Page 1

®

i-STAT

1

System Manual

Rev. Date: 08/14/06 Art: 714336-01E

Page 2

Patents

CA 1,281,072; CA 1,303,175; CA 1,330,888; CA 2,002,848; CA 2,087,720; CA 2,087,966;

CA 2,175,228; CA 2,193,000; CA 2,194,795; CA 2,221,178; EP 0408575; EP 0412119; EP 0434742; EP

0442969; EP 0505169; EP 0540691; EP 0543916; JP 2113412; JP 2521826; JP 2833809; JP 2948321;

JP 3093274; JP 3105919; JP 3105922; JP 3137612; JP 3269553; JP 3392871; US 4,864,229; US

4,933,048; US 4,954,087; US 5,008,616; US 5,096,669; US 5,112,455; US 5,121,050; US 5,124,661; US

5,200,051; US 5,447,440; US 5,466,575; US 5,514,253; US 5,554,339; US 5,605,664; US 5,609,824; US

5,614,416; US 5,628,961; US 5,789,253; US 5,821,399; US 5,837,446; US 6,030,827; US 6,379,883; US

6,438,498; US 6,750,053; US D332,833; US D337,164

Symbol Technologies Corporation is the owner of US Patent Nos. 4,758,717; 5,130,520; 5,262,628;

5,396,055; 5,532,469.

Trademarks

i-STAT is a registered trademark of Abbott Laboratories. MediSense is a registered trademark of

Abbott Laboratories. Precision and PCx are trademarks of Abbott Laboratories. Windows is a registered

trademark of Microsoft Corporation.

Abbott Point of Care Inc.

104 Windsor Center Drive

East Windsor, NJ 08520 • USA

Tel: (609) 443-9300

Fax: (609) 443-9310

©2006 Abbott Point of Care Inc. All rights reserved. Printed in USA.

Art: 714336-01E Rev. Date: 08/14/06

Emergo Europe

P.O. Box 18510

2502 EM The Hague

The Netherlands

Tel: (31)70 345 8570

Fax: (31)70 346 7299

Page 3

i-STAT 1 SYSTEM MANUAL CONFIGURATION

Please ensure that the contents of your System Manual are complete and up to date. In the event that your System

Manual does not contain the current configuration, it is recommended that you contact your i-STAT support provider.

As of April 2008, your i-STAT®1 System Manual should be configured with the contents as listed below and in the

order shown.

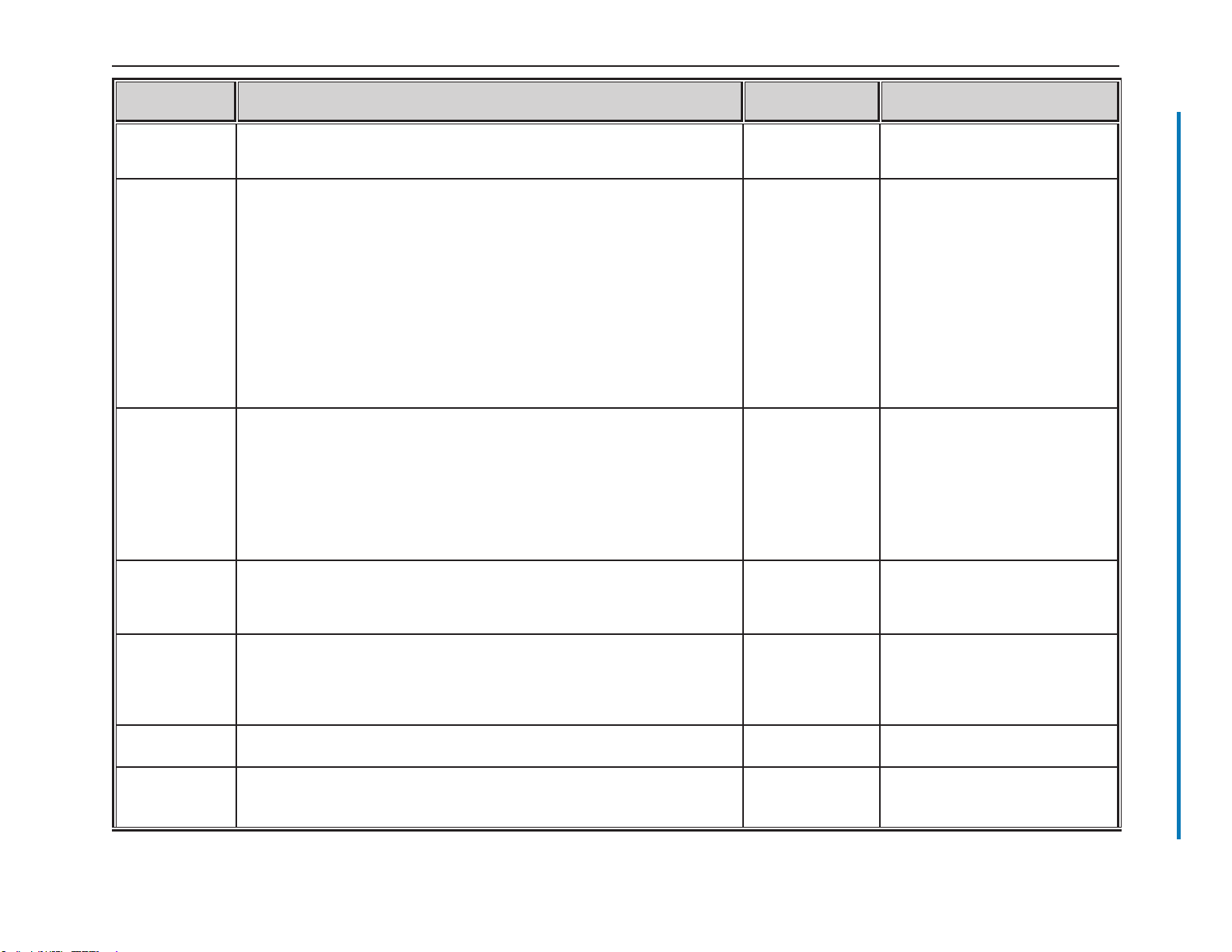

ITEM Art #

Cover Sheet ..................................................................................... 714336-01E

Configuration Sheet .......................................................................... 714419-01Y

Table of Contents.............................................................................. 714362-01G

Section 1 ........................................................................................... 714363-01K

Section 2 ........................................................................................... 714364-01H

Section 3 ........................................................................................... 714365-01C

Section 4 ........................................................................................... 714366-01B

Section 5 ........................................................................................... 714367-01B

Section 6 ........................................................................................... 714368-01E

Section 7 ........................................................................................... 714369-01D

Section 8 ........................................................................................... 714370-01C

Section 9 ........................................................................................... 714371-01D

Section 10 ......................................................................................... 714372-01G

Section 11 ......................................................................................... 714373-01C

Section 12 ......................................................................................... 714374-01E

Section 13 ......................................................................................... 714375-01C

Section 14 ......................................................................................... 714376-01F

Section 15 ......................................................................................... 714377-01F

Section 16 ......................................................................................... 714378-01C

Section 17 ......................................................................................... 714379-01E

Section 18 ......................................................................................... 714380-01E

Section 19 ......................................................................................... 714381-01E

Section 20 ......................................................................................... 714382-01C

Section 21 ......................................................................................... 714383-01E

Section 22 ......................................................................................... 714384-01D

CTI Sheets

Introduction ....................................................................................... 714258-01K

Sodium.............................................................................................. 714173-01H

Potassium ......................................................................................... 714174-01F

Chloride............................................................................................. 714175-01G

Urea Nitrogen/BUN ........................................................................... 714176-01H

Glucose............................................................................................. 714177-01G

Hematocrit/Hemoglobin..................................................................... 714178-01G

Ionized Calcium................................................................................. 714179-01H

PO

/ sO

.......................................................................................... 714180-01H

2

pH ..................................................................................................... 714181-01J

PCO

Total Carbon Dioxide/TCO2............................................................... 716661-01D

Creatinine.......................................................................................... 714183-01K

Lactate .............................................................................................. 714184-01F

Celite ACT......................................................................................... 714185-01E

Kaolin ACT........................................................................................ 715878-01D

Prothrombin Time PT/INR................................................................. 715236-01F

Cardiac Troponin I............................................................................. 715595-01F

Creatine Kinase MB / CK-MB............................................................ 716675-01B

B-Type Natriuretic Peptide/BNP........................................................ 716969-01A

2

/HCO3/BE/AG........................................................................... 714182-01M

2

Art.: 714419-01Y Rev. Date: 03/03/08

Page 4

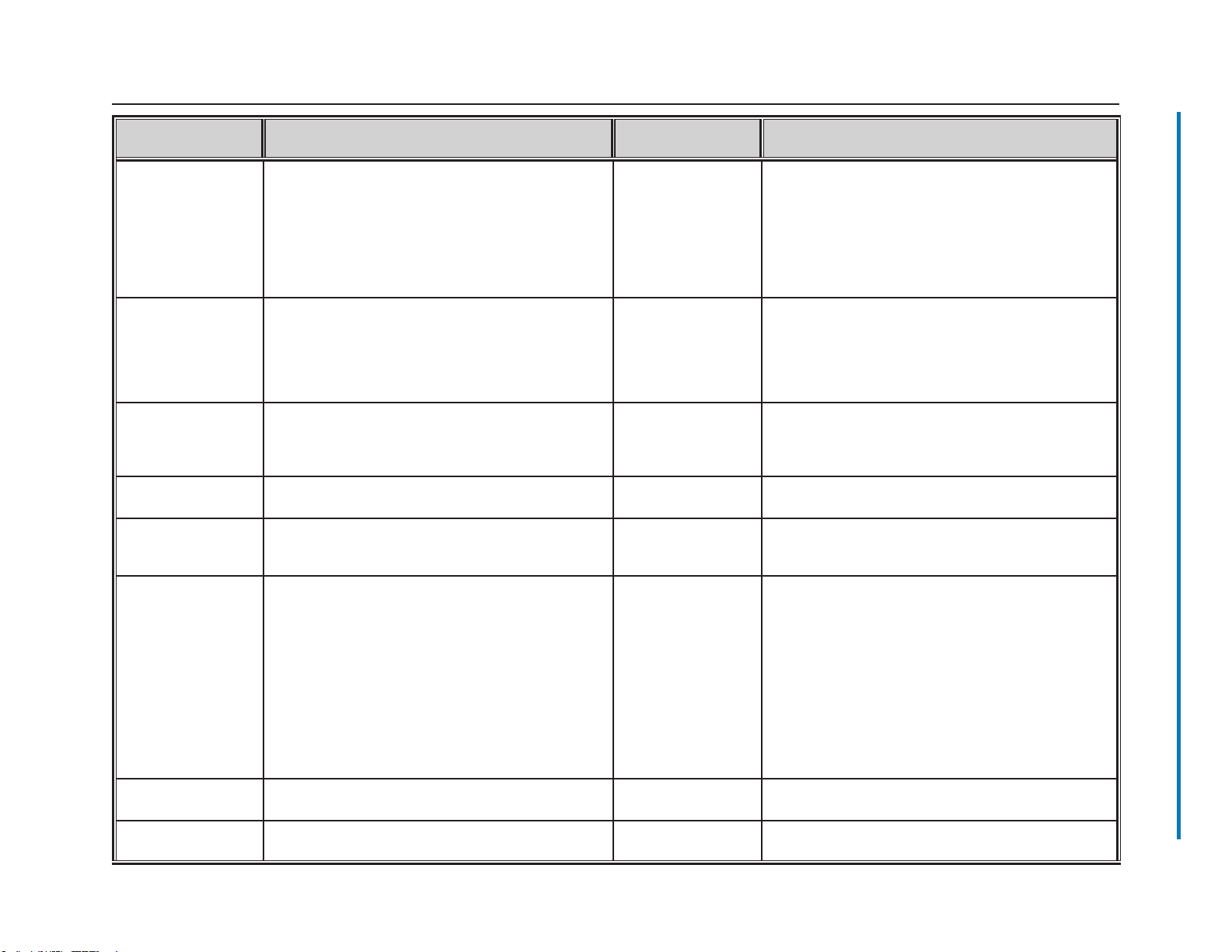

Technical Bulletins

Analyzer Coded Messages ............................................................... 714260-01G

Hematocrit Determination in the i-STAT System

and Comparison to Other Methods. .................................................. 714261-01C

Installation Guide for the Central Data Station to

Receive Data from a Philips Clinical Data Server ............................. 714270-01B

K

EDTA and K3EDTA Customization for

2

Hematocrit on the i-STAT System..................................................... 716240-01B

ACT Test Result Options: Prewarmed vs. Non-Prewarmed

Result Calibration Modes for the i-STAT 1 Analyzer ......................... 715617-01C

Support Services............................................................................... 716144-01G

Using i-STAT

®

Analyzer Customization Features to

Minimize ID Entry Errors. .................................................................. 720654-01A

April 2008 Update to the Central Data Station Version 5 .................. 721106-01A

Art.: 714419-01Y Rev. Date: 03/03/08

Page 5

Contents

INTRODUCTION .................................................................................................... 1 - 1

This Manual .......................................................................................................................................... 1 - 1

Intended Use ........................................................................................................................................ 1 - 1

Overview of the i-STAT System ............................................................................................................ 1 - 1

Components ........................................................................................................................................ 1 - 2

Selection of Components ....................................................................................................................

Summary of the Procedure .................................................................................................................. 1 - 2

Data Management ............................................................................................................................... 1 - 3

Interfacing ............................................................................................................................................ 1 - 3

Note Regarding System Reliability ...................................................................................................... 1 - 3

Symbols ............................................................................................................................................... 1 - 3

Warranty ............................................................................................................................................... 1 - 7

SyStem ComponentS

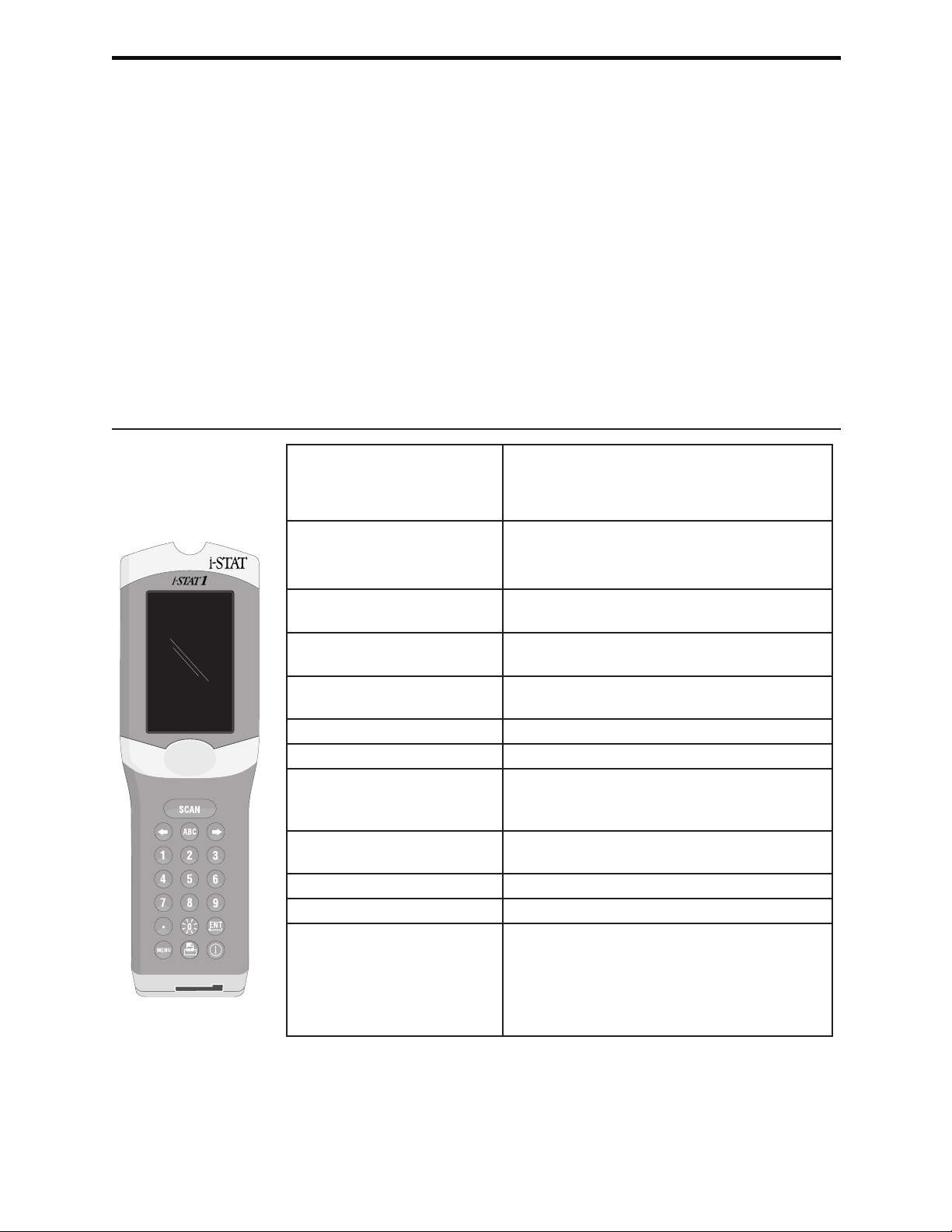

i-STAT 1 ANALYZER .............................................................................................. 2 - 1

Introduction .......................................................................................................................................... 2 - 1

