Page 1

Left Ventricular Assist System

Instructions for Use

Page 2

Page 3

Abbott

HEARTMATE 3™ LEFT VENTRICULAR ASSIST SYSTEM

Instructions for Use

Page 4

Page 5

™ Indicates a trademark of the Abbott group of companies.

‡ Indicates a third party trademark, which is property of its respective owner.

Pat. http://www.abbott.com/patents

© 2020 Abbott. All Rights Reserved.

Bluetooth and Bluetooth logo are registered trademarks of Bluetooth SIG, Inc.

iii

Page 6

Preface - - - - - - - - - - - - - - - - - - - - - - - - - - ix

1 Introduction - - - - - - - - - - - - - - - - - - - - 1-1

Understanding Warnings and Cautions - - - - - - - - - - - - - - - - - - - - - - - 1-2

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

Indications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-7

Contraindications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-7

Adverse Events - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-8

Pre-Use Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-8

Equipment Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-10

Required, Backup, and Optional Components and Equipment - - - - - - - - - - - - 1-15

Principles of Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-17

Explanation of Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-19

2 System Operations - - - - - - - - - - - - - - - - - 2-1

HeartMate 3™ Left Ventricular Assist Device Overview- - - - - - - - - - - - - - - - 2-2

System Controller Overview- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-8

The Backup System Controller- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-45

3 Powering the System - - - - - - - - - - - - - - - - 3-1

Power Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

Using the Power Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-4

Using the Mobile Power Unit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-34

Using HeartMate 14 Volt Lithium-Ion Batteries - - - - - - - - - - - - - - - - - - - - 3-51

Switching Power Sources - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-66

Battery Charger Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-73

Charging HeartMate Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-80

Calibrating HeartMate Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-84

Using the Charger to Check Battery Power - - - - - - - - - - - - - - - - - - - - - - 3-86

Care and Maintenance of the Battery Charger - - - - - - - - - - - - - - - - - - - - 3-87

4 HeartMate Touch™ Communication System - - - - - 4-1

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

Set Up the HeartMate Touch™ Communication System- - - - - - - - - - - - - - - - 4-7

Connect the HeartMate Touch™ Wireless Adapter to the

iv

Page 7

HeartMate Touch Communication System - - - - - - - - - - - - - - - - - - - - - - 4-11

Interface Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-20

HeartMate Touch™ App Views - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-21

Settings Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-23

Alarms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-40

Pump Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-50

Monitor View - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-55

Clinical View - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-56

Historical View - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-62

5 Surgical Procedures - - - - - - - - - - - - - - - - 5-1

Surgical Considerations- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

Equipment and Supplies Required for Implant - - - - - - - - - - - - - - - - - - - - 5-4

Preimplant Procedures- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-7

Unpacking - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-10

Unpacking the Pump and Accessories Tray - - - - - - - - - - - - - - - - - - - - - - 5-12

Unpacking the Sealed Outflow Graft - - - - - - - - - - - - - - - - - - - - - - - - - 5-16

Preparing the Sealed Outflow Graft - - - - - - - - - - - - - - - - - - - - - - - - - 5-17

Unpacking the System Controller - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-18

Unpacking the Modular Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-19

Connecting and Initializing the Sterile System Controller to Non-Sterile Equipment - 5-22

Preparing, Running, and Priming the Pump - - - - - - - - - - - - - - - - - - - - - - 5-25

Preparing the Coring Knife - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-34

Implant Procedures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-35

Postimplant Procedures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-60

Postimplant Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-66

Device Explant - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-70

6 Patient Care and Management - - - - - - - - - - - 6-1

Postoperative Patient Care - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

Ongoing Patient Assessment and Care - - - - - - - - - - - - - - - - - - - - - - - - 6-6

Important Clinical Considerations for HeartMate 3™ Patients - - - - - - - - - - - - 6-9

Using the Shower Bag - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-13

Wearing and Carrying System Components - - - - - - - - - - - - - - - - - - - - - 6-26

Preparing for Sleep - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-63

Ongoing System Assessment and Care - - - - - - - - - - - - - - - - - - - - - - - - 6-64

Educating and Training Patients, Families, and Caregivers- - - - - - - - - - - - - - 6-67

v

Page 8

7 Alarms and Troubleshooting - - - - - - - - - - - - 7-1

System Controller Alarms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-2

HeartMate Touch™ App Alarms - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-25

Handling Power Module Alarms - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-37

Mobile Power Unit Alarms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-40

Using the Charger to Check Battery or Charger Status - - - - - - - - - - - - - - - - 7-42

Guidelines for Power Cable Connectors - - - - - - - - - - - - - - - - - - - - - - - 7-45

What Not To Do: Driveline and Cables- - - - - - - - - - - - - - - - - - - - - - - - 7-46

8 Equipment Storage and Care - - - - - - - - - - - - 8-1

Storage and Transport - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-2

Cleaning and Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-4

Product Disposal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-11

A Summary of the Clinical Study - - - - - - - - - - - A-1

Pediatric Real-World Data - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-62

B Technical Specifications - - - - - - - - - - - - - - B-1

C Safety Testing and Classification - - - - - - - - - - C-1

D HeartMate 3™ Product List - - - - - - - - - - - - - D-1

E Symbols - - - - - - - - - - - - - - - - - - - - - - E-1

F Safety Checklists - - - - - - - - - - - - - - - - - - F-1

G Glossary - - - - - - - - - - - - - - - - - - - - - G-1

Index- - - - - - - - - - - - - - -

- -

- - - - - - - Index-1

vi

Page 9

Preface

This manual contains information needed to properly and safely operate the HeartMate 3™ Left

Ventricular Assist System. Users of the HeartMate 3 Left Ventricular Assist System should have a

practical knowledge of the principles of mechanical circulatory support and should be aware of the

physiological and psychological needs of a patient undergoing mechanical ventricular support. New

users should read this document in its entirety, before system operation. For experienced

practitioners, this manual may serve as a reference.

As with all prescription medical devices, clinical procedures should be conducted under the direction

of the prescribing physician. The professional staff at Abbott regularly provides laboratory training

and on-site, in-service programs.

ix

Page 10

INTRODUCTION

This section provides an introduction to the HeartMate 3™ Left Ventricular Assist System.

Understanding Warnings and Cautions - - - - - - - - - - - - - - 1-2

1

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

Indications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-7

Contraindications - - - - - - - - - - - - - - - - - - - - - - - - - - 1-7

Adverse Events - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-8

Pre-Use Requirements - - - - - - - - - - - - - - - - - - - - - - - - 1-8

Equipment Overview - - - - - - - - - - - - - - - - - - - - - - - - 1-10

Required, Backup, and Optional Components and Equipment - - - 1-15

Principles of Operation - - - - - - - - - - - - - - - - - - - - - - - 1-17

Explanation of Parameters - - - - - - - - - - - - - - - - - - - - - 1-19

1-1

Page 11

Chapter 1 Introduction

Understanding Warnings and Cautions

Warnings refer to actions or hazardous conditions that could cause serious injury or death if not

avoided. Ignoring a warning can cause sudden and serious injury, life-threatening harm, or death for

the user or patient.

Cautions refer to actions or potentially unsafe conditions that may cause injury, damage the

equipment, or affect how the system works. Ignoring a caution can cause patient or user injury, or

result in equipment failure or sub-optimal system operation. Although important for maximum safety

and optimal system function, usually cautions do not refer to life-threatening risks.

In this manual, warnings and cautions that are relevant to a specific procedure or piece of equipment

appear at the start of each applicable section.

WARNING !

Warnings appear in the manual in this format.

CAUTION !

Cautions appear in the manual in this format.

1-2

Page 12

Chapter 1 Introduction

Overview

The HeartMate 3™ Left Ventricular Assist System (LVAS) is a set of equipment and materials that

together comprise a medical device designed to provide therapeutic benefit to those affected with

advanced heart failure. In service, the LVAS assumes some or all of the workload of the left ventricle,

thereby restoring the patient's systemic perfusion while palliating the underlying pathology. The LVAS

features a Left Ventricular Assist Device (LVAD), a blood pump intended for long-term implantation in

such patients, an extracorporeal Controller, plus all of the features, controls, attachments, interfaces,

power sources, supporting equipment, labeling, and tools required to achieve the desired

therapeutic benefit. The HeartMate 3 Left Ventricular Assist System is intended for use inside or

outside the hospital, or for transportation of LVAD patients via ground ambulance, airplane, or

helicopter.

The LVAS may be used in any of two configurations. First, line power may be utilized through the

Power Module or the Mobile Power Unit (MPU) to run the LVAD indefinitely, convenient for sedentary

or sleeping periods. Second, portable Battery power may be utilized for limited periods, convenient

for active periods. Due to the bifurcation of the Patient Cable, switching among these configurations

or from one set of Batteries to another (as when one set has been depleted and a fully charged set is

available) may be accomplished without interrupting LVAS function. Whenever the Power Module is

used, a HeartMate Touch™ Communication System may also be used as a means of viewing

operating conditions, changing operating parameters, and manipulating stored data.

