Page 1

For use with the following list numbers:

13000, 13100, 13150

All codes

®

Technical Service Manual

430-600203-003, A (Rev. 05/2007)

Page 2

©

Hospira, Inc.

This document and the subject matter disclosed herein are proprietary information.

Hospira retains all the exclusive rights of dissemination, reproduction, manufacture, and sale.

Any party using this document accepts it in confidence, and agrees not to duplicate it in whole

or in part nor disclose it to others without the written consent of Hospira.

430-600203-003 (Rev. 07/05) GemStar

®

Page 3

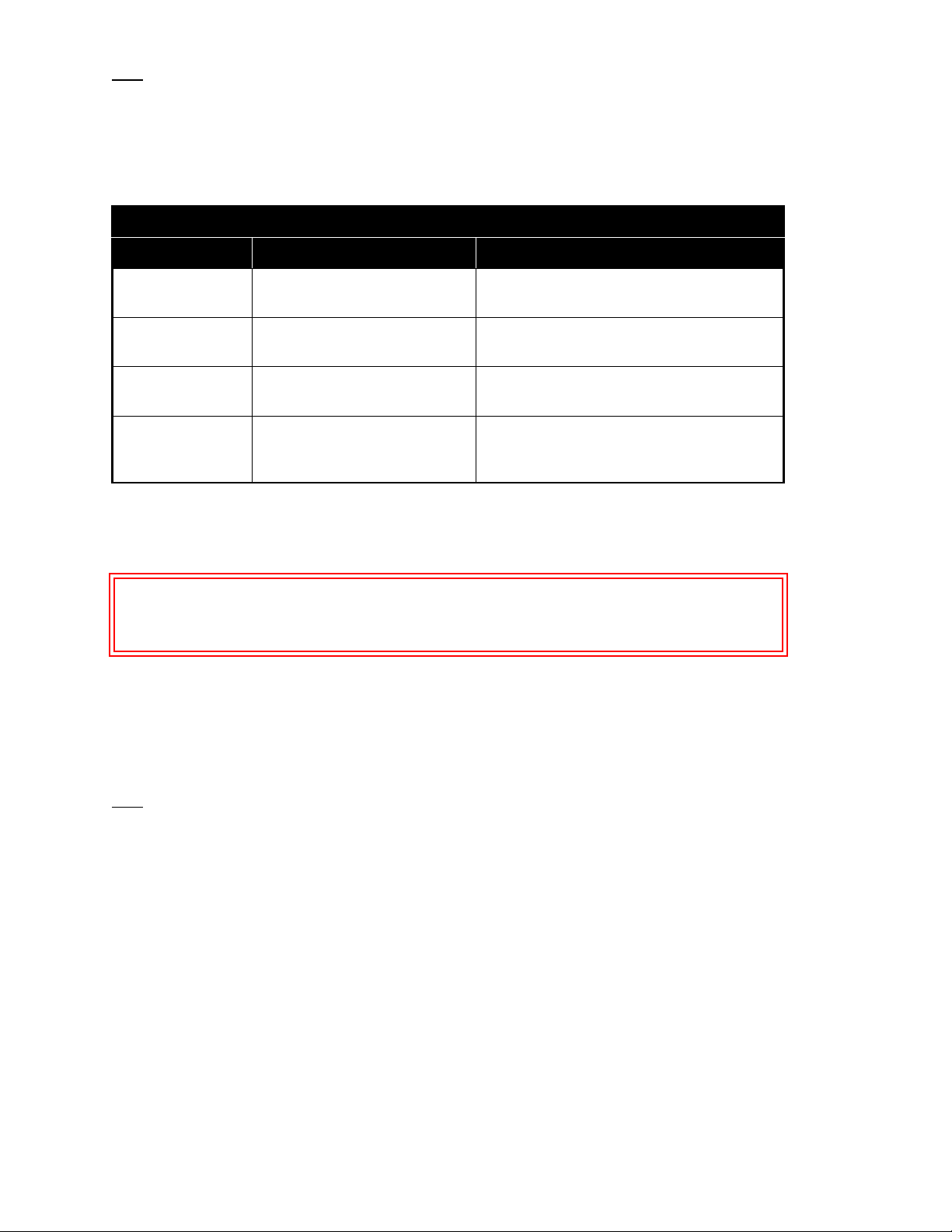

Change History

Part Number Description of Change

430-600203-001

(Rev. 04/00)

430-600203-002

(Rev. 12/02)

430-600203-A02

(Rev. 08/03)

430-600203-003

(Rev. 06/05)

Original issue

Second issue

Change Page issue

Updated cover and

copyright pages

Updated change history

Updated equipment

needed for Operation Test

in Section 5

Third issue

Incorporated Hospira

name change and updated

to current style

Updated cover, copyright,

and back page

Updated Section 1

and Section 4

Updated to include

EMC/IEC requirements

Added Appendix

Remove

and Destroy

Pages

cover

i to ii

5-19 to 5-20

Insert

Change

Pages

cover

i to ii

5-19 to 5-20

Technical Service Manual i 430-600203-003 (Rev. 07/05)

Page 4

CHANGE HISTORY

This page intentionally left blank.

