Page 1

SI-2P+

Dual Socket 604 Server Board

User’s Manual

4200-0333-02

Rev. 1.00

Page 2

Copyright and Warranty Notice

The information in this document is subject to change without notice and does not

represent a commitment on part of the vendor, who assumes no liability or

responsibility for any errors that may appear in this manual.

No warranty or representation, either expressed or implied, is made with respect to the

quality, accuracy or fitness for any particular part of this document. In no event shall

the manufacturer be liable for direct, indirect, special, incidental or consequential

damages arising from any defect or error in this manual or product.

Product names appearing in this manual are for identification purpose only and

trademarks and product names or brand names appearing in this document are

property of their respective owners.

This document contains materials protected under International Copyright Laws. All

rights reserved. No part of this manual may be reproduced, transmitted or transcribed

without the expressed written permission of the manufacturer and authors of this

manual.

SI-2P+

Page 3

Table Of Contents

Chapter 1. Introduction .................................................... 1-1

1.1. Features & Specifications....................................................... 1-1

1.2. Package Checklist (Standard Package) ..................................1-3

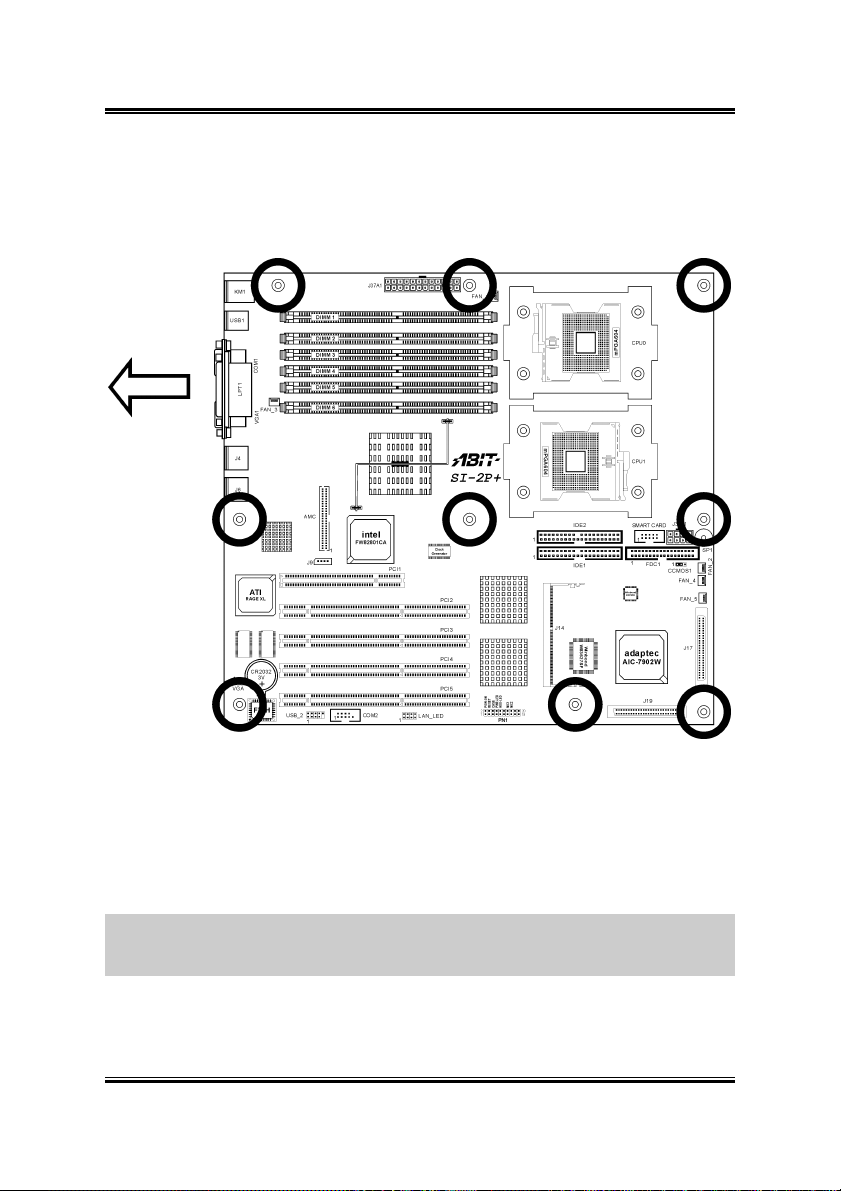

1.3. Layout Diagram...................................................................... 1-4

1.4. Jumpers & Connectors Description........................................ 1-5

Chapter 2. Hardware Setup.............................................. 2-1

2.1. Precautions .............................................................................2-1

2.2. Installing the Server Board..................................................... 2-2

2.3. Installing the CPU .................................................................. 2-3

2.3.1. Installing Retention Modules.............................................. 2-3

2.3.2. Installing CPU into Socket .................................................2-4

2.3.3. Installing Heatsink and Wind Tunnel .................................2-4

2.3.4. Installing Fan to Wind Tunnel Assemblies ........................2-5

2.4. System Memory .....................................................................2-6

2.4.1. Memory Configuration Table .............................................2-6

2.4.2. Installing and Removing Memory Modules .......................2-6

2.5. Connectors, Headers, and Switches .......................................2-8

2.5.1. EPS12V Power Connectors ................................................2-8

2.5.2. FAN Connectors .................................................................2-9

2.5.3. CMOS Memory Clearing Header .....................................2-10

2.5.4. Front Panel Switches & Indicators Headers .....................2-11

2.5.5. Floppy Disk Drive and IDE Connectors........................... 2-12

2.5.6. PCI Expansion Slots .........................................................2-13

2.5.7. COM Port Header .............................................................2-14

2.5.8. Additional USB Ports Header........................................... 2-15

2.5.9. LAN Active/Link Indicators Headers............................... 2-16

2.5.10. Onboard VGA Output Switch ..........................................2-17

2.5.11. Smart Card Reader Connector..........................................2-18

2.5.12. Agilent Management Connector.......................................2-19

2.5.13. IPMB Connector...............................................................2-20

User’s Manual

Page 4

2.5.14. Ultra 320 SCSI Channels Connectors ..............................2-21

2.5.15. Adaptec Zero Channel RAID (ZCR) SO-DIMM Interface

Riser..................................................................................2-23

2.5.16. External I/O Panel Connectors .........................................2-24

Chapter 3. BIOS Setup...................................................... 3-1

3.1. Main Menu .............................................................................3-2

3.2. Advanced Menu .....................................................................3-6

3.2.1. Advanced BIOS Features ...................................................3-6

3.2.2. Advanced Chipset Features ................................................3-8

3.2.3. Integrated Peripherals .......................................................3-10

3.2.4. Power Management Setup ................................................3-13

3.2.5. PnP/PCI Configurations ...................................................3-14

3.3. Security Menu ......................................................................3-16

3.4. PC Health Menu ................................................................... 3-17

3.5. Clk/Misc. Menu.................................................................... 3-18

3.6. Exit Menu ............................................................................. 3-19

Chapter 4. SCSI Utility ..................................................... 4-1

Chapter 5. Driver Installation .......................................... 5-1

5.1. Setup Items ............................................................................. 5-2

5.2. Installing Ultra320 SCSI Controller....................................... 5-3

5.2.1. Installing Windows 2000 with an Ultra320 SCSI Controller

............................................................................................5-3

5.2.2. Installing the Driver when Windows 2000 is Already

Installed ..............................................................................5-3

5.2.3. Changing SCSI Boot Controllers in Windows 2000 ..........5-4

Appendix A. Trouble Shooting ........................................... A-1

Appendix B. How to Get Technical Support ..................... B-1

SI-2P+

Page 5

Introduction 1-1

Chapter 1. Introduction

1.1. Features & Specifications

Processor

• Supports dual Intel

Cache up to 2.0GHz ~ 2.8GHz and higher

®

Xeon 400MHz/533MHz Processors with 512K L2

Chipset

• Intel

• 2x 82870P2 64-bit PCI/PCI-X Controller Hub 2 (P64H2)

• 82801CA I/O Controller Hub 3-S (ICH3-S)

®

E7501 Chipset Memory Controller Hub (MCH)

Memory

• 6x 184-pin DIMM sockets support 144-bit wide (Dual Channel)

PC2100/PC1600 (DDR266/DDR200) memory

• Up to 12GB, ECC, Registered memory capacity (Chipkill technology

support)

LAN

• Intel

• RX and TX IP and TCP/UDP checksum off-loading capabilities

• Front panel LAN Active/Link LED

®

82546 dual ports Gigabit Ethernet controller

Graphics

• Onboard ATi RAGE XL PCI interface VGA

• 4MB local SDRAM memory support

PCI Extension Slot

• 4x PCI-X, support 64bit one 133MHz and three 100MHz slots

• 1x PCI 32bit/32MHz

Storage

• Dual Ultra 320 SCSI based on Adaptec 7902 ASIC with optional

Adaptec Zero Channel RAID (ZCR) SO-DIMM interface riser

• Dual ATA 100 IDE port support up to 4 IDE drives

• 1x Floppy Port

Multi I/O Functions

• 2x Serial Ports / 1x Parallel Port

User’s Manual

Page 6

1-2 Chapter 1

• 1x PS/2 keyboard, 1x PS/2 mouse connector

• 2x USB external, 2x USB internal connectors

System BIOS

• AWARD Plug and Play BIOS supports APM, DMI, and ACPI

• Write-Protect Anti-Virus function, Wake on LAN by AWARD BIOS

• 4M-bit Flash ROM

Form factor

• EEB 3.0 Form Factor: 12in. x 13in. (305mm x 330mm)

• EPS12V PSU Connector

Miscellaneous

• Option for IPMI connector

Specifications and information contained herein are subject to change

without notice.

