AccuTemp E62301E070, E62081E060, E62083E100, E62083E150, E62401E060 Installation & Operator's Manual

...Page 1

EVOLUTION ELECTRIC STEAMER

INSTALLATION & OPERATOR MANUAL

Connection-less Model Double Stack

Connected Model

Drain pans are customer supplied

IMPORTANT WARRANTY INFORMATION

WARRANTY REGISTRATION - STARTUP FORM INSIDE THIS MANUAL MUST BE REMOVED,

COMPLETED, SIGNED BY CUSTOMER AND A COPY EMAILED, FAXED OR MAILED BACK TO

ACTIVATE THE LIMITED WARRANTY.

These installation instructions have been prepared for qualified electric

equipment installation personnel, who should perform the installation, initial

field start-up and complete the equipment adjustments described in this

manual.

Page 2

Installation Manual I Installation

TABLE OF CONTENTS

SAFETY WARNINGS INFORMATION PAGE 2

START UP FORM PAGE 3

GENERAL INFORMATION PAGE 5

INSTALLATION PAGE 7

OPERATION - USE PAGE 14

OPERATION CLEANING PAGE 18

TROUBLESHOOTING PAGE 21

SERVICE PAGE 22

PREVENTATIVE MAINTENANCE CHECKLIST PAGE 23

WARRANTY PAGE 24

DOCUMENT HISTORY

CURRENT

REVISION

1903 04/03/2019 1003 04/14/2010 Review and update of manual

MP4010-1903

DATE PRIOR

REVISION

DATE CHANGE

1

Page 3

Installation Manual I General Information

IMPORTANT FOR YOUR SAFETY

The safety instructions listed below on this page should be posted in a

prominent location as a reminder of safe practices as well as recommended

actions to follow in the event of an equipment or facility utility issue.

WARNING

In the event of a power failure, do not attempt to operate this appliance.

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury or death. Read the installation, operating, and maintenance instructions

thoroughly before installing or servicing this equipment.

WARNING

Only qualified service technicians/electricians should install this appliance to ensure that all

electrical and safety requirements are met and that all wiring is installed in accordance with

all national, state and local electrical codes.

MP4010-1903

2

Page 4

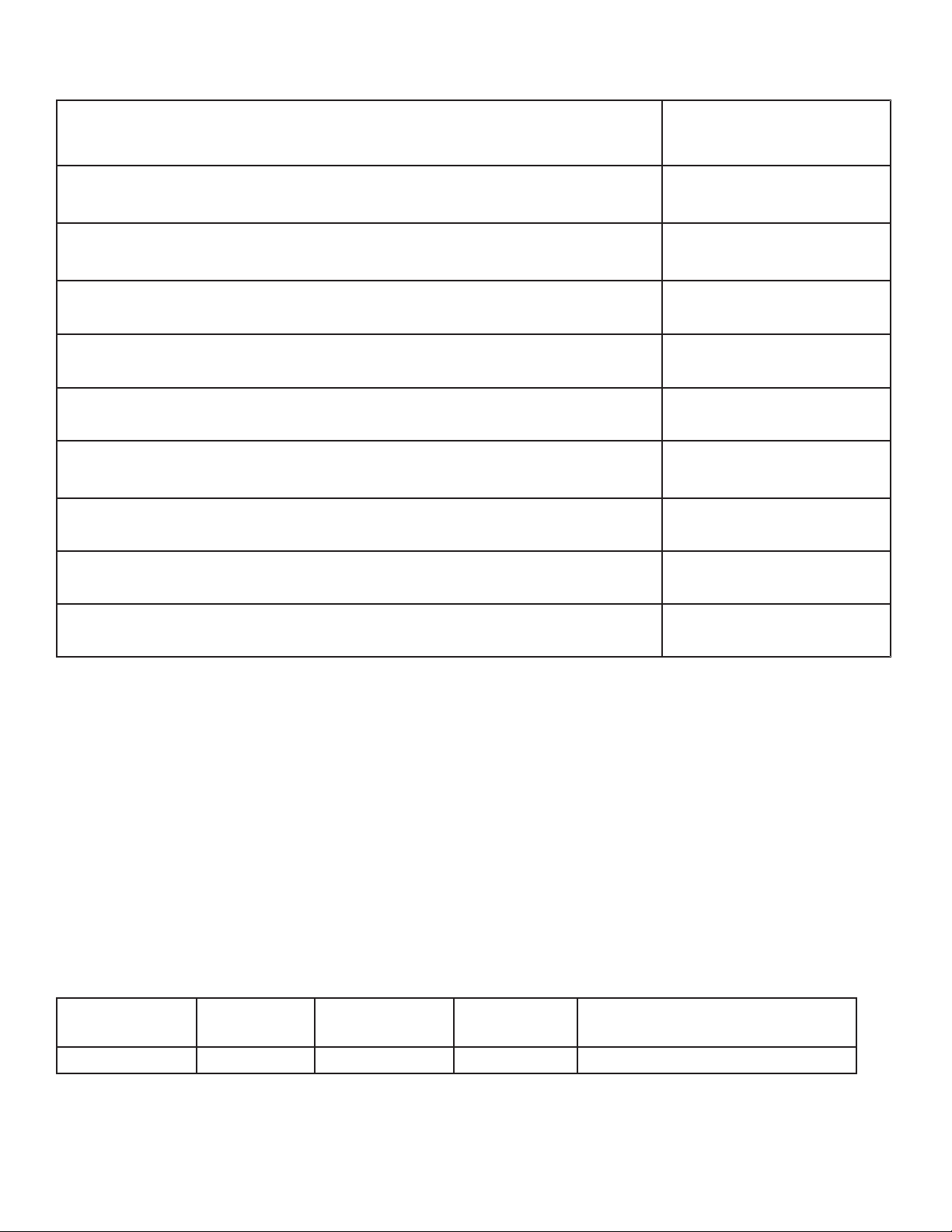

EVOLUTION Electric Steamer Start-Up Form

SERIAL NUMBER:

Location Name:

Street Address:

State/ Zip Code:

Building Name/#:

Contact Name:

Phone:

Email:

• AccuTemp Products, Inc. is not responsible for the installation, nor does it recommend modifications to the

electrical supply sources, Any in-field modifications made without written authorization from AccuTemp

Products, Inc. will void all written and oral warranties.

• It is recommended that the wall receptacle be placed as low as State and Local codes allow. Placement in high

heat zones will cause service issues that will not be covered under the product warranty.

THIS STARTUP FORM MUST BE COMPLETELY FILLED OUT, EMAILED, FAXED OR MAILED OR EMAILED TO THE

ACCUTEMP TECHNICAL & CUSTOMER SUPPORT DEPARTMENT, BEFORE THE WARRANTY IS ACTIVATED.

MODEL NUMBER:

Date:

Service Company:

Street Address:

State/ Zip Code:

Service Phone #:

Technicians Name:

Technicians Email:

Additional Info:

1. Is the steamer being installed at an altitude greater than 2,000 feet (Tick Box)

2. Is the steamer level? (Tick Box)

3. Is the wall receptacle positioned in a low heat zone? Note: It is recommended that the wall

receptacle be placed as low as State & Local codes allow. Placement in high heat-zones

like: just above, below, or beside the exhaust flue; will cause service issues that will not be

covered under the product warranty. (Tick Box)

4. If the steamer has legs, have the (4) rubber foot tips been installed (Tick Box)

5. Is the supply cord plugged into a wall outlet? (Tick Box)

6. Is the supply cord being hardwired, without the plug, to a breaker box

(if YES, be aware this voids the UL listing and may aect warranty. Tick Box)

7. Is the supply cord properly connected to GND (Tick Box)

8. What is the Electrical Breaker Amperage that will interrupt the Supply Voltage to the Unit:

Confirm Supply Power Electrical Readings

Phase: Single ϕ Three ϕ

Amperage Draw on each leg:

Single ϕ WHT BLK

Supply Voltage:

YES

NO

AMPS

208VAC 240VAC 440VAC 480VAC

MP4010-1903

Three ϕ WHT BLK RED

3

Page 5

EVOLUTION Steamer Start-Up Form (continued)

9. Is the correct NEMA Plug and Receptacle being used on the supply power cord?(Tick Box)

YES NO

Type of NEMA Plug Tick One Tick One

L6-30P (208/240V 6kW) L16-20P (480V 14kW)

L15-30P (208/240V 10kW) IEC 60309-2 (230/415V)

15-50P (208/240V 15kW)

Connected (Auto-fill) Models Only

10. Is the supply water pressure lower than 30PSI (Tick Box)

11. With the Steam Collector Pan removed and the Steam Chamber empty, does the AutoFill Water Stream hit the chamber floor half-way to three-quarters of the way towards the

opposite wall?

