Page 1

AT2T-2742-1 Rev. E

AccuTemp Products, Inc. · 8415 North Clinton Park · Fort Wayne, IN 46825 · +1 260 469 3040 · www.accutemp.net

Page 2

DOCUMENT HISTORY

Current revision: – Prior revision: None

Date: 8/4/05 Date: None

Change

Initial release.

_______________________________________________________________________

Current revision: A Prior revision: –

Date: 8/16/05 Date: 8/4/05

Change

Added pages 26, 28 – 30, and 34 – 36; Renumbered pages as necessary.

_______________________________________________________________________

Current revision: B Prior revision: A

Date: 10/7/05 Date: 8/16/05

Page Change

Added pages ii and 24 – 27; Modified pages 4 – 8 and 19 – 23; Renumbered pages as

necessary.

_______________________________________________________________________

Current revision: C Prior revision: B

Date: 10/12/05 Date: 10/7/05

Page Change

Added page iii; Modified pages iv, 19 – 27; Renumbered page iv.

_______________________________________________________________________

Current revision: D Prior revision: C

Date: 11/10/05 Date: 10/12/05

Page Change

Deleted pages ii, iii, and 25; Added pages 18, 33 and 34; Modified pages 13, 14, 25 –

32, and 35 – 40; Rearranged sections and pages for clarity; Renumbered pages as

necessary.

_______________________________________________________________________

AT2T-2742-1 Rev. E

ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL

Page i

Page 3

DOCUMENT HISTORY (cont.)

Current revision: E Prior revision: D

Date: 12/29/05 Date: 11/10/05

Page Change

Added page ii; Modified pages 18, 19, 22 – 24, 33, and 34.

_______________________________________________________________________

AT2T-2742-1 Rev. E

ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL

Page ii

Page 4

TABLE OF CONTENTS

DOCUMENT HISTORY i – ii

TABLE OF CONTENTS iii

SAFETY WARNINGS 1 – 2

THEORY OF OPERATION 3

INSTALLATION 4 – 12

• GENERAL REQUIREMENTS 4 – 6

• DROP-IN 7 – 12

OPERATION 13 – 14

SERVICE AND TROUBLESHOOTING 15 – 17

SERVICE PARTS CROSS-REFERENCE:

NAVY GRIDDLE MODEL NUMBERS 18

NAVY ELECTRIC GRIDDLE SERVICE PARTS 19 – 20

HIGH LIMIT OVERTEMP ASSEMBLY SERVICE PARTS 21

DROP-IN ELECTRIC GRIDDLE (WITH MDR) SERVICE PARTS 22

DROP-IN ELECTRIC GRIDDLE (WITH SSR) SERVICE PARTS 23

DROP-IN ELECTRIC GRIDDLE COMMON SERVICE PARTS 24

DROP-IN ELECTRIC GRIDDLE CONTROL BOX SERVICE PARTS 25 – 26

STANDARD ELECTRICAL GRIDDLE SCHEMATICS 27 – 34

DROP-IN ELECTRICAL GRIDDLE SCHEMATICS 35 – 40

WARRANTY 41

AT2T-2742-1 Rev. E

ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL

Page iii

Page 5

SAFETY WARNINGS

R

SYMBOL DEFINITIONS

Symbols are used to attract your attention to possible dangers. They are only effective

if the operator uses proper accident prevention measures. Some of the symbols are

boxed text, while other maybe just picture icons. Please give this information the

respect they deserve for safe operation.

WARNING TEXT BOXES

Below are definitions of the warning text boxes:

Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could

result in minor or moderate injury.

Advises reader of information or instructions vital to the operation or

maintenance of the equipment.

DANGE

WARNING

CAUTION

NOTE

AT2T-2742-1 Rev. E

ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL

Page 1 / 41

Page 6

SAFETY WARNINGS (cont.)

SYMBOL ICONS

Below are definitions of symbol icons used in this manual:

ALERT – Notifies the reader of an important message/warning, usually a safety related

message.

INFORMATION – Notifies the reader of important information that may or may not be

safety-related.

EARTH GROUND

DANGEROUS VOLTAGE

CAUTION, HOT SURFACE

AT2T-2742-1 Rev. E

ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL

Page 2 / 41

Page 7

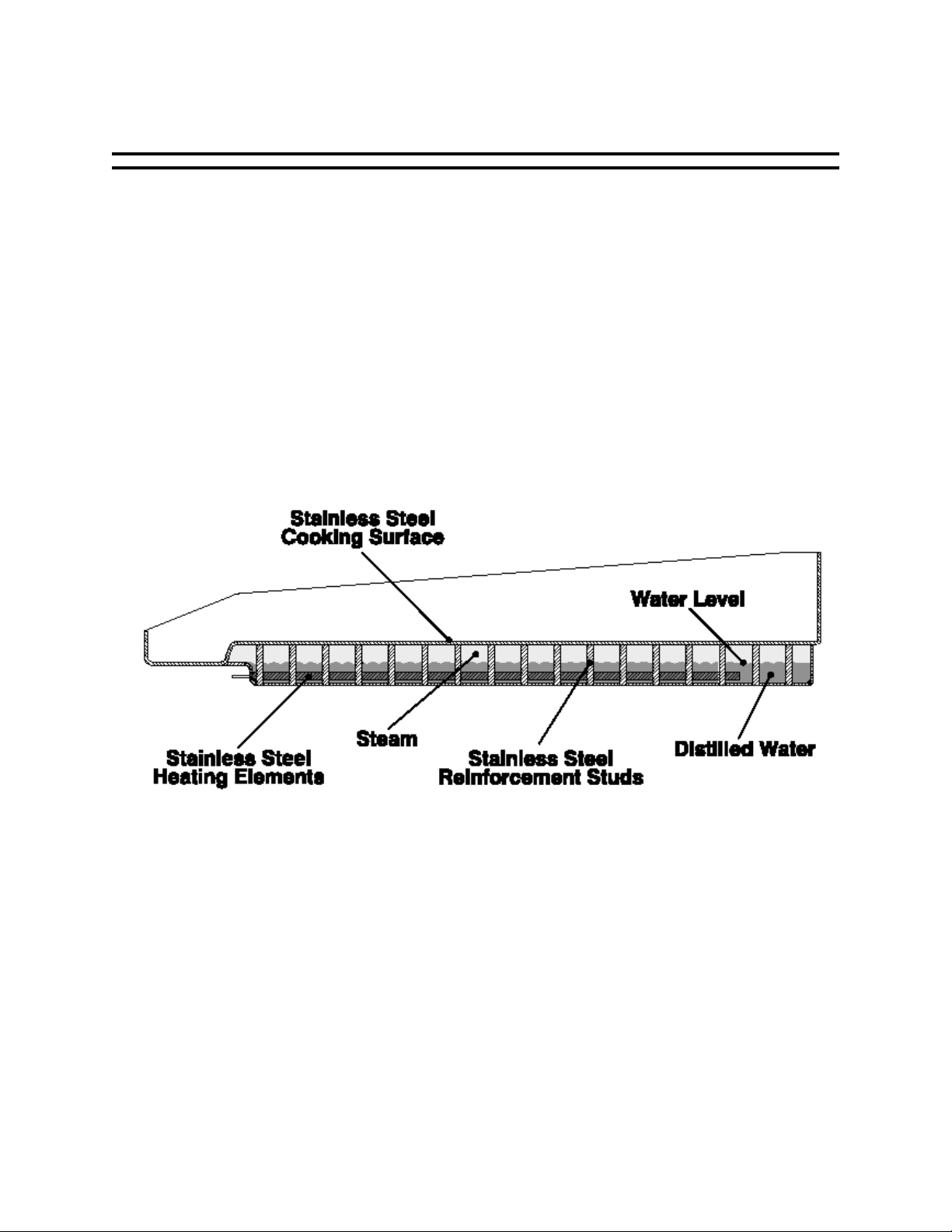

THEORY OF OPERATION

INTRODUCTION

The ACCU-STEAM™ griddle is constructed and uses technology like no other griddle

in the world. The diagram below is a cross-sectional view of the griddle. The griddle

cooking surface is the top of a chamber in which we have produced a unique

environment. Welded stainless steel reinforcement studs connect the chamber top to

the chamber bottom. The perimeter joints are all robotically welded and to produce a

vessel that is airtight, which is verified using a helium mass spectrometer. The

chamber is filled half full with distilled water. The remaining air is removed and the

chamber is welded shut. At this point, the chamber becomes a hermetically sealed

vessel, never to be opened again. The griddle steam chamber requires no water

or maintenance. A thermowell for a thermocouple to sense temperature and a

thermowell for the overtemp safety shutdown system are also welded into the griddle

steam chamber.

At temperatures below 212°F (100°C), the chamber is actually in a vacuum, similar to

that of a canning jar. At temperatures above 212°F (100°C), the chamber operates

under pressure. Located between the water and the bottom of the cooking surface is

the best heat transfer medium – steam, the most effective way to transfer heat. The

thermocouple senses the temperature of the steam and reports this data to the

thermostat, which energizes the heating elements. This system maintains the griddle

cooking surface temperatures to within ± 3°F (1.7°C) over the entire cooking surface

and provides a near instant temperature recovery, even in the same spot on the

griddle, when turning food in place.

AT2T-2742-1 Rev. E

ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL

Page 3 / 41

Page 8

INSTALLATION

Only qualified service technicians/electricians should perform the

installation to ensure that all electrical and safety requirements are met

and that all wiring is performed in accordance with all national, state and

LOCATION AND PLACEMENT

The AccuTemp ACCU-STEAM™ electric griddle has been designed to be placed on a

commercial kitchen counter-top, an AccuTemp griddle stand or directly onto any flat,

level surface.

The operating temperature ranges from 200°- 400°F (93°- 204°C). Since these

temperatures can also be found on surfaces around the perimeter of the griddle, care

should be given not to install griddle next to or against, objects or surfaces with a low

melting or flash point.

Temperatures on and around the griddle cooking surface could cause

LEVELING

The griddle must be installed in a level condition. An out-of-level condition may

cause damage to the griddle and damage of this type is not covered by warranty. Use a

spirit level resting on the griddle surface to ensure it is level front-to-back and left-toright.

If this is a counter-top installation, be sure to install the (4) rubber foot

tips provided with your griddle onto the four foot adjusters of each of the

griddle leg as shown. This will keep the griddle from sliding on the counter-top under

normal use. Once the rubber foot tips have been installed, adjust the four foot

adjusters up or down as needed to level the griddle.

If your griddle is attached to an AccuTemp stand with casters, ensure that the floor

surface is level and place the two locking casters to the “on” position.

WARNING

local electrical codes.

CAUTION

severe burns.

AT2T-2742-1 Rev. E

ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL

Page 4 / 41

Page 9

INSTALLATION (cont.)

R

IN-FIELD MODIFICATIONS

This griddle has a totally unique design and is constructed unlike any other griddle

on the market today. Any modification may permanently damage the griddle.

Any in-field modification made without written authorization from

AccuTemp will void all warranties.

Any in-field modifications that bypass the built-safety features of this

product will result in death or serious injury.

ELECTRICAL SUPPLY

The ACCU-STEAM™ griddle has been designed, manufactured and tested to meet or

exceed the demanding standards of safety set forth by Underwriters Laboratories, Inc.

To ensure that this high level of safety is maintained in your installation, it is important

that you read and understand the following information before attempting to plug in

your griddle.

ELECTRICAL REQUIREMENTS

Electrical requirements are listed on the data plate located on the right side of the

unit, near the front. All standard AccuTemp griddles are supplied with a 6ft (1.83m)

cord and the appropriate UL listed plug. Please note, that the plug is rated for 250VAC.

This plug is commonly used for both 208VAC and 240VAC installations. Make sure that

the voltage at your supply receptacle is within ± 10 % of the voltage listed on the

griddle data plate. Connection to any other voltage may cause damage to components

in the griddle and damage of this type is not covered under warranty.

GROUNDING INSTRUCTIONS

Grounding provides a path for electric current to reduce the risk of shock. This

product is equipped with a power cord having a grounding conductor and a grounding

plug.

WARNING

DANGE

This appliance must be properly grounded, in accordance with all National,

AT2T-2742-1 Rev. E

WARNING

State and local electrical codes.

ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL

Page 5 / 41

Page 10

INSTALLATION (cont.)

