openings should never be blocked by placing the product on a bed, sofa,

rug, or other similar surface. This product should never be placed near or

over a radiator or heat register, or in a built-in installation unless proper

ventilation is provided.

6 This product should be operated from the type of power indicated on the

marking label. If you are not sure of the type of power available, consult

your dealer or local power company.

7 Do not allow anything to rest on the power cord. Do not locate this

product where persons will walk on the cord.

8 If an extension cord is used with this product, make sure that the total

ampere rating of the equipment plugged into the extension cord does not

exceed the extension cord ampere rating. Also, make sure that the total

rating of all products plugged into the wall outlet does not exceed the fuse

rating.

9 Never push objects of any kind into this product through cabinet slots as

they may touch dangerous voltage points or short out parts that could

result in a fire or electric shock. Never spill liquid of any kind on the

product.

10 Do not attempt to service this product yourself, as opening or removing

covers may expose you to dangerous voltage points or other risks. Refer all

servicing to qualified service personnel.

11 Unplug this product from the wall outlet and refer servicing to qualified

service personnel under the following conditions:

a When the power cord or plug is damaged or frayed

b If liquid has been spilled into the product

c If the product has been exposed to rain or water

Page 14

xiv

d If the product does not operate normally when the operating

instructions are followed. Adjust only those controls that are covered

by the operating instructions since improper adjustment of other

controls may result in damage and will often require extensive work

by a qualified technician to restore the product to normal condition.

e If the product has been dropped or the cabinet has been damaged

f If the product exhibits a distinct change in performance, indicating a

need for service.

12 Replace the battery with the same type as the product's battery we

recommend. Use of another battery may present a risk of fire or explosion.

Refer battery replacement to a qualified serviceman.

13 Warning! Batteries may explode if not handled properly. Do not

disassemble or dispose of them in fire. Keep them away from children and

dispose of used batteries promptly. Dispose of used batteries according to

manufacturer's instructions.

14 Use only the proper type of power supply cord set (provided in your

accessories box) for this unit. It should be a detachable type: UL listed/CSA

certified, type SPT-2, rated 7A 125V minimum, VDE approved or its

equivalent. Maximum length is 15 feet (4.6 meters).

Page 15

European Community Statement

This equipment complies with the following European directives:

EMC Directive 89/336/EEC and amending Directives 92/31/EEC and 93/

68/EEC Low Voltage Directive 73/23/EEC.

xv

Page 16

xvi

Page 17

Chapter 1

Introduction

Page 18

This Chapter introduces the Altos S700 Series. The main

features of the Series are described along with a list of the

models that are available.

Page 19

Introduction

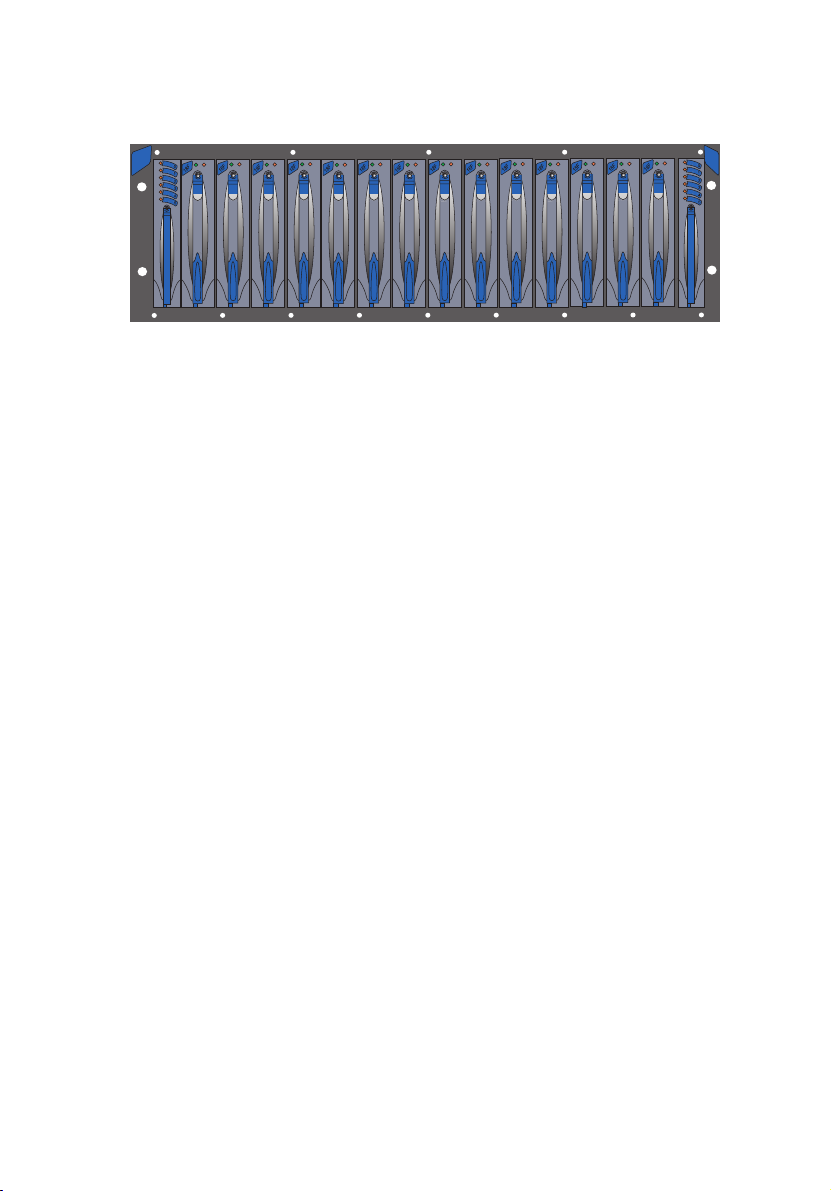

The Altos S700 Series provides a highly flexible, high performance

storage solution that evolves to meet your changing needs. Based on a

modular, “building block” enclosure design, the Altos S700 Series

offers exceptional scalability. Each enclosure supports up to 14 disk

drives, in a dense 3U form factor. As your storage needs grow, simply

add Altos S700 enclosures dynamically - up to a total of 8 enclosures.

The Altos S700 Series can be scaled in multiple dimensions, enabling

flexible configuration of capacity, performance and functionality, to

match and grow with virtually any application or IT environment. The

enclosure is available with your choice of copper, or optical I/O

modules, with RAID Controller option, and is downward compatible to

1Gbps, protecting your investment. A high performance, industry first

Quad Loop

700 MB/s from a single enclosure. 2Gb Fibre Channel connectivity

provides simplified cabling and extremely high bandwidth, for

outstanding performance in demanding applications.

1

(4 FCAL loops on one enclosure) capability provides over

1

Quad Loop functionality is only available on JBOD systems.

3

Page 20

Chapter 1 Introduction4

Features

• Redundant data paths with dual-ported fibre drives and dual

(200MB/s) fibre channel loops for a total of 400 MB/s.

• Quad Loop feature, provides over 700MB/s from a single enclosure.

• RAID controller option to give RAID functionality.

• Downward compatible to 1Gbps.

• Dense enclosure with 14 drives in a 3U form factor.

• Scalable to 112 drives, support for 15K rpm drives.

• Enhanced enclosure services (SES) monitoring and reporting.

• No single point of failure, with redundant, hot-swappable

components.

• Intuitive, comprehensive management with Spheras Storage

Manager.

• User installable, configurable and on-line maintainable.

• Industry-standard 19-inch rackmount or deskside configuration.

• Dual AC power supplies.

Disk Drive Carrier

The disk drive carrier supports one inch, SCA-2 direct attach disk drives.

The Altos S700 Series can hold up to fourteen disk drive carriers. The

disk drives can be hot swapped and the disk drive carriers provide for

blind mating.

Power Supplies

The Altos S700 Series uses two AC power supplies for normal

operation, providing redundancy of the power system. The power

supplies can be hot swapped. The AC power supplies provide 673 Watts

continuous output power and 853 Watts peak output power. The

power supplies provide active current sharing, power factor correction,

over current and over voltage protection is also provided. The power

supplies have individual power inputs.

