Page 1

SERIAL #

MODEL #

EVOLUTION ELECTRIC

MANUAL FOR

EEK

IMPORTANT WARRANTY INFORMATION:

For product warranty activation, the Product Registration Form must be submitted to

AccuTemp Products, Inc. after installation of the appliance.

Product Registration Form

These installation instructions have been prepared for qualied electric equipment

SP8017-1404

installation personnel, who should perform the installation, initial eld start-up and

complete the equipment adjustments described in this manual.

ACCUTEMP PRODUCTS, INC. · 8415 N. CLINTON PARK · FORT WAYNE, IN 46825 · 800.480.0415 · www.accutemp.net

Page 2

TABLE OF CONTENTS

TABLE OF CONTENTS 1

DOCUMENT HISTORY 1

SAFETY WARNINGS DEFINITIONS 2

INSTALLATION 3-4

OPERATION 5-12

BASIC TROUBLESHOOTING 13

SERVICE INFORMATION 14-39

SCHEMATICS 40-41

SERVICE PARTS 44-57

SERVICE CONTACT INFORMATION 58

WARRANTY STATEMENT 59

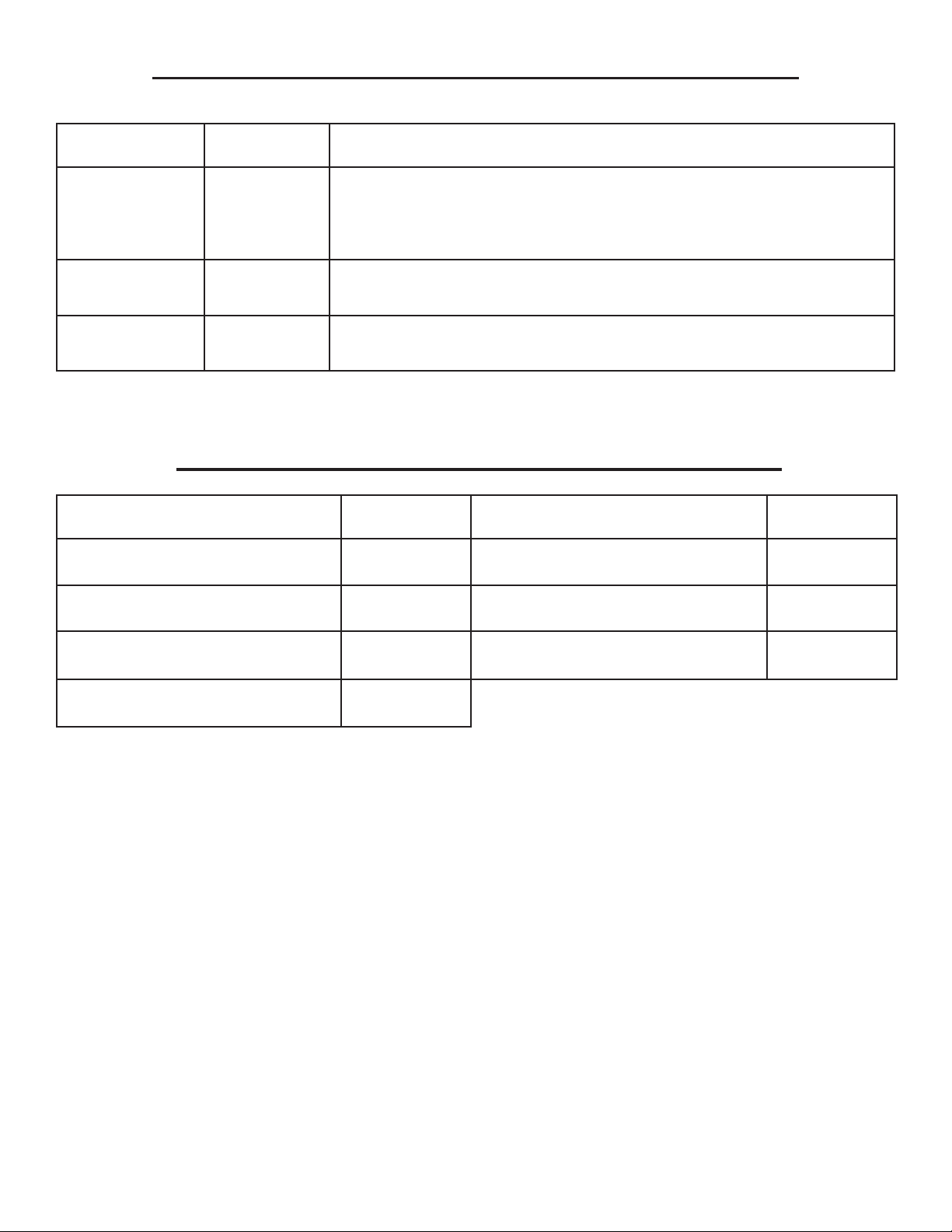

DOCUMENT HISTORY

CURRENT

REVISION

1404 4/21/14 1305 4/24/13 Changed document name from ESPEC to

CURRENT

REVISION

1305 5/13/13 1304 4/24/13 Page 44 - Updated graphic- Changed

REVISION DATE PRIOR

1304 4/24/13 1007 7/31/10 Page 6 - Change wire color,

REVISION DATE PRIOR

1007 7/31/10 N/A Initial release of manual

DATE PRIOR

REVISION

DATE PRIOR

REVISION

REVISION

REVISION

DATE CHANGE

EEK

DATE CHANGE

Schematic LT BLU to MED BLU

DATE CHANGE

Page 44 - Updated graphic

Page 49 & 50 - Updated Part Listing

DATE CHANGE

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 1

Page 3

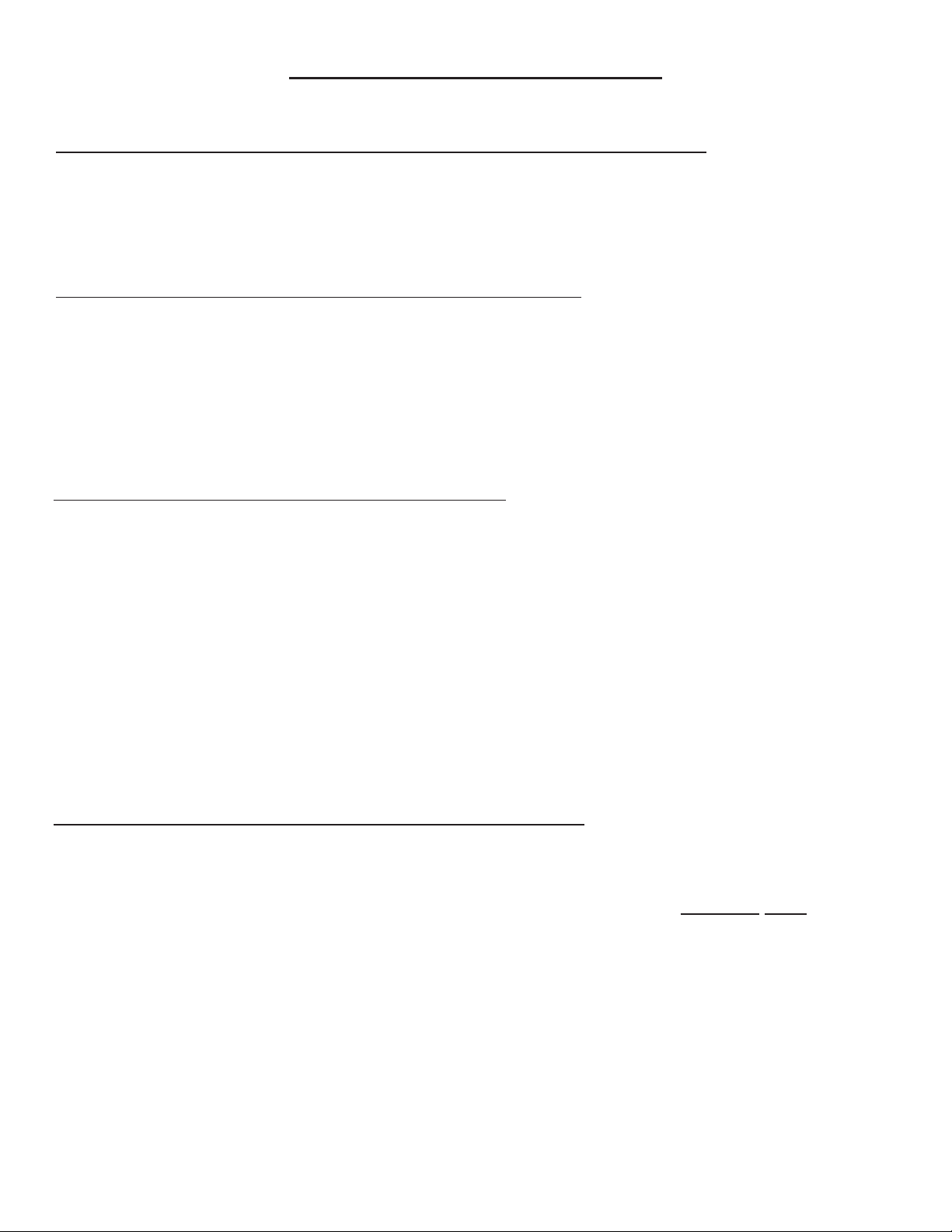

SAFETY WARNINGS

SYMBOL DEFINITIONS

Symbols are used to attract your attention to possible

dangers. They are only effective if the operator uses

proper accident prevention measures. Some of the

symbols are boxed text, while other maybe just

picture icons. Please give this information the respect

they deserve for safe operation.

WARNING TEXT BOXES

Below are denitions of the warning text boxes:

DANGER

SYMBOLS

Below are the denitions of the symbols used in

the manual

ALERT

Noties the reader of an important message or

warning, usually safety related

Indicates a imminently hazardous situation which,

if not avoided will, result in death or serious

injury

• WARNING

Indicates a potentially hazardous situation which,

if not avoided will, will result in death or serious

injury

CAUTION

Indicates a potentially hazardous situation which,

if not avoided will, will result in minor or moderate

injury

INFORMATION

Noties the reader of an important information.

CAUTION - HOT

CAUTION - HIGH VOLTAGE

NOTE

Advises reader of information or instructions vital

to the operation or maintenance of the equipment

SP8017-1404

EVOLUTION EEK STEAMER

EARTH GROUND

PAGE 2

Page 4

INSTALLATION

UNPACKING

This appliance was carefully inspected before

shipment from the factory. The transportation

company assumes full responsibility for safe delivery

to the customer until customer acceptance of the

package. Careful inspection of the packaging and the

appliance should be completed before acceptance from

the transportation company.

Only qualied service technicians/electricians should

perform the installation to ensure that all electrical

and safety requirements are met and that all wiring

and plumbing installations is preformed in accordance

with all national, state and local codes.

The installation must conform with local codes, or in

the absence of local codes, with the National Electric

Code.

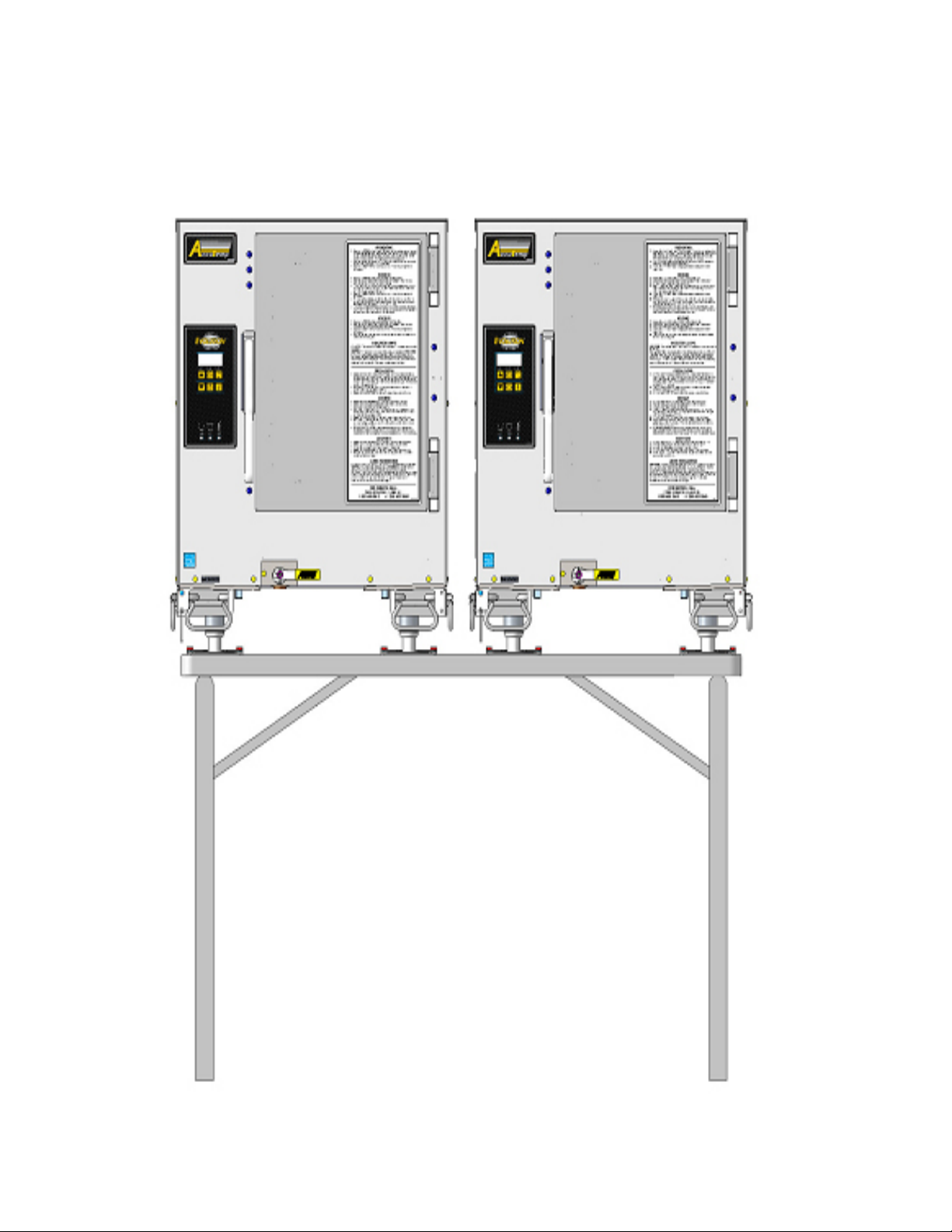

LOCATION AND PLACEMENT

The appliance must be placed on the AT1A-3780- 1

Steamer Table Assembly which is specially designed

for this application. Clearances must be maintained as

indicated for access to the circuit breaker inside the

power pack and for proper operation of the appliance

See Fig. 1 & Fig 2 for clearance specications.

