Page 1

INSTALLATION/OPERATORS MANUAL

ACCU-STEAM ELECTRIC G2 GRIDDLE

MODELS

EGF24A

EGF36A

EGF48A

EGF24B

EGF36B

EGF48B

WARNING

Improper installation, alteration,

adjustment,service, cleaning or maintenance

of this commercial appliance could result in

property damage, serious injury or death.

Read and understand the installation,

operational, maintenance instructions

before installing, servicing, or operating this

commercial appliance.

MP5018-1605

AccuTemp Products, Inc. · 8415 North Clinton Park · Fort Wayne, IN 46825 ·800 210-5907 · accutemp.net

Record the serial number, model number

(identication decal located on the left side panel

of the commercial appliance) , voltage and the

install date. Please have this information when

calling for assistance.

Serial Number:

Model:

Install Date:

NOTE

Page 2

TABLE OF CONTENTS

DESCRIPTION PAGE

Document History 1

Safety Warnings 2-3

Specications 4-7

Limited Warranty Policy 8

Warranty Registration Instructions 9

Installation/Operational Checklist & Warranty Registration Form 10-11

Installation Instructions 12-14

Operation Instructions 15-24

Cleaning Instructions 25-26

Planned Maintenance 27-28

Service & Troubleshooting 29-31

Schematics 32-36

Important Contact Information 37

DOCUMENT HISTORY

Current Revision Date Prior Revision Date

MP5018-1605 05/12/2016 N/A

Page 3

SAFETY WARNINGS

SYMBOL DEFINITIONS

Symbols are used to attract your attention to possible dangers. They are only effective if the

operator uses proper accident prevention measures. Some of the symbols are boxed text, while

other maybe just picture icons. Please give this information the respect they deserve for safe

operation.

DANGER

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in minor or moderate injury.

ALERT - Noties the reader of an important message/warning,

usually a safety related message.

Earth Ground

Dangerous Voltage

INFORMATION - Noties the reader of important information that

may or may not be safety related.

MP5018-1605

Caution Hot Surface

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 2

Page 4

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT: Read the following safety installation to avoid personal injury or death and to avoid

damage to the equipment or property

WARNINGS

Plug commercial appliance into a properly

grounded electrical outlet of the correct

voltage, size and plug conguration. If they

do not match, contact a qualied electrician

to determine the proper voltage and size and

install the proper electrical outlet.

To avoid any personal injury or damage to

the unit do not pull the commercial appliance

by the power cord.

To prevent any injury, discontinue any use if

power cord is frayed or worn.

To prevent any injury or damage this

commercial appliance must be installed by a

qualied electrician.

To avoid any injury, turn the power off, unplug

from the power source and allow to cool

before performing any maintenance.

To avoid electrical shock or personal injury,

do not steam clean or use excessive water

on this commercial appliance.

This product has no “user” serviceable parts.

To avoid injury or damage to the commercial

appliance use only Authorized AccuTemp

Service Agents and Genuine Replacement

Parts when service is required.

Genuine AccuTemp Replacement Parts

are specied to operate safely in the

environments in which they are used. Some

aftermarket parts or generic replacements

parts do not have the same specications to

operate safely in AccuTemp equipment. It is

imperative that to use Genuine AccuTemp

Replacement Parts to avoid injury or damage

to the commercial appliance.

Always disconnect from power source before

cleaning or servicing.

Any ineld modication that bypass the built-

in safety features will result in personal injury

or death.

This commercial appliance must be properly

grounded, in accordance with all National,

State or local electrical codes.

This commercial appliance has a totally

unique design and is constructed unlike

any other griddle on the market today. Any

modication may permanently damage the

griddle.

CAUTIONS

This commercial appliance must be level

for proper operation and to reduce possible

damage to this commercial appliance.

This commercial appliance is heavy, for

safe handling, the installer should obtain

help as needed or employ appropriate

material handling equipment to remove the

commercial appliance from the skid and

move to the nal location in the building.

Temperatures in and around the commercial

appliance are very hot and can cause severe

burns.

To avoid damage to the cooking surface

of this commercial appliance do not use

abrasive cleaners such as a griddle stone or

brick.

To avoid personal injury or damage to the

commercial appliance do not use a water jet

to clean this commercial appliance.

To avoid damage to the commercial

appliance do not leave a chlorine sanitizer in

contact with the stainless steel longer than

10 minutes.

To avoid severe burns slowly remove

the grease reservoir to avoid spilling the

contents. It is recommended to let it cool

before removing.

MP5018-1605

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 3

Page 5

Product Warranty

U.S. & Canada Sales Only

LIMITED WARRANTY

One Year Parts and LaborOne Year Parts and Labor

AccuTemp Products, Inc. ( AccuTemp ) warrants that your AccuTemp equipment will be free of defects in

material and workmanship under normal use for a period of twelve (12) months from installation or fteen (15)

months from date of shipment from AccuTemp, whichever date rst occurs (the Warranty Period ). Registration

of AccuTemp equipment is required at time

of installation.

Damage to AccuTemp equipment that occurs during shipment must be reported to the carrier, and is not

covered under this warranty. The reporting of any damage during shipment is the sole responsibility of the

commercial purchaser/user of such AccuTemp equipment.

AccuTemp provides an active service department, which should be contacted and advised of service issues

regardless of warranty period.

During the warranty period, AccuTemp agrees to repair or replace, at its option, F.O.B. factory, any part which

proves to be defective due to defects in material or workmanship, provided the equipment has not been altered

in any way and has been properly installed, maintained, and operated in accordance with the instructions in the

AccuTemp Owners Manual.

During the warranty period, AccuTemp also agrees to pay for any factory authorized equipment service agency

(within the continental United States and Canada) for reasonable labor required to repair or replace, at our

option, F.O.B. factory, any part which proves to be defective due to defects in materials or workmanship,

provided the service agency has received advance approval from AccuTemp factory service to perform the

repair or replacement. This warranty includes travel time not to exceed two hours and mileage not to exceed

50 miles (100 miles round trip), but does not include post start-up assistance or training, tightening of loose

ttings or external electrical connections, minor adjustments, gaskets, maintenance, or cleaning. AccuTemp will

not reimburse the expense of labor required to replace parts after the expiration of the warranty period.

Proper installation is the responsibility of the dealer, owner-user, or installing contractor and is not covered

by this warranty. While AccuTemp products are built to comply with applicable standards for manufacturers,

including Underwriters Laboratories (UL) and National Sanitation Foundation (NSF), it is the responsibility of

the owner and the installer to comply with any applicable local codes that may exist.