430-600203-003 (Rev. 07/05) ii GemStar

®

Page 5

Contents

Section 1

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 SCOPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 CONVENTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 ACRONYMS AND ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . 1-2

1.4 USER QUALIFICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.5 ARTIFACTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.6 ELECTROMAGNETIC COMPATIBILITY . . . . . . . . . . . . . . . . . . . 1-5

1.7 INSTRUMENT INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . 1-5

1.7.1 UNPACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.7.2 INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.7.3 SELF TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.8 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.8.1 THERAPIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.8.2 CONFIGURATION DIFFERENCES . . . . . . . . . . . . . . . . . . . 1-7

1.8.3 SAFETY FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.8.4 POWER SOURCES . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.8.5 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Section 2

WARRANTY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Section 3

SYSTEM OPERATING MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Section 4

THEORY OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 ELECTRO-MECHANICAL SYSTEMS . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1 CPU SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1.1 CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1.2 MEMORY . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.1.1.3 FPGA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.1.2 CPU SUPERVISORY FUNCTIONS . . . . . . . . . . . . . . . . . . . 4-4

4.1.2.1 SUPPLY MONITORING . . . . . . . . . . . . . . . . . . . . 4-4

4.1.2.2 POWER-ON RESET . . . . . . . . . . . . . . . . . . . . . . 4-5

4.1.2.3 MEMORY AND TIME RETENTION . . . . . . . . . . . . . . . 4-5

4.1.2.4 WATCHDOG FUNCTION . . . . . . . . . . . . . . . . . . . 4-5

4.1.2.5 CPU ERROR CHECKING/WATCHDOG CIRCUITRY . . . . . . . 4-5

4.1.2.6 WDT PIC/BEEPER PIC/BEEPER DRIVER. . . . . . . . . . . . . 4-6

4.1.3 DISPLAY MODULE/BACKLIGHT . . . . . . . . . . . . . . . . . . . 4-6

4.1.4 KEYPAD/LEDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.1.5 BOLUS SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.1.6 TIME-OF-DAY CLOCK . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.1.7 POWER INPUT SENSING/SELECTION CIRCUITRY . . . . . . . . . . . 4-8

4.1.8 INTERNAL POWER SUPPLIES. . . . . . . . . . . . . . . . . . . . 4-10

4.1.9 INFUSER ON/OFF CONTROL . . . . . . . . . . . . . . . . . . . . 4-10

4.1.9.1 POWER ON . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4.1.9.2 POWER OFF. . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4.1.10 MOTOR DRIVE CIRCUITS . . . . . . . . . . . . . . . . . . . . . 4-12

4.1.10.1 SPEED CONTROL . . . . . . . . . . . . . . . . . . . . . . 4-14

4.1.10.2 POWER CONSERVATION . . . . . . . . . . . . . . . . . . 4-15

Technical Service Manual iii 430-600203-003 (Rev. 07/05)

Page 6

CONTENTS

4.1.10.3 MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4.1.10.4 TACHOMETER . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4.1.10.5 REDUNDANT MOTOR CONTROL. . . . . . . . . . . . . . . 4-15

4.1.11 MOTOR TACHOMETER POWER CONSERVATION . . . . . . . . . . 4-16

4.1.12 OUTPUT SHAFT ENCODER . . . . . . . . . . . . . . . . . . . . . 4-16

4.1.13 AIR-IN-LINE SENSING. . . . . . . . . . . . . . . . . . . . . . . . 4-17

4.1.14 PROXIMAL PRESSURE MEASUREMENT . . . . . . . . . . . . . . . 4-17

4.1.15 DISTAL PRESSURE MEASUREMENT . . . . . . . . . . . . . . . . . 4-18

4.1.16 RS-232 INTERFACE SYSTEM . . . . . . . . . . . . . . . . . . . . . 4-18

4.2 CASSETTE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4.2.1 BODY AND TOP . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4.2.2 DIAPHRAGM . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4.2.3 FLOW STOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Section 5

MAINTENANCE AND SERVICE TESTS . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 ROUTINE MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1 CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1.1 SANITIZING . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.1.1.2 CLEANING THE CASSETTE POCKET

AND TUBING CHANNEL . . . . . . . . . . . . . . . . . . . 5-3

5.1.2 INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.1.2.1 MATERIALS REQUIRED . . . . . . . . . . . . . . . . . . . 5-4

5.1.2.2 LABEL INSPECTION . . . . . . . . . . . . . . . . . . . . . 5-4

5.1.2.3 LATCH MECHANISM INSPECTION . . . . . . . . . . . . . . 5-6

5.1.2.4 AIR SENSOR INSPECTION . . . . . . . . . . . . . . . . . . 5-7

5.1.2.5 PLUNGER AND PRESSURE SENSOR INSPECTION . . . . . . . 5-8

5.1.2.6 TOP CAP INSPECTION . . . . . . . . . . . . . . . . . . . . 5-9

5.1.2.7 BOTTOM CAP INSPECTION . . . . . . . . . . . . . . . . . 5-10

5.1.2.8 BEZEL, GRIP, AND KEYPAD INSPECTION . . . . . . . . . . . 5-11

5.1.2.9 BATTERY DOOR AND COMPARTMENT INSPECTION . . . . . 5-12

5.1.2.10 POWER-ON TEST. . . . . . . . . . . . . . . . . . . . . . . 5-15

5.1.2.11 RECHARGEABLE BATTERY PACK (OPTIONAL) . . . . . . . . 5-16

5.1.2.12 DOCKING STATION (OPTIONAL) . . . . . . . . . . . . . . 5-17

5.1.2.13 AC ADAPTOR (OPTIONAL) . . . . . . . . . . . . . . . . . . 5-19

5.1.2.14 REMOTE BOLUS CORD AND SWITCH (OPTIONAL) . . . . . . 5-20

5.2 OPERATION TEST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

5.2.1 EQUIPMENT REQUIRED . . . . . . . . . . . . . . . . . . . . . . . 5-21

5.2.2 TEST SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

5.2.3 PERFORMING THE OPERATION TEST . . . . . . . . . . . . . . . . 5-21

5.2.3.1 POWER TEST. . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5.2.3.2 KEYPAD TEST . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5.2.3.3 DISPLAY TEST . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5.2.3.4 LED TEST . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5.2.3.5 VOLUME ACCURACY TEST. . . . . . . . . . . . . . . . . . 5-23

