Page 1

IV Medication Management System

For use with list 40051-04

System

Operating

Manual

Abbott

Laboratories

North Chicago, IL 60064

USA

430-0637

1 -CO4 (Rev.

8/W

VERSION

1.11

SERIES

Page 2

Section 1

INTRODUCTION

Contents

1

- 1

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IV

1.1 FEATURES OF THE

1.2

SAFETYFEATURES

1.3

WARNINGS,CAUTIONS,ANDNOTES

MEDICATION MANAGEMENT SYSTEM

................................

......................

1.4 INSTRUMENT INSTALLATION PROCEDURES

1.4.1 UNPACKING INSTRUCTIONS

1.4.2 INSPECTION

...............................

1.4.3 40OOPLUSSELFTEST

1.4.4 PRINTERSETUP

.............................

.......................

..........................

Section 2

EQUIPMENT DESCRIPTION

2.1 BACKLITDISPLAYSCREEN

2.2 ESCAPEFUNCTION

2.3 BASESCREEN

..................................

...........................

...............................

2.4 PROGRAMMING INPUT INDICATOR (CURSOR)

2.5 LED STATUS INDICATORS

2.6 NOTATIONAREAS

2.7 PRINTER

.....................................

................................

............................

Section 3

SETUP . . . . . . . . . . . . . . . . . . . .

..=-...................3-1

..................

.................

.........

-

1

1

l-2

l-3

-

3

1

-

3

1

l-4

l-4

l-4

-

1

.

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-l

2-l

2-l

-

2

2

-

3

2

2-3

2-4

3.1 SETUPPROCEDURES

3.1.1 RESTOREPREVIOUSPROGRAMMING

3.1.2 INITIATE NEW PROGRAMMING

3.1.3

RESPONSETOLOWBAlITERYCONDI’TION

3.2 PRIMING PROCEDURES: PRIMARY ADMINISTRATION SET

3.2.1 CASSE’ITEPRIMINGMODES

CASSETTEPOWERPRIME(LINEA).

GRAVITYPRIME

3.2.2

3.2.1.1

3.2.1.2

PRIMINGTHECASSETI’E

3.2.3 PATIENTLINEPRIMINGMODES

3.2.3.1

PATlENTLINEPOWERPRIME

3.2.3.2 PATIENTLINEGRAVITYPRIME

3.2.4 PRIMINGTHEPATIENTLINE.

3.2.5

CASSE-ITE~ST

3.2.5.1

3.2.5.2

CASSE’lTETESTFAILED

CASSE’ITETEST

..............................

.......................

.........................

.........................

......................

.............................

SATISFACTORY

..................

.....................

...............

...........

..............

.....................

.................

.................

....................

................

3.3 PRIMING PROCEDURES: PRIMARY ADMINISTRATION SET

WITHGRAVITYFLGWPREVENTIONVALVE

3.4 PRIMING PROCEDURES: SECONDARY ADMINISTRATION SET

3.5 CONNECTINGASYRINGETOTHECASSE-ITE

3.6 CONNECTING A SYRINGE AND SYRINGE ADAPTOR TO THE CASSETTE

3.7 REMOVINGTHE CASSETTE

FROMTHE DEVICE

...................

........

................

...

...............

3

3

3

3

3-l

3-2

-

3

3-3

-

3

3-6

3-6

3-6

3-6

3-7

3-7

-

3

3-7

3-8

3-8

-

3-9

-

10

-

11

-

12

-

13

2

4

7

3

9

Omni-Flow 4000 Plus

IV

Medication Management System

iii

430-06371-004 (Rev.

4/!33)

Page 3

Contents

Section

PROGRAMMING

4

4.1 MAINTENANCE INFUSIONS

4.2 CONTINUOUS INFUSIONS

4.2.1

ML/HRINFUSIONS.

4.2.1.1 PROGRAMMING OR CHANGING AN

4.2.1.2 CHANGING AN

UNITOFMEASUREINFUSION

4.2.2 ALTERNATE UNITS OFMEASURE

4.2.2.1

PROGRAMMING A NEW ALTERNATE UNIT OF

MEASURE INFUSION

4.2.2.2 CHANGING

AN

4.2.2.3 CHANGING AN ALTERNATE UNIT OF MEASURE

INFUSIONTOML/HRINFUSION

4.2.3 CHANGINGTHEGLOBALBODYWEIGHT

4.2.4 CONCURRENTFLOW..

4.3 INTERMITTENT INFUSIONS

Section 5

ADDITIONAL OPERATING FEATURES

TOSTOPANYOFTHELINES

5.1

HOLDANDRESUMEFUNCTIONS

5.2

...........................

5.2.1 HOLDINDMDUALLINESORALLLINES

5.2.2 RESUMEINFUSIONSAFTERHOLD

LINESIJATUSFUNCTION

5.3

SPECLAL

5.4

5.4.1

AUTOMATIC AIR DETECTION AND ELIMINATION

5.5

EMPTYINGTHECOLLECTIONBAG

5.6

BA?TERY

5.7

ACCESSING HISTORY REPORTS

5.8

5.8.1

FUNCTIONS.

DESCRB?-I’ION

OPERATION

ACCESSING HISTORY REPORTS WITHOUT A PRINTER

.............................

..............................

OF SPECIAL FUNCTIONS

.............................

5.8.2 ACCESSING HISTORY REPORTS

5.8.2.1

5.8.2.2

DEVICESTATUSREPORT.

IVHISTORYREPORT

ML/HR

INFUSION TO AN ALTERNATE

ALTERNATE

........................

......................

........................

WITH

.....................

.

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ML/HR

INFUSION

(MCG/KG/MIN)

INFUSIONS

. . . . . . . . . . _ . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . .

UNITOF MEASURE INFUSION

................

...................

.................

...............

........

A PRINTER

..................

..........

.

4

. . . . . . . . . . . . . . . . . . . . . . . . . .

.

4

4-2

.

4

. . .

. . . . . . . . . . . . . . . .

.

4

. . . . . . . _ . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

.

4

. . . . . . . . . . . . . . . . . _ . . . . . . . .

.

5

. . . . . . . . . . . . . . . . . . . . . . . . . .

-

.

4-3

.

4

. . . .

.

4

.

.

4-5

. . . . . . . . . . . . . . .

.

4-6

. . . . . . . . . . . . . . .

.

4-7

5

5-

5

5

5

5

5-14

5-

1

-

1

-

2

-

2

-

4

-

8

-

1

5-l

5-2

5-2

5-3

5-3

5

5

-

-

-

-

-

-

4

-

5

-

4

-

5

11

11

12

13

13

14

14

Section 6

ALARMCONDITIONSANDDISPLAYS

6.1

FLUIDDELIVERYALARMS

6.2 PUMPING

6.3 WARNINGALARMS

Section

7

ALARMS..

............................

................................

TROUBLESHOOTING

7.1 TROUBLESHOOTING GUIDE

Section 8

CLEANING AND DISINFECTING

430-06371-804 (Rev.

7195)

.

............................

iv

.

6-l

. . . . . . . . . . . . . . . . . . . . . . . . .

6-2

..6- 3

6-3

-

1

.

7

. . . 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

1

.

7

System Operating Manual

. . . . . . . . . . . . . . . . . . . . . . . . . .

-

1

.

8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

Section 9

WARNINGS, CAUTIONS AND PRECAUTIONS

.....................

Contents

9-l

9.1 WARNINGS.

9.2 CAUTIONS

9.3 PRECAUTIONS

.................................

..................................

................................

Section 10

SERVICE AND PERFORMANCE INFORMATION . . . . . . . . . . . . . . . . . . . .

Section 11

4oooPLussETs

IVADMINISTRATIONSETS

11.1

11.2ACCESSORY

...................................

..........................

SETS

..............................

Section 12

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 13

KEYPAD

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-l

9-2

9-3

-

10

-

11

-

11

11-2

-

12

-

13

1

1

1

1

1

Section 14

-

1

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copyright 1996 Abbott Laboratories

All Rights Reserved

14

This document and the subject matter disclosed herein are proprietary information. Abbott Laboratories

retains all the exclusive rights of dissemination, reproduction, manufacture and sale. Any party using

this document accepts it in confidence, and agrees not to duplicate it in whole or in part nor disclose it to

others without the written consent of Abbott Laboratories.

Omni-Flow 4000 Plus IV Medication Management System

(Rev.

8/96)

V

430-06371

-CO4

Page 5

Section 1

INTRODUCTION

The Omni-Flow 4000

Omni-Flow 4000, with added data communications capability and new data entry screens which

incorporate automatic calculation, plus programming from alternate units of measure entry.

Plus IV Medication Management System incorporates all the features of the

1.1

FEATURES OF THE IV MEDICATION

MANAGEMENT SYSTEM

Incorporating microprocessor electronic design and safety features, the 4000 Plus represents a

major advance in instrumentation for the delivery and management of intravenous therapy.

The 4000 Plus includes the following capabilities of the Omni-Flow 4000:

Four-channel medication delivery through a single patient line

Programmable

Multi-dose containers

Programmable automatic in-line dilution

Programmable automatic flushing between incompatible medications

Any combination of both continuous and intermittent infusions

Real-time clock

irom

Infuses

Automatic air detection and elimination

Needleless connections

combinations of bags, bottles. and syringes

Additional capabilities of the 4000 Plus include:

ail

0

Programmable in

Q

RS-232 communication (for printers)

CI

Date/time stamp (optional) of blood chemistry, hematology, vital signs, and other medication

administration

Q

Detailed documentation, through the following printed reports (on demand):

-

Device Status Report:

Line status A, B, C, and D (ON, OFF, PGM, HLD, INF,

Dilution and flush data

Current infusion regimen details

Time and volume remaining in dose

-

IV Flow Sheet

Omni-Flow 4000 Plus IV Medication Management System

Mcg/Kg/Min

on

channels

l-l

DLY)

430-06371-004 (Rev.

4/93)

Page 6

Section 1 INTRODUCTION

-

IV History Report:

Line mode changes: off, on, intermittent infusion, hold, dilute, delay, flush, KVO,

programmed

Records details of infusion: as programmed, actual delivered, regimen changed

Records non-infusion event documentation: blood, hematology, blood chemistry,

vital signs

All events date/time stamped

P

Programming and

Selective hold for each medication

0

Advanced programming to preprogram all lines and place lines on hold

0

Automatic power prime of Line A for minimum solution waste

0

Prioritized alarms stacked and presented sequentially for resolution

CI

Additional alarms: full collection bag, transfer to battery, external communications fault

CI

User selected power-up defaults:

memory

retention following power OFF

IineD

until

needed

- Time: 12-hour AM/PM or 24-hour military format

-

KVO:

to 99.9

mL/hr,l.O

-

1 to 12 psi (in 1 psi increments)- Patient line occlusion alarm

- Units of temperature: degrees Centigrade or Fahrenheit

Callbacks-

0

Local display of IV History Report on LCD Display

1.2 SAFETY FEATURES

The 4000 Plus

maximiz

The device automatically performs a

when the [ON/CHARGE] switch is placed in the ON position

ION/CHARGEl

If the

most recent

during power up (see Section 3.

The device maintains duplicate programming memory.

information does not match, the device alarms

A two-step procedure is required to remove the cassette from the device

To change pumping instructions (rates, volume, stopping lines), two keys must be pressed

in order

A comprehensive self test

cassette, and interface. This 36-second cassette test is activated every time the [PRIME

PATIENT LINE) (ENTER) key sequence is pressed

progr

es

safety and reliability with the following features:

self

test of its electrical and mechanical components

switch is turned to CHARGE during infusion, the device retains the

amming

and infusion data in a nonvolatile memory. The data is reinstated

procedures)

Setup

I,

If the duplicate programming

identiiies

a variety of potential malfunctions within the device,

Note: The user can bypass the cassette test; however, Abbott Laboratories recommends the routine

use of this test.

430-06371-004 (Rev.

4/93)

l-2

System Operating Manual

Page 7

1.3 WARNINGS, CAUTIONS, AND NOTES

1.3

WARNINGS, CAUTIONS, AND NOTES

Throughout this manual, three types of alert messages are used: warnings, cautions, and notes,

as described below. Pay attention to all alert messages.

WARNING

A WARNING CONTAINS SPECIAL SAFETY EMPHASIS AND MUST BE OBSERVED AT ALL

TIMES.

FAILURE TO OBSERVE A WARNING IS POTENTIALLY LIFE THREATENING.

CAUTION: A CAUTION

information that could prevent irreversible damage or hardware failure. Neglecting to pay

attention to a CAUTION could result in serious injury.

.

Note:

A Note highlights information that helps explain a concept or procedure.

usuaIly

appears in front of a procedure or statement. It contains

1.4 INSTRUMENT INSTALLATION PROCEDURES

utilize

In order to fully

the System Operating Manual prior to use.

PRODUCT DAMAGE MAY OCCUR UNLESS PROPER CARE IS EXERCISED DURING THE

UNPACKING AND INSTALLATION PROCESS. THE BATTERY PACK MAY NOT BE FULLY

CHARGED UPON RECEIPT.

TEST.

Note:

Instrument

4000 Plus capabilities. it is important to become thoroughly familiar with

WARNING

lT

FAILS THE SELF

instahation

should be performed by qualified personnel only.

DO NOT PLACE THE DEVICE IN SERVICE IF

1.4.1

UNPACKING INSTRUCTIONS

Each shipping carton should contain the following items:

0

Omni-Flow 4000 Plus IV Medication Management System with attached power cord

Omni-Fiow

c3

Carefully remove the device from the shipping carton. The carton should be retained in the event

the device needs to be shipped.