Note: The Auto-Fill Valve has a maximum water supply pressure of 60 psi. If stream goes beyond ¾ or IF water

pressure gauge is > 60 psi, THEN install water regulator.

12. Is the chamber water level at (or just below) the stamped water line on inside left chamber

wall after auto fill has been completed? (Tick Box)

13. Is the Float Ball Installed in the unit? (Tick Box)

14. Is there a High Water alarm when the Float Ball is removed? (Tick Box)

All Models (Connected & Connection-less)

15. Does the Low Water Light and Alarm turn OFF once the chamber water level has reached the

middle of the Low Water Sensor? (Connected Water Models will only have the Low Water

Light and no Alarm. Tick Box.)

16. Has additional piping been added to the steam vent? (Tick Box)

Reference Page 12 for guidance.

YES

YES NO

NO

17. Verify the water temperature in COOK MODE (COO on digital display) °F

18. Does the unit cycle the heat once it is in COOK MODE? (Tick Box)

19. Is there any added drain hose/piping attached to the Steamer Drain System? Note: Does the

added drain hose/piping to the steamer meet the specifications listed on the instruction label

attached to the back of the steamer? (Tick Box)

20. If unit is part of a double stack, does the top steamer have a drain kit installed?

(If NO, Warranty is void until kit is installed. Tick Box).

21. Take photographs of install, including: Front of steamer, Side view of steamer, hook up and

supply. (Tick Box)

I accept this Start-up form as complete and accurate:

Signed: Restaurant Management

Date: / /

Print Name:

ACCUTEMP PRODUCTS INC.

4815 N CLINTON PARK DR - FORT WAYNE - IN - 46825

TELEPHONE: 800-480-0415, SERVICE@ACCUTEMP.NET

PRINTED IN USA

MP4010-1903

4

Page 6

Installation Manual I General Information

1. GENERAL INFORMATION

AccuTemp appreciates your decision to purchase our equipment.

Your new equipment combines the long-term experience of

the best chefs together with the latest scientific and modern

technologies. With the help of your new equipment, you shall

always achieve the highest quality dishes and a superior product.

To ensure that you succeed right from the beginning in gaining the

best results, we would like to provide you, through this manual,

with all the information necessary for smooth operation.

AccuTemp guarantees proper functioning and high-quality

service.

We oer:

•• 12-month guarantee of flawless operation of the equipment.

•• Warranty service and post-warranty support.

•• Technical and advisory services in connection with servicing

and maintenance.

•• Chef expert advisory service.

We hope that you enjoy working with AccuTemp equipment and

that you always have many satisfied guests.

This manual contains available information on the AccuTemp

equipment accessible at the time of publication of this manual. Errors and technical modifications are under the usual

provision.

1.1 Contact

1.2 Use of the operating instructions

Read carefully and follow the instructions for operation and

maintenance of your equipment. Should some of the procedures

be unclear, contact your salesperson for further assistance.

SYMBOLS USED

The symbols used here draw attention to activities that may

influence safety, health protection and the necessity for servicing.

They help you to prevent problems and the advice will make your

work easier.

WARNING

Indicates a potentially hazardous situation; which, if unchanged,

will result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation; which, if unchanged, will result in minor or moderate injury

NOTE

Advises reader of information or instructions vital to the

operation or maintenance of the equipment

EARTH GROUND

Should you have any questions we are at your service at the

following telephone numbers and addresses.

AccuTemp Products

8415 N Clinton Park Dr

Fort Wayne, IN 46825

Tel: 800 480-0415

Fax: 260 469-3045

E-Mail: service@accutemp.net

DANGEROUS VOLTAGE

HOT SURFACE

1.3 Warranty Restrictions

All the technical information, data, operation and maintenance

instructions contained in this operating manual correspond to the

final state upon delivery and were compiled with regard to our previous experience and to our best knowledge. We reserve the right

to carry out technical changes on the equipment described in this

operating manual as part of further development of the equipment.

We do not accept any responsibility for any damage or failures

arising from incorrect operation, lack of attention to this

manual, use of aggressive chemical cleaning products and

technically incorrect repairs. We call your attention to the fact

that this also applies to spare parts not delivered by us and

to accessory equipment not pre-tested and approved by us.

All modifications or changes made to the equipment through

your own eorts are not permitted for the reasons of safety

and relieves AccuTemp of any responsibility for damage arising

there from. Within the scope of the warranty obligations

negotiated in the contract under the exclusion of further claims,

we accept responsibility for accidental mistakes or neglects.

MP4010-1903

Claims for reimbursement for damages are not possible regardless

of upon what judicial reason such claim is made.

5

Page 7

Installation Manual I General Information

2. EQUIPMENT DATA PLATE

2.1 Labeling

Model: A B CCC D E FFF G H I J K

Where:

A is the base model E = Electric

B is the size of the unit: 6 pan

CCC is the supply Voltage

D is the number of phases: 1 or 3

E is the control series D=Manual Fill, E=Autofill

F is the energy input

G is the timer configuration

H is the thermostat configuration

I is the door configuration

J is the leg configuration

K is the HDW configuration

MP4010-1903

6

Page 8

Installation Manual I Installation

3 INSTALLATION

3.1 Installation Notice

Only qualified service technicians/electricians should perform

the installation to ensure that all electrica safety requirements are

met and that all wiring and plumbing installations are performed

in accordance with all national, state and local codes.

The installation must conform with local codes.

3.2 Unpacking

This appliance was carefully inspected before shipment from the

factory. The transportation company assumes full responsibility

for safe delivery to the customer until customer acceptance

of the package. Careful inspection of the packaging and the

appliance should be completed before acceptance from the

transportation company.

3.3 Steamer Lifting

Steamers are heavy enough to require additional manpower or

powered assistance when installing or moving the steamer.

When moving the equipment manually make sure there are

enough people for the task as the equipment is heavy.

FIGURE 1: EQUIPMENT CLEARANCE INFORMATION

FOR COMBUSTIBLE & NONCOMBUSTIBLE BUILDING MATERIALS

LOCATION COMBUSTIBLE NONCOMBUSTIBLE

SIDES

REAR

FOR OTHER SOURCES OF HEAT: FRYERS, OPEN RANGE, STEAM VENTS.

For open flame, this is the minimum distance from the flames while they

are in operation.

1” 0”

2” 0”

LOCATION

LEFT

RIGHT

REAR

Counter Top Placement

In a counter top installation the steamer can be leveled using

the adjustable legs. Once this is complete it is required that the

supplied (4) rubber foot tips be installed to keep the steamer

from possibly sliding on the counter top under normal use.

3.5 Stand Installation

If an AccuTemp Evolution Steamer Stand is used ensure the floor

is level and place the two locking casters to the “ON” position.

3”

3”

3”

Make sure the equipment is not dropped during moving.

People doing the carrying could be seriously injured and/or the

equipment damaged. The manufacturer does not accept any

responsibility for damage resulted from such actions.

3.4 Location and Placement

The AccuTemp Evolution steamer can be placed on a

commercial kitchen counter-top, flush mounted or installed

on a AccuTemp Evolution steamer stand. Provisions should be

incorporated in the kitchen to ensure an adequate supply of

fresh air for proper combustion and ventilation (FIGURE 1).

The steamer must be installed in a level condition. An out of

level condition may cause erratic operation and damage to

the steamer. Damage of this kind is not covered by the limited

warranty. Use a spirit level resting on the top surface of the

steamer to ensure it is level front to back and left to right.

For the correct operation of the steamer it is important that

it is leveled in a horizontal position.

Placement on an unlevel or uneven surface may result in

performance faults. Only professional installation of the device

guarantees it high-quality operation.

Check proper setting of the equipment by placing a hotel

pan filled with water inside the steamer and observing the water

level.

When using a stand that is equipped with casters, the floor

surface must be level and flat. Failure to do so can result in a

“tipping” hazard that could result in serious injury.