AccuTemp makes no other warranties or guarantees, whether expressed or implied, including any warranties

of performance, merchantability, or tness for any particular purpose. AccuTemp s liability on any claim of any

kind, including negligence, with respect to the goods and services covered hereunder, shall in no case exceed

the price of the goods and services, or parts thereof, which gives rise to the claim. In no event shall AccuTemp

be liable for special, incidental, or consequential damages, or damages in the nature of penalties.

This constitutes the entire warranty, which supersedes and excludes all other warranties, whether written, oral,

or implied.

IMPORTANT

Improper installation can affect your warranty. Installation is the responsibility of the Dealer, Owner/

User or the Installation Contractor. See: Section One, Installation of the Owner s Manual.

For Service Call 800-480-0415 or email: service@accutemp.net

MP5018-1605

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 4

Page 6

G2 Electric Tabletop Specications

MP5018-1605

Need Specication Sheets From Sales & Marketing

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 5

Page 7

G2 Electric Tabletop Specications

MP5018-1605

Need Specication Sheets From Sales & Marketing

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 6

Page 8

G2 Electric on a Stand Specications

MP5018-1605

Need Specication Sheets From Sales & Marketing

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 7

Page 9

G2 Electric on a Stand Specications

MP5018-1605

Need Specication Sheets From Sales & Marketing

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 8

Page 10

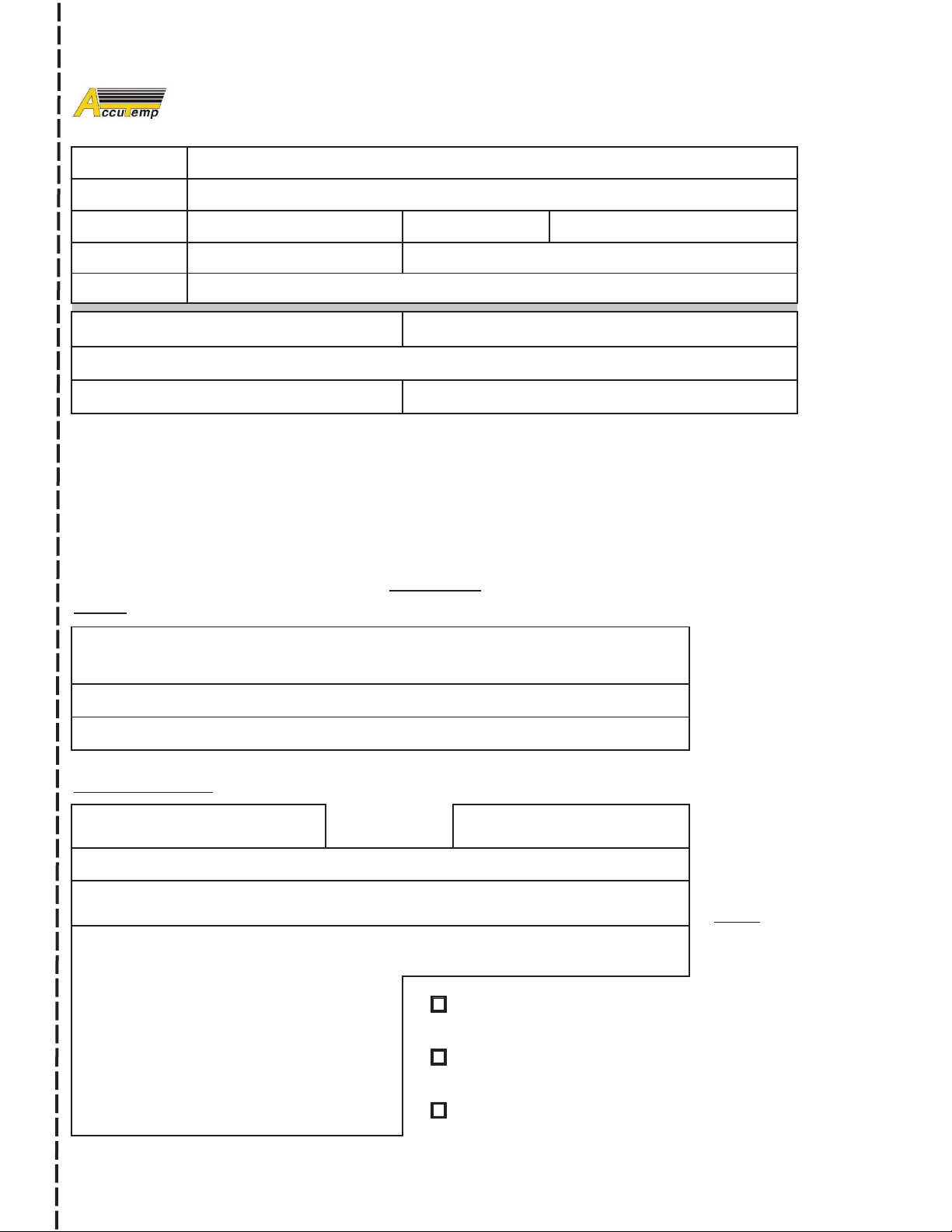

To register this AccuTemp product for warranty complete the following items:

1. Complete the Installation/Operational Checklist and Warranty Registration Form on pages 10-11

2. Mail, fax or scan and e-mail the form to AccuTemp Products, Inc to the contacts listed for each

type on the form.

If you have any questions about warranty registration please contact our technical service group.

They are available 7 days a week from 7:00 am to 7:00 PM EST.

Toll Free 800 480-0415

Ofce 260 469-3040

Fax 260 469-3045

Email -Service service@accutemp.net

Email-Parts parts@accutemp.net

Web Site www.accutemp.net

MP5018-1605

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 9

Page 11

Yes No

Yes No

Yes No

Yes No Yes No

Yes No

Yes No

15-50P

L16-20P

L16-30P

Store/Location:

Address:

Phone Number:

Fax Number:

Check-Off List

Model #

Serial #

Name of Service/Installer Company:

Is the correct NEMA Plug and Receptacle being used on the Supply Power Cord?

General :

Is the electrical wall receptacle positioned in a low heat-zone?

Note: It is recommended that the wall receptacle be

placed as low as State & Local codes allow. Placement in high heat-zones could cause damage to the electrical cord or plug

that would not be covered under the product warranty.

Is the griddle level, both side-to-side and front-to-back?

