Page 1

Acer Altos R510 (DDR2)

User’s Guide

Page 2

Copyright © 20

All Rights Reserved.

Acer Altos R510

User’s Guide

1st Issue: December 200

Changes may be made periodically to the information in this publication without obligation

to notify any person of such revision or changes. Such changes will be incorporated in new

editions of this manual or supplementary documents and publications. This company makes

no representations or warranties, either expressed or implied, with respect to the contents

herein and specifically disclaims the implied warranties of merchantability or fitness for a

particular purpose.

Record the model number, serial number, purchase date, and place of purchase information in

the space provided below. The serial number and model number are recorded on the label

affixed to your computer. All correspondence concerning your unit should include the serial

number, model number, and purchase information.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form or by any means, electronic, mechanical, photocopy, recording, or otherwise,

without the prior written permission of Acer Incorporated.

05 Acer Incorporated

(DDR2)

5

Model Number : _________________________________

Serial Number: ___________________________________

Purchase Date: ___________________________________

Place of Purchase: ________________________________

Acer and the Acer logo are registered trademarks of Acer Inc. Other company’s product

names or trademarks are used herein for identification purposes only and belong to their

respective companies.

Page 3

iii

Notices

FCC notice

Class A devices do not have an FCC logo or FCC IDE on the label. Class

B devices have an FCC logo or FCC IDE on the label. Once the class of

the device is determined, refer to the following corresponding

statement.

Class A equipment

This device has been tested and found to comply with the limits for a

Class A digital device pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This device generates, uses, and can radiate radio

frequency energy, and if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

Operation of this device in a residential area is likely to cause harmful

interference in which case the user will be required to correct the

interference at his own expense.

However, there is no guarantee that interference will not occur in a

particular installation. If this device does cause harmful interference to

radio or television reception, which can be determined by turning the

device off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the device and receiver

• Connect the device into an outlet on a circuit different from that

to which the receiver is connected

• Consult the dealer or an experienced radio/television technician

for help

Shielded cables

All connections to other computing devices must be made using

shielded cables to maintain compliance with FCC regulations.

Page 4

iv

Peripheral devices

Only peripherals (input/output devices, terminals, printers, etc.)

certified to comply with the Class A or Class B limits may be attached to

this equipment. Operation with noncertified peripherals is likely to

result in interference to radio and TV reception.

Caution: Changes or modifications not expressly approved by

the manufacturer could void the user’s authority, which is granted

by the Federal Communications Commission, to operate this

server.

Use conditions

This part complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Canadian users

This Class A/Class B digital apparatus meets all requirements of the

Canadian Interference-Causing Equipment Regulations.

Laser compliance statement

The CD-ROM drive in this server is a laser product. The CD-ROM drive’s

classification label (shown below) is located on the drive.

CLASS 1 LASER PRODUCT

CAUTION: INVISIBLE LASER RADIATION WHEN OPEN. AVOID

EXPOSURE TO BEAM.

Page 5

Important safety instructions

Read these instructions carefully. Save these instructions for future

reference.

1 Follow all warnings and instructions marked on the product.

2 Unplug this product from the wall outlet before cleaning. Do not

use liquid cleaners or aerosol cleaners. Use a damp cloth for

cleaning.

3 Do not use this product near water.

4 Do not place this product on an unstable cart, stand, or table. The

product may fall, causing serious damage to the product.

5 Slots and openings on the back or bottom side of the chassis are

provided for ventilation; to ensure reliable operation of the

product and to protect it from overheating, these openings must

not be blocked or covered. The openings should never be blocked

by placing the product on a bed, sofa, rug, or other similar surface.

This product should never be placed near or over a radiator or

heat register, or in a built-in installation unless proper ventilation

is provided.

6 This product should be operated from the type of power indicated

on the marking label. If you are not sure of the type of power

available, consult your dealer or local power company.

7 Do not allow anything to rest on the power cord. Do not locate

this product where persons will walk on the cord.

8 If an extension cord is used with this product, make sure that the

total ampere rating of the equipment plugged into the extension

cord does not exceed the extension cord ampere rating. Also,

make sure that the total rating of all products plugged into the

wall outlet does not exceed the fuse rating.

9 Never push objects of any kind into this product through chassis

slots as they may touch dangerous voltage points or short out

parts that could result in a fire or electric shock. Never spill liquid

of any kind on the product.

10 Do not attempt to service this product yourself, as opening or

removing covers may expose you to dangerous voltage points or

other risks. Refer all servicing to qualified service personnel.

11 Unplug this product from the wall outlet and refer servicing to

qualified service personnel under the following conditions:

v

Page 6

vi

a When the power cord or plug is damaged or frayed

b If liquid has been spilled into the product

c If the product has been exposed to rain or water

d If the product does not operate normally when the operating

instructions are followed. Adjust only those controls that are

covered by the operating instructions since improper

adjustment of other controls may result in damage and will

often require extensive work by a qualified technician to

restore the product to normal condition.

e If the product has been dropped or the cabinet has been

damaged

f If the product exhibits a distinct change in performance,

indicating a need for service.

12 Replace the battery with the same type as the product's battery we

recommend. Use of another battery may present a risk of fire or

explosion. Refer battery replacement to a qualified service

technician.

13 Warning! Batteries may explode if not handled properly. Do not

disassemble or dispose of them in fire. Keep them away from

children and dispose of used batteries promptly.

14 Use only the proper type of power supply cord set (provided in

your accessories box) for this unit. It should be a detachable type:

UL listed/CSA certified, type SPT-2, rated 7A 125V minimum, VDE

approved or its equivalent. Maximum length is 15 feet (4.6

meters).