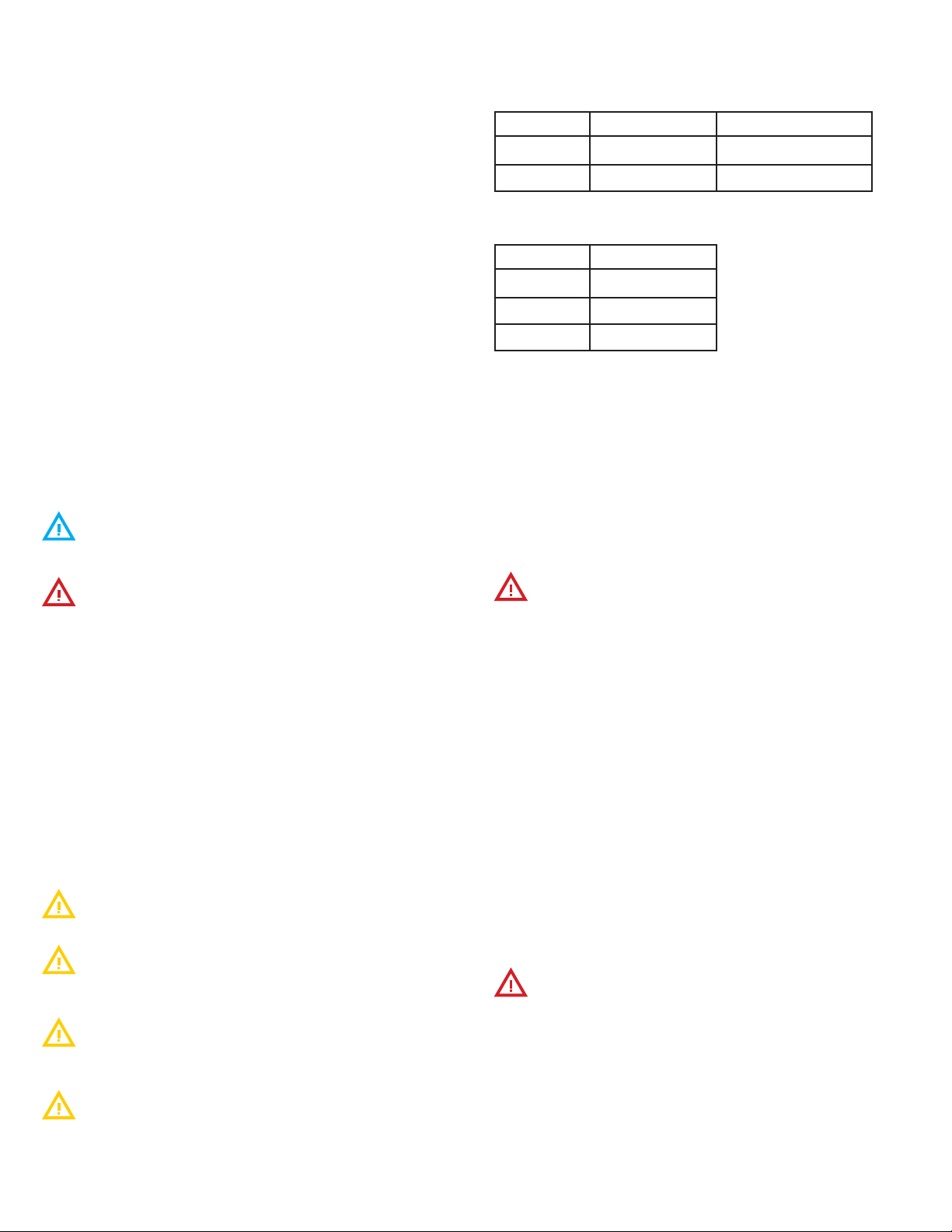

3.5.1 Single Steamer Stand Installation Instructions

The AccuTemp single stand can be equipped with adjustable

height feet or non-adjustable casters (FIGURE 3).

1. Before mounting a steamer on the stand with casters,

engage the two front locking casters, pressing on the “ON”

handle of the brake mechanism.

2. To mount the steamer, carefully lift and place it on the

horizontal mounting brackets ensuring that the (4) mounting

holes on the underside of the Evolution are lined up with

mounting holes of the brackets.

3. Then, using a 7/16” wrench, fasten one pair of the 1/4” -20

hex bolt and 1/4” split lock washer through the underside

of each stand bracket mounting hole into the Evolution and

tighten securely.

4. With the SNH-10 stand, level the steamer by adjusting the

feet found at the ends of each stand leg, either up or down

as needed.

When installing units on a double stand, always install the

lower unit first. Installing the upper unit first could cause the

stand to topple.

A minimum clearance of 10 inches must be allowed for

on the left hand side of the unit for maintenance access to the

unit. Failure to provide this may limit the eectiveness of service

dispatch and incur additional costs not covered by warranty.

MP4010-1903

7

Page 9

Installation Manual I Installation

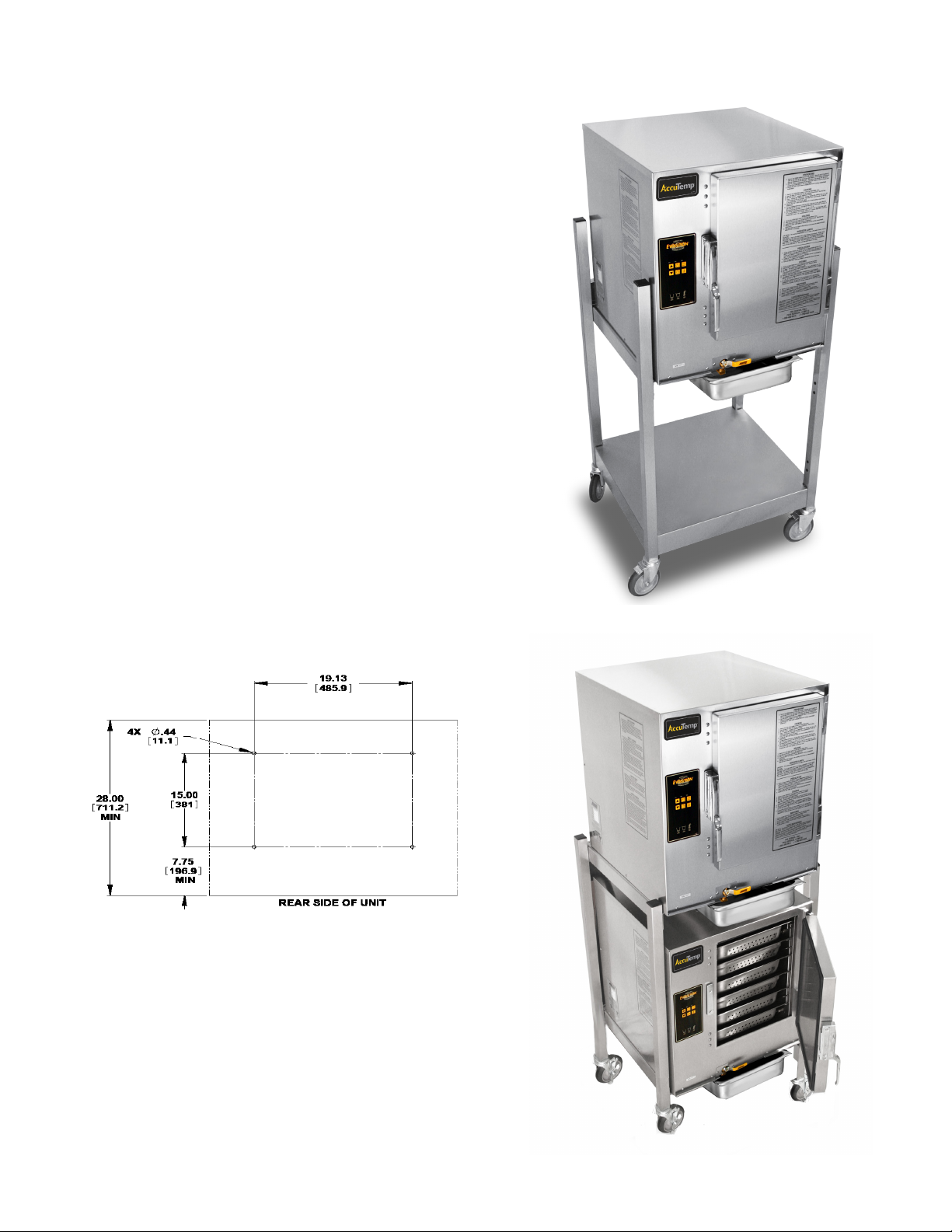

3.5.2 Double Stand Installation Instructions

The AccuTemp double stand can be equipped with adjustable

height feet or can be equipped with non-adjustable casters and

accommodates (2) E6 model Evolutions (FIGURE 4).