5.2.3.6 DISTAL OCCLUSION TEST . . . . . . . . . . . . . . . . . . 5-23

5.2.3.7 PROXIMAL OCCLUSION TEST . . . . . . . . . . . . . . . . 5-23

5.2.3.8 AIR-IN-LINE TEST . . . . . . . . . . . . . . . . . . . . . . 5-24

5.2.4 PRINTING THE TEST RESULTS. . . . . . . . . . . . . . . . . . . . 5-24

5.2.5 OPERATION TEST CHECKLIST. . . . . . . . . . . . . . . . . . . . 5-26

5.2.6 RESTORING THE INFUSER FOR USE . . . . . . . . . . . . . . . . . 5-27

5.3 PERIODIC MAINTENANCE INSPECTION. . . . . . . . . . . . . . . . . . 5-27

430-600203-003 (Rev. 07/05) iv GemStar

®

Page 7

FIGURES

Section 6

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 TECHNICAL ASSISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 TROUBLESHOOTING REFERENCES. . . . . . . . . . . . . . . . . . . . . 6-1

6.2.1 TROUBLESHOOTING TOOLS . . . . . . . . . . . . . . . . . . . . . 6-2

6.2.2 ALERT/ALARM MESSAGE INDEX . . . . . . . . . . . . . . . . . . . 6-2

6.2.3 PRINTING DEVICE HISTORY . . . . . . . . . . . . . . . . . . . . . 6-4

6.3 SERVICE ALARM CODES . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.3.1 SERVICE ALARM CODES - QUICK REFERENCE . . . . . . . . . . . . 6-4

6.3.2 SERVICE ALARM CODES - DETAILS . . . . . . . . . . . . . . . . . 6-8

6.4 OPERATIONAL ALARMS . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

Section 7

REPLACEABLE PARTS AND REPAIRS . . . . . . . . . . . . . . . . . . . . . . . 7-1

Section 8

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Section 9

DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

Technical Service Manual v 430-600203-003 (Rev. 07/05)

Page 8

TABLES

Figures

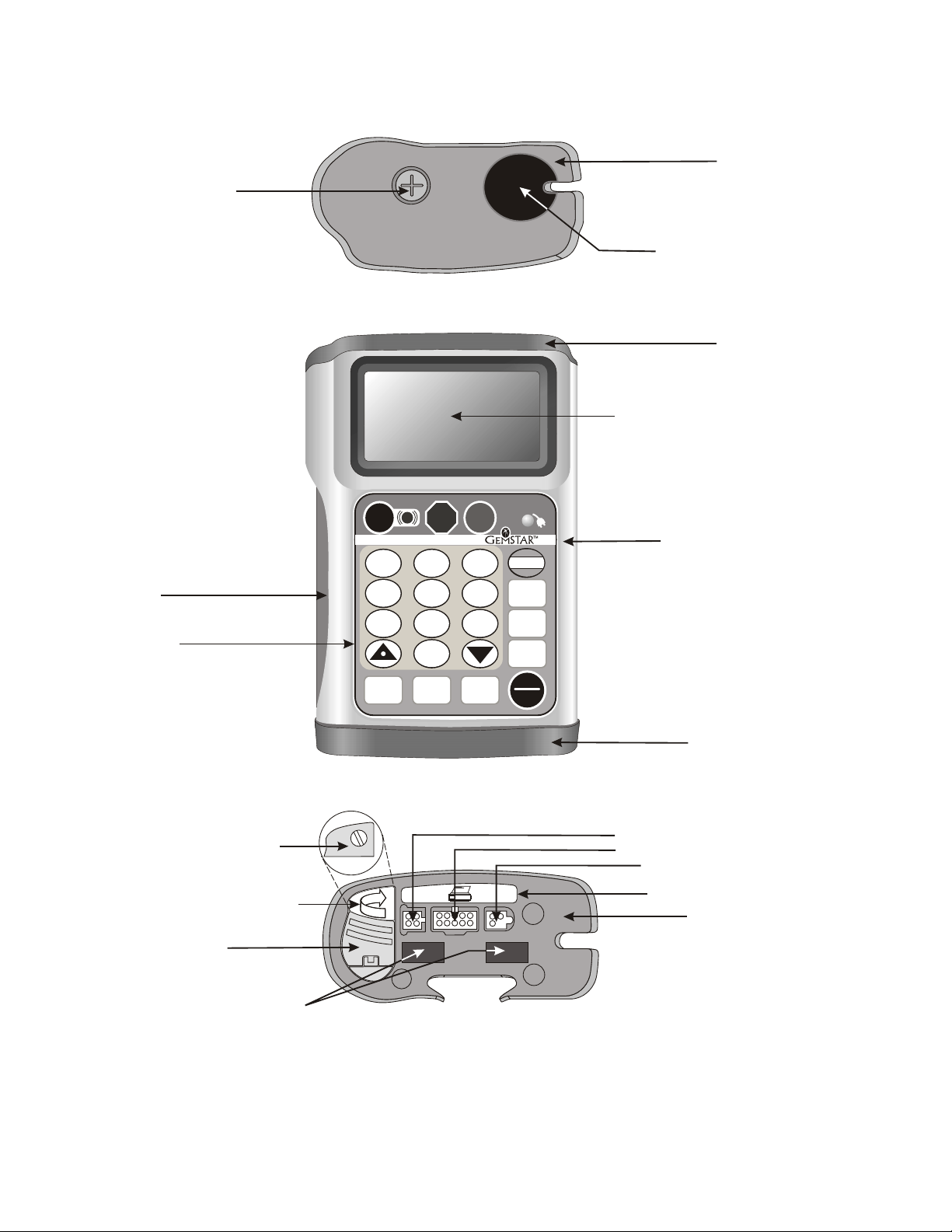

Figure 1-1. Illustration of the Infuser . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Figure 4-1. GemStar Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Figure 4-2. Board Connector References. . . . . . . . . . . . . . . . . . . . . . . 4-3

Figure 4-3. Power Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Figure 4-4. Power On/Off Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Figure 4-5. Motor Control Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Figure 4-6. Detail of Motor Circuit . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Figure 5-1. Cassette Pocket and Tubing Channel . . . . . . . . . . . . . . . . . . . 5-3

Figure 5-2. Label Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Figure 5-3. Cassette Retention and Ejection . . . . . . . . . . . . . . . . . . . . . 5-6

Figure 5-4. Air Sensor Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Figure 5-5. Plunger and Pressure Sensor Inspection . . . . . . . . . . . . . . . . . 5-8

