Page 1

TAGTEMP

ABUS TECHNOLOGIES INC.

Data Logger

User Manual

Page 2

WARNING

This manual should be passed on to the end user.

The contents of this manual are subject to change without prior notice.

All rights reserved.

ABUS gives no warranty of any kind with regard to this manual, including, but not limited to, fitness

for a particular purpose.

If any question arises or errors are found, or if any information is missing from this manual, please

TagTemp

inform your supplier or inform at info@abustek.com

The specifications mentioned in this manual are limited to those for the standard type under the

specified model number break-down and do not necessarily apply for customized instruments.

Please note that changes in the specifications, construction, or component parts of the instrument

may not immediately be reflected in this manual at the time of change.

If the customer or any third party is harmed by the use of this product, ABUS assumes no

responsibility for any such harm owing to any defects in the product which were not predictable, or

for any indirect damages.

Although Warning hazards are related to personal injury, and Caution hazards are associated

with equipment or property damage, it must be understood that operation of damaged equipment could,

under certain operational conditions, result in degraded process system performance leading to

personal injury or death. Therefore, comply fully with all Warning and Caution notices.

Information in this manual is intended only to assist our customers in the efficient operation of

our equipment. Use of this manual for any other purpose is specifically prohibited and its contents are

not to be reproduced in full or part without prior approval of Technical Communications Department,

ABUS Technologies

.

HEALTH AND SAFETY

To ensure that our products are safe and without risk to health, the following points must be

noted:

1. The relevant sections of these instructions must be read carefully before proceeding.

2. Warning labels on containers and packages must be observed.

3. Installation, operation, maintenance and servicing must only be carried out by suitably trained

personnel and in accordance with the information given. Any deviation from these instructions will

transfer the complete liability to the user.

4. Normal safety precautions must be taken to avoid the possibility of an accident occurring when

operating in conditions of high pressure and/or temperature.

5. Chemicals must be stored away from heat, protected from temperature extremes and powders kept

dry. Normal safe handling procedures must be used.

6. When disposing of chemicals ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual or any relevant hazard data

sheets (where applicable) may be obtained from the Company address on the back cover, together with

servicing and spares information.

ABUS TECHNOLOGIES INC.

2

Page 3

.

TagTemp

CATALOGUE

Contents Page No.

1. Introduction 4

2. Presentation

1.

Technical Parameters

2.

Panel Identification

3. Installation

1. Recommendation

2.

LogChat-II

Optic Interface IR-Link3

3.

Palmtop User

4.

4. Configuration

1. General information Field

2. Acquisition Field

3. Start Loggings Field

4. Stop Loggings Field

5. Channels Field

6. Palmtop User

5. Operation

1. Offloading Data

2. Visualization Data

3. Palmtop User

6. Maintenance

1. Observation

2. Troubleshooting

4

4

5

5

5

6

6

7

8

9

9

9

9

9

10

13

13

15

15

16

16

16

7. Safety Precautions 17

8. Warranty 17

ABUS TECHNOLOGIES INC.

3

Page 4

1. INTRODUCTION

TagTemp is a small portable electronic temperature logger. Its internal sensor

measures local environment temperature and logs such values in an electronic

memory. Logged data, or ACQUISITIONS, can be later viewed and analyzed on a PC

where they can be opened in tabular and graph forms.

The logger is supplied with LogChart-II software, which enables to set up the

logger operation mode. It is also used for viewing acquisitions. Other parameters such

as end of measurements, logging interval, etc., are easily defined through the

LogChart-II software.

Acquisitions can also be exported to be analyzed in other applications, such as

TagTemp

spreadsheet programs.

2. PRESENTATION

2.1 Technical Parameters

Measuring Range : Temperature: -20 °C ~ 70 °C.

Accuracy : ± 0.5 °C @ 25 °C.

± 2 °C max. along the entire measured range.

Note: A measurement error can be fixed using the OFFSET parameter in the LOGCHART-II software.

Measurement Resolutions : 0.1 °C.

Memory capacity : 16,000 or 16k logs.

Measurement Resolution : 1 second min.

18 hours max.

Supply : 3.6 V lithium battery (CR2032), built-in.

Estimated Autonomy : Higher than 365 days, with weekly data reading. Frequent

logged data readings may shorten battery life.