Omni-Flow 4000 Plus IV Medication Management System

4000 Plus System Operating Manual

-

3

1

430-06371-004 (Rev.

4193)

Page 8

1

Section

INTRODUCTION

1.4.2

INSPECTION

Inspect the packing container for visible shipping damage.

the delivering carrier immediately.

Freight claims or insurance claims must be

Should any damage be found, contact

filed

within seven

days.

Inspect the device for damage.

Do not use the device if it appears to be damaged; contact the

Abbott Laboratories Technical Service Center.

CAUTION: If device appears to be damaged, do not operate: return for service.

Plug the power cord into a 1

lO/

120 volt AC outlet. The device is ready for immediate AC use.

Do

not operate the device on battery power until it has been plugged into an electrical outlet for at

least 24 hours.

Locate the [ON/CHARGE] switch on the back of the device and toggle the switch to the ON position.

Unlock the cassette locking lever and remove the shipping cassette.

Cassettefrom

fhe Device, for additional information on removing a cassette. Discard the shipping

See Section 3.5,

Removing

the

cassette: do not use.

1.4.3

4000

Do not place the 4000 Plus in service until the

Procech.ues,

PLUS SELF TEST

self test has been conducted. See Section 3.1, Setup

for detailed information on the device self test.

1.4.4

PRINTER SETUP

The 4000 Plus allows the user to print history report information.

serial printers. The user should become thoroughly familiar with the system operating manual

which is included with the printer.

The following DIP switch configuration is for the Seiko DPU-4 11

printer. The printer operating manual should detail the printer DIP switch locations.

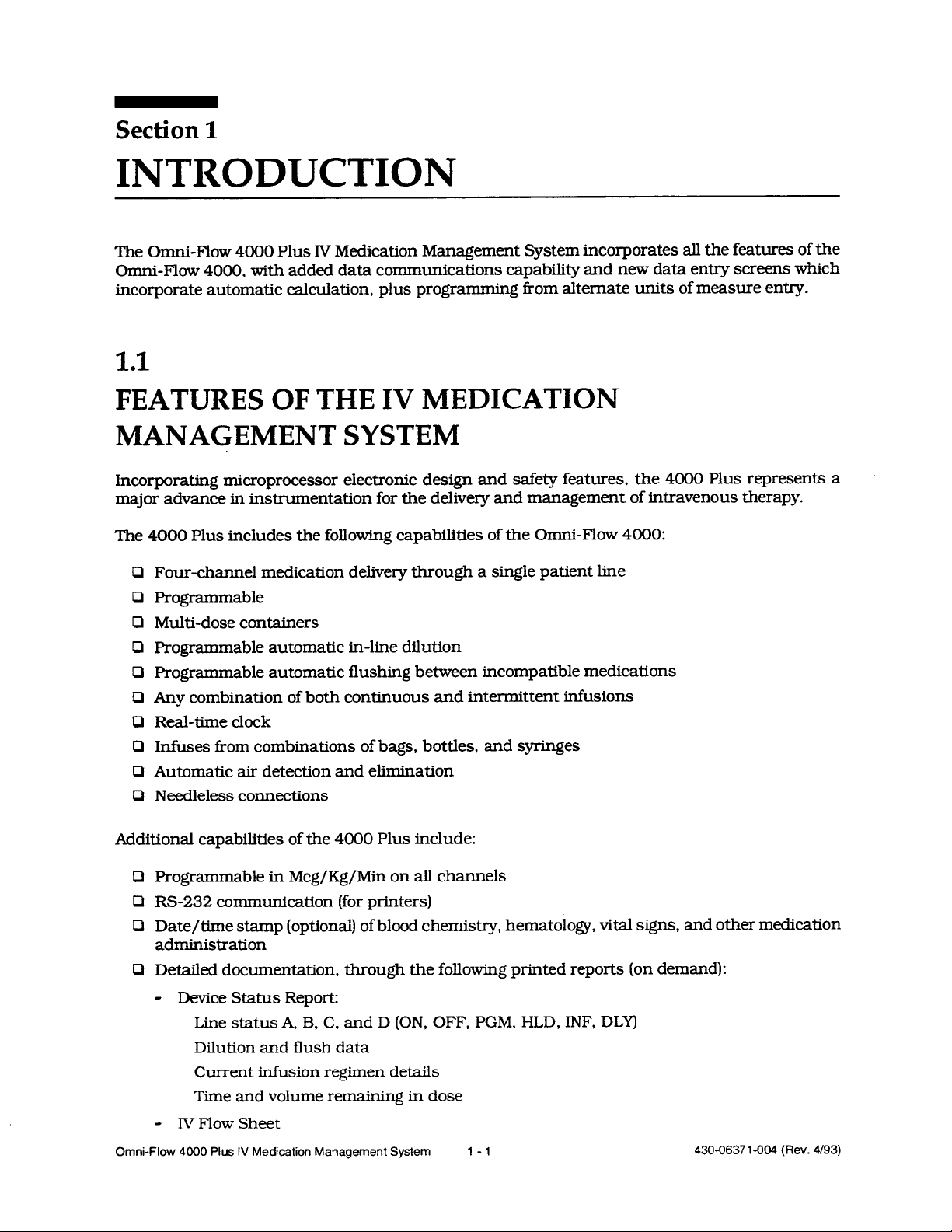

To set up the Seiko DPU-411 printer for use with the 4000 Plus, proceed as follows:

1.

Set the printer DIP switch configuration as shown in the following display:

DIP01

Note:

DIP01 switches set input data format, number of columns, and characters.

The device works with several

430-0637

l-004

(Rev.

4193)

l-4

System Operating Manual

Page 9

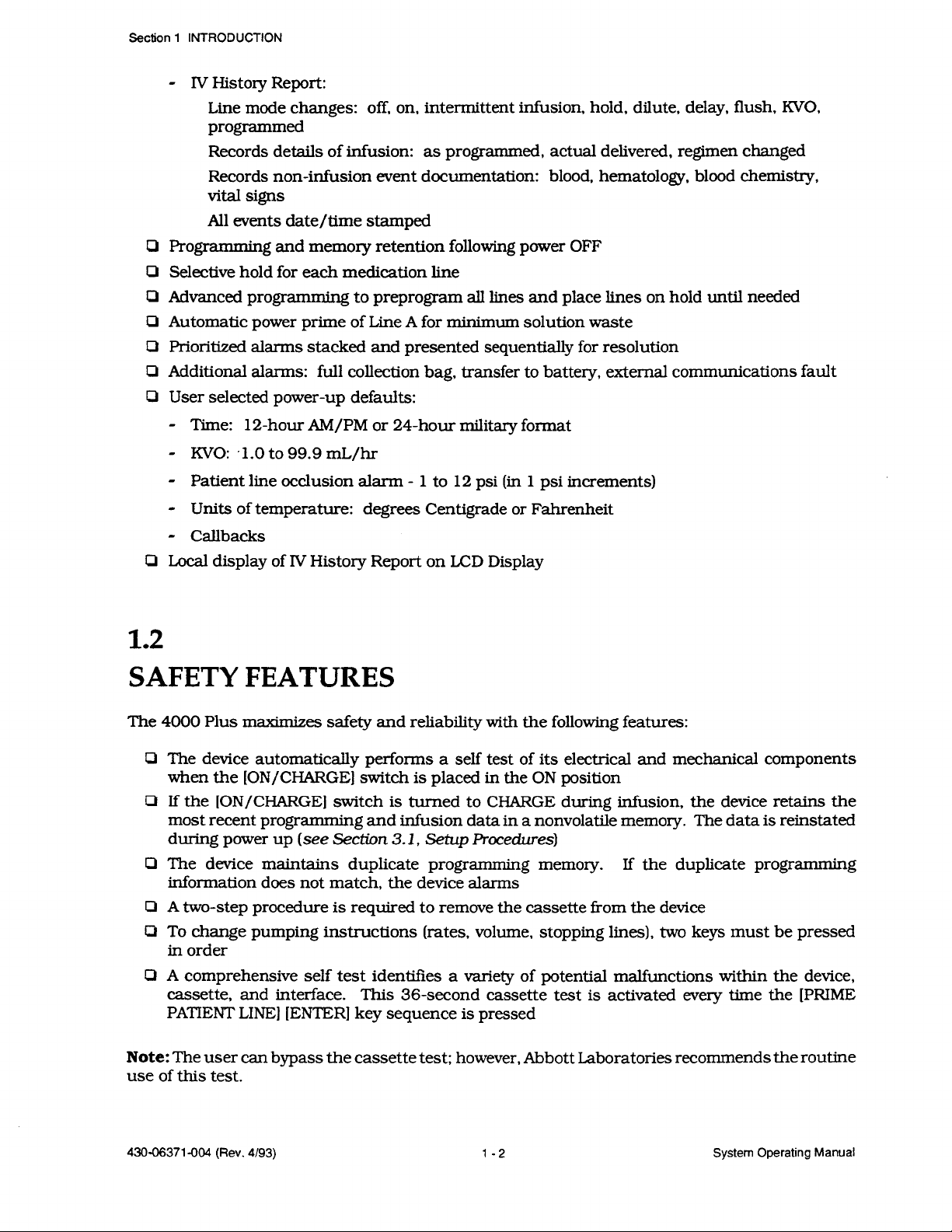

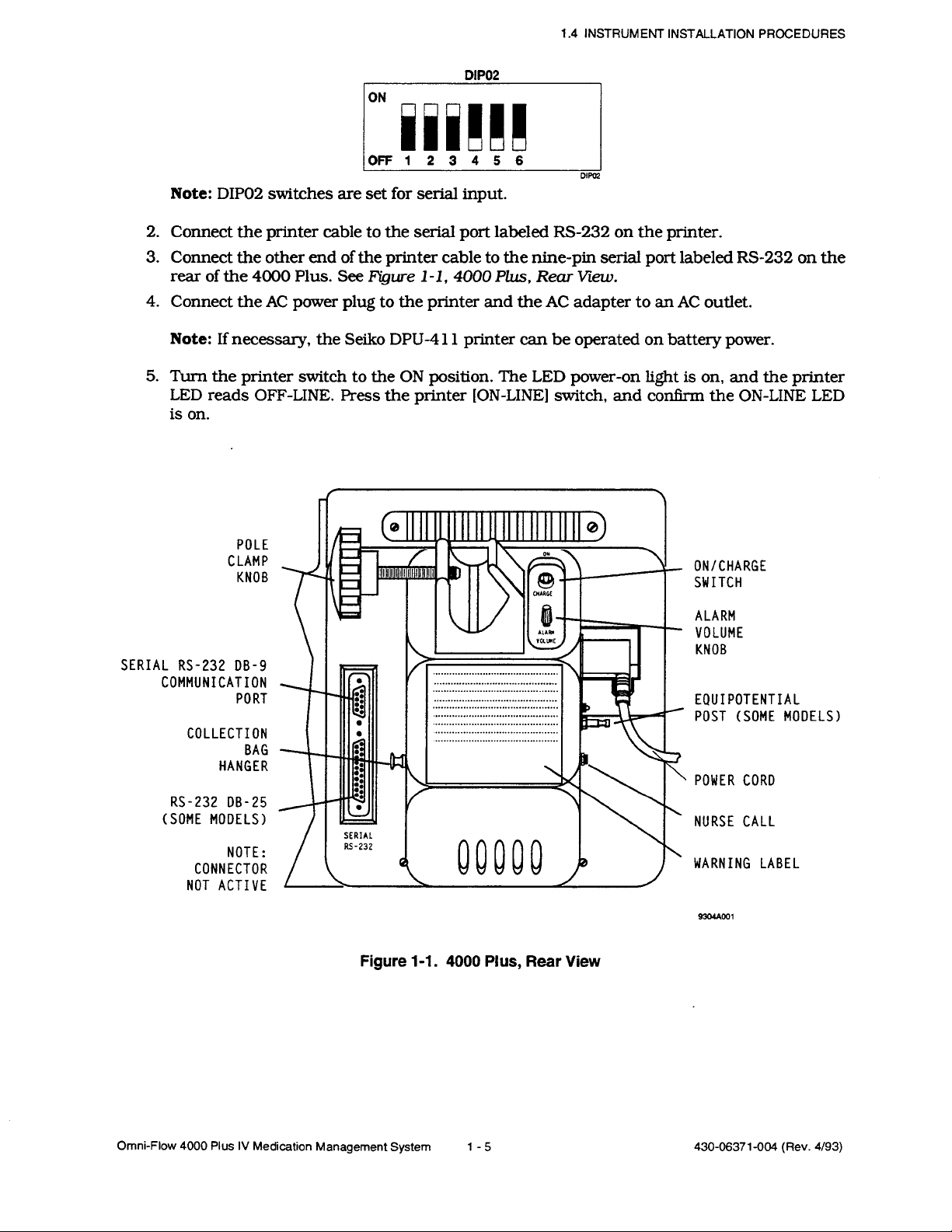

DIP02

1.4 INSTRUMENT INSTALLATION PROCEDURES

_iii!??I

Note:

DIP02 switches are set for serial input.