ELECTRICAL CONNECTIONS

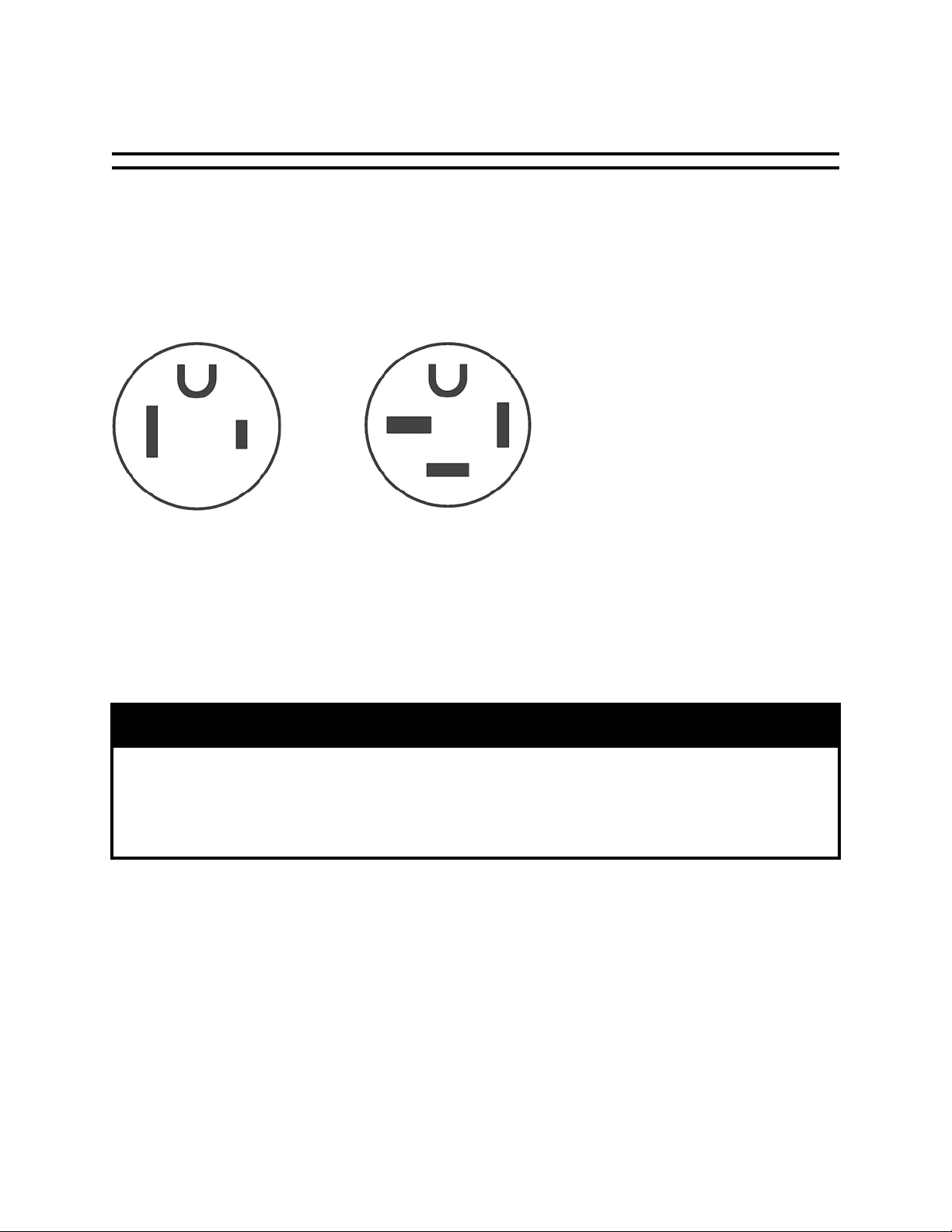

The receptacle requirements vary between models. If you have purchased a

single-phase model, you will need a NEMA 6-50R receptacle. If you have

purchased a three-phase model, you will need a NEMA 15-50R receptacle.

These receptacles are configured as shown below.

NEMA 6-50R NEMA 15-50R

GRIDDLE LIFTING

Griddles are heavy enough to require additional manpower or powered assistance

when installing or moving the griddle.

CAUTION

This appliance is heavy. For safe handling, the installer should obtain help

as needed or employ appropriate material handling equipment to remove

the appliance from the skid and move into its final destination.

AT2T-2742-1 Rev. E

ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL

Page 6 / 41

Page 11

INSTALLATION (cont.)

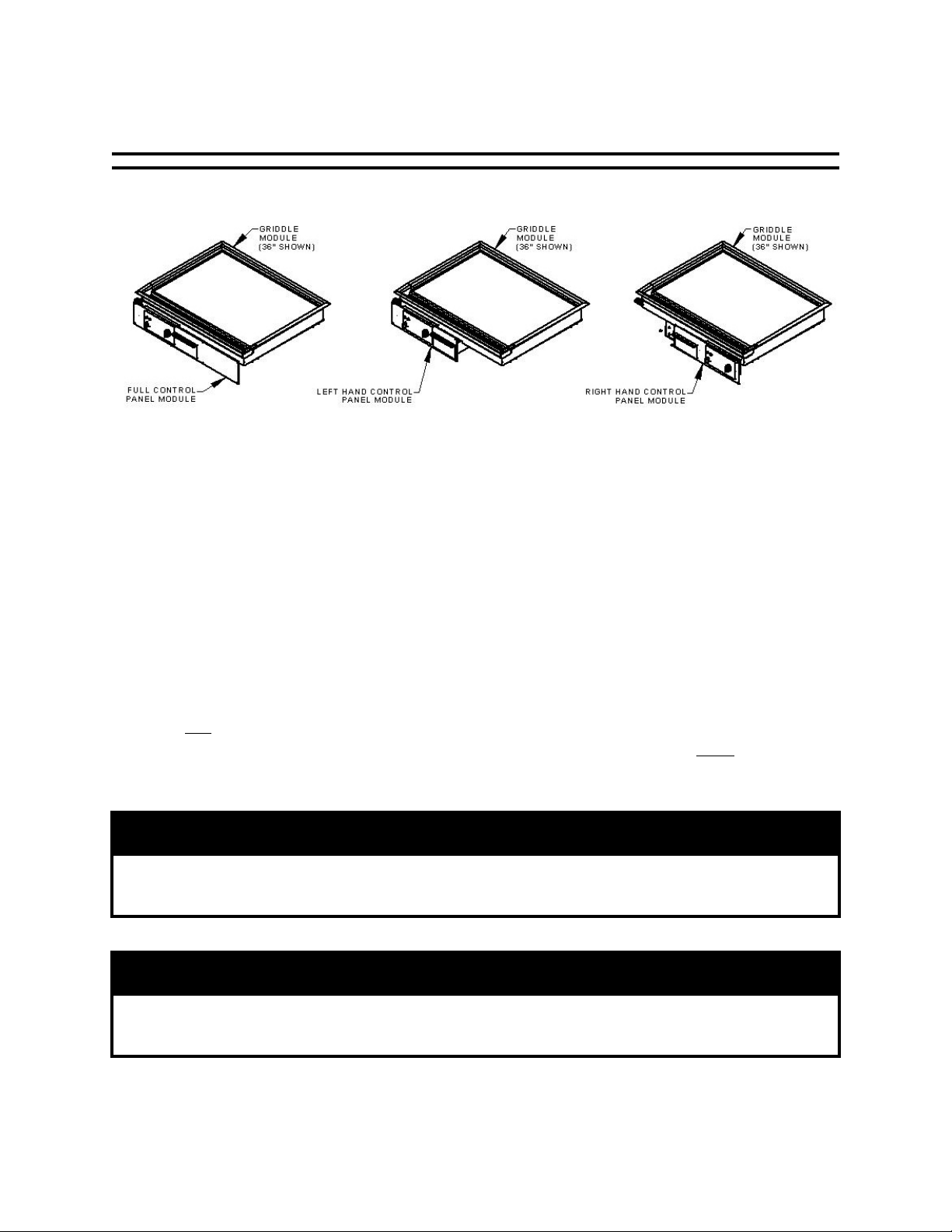

DROP-IN GRIDDLE

Fig. 1

Introduction

It is highly recommended that a survey of the kitchen site be conducted to

determine the requirements for the installation. Electrical supply, counter space as well

as counter arrangement are critical to the choice of Drop-In-Griddle options. The DropIn-Griddle is available in many options to accommodate size, control panel

arrangements and supply voltage. The model data label indicating the model

number, phase, voltage, current, wattage and UL information is located on

the bottom cover of the unit.

Counter designs that have an “L” arrangement such that the shortest part of the “L”

is to the

has an “L” arrangement such that the shortest part of the “L” is to the right may require

a “Left Hand Control Panel” option. See Figure 1 for views of these configurations.

left may require a “Right Hand Control Panel” option. A counter design that

WARNING

This product is to be installed in stainless steel or non-combustible

countertops only.

NOTE

Installation must allow inspection and serviceability to the underside of

the unit.

AT2T-2742-1 Rev. E

ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL

Page 7 / 41

Page 12

INSTALLATION (cont.)

DROP-IN GRIDDLE

GETTING STARTED

Please read and comprehend all instructions and manuals provided with each DropIn-Griddle. Read and understand all safety warnings and operator instructions for all

powered tools required to complete the installation of the Drop-In-Griddle.

Disconnect all power from house supply connection boxes at the appropriate

fuse panel and label the breakers “In service”. This is to warn others that work is

in process, preventing accidental electrocution.

TYPICAL TOOLS AND SUPPLIES REQUIREMENTS

• Putty knife

• Grease solvents

• Clean sponges or rags

• Latex gloves

• Caulking gun

• Approximately 3oz. NSF-approved aluminized silicone sealant

• Tape measure

• Carpenters square

• #2 Phillips screw driver

• Channel lock pliers

• ½ inch box/open wrench

• 3/8 inch nut driver

• 3/8 inch electric or cordless drill

• #25 drill bit

• 3/8 inch drill bit

• Saber saw with metal cutting blades

• Permanent marking pen, preferably a “Sharpie” fine point.

• 4 inch grinder. (If replacing an existing competitors griddle, it is recommend to

use a 4 inch grinder to clean off any welds, welded on brackets or framing

attached to the counter top.)

LIST OF PACKAGING REQUIREMENTS:

• (1) Owners/Installation Manual

• (1) Griddle Module

• (1) Control Panel Module

• (1) Cable Assembly

• (4) Grease Spout Extension

• (1) Grease Trough Assembly

• (1) Grease Tray Assembly

• (1) Grease Trough Hanger Bracket

• (1) Grease Trough Hanger

AT2T-2742-1 Rev. E

ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL

Page 8 / 41

Page 13

INSTALLATION (cont.)

DROP-IN GRIDDLE

• (8) 10-24 x 3/8 inch Self-Tapping Truss Head Screw

• (6) 10-24 x ½ inch Phillips Round Head Machine Screw

• (2) 5/16-18 X ¾ inch Carriage Head Bolt

• (2) 5/16 inch Lock Washer

• (2) 5/16-18 Hex Nut

• (8) 1/4-20 Nyloc Nut

• (4) Retainer Bracket

• (1) Thermostat Knob Guard

INSTALLATION PROCEDURE

1. Inspect the griddle packaging to ensure there are no missing components.

2. Complete the appropriate power disconnection procedures for existing

equipment or local power junction boxes.

3. Clean surfaces with grease solvents and dry off with clean rags or sponges.

4. Determine the location and orientation for the griddle and control panel modules.

Mark the centerline on the countertop for the griddle module, using a Carpenter’s

square. See Figure 2 for the countertop and control panel layouts. Continue the

centerline to the control panel module mounting surface. Accurate centerline

alignment of the countertop and control panel modules is critical to ensure the

correct alignment of the grease trough assembly to the griddle module.