A set of user manuals provides instructions at various levels appropriate for users to explain how to

use the equipment and how to interpret and respond to alarms. The LVAS is packaged for safe

transport and effective use in an operating room under sterile conditions.

The HeartMate 3 LVAD is part of the LVAS. See Figure 1.1.

Figure 1.1 HeartMate 3™ LVAS During Battery-Powered Operation

1-3

Page 13

Chapter 1 Introduction

Outflow Graft

with Bend Relief

Slide Lock

Motor

Rotor

Pump

Chamber

Rotor Magnet

Inflow Cannula

Pump

Cable

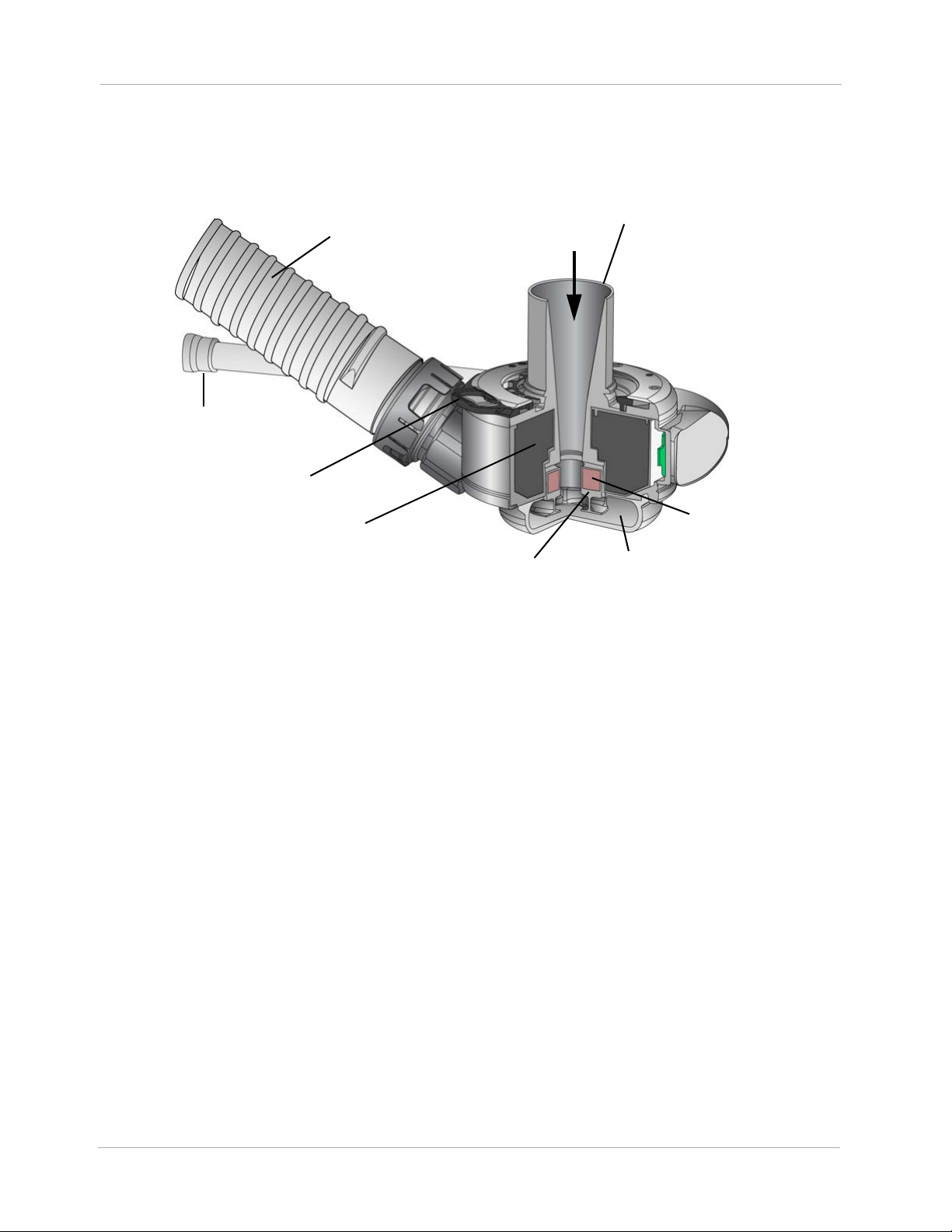

The LVAD is a blood pump intended for implantation in the thorax of patients affected with advanced

heart failure. The LVAD contains an Inflow Cannula, a Pump Cover, a Lower Housing, a Screw Ring

to attach the Pump Cover to the Lower Housing, a Motor, the Outflow Graft, and a Pump Cable.

Figure 1.2 Left Ventricular Assist Device Components

The LVAD is surgically connected to the patient's circulatory system via an Inflow Cannula placed

into the left ventricular apex, and an Outflow Graft anastomosed to the ascending aorta. The LVAD is

a centrifugal pump: ventricular blood is drawn into the Inflow Cannula along a central axis and is

expelled at right angles by and between the impeller blades of a Rotor rotating about the central

axis. The fluid thus angularly accelerated collects and travels around a volute before it is diffused to

a desired pressure and flow rate by being directed tangentially into the Outflow Graft.

The Rotor is fully supported by magnetic levitation, obviating mechanical or fluid bearings and

essentially eliminating Rotor mechanical wear as a reliability factor. Both drive (i.e. rotation) and

levitation of the Rotor is accomplished using a single Stator comprising iron pole pieces, a back-iron,

copper coils, and position sensors. By measuring the position of a permanent magnet in the Rotor

and appropriately controlling the current in the drive and levitation coils, the radial position and

rotational speed of the Rotor is actively controlled. Because of the permanent magnet's attraction to

the iron pole pieces, the rotor passively resists excursion in the axial direction, whether such

excursion is translation or tilting.

The electronics and software necessary to control motor drive and levitation are integrated into the

Lower Housing with the Stator, and all of these plus the Rotor are regarded to comprise the Motor.

1-4

Page 14

Chapter 1 Introduction

The Inflow Cannula is a cylindrical conduit with external size and features similar to those of the

HeartMate II™. It is rigidly affixed to the Pump Cover. During the implantation procedure, a Coring

Tool is used to resect a plug of myocardium at the left ventricular apex to allow insertion of the Inflow

Cannula into the left ventricle. An Apical Attachment Cuff is sewn to the epicardium, and a slide lock

is used to secure the Inflow Cannula and establish hemostasis.

The Outflow Graft assembly consists of a sealed woven polyester graft and the hardware necessary

to attach the graft to the Pump Cover. The distal end of the graft is designed to be cut to desired

length and sutured to the ascending aorta by an end-to-side anastomosis (only the graft is to be cut,

not the bend relief). A reinforced tube serves as a bend relief around the Outflow Graft to prevent

kinking and abrasion. The bend relief can be attached or removed and reattached during the

implantation procedure. If necessary, the Outflow Graft may be detached from the Pump Cover,

permitting pump replacement without re-anastomosis.

A Pump Cable is permanently attached to the Lower Housing to establish electrical connection with

the enclosed Motor via a hermetically sealed feed-through. This Pump Cable is tunneled through

subdermal abdominal tissue via a Tunneling Tool and is exteriorized through a skin wound prepared

with a Skin Coring Punch at a location deemed optimal for the patient and his equipment. The Pump

Cable extends only a few inches through this site. It is extended with a Modular Cable, which

connects the Pump (through the Pump Cable) to a System Controller and is readily replaceable

without surgery if necessary. The Pump Cable and Modular Cable, once connected, comprise the

Driveline. The Driveline contains duplicate sets of three conductors: two for power and ground, and

a third for communication.

The HeartMate 3 System Controller is also part of the Left Ventricular Assist System (LVAS). The

System Controller is an extracorporeal interface device that receives power from the Power Module,

the Mobile Power Unit, or portable Batteries, and appropriately delivers that power to the LVAD. It is

the primary user interface and has several important functions:

• Operating condition display,

• Source of audible and visible alarms,

• Communication link for transferring event/period log and alarm information, and

• Battery backup in the case of full power disconnection.

1-5

Page 15

Chapter 1 Introduction

WARNING !

• A thorough understanding of the technical principles, clinical applications, and risks

associated with left ventricular support is necessary before using the HeartMate 3 Left

Ventricular Assist System. Read this entire manual before attempting implantation of the Left

Ventricular Assist Device or before caring for HeartMate 3 patients. Completion of Abbott

HeartMate 3 Surgical Training Program is also required prior to use.

• Understanding the operating and safety aspects of the HeartMate 3 Left Ventricular Assist

System is critical for safe and successful use.

• All users, including clinicians, patients, and caregivers, must be trained on system operation

and safety before use.

• All users, including clinicians, patients, and caregivers, must be trained on any HeartMate 3

power accessories (Mobile Power Unit, Battery Charger, or HeartMate 14 Volt Lithium-Ion

batteries) before use.

• Do not use the HeartMate 3 Left Ventricular Assist Device in pregnant women or in women

likely to become pregnant. A growing fetus may dislodge the pump, which may result in

device failure, catastrophic bleeding, or death. Instruct women of childbearing age to use

reliable contraception if sexually active. Blood thinners have been associated with birth

defects. Anticoagulation regimens are contraindicated during pregnancy.