Page 21

5

Caution: Power supply cords shall have conductors with a crosssectional area not less than 4mm

corresponds to a minimum 10AWG wire.

2

. This cross-sectional area

Cooling System

Cooling is provided by the two Advanced Cooling Modules (ACMs)

located at the rear of the enclosure. Each of the ACM units contain two

variable speed fans. The enclosure requires four fans for normal

operation, but will operate correctly with one fan failed (redundancy is

lost if one fan is failed in either ACM), however, it is recommended

that the failed fan be replaced as soon as possible. The ACM units can

be hot swapped. The LS Module monitors and controls the speed of

each fan. The speed is set depending on the ambient temperature and

failed status. The fans are set to full speed if one fan is failed. The

following table shows how the fan speed relates to temperature

change.

ACM Speed

Speed 1 0 to 26

Speed 2 26 to 28

Speed 3 28 to 30

Ambient Temp (oC)

Full Speed 30 +

Note: All fans in an enclosure are set to the same speed.

Page 22

Chapter 1 Introduction6

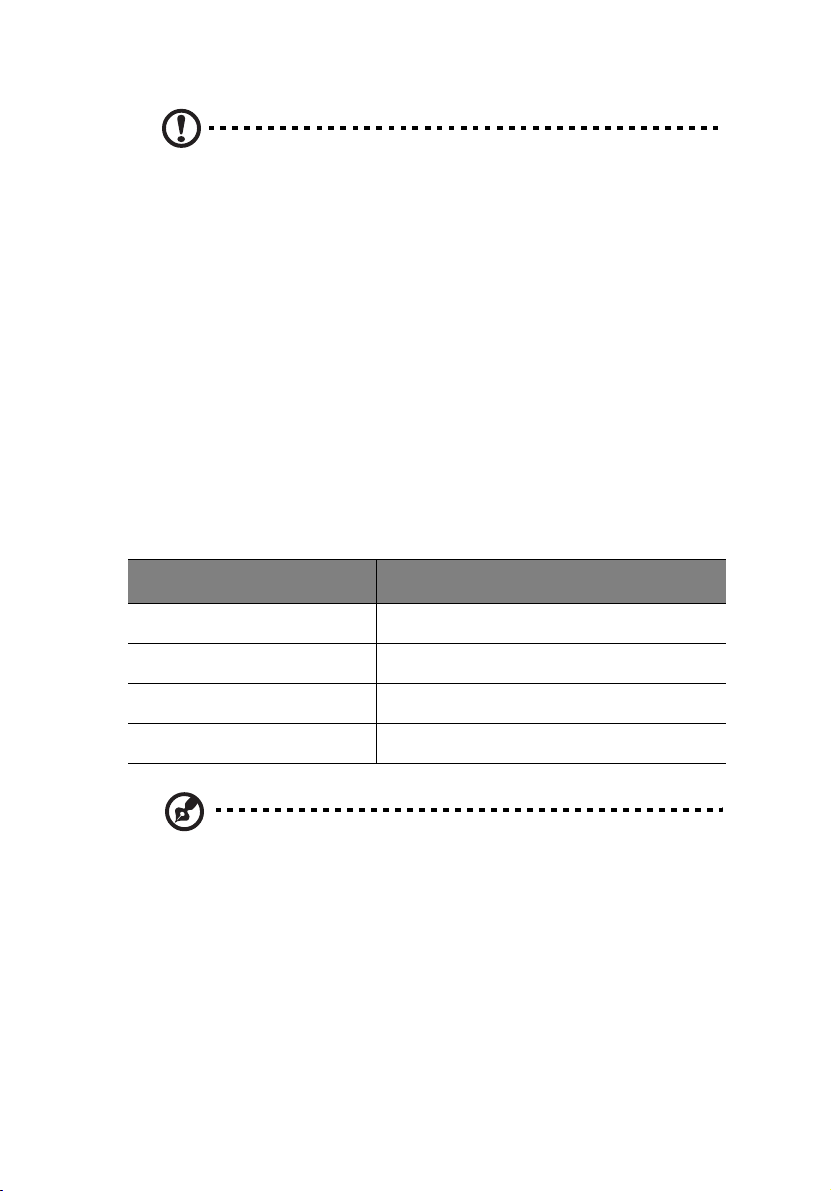

I/O Option Modules

The two rear I/O option slots (A and B) can contain a range of different

option modules. The LS module will detect the type of option module

installed.

I/O Option

Slot B

1

2

0

I

0

I

1

2

I/O Option

Slot A

Note: The above illustration shows the copper/copper I/O option

modules.

The available option modules are:

I/O Expansion Module - Copper/Copper

This 2Gb FC expansion module has two HSSDC connectors. The top

connector is the primary FC loop input port and the bottom connector

is available for FC loop expansion / input. A fibre channel loop back

terminator is not required.

I/O Expansion Module - Optical/Copper

This 2Gb FC expansion module has the SFF LC optical connector as the

FC Loop Input port. The FC loop expansion is carried out by the HSSDC

connector. A loop back terminator is not required.

Page 23

I/O Expansion Module- Optical/Optical

This 2Gb FC expansion module has two SFF LC optical connectors. The

top connector is the FC Loop Input port and the bottom connector is

for FC Loop Expansion. A loop back terminator is not required.

Altos S700 RAID Controller

The Altos S700 RAID Controller is a high performance controller,

providing two host fibre channel

interfaces. It is an intelligent, caching controller that supports

RAID levels 0, 1, 3, 5, 0+1, and JBOD. The controller enables

multiple hosts to access an array of disk drives, which can be

configured as one or more virtual storage devices (logical units).

and two device fibre channel

7

Page 24

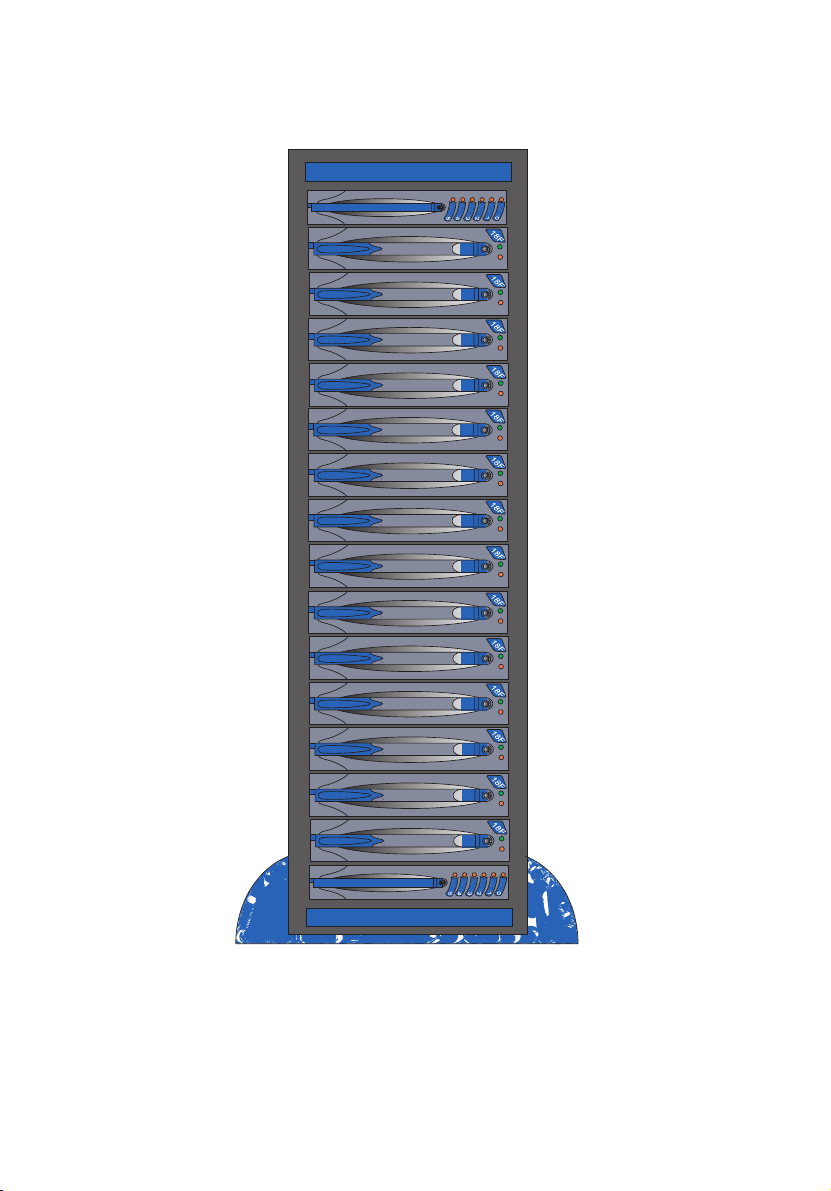

Figure 1-1: Altos S700 Series Tower Model

Chapter 1 Introduction8

Page 25

Figure 1-2: Altos S700 Series Rack Model

9

Page 26

Chapter 1 Introduction10

Page 27

Chapter 2

Installation and Setup

Page 28

This Chapter describes the installation and set up of the Altos S700 Series.