If this is a table-top installation, have the (4) rubber foot tip/boots been installed?

Electrical Connection :

Is the Supply Power Cord being plugged into a

wall outlet?

Is the Supply Power Cord being hardwired, without the plug, to a breaker box?

Is the Supply Power Cord properly connected to GND?

208/240VAC (All Models)

440/480VAC (24" Models)

440/480VAC (36" & 48" Models)

Type of NEMA Plug?

Installation/Operational Checklist &

Warranty Registration Form

ELECTRIC - ACCU-STEAM™

Failure to accurately complete and provide this Installation/Operational Checklist & Warranty

Registration Form to AccuTemp Products, may delay or void future Warranty Service Calls.

** AccuTemp Products, Inc. is not responsible for the installation and/or modifications to the electrical supply source. **

What is the Electrical Breaker Amperage that will interupt the Supply Voltage to the electric griddle?

AMPS

City:

State:

Zip:

Email:

Technician:

Phone Number:

MP5018-1605

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 10

Page 12

Single Φ

Supply Power Electrical Readings :

Temperature & Operational Verification :

I accept and submit this Installation/Operational Checklist & Warranty Registration Form as complete and accurate:

Restaurant/Facility Manager Approval:

Signature

Printed Name

Date:

Note: If the operating temperature is 250°F, then set Thermostat to 300°F and verify surface temperature. If the operating

Page: 2

Measured Amperage on

Mail

Fax

Email

Installation/Operational Checklist &

Warranty Registration Form

ELECTRIC - ACCU-STEAM™

Does the Supply Electrcial Power match the information on the griddle model number?

Phase (Φ)?

Measured Supply

Voltage?

Each Leg?

What is the customer's normal operating Thermostat temperature for the Griddle?

Note: DO NOT use an infrared or flat-top mercury thermometer.

Using a weighted contact temperature probe with digital thermometer, does the surface temperature (°F)

match the normal operating temperature (°F) set on the Thermostat?

temperature is 400°F, then set Thermostat to 400°F and verify surface temperature does not exceed 396°F on the high side

of the temperature drift/cycle.

Using a 9 square-grid-pattern on the griddle surface, are the surface temperatures consistant (±5°F)?

Does the Griddle heat light cycle OFF/ON once the surface temperature has reached the Thermostat setting?

1Φ =

208VAC 240VAC 440VAC 480VAC

WHT BLK 3Φ = RED WHT BLK

Yes No

Three Φ

°F

Yes No

Yes No

Yes No

Does the unit operate properly for 15 minutes after the griddle has reached operating temperature?

AccuTemp Products, Inc

Attn: Warranty Administration

Attn: Warranty Administration

260 469-3045

Attn: Warranty Administration

8415 North Clinton Park Dr.

Fort Wayne, IN 46825

Yes No

service@accutemp.net

MP5004-1401

MP5018-1605

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 11

Page 13

MODEL G2 ELECTRIC EGF SERIES

TABLE TOP & STAND

INSTALLATION INSTRUCTIONS

MP5018-1605

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 12

Page 14

INSTALLATION

TABLE TOP/STAND MODEL - EGF

WARNING

Improper installation, alteration,

adjustment,service, cleaning or maintenance of

this commercial appliance could result in property

damage, serious injury or death.

Read and understand the installation, operational

and maintenance instructions before installing,

servicing, or operating this commercial appliance.

WARNING

Only a qualied service or electrician should

complete the installation to ensure that all

electrical and safety requirements are met and

that all wiring is installed as per all current

National, State and Local electrical codes.

WARNING

Always disconnect from power source before

cleaning or servicing.

WARNING

This commercial appliance is heavy. For safe handling,

the installer should obtain help as needed or employ

appropriate material handling equipment to remove

the commercial appliance from the skid and move

into the nal destination.

Any in eld modications that bypasses the safety

features could result in injury or death.

IN-FIELD MODIFICATIONS

This commercial appliance has a totally unique

design and is constructed unlike any other griddle

on the market today. Any modication may

permanently damage the griddle.

WARNING

CAUTION

TOOLS REQUIRED:

Spirit Level Clamp Amp Meter

Phillips Screw Driver Weighted Temperature Probe

Small Blade Straight Screw Driver Digital Temperature Meter

Digital Volt Meter

LOCATION AND PLACEMENT

The ACCU-STEAM™ electric griddle has been

designed to be placed on a commercial kitchen

counter-top, an AccuTemp griddle stand or

directly onto any at, level surface that will

support the commercial appliance weight.

The operating temperature ranges from 200°400°F (93°- 204°C). Since these temperatures

can also be found on surfaces around the

perimeter of this commercial appliance, care

should be given not to install next to or against,

objects or surfaces with a low melting or ash

point.

MP5018-1605

Accu-Steam™ G2 Electric Installation and Operators Manual

LEVELING

The commercial appliance must be installed in

a level condition. An out-of-level condition may

cause uneven temperatures and in a severe

out of level condition damage to the commercial

appliance can occur. Use a spirit level resting

on the commercial appliance cooking surface to

ensure it is level front-to-back and left-to-right.

TABLE TOP

Install the (4) rubber foot tips provided with your

commercial appliance onto the four foot adjusters

of each of the commercial appliance legs. This

will keep the griddle from sliding on the counter-

PAGE 13

Page 15

INSTALLATION

top under normal use. Once the rubber foot tips

have been installed, adjust the four foot adjusters

up or down as needed to level the griddle side to

side and front to back.

ACCUTEMP STAND

If on an AccuTemp griddle stand with casters,

ensure that the oor surface is level and place

the two locking casters to the “on” position

and follow the leveling instructions to verify the

commercial appliance is level.

ELECTRICAL SUPPLY

The ACCU-STEAM™ griddle has been designed,

manufactured and tested to meet or exceed

the demanding standards of safety set forth by

Underwriters Laboratories, Inc. To to ensure

that this high level of safety is maintained in

your installation, it is important that you read

and understand the following information before

attempting to plug in your griddle.

be used with the appropriate receptacle.

Direct wiring will void the warranty.

GROUNDING INSTRUCTIONS

Grounding provides a path for electric current to

reduce the risk of shock. This product is equipped

with a power cord having a grounding conductor

and a grounding plug.

WARNING

This commercial appliance must be properly

grounded in accordance of all current National,

state and local codes. Never remove the ground

prong of the plug.

ELECTRICAL CONNECTIONS

The receptacle requirements vary between

models.

• For a 240 V single-phase model, you will need

a NEMA 6-50R receptacle.

