Page 1

EVOLUTION GAS STEAMER

EVOLUTION G asSteame rStart -Up Form

AccuTemp Products, Inc.

Location : ___________________A ddr ess: ________________________________

City:_________________ State: _______ Zip: _________ Ph#________________

SerialNumber _________ ModelNumber:_________________________________

ServiceAgency: ______________________ Technician:_____________________

NOTE:

AccuTempProducts, Inc. is not responsible for theinstallation and/or modifications to the electrical orgas supply

sources.

It is recommended that the wall receptacle be placed aslow as State and Local codes allow.Placement in high heat

zonessuch as, just above, below orbeside the exhaust flue, will causeservice issues that will not becovered under

theproduct warranty.

Ane xternal regulator sh ouldnot be used unless the supplygas pressure is more than 0.5 psig.)

If the altitude is greater tha n2, 000 feet above sea level, conta ct the AccuTemp Technica lS ervices Department to

verifythe correct orificesize for main burner.

1. Isthe steamer beinginstalled at analtitude greater than 2,000 feet?(circle one) Yes/ No

2. Is an external regulator connectedto the steamer? (circle one)Yes /No

3. Isthe 120 Vac or240 Vac wall receptacleposition in alow heat zone. (circleone) Yes / No

4. If the steamer has legs, havethe (4) rubber foot tips been installed?(circle one) Yes /No

5. Is the steamer level ?( circleone) Yes /No

6. Is thesteamer hard connectedto the gassupply line? (circleone) Yes / No

7. If the steameris connected witha flexible hose,is a restraining device used? (circle one) Yes / No

8. Gas Pressure Measurements: Natural : _____ 5” WC (Regulator Valve PressureTap – 1/8” NPT)

Propane: _____ 10” WC (Regulator Valve Pressure Tap –1/8” NPT)

9. Does the steamer operate properly when all gas appliances are operating? (circle one) Yes/ No

10. Verifythe water temperature in COOK MODE ( _______°F)

Iaccept this Start-UpForm as complete and accurate:

___________________________________Restaurant Management Date:___/___/___

Note: This Start-UpFormmust becompletelyfilledout and faxedor mailed to theAccuTempTechnical&

CustomerSupport Department, before thewarranty is activated.

AccuTempProducts, Inc

Attn: Technical& Customer SupportDepartment

8415North ClintonPark

Ft.Wayne, IN 46825

Phone:+1-260-469-0415 or 1-800-480-0415

Fax: +1-260-493-8914

INSTALLATION & OWNERS MANUAL

SERIAL #

MODEL #

Please ll in your Serial # and Model # for quick reference when calling

AccuTemp Technical Service for support.

IMPORTANT WARRANTY INFORMATION

WARRANTY REGISTRATION - STARTUP FORM INSIDE THIS MANUAL MUST BE

REMOVED, COMPLETED, SIGNED BY CUSTOMER AND A COPY EMAILED, FAXED OR

MAILED BACK TO ACTIVATE THE WARRANTY PERIOD.

MP4010-1003

These installation instructions have been prepared for qualied gas and

electric equipment installation personnel, who should perform the installation,

initial eld start-up and complete the equipment adjustments described in this

manual.

REGISTRATION AND STARTUP FORM

EVOLUTION GAS STEAMER

Page 2

This Page Left Intentionally Blank

MP4010-1003

EVOLUTION GAS STEAMER

Page 3

IMPORTANT FOR YOUR SAFETY

The safety instructions listed below on this page should be posted in a

prominent location as a reminder of safe practices as well as recommended

actions to follow in the event of an equipment or facility utility issue.

WARNING

In the event a gas odor is detected, shut down all appliances at the main

gas shut-off valve and contact the local gas company or gas supplier service.

WARNING

WARNING

In the event of a power failure, do not attempt to operate this appliance.

WARNING

Do not store or use gasoline or other ammable vapors or liquids in the vicinity of this or

any other appliance.

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury or death. Read the installation, operating, and maintenance instructions

thoroughly before installing or servicing this equipment.

WARNING

Only qualied service technicians/electricians should perform the installation to ensure

that all electrical and safety requirements are met and that all wiring is performed in

accordance with all national, state and local electrical codes.

MP4010-1003

EVOLUTION GAS STEAMER

Page 4

This Page Left Intentionally Blank

MP4010-1003

EVOLUTION GAS STEAMER

Page 5

EVOLUTION Gas Steamer Start-Up Form

AccuTemp Products, Inc.

Location: ___________________ Address: ________________________________

City: _________________ State: _______ Zip: _________ Ph#________________

Serial Number _________ Model Number: _________________________________

Service Agency: ______________________ Technician: _____________________

NOTE:

AccuTemp Products, Inc. is not responsible for the installation and/or modications to the •

electrical or gas supply sources.

It is recommended that the wall receptacle be placed as low as State and Local codes allow. •

Placement in high heat zones such as, just above, below or beside the exhaust ue, will cause

service issues that will not be covered under the product warranty.

An external regulator should not be used unless the supply gas pressure is more than 0.5 psig.)•

If the altitude is greater than 2,000 feet above sea level, contact the AccuTemp Technical Services •

Department to verify the correct orice size for main burner.

Is the steamer being installed at an altitude greater than 2,000 feet? (circle one) Yes / No1.

Is an external regulator connected to the steamer? (circle one) Yes / No2.

Is the 120 Vac or 240 Vac wall receptacle position in a low heat zone. (circle one) Yes / No3.

If the steamer has legs, have the (4) rubber foot tips been installed ? (circle one) Yes / No4.

Is the steamer level ? (circle one) Yes / No5.

Is the steamer hard connected to the gas supply line? (circle one) Yes / No6.

If the steamer is connected with a exible hose, is a restraining device used? (circle one) Yes / No7.

Gas Pressure Measurements: Natural : _____ 5” WC (Regulator Valve Pressure Tap – 1/8” NPT) 8.

Propane : _____ 10” WC (Regulator Valve Pressure Tap – 1/8” NPT)

Does the steamer operate properly when all gas appliances are operating? (circle one) Yes / No9.

Verify the water temperature in COOK MODE ( _______°F)10.

I accept this Start-Up Form as complete and accurate:

___________________________________ Restaurant Management Date: ___/___/___

Note: This Start-Up Form must be completely lled out, emailed, faxed or mailed to the AccuTemp

Technical & Customer Support Department, before the warranty is activated.