• Do not modify this equipment without authorization from Abbott. The use of unauthorized

replacement parts may affect the electromagnetic compatibility of the Mobile Power Unit with

other devices. Potential interference may occur between the Mobile Power Unit and other

devices.

• Certain parts of the HeartMate 3 Left Ventricular Assist System are not compatible with other

HeartMate systems. Only use HeartMate 3 parts with the HeartMate 3 system.

• The HeartMate 3 pump may cause interference with implantable cardiac defibrillators (ICD).

If electromagnetic interference occurs it may lead to inappropriate ICD therapy. The

occurrence of electromagnetic interference with ICD sensing may require adjustment of

device sensitivity and/or repositioning the lead.

1-6

Page 16

Chapter 1 Introduction

CAUTION !

• Limited clinical data are available for the HeartMate 3 LVAS in patients with a body surface

area (BSA) less than 1.0 m2 (see HeartMate 3 Pediatric Patients with a BSA below 1.0 m2

on page A-67). The clinical decision to implant the HeartMate 3 in patients with a BSA less

than 1.0 m2 should be based on individualized assessment of body habitus and device fit.

• The HeartMate 3 LVAS sterilant residuals may cause adverse biological effects in patients

with a body mass

carcinogenicity, and reproductive effects.

• Clinical procedures (including LVAS settings) should be conducted under the direction of the

prescribing physician

• Do not try to repair any of the HeartMate 3 system components. If components need service,

contact appropriate

of <25 kg, including irritation, organ damage, mutagenicity,

(Authorized Personnel) only.

personnel.

• Notify appropriate personnel if there is a change in how the pump works, sounds, or feels.

• Counsel the patient to avoid contact sports and jumping activities while implanted with the

pump. Contact sports or jumping can cause bleeding or damage the pump.

• Care should be taken

strangulation from the system’s cables.

• If HeartMate 3 patients are approved for showering, they must always use the Shower Bag.

When installed properly, the Shower Bag protects external system components from water or

moisture. If external system components have contact with water or moisture, the pump may

stop.

when small children or pets are present. There is a potential for

Indications

The HeartMate 3 Left Ventricular Assist System is indicated for providing short- and long-term

mechanical circulatory support (e.g., as bridge to transplant or myocardial recovery, or destination

therapy) in adult and pediatric patients with advanced refractory left ventricular heart failure and

with an appropriate body surface area.

Contraindications

The HeartMate 3 Left Ventricular Assist System is contraindicated for patients who cannot tolerate, or

who are allergic to, anticoagulation therapy.

1-7

Page 17

Chapter 1 Introduction

Adverse Events

Adverse events that may be associated with the use of the HeartMate 3™ Left Ventricular Assist

System are listed below. Adverse events are listed in anticipated decreasing order of frequency,

except for death, which appears first as it is a non-reversible complication:

•Death

• Bleeding

• Cardiac Arrhythmia

• Localized Infection

• Device Malfunctions

• Right Heart Failure

•Respiratory Failure

•Driveline Infection

•Sepsis

•Renal Dysfunction

• Other Neurological Event (not stroke-related)

•Stroke

•Hypertension

• Psychiatric Episode

• Venous Thromboembolism

• Hepatic Dysfunction

• Arterial Non-Central Nervous System (CNS) Thromboembolism

• Pericardial Fluid Collection

• Pump Pocket or Pseudo Pocket Infection

• Myocardial Infarction

• Wound Dehiscence

• Hemolysis (not associated with suspected device thrombosis)

•Pump Thrombosis

Pre-Use Requirements

A thorough understanding of the technical principles, clinical applications, and risks associated with

left ventricular support is required before using the HeartMate 3™ Left Ventricular Assist System.

1-8

Page 18

Chapter 1 Introduction

It is suggested that patients possess a minimum 5th grade educational level and shall be versed in

basic computer literacy (i.e., Microsoft‡ Windows

This manual contains important warnings, cautions, and instructions for use. Read this entire manual

before implanting a HeartMate 3 Left Ventricular Assist Device or before caring for HeartMate 3

patients. Completion of Abbott HeartMate 3 Surgical Training Program is also required.

If you have questions after reading this manual, please contact Abbott for assistance. See Abbott

contact information on the Back Cover of this manual.

‡ and Office software).

1-9

Page 19

Chapter 1 Introduction

Equipment Overview

The table below introduces the main parts of the system, along with useful accessories. All of these

items are described in more detail later in this manual.

Left Ventricular

Assist Device

The HeartMate 3™ Left Ventricular Assist Device

(frequently called the “pump”) is implanted in the chest

below the heart. One end is inserted into the apex of the

left ventricle; the other end connects to the ascending

aorta. The pump diverts blood from the weakened left

ventricle and pumps it to the aorta.

For more information, see page 1-17.

System Controller

14 Volt Lithium-Ion Batteries &

14 Volt Battery Clips

The System Controller is a small computer that controls

and monitors system operation. The System Controller

uses lights, sounds, and on-screen messages to

communicate with users about operating status and alarm

conditions. A Driveline, which passes through the

patient’s abdomen, connects the implanted pump to the

System Controller.

For more information, see page 2-8.

Two HeartMate 14 Volt Lithium-Ion batteries are used to

power the system during battery-powered operation, such

as when AC electricity is not wanted or unavailable.

Batteries are used in pairs and are inserted into a 14 Volt

battery clip. Both batteries are discharged together (not

one, then the other). Two power cables are required to

transfer battery power to the System Controller. When

fully charged, a pair of HeartMate 14 Volt Lithium-Ion

batteries can power the system for up to 10–17 hours,

depending on the activity level of the patient.

1-10

For more information, see page 3-51.

Table 1.1 HeartMate 3™ System Components

Page 20

Chapter 1 Introduction

Modular Cable

Power Module

Power Module Patient Cable

The Driveline consists of two cables: the Pump Cable

and the Modular Cable. One end of the Pump

Cable connects to the pump implanted in the

patient’s abdomen. The other end of that cable exits

the patient’s body. One end of the Modular Cable is

connected to the Pump Cable and the other end

connects to the System Controller.

The Power Module is for clinical use. The Power Module

plugs into an AC to provide power to the HeartMate 3

system. The Power Module is used when the patient is

indoors, stationary, or sleeping. A sleeping patient may

not hear low battery power alarms. The System Controller

and the Power Module are connected through the Power

Module patient cable. The cable transfers power from the

Power Module to the System Controller.

For more information, see page 3-4.

The Power Module patient cable connects the Power

Module to the System Controller. Connections are made

between white-to-white and black-to-black connectors.

Mobile Power Unit

HeartMate Touch

Communication System

For more information, see page 3-15.

The Mobile Power Unit™ is for home or clinical use when

the patient does not require monitoring using the

HeartMate Touch™ Communication System. The Mobile

Power Unit is used when the patient is indoors, stationary,

or sleeping, as a sleeping patient may not hear low

battery power alarms. The System Controller and the

Mobile Power Unit are connected through the Mobile

Power Unit patient cable. The cable transfers power from

the Mobile Power Unit to the System Controller.

For more information, see page 3-34.

The HeartMate Touch Communication System provides

clinicians with the ability to wirelessly monitor a patient’s

HeartMate system, program system parameters such as

pump speed, assess and track alarm conditions, and

view and save performance data. Its use during Left

Ventricular Assist Device implantation is required.

For more information, see page 4-2.

Table 1.1 HeartMate 3™ System Components (Continued)

1-11

Page 21

Battery Charger

Shower Bag

Chapter 1 Introduction

The Battery Charger calibrates, charges, and tests the

HeartMate 14 Volt Lithium-Ion batteries that are used to

power the system during battery-powered operation.

For more information, see page 3-73.

The Shower Bag is used to protect external system

components from water or moisture—outside in heavy

rain or snow, and always for every shower. HeartMate 3

patients may be allowed to shower when the Driveline

exit site has healed and with permission from their doctor.

If external system components have contact with water or

moisture, the system may fail to operate properly or the

patient may get a serious electric shock.

For more information, see page 6-13.

System Controller Neck Strap

Belt Attachment

The System Controller Neck Strap attaches to the System

Controller and is used to wear the System Controller

around the neck or across the body.

For more information, see page 6-28.

The belt attachment provides another way to wear the

System Controller.

For more information, see page 6-33.

Table 1.1 HeartMate 3™ System Components (Continued)

1-12

Page 22

Consolidated Bag

Battery Holster

Chapter 1 Introduction

The Consolidated Bag is a convenient way to carry two

HeartMate 14 Volt Lithium-Ion batteries and attached

battery clips during battery-powered operation.

For more information, see page 6-37.

The Battery Holster provides a convenient way to wear

two HeartMate 14 Volt Lithium-Ion batteries and attached

battery clips.

For more information, see page 6-46.

Holster Vest

The Holster Vest provides another way to wear the

HeartMate 14 Volt Lithium-Ion batteries and attached

battery clips.

For more information, see page 6-52.