Figure 5-6. Top Cap Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Figure 5-7. Bottom Cap Inspection . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Figure 5-8. Bezel, Grip, and Keypad Inspection . . . . . . . . . . . . . . . . . . . 5-11

Figure 5-9. Battery Door Engagement . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Figure 5-10. Battery Door Inspection. . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Figure 5-11. Battery Compartment Inspection. . . . . . . . . . . . . . . . . . . . . 5-14

Figure 5-12. Power-On Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Figure 5-13. Rechargeable Battery Pack . . . . . . . . . . . . . . . . . . . . . . . 5-16

Figure 5-14. Docking Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Figure 5-15. AC Adaptor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Figure 5-16. Remote Bolus Cord and Switch . . . . . . . . . . . . . . . . . . . . . 5-20

Figure 5-17. Sample Test Result Printout . . . . . . . . . . . . . . . . . . . . . . . 5-25

Figure 7-1. GemStar Infuser Exploded View. . . . . . . . . . . . . . . . . . . . . 7-1

Figure 9-1. GemStar Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Figure 9-2. GemStar Top Board . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Figure 9-3. GemStar Middle Board . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Figure 9-4. GemStar Bottom Board . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

Tables

Table 1-1. Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Table 1-2. Configuration List Numbers. . . . . . . . . . . . . . . . . . . . . . . 1-7

Table 1-3. Safety Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Table 5-1. Cleaning Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Table 5-2. GemStar Operation Test Checklist . . . . . . . . . . . . . . . . . . . . 5-26

Table 6-1. Troubleshooting Tools . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Table 6-2. Alert/Alarm Message Index . . . . . . . . . . . . . . . . . . . . . . . 6-2

Table 6-3. Service Alarm Codes - Quick Reference. . . . . . . . . . . . . . . . . . 6-4

Table 6-4. Service Alarm Codes - Details . . . . . . . . . . . . . . . . . . . . . . 6-8

Table 6-5. Operational Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

Table 9-1. Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Table A-1. Guidance and Manufacturer’s Declaration - Electromagnetic Emissions . . . A-1

Table A-2. Guidance and Manufacturer’s Declaration - Electromagnetic Immunity . . . A-2

Table A-3. Guidance and Manufacturer’s Declaration - Electromagnetic Immunity

for Life-Supporting Equipment and Systems . . . . . . . . . . . . . . . A-3

Table A-4. Recommended Separation Distances Between Portable and Mobile RF

Communications Equipment and the GemStar . . . . . . . . . . . . . . A-6

430-600203-003 (Rev. 07/05) vi GemStar

®

Page 9

Section 1

INTRODUCTION

The GemStar® is a single-channel infuser designed for use in home care and hospital

settings.

The infuser kit contains the following components:

-GemStar

- Two AA disposable batteries

- System Operating Manual

®

infuser

Note: Some international configurations contain a table-top 220 V

with a separate power cord.

1.1

SCOPE

This manual is organized into the following sections:

❏ Section 1 Introduction

❏ Section 2 Warranty

❏ Section 3 System Operating Manual

❏ Section 4 Theory of Operation

❏ Section 5 Maintenance and Service Tests

❏ Section 6 Troubleshooting

❏ Section 7 Replaceable Parts and Repairs

❏ Section 8 Specifications

❏ Section 9 Drawings

❏ Appendix

❏ Index

❏ Technical Service Bulletins

mains adaptor

AC

If a problem in device operation cannot be resolved using the information in this manual,

contact Hospira (see Section 6.1, Technical Assistance).

Specific instructions for operating the device are contained in the GemStar

Operating Manual. Provision is made for the inclusion of the system operating manual

in Section 3 of this manual.

®

System

Note: The terms “infuser” and “device” are used interchangeably throughout

the manual.

Note: Figures are rendered as graphic representations to approximate actual product.

Therefore, figures may not exactly reflect the product.

Technical Service Manual 1 - 1 430-600203-003 (Rev. 07/05)

Page 10

SECTION 1 INTRODUCTION

1.2

CONVENTIONS

The conventions listed in Table 1-1 are used throughout this manual.

Table 1-1. Conventions

Convention Use Example

Italic Reference to a section, figure,

table, or publication

[ALL CAPS] Keys Press [YES/ENTER]

ALL CAPS Display messages The infuser displays

Bold Emphasis CAUTION: Use proper ESD grounding

Throughout this manual, warnings, cautions, and notes are used to emphasize important

information as follows:

WARNING:

CAUTION: A CAUTION usually appears in front of a procedure or statement.

It contains information that could prevent hardware failure, irreversible damage

to equipment, or loss of data.

A WARNING CONTAINS SPECIAL SAFETY EMPHASIS AND MUST

BE OBSERVED AT ALL TIMES. FAILURE TO OBSERVE A WARNING

MAY RESULT IN PATIENT INJURY AND BE LIFE-THREATENING.

(see Section 6.1, Technical Assistance)

to continue.

END OF INFUSION

techniques when handling

components.

Note: A note highlights information that helps explain a concept or procedure.

1.3

ACRONYMS AND ABBREVIATIONS

This section contains the acronyms and abbreviations that appear in the text of this

manual.