Before You Use the Analyzer ............................................................................................................... 2 - 1

Specifications....................................................................................................................................... 2 - 2

Software ............................................................................................................................................... 2 - 3

Power ...................................................................................................................................................2 - 3

Disposable Batteries ............................................................................................................................ 2 - 3

Rechargeable Battery .......................................................................................................................... 2 - 3

Low Battery Warning............................................................................................................................ 2 - 3

Cartridge Port ...................................................................................................................................... 2 - 4

Test Strip Port ...................................................................................................................................... 2 - 4

Infrared Communication Window ........................................................................................................ 2 - 5

Thermal Control ................................................................................................................................... 2 - 5

Barometric Pressure Sensor ................................................................................................................ 2 - 5

Cartridge Test Cycle ............................................................................................................................. 2 - 5

Strip Test Cycle .................................................................................................................................... 2 - 5

Data Entry ............................................................................................................................................2 - 6

Storage of Results ............................................................................................................................... 2 - 6

LCD Display and Backlight .................................................................................................................. 2 - 7

Audible Indicator .................................................................................................................................. 2 - 7

Time Out .............................................................................................................................................. 2 - 7

Keypad ................................................................................................................................................. 2 - 8

i-STAT 1 Menu Tree .............................................................................................................................. 2 - 9

Test Menu ............................................................................................................................................. 2 - 10

Administration Menu ............................................................................................................................2 - 10

Analyzer Status .................................................................................................................................... 2 - 11

Data Review ......................................................................................................................................... 2 - 11

Quality Tests ......................................................................................................................................... 2 - 12

Customization ..................................................................................................................................... 2 - 13

Set Clock ............................................................................................................................................. 2 - 17

Transmit Data ....................................................................................................................................... 2 - 17

Utility .................................................................................................................................................... 2 - 17

Laser Barcode Scanner ....................................................................................................................... 2 - 18

Prompts and Messages ....................................................................................................................... 2 - 19

1 - 2

Art: 714362-01G Rev. Date: 09/13/06 i

Page 6

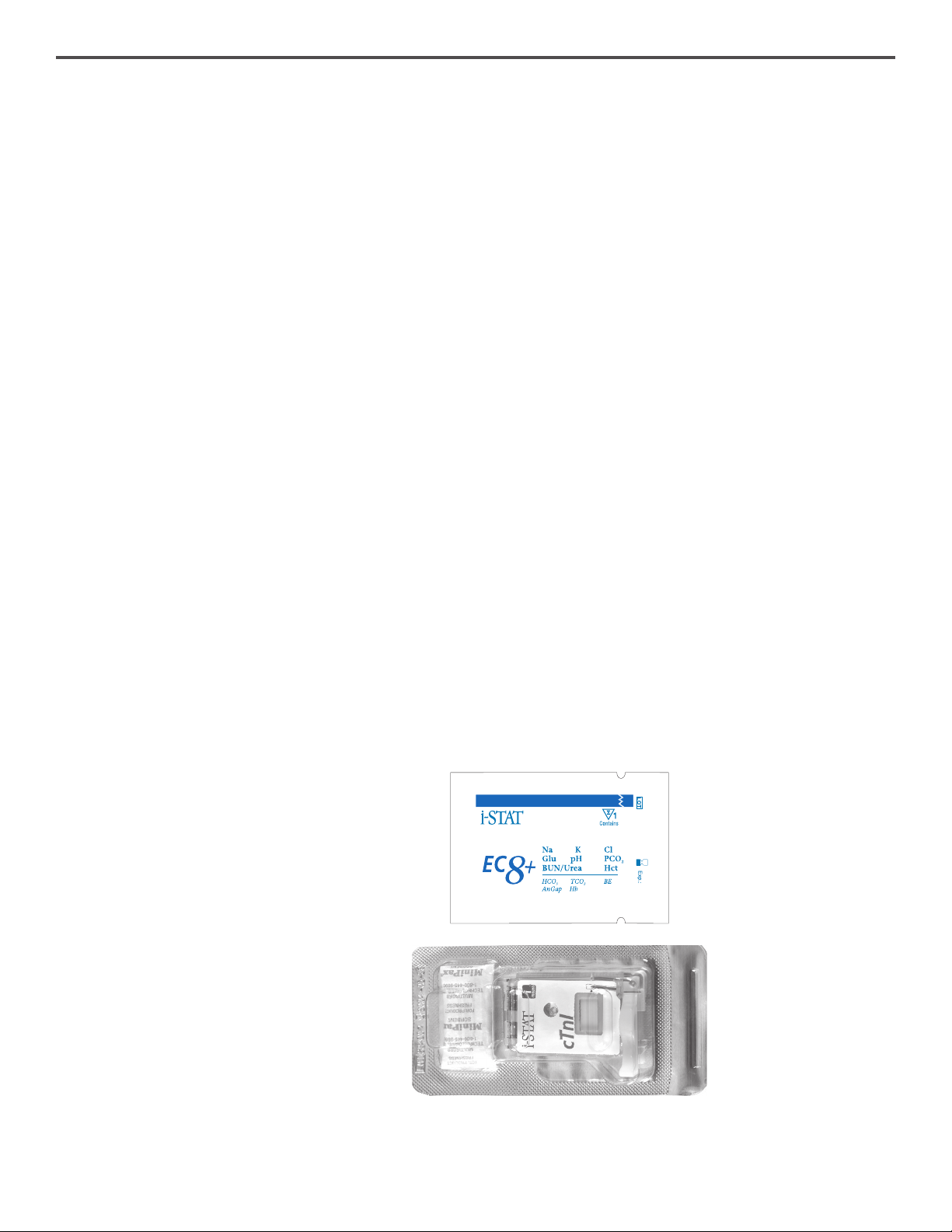

i-STAT CARTRIDGE ............................................................................................... 3 - 1

Contents .............................................................................................................................................. 3 - 1

Standardization and Calibration........................................................................................................... 3 - 3

Packaging ............................................................................................................................................ 3 - 3

Storage Conditions .............................................................................................................................. 3 - 4

Disposal ...............................................................................................................................................3 - 4

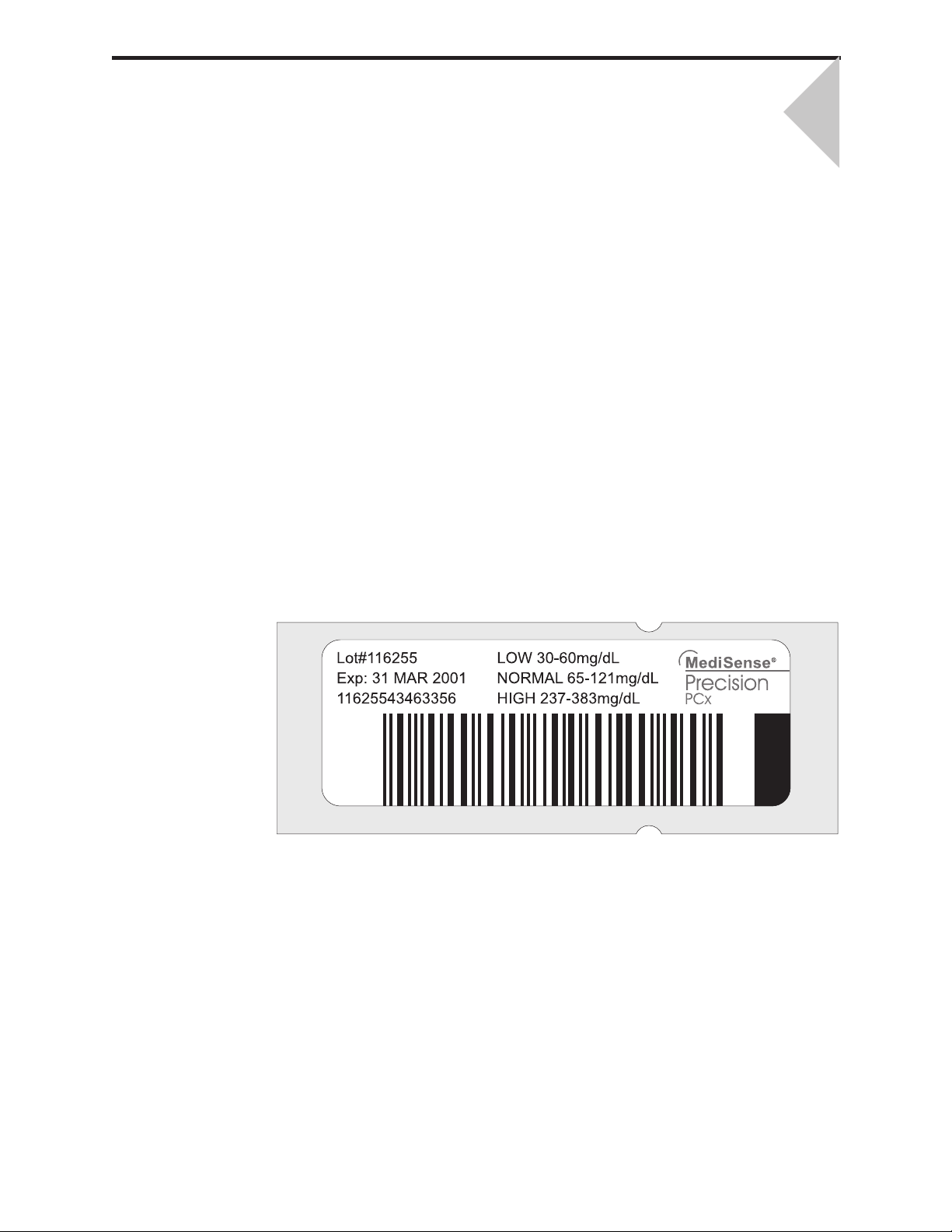

PRECISION PCx AND PCx PLUS BLOOD GLUCOSE TEST STRIPS .................4 - 1

ELECTRONIC SIMULATOR ................................................................................... 5 - 1

Internal Simulator ................................................................................................................................. 5 - 1

External Simulator ................................................................................................................................ 5 - 1

Operating Characteristics .................................................................................................................... 5 - 2

Cleaning the Simulator ......................................................................................................................... 5 - 2

i-STAT 1 DOWNLOADER ....................................................................................... 6 - 1

Function ............................................................................................................................................... 6 - 1

Specifications....................................................................................................................................... 6 - 2

Power Supply ....................................................................................................................................... 6 - 2

Downloader/Recharger Indicator LEDs ............................................................................................... 6 - 3

Power Requirements ............................................................................................................................ 6 - 3

Cautions ............................................................................................................................................... 6 - 3

Transmitting Data from Downloader to the Data Manager ..................................................................6 - 4

Transmitting Data from Downloader/Recharger to the Data Manager................................................. 6 - 4

Transmitted Information ....................................................................................................................... 6 - 4

Troubleshooting ................................................................................................................................... 6 - 5

Charging the Rechargeable Battery ..................................................................................................... 6 - 5

Charging Rechareable Battery in the External Recharge Compartment ............................................. 6 - 6

PORTABLE PRINTER .............................................................................................7 - 1

MARTEL Printer ......................................................................................................................................... 7 - 1

Overview .............................................................................................................................................. 7 - 1

Specifications....................................................................................................................................... 7 - 1

Supplies Provided with Printer ............................................................................................................. 7 - 2

Power ................................................................................................................................................... 7 - 2

Loading Paper ...................................................................................................................................... 7 - 2

Printing Directly from the Analyzer ....................................................................................................... 7 - 3

Printing Via a Downloader .................................................................................................................... 7 - 3

Printing Many Results .......................................................................................................................... 7 - 4

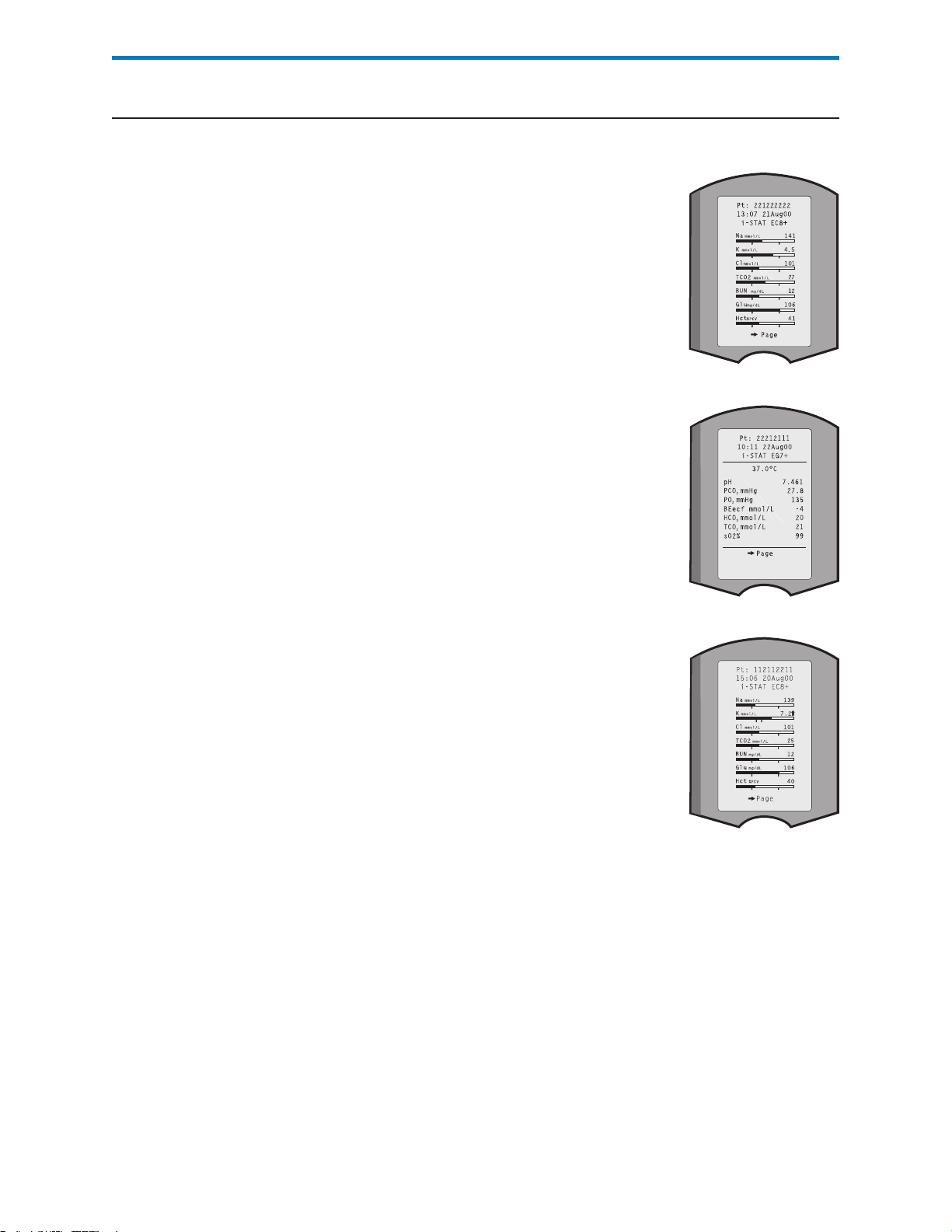

What is Printed ..................................................................................................................................... 7 - 4