AccuTemp Products, Inc

Attn: Technical & Customer Support Department

8415 North Clinton Park

Ft. Wayne, IN 46825

Phone: 260.469.0415 or 800.480.0415

Fax: 260.493.8914

email: service@accutemp.net

MP4010-1003

EVOLUTION GAS STEAMER

Page 6

This Page Left Intentionally Blank

MP4010-1003

EVOLUTION GAS STEAMER

Page 7

TABLE OF CONTENTS

TABLE OF CONTENTS PAGE 1

DOCUMENT HISTORY PAGE 1

SAFETY WARNINGS INFORMATION PAGES 2-3

INSTALLATION PAGES 4-12

OPERATION - ALL MODELS PAGES 13-16

OPERATION - CONNECTED PAGES 17-18

OPERATION CONNECTIONLESS PAGES 19-20

TROUBLESHOOTING PAGES 21-22

SERVICE PAGE 23

WARRANTY PAGE 24

DOCUMENT HISTORY

CURRENT

REVISION

1003 4/14/10 N/A N/A Initial release of manual

MP4010-1003

DATE PRIOR

REVISION

DATE CHANGE

EVOLUTION GAS STEAMER

1

Page 8

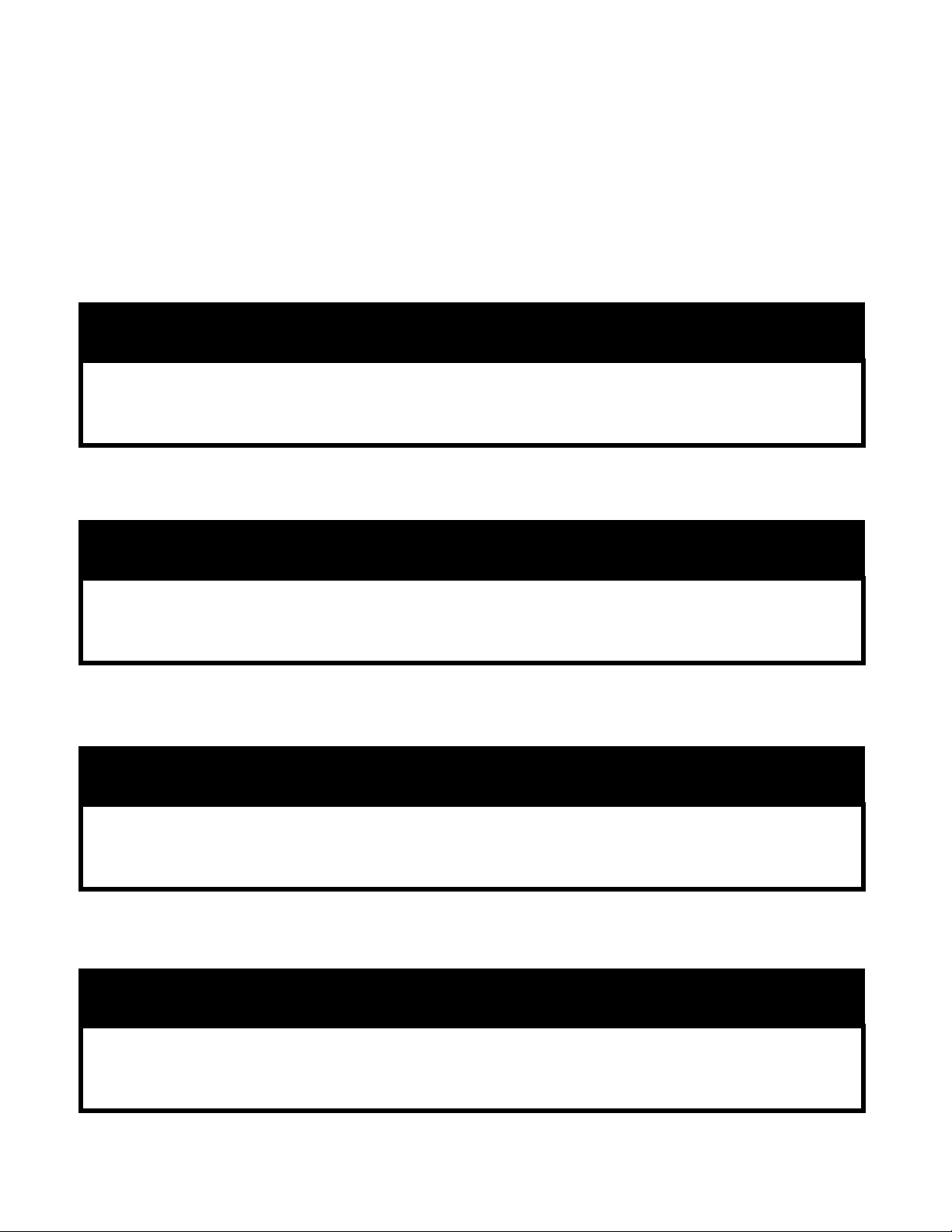

SAFETY WARNINGS

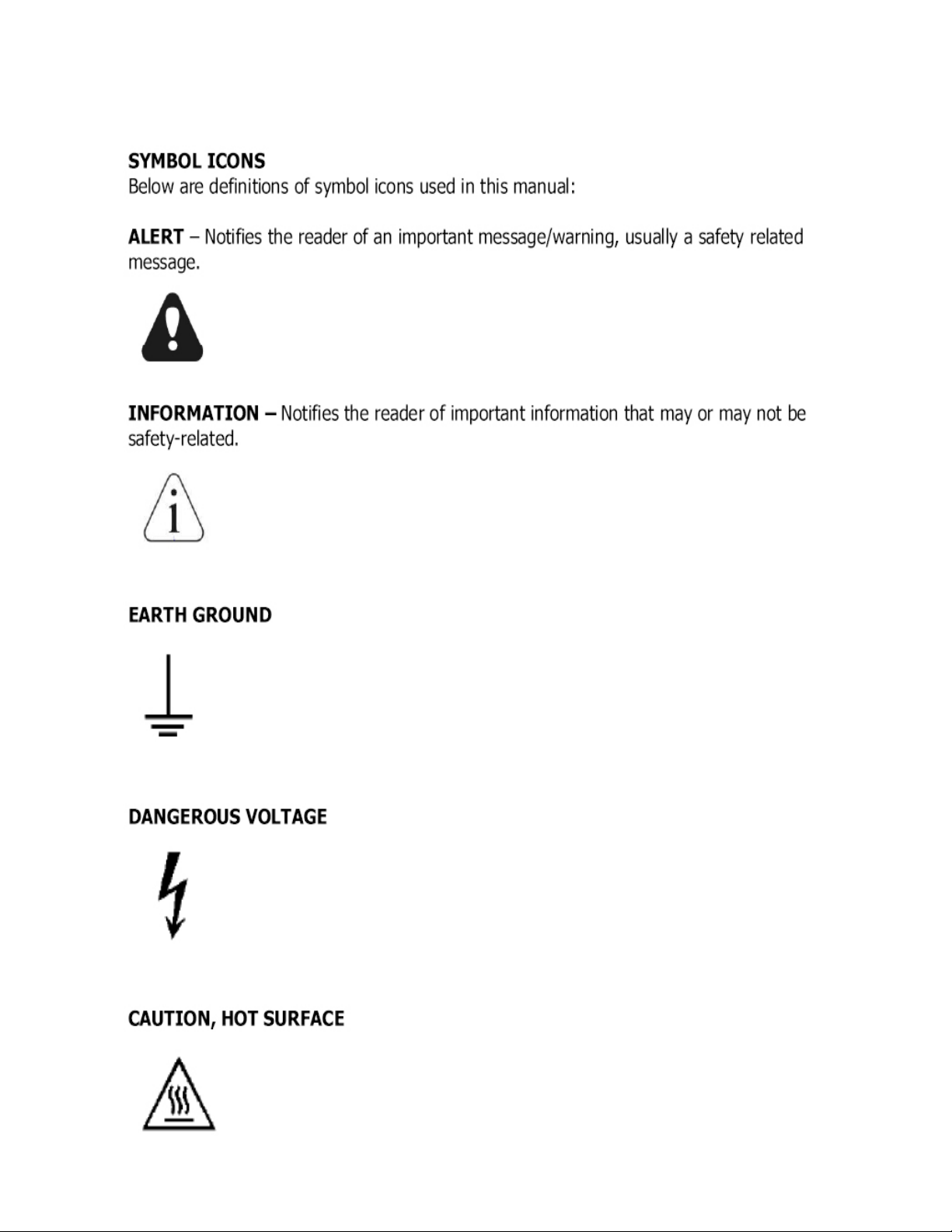

SYMBOL DEFINITIONS

Symbols are used to attract your attention to possible dangers. They are only effective if the operator

uses proper accident prevention measures. Some of the symbols are boxed text, while other maybe

just picture icons. Please give this information the respect they deserve for safe operation.

WARNING TEXT BOXES

Below are denitions of the warning text boxes:

DANGER

Indicates a imminently hazardous situation which, if not avoided will, result in death or

serious injury

WARNING•