A Ampere

AC Alternating current

A/D Analog-to-digital

ADC Analog-to-digital converter

CPU Central processing unit

CRC Cyclic redundancy check

DC Direct current

430-600203-003 (Rev. 07/05) 1 - 2 GemStar

®

Page 11

1.3 ACRONYMS AND ABBREVIATIONS

DMM Digital multimeter

ECG Electrocardiogram

EEG Electroencephalogram

EEPROM Electrically erasable programmable read-only memory

EL Electroluminescent

EMC Electromagnetic compatibility

EMG Electromyogram

EMI Electromagnetic interference

ESD Electrostatic discharge

ETO Ethylene oxide

FET Field effect transistor

FPGA Field programmable gate array

hr hour

Hz Hertz

IC Integrated circuit

IO Input/output

IV Intravenous

kHz Kilohertz

LCD Liquid crystal display

LED Light emitting diode

mA Milliampere

mcg Microgram

mg Milligram

MHz Megahertz

mL Milliliter

ms Millisecond

mV Millivolt

PFI Power fail input

PIC Programmable integrated circuit

PWA Printed wiring assembly

PWM Pulse width modulator

RAM Random access memory

ROM Read-only memory

RPM Revolutions per minute

TPN Total parenteral nutrition

UART Universal asynchronous receiver/transmitter

Technical Service Manual 1 - 3 430-600203-003 (Rev. 07/05)

Page 12

SECTION 1 INTRODUCTION

V Volts

Volts alternating current

V

AC

V

Collector voltage supply

CC

V

Volts direct current

DC

V

VTBI Volume to be infused

Primary power source

PWR

V

Volts root mean squared

rms

µA Microampere

µs Microsecond

1.4

USER QUALIFICATION

The infuser is intended for use at the direction or under the supervision of licensed

physicians or certified healthcare professionals who are trained in the use of the infuser

and the administration of parenteral fluids or drugs. Training should emphasize

preventing related IV complications, including appropriate precautions to prevent

accidental infusion of air.

1.5

ARTIFACTS

Non-hazardous, low level electrical potentials are commonly observed when fluids are

administered using infusion devices. These potentials are well within accepted safety

standards, but may create artifacts on voltage-sensing equipment such as ECG, EMG,

and EEG machines. These artifacts vary at a rate that is associated with the infusion rate.

If the monitoring machine is not operating correctly or has loose or defective connections

to its sensing electrodes, these artifacts may be accentuated so as to simulate actual

physiological signals. To determine if the abnormality in the monitoring equipment

is caused by the infuser instead of some other source in the environment, set the device

so that it is temporarily not delivering fluid. Disappearance of the abnormality indicates

that it was probably caused by the electronic noise generated by the infuser. Proper setup

and maintenance of the monitoring equipment should eliminate the artifact. Refer to the

appropriate monitoring system documentation for setup and maintenance instructions.

430-600203-003 (Rev. 07/05) 1 - 4 GemStar

®

Page 13

1.6 ELECTROMAGNETIC COMPATIBILITY

1.6

ELECTROMAGNETIC COMPATIBILITY

The GemStar® is compliant with IEC/EN 60601-1-2 (2001), and has been tested and found

to comply with electromagnetic compatibility (EMC) limits for the Medical Device Directive

93/42/EEC (EN 55011 Class B and EN 60601-1-2:2001). These limits are designed to

provide reasonable protection against harmful interference in a typical medical installation

(see the system operating manual).

CAUTION: Portable and mobile RF communications equipment, such as cellular

telephones, two-way radios, Bluetooth

proximity to the infuser may affect or degrade performance of the device. Operation

of the infuser under such conditions should be avoided.

There is a shared responsibility between manufacturers, customers, and users to assure

that medical equipment and systems are designed and operated as intended. Medical

electrical equipment requires special precautions regarding electromagnetic compatibility.

The electromagnetic environment should be managed to permit the infuser to perform as

intended without disturbing other equipment. The infuser should not be used adjacent to

or stacked with other equipment. If the device must be used adjacent to or stacked with

other equipment, monitor the equipment to assure there is no electromagnetic

interference, and verify normal infuser operation.

®

devices, and microwave ovens in close

1.7

INSTRUMENT INSTALLATION PROCEDURE

CAUTION: Infuser damage may occur unless proper care is exercised during

unpacking and installation.

CAUTION: Do not place the infuser in service if it fails the self test.

The instrument installation procedure consists of unpacking, inspection, and self test.

1.7.1

UNPACKING

Inspect the shipping container as detailed in Section 1.7.2. Use care when unpacking the

infuser. Retain the packing slip and save all packing material in the event it is necessary

to return the infuser to the factory. Verify the shipping container contains a copy of the

system operating manual.

Technical Service Manual 1 - 5 430-600203-003 (Rev. 07/05)

Page 14

SECTION 1 INTRODUCTION

1.7.2

INSPECTION

Inspect the shipping container for damage. Should any damage be found, contact the

delivering carrier immediately.

CAUTION: Inspect the infuser for evidence of damage. Do not use the device if it

appears to be damaged. Should damage be found, contact Hospira (see Section 6.1,

Technical Assistance).

Inspect the infuser periodically for signs of defects. Also inspect the infuser after repair

or during cleaning. Replace any damaged or defective external parts.

1.7.3

SELF TEST

CAUTION: Do not place the infuser in service if the self test fails.

At power-on, the infuser immediately enters an initialization mode and performs the

following self tests:

-RAM test

- ROM checksum calculation

- Motor control test

- Stuck key test

- PIC watchdog test

- CONFIG register test

- Battery voltage test

- Power loss completion test

- CRC verifications on all RAM areas protected by CRCs

- CRC on calibration data stored in the EEPROM

- Calibration data verification

The initialization mode completes in approximately 30 seconds. During this time the

infuser displays a message that the self tests are being performed. If any test fails,

the infuser alarms.

Note: The device does not infuse during the initialization mode.

After successful completion of the initialization mode, if there is not a current program

in the infuser, the device enters programming mode so the user can enter a new program.

If a program is already in the infuser, the user may:

- Use the current program. The infuser enters stop mode after the program is reviewed.

- Enter a new program. The infuser enters programming mode, then enters stop mode

after the program is reviewed.

Note: If the infuser has been powered-off for less than five minutes, a program

review is not required.

See Figure 1-1 for an illustration of the infuser.

430-600203-003 (Rev. 07/05) 1 - 6 GemStar

®

Page 15

1.8 OVERVIEW

1.8

OVERVIEW

The following sections describe therapy options, differences between therapies, safety

features, power sources, and basic operation of the infuser.

1.8.1

THERAPIES

The GemStar® offers the following seven types of therapy:

- Pain Management

- Total Parenteral Nutrition (TPN)

- Intermittent

-Weight Dosed

-Continuous

- mL/hr Only

-Variable Time

Note: The availability of these programs may vary, depending upon the configuration

of the infuser in use.