SI-2P+

Page 7

Introduction 1-3

1.2. Package Checklist (Standard Package)

(1) SI-2P+ Server Board

(1) Brief Installation Guide

(1) Driver & Utilities CD

(1) 34-pin FDD Cable

(2) 40-pin IDE ATA66 Cable

(1) 68-pin LVD/SE SCSI cable with terminator for (2) Ultra 320 SCSI devices

(2) 603/604-pin Retention Module

(2) 603-pin Retention Module w/Clip

(2) 604-pin Retention Module w/Clip

(1) I/O Shield

User’s Manual

Page 8

1-4 Chapter 1

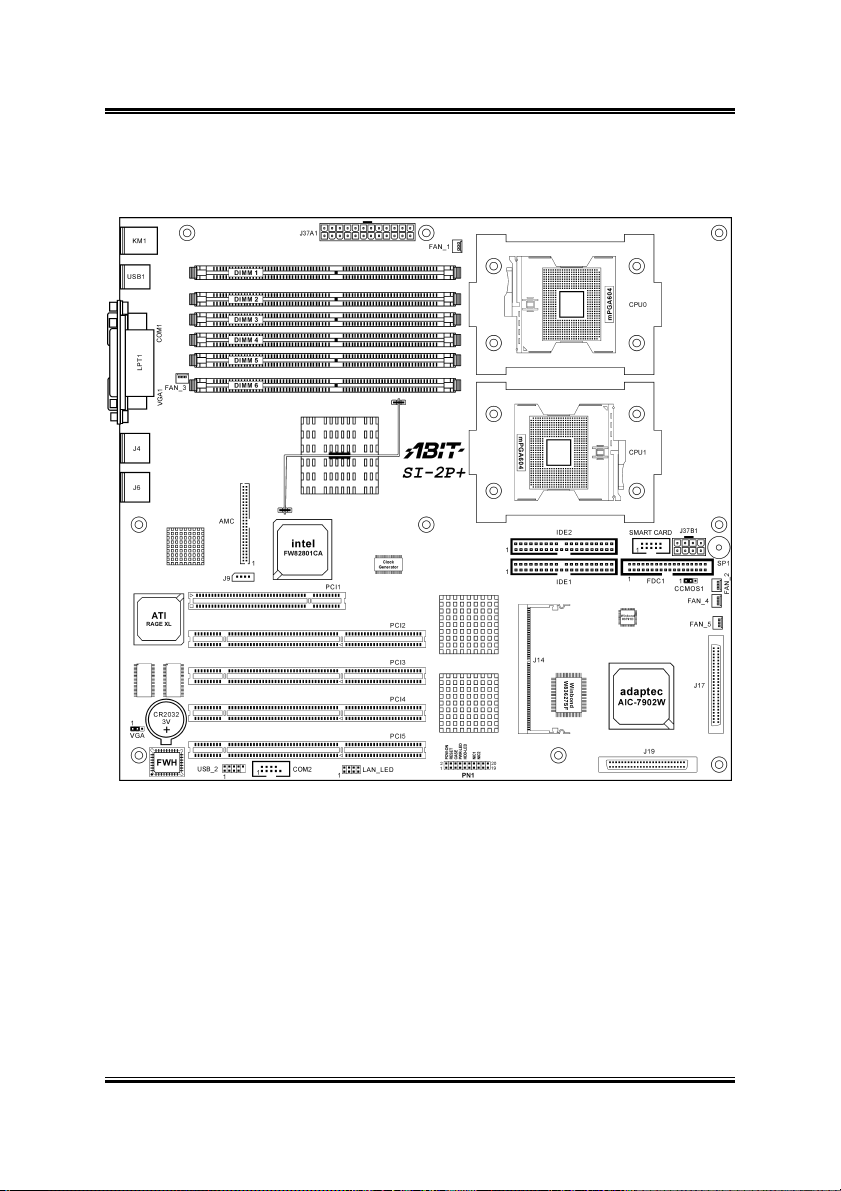

1.3. Layout Diagram

SI-2P+

Page 9

Introduction 1-5

1.4. Jumpers & Connectors Description

Jumpers Description Default Setting

CCMOS1 CMOS Clear Pins 1-2 (Normal)

VGA Onboard VGA Output Switch Pins 1-2 (Enable)

Connectors Description

AMC Agilent Management Connector

COM2 External COM2 Bracket Connector

DIMM 1~6 DDR DIMM Slots

FAN_1 CPU0 Fan

FAN_2 CPU1 Fan

FAN_3/4/5 System Fan

FDC1 Floppy Disk Drive Connector

IDE1/IDE2 Hard Disk Drives Connectors

J14 Adaptec Zero Channel RAID (ZCR) SO-DIMM interface

riser

J17 Ultra 320 SCSI Channel B Connector

J19 Ultra 320 SCSI Channel A Connector

J37A1 24-Pin EPS12V Power Connector

J37B1 8-Pin EPS12V Power Connector

J9 IPMB Connector

LAN_LED LAN Active/Link Indicators Headers

PCI1 PCI 32bit/33MHz

PCI2/4/5 PCI-X 64bit/100MHz

PCI3 PCI-X 64bit/133MHz

PN1 Front Panel Switch & Indicators Headers

SMART CARD Smart Card Reader Extension Cable Connector

USB_2 Additional USB Ports Connector

User’s Manual

Page 10

1-6 Chapter 1

SI-2P+

Page 11

Hardware Setup 2-1

Chapter 2. Hardware Setup

2.1. Precautions

Please pay attention to the following precautions before setting up any hardware.

1. Always switch off the power supply and unplug the power cord from the wall

outlet before installing the board or changing any settings.

2. Ground yourself properly by wearing a static safety wrist strap before removing

the board from the antistatic bag.

3. Hold the board by its edges. Avoid touching any component on it.

4. Avoid touching module contacts and IC chips

5. Place the board on a grounded antistatic surface or on the antistatic bag that came

with the board.

User’s Manual

Page 12

2-2 Chapter 2

2.2. Installing the Server Board

Before installing the server board, exam your chassis to ensure this server board fits

into it. Your chassis should support EEB 3.0 form factor.

1. Face the side of the I/O ports toward the control panel.

2. Locate the screw holes on the server board and the chassis base.

3. Place all the studs or spacers needed on the chassis base and have them tightened.

4. Line up all the screw holes on the board with those studs or spacers on the chassis.

5. Tightens all the screw holes.

ATTENTION: To prevent shorting the PCB circuit, please REMOVE the metal studs

or spacers if they are already secured on the chassis base and are without

mounting-holes on the server board to align with.

SI-2P+

Page 13

Hardware Setup 2-3

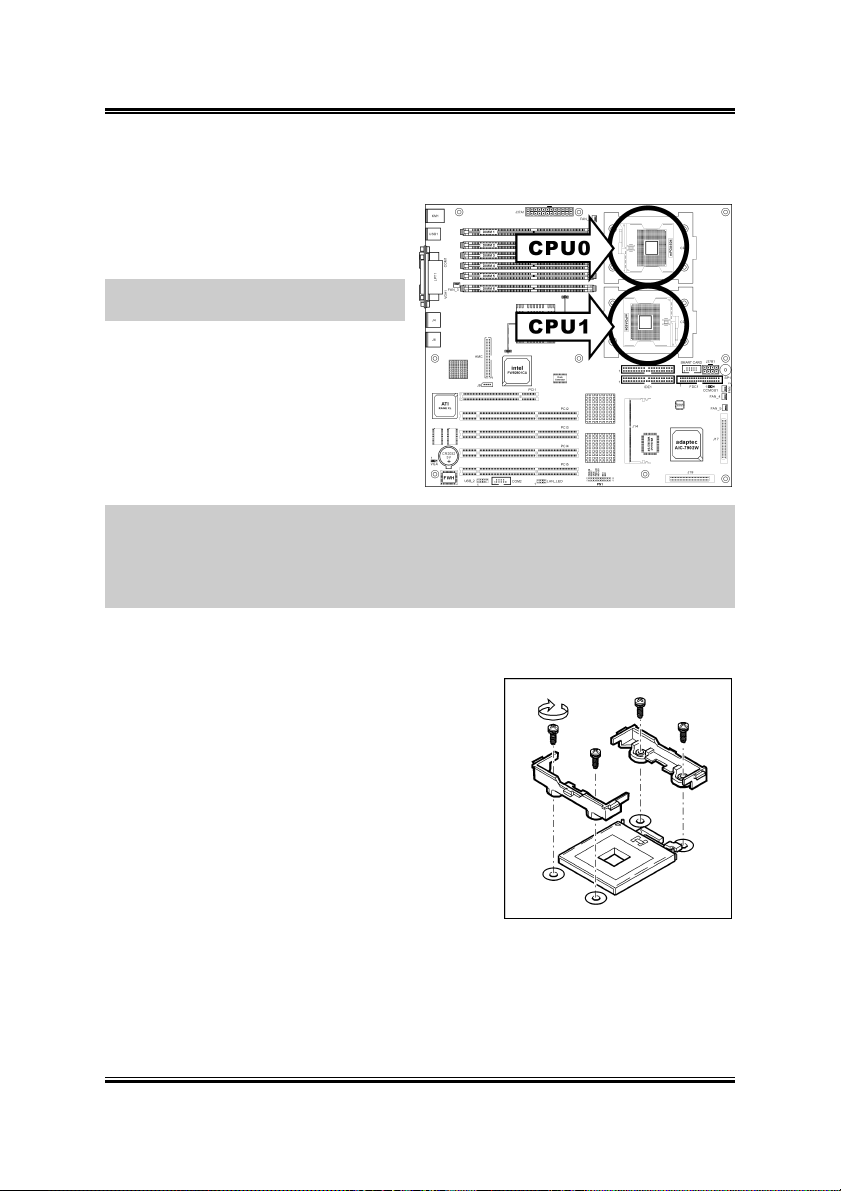

2.3. Installing the CPU

This server board provides dual 604-pin

Zero Insertion Force (ZIF) sockets to

install the Intel Xeon CPU.

NOTE: This server board also supports

the Xeon CPU of 603-pin package.

NOTE: This server board supports installing either one or two CPUs. To set up

system with only one CPU, you MUST install it in the Primary Processor Socket

(Socket CPU0 in this model). To install a second processor, you must verify that the

second processor is identical to the first processor of same voltage and speed. Using

non-identical processors could cause system failure.

2.3.1. Installing Retention Modules

1. Remove power from your system by unplugging

the AC power cord.

2. Remove the chassis cover (see your system or

chassis documentation for instructions).

3. Locate the CPU sockets.

4. Insert the retention modules and tighten four

retention screws.