Important safety instructions are discussed along with the electrical,

mechanical and environmental precautions that need to be taken. Items

that need to be set prior to operating the Altos S700 enclosure are also

described here.

Note: Please read this Chapter carefully before attempting to install

or operate the Altos S700 Series enclosure.

Page 29

Safety Statements

The following safety statements must be read before you install or

operate the Altos S700 Series. For language translations of these

statements refer to Appendix B.

Caution: This equipment is intended only for installation in a

restricted access location.

Caution: Before attempting to install or remove any of the

components, ensure that anti-static precautions are taken. The

minimum requirement is, a properly grounded anti-static wrist

strap and ground wire.

Caution: If any of the components are removed the resulting hole

must be blocked, by installing a component blank or replacing the

component. Failure to do so can seriously restrict air flow and

cooling.

13

Caution: This device should be connected to a power source

which carries a fuse or circuit breaker that is greater than the

rating of the shelf, but also complies with national wiring

standards.

Caution: Allow disk drives and power supplies to reach room

ambient temperature before powering on the shelf.

Caution: It is recommended that, if interconnecting equipment

resides within more than one equipment rack cabinets, these

equipment racks should be at the same ground potential.

Page 30

Chapter 2 Installation and Setup14

Warning: A possible shock hazard may exist in the area of

the fan connection.

Warning: Disconnect the power cords before removing a

power supply from the enclosure.

Page 31

15

Unpacking and Initial Setup

When you receive your system, visually inspect the exterior of the

packaging for any signs of damage. If any damage is found the carrier

and Acer should be informed immediately, and they will advise you of

the appropriate action. The cartons are sealed using packaging tape

which should be cut open in the normal manner. Exercise caution when

lifting out the components. At this point the contents should be

verified against the packing list and Acer should again be notified if

any discrepancies exist. Anti-static precautions must be observed

before removing any of the components.

Page 32

Chapter 2 Installation and Setup16

Installing the System in an Equipment Rack

Before installing the Altos S700 Series in an equipment rack, it is

essential that the following guidelines are complied with, to ensure

the safe and efficient operation of the system. The Altos S700 Series

can be installed in open or closed equipment racks, with a front width

of 19”, by observing the environmental, electrical, and mechanical

precautions described below.

Ambient Temperature

Installation of the rack system in a standard 19” cabinet may lead to a

differential between the room ambient temperature and the internal

ambient temperature of the rack environment. The operating

temperature of the Altos S700 Series is between 5

it is not recommended that the system be continuously run at these

extreme temperatures. Consideration should therefore be given to

ensure that the room ambient temperature is compatible with these

specifications.

o

C to 40oC. However,

Air Flow

To ensure that the internal heat build up is properly dissipated into the

room environment, air flow should in no way be restricted. It is

essential that no air vents are blocked, and that the system is a

minimum of one meter from a solid surface such as a wall or partition.

Air flow through the Altos S700 Series is from front to rear.

Mechanical Loading

Consideration should be given to the loading of any equipment racks.

To maintain a low centre of gravity (thus reducing the likelihood of

instability) racks should be loaded (where possible) from the bottom of

the equipment rack upwards. This is recommended to ensure personal

safety.

Caution: When installing or removing a rack mount enclosure,

remove all disk drives. It is recommended that you work with at

Page 33

least one other person when installing an enclosure. This is

necessary to prevent personal injury and damage to the enclosure.

17

Page 34

Chapter 2 Installation and Setup18

Electrical Considerations

When installing the Altos S700 Series the following electrical

considerations must be applied.

Circuit Overloading

Care should be taken to ensure that the current does not exceed the

rating of the power source circuitry. This includes cabling, power

distribution units, filters and any other devices through which the main

current flows. The electrical power rating of the enclosure is 100 - 240

VAC, 10 - 5 Amps (50/60 Hz), and this must be added to the power

demands of any other electrical devices installed in the equipment rack

to arrive at a total power consumption figure. In addition, surge

currents must be catered for. Disk drives may consume twice the

amount of current at start-up time as they do during steady state

operation.

Page 35

19

Setting Fibre Channel Loop Speed (2Gb or 1Gb)

The Altos S700 Series can be operated with fibre channel loop speeds

of either 2Gb (default) or 1Gb. The loop speed is set through the use of

a jumper (JP2) located on the LS Module.

Note: If the enclosure has dual LS modules the following

procedures must be applied to both LS modules.

2Gb Operation

To set the fibre channel loop speed to 2Gb operation:

1 Remove the LS Module from the front of the enclosure.

2 On the LS Module locate the jumper position JP2 (Figure 2-1).

3 Install a jumper at JP2.

4 Replace the LS module.

1Gb Operation

To set the fibre channel loop speed to 1Gb operation:

1 Remove the LS module from the front of the enclosure.

2 On the LS Module locate the jumper position JP2 (Figure 2-1).

3 For 1Gb operation there should be no jumper installed at JP2. If

one is installed, remove it.

4 Replace the LS module.

Page 36

Chapter 2 Installation and Setup20

Figure 2-1 Location of Jumpers on LS Module

Page 37

21

Split Fibre Channel Loop Operation (Quad Loop)

Note: Quad Loop is only available on JBOD systems

The Altos S700 Series LS module allows for split FC Loop operation,

with two dual fibre channel loops of seven disk drives each. In this split

loop mode the primary port (I/O Slot A) will form a loop using the first

seven drives, 1 to 7 (from right hand side of rackmount systems). The

expansion port (I/O Slot B) will form a second loop using the remaining

7 drives, 8 to 14 (from right hand side of rackmount systems). Default

is Single Loop (no jumper).

Note: If the enclosure has dual LS modules the following

procedures must be applied to both LS modules.

Caution: Enclosures operating in split loop mode can not be daisy

chained to other enclosures.

Setting Up Split Loop Operation

To operate the Altos S700 Series enclosure in split fibre channel loop

mode, follow this procedure:

1 Remove the LS module from the front of the enclosure.

2 On the LS Module locate the jumper position JP3 (Figure 2-1).

3 To operate in split loop mode, install a jumper at JP3.

4 Replace the LS module.

Removing Split Loop Operation

To remove split fibre channel loop operation from the Altos S700 Series

enclosure, follow this procedure:

1 Remove the LS module from the enclosure and locate jumper JP3

(Figure 2-1).

2 To remove split loop operation, remove jumper JP3.

Page 38

3 Replace the LS module.

Chapter 2 Installation and Setup22

Page 39

Configuration Rules

These rules must be applied when implementing the Altos S700 Series

configurations:

• When daisy chaining, both 2Gb enclosures must be configured

identically.

• 1Gb and 2Gb systems cannot be daisy chained together.

• Two LS modules and two I/O modules are required for dual drive

loops.

• Cannot mix optical and copper I/O modules in the same enclosure

(both I/O Modules must be the same).

• Cannot mix 1Gb and 2Gb LS and I/O modules, and 1Gb and 2Gb

cables.

• 2Gb JBOD and RAID enclosures require 2Gb cables.

• 2Gb JBOD enclosures require 2Gb disk drives.

• Disk drive blanks must be ordered for any empty drive slots.

• 2Gb copper JBOD expansion configurations must be the same as

the RAID configuration.

• 2Gb optical JBOD cannot be expansion enclosure for 2Gb RAID

configuration.