EQUIPMENT CLEARANCE REAR

7”

Fig 2

CAUTION

This appliance is extremely heavy. For safe

handling, the installer should obtain help

as needed or employ appropriate material

handling equipment to remove appliance

from it’s packaging and move it into its nal

location.

EQUIPMENT CLEARANCE SIDES

1”

SP8017-1404

Fig 1

1”

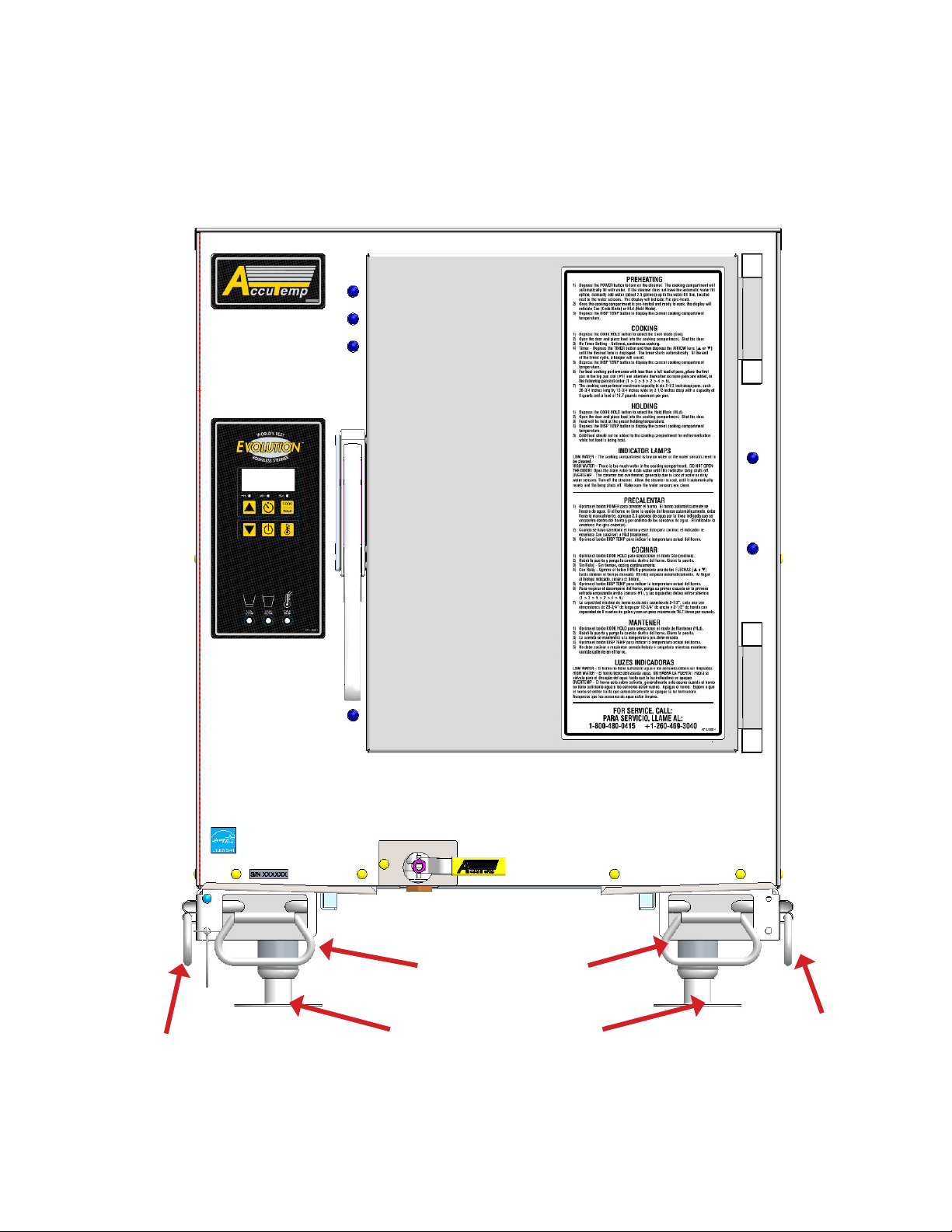

APPLIANCE LIFTING

Appliances are heavy enough to require

additional manpower or powered assistance

when installed on the stand. This model

Evolution incorporates front and side lifting

handles that must be used to lift the appliance

on to the stand. This table has retaining

brackets that the appliance anged feet must

slide into to secure it to the table. See Fig 3

EVOLUTION EEK STEAMER

Fig 3

LIFTING HANDLES

PAGE 3

Page 5

INSTALLATION

WARNING

LEVELING

This appliance must be installed in a level condition.

An out of level condition may cause erratic operation

and damage. Damage of this kind is not covered by

the limited warranty.

The appliance is leveled by screwing in and out the

four anged feet while using a spirit level front to

back and left to right.

The anged feet of the appliance are easier to adjust

if they are not interlocked into the retaining brackets

of the EEK table assembly. However it is possible to

adjust if interlocked into the retaining brackets of the

table assembly.

ELECTRICAL REQUIREMENTS

The AccuTemp Evolution Electric appliance has been

designed, manufactured and tested to meet

or exceed the Underwriters Laboratories safety

standards. To ensure safety is maintained in

your installation, it is important that the following

paragraphs are understood before attempting to

apply power to your appliance. If there is any doubt

as to whether your supply receptacle is of the correct

voltage, amperage, or is properly grounded, consult a

qualied electrician or authorized service agent.

POWER REQUIREMENTS

AC power requirements are listed on the data plate

located on the left side access panel on all Evolutions.

This appliance should never be connected to a

circuit operating at more than 150 VAC to ground

and should always be connected to an individual

branch circuit. Make sure the voltage at the supply

receptacle is within ±10% of the voltage listed on

the Evolution data plate. Connection to any other

voltage may permanently damage your appliance or

cause premature component failure. Damage of this

type is not covered under the product warranty. Each

Evolution Electric appliance for EEK comes equipped

with a power pack and an internal breaker that is rated

for the power requirements of each appliance. Damage

caused by removal or modication of the power pack

is not covered by appliance limited warranty.

Only personnel qualied to work with electricity

should install this equipment. Improper

installation can cause personal injury or damage

to the equipment.

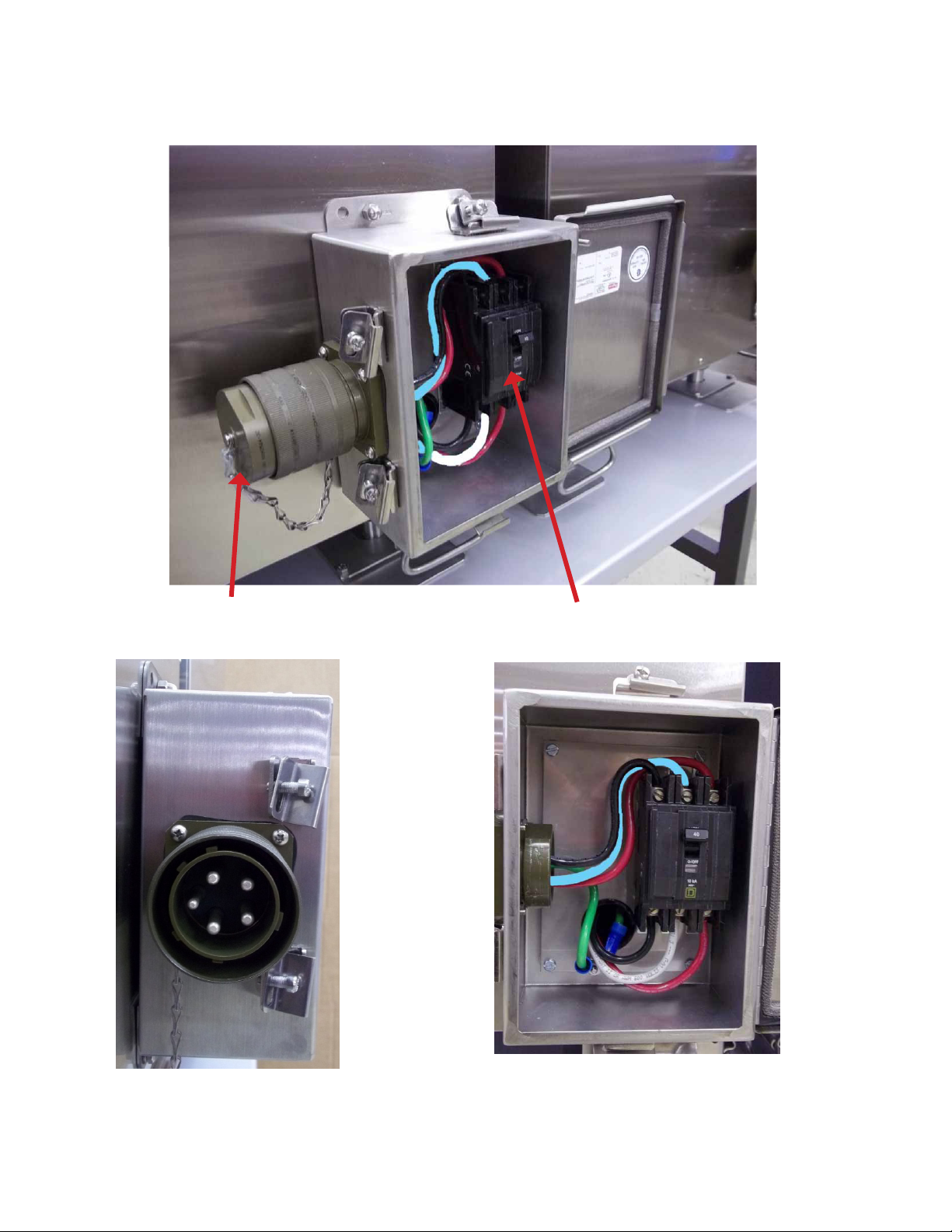

ELECTRICAL INSTALLATION

This appliance is designed with a power pack for

connection to a generator or line power. Always turn

the breaker off at the supply side before connecting

power to the appliance. If a generator is to be

used wait until the generator has stabilized before

connecting power. Connect appliance to power and

turn supply side breaker on and turn on Power Pack

breaker at appliance.

Close and secure the Power Pack.

DANGER

This appliance Must be properly grounded, in

accordance with all National, State and local

electrical codes.

GROUNDING INSTRUCTIONS

Grounding provides a path for electric current to

reduce risk of shock. This product is equipped with a

power pack. The power pack must be plugged into a

receptacle that is properly installed and grounded in

accordance with all National, State and local electrical

codes or in the absence of local electrical codes with

the National Electric Code, ANSI/NFPA 70, or the

Canadian Code, CSA C22.2 as applicable. Under no

circumstances shall the plugs grounding prong be cut

or bent to t a receptacle other than the one specied.

Do not use any adapters.

DANGER

Any in-eld modication made that bypass the

safety features of this appliance will result in

serious injury or death.

WARNING

Any in-eld modications made without written

authorization from AccuTemp Products, Inc. will

void all written and oral warranties.

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 4

Page 6

OPERATIONS

OPERATOR DISPLAY

OPERATING INSTRUCTIONS

& KEYPAD

DOOR LATCH

SIDE LIFT HANDLE

SP8017-1404

DRAIN VALVE

FRONT LIFT HANDLES

ADJUSTABLE FLANGED FEET

FIG 4

EVOLUTION EEK STEAMER

SIDE LIFT HANDLE

PAGE 5

Page 7

OPERATIONS

POWER PACK

GENERATOR CONNECTION

COVER CAP

CIRCUIT BREAKER

GENERATOR CONNECTION

SP8017-1404

FIG 5

EVOLUTION EEK STEAMER

PAGE 6

Page 8

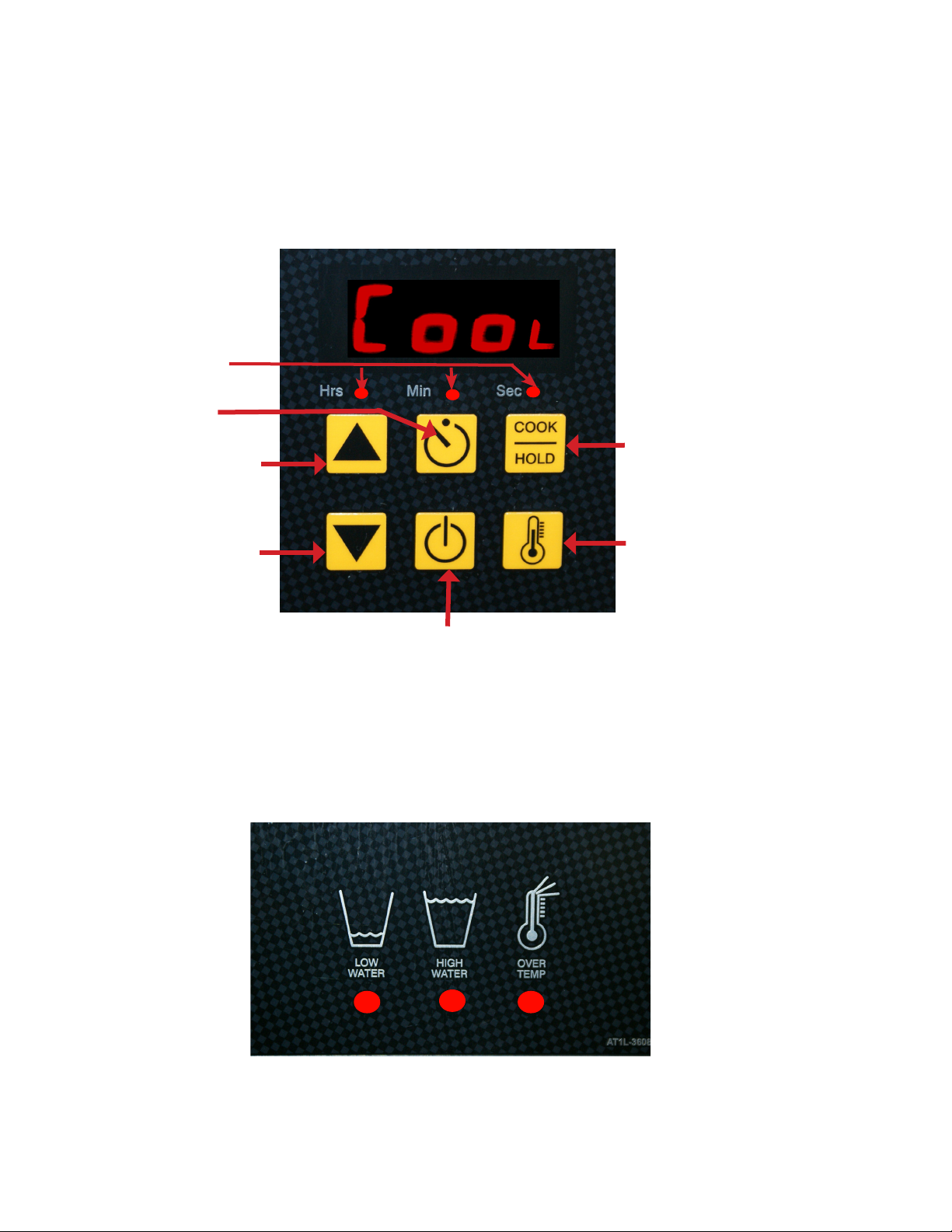

OPERATIONS

HRS/MIN/SEC

TIMER

INDICATORS

TIMER

Keypad & Display

INCREASE TIME

DECREASE TIME

COOK/HOLD

DISPLAY

TEMPERATURE

ON/OFF

FIG 6

Warning Indicators

SP8017-1404

FIG 7

EVOLUTION EEK STEAMER

PAGE 7

Page 9

OPERATIONS

SAFETY WARNINGS

WARNING

When accessing the cooking chamber , be sure to always stand back while slowing opening the door

to allow the chamber to vent off the steam. Never reach into the cooking chamber before it has

completely vented off the steam

Never reach into the cooking chamber or handle hot items without wearing the proper hot gloves.