User’s Manual

Page 14

2-4 Chapter 2

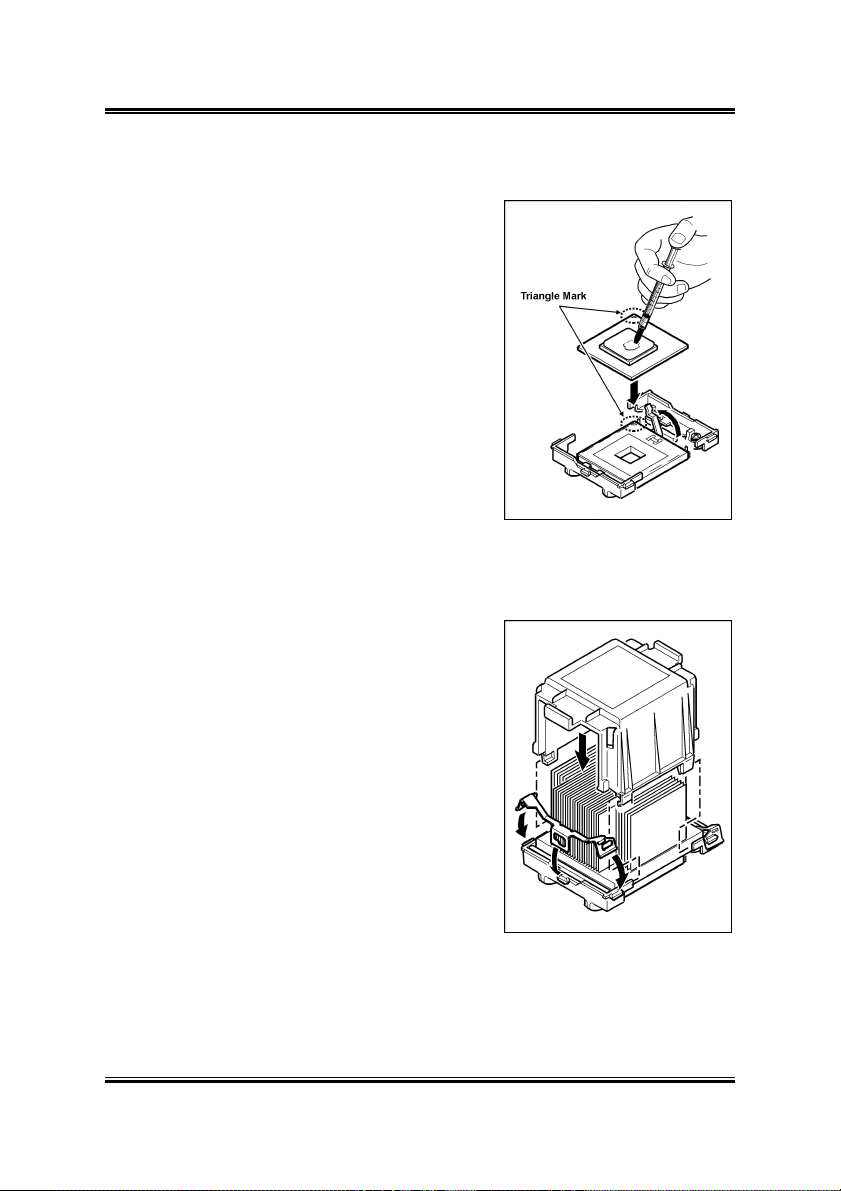

2.3.2.

1. Lift the socket lever upright to 115 degree at

2. Align the triangle mark on the CPU with the

3. Insert the CPU into the socket until it fits in

4. Apply thermal grease to the CPU with an

2.3.3.

1. Align the heatsink with the retention modules,

2. Position the retention clip over the plastic tab

3. Press downward on the retention clip ends until

4. Repeat steps 2-3 to install the other retention

5. Install the CPU wind tunnel center portion over

Installing CPU into Socket

least.

triangle cutout on the CPU socket.

place. Do not use extra force to insert CPU; it

only fit in one orientation. Close down the

socket lever to its locked position while firmly

pressing the CPU.

applicator.

Installing Heatsink and Wind Tunnel

and then place the heatsink onto the CPU.

and then engage the clip end-slot over the

plastic tab.

they engage the plastic tabs.

clip.

the heatsink. Note that the plastic tabs engage

the tabs on the retention clips.

SI-2P+

Page 15

Hardware Setup 2-5

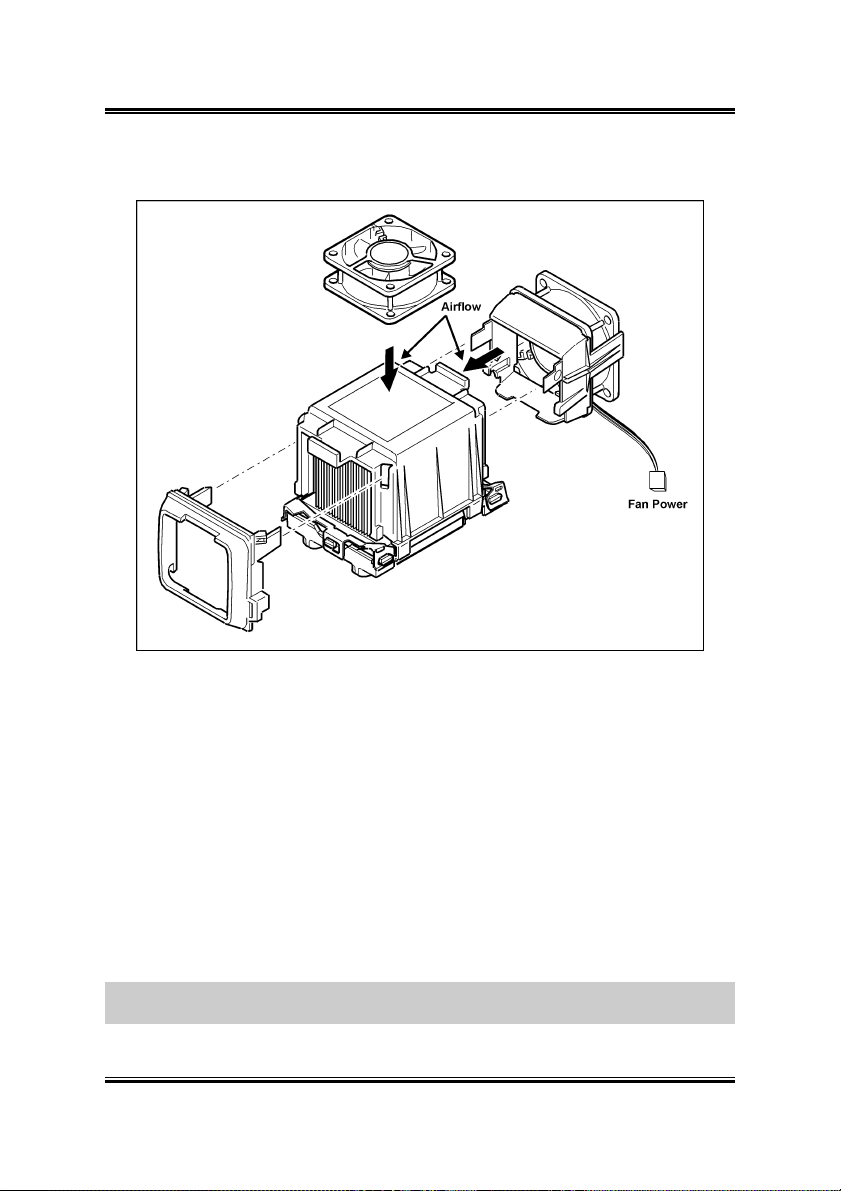

2.3.4. Installing Fan to Wind Tunnel Assemblies

1. Attach the cooling fan with its airflow direction pointed to heatsink to the air

intake portion of wind tunnel.

2. Attach the air intake assembly to the side of the wind tunnel nearest to the front of

the chassis.

Instead of attaching cooling fan to the side of the wind tunnel, the fan itself could

also be attached to the top of the center portion of wind tunnel.

3. Align the tabs on the assembly with the slots in the wind tunnel portion, and then

snap the lower portion of the fan holder over the tabs on the center portion.

4. Attach the air outlet portion of the wind tunnel.

5. Attach CPU Fan 1 power cable to the server board at location FAN1 and/or attach

CPU Fan 2 power cable at location FAN2.

NOTE: The system airflow should be toward the front of the chassis. If there are two

processors installed, the fans should be positioned side by side.