Page 7

Notices iii

FCC notice iii

Class A equipment iii

Shielded cables iii

Peripheral devices iv

Use conditions iv

Canadian users iv

Laser compliance statement iv

Important safety instructions v

1 System information 1

Product briefing 3

Processor 3

Memory subsystem 3

Storage 4

Graphics interface 4

Networking 4

I/O ports 4

Caring features 5

Product specification summary 6

2 System tour 7

System board 9

Connector and Header Locations 9

Configuration Jumpers 11

Serial Port Configuration Jumper 12

BIOS Select Jumper 13

Back Panel Connectors 14

External and internal structure 16

Front view (with bezel) 16

Front view (w/o bezel) 16

Front panel 17

Front Panel LED and Buttons description 17

Control Button Functions 18

LED Indicator Status 18

Rear view 20

Optional Peripherals 21

Internal components 22

Contents

3 Getting Started 23

Setting up the system 25

Preinstallation requirements 25

Page 8

Selecting a site 25

Checking the package contents 25

System startup 26

Turning on the system 26

Turning off the system 26

Power-on problems 27

4 Configuring the system 29

Upgrading the system 31

Installation precautions 31

ESD precautions 31

Preinstallation instructions 31

Post-installation instructions 32

Opening the server 33

Before opening the server 33

Removing the Chassis Cover 33

Installing the Chassis Cover 35

Removing and Installing the Front Bezel 36

Removing the Front Bezel 36

Installing the Front Bezel 36

Removing and Installing the Processor Air Duct 37

Removing the Processor Air Duct 37

Installing the Processor Air Duct 37

Removing and Installing the Air Baffle 38

Removing the Air Baffle 38

Installing the Air Baffle 40

Installing and Removing a Hard Disk Drive 41

Installing a Fixed SATA Hard Disk Drive 41

Removing a Fixed SATA Hard Disk Drive 46

Installing a SATA or SCSI Hot-swap Hard Disk Drive 48

Removing a SATA or SCSI Hot-swap Hard Disk Drive 50

Installing or Removing a Floppy Drive 52

Installing a Floppy Drive into Slimline Bay

(Backplane Installed) 52

Removing a Floppy Drive from the

Slimline Bay (Backplane Installed) 55

Installing a Floppy Drive into Slimline Bay

(No Backplane Installed) 55

Removing a Floppy Drive from the Slimline Bay

(No Backplane Installed) 60

Installing a Floppy Drive into the Converted

Hard Drive Bay (Back plane Installed) 61

Removing a Floppy Drive from the

Converted Hard Drive Bay 64

Installing or Removing a DVD/CD-RW or CD-ROM Drive 66

Page 9

Installing a DVD/CD-RW or CD-ROM Drive into

Slimline Bay (Backplane Installed) 66

Removing a DVD/CD-RW or CD-ROM Drive

from the Slimline Bay (Backplane Installed) 68

Installing DVD/CD-RW or CD-ROM Drive into

Slimline Bay (No Backplane Installed) 69

Installing and Removing a PCI Riser Connector 72

Installing a PCI Riser Connector 72

Removing a PCI Riser Connector 74

Installing and Removing a PCI Add-in Card 76

Installing a PCI Add-in Card 76

Removing a PCI Add-in Card 77

Installing and Removing the SATA or SCSI

Backplane (Optional) 79

Removing the SATA or SCSI Backplane 79

Installing the SCSI or SATA Backplane 80

Processor Installation and Upgrade 83

Installing or Replacing the Processor 83

Installing the Processor 83

Installing the Heat Sink(s) 85

Removing a Processor 86

Memory Installations and Upgrade 87

Upgrading the system memory 87

Memory Sparing 89

Installing and Removing Memory 90

Installing DIMMs 90

Removing DIMMs 91

5 BIOS setup 93

Using the BIOS Setup Utility 95

Entering BIOS 95

If You Cannot Access Setup 95

Setup Menus 95

BIOS Setup Utility 96

BIOS Setup Keyboard Command Bar Options 97

Main 99

Advanced 101

Upgrading the BIOS 138

Preparing for the Upgrade 138

Recording the Current BIOS Settings 138

Obtaining the Upgrade 139

Upgrading the BIOS 139

Clearing the Password 139

Clearing the CMOS 140

Page 10

6 Troubleshooting 143

Resetting the System 145

Problems following Initial System Installation 145

First Steps Checklist 145

Hardware Diagnostic Testing 146

Verifying Proper Operation of Key System Lights 147

Confirming Loading of the Operating System 147

Specific Problems and Corrective Actions 147

Power Light Does Not Light 148

No Characters Appear on Screen 148

Characters Are Distorted or Incorrect 149

System Cooling Fans Do Not Rotate Properly 150

Diskette Drive Activity Light Does Not Light 150

CD-ROM Drive or DVD/CD-RW Drive Activity

Light Does Not Light 150

Cannot Connect to a Server 151

Problems with Network 151

System Boots when Installing PCI Card 152

Problems with Newly Installed Application

Software152

Problems with Application Software that

Ran Correctly Earlier 152

Devices are not Recognized under

Device Manager (Windows* Operating System) 153

Hard Drive(s) are not recognized 153

Bootable CD-ROM Is Not Detected 154

Appendix A: Management software installation 157

Installing ASM 159

System requirements 159

ASM Agent 159

ASM Console 159

System setup 159

Installing ASM Agent (Windows version) 159

Installing ASM Console (Windows version) 160

Installing ASM Agent (Linux version) 160

Appendix B: Tool-less rail kit installation 163

Tool-less rail kit installation 165

Setting the Multi-Pin Adapters for Rack Type 165

Installing the Slide Rails into the Rack 166

Installing the Component into the Slide Rails 168

Cable Management ARM installation 169

Page 11

Required Installation Position of the CMA 170

Installing the CMA on the Slide Rails 171

Placing and Securing Cabling Within the CMA 172

General Safety Information 173

Appendix C: Sensor Table 175

Sensor Table 177

Appendix D: SATA RAID Configuration 179

Configuring the onboard SATA RAID 181

How to enable the onboard SATA RAID function 181

Loading the BIOS default setting 181

Enabling the onboard SATA RAID function 181

How to create RAID 1 volume 181

Enter the onboard SATA RAID Configuration

Utility 181

Loading onboard SATA RAID default setting 181

Creating RAID 1 volume 182

Initialising RAID Volume 182

Saving and Exiting the Embedded RAID

Configuration Utility 183

Index 185

Page 12

Page 13

1 System

information

Page 14

The Acer Altos R510 is a rack optimised dual

processor system loaded with features. The

system uses next generation technology to

offer excellent performance for cost sensitive

applications.

Page 15

Product briefing

This section provides basic information concerning the configuration

of your Altos R510 system.

Processor

• Single or dual Intel® XeonTM processors with 800 MHz FSB

TM

• CPU Hyper-Threading

• Supports Extended memory 64bit technology (EM64T)

Memory subsystem

• Six (184 - pin) DIMM slots

• DDR2 400 MHz registered memory modules supported

• Maximum upgrade - 12 GB

• 2-way memory interleaving supported

• SDDC (Single Device Data Correction) for memory error detection

and correction of any number of bit failures in a single x4 memory

device

• Memory sparing technology

• When memory sparing is enabled, the spare DIMM will not be

detected by OS

• The sparing DIMM will be reserved for standby purposes and

cannot be accessed by the system

• Please refer to page116 "Memory Configuration Sub-menu

Selections" for more information about configuring the memory

sparing in the BIOS Setup utility

Technology support

1

3

1

For example, if six 1GB DIMMs are installed (6 GB memory) only

4GB of memory (in DIMM 1B, 1A, 2B, 2A) can be accessed by the

system. Memory in DIMM 3B and DIMM 3A would be reserved as

spare DIMMs

Caution! When using multiple memory modules it is

recommended that you AVOID using modules from different

manufacturers or that run at different speeds from each other.

Page 16

4

Warning! Functionality issues may be encountered if mixed

memory types are installed on the same server board. DIMM

modules of identical type, banking and stacking technology, and

vendor should be installed in the Altos R510.

1 System information

Storage

• Slim-type IDE CD-ROM/DVD-ROM drive

• Slim-type 3.5 inch Floppy disk drive (optional)

• Support for three (max) SCSI hard disk drives 300 * 3 = 900GB or

three SATA hard disk drives 400 * 3 = 1.2TB

Warning: If FDD and CD-ROM are installed, R510 would support 2

hard disk drives only.

Graphics interface

• On-board ATI Rage XL video controller with 8MB SDRAM

Networking

• Two Integrated Gigabit Ethernet connections

• Intel 82541PI Gigabit Ethernet LAN controller

• Marvell 88E8050 Gigabit Ethernet LAN Controller

I/O ports

•Front

• One USB 2.0 port

• One SVGA video port

•Rear

• Two USB 2.0 port

• Two PS/2 ports (keyboard/mouse)

• Two LAN ports (RJ-45)

• One SVGA video port

Page 17

Serial ATA ports

• Two SATA ports

Service ID

• Front service ID button

• Front and rear service ID LED

Operating Systems supported

• Microsoft® Windows® Server 2003

• Red Hat Enterprise Linux 3.0/4.0

• Novell NetWare 6.5

• SCO Unixware 7.1.4

• SCO OpenServer 5.0.7

RAID (Optional)

• Embedded SATA Software RAID 0,1 supported

Caring features

5

Part of Acer’s mission, as a company that cares about its end users, is to

provide features that make operation, maintenance, and upgrading

your system simpler and faster. The Altos R510 is no exception to this

rule. The following features and options are provided.

• Cost efficient operation in a value oriented package

• Tool-less design

• Front accessible USB and VGA ports

TM

•Acer EasyBUILD

• Acer Server Manager (ASM) suite of comprehensive management

tools

• Flexibility for future expansion

for efficient system setup and installation

Page 18

6

1 System information

Product specification summary

Highlighted below are the system’s key features:

• Single or dual Intel

Technology

• 800 MHz FSB supports processor speeds from 3.6 GHz and above

®

•Intel

•Intel® E7320 Memory Controller Hub (MCH)

•Intel® 6300ESB I/O Controller Hub (ICH)

• Supports two PCI riser cards

• Low Profile: One 66/66MHz/3.3V PCI-X slot

• One full height riser slot supporting one of two riser card

• Option 1: One 64-bit/66MHz/3.3V PCI-X slot

• Option 2: One (x4) PCI-Express slot

• Six DIMM sockets supporting DDR2 400 registered ECC modules

• Media storage

• Optional slim-type 3.5 inch 1.44 MB floppy drive or Optical drive

• Additional media storage capacity

• Support for three 3.5 Inch SATA, or SCSI hard disk drives

• External ports

• PS/2 keyboard and mouse ports • Two LAN (RJ-45) ports

• Three USB ports (1 front, 2 rear) • 2 SVGA video ports (1

E7320 chipset consisting of:

options:

for a maximum memory capacity of 12 GB

®

XeonTM processor supporting Hyper-Threading

front, 1 rear

• Power supply unit (PSU)

• One 450W power supply

• Chassis Intrusion

• Chassis intrusion switch

• Lock attach point for chassis cover

• Up to five system fans

• Four dual rotor plus one single rotor system fans

• Tool less fan replacement

•LEDs

• Standard Control Panel: NIC1 Activity, NIC2 Activity & Power /

Sleep

• System Status LEDs can be viewed with bezel closed

•Service ID

Page 19

2 System tour

Page 20

This chapter provides locations of various

components and ports and instructions on

how to set up the system.