Steam coming out of the holes on the right side of the cooking chamber are invisible and can cause

severe burns

Never use wet or damp gloves as moisture can conduct heat quickly.

If a cover or covering is used on the cooking pans verify if liquid has accumulated on the top of the

cover or covering. If this has occured use precaution when removing the pan to avoid the liquid

from spilling as it can cause servere burns.

Keep the oor in front of the equipment clean and dry. If spills occur, clean immediately to avoid

potential injuries.

CAUTION

Do not manually ll water above the water level mark on the left side of the cooking chamber.

Do not use abrasive materials, such as wire brushes, metal scouring pads to clean the cooking

chamber bottom.

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 8

Page 10

OPERATIONS

DAILY PREP:

1. Place 4” full size steam table pan or a 1/1

gastronome pan with a minimum depth of 4”.

2. Close the drain valve

3. Fill with 2 1/2 gallons (9.5 Litres) of tap water.

4. Close Door

5. Press (On/Off) to start the preheat

process.

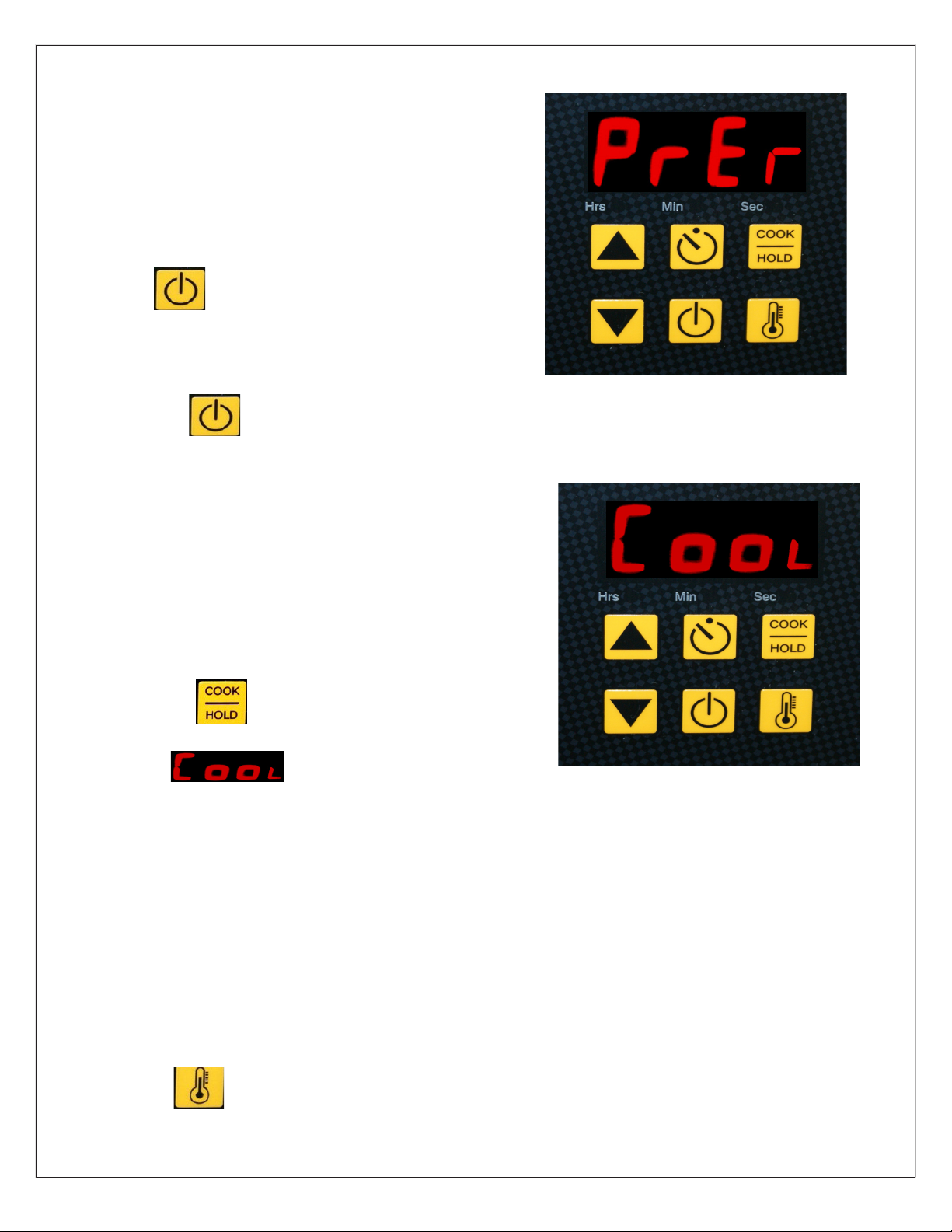

PREHEATING ( FIG 8)

1. Depress the (On/Off) key to turn on

the appliance. The display will indicate PrE.

2. Once the appliance is preheated to 195° F

the display will indicate COO (Cook Mode)

3. Place your product into the cooking chamber

starting from the top and working your way

from top to bottom until all 6 pans are in place.

Close the door to start the cooking process.

COOKING ( Fig 9 )

1. Depress the key to select the Cook

Mode (COO). Make sure that the appliance

displays

2. Open the door and place food into the

cooking chamber. Loading the pans from top

to bottom until all 6 pans 2 1/2” steam table

pans are in place. Close the door to start the

cooking process. For Partial Loads see Page

11, Fig 12.

Fig 8

Fig 9

3. Timer — Depress the TIMER button and

depress the ARROW keys [▲ or ▼] until the

desired time is displayed. The timer starts

automatically. At the end of the timed cycle, a

beeper will sound.

4. Press the key at any time to display

the current cooking chamber temperature.

SP8017-1404

EVOLUTION EEK STEAMER

NOTE:

The highest cooking temperature with no

product in the appliance is 212 °F(100°C)

at sea level. Higher elevations will decrease

the cooking temperature.

PAGE 9

Page 11

OPERATIONS

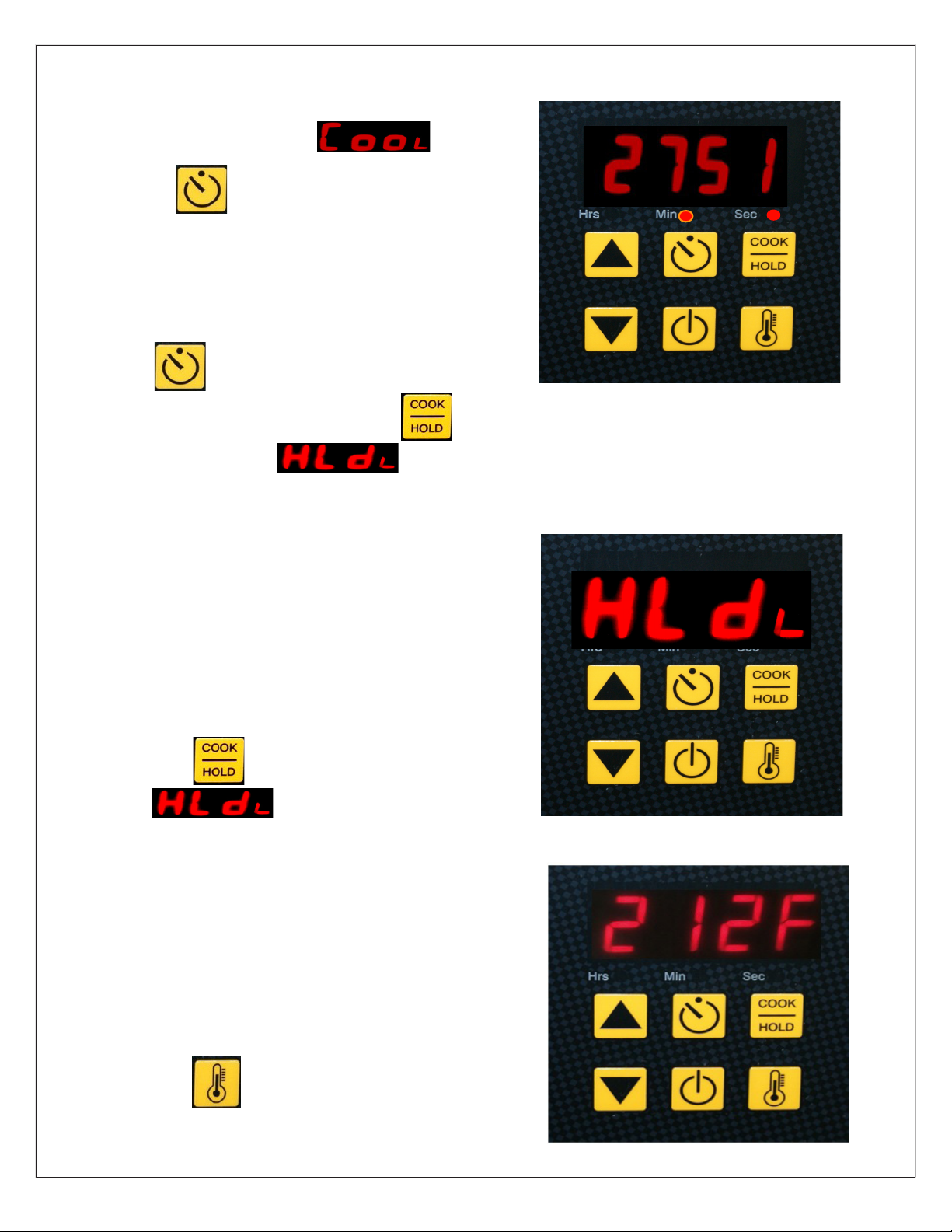

Timed Cooking (Fig 10)

1. Verify that the display reads

2. Depress the key to start the timer in the

default time.

3. To adjust depress the ARROW keys [▲ or ▼]

until the desired time is displayed. The timer

starts automatically and at the end of the timed

cycle a beeper will sound.

4. Press the key to silence the beeper.

To stop the cooking process press the

key until display reads

The food will be held at the default temperature

of 180°F(82.2°C)

Fig 9

HOLDING ( Fig 11 )

In “Hold” the appliance temperature is set for

180° F from the factory. The hold temperature

can be changed to a single value for

temperatures ranging from150° F to 190° F. (See

page 17 for programming this function).

Hold can also be used during downtimes to save

energy and water while keeping the appliance

preheated.

1. Depress the key to select the Hold

Mode

2. Open the door and place food into the

cooking chamber. Shut the door.

3. Food will be held at the preset holding

temperature. The factory default setting is set

at 180° F(82.2°C).

4. Depress the DISP TEMP button to

display the current cooking chamber

temperature.

Fig 10

DISPLAYING TEMPERTURE( Fig 12)

1. Depress the key to display the current

cooking chamber temperature chamber.

SP8017-1404

EVOLUTION EEK STEAMER

Fig 11

PAGE 10

Page 12

OPERATIONS

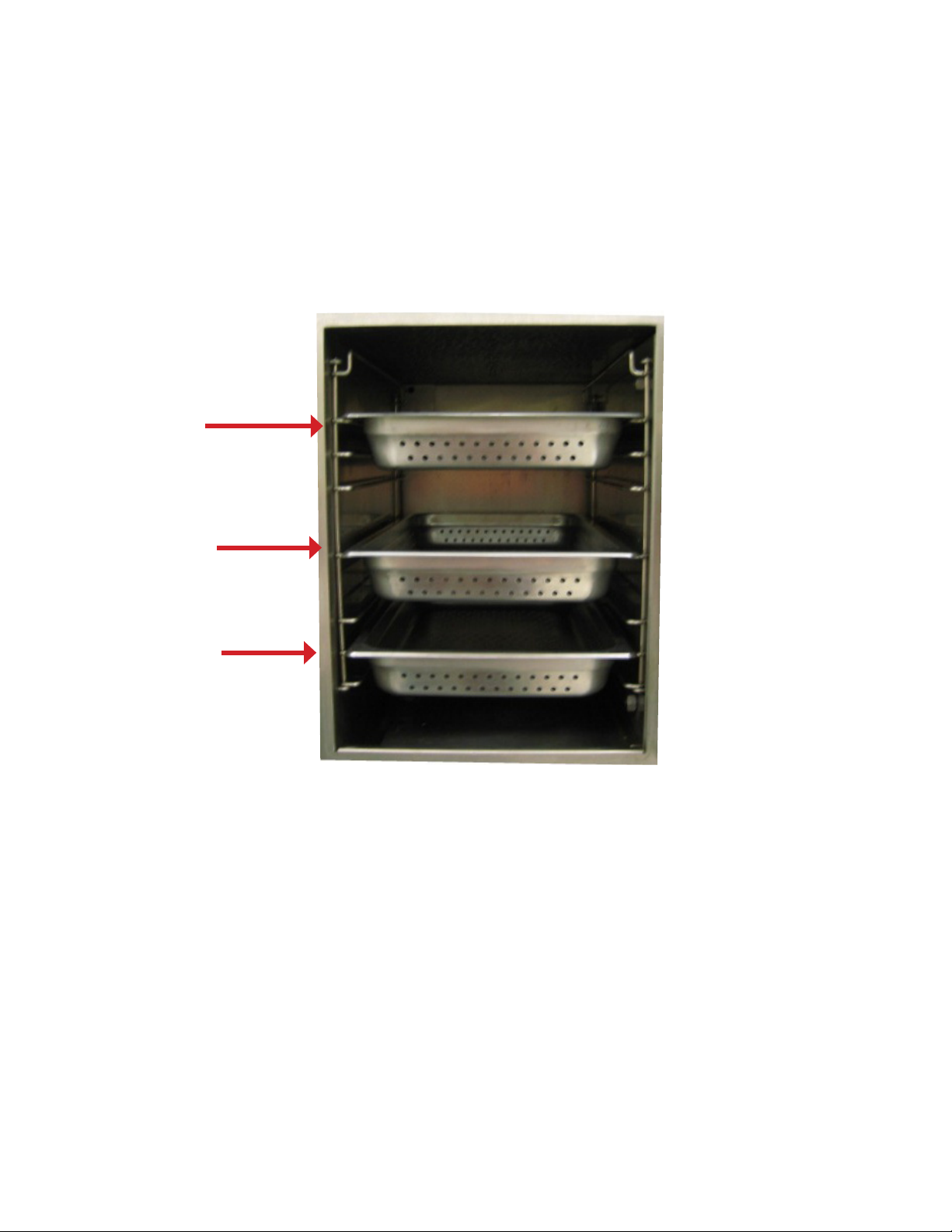

PARTIAL LOADS

The Evolution is designed to cook quickly with exceptional pan-to-pan uniformity on full loads of food.