User’s Manual

Page 16

2-6 Chapter 2

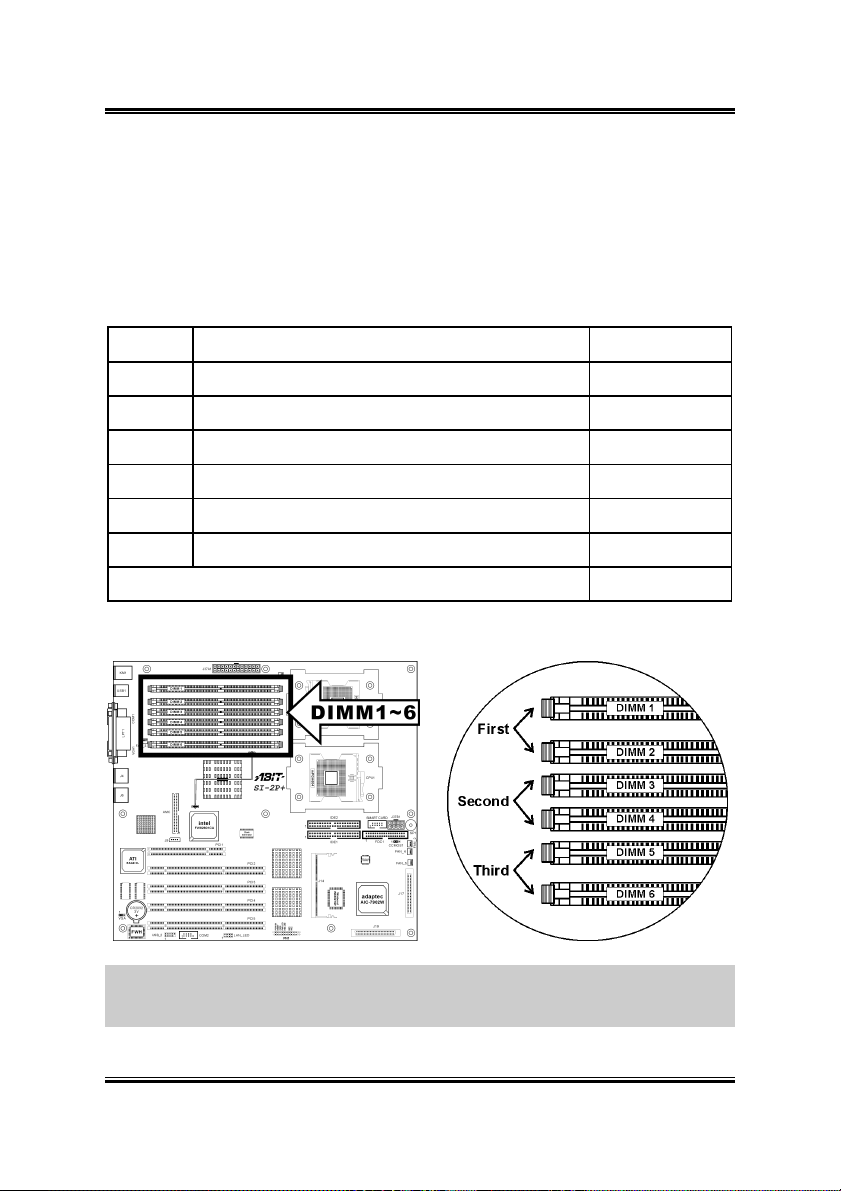

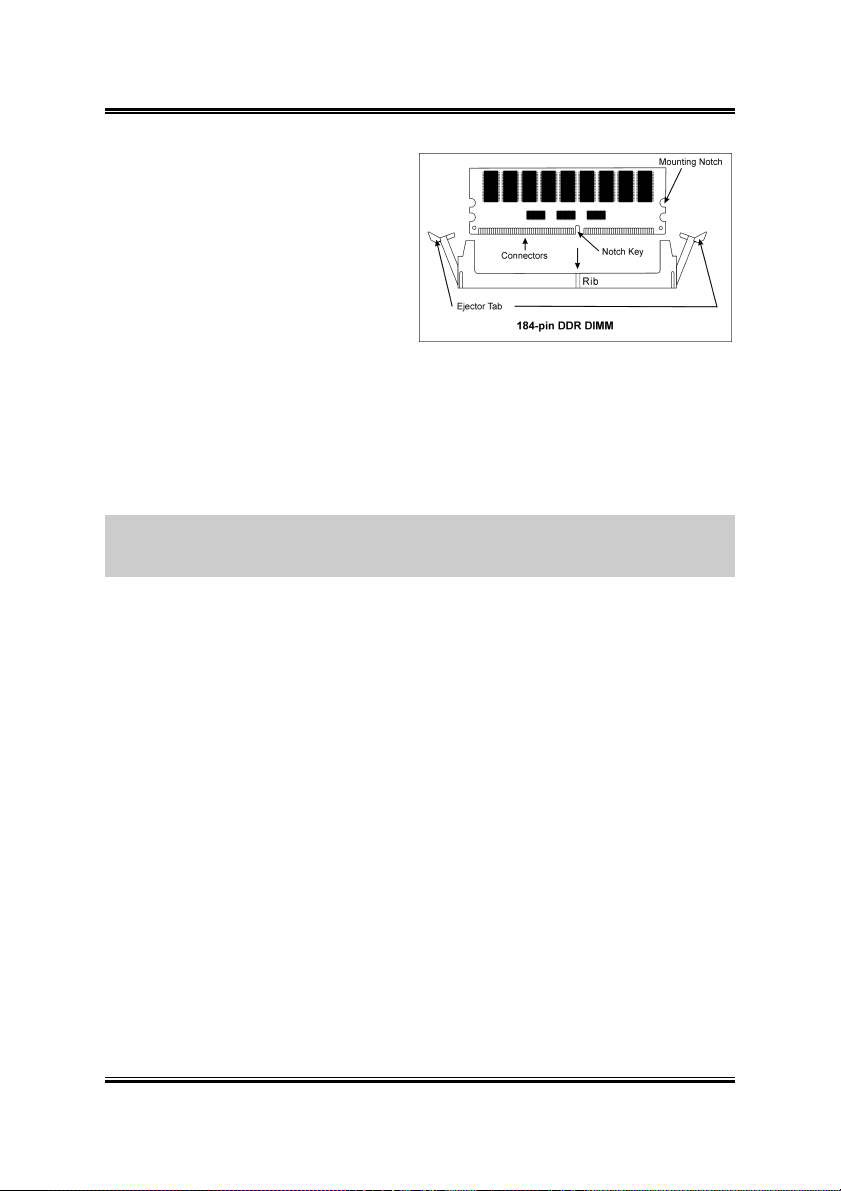

2.4. System Memory

This server board provides six 184-pin Double Data Rate (DDR) Dual Inline Memory

Module (DIMM) slots for Registered ECC DIMM modules with memory expansion

size up to 12GB (DDR266/DDR200).

2.4.1. Memory Configuration Table

DIMM Registered ECC DIMM Module Total Memory

1 128MB, 256MB, 512MB, 1GB, 2GB 128MB ~ 2GB

2 128MB, 256MB, 512MB, 1GB, 2GB 128MB ~ 2GB

3 128MB, 256MB, 512MB, 1GB, 2GB 128MB ~ 2GB

4 128MB, 256MB, 512MB, 1GB, 2GB 128MB ~ 2GB

5 128MB, 256MB, 512MB, 1GB, 2GB 128MB ~ 2GB

6 128MB, 256MB, 512MB, 1GB, 2GB 128MB ~ 2GB

Total System Memory 256MB ~ 12GB

2.4.2. Installing and Removing Memory Modules

ATTENTION: Populate the DDR DIMMs in-order and in-pair (of the same type

and size) by starting from DIMM1+DIMM2, DIMM3+DIMM4, to DIMM5+DIMM6.

The system may hang or appear unstable if the DIMM ordering is not followed.

SI-2P+

Page 17

Hardware Setup 2-7

Power off the computer and unplug the

AC power cord before installing or

removing memory modules.

1. Locate the DIMM slot on the board.

2. Hold two edges of the DIMM

module carefully, keep away of

touching its connectors.

3. Align the two notch keys on the

module with the two ribs on the slot.

4. Firmly press the module into the slots until the ejector tabs at both sides of the slot

automatically snaps into the mounting notch. Do not force the DIMM module in

with extra force as the DIMM module only fit in one orientation.

5. To remove the DIMM modules, push the two ejector tabs on the slot outward

simultaneously, and then pull out the DIMM module.

ATTENTION: As the static electricity can damage the electronic components of the

computer or optional modules, make sure you are discharged of static electricity by

touching a grounded metal object briefly before starting these procedures.

User’s Manual

Page 18

2-8 Chapter 2

2.5. Connectors, Headers, and Switches

All the connectors, headers and switches mentioned here are depending on your

system configuration. Some features you may (or may not) have to connect or to

configure depending on the peripherals you have connected.

WARNING: Always power off the computer and unplug the AC power cord before

adding or removing any peripheral or component. Failing to so may cause severe

damage to your server board and/or peripherals. Plug in the AC power cord only after

you have carefully checked everything.

2.5.1. EPS12V Power Connectors

These two connectors connect to EPS12V power supply. This server board requires an

EPS12V power supplier with 460W capacity at least for Pentium 4 Xeon CPU

system.

WARNING: This server board only supports EPS12V power supplies and will not

operate with other types. DO NOT use ATX 2.x, ATX12V and dual AMD power

supplies as they will damage the board and void your warranty.

NOTE: The auxiliary 12V power (J37B1) is necessary to support Intel Xeon CPUs.

Failing to provide such extra power will result in the system’s booting failure.

SI-2P+

Page 19

Hardware Setup 2-9

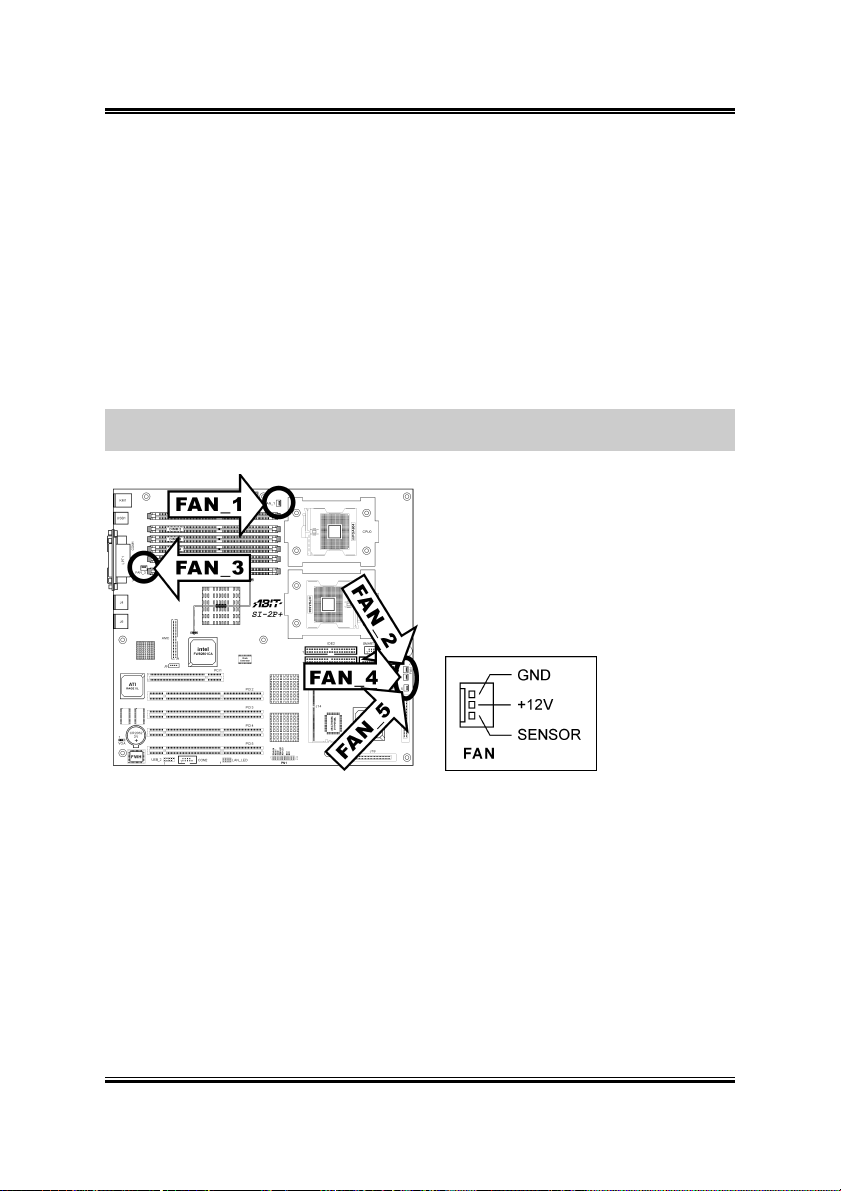

2.5.2. FAN Connectors

These 3-pin connectors each provide power to the cooling fans installed in your

system.

The CPU must be kept cool by using a powerful fan with heatsink. The system is

capable of monitoring the speed of the CPU fan.

• FAN_1: CPU0 Fan

• FAN_2: CPU1 Fan

• FAN_3/4/5: System Fan

WARNING: These fan connectors are not jumpers. DO NOT place jumper caps on

these connectors.

User’s Manual

Page 20

2-10 Chapter 2

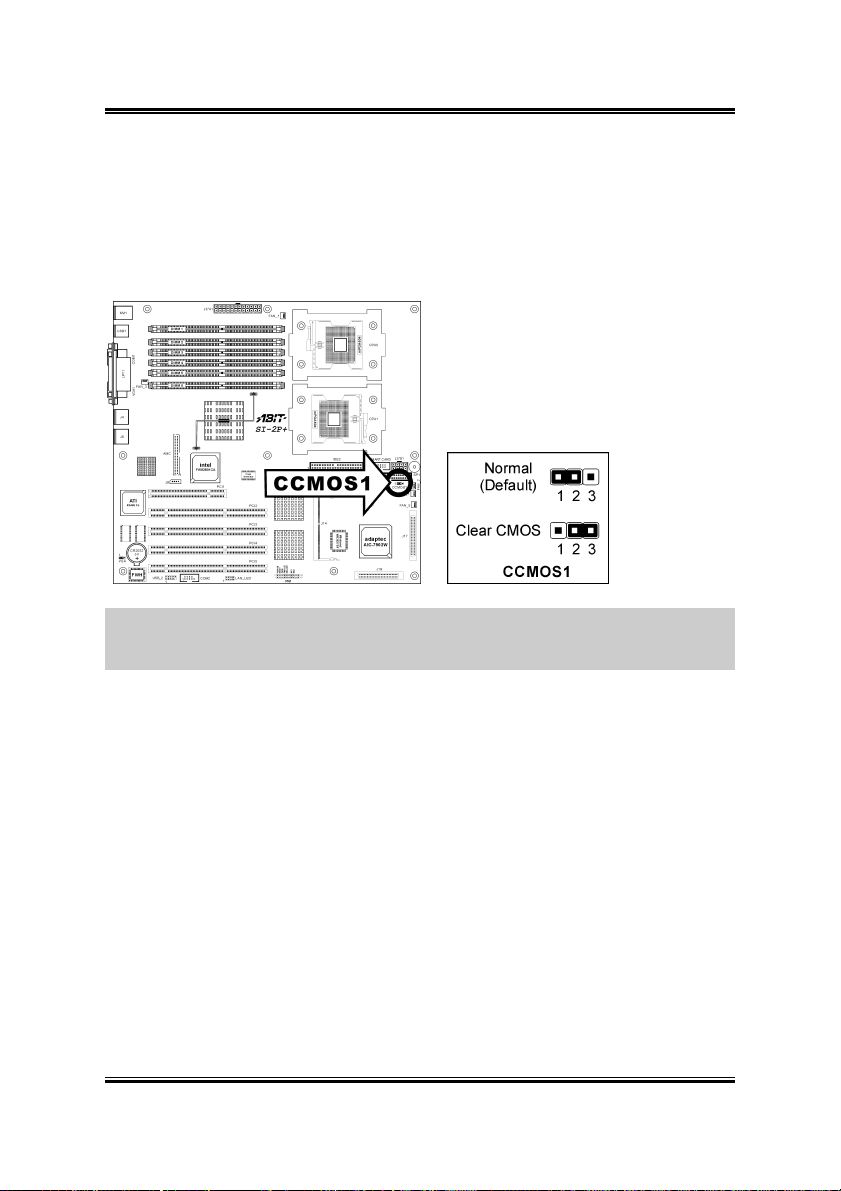

2.5.3. CMOS Memory Clearing Header

This header uses a jumper cap to clear the CMOS memory.