• 2Gb RAID controller has two SFF LC host connectors, an HSSDC

outpur connector and a RS232 port

• 2Gb RAID requires two LSMs.

• 2Gb RAID supports autonegiotate - operates at 1Gb or 2Gb.

23

Page 40

Chapter 2 Installation and Setup24

Supported Host Bus Adapters

Contact your sales person for a list of approved Host Bus Adapters.

Page 41

25

Supported Cables

Warning: Only the following APPROVED cables must be

used with the Altos S700 Series enclosures.

This section lists the cables that must be used with the Altos S700 Series

enclosure. Failure to adhere to these guidelines may cause the

enclosure to operate incorrectly.

Copper Cables

Only the following AMPHENOL copper Fibre Channel cables must be

used with the Altos S700 Series enclosure (copper applications).

Amphenol Cable Model Numbers:

Model No. Description

CA.S7002.001 .3m 2Gb Fibre Channel, copper cable, non-equalized,

CA.S7002.002 1m 2Gb Fibre Channel, copper cable, non-equalized,

CA.S7002.003 3m 2Gb Fibre Channel, copper cable, non-equalized,

CA.S7002.004 6m 2Gb Fibre Channel, copper cable, non-equalized,

HSSDC-HSSDC

HSSDC-HSSDC

HSSDC-HSSDC

HSSDC-HSSDC

Page 42

Chapter 2 Installation and Setup26

Optical Cables

The following Fibre Channel Optical cables are available from Acer.

Please contact your sales person for more details of approved cables:

• CA.S7002.005 : 0.3m, 2Gb FC optical cable

• CA.S7002.006 : 10m, 2Gb FC optical cable

• CA.S7002.007 : 30m, 2Gb FC optical cable

• CA.S7002.008 : 150m, 2Gb FC optical cable

Page 43

Chapter 3

JBOD Configurations

Page 44

This Chapter describes the procedure for connecting your Altos S700

Series JBOD system to a host computer(s). Detailed information on

how to configure and daisy chain enclosures is also provided along

with instructions on how to set the enclosure ID.

Page 45

Setting the Enclosure ID

Each of the fourteen disk drive slots of the Altos S700 Series has a

unique identifier assigned to it. This identifier is assigned using a

combination of the slot number and the enclosure ID.

The enclosure ID is set using the enclosure ID switch, located on the

rear of the Altos S700 (see Figure 3-1).

Note: The enclosure ID must be set prior to powering on the

enclosure.

Note: Each enclosure must have a separate ID when daisy chained

together.

Note: 2Gb Amphenol cables must be used if 2Gb operation is

required.

29

Note: Contact your sales person for a list of approved HBA’s.

Page 46

Figure 3-1 Location of Enclosure ID Switch

Chapter 3 JBOD Configurations30

1

2

0

I

Enclosure ID

Switch

1

This enclosure ID switch can be set to 0 through 7.

The graphic below shows the slot number and location.

Slot location when viewed from the front of the enclosure

1

2

0

I

LSM

Slot 12

Slot 13

Slot 11

Slot 9

Slot 10

Slot 7

Slot 8

Slot 5

Slot 6

Slot 3

Slot 4

Slot 1

Slot 2

Slot 0

LSM

Page 47

The fourteen disk drive slots (0 to 13), will be assigned an identifier

based on the enclosure ID and the slot number as shown below.

Enclosure ID

Drive Slot

Slot 0 3 18 33 48 63 78 93 108

Slot 1 4 19 34 49 64 79 94 109

Slot 2 5 20 35 50 65 80 95 110

Slot 3 6 21 36 51 66 81 96 111

Slot 4 7 22 37 52 67 82 97 112

Slot 5 8 23 38 53 68 83 98 113

Slot 6 9 24 39 54 69 84 99 114

Slot 7 102540557085100115

Slot 8 112641567186101116

Slot 9 122742577287102117

0 1 2 3 4 5 6 7

31

Slot 10 13 28 43 58 73 88 103 118

Slot 11 14 29 44 59 74 89 104 119

Slot 12 15 30 45 60 75 90 105 120

Slot 13 16 31 46 61 76 91 106 121

Page 48

Chapter 3 JBOD Configurations32

Configurations

This section describes the procedures for cabling the main

configurations of the Altos S700 Series JBOD.

Note: The following configuration procedures refer to connecting

the Altos S700 Series directly to the host system. It is also possible

to connect the system using a Hub/Switch.

Caution: Before working on the enclosure, ensure that anti-static

precautions have been taken. The minimum requirement is an

anti-static wrist strap and grounding wire.

Page 49

JBOD Configurations

There are two JBOD configurations covered in this Installation Guide:

• Dual FC Loop mode (including how to daisy chain enclosures)

• Quad Loop (single enclosure with 4 FCAL loops)

Note: The following examples show the Copper/Copper I/O

Module option for illustration purposes. The configuration

procedures are identical for all I/O Module options.

Dual FC Loop Configuration

Note: For dual FC Loop enclosures there must be two LS modules

installed in the enclosure.

This section describes the procedure for connecting a dual FC Loop

configuration to your host computer, and how to daisy chain these

enclosures together.

To connect the dual FC Loop enclosure to the host:

33

Note: You will need two HBA’s in your host system, or a single

HBA with support for two connections. A hub, switch or two hosts

with HBA may also be used.

1 Insert the connector on the first cable, into the top connector on

the first I/O module (see Figure 3-2).

2 Insert the other end of this cable into the connector on your HBA.

3 Insert the connector on the second cable, into the top connector

on the second I/O module (see Figure 3-2).

4 Insert the other end of this cable into the connector on your HBA.

Note: For details on your host and/or HBA refer to the

documentation that was supplied with the host / HBA.

Page 50

Chapter 3 JBOD Configurations34

T

Figure 3-2 Connecting dual FC Loop configuration to a host

o HBA

1

2

0

I

To HBA

1

2

0

I

See Appendix C for Loop Diagram.

To daisy chain enclosures together, connect link cables from the

bottom connectors on the I/O modules of the first enclosure to the top

connectors of the I/O modules on the next enclosure (see Figure 3-3).

Note: A maximum of eight enclosures may be daisy chained

together.

Page 51

Figure 3-3 Daisy chaining dual FC Loop enclosures

e

t

re

35

To HBA

To next

nclosure

To HBA

1

2

0

I

1

2

0

I

1

2

0

I

1

2

0

I

To nex

enclosu

See Appendix C for Loop Diagram.

Caution: When daisy chaining enclosures, you must ensure that

each enclosure has a unique Enclosure ID.

Quad Loop Configuration

Note: Quad loop configuration requires that the enclosure be

configured in split loop mode. To set split loop mode, a jumper

must be installed at jumper location JP3 on each LS module in the

enclosure.

Page 52

Chapter 3 JBOD Configurations36

4

D

This section describes the procedure for connecting the enclosure in

quad loop mode. For this configuration there must be two LS modules

and two I/O modules installed in the enclosure.

1 Remove both LS modules from the enclosure and install a jumper,

at jumper location JP3 if one is not already installed. This sets the

enclosure to operate in split loop mode.

2 Attach cables to the top and bottom connector of both I/O

modules (see Figure 3-4).

3 Attach the other end of these four cables to your host systems.

Figure 3-4 Cabling the Quad Loop Configuration

rives 1-7

Drives 1-7

1

2

Loop B

0

I

Drives 8-14

Drive 10

Drive 11

Drive 12

Drive 13

Drive 14

LSM

Drive 6

Drive 8

Drive 5

Drive 7

Drive 9

Drive 1

Drive 2

Drive 3

Drive 4

LSM

1

2

Loop A

0

I

Drives 8-1

Page 53

Connecting a Power Source

The Altos S700 enclosure supports dual AC power supplies. Only one

power supply is required for normal operation. However, a second,

optional power supply may be added to provide a redundant power

system. Each power supply has its own AC power inlet.

37

Caution: Power supply cords shall have conductors with a cross-

2

sectional area not less than 4mm

. This cross-sectional area

corresponds to a minimum 10AWG wire.

Connecting an AC Power Source

1 Ensure all cables have been attached as described in the preceding

sections.