AT2T-2742-1 Rev. E

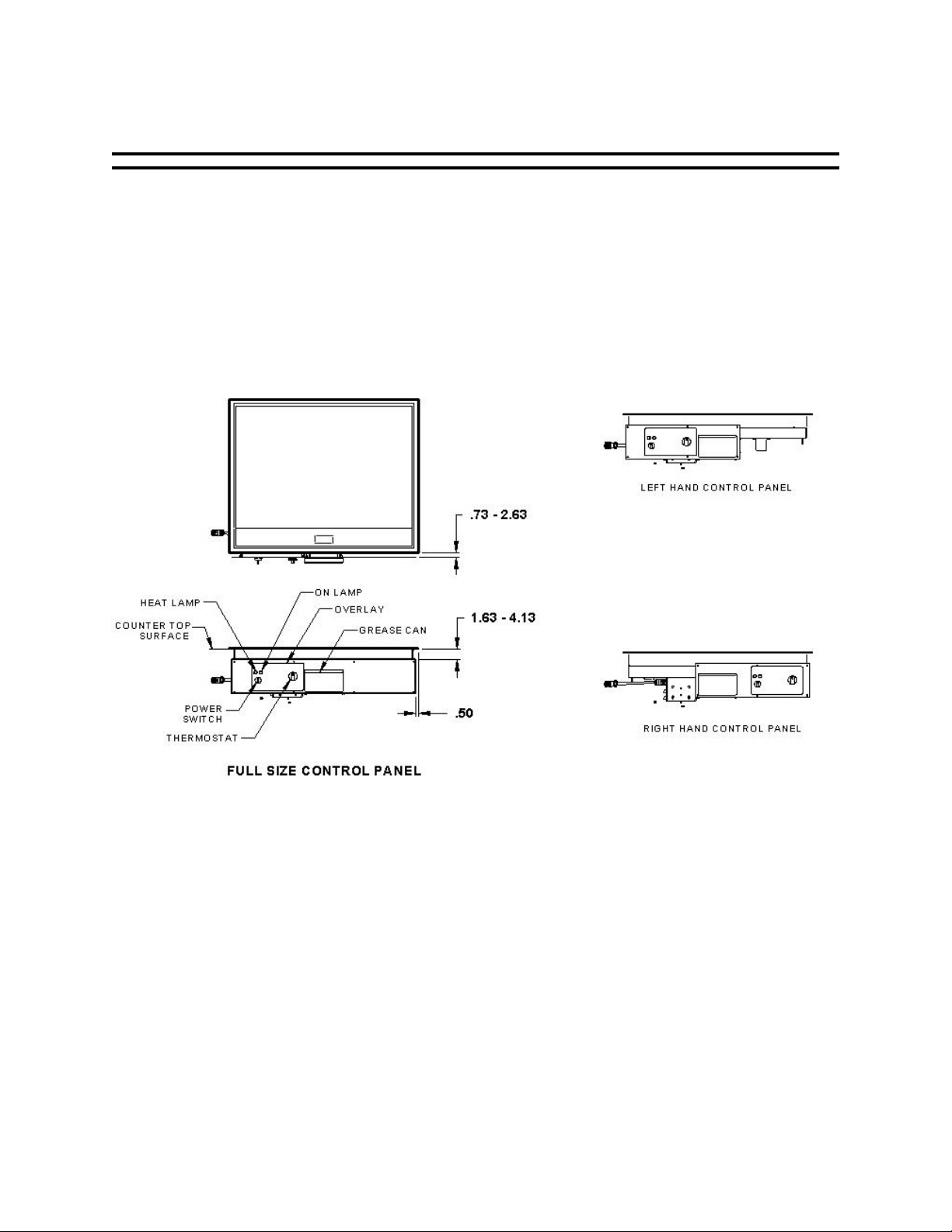

Fig. 2

ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL

Page 9 / 41

Page 14

INSTALLATION (cont.)

DROP-IN GRIDDLE

5. The dimensional relationship between the griddle module mounting flange and

the control panel module is shown in Figure 3. The griddle module mounting

flange overlaps the countertop cutout by 0.50 inches on all four sides. Mark the

griddle module cutout on the countertop such that the front edge of the griddle

module is 0.73 inches – 2.63 inches from the control panel module mounting

surface, as shown in Figure 3. Mark the control panel module cutout on the

control panel module mounting surface, as shown in Figure 2.

Fig. 3

6. Cut out the griddle and control panel module openings. Straighten out any dings

or bent edges in both cutouts to ensure adequate sealing between the new

griddle and the counter top surface and between the control panel and the front

surface of the counter.

7. Drill the mounting holes in the face of the counter using a #25 drill bit. Drill the

first set of holes and locate the remaining holes using the control panel as a

template.

8. Use a lifting device, if possible, to raise the griddle module above the counter

and position over cutout in countertop. Lower the griddle module carefully into

the cutout. Install the retainer clamps to the griddle module, using the ¼-20

nylock nuts (see drawing AT2A-3044, sheet 6).

AT2T-2742-1 Rev. E

ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL

Page 10 / 41

Page 15

INSTALLATION (cont.)

DROP-IN GRIDDLE

9. Install the control panel onto the counter face using #10-24 x 3/8 inch selftapping screws. Also, at this time, install the thermostat knob guard, if

necessary, by lining up the holes on the guard to the holes on the control panel

directly above and below the thermostat.

10. Install the grease trough hanger brackets onto the bottom side of the griddle

using (2) #10-24 X ½ inch Phillips round head machine screws and (2) 5/16-18

X ¾ inch carriage head bolts with (2) 5/16 inch lock washers and (2) 5/16-18

nuts (see drawing AT2A-3044, sheet 6). Leave the carriage bolts loose for

adjustment of the g rease trough.

11. Install the grease trough using (4) #10-24 X ½ inch Phillips round head machine

screws through the front panel opening and through the hanger bracket

assembly, installed in step 10.

12. Adjust the hanger bracket height so that the grease trough is setting level frontto-back and tighten the 5/16-18 nuts.

13. Install the appropriate size grease spout extension onto the griddle grease spout,

that ensures the bottom of the grease spout extension is flush to the inside

surface of the grease trough assembly (see drawing AT2A-3044, sheet 6).

14. Use the caulking gun to lay a 1/8” minimum diameter bead of the aluminized

silicone sealant around the griddle module mounting flange onto the counter top.

Use a gloved finger to wipe the sealant into a fillet shape.

15. Install the interconnect cable between the control panel module and the control

box, mounted on the bottom side of the griddle (see drawing AT2A-3044, sheet

6).

16. Set the on/off switch to the off position and set the temperature control knob to

the lowest setting.

17. Install the power cord into an appropriate sized electrical connection box with an

appropriate sized cord grip or cable strain relief. Complete the final

connections, testing the house supply wire first to ensure it is not live.

18. Turn on power to the griddle at the fuse panel.

19.Turn the griddle on and set the temperature control knob to a desired

setting. Wait a minimum of 20 minutes. Then use a suitable temperaturemeasuring device to check the griddle surface temperature. The surface

temperature should be within 5 – 7 °F of the temperature control knob setting.

If it is not, go to the calibration section and follow the calibration procedures.

20.This completes the drop-in griddle installation.

AT2T-2742-1 Rev. E

ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL

Page 11 / 41

Page 16

INSTALLATION (cont.)

DROP-IN GRIDDLE

CALIBRATION

The griddle has been pre-calibrated in the factory and should not require additional

calibration. If calibration is necessary, complete the following steps:

1. Remove the cover from the contactor box assembly to expose the

control components (see drawing AT2A-3044, sheets 4 or 5).

2. Locate the thermostat control circuit board (see drawing AT2A-2577) and identify

the two potentiometers. The “LO OFFSET” potentiometer is the only

potentiometer to be adjusted.

3. Make VERY SMALL adjustments. Observe the surface temperature, allowing a

minimum of five minutes for the griddle to stabilize before making any more

adjustments (see Figure 4).

4. When the surface temperature and the temperature control knob indicator are

within 5 – 7 °F of each other, reinstall the contactor box cover and this

calibration procedure is completed.

Figure 6

AT2T-2742-1 Rev. E

ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL

Page 12 / 41

Page 17

OPERATION

SEASONING

It is recommended that you clean your ACCU-STEAM™ griddle thoroughly before

turning your unit on. To clean the griddle surface, just simply wash the cooking surface

down with a solution of mild soap and water, and then rinse thoroughly with clean

water.

Once the cooking surface has been cleaned, set the thermostat to 200°F (93°C),

turn the griddle power switch to the “On” position and allow the griddle cooking surface

to heat for 10 minutes. Using a high temperature oil, such as

Shortening

Whirl

™ or equivalent, pour enough to cover the entire griddle

™,

surface. Do not use standard vegetable oil to season the griddle cooking

surface. It may cause food to stick and result in improperly cooked food. Work this

seasoning oil into the griddle surface with a regular heavy-duty scrub pad for about 5

minutes, making sure that you scrub the seasoning oil over the entire griddle-cooking

surface. After the entire griddle surface has been scrubbed with seasoning oil for 5

minutes, simply wipe or squeegee off excess oil from griddle surface. Your griddle is

now ready to use!

If you use chemicals to clean your griddle periodically or on a schedule,

you may need to repeat this process after the use of chemicals.

PREHEATING

Turn On switch to the “On” position and set the thermostat to the desired

temperature. The griddle will increase its surface temperature at an average rate of 15°

F (8°C) per minute. It takes approximately 22 minutes to raise the griddle from room

temperature to its maximum temperature of 400° F (204°C). The griddle will be

preheated when the “Heat” light starts to cycle on and off. Please use caution as

temperatures on and around the griddle cooking surface could cause severe

burns.

COOKING

Begin cooking only after the griddle has been preheated to the desired temperature.

Please note these facts:

• You can cook all the way to the edges of the griddle surface because the

temperature does not very across the entire cooking surface.

• You can turn the product to the same spot because the griddle has near

instant heat recovery.

• It will always cook the same, regardless of product load or surface coverage.

Accurate Cooking Temperatures

Because of the inaccurate surface temperatures and long recovery times common

with other griddles. It is doubtful you were cooking at the set temperature or the

temperature you wanted. Adjust the temperature on your A

CCU-STEAM™ griddle and it

Pan and Grill

AT2T-2742-1 Rev. E

ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL

Page 13 / 41

Page 18

OPERATION (cont.)

won’t change or vary by the location on the griddle surface. There are no hot or cold

zones.

Heat Lamp

It is normal for the heat light to cycle on and off. This light indicates when the

heaters are energized. You will soon notice how little they are energized to maintain

perfect surface temperatures on your griddle.

Grease Pan

Use caution when emptying the grease pan. The contents in this pan could cause

severe burns. The pan should be checked periodically and emptied as necessary to

prevent an overflow or dangerous condition.

CAUTION

The grease can contents could cause severe burns. Slowly remove the

grease can from the griddle to avoid spilling the contents.

DAILY CLEANING

Cleaning during the work shift can be performed with a sharp scraper. When heavy

cleaning at the end of a shift or periodically as needed, the following is recommended:

• Turn the griddle off and allow it to cool to between 220°F and 240°F

(104°F and 116°C). Use water, ice and/or griddle cleaner as needed. For

example, the 3M Scotch-Brite™ Quick Clean Griddle System provides the

Scotch-Brite™ polishing pads, quick clean liquid, pad holder and squeegee.

Clean-up is very easy using these tools with the quick clean liquid, water, ice

or combinations of these liquids.

• If a griddle with grease on the cooking surface is cleaned at a high

temperature using water or ice, the grease may splatter and cause

skin burns. Be very cautious!

• Do not use a griddle stone or brick to clean the griddle.

• Do not use a water-jet to clean the griddle.

NOTE

Never leave a chlorine sanitizer in contact with the stainless steel longer

than 10 minutes. Longer contact can cause corrosion.

AT2T-2742-1 Rev. E

ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL

Page 14 / 41

Page 19

SERVICE AND TROUBLESHOOTING

R

An AccuTemp Products, Inc. Technical Service Technician is available

Monday thru Sunday, 7:00am to 7:00pm EST.

+1-260-469-3040 or 1-800-480-0415

NO USER-SERVICEABLE PARTS

There are no user-serviceable parts. AccuTemp-authorized service personnel should

complete any servicing. Service performed by unauthorized personnel will void the

warranty.

There are no user-serviceable parts. To prevent electrical shock do not

open access panel covers.

Only qualified service technicians/electricians should perform the

installation to ensure that all electrical and safety requirements are met

and that all wiring is performed in accordance with all national, state and

local electrical codes.

Any in-field modification made without written authorization from

AccuTemp will void the warranty.

Any in-field modifications that bypass the built-safety features of this

product will result in death or serious injury.

NOTE

WARNING

WARNING

WARNING

DANGE

AT2T-2742-1 Rev. E

ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL

Page 15 / 41

Page 20

SERVICE AND TROUBLESHOOTING (cont.)

This appliance must be properly grounded, in accordance with all National,

State and local electrical codes.

Service must only be performed by AccuTemp Products, Inc.- authorized

service personnel. Service performed by unauthorized personnel will void

Use of any replacement parts other than those supplied by AccuTemp

Products, Inc. can cause injury to the operator or damage the appliance

and voids all warranties.

GENERAL SERVICE INFORMATION

Most conventional griddles require regularly scheduled service (i.e. recalibrating the

thermostat). The ACCU-STEAM™ griddle has no such requirements, due to its design.

BASIC TROUBLESHOOTING

Griddle will not turn on

• Make sure the griddle is plugged in and the “On/Off” switch is in the On

position.