Indicates a potentially hazardous situation which, if not avoided, will result in death or

serious injury

CAUTION

Indicates a potentially hazardous situation which, if not avoided will result in minor or

moderate injury

NOTE

Advises reader of information or instructions vital to the operation or maintenance of the

equipment

MP4010-1003

EVOLUTION GAS STEAMER

2

Page 9

SAFETY WARNINGS

MP4010-1003

EVOLUTION GAS STEAMER

3

Page 10

INSTALLATION

Only qualied service technicians/electricians should preform the installation to ensure that all

electrical, gas and safety requirements are met and that all wiring, gas and plumbing installations are

preformed in accordance with all national, state and local codes.

The installation must conform with local codes, or in the absence of local codes, with the National

Fuel Gas Code, ANSA/NFPA 54, or the Natural Gas and Propane Installation Code, CSA B149.1 as

applicable.

The appliance and its individual shutoff must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of 1/2 PSI(3.5kPA)

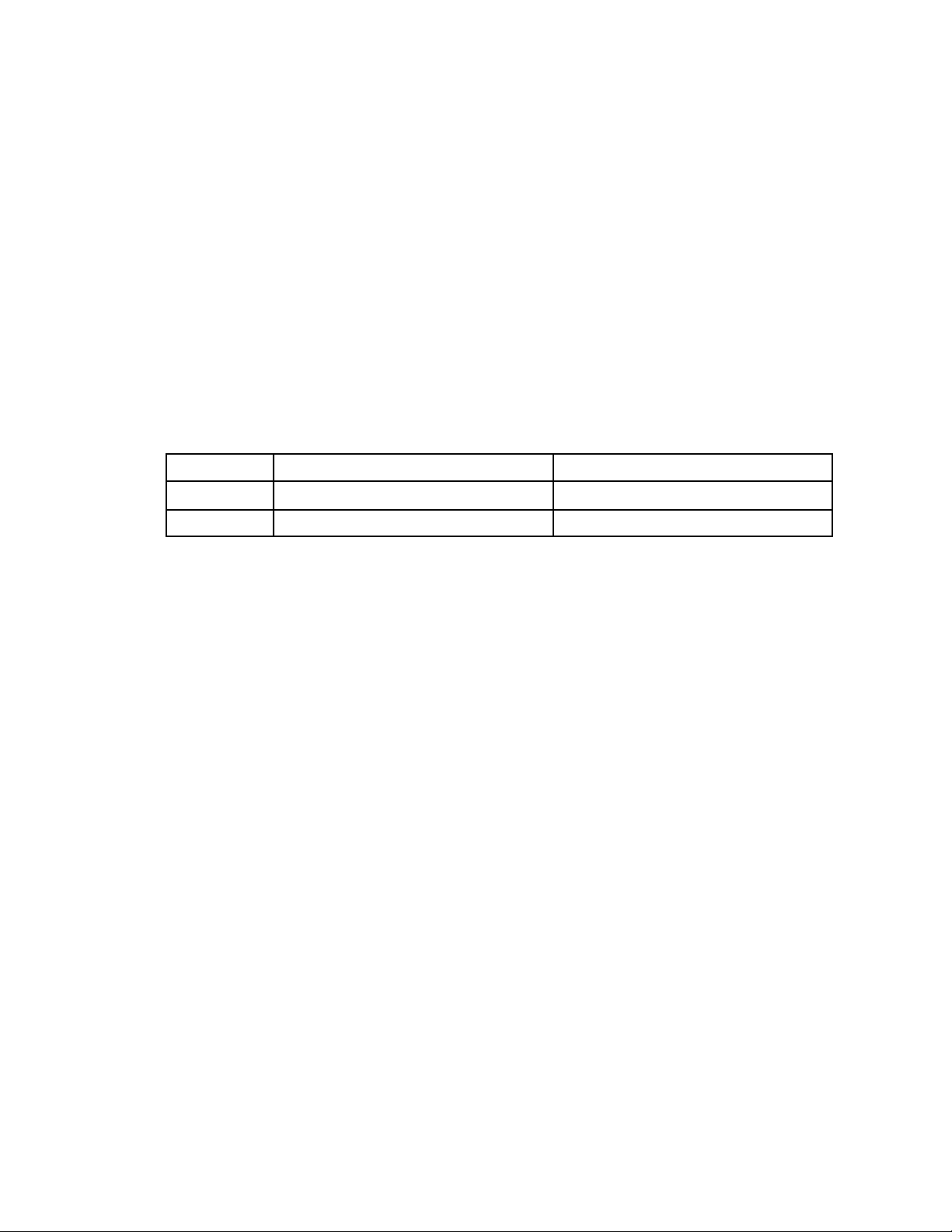

LOCATION AND PLACEMENT

The AccuTemp Evolution gas steamer can be placed on a commercial kitchen counter-top, ush

mounted or installed on a AccuTemp Evolution gas steamer stand. Provisions should be incorporated

in the kitchen to ensure an adequate supply of fresh air for proper combustion and ventilation. See