2 Attach the AC power cords to the power supplies and turn the

power supply switches to the On (-) position (see Figure 3-5).

Figure 3-5 Attaching the AC power cords

1

2

0

I

Insert Power cords into

power connectors

Warning: This equipment must be connected to an earthed

mains socket outlet. Ensure the power cabling provides

earthing continuity to the equipment.

1

2

0

I

Page 54

Chapter 3 JBOD Configurations38

Disk Drive Spin Up Sequence

At power on, the LS module will perform its internal start up

initialization routine. Then the LS module will assert the disk drive

START_1 and START_2 motor start signals low for disk drive slots 7

through 13, which will spin up the first 7 disk drives immediately. The

LS module will then assert the disk drive START_2 motor start signal

low and leave the START_1 motor start signal high for disk drive slots 0

through 6 which will command the second seven disk drives to spin up

after a delay of 12 seconds times the modulo 8 value of the numeric

SEL_ID of the disk drive.

Once the enclosure is powered up and all 14 drives are spun up as

depicted above, the enclosure will support immediate drive spin up

with two power supplies present.

Modulo 8

The drive spin up sequence above uses modulo 8 to calculate the spin

up delay. Modulo 8 is determined by:

(SHELF ID x DRIVE NUMBER)/8 = NUMBER + REMAINDER

It is the REMAINDER value that is used for the calculation as it is

always between 0 and 7 (hence modulo 8). The drive spin up time can

then be calculated as follows:

REMAINDER x MODE PAGE SETTING = SPIN UP DELAY (Seconds)

EXAMPLE:

Spin Up Delay would be 7 x 12, or 84 seconds.

A typical Mode Page Setting is 12, so if the Remainder = 7, the

Page 55

Chapter 4

RAID Configurations

Page 56

This chapter describes how to set up, configure and use the

Altos S700 Series RAID Controller. Some general information

about the RAID controller is also provided.

Page 57

41

Altos S700 Series RAID Controller Introduction

The Altos S700 RAID Controller is a high performance controller,

providing two host fibre channel

interfaces. It is an intelligent, caching controller that supports

RAID levels 0, 1, 3, 5, 0+1, and JBOD. The controller enables

multiple hosts to access an array of disk drives, which can be

configured as one or more virtual storage devices (logical units).

The controller provides continuous access to data in the event of a disk

drive failure. When configured in a dual-active controller system, the

RAID controller also provides continuous access to data in the event of

a controller failure. This dual-active controller system is one in which

two controllers share

access to the same array of disk drives. In the

event of a controller failure, controller operations are assumed

by the surviving controller through a failover process. The failed

controller can then be removed and replaced while the system

is online. The new controller resumes processing array

operations in a failback process. During failover and failback,

write cache coherency is maintained with the disk drives.

Three circuit boards make up the RAID Controller:

• Controller: The controller circuit board contains the main

controller and peripheral functions, including processor, controlstore memory, XOR engine and cache controller, and host and

device fibre channel input/output processors (IOPs).

• I/O: The I/O circuit board provides the interface to the disk drive

enclosure (device) and host as well as general support functions. It

also contains the switching power supply, which generates +3.3

Vdc and +2.5 Vdc from +5 Vdc, hot-swap circuits, and battery

backup unit (BBU) circuits.

1

• Ethernet

interface to the controller, and connections for debug and out-ofband service to the host and device PCI busses.

: The ethernet circuit board provides an ethernet

and two device fibre channel

The RAID Controller requires a minimum of two circuit boards: the

controller and I/O. The controller and I/O

circuit boards are

connected using two 38-pin controlled impedance connectors.

1

This option is not yet available. Please contact your sales person for availability information.

Page 58

Chapter 4 RAID Configurations42

The controller, I/O, and ethernet circuit boards are assembled

into a stack with the controller and ethernet boards mounted

to a controller cover plate and the I/O board mounted to the

controller board. When the ethernet circuit board is used, it is

mounted to the controller circuit board. Figure 4-1 shows the

three circuit boards in their relative positions.

Figure 4-1 RAID Controller Circuit Boards

Features of the RAID Controller include:

• Main processor coupled with a companion chip

• Proprietary XOR engine ASIC that provides data processing XOR

function and data cache SDRAM control

• Four 2Gb-capable fibre protocol chips for the device and host ports

• Dual internal 528 MB/s, 64-bit, 66 MHz PCI buses

• Separate memory areas for processor and user data

• Scalable data cache memory: 128, 256, 512 MB DIMMs

• 128 KB NVRAM configuration memory

• Real Time Clock

• 4 MB Flash PROM

• Transparent failover/failback with multiple target ID support

The I/O circuit board includes a Battery Backup Unit (BBU) that

maintains memory content in case of AC power failure. Power for the

BBU is provided by a battery pack mounted in the fan module of the

enclosure.

Page 59

43

RAID Controller Circuit Boards

This section gives a brief description of the RAID controller circuit

boards that are inside the RAID controller module.

Caution: The description of the RAID controller circuit boards

provided below is for information only. Only qualified service

personnel should open the RAID Controller module.

Controller Circuit Board

The controller circuit board oversees and regulates the flow of data

from a host through the I/O circuit board to the disk arrays in the Altos

S700 enclosure. The controller circuit board performs these operations

with a proprietary architecture, using the following components:

• Main microprocessor and companion chip

• Control-store memory

• Memory Controller/Hardware XOR Engine ASIC (XOR ASIC)

• Flash PROM

• Non-volatile RAM (NVRAM)

• Dual universal asynchronous receiver/transmitter (DUART)

• Fibre Channel I/O processors

• Cache DIMM memory

I/O Circuit Board

The I/O circuit board provides the interface between the enclosure and

a host, as well as general support functions. The I/O circuit board

provides the following:

• Connections to the host

• Connections to the enclosure

• Dual switching power supply for +3.3 V and +2.5 V

• Hot pluggability for the controller

• Support for the BBU

Page 60

Chapter 4 RAID Configurations44

The I/O circuit board has two SFF optical transceivers supporting

shortwave multimode fibre on the host side and a 90-pin controlled

impedance (50 Ohm) connector on the device side. An HSSDC

connector with repeaters on the expansion loop provides for a copper

connection between one of the device channels and an expansion

module. Port bypass circuitry on the I/O circuit board enables quadplex

operation on a second host loop. The I/O board has seven LEDs to

indicate subsystem status.

RS232 Serial Port

The 3-pin, RS232 Serial Port is located on the RAID controller and

provides VT100 terminal emulation capabilities. It can be used to

configure and manage the storage array. This RS232 port applicable

when attaching to operating systems that are not supported by Acer’s

management software, or for using a CLI to create scripts.