Operating temperature : From –20°C to 70°C.

Protection : IP67

Material : Polycarbonate

Dimensions : 30 x 47 x 0.47 mm

Logger-PC Data Rate : 40 seconds for 16,000 logs.

PC Interface : IR/USB Port or IR/Serial Port

Log-chart-II software requirement : Setup Software for Windows 95, 98, NT, 2000 and XP,

Menus in Portuguese, English, and Spanish.

Setup, reads and displays data on the screen.

ABUS TECHNOLOGIES INC.

4

Page 5

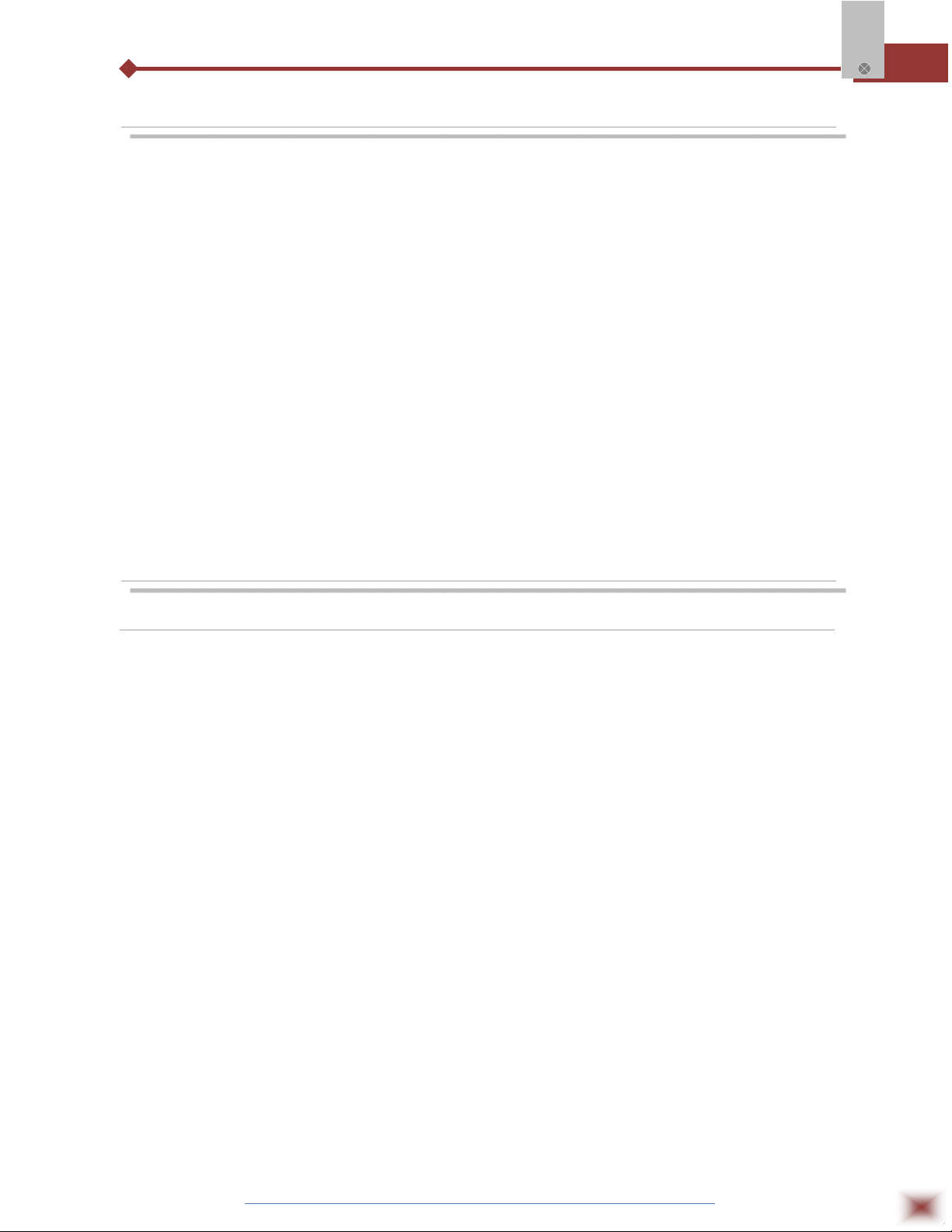

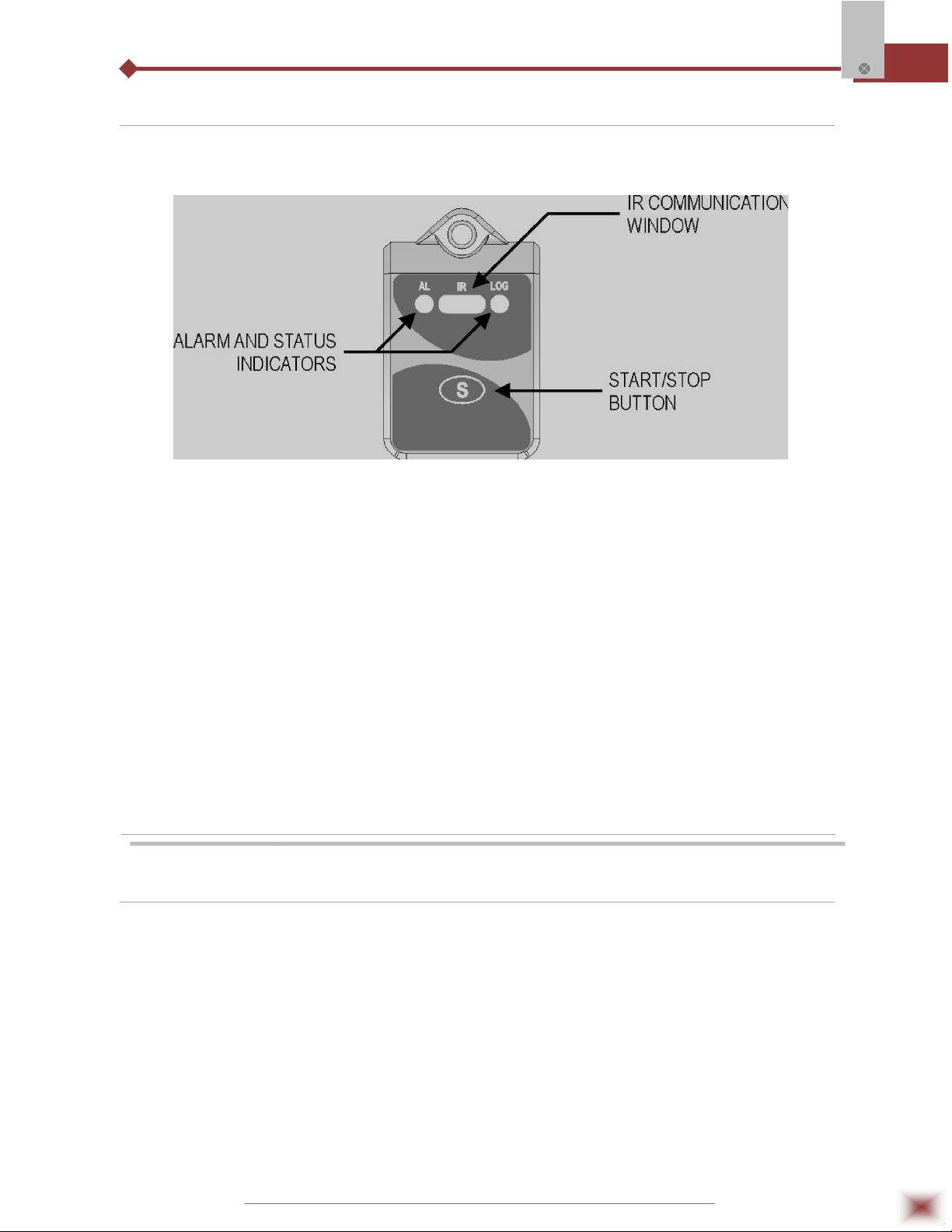

2.2 Panel Identification

The identification label is on the logger body. Check if the features described are in accordance

with your order. The following elements are shown in the logger front.

TagTemp

Logger Panel

Start/stop button (S): This button “wakes up” the logger whenever a communication between

logger and PC is intended to start. It can also be configured to start or

stop the temperature measurement process.

IR communication Window: PC - Logger communication area. During download, the communication

interface must be directed towards this window.