Table 1.1 HeartMate 3™ System Components (Continued)

1-13

Page 23

Travel Bag

Protection Bag

Chapter 1 Introduction

The Travel Bag provides a convenient way to carry and

transport the backup System Controller and spare

batteries.

For more information, see page 6-61.

The Protection Bag stores and protects the backup System

Controller.

For more information, see page 6-60.

ICU Cover

The disposable, non-sterile, single-patient use ICU Cover

is a location management accessory to secure the System

Controller to a visible location using the provided Clip.

For more information, see the ICU Cover Instructions for

Use shipped with the ICU Cover.

Table 1.1 HeartMate 3™ System Components (Continued)

1-14

Page 24

Chapter 1 Introduction

Required, Backup, and Optional Components and Equipment

The HeartMate 3™ Left Ventricular Assist System is designed for use both inside and outside of the

hospital. Specific system components and equipment may be required for each setting. Components

and equipment that are required for implant and ICU transfer are listed in Table 1.2.

.

Components Required for Implantation

and ICU Transfer

HeartMate 3 Implant Kit* Required Required

System Controller with 11 Volt Lithium-Ion

Backup Battery

Power Module with patient cable Required Required

Tablet for use with the HeartMate Touch App

and HeartMate Touch Wireless Adapter

One set of 4 rechargeable HeartMate 14 Volt

Lithium-Ion batteries

One set of 2 HeartMate 14 Volt battery clips and

battery clip cables

Battery Charger Required Not required

HeartMate 3 Tunneling Lance and Handle** Required

Apical coring knife** Optional

Primary Backup

Required Required

Required Required

Required Not required

Required Not required

Skin coring punch (6 mm)* Optional

Apical cuff** Optional

Outflow Graft Thread protectors** Optional

Modular Cable Cap Optional

* Some “Optional” items are included in the HeartMate 3 Implant Kit.

** Also available separately.

1-15

Table 1.2 Components for Implant

Page 25

Chapter 1 Introduction

Components and equipment that are required for a discharged patient are listed in

Table 1.3. Patients discharged to a lower care facility or to their homes must be trained in device

use, maintenance, and troubleshooting. In addition, device malfunction may necessitate emergency

treatment. Therefore, patients should not be more than two hours from a healthcare facility that has

trained personnel who are capable of treating a HeartMate 3 patient.

Components for a Discharged Patient Primary Backup

Implanted HeartMate 3 Left Ventricular Assist

Device

System Controller with 11 Volt Lithium-Ion

backup battery

Mobile Power Unit Required Not Required

One set of 4 rechargeable HeartMate 14 Volt

Lithium-Ion batteries

One set of 2 HeartMate 14 Volt battery clips Required Not Required

Battery Charger Required Not Required

One set of wear & carry accessories,

including: Shower Bag, Protection Bag for

backup System Controller, holster vest, belt

attachment accessory, and System Controller

Neck Strap

HeartMate 3 Patient Handbook Required Not Required

Required n/a

Required Required

Required Required

Required Not Required

Table 1.3 Components for Discharged Patients

CAUTION !

Confirm that the patient’s backup System Controller has had the 11 Volt Lithium-Ion backup

battery installed and the time and date have been set.

WARNING !

A backup System Controller and charged batteries must remain with the patient at all times

for use in an emergency. Patient and caregiver training must address this crucial need.

1-16

Page 26

Chapter 1 Introduction

Principles of Operation

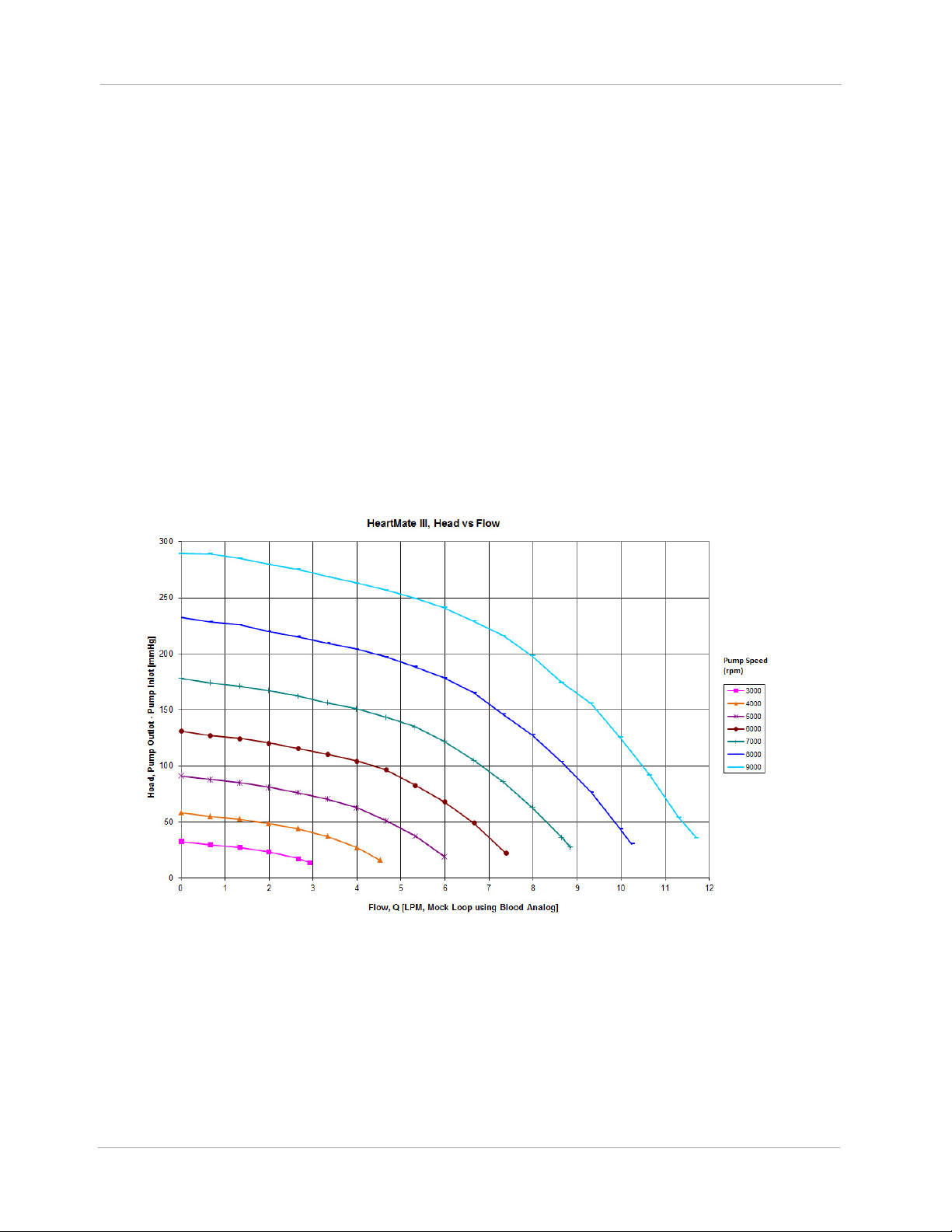

The HeartMate 3™ LVAD is a centrifugal pump that produces flow in the patient's circulatory system

by angularly accelerating and expelling blood that enters it. From a clinical viewpoint, this

mechanical pump works in concert with the native heart to which it is attached. It is a parallel

arrangement - ventricular blood may flow either through the LVAD or the aortic valve to reach the

aorta - the proportion of which depends greatly upon the degree of the patient's cardiac function

and the set-speed of the LVAD.

As for any continuous flow pump (axial, centrifugal, or mixed), the volume flow rate through the

pump is directly related to the pressure across the pump and inversely related to the resistance.

Clinically, the volume flow rate through the Pump is the difference between aortic and left ventricular

pressure, and systemic vascular resistance. This relationship can be characterized at any rotor

speed, and the family of curves derived in steady-state at different speeds is commonly termed “H-Q

curves”, or the pressure head (H) - volume flow rate (Q) relationship. HeartMate 3 H-Q curves are

shown in Figure 1.3.

Figure 1.3 Pressure Head-Flow (H-Q) Relationship

Similarly, there is a characteristic relationship between pump power and volume flow rate. Total

power consumption includes hydraulic power (useful blood pressure and flow), viscous losses,

electrical resistance losses, and others. The relationship between hydraulic power and volume flow

1-17

Page 27

Chapter 1 Introduction

rate is always direct, but the various losses have a multitude of dependencies that make inflections in

the relationship possible.

In general, if the speed is set optimally, LVAD flow will be unidirectional towards the aorta and much

greater than cardiac output, which may be minimal or zero if the presence of the LVAD keeps the

aortic pressure above the ventricular pressure even during systole. If the LVAD speed is set too high,

the inflow pressure may fall to the extent that it attempts to recruit blood from the left ventricle, left

atrium, and pulmonary vasculature that simply is not there, resulting in collapse of the left ventricle

and potential arrhythmia. The HeartMate 3 LVAS employs a feature called Pulsatility Index (PI)

Detection to recognize and avert this condition. When the degree of pulsatility measured in the

electrical current waveform has fallen below a preset value, the system regards this as a risk of

ventricular suction and quickly lowers the rotor speed to a preset, programmable Low Speed Limit,

then immediately but gradually returns the rotor to its original speed. The HeartMate 3 has an

intrinsic limit somewhat above 9000rpm. The system accordingly precludes setting the speed above

9000rpm. Conversely, if the LVAD speed is set too low, support for the failing heart may be

insufficient. The HeartMate 3 LVAS uses the same Low Speed Limit mentioned above to limit how low

the speed may be set. This is to avoid profound retrograde flow (aorto-ventricular shunt). The Low

Speed Limit is settable within a range to accommodate customization for a variety of patients.