serial

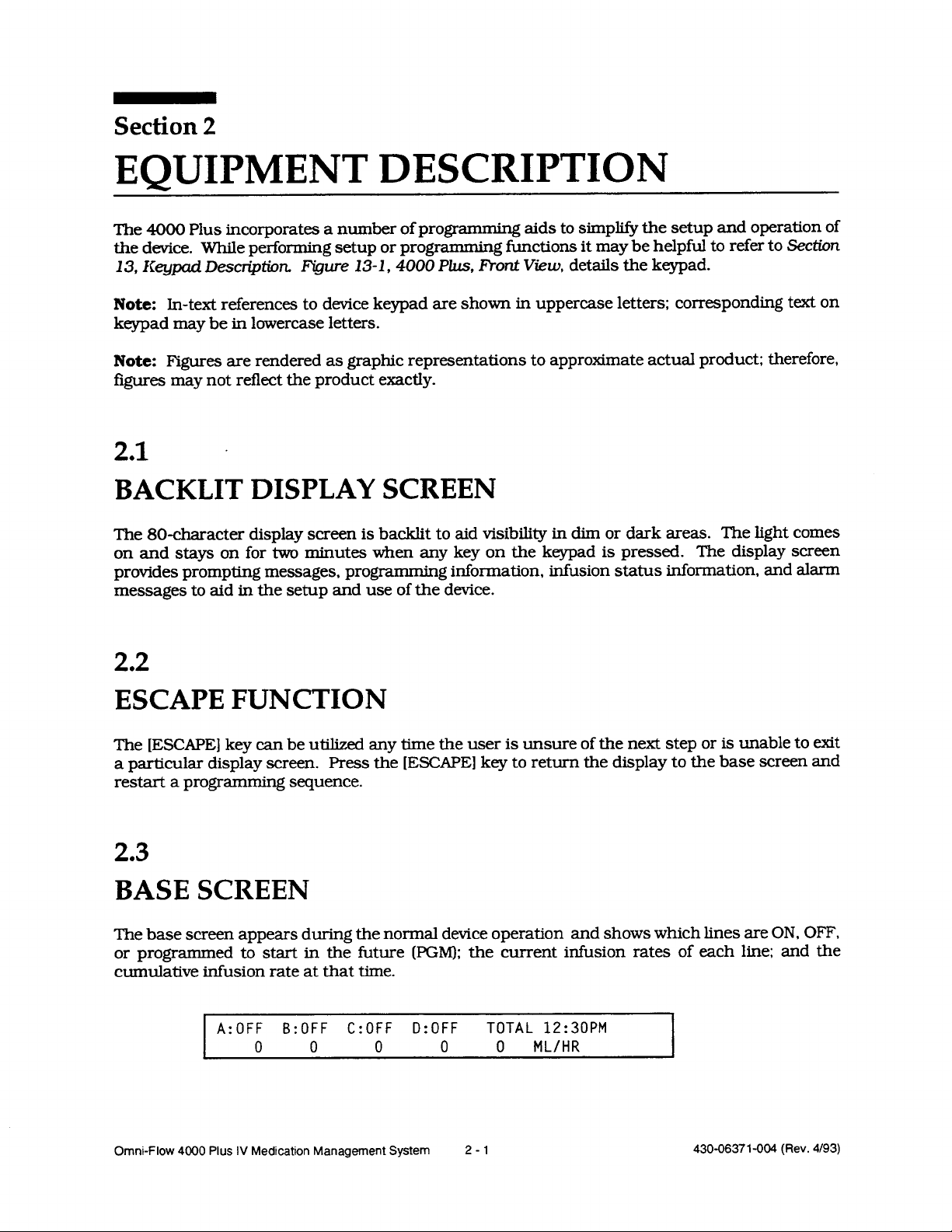

2.

Connect the printer cable to the

3.

Connect the other end of the printer cable to the nine-pin serial port labeled IRS-232 on the

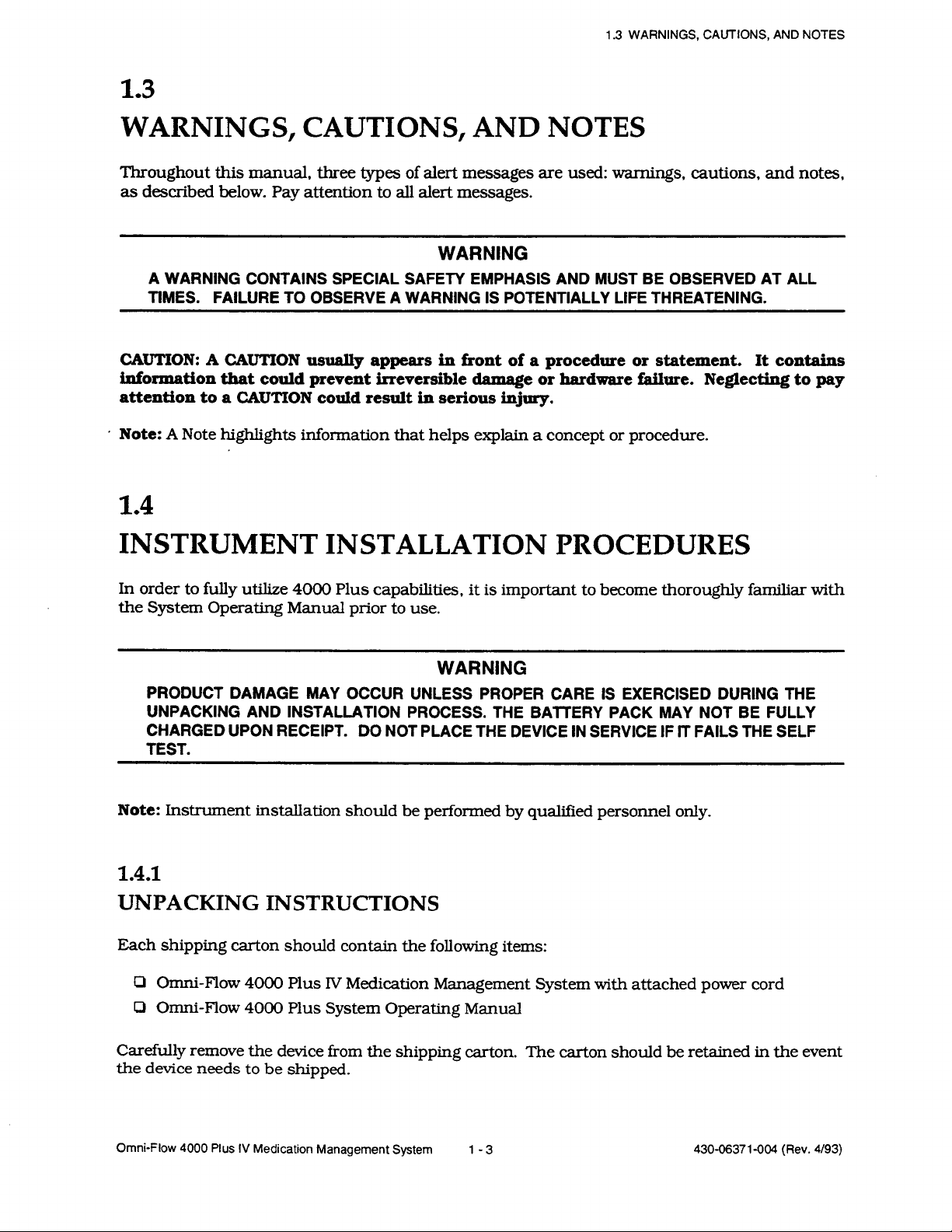

rear of the 4000 Plus. See Figure

4.

Connect the AC power plug to the printer and the AC adapter to an AC outlet.

Note:

If necessary, the Seiko DPU-4 11 printer can be operated on battery power.

port labeled RS-232 on the printer.

1

-I, 4000 Plus,

Rear

DIP@2

view.

5. Tum the printer switch to the ON position. The LED power-on light is on, and the printer

LED reads OFF-LINE. Press the printer [ON-LINE] switch, and

con&m

the ON-LINE LED

is on.

POLE

CLAMP

KNOB

ON/CHARGE

SWITCH

SERIAL RS-232 OB-9

COMMUNICATION

PORT

COLLECTION

BAG

HANGER

RS-232 OB-25

(SOME MODELS)

NOTE:

CONNECTOR

NOT ACTIVE

Figure

l-l. 4000

ALARM

VOLUME

KNOB

EQUIPOTENTIAL

POST (SOME MODELS)

POWER CORD

NURSE CALL

WARNING LABEL

Plus, Rear View

Omni-Flow 4000 Plus IV Medication Management System

1-5

430-06371-004 (Rev.

4/93)

Page 10

Section 2

EQUIPMENT

The 4000 Plus incorporates a number of prog

the device. While performing setup or progr

Ikypad

13,

Note:

keypad may be in lowercase letters.

Note: Figures are

figures may not reflect the product exactly.

Description

In-text references to device keypad are shown in uppercase letters; corresponding text on

Figure

rendered as graphic representations to approximate actual product; therefore,

DESCRIPTION

’

g aids to simplify the setup and operation

13-1,400O

amming

Plus,

functions it may be helpful to refer to Section

View, details the keypad.

Front

of

2.1

BACKLIT DISPLAY SCREEN

8O-character

The

on and stays on for two minutes when any key on the keypad is pressed. The display screen

provides prompting messages, prog

messages to aid in the setup and use of the device.

display screen is

back& to aid visibility in dim or dark areas.

*

g information, infusion status information, and alarm

The light comes

2.2

ESCAPE FUNCTION

The (ESCAPE] key can be utilized any time the user is unsure of the next step or is unable to exit

a particular display screen.

restart a programming sequence.

Press the [ESCAPE] key to return the display to the base screen and

2.3

BASE SCREEN

The base screen appears during the normal device operation and shows which lines are ON, OFF,

(PGM);

or programmed to start in the future

cumulative infusion rate at that time.

A:OFF B:OFF C:OFF

0 0 0

the current infusion rates of each line; and the

D:OFF

0 0

TOTAL

12:30PM

ML/HR

Omni-Flow 4000 Plus IV Medication Management System

2-l

430-06371-004 (Rev.

4/93)

Page 11

Section 2 EQUIPMENT DESCRIPTION

The base screen is the device status screen. During programming or operation, an intermittent

beeping tone alerts the user that the device is not in the base screen. The beeping tone is a reminder

ramming sequence is not complete. This reminder tone ceases upon return

to the user that a

prog

to the base screen.

The base screen

utilizes

each individual line:

ON

Indicates the line is currently running in the

Indicates the line is infusing an

running in the maintenance mode of operation.

DIL

LineAis

Indicates that Line A is

Indicates that Line A

intermittent infusion.

PGM

Indicates that an intermittent line is programmed to deliver a dose of medication

sometime in the future,

AND/OR

line

A is running in maintenance mode while another

if

MD

intermittent

Indicates that line operation is suspended either due to an

dose.

the user placing it on hold.

DLY

Indicates a programmed intermittent infusion

preceding intermittent infusion, being on hold (HLD), or due to a

the following indicators to assist in determining the pumping status of

diluting

is_flushing

a drug on another line.

the cassette and patient line after or before an

intenniftent

dose to the patient. Also appears if

coRtiRuous

(PGM)

mode of operation.

line

is delivering an

alarm

condition or

is being delayed due to a

flush

OFF

Indicates the line has been stopped and is OFF.

2.4

PROGRAMMING INPUT INDICATOR (CURSOR)

A flashing programming input indicator (cursor) automatically appears on the display screen at

the first information entry point.

Press the [NEXT] key to move the cursor forward.

[LAST] key to move the cursor backwards. To clear any entry where the cursor is flashing, press

the [CLEAR

Note: Several

ENTRYI

key.

programming screens do not allow an advance to the next screen if all the necessary

programming information has not been entered on that screen (i.e.,

total volume on a continuous infusion, the screen cannot be advanced).

automaticahy

moves to the entry point which is missing the required programming information.

The cursor must be moved to the next entry point on the screen.

To move to a previous entry point, press the

a

rate is entered, but not a

if

In these cases, the cursor

430-06371-004 (Rev.

4193)

2-2

System Operating Manual

Page 12

2.5 LED STATUS INDICATORS

2.5

LED STATUS INDICATORS

The front panel LED indicators located next to the alphabetical line designations (A, B, C. D),

indicate their status as follows:

D

Off when the line is off

D

Flashing when the line is infusing medication

tJ

On steadily when the line is programmed to start at a future time or the infusion of a line is

suspended (on hold).

The LED indicators located on the left side of the front panel indicate their status as follows:

-

P

AC POWER

BATTERY

LI

Q

ALARM-ill

Ij’igure

See

illuminated (green) when the device is operating on AC power.

-

illuminated (yellow) when the device is operating on battery power.

13-1,

uminated

4000

(red) when the device is in an alarm condition.

l+ont View, for location of the LED indicators.

Plus,

2.6

NOTATION AREAS

D)

The white area next to the alphabetical line designations (A, B, C,

making notations about the medication or the programming on that line.

pen or pencil should be used for these notations.

or a soft eraser.

This area can be cleaned with an alcohol swab

on the front panel are for

Anon-permanent felt-tip

Omni-Flow 4000 Plus IV Medication Management System

2-3

430-06371-004 (Rev.