Page 21

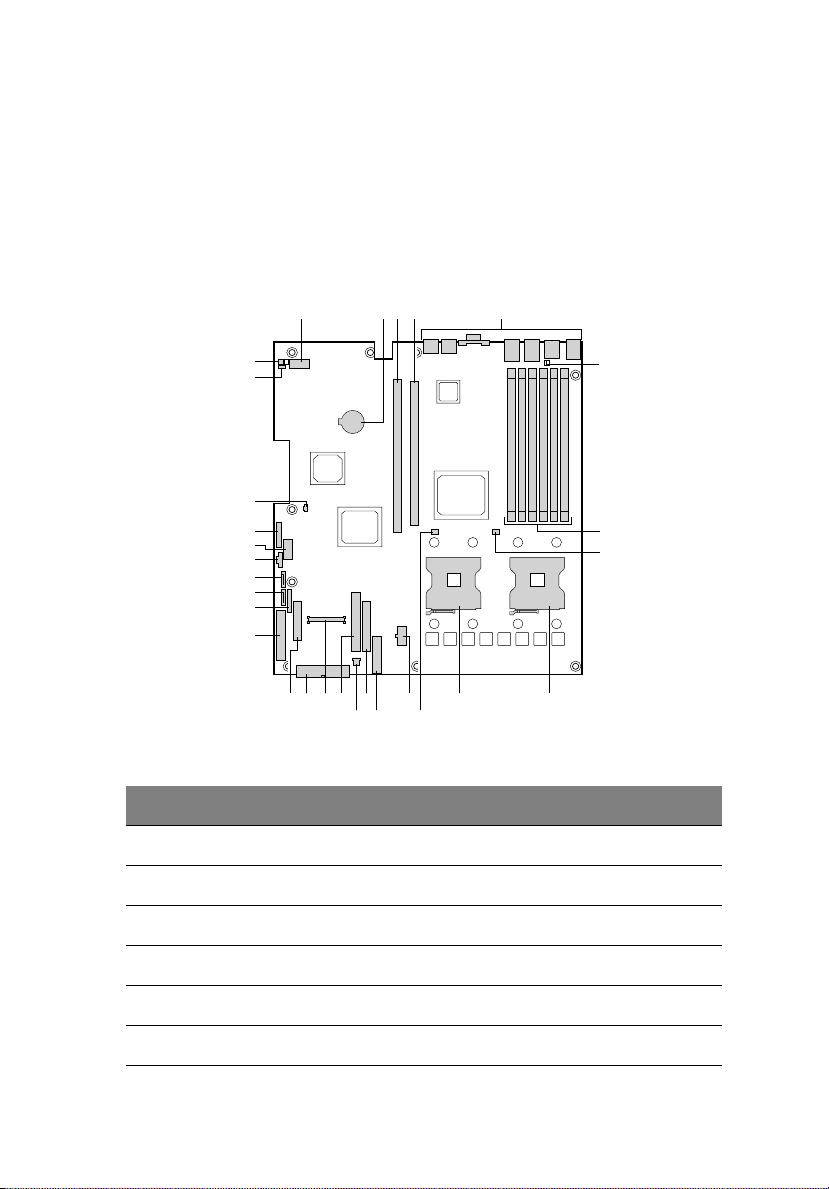

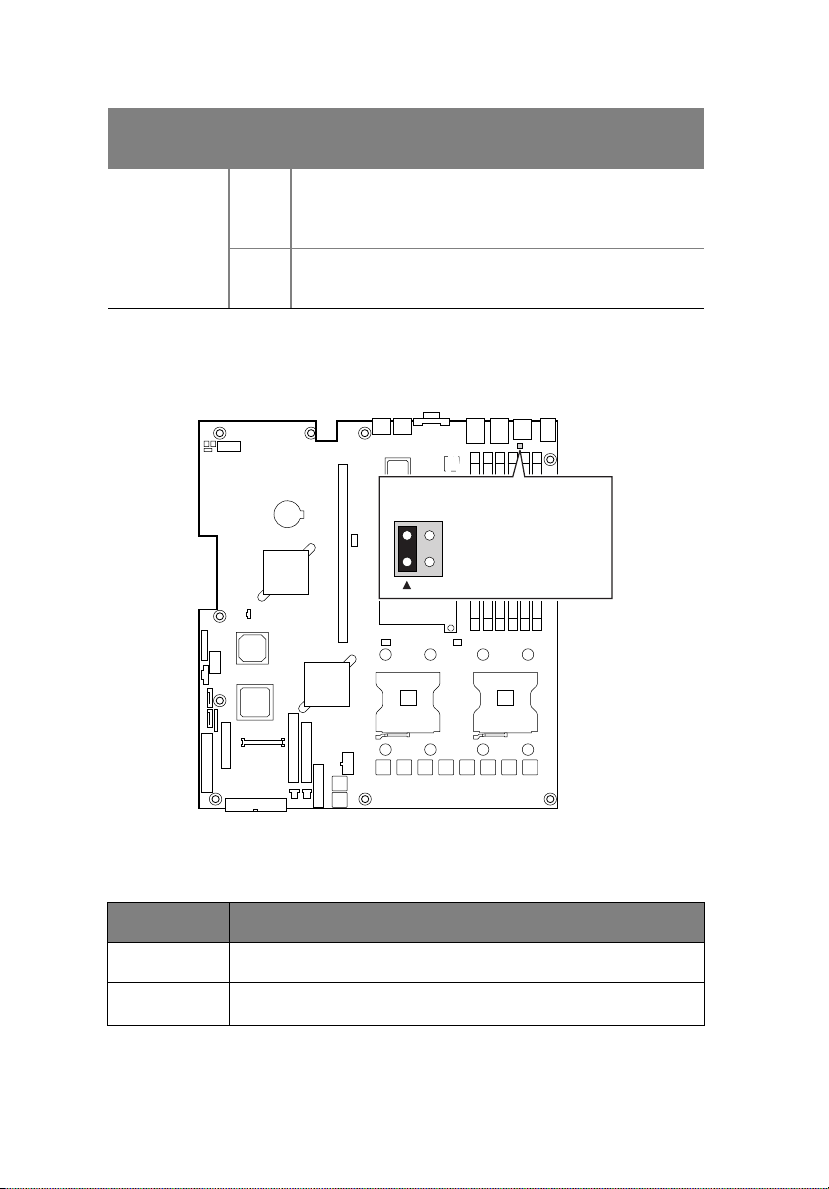

System board

Connector and Header Locations

The mainboard of the R510 becomes accessible once you open the

system. The figure below is provided to help you indentify and locate

connectors, slots and ports.

A B C E

D

9

CC

BB

AA

Z

Y

X

W

V

U

T

RS

PON

Q

K

M

Item Description

A Serial Port A

B Battery

C Full-height PCI slot

F

G

H

IJL

D Low-profile PCI slot

E Back panel I/O ports

F serial port selection jumper

Page 22

10

Item Description

G DIMM sockets (DIMM 1B, 1A, 2B, 2A, 3B, and 3A)

H Processor 1 fan header

I Processor 1 socket

J Processor 2 socket

K Processor 2 fan header

L +12V processor power connector

M Fan board connector

N Floppy connector

O PCI fan connector

P IDE connectors

Q 100-pin Floppy/Front Panel/ATA connector

R Main power connector

2 System tour

S 50-pin front panel connector

T 34-pin front panel connector

U Configuration jumpers

V SATA 1 connector

W SATA connector

X Power supply connector

Y OEM RMC connector

Z Power supply connector

AA IDE power connector

BB BIOS Select jumper

CC Chassis intrusion header

Page 23

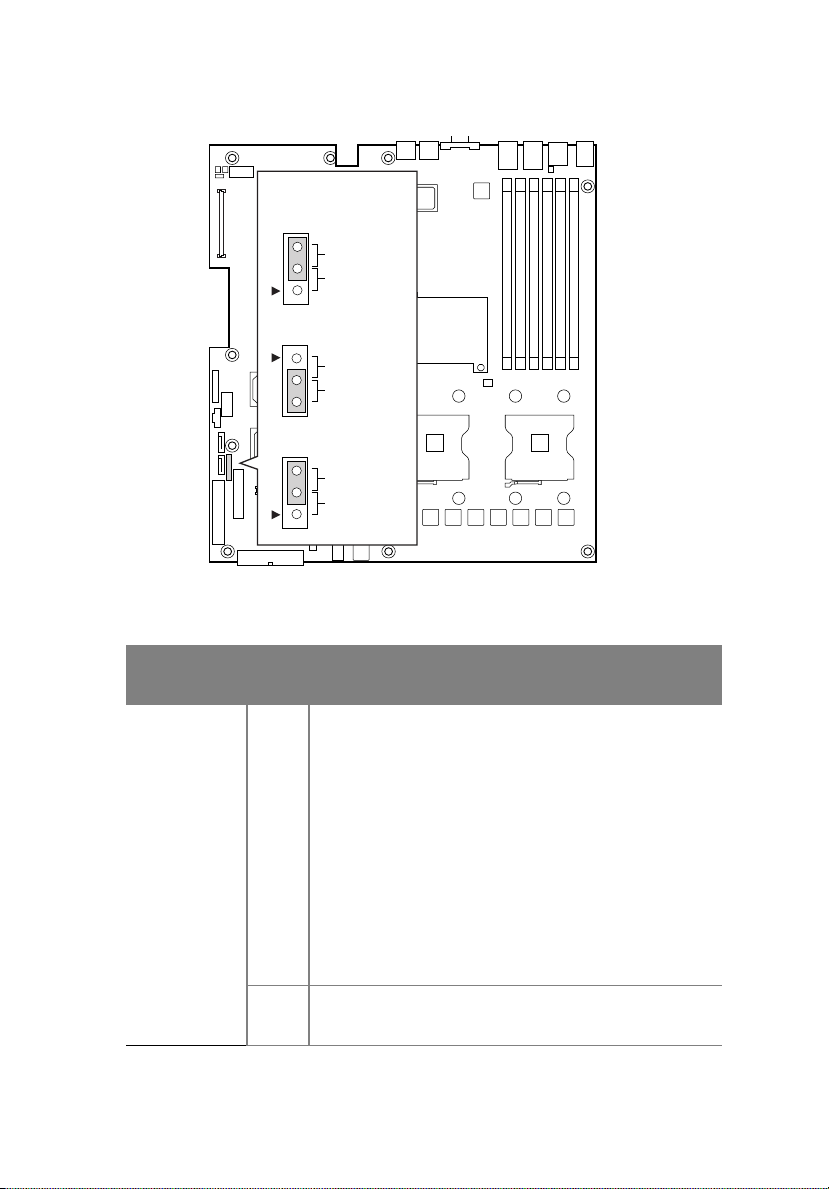

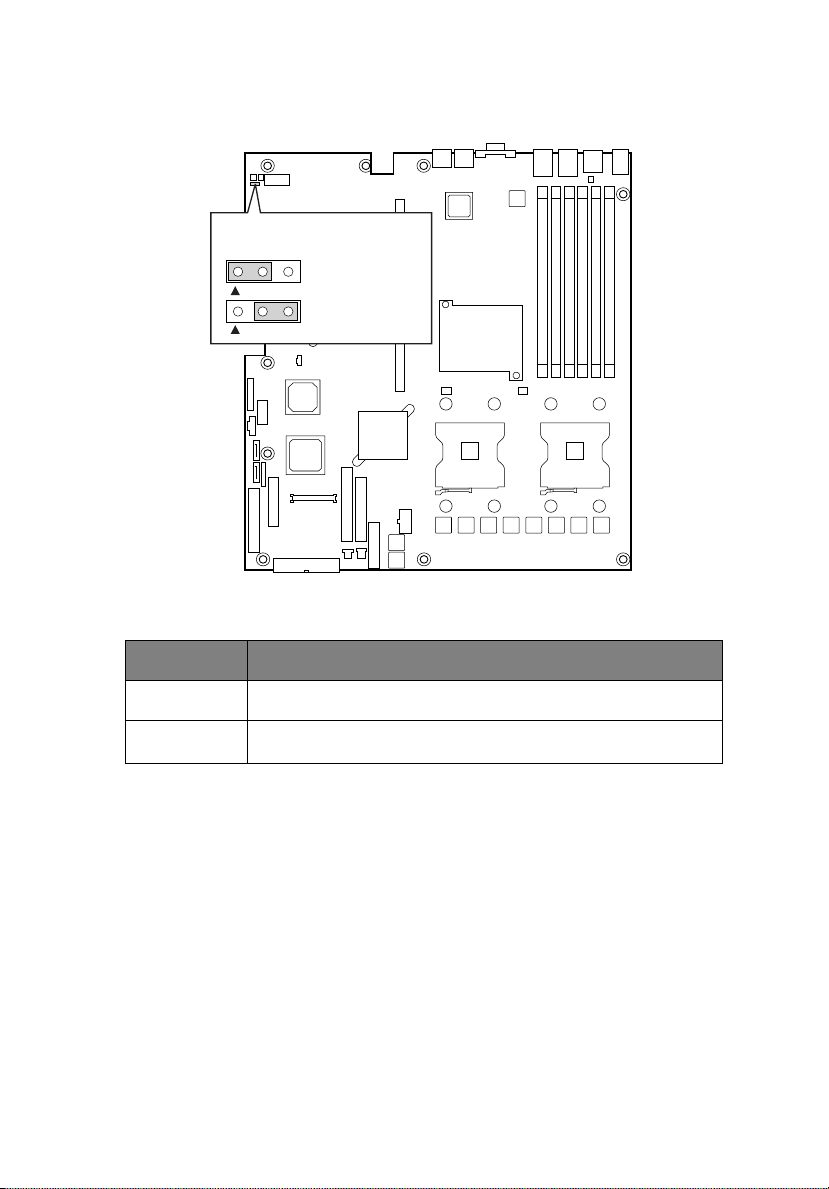

Configuration Jumpers

J1H2, J1H3, J1H5

J1H2 Pass Clr

3

Protect

2

Erase

J1H3 Rcvr Boot

Recovery Boot

2

Normal Boot

3

J1H5 CMOS Clr

3

BMC Control

2

Force Erase

11

Jumper

Name

J1H2

Password

Clear

J1H3

Recovery

Boot

Pins What happens at system reset??