• Pin 1-2 shorted (default): Normal operation.

• Pin 2-3 shorted: Clear CMOS memory.

ATTENTION: Turn the system power off first (including the +5V standby power)

before clearing the CMOS memory. Failing to do so may cause your system to work

abnormally or malfunction.

SI-2P+

Page 21

Hardware Setup 2-11

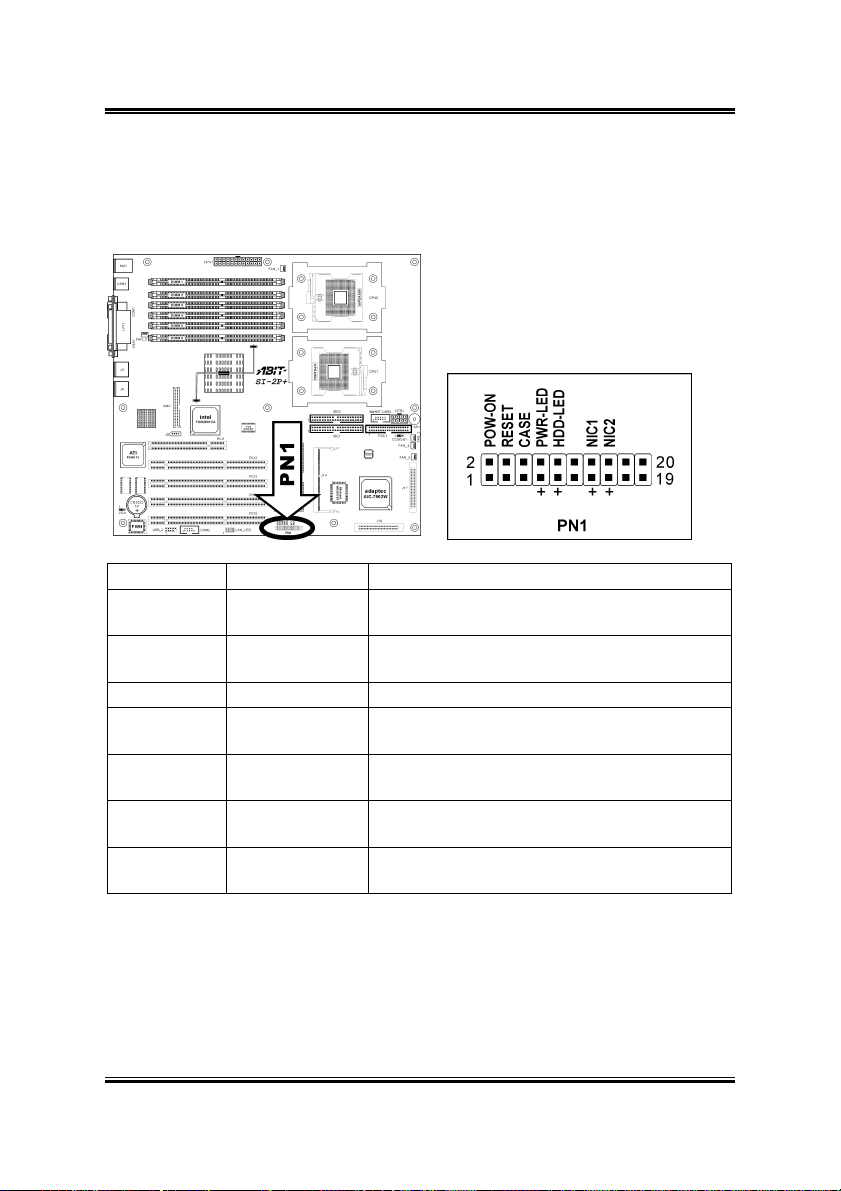

2.5.4. Front Panel Switches & Indicators Headers

These headers are used for connecting switches and LED indicators on the chassis

front panel. The mark “+” stands for positive polarity of LED connection.

Pin Number Pin Assignment Definition

Pin 1, 2 POW-ON

Pin 3, 4 RESET

Pin 5, 6 CASE Case-Open Detection Header

Pin 7, 8 PWR-LED

Pin 9, 10 HDD-LED

Pin 13, 14 NIC1

Pin 15, 16 NIC2

Connects to the Power Switch cable of chassis

front panel.

Connects to the Reset Switch cable of chassis

front panel.

Connects to the Power LED cable of chassis

front panel.

Connects to the HDD LED cable of chassis

front panel.

Network Interface Controller 1 Active/Link

Indicator

Network Interface Controller 2 Active/Link

Indicator

User’s Manual

Page 22

2-12 Chapter 2

2.5.5. Floppy Disk Drive and IDE Connectors

The FDC1 connector connects up to two floppy drives with a 34-wire, 2-connector

floppy cable. Connect the single end at the longer length of ribbon cable to this FDC1,

and the two connectors on the other end to the floppy disk drives. Generally you need

only one floppy disk drive in your system.

The IDE1/IDE2 port connects up to two

IDE drives at Ultra ATA/100 mode by one

40-pin, 80-conductor, and 3-connector Ultra

ATA/66 ribbon cables. Connect the single

end (blue connector) at the longer length of

ribbon cable to the IDE port on server board,

and the other two ends (gray and black

connector) at the shorter length of the

ribbon cable to the connectors on hard

drives.

NOTE: The red line on the ribbon cable should be aligned with pin-1 on this

connector.

SI-2P+

Page 23

Hardware Setup 2-13

2.5.6. PCI Expansion Slots

PCI1: Supports PCI 32bit/33MHz.

PCI2/4/5: Supports PCI-X 64bit/100MHz.

PCI3: Supports PCI-X 64bit/133MHz.

User’s Manual

Page 24

2-14 Chapter 2

2.5.7. COM Port Header

This header provides connection to external COM Ports through an extension cable

and bracket.

SI-2P+

Page 25

Hardware Setup 2-15

2.5.8. Additional USB Ports Header

This header provides two additional USB ports connection through an extension cable

and bracket.

Pin Pin Assignment Pin Pin Assignment

1 VCC 2 VCC

3 Data0 - 4 Data1 -

5 Data0 + 6 Data1 +

7 Ground 8 Ground

9 NC 10 NC

User’s Manual

Page 26

2-16 Chapter 2

2.5.9. LAN Active/Link Indicators Headers

These headers are used for connecting LED indicators for LAN status. The mark “+”

stands for positive polarity of LED connection.

Pin Number Definition

Pin 1, 2 LAN Port J4 Active Indicator

Pin 3, 4 LAN Port J4 Link Indicator

Pin 5, 6 LAN Port J6 Active Indicator

Pin 7, 8 LAN Port J6 Link Indicator

SI-2P+

Page 27

Hardware Setup 2-17

2.5.10. Onboard VGA Output Switch

This header serves as a switch to select the VGA output from onboard VGA1

connector or from add-on optional VGA card at PCI slot.

To select the onboard VGA output, short pin-1 and pin-2 (default setting). For

external VGA card operation through PCI slot, short pin-2 and pin-3.

User’s Manual

Page 28

2-18 Chapter 2

2.5.11. Smart Card Reader Connector

This connector provides connection to the optional Smart Card Reader device through

an extension cable and bracket.

Pin Pin Assignment Pin Pin Assignment

1 VCC 2 GND

3 SCPWR 4 SCRST

5 NC 6 NC

7 SCIO 8 NC

9 SCCLK 10 SCPSNT

SI-2P+

Page 29

Hardware Setup 2-19

2.5.12. Agilent Management Connector

This server board provides one onboard 50-pin AMC connector. The AMC is a

standard connector for server or communication system motherboards. It includes all

signals needed for IPMI-complaint baseboard management.

NOTE: The AMC does not support “Hot Plug”. The RMC or motherboard itself can

be damaged if the AMC cables is plugged or unplugged while power is present.

User’s Manual

Page 30

2-20 Chapter 2

2.5.13. IPMB Connector

This server board provides one onboard 4-pin IPMB connector to transfer intelligent

platform management information.

SI-2P+

Page 31

Hardware Setup 2-21

2.5.14. Ultra 320 SCSI Channels Connectors

The onboard SCSI controller provides Ultra 320 SCSI channels through these two

connectors.

Both J17 and J19 connectors provide two 68-pin Ultra 320 SCSI channels. Each

channel supports up to 15 devices (ID0~ID15) on a standard Ultra 320 SCSI LVD

(Low Voltage Differential) cable, configuration up to 12 meters. In a point-to-point

arrangement, cabling can extend 25 meters.

Each device has its own individual SCSI ID number, but none of the devices

connected can use ID7, which is reserved for SCSI controller.

User’s Manual

Page 32

2-22 Chapter 2

In order to prevent signal loss, a 68-pin twisted

ribbon cable (LVD) with external SCSI terminator is

necessary to connect Ultra 320 SCSI hard drive to

this board. All termination jumpers on the SCSI

devices must be removed when using the external

SCSI terminator.

IMPORTANT: Each channel should have only one

type of SCSI standard. A mixed setup with different

standard on the same channel will decrease the

performance to the slowest device.

SI-2P+

Page 33

Hardware Setup 2-23

2.5.15. Adaptec Zero Channel RAID (ZCR) SO-DIMM Interface Riser

The J17 and J19 connector can also be used to setup a RAID system by installing an

optional Adaptec RAID card - 2015S to this connector.

User’s Manual

Page 34

2-24 Chapter 2

2.5.16. External I/O Panel Connectors

• Mouse: PS/2 mouse connector.