Status indicator (LOG): While in stand-by (not logging) or after a series of measurements, it

flashes once at every four seconds. During logging it flashes twice at

every four seconds.

Alarm Indicator (AL): Warns the user as to alarm conditions. Whenever an alarm situation

takes place it will flash once at every four seconds, until a new

configuration is applied to the logger.

3. INSTALLATION

3.1 Recommendation

1. Signal wires should be installed in grounded conduits and away from power or contactor wires.

2. Instruments must be powered only by an exclusive power supply.

3. System failure should always be taken into account when designing a control panel to avoid

irreversible damage to equipment or people.

4. Installing RC filters (47R and 100nF, serial) is strongly recommended at contactor coils or any other

inductors.

ABUS TECHNOLOGIES INC.

5

Page 6

3.2 LogChart-II

3.2.1 INSTALLING LOGCHART-II

The LogChart II is the software provided with the logger to allow for configuration and data

collection. To install the LogChart II, execute the LC_II_Setup.exe program provided in the CD. The

installation wizard will then guide you throughout the installation process.

Note: Be sure your Windows date separator is configured as a slash: dd/mm/yy or dd/mm/yyyy.

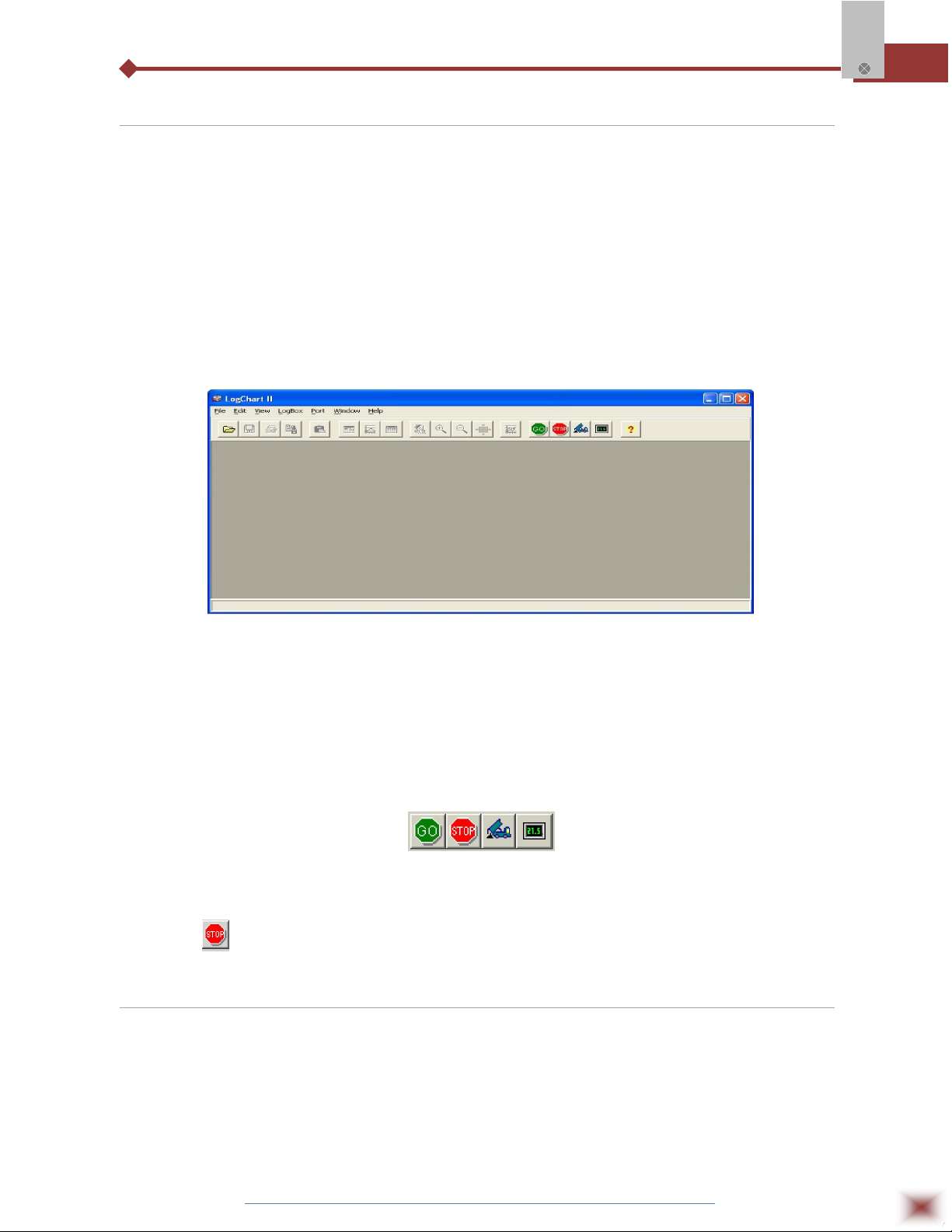

3.2.2 RUNNING LOGCHART-II

Start the program. The main window will appear on the screen, as shown in Figure below.

TagTemp

LogChart-II main window

The LogChart II requires a communication port to talk to the logger. Select one and connect the

corresponding wand IR-LINK3 to it. Click on the menu Port. Clicking on the menu Port, all free

communication ports available in the computer will be listed (usually COM2, once the mouse is

frequently connected at COM1). The chosen port will be remembered next times the LogChart II is

initiated. When the selected port is successfully opened, the LogChart II initial screen is opened,

enabling the buttons below:

Buttons enabled when the communication port of choice is valid

In case the user wants to stop the process while data logging is running, the button “Stop” must

be pressed:

3.3 Optic Interface IR-Link3

Configuring, monitoring or downloading data from the logger through LogChart-II requires that

the IR-LINK3 communication interface be connected to your PC. This interface is sold separately. The

IR-LINK3 interface sends and receives data to/from the logger through infrared signals.

ABUS TECHNOLOGIES INC.

6

Page 7

3.3.1 IR-Link3 for RS232

This interface has a DB9 terminal that must be connected to the PC serial port. In the “Port”

menu, select the port which corresponds to the physical port where the interface is connected.

3.3.2 IR-Link3 for USB

This interface has a USB terminal. Plugging this USB interface to the PC, the Windows wizard