ELECTRICAL REQUIREMENTS

Electrical requirements are listed on the data

plate located on the front of the commercial

appliance, . All standard AccuTemp griddles

are supplied with a 6ft (1.83m) cord and the

appropriate UL listed plug. Make sure that the

voltage at your supply receptacle is within ±

10 % of the voltage listed on the griddle data

plate. Connection to any other voltage may

cause damage to components in the commercial

appliance. The commercial appliance plug must

• For a 208/240V three-phase model, you will

need a NEMA 15-50R receptacle.

• For a 440V/480V three-phase model you will

need a NEMA L16-30R receptacle.

See Fig. 1

ELECTRICAL SUPPLY

The ACCU-STEAM™ griddle has been designed, manufactured and tested to meet or exceed the

demanding standards of safety set forth by Underwriters Laboratories, Inc. To to ensure that this

high level of safety is maintained in your installation, it is important that you read and understand the

following information before attempting to plug in your griddle.

ELECTRICAL REQUIREMENTS

Electrical requirements are listed on the data plate located on the right side of the unit, near the front.

All standard AccuTemp griddles are supplied with a 6ft (1.83m) cord and the appropriate UL listed

plug. Make sure that the voltage at your supply receptacle is within ± 10 % of the voltage listed on

the griddle data plate. Connection to any other voltage may cause damage to components in the

commercial appliance. The commercial appliance plug must be used with the appropriate receptacle.

Direct wiring will void the warranty.

240V Single Phase

MP5018-1605

NEMA 6-50R

Accu-Steam™ G2 Electric Installation and Operators Manual

NEMA 15-50R

208/240V 3 Phase

Fig. 1

NEMA L16-30R

440/480V 3 Phase

PAGE 14

Page 16

Page 17

OPERATION

MP5018-1605

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 15

Page 18

OVERVIEW OF OPERATION

INTRODUCTION

The ACCU-STEAM G2™ griddle is constructed and uses technology like no other griddle in the

world. The stainless steel cooking surface is heated by steam. The griddle steam chamber requires

no additional liquid or maintenance. A temperature sensor to sense temperature and a the over temp

safety shutdown system are part of the griddle assembly. At temperatures below 212°F (100°C),

the chamber is actually in a vacuum, similar to that of a canning jar. At temperatures above 212°F

(100°C), the chamber operates under pressure. The temperature sensor senses the temperature of

the steam and reports this data to the temperature control electronics, which energizes the heating

system. This system maintains the griddle cooking surface temperatures to within ± 5°F (2.7°C) over

the entire cooking surface and provides a near instant temperature recovery, even in the same spot

on the griddle, when turning food in place. (See Fig. 2)

MP5018-1605

Fig. 2

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 16

Page 19

OVERVIEW

Data Tag

Stainless Steel Cooking Surface

Overll Grease Drawer Hole

Display/Operational Keypad

Grease Drawer

Data Tag

Adjustable Bullet Feet

Fig. 3

MP5018-1605

Operation/Fault Indicators

Display/Operational Keypad

Fig. 4

Tech Support Contact Info

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 17

Page 20

Overview Digital Temperature Control

OPERATION

The commercial appliance digital temperature control is easy to operate and requires lile

customer interface.

OPERATOR DISPLAY AND KEYPAD

OPERATOR DISPLAY

200F

LED 1

PROGRAM KEY

PROGRAM KEY

LED 3

LED 2

PRESET TEMP 1 KEY

PRESET TEMP 2 KEY

TEMPERATURE

DISPLAY KEY

ON/OFF

KEY

Fig. 5

MP5018-1605

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 18

Page 21

General

OPERATION

This commercial appliance has a digital control temperature board that has two modes of

operation.

• Operational Mode

• Manager Mode

Operational mode is the most used mode and

the commercial appliance operates as the

keyboard overlay indicates during day to day

product production. (See Fig. 5)

Operational Mode Key Functions

ON/OFF Key - Dual Function Key; In the off

mode when pressed it turns on the griddle.

When on pressing and holding the key for ve

seconds turns the commercial appliance off.

Up Arrow Key - This key when pressed will

increase the set cooking temperature.

Down Arrow Key - This key when pressed

will decrease the set cooking temperature.

PRESET TEMP 1 Key - When pressed

and held for three seconds the system will

select the preset set temperature that was

set previously or the factory default of 375°F.

LED 2 will ash and the display will show the

current temperature and increase or decrease

depending on the set temperature until it

has reached the set preset temperature for

that preset key and then go solid and the set

display temperature will remain at the set

temperature until the commercial appliance

is turned off and back on. As the temperature

cools or product is added LED 2 will ash

indicating that the heating system is on and

will go solid when the set temperature is

reached.

has reached the set preset temperature for

that preset key and then go solid and the set

display temperature will remain at the set

temperature until the commercial appliance is

turned off and back on. As the temperature

cools or product is added LED 3 will ash

indicating that the heating system is on and

will go solid when the set temperature is

reached.

Display Temperature Key-When

pressed displays the current temperature

of the cooking surface.

Manager Mode Programming

Prior to using the commercial appliance a few

operational items need to be determined.

• Default set temperature

• Preset 1 set temperature

• Preset 2 set temperature

• Operator lockout of set temperatures or “on

the y” temperature set

Default Set Temperature - is the temperature

that the commercial appliance will heat up to

when turned on.

Preset 1 Set Temperature - is an alternative

set temperature that the commercial appliance

will heat up to when activated from the keypad.

Preset 2 Set Temperature - is an alternative

set temperature that the commercial appliance

will heat up to when activated from the keypad.

Set Temperature Lockout - If turned on

in the manager mode it will lock in the set

temperatures that were last saved in memory.

If not set to active the set temperatures can be

set lower or higher than the last saved value.

PRESET TEMP 2 Key - When pressed and

held for three seconds the system will select

that preset set temperature that was set

previously or the factory default of 400°F.

LED 3 will ash and the display will show the

current temperature and increase or decrease

depending on the set temperature until it

MP5018-1605

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 19

Page 22

OPERATION

070F

375°F

350F

Fig. 7Fig. 6

Press the ON/OFF switch (See FIG 1) and

the griddle will start to pre-heat and LED 1 will blink

Any time the commercial appliance is turned on it

will operate and heat to the default set temperature.

(Factory default is 350°F.)

The display will show the current temperature until

the set temperature is met, then LED 1 will go solid.

(See Fig. 6) The display will remain at the set

temperature unless the griddle is turned off and

back on.