Fig. 1

EQUIPMENT CLEARANCE

LOCATION COMBUSTIBLE NONCOMBUSTIBLE

SIDES 1” 0”

REAR 2” 0”

Fig. 1

UNPACKING

This appliance was carefully inspected before shipment from the factory. The transportation

company assumes full responsibility for safe delivery to the customer until customer acceptance of

the package. Careful inspection of the packaging and the appliance should be completed before

acceptance from the transportation company.

STEAMER LIFTING

Steamers are heavy enough to require additional manpower or powered assistance when installing or

moving the steamer.

LEVELING

The steamer must be installed in a level condition. An out of level condition may cause erratic operation and damage to the steamer. Damage of this kind is not covered by the limited warranty. Use a

spirit level resting on the top surface of the steamer to ensure it is level front to back and left to right.

COUNTER TOP INSTALLATION

In a counter top installation the steamer is leveled using the adjusters on the legs of the steamer.

Once this is complete it is required that the supplied (4) rubber foot tips must be installed to keep the

steamer from possibly sliding on the counter top under normal use.

STAND INSTALLATION

If a AccuTemp Evolution Gas Steamer Stand is used ensure the oor is level and place the two locking casters to the “ON” position.

All AccuTemp Evolution Gas Steamer Stand with casters, shall be made with a connector that complies with the Standard for Connectors for Movable Gas Appliances, ANSI Z21.69 or CAN/CGA 6.16

and a quick disconnect device that complies with the Standard for Quick Disconnect Devices for Use

with Gas Fuel, ANSI Z21.41 or CAN1-6.9.

MP4010-1003

EVOLUTION GAS STEAMER

4

Page 11

INSTALLATION

WARNING

When using a stand that is equipped with casters, the oor surface must be level and

at. Failure to do so can result in a “tipping” hazard that could result in

serious injury.

STAND INSTALLATION

If a AccuTemp Evolution Gas Steamer Stand is used ensure the oor is level and place the two locking casters to the “ON” position.

All AccuTemp Evolution Gas Steamer Stand with casters, shall be made with a connector that complies with the Standard for Connectors for Movable Gas Appliances, ANSI Z21.69 or CAN/CGA 6.16

and a quick disconnect device that complies with the Standard for Quick Disconnect Devices for Use

with Gas Fuel, ANSI Z21.41 or CAN1-6.9.

SINGLE STEAMER STAND INSTALLATION

The AccuTemp single stand can be equipped with adjustable height feet or non-adjustable casters.

Before mounting a steamer on the stand with casters, engage the two front locking casters, pressing

on the “ON” handle of the brake mechanism. To mount the steamer, carefully lift and place it on the

horizontal mounting brackets ensuring that the (4) mounting holes on the underside of the Evolution

are lined up with mounting holes of the brackets. Then, using a 7/16” wrench, fasten one pair of the

1/4” -20 hex bolt and 1/4” split lock washer through the underside of each stand bracket mounting

hole into the Evolution and tighten securely. With the SNH10 stand, level the steamer by adjusting the

feet found at the ends of each stand leg, either up or down as needed.

DOUBLE STEAMER STAND INSTALLATION

The AccuTemp double stand can be equipped with adjustable height feet or can be equipped with

non-adjustable casters and accommodates (2) E6 model Evolutions. Before mounting a steamer

on a stand with casters engage the brakes on the two front locking casters, pressing on the “ON”

handle of the brake mechanism. Always mount the rst EVOLUTION on the bottom of the stand. To

mount the bottom steamer, carefully lift and place it on the horizontal mounting brackets, ensuring

that the (4) mounting holes on the underside of the Evolution are lined up with the mounting holes on

the brackets. Then, using a 7/16” wrench, fasten one pair of the 1/4"-20 hex bolts and 1/4" split lock

washers through the underside of each stand bracket mounting hole into the Evolution and tighten

securely. Once the bottom steamer has been installed, carefully lift and place the top Evolution

steamer on the horizontal mounting brackets, ensuring that the (4) mounting holes on the underside

of the Evolution are lined up with the mounting holes on the brackets. Then, using a 7/16” wrench,

fasten one pair of the 1/4"-20 hex bolts and 1/4" split lock washers through the underside of each

stand bracket mounting hole and tighten securely. With the SNH20 stand, level the appliances by

adjusting the feet found at the ends of each stand leg, either up or down as needed.

MP4010-1003

EVOLUTION GAS STEAMER

5

Page 12

INSTALLATION

FLUSH MOUNT

To Flush mount the appliance to a counter to:,

Drill 4 holes per above drawing. 1.

Attach the appliance to counter top with (4) 1/4-20 x 3/4” hex head bolts and 1/4-20 split lock 2.

washers.

Apply a bead of high temp food grade silicone caulking around the perimeter and smooth out.3.

Fig.2

STEAMER CONNECTIONS

The Evolution Gas Steamer is available in a connected and connection less models.

Both the connection-less and connected model will require a gas connection and a electrical

connection.

CONNECTED

The connected model in addition to the gas and electrical connection will require a water connection

and access to a oor drain or sink to route a drain hose (not supplied) to allow condensate to be

removed and to drain the steamer when required.