• Check the facility circuit breaker (or fuse) supplying the unit.

• Call AccuTemp Products, Inc Technical Service at +1-260-469-3040 or toll

free at 1-800-480-0415.

Heat light will not come on

• Make sure the griddle is not hotter than the temperature you have it set for.

If you have turned down the temperature of the griddle, the heat light will

not come on again until the cooking surface drops below the temperature you

have set.

• See if the heat light is coming on intermittently. While operating in a normal

condition, the heat light cycles on and off periodically when at temperature.

WARNING

NOTE

the warranty.

WARNING

AT2T-2742-1 Rev. E

ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL

Page 16 / 41

Page 21

SERVICE AND TROUBLESHOOTING (cont.)

• Call AccuTemp Products, Inc Technical Service at +1-260-469-3040 or toll

free at 1-800-480-0415.

Uneven or inaccurate surface temperatures

• Verify the surface temperature with an accurate surface probe thermometer.

Use of an infrared thermometer will not give an accurate reading of the

griddle surface temperatures.

• Call AccuTemp Products, Inc Technical Service at +1-260-469-3040 or toll

free at 1-800-480-0415.

Unit will not turn off

• This system, which is extremely rare, indicates a serious control malfunction.

• Turn off the griddle’s electrical supply at the source.

• Call AccuTemp Products, Inc Technical Service at +1-260-469-3040 or toll

free at 1-800-480-0415.

An AccuTemp Products, Inc. Technical Service Technician is available

Monday thru Sunday, 7:00am to 7:00pm EST.

+1-260-469-3040 or 1-800-480-0415

NOTE

AT2T-2742-1 Rev. E

ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL

Page 17 / 41

Page 22

SERVICE PARTS CROSS-REFERENCE:

NAVY GRIDDLE MODEL NUMBERS

COUNTERTOP MODELS

Service

Model

EGF4403B3602-00 AT2A-3044 19 and 21 AT2T-2947 34

EGF4403B2405-T3 AT2A-3044 19 and 21 AT2T-2947 34

EGF4403B3605-T3 AT2A-3044 19 and 21 AT2T-2947 34

EGF4403B4805-T3 AT2A-3044 19 and 21 AT2T-2947 34

[Models manufactured after 5/31/05]

EGF4403B3602-00 AT2A-3044 19 – 21 AT2T-2947 33 31

EGF4403B2405-T3 AT2A-3044 19 – 21 AT2T-2947 33 31

EGF4403B3605-T3 AT2A-3044 19 – 21 AT2T-2947 33 31

EGF4403B4805-T3 AT2A-3044 19 – 21 AT2T-2947 33 31

DROP-IN MODELS

Model

EGD4403B3606-00 AT2A-3044

EGD4403B4806-00 AT2A-3044

EGD4403B3606-00 AT2A-3044

EGD4403B4806-00 AT2A-3044

Parts

Drawing

Number

[Models manufactured prior to 6/1/05]

Service

Parts

Drawing

Number

[Models manufactured prior to 6/1/05]

[Models manufactured after 5/31/05]

Service

Parts –

Owners

Manual

Page(s)

Service

Parts –

Owners

Manual

Page(s)

21, 22, 24

and 25

21, 22, 24

and 25

21, 23, 24

and 26

21, 23, 24

and 26

Schematic

Drawing

Number

Schematic

Drawing

Number

AT2T-2713 39

AT2T-2713 39

AT2T-2713 36

AT2T-2713 36

Schematic – Owners

Manual Page(s)

Prior to

9/23/05

Schematic – Owners

Manual Page(s)

After

9/22/05

AT2T-2742-1 Rev. E

ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL

Page 18 / 41

Page 23

C

Rev.Drawing No.:Size:

Sheet 1 of 6

8415 N. Clinton Park

Fort Wayne, IN 46825

AccuTemp Products, Inc.

AT2A-3044

EDR: 085

SERVICE PARTS LIST

NAVY ELECTRIC GRIDDLE

Title:

Date

1-24-05DPS

ATP 1-24-05

Name

Unless otherwise specified,

Dimensions: Inches

GLS 1-24-05

Project Eng

Drawn

Checked

Bends: 90

Tolerances:

Material:

Angular 1°

2 Place Decimal .02

3 Place Decimal .005

T.I.R .005

D

Scale: 1:8

GD&T Per ANSI Y14.5M

N/A

Finish:

Do Not Scale Drawing

Comments:

N/A

√125 Micro Inches

C

1 AT0E-1587-2 34 3 POLE CONTACTOR

B

4 AT0F-2755-41040 33 #10-24UNC X 1/2 PHIL RD HD MACH SCREW

1 AR AT2M-3183-3 32 BAR, 48" GRIDDLE GRAB

B

1 AR AT2M-3183-2 32 BAR, 36" GRIDDLE GRAB

1 AR AT2M-3183-1 32 BAR, 24" GRIDDLE GRAB

B

B

2 AT2H-3184-1 31 END BRKTS, GRIDDLE GRAB BAR

2 AT0F-2875-71080 30 3/8-16UNC X 1 HEX HD MACH SCREW

2 AT0F-2778-71001 29 3/8-16 UNC-2B 316 SS HEX NUT

B

B

B

4 AT0F-2755-41050 21 #10-24UNC X 5/8 PHIL RD HD MACH SCREW

4 AT2A-3032-3 20 3.00" LEG ASSEMBLY

1 AT0F-2632-40001 19.7 #10-24 NUT, ACORN

1 AT0F-1922-40000 19.6 #10 WASHER LOCK, SS HELICAL SPRING

1 AT0F-1052-43010 19.5 WASHER, #10 TYPE B CUSTOM

1 AT0F-3012-1 19.4 SPACER, ROUND

1 AT2M-3008-1 19.3 LEVER, GREASE PAN

1 AT2M-2551-2 19.2 GREASE TRAY FACE PLATE

1 AT0F-1046-41040 19.1 #10-24 x 1/2 PHLP TRUSS HEAD

1 AT2A-2552-2 19 ASSY, BAFFLED LOCKING GREASE TRAY

1 AT2A-2529-2 18 GREASE TROUGH ASSY

1 AT0A-2788-14 17 POWER CABLE ASSY

1 AT0E-1049-5 16 1" STRAIN RELIEF

1 AT0A-2876-2 15 MDR WITH TERMINALS

1 AT2E-1220 14 RELAY, 240V MERCURY DISPLACEMENT

1 AT2E-1035 13 RELAY, 208V MERCURY DISPLACEMENT

1 AT0E-3025-2 12 INSULATOR STRIP, 4 POSITION DOUBLE ROW

1 AT0E-1134-4 11 4 POSITION TERMINAL BLOCK

1 AT2M-1559-1 10 COVER

1 AT2A-2916-1 9 HIGH LIMIT OVERTEMP ASSEMBLY

1 AT0E-2662-3 8 TRANSFORMER

1 AT2M-1740 28 SKIRT, LEFT SIDE (24" DEEP GRIDDLE)

1 AT2M-1739 27 SKIRT, RIGHT SIDE (24" DEEP GRIDDLE)

8 AT0F-2875-51062 26 1/4-20 X 3/4 HEX HD MACH SCREW

2 AT0F-2691-41002 25 #10-24 NYLOC NUT

4 AT0F-2777-31030 24 #8 TYPE AB X 3/8 TRUSS HEAD SCREW

2 AT0F-2755-41070 23 #10-24UNC X 7/8 PHIL RD HD MACH SCREW

16 AT0F-1046-31030 22 #8-32 x 3/8 PHLP TRUSS HEAD

17

B

B

C

B

2

22

B

3

6

34

B

1 AT0E-1587-1 7 3 POLE CONTACTOR

1 AR AT2M-1738 6 SKIRT, FRONT (48" GRIDDLE)

B

1 AR AT2M-2187 6 SKIRT, FRONT (36" GRIDDLE)

B

1 AR AT2M-2186 6 SKIRT, FRONT (24" GRIDDLE)

B

1 AT2G-1026 5 GASKET, CONTROL PANEL, EG

1 AT0E-2659-1 4.7 MOUNTING LATCH

2 AT0E-2657-1 4.6 CONTACT BLOCK

1 AT0E-1800-5 4.5 INDICATOR LAMP RED NEON 250V

1 AT0E-1800-4 4.4 INDICATOR LAMP GRN NEON 250V

1 AT2E-1034 4.3 THERMOSTAT

1 AT0H-1455-2 4.2 KNOB FOR D SHAFT

1 AT0E-1755-1 4.1 ON/OFF SWITCH

1 AT2A-3189-1 4 ASSY, ELECTRIC GRIDDLE CONTROL PANEL

B

1 AT2G-1022 3 GASKET, ACCESS POWER TERMINAL, EG

1 AT2M-1021 2 PANEL, ACCESS POWER TERMINAL, EG

1 AT2A-2185 1 WELD ASSY, CHAMBER

QTY PART NUMBER ITEM DESCRIPTION

B

33

16

27

7

26

20

C

5

8

SEE SHEET #3

"HIGH LIMIT OVERTEMP ASSEMBLY

DETAIL VIEW"

9

25

ITEM NO 15 MDR USED ON ALL ELECTRIC COUNTERTOP GRIDDLES

1

NOTES:

WITH MFR DATE OF 1-26-05 THRU PRESENT

ITEM NO 14 MDR USED ON 440/240V GRIDDLES

2

ITEM NO 13 MDR USED ON 208V GRIDDLES

3

WITH MFR DATE PRIOR TO 1-26-05

WITH MFR DATE PRIOR TO 1-26-05

4. FOR USE IN 440/480 PRIMARY VOLTAGE UNITS ONLY

ITEM NO 7 CONTACTOR USED ON ALL ELECTRIC COUNTERTOP GRIDDLES

5

WITH MFR DATE OF 1-1-05 THRU PRESENT

ITEM NO 34 CONTACTOR USED ON ALL ELECTRIC COUNTERTOP GRIDDLES

6

WITH MFR DATE PRIOR TO 1-1-05

10

24

C

C

12

3

2

11

13

14

B

1

1

B

30

28

B

B

32

6

23

4.6

B

33

15

4.3

5

31

B

29

31

19

19.1

19.219.3

18

21

4.7

4.4

4.1

4.2

22

4

12/30/05 DPS/ATP

12/2/05 DPS/ATP

4.5

19.4

19.5

19.6

19.7

AT2T-2741-1 Rev. E ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL Page 19 / 41

REVISIONS

ADDED: (SHT 1) ITM 34, FLAG NOTE NEXT TO

ITM 7, NOTES 5 & 6

RMV’D: (SHT 1) ITM 29 AT2H-2357, CHG’D:

DWG TITLE WAS ELECTRIC GRIDDLE

SERVICE PARTS LIST, (SHT 1) ITM 1 AT2A-

2185 WAS AT2A-2185-10, ITM 4 AT2A-3189-1

WAS AT2A-CP2, ITM 6 AT2M-2187 QTY 1 AR

WAS 1, ITM 17 AT0A-2788-14 WAS AT0A-2788-

9, ITM 21 QTY 4 WAS 6, ITM 23 AT0F-2755-

41070 WAS AT0F-2755-41060, ITM 25 QTY 2

WAS 4, ITM 30 AT0F-2875-71080 WAS AT0F-

2061-41060, (SHT 4) ITM 5 AT0F-2755-41040

WAS AT0F-1017-41002, (SHT 5) ITM 4 AT0F-

2755-41040 WAS AT0F-1017-41002, (SHT 6) ITM

1 AT2A-2520 WAS AT2A-2520-2, ITM 3 AT2A-

2552-3 WAS AT2A-2552-1, ITM 4 AT2A-2529-3

WAS AT2A-2529-1, ADDED: (SHT 1) ITM 6

AT2M-2186, ITM 6 AT2M-1738, ITM 29 AT2A-

2778-71001, ITM 31, ITM 32, ITM 33, (SHT 6) ITM

20

253 C

243 B

234 A CHG'D: SHT #5 WAS SHT #4, ADDED SHT #4 08-09-05 ALB

ECN REV DESCRIPTION DATE APPR

Page 24

C

Rev.Drawing No.:Size:

Sheet 2 of 6

8415 N. Clinton Park

Fort Wayne, IN 46825

AccuTemp Products, Inc.