4193)

Page 13

Section 2 EQUIPMENT DESCRIPTION

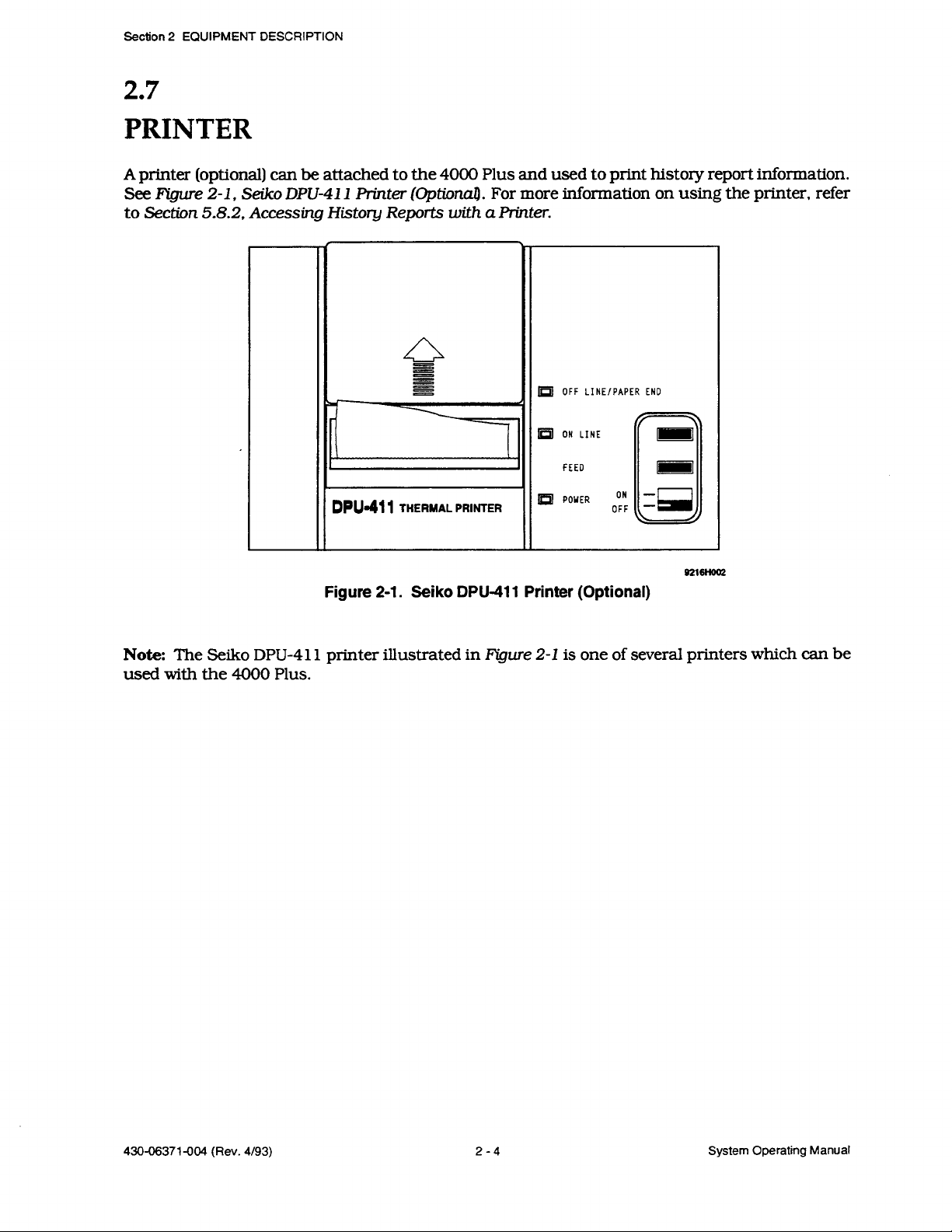

2.7

PRINTER

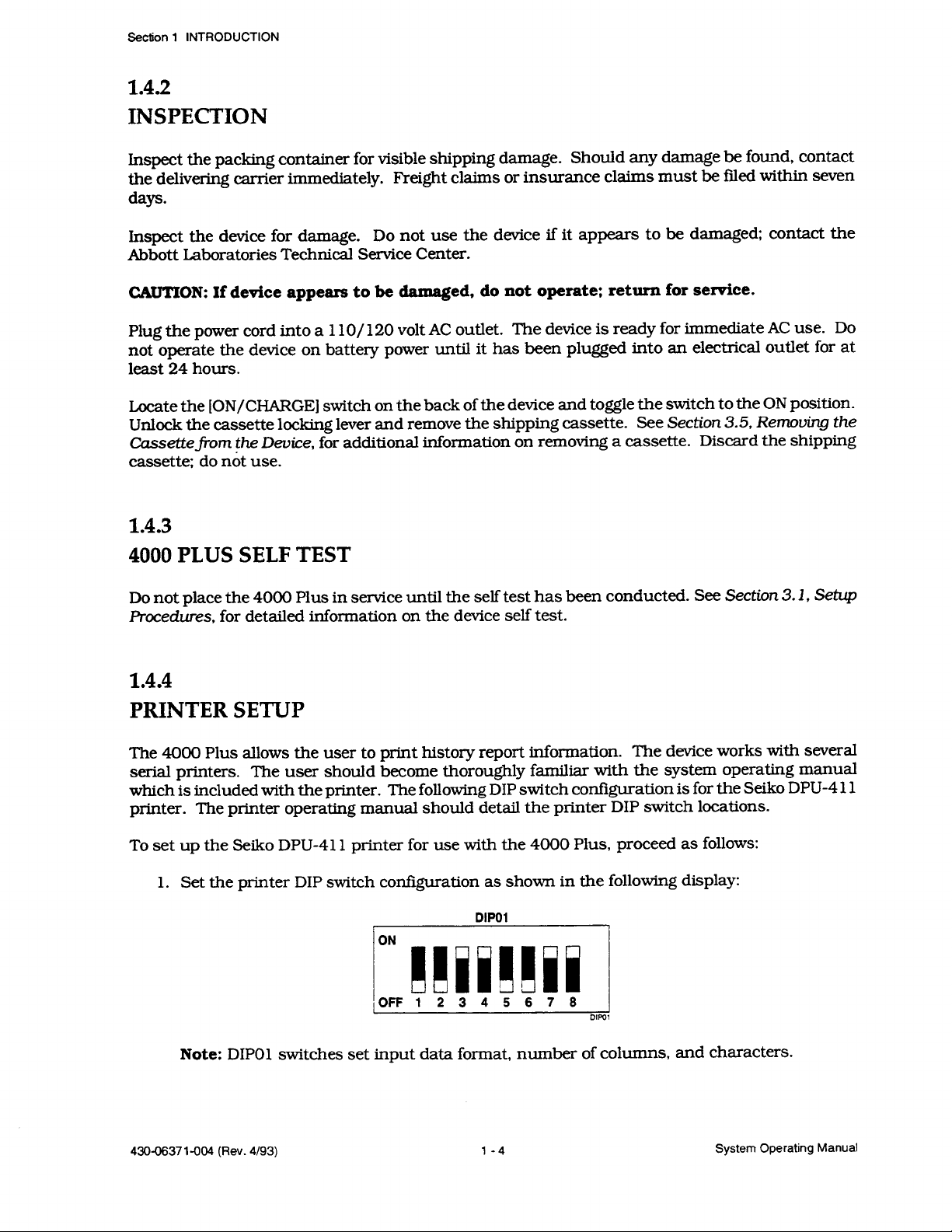

A printer (optional) can be attached to the 4000 Plus and used to print history report information.

See Figure

to Section

58.2,

DPU-41

2-I, Seiko

I

printer

(Optima&

Accessing History Reports with a Printer.

s

gg

-

For more information on using the printer, refer

m

OFF LINE/PAPER END

1

DPUJl

Figure 2-1. Seiko

THERMAL PRINTER

DPU-411

6216H602

Printer (Optional)

Note: The Seiko DPU411 printer illustrated in Figure 2-I is one of several printers which can be

used with the

4000

Plus.

430-06371-004 (Rev.

4/93) 2-4

System Operating Manual

Page 14

Section

3

SETUP

The following sections detail setup and priming procedures for the 4000 Plus.

Intmniuction,

1,

Keypad Description,

Plus,

4000

Note:

to AC power for at least 24 hours.

Rear Viw, for overview illustrations of the device.

Prior to placing the 4000 Plus in service, fully recharge the battery by connecting the device

me

13-1,400O

Plus,

Front View and Section

See Section

3.1

SETUP PROCEDURES

WARNING

ARRANGE TUBING, CORDS, AND CABLES TO MINIMIZE THE RISK OF PATIENT

STRANGULATION OR ENTANGLEMENT.

CAUTIOlt

audible.

the back of the device.

Abbott Laboratories

To set up the 4000 Plus, proceed as follows:

When

If the

programming

co&rmatory beep is inaudible, adjust the

Tech&al

the device, the confirmatory response beep should be clearly

ALARM

If after adjustment the beep is still inaudible, contact

Support Operations.

VOLUME knob located on

Figure

13,

l-l,

1.

Use the pole clamp to attach the device to an IV pole.

2.

Connect the power cord to a properly grounded 1

3. Toggle the (ON/CHARGE] switch to the ON position.

Note:

the cassette holster. If the service code appears, remove the cassette and cycle the power to

the device (power the device off, then on by toggling the

then

Confkm

4.

lights are off.

At power on, the device performs its self-test diagnostics.

seconds during which time the screen displays the following message:

Upon successful completion of the self test, the Restore Previous Programming screen displays the

following setup questions:

A service code may be displayed if the device is turned on with a cassette locked in

ON). The service code is cleared.

that the green AC POWER indicator is illuminated and that all other LED indicator

>>>>>>>> SELF TEST IN PROGRESS

ABBOTT 4000 PLUS

RESTORE PREVIOUS PROGRAMMING

CLEAR IV HISTORY

YIN? NO

lo/120 volt AC outlet.

]ON/CHARGE)

The self test lasts approximately six

<<<<<<<(

Y/N?

[ENTE:;

switch to CHARGE,

Omni-Flow 4000 Plus IV Medication Management System 3-l

430-06371-804 (Rev.

7/95)

Page 15

Section 3 SETUP

Note: The

Restore Previous Programming screen displays two setup questions. Select YES or NO

to each query before pressing the [ENTER] key. The [ENTER] key enters all setup instructions

into device memory.

3.1.1

RESTORE PREVIOUS PROGRAMMING

progr

To restore previous

Select YES to Restore Previous Programming Y/IV?. Previous programming is restored to

1.

the device.

When YES is selected to Restore

0

IV Flow Sheet

Q

Line Progr

Select NO to Clear

2.

Note:

Select YES

amming

amming:

N

to

at the Restore Previous Programming screen, proceed as follows:

Preuious

Programming Y/IV?, the following data is restored:

Any lines that were not OFF are put on HLD

Histo

y Y/N?. Previous IV history is retained.

IV

Clear

History Y/N? to remove previous patient IV history.

Press the [ENTER] key to enter all setup instructions into device memory.

3.

Note:

power is down.

During a power shut down, programmed start times for lines are delayed for as long as the

Upon power up and restoring previous programming, the user should review the

programmed information before pressing the [RESUME] key to begin programmed infusions.

Note;

conditions occur, the Restore Previous Programming

To reduce the likelihood of restoring corrupted line programming after Service Code

option is not available after the occurrence

of certain Service Code alarms. In this case, the following screen is displayed after turning power

on:

INSERT CASSETTE AND LOCK IN PLACE

4-JUN-92

PRESS [ENTER]

11:05

AM

3.1.2

INITIATE NEW PROGRAMMING

To initiate new progr

1.

Select NO to Restore Previous Programming Y/N?. Previous programming is removed from

the device.

2.

Press the [ENTER] key. The Insert Cassette and Lock In

amming

at the Restore

Preuims Programming screen, proceed as follows:

Place

screen is displayed:

INSERT CASSETTE AND LOCK IN PLACE.

11:30

ZO-MAR-92 PRESS [ENTER]

AM

Confirm the correct date and time are displayed on the Insert Cassette and Lock In

If the date and time are correct, press the [ENTER] key.

Proceed to Section 3.2, Priming Procedures:

Primay Administration Set

430-0637 1 -A04 (Rev.

4194)

3-2

System Operating Manual

Place

screen.

Page 16

If the date and time are incorrect on the Insert Cassette and

(ESCAPE] key. The Bypass Cassette Test screen is displayed:

BYPASS CASSETTE TEST? NO

PRESS [ENTER]

3.1 SETUP PROCEDURES

Lack

In Place screen, press the

Press the

Refer to Section 5.4, Special

to set date, time, and display format.

toggling the ION/CHARGE] switch to CHARGE, then ON.

the

SelfTest

(YES/NO] key to change NO to YES. Press the [ENTER] key. The base screen is displayed:

A:OFF B:OFF C:OFF

I

0 0 0

~&ions,

D:OFF

TOTAL

0

0

for detailed instructions on using [SPECIAL

12:3OPM

When date and time are correct, cycle the device power by

Cycling the power returns the device to

screen, followed by the Restore Previous Programming screen.

Repeat Steps 1 and 2 as follows:

1.

Select NO to Restore

Previous

Programming Y/N?.

Previous programming is removed from

the device.

Insert

2.

Press the (ENTER] key.

The

Cassette and Lock In Place screen is displayed.

the correct date and time are displayed on the screen.

Proceed to Section 3.2, Priming Procedures:

3.

Note:

Do not bypass the cassette test.

Primay Administration Set.

3.1.3

RESPONSE TO LOW BATTERY CONDITION

ML/HR

I

FUNCTIONI(

1

I

Coniirm

If

a low battery condition is detected by the device self test, the Current

HR

11:35

CURRENT TIME

DATE

(DD-MM-W) :

1.

Confii

2.