See Fig. for identications of the required steamer connections. See Fig. 3

CONNECTIONLESS

This model must be manually lled with tap water and must be lled throughout the cooking process

to assure consistent cook times. Do not use the “Low Water Indicator” as your indication that this

steamer requires water as this actually turns off the heat to the product thus stopping the cooking

process. A full size steam table pan or a 1/1 gastronome pan must installed in rails under the steamer

any time the steamer is operating and anytime that the steamer is being cleaned or drained of the

water in the cooking chamber. Failure to follow this directions will cause a the steamer to fail which is

not covered under the limited warranty. See Fig. 4

MP4010-1003

EVOLUTION GAS STEAMER

6

Page 13

INSTALLATION

CONNECTED EVOLUTION GAS STEAMER

STEAM EXHAUST VENT

DO NOT CONNECT TO GAS,

DRAIN OR WATER INLET

GAS EXHAUST FLUE

GAS CONNECTION

DRAIN CONNECTION

CONNECTED STEAMERS

ONLY

WATER CONNECTION

CONNECTED STEAMERS

ONLY - 60 PSI MAXIMUM

WATER PRESSURE

MP4010-1003

Fig. 3

EVOLUTION GAS STEAMER

7

Page 14

INSTALLATION

CONNECTIONLESS

OPERATOR KEYPAD

DATA TAG

Drain Pan - Customer

Supplied

DRAIN VALVE

MP4010-1003

Fig. 4

EVOLUTION GAS STEAMER

8

Page 15

INSTALLATION

ELECTRICAL REQUIREMENTS

The electrical voltage requirement is listed on the data plate that is located on the lower left side

panel. All AccuTemp Evolution Gas Steamers are supplied with a power cord and plug that must be

connected to a standard a 15A (120V) or 20A (240V) grounded receptacle. Make sure the voltage

is within 10% of the voltage listed on the steamer data plate. Connection to any other voltage not

identied on the data plate will cause damage to the components and is not covered under warranty.

GROUNDING INSTRUCTIONS

Grounding provides a path for electric current to reduce risk of shock. This product is equipped with

a power cord having a grounding plug. The plug must be plugged into a receptacle that is properly

installed and grounded in accordance with all National, State and local electrical codes or in the

absence of local electrical codes with the National Electric Code, ANSI/NFPA 70, or the Canadian

Code, CSA C22.2 as applicable. Under no circumstances shall the plugs grounding prong be cut or

bent to t a receptacle other than the one specied. Do not use any adapters.

WARNING

This appliance Must be properly grounded, in accordance with all National, State and

local electrical codes.

DANGER

Any in-eld modication made that bypass the safety features of this appliance will

result in serious injury or death.

WARNING

Any in-eld modications made without written authorization from AccuTemp

Products, Inc. will void all written and oral warranties.

MP4010-1003

EVOLUTION GAS STEAMER

9

Page 16

INSTALLATION

GAS CONNECTION - See Fig 5

The Evolution Gas Steamer is manufactured for the use of gas indicated on the data plate. Contact

AccuTemp Products Technical Service Department if your gas supply does not match the gas

indicated on the steamer data plate.

All gas connectors must be in accordance with the local codes and must comply with the latest edition

of the National Fuel Federal Gas Codes, ANSI Z223.1.

A separate gas shutoff valve (not supplied) should be installed in the gas supply line. Use a 1/2” or

larger diameter gas supply line to connect this steamer to the facility supply manifold to ensure a

sufcient volume of gas. The facility supply regulator and manifold must be sized according to the gas

load of all appliances connected to it. If other gas appliances are connected to the supply manifold,

their gas load must be added to the calculations for properly sizing the supply manifold and regulator.

Note: Flexible residential appliance connection hoses are not suitable for this appliance and will void

any warranty.

If your steamer is location is at an altitude of 2000 feet or higher, the orice must be changed to allow

appropriate gas supply to the burners. Please contact the AccuTemp Products Technical Services

Department for assistance.

The steamer is supplied with an internal gas regulator that is set for the gas type and pressures on

the steamer data plate. An external regulator is not required unless the gas supply pressure is more

than 0.5psig. If an external regulator is required it must be rated 125% of the steamer BTUH rate at

the pressure higher than the rated regulated pressure.

Fig. 5

GAS PRESSURE VERIFICATION

The gas supply pressures for the internal regulator must be veried with a calibrated manometer

while the appliance is operating in maximum load condition. A 1/8” NPT tap is provided in the

front of the internal regulator to measure the burner supply pressure. See Fig.6 Use a pipe joint

compound or sealant designed for the use with liqueed petroleum gas when replacing the 1/8”

NPT tap.

Do not use an excessive amount of sealant in order to prevent potential obstruction of the

gas control valve.

GAS PRESSURE ADJUSTMENT

GAS PRESSURE TAP

1. Remove dust cap

2. Turn adjustment screw to

Turn adjustment screw

clockwise to increase

pressure and counter

adjust pressure

Burner must be on before

clockwise to decrease

pressure.

adjusting

Fig. 6

MP4010-1003

EVOLUTION GAS STEAMER

10

Page 17

INSTALLATION

WATER LINE CONNECTION - CONNECTED MODELS

The Installer/Owner is responsible for the water connection of this appliance. This appliance is to be installed

to comply with all applicable federal, state, or local plumbing codes. The installation requires a check-valve

(or other approved anti-back ow / anti-siphon device) (not provided) in all supply lines in accordance with and

as required by local, state, and national health, sanitation, and plumbing codes.

Check local codes to determine exactly what type of anti-back ow / anti-siphon device is •

necessary to meet local requirements.

Design the water supply line so the unit can be moved for service. Install a manual water •

valve between the water supply line and the steamer supply line.

The Garden Hose Thread (GHT) connector used must be suitable for potable water•

Do not apply pipe thread sealant to GHT connections.•

Install a manual water shut-off valve (not provided)•

between the cold water supply line and the

appliance.

Either hot or cold water can be connected to the steamer. If hot is used, temperature •

must be less than 180°F.

A reinforced rubber or braided stainless steel appliance hose rated for the temperature and •

pressure of the water supply with a 3/4” garden hose type connection is required.

The hose must not be sharply bent, kinked or twisted.•

If the steamer is close to a wall, use a right angle tting to prevent kinking the hose•

Flush the water supply lines before connecting the lines to the appliance.•

Connect the water supply lines to the steamer.•

See Fig.7

QUICK DISCONNECT GAS CONNECTION - CUSTOMER

SUPPLIED

WATER LINE CONNECTION - CUSTOMER

SUPPLIED - 60 PSI MAXIMUM WATER PRESSURE

DRAIN HOSE - CUSTOMER SUPPLIED

Fig. 7

MP4010-1003

EVOLUTION GAS STEAMER

11

Page 18

VENTILATION

The steamer produces water vapor along with the extremely hot products of combustion.

Applicable federal, state and/or local plumbing codes will dictate when and if a hood is required.

When installing a gas red appliance in any location, provisions should be made for adequate make

up air. Additionally the appliance should not be positioned in locations where the appliance is subject

to drafts.

Air Supply

It is necessary that enough room air be allowed to compensate for the amount of air removed by any

ventilation system. All gas appliances require sufcient air to operate

Large objects should not be placed around the appliance which might obstruct air ow. Do not

obstruct the ow of combustion and ventilation air.