1-2 If these pins are jumpered, administrator and user

passwords will be cleared on the next reset. These

pins should not be jumpered for normal operation.

2-3 These pins should be jumpered for normal system

operation

1-2 If these pins are jumpered, the system will attempt

to recover the BIOS by loading the BIOS code into

the flash device from a floppy disk. This jumper is

typically used when the BIOS has become corrupted.

These pins should not be jumpered for normal

operation.

2-3 These pins should be jumpered for normal system

operation.

Page 24

12

2 System tour

Jumper

Name

J15H CMOS

Clear

Pins What happens at system reset??

1-2 If these pins are jumpered, the CMOS settings will

be cleared on the next reset. These pins should not

be jumpered for normal operation.

2-3 These pins should be jumpered for normal system

operation.

Serial Port Configuration Jumper

J8A3

34

1-3: DCD to DTR (Defa

2-4: DSR to DTR

2

TP00944

Pins What happens at system reset??

1-3 Serial port is configured for DCD to DTR (default)

2-4

Serial port is configured for DSR to DTR

Page 25

BIOS Select Jumper

J1A4

BIOS Select

1-2: Normal

Operation (Default)

3

2-3: Force to

Lower Bank

3

13

Pins What happens at system reset??

1-2 System is configured for normal operation

2-3

Force BIOS to lower bank

Page 26

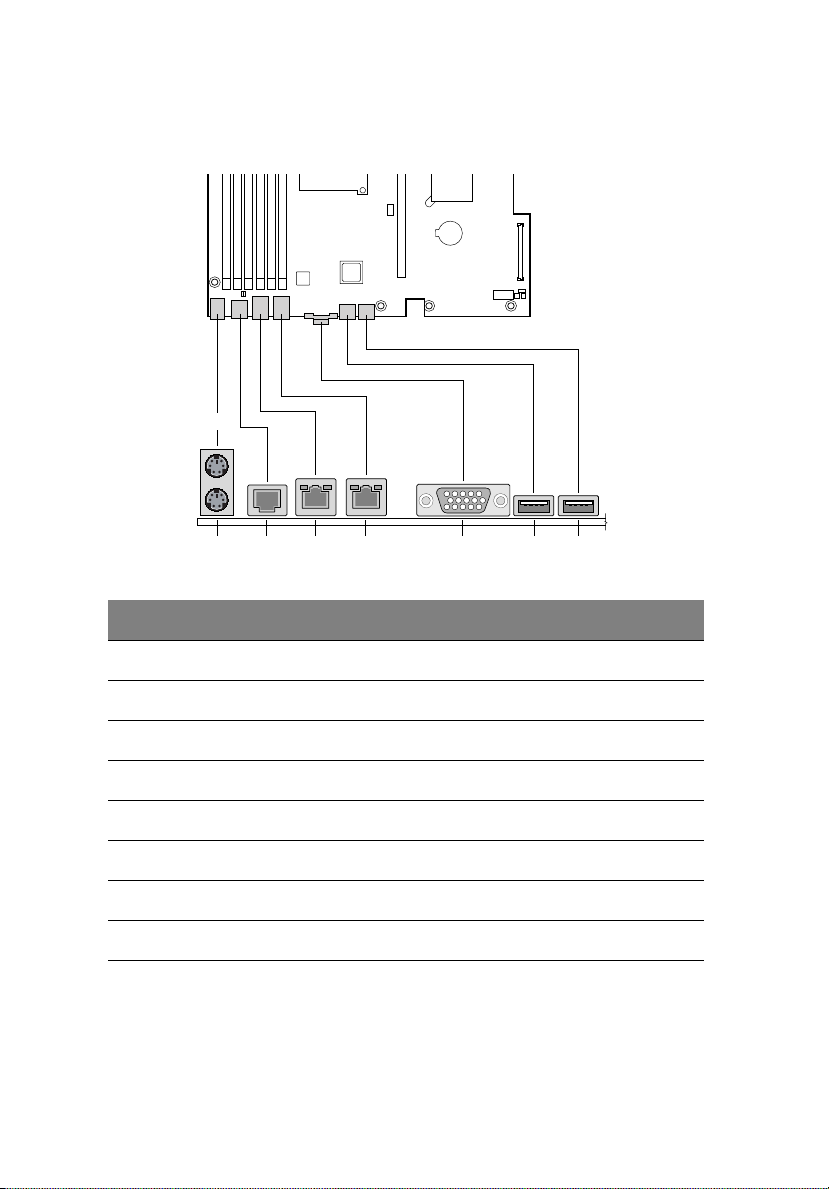

14

Back Panel Connectors

A

Item Description

2 System tour

FC D E G HB

TP00943

A PS/2 Mouse port

B PS/2 Keyboard port

C Com Port (RJ-45 connector)

D Gigabit LAN # 1 Port (RJ45)

E Gigabit LAN # 2 Port (RJ45)

F Video Port

G USB port #1

H USB port #2

Page 27

The NIC LEDs at the right and left of each NIC provide the following

information.

15

LED

Color

Left

LED

Left

LED

Left

LED

Right

LED

Right

LED

Right

LED

LED State Description

Off No network connection

Solid Amber Network connection in place

Blinking Amber Transmit/receive activity

Off 10 Mbps connection

(if left LED is on or blinking)

Solid Amber 100 Mbps connection

Solid Green 1000 Mbps connection

Page 28

16

External and internal structure

Front view (with bezel)

No. Description

A Name Plane

BLEDs

Front view (w/o bezel)

A

2 System tour

B

No. Description

A Slimline DVD/CD-RW, CD-ROM or FDD Bay

B 3.5” HDD Bay

Page 29

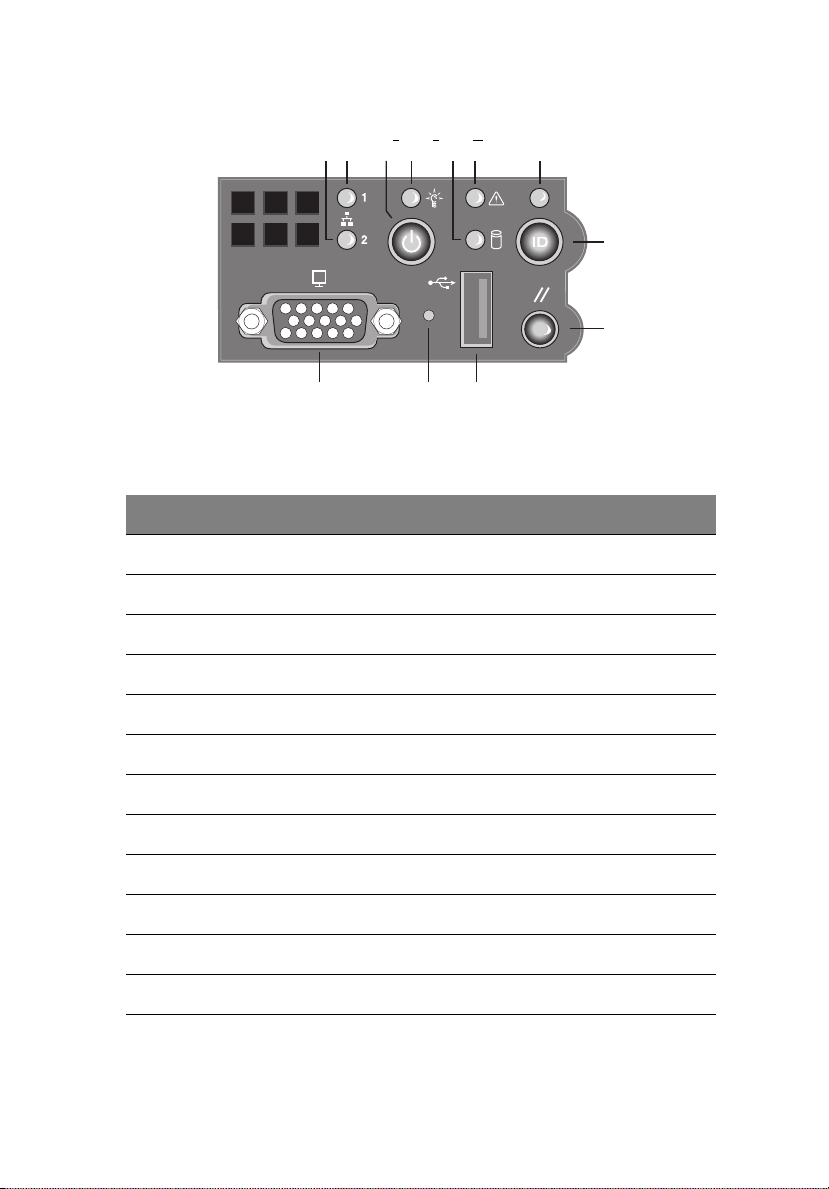

Front panel

BA F GEDC

L JK

Front Panel LED and Buttons description

Item Description

A LAN #2 Activity LED

B LAN #1 Activity LED

C Power button

17

H

I

DPower LED

E Hard Drive Activity LED

F System Status LED

G Service ID LED

H Service ID Button

I System Reset Button

JUSB connector

K Recessed NMI Button (Tool Required)

LVGA connector

Page 30

18

Control Button Functions

Item Description

2 System tour

Power/

Sleep

button

Reset

button

ID button Toggles the front panel ID LED and the baseboard ID LED on

NMI button Puts the server in a halt-state for diagnostic purposes.