Excellent pan-to-pan uniformity can be achieved with partial loads if the pans are optimally placed in

the appliance. For partial loads using 2½” deep pans, the top position in the appliance is used rst

followed by the second pan placed in third pan position from the top and then the third pan in the fth

pan position from the top. Placing the pans in these positions will optimize the cooking time and panto-pan uniformity. See Fig 13

1st PAN

2nd PAN

3rd PAN

Fig 13

DAILY PREPARATION FOR USE - CONNECTIONLESS MODEL

Preparing the Evolution Connection-Less model for use each day requires very little time and effort.

Simply verify that the appliance is clean, the drain valve is in the closed position and the cooking

chamber is lled with approximately 2½ Gallons of tap water. Close the door and push the ON/Off key

on the keypad. The water level will need to be monitored and lled as required. Do not use the low

water warning lamp as the indicator to check the water level as this can damage the appliance over

time.

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 11

Page 13

OPERATIONS

CLEANING

The following cleaning instructions are for typical operations. A higer frequency of the weekly cleaning

procedure may be required for high volume users and after protien prepartion. Failure to follow the cleaning

instructions may cause slower cooking times and intermittent operations of the appliance. It is recommended

that the door is left open after cleaning to extend the life of the gasket materials.

MATERIALS REQUIRED

White vinegar

Dishwashing liquid

Non-metalic scrubing pad

5 Gallons tap water

Cleaning towels

High quality stainless steel cleaner and polish.

Warning: Do not use a water jet

or pressure washer to clean the

appliance

DAILY CLEANING

1. Turn the appliance off and wait for the appliance and water reserve to cool.

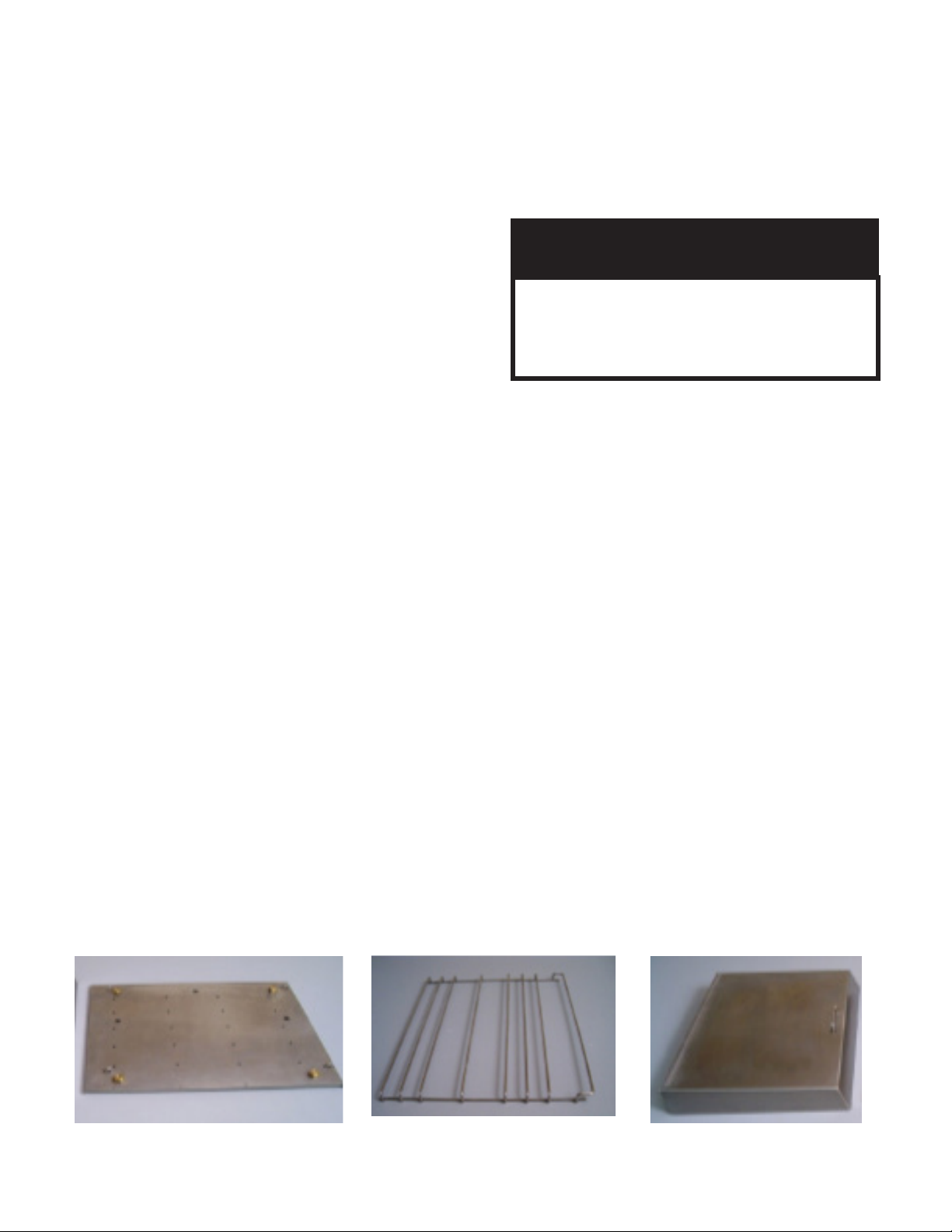

2. Open the drain valve and allow the cooking chamber to drain completely. Remove the pan rails and

steam collector (Fig 14) Wipe the inside of the cooking chamber, water sensors, pan rails and steam

collector with a clean cloth. Clean the door gasket, inside of door and front face of the cooking chamber.

3. Install the steam collector and pan rails. Once the water in the drain pan has sufciently cooled

empty the drain pan wipe down and replace. Leave the door and drain valve open overnight.

WARNING

4. Clean the exterior with soap and clean tap water and a use a high quality stainless steel cleaner.

WEEKLY CLEANING

1. Close the drain valve and add 1 cup (8 ounces or 0.24 liters) of white vinegar to the cooking chamber

and ll with approximately 2½ Gallons of tap water , shut the door and turn the appliance on.

2. After 15 minutes, turn the appliance off and allow the appliance and water reserve to cool. Open the

drain valve and allow to drain completely.

3. To rinse close the drain valve, ll with approximately 2½ gallons tap water, close the door and turn the

appliance on. Let it run for 15 minutes, turn the appliance off and allow the appliance and water reserve

to cool. Open the drain valve and allow the cooking chamber to drain completely.

4. Remove the pan racks, steam collector and steam distributor for cleaning. Clean the upper and lower

water sensors with a non-metallic cleaning pad. Wipe the inside of the cooking chamber, water sensors,

pan rails (Fig 14),steam distributor front and back (Fig. 14), steam collector top, bottom and sides (Fig.

14).

5. Install the steam collector rst, resting the steam distributor on top of the collector align the retaining

fasteners and hand tighten and then install the pan rails. Once the water in the drain pan has suffently

cooled empty the drain pan and wipe down and replace. Leave door and drain valve open overnight.

Steam Distributor

Pan Rail

Steam Collector

SP8017-1404

Fig 14

EVOLUTION EEK STEAMER

PAGE 12

Page 14

BASIC TROUBLESHOOTING

WARNING LIGHTS

LOW WATER — The steamer is low on water or

the water sensors need to be cleaned.

HIGH WATER (CONNECTED MODELS ONLY)

Not Utilized on this model

OVER TEMP — The appliance has overheated.

It may have run out of water. Carefully open the

door, allowing steam to escape and then check

the water level in the bottom of the steamer If

it is nearly empty, Clean the water level sensor

probes (white buttons) located in the front left

corner and the wall immediately around them

being careful not to get burned (protective

gloves are strongly recommended). Refill the

steamer with 2 1/2 gallons of tap water and

restart

Food Is Under Cooked

Try using perforated pans as they allow steam

to penetrate from all directions, maximizing

heat transfer and giving you the shortest

cooking times. Try distributing the product

more evenly within the appliance and or pans,

if possible.

Make sure the water drain valve on the front

of the Evolution is tightly closed.

The steamer may appear to be cooking normally

if the valve is slightly open but efciency may

be compromised.

Check the door seal for food debris. Food

debris on the face of the door seal or under ap

may cause steamer to appear to be cooking

normally but efciency may be compromised.

Nicks or cuts in the door seal may also cause

inefcient cooking.

If the steamer has plenty of water, allow it to cool.

This normally takes a few minutes. When the

Over Temp light goes out, restart the steamer.

Food Is Over Cooked

Check that the proper cook time is being used.

Food Is Under Cooked

Make sure you are using adequate time

a. Extra time may be required if pans are

covered or if product is left in plastic bags

or similar packaging.

Make sure the door is closed. When the

door opens the heat is turned off until it

is shut

Make sure the steamer is in the Cook Mode;

Push the Display Temperature button to

ensure the steamer is at the boiling point

of water taking into account your elevation

above sea level. If it isn’t the appliance

maybe in the Hold Mode. Variations

in temperature can also be caused by

frozen product just being put in or with the

connected model a fresh measure of tap

water was activated. These will shortly

come up to temperature as long as the door

is closed.

Steamer won’t come on

Verify that the breaker in the power pack is in

the active position

Verify that the power pack is plugged in

Steamer doesn’t heat

If the operator’s display doesn’t light up, See

section“ Steamer won’t come on”.

Verify the steamer door is closed, as the

heat won’t turn on if the door is open.

Steam comes out the door

Verify that the door is completely closed and

latched.

If the appliance was just lled with water, wait

a minute to see if it stops. After the steamer is

relled with water it is normal for some steam

to come out the door for a brief amount of

time, usually less than one minute.

Steamer Temperature is low

Make sure door is closed

Verify that the low water light isn’t on

Verify the appliance is in the Cook Mode not

the Hold Mode

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 13

Page 15

SERVICE INFORMATION

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 14

Page 16

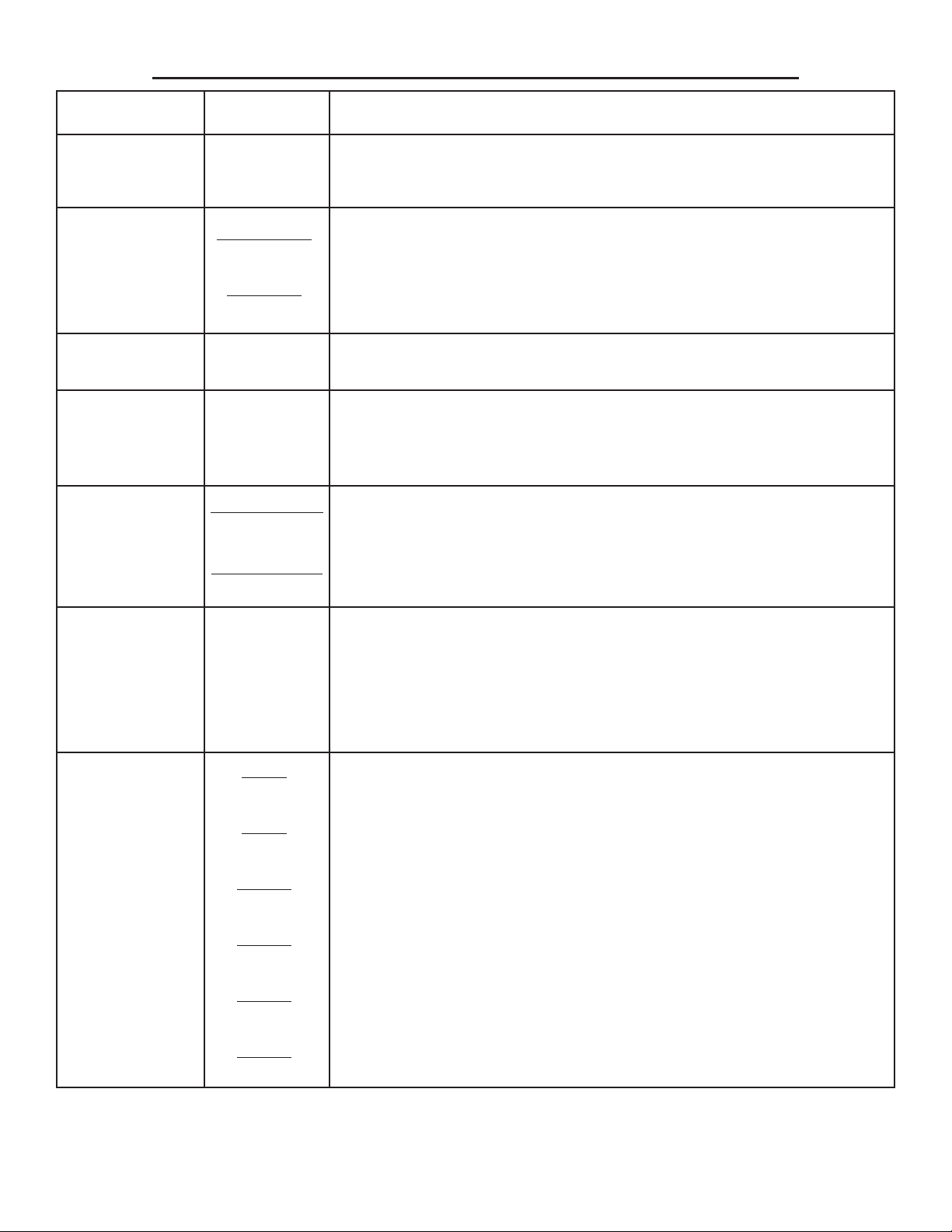

PURPOSE REFERENCE OF MAIN COMPONENTS

Component Part # Purpose

Auto-Fill Valve

(OPTIONAL)

AT1A-3841-1

Reed Switch:

Water Over-Fill

AT0A-3519-2

Sensor Switch

(OPTIONAL)

Float Ball:

AT0P-3233-1

Control Relay #1

(AC)

AT0E-2825-5

Door Switch AT0A-3660-1

S#: 34769 & Up

Chamber

Pressure Switch

AT0E-3617-2

S#: 34768 & Lower

AT1A-3847

• Solenoid Valve that allows water to ow into the steam chamber; that

is controlled automatically by the Water Board based on inputs from

the Water Sensor Probes.