Do not permit fans to blow at the appliance, and wherever possible, avoid open windows near to the

sides and back of the appliance. Check wall fans to make sure air cross currents are not created in

the room.

DRAIN LINE CONNECTION –CONNECTED MODELS ONLY

Floor Drain

The steamer should be located close to but not over a oor drain. Connect a ¾” ID reinforced rubber

hose rated for 212°F or higher to the drain tting on rear of the steamer with a hose clamp.

Run the hose to the drain. DO NOT directly plumb the steamer to the drain, Leave a one-inch air gap

between the hose and the drain.

Optional Drain Connection

Run the hose to a funnel tting leaving a one-inch gap between the hose and the top of the funnel as

shown in Fig 5. The drain hose must slope toward the oor drain or funnel.

MP4010-1003

EVOLUTION GAS STEAMER

12

Page 19

OPERATION

SAFETY

WARNING

Be sure all operators read, understand and follow the information contained in this

manual including caution warnings, operating instructions and safety instructions.

WARNING

When accessing the cooking chamber, be sure to always stand back while slowing

opening the door to allow the chamber to vent off the steam. Never reach into the cooking

chamber before it has completely vent off the steam

WARNING

Never reach into the cooking chamber or handle hot items without wearing the proper

hot gloves. Steam coming out of the holes on the right side of the cooking chamber is

invisible and can cause severe burns

WARNING

Never use wet or damp gloves as moisture can conduct heat quickly.

WARNING

Never reach into the cooking chamber or handle hot items without wearing the proper

hot gloves. Steam coming out of the holes on the right side of the cooking chamber is

invisible and can cause severe burns

WARNING

Keep the oor in front of the equipment clean and dry. If spills occur, clean immediately

to avoid potential injuries.

WARNING

Do not manually ll water above the water level mark on the left side of the cooking

chamber.

WARNING

Do not use abrasive materials, such as wire brushes, metal scouring pads or to clean the

cooking chamber bottom.

MP4010-1003

EVOLUTION GAS STEAMER

13

Page 20

OPERATION

INTRODUCTION

The AccuTemp Evolution gas steamer uses the time proven method of cooking with steam. Once

the cooking time expires, the steamer can be set to the “Hold Mode”. In this mode, the controller

regulates the internal temperature. At this time, steam is no longer generated and the cooking

chamber is held at the preset temperature at a relative humidity of 100%. This eliminates food from

drying out by suppressing the evaporation of the products natural moisture. As a result, most food

products can be held in a ready-to-serve state for several hours after cooking, with no appreciable

loss in taste, appearance or consistency. See Fig. 8

OPERATOR DISPLAY

& KEYPAD

WARNING INDICATORS

Picture of Evolutin Gas Steamer Front

MAGNETIC DOOR LATCH

DRAIN VALVE

MP4010-1003

Drain Pan - Customer Supplied

Fig. 8

EVOLUTION GAS STEAMER

14

Page 21

On/Off

Fig. 6

High Water Lamp

Timer

Cook or Hold

Operator Display

Pre-Heat mode displayed

Increase Time

Display Temperature

Decrease Time

Low Water

Lamp

Over

Temperature

Lamp

Fig. 8

OPERATION

OPERATION

Fig. 9

Fig. 10

MP4010-1003

EVOLUTION GAS STEAMER

15

Page 22

OPERATION

PARTIAL LOADS

The Evolution is designed to cook quickly with exceptional pan-to-pan uniformity on full loads of food.

Excellent pan-to-pan uniformity can be achieved with partial loads if the pans are optimally placed

in the steamer. For partial loads using 2½” deep pans, the top position in the steamer is used rst

followed by the second pan placed in third pan position from the top and then the third pan in the fth

pan position from the top. (See Fig. 11) Placing the pans in these positions will optimize the cooking

time and pan-to-pan uniformity.

FIRST PAN

SECOND PAN

THIRD PAN

MP4010-1003

Fig. 11

EVOLUTION GAS STEAMER

16

Page 23

OPERATION

DAILY PREPARATION FOR USE - CONNECTED MODELS

Preparing the Evolution Connected model for use each day requires very little time

and effort. Simply verify that the steamer is clean, the water line to the steamer is

turned on and the drain valve is in the closed position. Close the door and push the

ON/Off key on the keypad. The steamer will automatically ll and preheat.

Since the Evolution automatically senses the water level and rells as required.

there is no need to manually ll the steamer.

PREHEATING ( Fig.12)

1) Depress the On/Off Key to turn on the steamer. The display will indicate PrE while

in Cook Mode and the temperature while in the Hold Mode.

2) Once the steamer is preheated and ready to cook, the display will indicate the

COO (Cook Mode) or HLd (Hold Mode).

3) Depress the DISP TEMP button to display the current cooking temperature.

COOKING ( Fig. 13)

1) Depress the COOK/HOLD button to select the Cook Mode (COO).

Fig. 12

2) Open the door and place food into the cooking chamber. Shut the door.

Cooking begins immediately.

3) Timer — Depress the TIMER button and depress the ARROW keys [▲ or ▼] until

the desired time is displayed. The timer starts automatically. At the end of the timed

cycle, a beeper will sound.

4) Depress the DISP TEMP button to display the current cooking chamber

temperature.

HOLDING (Fig. 14)

In “Hold” the steamer temperature is set for 180° F from the factory. The hold

temperature can be changed to a single value for temperatures ranging from

150°F to 190°F if required. Contact the AccuTemp Technical Service Department

for assistance at 800.480.0415 or 260.469.3040. Hold can also be used during

downtimes to save energy and water while keeping the steamer preheated.

1) Depress the COOK/HOLD button to select the Hold Mode (HLd).

2) Open the door and place food into the cooking chamber. Shut the door.

3) Food will be held at the preset holding temperature. The factory setting is set at

180° F.

4) Depress the DISP TEMP button to display the current cooking chamber

temperature.

Fig. 13

Fig. 14

MP4010-1003

EVOLUTION GAS STEAMER

17

Page 24

OPERATIONS

CLEANING - CONNECTED MODELS

WARNING

Warning: Do not use a water jet or pressure washer to clean the steamer

DAILY CLEANING

Turn the steamer off and wait for the steamer to cool.1.

Open the drain valve and allow the cooking compartment to drain completely. Remove the 2.

pan racks, steam collector, overll sensor and condensate tray for cleaning. Wipe the inside

of the cooking chamber, water sensors, pan rails, steam collector, overll sensor, and

condensate tray with a clean cloth. Clean the door gasket, inside of door and front face of the

cooking chamber.