Cautions ............................................................................................................................................... 7 - 4

Troubleshooting ................................................................................................................................... 7 - 5

DATA MANAGEMENT ............................................................................................ 8 - 1

Introduction .......................................................................................................................................... 8 - 1

Components ........................................................................................................................................ 8 - 1

Data Manager ...................................................................................................................................... 8 - 2

i-STAT Central Data Station Version 5 Software .................................................................................. 8 - 2

Downloader and Downloader/Recharger ............................................................................................. 8 - 3

IR Link .................................................................................................................................................. 8 - 3

LIS/HIS Interface .................................................................................................................................. 8 - 3

Standard Data Management Configuration ......................................................................................... 8 - 4

Connecting Components ..................................................................................................................... 8 - 4

CUSTOMIZATION .................................................................................................. 9 - 1

ii Art: 714362-01G Rev. Date: 09/13/06

Page 7

proCedureS

SAMPLE COLLECTION ......................................................................................... 10 - 1

Specimen Collection ............................................................................................................................ 10 - 1

Venipuncture - General ........................................................................................................................ 10 - 1

Venipuncture - pH, PCO2, Electrolyte, Chemistry, and Hematocrit Tests .......................................... 10 - 2

Venipuncture - Coagulation Tests ........................................................................................................ 10 - 4

Venipuncture - Glucose Test Strip ....................................................................................................... 10 - 4

Arterial Puncture - General .................................................................................................................. 10 - 4

Arterial Puncture - Blood Gas, Electrolyte, Chemistry, and Hematocrit Tests .................................... 10 - 4

Arterial Puncture - Coagulation Tests ................................................................................................. 10 - 6

Arterial Puncture - Glucose Test Strips ............................................................................................... 10 - 6

Indwelling Line ..................................................................................................................................... 10 - 6

Skin Puncture ....................................................................................................................................... 10 - 7

Sample Transfer Devices ..................................................................................................................... 10 - 7

References ........................................................................................................................................... 10 - 8

PROCEDURE FOR HANDLING CARTRIDGES .................................................... 11 - 1

Preparation for Testing ......................................................................................................................... 11 - 1

Filling and Sealing Cartridge Using Transfer Device ............................................................................ 11 - 2

Filling and Sealing PT/INR Cartridges Using Direct Fingerstick Sampling .......................................... 11 - 2

Filling and Closing a cTnI Cartridge Using Transfer Device ................................................................. 11 - 3

Inserting and Removing the Cartridge From the Analyzer ................................................................... 11 - 4

Incorrect Procedure ............................................................................................................................. 11 - 5

PROCEDURE FOR CARTRIDGE TESTING .......................................................... 12 - 1

Cautions ............................................................................................................................................... 12 - 1

Performing Patient Analysis with Cartridge – Information First Disabled ............................................ 12 - 2

Performing Patient Analysis with Cartridge – Information First Enabled ............................................. 12 - 4

Interpretation of Displayed Results ..................................................................................................... 12 - 7

Troubleshooting ................................................................................................................................... 12 - 9

PROCEDURES FOR GLUCOSE TEST STRIP TESTING ..................................... 13 - 1

Operating Guidelines for All Samples .................................................................................................. 13 - 1

Performing Patient Glucose Assay with Test Strip .............................................................................. 13 - 2

Caution ................................................................................................................................................. 13 - 4

Interpretation of Displayed Results ...................................................................................................... 13 - 5

Troubleshooting ................................................................................................................................... 13 - 6

QUALITY CONTROL .............................................................................................. 14 - 1

Overview ............................................................................................................................................. 14 - 1

Quality Control for i-STAT Cartridges and the Analyzer’s Cartridge Test Cycle ................................... 14 - 1

Controls for Blood Gas/Electrolyte/Metabolite Cartridges (Except CHEM8+ Cartridges) ................... 14 - 3

Correction of PO2 at Extreme Altitude................................................................................................. 14 - 5

Controls for CHEM8+ Cartridges ......................................................................................................... 14 - 6

RNA® Medical Hematocrit Control ....................................................................................................... 14 - 8

Meter Trax™ Controls for Hematocrit Sensor...................................................................................... 14 - 9

Controls for ACT Cartridges ................................................................................................................ 14 - 9

Controls for PT/INR Cartridges ............................................................................................................ 14 - 10

Controls for cTnI Cartridges................................................................................................................. 14 - 12

Cliniqa Liquid QC™ Cardiac Marker Controls for i-STAT .................................................................... 14 - 13

i-STAT BNP Controls ............................................................................................................................ 14 - 14

Performing Electronic Simulator Test ................................................................................................... 14 - 15

Procedure for Internal Electronic Simulator ......................................................................................... 14 - 15

Procedure for External Electronic Simulator ........................................................................................ 14 - 15

Troubleshooting Failed Electronic Simulator Test ................................................................................ 14 - 16

Checking the Thermal Probes in the i-STAT Analyzers ........................................................................ 14 - 17

Art: 714362-01G Rev. Date: 09/13/06 iii

Page 8

Procedure to Check Ambient Temperature .......................................................................................... 14 - 19

Performing Control Test on Cartridge .................................................................................................. 14 - 19

Troubleshooting Out-of-Range Control Results on Cartridge ............................................................. 14 - 21

Controls for Glucose Test Strip ............................................................................................................ 14 - 21

Recommendations for Glucose Test Strips ......................................................................................... 14 - 22

Performing Control Test with Glucose Strip ......................................................................................... 14 - 22

Troubleshooting Out-of-Range Results on Test Strips ........................................................................ 14 - 24

Quality Control Log Sheets .................................................................................................................. 14 - 25

CALIBRATION VERIFICATION .............................................................................. 15 - 1

Calibration Verification for

Blood Gas/Electrolyte/Metabolite Cartridges (Except CHEM8+ Cartridges) ....................................... 15 - 1

i-STAT Calibration Verification Set ....................................................................................................... 15 - 2

i-STAT CHEM8+ Calibration Verification Set ........................................................................................ 15 - 3

i-STAT Cardiac Marker Calibration Verification Set .............................................................................. 15 - 5

i-STAT BNP Calibration Verification Set ............................................................................................... 15 - 6

RNA® Medical Hematocrit Calibration Verification Controls ................................................................ 15 - 7

Verification Procedure for Hematocrit .................................................................................................. 15 - 8

Verification Procedure for ACT ............................................................................................................. 15 - 9

Procedure for Cartridges ..................................................................................................................... 15 - 10

Troubleshooting Cartridge Tests .......................................................................................................... 15 - 11

Linearity/Calibration Verification Test for Test Strips ............................................................................ 15 - 12

Troubleshooting Strip Tests.................................................................................................................. 15 - 13

PROFICIENCY or EXTERNAL QUALITY CONTROL TESTING ........................... 16 - 1

Purpose ................................................................................................................................................ 16 - 1

General Procedure ............................................................................................................................... 16 - 1

Procedure For Cartridges .................................................................................................................... 16 - 1

Troubleshooting ................................................................................................................................... 16 - 3

Procedure for Test Strips ..................................................................................................................... 16 - 4

Care and Software updateS

ROUTINE CARE of the ANALYZER and DOWNLOADER ................................... 17 - 1

Drying a Wet Analyzer or Downloader ................................................................................................ 17 - 1

Cleaning the Analyzer and Downloader ............................................................................................... 17 - 1

Removing and Replacing Disposable Batteries ................................................................................... 17 - 2

Removing and Replacing the Rechargeable Battery ........................................................................... 17 - 3

UPDATING THE SOFTWARE ................................................................................. 18 - 1

CLEW .................................................................................................................................................. 18 - 1

Application Software ............................................................................................................................ 18 - 1

Software Updates ................................................................................................................................ 18 - 1

Updating Analyzer Software: JAMMLITE Utility ................................................................................... 18 - 2

Troubleshooting ................................................................................................................................... 18 - 8

Analyzer-to-Analyzer Software Updates .............................................................................................. 18 - 9

Performing a JAMS and CLEW update on an i-STAT 1 Analyzer using

the Customization Workspace ............................................................................................................ 18 - 10

troubleShooting the analyzer

TROUBLESHOOTING THE ANALYZER ................................................................ 19 - 1

Introduction .......................................................................................................................................... 19 - 1

Information Needed ............................................................................................................................. 19 - 1

Startup Messages ................................................................................................................................ 19 - 2

iv Art: 714362-01G Rev. Date: 09/13/06

Page 9

Test Cycle Messages and Quality Check Codes ................................................................................. 19 - 3

Glucose Strip Errors ............................................................................................................................. 19 - 6

No Display ............................................................................................................................................ 19 - 7

“Cartridge Locked” Not Removed ....................................................................................................... 19 - 7

theory

THEORY .................................................................................................................. 20 - 1

Analyzer Functions ............................................................................................................................... 20 - 1

Electrochemical Measurements ........................................................................................................... 20 - 3

Determination of Test Results .............................................................................................................. 20 - 4

Determination of Cell Concentration .................................................................................................... 20 - 5

CPB ...................................................................................................................................................... 20 - 5

Determination of Coagulation Endpoints ............................................................................................. 20 - 7

Quality Control and the i-STAT System ................................................................................................ 20 - 7

Quality Control and the i-STAT Coagulation Tests ............................................................................... 20 - 13

downloader programming

DOWNLOADER PROGRAMMING AND WIRING ................................................. 21 - 1

Programming the Network Downloaders ............................................................................................. 21 - 1

Wiring the Downloaders ....................................................................................................................... 21 - 6

Central data Station

CENTRAL DATA STATION ..................................................................................... 22 - 1

i-STAT License Agreement and Warranty for Central Data Station Program ....................................... 22 - 1

Installation Of The Central Data Station............................................................................................... 22 - 3

General Procedures and Conventions ................................................................................................. 22 - 5

Customization of the Central Data Station .......................................................................................... 22 - 9

Interface Program Customization ........................................................................................................ 22 - 15

Overview of the Central Data Station Program .................................................................................... 22 - 17

Administration Tools ............................................................................................................................. 22 - 19

Instrument and Location Workspace ................................................................................................... 22 - 19

Operator Workspace ............................................................................................................................ 22 - 25

Operator List Import ............................................................................................................................. 22 - 31

Database Maintenance ........................................................................................................................ 22 - 33

Inventory Workspace ........................................................................................................................... 22 - 37

Customization Workspace ................................................................................................................... 22 - 43

User Administration Workspace .......................................................................................................... 22 - 51

Password Management ....................................................................................................................... 22 - 53

Data Viewers ........................................................................................................................................ 22 - 55

Data Export .......................................................................................................................................... 22 - 62

Monitors ............................................................................................................................................... 22 - 63

Reports ................................................................................................................................................ 22 - 65

System ................................................................................................................................................. 22 - 68

Windows Operating System and Language Support .......................................................................... 22 - 69

Art: 714362-01G Rev. Date: 09/13/06 v

Page 10

Cartridge and teSt information

Cartridge and Test Information

Sodium

Potassium

Chloride

BUN/Urea

Glucose

Hematocrit/Hemoglobin

Ionized Calcium

PO

2

pH

PCO

2

Total Carbon Dioxide/TCO

Creatinine

Lactate

Celite ACT

Kaolin ACT

Prothrombin Time PT/INR

Cardiac Troponin I

Creatine Kinase MB/CK-MB

2

B-Type Natriuretic Peptide/BNP

teChniCal bulletinS

vi Art: 714362-01G Rev. Date: 09/13/06

Page 11

INTRODUCTION

1

This Manual

Intended Use

Overview of the

i-STAT System

This manual describes the i-STAT1 Analyzer and the Central Data Station software.

Related sections are grouped behind tabs.

The i-STAT Portable Clinical Analyzer and the Philips Medical Systems Blood

Analysis Module (formerly supplied by Agilent Technologies, and Hewlett-Packard,

Inc., for the Viridia CMS Patient Monitors) are described in a separate manual.

The i-STAT 1 Analyzer is intended for use with i-STAT cartridges for in vitro

quantification of various analytes in whole blood and with the Abbott MediSense

Precision PCx Blood Glucose Test Strip for the in vitro quantification of glucose

in whole blood. Analyzers, cartridges, and test strips should be used by healthcare

professionals trained and certified to use the system and should be used according

to the facility’s policies and procedures.

In the USA, for the purpose of CLIA compliance, the i-STAT CHEM8+ cartridge is

categorized as Waived. All other i-STAT cartridges are categorized as moderate

complexity.

The i-STAT System incorporates a comprehensive group of components needed

to perform blood analysis at the point of care. A portable handheld analyzer, a

cartridge with the required tests, and 2-3 drops of blood will allow the caregiver

to view quantitative test results for blood gas, chemistry and coagulation tests in

approximately two minutes. Glucose results are available from the Precision PCx

Blood Glucose Test Strip in as little as 20 seconds on the handheld analyzer.

Portable printers and infrared communication devices allow all patient information

obtained at the bedside to be printed on demand and transmitted to centralized

information systems for record keeping and billing.

The Central Data Station program provides system management tools including

real-time monitoring of testing and operator competency.