If the date and time are incorrect, use the (NEXT] key and

the correct date and time are displayed on the Current

PM 24

30-MAR-92

TIME Y/N? NO

[ENTERI

[LAST]

as appropriate. Overwrite the old data with the new data.

Note:

Refer to Section 5.4, Special Functions, for more detailed information on setting date

and time.

3.

Upon data entry completion, press the [ENTER] key. The KVO Rate screen is displayed:

KVO RATE:

MAX OCCLUSION:

I

4.

Confirm

5.

If the default

that the correct information displays on the KVO Rate screen.

cursor as appropriate.

l.OML/HR

lOPSI

values

are to be changed, use the [NEXT] and [LAST] keys to position the

[ENTER1

Enter values for KVO and Maximum Patient Line Occlusion

Pressure. The values entered become the default settings for the device.

Note: Default settings remain in device memory when the device is turned off or on.

Time

screen is displayed:

Time

screen.

key to position the cursor

I

Omni-Flow 4000 Plus IV Medication Management System

3-3

430-06371

-A04

(Rev.

4/94)

Page 17

Section 3 SETUP

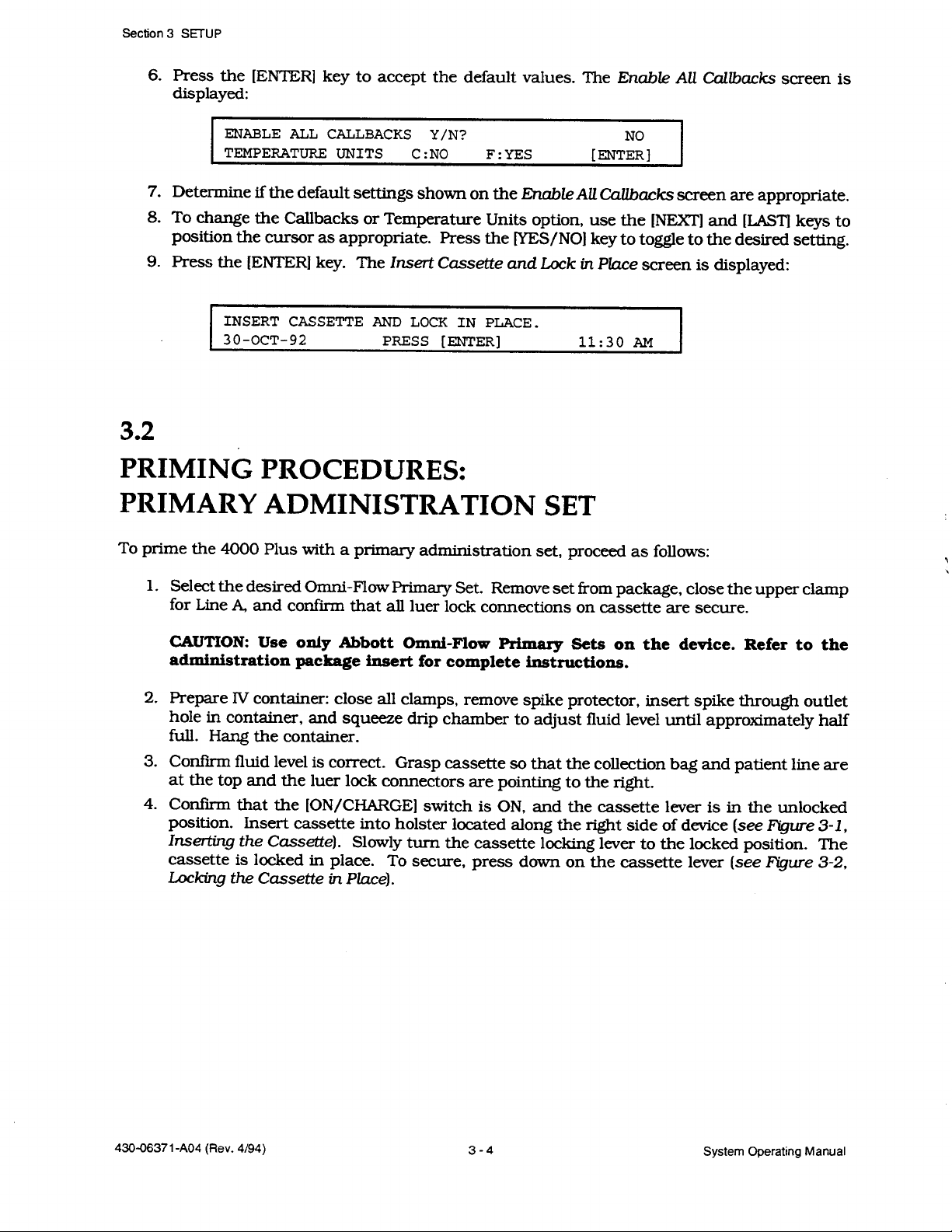

6. Press the

(ENTER] key to accept the default values. The

Enable

Callbacks

AU

displayed:

ENABLE ALL CALLBACKS Y/N?

TEMPERATURE UNITS

7.

Determine if the default settings shown on the

C:NO

F:YES

Enable

[ENT:]

AU Callbacks screen are appropriate.

8. To change the Callbacks or Temperature Units option, use the [NEXT] and

position the cursor as appropriate.

9.

Press the [ENTER] key. The Insert Cassette and Lock in

INSERT CASSETTE AND LOCK IN PLACE.

30-OCT-92

pmss [E NTER]

Press the

(YES/NO1

key to toggle to the desired setting.

11:30

Place

screen is displayed:

AM

3.2

PRIMING PROCEDURES:

PRIMARY ADMINISTRATION SET

screen is

(LAS?1

keys to

To prime the 4000 Plus with a primary administration set, proceed as follows:

1.

Select the desired Omni-Flow Primary Set.

A,

for Line

CAUTION:

and confirm that all luer lock connections on cassette are secure.

Use only Abbott Omni-Flow Primary Sets on the device. Refer to the

Remove set

from

package, close the upper clamp

administration package insert for complete instructions.

2.

Prepare IV

container: close all clamps, remove spike protector, insert spike through outlet

hole in container, and squeeze drip chamber to adjust fluid level until approximately half

full. Hang the container.

3.

Confii fluid level is correct.

Grasp cassette so that the collection bag and patient line are

at the top and the luer lock connectors are pointing to the right.

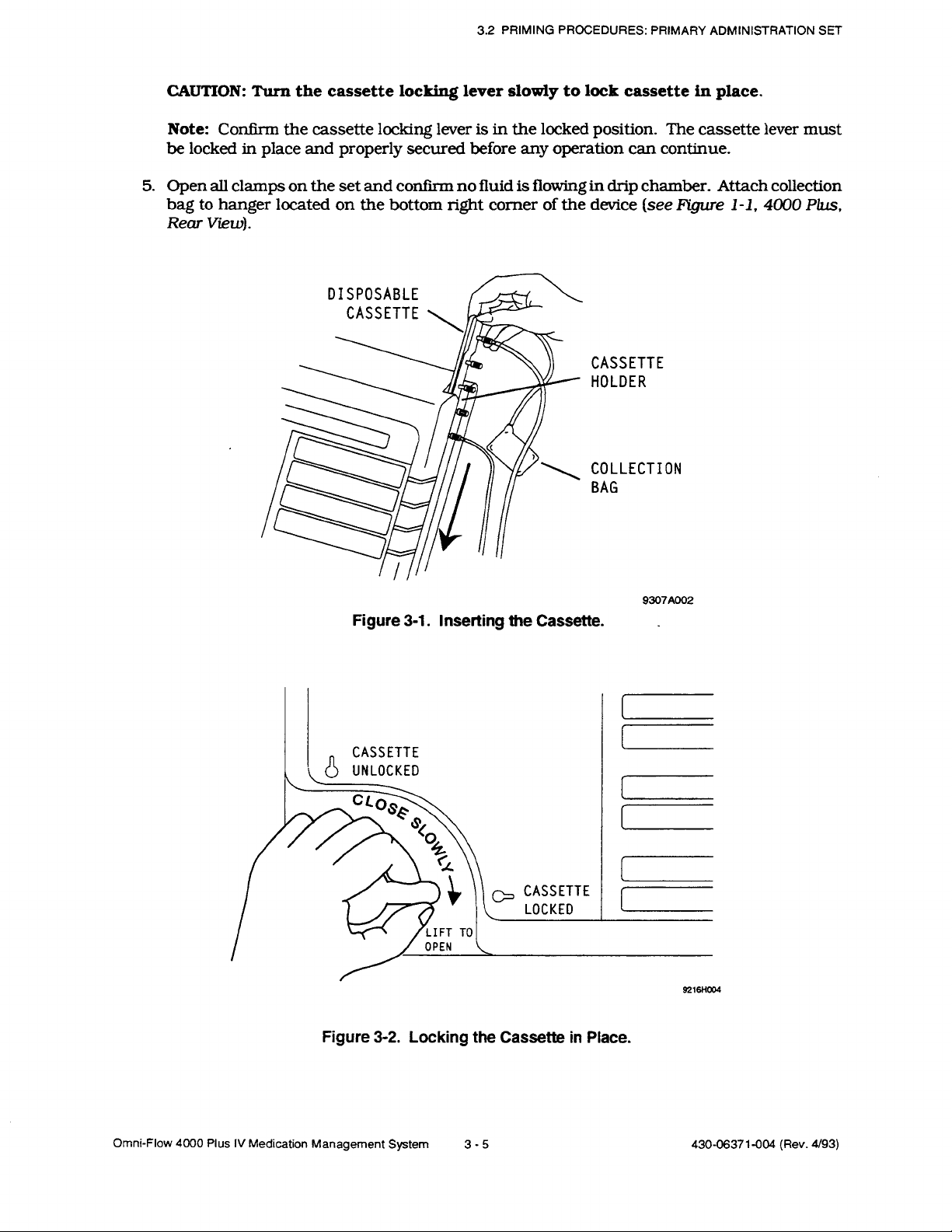

4.

Confii

that the (ON/CHARGE] switch is ON, and the cassette lever is in the unlocked

position. Insert cassette into holster located along the right side of device (see

Inserting

the Cassette). Slowly turn the cassette locking lever to the locked position. The

cassette is locked in place. To secure, press down on the cassette lever (see

in

Locking the Cassette

Place).

l?gure

Figure

3-1,

3-2,

430-0637

-A04 (Rev.

1

4194)

3-4

System Operating Manual

Page 18

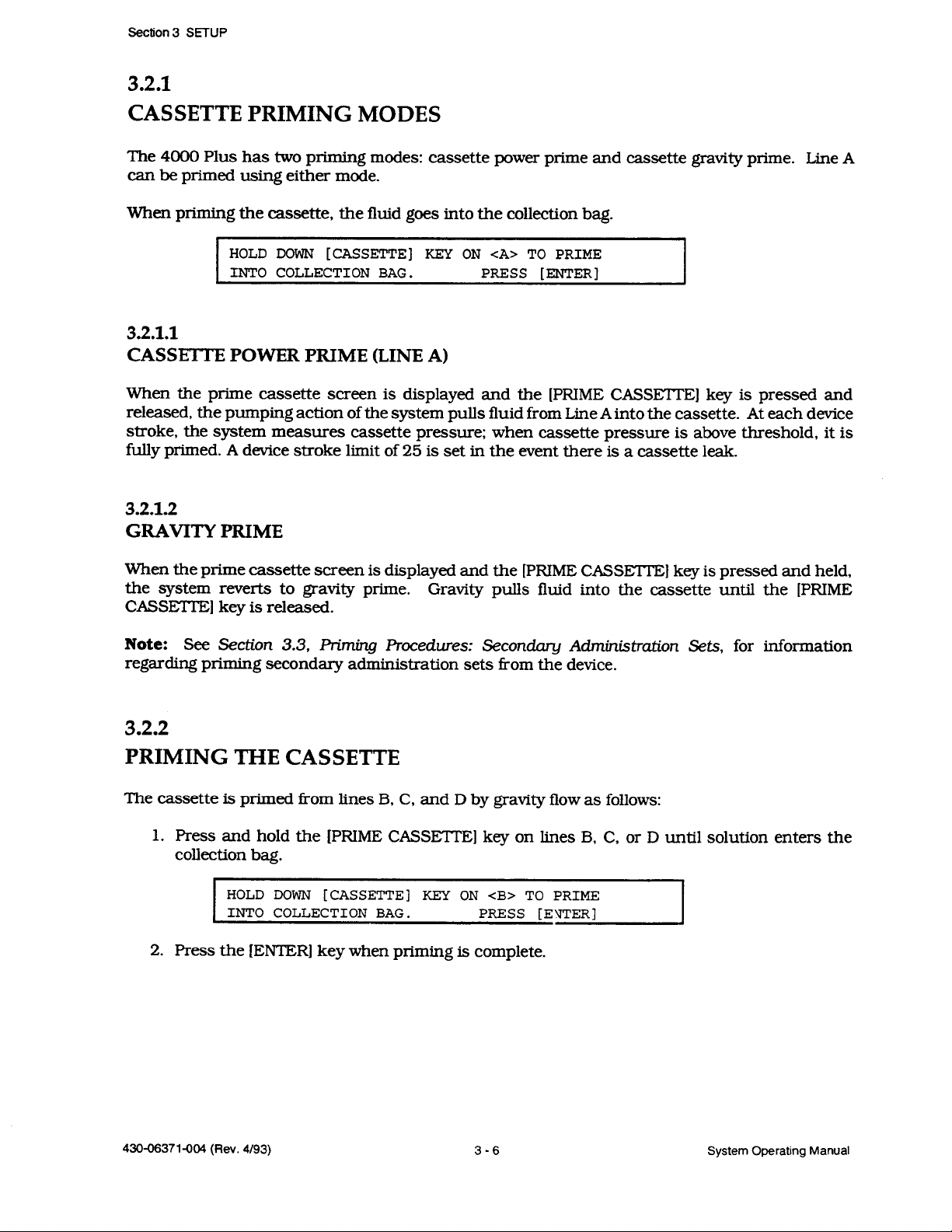

CAUTION:

Turn

the

cassette

3.2 PRIMING PROCEDURES: PRIMARY ADMINISTRATION SET

locking lever slowly to lock cassette in place.