1. Before mounting a steamer on a stand with casters engage

the brakes on the two front locking casters, pressing on the

“ON” handle of the brake mechanism.

2. Always mount the first EVOLUTION on the bottom of the

stand. To mount the bottom steamer, carefully lift and place

it on the horizontal mounting brackets, ensuring that the (4)

mounting holes on the underside of the Evolution are lined

up with the mounting holes on the brackets.

3. Then, using a 7/16” wrench, fasten one pair of the 1/4”-20

hex bolts and 1/4” split lock washers through the underside

of each stand bracket mounting hole into the Evolution and

tighten securely.

4. Once the bottom steamer has been installed, carefully

lift and place the top Evolution steamer on the horizontal

mounting brackets, ensuring that the (4) mounting holes

on the underside of the Evolution are lined up with the

mounting holes on the brackets.

5. Then, using a 7/16” wrench, fasten one pair of the 1/4”-20

hex bolts and 1/4” split lock washers through the underside

of each stand bracket mounting hole and tighten securely.

6. With the SNH-20 stand, level the appliances by adjusting the

feet found at the ends of each stand leg, either up or down

as needed.

FIGURE 3: MANUAL FILL UNIT ON SINGLE STAND

3.5.3 Flush Mount Installation

To Flush mount the appliance to a counter, follow these steps:

1. Drill 4 holes as seen in FIGURE 2.

2. Attach the appliance to counter top with (4) 1/4-20 x 3/4”

hex head bolts and 1/4-20 split lock washers.

3. Apply a bead of high temp food grade silicone caulking

around the perimeter and smooth out.

FIGURE 2

FIGURE 4: MANUAL UNITS ON A DOUBLE STAND

MP4010-1903

8

Page 10

Installation Manual I Installation

3.6 Steamer Connections

The Evolution Electric Steamer is available in a connected and

connection-less models.

Both the connection-less and connected model will require a

an electrical connection.

CONNECTED UNITS:

The connected model in addition to the electrical connection

will require a water connection and access to a floor drain or

sink to route a drain hose (not supplied) to allow condensate to

be removed and to drain the steamer when required.

See FIGURE 5 for identifications of the required steamer

connections.

CONNECTIONLESS UNITS:

This model must be manually filled with tap water and must be

filled throughout the cooking process to assure consistent cook

times.

Do not use the “Low Water Indicator” as your indication

that this steamer requires water as this actually turns o the

heat to the product thus stopping the cooking process.

A full size steam table pan or a 1/1 gastronome pan must

installed in rails under the steamer any time the steamer is

operating and anytime that the steamer is being cleaned or

drained of the water in the cooking chamber. Failure to follow

this directions will cause a the steamer to fail which is not

covered under the limited warranty (FIGURE 6).

FIGURE 6: MANUAL FILL UNIT ON SINGLE STAND

DRAIN PAN

FIGURE 5 TEXT ENCIRCLED BOLD ARE SHARED

CONNECTIONS BETWEEN BOTH MANUAL AND AUTOFILL

UNITS

3/4” Cooking Chamber Exhaust Vent

Power Plug

3/4” GHT Potable Water

Connection (Connected Models

Only)

MP4010-1903

9

Page 11

Installation Manual I Installation

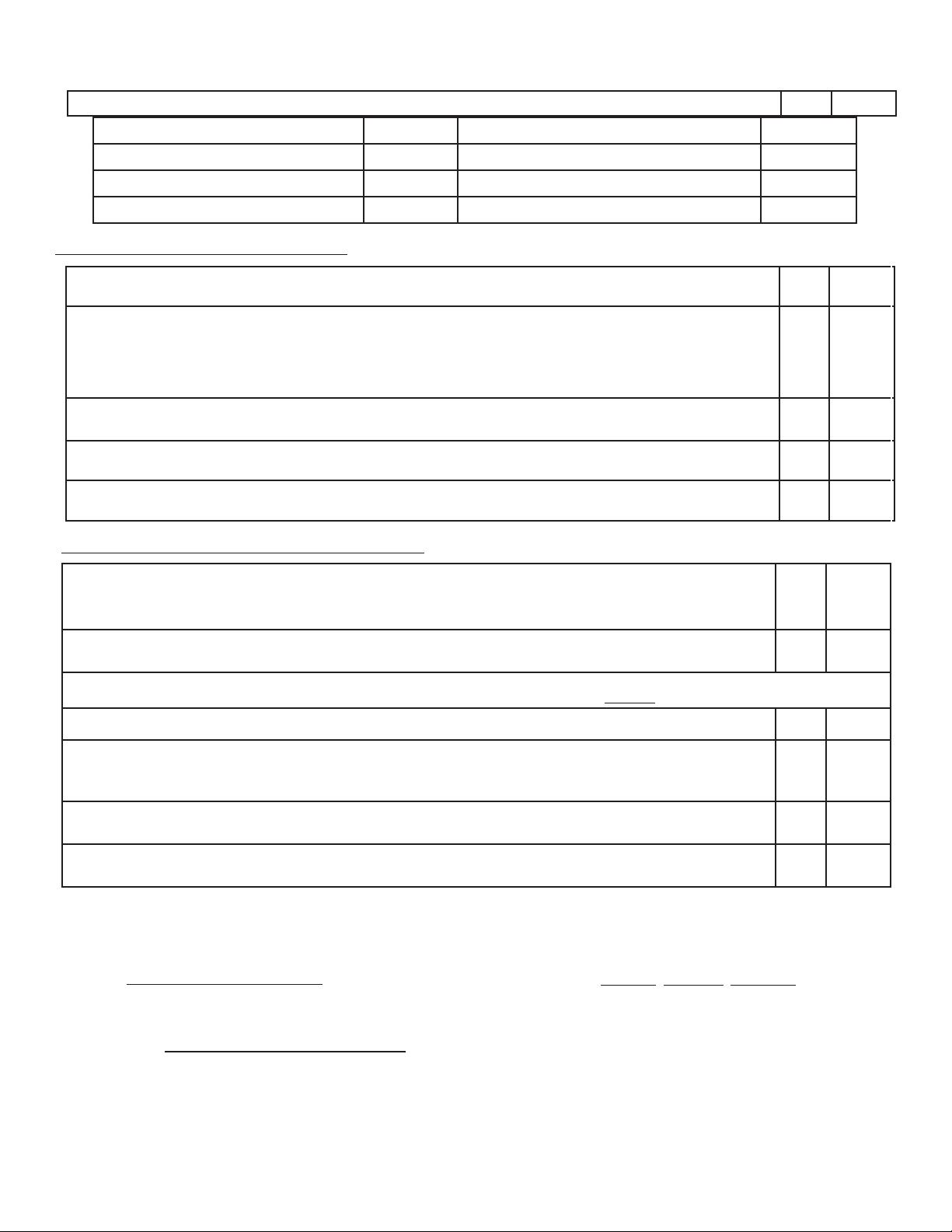

E6 TABLETOP CONNECTED EVOLUTION

6 Pan, Electric Boiler-free Convection

Countertop Steamer

Steamer Model “E” Specifications

Model #

E62081E060 E62083E100 E62083E150 E62301E070 E62401E060 E62403E110 E62403E130 E64155E110 E64803E140

E6 TABLETOP CONNECTIONLESS EVOLUTION

6 Pan, Electric Boiler-free Convection

Connectionless Countertop Steamer

1331 3 31 5 3

3.7 Electrical Requirements and Notices

The electrical voltage requirement is listed on the data plate that is located on the lower left side panel.

All AccuTemp Evolution Electric Steamers are supplied with a power cord and plug that must be connected to the

specified receptacle, see below for reference.

Make sure the voltage is within 10% of the voltage listed on the steamer data plate.

Connection to any other voltage not identified on the data plate will cause damage to the components and is not covered under

warranty.

Grounding provides a path for electric current to reduce risk of shock.

This product is equipped with a power cord having a grounding plug. If plug is removed or hard wired, UL approval is lost.