AT2A-3044

EDR: 085

SERVICE PARTS LIST

NAVY ELECTRIC GRIDDLE

Title:

Date

07-14-05DPS

Name

A BREMER 07-13-05

Drawn

Checked

Unless otherwise specified,

Dimensions: Inches

Bends: 90

Tolerances:

Angular 1°

N/A

G SEITZ 07-15-05

Proj Eng

Material:

2 Place Decimal .02

3 Place Decimal .005

T.I.R .005

D

Scale: 1:8

N/A

Finish:

Do Not Scale Drawing

Comments:

√125 Micro Inches

GD&T Per ANSI Y14.5M

4 AT0F-1017-41002 17 #10-24UNC HEX SERRATED NUT

4 AT0F-2666-40000 16 #10 LOCK WASHER INTERNAL TOOTH

4 AT0F-2755-41040 15 #10-24UNC X 1/2 PHIL RD HD MACH SCREW

4 AT0F-2666-30000 14 #8 LOCK WASHER INTERNAL TOOTH

4 AT0F-2755-31040 13 #8-32UNC X 1/2 PHIL RD HD MACH SCREW

1 AT0A-3112-1 12 ASSY, HARNESS

1 AT0A-3112-2 11 ASSY, HARNESS

1 AT0A-3112-3 10 ASSY, HARNESS

1 AT0A-3112-4 9 ASSY, HARNESS

1 AT0A-3111-2 8 CONTROL INPUT HARNESS

1 AT0A-3111-1 7 CONTROL INPUT HARNESS

2 AT0E-2059-3 6 RELAY, SOLID STATE

2 AT0E-2996-1 5 PAD, SSR HEAT SINK

2 AT0E-2206-3 4 HEAT SINK, 3.43" LONG

1 AT0H-2576-1 3 GROMMET, 7/8" NYLON

1 AT2M-3104-1 2 COVER, RELAY ENCLOSURE

1 AT2M-3103-1 1 CHASSIS, RELAY ENCLOSURE

QTY PART NO. ITEM DESCRIPTION

1

3

17

5

4

ELECTRIC GRIDDLE WITH SSR

(36" WIDE MODEL BOTTOM VIEW SHOWN)

6

14

13

12

11

10

9

7

8

2

16

15

AT2T-2741-1 Rev. E ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL Page 20 / 41

Page 25

C

Rev.Drawing No.:Size:

Sheet 3 of 6

8415 N. Clinton Park

Fort Wayne, IN 46825

AccuTemp Products, Inc.

AT2A-3044

EDR: 085

SERVICE PARTS LIST

#6-32UNC X 1 1/4 PHIL RD HD MACH SCREW

11

NAVY ELECTRIC GRIDDLE

Title:

Date

1-24-05DPS

ATP 1-24-05

Name

WASHER 1/4 TYPE B PLAIN

#6-32 NYLOC NUT

9

10

Unless otherwise specified,

Dimensions: Inches

GLS 1-24-05

Project Eng

Drawn

Checked

Bends: 90

Tolerances:

Material:

Angular 1°

2 Place Decimal .02

3 Place Decimal .005

T.I.R .005

D

Scale: 1:8

N/A

√125 Micro Inches

GD&T Per ANSI Y14.5M

N/A

Finish:

Do Not Scale Drawing

Comments:

AT0F-2755-21102

2

2 AT0F-1017-41002 12 #10-24UNC HEX SERRATED NUT

2

AT0F-1052-51002

2

AT0F-2691-21002

1 AT0E-1759-1 8 MICROSWITCH COVER

1 AT2E-1639-1 7 MICROSWITCH

1 AT2H-1640-1 6 EXTENSION SPRING

1 AT2M-1558-1 5 BRACKET, SWITCH

1 AT2H-1365-1 4 COMPRESSION SPRING

1 AT2F-1367-1 3 WASHER, TYPE A

1 AT2M-2860-1 2 SOLDER WASHER

1 AT2M-2861-1 1 WIRE ROD

QTY PART NO. ITEM DESCRIPTION

11

8

12

7

6

5

4

DETAIL VIEW

HIGH LIMIT OVERTEMP ASSEMBLY

2

1

3

10

9

AT2T-2741-1 Rev. E ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL Page 21 / 41

Page 26

C

Rev.Drawing No.:Size:

Sheet 4 of 6

8415 N. Clinton Park

Fort Wayne, IN 46825

AccuTemp Products, Inc.

AT2A-3044

EDR: 085

SERVICE PARTS LIST

12

NAVY ELECTRIC GRIDDLE

Title:

Date

1-24-05DPS

ATP 1-24-05

Name

Unless otherwise specified,

Dimensions: Inches

GLS 1-24-05

Project Eng

Drawn

Checked

Bends: 90

Tolerances:

Material:

Angular 1°

2 Place Decimal .02

3 Place Decimal .005

T.I.R .005

D

Scale: 1:8

N/A

√125 Micro Inches

GD&T Per ANSI Y14.5M

N/A

Finish:

Do Not Scale Drawing

Comments:

10

9

8

7

13

11

DROP-IN ELECTRIC GRIDDLE CONTROL PANEL

(FULL WIDTH CONFIGURATION SHOWN)

1 AT0E-2705-2 12 REMOTE POT & HARNESS

1 AT0H-1455-1 11 KNOB WITH SET SCREW

1 AT0E-2657-1 10 CONTACT BLOCK

1 AT0E-1800-2 9 INDICATOR LAMP RED INCANDESCENT 28V

1 AT0E-1800-1 8 INDICATOR LAMP GRN INCANDESCENT 28V

1 AT2M-2907-1 13 THERMOSTAT GUARD BRKT

1 AT0E-1755-1 7 ON/OFF SWITCH

QTY PART NO ITEM DESCRIPTION

1 AT2M-1559-2 6 COVER

2 AT0F-2755-41040 5 #10-24UNC X 1/2 PHIL RD HD MACH SCREW

B

8 AT0F-2777-31030 4 #8 TYPE AB X 3/8 TRUSS HEAD SCREW

1 AT2M-2561-2 3 BOX COVER, CONTACTOR

1 AT2A-2577-2 2 CONTROL BOX ASSEMBLY

1 AT2A-2520 1 GRIDDLE ASSEMBLY

QTY PART NO ITEM DESCRIPTION

B

(36" WIDE MODEL BOTTOM VIEW SHOWN)

DROP-IN ELECTRIC GRIDDLE WITH MDR

5

3

4

2

4

6

1

SEE SHEET 3 "HIGH LIMIT OVERTEMP ASSEMBLY DETAIL VIEW"

AT2T-2741-1 Rev. E ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL Page 22 / 41

Page 27

C

Rev.Drawing No.:Size:

Sheet 5 of 6

8415 N. Clinton Park

Fort Wayne, IN 46825

AccuTemp Products, Inc.

AT2A-3044

EDR: 085

SERVICE PARTS LIST

11

10

NAVY ELECTRIC GRIDDLE

Title:

Date

02-03-04GLS

ALB 02-03-04

Name

Unless otherwise specified,

Dimensions: Inches

GLS 02-03-04

Project Eng

Drawn

Checked

Bends: 90

Tolerances:

Material:

Angular 1°

2 Place Decimal .02

3 Place Decimal .005

T.I.R .005

D

Scale: 1:12

GD&T Per ANSI Y14.5M

N/A

Finish:

Do Not Scale Drawing

Comments:

N/A

√125 Micro Inches

12

13

DROP-IN ELECTRIC GRIDDLE CONTROL PANEL

AT2M-1559-2 6 COVER

1 AT2M-2907-1 13 THERMOSTAT GUARD BRKT

1 AT0H-1455-1 12 KNOB WITH SET SCREW

1 AT0E-2705-2 11 REMOTE POT & HARNESS

1 AT0E-2657-1 10 CONTACT BLOCK

1 AT0E-1800-1 9 INDICATOR LAMP GRN INCANDESCENT 28V

1 AT0E-1800-2 8 INDICATOR LAMP RED INCANDESCENT 28V

1 AT0E-1755-1 7 ON/OFF SWITCH

QTY PART NO. ITEM DESCRIPTION

1

1 AT2M-2646-1 5 COVER CONTROL BOX

4 AT0F-2755-41040 4 #10-24UNC X 1/2 PHIL RD HD MACH SCREW

8 AT0F-2777-31030 3 #8 TYPE AB X 3/8 TRUSS HEAD SCREW

1 AT2A-2577-3 2 CONTROL BOX ASSEMBLY

1 AT2A-2520 1 GRIDDLE ASSEMBLY

QTY PART NO. ITEM DESCRIPTION

B

(FULL WIDTH CONFIGURATION SHOWN)

8

9

7

DROP-IN ELECTRIC GRIDDLE WITH SSR

(36" WIDE MODEL BOTTOM VIEW SHOWN)

B

4

1

3

5

2

3

6

SEE SHEET 3 "HIGH LIMIT OVERTEMP ASSEMBLY DETAIL VIEW"

AT2T-2741-1 Rev. E ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL Page 23 / 41

Page 28

C

Rev.Drawing No.:Size:

Sheet 6 of 6

8415 N. Clinton Park

Fort Wayne, IN 46825

AccuTemp Products, Inc.

AT2A-3044

EDR: 085

SERVICE PARTS LIST

NAVY ELECTRIC GRIDDLE

Title:

Date

09-02-05DPS

ALB 09-02-05

Name

Unless otherwise specified,

Dimensions: Inches

DPS 09-02-05

Project Eng

Drawn

Checked

Bends: 90

Tolerances:

Material:

Angular 1°

2 Place Decimal .02

3 Place Decimal .005

T.I.R .005

D

Scale: 1:8

GD&T Per ANSI Y14.5M

N/A

Finish:

Do Not Scale Drawing

Comments:

N/A

√125 Micro Inches

12

1 AT2M-2907-1 20 THERMOSTAT GUARD BRKT

B

8 AT0F-2777-41040 19 #10 TYPE AB X 1/2 TRUSS HEAD SCREW

6 AT0F-2755-41040 18 #10-24UNC X 1/2 PHIL RD HD MACH SCREW

2 AT0F-2778-61000 17 5/16-18 UNC-2B SS HEX NUT

2 AT0F-1922-60000 16 5/16" WASHER LOCK, HELICAL SPRING

2 AT0F-1921-61060 15 BOLT, 5/16-18 UNC 2A X 3/4" CARRIAGE

1 AT2T-2742-1 14 ELECTRIC GRIDDLE OWNERS MANUAL

8 AT0F-2691-51002 13 1/4-20 NYLOC NUT

4 AT2M-2535-1 12 RETAINER BRACKET

1 AT2A-2764-1 11 CABLE ASSEMBLY

1 AT2A-2592-5 10 5" GREASE SPOUT EXTENSION

1 AT2A-2592-3 9 3" GREASE SPOUT EXTENSION

1 AT2A-2592-1 8 1" GREASE SPOUT EXTENSION

1 AT2A-2592-2 7 2" GREASE SPOUT EXTENSION

1 AT2M-2554-1 6 GREASE TROUGH HANGER

1 AT2M-2553-1 5 GREASE TROUGH HNGR BRKT

1 AT2A-2529-3 4 GREASE TROUGH ASSY

B

1 AT2A-2552-3 3 ASSY, LONG BAFFLED LOCKING GREASE TRAY

B

1 AT2A-2526-1 2 CONTROL PANEL ASSY - FULL

1 AT2A-2520 1 GRIDDLE ASSEMBLY

QTY PART NO. ITEM DESCRIPTION

B

13

18

16

17

5

15

6

14

7

B

4

18

19

B

20

8

9

10

1

B

3

2

11

OF ITEM #2

TO BACK SIDE

AT2T-2741-1 Rev. E ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL Page 24 / 41

Page 29

F

Rev.Drawing No.:Size:

Sheet 1 of 2

8415 N. Clinton Park

Fort Wayne, IN 46825

AccuTemp Products, Inc.

4

CONTROL

BOX ASSEMBLY

AT2A-2577

EDR: 038B

D

Title:

Date

2/3/2004GLS

ALB 8/1/2003

Name

GLS 2/3/2004

Project Eng

Drawn

Checked

N/A

Material:

Scale: 1:2

N/A

Finish:

NOTES: UNLESS OTHERWISE SPECIFIED

Do Not Scale Drawing

Unless otherwise specified,

Dimensions: Inches

Bends: 90

Tolerances:

Angular 1°

FOR AT2A-2577-2 WIRING SCHEMATIC SEE DRAWING AT2T-2767-2 OR1.

DRAWING AT2T-2713 SHEETS 4, 5, OR 6.