As with any cooking commercial appliance the

temperature will drop as new product is added and

the griddle will activate the heating cycle. LED 1

will blink until the set temperature is reached and

then go solid. The display will remain at the set

temperature unless the commercial appliance is

turned off and back on.

PRESETS

Press the ON/OFF switch (See Fig. 6) and the

griddle will start to pre-heat and LED 1 will blink .

Press and hold any PRESET KEY or

(See Fig. 7) for three seconds or until the LED 2 or LED

3 blinks.

The selected preset LED will blink and the display will

show the current temperature and increase or decrease

depending on the set temperature until it has reached

the set preset temperature for that preset key and then

go solid and the set display temperature will remain at

the set temperature until the griddle is turned off and

back on. This cycling of the LED will continue as long

as the commercial appliance is on.

The factory defaults for the preset keys are:

400°F.

MP5018-1605

Please use caution as temperatures on and around the griddle

cooking surface could cause severe burns.

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 20

Page 23

DIGITAL TEMPERATURE CONTROL QUICK REFERENCE

MODE LED Indicators DISPLAY NOTES

Off All LED’s are off when

powered down.

Warm Up / Cool

Down

Ready Mode LED above the

Set Temperature

(On the y)

Select Preset

Temperature

Set Preset

Temperature

Blinking LED

above the selected

temperature key (LED

1, 2 or 3). If default

condition then LED 1.

If Preset 2 is selected

then LED 3 If Preset 1

then LED 2

selected key will be

ON

All indicator LEDs

blinking

Selected Preset

indicator LED blinking

All indicator LEDs

blinking. Then the

selected preset key

will blink for 3 -5

seconds.

Off when powered down.

When powered On, the

controller would FLASH

at a 1 Hz rate the current

set temperature for 5

seconds. After this period

the controller would go

to Warm Up / Cool Down

Mode.

Actual temperature when

no keys depressed, or set

temperature of

Preset/Manual key when

key is held.

Cook set point temperature

when no keys depressed,

or set temperature of

Preset/Manual key when

key is held.

Set Point Value To set temperature, press either the UP

Set Point Value To select an alternate preset temperature, if

Set Point Value Use the same process to change the

To turn unit on: depress the On/Off key.

To turn off the unit, disable outputs, save

the current set point temperature (see

details in “Other Features”) and turn off the

display: press and hold the On/Off key for

approximately ve seconds.

Upon power-on or whenever another

temperature setting is made, the unit will

enter this mode and will exit this mode only

when the actual temperature has regulated.

Once has regulated, the indicator LED above

the selected key will go to solid ON and the

set point value will be displayed.

arrow key or the DOWN arrow key and hold

for approximately 3 seconds. The controller

will load and display Default Cook Temp

and enter set temperature mode. Press the

UP arrow key to increment or the DOWN

arrow key to decrement from the current

temperature setting. Wait for ve seconds.

If there are no other key presses, the unit will

auto start to the new setting. Press the On/

Off key to exit without saving.

in Preset Temp 1 setting, press Preset Temp 2

key and hold for approximately 3 seconds. If

in Preset Temp 2 setting, press Preset Temp 1

key and hold for approximately 3 seconds.

temperature as detailed in Set Temperature

(On the y) to adjust the Set Temperature.

Once the correct temperature is displayed,

and before the ve second time out, press

and hold the Preset Temp 1 key or the Preset

Temp 2 key to save the displayed value to

the desired preset key and to exit this mode.

Press the On/Off key to exit without saving.

Default values for Preset 1 = 375°F. Default

values for Preset 2 = 400°F

MP5018-1605

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 21

Page 24

DIGITAL TEMPERATURE CONTROL QUICK REFERENCE

MODE LED Indicators DISPLAY NOTES

Display

Temperature

Mode

User Lockout

Mode

(Managers Mode)

Current Temperature

function LED on

All LEDS on solid Set Point Value To Set USER LOCKOUT mode, press and

Actual temperature Pressing the DISPLAY TEMP key will display

the current actual temperature when the unit

is in Ready Mode.

hold the On/Off key and the DISPLAY TEMP

key for approximately 4 seconds while the

controller is ON. After 4 seconds, the USER

LOCKOUT parameter will toggle and the display will show either “Loc” or “ULoc”. When

buttons are released, the controller will store

the new USER LOCKOUT parameter value

into NVM.

MP5018-1605

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 22

Page 25

OPERATION

FIRST STEP

It is recommended that you clean your

ACCU-STEAM™ griddle thoroughly before using

it for the rst time. To clean the griddle surface,

just simply wash the cooking surface down with

a solution of mild soap and water, then rinse

thoroughly with clean water and wipe dry with a

clean towel.

WARNING

Please use caution as temperatures on and around

the griddle cooking surface could cause severe

burns.

SEASONING

Once the cooking surface has been cleaned,

turn the commercial appliance on via the digital

control key pad and set temperature to 200°F.

(93°C), and allow the griddle cooking surface to

heat for 10 minutes. Using a high temperature

oil, such as Pan and Grill Shortening™, Whirl™

or equivalent, pour enough to cover the entire

griddle surface. Do not use standard vegetable

oil to season the griddle cooking surface. It

may cause food to stick and result in improperly

cooked food. Work this seasoning oil into the

griddle surface with a regular heavy-duty scrub

pad for about 5 minutes, making sure that you

scrub the seasoning oil over the entire griddlecooking surface. After the entire griddle surface

has been scrubbed with seasoning oil for 5

minutes, simply wipe or squeegee off excess oil

from griddle surface. Your griddle is now ready to

use!

If you use chemicals to clean your griddle

periodically or on a schedule, you may need

to repeat this process after the use of these

chemicals.

griddle will be preheated when the selected set

temperature is displayed and the corresponding

LED goes solid. Please use caution as

temperatures on and around the griddle cooking

surface could cause severe burns.

COOKING

Begin cooking only after the griddle has been

preheated to the desired temperature. Please

note these facts:

• You can cook all the way to the edges of the

cooking surface because the temperature

does not very across the entire cooking

surface.

• You can turn the product to the same spot

because the cooking surface has near

instant heat recovery.

• It will always cook the same, regardless of

product load or surface coverage.

Accurate Cooking Temperatures

Because of the inaccurate surface temperatures

and long recovery times common with other

griddles cooking surfaces. It is doubtful you were

cooking at the set temperature or the temperature

you wanted. Adjust the temperature on the

Accu-Steam ™griddle and it will not change or

vary by the location on the griddle surface. There

are no hot or cold zones.