1.8.2

CONFIGURATION DIFFERENCES

The infuser is shipped from the factory with one of the configurations described

in Table 1-2. The infuser configuration is easily identified by the end cap color.

Table 1-2. Configuration List Numbers

Therapies 13000 (Blue) 13100 (Gray) 13150 (Yellow)

Pain Management

TPN

Intermittent

Weight Dosed

Continuous

mL/hr Only

Variable Time

Technical Service Manual 1 - 7 430-600203-003 (Rev. 07/05)

Page 16

SECTION 1 INTRODUCTION

1.8.3

SAFETY FEATURES

Table 1-3 describes the special safety features of the GemStar®.

Table 1-3. Safety Features

Safety Feature Description

Proximal occlusion detection Strain gauge

Distal occlusion detection Strain gauge

Settings: low, medium, and high sensitivity

Air-in-line detection Ultrasonic settings: 0.5 mL, 2 mL, and Off

Motor monitoring circuit Redundant and independent monitoring

systems

Motor parameter monitoring Motor encoder and camshaft flag monitored

by optical sensor

Self tests Initialization and self test at power-on

Continuous self tests during operation

1.8.4

POWER SOURCES

The infuser can be powered by two internal AA disposable batteries, an external

rechargeable battery pack, AC mains adaptor, or docking station. External supply voltage

must not exceed 3.3 V

Install two fresh, disposable AA batteries for backup power when using an external power

source. The infuser will continue to operate on backup power if the external power

source fails.

CAUTION: To assure proper operation when using internal batteries, always

replace both batteries with fresh, disposable AA batteries when a change is required.

Use of rechargeable batteries in the battery compartment is not recommended.

CAUTION: Always connect to a grounded AC outlet when using the AC adaptor.

Use only an AC adaptor specifically labeled for use with the GemStar

battery pack. During charging, if the battery pack becomes hot to the touch,

immediately disconnect from AC power and contact Hospira Technical Support

Operations.

CAUTION: Do not touch exposed connectors on the bottom of the infuser. Exposed

connectors are susceptible to electrostatic discharge (ESD) damage.

DC

.

®

to charge the

430-600203-003 (Rev. 07/05) 1 - 8 GemStar

®

Page 17

1.8 OVERVIEW

1.8.5

OPERATION

The infuser is microprocessor-based and is programmed using a 23-key keypad on

the front of the device (see Figure 1-1). The 16-character-by-4-line backlight display

indicates the status of the infuser.

The infuser has up to seven therapies available, depending on its configuration. Delivery

rates and bolus dosage amounts are programmed in one of three units of measure:

milliliters (mL), milligrams (mg), or micrograms (mcg). A loading dose is programmable for

immediate delivery or delayed delivery. Bolus doses can be programmed to begin delivery

on-demand.

To program the infuser, the operator selects the following:

- Therapy type

- Delivery type: volume delivery (mL) or mass delivery (mg or mcg)

- Concentration (only if mass delivery is selected)

- Delivery rate

- Loading dose, if desired

- Bolus dose, if desired

- Total amount to be delivered: volume to be infused (VTBI)

If mass delivery is selected, the infuser automatically converts mg or mcg to the closest

number of tenths-of-mL. The amount of fluid delivered is shown on the display.

When a bolus is programmed, a minimum lockout time between boluses must also

be programmed. In addition to the lockout time, the operator can also program the

maximum total volume that can be delivered in a selected period.

The infuser contains a time-of-day clock and event history storage capability. The program

settings, significant events that take place while a protocol is running, and the associated

time and date, can be reviewed on the display. The event history can be printed to a

compatible printer or downloaded as an ASCII text file to a computer with the use of the

GemStar

For specific instructions regarding infuser operation and optional system components,

refer to the system operating manual.

®

serial printer cable.

Technical Service Manual 1 - 9 430-600203-003 (Rev. 07/05)

Page 18

SECTION 1 INTRODUCTION

BOLUS (BUTTON)

TOP CAP

GRIP

KEYPAD

SILENCE

1

4

7

PURGE

TOP VIEW

START

STOP

2

5

3

6

89

0

NOHELP

POWER

ON/OFF

BACK-UP

CHANGE

OPTIONS

YES

ENTER

CASSETTE EJECT

BUTTON

TOP CAP

BEZEL DISPLAY WINDOW

BEZEL ASSEMBLY

BOTTOM CAP

FRONT VIEW

BATTERY DOOR RECESS

BATTERY DOOR VOID LABEL

BATTERY DOOR

BATTERY PACK CONNECTOR

3 VDC BOLUS

BOTTOM VIEW

AC POWER CONNECTOR

DATAPORT CONNECTOR

BOLUS CONNECTOR

CONNECTOR LABEL

BOTTOM CAP

04K02001

Figure 1-1. Illustration of the Infuser

430-600203-003 (Rev. 07/05) 1 - 10 GemStar

®

Page 19

Section 2

WARRANTY

Subject to the terms and conditions herein, Hospira, Inc., herein referred to as Hospira,

warrants that the product shall conform to Hospira's standard specifications and be free

from defects in material and workmanship under normal use and service for a period of

one year after purchase. Hospira makes no other warranties, express or implied, as to

merchantability, fitness for a particular purpose, or any other matter.

Purchaser's exclusive remedy shall be, at Hospira's option, the repair or replacement

of the product. In no event shall Hospira's liability arising out of any cause whatsoever

(whether such cause be based in contract, negligence, strict liability, other tort,

or otherwise) exceed the price of such product, and in no event shall Hospira be liable for

incidental, consequential, or special damages or losses or for lost business, revenues,

or profits. Warranty product returned to Hospira must be properly packaged and sent

freight prepaid.

The foregoing warranty shall be void in the event the product has been misused, damaged,

altered, or used other than in accordance with product manuals so as, in Hospira's

judgment, to affect its stability or reliability, or in the event the serial or lot number has

been altered, effaced, or removed.