1 AT2A-2760-2 26 CABLE ASSEMBLY

2 AT0F-2668-1 27 #10-24 HEX NUTSERT

1 AT0E-3025-2 25 INSULATOR STRIP, 4 POSITION DOUBLE ROW

2 AT0F-2755-41050 24 #10-24UNC X 5/8 PHIL RD HD MACH SCREW

2 AT0A-2615-5 23 WIRE HARNESS

1 AT0A-2615-3 22 WIRE HARNESS

1 AT0A-2615-2 21 WIRE HARNESS

4 AT0F-1017-41001 20 #10-24UNC HEX SERRATED NUT

1 AT0E-1134-4 19 4 POSITION TERMINAL BLOCK

4 AT0F-2755-41040 18 #10-24UNC X 1/2 PHIL RD HD MACH SCREW

2 AT0E-2731-2 17 FUSE 1¼ AMP 250V

1 AT0A-2876-1 16 MDR WITH TERMINALS

1 AT0E-2662-5 15 TRANSFORMER

1 AT0A-2617-1 14 5.0" HIGH TEMP WIRE ASSEMBLY WHITE

1 AT0A-2761-1 13 CABLE GROUND WIRE ASSY

1 AT0A-2736-8 12 MOV- TERMINALS ASSEMBLY

1 AT0A-2736-7 11 MOV- TERMINALS ASSEMBLY

4 AT0F-2777-31030 10 #8 TYPE AB X 3/8 TRUSS HEAD SCREW

2 AT0F-2755-41020 9 #10-24UNC X 1/4 PHIL RD HD MACH SCREW

4 AT0F-2755-21050 8 #6-32UNC X 5/8 PHIL RD HD MACH SCR

6 AT0F-2755-21020 7 #6-32UNC X 1/4 PHIL RD HD MACH SCR

1 AT0E-2708-1 6 3AG OMNI-BLOK FUSE BLOCK 2 POS

1 AT0E-2705-1 5 ZYTRON THERMOSTAT

2 AT0H-2887-1 3 CABLE TIE MOUNT

1 AT0E-1587-4 2 3 POLE CONTACTOR

PART NO. ITEM DESCRIPTION

1 AT2M-2560-2 1 BOX, CONTROL

√125 Micro Inches

2 Place Decimal .02

3 Place Decimal .005

GD&T Per ANSI Y14.5M

T.I.R .005

Comments:

QTY

AT2A-2577-2

F

E

E

E

C

C

C

E

E

E

F

8

5

D

15

D

23

7

D

D

D

22

23

21

E

3

6

17

7

2

9

E

25

AT2A-2577-2

E

19

24

F

27

12

18

14

16

C

11

20

GLS / ALB

GLS / AP

GLS / ALB

GLS

GLS / ALB

GLS / ALB

1

EF

26

13

D

10

AT2T-2741-1 Rev. E ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL Page 25 / 41

08-12-05

RMV’D: AT2A-2577-1/SHT 1, CHG’D: SHT 1/AT2A-2577-2 WAS SHT

AT2M-2668-1

2/AT2A-2577-2, (AT2A-2577-2) NOTE 1 WAS FOR AT2A-2577-2

WIRING SCHEMATIC SEE DRAWING AT2T-2767-2, ITM 1 AT2M-2560-

2 WAS AT2A-3028-2, ADDED: AT2A-2577-3, (AT2A-2577-2) ITM 27

216 F

12-10-04

AT0F-2047-1 ITMNO 4, AT2M 2560-2 ITMNO 1, CHG’D: (SHT 2) ITMNO

RMV’D: (SHT 1) AT0F-2047-1 ITMNO 4, AT2M 2560-1 ITMNO 1, (SHT2)

20 AT0E-1134-4 WAS AT0E-1134-1, ITMNO 8 QTY 4 WAS 6, ADDED:

(SHT 1) AT2A-3028-1 ITMNO 1, (SHT 2) AT0F-2755-41050 ITMNO 25,

183 E

06-03-04

AT0E-3025-2 ITMNO 26, AT2A-3028-2 ITMNO 1

CHG'D: (SHT 1) ITEM 20 AT0E-2662-5 WAS AT0A-2779-1; ITEM 19

MOVE PICTORIALLY: ADDED ITEMS 25, 26 & 27: CHG'D (SHT 2) ITEM

16 AT0E-2662-5 WAS AT0A-2779-1; ITEM 14 MOVE PICTORIALLY:

112 D

05-04-04

04-26-04

02-12-04

REVISIONS

ADDED ITEMS 22, 23 & 24

AT0E-1134-3; AT0F-2755-21020 QTY 4 WAS 2; AT0F-2755-21050 GP-1

CHG'D #6-32UNC X 5/8 WAS #6-32UNC X 1/2; AT0E-1134-1 WAS

QTY 4 WAS 6 & GP-2 QTY 6 WAS 8; ITEM 18: AT0E-2731-2 WAS AT0E-

095 C

AT1E-2576-2 PER ECN 081, ADDED SHEET 2 (AT2A-2577-2)

2731-3; ITEM#3 AT0H-2887-1 WAS AT0H-2576-2; ON AT2A-2577-2

ROTATED ITEM #12 108º

CHG'D: ITEM #17 WAS AT0E-2736-2, ITEM # 2 (AT0H-2576-2) WAS

CHG AT0A-2617 WAS AT0E-2617; AF0H-2666 WAS AT1F-2666

088 B

065 A

ECN REV DESCRIPTION DATE APPR

Page 30

F

Rev.Drawing No.:Size:

Sheet 2 of 2

8415 N. Clinton Park

Fort Wayne, IN 46825

AccuTemp Products, Inc.

CONTROL

BOX ASSEMBLY

AT2A-2577

EDR: 038B

D

Title:

Date

2/3/2004GLS

ALB 8/1/2003

Name

GLS 2/3/2004

Project Eng

Drawn

Checked

N/A

Material:

Scale: 1:8

N/A

Finish:

NOTES: UNLESS OTHERWISE SPECIFIED

Do Not Scale Drawing

Unless otherwise specified,

Dimensions: Inches

Bends: 90

Tolerances:

Angular 1°

2 Place Decimal .02

3 Place Decimal .005

T.I.R .005

FOR AT2A-2577-3 WIRING SCHEMATIC SEE DRAWING AT2T-2767-1 OR1.

DRAWING AT2T-2713 SHEETS 1, 2, OR 3.

Comments:

GD&T Per ANSI Y14.5M

√125 Micro Inches

PART NO. ITEM DESCRIPTION

QTY AT2A-2577-3

1 AT0A-2617-33 32 8.0" HIGH TEMP WIRE ASSEMBLY BLACK

1 AT0A-2617-32 31 7.0" HIGH TEMP WIRE ASSEMBLY BLACK

1 AT0A-2617-31 30 6.0" HIGH TEMP WIRE ASSEMBLY RED

1 AT0A-2617-3 29 5.0" HIGH TEMP WIRE ASSEMBLY RED

1 AT2A-2760-4 28 CABLE ASSEMBLY

1 AT0A-2617-1 27 5.0" HIGH TEMP WIRE ASSEMBLY WHITE

2 AT0A-2615-5 26 WIRE HARNESS

1 AT0A-2615-3 25 WIRE HARNESS

1 AT0A-2615-2 24 WIRE HARNESS

1 AT0A-2761-1 23 CABLE GROUND WIRE ASSY

4 AT0F-2666-30000 22 #8 LOCK WASHER INTERNAL TOOTH

4 AT0F-2668-1 21 #10-24 HEX NUTSERT

5 AT0F-1017-41001 20 #10-24UNC HEX SERRATED NUT

7 AT0F-2755-41050 19 #10-24UNC X 5/8 PHIL RD HD MACH SCREW

2 AT0F-2755-41020 18 #10-24UNC X 1/4 PHIL RD HD MACH SCREW

4 AT0F-2755-31030 17 #8-32UNC X 3/8 PHIL RD HD MACH SCR

4 AT0F-2777-31030 16 #8 TYPE AB X 3/8 TRUSS HEAD SCREW

4 AT0F-2755-21050 15 #6-32UNC X 5/8 PHIL RD HD MACH SCR

6 AT0F-2755-21020 14 #6-32UNC X 1/4 PHIL RD HD MACH SCR

2 AT0E-2996-1 13 PAD, SSR HEAT SINK

2 AT0E-2059-3 12 RELAY, SOLID STATE

2 AT0E-2206-3 11 HEAT SINK, 3.43" LONG

2 AT0H-2887-1 10 CABLE TIE MOUNT

1 AT0A-2736-8 9 MOV- TERMINALS ASSEMBLY

1 AT0E-2662-5 8 TRANSFORMER

2 AT0E-2731-2 7 FUSE 1¼ AMP 250V

1 AT0E-2708-1 6 3AG OMNI-BLOK FUSE BLOCK 2 POS

1 AT0E-3025-2 5 INSULATOR STRIP, 4 POSITION DOUBLE ROW

1 AT0E-1134-4 4 4 POSITION TERMINAL BLOCK

1 AT0E-2705-1 3 ZYTRON THERMOSTAT

1 AT0E-1587-4 2 3 POLE CONTACTOR

1 AT2M-2560-3 1 BOX, CONTROL

12

22

17

30

29

23

28

19

20

27

18

19

4

9

5

2

7

6

15

11

13

32

31

3

26

24

25

20

F

8

AT2A-2577-3

14

19

16

10

1

21

AT2T-2741-1 Rev. E ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL Page 26 / 41

Page 31

G

R E D , # 3 W A S B L K , # 4 W A S B L K , # 5 W A S

Rev.Drawing No.:

Sheet 1 of 8

8415 N. Clinton Park

Fort Wayne, IN 46825

AccuTemp Products, Inc.

SPECIFICATIONS

22" & 24" MOD ELS

36" & 48" MOD ELS

240V unit, 18.0 OHM, 3.2KW ea.

208V unit, 13 .52 OHM, 3.2KW ea.

HEATER ELEMENT ELECTRICAL

208V unit, 9.11 OHM, 4.75KW ea.

240V unit, 12 .13 OHM, 4.75KW ea.

Title:

8/17/04

8/17/04

Date

08/17/04

K TYPE

YEL RED

o

t

R2

R1 R3

6

N

L3

RED

L3

MDR

RED

L3

MASTER

CONTACTOR

3

1

542

L2

L1

BLK

WHT

L1

BLK

WHT

L2

L1

BLK

WHT

VIO

RLY 2

WHT

ORN

RED

RLY 1

WHT

ORN

WHT VIO YEL REDORN

ZR1

PWR NA C OM OUTPUT + -

1 2 3 4 5 6 7

N.O.

N.C.

SW2

O.T. SW

RED

RED

1 P1 2

1 J1 2

RED

ORN

K TYPE CONTROLLER CAL OFFSET ADJ

VIO

LT2

HEAT

WHT

LT1

PWR

ORN

Name

G. SEITZ

G. SEITZ

D. STANLEY

Drawn

Project Eng

Checked

Bends: 90

Tolerances:

Angular 1°

Unless otherwise specified,

Dimensions: Inches

0 1 / 2 8 /0 5 G . S E I T Z

R E V IS I O N S

W H T , # 6 W A S W H T

W IR E C O N N E C T IO N S A L L S H E E T S ,

A L L S H E E T S ) # 1 W A S R E D ,# 2 W A S

R M V ' D : # 1 D E S I G N A T IO N F O R H E A T E R

C H G 'D : (H E A T E R W IR E D E S I G N A T I O N -

1 8 3 A A D D E D : 4 P O S IT IO N T E R M I N A L S T R IP 1 2 / 1 3 / 0 4 G . S E IT Z

1 9 7 B

E C N R E V D E S C R IP T IO N D A T E A P P R

AT2T-2947-1

AT2T-2947

EDR: 061

C

SCHEMATIC, ELEC GRIDDLE

Size:

Scale: 16:1

Material:

Finish:

Do Not Scale Drawing

2 Place Decimal .02

3 Place Decimal .005

T.I.R .005

125 Micro Inches

GD&T Per ANSI Y14.5M

Comments:

0 2 / 0 9 /0 5 G . S E I T Z

0 5 / 1 8 /0 5 G . S E I T Z

0 7 / 2 6 /0 5 G . S E I T Z

1 1 / 1 0 /0 5 G . S E I T Z

M D R

2 9 4 7 -7 & A T 2 T - 2 9 4 7 -8

( A T 2 T - 2 9 4 7 -4 T H R U - 6 )