The plug must be plugged into a receptacle that is properly installed and grounded in accordance with all National, State and

local electrical codes or in the absence of local electrical codes with the National Electric Code, ANSI/NFPA 70, or the Canadian

Code, CSA C22.2 as applicable.

Under no circumstances shall the plugs grounding prong be cut or bent to fit a receptacle other than the one specified.

Do not use any adapters.

Any in-field modification made that bypass the safety features of this appliance will result in serious injury or death. DO NOT

DIRECT WIRE THIS APPLIANCE.

Any in-field modifications made without written authorization from AccuTemp Products, Inc. will void all written and oral

warranties.

ELECTRICAL SPECIFICATIONS

CONNECTED

Volts AC

Phase

Amps

Breaker Size

Watts (kW)

NEMA Plug

208 208 208 230 240 208 240 240

133 1 1 3 3 5 3

29 28 42 32 25 22 26 32 14 14 15 16 17

30 amp 30 amp 50 amp 50 amp 30 amp 30 amp 50 amp 20 amp 20 amp

6 10 15 7 6 8 11 13 9 10 11 12 14

L6-30P L15-30P 15-50P IEC 60309-2

CONNECTIONLESS

E62081D060 E62083D100 E62083D150 E62401D060 E62403D110 E62403D130 E62301D070 E64155D110 E64803D140

Model #

Volts AC

Phase

Amps

Breaker Size

Watts (kW)

NEMA Plug

380 400 41 5

220/250V

Steamer Model “D” Specifications

208 208 208 240 208 240 240 230

29 28 42 25 22 26 32 32 14 14 15 16 17

30 amp 30 amp 50 amp 30 amp 30 amp 50 amp 50 amp 20 amp 20 amp

6 10 15 6 8 11 13 7 9 10 11 12 14

L6-30P L15-30P 15-50P L6-30P L15-30P 15-50P IEC 60309-2

L6-30P L15-30P 15-50P IEC 60309-2

220/250V

220/380-240/415V

380 400 41 5

IEC 60309-2

220/380-240/415V

440 480

L16-20P

440 480

L16-20P

MP4010-1903

10

Page 12

Installation Manual I Installation

3.9 Connected Model - Additional Connections

3.9.1 Supply Water Line (FIGURE 11)

The installation of the water connection to the appliance is

the responsibility of the owner and or installer.

An inlet strainer in water inlet must be used, removal of

strainer voids steamer warranty.

The installation of this appliance should comply with all

applicable federal, state or local plumbing codes.

The installation requires a check valve (or other approved

anti-back flow/ anti-siphon device) in all supply lines in accordance with and as required by local, state and national health,

sanitation and plumbing codes. AccuTemp does NOT provide a

check valve with the steamer.

• Design the water supply line so the unit can be moved for

service. Install a manual water shuto valve between the

water supply line and the steamer supply line.

• A reinforced rubber or braided stainless steel appliance

hose rated for the temperature and pressure of the

water supply with a 3/4” garden hose type connection is

required.

• The Garden Hose Thread (GHT) connector used must

be suitable for potable water

• Do not apply pipe thread sealant to GHT

connections.

• Either hot or cold water can be connected to the

steamer. If hot is used, temperature must be less

than 180°F.

• The hose must not be sharply bent, kinked or twisted.

• If the steamer is close to a wall, use a right angle fitting to

prevent kinking the hose

• The Auto-Fill Valve has a maximum water supply pressure

of 60 psi. If stream goes beyond ¾ or IF water pressure

gauge is > 60 psi, THEN install water regulator.

• Flush the water supply lines before connecting the lines to

the appliance.

• Connect the water supply lines to the steamer.

FIGURE 10

CONNECTED UNIT

WATER INLET

FIGURE 11

CONNECTIONLESS

STEAM EXHAUST VENT

DO NOT CONNECT TO GAS,

DRAIN OR WATER INLET

3.9.2 Drain Line Connection

Floor Drain

The steamer should be located close to, but not within

20” or directly over, a floor drain.

• Connect a ¾” ID reinforced rubber hose rated for 212°F

or higher to the drain fitting on rear of the steamer with a

hose clamp (Connected Units ONLY).

• Run the hose to the drain. DO NOT directly plumb the

steamer to the drain, Leave a one-inch air gap between the

hose and the drain.

• The hose must drop 1/4” (inch) per foot to the drain.

• Ensure no loops form in the drain line as this can cause a

backup and will aect the operation of the unit

The unit should not be located within 20” of a floor drain.

Optional Drain Connection

Run the hose to a funnel fitting leaving a one-inch gap between

the hose and the top of the funnel. The drain hose must slope

toward the floor drain or funnel.

MP4010-1903

POWER CORD

11

Page 13

Installation Manual I Installation

3.10 Ventilation

DO NOT connect Drain or Vent lines on multiple

appliances. Each appliance should have its own dedicated

drain and vent.

The steam vent is provided with a 45 ° elbow. The steam

vent must not be obstructed. An obstruction will prevent

correct operation of the steamer.

Applicable federal, state and/or local plumbing codes will

dictate when and if a hood is required.

3.10.1 Steam Vent Extension

When adding anything to the vent on the Evolution steamer,

care must be taken to prevent doing anything that puts a back

pressure on the steamer. Back pressure on the steamer may

interfere with the pressure switch that controls the heaters.

When the pressure switch senses pressure in the steamer

that is 0.5” of water column or more, it turns the heaters o.

Therefore, anything on the vent putting a pressure of just 0.5”

water column on the steamer turns the heaters o and prevents

them from coming on again until the pressure is relieved.

Intermittent operation of the steamer can often be traced to

restrictions, low spots or a plugged condensate drain in the vent

fitting assembly.

Extension Sloping Upward (FIGURE 12)

1. Use nominal ¾” copper, brass or stainless steel to prevent

flow restrictions. Larger inside diameter (ID) can be used also

2. Pipe should slope upward a 1/4” per foot from the steamer

vent toward a vent hood to allow water condensing in it to

run back to the steamer and down the drain line. Minimum

recommended slope is ¼” per foot of hose length.

3. Use rigid pipe rather than flexible tubing or hose to prevent

dips or sags in the pipe that may collect water. A puddle

of water in the piping just ½” deep will cause the steamer

to malfunction. Recommended pipe materials are rigid ¾”

copper tubing (7/8” OD) or brass/ 18-8 stainless steel pipe

(3/4 NPT or larger). Pipe hangers or pipe supports should be

used every six feet to prevent long runs from sagging.

4. A pipe union should be installed next to the steamer to

permit the vent to be easily disconnected. This allows the

steamer to be easily moved for servicing.

5. Total length of extended vent piping should not exceed 15

feet.

To prevent putting a back pressure on the steamer, vent piping

should have no restrictions and no low spots where water can

accumulate. Ventilation piping can be directed upwards toward

hoods or downward towards floor drains. Slightly dierent

approaches are required for each application.

FIGURE 12

18” - 36” Long = 3/4” Diameter brass pipe (both ends

threaded)

45 ° Elbow = 3/4” Diameter

brass pipe (both ends female)

6” - 10” Long - 3/4” Diameter

brass pipe (both ends threaded

male)

MP4010-1903

12

Page 14

Installation Manual I Installation

Extension Sloping Downwards (FIGURE 13)

1. Use nominal ¾” or larger inside diameter (ID) to prevent

flow restrictions.

2. Pipe should slope downwards from the steamer vent

to a floor drain to allow water condensing in it to run

unimpeded into the floor drain.

3. For downward sloping extension to a floor drain ONLY

– ¾ ID or larger reinforced silicone hose (auto radiator

hose) may be used. The hose end must be open and not

submerged. Avoid any low spots that will cause puddles of

water and increase of back pressure.

4. Total length of extended vent piping should not exceed 15

feet.

Mounting vent Extensions On Two Steamers on a Double

Stack Stand.

DO NOT connect Drain or Vent lines on multiple

appliances. Each appliance should have its own dedicated

drain and vent.

Each steamer’s vent must be extended individually. Tying multiple vents together will result in the steamers being unable to

regulate heat.

FIGURE 13 USING RIGID

PIPING

6” - 12” Long - 3/4” Diameter

brass pipe (both ends threaded

male)

45 ° Elbow = 3/4”

Diameter

brass pipe (both ends

female)

3/4” Diameter

brass pipe (both

ends threaded) or

reinforced silicone

hose.