Art: 714363-01K Rev. Date: 03/03/08 1-1

Page 12

Components

The i-STAT System consists of:

i-STAT Cartridges

Abbott MediSense Precision PCx and PCx Plus Blood Glucose Test

Strips

i-STAT 1 Analyzer

i-STAT Portable Clinical Analyzer

Philips Medical Systems Blood Analysis Module (used in conjunction

with a patient monitor)

Portable Printer

Quality Assurance Materials

• Electronic Simulator

• Control Solutions

• Calibration Verification Set (for cartridges)

• Linearity Assessment Kit (for test strips)

Data Management System

• i-STAT 1 Downloader

• i-STAT 1 Downloader/Recharger

• IR Link for Portable Clinical Analyzer

•

Data Manager

Central Data Station (data management software for cartridges)

QC Manager (data management software for test strips)

Selection of

Components

Summary of the

Procedure

Data Manager Printer

LIS/HIS Interface Software

The selection of system components is dependent on factors unique to each

facility such as:

Types of tests to be performed

Number of testing sites

Number of tests per site

System administration requirements

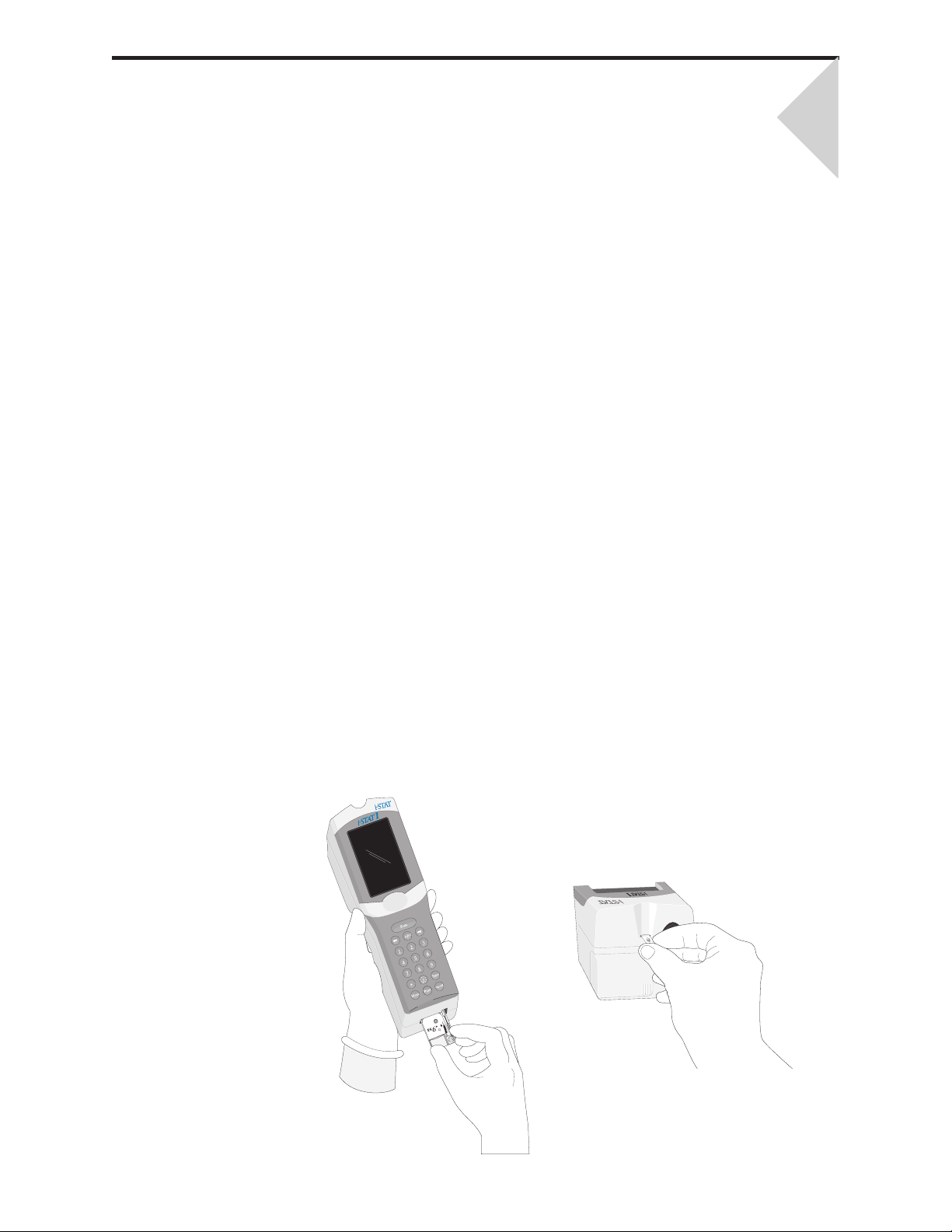

To perform cartridge testing, the operator fills a cartridge with sample, seals the

cartridge with its snap closure, and inserts the cartridge into the analyzer. Inserting the

cartridge activates the analyzer. Alternatively, the cartridge test cycle can be initiated

from the keypad/menu system. The unit-use cartridge contains all components to

perform one or more tests including: calibrating solution, sample handling system,

sensors and reagents. The analyzer automatically controls all steps in the testing cycle,

which may include: fluid movement, reagent mixing, calibration and thermal control.

Quality checks are performed continuously throughout the test cycle. Operator and

patient IDs and patient chart information can be entered. When the test cycle is

completed, results are displayed and the test record is stored. To perform glucose

test strip testing, the operator selects a the glucose strip option from the menu, scans

the test strip barcode, inserts the test strip into the analyzer test strip port and applies

sample to the test strip. This degree of automation, along with the ability to test fresh

whole blood, eliminates many sources of error as well as time-consuming and costly

steps inherent in other methods.

1-2 Art: 714363-01K Rev. Date: 03/03/08

Page 13

Data Management

Test records can be transmitted to the Data Manager where they can be printed

and/or transmitted to the Laboratory Information System or Hospital Information

System. An optional portable printer enables the operator to print results at the

point of care.

Interfacing

The Data Manager can be interfaced to a Laboratory Information System (LIS)

or Hospital Information System (HIS) to automate billing and patient record

keeping.

Note Regarding

System Reliability

The i-STAT System automatically runs a comprehensive set of quality checks of

analyzer and cartridge performance each time a sample is tested. This internal quality

system will suppress results if the analyzer or cartridge does not meet certain internal

specifications (see Quality Control section in System Manual for detailed information).

To minimize the probability of delivering a result with medically significant error the

internal specifications are very stringent. It is typical for the system to suppress a

very small percentage of results in normal operation given the stringency of these

specifications. If however the analyzer or cartridges have been compromised,

results may be persistently suppressed, and one or the other must be replaced to

restore normal operating conditions. Where unavailability of results while awaiting

replacement of analyzers or cartridges is unacceptable, Abbott Point of Care Inc.

recommends maintaining both a backup i-STAT System analyzer and cartridges

from an alternate lot number.

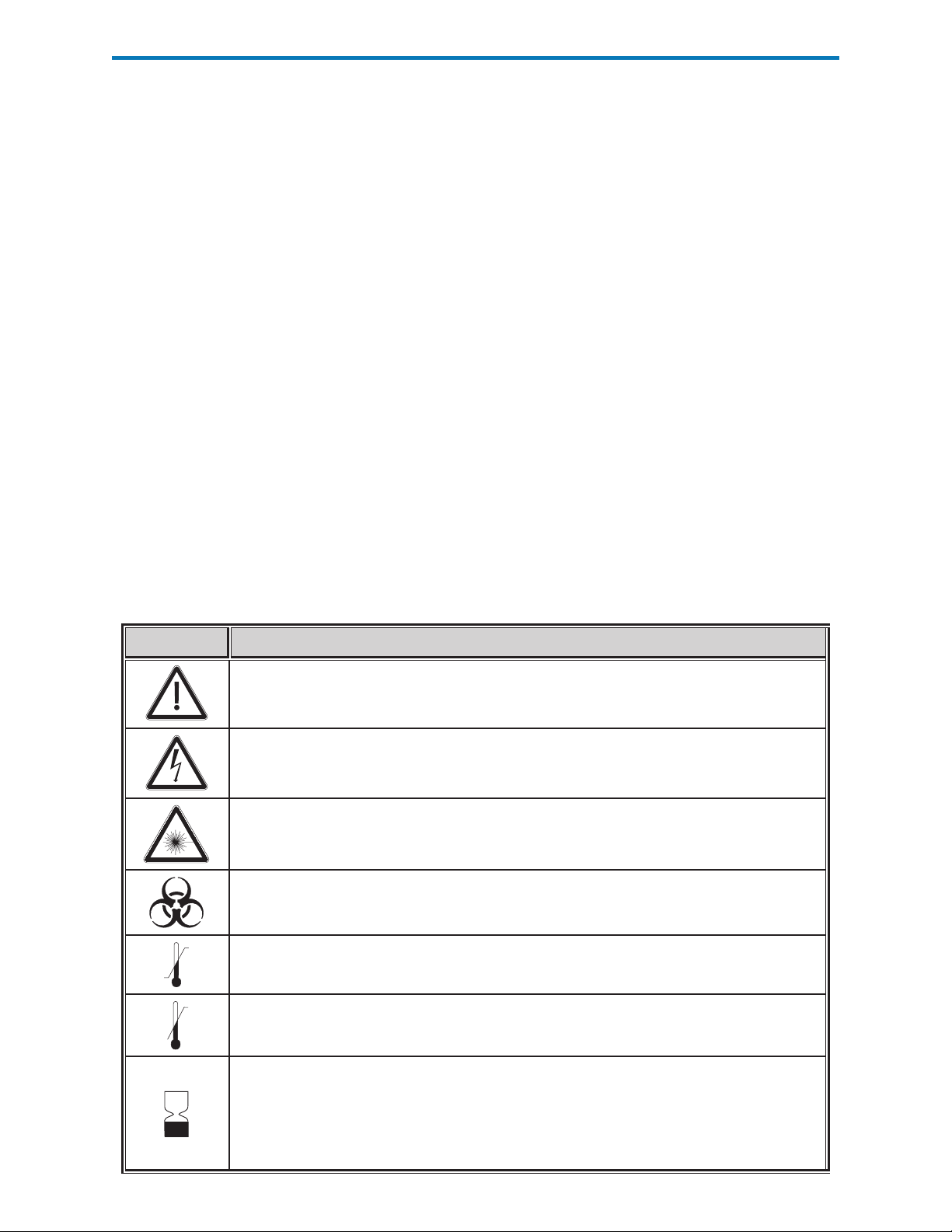

Symbols Symbols can be helpful in reducing the necessity for translating important information

into multiple languages, particularly where space is limited. The following symbols

may be found on components of the i-STAT System.

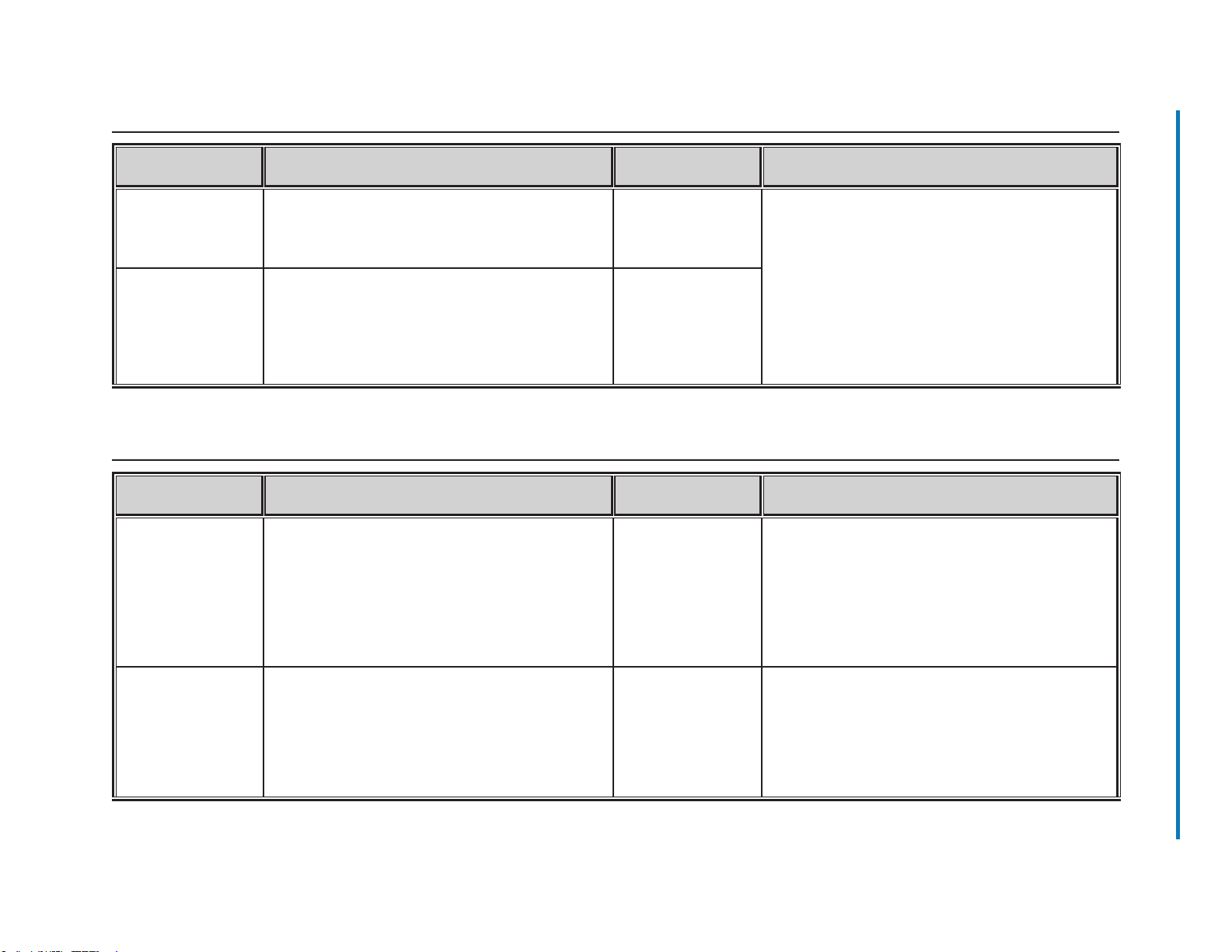

Symbol Definition

Attention: See instructions for use.

Caution: Risk of electrical shock.

Laser radiation hazard symbol.

Biological Risks.

Temperature limitations. The upper and lower limits for storage are adjacent to

upper and lower arms.

Upper limit of temperature.

The upper limit for storage is adjacent to the upper arm

Use by or expiration date.

An expiration date expressed as YYYY-MM-DD means the last day the product can be

used.

An expiration date expressed as YYYY-MM means the product cannot be used past the

last day of the month specified.

Art: 714363-01K Rev. Date: 03/03/08 1-3

Page 14

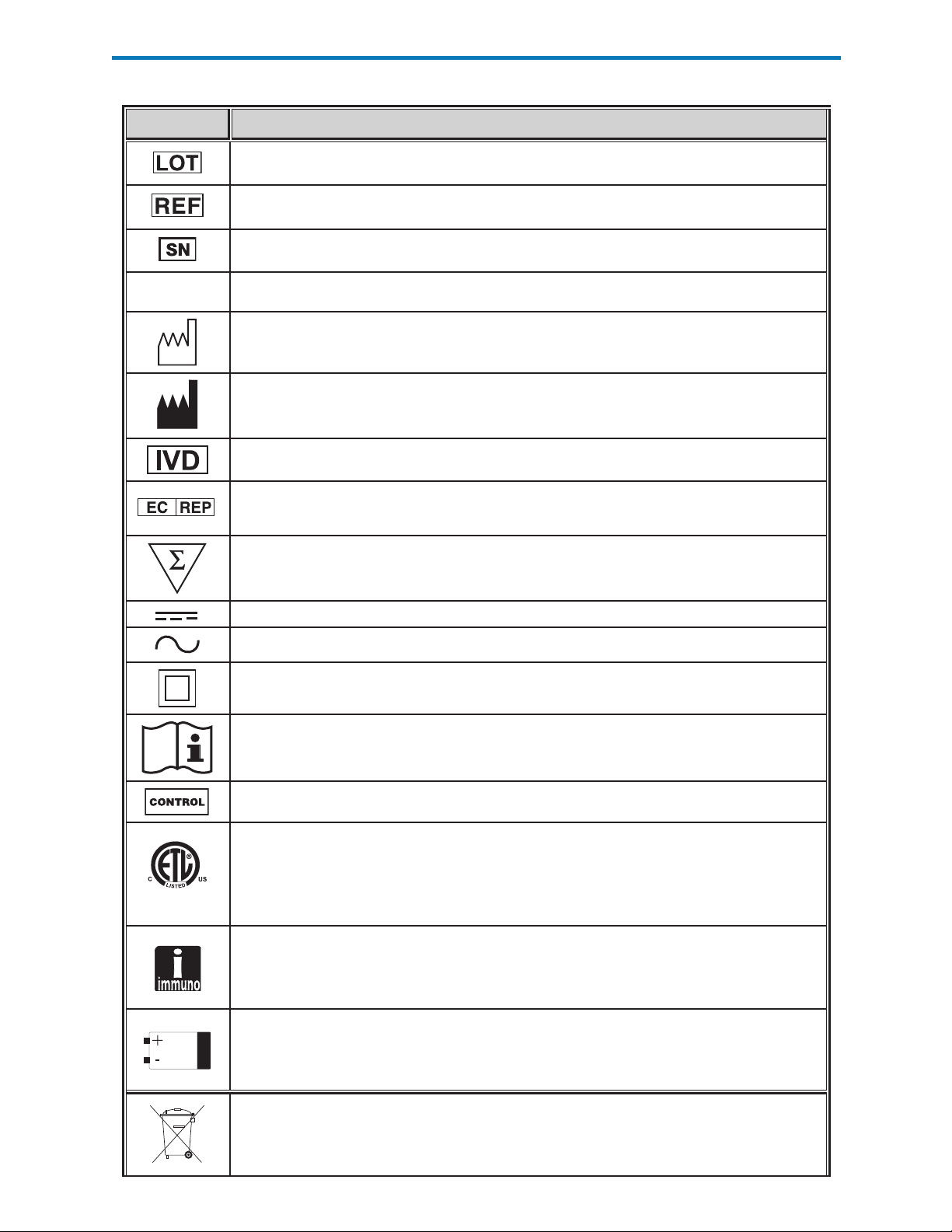

Symbol Definition

Manufacturer's lot number or batch code. The lot number or batch will appear

adjacent to this symbol.