The foregoing warranty shall also be void in the event any person, including the Purchaser,

performs or attempts to perform any major repair or other service on the product without

having been trained by an authorized representative of Hospira and using Hospira

documentation and approved spare parts. For purposes of the preceding sentence,

“major repair or other service” means any repair or service other than the replacement

of accessory items such as batteries, flow detectors, detachable AC power cords, and

patient pendants.

In providing any parts for repair or service of the product, Hospira shall have no

responsibility or liability for the actions or inactions of the person performing such repair

or service, regardless of whether such person has been trained to perform such repair

or service. It is understood and acknowledged that any person other than a Hospira

representative performing repair or service is not an authorized agent of Hospira.

Technical Service Manual 2 - 1 430-600203-003 (Rev. 07/05)

Page 20

SECTION 2 WARRANTY

This page intentionally left blank.

430-600203-003 (Rev. 07/05) 2 - 2 GemStar

®

Page 21

Section 3

SYSTEM OPERATING MANUAL

A copy of the system operating manual is included with every GemStar® infuser.

Insert a copy here for convenient reference. If a copy of the system operating manual is not

available, contact Hospira (see Section 6.1, Technical Assistance).

Technical Service Manual 3 - 1 430-600203-003 (Rev. 07/05)

Page 22

SECTION 3 SYSTEM OPERATING MANUAL

This page intentionally left blank.

430-600203-003 (Rev. 07/05) 3 - 2 GemStar

®

Page 23

Section 4

THEORY OF OPERATION

This section describes the theory of operation for the GemStar®. The theory of operation

details the electro-mechanical and cassette systems. Related drawings are provided

in Section 9.

4.1

ELECTRO-MECHANICAL SYSTEMS

The following sections describe the functions and electronic circuitry of the infuser.

4.1.1

CPU SYSTEM

The central processing unit (CPU) system consists of the following components:

❏ CPU: controls infuser operation

❏ Memory

- RAM: stores temporary therapy program data; stores ROM program during

software updates

- ROM: stores the operating program

❏ Field programmable gate array (FPGA): provides auxiliary logic functions to operate

the infuser

®

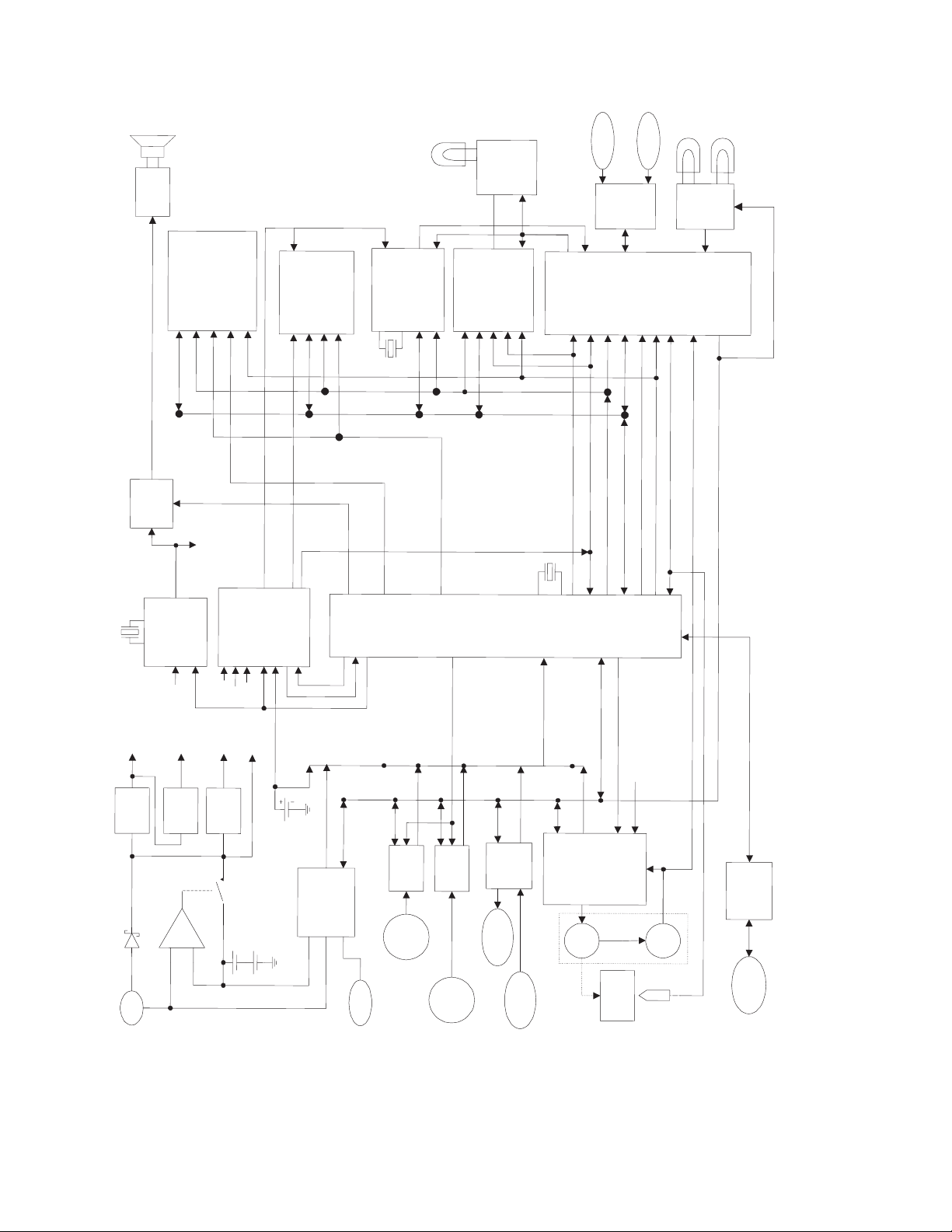

See Figure 4-1, GemStar

4.1.1.1

Block Diagram, and Figure 4-2, Board Connector References.