Avoid low spots.

Total length should

not exceed 15 feet.

FIGURE 14

18” - 36” Long = 3/4” Diameter brass pipe (both ends

threaded)

Rotate factory

elbow to point

downwards

For the both steamers, follow the instructions as provided above

in Extension Sloping Upward.

The lower steamer’s vent must exit above the top of the upper

steamer (FIGURE 14).

When designing the extension to slope downwards, whether using rigid or flexible hosing, pipe hangers or pipe supports should

be used every six feet to prevent long runs from sagging. The

end of the hose/pipe should not be submerged to prevent steam

backups (FIGURE 15).

45 ° Elbow = 3/4” Diameter

brass pipe (both ends female)

6” - 10” Long - 3/4” Diameter

brass pipe (both ends threaded

male)

FIGURE 15

Two ¾ ID or larger reinforced

silicone hose (auto radiator

hose) may be used, allowing

a 1/4 Total Length MUST NOT

exceed 15 feet. Hoses must

not be joined in any way

No loops in hose - preventing

condensation

MP4010-1903

Ends of hose must be open

to air and not submerged

13

Page 15

Installation Manual I Operation

4. OPERATION

RISKS RESULTING FROM CONTACT WITH VERY HOT

OBJECT:

STEAM

When opening the door, particularly during steamer

operation, always stand in such a way that the hot steam

escaping from the partially open door cannot scald you.

Open the door only partially and open fully only once the

steam has escaped.

HOT

Hot areas may form during the cooking process, especially

on the cookware, grills and the inner side of the door. Use

protective gloves whenever handling hot objects.

During the cooking process, do not handle cookware

containing liquids or liquid foodstus located above eye level.

Danger of burns.

Be sure all operators read, understand and follow

the information contained in this manual including caution

warnings, operating instructions and safety instructions.

4.2 Sequence of Operation

• When power button is depressed digital display will power

on and display “PrE.”

• On connected models, low water light will illuminate and

unit will begin to fill. On connectionless models, low water

light will illuminate and alarm will sound until water is

added to the cooking chamber up to the water fill level.

• When the unit has finished filling, low water light will

extinguish and alarm will stop. Unit will begin to heat, do

not open door as this will slow preheat process.

• Pressing the temperature button will allow users to see

current temperature.

• Unit will display “Coo” on display when cooking

temperature (approx 212F) has been achieved. The unit

will maintain this temperature until powered o or user

switches to Hold mode. Product can now be added.

OPERATOR DISPLAY &

KEYPAD

FIGURE 16

MAGNETIC

DOOR LATCH

When accessing the cooking chamber, be sure to always

stand back while slowing opening the door to allow the

chamber to vent o the steam. Never reach into the

cooking chamber before it has completely vent o the

steam.

Never use wet or damp gloves as moisture can conduct

heat quickly.

Keep the floor in front of the equipment clean and dry. If

spills occur, clean immediately to avoid potential injuries.

Do not manually fill water above the water level mark on

the left side of the cooking chamber.

Do not use abrasive (or steel) materials, such as

wire brushes, metal scouring pads to clean the cooking

chamber bottom.

4.1 Operation Introduction

The AccuTemp Evolution steamer uses the time proven method

of cooking with steam. Once the cooking time expires, the

steamer can be set to the “Hold Mode”. In this mode, the

controller regulates the internal temperature. At this time,

steam is no longer generated and the cooking chamber is held

at the preset temperature at a relative humidity of 100%. This

eliminates food from drying out by suppressing the evaporation

of the products natural moisture. As a result, most food

products can be held in a ready-to-serve state for several hours

after cooking, with no appreciable loss in taste, appearance or

consistency.

DRAIN VALVE

DRAIN PAN CUSTOMER SUPPLIED

MP4010-1903

14

Page 16

Installation Manual I Operation

SET TIMER

FIGURE 17

OPERATOR

DISPLAY

INCREASE

VARIABLE

DECREASE

VARIABLE

ON/OFF

COOK or HOLD

DISPLAY

TEMPERATURE

OVERTEMPERATURE

LAMP

MP4010-1903

LOW WATER LAMP

HIGH WATER LAMP

15

Page 17

Installation Manual I Operation

4.3 Partial Loads

The Evolution is designed to cook quickly with exceptional

pan-to-pan uniformity on full loads of food. Excellent pan-topan uniformity can be achieved with partial loads if the pans are

optimally placed in the steamer.

For partial loads using 2½” deep pans, the top position in the

steamer is used first followed by the second pan placed in

third pan position from the top and then the third pan in the

fifth pan position from the top (FIGURE 18). Placing the pans in

these positions will optimize the cooking time and pan-to-pan

uniformity.

FIGURE 18

FIRST PAN

4.4 Daily Preparation for Use - Connected

Preparing the Evolution Connected model for use each day

requires very little time and eort. Simply verify that the steamer

is clean, the water line to the steamer is turned on and the drain

valve is in the closed position. Close the door and push the ON/

OFF key on the keypad. The steamer will automatically fill and

preheat.

Since the Evolution automatically senses the water level and

refills as required. There is no need to manually fill the steamer.

PREHEATING

1. Depress the On/O Key to turn on the steamer. The display

will indicate PrE while in Cook Mode and the temperature

while in the Hold Mode.

2. Once the steamer is preheated and ready to cook, the

display will indicate the COO (Cook Mode) or HLd (Hold

Mode).

3. Depress the DISP TEMP button to display the current

cooking temperature.

COOKING

1. Depress the COOK/HOLD button to select the Cook Mode

(COO).

2. Open the door and place food into the cooking chamber.

Shut the door. Cooking begins immediately.

SECOND PAN

THIRD PAN

3. Timer — Depress the TIMER button and depress the

ARROW keys until the desired time is displayed. The timer

starts automatically. At the end of the timed cycle, a beeper

will sound.

4. Depress the DISP TEMP button to display the current

cooking chamber temperature.

HOLDING

In “Hold” the steamer temperature is set for 180° F from the

factory. The hold temperature can be changed to a single value

for temperatures ranging from

150°F to 190°F if required. Contact the AccuTemp Technical

Service Department for assistance at 800.480.0415. Hold can

also be used during downtimes to save energy and water while

keeping the steamer preheated.

1. Depress the COOK/HOLD button to select the Hold Mode

(HLd).

2. Open the door and place food into the cooking chamber.

Shut the door.

3. Food will be held at the preset holding temperature. The

factory setting is set at 180° F.

4. Depress the DISP TEMP button to display the current

cooking chamber temperature.

MP4010-1903

16

Page 18

Installation Manual I Operation

ACCUTEMP EVOLUTION POWER PLATE

4.5 Daily Preparation for Use - Connectionless Model

Preparing the Evolution Connection-Less model for use each

day requires very little time and eort. Simply verify that the

steamer is clean, the drain valve is in the closed position and the

cooking chamber is filled with approximately 2½ Gallons of tap

water. Close the door and push the ON/OFF key on the keypad.

The water level will need to be monitored and filled as required.

Do not use the low water warning lamp as the indicator to

check the water level as this can damage the steamer over time.

PREHEATING

1. Depress the ON/OFF Key to turn on the steamer. The

display will indicate PrE.

2. Once the steamer is preheated and ready to cook, the

display will indicate COO (Cook Mode) or HLd (Hold Mode).

3. Depress the DISP TEMP button to display the current

cooking chamber temperature. MAX temperature at sea

level in 212°F

COOKING

1. Depress the COOK/HOLD button to select the Cook Mode

(COO).

2. Open the door and place food into the cooking chamber.

Shut the door.

Cooking begins immediately.

3. Timer — Depress the TIMER button and depress the

ARROW keys until the desired time is displayed. The

timer starts automatically. At the end of the timed cycle, a

beeper will sound.

4. Depress the DISP TEMP button to display the current

cooking chamber temperature.

HOLDING

4.6 Power Plate Setting

If using a Connection-less unit, do not adjust the power

plate in the unit. It will aect the water evaporation ratio

and cause the unit to be filled more regularly

The Power Plate has 3 settings:

• Batch - Factory Setting - Slowest Cook

• A la Carte

• Power Steam - Fastest Cook

Instructions to Adjust:

Tools Required

7/16” wrench or 7/16” socket wrench or adjustable wrench

Batch

1. Leave as received from the factory.

A la Carte

1. Remove the acorn nut and lock washer.

2. Remove the Power Plate and flip it so the larger size hole is

lined up over the large vent hole.