Toggles the system power on/off. Sleep button for

ACPI-compatible operating systems.

Reboots and initializes the system.

and off. The baseboard LED is visible from the rear of the

chassis and allows you to locate the server from the rear of a

rack of systems.

LED Indicator Status

Item Description

NIC 1 activity

LED

NIC 2 activity

LED

Power/Sleep

LED

Continuous green light indicates a link between the system

and the network to which it is connected.

Blinking green light indicates network activity.

Continuous green light indicates the system has power

applied to it.

Blinking green indicates the system is in S1 sleep state (see

Note )

No light indicates the power is off / is in ACPI S4 or S5 state.

Hard disk

drive

status LED

System

Status LED

Random blinking green light indicates hard disk drive

activity (SATA).

No light indicates no hard disk drive activity.

Solid green indicates normal operation

Blinking green indicates degraded performance

Solid amber indicates a critical or non-recoverable condition

Blinking amber indicates a non-critical condition

No light indicates POST is running or the system is off (see

Note 1)

Page 31

Item Description

19

System

Identification

LED

Note: If the system is powered down without going through the BIOS, the

LED state that was in effect at the time of the power-down is restored when

the system is powered back on or until the BIOS clears the LED. If the system

is not powered down normally, the Power LED may blink and the System

Status LED may be off due to a failure or configuration change that

prevents the BIOS from running.

Note: After you press the Service ID button, the Service ID LED will

blink 15 times and turn off automatically. You can only turn it off

through Acer Server Management (ASM).

Solid blue indicates system identification is active

No light indicates system identification is not activated

Page 32

20

Rear view

Item Description

A PS2 Mouse Port

B Low profile PCI card bracket

C Full height PCI card bracket

D AC Power receptacle

E PS2 keyboard Ports

F RJ45 Serial B port

2 System tour

G LAN #1 Connector

H LAN #2 Connector

I Video Connector

J USB #1 Connector

K USB #2 Connector

L Power Supply Fans

Page 33

Optional Peripherals

A

B

Item Description

A Slim-line Device cage, support for FDD / DVD / CD-ROM drive

B Hard Drive Bays (3)

21

Page 34

22

9

Internal components

C

B

A

2 System tour

E

D

F

G

J

I

Item Description

A Slimline drive bay

B Backplane (optional)

C Power supply air baffle

D Power supply

E PCI add-in card riser assembly

F Server board

G Processor air duct

H Fan module

I Control panel

J Hard drive bays

H

TP012

Page 35

3 Getting Started

Page 36

This chapter gives information on setting up and

starting to use your system

Page 37

Setting up the system

Preinstallation requirements

Selecting a site

Before unpacking and installing the system, select a suitable site for

the system for maximum efficiency. Consider the following factors

when choosing a site for the system:

• Near a grounded power outlet

• Clean and dust-free

• Stable surface free from vibration

• Well-ventilated and away from sources of heat

• Secluded from electromagnetic fields produced by electrical

devices such as air conditioners, radio and TV transmitters, etc.

Checking the package contents

Check the following items from the package:

• Acer Altos R510 system

• Acer EasyBUILD

• Acer Altos R510 Accessory box

TM

25

If any of the above items are damaged or missing, contact your dealer

immediately.

Save the boxes and packing materials for future use.

Page 38

26

3 Getting Started

System startup

Turning on the system

After making sure that you have properly set up the system and

connected all the required cables, you can now power on the system.

To power on the system, press the power button on the front panel.

Refer to “Front view (w/o bezel)” on page 16, for help locating the

power button.

The system starts up and displays a welcome message. After that, a

series of power-on self-test (POST) messages appears. The POST

messages indicate if the system is running well or not.

Note: If the system does not turn on or boot after pressing the

power button, go to “Power-on problems” on page 27 for

possible causes of boot failure.

Aside from the POST messages, you can determine if the system is in

good condition by checking if the following occur during startup:

• Power indicator on the front panel lights up (green)

• Num Lock, Caps Lock, and Scroll Lock indicators on the keyboard

light up

Turning off the system

To turn off the server, on the Windows task bar click on the Start

button, point to Shut Down..., select Shut down from the drop-down

window then click on OK. You can then turn off all peripherals

connected to your server.

If you are unable to shutdown the server within Windows, press and

hold the power button for at least four seconds to force quit all

applications and shut down.

Page 39

Power-on problems

If the system does not boot after you have applied power, check the

following factors that might have caused the boot failure.

• The external power cable may be loosely connected.

Check the power cable connection from the power source to the

power cable socket on the rear panel. Make sure that the cable is

properly connected to the power source and to the power cable

socket.

• No power comes from the grounded power outlet.

Have an electrician check your power outlet.

• Loose or improperly connected internal power cables.

Check the internal cable connections. If you are not confident to

perform this step, ask a qualified technician to assist you.

Warning! Make sure all power cords are disconnected from the

electrical outlet before performing this task.

Note: If you have gone through the preceding actions and the

system still fails to boot, ask your dealer or a qualified technician

for assistance.

27

Page 40

28

3 Getting Started

Page 41

4 Configuring

the system

Page 42

This chapter discusses the precautionary

measures and installation procedures you

need to know when upgrading the system.

Page 43

31

Upgrading the system

Certain components of the Altos R510 are upgradeable such as the

drives, the CPU, the memory, and the expansion cards. However, for

safety purposes, we do not recommend that you perform these

upgrades yourself. If you want to replace or upgrade any of these

components, contact your Acer dealer or a qualified service technician

for assistance.

Important: Observe the installation precautions described in the

subsequent section when installing or removing a server

component.

Installation precautions

Before you install any server component, we recommend that you read

the following sections. These sections contain important ESD

precautions along with preinstallation and post-installation

instructions.

ESD precautions

Electrostatic discharge (ESD) can damage the processor(s),

motherboard, disk drive(s), expansion board(s), or other components.

Always observe the following precautions before you install server

components:

1 Do not remove a component from its protective packaging until

you are ready to install it.

2 Wear a wrist grounding strap and attach it to a metal part of the

server before handling components. If a wrist strap is not

available, maintain contact with the server throughout any

procedure requiring ESD protection.

Preinstallation instructions

Always observe the following before you install any component:

1 Turn off the system and all the peripherals connected to it.

2 Unplug all cables from the power outlets.

3 Open the system according to the instructions on page 35.

Page 44

32

4 Configuring the system

4 Follow the ESD precautions described in this section when

handling a server component.

5 Remove any expansion board(s) or peripheral(s) that block access

to the DIMM socket or other component connector.

See the following sections for specific installation instructions on the

component you want to install.

Warning! Failure to properly turn off the server before you start

installing components may cause serious damage. Do not attempt

the procedures described in the following sections unless you are

a qualified service technician.

Post-installation instructions

Observe the following after installing a server component:

1 See to it that all components are installed according to the

described step-by-step instructions.

2 Reinstall any expansion board(s) or peripheral(s) that you have

previously removed.

3 Reinstall the chassis panels.

4 Connect the necessary cables.

5 Turn on the system.

Page 45

33

Opening the server

Caution! Before you proceed, make sure that you have turned off

your system and all peripherals connected to it. Read the

“Preinstallation instructions” on page 31.

You need to open the Altos R510 before you can install additional

components. The top panel is removable to allow access to the system’s

internal components. Refer to the following sections for instructions.

Before opening the server

Before opening the server, observe the following precautions:

1 Turn off the system and all the peripherals connected to it.

2 Unplug all cables from the power outlets.

3 Place the system unit on a flat, stable surface.

Note: Because of the R510 design specification, the top panel

needs to be removed to access the system board.

Removing the Chassis Cover

The Altos R510 Server must be operated with the top cover in place to

ensure proper cooling. You will need to remove the top cover to add

or replace components inside of the platform. Before removing the top

cover, power down the server system and unplug all peripheral devices

and the AC power cable. None of the components inside of the

platform is hot-swappable.

1 Observe the safety and ESD precautions at the beginning of this

book.

2 Turn off all peripheral devices connected to the server. Turn off

the server.

3 Disconnect the AC power cord.

4 Remove the shipping screw (A) if it is installed.

Page 46

34

5 While holding the blue button (B) at the top of the chassis in, slide

the top cover back until it stops (C).

6 Lift the cover straight up to remove it from the platform.

4 Configuring the system

B

C

A

Page 47

35

Installing the Chassis Cover

1 Place the cover over the chassis so that the side edges of the cover

sit just inside the chassis sidewalls.

2 Slide the cover forward until it clicks into place (A).

3 (Optional) Insert the shipping screw (B) at the center of the top

cover.

4 Reconnect all peripheral devices and the AC power cord.

A

B

Page 48

36

4 Configuring the system

Removing and Installing the Front Bezel

Removing the Front Bezel

Use the steps below to remove the front bezel.

1 Pull the bezel out from the chassis.

Installing the Front Bezel

Use the steps below to install the Altos R510’s front bezel. The front

bezel is optional.

1 Push the bezel onto the front of the chassis until it clicks into

place.

Page 49

37

Removing and Installing the Processor Air Duct

Always operate your Altos R510’s chassis with the processor air duct in

place. The air duct is required for proper airflow within the chassis.

For instructions on adding or replacing a processor, first remove the

processor air duct and the processor air dam, and then see page 83 for

instructions on processor installations and removals. Return to these

instructions to reinstall the processor air dam and processor air duct

after installing your processor and heat sink.

Removing the Processor Air Duct

1 Remove the chassis cover. For instructions, see "Removing the

Chassis Cover."

2 Lift the processor air duct from its location over the two processor

sockets.

Installing the Processor Air Duct

1 If you are installing the processor air duct for the first time after

installing a second processor, break out the airflow tab over on the

side of the processor air duct that will fit over the CPU2 processor

socket.