Catalog number, list number, or reference number. The number adjacent to this

symbol is used to reorder the product.

Serial number. The serial number will appear adjacent to this symbol.

MN

Model number. The model number will appear adjacent to this symbol.

Date of manufacture.

Manufacturer

In vitro diagnostic medical device.

Authorized Representative for Regulatory Affairs in the European

Community.

Contains sufficient for < n > tests.

Direct Current (DC)

Alternating Current (AC)

Class II Construction

Consult instructions for use or see System Manual for instructions.

Control

Signifies that the product bearing the ETL Listed mark complies with both U.S. and

Canadian product safety standards:

UL 61010A-1

CAN/CSA C22.2 No. 1010.1-92

i/immuno: Cartridges bearing this symbol must be run on i-STAT analyzers that also

bear this symbol.

Battery: i-STAT 1 Analyzer low battery icon (flashes on lower left side of display

screen).

Separate waste collection for this electrical/electronic item indicated.

1-4 Art: 714363-01K Rev. Date: 03/03/08

Page 15

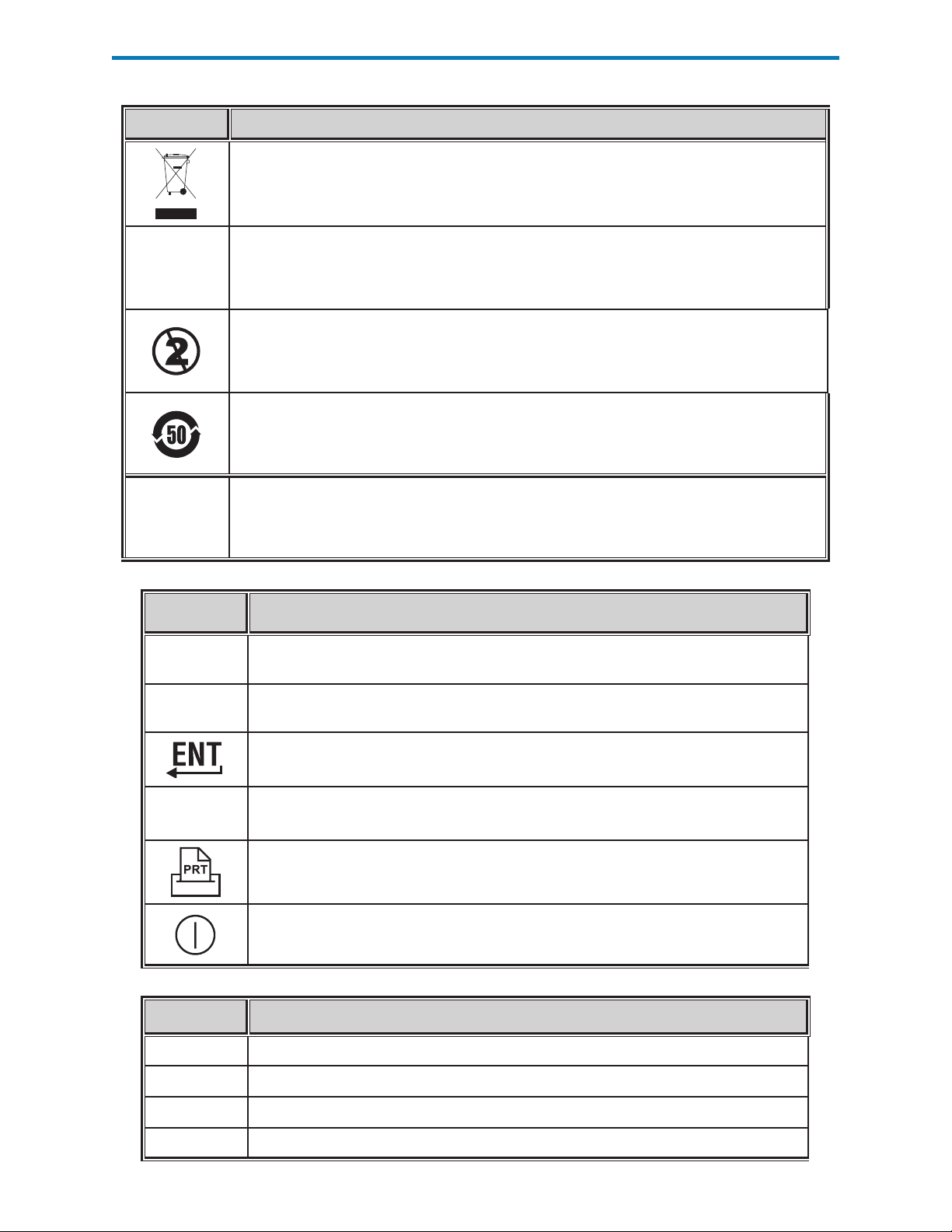

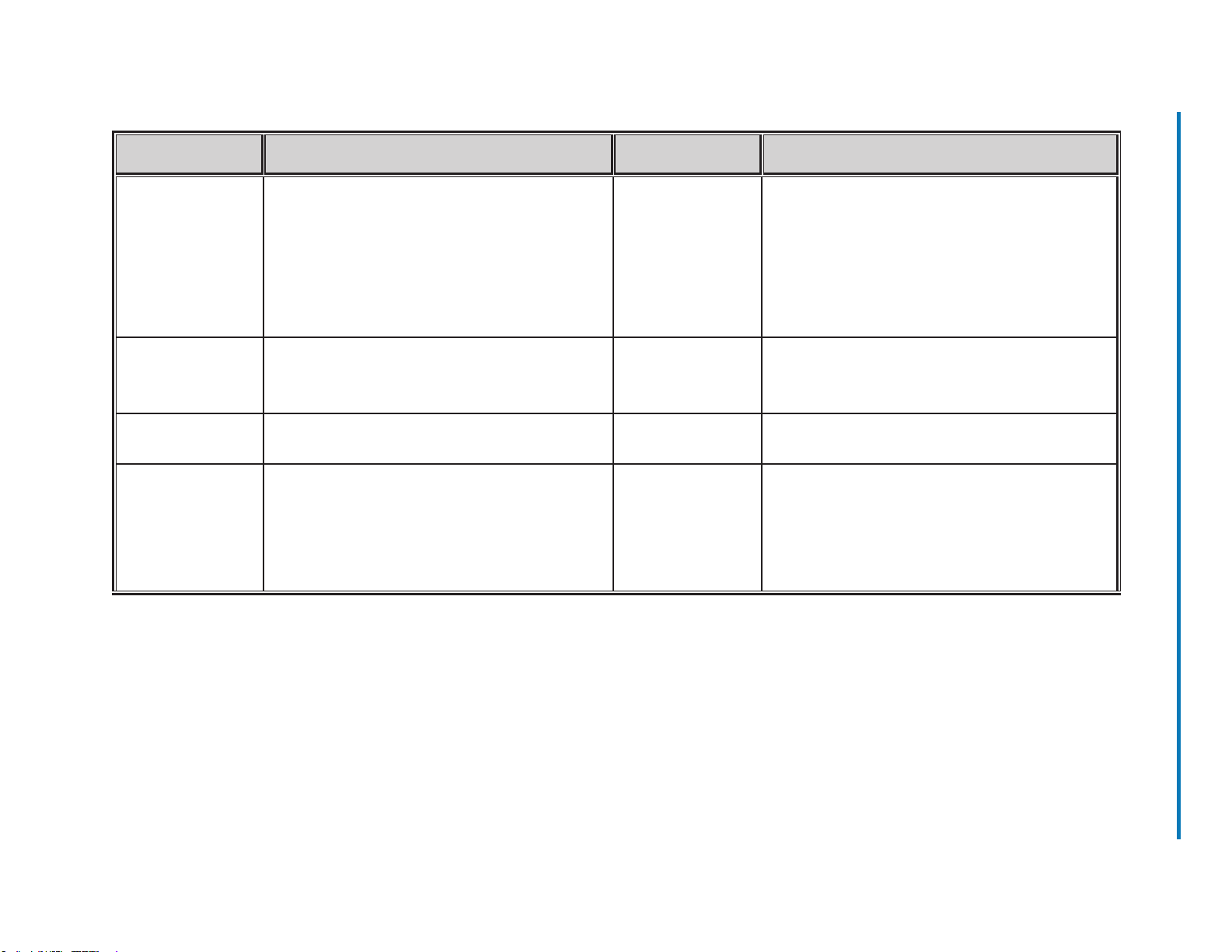

Symbol Definition

Separate waste collection for this electrical/electronic item indicated; Equipment

manufactured / put on the market after 13 August 2005; Indicates compliance with

Article 10(3) of Directive 2002/96/EC (WEEE) for the European Union (EU).

BODxxxx-xx Born On Date: the label BODxxxx-xx defines the year and month of manufacture.

Do not reuse.

This symbol is used for compliance with the China RoHS regulation(s). It indicates

in years the Environmentally Friendly Use Period (EFUP) for the labeled electronic

medical device product

As the Martel Printer is incapable of printing the ↑ or ↓ symbols, this symbol

<< >>

appears on the Martel printout next to results which are outside the action range

limits.

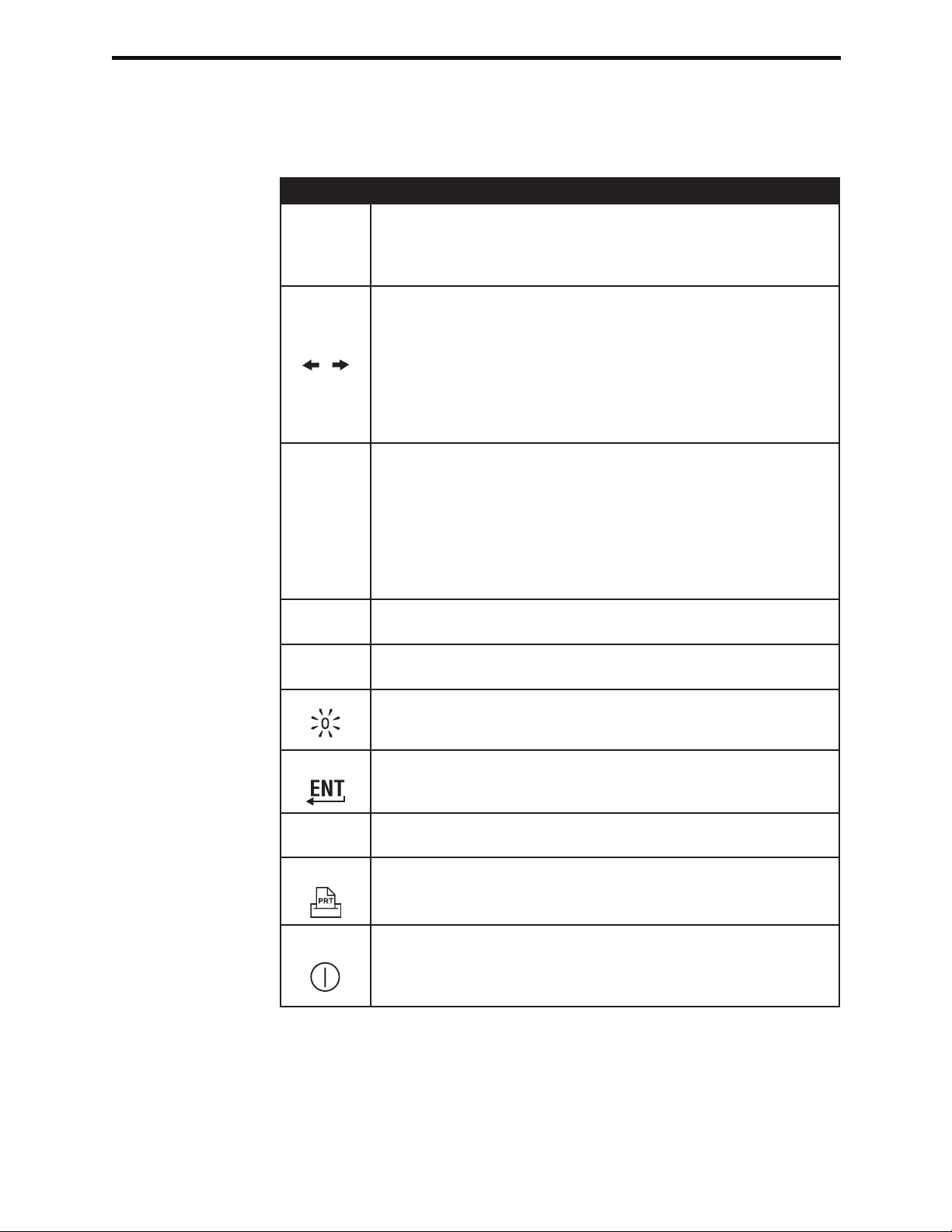

Symbol The following symbols are used on the i-STAT 1 keypad.

SCAN

ABC

MENU

Symbol

DIS

Key used to scan information into the analyzer.

Key used to enter letters.

Key used to enter information.

Key used to access the analyzer's menu.

Key used to print a test record.

Key used to turn the analyzer off and on.

The following symbols are used on the i-STAT Portable Clinical Analyzer Keypad

Key used to activate the display.

ENT

PRT

CLR

Art: 714363-01K Rev. Date: 03/03/08 1-5

Key used to enter information.

Key used to print a test record.

Key used to clear an incorrect entry.

Page 16

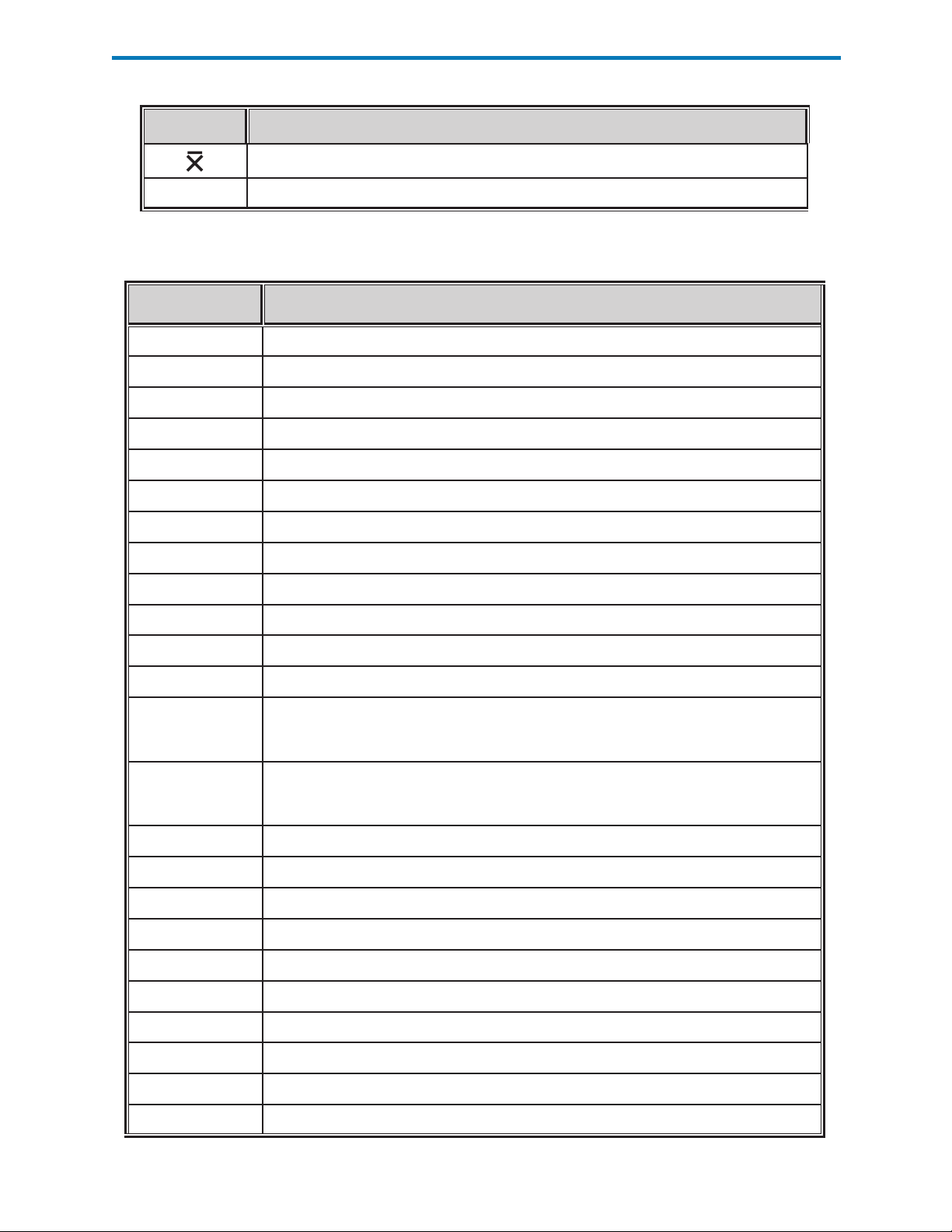

Symbol

The following symbols are used on i-STAT Value Assignment Sheets

Mean

R

Symbol TEST

Na

K

Cl

Glu

Lac

Crea

pH

PCO

PO

2

iCa

Range

Sodium

Potassium

Chloride

Glucose

Lactate

Creatinine

pH

2

Partial pressure of carbon dioxide.