for new USB devices pops-up automatically. Select then the IRLink driver provided in

d:\IRLink_Driver. (d: is the driver used in the installation). After installation is completed, the IR-LINK3

interface is recognized whenever it is connected to the PC. After the USB driver installation, the

LogChart II must be opened again. In the “Port” menu, choose the same port selected for the optical

interface communication using the menu Port.

3.4 Palmtop User

Most of the functionality of the LogChart II is available for the PDA Palm running the LogChart

TagTemp

PalmOS software. The program is delivered with the logger. The stalled in the Palmtop through a

HotSync process (data synchronization between a Palmtop and a PC).

The user needs the Palm Desktop and the LogChart II software installed in his machine. It is

recommended to execute the Palm HotSync before installing the LogChart PalmOS.

To install the software, insert the disk in the driver, click on Start and Execute in the windows

task bar. Then, type d:\LogChart PalmOS\LCP_Setup, d: is the driver used in this example. Press

“OK”. The software will guide you over the installation process.

Executing a new HotSync will install the LogChart PalmOs software in the Palm. The LogChart

icon will be added to the Palm home screen.

Starting the LogChart PalmOS application will display the Recorded Data screen on the Palm

from where it is possible to access the logger to change settings and collect data, as well as to access

collected data.

Recorded Data screen

ABUS TECHNOLOGIES INC.

7

Page 8

4. CONFIGURATION

Make sure the IR-LINK3 wand is connected to the PC. The interface must be

pointed towards the logger communication window (see Figure below) at a distance of

about 15 cm.

TagTemp

Infrared interface position

Click the button to start the communication between the logger and the

software; the Parameters Configuration window is then displayed (as shown in figure

Configuration Window, below), showing the current configuration and information

about the logger.

New configuration parameters defining the operation mode for a new

application can be entered. The user can also obtain general information about the

device. The fields of the configuration window are described below:

Configuration window

ABUS TECHNOLOGIES INC.

8

Page 9

4.1 General Information Field

Area with information about the logger, such as Model, Serial Number, Logger Date/Time, PC

Date/Time, firmware version, memory capacity and number of acquisitions stored in memory, etc. In this

field, time is constantly updated while the communication between logger and computer is taking place.

4.2 Acquisitions Field

Interval: Defines the interval between readings: The minimum interval is (1) second and maximum is

(18) hours.