Note:

Con&m

the cassette

locking lever is in the locked position. The cassette lever must

be locked in place and properly secured before any operation can continue.

Open all clamps on the set and confirm no fluid is flowing in drip chamber. Attach collection

5.

bag to hanger located on the bottom right comer of the device (see Figure l-l, 4000 Plus,

Rear View).

CASSETTE

HOLDER

COLLECTION

BAG

Figure 3-1. Inserting the Cassette.

CASSETTE

~8

UNLOCKED

OPEN

<

Figure 3-2. Locking the Cassette in Place.

9307AOO2

_

9216H02-4

Omni-Flow 4000 Plus IV Medication Management System

3-5

430-06371-004 (Rev.

4193)

Page 19

Section 3 SETUP

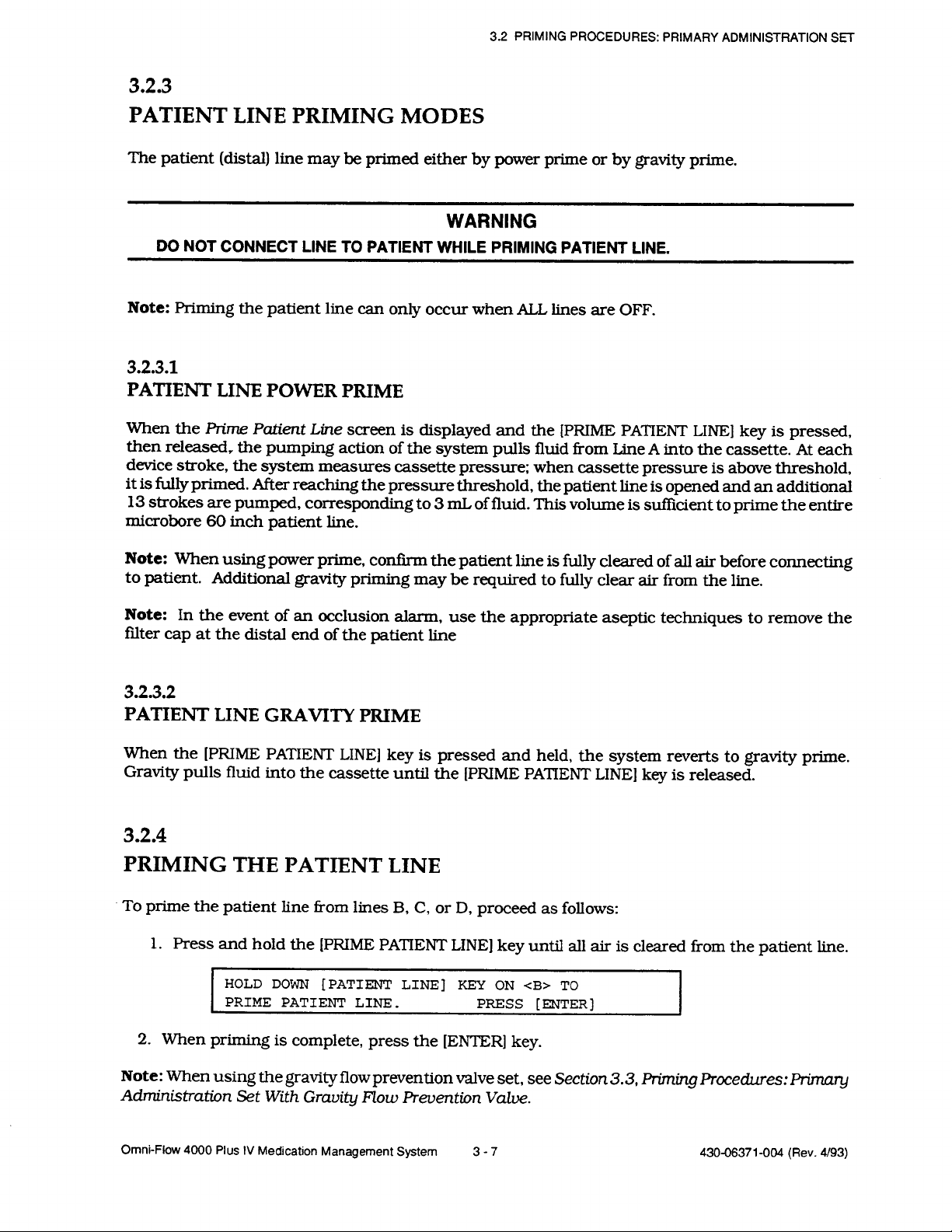

3.2.1

CASSETTE PRIMING MODES

The 4000 Plus has two priming modes: cassette power prime and cassette gravity prime.

Line A

can be primed using either mode.

When priming the cassette, the fluid goes into the collection bag.

<A>

HOLD

DOWN [C AS SETTE ] KEY

INTO COLLECTION BAG.

0~

TO PRI ME

PRESS [ENTER]

3.2.1.1

CASSETTE POWER PRIME (LINE A)

When the prime cassette screen is displayed and the [PRIME CASSETTE] key is pressed and

Ainto

released, the pumping action of the system pulls fluid from Line

the cassette.

stroke, the system measures cassette pressure; when cassette pressure is above threshold, it is

fully primed. A device stroke limit of 25 is set in the event there is a cassette leak.

3.2.1.2

GRAVITYPRIME

When the prime cassette screen is displayed and the (PRIME CASSETTE1 key is pressed and held,

the system reverts to gravity prime.

Gravity pulls fluid into the cassette until the (PRIME

CASSETTE] key is released.

At each device

Note: See

regarding priming secondary administration sets

Section 3.3, Priming Procedures: Secondary Administration Sets, for information

Tom

the device.

3.2.2

PRIMING THE CASSETTE

The cassette is primed from lines B, C, and D by gravity flow as follows:

1. Press and hold the [PRIME CASSETTE] key on lines B, C, or D until solution enters the

collection bag.

~0

PRIME

DowN

HOLD

INTO COLLECTION BAG. PRESS

2.

Press the [ENTER] key when priming is complete.

[CASSETT E] KEY ON

<B>

[E:;T]

4193)

3-6

System Operating Manual430-06371-004 (Rev.

Page 20

3.2

PRIMING PROCEDURES: PRIMARY ADMINISTRATION SET

3.2.3

PATIENT LINE PRIMING MODES

The patient (distal) line may be primed either by power prime or by gravity prime.

WARNING

DO NOT CONNECT LINE TO PATIENT WHILE PRIMING PATIENT LINE.

Note: Priming the

patient line can only occur when ALL lines are OFF.

3.2.3.1

PATIENT LINE POWER PRIME

prime

When the

then released, the pumping action of the system pulls fluid from Line A into the cassette. At each

device stroke, the system measures cassette pressure; when cassette pressure is above threshold,

it is fully primed. After reaching the pressure threshold, the patient line is opened and an additional

13 strokes are pumped, corresponding to 3

microbore 60 inch patient line.

Note:

When using power prime,

to patient.

Note:

In the event of an occlusion alarm, use the appropriate aseptic techniques to remove the

filter cap at the distal end of the patient line

3.2.3.2

PATIENT LINE GRAVITY PRIME

When the [PRIME PATIENT LINE] key is pressed and held, the system reverts to gravity prime.

Gravity pulls fluid into the cassette until the [PRIME PATIENT LINE] key is released.

Patient Line screen is displayed and the (PRIME PATIENT LINE] key is pressed,

mL

of fluid. This volume is

sufficient

to prime the entire

con&m the patient line is fully cleared of all air before connecting

Additional gravity priming may be required to fully clear air from the line.

3.2.4

PRIMING THE PATIENT LINE

i?om

T

O

prime the

1.

Press

patient line

and hold the [PRIME PATIENT LINE] key until all air is cleared from the patient line.

DO'~~N

HOLD

PRIME PATIENT LINE.

2. When priming is complete, press the (ENTER] key.

Note:

When using the

gravity

Administration Set With

1V

Omni-Flow 4000 Plus

Medication Management System 3-7

lines B, C, or D, proceed as follows:

[PATIENT

flow

Grauity

LINE ] KEY ON

PRESS

prevention valve set, see Section 3.3, Priming

Plow Prevention Value.

<B>

TO

[ ENTER ]

Procedures:

430-0637 l-004 (Rev.

Primary

4193)

Page 21

Section 3 SETUP

3.2.5

CASSETTE TEST

The device performs a cassette test for approximately 36 seconds.

CAUTIONz

It is extremely important to always perform the cassette test when inserting a

new cassette.

CASSETTE TEST IN PROGRESS

ABBOTT 4000 PLUS

When the cassette test is completed, one of two screens is displayed: Possible Faulty Cassette

?&~pe

screen, or Select Infusion

screen.

3.2.5.1

CASSETTE TEST FAILED

If

the cassette

fails the cassette test, the device alarms and the Possible Faulty Cassette screen is

displayed:

+

-POSSIBLE FAULTY

REPRIME OR REPLACE CASSETTE

CASSETTE-

[MUTE1

If the cassette fails the cassette test, proceed as follows:

1.

Silence the alarm by pressing the (MUTE] key. To clear the alarm, press the (MUTE1 key

again. Check for air bubbles, and

2.

Prime the cassette as described in Section 3.2.2. Prime the patient line as described in

reprime

if necessary.

Section 3.2.4.

3.

Ifit

fails the cassette test again, replace cassette. Prime new cassette as described in Section

3.2.2.

Prime the patient line as described in Section 3.2.4. If two cassettes fail in a row,

send the device to clinical engineering.

430-06371-004 (Rev.

4193)

3-8

System Operating Manual

Page 22

3.3 PRIMING PROCEDURES: PRIMARY ADMINISTRATION SET WITH GRAVITY FLOW PREVENTION VALVE

3.2.5.2

CASSETTE TEST SATISFACTORY

If the cassette test is satisfactorily completed, the following screen is displayed:

SELECT INFUSION TYPE

PRESS [CONTINUOUS] OR [INTERMITTENT]

To prepare for connecting IV containers or syringes to the remaining three lines, press the

[ESCAPE] key. The base screen is displayed.

THE DEVICE IS NOW READY FOR CONNECTING

REMAINING THREE LINES.

lV CONTAINERS OR SYRINGES TO THE

3.3

PRIMING PROCEDURES:

PRIMARY ADMINISTRATION SET WITH GRAVITY

FLOW PREVENTION VALVE

from

CAUTIONS:

cassette is removed from the device without closing the clamps. The gravity flow prevention

valve does not prevent mixing of drug lines. Close all clamps before removing cassette.

The gravity flow prevention valve requires pressure to open (1.5 to 5.0 psi). The device

occlusion pressure setting may require adjustment to prevent nuisance occlusion alarms.

Note:

insert of the administration set. These instructions apply to the 4000 Plus only.

To prime the

valve,

These

proceed as follows:

The gravity flow prevention valve protects the patient

instructions offer an alternative priming procedure to those found on the package

4000

Plus with a primary administration set containing the gravity flow prevention

free flow if the

1.

Remove the primary set from package, close the upper clamp for Line A, and

all luer lock connections on the cassette are secure.

CAUTION:

administration package insert for complete instructions.

2.

Prepare IV container: close all clamps, remove spike protector, insert spike

hole in container, and squeeze drip chamber to adjust fluid level until approximately half

full. Hang the container.

3.

Confirm fluid level is correct. Grasp cassette so that the collection bag and patient line are

at the top and the luer lock connectors are pointing to the right.

4.

Confii

position. Insert cassette into holster located along the right side of device (see Figure

Inserting

cassette is locked

Locking

Omni-Flow 4000 Plus IV Medication Management System

Use only Abbott Omni-Flow

that the (ON/CHARGE] switch is ON, and the cassette lever is in the unlocked

the

Cassette). Slowly turn the cassette locking lever to the locked position. The

in

place.

the Cassette in Place).

To secure, press down on the cassette lever (see Figure 3-2,

primary

3-9

confii

Sets on the device. Refer to the

throu$

430-06371 -A04 (Rev.

that

outlet

3-l.

4/94)

Page 23

Section 3 SETUP

CAUTION: Turn the cassette locking lever slowly to lock cassette in place.

Note:

be locked in place and properly secured before any operation can continue.

5.

Open all clamps on the set and confirm no fluid is flowing in drip chamber. Attach collection

bag to hanger located on the bottom right comer of the device (see Figure l-l, 4000

Rear View).

6.

Prime the cassette using the Line A [PRIME CASSETTE] key until all air is cleared from the

cassette into the collection bag. Press the [ENTER] key.

7.

Attach any extension set or other devices to the gravity flow prevention valve located at the

distal end of the patient line (do not attach to a venipuncture device).

8.