• Magnetic Reed Switch is used in conjunction with a Float Ball. If the

water rises too high, the switch opens and turns off the steamer.

• When the switch opens, the High Water Overll LED will light. The

user will have to drain the water out and turn the steamer back ON;

otherwise, the steamer will remain shutdown.

• Controls AC Volt input & output signals which provide actions from

the Water Sensor Board and Auto-Fill Valve (if installed).

• Magnetic Switch used to ensure that the door is closed and latched

prior to generating steam

• Solid State Relay(s) will not activate if this switch is not closed

(Door Open).

• Normally closed switch that allows pressure to build-up inside the

steam chamber.

• Opens when the steam chamber pressure reaches 1/2 PSI.

• Solid State Relay(S) will not activate if this switch is not closed

(Switch Open).

Solid State Relay AT0E-2059-3

6 KW:

AT1A-3530-1

8 KW:

AT1A-3530-2

10 KW:

Cast Heater

Replacement Kit

AT1A-3530-3

12 KW:

AT1A-3530-4

14 KW:

AT1A-3530-6

17 KW:

AT1A-3530-7

• Provides line voltage to the Cast Heater elements, once the Controller

/Keypad Board sends the 24V control signal to the relay(s).

• The relay(s) are only activated if the Door Switch & Chamber

Pressure Switch are closed.

• The number of Solid State Relays used, depends on the phase and

wattage needs of the unit.

• Transfers the heat, generated from the internal elements; to boil the

water to create steam.

• Cast Heater can be wired to single or 3 phase; and have a parallel,

delta, or wye conguration.

• Cast Heater must be replaced with the same wattage heater as

specied in the model number.

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 15

Page 17

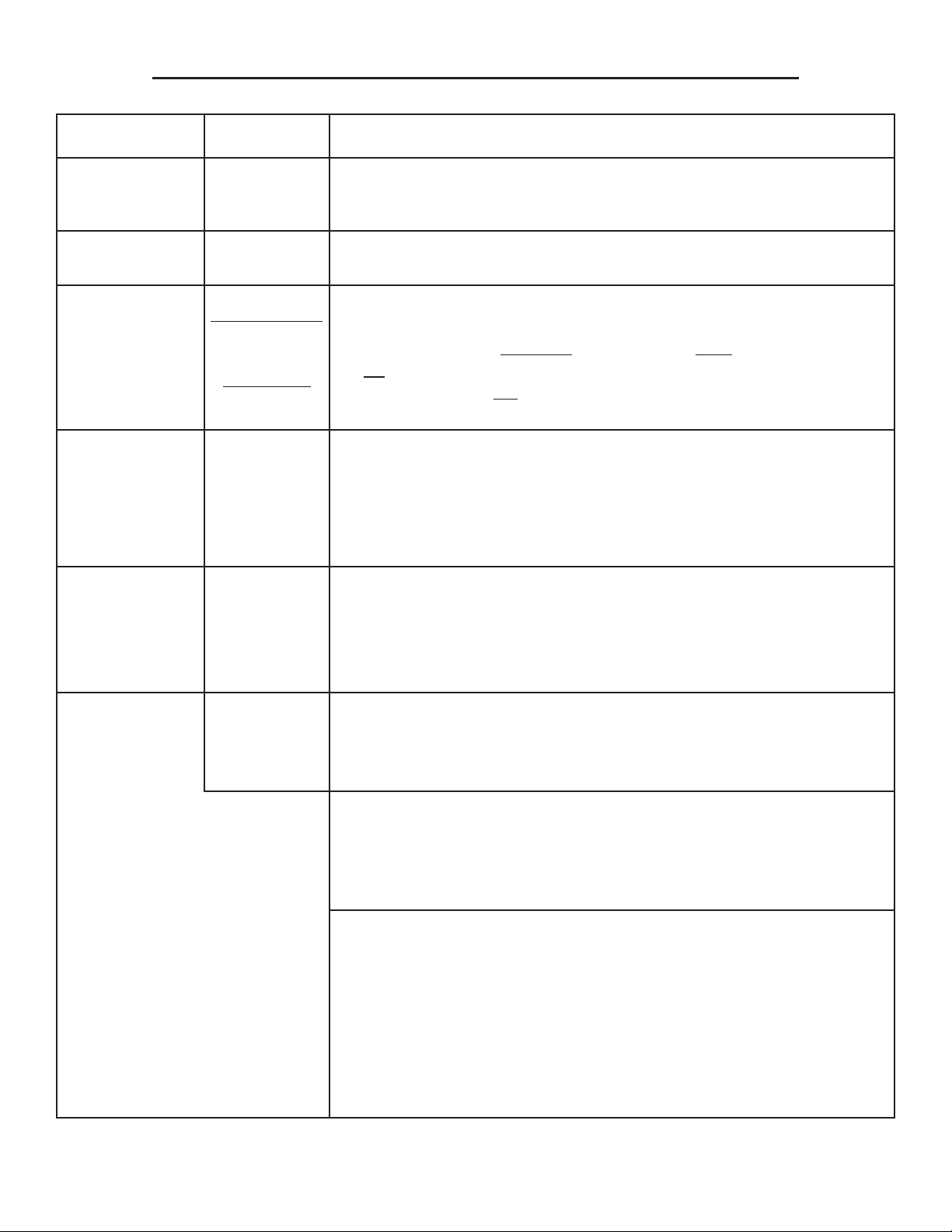

PURPOSE REFERENCE OF MAIN COMPONENTS

Component Part # Purpose

Contactor

(3 Pole)

AT0E-1587-4

Transformer AT0E-2662-5

12KW & Lower

Overtemp Switch

AT1E-2653-3

(Thermal Limit

SW3)

14KW & Up

AT1E-2653-4

Control / Keypad

Board

Water Sensor

Control Board

AT0E-3625-1

AT0E-3230-2

• Provides line voltage to the Solid State Relay(s), when the contactor’s

coil is closed by the control signal sent from the Water Control Board.

• Provides line voltage to the Transformer.

• Steps-down the Supply Line Voltage to 24 -28VAC.

• Normally closed switch that provides a safety feature to the machine

in case the Cast Heater overheats.

• If the Cast Heater overheats, the switch will open and turn the steamer

off; while lighting the red LED Overtemp Light on the Control Panel.

• The steamer will not turn on until the temperature has dropped

enough to allow the Overtemp Switch to close again.

• Human interface for steamer operations through push-buttons,

operations, & display readouts.

• Provides power to the Solid State Relay(s) (24VDC).

• Receives input from the Temperature (RTD) Sensor and displays the

water temperature on the LED readout.

• Maintains the preset HOLD temperature.

• Receives inputs from Water Sensor Probes and implements

corresponding actions for those inputs based on the water level in the

steam chamber.

• Controls the Auto-Fill Valve (if installed) and receives inputs that

provides actions for the desired water level needs.

• Teon exterior with a stainless steel center that uses the minerals

Water Sensor

Probe

AT1E-2652-1

in the water to complete the electrical circuit to the Water Control

Board.

• MUST BE CLEAN TO WORK PROPERLY.

• Once the Low Water Sensor is satised, it will allow the Solid State

Low Water Level

Probe

Relay(s) to activate.

• If the water level is below the sensor, the Water Board will activate

the Auto-Fill Valve (if installed) lling the unit the water until the

High Limit Water Sensor is satised.

• On initial chamber water ll, once the water level reaches and

satises the Operational Water Sensor, the Water Board will keep the

Auto-Fill Valve open for 30 additional seconds..

High Limit

Water Level

Probe

• After initial chamber water ll, when the water level drops below the

sensor’s operational level; the Water Board will open the Auto-Fill

Valve for 30 seconds to raise the water level back above the High

Limit Water Sensor.

• This process will repeat as long as the water level stays above the

Low Water Sensor.

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 16

Page 18

PURPOSE REFERENCE OF MAIN COMPONENTS

Component Part # Purpose

Temperature

(RTD)

Sensor

Door Assembly AT1A-3600-1

Drain Valve AT1P-2239-1

AT0E-3626-1

ADDITIONAL COMPONENT PART NUMBERS

Component Part # Component Part #

Pilot Lamp, 24V Red AT0E-1800-2 Door Hinge (Pair) AT1H-2058-3

Fuse, 1.25A 250V AT0E-2731-2 Door Latch Assy, Ceramic Magnet AT1H-3609-1

• Provides temperature input to Control/Keypad Board, which displays

the temperature in the steam chamber based on resistance changes

from the Temperature (RTD) Sensor.

• Used to maintain the preset HOLD mode temperature.

• Keeps the steam trapped inside the steam chamber to allow pressure

to build and cycle the Chamber Pressure Switch.

• Manually Open/Close valve used to drain water from the steam

chamber.

Gasket, Door AT1G-2633-1 Door Latch Mounting Plate AT1M-3046-1

Inner Door Assembly AT1A-3647-1

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 17

Page 19

SEQUENCE OF OPERATION

INDICATORS AND WATER CONTROL BOARD OPERATION:

PWR Button Pushed & Water Level Is Below the Low Water Level Sensor

• The Low Water Light Indicator will be ON and Alarm will sound.

• PRE is displayed on the Control/Keypad Board.

• (The red LED light on the Water Sensor Board will be ashing continuously.)

PWR Button Pushed & Low Water Level Sensor Is Satised

• The Low Water Light Indicator and Alarm (only manual ll units use an alarm for low water

condition), will be OFF.

• This is minimum water level needed for the Contactor to close and turn the Cast Heater ON.

• (The red LED light on the Water Sensor Board will have about a 1 second ash delay.)

CAST HEATER GENERATING HEAT OPERATION:

Power Cord Plugged-In & PWR Button Not Pushed

• Line Voltage comes into the 3 Pole Contactor’s L1 - L3 terminals. (Refer to the unit’s

specic wiring schematics to determine the wire color to “L” Terminal location.)

• Line Voltage is then taken off of L1 & L2 of the Contactor and applied to the Transformer,

which steps-down the Line Voltage to 24VAC.

• From the two, 1.25Amp, fuses; power goes through the Overtemp Switch, then goes to

the Water Sensor Board, to Control Relay #1 (CR#1) coil, to the High Water Overll Reed

Switch (Auto-Fill Only), to the Control/Keypad Board, and to Pin 6 of CR#1. Power also

ows through CR#1, Control/Keypad Board, Water Sensor Board and Contactor (once the

water level condition is met).

• (The red LED light on the Water Sensor Board will be ashing continuously.)

PWR Button Pushed & Low Water Level Sensor Is Satised

• (The red LED light on the Water Sensor Board will have about a 1 second ash rate.)

• The Water Sensor Control Board’s K2 Relay will close, sending power to the Contactor’s

coil; closing the contacts and allowing Line Voltage to be sent to the normally open Solid

State Relay(s).

• The Control/Keypad Board will send a 24VAC signal to the Solid State Relay(s); closing the

Relay(s) (as long as the Door Switch and the Chamber Pressure Switch are closed).

• The Solid State Relay(s) then pass Line Voltage to the Cast Heater’s Elements generating

heat evenly over the bottom of the steam chamber; creating steam for cooking.

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 18

Page 20

SEQUENCE OF OPERATION

Temperature Sensor (RTD) and Control/Keypad Board

• As the water temperature rises, the RTD will provide a signal, based on the resistance of the

sensor, to the Control/Keypad Board to provide a digital temperature display.

• Control Panel will show PRE (Preheat) on initial start-up until the steam chamber reaches

195°F, then COO (Cook) will be displayed between 195°F and 212°F.

• The operating default mode on initial PWR ON is COOK mode; which automatically causes

the steamer to go to the normal operating boiling point, which is 212°F at sea level.

• In COOK mode, the 24VAC output from the Control/Keypad Board is continuously on, so

that the unit’s temperature is controlled by the Chamber Pressure Switch, which opens at 1/2

PSI (13.9 “ water column) or higher.

• In HOLD mode (HLD), the steamer’s regulated temperature will change to the HOLD

temperature’s preset value. The Control/Keypad Board will regulate temperature via the

RTD input, based on the current HOLD mode preset value. (This value can be changed

using the program function on the Control/Keyboard Control.)

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 19

Page 21

MODIFYING CONTROL / KEYPAD PROGRAM SETTINGS

Hrs/Min/Sec

LED Lights

UP Arrow

DOWN Arrow

S1 - Increase Program Item (Will cycle the Hrs/Min/Sec LED light)

S4 - Decrease Program Item (Will cycle the Hrs/Min/Sec LED light)

S3 - Increase Program Value (Will change the Digital Readout display)

S6 - Decrease Program Value (Will change the Digital Readout display)

S2 - Exit & Save

ENTERING PROGRAM MODE: Simultaneously, depress and hold S4 & S6 for minimum of 8 seconds or

until the Hrs LED blinks and the display shows a Hold Temp number (default is 180°F). Now the Controller

can operate under the Program Function Parameters.