3. Slide the Power Plate onto the stud and install the lock

washer then the acorn nut and tighten.

Power Steam

1. Remove the acorn nut and lock washer.

2. Remove the power plate from the mounting stud.

3. Rotate plate so that the large rear vent is not covered by

the plate.

4. Slide onto the stud and install the lock washer then the

acorn nut and tighten.

In “Hold” the steamer temperature is set for 180°F

from the factory. The hold temperature can be changed to a

single value for temperatures ranging from 150° F to 190° F if

required. Contact the AccuTemp Technical Service Department

for assistance at 800.480.0415. Hold can also be used during

downtimes to save energy and water while keeping the steamer

preheated.

1. Depress the COOK/HOLD button to select the Hold Mode

(HLd).

2. Open the door and place food into the cooking chamber.

Shut the door.

3. Food will be held at the preset holding temperature. The

factory default setting is set at 180° F.

4. Depress the DISP TEMP button to display the current

cooking chamber temperature.

FIGURE 19

Batch

A la Carte

Power Steam

MP4010-1903

17

Page 19

Installation Manual I Operation

4.7 Cleaning

Do not use a water jet or pressure washer to clean the

steamer.

After cleaning procedure is complete, steamer door must

be left open to allow steamer to dry. Not doing so will

decrease life of door gasket and accelerate corrosion.

If local water conditions cause rust inside the steamer or

heavy mineral buildup, request the AccuTemp Additional

Cleaning Recommendations.

4.7.1 Daily Cleaning - Connected

4.7.2 Daily Cleaning - Connectionless

1. Close the drain valve and add 1 cup (8 ounces or 0.24

liters) of white vinegar to the cooking compartment.

Start the steamer in the Cook Mode. The cooking

compartment will automatically fill with water. After 15

minutes, turn the steamer o and allow the steamer

to cool to 140°F or lower. Then open the drain valve

and allow the water in the cooking chamber to drain

completely.

2. Turn the steamer o and wait for the steamer to cool.

1. Close the drain valve and add 1 cup (8 ounces or 0.24

liters) of white vinegar to the cooking compartment.

Start the steamer in the Cook Mode. The cooking

compartment will automatically fill with water. After 15

minutes, turn the steamer o and allow the steamer

to cool to 140°F or lower. Then open the drain valve

and allow the water in the cooking chamber to drain

completely.

2. Turn the steamer o and wait for the steamer to cool below

100° F

3. Open the drain valve and allow the cooking compartment

to drain completely. Remove the pan racks, steam

collector, overfill sensor and condensate tray for cleaning.

Wipe the inside of the cooking chamber, pan rails, steam

collector, overfill sensor, and condensate tray with a

clean cloth (FIGURE 19). Clean the door gasket, inside of

door and front face of the cooking chamber. Clean water

sensors with a non metallic cleaning pad. Wipe down

corners of cooking chamber

4. Re-install the overfill sensor, steam collector, pan rails and

condensate tray. Leave the door open overnight.

(NOTE: The steamer will not operate without the overfill

sensor. An alarm will also sound).

3. Open the drain valve and allow the cooking chamber

to drain completely. Remove the pan rails (FIGURE 19)

and steam collector. Wipe the inside of the cooking

chamber, water sensors, pan rails and steam collector

with a clean cloth. Clean the door gasket, inside of door

and front face of the cooking chamber.

4. Install the steam collector and pan rails. Once the

water in the drain pan has suciently cooled empty

the drain pan wipe down and replace. Leave the door

open overnight.

MP4010-1903

18

Page 20

Installation Manual I Operation

4.7.3 Weekly Cleaning - Connected

1. Close the drain valve and add 1 cup (8 ounces or 0.24

liters) of white vinegar to the cooking compartment.

Start the steamer in the Cook Mode. The cooking

compartment will automatically fill with water. After 15

minutes, turn the steamer o and allow the steamer

to cool to 140°F or lower. Then open the drain valve

and allow the water in the cooking chamber to drain

completely.

2. To rinse close the drain valve and start the steamer

in the Cook Mode. The cooking compartment will

automatically fill with water. After 15 minutes turn the

steamer o and allow it to cool to 140°F or lower. Open

the drain valve and let it drain completely.

3. Remove the cooking chamber components in this

or der : pan rails, steam distributor, steam collector,

overfill sensor, power plate and dry them with a

clean dry cloth.

4. Clean the water sensors with a non-metallic cleaning pad

to remove any scale of debris left over after the cleaning

process. Wipe with a clean dry cloth.

5. Wipe the inside of the cooking chamber with a clean

dry cloth make sure to dry around the corners and seams

of the cooking chamber (FIGURE 19).

FIGURE 20

PAN RACKS

PAN RACKS

STEAM

DISTRIBUTOR

6. Install the overfill sensor and the steam collector, resting

the steam distributor on top of the steam collector align

the 4 retaining fasteners and hand tighten, then install the

pan rails and the condensate tray. Leave the door open

overnight.

(NOTE: The steamer will not operate without the overfill

sensor.)

4.7.4 Weekly Cleaning - Connection-less

1. Close the drain valve and add 1 cup (8 ounces or

0.24 liters) of white vinegar to the cooking chamber

and fill with approximately 2½ Gallons of tap water, shut

the door and turn the steamer on.

2. After 15 minutes, turn the steamer o and allow the

steamer to cool. Open the drain valve and allow the

cooking chamber to drain completely.

3. To rinse close the drain valve, fill with approximately

2½ Gallons tap water, close the door and start the

steamer Cook Mode. Let it run for 15 minutes, turn the

steamer o and allow the steamer to cool. Open the

drain valve and allow the cooking chamber to drain

completely.

4. Remove the pan racks, steam collector and steam

distributor for cleaning. Clean the water sensors

with a non-metallic cleaning pad. Wipe the inside of

the cooking chamber, water sensors, pan rails, steam

distributor and steam collector (FIGURE 19).

LOW WATER

SENSOR

STEAM

COLLECTOR

OVER FILL SENSOR FLOAT

UPPER LEVEL

WATER SENSOR

LEFT WALL OF COOKING

CHAMBER

5. Install the steam collector first, resting the steam

distributor on top of the collector align the ( 4)

retaining fasteners and hand tighten and then install

the pan rails. Leave door open overnight.

MP4010-1903

DRAIN

19

Page 21

Installation Manual I Operation

4.7.5 How to to Protect Stainless Steel

All materials used in manufacturing AccuTemp products undergo

multiple thorough quality inspections, as does the production

process itself. For producing the internal parts of the appliance,

AccuTemp uses high-quality steel. These are steels commonly

indicated as corrosion-resistant or stainless, due to their

heightened resistance to corrosion. The surface of these

materials

is further treated during the manufacturing process (passivation

or electromechanical polishing) to increase their corrosion

resistance. However, improving these steels’ corrosion resistance

does not mean that corrosion can never occur at all.

If corrosion starts on these types of steel, there may be one or

a combination of the factors listed below (it just takes a short

time for corrosion to develop):

1. Using water that has:

a. High chloride or sulphate content (such as table salt

NaCl,etc.)

b. High content of metals with opposite electrochemical

potential.

c. High oxygen content (HNO3, Cu2+, Fe2+).

d. pollutants (CO₂, H₂S, SO₂, iron).

e. High chlorine content.

f. High acidity.

g. Greater surface roughness due to improper cleaning.

2. Decreased possibility of natural passivation of material

surface due to the presence of deposits:

a. of calcium (due to hard water).

b. of biological substances (food residues).

3. Surface contamination by iron (such as due to use

of inappropriate cooking containers or cleaning with

mechanical metal objects).

To protect the equipment, we would recommend the following

steps:

1. Use the proper tools. Never use sandpaper on stainless steel,

as it can cause scratches in the steel, allowing corrosion

to form. Use non-abrasive tools, like soft cloths and plastic scouring pad, stainless steel pads (scrub in direction of

polishing marks).

2. Clean with the polish lines or “grain” Scrub in a motion parallel to the lines when visible lines are present. Use a soft cloth

or plastic scouring pad when grain cannot be seen.