2 Place the processor air duct over the two processor sockets,

regardless of whether one or two processors is installed. The front

edge of the air duct should contact the front fan module and the

top of the installed air duct should be flush with the top surface of

Page 50

38

the power supply. Use caution not to pinch or disengate cables

that may be near or under the air duct.

4 Configuring the system

Removing and Installing the Air Baffle

Some installation processes will require that you remove the air baffle

that is placed behind the hard drive bays, next to the fan module near

the front of your server. The steps below describe how to remove and

then install the air baffle. Use these steps only when it is indicated as

necessary for a component installation process.

Always operate your R510 chassis with the air baffle in place. The air

baffle is required for proper airflow within the chassis.

Removing the Air Baffle

1 Observe the safety and ESD precautions at the beginning of this

book. See “Safety Information.”

2 Power down the server and unplug all peripheral devices and the

AC power cable.

3 Remove the chassis cover. For instructions, see “Removing the

Chassis Cover.”

4 Note how the cables are routed over and under the air baffle. You

will need to re-route these cables.

Page 51

5 Pull up on the air baffle to remove it. See the figure below. You

may need to remove or hold cables out of the way.

TP0131

39

Page 52

40

4 Configuring the system

Installing the Air Baffle

1 Lower the baffle into the chassis between the power supply and

the drive bay area, to the left of the fan module.

2 While setting the baffle into place, route the cables beneath it

appropriately.

3 Fit the tab that extends from the front of the baffle under the

drive bay area.

4 Line up the guide pins on the baffle with the matching holes in the

chassis floor and in the backplane if you have a backplane

installed. See letter “A” in the figure below.

5 Push down firmly on the air baffle to secure it to the chassis.

Page 53

41

Installing and Removing a Hard Disk Drive

Up to three hard drives of one of the following types can be installed,

depending on the hard drive installation option used in your server

chassis and the drives supported by your server board.

1 Three fixed SATA drives or three fixed SCSI drives if the fixed drive

kit is installed.

2 Three hot-swap SATA drives if the SATA backplane is installed.

3 Three hot-swap SCSI drives if the SCSI backplane is installed.

NOTE: The Altos R510 does not support all hard drives. Contact

your local Acer dealer for details of supported hardware.

Installing a Fixed SATA Hard Disk Drive

Use these instructions only if you have installed the fixed drive kit.

CAUTION:Fixed drives are NOT hot swappable. Before removing or

replacing the drive, you must first take the server out of service,

turn off all peripheral devices connected to the system, turn off

the system by pressing the power button, and unplug the AC

power cord from the system or wall outlet.

1 Observe the safety and ESD precautions at the beginning of this

book. See “Safety Information.”

2 Power down the server and unplug all peripheral devices and the

AC power cable.

3 Remove the front bezel if it is installed. For instructions, see

“Removing and Installing the Front Bezel.”

4 Remove the chassis cover. For instructions, see “Removing the

Chassis Cover.”

5 Press the latch on the back of the fixed drive carrier and slide it out

of the bay. See letter “A” in the figure below to identify the latch

at the rear of the carrier.

Page 54

42

4 Configuring the system

6 Remove the four screws that attach the plastic retention device or

the previously installed hard drive to the drive carrier. Two screws

are at each side of the retention device or the hard drive. Store the

plastic retention device for future use.

7 With the drive circuit-side down, position the connector end of the

drive so that it is facing the back of the carrier.

8 Attach the hard drive to the carrier using the four screws removed

from the carrier.

Page 55

43

9 Insert the drive into the bay until it clicks into place.

10 If it is not already installed, connect the SATA power cable adapter

to the 3x2 power supply cable that extends from your power

supply. See letters “A” and “B” in the figure below. The power

cable adapter was provided to you with the fixed drive kit.

B

A

Page 56

44

4 Configuring the system

11 For each drive you install, route one SATA data cable from the

server board or add-in card to the hard drive, with the right-angle

end of the SATA data cable connected to the server board or addin card SATA connector. See your server board documentation or

add-in card documentation for assistance in locating the SATA

connectors on the board or add-in card.

12 See letters “C”, “D”, and “E” in the figure below and the arrow

that leads from them to the component in the chassis. This

component is the air baffle that is referred to in the following

steps. The letters “C” and “D” point to the cutouts that are

referred to in the step below. The letter “E” is the tab at the top of

the air baffle.

13 Data cables for drives installed to the right of the air baffle must

be routed through the two cutouts in the top of the air baffle

(letters “C” and “D” in the figure) and under the tab (letter “E”).

The data cable for a drive installed to the left of the air baffle must

be routed through the rear cutout of the air baffle (letter “D”)

and under the tab (letter “E”). You may need to remove the air

baffle to route the cables underneath it. To see how to remove

and then install the air baffle, see “Removing and Installing the Air

Baffle. “

14 Connect the loose end of the data cable to the rear of the SATA

drive. See letter “A” in the figure to identify the location of the

connector at the rear of the SATA drive.

Page 57

A

B

E

D

C

A

15 See letter “B” in the figure below and the arrow that leads from

this letter to the component in the chassis. This component is the

air baffle that is referred to in the following steps. The letter “B”

points to the cutout that is referred to.

16 Power cables for drives installed to the right side of the air baffle

must be routed beneath the front cutout in the underside of the

air baffle. The power cable for a drive installed to the left of the

air baffle does not need to be routed under the air baffle. See

letter “B” in the figure below to identify the air baffle and the

cutout area. You may need to remove the air baffle to route cables

underneath it. To see how to remove and then install the air

baffle, see “Removing and Installing the Air Baffle. “

17 Connect the SATA power cable adapter end(s) to the rear of the

SATA drive. See letter “A” in the figure below to locate the

connector on the SATA drive.

45

Page 58

46

4 Configuring the system

A

B

A

18 (Optional) Install the front bezel. For instructions, see “Removing

and Installing the Front Bezel.”

19 Install the chassis cover. For instructions, see “Installing the Chassis

Cover.”

20 Plug all peripheral devices and the AC power cable back into the

server.

Removing a Fixed SATA Hard Disk Drive

CAUTION: Fixed drives are NOT hot swappable. Before removing

or replacing the drive, you must first take the server out of service,

turn off all peripheral devices connected to the system, turn off

the system by pressing the power button, and unplug the AC

power cord from the system or wall outlet.

Page 59

47

1 Observe the safety and ESD precautions at the beginning of this

book. See “Safety Information.”

2 Power down the server and unplug all peripheral devices and the

AC power cable.

3 Remove the chassis cover. For instructions, see “Removing the

Chassis Cover.”

4 Remove the front bezel if it is installed. For instructions, see

“Removing and Installing the Front Bezel.”

5 Disconnect the SATA data connector and power cables from the

rear of the SATA drive.

6 Press the latch on the back of the fixed drive carrier and slide it out

of the bay.

7 Remove the four screws that attach the hard drive to the drive

carrier. Lift the drive from the carrier. Store the drive in an antistatic bag.

8 If you are not installing a new drive, place the plastic retention

device into the drive carrier, using the four screws you removed

from the hard drive.

9 Insert the screws that held the drive in the carrier into the screw

locations on the carrier for future use.

10 Slide the drive carrier back into the chassis until it clicks into place.

NOTE:For proper airflow, the hard drive carrier must be replaced

in the chassis, even if no hard drive is installed in it.

11 (Optional) Install the front bezel. For instructions, see “Removing

and Installing the Front Bezel.”

12 Install the chassis cover. For instructions, see “Removing the

Chassis Cover.”

13 Plug all peripheral devices and the AC power cable back into the

server.

Page 60

48

4 Configuring the system

Installing a SATA or SCSI Hot-swap Hard Disk Drive

Use these instructions only if you have installed the SATA or SCSI

backplane kit. Please refer to Page 79 for details of how to install the

backplane.

1 Remove the front bezel if it is installed. For instructions, see

“Removing and Installing the Front Bezel.”

2 Press in on the green latch at the front of the hard drive carrier.

See letter “A” in the figure below.

3 Pull out on the black lever and slide the carrier from the chassis.

See letter “B” in the figure below.

B

A

4 Remove the four screws that attach the plastic retention device or

the previously installed hard drive to the drive carrier. Two screws

are at each side of the retention device or the hard drive. Store the

plastic retention device for future use.

Page 61

49

A

5 Remove the hard drive from its wrapper and place it on an

antistatic surface.

6 Set any jumpers and/or switches on the drive according to the

drive manufacturer’s instructions.

7 With the drive circuit-side down, position the connector end of the

drive so that it is facing the rear of the drive carrier.

Page 62

50

8 Align the holes in the drive to the holes in the drive carrier and

attach it to the carrier with the screws that were attached to the

plastic retention device.

9 With the black lever in the fully open position, slide the drive

assembly into the chassis. The green latch at the front of the drive

carrier must be to the right. Do not push on the black drive carrier

lever until the lever begins to close by itself.

10 When the black drive carrier lever begins to close by itself, push on

it to lock the drive assembly into place.

11 (Optional) Install the front bezel.

4 Configuring the system

A

B

Removing a SATA or SCSI Hot-swap Hard Disk Drive

Use these instructions only if you have installed the SATA or SCSI

backplane kit.

Page 63

1 Remove the front bezel if it is installed. For instructions, see

“Removing and Installing the Front Bezel.”

2 Press in on the green latch at the front of the hard drive carrier.

3 Pull out on the black lever to slide the carrier from the chassis.

4 Remove the four screws that attach the hard drive to the drive

carrier. Lift the drive from the carrier. Store the drive in an antistatic bag.

5 If you are not installing a new drive, place the plastic retention

device into the drive carrier, using the four screws you removed

from the hard drive.

6 Insert the screws that held the drive in the carrier into the screw

locations on the carrier for future use.

7 With the black lever in the fully open position, slide the drive

carrier into the chassis. The green latch must be to the right. Do

not push on the black lever until the lever begins to close by itself.

NOTE:For proper airflow, the hard drive carrier must be replaced

in the chassis, even if no hard drive is installed in it.

51

8 When the black lever begins to close by itself, push on it to lock

the drive carrier into place.