S1

S4

POWER

S5

S2

TIMER

S3

S6

COOK/HOLD

TEMP Display

Program Mode Function Parameter Table

Hrs LED Min LED Sec LED PARAMETER MIN MAX ELECTRIC

Blink OFF OFF HOLD Temp Value = Degree F MIN Temp MAX Temp 180

ON OFF OFF Default Timer Value = Hours 0 8 0

OFF ON OFF Default Timer Value = Minutes 0 59 30

OFF OFF ON TEMP Probe Offset = Degree F 0 50 0

ON ON ON TEMP Probe Offset = Neg/Pos Diff NEG = 1 POS = 0 0

Blink Blink Blink Hysteresis

ON Blink Blink TEMP Regulating Mode

Blink ON Blink Proportioning BAND TIME 4 10 10

Blink Blink ON Proportioning BAND WIDTH 4 10 10

TO RESET CONTROLLER TO FACTORY DEFAULT VALUES,

PRESS AND HOLD S4, THEN PRESS S5.

SP8017-1404

EVOLUTION EEK STEAMER

2 10

On/Off = 0 PID = 1

2

1

PAGE 20

Page 22

START

TROUBLESHOOTING FLOW-DIAGRAM

POWER

ON

NO

Steamer

Plugged-In

YES

Breaker

ON

YES

Check

Internal

Power

Voltages

SEE C

Component

Voltages

Correct

YES

Call

AccuTemp

Service

NO

NO

NO

YES

SEE

SEE

SEE

A

B

D

WARNING

LIGHTS

YES

Control Panel

Error Code

NO

Low Water

Light

NO

Over Temp

Light

NO

High Water

Light

YES

Float Ball

Installed

YES

Call

AccuTemp

Service

YES

YES

YES

NO

NO

SEE

SEE

SEE

SEE

E

F

G

H

STEAMER

HEATING

YES

Temp

Low

NO

Steam Out

The Door

NO

Food Over

Cooked

NO

Food

Under

Cooked

YES

Different

Problem

With

Steamer

Operations

YES

NO

YES

YES

YES

YES

NO

SEE

I

SEE

J

SEE

K

SEE

L

SEE

M

DONE

WITH

CHART

Call

AccuTemp

Service

(800) 480-0415 or service@accutemp.net

Call

AccuTemp

Service

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 21

Page 23

REF

FLOW-DIAGRAM REFERENCE TROUBLESHOOTING CHART

LETTER

POSSIBLE CAUSE EVALUATION

A Power Cord Disconnected

B Breaker Is Tripped

Transformer

Conrm proper voltage is present at receptacle.

Plug-in Power Cord.

Unplug steamer and check voltage at receptacle.

Reset Breaker

Check for proper incoming voltage to the primary side

and 24V on the secondary side.

C Fuses Check for continuity.

Over-Temp Switch

Control panel not responding.

Check between the common wire, terminal # 6 on the

control relay and the brown wire after the fuse.

Check for 24VAC incoming power at pins J2-1 & J2-2.

Check for out put at pins J7-3 & J7-4 - 24VAC ON/OFF

Check the wiring to the component; including the

D Bad Component or Faulty Wiring

wire-to-connectors, GND’s, and damage.

If component O/P bad, then may need replaced.

E

Error Code: -1F or -99F for RTD

probe.

Check for 1000 ohms (at room temp) on Digital

Controller Board on J3 - Pins 1 & 2.

EC: -1F = Open sensor EC: -99F = Shorted sensor

F Low Water Sensor Not Being Met

G Steamer Has Over-Heated

Too Much Water In Steam Chamber

H Operational Water Level Sensor Faulty

Float Ball & Reed Sensor Faulty

Ensure water is at the max water level line inside the

steam chamber.

Ensure that the Low Water Sensor is cleaned and that

the Water Board is working properly.

Check that the water level inside steam chamber is not

empty; and rell if needed.

If an Auto-Fill unit, then ensure that water supply is not

shut-off.

Ensure Water Sensors are clean.

DO NOT OPEN DOOR!

Open Drain Valve until the High Water Light goes off.

If light DOES NOT go out and no water in steamer,

then possibly a sensor fault.

Ensure the top Water Sensor is clean.

Check that Water Board is working properly.

Ensure Float Ball is not stuck on the Sensor Post.

Ensure Sensor Post & inside of the Float ball is clean.

Check continuity of the Reed Switch (Float over sensor

creates continuity; Float off sensor creates open.)

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 22

Page 24

FLOW-DIAGRAM REFERENCE TROUBLESHOOTING CHART

REF

LETTER

POSSIBLE CAUSE EVALUATION

Control Panel Check for 24VDC output (J7 Pins 1 & 2).

Ensure Door is shut and handle is latched.

Door Switch Not Engaging

Check the Door Switch for continuity with Door closed.

Check the butt splices and wire connections for good

crimps.

Chamber Pressure Switch

Switch is normally closed.

Check the Chamber Pressure Switch for continuity.

Relay is normally open.

Time Delay Relay #1 (5 sec)

Check for continuity during the rst 5 -10 secs of

pressing PWR ON button.

Check for 24-30VDC at Pins 7 & 8 on the CR2 Coil.

Control Relay #2

Check for 24VAC on pin 3.

Ensure Relay Contacts are closing and not stuck open.

Switch is normally open.

Fan Pressure Switch

Check that switch closes at .2” Water Column (WC) &

that voltage is present on Lt Blue wire to Spark Module

at pin PSW.

Check that the vent is set for:

Power Burner Fan

3.5” for Natural Gas & 3” for Propane.

If vent is to large, then unit will not ignite.

I

Check the Red LED light on the module for the

following indications (listed on the module):

Ignition (Spark) Module

Constant ON red LED = Bad Ignition Module.

1 Flash = Air Vent Blockage.

2 Flashes = Flame with No Call For Heat

3 Flashes = Ignition Lookout (No Gas Present)

Check that the probes are not oxidized or broken.

Check that the Ignition Cable has a good connection to

Ignition Probe & Cable

Ignition Probe.

Verify that the Ignition Probes are in the correct position to the Burner’s surface as required.

Check to ensure that the Time Delay Relay #2 is

Gas Enrichment Valve

opening the Gas Enrichment Valve for 4 secs.

(Signal from Spark Module out of pin V1.)

Ensure that the valve is engaging.

Gas Valve Control

Check that the Gas Pressure is at the correct WC value:

5” for Natural Gas & 10” for Propane.

Verify that the incoming gas pressure from the External

External Supply Gas Press. Regulator

Regulator is between WC values:

7” - 10” Natural Gas & 11” - 13” Propane.

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 23

Page 25

LOCATION OF ELECTRICAL COMPONENTS

Solid

State

Relays

&

Heat

Sinks

Power Cord Contactor

Chamber Pressure Switch

Heater/PWR

Terminal Strip

Control/

Keypad

Board

Water Sensors

Transformer Fuses Water Sensor

Control Board

SP8017-1404

EVOLUTION EEK STEAMER

Control

Relay #1

PAGE 24

Page 26

ELECTRICAL COMPONENTS REMOVAL & INSTALLATION

CORD & PLUG ASSEMBLY

1. Unplug the Unit.

2. Remove the Left-Side Panel by removing the

Sheet Metal Screws holding it in place.

3. Disconnect the Power Cord Leads (Black,

White, Red, and/or Green) from L1-3 of the

Contactor (note the wire color to its location

terminal).

4. On the inside of the unit, remove the retaining

nut on the threads of the Power Cord Cable

Fitting & pullout the Power Cord.

5. Re-install in reverse order.

FUSES

1. Unplug the Unit.

2. Remove the Left-Side Panel by removing the

Sheet Metal Screws holding it in place.

3. Pry the Fuses out of the Fuse Block with a

at-head screwdriver or fuse puller.

4. Re-install in reverse order.

CONTACTOR

1. Unplug the Unit.

2. Remove the Left-Side Panel by removing the

Sheet Metal Screws holding it in place.

3. Disconnect the wires (note the wire color to its

location terminal).

4. Remove the 2 mounting nuts and then remove

the Contactor.

5. Re-install in reverse order.

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 25

Page 27

ELECTRICAL COMPONENTS REMOVAL & INSTALLATION

TRANSFORMER

1. Unplug the Unit.

2. Remove the Left-Side Panel by removing the

Sheet Metal Screws holding it in place.

3. Disconnect the wires (note the wire color to its

location terminal).

4. Remove the 2 mounting nuts and then remove

the Transformer.

5. Re-install in reverse order.

WATER SENSOR CONTROL BOARD

1. Unplug the Unit.

2. Remove the Left-Side Panel by removing the

Sheet Metal Screws holding it in place.

3. Disconnect the wires (note the wire color to its

location terminal).

4. Carefully, push in the locking leg on the 4

plastic posts while pulling the Water Board up

off the posts (note the board’s orientation).

5. Remove the Water Board.

6. Re-install in reverse order.

CONTROL RELAY #1

1. Unplug the Unit.

2. Remove the Left-Side Panel by removing the

Sheet Metal Screws holding it in place.

3. Disconnect the wires (note the wire color to its

location terminal).

4. Remove the 2 mounting screws and then

remove Control Relay #1.

5. Re-install in reverse order.

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 26

Page 28

ELECTRICAL COMPONENTS REMOVAL & INSTALLATION

WATER SENSORS

1. Unplug the Unit.

2. Remove the Left-Side Panel by removing the

Sheet Metal Screws holding it in place.

3. Open the door and ensure that all the water is

drained from the steam chamber.

4. Disconnect the wire from the backside of the

Water Sensor (access via left-side panel).

5. Remove the retaining nut that mounts the Water

Sensor to the Steam Chamber.

6. Push the Water Sensor through the hole in the

steam chamber from the backside.

7. Re-install in reverse order. Torque Sensor

Nuts to between 12-15 In-Lbs.

CONTROL / KEYPAD BOARD

1. Unplug the Unit.

2. Remove the Left-Side Panel by removing the

Sheet Metal Screws holding it in place.

3. Disconnect the wires (note the wire color to its

location terminal).

4. Remove the 7 mounting nuts and then remove

the Control Panel CCA.

5. (If accessing the Program Mode is needed, go

to page 8 for more details.)

6. Re-install in reverse order.

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 27

Page 29

ELECTRICAL COMPONENTS REMOVAL & INSTALLATION

DOOR SWITCH

Door Latch on the Left-Hand Side

1. Unplug the Unit.

2. Remove the Left-Side Panel by removing the

Sheet Metal Screws holding it in place.

3. Disconnect the probe wires: Control/Keypad

Panel J7 Pin 1 & the White/Brown wire from

the Chamber Pressure Switch (the wires to the

location pins are enter-changeable).

4. Push back the insulation, so you can access the

other mounting nut to be removed.

5. Remove the 2 mounting nuts and then remove

the Door Switch. Fg 15

6. Re-install in reverse order.

Fg 16

Fg 15

Door Latch on the Right-Hand Side

1. Unplug the Unit.

2. Remove the Left-Side, Right-Side, and Top

Panel by removing the Sheet Metal Screws

holding it in place.

3. Disconnect the probe wires: Control/Keypad

Panel J7 Pin 1 & the White/Brown wire from

the Chamber Pressure Switch; and pull the

wires up, over the top of the steamer (the wires

to the location pins are enter-changeable).

4. Remove the insulation on the right side, to

access the Door Switch to be removed. Fg 16

5. Remove the 2 mounting nuts and then remove

the Door Switch. Fg 17 Re-install in reverse

order.

Fg 17

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 28

Page 30

ELECTRICAL COMPONENTS REMOVAL & INSTALLATION

CHAMBER PRESSURE SWITCH

1. Unplug the Unit & remove the Left-Side Panel

by removing the Sheet Metal Screws holding it

in place.

2. Disconnect the Wiring Terminals from the

Chamber Pressure Switch (note the wire color

to its location terminal).

3. Remove the hose clamp and disconnect the

hose from the Chamber Pressure Switch.

4. Remove the 2 mounting nuts holding the

Chamber Pressure Switch to chamber cavity.

5. Remove the Chamber Pressure Switch

6. Re-install in reverse order.

SOLID STATE RELAY (SSR)

1. Unplug the Unit.

2. Remove the Left-Side Panel by removing the

Sheet Metal Screws holding it in place.

3. Disconnect the wires for the desired SSR

being replaced (note the wire color to its

location terminal).

4. Remove the thread-cover nuts on the back of

the steamer, while removing the 2 mounting

bolts holding the SSR Assy to the inside-back

of the component chamber; and then remove

the desired Solid State Relay.

5. Re-install in reverse order.

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 29

Page 31

ELECTRICAL COMPONENTS REMOVAL & INSTALLATION

TEMPERATURE (RTD) SENSOR

1. Unplug the Unit.

2. Remove the Left-Side, Right-Side, and Top

Panel by removing the Sheet Metal Screws

holding it in place.

3. Disconnect the probe wires from the Control/

Keypad Panel and pull them from the left, over

the top, to the steamer’s right-side (the wires

to the location pins are enter-changeable).

4. Remove the mounting nut and then remove the

Temperature (RTD) Sensor.

5. Re-install in reverse order. Ensure Thermal

Paste is applied to the Temperature (RTD)

Sensor.

OVERTEMP SWITCH (THERM LIMIT SW3)

1. Unplug the unit.

2. Using an additional person, turn the unit

upside-down and remove its legs. (Unbolt unit

from stand and then turn unit upside-down if

applicable.)

3. Remove Left-Side Panel & Bottom CoverPanel

by removing the Sheet Metal Screws holding it

in place. (Remove Drain Pan Rails if

applicable.)

4. Remove the Insulation as needed to provide

access to remove the Overtemp Switch from

the bottom of the Cast Heater. (Note the

insulation location for proper tting when

re-installed.)

5. Disconnect the wires to the Overtemp Switch

(note the wire color to the location pin).

6. Unscrew the Overtemp Switch, and remove it

from the bottom of the Cast Heater.

7. Re-install in reverse order. Ensure Thermal

Paste is applied to the Overtemp Switch and

its threading.

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 30

Page 32

LOCATION OF CAST HEATER

Cast Heater

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 31

Page 33

CAST HEATER REMOVAL & INSTALLATION

NOTE

The 1/4-20# Nut Special Locking Nut, Can Only Be Used Once.

Ensure That A New Cast Heater Replacement Kit Is Ordered and Received; Prior to

Removing or Installing the Cast Heater.

Part #: AT1A-3530-5

*

Order the Cast Heater Replacement Kit for the Correct Heater Wattage Required.