• Keyboard: PS/2 keyboard connector.

• USB1: Universal Serial Bus connector.

• LPT1: Parallel port connector.

• COM1: Serial port connector

• VGA1: Monitor signal connector.

• J4, J6: Local Area Network connector.

SI-2P+

Page 35

BIOS Setup 3-1

Chapter 3. BIOS Setup

This motherboard provides a programmable EEPROM that you can update the BIOS

utility. The BIOS (Basic Input/Output System) is a program that deals with the basic

level of communication between processor and peripherals. Use the BIOS Setup

program only when installing motherboard, reconfiguring system, or prompted to

“Run Setup”. This chapter explains the Setup Utility of BIOS utility.

After powering up the system, the BIOS message appears on the screen, the memory

count begins, and then the following message appears on the screen:

Press DEL to run setup

If this message disappears before you respond, restart the system by pressing <Ctrl> +

<Alt> + <Del> keys, or by pressing the Reset button on computer chassis. Only when

it failed by these two methods can you restart the system by powering it off and then

back on.

NOTE: In order to increase system stability and performance, our engineering staffs

are constantly improving the BIOS menu. The BIOS setup screens and descriptions

illustrated in this manual are for your reference only, may not completely match what

you see on your screen.

After pressing <Del> key, the main menu screen appears.

User’s Manual

Page 36

3-2 Chapter 3

3.1. Main Menu

Date (mm:dd:yy)

This item sets the date you specify (usually the current date) in the format of [Month],

[Date], and [Year].

Time (hh:mm:ss)

This item sets the time you specify (usually the current time) in the format of [Hour],

[Minute], and [Second].

IDE Primary Master, IDE Primary Slave, IDE Secondary Master, and IDE

Secondary Slave

Move cursor to item “IDE Primary Master”, “IDE Primary Slave”, “IDE Secondary

Master” or “IDE Secondary Slave”, and then press <Enter> key to enter a sub-menu.

SI-2P+

Page 37

BIOS Setup 3-3

IDE Primary/Secondary Master/Slave

IDE HDD Auto-Detection

This item allows you to detect the parameters of IDE drives by pressing the <Enter>

key. The parameters will automatically be shown on the screen.

IDE Primary Master

When set to [Auto], the BIOS will automatically check what kind of IDE drive you

are using. If you want to define your own drive by yourself, set it to [Manual] and

make sure you fully understand the meaning of the parameters. Refer to the manual

provided by the device manufacturer to get the settings right.

Access Mode

This item selects the mode to access your IDE devices. Leave this item to its default

[Auto] settings to let BIOS detects the access mode of your HDD and makes decision

automatically.

Capacity

This item automatically displays your HDD size. Note that this size is usually slightly

greater than the size given by a disk-checking program of a formatted disk.

NOTE: The following [Cylinder], [Head], [Precomp], [Landing Zone], and [Sector]

items are available when you set the item “IDE Primary Master” to “Manual”.

User’s Manual

Page 38

3-4 Chapter 3

Cylinder

This item configures the numbers of cylinders.

Head

This item configures the numbers of read/write heads.

Precomp

This item displays the number of cylinders at which to change the write timing.

Landing Zone

This item displays the number of cylinders specified as the landing zone for the

read/write heads.

Sector

This item configures the numbers of sectors per track.

Drive A

This item sets the type of floppy drives installed.

[None]: No floppy drive installed

[360K, 5.25 in.]: 5.25-inch standard drive; 360KB capacity

[1.2M, 5.25 in.]: 5.25-inch AT-type high-density drive; 1.2MB capacity

[720K, 3.5 in.]: 3.5-inch double-sided drive; 720KB capacity

[1.44M, 3.5 in.]: 3.5-inch double-sided drive; 1.44MB capacity

[2.88M, 3.5 in.]: 3.5-inch double-sided drive; 2.88MB capacity

Halt On

This item determines whether the system stops if an error is detected during system

boot-up.

[All Errors]: The system-boot will stop whenever the BIOS detect a non-fatal error.

[No Errors]: The system-boot will not stop for any error detected.

[All, But Keyboard]: The system-boot will stop for all errors but keyboard error.

[All, But Diskette]: The system-boot will stop for all errors but disk error.

[All, But Disk/Key]: The system boot will stop for all errors but disk or keyboard

error.

SI-2P+

Page 39

BIOS Setup 3-5

Base Memory

This item displays the amount of base memory installed in the system. The value of

the base memory is typically 640K for system with 640K or more memory size

installed on the motherboard.

Extended Memory

This item displays the amount of extended memory detected during system boot-up.

Total Memory

This item displays the total memory available in the system.

User’s Manual

Page 40

3-6 Chapter 3

3.2. Advanced Menu

3.2.1. Advanced BIOS Features

CPU Hyper-Threading

This option enables or disables the processor’s Hyper-Threading Technology.

SI-2P+

Page 41

BIOS Setup 3-7

Leave this item to its default setting to enable the simultaneous multi-threaded (SMT)

processor so as to make one physical processor looks like two logical processors to

the OS and applications.

This option is for CPU with Hyper-Threading Technology only. For more information

on “Hyper-Threading Technology”, please visit Intel Web site at

http://www.intel.com/homepage/land/hyperthreading.htm

http://www.intel.com/design/chipsets/ht/

.

,

Quick Power On Self Test

When set to [Enabled], this item speeds up the Power On Self Test (POST) after

powering on the system. The BIOS shorten or skip some check during the POST.

Hard Disk Boot Priority

This item selects the hard disks booting priority. By pressing <Enter> key, you can

enter its submenu where the hard disks detected can be selected for the booting

sequence to boot up system.

This item functions only when there is the option of [Hard Disk] in any one of the

First/Second/Third Boot Device items.

First Boot Device / Second Boot Device / Third Boot Device / Boot Other

Device

Select the drive to boot first, second and third in the [First Boot Device], [Second

Boot Device], and [Third Boot Device] fields respectively. The BIOS will boot the

operating system according to the sequence of the drive selected. Set [Boot Other

Device] to [Enabled] if you wish to boot from another device other than these three

items.

Boot Up NumLock Status:

This item determines the default state of the numeric keypad at system booting up.

[On]: The numeric keypad functions as number keys.

[Off]: The numeric keypad functions as arrow keys.

Security Option

This item determines when the system will prompt for password - every time the

system boots or only when enters the BIOS setup.

[Setup]: The password is required only when accessing the BIOS Setup.

[System]: The password is required each time the computer boots up.

User’s Manual

Page 42

3-8 Chapter 3

NOTE: Don’t forget your password. If you forget the password, you will have to

open the computer case and clear all information in the CMOS before you can start up

the system. But by doing this, you will have to reset all previously set options.

MPS Version Control For OS

This item specifies which version of MPS (Multi-Processor Specification) this board

will use. The options are 1.1 and 1.4. The default setting is 1.4. If you use an older OS

for dual processor executing, please set this option to 1.1.

Small Logo(EPA) Show

This item determines to show the EPA logo when booting.

3.2.2. Advanced Chipset Features

DRAM Timing Control

This item controls the DRAM timing. Press <Enter> key to enter its menu.

SI-2P+

Page 43

BIOS Setup 3-9

Memory Type

This item displays the type of memory module you are using.

Memory Frequency

This item displays the frequency of memory module you are using.

DRAM Timing Selectable

This item sets the optimal timings for the following four items, depending on the

memory module you are using. The default setting “By SPD” configures these four

items by reading the contents in the SPD (Serial Presence Detect) device. The

EEPROM on the memory module stores critical parameter information about the

module, such as memory type, size, speed, voltage interface, and module banks.

CAS Latency Time

This item controls the latency between the DRAM read command and the time that

the data becomes actually available.

Active to Precharge Delay

This item controls the number of DRAM clocks used for DRAM parameters.

DRAM RAS# to CAS# Delay

This item controls the latency between the DRAM active command and the read/write

command.

User’s Manual

Page 44

3-10 Chapter 3

DRAM RAS# Precharge

This item controls the idle clocks after issuing a precharge command to the DRAM.

Delayed Transaction

When set to [Enabled], the PCI bus will be freed up when the CPU is accessing 8-bit

ISA cards. This will allow PCI and ISA buses to be used more efficiently and

prevents performance dropping on the PCI bus. This process normally consumes

about 50-60 PCI clocks without PCI delayed transaction. Leave this item to its default

[Disabled] setting when using ISA cards that are not PCI 2.1 compliant.

3.2.3. Integrated Peripherals

Onboard IDE-1 Controller

This item enables or disables the onboard IDE-1 controller.

Onboard IDE-2 Controller

This item enables or disables the onboard IDE-2 controller.

USB Controller

This option enables or disables the USB controller.

SI-2P+

Page 45

BIOS Setup 3-11

USB Keyboard Support

This item allows you to select [BIOS] for using USB keyboard in DOS environment,

or [OS] in OS environment.

USB Mouse Support

This item allows you to select [BIOS] for using USB mouse in DOS environment, or

[OS] in OS environment.

Onboard LAN Controller

This item enables or disables the onboard LAN controller.

Onboard LAN Boot ROM

This item allows you to use the boot ROM (instead of a disk drive) to boot-up the

system and access the local area network directly.

Onboard SCSI Controller

This item enables or disables the onboard SCSI controller.

Onboard FDD Controller

This item enables or disables the onboard FDD controller.

Onboard Serial Port 1

This item determines which I/O addresses the onboard Serial Port 1 controller will

access.

[Auto]: The system automatically select an I/O address for the onboard Serial Port 1.

[3F8/IRQ4, 2F8/IRQ3, 3E8/IRQ4, 2E8/IRQ3]: Allows you to manually select an

I/O address for the onboard Serial Port 1.

[Disabled]: Disables the onboard Serial Port 1.

Onboard Serial Port 2

This item determines which I/O addresses the onboard Serial Port 2 controller will

access.

[Auto]: The system automatically select an I/O address for the onboard Serial Port 2.

[3F8/IRQ4, 2F8/IRQ3, 3E8/IRQ4, 2E8/IRQ3]: Allows you to manually select an

I/O address for the onboard Serial Port 2.

[Disabled]: Disables the onboard Serial Port 2.

User’s Manual

Page 46

3-12 Chapter 3

Onboard Parallel Port

This item specifies the I/O address used by the parallel port.

[Disabled]: This option prevents the parallel port from accessing any system

resources. When the value of this option is set to [Disabled], the printer port becomes

unavailable.

[378]: This option allows the parallel port to use [378] as its I/O port address. The

majority of parallel ports on computer systems use IRQ7 and I/O Port 378H as the

standard setting.

[278]: This option allows the parallel port to use [278] as its I/O port address.

[3BC]: This option allows the parallel port to use [3BC] as its I/O port address.

Parallel Port Mode

This item specifies the parallel port mode.

[SPP]: (Standard Parallel Port) Allows bi-directional parallel port operation at normal

speed.

[EPP]: (Enhanced Parallel Port) Allows bi-directional parallel port operation at

maximum speed.