9 (Optional) Install the front bezel. For instructions, see “Removing

and Installing the Front Bezel.”

Page 64

52

4 Configuring the system

Installing or Removing a Floppy Drive

Floppy drives are installed in different ways, depending on the

following items:

1 The SATA or SCSI backplane is installed and you want to install the

floppy drive into the slimline drive bay.

2 No backplane is installed and you want to install the floppy drive

into the slimline drive bay.

3 The SATA or SCSI backplane is installed and you have installed a

CD-ROM or DVD/CD-RW drive into the slimline drive bay. You

want to install the floppy drive into a bay that was intended for a

hard drive (optional conversion kit is required).

Look carefully at the heading titles below before beginning your

installation to be sure you are following the correct instructions for

your system.

CAUTION:Floppy drives are NOT hot swappable. Before removing

or replacing the drive, you must first take the server out of service,

turn off all peripheral devices connected to the system, turn off

the system by pressing the power button, and unplug the AC

power cord from the system or wall outlet.

Installing a Floppy Drive into Slimline Bay (Backplane Installed)

Use these instructions if you are installing a floppy drive into the Altos

R510’s slimline drive bay at the upper left side of your chassis and your

system includes either the SATA or SCSI backplane. You will know if

you have one of these backplanes installed if you can install either hotswap SATA or hot-swap SCSI drives.

NOTE: The carrier for the slimline floppy drive that is used in these

instructions was sent to you in the hardware kit that came with

your system.

1 Observe the safety and ESD precautions at the beginning of this

book. See “Safety Information.”

Page 65

2 Power down the server and unplug all peripheral devices and the

AC power cable.

3 Remove the chassis cover. For instructions, see “Removing the

Chassis Cover.”

4 Remove the front bezel if it is installed. For instructions, see

“Removing and Installing the Front Bezel.”

5 Align the two holes at the left side of the floppy drive with the

two cutouts in the floppy drive carrier. See letter “A” in the figure

below.

6 Lower the right side of the floppy drive into the carrier until it

clicks into place. See letter “B” in the figure below.

A

53

B

7 Open the connector on the rear of the floppy drive by pulling up

on the connector cover. See letter “A” in the figure below.

8 Insert one end of the 26-pin floppy drive flat flex cable end into

the connector. See letter “B” in the figure below.

9 Push down on the connector cover to lock the cable into place. See

letter “C” in the figure below.

Page 66

54

4 Configuring the system

10 Slide the floppy drive assembly into the slimeline bay of the chassis

until it clicks into place. See letter “A” in the figure below.

11 Open the connector labeled “Floppy Con” on the backplane by

pulling up on the connector cover. See letter “B” in the figure

below.

12 Insert the loose end of the floppy cable into the backplane

connector. See letter “C” in the figure below.

13 Push in on the connector cover to lock the cable into place. See

letter “D” in the figure below.

14 Install the chassis cover. For instructions, see “Installing the Chassis

Cover.”

15 (Optional) Install the front bezel. For instructions, see “Removing

and Installing the Front Bezel.”

16 Plug all peripheral devices and the AC power cable back into the

server.

Page 67

55

Removing a Floppy Drive from the Slimline Bay (Backplane Installed)

1 Observe the safety and ESD precautions at the beginning of this

book. See “Safety Information.”

2 Power down the server and unplug all peripheral devices and the

AC power cable.

3 Remove the chassis cover. For instructions, see “Removing the

Chassis Cover.”

4 Remove the front bezel if it is installed. For instructions, see

“Removing and Installing the Front Bezel.”

5 Pull up at the top of the connector on the backplane labeled

“Floppy Con” to release the flat flex cable from it.

6 Push in on the blue lever at the rear of the drive carrier.

7 Slide the floppy drive carrier out through the front of the chassis.

8 Remove the flat flex cable from the rear of the floppy.

9 Press downward on the side of the carrier to release the drive from

the drive carrier.

10 Store the floppy drive carrier and the flat flex cable for future use.

11 Install the slimline filler panel into slimline bay if no drive is to be

installed into the bay.

12 Install the chassis cover. For instructions, see “Installing the Chassis

Cover.”

13 (Optional) Install the front bezel. For instructions, see “Removing

and Installing the Front Bezel.”

14 Plug all peripheral devices and the AC power cable back into the

server.

Installing a Floppy Drive into Slimline Bay (No Backplane Installed)

NOTE: The carrier for the slimline floppy drive that is used in these

instructions was sent to you in the hardware kit that came with

your Altos R510 Server Chassis. The interposer board and floppy

Page 68

56

drive power adapter cable used in these instructions was sent to

you with your fixed drive kit.

4 Configuring the system

1 Observe the safety and ESD precautions at the beginning of this

book. See “Safety Information.”

2 Power down the server and unplug all peripheral devices and the

AC power cable.

3 Remove the chassis cover. For instructions, see “Removing the

Chassis Cover.”

4 Remove the front bezel if it is installed. For instructions, see

“Removing and Installing the Front Bezel.”

5 Align the two holes at the left side of the floppy drive with the

two cutouts in the floppy drive carrier. See letter “A” in the figure

below.

6 Lower the right side of the floppy drive into the carrier until it

clicks into place. See letter “B” in the figure below.

A

B

7 Open the connector on the rear of the floppy drive by pulling up

on the connector cover. See letter “A” in the figure below.

8 Insert one end of the 26-pin flat flex cable end into the connector.

See letter “B” in the figure below.

Page 69

57

9 Push down on the connector cover to lock the cable into place. See

letter “C” in the figure below.

10 Open the connector on the interposer board by pulling out on the

connector cover. See letter “D” in the figure below.

11 Insert the loose end of the floppy cable into the interpose board

connector. See letter “E” in the figure below.

12 Push in on the connector cover to lock the cable into place. See

letter “F” in the figure below.

13 Lower the interposer board into the floppy drive tray at the rear of

the floppy drive and engage the notch on the board. See Letter

“A” in the figure below.

14 Attach the interposer board to floppy drive with the screw that

was included with the interposer board. See letter “B” in the

figure below. In the diagram, the flat flex cable been removed for

clarity.

Page 70

58

4 Configuring the system

A

B

15 Slide the floppy drive assembly into the chassis until it clicks into

place. See letter “A” in the figure below.

16 Connect the 2x2 end of the floppy drive power cable that was

included with your kit to the 2x2 power connector on the SATA

power adapter cable. See letters “B” and “C” in the figure below.

17 Connect the remaining end of the floppy drive power cable to the

power connector on the rear of the floppy drive. See letter “D” in

the figure.

18 Connect the floppy drive data cable that was included with your

kit between the floppy drive data connector and the server board.

See letters “E” and “F” in the figure. See your server board

documentation for assistance in locating the connector location on

the server board.

19 Route the floppy drive data cable over the air baffle, as shown in

the diagram below.

Page 71

20

59

F

A

C

B

E

E

D

D

F

B

C

TP01174

21 Install the chassis cover. For instructions, see “Installing the Chassis

Cover.”

22 (Optional) Install the front bezel. For instructions, see “Removing

and Installing the Front Bezel.”

23 Plug all peripheral devices and the AC power cable back into the

server.

Page 72

60

4 Configuring the system

Removing a Floppy Drive from the Slimline Bay (No Backplane Installed)

1 Observe the safety and ESD precautions at the beginning of this

book. See “Safety Information.”

2 Power down the server and unplug all peripheral devices and the

AC power cable.

3 Remove the chassis cover. For instructions, see “Removing the

Chassis Cover.”

4 Remove the front bezel if it is installed. For instructions, see

“Removing and Installing the Front Bezel.”

5 Detach the power and data cables from the rear of the floppy

drive.

6 Detach the data cable from the server board and remove the cable

from the chassis.

7 Push in on the blue lever at the rear of the drive carrier.

8 Slide the floppy drive carrier out through the front of the chassis.

9 Remove the screw that attaches the interposer board to the drive.

Lift the interposer board from the drive.

10 Remove the flat flex cable from the floppy drive and from the

interposer board.

11 Press downward on the side of the carrier to release the drive from

the drive carrier.

12 Store the floppy drive carrier, the interposer board, the flat flex

cable, and the floppy drive data cable for future use.

13 Install the slimline filler panel into slimline bay if no drive is to be

installed into the bay.

14 Install the chassis cover. For instructions, see “Installing the Chassis

Cover.”

15 (Optional) Install the front bezel. For instructions, see “Removing

and Installing the Front Bezel.”

16 Plug all peripheral devices and the AC power cable back into the

server.

Page 73

61

Installing a Floppy Drive into the Converted Hard Drive Bay (Backplane Installed)

The slimline floppy drive conversion kit can only be installed into a

system that is using either the SATA or the SCSI backplane. You will

know if you have one of these backplanes installed if you can install

either hot-swap SATA or hot-swap SCSI drives. The conversion kit must

be installed in the left hard drive bay.

1 Observe the safety and ESD precautions at the beginning of this

book. See “Safety Information.”

2 Power down the server and unplug all peripheral devices and the

AC power cable.

3 Remove the chassis cover. For instructions, see “Removing the

Chassis Cover.”

4 Remove the front bezel if it is installed. For instructions, see

“Removing and Installing the Front Bezel.”

5 Remove the left hot-swap hard drive carrier from the chassis.

6 Remove the screws that attach the slide rails to the floppy drive

conversion kit carrier.

7 Slide the floppy drive into the drive carrier, rear of the drive first,

with the underside of the drive facing down.

8 Line up the holes in the side of the drive with the holes in the

carrier. See letter “A” in the figure below.

Page 74

62

4 Configuring the system

A

A

9 Attach the floppy drive to the carrier with the screws that came

with your floppy drive conversion kit. One screw attaches at each

side.

10 Reattach the slide rails onto the floppy drive conversion kit carrier.

Page 75

63

11 Open the connector on the rear of the floppy drive by pulling up

on the connector cover.

12 Insert one end of the flat flex cable end into the floppy drive

connector.

13 Push down on the connector cover to lock the cable into place.

14 Slide the carrier assembly into the left hard drive bay until it clicks

into place. See letter “A” in the figure below.