Thermal

Paste

Overtemp

Switch

* (See Page 4)

Cast Heater

1/4-20#

Locking

Nuts

Paint

Brush

SP8017-1404

EVOLUTION EEK STEAMER

Installation

Instructions

PAGE 32

Page 34

CAST HEATER REMOVAL & INSTALLATION

REMEMBER:

• AN ADDITIONAL PERSON IS REQUIRED, WHEN CONDUCTING

MAINTENANCE INVOLVING TURNING THE UNIT OVER.

• IF HEATER WIRES HAVE NON-BRAIDED INSULATION, THE HEATER IS

NOT A CAST HEATER. CONTACT ACCUTEMP SERVICE AT 800-480-0415.

• USE THE INCLUDED CAST HEATER REPLACEMENT KIT INSTRUCTION

BOOKLET IN CONJUNCTION WITH THE REMOVAL & INSTALLATION

PROCEDURES IN THIS MANUAL.

CAST HEATER

1. Unplug the unit and drain all the water out

of the steamer.

2. Remove Left-Side by removing the Sheet

Metal Screws holding it in place.

3. Disconnect the 6, braided-insulation,

Heater Wires from their Terminal Board

Connections. (Note the heater wires’

numbers to their location terminals.)

4. Using an additional person, turn the unit

upside-down and remove its legs. (Unbolt

unit from stand and then turn unit upsidedown if applicable.)

5. Remove the Bottom Cover by removing

the Sheet Metal Screws holding it in place.

(Remove Drain Pan Rails if applicable.)

6. Remove insulation as needed to access the

Cast Heater. (Note the insulation’s location

to ensure proper tting when re-installed.)

7. Disconnect the wires to the Overtemp

Switch (note the wire color to its location

pin).

8. Unscrew the Overtemp Switch, and remove

it from the bottom of the Cast Heater. F-A

9. Remove any insulation and thread lock

material from the heater studs using a

scouring pad.

F-A

F-D

F-E

F-B

F-F

F-C

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 33

Page 35

CAST HEATER REMOVAL & INSTALLATION

18

22

24

6

14

16711

2

10

12

3

1951713

21

15

23

8

20

19

NOTE

If Heater Studs are Discovered Broken While Removing the Cast Heater

OR

If a Heater Stud Breaks-Off While Removing or Installing the Cast Heater

Call AccuTemp Service Dept (800) 480-0415.

CAST HEATER (CON’T)

10. Using Fig G, loosen all 24 nuts by starting with Nut #24 and working down to #1.

11. Remove all 24; Locking Nuts (F-C), Lock Washers (F-D) & Flat Washers (F-E) from the

Cast Heater. (Discard the used Locking Nuts; keep and clean the Lock & Flat Washers.)

12. Remove both Heater Mounting Brackets from the top of the heater by letting them hang, by

the wires, over the electrical compartment. F-B

13. Remove the Cast Heater. F-F (Might have to lift heater by its heater wires, or use a

at-head screwdriver to pry up the Cast Heater from the Thermal Compound.)

14. Re-install in reverse order. SEE NEXT PAGE FOR INSTALLATION NOTES.

Heater

Wires

Should

Be On

Terminal

Block Side

4

Steamer

Fig G

Only using a brass or stainless-steel brush; scrape, remove, and

clean-off any remaining Thread Sealant and Thermal Compound

residue from the bottom of the steamer, even around the studs.

Front

Side

Of

The

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 34

Page 36

CAST HEATER INSTALLATION NOTES & CAUTIONS

1348765

12

10

11915

1316141922

241820

232117

NOTE

CAST HEATER’S SHINY SIDE FACES THE BOTTOM OF THE STEAMER!

Using a Paint Brush, Apply Thermal Paste to the Shiny Side of the Cast Heater.

Bellevelle Washers should look like mini-volcanos when placed on heater stud.

The HEX Locking Nut Needs to be Torqued Between 23 - 27 IN-LBS.

Tighten Starting with Nut #1 and Follow the Numbered Layout Pattern to Nut #24.

Tighten Twice in This Pattern.

2

Notch

Cut-Out

Goes

Towards

the

Front

Side

of

the

Steamer

CAUTION

DO NOT OVER TORQUE THE LOCKING NUTS.

Over Torquing The Zinc Nuts Can Cause the Studs to Break-Off. This Will Cause

Heating Issues; and the Steamer Will Not Operate Correctly or Safely.

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 35

Page 37

DOOR COMPONENTS REMOVAL & INSTALLATION

DOOR ASSEMBLY

1. Unplug the unit and shut the Door.

2. Remove the Hinge Covers. Fig J

3. Remove the 3 hinge screws going into the face

of the steamer of the Bottom Hinge. Fig K

4. While supporting the Door on the hinge-side,

remove the 3 hinge screws into the face of the

steamer of the Top Hinge.

5. Pull the door handle and remove the Door.

6. Re-install in reverse order. Ensure

Anti-sieze is re-applied to all hinge screws.

If the Door Handle Latch Is Moved to the Opposite

Side, Ensure That the Door Switch Is Moved to the

Corresponding Door Handle Latch Side .

Fig J

Fig K

Face Screws

STEAMER WILL NOT OPERATE IF NOT DONE.

INNER-DOOR PANEL

1. Unplug the unit and shut the Door.

2. Remove the Hinge Covers. Fig J

3. Remove the very bottom screw on the door

hinge-side of the Bottom Hinge.

4. Remove the very top screw on the door

hinge-side of the Top Hinge.

5. Pull the door handle and open the door

6. Lift and pull out the Inner Door Panel.

7. Re-install in reverse order. Ensure

Anti-sieze is re-applied to all hinge screws.

Ensure That the Inner Door is Reinstalled with its

Middle Brace Bar Behind the Door Latch Tab. Fig L

Also, Ensure That the Screw Retainer Openings are

Lined-Up with the Door’s Hinge Side. Fig M

Inner Door

Fig L

Fig M

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 36

Page 38

DOOR COMPONENTS REMOVAL & INSTALLATION

DOOR HANDLE LATCH ASSEMBLY

1. Unplug the unit & shut the Door.

2. Remove the Hinge Covers. Fig J

3. Remove the very bottom screw on the door

hinge-side of the Bottom Hinge & remove the

very top screw on the door-side hinge of the

Top Hinge.

4. Pull the door handle and open the door

5. Lift and pull out the Inner Door Panel.

6. Remove the 3 mounting nuts and screws,

holding the Door Handle Latch to the side of

the door, and the Inner Door Holding Tab.

7. Remove the Door Handle Latch Assembly.

8. Re-install in reverse order. Ensure

Anti-sieze is re-applied to all hinge screws.

DOOR HINGE

1. Unplug the unit & shut the Door.

2. Remove the Hinge Covers. Fig J

3. Remove the 3 hinge screws going into the face

of the steamer of the Bottom Hinge.

4. While supporting the Door on the hinge-side,

remove the 3 hinge screws into the face of the

steamer of the Top Hinge.

5. Pull the door handle and remove the Door.

6. Remove the very bottom screw on the door

hinge-side of the Bottom Hinge & remove the

very top screw on the door-side hinge of the

Top Hinge.

7. Lift and pull out the Inner Door Panel.

8. Remove the remaining door-side screws for

the hinge or hinges to be replaced. (Note the

orientation of the Hinge Spacer Bars as they

relate to the Hinge orientation.)

9. Remove the Door Hinge or Hinges.

10. Re-install in reverse order. Ensure

Anti-sieze is re-applied to all hinge screws.

Ensure That the Inner Door is Reinstalled

with its Middle Brace Bar Behind the

Door Latch Tab. Fig L

Also, Ensure That the Screw Retainer

Openings are Lined-Up with the Door’s

Hinge Side. Fig M

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 37

Page 39

DOOR COMPONENTS REMOVAL & INSTALLATION

DOOR GASKET

1. Unplug the unit & shut the Door.

2. Remove the Hinge Covers. Fig J

3. Remove the very bottom screw on the door

hinge-side of the Bottom Hinge & remove the

very top screw on the door-side hinge of the

Top Hinge.

4. Pull the door handle and open the door

5. Lift and pull out the Inner Door Panel.

6. Remove the 6, Gasket retaining brackets by

removing the 12 nyloc mounting nuts holding

them in place.

7. Remove the Door Gasket.

8. Re-install in reverse order. Ensure

Anti-sieze is re-applied to all hinge screws.

INSTALLATION NOTE:

• Make sure the new Door Gasket is

untangled.

• Starting at one corner, stretch the Gasket

to the opposite corner.

• Repeat this sequence until all 4 corners

are seated.

• Push the Gasket down all the way around

to ensure the Gasket seats rmly on the

inner door.

Ensure That the Inner Door is Reinstalled with its

Middle Brace Bar Behind the Door Latch Tab. Fig L

Also, Ensure That the Screw Retainer Openings are

Lined-Up with the Door’s Hinge Side. Fig M

Gasket Retaining

Brackets

Gasket

Gasket Retaining

Bracket

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 38

Page 40

DISTRIBUTION PANEL ASSEMBLY REMOVAL & INSTALLATION

Distribution Panel

AT1A-3667-2

Distribution

Gasket

# 6-32 Retaining

Bracket Nuts

(QTY 6)

DOOR GASKET

1. Unplug the unit & open the door.

2. Remove the pan rails, steam collector and then

loosen the 4 retaining knobs and remove the

distributor panel assembly.

3. Remove both gasket retaing brackets by removing the #6-32 nuts (QTY 6) . Remove the

retaining brackets. Remove the old gasket.

4. Install the new gasket in the same orientation

as removed.

5. Install retaining brackets and quantity

6 - # 6-32 nuts to the panel studs. Do not

overtighten the nuts.

Retaining Bracket

(QTY 2)

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 39

Page 41

SERVICE INFORMATION

Conventional Appliances require scheduled maintenance (such as boiler

maintenance) at frequent intervals) The Evolution design doesn’t require this type

of scheduled maintenance. It is recommended that you schedule a yearly review

of the Evolution with a AccuTemp Authorized Service Representative to keep your

appliance in optimal operation.

GENERAL SERVICE INFORMATION

All service request during the warranty period of this appliance must be

directed to the AccuTemp Products, Inc. Technical Services Department or

the service call may not be covered by the limited warranty.

INFORMATION

INFORMATION

WARNING

Only an AccuTemp Products Inc. Authorized Service Personnel or Representative

must perform service. Service performed by unauthorized personnel will void all

warranties.

INFORMATION

IMPORTANT SERVICE INFORMATION

AccuTemp Product, Inc. Technical & Customer Support Technician is

available Monday thru Sunday, 7:00am to 7:00pm EST.

800.480.0415 or 260.469.3040

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 40

Page 42

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 41

Page 43

SCHEMATICS

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 42

Page 44

Title:

Rev.Drawing No.:

AT1T-3595

ATMOSPHERIC

SCHEMATIC, STEAMER,

8415 N. Clinton Park

Fort Wayne, IN 46825

G

AccuTemp Products, Inc.

G

D

DEF

G

G

G

RED

RED

HEATING EL EMENTS

BLK

WHT

R2

R3

R1

BLK

BLK

ZR2

275V

WHT

BLK

WHT

RED

ZR5

275V

L3

CONTACTOR

ZR1

30V

L2

L1

GRN

WHT

G

X

Z

Y

ORN

WHT

AT1T-3595-2

3 PHASE, 208V - 240V

(ATMOSPHERIC

STEAMER)

YEL

RED

YEL

BRN

1.25 A

F2

1.25 A

F1

YEL

BRN

480V

440V

240V

208V

COM

AT0E-2662-5

24V

2

1

3

4

5

6

BLK

L1

SSR1

3

+

4

-

T1

L1

SSR2

3

+

4

-

T1

ORN

BLK

RED

RED

WHT/BRN

BRN

THERMAL

LIMITS W3

VIO

ON/

OFF

1 2

J2

1 2 3 4 5 6

J7

+24V

GND

SENSOR

INPUT

POWER

INPUT

DIGITAL

CONTROLLER

RED

RED

PRTD

1 2

J3

1 2

J10

BLK

RED

WHT/BRN

DOORSW

WHT/BRN

DK BRN

PNK

YEL

LOW

WATER

YEL

HIGH

WATER

OVER

TEMP

FILL

W. VLV.

ZR7 275V

*

AUTO-FILL ONLY

YEL

GRN

LT BLU

ORN

N.O. N.C.

COM

N.O. N.C.

COM

L1L2

PRB1

WATERSENSOR BOARD

GND

PRB2

AUTO-FILL OPTION ONLY

K2

K1

J5

J6

J7J8 J9

J1

J2

J3

J4

HIGHLIMIT LOW LIMIT

*DK BRN

*BLU

VIO

VIO

WHT/GRY

VIO

*H. W. LIMIT SW7

*BLK

*BLK

VIO

YEL

N.O.

N.C.

COM

7

4

1

N.O.

N.C.