CHECKING SURFACE TEMPERATURE

This griddles digital temperature control and

temperature sensor are more accurate than any

other device to measure the surface temperature.

Any other digital device may show a difference.

The important use of the external temperature

measuring device is to ascertain that the

temperatures are within ±5°F across the entire

surface of the griddle.

PREHEATING

Press the ON/OFF and set the desired

temperature. The griddle will increase its surface

temperature at an average rate of 15° F (8°C)

per minute. It takes approximately 25 minutes

to raise the griddle from room temperature to its

maximum temperature of 400° F (204°C). The

MP5018-1605

Accu-Steam™ G2 Electric Installation and Operators Manual

Due to the construction material of the cooking

surface an infrared temperature probe can’t

be used. The proper measurement tools to us

is a weighted temperature probe and digital

temperature meter. (See Fig. X3)

PAGE 23

Page 26

OPERATION

It is normal for the heat light to cycle on and off.

This light indicates when the heaters are

energized. This will be more noticeable as you add

cold product to the cooking surface. You will soon

notice how little they are energized to maintain

perfect surface temperatures on your griddle.

Weighted Temperature Probe

Fig. 8

NOTE

Do not use an infrared or a mechanical temperature

gauge to measure the surface temperature of the

griddle as it will not be accurate and will provide a

false temperature reading of the cooking surface

temperature.

Digital Temperature Reading Device

WARNING

The grease can contents could cause severe burns. Slowly remove the grease

container from the commercial appliance to avoid spilling the contents.

Grease Container

The grease container is located on the front

right side of the commercial appliance and has

a gripping handle on the front and the inside

middle to assist in safely managing the hot

contents. Use caution when emptying the grease

pan as contents in this container could cause

severe burns. The grease container should be

checked periodically and emptied as necessary

to prevent an overow or dangerous condition.

To assist in indicating an overll condition a hole

located on the front of the container will allow

grease to escape when overlled.

WARNING

Allow the grease container contents to cool

below 140°F before removing. Be careful not

to spill the contents of the grease container as

it can cause a slipping condition which could

cause a personal injury

MP5018-1605

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 24

Page 27

CLEANING

WARNING

Always disconnect from power source before

cleaning or servicing.

WARNING

If the cooking surface of the commercial appliance

has standing grease and the griddle is at a

high temperature using water or ice can cause

the grease to splatter and cause skin burns.

WARNING

The grease can contents could cause severe

burns. Slowly remove the grease can from

the griddle to avoid spilling the contents.

MP5018-1605

Accu-Steam™ G2 Electric Installation and Operators Manual

CAUTION

Do not use a water-jet to clean this

commercial appliance as it can

harm the electronic components.

CAUTION

Do not use a commercial appliance

stone or brick to clean griddle cooking

surface. Only use a fabric scrub pad.

PAGE 25

Page 28

DAILY CLEANING

Cleaning the cooking surface during the work

shift can be performed with a sharp scraper.

When heavy cleaning at the end of a shift or

periodically through the day is needed, the

following is recommended:

• Empty the grease pan as often as needed

and always prior to end of shift cleaning.

• Turn the griddle off and allow it to cool

to between 220°F and 240°F (104°C

and 116°C). Scrape off heavy deposits

and remove any standing grease before

proceeding with the cleaning process.

• Use water, ice and/or griddle cleaner as

needed. For example, the 3M ScotchBrite™ Quick Clean Griddle System

provides the Scotch-Brite polishing

pads, quick clean liquid, pad holder and

squeegee. Clean-up is very easy using

these tools with the quick clean liquid,

water, ice or combinations of these liquids.

Seasoning the cooking surface after the

daily cleaning is recommended.

• After the non-cooking surfaces are cool to

the touch. Empty the grease pan and wash

with a mixture of dish detergent and clean

water and dry with a clean dry cloth.

• Clean the non-cooking surfaces with a

damp cloth and dry with a clean dry cloth.

Use a high quality stainless steel cleaner

on a clean cloth to reduce grease buildup.

Follow the manufacturers instructions

located on the cleaner.

• It is recommended that a high quality

stainless steel polish be used on the

non-cooking surfaces as the last step in

keeping surfaces in new like condition and

lengthen the usable life of this commercial

appliance. Follow the manufacturers

instructions located on the polish.

Cleaning the Cooking Surface

Step 1

Scrape off Heavy Deposits

Step 2

Cool griddle to 220°F and apply

water or ice. Use a long handled

nonmetallic scrub to scrub the

cooking surface.

Step 3

Add additional water or ice and

using a long handle squeegee and

pull to the grease trough.

MP5018-1605

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 26

Page 29

Planned Maintenance

WARNING

Always disconnect from power source before

cleaning or servicing.

WARNING

Any in-eld modication that bypass the built in safety

features of this commercial appliance will result in

death or serious injury.

WARNING

Use of any replacement parts other than those supplied

by AccuTemp can cause injury to the operator or damage

the commercial appliance and voids all warranties

MP5018-1605

Accu-Steam™ G2 Electric Installation and Operators Manual

WARNING

There are no user-serviceable parts. To prevent

electrical shock do not open the access panel

covers

NOTE

Service should be completed by AccuTemp

authorized service groups. Service completed

by unauthorized groups will void all factory

warranties.

NOTE

AccuTemp Technical Service must be contacted for

all warranty service requests. If not the warranty claim

maybe denied.

PAGE 27

Page 30

PM TASK DESCRIPTION

Daily Biannual Yearly

Verify that the appliance is level and properly located under the

hood.

Verify that the temperature controller is working properly, that

there are no rips in the label.

Check that the splash shield at the top of the control panel is under the rail provided. If not water and or grease can migrate into

control panel.

Inspect the control compartment for foreign particulate and any

loose wiring or connections.

Check that the power supply cord is not frayed, outer covering is

not degraded or any bare cooper is visible. Replace if required.

Verify amp draw to listed amp requirements on the data tag of the

appliance.

If on an AccuTemp Stand verify mounting fasteners are in place

and tight. If not correct. If the stand has casters check that the

wheels are intact and that they mounted correctly. If grease

covered clean with a mild detergent and clean water. Dry

completely . Apply a food grade silicone to the locking mechanism.

X X

X X X

X X

X X

X X X

X X

X X X

Complete a 9 point temperature test to check for even

temperature across the surface of the cooking surface.