15 Open the connector labeled “Floppy Con” on the backplane by

pulling up on the connector cover. See letter “B” in the figure

below.

16 Insert the loose end of the flat flex cable into the backplane

connector. See letter “C” in the figure below.

17 Push in on the connector cover to lock the cable into place. See

letter “D” in the figure below.

Page 76

64

18 Install the chassis cover. For instructions, see “Installing the Chassis

Cover”

19 (Optional) Install the front bezel. For instructions, see “Removing

and Installing the Front Bezel.”

20 Plug all peripheral devices and the AC power cable back into the

server.

4 Configuring the system

Removing a Floppy Drive from the Converted Hard Drive Bay

1 Observe the safety and ESD precautions at the start of this book.

2 Power down the server and unplug all peripheral devices and the

AC power cable.

3 Remove the chassis cover. For instructions, see “Removing the

Chassis Cover.”

4 Remove the front bezel if it is installed. For instructions, see

“Removing and Installing the Front Bezel.”

Page 77

65

5 Open the connector labeled “Floppy Con” on the backplane by

pulling up on the connector cover. Remove the flat flex cable from

the backplane.

6 Push in on the lever at the rear of the floppy carrier and slide the

drive from the front of the chassis.

7 Open the connector cover on the rear of the floppy drive by

pulling up on it. Release the flat flex cable from the drive.

8 Remove the two screws at each side that hold the drive rails to the

drive carrier. Lift the two rails from the carrier.

9 Disconnect the two screws attaching the drive to the converted

hard drive bay carrier.

10 Install an empty hot-swap hard drive carrier into chassis drive bay

if no floppy or hard drive is to be installed into the bay.

11 Store the screws, the converted drive bay carrier, the side rails, and

the flat flex cable for future use.

12 Install the chassis cover. For instructions, see

13 (Optional) Install the front bezel.

14 Plug all peripheral devices and the AC power cable back into the

server.

Page 78

66

4 Configuring the system

Installing or Removing a DVD/CD-RW or CD-ROM Drive

CAUTION: DVD/CD-RW and CD-ROM drives are NOT hot

swappable. Before removing or replacing the drive, you must first

take the server out of service, turn off all peripheral devices

connected to the system, turn off the system by pressing the

power button, and unplug the AC power cord from the

system or wall outlet.

Installing a DVD/CD-RW or CD-ROM Drive into Slimline Bay (Backplane Installed)

NOTE: The carrier for the slimline DVD/CD-RW drive / CD-ROM

drive was pre-installed in the slimline drive bay of your Altos R510

Server Chassis.

1 Observe the safety and ESD precautions at the beginning of this

book. See “Safety Information.”

2 Power down the server and unplug all peripheral devices and the

AC power cable.

3 Remove the chassis cover. For instructions, see “Removing the

Chassis Cover.”

4 Remove the front bezel if it is installed. For instructions, see

“Removing and Installing the Front Bezel.”

5 Push in on the blue lever at the rear of the DVD/CD-RW or CD-ROM

drive carrier and push the carrier out through the front of the

chassis.

6 Align the two holes at left edge of DVD/CD-RW or CD-ROM drive

with the cutouts in drive carrier. See letter “A” in the figure

below.

7 Lower the right side of the DVD/CD-RW or CD-ROM drive into the

carrier until it clicks into place. See letter “B” in the figure below.

Page 79

67

8 Use the two screws indicated in the figure to attach the interposer

board to the DVD/CD-RW or CD-ROM drive. See letters “C” and

“D” in the figure.

9 Attach the 44-pin CD-ROM drive cable to the exposed side / back

of the interposer board. See letter “E” in the figure.

10 Slide the DVD/CD-RW or CD-ROM drive carrier into the chassis. See

letter “A” in the figure below.

11 Connect the loose end of the CD-ROM drive cable to the backplane

connector. See letter “B” in the figure.

Page 80

68

A

12 Install the chassis cover. For instructions, see “Installing the Chassis

Cover.”

13 (Optional) Install the front bezel. For instructions, see “Removing

and Installing the Front Bezel.”

14 Plug all peripheral devices and the AC power cable back into the

server.

4 Configuring the system

B

Removing a DVD/CD-RW or CD-ROM Drive from the Slimline Bay (Backplane Installed)

1 Observe the safety and ESD precautions at the beginning of this

book. See “Safety Information.”

2 Power down the server and unplug all peripheral devices and the

AC power cable.

3 Remove the chassis cover. For instructions, see “Removing the

Chassis Cover.”

4 Remove the front bezel if it is installed.

5 Disconnect the CD-ROM data cable from the backplane.

6 Push in on the blue lever at the rear of the drive carrier. Slide the

drive carrier out through the front of the chassis.

7 Press downward on the side of the carrier release the drive from

the drive carrier.

Page 81

69

8 Disconnect the data cable from the rear of the DVD/CD-RW or CD-

ROM drive.

9 Remove the two screws at the rear of the DVD/CD-RW or CD-ROM

drive to disconnect the interposer board.

10 Store the screw and interposer board for future use. Suggestion:

tape the screw to the drive carrier.

11 Slide the empty drive carrier into the chassis until it clicks into

place.

12 Install the chassis cover. For instructions, see “Installing the Chassis

Cover.”

13 (Optional) Install the front bezel. For instructions, see “Removing

and Installing the Front Bezel.”

14 Plug all peripheral devices and the AC power cable back into the

server.

Installing DVD/CD-RW or CD-ROM Drive into Slimline Bay (No Backplane Installed)

NOTE: The carrier for the slimline DVD/CD-RW drive / CD-ROM

drive was pre-installed in the slimline drive bay of your Altos R510

Server Chassis. The interposer board and floppy drive power

adapter cable used in these instructions was sent to you with your

fixed drive kit.

1 Observe the safety and ESD precautions at the beginning of this

book. See “Safety Information.”

2 Power down the server and unplug all peripheral devices and the

AC power cable.

3 Remove the chassis cover. For instructions, see “Removing the

Chassis Cover.”

4 Remove the front bezel if it is installed. For instructions, see

“Removing and Installing the Front Bezel.”

5 Push in on the blue lever at the rear of the DVD/CD-RW or CD-ROM

drive carrier and push the carrier out through the front of the

chassis.

Page 82

70

4 Configuring the system

6 Align the two holes at left edge of DVD/CD-RW or CD-ROM drive

with the cutouts in drive carrier. See letter “A” in the figure

below.

7 Lower the right side of the DVD/CD-RW or CD-ROM drive into the

carrier until it clicks into place. See letter “B” in the figure below.

8 Use the two screws indicated in the figure to attach the interpose

board to the DVD/CD-RW or CD-ROM drive. See letters “C” and

“D” in the figure.

9 Insert the DVD/CD-RW or CD-ROM drive carrier into the chassis.

See letter “A” in the figure below.

10 If it is not already connected, connect the 2x3 end of the DVD/CD-

RW or CD-ROM drive power cable that was included with your

fixed drive kit to the 2x3 power connector on the SATA power

adapter cable. See letters “B” and “C” in the figure below.

11 Connect the drive power cable to the power connector on the rear

of the DVD/CD-RW or CD-ROM drive. See letter “D” in the figure.

12 Connect the DVD/CD-RW or CD-ROM drive data cable that was

included with your kit between the interposer board and the IDE

connector on the server board. See letters “E” and “F” in the

figure below. See your server board documentation for assistance

in locating the connector location on the server board.

13 Route the DVD/CD-RW or CD-ROM drive data cable over the top of

air baffle, as shown in the diagram below.

Page 83

71

14 Install the chassis cover. For instructions, see “Installing the Chassis

Cover.”

15 (Optional) Install the front bezel. For instructions, see “Removing

and Installing the Front Bezel.”

16 Plug all peripheral devices and the AC power cable back into the

server.

F

C

B

E

D

F

B

C

E

D

A

Page 84

72

4 Configuring the system

Installing and Removing a PCI Riser Connector

CAUTION: PCI riser connectors are NOT hot swappable. Before

removing or replacing the riser connector, you must first take the

server out of service, turn off all peripheral devices connected to

the system, turn off the system by pressing the power button, and

unplug the AC power cord from the system or wall outlet.

Installing a PCI Riser Connector

To install the PCI riser connector, use the following instructions.

1 Observe the safety and ESD precautions at the beginning of this

book. See “Safety Information.”

2 Power down the server and unplug all peripheral devices and the

AC power cable.

3 Remove the chassis cover. For instructions, see “Removing the

Chassis Cover.”

4 Pull up on the two latches on the assembly. See letter “A” in the

figure below.

5 Lift the PCI riser assembly from the chassis.

Page 85

73

6 Line up the screws on the riser assembly with the slot and the large

hole on the riser connector.

7 Press and hold the blue riser locking lever. See letter “A” in the

figure below.

8 Place riser connector onto the retention pins.

9 Slide the riser connector to the right to lock it into place.

10 Release the blue locking lever.

11 Install a PCI add-in card, if desired. For instructions, see “Installing

a PCI Add-in Card.”

12 Position the riser assembly over the PCI sockets on the server board

(see letter “A” in the figure below), lining up the four hooks at the

rear of the riser assembly (see letter “B”) with the four slots in the

rear of the chassis (see letter “C”).

13 Push the riser assembly down until the assembly is securely seated.

Page 86

74

14 Install the chassis cover. For instructions, see “Installing the Chassis

Cover.”

15 Plug all peripheral devices and the AC power cable back into the

server.

4 Configuring the system

Removing a PCI Riser Connector

The PCI riser connector can be replaced if it fails or if a different option

is required. To replace the PCI riser connector, use the following

instructions to remove it, and then follow the instructions under

“Installing a PCI Riser Connector” to install a new riser connector.

NOTE: To eliminate the possibility of installing the replacement

connector on the wrong side of the PCI riser assembly, replace one

connector at a time.

1 Observe the safety and ESD precautions at the beginning of this

book. See “Safety Information.”

2 Power down the server and unplug all peripheral devices and the

AC power cable.

3 Remove the chassis cover. For instructions, see “Removing the

Chassis Cover.”

Page 87