[ECP]: (Extended Capabilities Port) Allows bi-directional parallel port operation at a

speed faster than the normal mode’s data transfer rate.

[EPP+ECP]: Using parallel port as EPP & ECP mode.

EPP Mode Select

This item selects the EPP mode.

ECP Mode Use DMA

This item selects the DMA channel of the parallel port.

PWRON After PWR-Fail

This item sets the system action after a power failure.

SCR Port Address

This item sets the I/O address and IRQ of the onboard SCR (Smart Card Reader) port.

SCR Port IRQ

After enabling the SCR port, here you can set the IRQ for SCR port.

SI-2P+

Page 47

BIOS Setup 3-13

3.2.4. Power Management Setup

Soft-Off by PWR-BTTN

This item selects the method of powering off your system:

[Hold 4 Sec.]: Pushing the power button for more than 4 seconds will power off the

system. This will prevent the system from powering off in case you accidentally hit or

pushed the power button.

[Instant-Off]: Pressing and then releasing the power button at once will immediately

power off the system.

Wake-Up by PCI card/LAN

When set to [Enabled], access to the onboard LAN or a PCI card such as a modem or

LAN card will cause the system to wake up. The PCI card must support the wake up

function.

Resume by Alarm

When set to [Enabled], you can set the date and time you would like the Soft-Off PC

to power-on in the “Date (of Month) Alarm” and “Time (hh:mm:ss) Alarm” items.

However, if the system is being accessed by incoming calls or the network (Resume

On Ring/LAN) prior to the date and time set in these items, the system will give

priority to the incoming calls or network instead.

User’s Manual

Page 48

3-14 Chapter 3

Date (of Month) Alarm

[0]: This option power-on the system everyday according to the time set in the “Time

(hh:mm:ss) Alarm” item.

[1-31]: This option selects a date you would like the system to power-on. The system

will power-on on the date set, and the time set in the “Time (hh:mm:ss) Alarm” item.

Time (hh:mm:ss) Alarm

This item sets the time you would like the system to power-on.

3.2.5. PnP/PCI Configurations

Force Update ESCD

When set to [Enabled], the BIOS will reset the ESCD (Extended System

Configuration Data) once automatically next time you boot up. It will then recreate a

new set of configuration data. But the next time you boot up, this option will

automatically be set as Disabled.

Resources Controlled By

This item configures all of the boot and Plug-and-Play compatible devices.

[Auto(ESCD)]: The system will automatically detect the settings.

[Manual]: Choose the specific IRQ resources in the “IRQ Resources” menu.

SI-2P+

Page 49

BIOS Setup 3-15

IRQ Resources

Click <Enter> key to enter its submenu:

This item sets each system interrupt to either [PCI Device] or [Reserved].

User’s Manual

Page 50

3-16 Chapter 3

3.3. Security Menu

Set Supervisor Password

This option protects the BIOS configuration or restricts access to the computer itself.

The Supervisor Password is used to protect the stored CMOS options from being

changed by unauthorized users.

Set User Password

This option protects the BIOS configuration or restricts access to the computer itself.

The User Password requires all users to enter a password in order to use the system,

and/or enter the BIOS setup (but can’t change its contents).

SI-2P+

Page 51

BIOS Setup 3-17

3.4. PC Health Menu

Shutdown Temperature

This item sets the temperature that would shutdown the system automatically in order

to prevent system overheats.

CPU Warning Temperature

This item selects the CPU’s warning temperature limit. Once the system has detected

that the CPU’s temperature exceeded the limit, warning beeps will sound.

NOTE: The onboard hardware monitor function is capable of detecting these system

health conditions. If you want a warning message to pop-up or a warning alarm to

sound when an abnormal condition occurs, you must install the “Hardware Doctor”

utility. This utility is included in the “Driver & Utility CD” that came packed with this

motherboard.

All Voltages, Fans Speed and Thermal Monitoring

These unchangeable items list the current status of the CPU and environment

temperatures, fan speeds, and system power voltage.

NOTE: The hardware monitoring features for temperatures, fans and voltages will

occupy the I/O address from 294H to 297H. If you have a network adapter, sound

card or other add-on cards that might use those I/O addresses, please adjust your

add-on card I/O address to avoid using these addresses.

User’s Manual

Page 52

3-18 Chapter 3

3.5. Clk/Misc. Menu

CPU Clock Ratio

This option selects the CPU clock ratio. Please type in the correct multiple for your

CPU.

Case-Open Detection

This option controls the function for case-opening detection via JP3 header.

BIOS Protect Control

This option protects for accidentally BIOS writing attempt.

NOTE: Make sure to set this item to “Unprotected” when flashing the BIOS.

SI-2P+

Page 53

BIOS Setup 3-19

3.6. Exit Menu

Once you have made all your selections in the previous BIOS setup menu, you have

to save the settings and exit the setup menu. Select the Exit Menu in the menu bar to

show the following menu:

NOTE: Pressing <ESC> does not exit this menu. You have to select one of the

options in this menu, such as “Exit Without Saving” to exit the menu without saving

your previous settings.

Load Fail-Safe Defaults

This option loads the BIOS default values for the most stable, minimal-performance

system operations.

Load Optimized Defaults

This option loads the BIOS default values that are factory settings for

optimal-performance system operations.

Save & Exit Setup

This option saves your selections and exits the setup menu.

Exit Without Saving

This option exits the setup menu without saving any change.

User’s Manual

Page 54

3-20 Chapter 3 3-20 Chapter 3

SI-2P+

SI-2P+

Page 55

SCSI Utility 4-1

Chapter 4. SCSI Utility

To enter the SCSI configuring menu, reboot the system, press <Ctrl> and <A> key

when the following message appears:

Press <Ctrl> <A> for SCSISelect(TM) Utility

The following screen appears. Select the channel you want to enter the SCSI

configuring menu.

Move the <Up> or <Down> arrow key to select the channel your SCSI devices

attached, and then press <Enter> key to enter. Press <Esc> key will exit this menu.

The following screen appears. Here in this option, you can configure the SCSI

controller, or run the SCSI Disk Utilities.

Move the <Up> or <Down> arrow key to select the option you want and press

<Enter> key to enter. Press <Esc> key will exit this menu.

User’s Manual

Page 56

4-2 Chapter 4

This is the “Configure/View SCSI Controller Settings” menu. Carefully configure

your settings. Press <F6> key will reset to SCSI Controller defaults.

This is the “SCSI Disk Utilities” menu. SCSI ID #7 is reserved for SCSI controller

only.

SI-2P+

Page 57

Driver Installation 5-1

Chapter 5. Driver Installation

All the necessary drivers are included within the Drivers & Utilities CD that came

packaged with your board. The display shown in the following figure should appear

after inserting this CD into your CD-ROM drive, if not, enter [My Computer]

[CD-ROM] Drive double click [autorun.exe]. Please follow the on-screen

instruction.

User’s Manual

Page 58

5-2 Chapter 5

5.1. Setup Items

• Intel Chipset Software Utility

Install Intel chipset driver for Windows Operating System.

• ATI VGA Driver

Install ATI VGA graphic driver for Windows Operating System.

• Intel LAN Driver

Install the drivers needed to run Fast Ethernet controller. The operating

systems supported are Windows, Windows XP 64-bit, Linux, Netware, and

FreeBSD.

• Adaptec Ultra320 Driver

Install Adaptec Ultra320 SCSI driver for Windows Operating System.

• Manual

View the user’s manual in PDF.

• Utility

Click to enter the sub-screen for installing software like Storage Management,

Award Flash, DirectX8.1, LoFormat, and Utility Acrobat Reader.

• Hardware Doctor

Install the Hardware Doctor program for monitoring the system health.

• Browse CD

Browse the contents of this CD-ROM.

• Close

Exit the CD setup Items Menu.

SI-2P+

Page 59

Driver Installation 5-3

5.2. Installing Ultra320 SCSI Controller

5.2.1.

5.2.2.

Installing Windows 2000 with an Ultra320 SCSI Controller

1. Start your system with the Windows 2000 Boot CD-ROM in the

CD-ROM drive. Note: When using a CD-ROM drive to install Windows

2000 from the bootable CD-ROM, make sure Bootable CD-ROM support

is enabled. This is done through the System BIOS Setup Utility.

2. Press F6 when this message is displayed: “Press F6 if you need to install

third-party SCSI drivers”.

3. When prompted, press “S” to supply the new driver.

4. Insert the Adaptec Ultra320 FMS driver disk when the setup prompts you

to insert the manufacturer supplied disk into drive A, and press Enter.

5. The screen displays the adapter drivers supported on the disk. Select

“Adaptec Ultra320 SCSI Cards (Win2000)” and continue with the rest of

the Windows 2000 installation.

6. Your system will reboot once more to finish setting up Windows 2000.

Installing the Driver when Windows 2000 is Already Installed

1. Start Windows 2000. Windows 2000 will automatically discover the new

hardware and start the Found New Hardware Wizard to guide you through

the device driver installation.

2. At the Welcome to the Found New Hardware Wizard window, select

Next.

3. On the Install Hardware Device Drivers screen, select Display a list of the

known drivers for this device, and click Next.

4. Select the Have Disk button. You will be prompted to insert the

manufacturer supplied disk. Insert the Adaptec Ultra320 FMS driver disk

in your disk drive and enter the following path, then click OK.

a:\win2000

5. Select the Adaptec Ultra320 driver from the list, then click the Next

button.

6. Click the Next button again to confirm the installation of the driver. You

may be prompted with this warning message: “The software you are about

to install does not contain a Microsoft digital signature ...” Ignore the

User’s Manual

Page 60

5-4 Chapter 5

warning and click Yes to continue the installation.

7. When the driver is copied on the hard drive, click Finish.

8. You will be prompted to restart the computer. Select Yes.

5.2.3. Changing SCSI Boot Controllers in Windows 2000

1. With the existing controller still installed, install the Ultra320 controller

into your system. Do not attach any devices to it at this time.

2. Boot up the operating system. Install the driver for the Adaptec Ultra320

Adapter.

3. Shut down Windows 2000. Turn off your system if necessary.

4. Switch the bootable hard drive from the old SCSI controller to the

Ultra320 controller and boot up your computer.

SI-2P+

Page 61

Trouble Shooting A-1

Appendix A. Trouble Shooting

Why the system shows incorrect CPU speed in Win2K

If you run Msinfo32.exe on a computer that has an Intel Pentium 4 Xeon 2.2-GHz or

faster processor, a very high processor speed may be shown. The Processor

information on the System Summary page shows the correct name, family, model and

stepping for the processor, but the approximate speed may be 37,000 MHz or faster.

This is because the speed of the newest Pentium processors exposes a limitation in the

speed calculation code in Msinfo32.exe.

To resolve this problem, refer to the hotfix described in the Microsoft Knowledge

Base article: “Q302857 WMI Win32_Group ASSOCIATORS Queries Are Not

Optimized”.