Re-install the overll sensor, steam collector, pan rails and condensate tray. Leave the door 3.

open overnight.

(NOTE: The steamer will not operate without the overll sensor.)

WEEKLY CLEANING

Close the drain valve and add 1 cup (8 ounces or 0.24 liters) of white vinegar to the 1.

cooking compartment. Start the steamer in the Cook Mode. The cooking compartment will

automatically ll with water. After 15 minutes, turn the steamer off and allow the steamer

to cool. Then open the drain valve and allow the water in the cooking chamber to drain

completely.

To rinse close the drain valve and start the steamer in the Cook Mode. The cooking 2.

compartment will automatically ll with water. After 15 minutes turn the steamer off and allow

it to cool. Open the drain valve and let it drain completely.

Remove the pan rails, steam distributor, steam collector, overll sensor and condensate tray 3.

for cleaning. Clean the water sensors with a non-metallic cleaning pad.

Wipe the inside of the cooking chamber, water sensors, pan rails (Fig. 13), steam 4.

distributor (Fig. 13), steam collector (Fig. 13), overll sensor (Fig. 13), and condensate tray

with a clean cloth.

Install the overll sensor and the steam collector , resting the steam distributor on top of the 5.

steam collector align the 4 retaining fasteners and hand tighten, then install the pan rails and

the condensate tray. Leave the door open overnight.

(NOTE: The steamer will not operate without the overll sensor.)

STEAM

COLLECTOR

MP4010-1003

STEAM

DISTRIBUTOR

PAN RAIL

Fig. 15

EVOLUTION GAS STEAMER

OVER FILL

SENSOR

18

Page 25

OPERATIONS

DAILY PREPARATION FOR USE - CONNECTIONLESS MODEL

Preparing the Evolution Connection-Less model for use each day requires very little

time and effort. Simply verify that the steamer is clean, the drain valve is in the

closed position and the cooking chamber is lled with approximately 2½ Gallons of

tap water. Close the door and push the ON/Off key on the keypad. The water level

will need to be monitored and lled as required. Do not use the low water warning

lamp as the indicator to check the water level as this can damage the steamer over

time.

PREHEATING ( Fig. 16)

1) Depress the On/Off Key to turn on the steamer. The display will indicate PrE.

2) Once the steamer is preheated and ready to cook, the display will indicate

COO (Cook Mode) or HLd (Hold Mode).

3) Depress the DISP TEMP button to display the current cooking chamber

temperature.

COOKING ( Fig. 17)

1) Depress the COOK/HOLD button to select the Cook Mode (COO).

2) Open the door and place food into the cooking chamber. Shut the door.

Cooking begins immediately.

3) Timer — Depress the TIMER button and depress the ARROW keys [▲ or ▼]

until the desired time is displayed. The timer starts automatically. At the end of

the timed cycle, a beeper will sound.

4) Depress the DISP TEMP button to display the current cooking chamber

temperature.

HOLDING (Fig. 18)

In “Hold” the steamer temperature is set for 180°F from the factory. The hold

temperature can be changed to a single value for temperatures ranging from150°

F to 190° F if required. Contact the AccuTemp Technical Service Department

for assistance at 800.480.0415 or 260.469.3040. Hold can also be used during

downtimes to save energy and water while keeping the steamer preheated.

1) Depress the COOK/HOLD button to select the Hold Mode (HLd).

2) Open the door and place food into the cooking chamber. Shut the door.

3) Food will be held at the preset holding temperature. The factory default setting is

set at 180° F.

4)Depress the DISP TEMP button to display the current cooking chamber

temperature.

Fig. 16

Fig. 17

Fig. 18

MP4010-1003

EVOLUTION GAS STEAMER

19

Page 26

OPERATIONS

CLEANING - CONNECTIONLESS

WARNING

Warning: Do not use a water jet or pressure washer to clean the steamer

DAILY CLEANING

Turn the steamer off and wait for the steamer to cool.1.

Open the drain valve and allow the cooking chamber to drain completely. Remove the 2.

pan rails (Fig. 17) and steam collector. Wipe the inside of the cooking chamber, water

sensors, pan rails and steam collector with a clean cloth. Clean the door gasket, inside of

door and front face of the cooking chamber.

Install the steam collector and pan rails. Once the water in the drain pan has 3.

sufciently cooled empty the drain pan wipe down and replace . Leave the door open

overnight.

WEEKLY CLEANING

Close the drain valve and add 1 cup (8 ounces or 0.24 liters) of white vinegar to the 1.

cooking chamber and ll with approximately 2½ Gallons of tap water , shut the door and turn

the steamer on.

After 15 minutes, turn the steamer off and allow the steamer to cool. Open the drain valve 2.

and allow the cooking chamber to drain completely.

To rinse close the drain valve, ll with approximately 2½ Gallons tap water , close the 3.

door and start the steamer Cook Mode. Let it run for 15 minutes, turn the steamer off and

allow the steamer to cool. Open the drain valve and allow the cooking chamber to drain

completely.

Remove the pan racks, steam collector and steam distributor for cleaning. Clean the water 4.

sensors with a non-metallic cleaning pad. Wipe the inside of the cooking chamber, water

sensors, pan rails (Fig. 19),steam distributor (Fig. 19), steam collector (Fig. 19).

Install the steam collector rst, resting the steam distributor on top of the collector align the 5.

( 4) retaining fasteners and hand tighten and then install the pan rails. Leave door open

overnight.

STEAM

COLLECTOR

MP4010-1003

STEAM

DISTRIBUTOR

EVOLUTION GAS STEAMER

PAN RAIL

Fig. 19

20

Page 27

TROUBLESHOOTING

WARNING LIGHTS

LOW WATER

The steamer is low on water or the water sensors need to be cleaned.•

HIGH WATER (CONNECTED MODELS ONLY)

There is too much water in the steamer. Open the drain valve and drain water until this •

Indicator lamp goes off.

OVER TEMP

The steamer has overheated. It may have run out of water. Carefully open the door, allowing •

steam to escape and then check the water level in the bottom of the steamer If it is nearly

empty, check the water supply to make sure it isn’t turned off. Clean the water level sensor

probes (white buttons) located in the front left corner and the wall immediately around them

being careful not to get burned (protective gloves are strongly recommended). Turn the

steamer back on and it should rell. If the steamer has plenty of water, allow it to cool. This

normally takes a few minutes. When the Over Temp light goes out, restart the steamer.

Food Is Over Cooked

Check that the proper cook time is being used.•

Food Is Under Cooked

Make sure you are using adequate time a. Extra time may be required if pans are covered or •

if product is left in plastic bags or similar packaging.