Partial pressure of oxygen.

Ionized Calcium

BUN/UREA

Hct

ACTc

Celite ACT

ACTk

Kaolin ACT

PT/INR

Hb

TCO2

HCO3

BE (b&ecf)

AnGap

sO2

cTnI

CK-MB

Urea nitrogen/Urea

Hematocrit

Activated Clotting Time with Celite® activator.

Activated Clotting Time with Kaolin activator.

Prothrombin Time / International Normalized Ratio

Hemoglobin

Total carbon dioxide concentration.

Bicarbonate

Base excess (b for blood, ecf for extra cellular fluid)

Anion Gap

Oxygen saturation

Cardiac Troponin I

Creatine Kinase MB Isoenzyme

BNP

1-6 Art: 714363-01K Rev. Date: 03/03/08

B-type Natriuretic Peptide

Page 17

Warranty

Abbott Point of Care Inc. warrants this medical product (excluding disposable or

consumable supplies) against defects in materials and workmanship for one year

from the date of shipment. If Abbott Point of Care Inc. receives notice of such

defects during the warranty period, Abbott Point of Care Inc. shall, at its option,

either repair or replace products which prove to be defective. With respect to

software or firmware, if Abbott Point of Care Inc. receives notice of defects in

these products during the warranty period, Abbott Point of Care Inc. shall repair or

replace software media and firmware which does not execute their programming

instructions due to such defects. Abbott Point of Care Inc. does not warrant that the

operating of the software, firmware or hardware shall be uninterrupted or error free.

If Abbott Point of Care Inc. is unable, within a reasonable time, to repair or replace

any product to a condition as warranted, Buyer shall be entitled to a refund of the

purchase price upon return of the product to Abbott Point of Care Inc..

Note: Warranty rights may vary from state to state, province to province and

country to country.

Limitations of

Warranty

Selling or Leasing the

i-STAT System

The foregoing warranty shall not apply to defects resulting from:

1 Improper or inadequate maintenance by Buyer or an unauthorized

person,

2

Using accessories and/or consumables that are not approved by Abbott

Point of Care Inc.,

3 Buyer-supplied software or interfacing,

4 Unauthorized repairs, modifications, misuse, or damage caused by

disposable batteries, or rechargeable batteries not supplied by Abbott

Point of Care Inc..

5 Operating outside of the environmental specifications of the product, or

6 Improper site preparation or maintenance.

THE WARRANTY SET FORTH ABOVE IS EXCLUSIVE AND NO OTHER WARRANTY,

WHETHER WRITTEN OR ORAL, IS EXPRESSED OR IMPLIED. ABBOTT

SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OR MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE.

If you sell an i-STAT analyzer, please notify Abbott Point of Care Inc. so that

we can enter the new owner into our software update database. If you rent an

i-STAT analyzer and do not intend to provide software updates to the leaser, please

notify Abbott Point of Care Inc. so that we can enter the leaser into our software

database.

Art: 714363-01K Rev. Date: 03/03/08 1-7

Page 18

Page 19

INTRODUCTION

The i-STAT 1 Analyzer is used in conjunction with i-STAT cartridges for the

simultaneous quantitative determination of specific analytes in whole blood and with

the MediSense Precision PCx and PCx Plus Glucose Test Strips for the quantitative

measurement of glucose in whole blood.

Refer to the Cartridge and Test Information section of this manual for information

on analytes that can be measured using i-STAT cartridges.

BEFORE YOU USE THE ANALYZER

i-STAT 1 ANALYZER

2

Install Batteries

Check Date and

Time

Check Software

Customization

Two disposable lithium batteries are supplied with the analyzer. See the Care of the

Analyzer section in this manual for the procedure to install the disposable batteries.

If a rechargeable battery is to be used, the disposable batteries can be used while

the rechargeable battery pack is charged in the Downloader/Recharger. Charge

rechargeable batteries fully before use. See the i-STAT 1 Downloader section for

this procedure. When using a rechargeable battery, store the disposable battery

carrier for possible future use.

Press the On/Off key and check that the date and time at the top of the display are

correct. To change the date and time, see Administration Menu in this section.

Caution

or replaced will have standard CLEW and application software. If a different

CLEW and/or application software is in use in your facility, it must be installed

in new, repaired or replaced analyzers before they are put into use. Check the

Analyzer Status page for the installed CLEW and application software. See under

“Standardization and Calibration” in section 3 of this manual for an explanation

of CLEW.

Analyzers can be customized for many site-specific testing requirements. See the

Customization section for a list of customizable parameters and their default values.

To change the customization profile via the analyzer keypad see “Customization”

under “Administration” in this section of the manual. To change the customization

profile via the Central Data Station, see the “Customization Workspace” in the

Central Data section of this manual.

: New analyzers or analyzers that have been repaired and returned

Caution: New analyzers or analyzers that have been repaired and returned or

replaced will have the factory default settings in the customization profile, as

indicated by the DEFAULT0 on the Analyzer Status page. If analyzers in your facility

do not use the default customization profile, the appropriate customization profile

should be installed before a new, repaired or replaced analyzer is put into use.

The i-STAT 1 Analyzer is shipped with the glucose test strip functionality disabled.

The glucose test strip functionality can be enabled through the Customization

function on the Central Data Station or analyzer.

Older i-STAT 1 analyzers may have the test strip port blocked. The test strip port

can be unlocked as follows. A small flat-head screwdriver is needed to remove

the plug.

Art: 714364-01H Rev. Date: 03/03/08 2-1

Page 20

1 Hold the analyzer with the test strip port facing you and the display

facing up.

2 Hold the screwdriver with the blade horizontal. Carefully insert the blade

into the horizontal gap under the plug.

3 Pry up gently until the plug pops free. Take care not to force the

screwdriver into the port.

4 Remove the screwdriver and then remove the plug. The plug can be

replaced if necessary.

Perform Quality

Check

DESCRIPTION

Specifications

Use the Electronic Simulator to verify the cartridge-reading performance of new

or repaired analyzers.

Use QC protocols to verify the test strip-reading performance of new or repaired

analyzers.

DIMENSIONS Width 7.68 cm (3.035 in.)

Length 23.48 cm (9.245 in.)

Depth 7.24 cm (2.85 in.)

WEIGHT With rechargeable battery 650 grams (22.9

oz.)

With disposable battery 635 grams (22.4 oz.)

POWER Two 9-volt lithium batteries, or rechargeable

battery.

CALIBRATION

MEMORY/CLOCK BACKUP

POWER

DISPLAY

COMMUNICATION LINK Infrared light-emitting diode (LED)

OPERATING TEMPERATURE

TRANSPORT

TEMPERATURE

RELATIVE HUMIDITY

BAROMETRIC PRESSURE 300-1000 mmHg

LASER SCANNER

Factory: electronic, mechanical, thermal,

pressure

Lithium Battery

Dot matrix supertwist liquid crystal

15-40°C (59-104°F) for Medisense strip

testing

16-30°C (61-86°F) for i-STAT cartridge testing

-10-46°C (14-115°F)

90% (maximum) non-condensing

Complies with U.S. 21 CFR 1040.10 and

1040.11 except for deviations pursuant to

laser Notice No. 50, dated July 26, 2001.

EN 60825-1:1994 + A1:2002 + A2:2001

IEC 60825-1:1993 + A1:1997 + A2:2001

2-2 Art: 714364-01H Rev. Date: 03/03/08

Page 21

Software

All analyzer functions are controlled by application software that can be updated

as additional tests and features are developed. Coefficients used to maintain the

accuracy of cartridge results over time are programmed into the analyzer via CLEW

software updates every four months. See under “Standardization and Calibration”

in section 3 of this manual for an explanation of CLEW.

Note: Calibration information for the glucose test strips is included in the barcode

on the foil packet in which each test strip is packaged. The analyzer requires

that this information be scanned or entered via the keypad before the test

strip can be inserted into the analyzer.

Power

Battery

Compartment

Disposable Batteries

Rechargeable

Battery

There are two power options for the analyzer: disposable and rechargeable. The

analyzer is shipped with two disposable 9-volt lithium batteries and a battery carrier.

Lithium batteries may be ordered from i-STAT or obtained locally. ULTRALIFE

lithium batteries (ULTRALIFE Batteries, Inc., Newark, NY, USA) are recommended.

Only i-STAT rechargeable batteries may be used.

The battery compartment is located at the display end of the analyzer next to

the laser barcode scanner window. The procedure for changing disposable and

rechargeable batteries can be found in the Routine Care of the Analyzer and

Downloader section of this manual.

The analyzer requires two 9-volt lithium batteries. The lifetime for a set of batteries

is mainly dependent on the mix of cartridges in use. Cartridges that require thermal

control consume more energy because of heating. Coagulation and immunoassay

cartridges consume more energy because of the longer test cycle. A minimum

of 400 thermally controlled cartridge uses, about 100 coagulation cartridges, 50

immunoassay cartridges, or about 1,000 glucose test strips can be expected before

replacement is necessary. Backlighting, if used continuously, may reduce battery

life up to 50%. Extensive laser scanning will affect battery life slightly.

The lithium batteries should be removed from the analyzer when long periods, such

as six months, of no use are anticipated.

The analyzer can be powered by a nickel-metal-hydride rechargeable battery. The

battery capacity for one full charge is 30% (minimum) of the capacity of one set of

disposable lithium batteries (see above). If the analyzer is not in use, batteries will

lose approximately 10-30% of their charge over 30 days if not recharged.

Store rechargeable batteries in a cool dry place when not in use.

The battery recharges when the analyzer is placed in a Downloader/Recharger.

The battery pack can be removed from the analyzer and placed in the separate

recharging compartment on the Downloader/Recharger. Full recharge from a

discharged state takes approximately 40 hours. The analyzer will display “Low

Battery” when battery recharge is needed.

Caution: Do not sho rt circui t, inc iner ate or mutilate the recharegable

batteries.

Low Battery

Warning

The analyzer will display “Low Battery” when the On/Off key is pressed. Additionally,

a flashing battery icon will display on the results screens, as well as the Test Menu

and Administration Menu screens when battery replacement is needed. Data is

not lost when batteries are fully discharged.

Art: 714364-01H Rev. Date: 03/03/08 2-3

Page 22

Additional Power

A lithium battery inside the analyzer maintains the clock/calendar and customization

profile. This battery should last seven years.

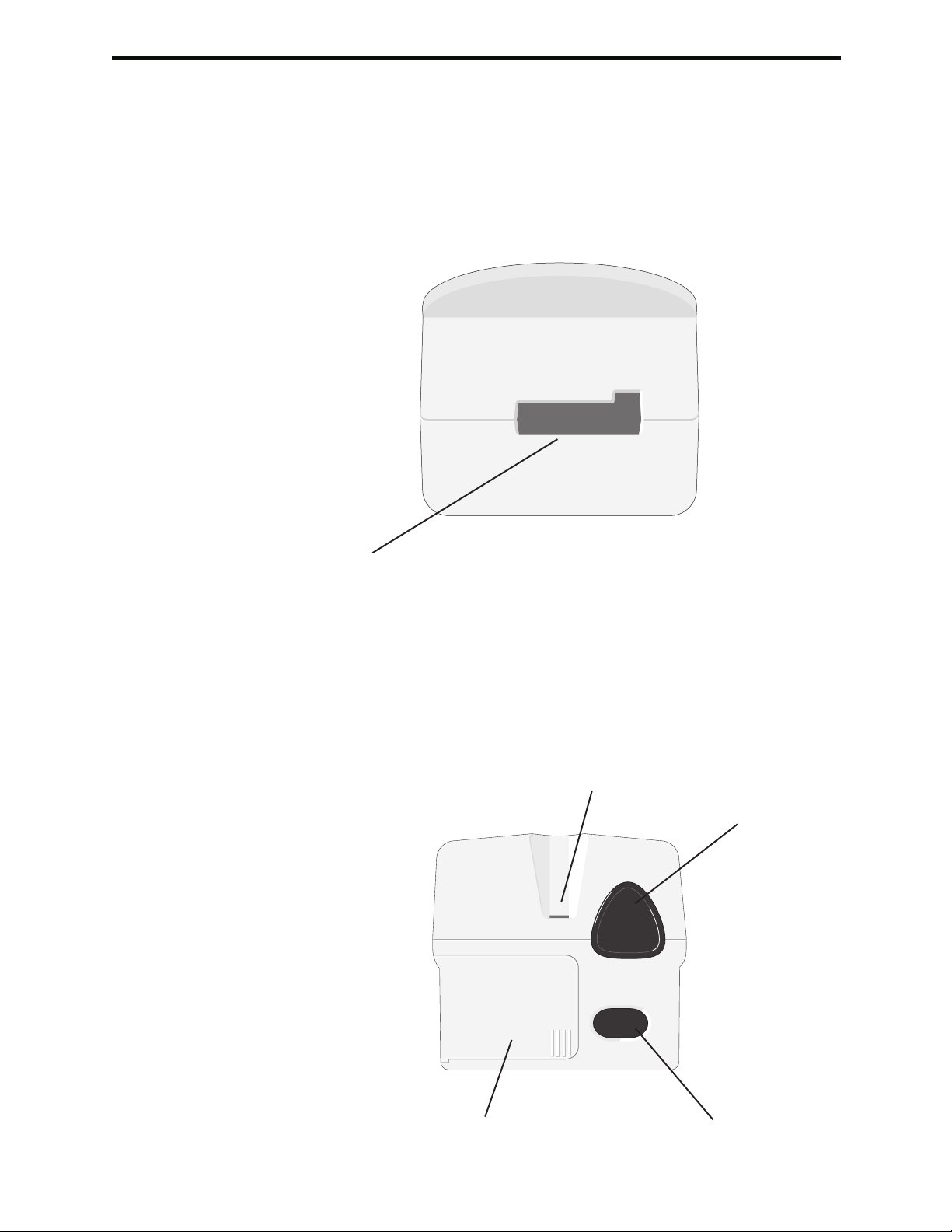

Cartridge Port

Cartridges and the Electronic Simulator are inserted into the analyzer through the

cartridge port on the keypad end of the analyzer. Unless the analyzer is customized

to require information input before a test, inserting a cartridge or Electronic Simulator

initiates the test cycle (i.e., the analyzer does not need to be turned on first). The

cartridge and test strip ports cannot be used simultaneously.

i-STAT Cartridge Port

Test Strip Port

Precision PCx and PCx Plus Blood Glucose Test Strips are inserted into the analyzer

through the test strip port on the display end of the analyzer when prompted by

the analyzer.