Check for grease buildup in the grease drawer container and

clean it with a damp towel saturated with a mild detergent and

clean water. Dry with a clean dry towel.

After all metallic areas are cool to the touch Clean external metal

surfaces except the cooking surface. with a damp clean towel

saturated with a mild detergent and clean water. Dry with a clean

dry towel.

Season the cooking surface as as outlined in this manual.

X X

X X X

X X X

X

MP5018-1605

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 28

Page 31

SERVICE & TROUBLESHOOTING

WARNING

Always disconnect from power source before

cleaning or servicing.

WARNING

Any in-eld modication that bypass the built in safety

features of this commercial appliance will result in

death or serious injury.

WARNING

Use of any replacement parts other than those supplied

by AccuTemp can cause injury to the operator or damage

the commercial appliance and voids all warranties

MP5018-1605

Accu-Steam™ G2 Electric Installation and Operators Manual

WARNING

There are no user-serviceable parts. To prevent

electrical shock do not open the access panel

covers

NOTE

Service should be completed by AccuTemp authorized

service groups. Service completed by unauthorized

groups will void all factory warranties.

NOTE

AccuTemp Technical Service must be contacted for

all warranty service requests. If not the warranty claim

maybe denied.

PAGE 29

Page 32

SERVICE AND TROUBLESHOOTING

An AccuTemp Products, Inc. Technical Service Technician is available:

Monday thru Sunday, 7:00am to 7:00pm EST.

Toll Free 800 480-0415

Ofce 260 469-3040

Fax 260 469-3045

Email -Service service@accutemp.net

Email-Parts parts@accutemp.net

Web Site www.accutemp.net

WARRANTY SERVICE PROCEDURE

• Contact the AccuTemp Technical Service group for all warranty service requests.

• Be prepared to supply the serial number, address, location phone and contact for the location.

• Be prepared to complete a few simple tasks to help evaluate the problem.

• If the problem requires service at the location the AccuTemp Technical Service group will dispatch

the nearest authorized service agent.

NOTE

Service should be completed by AccuTemp

authorized service groups. Service completed

by unauthorized groups will void all factory

warranties.

AccuTemp Technical Service must be contacted for

all warranty service requests. If not the warranty claim

maybe denied.

NOTE

MP5018-1605

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 30

Page 33

SERVICE AND TROUBLESHOOTING

BASIC TROUBLESHOOTING

Griddle will not turn on

• Make sure the griddle is plugged in.

• Check the facility circuit breaker (or

fuse) supplying the unit

Heat light will not come on

• Make sure the griddle is not hotter than

the temperature you have it set for. If

you have turned down the temperature

of the griddle, the heat light will not

come on again until the cooking

surface drops below the temperature

you have set.

• See if the heat light is coming on

intermittently. While operating in

a normal condition, the heat light

cycles on and off periodically when at

temperature.

Uneven or inaccurate surface temperatures

• Verify griddle is level front to back and

side to side.

• Verify the surface temperature with

an accurate digital surface probe

thermometer.

• Use of an infrared or mechanical

thermometer will not give an accurate

reading of the griddle surface

temperatures.

• Contact AccuTemp Technical Service

for additional instructions.

Error 002

• Open Temperature Sensor

FAULT - (Gas Only) When this error is lit an

ignition failure of the appliance has occurred.

To correct turn the appliance off and wait 1

minute and then turn the appliance back on.

OVERTEMP - When this error is lit an

overtemp condition was sensed and will turn

off the appliance power. To correct turn the

appliance off and then back off to reset.

Fault Indicators

Unit will not turn off

• This symptom, which is extremely rare,

indicates a serious control malfunction.

• Turn off the griddle’s electrical supply

at the source and contact AccuTemp

Technical Service for additional

Instructions.

• Make sure to hold the On/Key for 3

seconds until the display turns off

Preset Temperatures are not working•

• Make sure to hold the On/Key until the

display turns off.

Error 001

• Shorted Temperature Sensor

MP5018-1605

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 31

Page 34

Page 35

SCHEMATICS

WARNING

Always disconnect from power source before

cleaning or servicing.

WARNING

Any in-eld modication that bypass the built in safety

features of this commercial appliance will result in

death or serious injury.

WARNING

Use of any replacement parts other than those supplied

by AccuTemp can cause injury to the operator or damage

the commercial appliance and voids all warranties

MP5018-1605

Accu-Steam™ G2 Electric Installation and Operators Manual

WARNING

There are no user-serviceable parts. To prevent

electrical shock do not open the access panel

covers

NOTE

Service should be completed by AccuTemp authorized

service groups. Service completed by unauthorized

groups will void all factory warranties.

NOTE

AccuTemp Technical Service must be contacted for

all warranty service requests. If not the warranty claim

maybe denied.

PAGE 32

Page 36

MODEL EGF

1Ø 208/240V AT2T-3912-2

A

Rev.

R3

R2

R1

3/A1

2

3

6

4

1

HEATING ELEMENTS

2

1

BLK

WHT

4

3

T1

5

BLK

ORN

RED

(-)

(+)

4/A2

AT2T-3912-2

-ELECTRIC -)

SSR 1

L1

BLK

1000O

1Ø 208V-240V

(MODULAR GRIDDLE

J3

1 2

PRTD

INPUT

SENSOR

DIGITAL

8415 N. Clinton Park

Fort Wayne, IN 46825

AccuTemp Products, Inc.

G2 GRIDDLE

SCHEMATIC,

AT2T-3912

CONTROLLER

GRY

J7

ON/

WHT/GRAY

ZR2

275V

BLK

WHT

BRN

30V

L3

CONTACTOR

L1

L2

WHT

BLK

WHT

ZR1

YEL

BLK

100 O

WHT/BRN

ORN

1 2 3 4 5 6

YEL

1 2

VIO

VIO

WHT/BRN

PRTD

OFF

GND

+24V

J2

INPUT

POWER

HIGH LIMIT

CONTROLLER

L1 L2 N.C. N.O. COM *RTD* RESET

BRN

TEMP

OVER

WHT

MP5018-1605

VIO

YEL

VIO

24V

VIO

YEL

GRN

1

2

3

4

J1

GRN

TIMER

REMOTE

OPTIONAL

YEL

Accu-Steam™ G2 Electric Installation and Operators Manual

RED

HEAT

.75 A

F

2

.75 A

F

1

COM

208

240

440

480

AT0A-2662-5

PAGE 33

Page 37

MODEL EGF

3Ø 208/240V AT2T-3912-3

A

Rev.