Make sure the door is closed. When the door opens the heat is turned off until it is shut•

Make sure the steamer is in the Cook Mode; Push the Display Temperature button to ensure •

the steamer is at the boiling point of water taking into account your elevation above sea

level. If it isn’t the steamer maybe in the Hold Mode. Variations in temperature can also be

caused by frozen product just being put in or with the connected model a fresh measure of

tap water was activated. These will shortly come up to temperature as long as the door is

closed.

—

DO NOT OPEN THE DOOR!

Try using perforated pans as they allow steam to penetrate from all directions, maximizing •

heat transfer and giving you the shortest cooking times. Try distributing the product more

evenly within the steamer and or pans, if possible.

For partial loads using 2½ ” pans the top position in the steamer is used rst followed by the •

third pan position from the top and then the fth pan position from the top. Placing the pans

in these positions will optimize the cooking time and pan-to- pan uniformity.

Make sure the water drain valve on the front of the Evolution is tightly closed.•

The steamer may appear to be cooking normally if the valve is slightly open but efciency •

may be compromised.

Check the door seal for food debris. Food debris on the face of the door seal or under ap •

may cause steamer to appear to be cooking normally but efciency may be compromised.

Nicks or cuts in the door seal may also cause inefcient cooking.•

MP4010-1003

EVOLUTION GAS STEAMER

21

Page 28

TROUBLESHOOTING

Steamer won’t come on

Verify that the steamer is plugged into the proper outlet.•

Verify that the breaker is turned on.•

If the “High Water” warning light is on open the drain valve and drain the water until the light •

goes out.

Verify that the oat is in place.•

Steamer doesn’t heat

If the operator’s display doesn’t light up, See section“ Steamer won’t come on”. •

Verify the steamer door is closed, as the heat won’t turn on if the door is open.•

Steam comes out the door

Verify that the door is completely closed and latched.•

Wait a minute to see if it stops. After the steamer rells with water it is normal for some •

steam to come out the door for a brief amount of time, usually less than one minute.

Steamer Temperature is low

When the steamer automatically rells the fresh water-cools the steamer off for a brief •

period of time, but the steamer will reheat quickly.

If these don’t solve your problem contact our Technical Service Department.

Phone - 800.480.0415 or 260.469.3040•

Email - • service@accutemp.net

Web site - • www.accutemp.net

MP4010-1003

EVOLUTION GAS STEAMER

22

Page 29

SERVICE

INFORMATION

Conventional Steamers require scheduled maintenance (such as boiler maintenance)

at frequent intervals) The Evolution design doesn’t require this type of scheduled

maintenance. It is recommended that you schedule a yearly review of the Evolution

with a AccuTemp Authorized Service Representative to keep your steamer in optimal

operation

INFORMATION

GENERAL SERVICE INFORMATION

All service request during the warranty period of this appliance must be

directed to the AccuTemp Products, Inc. Technical Service Department or the

service call may not be covered by the limited warranty.

WARNING

Only an AccuTemp Products Inc. Authorized Service Personnel or Representative must

perform service. Service performed by unauthorized personnel will void all warranties.

INFORMATION

IMPORTANT SERVICE INFORMATION

AccuTemp Product, Inc. Technical & Customer Support Technician is

available Monday thru Sunday, 7:00am to 7:00pm EST.

800.480.0415 or 260.469.3040

MP4010-1003

EVOLUTION GAS STEAMER

23

Page 30

LIMITED WARRANTY

One Year– Parts and Labor

U.S. & Canada Only

AccuTemp Products, Inc. (AccuTemp) warrants that your AccuTemp equipment will be free of

defects in material and workmanship under normal use for a period of twelve (12) months from

installation or fteen (15) months from date of shipment from AccuTemp, whichever date rst

occurs (the Warranty Period). Registration of AccuTemp equipment is required at the time of

installation. Damage to AccuTemp equipment that occurs during shipment must be reported to

the carrier, and is not covered under this warranty. The reporting of any damage during shipment is

the sole responsibility of the commercial purchaser/user of such AccuTemp equipment.

AccuTemp provides an active service department, which should be contacted and advised of

service issues, regardless of the warranty period. During the warranty period, AccuTemp must be

contacted for warranty repairs and agrees to repair or replace, at its option, F.O.B. factory,

any part which proves to be defective due to defects in material or workmanship, provided

the equipment has not been altered in any way and has been properly installed, maintained,

and operated in accordance with the instructions in the AccuTemp Owners Manual. During the

warranty period, AccuTemp also agrees to pay for any factory authorized equipment service

agency (within the continental United States and Canada) for reasonable labor required to

repair or replace, at our option, F.O.B. factory, any part which proves to be defective due

to defects in materials or workmanship, provided the service agency has received advance

approval from AccuTemp factory service to perform the repair or replacement. This warranty

includes travel time not to exceed two hours and mileage not to exceed 50 miles (100 miles

round trip), but does not include post start-up assistance or training, tightening of loose ttings or

external electrical connections, minor adjustments, maintenance, or cleaning. AccuTemp will not

reimburse the expense of labor required to replace parts after the expiration of the warranty

period.

Proper installation is the responsibility of the dealer, owner-user, or installing contractor and is

not covered by this warranty. Improper installation can affect your warranty. Installation is the

responsibility of the Dealer, Owner/User or the Installation Contractor. See the Installation

section of the Owners Manual. While AccuTemp products are built to comply with applicable

standards for manufacturers, including Underwriters Laboratories (UL) and National Sanitation

Foundation (NSF), it is the responsibility of the owner and the installer to comply with any

applicable local codes that may exist.

AccuTemp makes no other warranties or guarantees, whether expressed or implied, including

any warranties of performance, merchantability, or tness for any particular purpose. AccuTemp

liability on any claim of any kind, including negligence, with respect to the goods and services

covered hereunder, shall in no case exceed the price of the goods and services, or parts

thereof, which gives rise to the claim. In no event shall AccuTemp be liable for special,

incidental, or consequential damages, or damages in the nature of penalties.

This constitutes the entire warranty, which supersedes and excludes all other

warranties, whether written, oral, or implied.

MP4010-1003

EVOLUTION GAS STEAMER

24

Page 31

INFORMATION

IMPORTANT SERVICE INFORMATION

AccuTemp Product, Inc. Technical & Customer Support Technician is

available Monday thru Sunday, 7:00am to 7:00pm EST.

800.480.0415 or 260.469.3040

Phone - 800.480.0415 or 260.469.3040•

Email - • service@accutemp.net

Web site - • www.accutemp.net

MP4010-1003

EVOLUTION GAS STEAMER

Loading...

Loading...