User’s Manual

Page 62

A-2 Appendix A

How to improve system performance for RedHat 7.2 and

RedHat 7.3

It is recommended to upgrade RedHat 7.2 to version 7.3, since there are many

improvements as well as kernel upgrade. Currently there is limitation about

multi-processor handling irq in RedHat 7.3. It is suggested to download the latest

kernel in order to improve the performance. The latest kernel 2.4.18 need patch to fix

multi-processor handle irq limitation. Please use the following steps to build the

kernel.

Download the latest kernel from http://www.kernel.org

linux-2.4.18.tar.gz .

# mv linux-2.4.18.tar.gz /usr/src

# gunzip linux-2.4.18.tar.gz (unpack the kernel)

# tar xvf linux-2.4.18.tar (extract form kernel tar file)

# patch -p0 < irq.patch (update necessary patch)

# cd linux

# make mrproper

# make xconfig

# make dep

# make clean

# make bzImage

# cp /usr/src/linux/arch/i386/boot/bzImage /boot/vmlinuz-24188irqbal

# make modules

# make modules_install

# mkdinitrd /boot/initrd.2.4.18.img 2.4.18

# cp /usr/src/linux/System.map /boot/System.map-2.4.18-irqbal

# cd /boot

# ln -s System.map-2.4.18-irqbal System.map

# add following entries to /etc/lilo.conf

image=/boot/vmlinuz-24188irqbal

label=lin24188irqbal

initrd=/boot/initrd-2.4.18.img

read-only

root=/dev/hda2

# lilo

# reboot

, for example:

SI-2P+

Page 63

Trouble Shooting A-3

How to access system memory in excess of 4GB for Microsoft

Windows 2000 Advanced Server and Datacenter Server

Microsoft Windows 2000 Advanced Server and Datacenter Server support memory in

excess of 4GB of RAM by way of the Intel Physical Addressing Extension (PAE)

specification. Windows 2000 Advanced Server is limited to 8GB, and Windows 2000

Datacenter Server is limited to 64GB.

You can enable PAE in the “Boot.ini” file. To enable PAE, follow these steps:

1. Locate the Boot.ini file, typically in the root folder (for example, C:) and

remove its read-only attribute.

2. Open the Boot.ini file, and then add the /PAE parameter to the ARC path, as

shown in bold format in the following example:

multi(0)disk(0)rdisk(0)partition(2)\WINNT= “Windows 2000 Advanced

Server” /PAE /basevideo /sos

3. On the File menu, click Save.

4. Restore the read-only attribute to the Boot.ini file.

Even with PAE enabled, the underlying architecture of the system is still based on

32-bit linear addresses. This effectively retains the 2GB of application space and the

2GB of kernel mode space because only 4GB of addresses are available. However,

multiple processes can immediately benefit from the increased RAM because they are

less likely to encounter physical memory restrictions and begin paging. Additionally,

applications can be modified to use the AWE API to allocate memory outside of the

applications process space, bypassing the 2-GB limit for applications.

User’s Manual

Page 64

A-4 Appendix A

Why the system hung when it detects AIC7xxx driver under

RedHat 7.2

The AC7xxx driver in RedHat 7.2 is old for AIC-7902. Please use the following steps

to do the installation:

1. Boot from RedHat 7.2 CD-ROM.

2. At boot prompt, type <expert noprobe>.

3. Select the appropriate language, country, and etc.

4. Choose “add devices” to list device drivers.

5. Select “new experimental .... aic7xxx_mod”. The aic7xxxx_mod will be

loaded, instead of the regular aic7xxx driver.

6. Complete the installation.

SI-2P+

Page 65

How to Get Technical Support B-1

Appendix B. How to Get Technical Support

(From our website) http://www.abit.com.tw

(In North America) http://www.abit-usa.com

(In Europe) http://www.abit.nl

Thank you for choosing ABIT products. ABIT sells all our products through

distributors, resellers and system integrators; we have no direct sales to end-users.

Before sending email for tech support please check with your resellers or integrators if

you need any services, they are the ones who sold you your system and they should

know best as to what can be done, how they serve you is a good reference for future

purchases.

We appreciate every customer and would like to provide the best service to you.

Providing fast service to our customers is our top priority. However we receive many

phone calls and a huge amount of email from all over the world. At the present time it

is impossible for us to respond to every single inquiry. Therefore it is quite possible

that if you send an email to us that you may not receive a response.

We have done many compatibility tests and reliability tests to make sure our products

have the best quality and compatibility. In case you need service or technical support,

please understand the constraint we have and always check with the reseller who

sold the product to you first.

To expedite service, we recommend that you follow the procedures outlined below

before contacting us. With your help, we can meet our commitment to provide the

best service to the greatest number of ABIT customers:

1. Check the Manual. It sounds simple but we have taken a lot of care in making a

well-written and thorough manual. It is full of information that doesn't only

pertain to motherboards. The CD-ROM included with your board will have the

manual as well as drivers. If you don't have either one, go to our Program

Download Area of the Website or FTP server.

2. Download latest BIOS, software or drivers. Please go to our Program

Download area on our Website to check to see if you have the latest BIOS. They

are developed over periods of time to fixes bugs or incompatibilities. Also please

make sure you have the latest drivers from your peripheral cards makers!

3. Check the ABIT Technical Terms Guide and FAQ on our Website. We are

trying to expand and make the FAQs more helpful and information rich. Let us

know if you have any suggestions. For hot topics check out our HOT FAQ!

User’s Manual

Page 66

B-2 Appendix B

4. Internet Newsgroups. They are a great source of information and many people

there can offer help. ABIT's Internet News group,

alt.comp.periphs.mainboard.abit

information and discuss experiences they have had with ABIT products. Many

times you will see that your question has already been asked before. This is a

public Internet news group and it is reserved for free discussions. Here is a list of

some of the more popular ones:

alt.comp.periphs.mainboard.abit

comp.sys.ibm.pc.hardware.chips

alt.comp.hardware.overclocking

alt.comp.hardware.homebuilt

alt.comp.hardware.pc-homebuilt

5. Ask your reseller. Your ABIT authorized distributor should be able to provide

the fastest solution to your technical problem. We sell our products through

distributors who sell to resellers and stores. Your reseller should be very familiar

with your system configuration and should be able to solve your problem much

more efficiently than we could. After all, your reseller regards you as an important

customer who may purchase more products and who can urge your friends to buy

from him or her as well. They integrated and sold the system to you. They should

know best what your system configuration is and your problem. They should have

reasonable return or refund policies. How they serve you is also a good reference

for your next purchase.

, is an ideal forum for the public to exchange

6. Contacting ABIT. If you feel that you need to contact ABIT directly you can

send email to the ABIT technical support department. First, please contact the

support team for the branch office closest to you. They will be more familiar with

local conditions and problems and will have better insight as to which resellers

offer what products and services. Due to the huge number of emails coming in

every day and other reasons, such as the time required for problem reproduction,

we will not be able to reply to every email. Please understand that we are selling

through distribution channels and don't have the resources to serve every end-user.

However, we will try to do our best to help every customer. Please also remember

that for many of our technical support team English is a second language, you will

have a better chance of getting a helpful answer if your question can be

understood in the first place. Be sure to use very, simple, concise language that

clearly states the problem, avoid rambling or flowery language and always list

your system components. Here is the contact information for our branch offices:

SI-2P+

Page 67

How to Get Technical Support B-3

North America and South America:

ABIT Computer (U.S.A.) Corporation

45531 Northport Loop West,

Fremont, California 94538, U.S.A.

Tel: 1-510-623-0500

Fax: 1-510-623-1092

sales@abit-usa.com

technical@abit-usa.com

http://www.abit-usa.com

U.K. and Ireland:

ABIT Computer (U.K.) Corporation Ltd.

Unit 3, 24-26 Boulton Road,

Stevenage, Herts SG1 4QX, U.K.

Tel: 44-1438-228888

Fax: 44-1438-226333

sales@abitcomputer.co.uk

technical@abitcomputer.co.uk

Germany, Benelux (Belgium, Netherlands, Luxembourg),

Denmark, Norway, Sweden, Finland, and Switzerland:

AMOR Computer B.V. (ABIT’s European Office)

Van Coehoornstraat 7,

5916 PH Venlo, The Netherlands

Tel: 31-77-3204428

Fax: 31-77-3204420

sales@abit.nl

technical@abit.nl

http://www.abit.nl

Austria, Czech, Romania, Bulgaria, Yugoslavia, Slovakia,

Slovenia, Croatia, Bosnia, Serbia, and Macedonia:

Asguard Computer Ges.m.b.H

Schmalbachstrasse 5,

A-2201 Gerasdorf/Wien, Austria

Tel: 43-1-7346709

Fax: 43-1-7346713

asguard@asguard.at

User’s Manual

Page 68

B-4 Appendix B

Japan:

ABIT Computer (Japan) Co. Ltd.

Fax: 81-3-5396-5110

http://www.abit4u.jp

Shanghai:

ABIT Computer (Shanghai) Co. Ltd.

Tel: 86-21-6235-1829

Fax: 86-21-6235-1832

http://www.abit.com.cn

Russia:

ABIT Computer (Russia) Co. Ltd.

Fax: 7-095-937-2837

techrussia@abit.com.tw

http://www.abit.ru

France, Italy, Spain, Portugal, and Greece:

ABIT Computer France SARL

Tel: 33-1-5858-0043

Fax: 33-1-5858-0047

http://www.abit.fr

All other territories not covered above please contact

Taiwan Head Office:

When contacting our headquarters please Note we are located in Taiwan and we are

8+ GMT time. In addition, we have holidays that may be different from those in your

country.

ABIT Computer Corporation

No.323, Yang Guang St., Neihu,

Taipei, 114, Taiwan

Tel: 886-2-8751-8888

Fax: 886-2-8751-3382

server_sales@abit.com.tw

market@abit.com.tw

technical@abit.com.tw

http://www.abit.com.tw

SI-2P+

Page 69

How to Get Technical Support B-5

7. RMA Service. If your system has been working but it just stopped, but you have

not installed any new software or hardware recently, it is likely that you have a

defective component. Please contact the reseller from whom you bought the

product. You should be able to get RMA service there.

8. Reporting Compatibility Problems to ABIT. Because of tremendous number of

email messages we receive every day, we are forced to give greater weight to

certain types of messages than to others. For this reason, any compatibility

problem that is reported to us, giving detailed system configuration information

and error symptoms will receive the highest priority. For the other questions, we

regret that we may not be able to reply directly. But your questions may be posted

to the Internet news group in order that a larger number of users can have the

benefit of the information. Please check the news group from time to time.

Thank You

ABIT Computer Corporation

http://www.abit.com.tw

User’s Manual

Page 70

B-6 Appendix B

Technical Support Form

Company Name: Phone Number:

Contact Person: Fax Number:

E-mail Address:

Model * BIOS ID # *

Motherboard Model No. DRIVER REV

OS/Application *

Hardware Name Brand Specifications

CPU *

IDE1

HDD

CD-ROM-Drive

System Memory

ADD-ON CARD

IDE2

IDE1

IDE2

Problem Description:

SI-2P+

Loading...

Loading...