3. Use alkaline, alkaline chlorinated or non-chloride containing

cleaners. Ask your supplier for an alternative if your present

cleaner contains chlorides. Avoid cleaners containing quaternary salts to avoid pitting and rusting.

4. Keep your food equipment clean. Following the cleaning

instructions in Section 4.6 will greatly reduce the chances of

corrosion and rust.

5. Rinse and wipe equipment and supplies if chlorinated

cleaners are used, dry immediately. Wipe o standing water

as soon as possible, especially when it contains cleaning

agents.

6. Never use hydrochloric acid (muriatic acid) on stainless steel.

7. Regularly re-passivate with oxalic acid (Bar Keepers Friend or

equivalent) or citric acid (Citri-surf / Citri-clean or equivalent) . Note – these materials are stronger and more eective than vinegar. These water based acids remove traces of

steel and activate the chromium oxide passive layer.

4. By use of unsuitable cleaning chemicals.

8. Always rinse the unit with clean water and dry with the

steamer door and drain valve open.

MP4010-1903

20

Page 22

Installation Manual I Service and Troubleshooting

5. Troubleshooting

5.1 Steamer Will Not Power On

• Verify that the steamer is plugged into the proper outlet.

• Verify the the external breaker is on.

• If the ‘High Water’ warning light is on open the drain valve to drain the water until the light goes

out.

• Verify that the float ball is in place.

5.2 Steamer Will Not Fill with Water

• Ensure water supply to unit is turned on.

• Clean two water sensors in cooking cabinet

5.3 Steamer is Overfilling with Water (Connected)

• Ensure unit is level.

• Clean two water sensors in cooking cabinet.

5.4 Steamer Does Not Heat

• If the operators display doesn’t light up, see Section 5.1.

• Verify the steamer door is closed, as the unit will not heat when the door is open.

5.5 Steam Comes Out of Door (Overpressure)

• Verify that the door is completely closed and latched.

• Wait a minute to see if it stops. After the steamer refills with water it is normal for some steam to

come out the door for a brief amount of time, usually less that one minute.

5.6 Steamer Temperature is Low

• When the steamer automatically refills the fresh water, the temperature of the steamer will drop.

The steamer should reheat quickly.

• If -99F or -1F appears call AccuTemp for assistance.

• If frozen product is added the temperature will take time to recover.

5.7 Food is Undercooked

• Verify that the door is completely closed and latched.

• Opening and closing the door frequently can lower the temeperature and increase cook times.

• Verify the steam vent is clear of debris.

• Call AccuTemp for assistance with recipe timing.

If these don’t solve your problem contact our Technical Service Department.

• Hours: 7AM - 7PM EST 7 Days a Week (excluding certain Holidays)

• Phone - 800.480.0415 or 260.469.3040

• Email - service@accutemp.net

• Web site - www.accutemp.net

MP4010-1903

21

Page 23

Installation Manual I Service and Troubleshooting

SERVICE

Conventional Steamers require scheduled maintenance (such as boiler maintenance)

at frequent intervals) The Evolution design doesn’t require this type of scheduled

maintenance. It is recommended that you schedule a yearly review of the Evolution

with a AccuTemp Authorized Service Representative to keep your steamer in optimal

operation

INFORMATION

INFORMATION

GENERAL SERVICE INFORMATION

All service request during the warranty period of this appliance must be

directed to the AccuTemp Products, Inc. Technical Service Department or

the service call may not be covered by the limited warranty.

WARNING

Only an AccuTemp Products Inc. Authorized Service Personnel or Representative

must perform service. Service performed by unauthorized personnel will void all

warranties.

INFORMATION

MP4010-1903

IMPORTANT SERVICE INFORMATION

AccuTemp Product, Inc. Technical & Customer Support Technician is

available Monday thru Sunday, 7:00am to 7:00pm EST.

800.480.0415 or 260.469.3040

Email: service@accutemp.net

22

Page 24

Installation Manual I Service and Troubleshooting

PREVENTATIVE MAINTENANCE

Note: Accutemp approved service providers should complete any tasks involving access to

electrical systems.

PM TASK DECRIPTION DAILY ANNUAL

Verify that the Steamer is level.

Verify the operation of the control panel. When a button is pressed the

display should register the input and a beep should sound.

Verify the operation of the indicator lamps.

Clean water fill sensors and overfill float with non abrasive metallic pad.

DO NOT use sandpaper.

(AUTO-FILL ONLY) Ensure unit fills with water to the water level line.

Inspect external drain-lines for leaks. Repair if found.

Lubricate hinges and door latch with a food grade silicon spray

Lubricate stand casters

Inspect AC power cord for degradation or bare wires. Replace if defective

or suspect

Inspect door gasket for cuts and degradation. Replace if damaged. We

suggest replacing once a year.

Inspect Steam distribution panel gasket for cuts and degradation. Replace

if damaged. We suggest replacing once a year

Inspect and clean steam vent, condensate line fittings and hoses.

Inspect the control compartment for foreign particulate and any loose

wiring or connections.

Check Pressure Switch for correct operation. Recommend to replace

every two years.

Inspect external and internal water connections and condensate lines for

degradation and leaks. Replace as necessary

X

X

X

X

X

X X

Monthly

Monthly

X

X

X

X

X

X

X

MP4010-1903

23

Page 25

Installation Manual I Service and Troubleshooting

LIMITED WARRANTY

One Year– Parts and Labor

U.S. & Canada Only

AccuTemp Products, Inc. (AccuTemp) warrants that your AccuTemp equipment will be free of

defects in material and workmanship under normal use for a period of twelve (12) months

from installation or fifteen (15) months from date of shipment from AccuTemp, whichever date

first occurs (the Warranty Period). Registration of AccuTemp equipment is required at the

time of installation. Damage to AccuTemp equipment that occurs during shipment must be

reported to the carrier, and is not covered under this warranty. The reporting of any damage

during shipment is the sole responsibility of the commercial purchaser/user of such AccuTemp

equipment.

AccuTemp provides an active service department, which should be contacted and advised

of service issues, regardless of the warranty period. During the warranty period, AccuTemp

must be contacted for warranty repairs and agrees to repair or replace, at its option,

F.O.B. factory, any part which proves to be defective due to defects in material or

workmanship, provided the equipment has not been altered in any way and has been properly

installed, maintained, and operated in accordance with the instructions in the AccuTemp

Owners Manual. During the warranty period, AccuTemp also agrees to pay for any factory

authorized equipment service agency (within the continental United States and Canada) for

reasonable labor required to repair or replace, at our option, F.O.B. factory, any part which

proves to be defective due to defects in materials or workmanship, provided the service

agency has received advance approval from AccuTemp factory service to perform the repair or

replacement. This warranty includes travel time not to exceed two hours and mileage not to

exceed 50 miles (100 miles round trip), but does not include post start-up assistance or training,

tightening of loose fittings or external electrical connections, minor adjustments, maintenance,

or cleaning. AccuTemp will not reimburse the expense of labor required to replace parts after

the expiration of the warranty period.

Proper installation is the responsibility of the dealer, owner-user, or installing contractor and

is not covered by this warranty. Improper installation can aect your warranty. Installation

is the responsibility of the Dealer, Owner/User or the Installation Contractor. See the

Installation section of the Owners Manual. While AccuTemp products are built to comply

with applicable standards for manufacturers, including Underwriters Laboratories (UL) and

National Sanitation Foundation (NSF), it is the responsibility of the owner and the installer to

comply with any applicable local codes that may exist.

AccuTemp makes no other warranties or guarantees, whether expressed or implied, including

any warranties of performance, merchantability, or fitness for any particular purpose.

AccuTemp liability on any claim of any kind, including negligence, with respect to the

goods and services covered hereunder, shall in no case exceed the price of the goods

and services, or parts thereof, which gives rise to the claim. In no event shall AccuTemp

be liable for special, incidental, or consequential damages, or damages in the nature of

penalties.

This constitutes the entire warranty, which supersedes and excludes all other

warranties, whether written, oral, or implied.

MP4010-1903

24

Page 26

Page 27

IMPORTANT SERVICE INFORMATION

AccuTemp Product, Inc. Technical & Customer Support Technician is

available Monday thru Sunday, 7:00am to 7:00pm EST.

800.480.0415 or 260.469.3040

• Phone - 800.480.0415 or 260.469.3040

• Email - service@accutemp.net

• Web site - www.accutemp.net

Loading...

Loading...