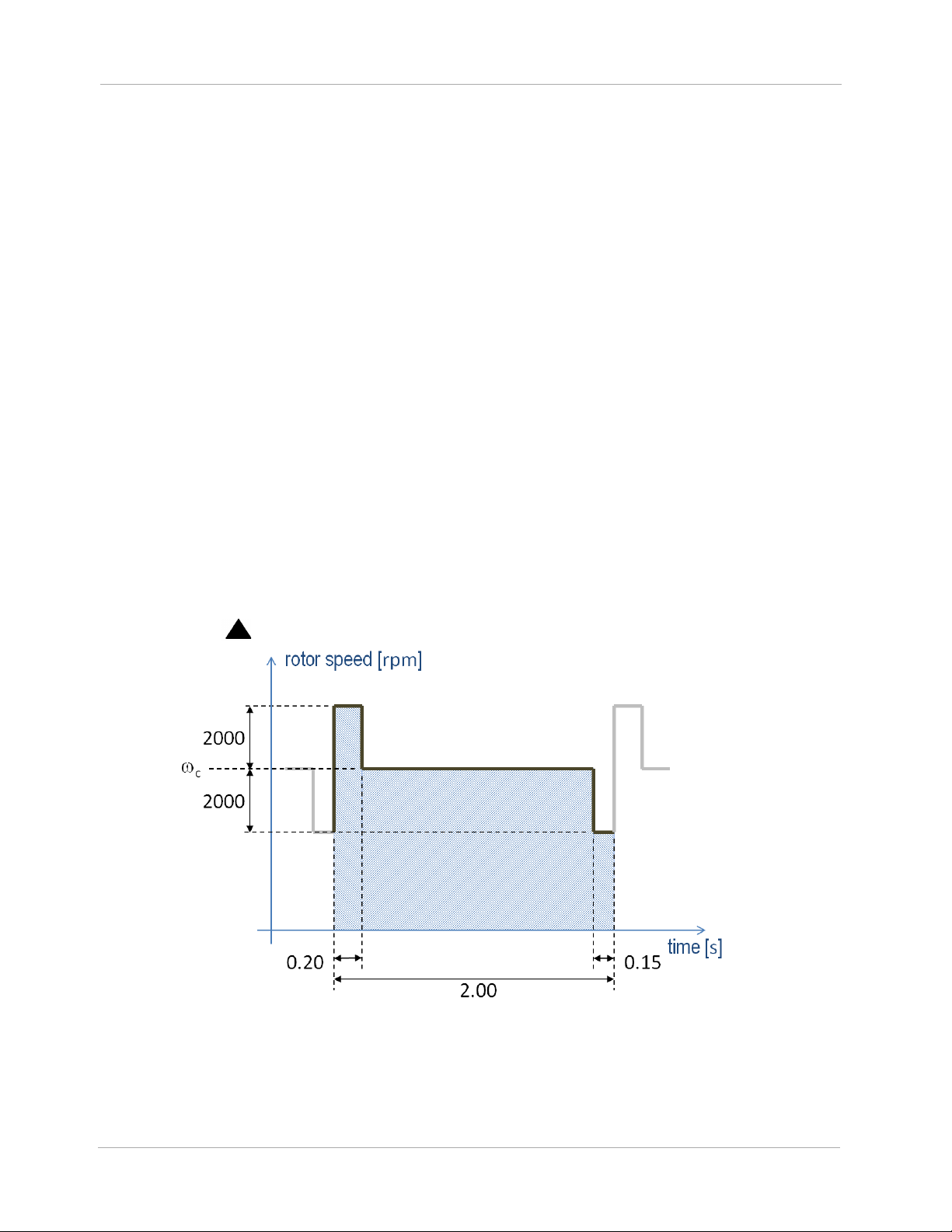

The HeartMate 3 employs a feature called Artificial Pulse that adds an element to the discussion

about rotor speed (Figure 1.4). Although the clinician will set only a single speed,

in Figure

c

1.4, the rotor speed will periodically depart from this value in order to contribute a flow disruption

that in some ways mimics native cardiac contractility. This artificial pulse “beats” 30 times per

minute, asynchronously with the heart. The Artificial Pulse mode is indicated on the System Controller

by the use of a ( ) symbol.

1-18

Figure 1.4 Artificial Pulse

Page 28

Chapter 1 Introduction

Explanation of Parameters

Speed

The HeartMate 3™ Left Ventricular Assist Device operates at a fixed speed (see Optimal Fixed Speed

on page 4-25) determined by the physician during a speed ramp study.

Note: The term “fixed speed” is a speed fixed, or set, by the clinician, i.e.,

Figure 1.4. This should not be confused with the concept of a constant speed mode, as opposed to

an artificial pulse mode. Either mode requires a fixed speed, set by the clinician.

A pre-programmed artificially induced pulse is intermittently generated, changing pump speed. The

“low speed limit” for the device is the lowest speed at which it allowed to operate.

During a suction event, device speed drops to the “low speed limit” and then ramps up to the fixed

speed unless another Pulsatility Index (PI) event is detected. If another PI event is detected, the device

drops to the “low speed limit” again and then ramps back up. This cycle repeats as long as PI events

are detected. Large changes in speed may indicate an abnormal condition that should be evaluated

for cause.

c

in

Power

Device power is a direct measurement of pump motor voltage and current. Changes in pump speed,

flow, or physiological demand can affect pump power. Gradual power increases (over hours or

days) may signal thrombus deposits inside the pump, aortic or insufficiency. Gradual power

decreases may indicate an obstruction of flow and should be evaluated. Depending on the speed of

the pump, power values greater than 10 to 12 watts (W) also can indicate the presence of a

thrombus. Abrupt changes in power should be evaluated for cause.

Flow

Device flow and power generally retain a linear relationship at a given speed. However, while

power is directly measured by the System Controller, the reported flow is estimated, based on

power. Since the flow displayed on the System Controller is a calculated value, it somewhat

underestimates actual flow at high flows.

Any increase in power not related to increased flow (such as thrombus) causes erroneously high flow

readings. Conversely, an occlusion of the flow path decreases flow and causes a corresponding

decrease in power. In either situation, pump output should be assessed.

1-19

Page 29

Chapter 1 Introduction

Pulsatility Index (PI)

When the left ventricle contracts, the increase in ventricular pressure causes an increase in pump

flow during cardiac systole. The magnitude of these flow pulses are measured and averaged over

15-second intervals to produce a “Pulsatility Index” (occasionally shortened to “PI” for on-screen

messages).

The PI calculation represents cardiac pulsatility. PI values typically range from 1 to 10. In general,

the magnitude of the PI value is related to the amount of assistance provided by the pump. Higher

values indicate more ventricular filling and higher pulsatility (ie, the pump is providing less support to

the left ventricle). Lower values indicate less ventricular filling and lower pulsatility (ie, the pump is

providing greater support and further unloading the ventricle).

PI values should be routinely monitored and should not vary significantly during resting conditions.

Under otherwise stable conditions, a significant drop in value may indicate a decrease in circulating

blood volume. Pulsatility Index values near or above 10 may indicate potential problems. For PI

values near 10 or above, please contact Abbott. For Abbott contact information, see the Back Cover

of this manual.

IMPORTANT! One single pump parameter is not a surrogate for monitoring the overall clinical

status of the patient. Any change in parameters should be evaluated with all clinical considerations

taken into account.

1-20

Page 30

SYSTEM OPERATIONS

This section describes the primary system operations of the HeartMate 3™ Left Ventricular Assist

System.

HeartMate 3™ Left Ventricular Assist Device Overview - - - - - - 2-2

2

System Controller Overview - - - - - - - - - - - - - - - - - - - - 2-8

The Backup System Controller - - - - - - - - - - - - - - - - - - - 2-45

2-1

Page 31

Chapter 2 System Operations

HeartMate 3™ Left Ventricular Assist Device Overview

The HeartMate 3™ Left Ventricular Assist Device (Figure 2.1) is a centrifugal flow rotary heart

pump that is connected in parallel to the native circulation. The inflow cannula of the Left Ventricular

Assist Device attaches to the apex of the left ventricle. Its sealed outflow graft connects to the

ascending aorta (Figure 2.2). Frequently, the HeartMate 3 Left Ventricular Assist Device is called

the “pump.”