Page 61

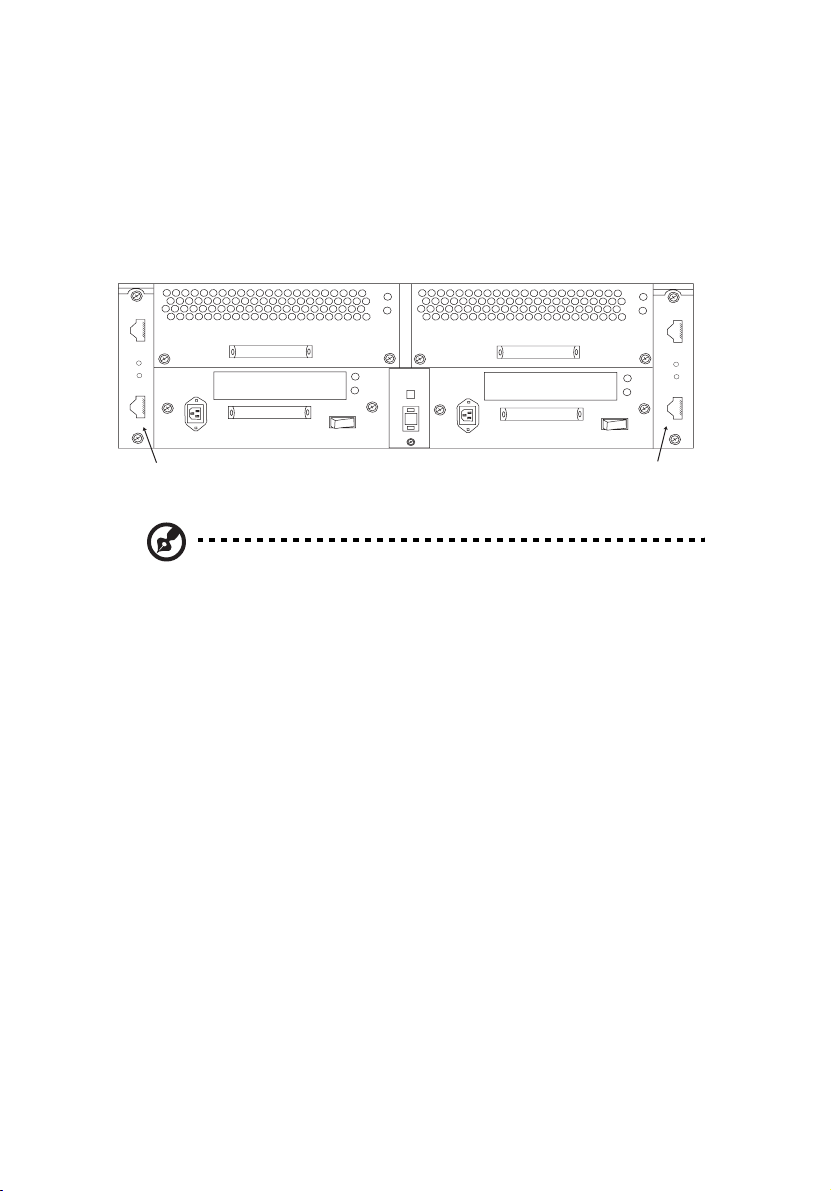

RAID Controller Location

er

R

or

The RAID controller is installed in the rear of the enclosure in the

location shown in Figure 4-2.

Figure 4-2 RAID Controller location

AID Controller

1

2

RAID Controll

1

2

45

1

2

3

4

5

6

7

0

I

1

2

3

4

5

6

7

0

I

The above illustration shows a dual RAID configuration.

The main parts of the RAID Controller are described in Figure 4-3.

Figure 4-3 Main components of RAID controller

HSSDC Connect

RS232

FC Host Connectors (SSF optical)

1

2

3

Status LEDs

4

5

6

7

Page 62

Chapter 4 RAID Configurations46

RAID Controller Status LEDs

The RAID controller has 7 Status LEDs as shown above. describes what

these LEDs signify.

Controller Status LEDs

LED Description

1 Yellow - Not Ready. Normally Off. Goes On during power up

2 Green - Ready. Normally On

3 Green - Dirty Cache. On when there is data in cache.

4 Yellow - BBU Fault. Normally Off.

5 Green - Partner Fail. Normally Off

6 Green - Device Activity i.e. on drive channels. Flashes with

7 Green - Host Activity. Flashes with activity.

sequence.

activity.

Page 63

47

RAID Controller Configurations

This section describes how to cable the two standard RAID controller

configurations: Single RAID Controller and Dual RAID Controller (dual

active). The procedure for daisy chaining these standard configurations

to expansions enclosures is also described. This section also describes

how to set the enclosure ID.

Page 64

Chapter 4 RAID Configurations48

Setting the Enclosure ID

Each of the fourteen disk drive slots of the Altos S700Altos S700 Series

has a unique identifier assigned to it. This identifier is assigned using a

combination of the Slot number and the enclosure ID.

The enclosure ID is set, using the enclosure ID switch, located on the

rear of the Altos S700 (see Figure 4-4).

Note: The enclosure ID must be set prior to powering on the

enclosure.

Note: Each enclosure must have a separate ID when daisy chained

together.

Figure 4-4 Location of Enclosure ID Switch

1

2

1

2

3

4

5

6

7

0

I

Enclosure ID

Switch

1

This enclosure ID switch can be set to 0 through 7.

1

2

1

2

3

4

5

6

7

0

I

Page 65

The graphic below shows the slot number and location.

o

Slot location when viewed from the front of the encl

LSM

Slot 13

Slot 1

Slot 2

Slot 0

LSM

Slot 3

Slot 4

Slot 5

Slot 6

Slot 7

Slot 8

Slot 9

Slot 10

Slot 11

Slot 12

The fourteen disk drive slots (0 to 13), will be assigned an identifier

based on the enclosure ID and the slot number as shown in .

Disk Drive Identifier Table

49

Enclosure ID

Drive Slot

Slot 0 3 18 33 48 63 78 93 108

Slot 1 4 19 34 49 64 79 94 109

Slot 2 5 20 35 50 65 80 95 110

Slot 3 6 21 36 51 66 81 96 111

Slot 4 7 22 37 52 67 82 97 112

Slot 5 8 23 38 53 68 83 98 113

Slot 6 9 24 39 54 69 84 99 114

Slot 7 102540557085100115

Slot 8 112641567186101116

Slot 9 122742577287102117

Slot 10 13 28 43 58 73 88 103 118

Slot 11 14 29 44 59 74 89 104 119

Slot 12 15 30 45 60 75 90 105 120

0 1 2 3 4 5 6

7

Page 66

Chapter 4 RAID Configurations50

Enclosure ID

Drive Slot

Slot 13 16 31 46 61 76 91 106 121

0 1 2 3 4 5 6

7

Page 67

51

Configurations

This section shows how to connect the RAID enclosures to a host

system(s). The procedure for daisy chaining the enclosures together is

also described.

Single RAID Controller Configuration

In this configuration only one RAID controller is installed in the

enclosure’s I/O slot. The second I/O slot must contain an I/O module or a

blank plate.

Caution: For all RAID configurations, there must be two LS

modules installed in the enclosure.

Note: The following configuration procedures refer to connecting

the Altos S700 Series directly to the host system. It is also possible

to connect the system using a Hub/Switch.

Caution: Before working on the enclosure, ensure that anti-static

precautions have been taken. The minimum requirement is an

anti-static wrist strap and grounding wire.

To connect this configuration to a host system, follow this procedure:

Connecting a Single RAID Controller to a Host

1 Plug both host cables into the host connectors on the RAID

controller (see Figure 4-5).

Note: For single HBA configurations only one host connector will

need to be used.

2 Connect the opposite ends of these host cables, to the HBA’s of the

host system.

Note: For details on your host and/or HBA refer to the

documentation that was supplied with the host / HBA.

Page 68

Chapter 4 RAID Configurations52

Figure 4-5 Single RAID Controller to Host Connector

1

2

0

I

1

2

HBA 1

1

2

HBA 2

3

4

5

6

0

I

7

Daisy Chaining a Single Controller Enclosure

To daisy chain the RAID enclosure to an expansion enclosure, connect

link cables from the RAID controller to the top connectors of the I/O

modules of the expansion enclosure (see Figure 4-6).

Note: A maximum of eight enclosures may be daisy chained

together.

Page 69

Figure 4-6 Daisy Chaining Single Controller Enclosure

L

53

ink Cable

I/O Module

1

2

0

I

Connect this

To next

enclosure

cable for dual

loop operation

1

2

0

I

Total of 8 enclosures may be daisy chained together.

Link Cable

Caution: When daisy chaining enclosures, you must ensure that

each enclosure has a unique Enclosure ID.

RAID Controller

1

2

0

I

1

2

0

I

To next

enclosure

HBA 1

1

2

HBA 2

3

4

5

6

7

Page 70

Chapter 4 RAID Configurations54

Dual RAID Controller Configuration

In this configuration two RAID Controllers are installed in the

enclosures I/O slots.

Note: The following configuration procedures refer to connecting

the Altos S700 Series directly to the host system. It is also possible

to connect the system using a Hub/Switch.

Caution: Before working on the enclosure, ensure that anti-static

precautions have been taken. The minimum requirement is an

anti-static wrist strap and grounding wire.

To connect this configuration to a host system, follow this procedure:

Connecting Dual RAID Controllers to a Host System

Note: This example configuration assumes that the RAID

enclosure is being attached to two separate host systems, each

containing two HBA’s. Other configurations, such as one host with

4 HBA’s are also possible.

1 Plug two host cables in to the host connectors of the first RAID

controller (one cable into each FC connector).