Note: When the type of value logged is maximum or minimum values, the minimum interval is 10

seconds.

In Daily repetitions the user defines the time that daily logs will take place.

Estimated time: In this parameter, the logger informs the user how long it will take to occupy the full

memory, in the conditions set up during configuration.

4.3 Start Loggings Field

Immediately: start as soon as set up is ready and sent (OK) to the logger.

Start via Palm: start with a command sent via PDA, which runs the software Log Chart Palm-OS. For

further information, see PDA User section in this guide.

Date: readings start at predefined date and time.

Via Start/Stop Button: starts and interrupts readings by pressing the Start/Stop button, in the frontal

part of the logger, for two seconds. See Figure 01.

Setpoint: acquisitions start when a temperature setpoint is reached. In this option, the setpoint value is

defined in the Channels field, where the Alarm parameter is replaced by setpoint.

4.4 Stop Loggings Field

TagTemp

Full Memory: readings can be stored up to the full memory capacity is reached.

Don’t stop (Wrap around): readings are continuous, replacing old records with new ones as the

number of readings overpass the memory capacity.

After: the logger stops readings after a certain number of readings.

Date: Readings stop at user-predefined date and time. In case the logger memory capacity is reached

before the date defined, readings are stopped.

4.5 Channels Field

By selecting the “Channels” option, the user is able to choose the individual settings for each

input channel, as Figure below shows.

Unit: Defines the unit of the value measured: ºC or ºF for channel 1 (temperature).

Value: It defines how the value measured will be registered. Options are:

Instantaneous: The value logged will be exactly the value measured at each interval defined.

Measurement is taken at the end of the defined interval. The minimum interval between

measurements is 1 seconds.

ABUS TECHNOLOGIES INC.

9

Page 10

Maximum: The value logged will be the maximum value found within ten consecutive

measurements taken within a predefined interval. The minimum interval between

measurements is 10 seconds.

Minimum: The value logged will be the minimum value found within ten consecutive

measurements taken within a predefined interval. The minimum interval between

measurements is 10 seconds.

Offset: Makes possible to correct the value logged.

Alarm: Defines limit values that, when exceeded, characterize an alarm condition. Alarm events are

informed to the user through a flashing mode of the Alarm Indicator.

After filling all the fields select OK and settings will be sent to the logger.

4.6 Palmtop User

To have communication between the logger and the PDA established, the user must align the

PDA infrared wand to the logger communication window, run the LogChart Palm-OS software, wake up

the logger and press Search Device in the Recorded Data screen.

When the PDA finds the logger, the Monitoring screen will be displayed. The screen displays

values of variables measured, configuration information and current logger status.

TagTemp

PDA Monitoring screen

Buttons are assigned the following functions:

Search: It allows "searching" for another logger or reconnect communication lost for any reason. After

finding a logger, the PDA displays a new Monitoring screen.

Download: Offload logged data. Download can be partial and it does not interfere in the ongoing

measurement process.

More Info: Displays further information on the connected logger, such as model, serial number, version

and memory capacity.

Settings: Accesses the Settings screen, which allows for modifying the logger configuration.

Data Base: Displays the Recorded Data screen listing all the processes stored and processed in the

PDA data base.

ABUS TECHNOLOGIES INC.

10

Page 11

TagTemp

Recorded Data Details screen

Configuring the Logger – Settings

During configuration, the logger and the PDA ports must be aligned.

Press Settings in the Monitoring screen. The screen Settings is opened and provides the required

parameters for configuring the logger.

PDA Settings screen

The parameters to be defined are:

Title: Name of the process.

Input: Enables the user to select the temperature unit.

Start (start of acquisitions): Defines the measurement start mode. Options are:

Immediately: The logger starts logging as soon as configuration is sent to the logger.

By date/time: Start in defined data and time, always after current time. It is possible to perform

daily repetitions. If this option is selected, a new box to define the stop logging time is displayed.

By <Start> Button: Press the Start_Now button from the Monitoring screen to start logging.

The PDA must be turned towards the logger.

By Setpoint value: Measurements start when a temperature setpoint is reached. With this option it

is also possible to start measurements above (log Above) or below (log Below) a temperature

setpoint (channel 1). This option is not valid for alarms that have already been set up.