COM

8

5

2

3

6

TAN

FAULT

ALARM

BLU

YEL

MANUAL

FILL

ONLY

YEL

MANUAL FILL

ONLY

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 43

Page 45

SERVICE PARTS

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 44

Page 46

Power Pack

AT1A-3765-1 REV A

11

RED

5

GREEN

D

11

BLACK

9

7

15

4

3

9

8

ITEM

NUMBER

8

9

8

10

8

6

1

2

6

PART NUMBER DESCRIPTION

1 AT0H-3718-2 ENCLOSURE, HOFFMAN

2 AT0A-3790-1 ASSEMBLY, CIRCULAR CONNECTOR HARNESS

3 AT0H-3785-2 PLATE MOUNTING

4 AT0H-3802-1 FOOT, MOUNTING CIRCUIT BREAKER

5 AT0E-3786-3 BREAKER, CIRCUIT

6 AT0F-2755-40050 SCREW #10-32UNF X 5/8 PHILLIPS ROUND HEAD MACHINE

7 AT0F-2755-40010 SCREW #10-32UNF X 3/8 PHILLIPS ROUNG HEAD MACHINE

8 AT0F-2666-40000 WASHER, #10 INTERNAL TOOTH LOCK

9 AT0F-2778-40001 NUT, #10-23UNC-2B HEX MACHINE SCREW

10 AT0H-2576-3 GROMMET, 1 1/2” NYLON

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 45

Page 47

COMMON COMPONENTS ASSEMBLY

AT1A-3572-1 REV P

29

43

32

31

30

SP8017-1404

28

27

26

SEE PAGES 49 & 50 FOR ITEM LISTING

EVOLUTION EEK STEAMER

PAGE 46

Page 48

COMMON COMPONENTS ASSEMBLY

AT1A-3572-1 REV P

100

99

74

60

76

7

6

73

70

SP8017-1404

SEE PAGES 49 & 50 FOR ITEM LISTING

EVOLUTION EEK STEAMER

PAGE 47

Page 49

COMMON COMPONENTS ASSEMBLY

5

63

3

37

63

61

63

77

5

2

1

93

33

23 25

24

68

57

53

57

41

106

51

106

85

18

106

4

63

63

86

22

83

72

69

91

36

78

36

17

36

79

36

50

36

16

106

38

36

44

36

75

8

87

88

63

76

60

96

67

52

93

42

97

62

93

98

64

102

64

103

69

72

95

62

105

K

108

109

71

107

62

64

102

100

102

AT1A-3572-1 REV P

SEE PAGES 49 & 50 FOR ITEM LISTING

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 48

Page 50

COMMON COMPONENTS ASSEMBLY

AT1A-3572-1 REV P

SEE PAGES 49 & 50 FOR ITEM LISTING

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 49

Page 51

COMMON COMPONENTS ASSEMBLY

AT1A-3572-1 REV P

ITEM PART NUMBER DESCRIPTION

1 AT1A-3573-1 CHAMBER WELD ASSEMBLY

2 AT1A-3629-1 ASSEMBLY, TOP PANEL

3 AT1A-3596-1 PANEL, BOTTOM ASSEMBLY

4 AT1M-3588-1 PANEL, BACK

5 AT1M-3587-1 PANEL, SIDE

6 AT1A-3610-2 HEATING MOUNTING BRACKET ASSEMBLY

7 AT1A-3610-1 HEATER MOUNTING BRACKET ASSEMBLY

8 AT1A-3590-1 COMPONENT BRACKET ASSEMBLY

16 AT0P-1456-3 FITTING FEMALE 3/8” NPT X 1/4 BARB

17 AT0P-2628-1 ELBOW 90

18 AT0P-3614-1 TEE, BULLHEAD 1/2x3/4x1/2 NPT

22 AT0H-3623-1 SPACER, ROUND CLEAR HOLE

23 AT0H-3623-2 SPACER ROUND CLEAR HOLE

24 AT1M-3607-1 BRACKET INDICATOR LAMP

25 AT0E-1800-2 INDICATOR LAMP RED INCANDESCENT 28V

26 AT1I-2866-24 INSULATION ,BOTTOM FRONT

27 AT1I-2866-25 INSULATION ,BOTTOM MIDDLE

28 AT1I-2866-26 INSULATION, BOTTOM BACK

29 AT1I-2866-28 INSULATION, TOP

30 AT1I-2866-29 INSULATION, LEFT SIDE WALLS

31 AT1L-2866-23 INSULATION, RIGHT SIDE

32 AT1L-2866-27 INSULATION, BACK WALLS

33 AT1M-2573-3 DRIP EDGE

35 AT1M-3348-1 COVER , STEAM DRAIN

36 AT0H-3201-1 PIPE THREAD SEALANT

37 AT1L-2624-1 LABEL

38 AT1P-2239-1 BALL VALVE

39 AT1L-3357-1 LABEL, SERIAL NUMBER DATA

40 AT0P-3233-1 FLOAT, ROUND

41 AT0P-3616-1 ELBOW, 90° HOSE BARB 1/2 X 1/4

42 AT0E-3626-1 TEMPERATURE SENSOR, RTD

43 AT1I-2866-31 INSULATION, BACK TOP

44 AT0P-3613-2 BUSHING, 3/8 NPT X 1/4 NPT HEX

45 AT1A-3387-2 LOOSE PIECES,STEAMER

50 AT0P-2841-2 HEX HEAD PLUG CORED

51 AT1P-2555-32011 SILICONE HOSE 1/4" ID X 1.25" LG

53 AT1P-2555-32220 SILICONE HOSE, 1/4”ID X 22” LG

54 AT0P-3833-63122 SILICONE HOSE, 1/2”ID X 12.5”

55 AT0P-3477-83022 HOSE, SILICONE, BRAIDED REINFORCED 3/4” IDx 2 1/2” LG

57 AT0P-2714-5 HOSE CLAMP 1/2” ID

59 AT1E-2652-1 PROBE, WATER SENSOR

60 AT0F-2755-41042 SCREW, #10-24UNC X 1/2 PHILIPS

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 50

Page 52

COMMON COMPONENTS ASSEMBLY

AT1A-3572-1 REV P

ITEM PART NUMBER DESCRIPTION

62 AT0F-1046-41030 SCREW, #10-24X 3/8” TRUSS HEAD

63 AT0F-2777-31030 SCREW, #8 TYPE ABX3/8 TRUSS HEAD

64 AT0F-2061-41080 SCREW, #10-24X 1” FLAT HEAD MACHINE

67 AT0F-2778-11002 NUT, #4-40 UNC-2B ZINC PLATED HEX MACHINE

68 AT0F-2691-21002 NUT, #6-32 NYLOC

69 AT0F-3621-1 NUT, 36-32UNC-2B UNDER SIZE MACHINE SCREW HEX

70 AT0F-3401-1 NUT, SPECIAL LOCKING 1/4-20UNC-2B

71 AT0F-2632-51006 NUT, 1/4-20 ACORN

72 AT0F-2666-21006 WASHER, #6 EXTERNAL TOOTH LOCK WASHER

73 AT0F-2663-2 WASHER, 0.937 BELLEVILLE

74 AT0F-3405-1 WASHER, ROUND FLAT

75 AT0H-3643-1 PLUG, DOME 1.25 DIA

76 AT0F-1052-410002 WASHER, #10 TYPE B PLAIN

77 AT1L-3608-1 OVERLAY, STEAM CONTROL PANEL

78 AT0P-3615-1 ELBOW, 90° STREET 1/2 NPT

80 AT1A-3601-1 WIRE RACK ASSEMBLY

83 AT0E-3625-1 CONTROLLER, QUANTEM SERIES 130

84 AT1A-3605-1 STEAMER WIRING HARNESS

85 AT0E-3617-1 SWITCH, AIR PRESSURE

86 AT0A-3660-1 SENSOR MAGNETIC PROXIMITY ASSEMBLY

87 AT0L-3659-1 OVERLAY, ACCUTEMP LOGO

88 AT1L-3658-1 OVERLAY, STEAMER OPERATING INSTRUCTIONS

89 AT1A-3663-1 ENCLOSER, STEAM COLLECTOR ASSEMBLY

91 AT0P-3613-1 BUSHING, 1/2 NPTX1/4 NPT HEX

93 AT0F-1017-41002 NUT, #10-24 UNC HEX SERRATED

95 AT1M-3606-1 BRACKET REAR SUPPORT

96 AT0F-2666-10006 WASHER, #4 INTERNAL TOOTH

97 AT0H-3412-2 WAKEFIELD THERMAL JOINT COMPOUND 2 OZ

98 AT0F-3405-2 WASHER, ROUND FLAT

100 AT1A-3530- CAST HEATER KIT (INCLUDES ITEMS 70,73,99,100)

102 AT0H-3065-3 THREAD LOCKER 248

103 AT0L-3682-1 DECAL, ENERGY STAR

105 AT1L-3665-2 LABEL, STEAM EXHAUST VENT

106 AT0P-2714-7 HOSE CLAMP .500+ O.D. HOSE

107 AT0F-1922-50000 WASHER, 1/4” HELICAL SPRING LOCK

108 AT0P-3512-32000 NIPPLE, CLOSE, BRASS-1/2” NPT

109 AT1M-3865-1 PLATE, CHAMBER RESTRICTOR

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 51

Page 53

15

DOOR CONFIGURATION

AT1A-3600-1 REV E

1

2

ITEM PART NUMBER DESCRIPTION

1 AT1A-3645-1 DOOR ASSEMBLY

2 AT1H-3609-1 SPACER

3 AT1H-3609-H LATCH,STRIKE

4 AT1H-3609-J LATCH SPACER

15 AT0F-1046-41030 SCREW, #10-24 X 3/8 PHLP TRUSS HEAD

SP8017-1404

4

EVOLUTION EEK STEAMER

3

PAGE 52

Page 54

DOOR ASSEMBLY

AT1A-3645-1 REV A

ITEM PART NUMBER DESCRIPTION

1 AT1A-3646-1 OUTER DOOR ASSEMBLY

2 AT1A-3647-1 INNER DOOR ASSEMBLY

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 53

Page 55

OUTER DOOR ASSEMBLY

AT1A-3646-1 REV A

7

ITEM PART NUMBER DESCRIPTION

1 AT1M-3648-1 OUTER DOOR PANEL

2 AT1M-2689-1 HINGE MOUNTING PLATE

3 AT1M-3046-1 LATCH MOUNTING PLATE RIGHT HAND

4 AT1M-3466-2 BRACKET, DOOR

5 AT1H-2058-3 HINGE, STEAMER DOOR

6 AT1H-3609-1 LATCH HANDLE ASSEMBLY

7 AT0F-2061-41060 SCREW, #10-24 x 1¾” FLAT HD MACHINE

8 AT0F-2691-41011 NUT, #10-24 WAXED NYLOC

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 54

Page 56

INNER DOOR ASSEMBLY

AT1A-3647-1 REV A

ITEM PART NUMBER DESCRIPTION

1 AT1A-3649-1 PANEL, INNER DOOR WELDMENT

2 AT1M-3651-1 Z BRACKET, INNER DOOR

3 AT1M-3466-1 BRACKET, DOOR

4 AT1M-3466-2 BRACKET, DOOR

5 AT1M-3653-1 SPRING, INNER DOOR

6 AT1M-3524-1 RETAINER, SIDE DOOR GASKET

7 AT1M-3652-1 RETAINER, DOOR GASKET

8 AT1M-3507-1 RETAINER, SIDE SMALL DOOR GASKET

9 AT1G-2633-1 INNER DOOR GASKET

10 AT0F-2691-41011 NUT, #10-24 WAXED NYLOC

11 AT0F-1052-51000 WASHER 1/4 TYPE B PLAIN STAINLESS STEEL

12 AT0F-3368-2 BLIND RIVET

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 55

Page 57

DISTRIBUTION PANEL ASSEMBLY

AT1A-3667-2 REV C

ITEM PART NUMBER DESCRIPTION

1 AT1A-3603-2 DISTRIBUTION PANEL ASSEMBLY

2 AT1G-3669-1 GASKET, DISTRIBUTION PANEL

3 AT0H-3656-1 KNOB

4 AT0F-3657-1 E-RING, RETAINING

5 AT1M-3619-1 STRIP, GASKET HOLD DOWN

6 AT0F-2778-21007 NUT, #6-32UNC-2B BRASS HEX MACHINE SCREW

7 AT0F-2666-21006 WASHER, #6 EXTERNAL TOOTH LOCK

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 56

Page 58

1

6

5

4

3

2

7

STEAMER TABLE ASSEMBLY

AT1A-3780-1 REV B

ITEM PART NUMBER DESCRIPTION

1 AT0H-3781-1 TABLE, ALUMINUM FOLDING

2 AT1M-3782-1 BRACKET, FLANGE MOUNTING

3 AT1M-3782-3 BRACKET, FLANGE MOUNTING

4 AT1M-3782-2 BRACKET, FLANGE MOUNTING

5 AT0F-2875-51081 SCREW, 1/4-20UNC X 1 HEX HEAD MACHINE

6 AT0F-1052-51000 WASHER 1/4 TYPE B PLAIN STAINLESS STEEL

7 AT0F-2691-51001 NUT, 1/4-20 NYLOC

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 57

Page 59

INFORMATION

IMPORTANT SERVICE INFORMATION

AccuTemp Product, Inc. Technical & Customer Support Technician is

available Monday thru Sunday, 7:00am to 7:00pm EST.

800.480.0415 or 260.469.3040

• Phone - 800.480.0415 or 260.469.3040

• Email - service@accutemp.net

• Web site - www.accutemp.net

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 58

Page 60

LIMITED WARRANTY

One Year– Parts and Labor

U.S. & Canada Only

AccuTemp Products, Inc. (AccuTemp) warrants that your AccuTemp equipment will be free of

defects in material and workmanship under normal use for a period of twelve (12) months from

installation or fteen (15) months from date of shipment from AccuTemp, whichever date rst

occurs (the Warranty Period). Registration of AccuTemp equipment is required at the time of

installation. Damage to AccuTemp equipment that occurs during shipment must be reported to

the carrier, and is not covered under this warranty. The reporting of any damage during shipment is

the sole responsibility of the commercial purchaser/user of such AccuTemp equipment.

AccuTemp provides an active service department, which should be contacted and advised of

service issues, regardless of the warranty period. During the warranty period, AccuTemp must be

contacted for warranty repairs and agrees to repair or replace, at its option, F.O.B. factory,

any part which proves to be defective due to defects in material or workmanship, provided

the equipment has not been altered in any way and has been properly installed, maintained, and

operated in accordance with the instructions in the AccuTemp Owners Manual. During the warranty

period, AccuTemp also agrees to pay for any factory authorized equipment service agency (within

the continental Applianceed States and Canada) for reasonable labor required to repair or replace,

at our option, F.O.B. factory, any part which proves to be defective due to defects

in materials or workmanship, provided the service agency has received advance approval from

AccuTemp factory service to perform the repair or replacement. This warranty includes travel time not

to exceed two hours and mileage not to exceed 50 miles (100 miles round trip), but does not include

post start-up assistance or training, tightening of loose ttings or external electrical connections, minor

adjustments, maintenance, or cleaning. AccuTemp will not reimburse the expense of labor required

to replace parts after the expiration of the warranty period.

Proper installation is the responsibility of the dealer, owner-user, or installing contractor and is

not covered by this warranty. Improper installation can affect your warranty. Installation is the

responsibility of the Dealer, Owner/User or the Installation Contractor. See the Installation

section of the Owners Manual. While AccuTemp products are built to comply with applicable

standards for manufacturers, including Underwriters Laboratories (UL) and National Sanitation

Foundation (NSF), it is the responsibility of the owner and the installer to comply with any

applicable local codes that may exist.

AccuTemp makes no other warranties or guarantees, whether expressed or implied, including

any warranties of performance, merchantability, or tness for any particular purpose. AccuTemp

liability on any claim of any kind, including negligence, with respect to the goods and services

covered hereunder, shall in no case exceed the price of the goods and services, or parts

thereof, which gives rise to the claim. In no event shall AccuTemp be liable for special,

incidental, or consequential damages, or damages in the nature of penalties.

This constitutes the entire warranty, which supersedes and excludes all other

warranties, whether written, oral, or implied.

SP8017-1404

EVOLUTION EEK STEAMER

PAGE 59

Page 61

Loading...

Loading...