Figure 2.1 HeartMate 3™ Left Ventricular Assist Device

2-2

Page 32

Chapter 2 System Operations

Figure 2.2 HeartMate 3™ Implant

Configuration

Inflow

Cannula

Outflow

Graft

Function

The LVAD uses a rotary blood pump to generate flow and assist the left ventricle. It is a

centrifugally-configured device so that the paths of the entering and exiting flow stream are

perpendicular to the pump’s axis. The device has only one moving part, the rotor assembly, which is

fully (i.e., actively) magnetically levitated within the flow stream. The pump is driven by an external

power source via a Driveline.

The pump operates in parallel with the heart, such that either can supply blood to the aorta. The

LVAD can generate a blood flow up to 10 liters per minute (lpm). Blood enters the pump from the left

ventricle through an Inflow Cannula. Blades on the spinning rotor move the blood through the pump

to an Outflow Cannula and ultimately to the native circulation.

Implant Location

The HeartMate 3™ Left Ventricular Assist Device is implanted in the chest (see Figure 2.2). For

more information, see Implant Procedures on page 5-35

.

2-3

Page 33

Chapter 2 System Operations

The HeartMate 3 LVAD is part of the Left Ventricular Assist System (Figure 2.3).

Figure 2.3 HeartMate 3™ LVAS During Battery-Powered Operation

Driveline

The Driveline consists of two cables: the Pump Cable, that extends from the Left Ventricular Assist

Device through the skin, and the Modular Cable which connects the Pump Cable to the System

Controller. The Driveline contains six wires—three primary wires and three backup wires—that

power the Pump Motor and facilitates communication with the System Controller.

To reduce infection, the Driveline is covered with woven polyester, which encourages tissue ingrowth

at the skin line. Over time, tissue bonds to the textured material and anchors the external surface of

the Driveline to the surrounding tissue. After emerging from the body, the Driveline has a Modular

Connector that joins the Pump Cable to the Modular Cable. The Modular Cable then has an electric

connector that attaches to the System Controller.

Experience with other LVADs has shown that wear and fatigue of the Driveline may result in damage

that can interrupt device function. Such damage may require another operation to replace the pump,

or result in death. For information about caring for the Driveline, see Care of the Driveline on page

8-5.

2-4

Page 34

Chapter 2 System Operations

Pump Cable

Modular Cable

Driveline (both

cables when

connected)

Driveline damage due to wear and fatigue may occur in both the externalized (Modular Cable) and

implanted portions (Pump Cable) of the lead. Damage to the conductors within the Driveline may or

may not be preceded by visible damage to the outer layer of the Driveline.

Driveline damage may be evidenced by the following:

• A Driveline Power Fault, Driveline Comm Fault, or Communication Fault alarm on the System

Controller.

• Transient alarms due to short or open circuits, often associated with movement of the patient or

the lead.

• Fluid leakage from the external portion of the Pump Cable.

• Cessation of pumping.

WARNING !

If the Driveline or Driveline connector appears damaged, contact Abbott for assistance. Refer

to the Back Cover of this manual for Abbott contact information.

X-ray images and System Controller log files are useful to assess the extent and location of the

damage. If the Driveline or Driveline conductors are damaged internal to the patient’s body, the

pump should be replaced as soon as possible. If it has been determined that the damage has been

detected in the Modular Cable, it can be replaced. Please refer to Replacing the Modular Cable on

page 2-62 for the procedure for exchanging the Modular Cable.

Figure 2.4 Driveline

2-5

Page 35

Chapter 2 System Operations

Powering the Pump Motor

The Left Ventricular Assist Device Motor is powered through the System Controller by one of three

sources: the Power Module or the Mobile Power Unit that is connected to an AC electrical outlet (see

Using the Power Module on page 3-4), or two HeartMate 14 Volt Lithium-Ion Direct Current (DC)

Batteries (see Using HeartMate 14 Volt Lithium-Ion Batteries on page 3-51).

Note: The Backup System Controller is charged every six months.

Acceptable Operating Conditions

For safe and optimal use of HeartMate system components, follow the operating guidelines listed

here. Operating system components outside of the environmental parameters listed below may affect

device operation.

Equipment

Power Module

Mobile Power Unit

Tablet for use with

the HeartMate

™ App

Touch

HeartMate Touch

Wireless Adapter

HeartMate 14 Volt

Lithium-Ion

Batteries

Battery Charger

a

Acceptable

Temperature

Range F (C)

32°F to 104°F

(0°C to 40°C)

32°F to 104°F

(0°C to 40°C)

32°F to 95°F

(0°C to 35°C)

32°F to 104°F

(0°C to 40°C)

32°F to 104°F

(0°C to 40°C)

32°F to 104°F

(0°C to 40°C)

Relative

Humidity

20% to 75%

20% to 93%

20% to 95%

20% to 75%

20% to 75%

20% to 75%

Air Pressure

mm Hg (hPA)

525 to 795

(700 to 1060)

525 to 795

(700 to 1060)

535 to 795

(710 to 1060)

525 to 795

(700 to 1060)

525 to 795

(700 to 1060)

525 to 795

(700 to 1060)

System Controller,

Backup System

Controller

11 Volt

Lithium-Ion

Backup Battery

a, b

32°F to 104°F

(0°C to 40°C)

32°F to 104°F

(0°C to 40°C)

2-6

20% to 93%

20% to 93%

525 to 795

(700 to 1060)

525 to 795

(700 to 1060)

Table 2.1 Operating Conditions

Page 36

Chapter 2 System Operations

a Standby components (extra 14 Volt Lithium-Ion batteries, backup System Controller) should be maintained at conditions within the

acceptable ranges so that they are available for immediate use. A backup System Controller and charged batteries must remain with

the patient at all times for use in an emergency. Patient and caregiver training must address this crucial need.

Every six months, the “sleeping” backup System Controller must be connected to a power source to charge the 11 Volt Lithium-Ion backup battery inside.

b

If the 11 Volt Lithium-Ion backup battery inside the backup System Controller is not charged every six months, its charge level will diminish and there may

not be sufficient power to support the pump if the backup System Controller is in use during a power emergency (see Maintaining Backup System Controller

Readiness: Six Month Charging and Self Test

on page 2-51).

2-7

Page 37

Chapter 2 System Operations

HeartMate 3

Left Ventricular

Assist Device

System Controller

Driveline

System Controller Overview

The HeartMate 3™ System Controller acts as the central power and communication hub for the

HeartMate 3 LVAS. It passes power from the Power Module, the Mobile Power Unit, Lithium-Ion

Batteries, or its own integrated emergency backup supply, down to the LVAD via the Driveline. The

HeartMate 3 System Controller constantly monitors system performance through communication with

the implanted LVAD and Controller internal measurements and alerts the user to any alarm conditions

by activating membrane panel LEDs and integrated audio annunciators. Further information on alarm

conditions as well as system status can be attained by the user from the front panel LCD on the

System Controller. When connected to a HeartMate Touch™ Communication System, the System

Controller sends information regarding the System Controller and Pump Status once per second to

provide additional information to the user. This link also allows the clinician to set new patient

operating parameters (e.g. pump speed) and provides a link for downloading trend and/or event

recorder data.

The System Controller has been designed with redundant power and communication lines to the

pump Driveline. This not only provides for a robust continuous operation of the implanted pump in

the event of a fault situation, but also alerts the user to possible Driveline degradation.

The System Controller is the chief decision making component of the system. It instructs the pump at

which speed to operate, either by passing a command sent by the HeartMate Touch Communication

System or when in Power Saver mode or at a Pulsatility Index (PI) event detection.

The System Controller connects to the LVAD

via a Driveline that passes through the

patient’s abdomen. The Driveline carries

power to the pump. The Driveline also

supplies information from the pump to the

System Controller (Figure 2.5).

The System Controller uses sounds, lights,

symbols, and on-screen messages to

communicate with users (Figure 2.6).

Figure 2.5 HeartMate 3™ Left Ventricular Assist System

2-8

Page 38

Chapter 2 System Operations

System Controller

Driveline Connector

Backup

Battery

(inside)

User

Interface

Power Cable

Connectors

• System Controller Driveline

Connector: links the Modular

Cable portion of the Driveline

to the System Controller.

• Power Cable Connectors: link

external power source (Power

Module, Mobile Power Unit, or

2 HeartMate 14 Volt

Lithium-Ion Batteries) to the

System Controller.

• User Interface: buttons, lights,

and screen where system data,

alarms, and user instructions

appear.

• Backup battery: located inside

the System Controller, powers

the pump for at least 15

minutes during a power-loss

emergency.

Power Cable

Connectors

Red Button

System Controller Driveline

Connector Alignment Arrow

System Controller Driveline

Connector

Safety Lock

Driveline Cable

Connector White

Alignment Arrow

Figure 2.6 System Controller Major Components

2-9

Page 39

Chapter 2 System Operations

The System Controller is described in the following sections:

System Controller User Interface Overview

This section describes the visual display of system operations and

on-screen messages.

System Controller Driveline Connector

This section provides instructions on connecting and disconnecting the

Driveline.

System Controller Power Cable Connectors

This section describes two power cables on the System Controller

(one white and one black) that connect the System Controller to either

the Power Module, the Mobile Power Unit, or two 14 Volt Lithium-Ion

batteries.

See page 2-14.

See page 2-20.

See page 2-26.