By TagTemp button: Starts when the Start/Stop button at the frontal side of the logger is

pressed.

Stop: Defines the measurements stop mode: Options are:

Full memory: Loggings can be stored up to the logger full memory capacity is reached.

Wrap around: Logging never stops. When the logger maximum memory capacity is reached,

oldest records are overwritten by newest data.

After loggings: The logging will stop after the number of readings are defined.

ABUS TECHNOLOGIES INC.

11

Page 12

By date/time: Logging is stopped on user-defined date and time

Interval: Defines the interval between readings: hour, minutes and seconds. When the logging mode is

set to the instantaneous the minimum interval is 1 second. For maximum and minimum values, the

minimum interval is 10 seconds in both models.

Misc: Shows the Logging Mode parameter that defines how measured value will be logged. Options

are:

Instantaneous: The value logged will be exactly the value measured at each interval.

Measurement is taken at the end of the defined interval. The minimum interval between

measurements is 1 second.

Minimum: The value logged will be the minimum value found within ten consecutive

measurements taken within an interval. The minimum interval between measurements is 10

second.

Maximum: The value logged will be the maximum value found within ten consecutive

measurements taken within an interval. The minimum interval between measurements is 10

second.

Alarms: Enables an alarm that is triggered according to user-defined parameters. Values shown in the

temperature unit selected.

TagTemp

PDA Alarm Settings screen

Clocks: Provides access to Logger and PDA clocks. When a new configuration is sent to the logger,

clocks are updated.

Offset: allows fine offset adjustment on the measured value. The Reset button clears changes made

and the logged values are the measured values again.

Offset adjust screen

After configuring clocks in the Settings screen, click Apply to send this configuration to the Logger,

returning to the Monitoring screen.

Sending a new configuration implies the exclusion of all data collected present in the logger memory.

ABUS TECHNOLOGIES INC.

12

Page 13

5. OPERATION

Data collected are send from logger to PC. Data can be collected any time, at

the end of the acquisition process or while they are being acquired. If data collection

takes place during the acquisition process, the process will not be interrupted,

following the logger configuration.

It is important to "wake up" the logger before starting communication.

5.1 Offloading Data

The transference of data to a PC is accomplished by using the LogChart II software. Data can

be collected anytime and saved in files for future analysis (menu “File Save” or “File Save as”). Help can

be accessed from the LogChart-II software when necessary. Offloading data: data offload is

accomplished by clicking on the button , or using the LogChart-II menu. During data transference, a

TagTemp

status bar indicates remaining data to be transferred. Data offloading time is proportional to the number

of readings logged. At the end of data transference, the Graph window is displayed as shown blow.

5.1.1 Graph window

The Graph is a convenient tool for analysis. It enables the logger acquisitions to be read in the

form of a “values x time” graph. As one moves the mouse in the chart area, the time and the value of

the records of each channel are shown in the field located in the bottom of the window.

Zooming in and out are implemented. It is possible to select an area by clicking and dragging

the mouse, thus creating a zoom region, starting at the upper left position of the region of interest.

Graph window.

NOTE: The command Offload acquisitions does not interrupt the process of data logging and reading.

Other two windows can be easily opened: General information window and Tables window.

ABUS TECHNOLOGIES INC.

13

Page 14

5.1.2 General information table

Displays information about the logger that registered data: its features and configurations, and

details about data acquired.

TagTemp

General Information window

5.1.3 Acquisitions Table Window

Data acquired by one or both input channels (user-defined) are displayed in engineering units in

a table format. The table displays register number, date/time and the record values.

Screenshot showing the acquisitions table

ABUS TECHNOLOGIES INC.

14

Page 15

5.2 Visualization Data

Three windows support data visualization: Graph, Acquisitions Table and General Information

windows. Data can be originated from direct reading from the logger or from a file previously recorded in

a computer. Once the windows are open, data can be saved in a file (.lch), printed on a graph or

exported to a text file (.txt or .dat).

5.3 Palmtop User

5.3.1 DOWNLOADING DATA FROM THE LOGGER

In the Monitoring screen, the Download button performs the transfer of the data from the Log

Box to the PDA. Download can be partial and it does not interfere in the ongoing acquisition process.