2 Plug the opposite ends of these cables into the HBA’s of the first

host system (see Figure 4-7)

3 Plug two host cables in to the host connectors of the second RAID

controller (one cable into each FC connector).

4 Plug the opposite ends of these cables into the HBA’s of the second

host system (see Figure 4-7)

Page 71

Figure 4-7 Dual RAID Controller Configuration

55

Host B

HBA 1

HBA 2

1

2

1

2

3

4

5

6

7

0

I

1

2

Host A

HBA 1

1

2

HBA 2

3

4

5

6

7

0

I

Daisy Chaining a Dual Controller Enclosure

To daisy chain the RAID enclosure to an expansion enclosure, connect

link cables from the RAID enclosure to the top connectors of the I/O

modules of the expansion enclosure (see Figure 4-8).

Note: A maximum of eight enclosures may be daisy chained

together.

Page 72

Chapter 4 RAID Configurations56

Figure 4-8 Daisy Chaining a Dual Controller Enclosure

Host B

HBA 1

HBA 2

1

2

1

2

3

4

5

To next

enclosure

6

7

Link Cable

Total of 8 enclosures may be daisy chained together.

0

I

Link Cable

1

2

0

I

Caution: When daisy chaining enclosures, you must ensure that

each enclosure has a unique Enclosure ID.

I

I

1

2

0

1

2

0

enclosure

To next

Host A

HBA 1

1

2

HBA 2

3

4

5

6

7

Page 73

Connecting a Power Source

The Altos S700 enclosure supports dual AC power supplies. Only one

power supply is required for normal operation. However, a second,

optional, power supply may be added to provide a redundant power

system. Each power supply has its own AC power inlet.

57

Caution: Power supply cords shall have conductors with a cross-

2

sectional area not less than 4mm

. This cross-sectional area

corresponds to a minimum 10AWG wire.

Connecting an AC Power Source

1 Ensure all cables have been attached as described in the preceding

sections.

2 Attach the AC power cords to the power supplies and turn the

power supply switches to the On (-) position (see Figure 4-9).

Figure 4-9 Attaching the AC power cords

1

2

1

2

3

4

5

6

7

0

I

Insert Power cords into

power connectors

Warning: This equipment must be connected to an earthed

mains socket outlet. Ensure the power cabling provides

earthing continuity to the equipment.

1

2

1

2

3

4

5

6

0

I

7

Page 74

Chapter 4 RAID Configurations58

Disk Drive Spin Up Sequence

At power on, the LS module will perform its internal start up

initialization routine. Then the LS module will assert the disk drive

START_1 and START_2 motor start signals low for disk drive slots 7

through 13, which will spin up the first 7 disk drives immediately. The

LS module will then assert the disk drive START_2 motor start signal

low and leave the START_1 motor start signal high for disk drive slots 0

through 6 which will command the second seven disk drives to spin up

after a delay of 12 seconds times the modulo 8 value of the numeric

SEL_ID of the disk drive.

Once the enclosure is powered up and all 14 drives are spun up as

depicted above, the enclosure will support immediate drive spin up

with two power supplies present.

Modulo 8

The drive spin up sequence above uses modulo 8 to calculate the spin

up delay. Modulo 8 is determined by:

(SHELF ID x DRIVE NUMBER)/8 = NUMBER + REMAINDER

It is the REMAINDER value that is used for the calculation as it is

always between 0 and 7 (hence modulo 8). The drive spin up time can

then be calculated as follows:

REMAINDER x MODE PAGE SETTING = SPIN UP DELAY (Seconds)

EXAMPLE:

Spin Up Delay would be 7 x 12, or 84 seconds.

A typical Mode Page Setting is 12, so if the Remainder = 7, the

Page 75

Chapter 5

System Monitoring

Page 76

This Chapter describes the devices used to monitor the Altos

S700 Series. The location of the monitoring LEDs and how to

interpret them is described.

Page 77

61

Overview

The front mounted LS module is the main monitoring device of the

Altos S700 Series. This module is complemented by status and fault

LEDs, mounted on all the major components of the enclosure, such as,

disk drives, power supplies, Advanced Cooling Modules (ACMs), and

RAID Controller. All these monitoring devices are discussed in the

following sections.

Page 78

Chapter 5 System Monitoring62

LS Module

The LS Module (Loop Resiliency and SES Module) provides monitoring

and control for the Altos S700 Series. The module reports status and

receives control information over the Enclosure Services Interface (ESI)

port of any of the fourteen disk drives installed in the enclosure. The LS

Module also provides loop resiliency for the Fibre Channel loop (in the

form of Port Bypass Circuits).

1

The Altos S700 Series contains one LS Module

second optional LS Module is available to provide active/passive failover for the enclosure services communication, and to provide a

second Fibre Channel Loop. Only one LS Module communicates (using

ESI communication) with the host system at any one time, but both LS

modules will continuously monitor the system. If the active LS Module

fails, then the ESI communication with the host system will be taken

over by the passive LS Module.

LS Module Features

• Monitoring/Control for 2 Power Supplies and 2 ACMs

• Reports status and receives control information via the FC loop

• Microcontroller for data processing, control and communications

• Volatile and non-volatile memory for the microcontroller

• Temperature sensor

• Audible alarm with manual and software disable

• FC link monitoring and status information

• Firmware download capability

• Reporting of PSU, LS module, I/O module, and backplane serial

number and revision

• I/O module and backplane type reporting

• Control of 6 front LEDs for enclosure and module status

• I/O option slot status monitoring

1

For RAID configurations, there must be two LS modules installed.

as standard. However, a

Page 79

63

L

L

L

L

L

L

Altos S700 Enclosure LEDs

The Altos S700 Series has six LEDs located on each of the front

mounted LS Modules. These LEDs show the status of the enclosure

power, Fibre Channel Loops, LS Module status and the operating mode

of the enclosure (1GB or 2Gb operation). Figure 5-1 shows the location

of the LEDs

Figure 5-1 Location of Altos S700 Enclosure LEDs

ED 0

ED 1

ED 2

ED 3

ED 4

ED 5

0

1

2

3

4

5

Page 80

Chapter 5 System Monitoring64

The table below shows the meaning of each of the LEDs, and how to

interpret them.

Description Color Indication

LED 0 Power On Green Normally ON, indicates power is applied.

LED 1 Shelf Fault Amber Normally OFF indicates no faults exist in

LED 2 FC Loop A Green ON indicates FC Loop A closed. OFF

LED 3 FC Loop B Green ON indicates FC Loop B closed. OFF

LED 4 LS Fault Amber Normally OFF indicating that the LS

LED 5 2Gb Operation Green ON indicates the FC loop is operating at

OFF indicates no power.

the enclosure. ON indicates a fault.

Flashing of this LED indicates the both a

1GB and a 2Gb I/O module has been

detected.

indicates FC Loop A open

indicates FC Loop B open.

Module has no fault. ON indicates an LS

Module fault. Flashing of this LED

indicates that the LS is a 1GB LS module in

a 2Gb system.

2Gb/Sec speed. OFF indicates the FC Loop

is operating at 1GB/Sec Speed. Flashing

of this LED indicates that the LS module is

set to an incorrect speed.

Note: If enabled, the audible alarm will sound when an error is

detected.

Caution: If 1GB and 2Gb hardware is mixed in an enclosure at

power up, and the enclosure is set to 2Gb, the drives will not spin

up and LEDs 1 and 5 will be flashing.

Page 81

65

Disk Drive LEDs

Each disk drive carrier has two LED indicators visible from the front of

the Altos S700 enclosure. The green disk drive ready LED is controlled

by the disk drive, and the bi-colour LED is controlled by the LS Module.

The following table shows how to interpret these LEDs.

Drive Ready

Green LED

Drive Controlled Off Off Slot empty, ready for insert

Drive Controlled On Off Drive online, ready for

Drive Controlled ON 125ms

Drive Controlled ON 250ms

Drive Controlled On 500ms

Drive Controlled Off On 125ms

Drive Controlled Off

a.