C H G 'D : (S H T S 1 -3 ) M D R L E G

C H G ’D : T IT L E S C H E M A T I C , E L E C

E L E C T R I C A L S P E C S D A T A F I E L D ,

C H G 'D : (S H T S 1 ,2 & 3 ) R O U T I N G O F

T O H E A T L IG H T , A D D E D : S H T S 4 , 5 & 6

A D D E D : ( A L L S H E E T S ) M O V A C R O S S

L T 1 C O N N E C T I O N F R O M C O N T A C T O R

G R ID D L E W A S S C H E M A T I C , G R I D D L E ,

D E S IG N A T IO N L 3 W A S L 2 , M O V E D P W R

R L Y -1 T O T E R M I N A L 4 O N T H E R M O S T A T

C O M M O N W H T C O N D U C T O R F R O M M D R

C H G 'D : (S H T S 1 ,2 , 4 , 5 ) H E A T E R E L E M E N T

A D D E D : S H E E T 7 & 8 S C H E M A T I C S A T 2 T -

2 0 2 C

2 2 5 D

2 4 3 F

2 3 4 E

1 2 /2 9 / 0 5 G . S E ITZ

ORN

SW1

ON/OFF

BLK

RED

BLK

WHT

GRN

AT2T-2742-1 Rev. E ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL Page 27 / 41

208V/240V DELTA MDR HEATER CONFIGURATION

R E V IS IO N S

4 4 0 /4 8 0 V D E LT A M D R H E A T E R

S S R H E A TE R C O N F IG U R A T IO N

(S H T 7 ) 4 4 0 / 4 8 0 V D E L T A S S R H E A T E R

C H G 'D : C O N F IG U R A T IO N D E S C R IP TI O N

C O N F IG U R A TI O N W A S 4 4 0 / 4 80 V D E L TA

C O N F IG U R A TI O N W A S 4 4 0 / 4 80 V D E L TA

M D R H E A TE R C O N F I G U R A TI O N , (S H T 8 )

2 5 2 G

E C N R E V D E S C R IP TIO N D A T E A P P R

Page 32

G

Rev.Drawing No.:

Sheet 2 of 8

8415 N. Clinton Park

Fort Wayne, IN 46825

24" MODELS

SPECIFICATIONS

HEATER ELEMENT ELECTRICAL

36" & 48" MODELS

380V unit, 18.0 OHM, 2.680KW ea.

415V unit, 18.0 OHM, 3.197KW ea.

440V unit, 18.0 OHM, 3.594KW ea.

480V unit, 18.0 OHM, 4.277KW ea.

380V unit, 9.11 OHM, 5.300KW ea.

415V unit, 12.13 OHM, 4.745KW ea.

440V unit, 12.13 OHM, 5.334KW ea.

480V unit, 12.13 OHM, 6.346KW ea.

K TYPE

YEL RED

o

t

R2

ORN

AccuTemp Products, Inc.

AT2T-2947

EDR: 061

SCHEMATIC, ELEC GRIDDLE

Title:

Date

8/17/04

8/17/04

08/17/04

Name

G. SEITZ

G. SEITZ

D. STANLEY

Drawn

Project Eng

Checked

C

Size:

Scale: 16:1

Material:

Finish:

R1 R3

WHT VIO YEL REDORN

2

6

4

N

L3

5

RED

L3

MDR

RED

L3

MASTER

CONTACTOR

3

1

L2

L1

BLK

WHTWHT

L1

BLK

L2

L1

BLK

WHT

VIO

RLY 2

WHT

ORN

RED

RLY 1

WHT

ZR1

PWR NA COM OUTPUT + -

1 2 3 4 5 6 7

N.O.

N.C.

SW2

O.T. SW

RED

RED

1 P1 2

1 J1 2

RED

ORN

K TYPE CONTROLLER CAL OFFSET ADJ

VIO

LT2

HEAT

LT1

PWR

ORN WHT

AT2T-2947-2

ORN

SW1

ON/OFF

BLK

Bends: 90

Tolerances:

Angular 1°

2 Place Decimal .02

Unless otherwise specified,

Dimensions: Inches

380V - 480V WYE MDR HEATER CONFIGURATION

Do Not Scale Drawing

Comments:

3 Place Decimal .005

T.I.R .005

125 Micro Inches

GD&T Per ANSI Y14.5M

240V

220V/

COM

480V

440V

TO COMMON (WHT) AT RLY1

OMIT TRANSFORMER

CONNECT SUPPLY NEUTRAL

CONNECT L1 (BLK) TO SW1

L3 RED

L1 BLK

L2 WHT

GRN

*NEUTRAL

5 WIRE SYSTEM (4 WIRE W/GND)

AT2T-2742-1 Rev. E ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL Page 28 / 41

Page 33

G

Rev.Drawing No.:

Sheet 3 of 8

8415 N. Clinton Park

Fort Wayne, IN 46825

AccuTemp Products, Inc.

AT2T-2947

3.2KW ea.

1Ø MODELS

ELECTRICAL

SPECIFICATIONS

HEATER ELEMENT

240V unit, 18.0 OHM,

K TYPE

YEL RED

o

t

ORN

SCHEMATIC, ELEC GRIDDLE

Title:

Date

8/17/04

8/17/04

08/17/04

Name

G. SEITZ

G. SEITZ

D. STANLEY

Drawn

Material:

Project Eng

Checked

EDR: 061

C

Size:

Scale: 16:1

Finish:

R1 R3R2

2

143

N

L2

L3

6

RED

L2

MDR

L3

MASTER

CONTACTOR

L1

5

BLK

L1

BLK

RED

L2

L1

BLK

WHT

VIO

RLY 2

WHT

ORN

RED

RLY 1

WHT

WHT VIO YEL REDORN

ZR1

PWR NA COM OUTPUT + -

1 2 3 4 5 6 7

N.O.

N.C.

SW2

O.T. SW

RED

RED

1 P1 2

1 J1 2

RED

ORN

K TYPE CO NTROLLER CAL OFFS ET ADJ

VIO

LT2

HEAT

WHT

LT1

PWR

ORN

ORN

SW1

ON/OFF

BLK

AT2T-2947-3

Bends: 90

Tolerances:

Angular 1°

2 Place Decimal .02

Unless otherwise specified,

Dimensions: Inches

240V SINGLE PHASE MDR HEATER CONFIGURATION

Do Not Scale Drawing

Comments:

3 Place Decimal .005

T.I.R .005

125 Micro Inches

GD&T Per ANSI Y14.5M

BLK

WHT

GRN

AT2T-2742-1 Rev. E ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL Page 29 / 41

Page 34

G

Rev.Drawing No.:

Sheet 4 of 8

8415 N. Clinton Park

Fort Wayne, IN 46825

AccuTemp Products, Inc.

AT2T-2947

SPECIFICATIONS

22" & 24" MODELS

36" & 48" MODELS

240V unit, 18.0 OHM, 3.2KW ea.

208V unit, 13.52 OHM, 3.2KW ea.

HEATER ELEMENT ELECTRICAL

208V unit, 9.11 OHM, 4.75KW ea.

240V unit, 12.13 OHM, 4.75KW ea.

6RED

N

L2

L3

R2

R1 R3

3

1

542

L1

BLK

WHT

SSR 2

K TYPE

o

t

VIO

WHT

ORN

WHT VIO YEL RED

ZR1

PWR NA COM OUTPUT + -

1 2 3 4 5 6 7

ORN

K TYPE CONTROLLER CAL OFFSET ADJ

SCHEMATIC, ELEC GRIDDLE

Title:

Date

8/17/04

8/17/04

08/17/04

Name

G. SEITZ

G. SEITZ

D. STANLEY

Drawn

Material:

Project Eng

Checked

Bends: 90

Tolerances:

Angular 1°

2 Place Decimal .02

Unless otherwise specified,

Dimensions: Inches

3 Place Decimal .005

EDR: 061

C

Size:

Scale: 16:1

Finish:

Do Not Scale Drawing

T.I.R .005

125 Micro Inches

GD&T Per ANSI Y14.5M

Comments:

VIO

SSR 1

WHT

RED

L3

MASTER

CONTACTOR

BLK

WHT

ORN

L2

L1

BLK

WHT

RED

RLY 1

WHT

N.O.

N.C.

SW2

O.T. SW

RED

1 P1 2

1 J1 2

RED

VIO

LT2

HEAT

LT1

PWR

ORN WHT

AT2T-2947-4

RED

ORN

ORN

SW1

ON/OFF

BLK

208V/240V DELTA SSR HEATER CONFIGURATION

RED

BLK

WHT

GRN

AT2T-2742-1 Rev. E ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL Page 30 / 41

Page 35

G

Rev.Drawing No.:

Sheet 5 of 8

8415 N. Clinton Park

Fort Wayne, IN 46825

AccuTemp Products, Inc.

24" MODELS

SPECIFICATIONS

HEATER ELEMENT ELECTRICAL

36" & 48" MODELS

380V unit, 18.0 OHM, 2.68 0KW ea.

415V unit, 18.0 OHM, 3.19 7KW ea.

440V unit, 18.0 OHM, 3.59 4KW ea.

480V unit, 18.0 OHM, 4.27 7KW ea.

380V unit, 9.11 OHM, 5.30 0KW ea.

415V unit, 12.13 OHM, 4.745KW ea.

440V unit, 12.13 OHM, 5.334KW ea.

480V unit, 12.13 OHM, 6.346KW ea.

R2

R1 R3

2

6

4

N

L3

5

RED

3

1

L2

L1

BLK

WHT

K TYPE

o

t

ORN

Title:

Date

8/17/04

8/17/04

08/17/04

Name

G. SEITZ

G. SEITZ

D. STANLEY

Drawn

Project Eng

Checked

AT2T-2947

EDR: 061

C

SCHEMATIC, ELEC GRIDDLE

Size:

Scale: 16:1

Material:

Finish:

VIO

Bends: 90

Tolerances:

Angular 1°

2 Place Decimal .02

Unless otherwise specified,

Dimensions: Inches

SSR 2

WHT

VIO

SSR 1

WHT

RED

L3

MASTER

CONTACTOR

BLK

WHT

ORN

L2

L1

BLK

WHT

RED

RLY 1

WHT

WHT VIO YEL REDORN

ZR1

PWR NA COM OUTPUT + -

1 2 3 4 5 6 7

N.O.

N.C.

SW2

O.T. SW

RED

RED

1 P1 2

1 J1 2

RED

ORN

K TYPE CONTROLLER CAL OFFSET ADJ

VIO

LT2

HEAT

WHT

LT1

PWR

ORN

AT2T-2947-5

380V - 480V WYE SSR HEATER CONFIGURATION

ORN

SW1

ON/OFF

BLK

3 Place Decimal .005

Do Not Scale Drawing

T.I.R .005

125 Micro Inches

GD&T Per ANSI Y14.5M

Comments:

240V

220V/

COM

480V

440V

TO COMMON (WHT) AT RLY1

OMIT TRANSFORMER

CONNECT SUPPLY NEUTRAL

CONNECT L1 (BLK) TO SW1

L3 RED

L1 BLK

L2 WHT

GRN

*NEUTRAL

5 WIRE SYSTEM (4 WIRE W/GND)

AT2T-2742-1 Rev. E ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL Page 31 / 41

Page 36

G

Rev.Drawing No.:

Sheet 6 of 8

8415 N. Clinton Park

Fort Wayne, IN 46825

AccuTemp Products, Inc.

AT2T-2947

EDR: 061

C

SCHEMATIC, ELEC GRIDDLE

Title:

Size:

3.2KW ea.

1Ø MODELS

ELECTRICAL

SPECIFICATIONS

HEATER ELEMENT

240V unit, 18.0 OHM,

R1 R3R2

2

143

Date

8/17/04

8/17/04

08/17/04

Name

G. SEITZ

G. SEITZ

D. STANLEY

Scale: 16:1

N

L2

L3

6

RED

L3

MASTER

CONTACTOR

L1

5

BLK

VIO

SSR 1

WHT

BLK

RED

ORN

L2

L1

BLK

WHT

RED

RLY 1

WHT

K TYPE

o

t

ORN

WHT VIO YEL R EDORN

ZR1

PWR NA COM OUTPUT + -

1 2 3 4 5 6 7

N.O.

N.C.

SW2

O.T. SW

RED

RED

1 P1 2

1 J1 2

RED

ORN

K TYPE CONTROLLER CAL OFFSET ADJ

VIO

LT2

HEAT

WHT

LT1

PWR

ORN

ORN

SW1

ON/OFF

BLK

Drawn

Material:

Finish:

Project Eng

Checked

Bends: 90

Tolerances:

Angular 1°

2 Place Decimal .02

Unless otherwise specified,

Dimensions: Inches

3 Place Decimal .005

Do Not Scale Drawing

T.I.R .005

125 Micro Inches

GD&T Per ANSI Y14.5M

Comments:

AT2T-2947-6

240V SINGLE PHASE SSR HEATER CONFIGURATION

BLK

WHT

GRN

AT2T-2742-1 Rev. E ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL Page 32 / 41

Page 37

G

Rev.Drawing No.:

Sheet 7 of 8

8415 N. Clinton Park

Fort Wayne, IN 46825

AccuTemp Products, Inc.