Performing a System Controller Self Test

This section provides instructions on how to perform a daily self test to

check the function of the System Controller’s audible and visual

alarms.

See page 2-29.

System Controller Battery Power Gauge

This section describes the battery power gauge function to show the

approximate charge status of the power source that is connected to

the System Controller’s power cables.

See page 2-30.

System Controller Operating Modes

This section describes the System Controller’s three operating modes

(Run, Sleep, and Charge) and provides an overview with instructions

on how to switch between modes.

See page 2-33.

System Controller Backup Battery Power

This section provides a functional overview with instructions on how

to replace the 11 Volt Lithium-Ion backup battery that is inside the

System Controller.

2-10

See page 2-39.

Page 40

Chapter 2 System Operations

System Controller Warnings and Cautions

WARNING !

• Check the System Controller Driveline connector to confirm that the Driveline is securely

inserted in the socket. If the Driveline disconnects from the System Controller, the pump stops.

If the Driveline disconnects from the System Controller, promptly reconnect it to resume pump

operation.

• At least one System Controller power cable must be connected to a power source (Power

Module, Mobile Power Unit, or two HeartMate 14 Volt Lithium-Ion batteries) at all times.

• Keep the System Controller power cables dry and away from water or liquid. If the System

Controller power cables come into contact with water or liquid, the system may fail to operate

properly or you may get a serious electric shock.

• Do not allow patients to swim or take tub baths while implanted with the Left Ventricular Assist

Device. Patient immersion in water may cause the device to stop.

• Do not allow patients to shower without a doctor’s permission. HeartMate 3™ patients may

be allowed to shower, but only after sufficient post-operative healing and with a doctor’s

permission.

• If external system components have contact with water or moisture, the Pump may stop. If a

HeartMate 3 patient is approved for showering, he or she must always use the Shower Bag

during every shower. The Shower Bag protects external system components from water or

moisture.

• The 11 Volt Lithium-Ion backup battery should be used only for temporary support during a

power-loss emergency. The 11 Volt Lithium-Ion backup battery inside the HeartMate 3 System

Controller provides enough power to run the implanted HeartMate 3 pump for at least 15

minutes if the main power source (either the Power Module, Mobile Power Unit, or two

HeartMate 14 Volt Lithium-Ion batteries) is disconnected or fails. Inappropriate use of the 11

Volt Lithium-Ion backup battery may result in diminished run time during a power-loss

emergency.

• Do not use damaged, defective, or expired 11 Volt Lithium-Ion backup batteries in the System

Controller. Using a damaged, defective, or expired System Controller backup battery may cut

operating time during an emergency or cause the pump to stop.

• Use only a Abbott-supplied HeartMate 14 Volt Lithium-ion battery with the HeartMate 3

System Controller. Using another battery may cause the pump to stop.

• Do not open, crush, heat above 104°F (40°C), or incinerate batteries because of the risk of

fire and burns. Follow manufacturer’s instructions.

• Malfunction of the 11 Volt Lithium-Ion backup battery may cause the System Controller to

become excessively hot. If this occurs, switch to the backup System Controller.

2-11

Page 41

Chapter 2 System Operations

CAUTION !

• Do not drop the System Controller or subject it to extreme physical shock.

• Instruct patients (and family member or caregiver) to advise hospital personnel immediately if

they drop the System Controller. Emphasize to users the importance of not waiting to report a

dropped System Controller, even if everything seems fine. Dropping the System Controller

can cause trauma or tissue damage at the Driveline exit site, which can increase the patient’s

risk of serious infection.

• Instruct the patient to stabilize their Driveline at all times to avoid pulling on or moving the

Driveline at the exit site. Pulling on or moving the Driveline can keep the exit site from healing

or damage an already healed exit site. Exit site trauma or tissue damage can increase the

patient’s risk of getting a serious infection. Emphasize to the patient and/or family member

or caregiver the importance of not pulling on or moving the Driveline.

• Do not twist, kink, or sharply bend the Driveline, System Controller power cables, Power

Module patient cable, or Mobile Power Unit patient cable, which may cause damage to the

wires inside, even if external damage is not visible. Damage to the Driveline or cables could

cause the Left Ventricular Assist Device to stop. If the Driveline or cables become twisted,

kinked, or bent, carefully unravel and straighten.

• The 11 Volt Lithium-Ion backup battery inside the backup System Controller must be charged

at least once every six months. Failure to charge the 11 Volt Lithium-Ion backup battery inside

the backup System Controller may result in diminished or no support during a power-loss

emergency when the backup System Controller is in use.

• Damage to the redundant electrical wires inside the Driveline can occur that is not visible to

the user. Signs of Driveline damage include (but are not limited to):

- The System Controller alarming when the Driveline is moved or when the patient

changes position.

- Driveline Power Fault or Driveline Communication Fault yellow wrench and audio alarm

(see System Controller User Interface Components on page 2-15).

- Fluid oozing from the external portion of the Pump Cable.

- Pump stoppage.

• When connecting power cable connectors, do not try to join them together without first

aligning the half circles inside the connectors. Joining together misaligned power cable

connectors may damage them.

2-12

Page 42

Chapter 2 System Operations

CAUTION ! (Continued)

• Never use tools to tighten power cable connectors; securely hand tighten only. Using tools

may damage the connectors.

• Confirm that the patient’s backup System Controller has had the 11 Volt Lithium-Ion backup

battery installed and the time and date have been set.

• A backup System Controller and charged batteries must remain with the patient at all times

for use in an emergency. Patient and caregiver training must address this crucial requirement.

• The System Controller uses lights, sounds, and on-screen messages to communicate with users

about system operation. HeartMate 3 patients with sight or hearing impairment may need

extra help using the System Controller.

• Do not place the System Controller on bare skin for an extended time. The System Controller

surface temperature can become uncomfortably warm, especially when the room

temperature is above 104°F (40°C).

2-13

Page 43

Chapter 2 System Operations

Battery Button

Cable

Disconnect

Symbols

Status Symbols

Silence Alarm Button

Pump

Running

Symbol

User

Interface

Screen

Display

Button

System Controller User Interface Overview

The user interface on the System Controller is the primary interface for users during routine system

operation. It uses sounds, lights, symbols, and on-screen messages to communicate about how the

system is working. The user interface provides a visual display of system operation and on-screen

messages that instruct how to respond to alarms and other situations (Figure 2.7).

HeartMate 3™ patients (and their family members/caregivers) must be thoroughly trained on how to

interpret and use the user interface prior to discharge (see Educating and Training Patients, Families,

and Caregivers on page 6-67).

For situations that require attention, and depending on the urgency, the System Controller issues

include one of two types of alarms: hazard and advisory. Hazard alarms occur for conditions that

are potentially life threatening for the patient and require immediate attention. Advisory alarms are

important, but not life threatening. For more information on System Controller alarms and how to

resolve them, see Alarms and Troubleshooting on page 7-1.

2-14

Figure 2.7 System Controller User Interface

Page 44

Chapter 2 System Operations

System Controller User Interface Components

The buttons, lights, symbols, and display screen on the user interface are introduced below in Table

2.2.

Pump Running

Symbol

The Pump Running symbol on the user interface is illuminated green when

the Left Ventricular Assist Device is running.

Low Battery

Alarm

Yellow Wrench

Alarm

Red Heart Alarm

The red low battery symbol illuminates when less than 5 minutes of

battery power remain (applicable only during 14 Volt Lithium-Ion

battery-powered operation).

This is a Hazard alarm. When the red battery symbol illuminates,

immediately replace the depleted batteries with a fully-charged pair, or

switch to the Power Module or the Mobile Power Unit.

For more information, see page 7-15.

The yellow wrench symbol illuminates when the System Controller detects

a mechanical, electrical, or software issue with the system.

This is an Advisory alarm. When the yellow wrench illuminates, check

the screen for troubleshooting instructions.

For more information, see page 7-8.

The red heart symbol illuminates when the System Controller detects a

problem that could cause serious injury or death.

This is a Hazard alarm. When the red heart illuminates, check the

screen for instructions and take immediate action to resolve the problem.

For more information, see page 7-6.

Black Power

Cable Alarm

The yellow light near the black power cable connector illuminates when

the black power cable becomes loose or disconnects from the System

Controller.

This is an Advisory alarm. If the black power cable disconnects or

becomes loose, promptly restore the connection.

For more information, see page 7-17.

Table 2.2 System Controller Symbols, Alarms, Buttons

2-15

Page 45

Chapter 2 System Operations

White Power

Cable Alarm

Driveline

Connector Alarm

Battery Power

Gauge

The yellow light near the white power cable connector illuminates when

the white power cable becomes loose or disconnects from the System

Controller.

This is an Advisory alarm. If the white power cable disconnects or

becomes loose, promptly restore the connection.

For more information, see page 7-17.

The red light near the Driveline connector illuminates when the Driveline

becomes loose or disconnects from the System Controller.

This is a Hazard alarm. If the Driveline loosens or disconnects from the

System Controller, promptly restore the connection. If the Driveline is not

reconnected immediately, the pump stops.

For more information, see page 7-13.