Press the Line A (PRIME PATIENT LINE] key to power prime the patient line.

flow prevention valve prevents gravity prime mode from priming the patient line.

Note:

10

unul

9.

Press the (ESCAPE] key. When the Cassette Test Screen displays, enter YES to bypass the

cassette test and return to the base screen.

10.

When the base screen displays, press Line A [PRIME PATIENT LINE] to power prime the

patient line.

11

Press the

test.

12.

Determine if the venipuncture device is indwelling.

indwelling, prepare and insert the venipuncture device in the patient per hospital

procedure.

13.

Attach the primed patient line to the venipuncture device.

Con&m

the cassette

locking lever is in the locked position. The cassette lever must

Plus,

The gravity

additional power primes are needed to prime the patient line, repeat Steps 9 and

If

primed.

[ENTER] key when the patient line is fully primed. The device preforms a cassette

If the venipuncture device is not

THE LINE IS NOW READY FOR PROGRAMMING.

3.4

PRIMING PROCEDURES:

SECONDARY ADMINISTRATION SET

To prime the 4000 Plus with a secondary administration set, proceed as follows:

1.

Select the

desired Omni-Flow Secondary Set.

CAUTION: Use only Abbott Omni-Flow Secondary Sets. Refer to the administration

package insert for complete instructions.

2.

Prepare IV

container:

close all clamps, remove spike protector, insert spike through outlet

hole in container, and squeeze drip chamber to adjust fluid level until approximately half

full. Hang container.

3.

Confirm fluid level is correct. Remove distal cap

4.

Remove the luer lock protector for the cassette line to be used.

cassette.

Remove set from package; close clamp.

from

secondary set.

Connect secondary set to

Note: An

prime prior to connecting the

430-0637 1 -A04 (Rev.

alternative method

is to

secondq

4l94)

open the

clamp and clear all air from the set by gravity

set to the cassette.

3-

10

System Operating Manual

Page 24

3.5 CONNECTING A SYRINGE TO THE CASSETTE

5.

Prime the line by pressing the appropriate [PRIME CASSETTE] key until no air bubbles are

visible in the connection site or cassette.

THE LINE IS NOW READY FOR PROGRAMMING.

4000

To prime the

as follows:

1. Put all lines on hold.

2. Connect and prime secondary set as described above.

3. Press the [RESUME] key, then the [ENTER] key.

CAUTION:

or&inaUy

Fluid

bag.

sequence.

Plus with a secondary administration set while other lines are running, proceed

fluid

Priming directs

in the cassette may be displaced into the collection bag by the priming

air

and

out through the cassette and into the collection

3.5

CONNECTING A SYRINGE TO THE CASSETTE

Note:

To connect a syringe to the cassette, proceed as follows:

Note:

during cassette prime.

THE LINE IS NOW READY FOR PROGRAMMING.

For syringe infusions, only use 20 cc to 60 cc size syringes.

1.

Remove luer lock protector for the cassette line to be used.

compatible stop-cock or syringe support elbow into the cassette.

2.

Connect the syringe to the stop-cock or elbow, with the syringe in a vertical position (see

Figure

3-3, Syringe Connected to the Cassette).

cassette.

3.

If air bubbles are visible in the connection sight or cassette, prime the line by pressing the

appropriate [PRIME CASSETTE] key.

Syringes may not prime easily with gravity flow.

.

Open fluid pathway from syringe to the

Some force may be required on the plunger

Connect an Omni-Flow

Figure 3-3. Syringe Connected to the Cassette

Omni-Flow 4000 Plus IV Medication Management System

3-11

430-06371 -A04 (Rev.

4/94)

Page 25

Section 3 SETUP

3.6

CONNECTING A SYRINGE AND SYRINGE

ADAPTOR TO THE CASSETTE

A syringe adaptor serves to vent the syringe, making it less susceptible to plunger stopper

resistance. When programming the 4000 Plus and using the syringe adaptor, it is recommended

that the Syringe option be set to NO.

To attach a syringe and syringe adaptor to the cassette, proceed as follows:

1.

Prepare the syringe using aseptic technique.

2.

Attach the adapter to the syringe (see Figure 3-4, Connecting Syringe

to Cassette).

3.

Attach an Omni-Flow compatible stop-cock or a syringe support elbow to the adaptor (see

Figure 3-4).

4.

Prime the adaptor and stop-cock/syringe support elbow.

5.

Remove the luer lock protection for the cassette line to be used.

or syringe support elbow to the cassette.

and

Syringe Adaptor

Connect primed stop-cock

THE LINE IS NOW READY FOR PROGRAMMING.

U

Figure 3-4. Connecting Syringe and Syringe Adaptor to

'SYRINGE

Cassette

3-

4l94)430-06371-A04 (Rev.

12

System Operating Manual

Page 26

3.7 REMOVING THE

CASSRTE

FROM THE DEVICE

3.7

REMOVING THE CASSETTE FROM THE DEVICE

WARNING

REMOVING

UNRESTRICTED FLOW. All CLAMPS MUST BE CLOSED TO PREVENT FLOW TO PATIENT

AND/OR MIXING OF DRUGS.

To remove a cassette from the 4000 Plus, proceed as follows:

1.

Confirm that the ION/CHARGE] switch is ON and all lines are OFF.

2.

Close clamps on all lines to prevent free flow and/or mixing of drugs.

3. Lift cassette locking lever and turn counterclockwise. Allow approximately 3 seconds for

the piston to retract.

4. Pull cassette from holster.

CASSElTE FROM DEVICE WITHOUT CLOSING LINE CLAMPS MAY RESULT IN

a

cassette becomes jammed or a Pump Service Code 0800 occurs while inserting or removing

If

the cassette, proceed as follows:

1.

Cycle the device power. Toggle the [ON/CHARGE] switch to CHARGE, then ON.

2.

Push the cassette completely down in the holster until it is securely seated.

3.

Confih-m

4.

Proceed with programming.

the self test completes.

Omni-Flow 4000 Plus IV Medication Management System

3-13

430-06371 -A04 (Rev.

4/94)

Page 27

Section 4

PROGRAMMING

amming

When

during programming.

CAUTION:

into the

progr

drip

After

chamber on each appropriate

the 4000 Plus, listen for the device response (audible

programming

confirmatory

the device, ensure that pumping has begun by

fill

stroke for each line in use.

verifying

beep)

flow

4.1 MAINTENANCE INFUSIONS

The 4000

to deliver when an intermittent line is infusing) or in the maintenance mode (device stops delivering

when an intermittent line is infusing and restarts when the intermittent line stops infusing).

If an intermittent with dilution programmed on Lines B. C, or D is put on hold, and a maintenance

infusion was previously prgrammed on Line

programming on Line A continues.

To set up line A, proceed as follows:

1.

Plus can infuse on Line A in either the continuous mode of operation (device continues

A,

the dilution is put on hold and the maintenance

Press the [MAINTENANCE INFUSION]

key for Line A

A> MAINTENANCE

TOTAL VOLUME: 0 ML

Set

2.

3.

Note:

flushing or diluting mode. If Line A is flushing or diluting, the display only allows the entry of a

new source container volume.

Omni-Flow 4000 Plus IV Medication Management System

a rate using the numeric keys, then press the [NEXT] key.

Note:

appears on the display screen.

specifications.

Set a Total Volume to be infused using the numeric keys, then press the

start the line.

The

Maintenance or continuous rate on Line A can only be changed when Line A is not in the

If the line rate chosen exceeds the combined maximum rate of the device. a message

A> MAINTENANCE

TOTAL VOLUME: 250ML

base screen is displayed:

r

A: INF B: OFF C: OFF D: OFF TOTAL

5.0

RATE:5_0ML/HR

Refer to Section 12,

RATE:5.0ML/HR

0 0 0

4-l

[ENTER]

[ENTER]

5.0

12:30

Spec~@cations,

PM

ML/HR

for rate range

[ENTER]

430-0637 l-004 (Rev.

key to

4193)

Page 28

Section 4 PROGRAMMING

4.2

CONTINUOUS INFUSIONS

The 4000

the user two methods of programming:

Note:

continuous mode, press the [CONTINUOUS INFUSION] key. Use the [NEXT] and

Plus infuses up to four medications at the same time in the continuous mode and offers

ML/HR

To change either the rate in MCG or

mL/hr,

MCG/KG/MIN.

and

or total volume on any line operating in the

[LASTI

keys to

move the cursor to the desired field that requires a change. Any change may be made while the

line is operating; there is no need to stop the flow. After making a change, press the

[ENTER]

key

and the device begins operating at the new rate and/or volume immediately.

Note:

without

Note:

ConcurrentFlow).

Note:

not stop.

Continuous infusions may not be programmed over Maintenance or Intermittent infusions

first

stopping the Maintenance or Intermittent infusion.

Concurrent flow exists when two or more drugs are given simultaneously (see Section

Continubus

infusions are rate

specific

and alarm when dose is complete. The infusion does

4.2.4,

The device keeps pumping at programmed rate and does not go to KVO.

4.2.1

ML/HR

The following sections detail the required steps to program an

change an

INFUSIONS

mL/hr

infusion.

mL/hr

infusion and the steps to

4.2.1.1

PROGRAMMING OR CHANGING AN

mL/hr

To program a new

1.

Press the [CONTINUOUS INFUSION] key for

B>

RATE:

Note:

If [CONTINUOUS INFUSION] was pressed in error or there is a need to begin again,

infusion, or change an existing

VOL:

OMCG/KG/MIN OMG IN OML [ENTER]

press the [ESCAPE] key to return to the base screen.

2.

The cursor appears in the RATE field. Enter the delivery rate. Use the

VOL

the cursor to the

Note:

If the line

field.

rate chosen exceeds the combined maximum rate of the device, a message

appears on the display screen.

Enter the volume to be delivered.

Refer to Section 12,

specifications.

3.

Press the [ENTER] key to start the infusion.

ML/HR INFUSION

mL/hr

the

line used. The following screen is displayed:

OML WT: OKGOMLIHR

Spectfications,

infusion, proceed as follows:

[NEml key to move

DeZiue

y Rate Range, for

430-06371-004 (Rev.

4/93)

4-2

System Operating Manual

Page 29

4.2.1.2

CHANGING AN

ML/HR INFUSION TO AN ALTERNATE UNIT OF MEASURE

INFUSION

To change an existing

1.

Press the [CONTINUOUS INFUSION] key for the line used. For example, when using line

mL/hr

B, the following screen is displayed:

4.2 CONTINUOUS INFUSIONS

infusion to an alternate unit of measure infusion, proceed as follows:

B>

RATE:

2.

Since the line has previously been programmed in

ML/HR

3.

Use the

Note: If

4.

Use the [NEXT] key to move the cursor to the

field.

[NEXTI

programming in MCG/MIN is desired, enter a body weight of one (1).

MCG/KG/MIN

5.

Use the

6.

Use the

Note: If

[NEXTI

[NEXTI

B>

RATE:

3.OOMCG/KG/MIN

no

15.0ML/HR

OMCG/KG/MIN OMG IN

key to enter the appropriate global body weight, if one does not already exist.

rate.

key to move the cursor to the

key to move the cursor to the

16.9ML/HR

entry is made in the Volume field, the volume entered in the

VOL:

VOL:

2OOMG

25OML

MG

ML

25OML

IN

w"r:

OML

field, and enter the medication dose.

field.

WI':

25OML

OKG

CENTER1

mL/hr,

MCG/KG/MUV

the cursor will appear in the

field, and enter the

Enter the diluent volume.

75.OKG

[ENTER]

ML

field becomes

the default container volume.

Note: The

7.

To start the infusion, press the [ENTER] key. The following screen is displayed:

calculated delivery rate in

ML/HR

appears in the

ML/HI?

Rate field.

D:OFF

A:INF B:ON C:OFF

35.0 16.9

In this

35

example, the base screen shows Line A has been programmed as a maintenance at

mL/hr.

Line B runs at 16.9

until stopped.

(The

mL/hr

0

rate for Line B is the calculated result of the

TOTAL

0

mL/hr

in a continuous mode of operation and continues

program.) The base screen only displays delivery rates in

Omni-Flow 4000 Plus IV Medication Management System 4

51.9

-

3

12:30PM

ML/HR

mL/hr.

MCG/KG/MIN

430-06371-004 (Rev.

4/93)

Page 30

Section 4 PROGRAMMING

4.2.2

ALTERNATE UNITS OF MEASURE

‘I&e

following sections detail the required steps to program an alternate unit of measure infusion

(MCG/KG/MIN)

INFUSIONS

and the steps to change a unit of measure infusion.

The

Note:

4000 Plus will not accept

specified (non-zero): rate

weight

&VT).

MCG/KG/MIN

(MCG/KG/MIN),

dose amount

programming unless all data fields are

(MG],

diluent volume (ML], and body

4.2.2.1

PROGRAMMING A NEW ALTERNATE UNIT OF MEASURE INFUSION

To program a new alternate unit of measure (MCG/KG/MIN) infusion, proceed as follows:

Press the [CONTINUOUS INFUSION] key for the line used.

1.

For example, when using line

B, the following screen is displayed:

B>

RATE:

OMCIG/KG/MIN

2.

The cursor is in the

OML/HR

ML/H.R

field. Use the (NEXT] key to move the cursor to the

VOL:

OMG IN

om

WT:

OML

OKG

rENTERi

I

VOL

field,

and enter the container volume.

VOL

Note:

If no entry is made in the

field, the volume entered in the ML field becomes the

default container volume.

3.