22" & 24" MODELS

HEATER ELEMENT ELECTRICAL

440/480V unit, 60.60 OHM , 3.2/3.81KW ea.

440/480 V unit, 40.76 OH M, 4.75/5.65KW ea.

654

N

L2

L3

RED

R2

R1 R3

3

1

2

L1

BLK

WHT

SSR 1 SSR 2

K TYPE

o

t

ORN

VIO

WHT VIO YEL REDO RN

WHT

VIO

WHT

ZR1

K TYPE CO NTROLLER CAL OFFSET ADJ

PWR N A COM OUTPUT + -

1 2 3 4 5 6 7

VIO

LT2

HEAT

WHT

SCHEMATIC, ELEC GRIDDLE

Title:

Date

8/17/04

8/17/04

08/17/04

Name

G. SEITZ

G. SEITZ

D. STANLEY

Drawn

Material:

Project Eng

Checked

Bends: 90

Tolerances:

Angular 1°

2 Place Decimal .02

Unless otherwise specified,

Dimensions: Inches

3 Place Decimal .005

EDR: 061

C

Size:

Scale: 16:1

Finish:

Do Not Scale Drawing

T.I.R .005

125 Micro Inches

GD&T Per ANSI Y14.5M

Comments:

SPECIFICATIONS

AT2T-2947

36" & 48" MODELS

LT1

PWR

ORN

RED

L3

MASTER

CONTACTOR

BLK

WHT

ORN

L2

L1

BLK

WHT

RED

RLY 1

WHT

240V

220V/

COM

440V

480V/

N.O.

N.C.

SW2

O.T. SW

RED

RED

1 P1 2

1 J1 2

RED

ORN

ORN

SW1

ON/OFF

BLK

G

AT2T-2947-7

440/480V DELTA SSR HEATER CONFIGURATION

L3 RED

L1 BLK

L2 WHT

GRN

AT2T-2742-1 Rev. E ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL Page 33 / 41

Page 38

G

Rev.Drawing No.:

Sheet 8 of 8

8415 N. Clinton Park

Fort Wayne, IN 46825

AccuTemp Products, Inc.

AT2T-2947

SPECIFICATIONS

22" & 24" MODELS

36" & 48" MODELS

SCHEMATIC, ELEC GRIDDLE

HEATER ELEMENT ELECTRICAL

440/480V unit, 60.6 0 OHM, 3.2/3.81KW ea.

440/480V unit, 40.7 6 OHM, 4.75/5.65KW ea.

K TYPE

YEL RED

o

t

ORN

R2

R1 R3

WHT VIO YEL REDORN

654

N

L3

3

1

2

L2

L1

ZR1

PWR NA COM OUTPUT + -

1 2 3 4 5 6 7

K TYPE CONTROLLER CAL OFFSET ADJ

Title:

Date

8/17/04

8/17/04

08/17/04

Name

G. SEITZ

G. SEITZ

D. STANLEY

Drawn

Material:

Project Eng

Checked

Bends: 90

Tolerances:

Angular 1°

2 Place Decimal .02

Unless otherwise specified,

Dimensions: Inches

3 Place Decimal .005

EDR: 061

C

Size:

Scale: 16:1

Finish:

Do Not Scale Drawing

T.I.R .005

125 Micro Inches

GD&T Per ANSI Y14.5M

Comments:

RED

L3

MDR

RED

L3

MASTER

CONTACTOR

BLK

WHTWHT

L1

BLK

L2

L1

BLK

WHT

VIO

RLY 2

WHT

N.O.

N.C.

ORN

RED

RLY 1

WHT

240V

220V/

COM

440V

480V/

SW2

RED

1 P1 2

1 J1 2

RED

O.T. SW

VIO

LT2

HEAT

LT1

PWR

ORN WHT

AT2T-2947-8

RED

ORN

ORN

SW1

ON/OFF

BLK

G

440/480V DELTA MDR HEATER CONFIGURATION

L3 RED

L1 BLK

L2 WHT

GRN

AT2T-2742-1 Rev. E ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL Page 34 / 41

Page 39

H

R E D , # 3 W A S B L K , # 4 W A S B L K , # 5 W A S

D E S IG N A T I O N L 3 W A S L 2 , ( S H T 6 ) M O V E D

Rev.Drawing No.:

Sheet 1 of 6

8415 N. Clinton Park

ea.

24" MODELS

SPECIFICATIONS

36" & 48" MODELS

240V unit, 12.13 OHM, 4.75KW

240V unit, 18.0 OHM, 3.2KW ea.

208V unit, 13.52 OHM, 3.2KW ea.

HEATER ELEMENT ELECTRICAL

208V unit, 9.11 OHM, 4.75KW ea.

CONTROL

THERMOSTAT

Fort Wayne, IN 46825

Accutemp Products, Inc.

AT2T-2713

24 VAC CONTROL

GRIDDLE SCHEMATIC

EDR: 038B

LT2

HEAT

3 2 1

P4

J4

J TYPE

WHT RE D

ORN WHT REDRED

o

t

R2

R1 R3

AT0E-2705-1

ALTERNATE CONTROL PANEL WIRING

WHT

4

1

2

6

N

L3

RED

ZR2

RED

AT0E-2736-5

L

3

L2

WHT

WHT

L2L

WHT

3

5

1 2 3 C OM N.O. 4 5

L1

BLK

WHT

SSR 1 SSR 2

ZR1

BLK

RED

1

AT2E-1587-4

BLK

ZR4

RLY 1

AT0E-2736-8

WHT

F1

PWR NC COM OUTPUT OUTPUT + -

N.O.

N.C.

AT2A-2916-2

SW2

O.T. SW

RED

RED

1 P4 2

1 J4 2

BLK

BLK

AT0A-2758-1

1 P3 2

1 J3 2

BLK

BLK

BLK

WHT

F2

3AG .5A

AT0E-2731-1

BLK

P5

WHT

1 2 3

J TYPE CONTROLLER CAL OFFSET ADJ

RED

ENCLOSURE

CONTACTOR

AT2A-2764-1

AT2A-2760-1

BLK

WHT

RED

WHT

RED ORN

BLK

GRNBLU

BLK

WHT/

P2

J2

1 2 3 4 5 6 7

ORN

RED

1 2 3 4 5 6 7

BLK WHT

AT0A-2761-1

3 2 1

LT1

PWR

BLK

J1

RED

-LATCHING START CONFIGURATION-

1 2 3 4 5 6 7

BLK

GRN

AT2A-2763-1

3 2 1

3 2 1

AT2A-2762-1

BLK

J1

P1

1 2 3 4 5 6 7

1 2 3 4 5 6 7

ORN

WHT

RED

2

N.C.

P4

J4

WHT

RED

WHT

RED

1

N.O.

CR

COM

ORN

GRN

START

RUN

OFF

RED

THERMOSTAT

WHT

ON/OFF

RED

BLK

PANEL

CONTROL

BLK

SW1

NC

BLK

CONTROL

LT2

HEAT

LT1

PWR

AT0E-1800-1 AT0E-1800-2

SW1

AT2E-1755

AT2T-2713-1

PANEL

CONTROL

208/240V DELTA SSR HEATER CONFIGURATION

Title:

Date

2/04/04

2/04/04

10/15/03

Name

G. SEITZ

G. SEITZ

G. SEITZ

Drawn

Project Eng

Checked

Bends: 90

Tolerances:

Unless otherwise specified,

Dimensions: Inches

Angular 1°

1 / 9 / 2 0 0 4 G L S

3 / 9 / 2 0 0 4 G L S

R E V IS IO N S

R E L E A S E D 2 / 4 / 2 0 0 3 G L S

4 4 0 /4 8 0 V W Y E H E A T E R C O N F IG

C O N N E C T IO N O N S H E E T S 1 , 2 , 3

C H G 'D : N A M E W A S A T 2 E - 2 7 1 3 , A D D E D :

C H G 'D : P O L A R I T Y F O R T H E R M O C O U P L E

A

0 7 7 B

E C N R E V D E S C R I P T IO N D A T E A P P R

8/1 2/2005 GLS

REV ISIONS

C

Scale: 1:1

Size:

AVERY #6573

Material:

Finish:

Do Not Scale Drawing

GD&T Per ANSI Y14.5M

125 Micro Inches

2 Place Decimal .02

3 Place Decimal .005

T.I.R .005

Comments:

4 / 2 3 / 2 0 0 4 G L S

A T O E - 2 7 3 6 -2 , A D D E D : S H E E T S 4 , 5 , 6

C H G 'D : (S H E E T S 1 , 2 ,3 ) Z R 6 & Z R 7 W A S

C H G 'D : (S H T S 4 - 6 ) T E R M IN A L S T R IP W A S

0 8 8 C

2 / 9 / 2 0 0 5 G L S

1 2 / 2 / 2 0 0 4 G L S

1 / 2 8 / 2 0 0 5 G L S

W IR IN G

3 P O S . , (S H T 5 & 6 ) R E - R O U T E D H E A T E R

1 8 3 D

P O S IT IO N

W H T , # 6 W A S W H T

C H G 'D : (S H T S 4 - 6 ) M D R L E G

W IR E C O L O R "R E D " TO C O R R E C T

W IR E C O N N E C T IO N S A L L S H E E T S ,

A L L S H E E T S ) # 1 W A S R E D , # 2 W A S

R M V 'D : # 1 D E S IG N A T IO N F O R H E A T E R

C H G 'D : (H E A T E R W IR E D E S I G N A T I O N -

1 9 7 E

2 0 2 F

24V

480V

440V

240V

208V

AT0E-2662-5

FINAL SELECTION OF

PRIMARY VOLTAGE TO BE

MADE IN FINAL ASSEMBLY

RED

BLK

WHT

GRN

COM

AT2T-2742-1 Rev. E ACCU-STEAM ELECTRIC GRIDDLE OWNERS MANUAL Page 35 / 41

SY STEM FOR SOLID STATE RELA YS

CHG 'D: ( SHEE TS 1-3) RECO NFIGURE D

234 H

ECN RE V DES CRIPTION DATE AP PR

Page 40

H

DESCRIPTION

DATE

APPR

DESCRIPTION

DATE

APPR

Rev.Drawing No.:

Sheet 2 of 6

8415 N. Clinton Park

Fort Wayne, IN 46825

24" MODELS

SPECIFICATIONS

HEATER ELEMENT ELECTRICAL

2

516

N

4

36" & 48" MODELS

CONTROL

480V unit, 18.0 OHM, 4.277KW ea.

440V unit, 18.0 OHM, 3.594KW ea.

L3

RED

480V unit, 12.13 OHM, 6.346KW ea.

440V unit, 12.13 OHM, 5.334KW ea.

3 2 1

P4

J4

J TYPE

WHT R ED

ORN WHT REDRED

o

t

R2

R1 R3

AT0E-2705-1

ALTERNATE CONTROL PANEL WIRING

WHT

3

1 2 3 COM N.O. 4 5

L2

L1

WHT

BLK

PWR NC COM OUTPUT OUTPUT + -

BLK

P5

WHT

1 2 3

J TYPE CONTROLLER CAL OFFSET ADJ

RED

3 2 1

BLK

J1

RED

-LATCHING START CONFIGURATION-

1 2 3 4 5 6 7

BLK

GRN

ORN

WHT

RED

1

2

N.O.

N.C.

CR

COM

THERMOSTAT

LT2

HEAT

LT1

PWR

PANEL

CONTROL

WHT

RED

BLK

START

RUN

SW1

OFF

RED

NC

BLK

AccuTemp Products, Inc.

AT2T-2713

24VAC CONTROL

GRIDDLE SCHEMATIC

Title:

Date

2/04/04

2/04/04

01/09/04

Name

G. SEITZ

G. SEITZ

G. SEITZ

Drawn

Material:

Project Eng

Checked

Bends: 90

Tolerances:

Unless otherwise specified,

Dimensions: Inches

Angular 1°

2 Place Decimal .02

3 Place Decimal .005

EDR: 038B

C

Scale: 1:1

Size:

AVERY #6573

Finish:

Do Not Scale Drawing

GD&T Per ANSI Y14.5M

125 Micro Inches

T.I.R .005

Comments:

WHT

SSR 1 SSR 2

ZR2

RED

AT0E-2736-5

WHT

L2L

L

3

WHT

ZR1

BLK

RED

1

AT2E-1587-4