The shelf fault Amber LED is On. This is visible from the front of the enclosure

Bicolor LED

Green

Off 125ms

Off 250ms

Off 125ms

Off

Bicolor LED

Amber

Off

Off

Off

Off

Off

Off

Off 125ms

On 125ms

Off 750ms

Condition

operation

Drive Identify (POD)

Prepare for removal

Drive Rebuild

Drive Fail

Drive off-line, Loop A or

a

Loop B

Note: If enabled, the audible alarm will sound when an error is

detected.

Page 82

Figure 5-2 Disk Drive Carrier LEDs

Chapter 5 System Monitoring66

Disk Drive Ready

(Green)

BiColor LED

(Green/Amber)

18F

Page 83

67

Power Supply LEDs

The Altos S700 Series uses two AC power supplies. The AC power

supplies provide 853W peak output power and 673W continuous

output power.

The Altos S700 Series power supply has two LED indicators on it, which

are visible from the rear of the enclosure. The green Power OK LED is

on when the power supply is operating normally. This green LED is

driven by the power supply, and indicates that the power supply

output voltages are operating normally. The power supply amber Fault

LED is driven by the LS Module and power supply. This amber LED is ON

when the LS Module detects a power supply fault, or it will flash, when

the power supply Locate feature is selected.

Note: If enabled, the audible alarm will sound when an error is

detected

Figure 5-3 Power Supply LEDs

Fault LED

Power OK

0

I

Page 84

Chapter 5 System Monitoring68

Advanced Cooling Module (ACM) LEDs

The Altos S700 Series has two variable speed fans per advanced cooling

module. Each of the two ACMs on the rear of the Altos S700 Series

enclosure has two fault LEDs visible from the rear of the enclosure. The

LEDs are labeled “1” and “2” to correspond with the two fans inside

the ACM assembly. These LEDs are normally off and will only be on

when a fault is detected in a fan by the LS Module.

Note: The audible alarm will sound when an error is detected.

Figure 5-4 Advanced Cooling Module LEDs

Fan2

Fan1

1

2

Fan1 Fault

Fan2 Fault

Page 85

RAID Controller LEDs

or

The RAID controller has 7 LEDs located and numbered as shown.

Figure 5-5 RAID controller LEDs

HSSDC Connect

69

RS232

FC Host Connectors (SSF optical)

1

2

3

4

5

6

7

Status LEDs

The table below describes the LEDs meaning.

Controller Status LEDs

LED Description

1 Yellow - Not Ready. Normally Off. Goes On during power up

sequence.

2 Green - Ready. Normally On

3 Green - Dirty Cache. On when there is data in cache.

4 Yellow - BBU Fault. Normally Off.

5 Green - Partner Fail. Normally Off

6 Green - Device Activity i.e. on drive channels. Flashes with

activity.

7 Green - Host Activity. Flashes with activity.

Page 86

Chapter 5 System Monitoring70

Page 87

Chapter 6

Installing and

Removing Components

Page 88

This Chapter describes the procedures for installing and removing

the replaceable components in the Altos S700 Series.

Warning: The module handles are to facilitate the easy

insertion and removal of the modules, they should not

be used to lift and/or carry the enclosure.

Page 89

Location of the Components

r

Disk Drives

Module

ACMs

73

LS

Module

I/O Module/

RAID Controller

1

2

0

I

Power Supplies

1

2

0

I

I/O Module/

RAID Controlle

Page 90

Chapter 6 Installing and Removing Components74

Installing and Removing a Disk Drive Carrier

The disk drive carriers are located in the front of the enclosure. Follow

these procedures to install and remove the disk drive carrier.

Installing a Disk Drive Carrier

1 Select the disk drive slot into which the disk drive carrier is to be

installed and remove the carrier blank if there is one installed.

2 Orient the disk drive carrier such that the LEDs are on the top (on

the right for desk side systems).

3 With the cam lever fully open slide the carrier into the slot until

the lever starts to close.

4 Fully close the cam lever. The lever is fully closed, and the drive

locked in place, when the lever “clicks” into position.

Removing a Disk Drive Carrier

1 Using your finger, release the locking tab by pressing it in the

direction shown in Figure 5-1, and pull the cam lever towards you.

2 Fully open the cam lever. (approx. 90

3 With the cam lever open wait for at least one minute to allow the

disk drive to spin down fully before removing it.

4 Gently, pull the disk drive carrier out of the enclosure.

o

to enclosure).

Caution: Immediately replace the disk drive carrier or install a

disk drive carrier blank to maintain correct airflow.

Page 91

Figure 6-1 Disk Drive Carrier

Push locking tab in this direction to open

18F

75

Cam Lever

Page 92

Chapter 6 Installing and Removing Components76

Installing and Removing an LS Module

The LS Modules are located in the front of the enclosure. Follow these

procedures to install and remove the LS Modules.

Installing an LS Module

1 Select the LS Module slot in to which the LS Module is to be

inserted and remove the LS blank if one is installed.

2 Orient the LS Module such that the LEDs are on the top (on the

right for deskside systems).

3 With the cam lever fully open slide the LS Module into the slot

until the lever starts to close.

4 Fully close the cam lever. The lever is fully closed, and the LS

Module locked in place, when the lever “clicks” into position.

Removing an LS Module

1 Using your finger, release the locking tab by pressing it in the

direction shown in Figure 5-2, and pull the cam lever towards you.

2 Fully open the cam lever (approx. 90

3 Gently, pull the LS Module out of the enclosure.

o

to enclosure).

Caution: Immediately replace the LS Module to maintain correct

airflow.

Page 93

Figure 6-2 LS Module

Push locking tab in this direction to open

77

0

1

2

3

4

5

Cam Lever

Page 94

Chapter 6 Installing and Removing Components78

Installing and Removing a Power Supply

The power supplies are located in the rear of the enclosure. Follow

these procedures to install and remove the power supplies.

Installing a Power Supply

1 Select the power supply slot into which the power supply is to be

inserted and remove the carrier blank if there is one installed.

2 Orient the power supply, such that the LEDs are on the top (on the

right hand side for rack mount systems).

3 Gently slide the power supply into the empty power supply slot.

4 Secure in place using the two fixing screws (torque setting 0.3Nm).

5 Install the power cable.

Removing a Power Supply

1 Turn off the power supply, and remove the power cable.

2 Loosen the two fixing screws.

3 Using the power supply handle, gently slide it out of the enclosure.

Caution: Immediately replace the power supply carrier or install a

power supply carrier blank to maintain correct airflow.

Figure 6-3 Power Supply

Inlet

AC

Handle

0

I

Switch

On/Off

Page 95

79

Installing and Removing an Advanced Cooling Module

The advanced cooling modules are located in the rear of the enclosure.

Follow these procedures to install and remove the advanced cooling

modules.

Installing an Advanced Cooling Module

1 Select the advanced cooling module slot into which the module is

to be installed.

2 Orient the module, such that the LEDs are on the top (on the right

hand side for rack mount systems).

3 Gently slide the ACM into the empty ACM slot.

4 Secure in place using the two fixing screws (torque setting 0.3Nm).

Removing an Advanced Cooling Module

1 Loosen the two fixing screws.

2 Using the advanced cooling module handle, gently slide it out of

the enclosure.

Caution: Immediately replace the ACM to maintain correct

airflow.

Figure 6-4 Advanced Cooling Module

Handle

LEDs

1

2

Page 96

Chapter 6 Installing and Removing Components80

Installing and Removing an I/O Module/RAID Controller

Note: In the following section, “I/O Module” is taken to include

the RAID Controller in addition to the I/O Module.

The I/O module is located in the rear of the enclosure. Follow these

procedures to install and remove the I/O module.

Installing an I/O Module/RAID Controller

1 Remove the I/O module blank if there is one installed.

2 Gently insert the I/O module into the slot.

3 Secure in place using the two fixing screws (torque setting 0.3Nm).

4 Connect the cables as described in Chapter 3.

Removing an I/O Module/RAID Controller

1 Remove all cables.

2 Loosen the two fixing screws.

3 Using the module handle, gently slide the I/O Module out of the

slot.

Caution: Immediately replace the carrier or install an I/O module

blank to maintain correct airflow.

Page 97

Appendix A

Safety Statement

Translations

Page 98

Caution:

This equipment is intended only for installation in a restricted

access location.

Caution: Dieses Gerät sollte nur an einem Ort mit

Zugangskontrolle installiert werden.