Use the

[NEXTl

key to move the cursor to the

weight, if one does not already

Note:

4.

Use the

5.

Use the

6.

Use the

Note: The

7.

To start the

If

programming in MCG/MIN is desired, enter a body weight of one

[NEXTI

key to move the cursor to the

[NEXTI

key to move the cursor to the

[NEXTI

key to move the cursor to the

calculated delivery rate in

infusion,

A:INF B:ON C:OFF

35.0

I

press the [ENTER] key. The following screen is displayed:

16.9 0

&St.

D:OFF

ML/HR

TOTAL

51.9

0

WTfield

MCG/KG/MINfield

MG

ML

appears in the

12:3OpM

and enter the appropriate global body

(

1).

and enter the desired rate.

field, and enter the medication dose.

field.

ML/HR

Enter the diluent volume.

ML/HI?

Rate field.

I

In this example, the base screen shows Line A has been programmed as a maintenance at

35

mL/hr.

Line B runs at 16.9

until stopped.

(The

mL/hr

mL/hr

rate for Line B is the calculated result of the

program.) The base screen only displays delivery rates in

in a continuous mode of operation and continues

MCG/KG/MIN

mL/hr.

8.

Repeat Steps 1 through 7 for each line to operate in a continuous mode of operation.

430-06371X104 (Rev.

4/93) 4-4

System Operating Manual

Page 31

4.2.2.2

CHANGING AN ALTERNATE UNIT OF MEASURE INFUSION

4.2 CONTINUOUS INFUSIONS

To change an alternate unit of measure infusion

Press the [CONTINUOUS INFUSION] key for the line used. For example, when using line

1.

(MCG/KG/MIN],

B, the following screen is displayed:

RATE:

3.00MCG/KG/MIN

Since the

2.

line has previously been programmed in Alternate units of Measure,

will appear in the

16.9ML/HRB>

MCG/KG/MIN

VOL:

2OOMG

field.

250ML WT:

IN

Confirm

Lmchanged.

Note: If

Enter new

3.

4.

Use the

5.

Use the

Note: If

programming in MCG/MIN is desired, enter a body weight of one

MCG/KG/MIN

[NEXTI

key to move the cursor to the

[NEXTj

key to move the cursor to the ML field.

no entry is made in the

rate.

Volume

MG

field, the volume entered in the

the default container volume.

Note: The

6.

To start the infusion, press the [ENTER] key. The following screen is displayed:

calculated delivery rate in

ML/HR

appears in the

proceed as follows:

75.OKG

25OML

[ENTER]

the cursor

(

1).

to remain

that global body weight is

field, and enter the medication dose.

Enter the diluent volume.

ML

field becomes

ML/HI?

Rate field.

.

35.0 16.9

0

D:OFF

0

TOTAL A:INF B:ON C:OFF

51.9

12:3OpM

ML/HR

In this example, the base screen shows Line A has been programmed as a maintenance at

35

until stopped.

program.) The base screen only displays delivery rates in

4.2.2.3

mL/hr.

Line B runs at 16.9

mL/hr

(The

mL/hr

rate for Line B is the calculated result of the

in a continuous mode of operation and continues

mL/hr.

CHANGING AN ALTERNATE UNIT OF MEASURE INFUSION TO

INFUSION

To change an alternate unit of measure infusion to

1. Press the

[CONTINUOL

S INFUSION] key for the line used. For example, when using line

mL/hr,

proceed as follows:

B, the following screen is displayed:

B>

RATE:

3.OOMCG/KG/MIN

2. Since the

line was previously programmed in alternate units of measure, the cursor will

appear in the

3.

Use the [LAST] key to move the cursor to the

16.9MWHR

MCG/KG/MIN

field.

VOL: 250ML WT:

2OOMG

IN 250ML [ENTER]

W7’field.

75.OKG

Press [CLEAR

body weight.

MCG/KG/MIN

MLJHR

ENTRY to clear the

Omni-Flow 4000 Plus IV Medication Management System

4-5

430-06371-004 (Rev.

4/93)

Page 32

Section 4 PROGRAMMING

4.

Use the [LAST] key to move the cursor to the

5.

Use the [LAST] key to move the cursor to the

Note:

If the line

rate chosen exceeds the combined maximum rate of the device, a message

VOL

ML/MI

appears on the display screen. Refer to Section 12.

field.

Enter the volume to be delivered.

field and enter the desired rate.

Spec~$ica.tions.

DeUuey

Rate Range, for

specifications.

6.

Press the [ENTER] key to start the infusion.

4.2.3

CHANGING THE GLOBAL BODY WEIGHT.

The global body weight is established when the first weight and concentration are entered on a

continuous line. Entries in both fields are required to program in MCG. The patient weight must

be consistent on all lines with the exception of 1 kg to program in MCG/MIN. If another weight is

entered, the following screen is displayed:

GLOBAL BODY WEIGHT CANNOT BE CHANGED

[ESC

AP

WHILE LINES ARE INFUSING

Global body weight can be changed only while lines are stopped or while no other line is running

in

MCG/KG/MIN.

When a new body weight is entered, the following screen is displayed:

E]

BODY WT. CHANGED FROM _KG

[ENTER] TO ACCEPT [ESCAPE] TO REVISE

Pressing [ENTER] starts the line and establishes a new

TO-KG

global

body weight. The [ESCAPE] key

causes the line programming screen to appear with the cursor in the global body weight field.

When subsequent lines programmed in MCG are restarted, the new global

and the

mL/h.r

rate is adjusted based on the

MCG/KG/MIN

field and new weight.

body

weight appears

To accept the new global body weight and adjusted delivery rate for lines programmed in MCG,

press the [CONTINUOUS INFUSION] key for the respective line, and then confii the new setting

by pressing the [ENTER] key.

If a line was previously programmed with a weight of 1 kg, its body weight is retained when the

global body weight is changed.

If the global body weight is changed to 1 kg, or 1 kg is changed to global body weight, the

WT

MCG/KG/MmT

previous

and Concentration fields

mL/hr

value remains unchanged.

To change from MCG programming to

are

tiL/hr

erased as the cursor is moved ii-om the

programming,

enter a zero in the body weight field.

field. The

When [ENTER] is pressed, or as the cursor is moved from the weight field, it erases the

MCG/KG/MIN

into this screen. The previous

field and Concentration field values. The global body weight appears upon re-entry

mL/hr

value remains until changed.

430-0637 l-004 (Rev.

4/93)

4-6

System Operating Manual

Page 33

4.2.4

CONCURRENT FLOW

4.2 CONTINUOUS INFUSIONS

Variation in patient response

may occur when delivering certain short half-life drugs if the

difference of the delivery rates between the lines is large. Drugs with a short half-life (approximately

six minutes or less when given intravenously] include the following:

0

Nitroglycerine

Q

Nitroprusside

Norepinephrine

P

CI

Oxytocin

0

Procainamide

0

Trimethaphan

Note:

D

Dobutamine

D

Dopamine

LI

Epinephrine

0

Esmolol

D

Isoproterenol

D

Lidocaine

This list is not intended to be all-inclusive of drugs with a short half-life (critical drugs].

Clinicians should be familiar with the pharmacodynamics of any critical drug before

administration.

The following delivery rate guidelines represent a worst-case

scenaxio

of a nitroprusside infusion

in combination with one or more drugs. This example represents an unlikely extreme since it

considers a 20 second half-life for nitroprusside which is widely regarded as the drug with the

shortest half-life in humans (reference the British Journal of Anesthesiology). These guidelines

for nitroprusside would avoid variations in patient response in such an extreme case:

If nitroprusside (with a 20 second half-life) is to be infused at a rate of less than 10.0

mL/hr,

the combined infusion rate of drugs on the other three lines should be no greater than five

times the critical drug (nitroprusside) rate.

If nitroprusside (with a 20 second half-life) is to be infused at a rate of 10.0 to 20.0

mL/hr,

the combined infusion rate of drugs on the other three lines should be no greater than 10

times the critical drug (nitroprusside) rate.

mL/hr

Ifnitroprusside (with a 20 second half-life) is to be infused at a rate of 20.0

or greater,

the combined infusion rate of drugs on the other three lines can be programmed at any desired

rate.

This information is presented to inform clinicians of a rare situation that could be misinterpreted

if they are unfamiliar with this phenomenon.

CAUTION:

When infusing short half-life drugs at a low flow rate, automatic air elimination

interrupts the delivery of medication to the patient. This medication interruption is

dependent upon the infusion rate aud may cause a change in patient parameters.

Omni-Flow 4000 Plus IV Medication Management System

4-7

430-06371-004 (Rev.

4/93)

Page 34

Section 4 PROGRAMMING

4.3

INTERMITTENT INFUSIONS

The

4000 Plus can infuse

be infused on Lines B, C, and D.

To set up lines B, C, and D as intermittent infusions, proceed as follows:

1.

Press the

Input the volume of EACH dose infused.

2.

[INTERMITTENT

B>

EACH DOSE:

(RATE:

B>

EACH

(RATE:

as many as three intermittent medications. These medications can only

INFUSION] key on the line used.

(HRS:MIN)

0:OO

0:OO

[ENTER1

(HRS:MIN)

CENTER]

OML OVER

OML/HR)

DOSE:5O.OML

OML/HR)

0

Q:

OVER

0

Q:

X: 1

X: 1

3.

Press

the

Note:

Note:

[NEXTI

B>

EACH

(RATE:

Rate has been automatically calculated.

the

line

If

Input the total time EACH dose is to be infused.

key.

DOSE:50_OML

15OML/HR)

rate chosen exceeds the combined maximum rate of the device, an alert

message appears on the display.

specifications.

STARTING LINE WOULD CAUSE MAXIMUM RATE

-

REPROGRAM

50.oML

If this

Press the

4.

Press the

5.

TO BE EXCEEDED

is a single dose, proceed to Step 6.

[NEXf] key. Input the dosing frequency

B>

EACH DOSE:

(RATE:

[NEXTI

B>

EACH

(RATE:

15OML/HR)

key. Input the total number of doses to be delivered

DOSE:50_0ML

15OML/HR)

(HRS:MIN)

0:20

OVER

0

Q:

X: 1

[ENTERI

Refer to Section 12, Specifications, for delivery rate range

[ENTER1

(9)

(the number of hours between doses].

OVER

X:0

Q: 6

OVER

Q: 6 X: 4

0:20

0:20

(HRSZMIN)

[ENTERI

(HRS/MIN)

[ENTI:R]

(x).

Note: A

the total of the dosing frequency times the number of doses cannot exceed 24.

6.

Press the [ENTER] key.

B>

Callback

The

default to NO. If

430-06371-004 (Rev.

maximum of 24 hours of intermittent infusions can be programmed for a line: i.e.,

CALLBACK Y/N: NO

DILUTION Y/N: NO

Y/N,

Syringe Y/N,

“10

is correct, proceed to Step 7.

4/93)

SYRINGE Y/N: NO

(ENTER]

and Dilution Y/N queries (as shown in the above screen]

4-8

System Operating Manual

Page 35

INTERMllTENT INFUSIONS

4.3

To answer YES to any of the queries (Callback Y/N, Syringe Y/N, or

the

[NEXT1

key to move to the desired field. Press the

[YES/NO]

key to

Dilufion

change

Y/N), press

the selection.

When selections are correct, proceed to Step 7.

CALLBACIG

Callback

Callback can be canceled in two ways:

Callback

To

be called to the device each time the line starts and stops, select YES to

Y/N.

When called to the device, stop the

Y/N; or use

[SPECIAL

stop the line, re-enter the screen, and select NO to

FUNCTION][5]

(see

alarm

by pressing the [MUTE] key twice.

Section

5.4, Special Functions,

for more

information about use of special functions).

SYRINGE:

Note: Failure

If

infusing directly from a syringe, select YES to Syringe Y/N.

to select YES to Syringe

Y/Nmay

cause an occlusion alarm due to a sticking

syringe plunger.

Line

DlLUTION:

To dilute a concentrated medication with the solution running on

A, select

YES to Dilution Y/N.

All dilutions are made with the solution on Line A. The only infusions that can be

programmed for dilution are intermittent infusions (B. C, or D). The screens necessary to

perform a dilution are accessible during the programming of an intermittent infusion.

If YES is selected to Dilution Y/N, press the [ENTER] key. The following screen is displayed:

DILUTION VOLUME:

DILUTION RATE:

OML FROM LINE A

OML/HR

[ENTER]

Input either a per dose dilution volume or a dilution rate. The device calculates the other

value automatically, based on the dose time

[NJZXTI

by pressing the

7.

To begin infusing immediately, press the [ENTER] key.

B>START

AT

TIME NOW

key.)

12:30

12:30

HR

HR

pr~eviously

[ENTER]

entered.

(Move cursor, if necessary,

Line B has begun to infuse its dose.

150

12:30PM

ML/HR

I

A:OFF B:INF C:OFF

150

I

Note:

0

To cancel the dilution of a particular line, STOP and reprogram the line being diluted

by changing YES to NO.

D:OFF

TOTAL

0 0

Recheck the number of doses remaining in the container and the

start time of the next dose.

Alternately, to delay the start of the line up to 23 hours, input a start time using the keypad

8.

numeric keys.

Correct

AM/PM,

if

necessary, by pressing the

[NEXT]

key once, then the

[AM/PM1

key.

B>START

AT 4:00 PM

TIME NOW

12:30

PM

Line B now shows that it is programmed to start, but does not start infusing its first dose

until the time set. Press [ENTER] to return to the base screen.