The data base of loggings is displayed in the Recording Data screen, identified with the name assigned

to the process (Title) and the date it was downloaded. Should the PDA batteries be discharged, all

readings will be lost.

5.3.2 FILES VISUALIZATION

The Recorded Data screen lists the data base logged and stored in the PDA. To access data,

select the desired data base and tap on Details. Recorded Data Details screen shows information

about the data base. View Data shows in table format the logged values and the date and time they

were performed. Press Delete to erase the selected data base.

5.3.3 TRANSFERRING DATA TO YOUR DESKTOP

HotSync of data stored in a PDA to a PC is performed through a conduit installed together with

the LogChart Palm-OS. The conduit converts the data collected by the LogChart Palm-OS to a file

compatible with the LogChart-II software.

To access the conduit options, the HotSync Manager software must be active. Click with the

right mouse button on the HotSync Manager in the Windows Taskbar. Select in the drop-down menu

the option Custom. Select ABUS LogChart Conduit and click Change. The following window will be

exhibited:

TagTemp

LogChart Conduit options

Handheld overwrites Desktop: LogChart Palm-OS files are transferred to the Desktop.

Save in: Choose a directory to record files generated during data

synchronization.

Leave Data on Palm: Option to keep or delete the data in the PDA after HotSync.

Do nothing: Data synchronization will not be performed;

Set as default: The same settings will be used in the next HotSync processes.

ABUS TECHNOLOGIES INC.

15

Page 16

6. MAINTENANCE

6.1 Observation

1. The logger is an electronic device and some basic care is required:

2. When opening the device for battery replacement or connecting sensors avoid touching the circuit

for not causing damages resulting from static electricity.

3. When the device is opened, avoid liquid and/or dust contact.

4. Use a screwdriver to open the case cover.

5. Pay attention to batteries polarity: The positive terminal should be placed directed towards the

center of the device.

6. Worn batteries should not be recharged, dismantled or incinerated. After use, batteries must be

disposed according to local legal rules or returned to ABUSTEK.

7. After placing batteries back to the logger, make sure the cover is firmly attached to the socket.

TagTemp

6.2 Troubleshooting

FAULT POSSIBLE CAUSE RESOLUTION

1. The LED flashing light is

LED is not

Flashing

No

Communication

intentionally weak, and it can be

difficult to see it in illuminated

environments.

2. Make sure it is not flashing at all.

Communication with the logger fails

1. Make sure the battery is installed

correctly;

2. Make sure the battery is not

discharged;

1. Make sure the COMM port is

selected correctly and there is no

other program using the same port

during communication attempts;

2. Make sure there is no physical

obstacle blocking the infrared

signal;

3. Make sure the cable is well

connected to the PC port;

4. Make sure the port selected does

not present any problem;

ABUS TECHNOLOGIES INC.

16

Page 17

7. SAFETY PRECAUTIONS

1. The unit should be powered for 15 minutes before use.

2. Use in ambient temperature of 0-60˚C.

3. Avoid vibrations, shock, excessive dust, corrosive chemical materials or gaseous

environment.

4. Input wire should not be too long. If measured signal have to be far away from the

unit, please use 2-core shielded cable.

5. Use this instrument in the scope of its specifications, otherwise fire or malfunctions

may result.

6. Contact of the instrument, with organic solvents or oils should be avoided.

TagTemp

7. Do not turn on the power supply until all of the wiring is completed. Otherwise

electrical shock, fire or malfunction may result.

8. Do not disassemble, repair or modify the instrument.

9. All connections should be tightened properly.

10. Power supply should be constant, should not be fluctuating.

8. WARRANTY

ABUS provides the original purchaser of this instrument a one (1) year warranty

against defects in material and workmanship under the following terms:

The one year warranty begins on the day of shipment as stated on the sales bill.

During the warranty period all costs of material and labor will be free of charge

provided that the instrument does not show any evidence of misuse.

For maintenance, return the instrument with a copy of the sales bill to our factory.

All transportation and insurance costs should be covered by the owner of the

equipment.

Should any sign of electrical or mechanical shock, abuse, bad handling or misuse

be evident the warranty voids and maintenance costs will be charged.

ABUS TECHNOLOGIES INC.

www.abustek.com, E-M ail: info@abustek.com

ABUS TECHNOLOGIES INC.

17

Loading...

Loading...