The battery power gauge shows the approximate charge status of the

power source that is connected to the System Controller’s white and black

power cables—either the 14 Volt Lithium-Ion batteries or the Power

Module. The number of green bars means power remaining. The more

green bars mean more power remaining.

For more information, see page 2-30.

Yellow diamond = less than 15 minutes of battery power remain.

Appearance of this symbol indicates an Advisory alarm. If the yellow

diamond comes on, promptly replace the low batteries with two

fully-charged batteries, or switch to the Power Module or the Mobile

Power Unit. Do this as soon as possible.

For more information, see page 7-18.

IMPORTANT! The battery power gauge does not show the

charge status of the System Controller’s backup battery (the battery

inside the System Controller). To check the status of the System

Controller’s backup battery, see Viewing Pump and System Information on page 2-18.

Table 2.2 System Controller Symbols, Alarms, Buttons (Continued)

2-16

Page 46

Chapter 2 System Operations

The battery button is used for the following:

• Operating the battery power gauge: Press and release the

battery button.

For more information, see page 2-30.

Battery Button

Silence Alarm

Button

• Starting a System Controller self test: Press and hold the

battery button for 5 seconds and then release it. Perform a self test

daily on your running System Controller, and monthly on your backup

System Controller when it is in Charge Mode.

For more information, see page 2-29.

• Putting a running System Controller into Sleep Mode:

When a System Controller is no longer in use, it can be put to sleep

by disconnecting the Driveline and power source, and pressing and

holding the battery button for 5 seconds and then releasing it.

For more information, see page 2-38.

The silence alarm button is used for the following:

• Silencing an active alarm: Press and release the silence alarm

button to silence an active alarm on the System Controller. How long it

is silenced depends on the alarm (see Alarms and Troubleshooting on

page 7-1). The LCD screen on the System Controller will display the

audio alarm silence symbol.

IMPORTANT! Using the silence alarm button only silences the

alarm. It does not fix the alarm condition.

• Viewing the last six System Controller alarms on the

screen: Press and release the silence alarm button ( ) and the

display button ( ) at the same time to display the last six System

Controller alarms on the screen.

Display Button

For more information, see page 7-3.

The display button activates the information display screen. Press and

release the display button one or more times repeatedly to display

information about pump speed, power, flow, pulsatility index, and the

charge status of the System Controller’s 11 Volt Lithium-Ion backup

battery. The display button is functional only when a System Controller is

in use.

For more information, see page 2-19.

Table 2.2 System Controller Symbols, Alarms, Buttons (Continued)

2-17

Page 47

Chapter 2 System Operations

Pulse Mode

The presence of the black triangle indicates that the HeartMate 3 system

is operating in Pulse Mode. Once every 2 seconds, the HeartMate 3

pump will automatically modify its speed to create an artificial pulse.

Table 2.2 System Controller Symbols, Alarms, Buttons (Continued)

Viewing Pump and System Information

Viewing information about the pump is useful when recording daily values or trying to resolve system

problems on the telephone. When the System Controller is running, the user interface can display the

following information about current system operations:

• Speed

• Mode (indicated as Pulse Mode by symbol)

•Flow

• Pulsatility Index (abbreviated as “PI” on the screen)

•Power

• Charge status of the System Controller’s backup battery (11 Volt Lithium-Ion)

To view information on the user interface screen, press and release the display button ( ). Each

push of the display button brings up a new screen. Each screen illuminates for 15 seconds before it

goes black, unless another button is pushed. The screens are always displayed in the same order,

starting with the first (Speed) screen. A dot at the bottom of each screen provides navigational

information about which of the five screens is in view.

2-18

Page 48

Chapter 2 System Operations

Table 2.3 shows the display sequence.

Button

Press

Press

Press

Press

Press

Press

Description

Press display button

ONCE

Press display button

TWO times

Press display button

THREE times

Press display button

FOUR times

Press display button

FIVE times

Screen

Displayed

(Example)

Meaning

Pump speed in revolutions per minute

(RPM)

Triangle indicates that the pump

is in Pulse Mode.

Pump flow in liters per minute (LPM)

Pulsatility Index (PI)

Power in watts (W)

The System Controller’s backup battery

(located inside the System Controller

and used to temporarily run the pump

during a power emergency) has three

charge status states:

1. Charged (ready for use).

2. Charging (actively charging).

3. Fault (there is a fault or problem with

the backup battery that could affect its

reliability).

Press

Press display button

SIX times

Blank screen indicates the screen is off,

which is normal.

Table 2.3 System Controller Display Screen Sequence

Note: On-screen messages come in many different languages and can be changed from the

HeartMate Touch™ App to support your patient’s needs. See System Controller Language on page

4-37.

2-19

Page 49

Chapter 2 System Operations

System

Controller

Driveline

Connector

System Controller Driveline Connector

The System Controller Driveline Connector attaches the Driveline (comprised of the Pump Cable and

the Modular Cable) to the System Controller (Figure 2.8). The System Controller Driveline

Connector uses a double-lock feature that lowers the risk of accidentally disconnecting the Driveline.

Figure 2.8 System Controller Driveline Connector on the System Controller

The System Controller continually monitors the connection status of the System Controller Driveline

Connector. If the System Controller detects a problem, it immediately alarms.

2-20

Page 50

Chapter 2 System Operations

Safety

Lock

The Driveline is initially connected to the patient’s System Controller during the procedure to implant

the Left Ventricular Assist Device. The same System Controller remains in use unless it requires

replacement for clinical or technical reasons (see The Backup System Controller on page 2-45).

It is impossible to connect (or disconnect) the Driveline without first rotating the Safety Lock on the

back of the System Controller into the “unlocked” position.

Figure 2.9 Move the Safety Lock to the Unlocked Position

When the Driveline is properly and fully inserted into the System Controller Driveline Connector port,

the Driveline cannot be removed without firmly pressing the red button under the raised Safety Lock

(Figure 2.9).

If there is a problem with the Driveline connection, the System Controller alarms immediately.

2-21

Page 51

Chapter 2 System Operations

Connecting the Driveline to the System Controller

FOR THIS TASK YOU NEED:

A running System Controller, programmed with patient-specific settings

TO CONNECT THE DRIVELINE TO THE SYSTEM CONTROLLER:

1. Orient the System Controller so the display is facing down.

2. Rotate the Safety Lock to the unlocked position (Figure 2.10).

Figure 2.10 Unlock the Safety Lock

CAUTION !

Do NOT insert a misaligned Driveline Cable Connector. When inserting the Driveline Cable Connector, do NOT orient the System Controller so the display is facing up.

3. Align the WHITE arrow/alignment mark on the Driveline Cable Connector with the WHITE

arrow on the System Controller Driveline Connector(Figure 2.11).

2-22

Figure 2.11 Align the Arrows

Page 52

Chapter 2 System Operations

4. Insert the Driveline Cable Connector into the socket (Figure 2.12), pressing firmly until it snaps

into place. The Left Ventricular Assist Device may take up to 10 seconds to start running when the

cable is fully and properly inserted in the socket (if pump set speed is set above 4000 rpm.

IMPORTANT! The arrow/alignment mark on the driveline is no longer visible when properly

connected.

Figure 2.12 Insert and Lock the Driveline Into the Socket

Note: The Safety Lock cannot move to the locked position unless the Driveline is fully and properly

inserted.

5. Move the Safety Lock to the locked position, so that it covers the red button.

IMPORTANT! If the Safety Lock does not fully cover the red button, the driveline is not connected.

Disconnect and reconnect the driveline.

6. Tug on the inserted metal end of the Modular Cable to check the connection. Do not pull on or

bend the Driveline. If there is a problem with the connection, the System Controller immediately

alarms with a Driveline Disconnected alarm. This is a Hazard alarm.

CAUTION !

Do not pull on or bend the Driveline that connects the pump to the System Controller. Pulling on or

bending the Driveline may damage wires inside, even if external Driveline damage is not visible.

2-23

Page 53

Chapter 2 System Operations

Disconnecting the Driveline from the System Controller

WARNING !

• Failure to connect to a running System Controller may result in serious injury or death.

• Failure to adhere to the following instructions may result in serious injury or death.

FOR THIS TASK YOU NEED:

A running System Controller

TO DISCONNECT THE DRIVELINE FROM THE SYSTEM CONTROLLER:

1. Orient the System Controller so the display is facing down.

2. Rotate the Safety Lock to the unlocked position (see Figure 2.13).

2-24

Figure 2.13 Unlock the Safety Lock

Page 54

Chapter 2 System Operations

3. Firmly press the red button under the Safety Lock, while pulling the System Controller Driveline

Connector from the socket. Grasp the bend relief of the Modular Cable while removing it. Do not

pull on or bend the System Controller Driveline Connector (see Figure 2.14).

Figure 2.14 Grasp the Metal End and Remove the Driveline

WARNING !

The Left Ventricular Assist Device stops if the Driveline is disconnected from the System Controller.

If the Driveline is disconnected, reconnect it as quickly as possible to restart the pump. If the System Controller does not work, replace with a backup System Controller.

2-25

Page 55

Chapter 2 System Operations

White

Connector

Black

Connector

System Controller Power Cable Connectors