Precision PCx and PCx Plus

Glucose Test Strip Port

Infrared Communication

Window

Battery Compartment Laser Barcode Scanner

Window

2-4 Art: 714364-01H Rev. Date: 03/03/08

Page 23

Infrared

Communication

Window

The Infrared Communication Window provides the analyzer with two-way

communication to the Central Data Station via a Downloader, allows analyzerto-analyzer software updates, and allows analyzer-to-printer communication for

printing.

Thermal Control

Barometric Pressure

Sensor

Cartridge Test Cycle

The analyzer contains a thermal control subsystem of thermistors and heating

contact wires that controls the temperature of the sensors and fluids that come

into contact with the sensors to 37°C. This subsystem is activated automatically

when a cartridge containing tests which require thermal control at 37°C is inserted

into the analyzer.

The analyzer contains a solid-state barometric pressure sensor, which determines

the ambient atmospheric pressure used for the PO2 sensor calibration.

An operator starts a cartridge test cycle either by inserting a cartridge into the

analyzer or by selecting the i-STAT Cartridge option from the Test or Quality Tests

Menu.

The analyzer:

makes electrical contact with the cartridge

identifies the cartridge type

releases calibration fluid to the sensors (when applicable)

mixes sample and reagent (when applicable)

measures barometric pressure

heats the sensors to 37°C (when required by the test )

measures electrical signals generated by the sensors and calibration

fluid (when applicable)

displaces the calibrant solution with sample (when applicable)

measures electrical signals generated by the sensors and sample

accepts the operator and patient IDs scanned or entered by the

operator

accepts chart page information

calculates and displays results

stores results

Strip Test Cycle

An operator starts a test strip test cycle by selecting the PCx Glucose Strip option

from the Test or Quality Tests Menu.

The analyzer:

accepts test strip lot data

prompts the operator to insert the test strip

prompts the operator to apply the sample

measures electrical signals generated by the glucose sensor and sample

accepts the operator and patient IDs scanned or entered by the

operator

accepts chart page information entered by the operator

calculates and displays results

stores results

Art: 714364-01H Rev. Date: 03/03/08 2-5

Page 24

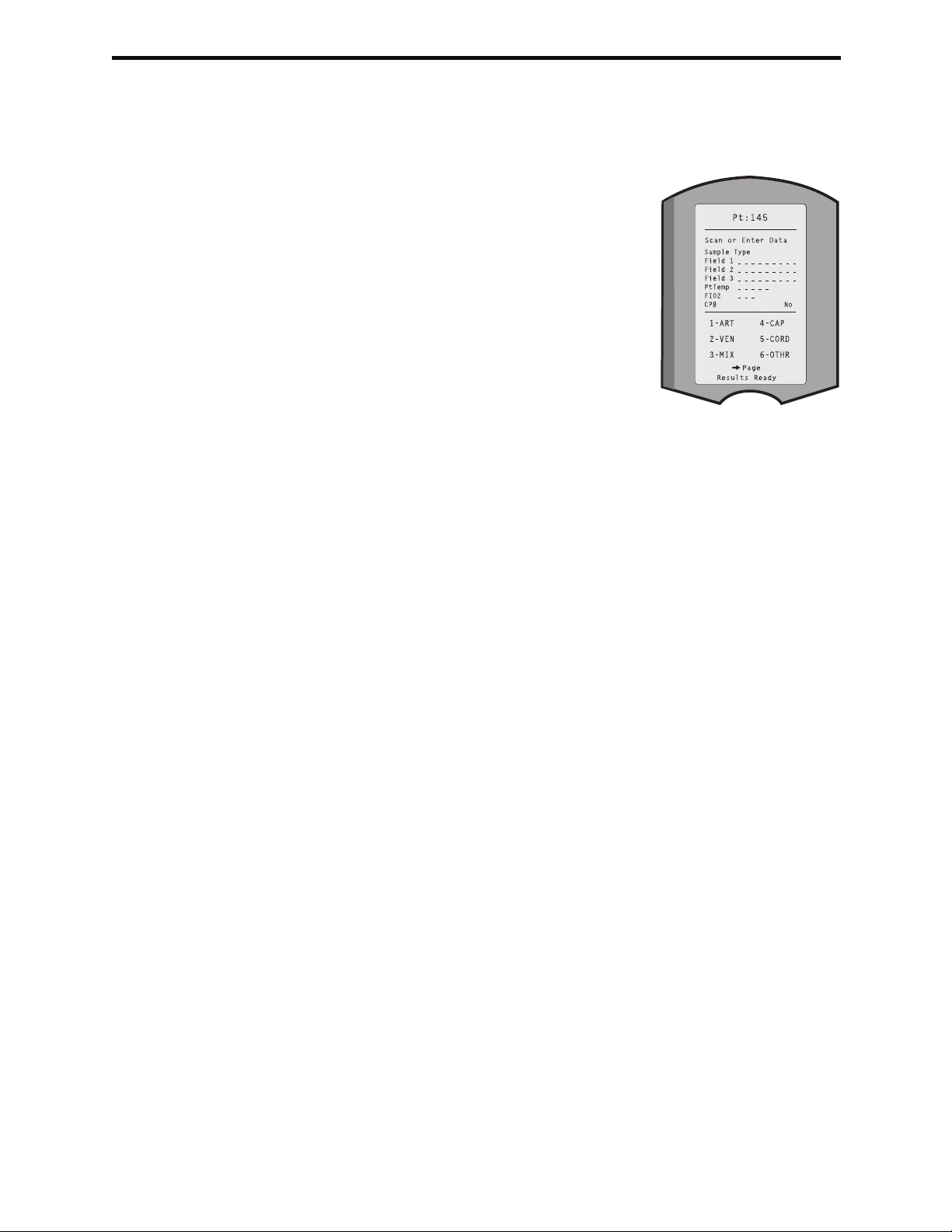

Data Entry

Data that can be scanned into the analyzer or entered via the keypad include:

Operator ID

Patient ID, Proficiency ID, or Simulator ID

Cartridge and Strip Lot Number

Control Lot Number

Cal Ver Kit Lot Number

Comment codes for patient and control

results

Chart Page

Sample Type

Patient Temperature - The analyzer

will interpret numbers between 50.0

and 110.0 as degrees Fahrenheit

and between 10.0 and 45.0 as

degrees centigrade. When a patient

temperature is entered, blood gas

results will be displayed at both 37°C and the patient's temperature.

FIO2

Free Fields: three fields, up to 9 characters each

See the Customization section in this manual for barcode formats recognized by

the analyzer.

Storage of Results The analyzer automatically stores up to 5,000 test records. A test record consists

of:

a set of results

the date and time the test was performed

the cartridge type

all information entered by barcode scanner or keypad including:

Operator and Patient IDs

Lot numbers for controls, cartridges and test strips

Chart page data

Serial number of the Electronic Simulator

the serial number of the analyzer

the number of times the analyzer has been used

the software and CLEW versions installed in the analyzer

the name of the analyzer’s customization profile

Quality Check Codes, which may appear during the test cycle indicating a problem

with the sample, calibration, sensors, mechanical or electrical functions of the analyzer,

are also stored.

The Analyzer Status option under the Administration Menu lists the number of stored

records as “Total” and “Unsent” records. Test records are stored as “Unsent” until

the analyzer uploads data to the Central Data Station at which time the records are

marked as sent. The analyzer can be customized to display a Memory Full prompt or

to disable testing until data is transmitted to the Central Data Station. Otherwise, the

oldest data is overwritten when the memory becomes full. Stored test records can be

reviewed through the Data Review option on the Administration Menu screen described

later in this section.

2-6 Art: 714364-01H Rev. Date: 03/03/08

Page 25

LCD Display and

Backlight

Test results, operator prompts and other messages are displayed on the analyzer’s

LCD Screen. The backlight for the display is turned on and off by pressing the 0

key for one second. The backlight will automatically turn off after ninety seconds

and when the analyzer powers down or is turned off. The backlight cannot be

turned on while data entry screens are displayed.

Audible Indicator

Time Out

The analyzer will beep to indicate:

whenever a key is pressed.

a successful barcode entry.

sample detection on glucose test strip

tests.

results are ready.

a Quality Check Message is displayed.

The analyzer can be customized to disable

beeping when a key is pressed or results or

messages are displayed.

The analyzer automatically turns off after a

certain period of inactivity.

Results displayed: Results are displayed for 2 minutes before the

analyzer turns off provided that a mandatory Comment Code prompt is not

displayed. This Inactivity Time Out default time can be increased using

Customization.

If a mandatory Comment Code prompt is displayed, the analyzer will turn

off after 15 minutes or after the Inactivity Time Out, whichever is greater. In

the case of a missed required Comment Code, results will be stored and “_

_ _” will be entered as the Comment Code.

Prompting for mandatory data when results are ready for display:

The analyzer will turn off after 15 minutes or after the Inactivity Time Out,

whichever is greater, if there is no response to a mandatory data prompt.

A mandatory data prompt is a prompt for information that must be entered

before pending results are displayed.

In the case of a missed mandatory data prompt, results will not be stored

and the test record will state “Test Cancelled by Operator.”

Waiting for insertion of cartridge: After the prompt “Insert Cartridge”

is displayed, the analyzer will wait 15 minutes for the operator to insert a

cartridge unless the analyzer is in the Proficiency path, in which case the

analyzer will wait 5 minutes. If a cartridge is not inserted, the analyzer will

turn off. This timeout cannot be customized.

Waiting for insertion of test strip: After the prompt “Insert Strip” is

displayed, the analyzer will wait 2 minutes for the operator to insert a test

strip. If a test strip is not inserted, the analyzer will turn off. This timeout

cannot be customized.

Other: The analyzer will turn off after 2 minutes of inactivity (no keys pressed)

in all other circumstances.

Art: 714364-01H Rev. Date: 03/03/08 2-7

Page 26

Keypad There are 19 keys located directly below the display. When using the keypad to enter

information, the number of dashes in the data entry line will indicate how many characters

can be entered on the line. The dash where the next entry will be placed will flash.

Key Function

Activates the barcode scanner. Information that can be entered

SCAN

ABC

0 – 9

•

into the analyzer via the scanner includes: operator ID, patient ID,

control, cartridge and test strip lot number, patient chart data and

comment codes.

Used to move the cursor on the Set Clock screen and to move

up and down the alphabet when the ABC key is pressed. The

(right arrow) key is used as a page key to move from one

screen to the next. When Patient ID Recall is enabled, the

key will recall the last patient ID when the analyzer is prompting

for Patient ID. The (left arrow) key is used to backspace and

clear keypad entries, and to move backward through the screens

within a menu.

Used to enter alpha characters on data entry screens. When

the ABC key is pressed the letter A is entered. The arrow keys

are used to move up and down the alphabet. To enter a second

letter, press the ABC key once to move to the next position and

again to enter an A. To enter a number after a letter, press a

numbered key. To erase a letter, press the ABC key to move to

the next position, then use the key to backspace and clear the

letter.

Used to enter digits on data entry screens and to select menu

options and stored records.

Enters a decimal point or a comma separator according to the

analyzer’s Customization Profile.

Used to turn the screen backlight on and off.

Enter Used to respond to a prompt to complete an action, such as

entering an operator or patient ID via the keypad.

MENU

Print Used to print either directly to the portable printer or to the

On/Off

2-8 Art: 714364-01H Rev. Date: 03/03/08

Used to return to the previous menu and switch between the Test

and Administration Menus.

portable printer attached to a Downloader.

Turns the analyzer on or off. When the analyzer is on, the On/Off

key must be pressed for a second to turn the analyzer off. This

key is inactive when a test is in progress and when the analyzer

is prompting for mandatory data.