R3

HEATING ELEMENTS

3

2

1

WHT

5

4

6

1

2

BLK

4

3

RED

(-)

(+)

4/A2

3/A1

SSR 2

L1

T1

RED

RED

ORN

ORN

(-)

(+)

4/A2

3/A1

AT2T-3912-3

3Ø 208V-240V

SSR 1

L1

T1

BLK

BLK

RED

PRTD

1000O

(MODULAR GRIDDLE

J3

1 2

INPUT

SENSOR

DIGITAL

8415 N. Clinton Park

Fort Wayne, IN 46825

AccuTemp Products, Inc.

G2 GRIDDLE

SCHEMATIC,

AT2T-3912

-ELECTRIC -)

CONTROLLER

GRY

J7

ON/

WHT/GRAY

ZR2

ZR5

275V

RED

WHT

L3

CONTACTOR

L2

275V

BLK

BRN

30V

L1

ZR1

YEL

ORN

1 2 3 4 5 6

YEL

1 2

VIO

VIO

WHT/BRN

100 O

PRTD

OFF

GND

+24V

J2

INPUT

POWER

HIGH LIMIT

CONTROLLER

WHT

RED

WHT

MP5018-1605

BLK

BLK

WHT

VIO

YEL

GRN

1

2

3

4

X

G

Y

Z

GRN

J1

TIMER

REMOTE

OPTIONAL

WHT/BRN

YEL

Accu-Steam™ G2 Electric Installation and Operators Manual

L1 L2 N.C. N.O. COM *RTD* RESET

BRN

TEMP

OVER

VIO

VIO

24V

YEL

RED

HEAT

.75 A

F

2

.75 A

F

1

COM

208

240

440

480

AT0A-2662-5

PAGE 34

Page 38

MODEL EGF

3Ø 440V-480V AT2T-3912-4

A

Rev.

R3

RED

HEATING ELEMENTS

3

2

2

1

WHT

3

BLK

4

5

4

1 6

RED

(-)

(+)

4/A2

3/A1

SSR 2

L1

T1

RED

RED

ORN

ORN

(-)

(+)

4/A2

3/A1

AT2T-3912-4

-ELECTRIC -)

3Ø 440V-480V

SSR 1

L1

T1

BLK

RED

PRTD

1000O

(MODULAR GRIDDLE

J3

1 2

INPUT

SENSOR

DIGITAL

8415 N. Clinton Park

Fort Wayne, IN 46825

AccuTemp Products, Inc.

G2 GRIDDLE

SCHEMATIC,

AT2T-3912

CONTROLLER

GRY

J7

ON/

WHT/GRAY

ZR2

ZR5

275V

RED

WHT

L3

CONTACTOR

L2

275V

BLK

BRN

30V

L1

ZR1

YEL

100 O

ORN

1 2 3 4 5 6

YEL

1 2

VIO

VIO

WHT/BRN

PRTD

OFF

GND

+24V

J2

INPUT

POWER

HIGH LIMIT

CONTROLLER

WHT

RED

WHT

MP5018-1605

BLK

BLK

WHT

VIO

YEL

GRN

1

2

3

4

X

G

Y

Z

GRN

J1

TIMER

REMOTE

OPTIONAL

WHT/BRN

YEL

Accu-Steam™ G2 Electric Installation and Operators Manual

L1 L2 N.C. N.O. COM *RTD* RESET

BRN

TEMP

OVER

VIO

VIO

24V

YEL

RED

HEAT

.75 A

F

2

.75 A

F

1

COM

208

240

440

480

AT0A-2662-5

PAGE 35

Page 39

MODEL EGF

3Ø 380V-415V AT2T-3912-5

A

Rev.

R3

RED

HEATING ELEMENTS

3

2

2

1

WHT

3

BLK

4

5

4

1 6

RED

(-)

(+)

4/A2

3/A1

SSR 2

L1

T1

RED

RED

ORN

(+)

3/A1

SSR 1

T1

BLK

RED

ORN

(-)

4/A2

AT2T-3912-5

3Ø 380V-415V

-ELECTRIC)

(MODULAR GRIDDLE

L1

BLK

J3

1 2

PRTD

1000O

INPUT

SENSOR

DIGITAL

8415 N. Clinton Park

Fort Wayne, IN 46825

AccuTemp Products, Inc.

G2 GRIDDLE

SCHEMATIC,

AT2T-3912

CONTROLLER

GRY

J7

ON/

WHT/GRAY

ZR2

ZR5

275V

RED

WHT

L3

CONTACTOR

L2

RED

WHT

275V

BLK

BRN

30V

L1

BLK

ZR1

YEL

BLK

WHT

100 O

WHT/BRN

ORN

1 2 3 4 5 6

YEL

1 2

VIO

VIO

WHT/BRN

PRTD

L1 L2 N.C. N.O. COM *RTD* RESET

OFF

GND

+24V

J2

INPUT

POWER

HIGH LIMIT

CONTROLLER

BRN

TEMP

OVER

L3

r

c

h

1

6

,

2

:

D

e

it

S

z

G

T

E

S

L

V

A

A

S

0

W

e

d

n

e

s

d

a

y

,

M

a

MP5018-1605

VIO

YEL

VIO

24V

VIO

YEL

GRN

1

2

3

4

WHT

L2

L1

N

G

1

6

9

:

2

3

:

5

4

M

A

GRN/YEL

J1

TIMER

REMOTE

OPTIONAL

YEL

Accu-Steam™ G2 Electric Installation and Operators Manual

RED

HEAT

.75 A

F

2

.75 A

F

1

COM

208

240

440

480

AT0A-2662-5

PAGE 36

Page 40

INFORMATION

IMPORTANT SERVICE INFORMATION

Must contact AccuTemp Products Technical Service for all

warranty service requests for authorization and dispatch of

authorized service providers.

INFORMATION

IMPORTANT SERVICE INFORMATION

AccuTemp Product, Inc. Technical & Customer Support Technician is

available Monday thru Sunday, 7:00am to 7:00pm EST

800 480-0415 or 260 469-3040

TECHNICAL SERVICE

TOLL FREE 800 480-0415

PHONE 260 469-3040

FAX 260 460-3045

E-MAIL service@accutemp.net

Hours of Operation 7:00 am - 7:00 pm EST - 7 days a week

MP5018-1605

Accu-Steam™ G2 Electric Installation and Operators Manual

PAGE 37

Page 41

NOTES

Page 42

Loading...

Loading...