Page 27

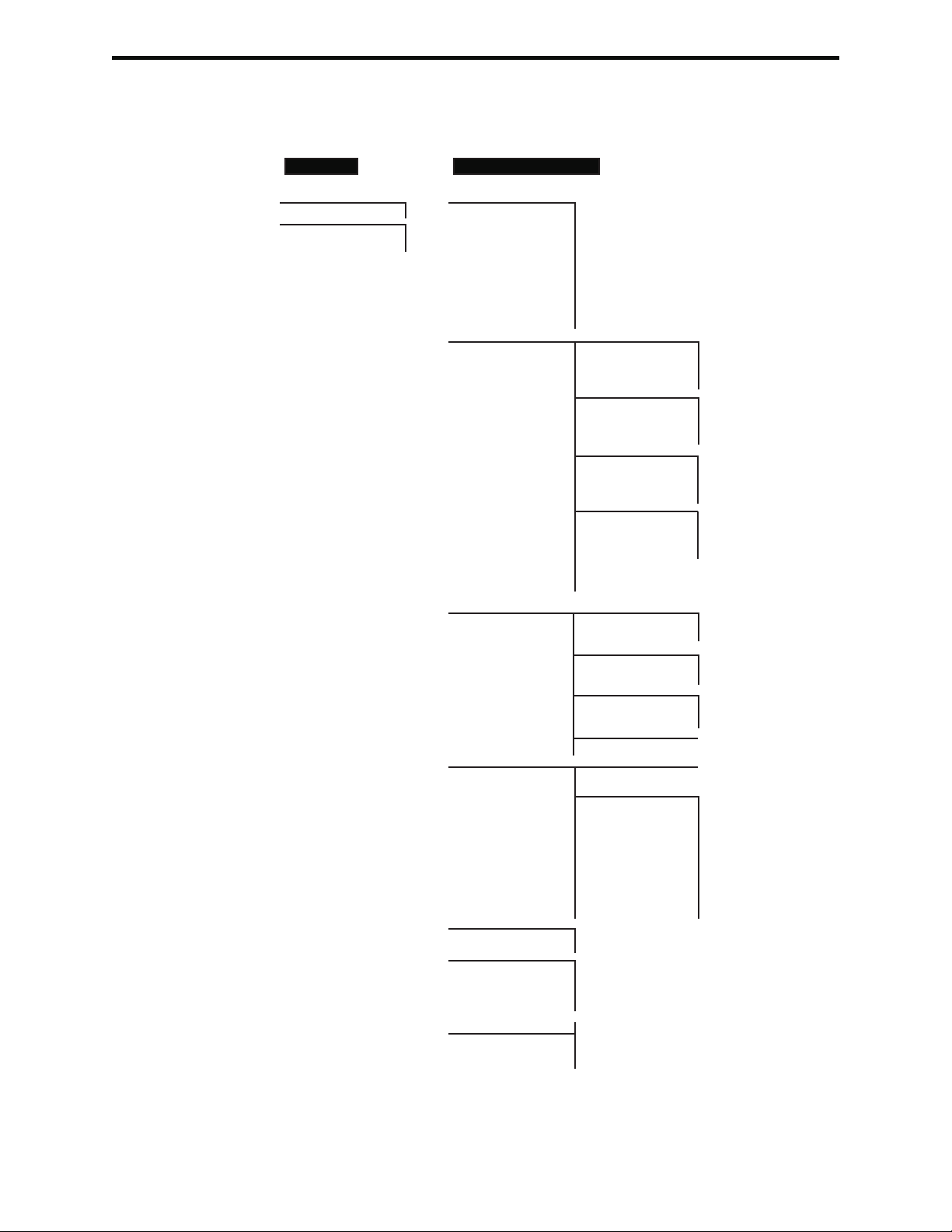

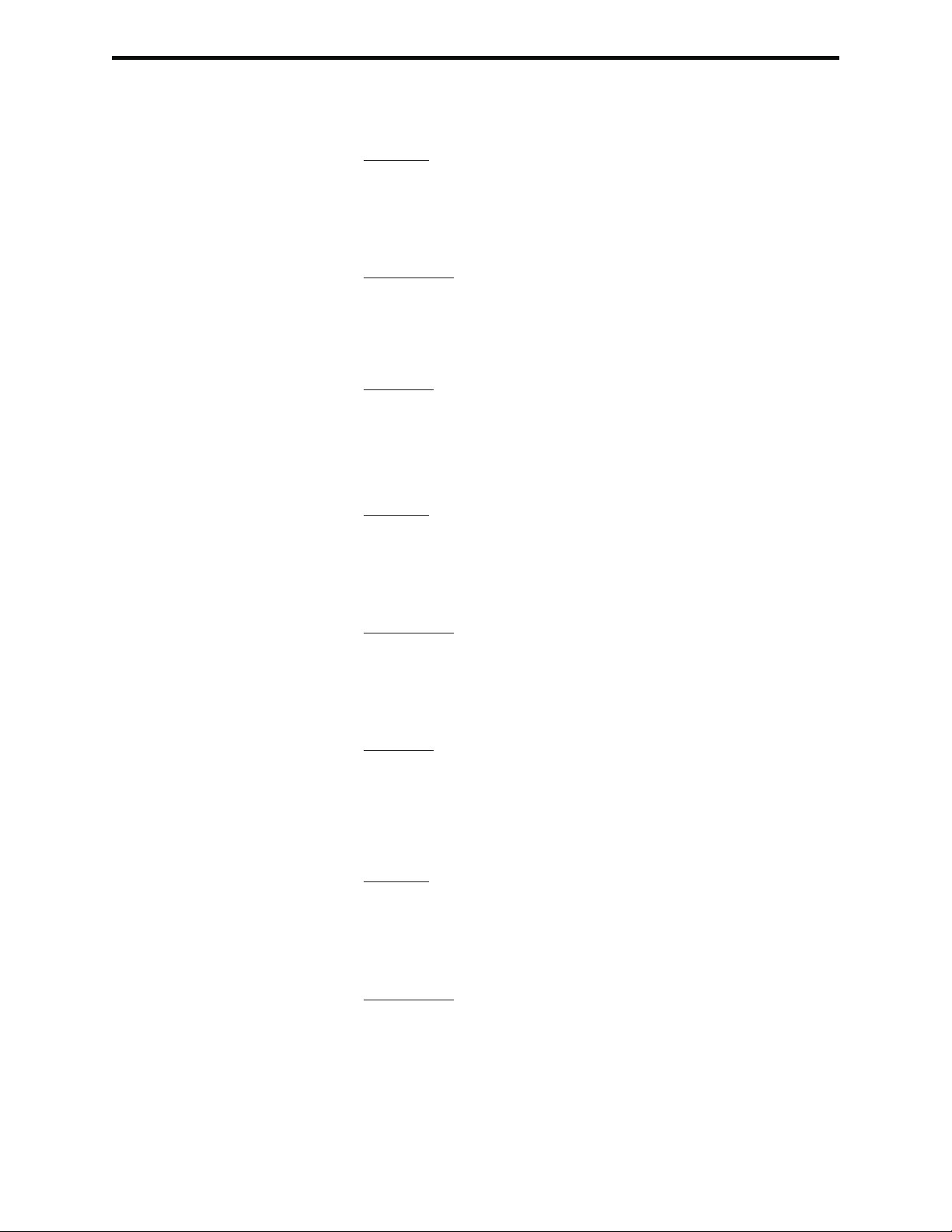

i-STAT 1 Menu Tree

There are two main menus: The Test Menu and the Administration Menu. If the

glucose test strip function is disabled, test strip options will not be displayed.

Test Menu Administration Menu

1- Last Result 1. Analyzer Status Temp

2- i-STAT Cartridge Pressure

3- PCx Glucose Strip 1- Patient Battery

2- Control Uses

Serial

CLEW

Version

Custom

Stored Records

2- Data Review 1-Patient

2-Control 1- i-STAT Cartridge

2- PCx Glucose Strip

3- All

3-Proficiency 1- i-STAT Cartridge

2- PCx Glucose Strip

3- All

4-Cal Ver 1- i-STAT Cartridge

2- PCx Glucose Strip

3- All

5- Simulator

6- All

7- List

3-Quality Tests 1-Control 1- i-STAT Cartridge

2- PCx Glucose Strip

2- Proficiency 1- i-STAT Cartridge

2- PCx Glucose Strip

3- Cal Ver 1- i-STAT Cartridge

2- PCx Glucose Strip

4- Simulator

4- Customization 1- View

2-Change 1- Analyzer

2- ID Entry

3- Patient Tests

4- QC Tests

5- Results

6- Password

7- Restore Factory

Settings

5- Set Clock

6- Transmit Data 1- Most Recent

2- This Month

3- Last Month

4- All

7-Utility 1- Send Software

2- Clear Memory

Art: 714364-01H Rev. Date: 03/03/08 2-9

Page 28

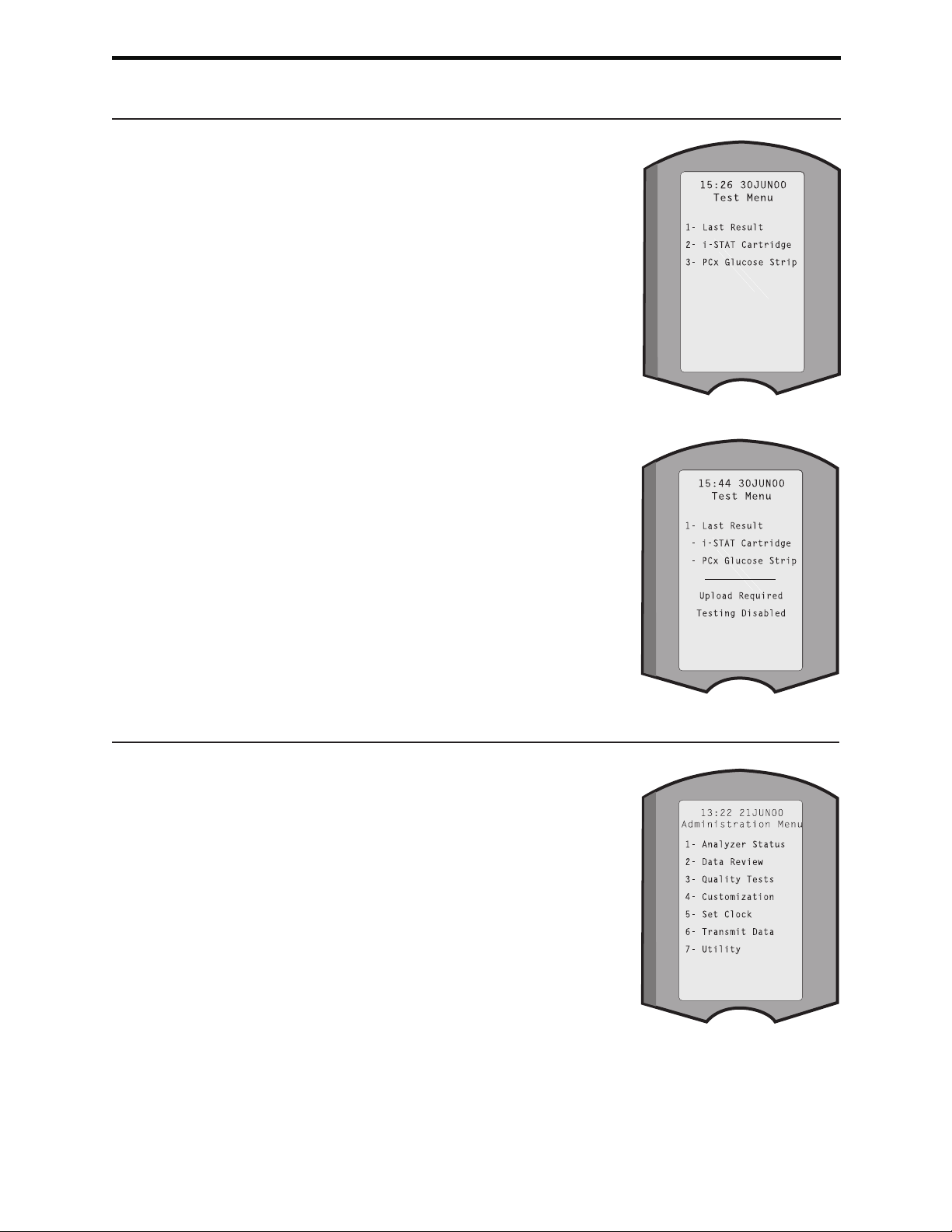

TEST MENU

The Test Menu is displayed when the analyzer is

turned on using the On/Off key.

The options are:

1 - Last Result

2 - i-STAT Cartridge

3 - PCx Glucose Strip

1 - Patient

2 - Control

Options 2 and 3 are used for testing patient

samples. For the glucose test strip, controls can

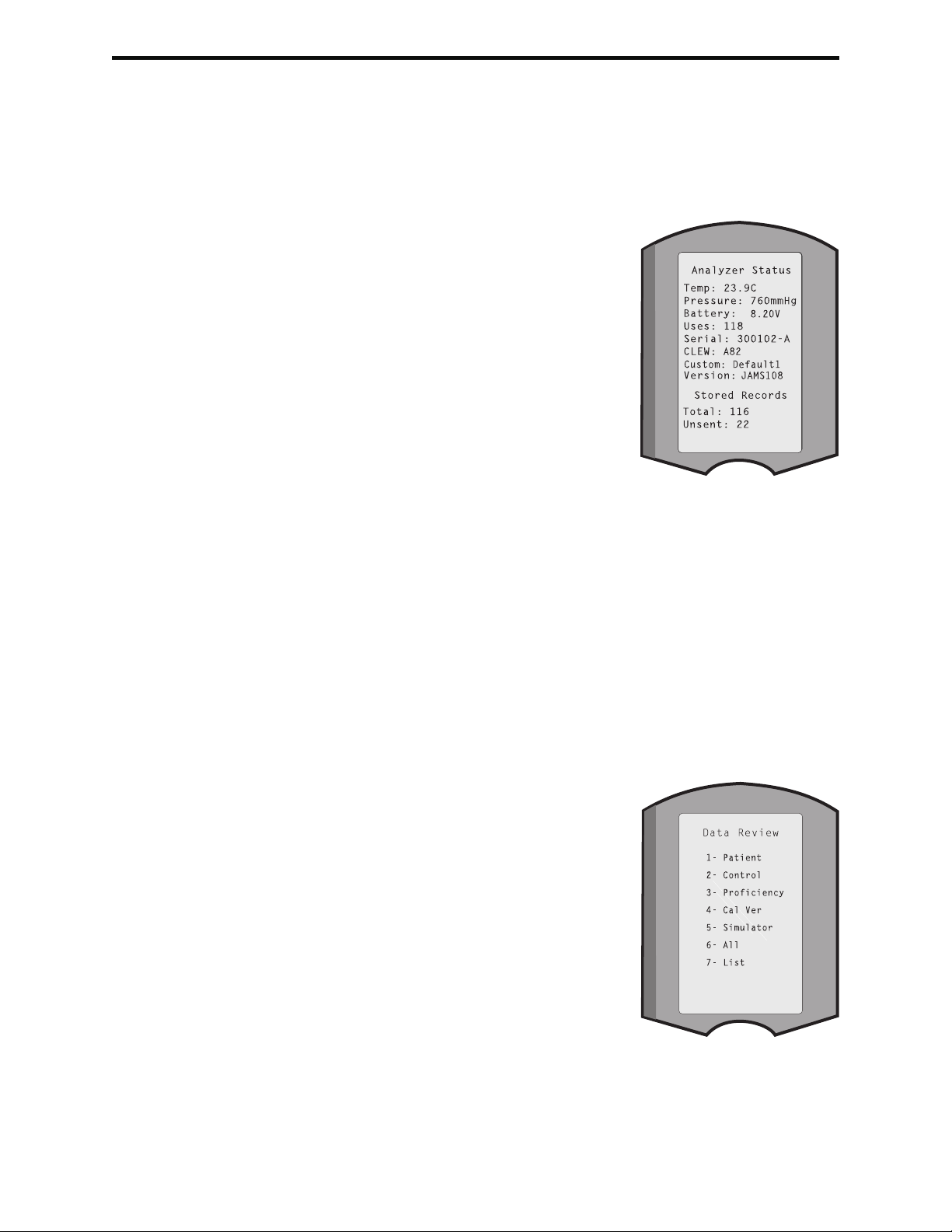

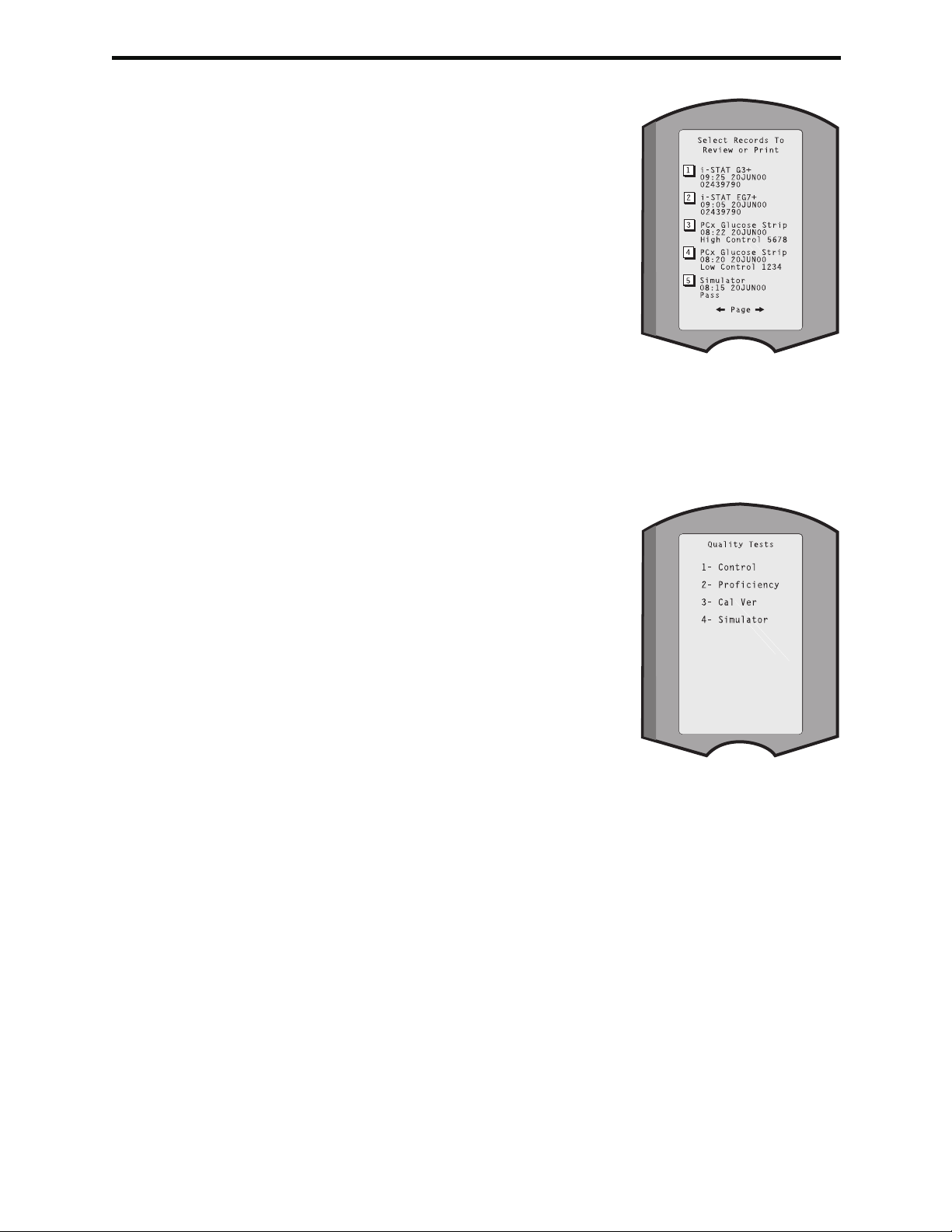

also be tested from the Test Menu. Testing controls