CPU

The CPU (U2) is a Motorola MC68L11K1 8-bit processor powered by 3.3 VDC. It operates

at 2 MHz using a self-contained buffer and crystal Y1. The clock is divided by four to

provide a 500 kHz bus clock (E-clock). Capacitors C9 and C11 provide the proper loading

of the crystal.

The CPU provides the following:

- Separate data, address, and extended

address lines

- On-chip 8-channel, 8-bit

analog-to-digital converter

- On-chip EEPROM for non-volatile

configuration status

- Serial UART port

- Serial peripheral port

- 4-channel, 8-bit pulse-width

modulated output

- Non-maskable and maskable

interrupt inputs

Technical Service Manual 4 - 1 430-600203-003 (Rev. 07/05)

- General purpose input and output

lines (I/O)

Page 24

SECTION 4 THEORY OF OPERATION

Audio

Driver

Backup Power

U7

ROM

512K x 8

(29BV040)

FLASH MEM

D

XA

CS

A

R/W

U8

32K x 8

D

CS

SRAM

A

LED

LED

(Red)

Alarm

Power

(Yellow)

Bolus Jack

Interface

U9

FPGA

A

D

CS / IRQCS/IRQ

R/WR/W

Keypad

LED Drive

/Shaft IRQ

Encoder Signal

Digital Port I/O

CS

E-CLK

Bolus Switch

/TOD IRQ

/RST/RST

U10

DRIVER

BACKLIGHT

CS

IRQ

/TOD

CLOCK

D

CS

A

EL Backlight

CS

DISPLAY

D

E-CLK

A0

/RST

R/W

Backup Power

U3

XA

TIME-OF-DAY

Y2

Address Bus

Data Bus

XA(13..18)

Bus

Ext Addr

Digital Ports

Y201

U105

U201

+5V

+5V

DC-DC

PIC

BEEPER

Power Select

12C508

WD Fault

U202

WDT PIC

+3.3V

U108

Switch

12C508

WDTri

-5V

-5V

DC-DC

To motor drive

Y1

/RST

SUPERVISOR

+3.3V

VPWR

Backup Power

WDTri

g

Backup Battery

RAMCS

/XIRQ

RAMCS1

U1

MICRO-P

g

+5V

VPWR

+3.3V

PWM3

/XIRQ

RAMCS1

Ext-Addr

CS Flash

g

WDTri

U2

68L11K1

SDI

Microcontroller

E-CLK

A/D Input

A/D Input Ports

Digital Ports

U109

+3.3V

DC-DC

BT201

Battery

Lithium

Air

Ultrasonic

Piezo

Air Transmit

Circuit

U101, U102,

U103, U104

AA

Internal

Batteries

Power Sensing

Proximal

Pressure

Pressure

Proximal

Circuit

Sensor

Distal

Circuit

Pressure

MOTOR DRIVE

Motor

Addr

Digital I/O

and

CIRCUIT

Data

PW1

D/C-D/C

CONVERTER

WD Fault

Motor

/Shaft IRQ

SCI

Encoder

Motor Encoder Signals

Output Shaft Encoder Signals

RS232

INTERFACE

LT1331

Connector

Distal

Ext

Power

Signal

Ext_Pwr

Sensor

Pressure

Piezo

Air Receive

Drive

Mechanics

Output

Shaft

Encoder

Serial Data

Figure 4-1. GemStar® Block Diagram

430-600203-003 (Rev. 07/05) 4 - 2 GemStar

04K02010

®

Page 25

000

TOP BOARD

CPU, MEMORY, RTC, SERIAL PORT

4.1 ELECTRO-MECHANICAL SYSTEMS

J1

DISPLAY

CHASSIS GROUND

CONTACT

BATTERY SPRING

BATTERY CONTACT

MOTOR

J101

J104

J108

J106

J2

J102

J105

J3

J103

100

MIDDLE BOARD

MOTOR CONTROL,

POWER CONVERSION

J4

J110

J109

J107

PUMP BOTTOM

EXTERNAL CONNECTOR

KEYPAD

AIR

RECEIVER

AIR

TRANSMITTER

J203

J204

J205

200

BOTTOM BOARD

J207

J206

AUDIBLE BEEPER

PRESSURE SENSOR, AIR SENSOR

PROXIMAL

PRESSURE

DISTAL

PRESSURE

J201

J202

04K02002

Figure 4-2. Board Connector References

Technical Service Manual 4 - 3 430-600203-003 (Rev. 07/05)

Page 26

SECTION 4 THEORY OF OPERATION

4.1.1.2

MEMORY

The operating program is stored in a 512K x 8 flash ROM (U7) that can be reprogrammed

with software updates.

Note: The program cannot be modified without special tools and protocols.

A 32K x 8 low-power static RAM (U8) is used to store the following data:

- Specific patient delivery protocols

-User options

- History records

- Operating program during Flash ROM programming

When the infuser is powered off, an on-board lithium battery provides power

to the RAM chip.

4.1.1.3

FPGA

The FPGA (U9) is a specially programmed IC that incorporates auxiliary logic for the

infuser. The FPGA provides the following:

-Input/output mapping

- Keypad interface

- Buffering and control of interrupt signals

- Additional logic interfaces for the infuser

- Motor encoder logic

The FPGA interfaces to the CPU through the address and data bus.

4.1.2

CPU SUPERVISORY FUNCTIONS

A MAX793R supervisory IC (U1) provides a secondary check for proper CPU functioning

and monitors the following:

- Primary power source (V

- 3.3 volt power supply (V

- Battery backup switch over

- Power-on and brownout reset

4.1.2.1

SUPPLY MONITORING

PWR

CC

)

)

Whenever the 3.3 V power supply (VCC) drops below a safe system operating voltage

of 2.6 V

watchdog circuitry to sound an alarm. U1 also monitors the primary power (V

provides early detection of loss of primary power to the infuser. If V

power fail input (PFI) voltage of approximately 1.3 V

be expected. When this happens, U1 interrupts program execution with a non-maskable

interrupt via signal /PFO. This interrupt signals the microprocessor to execute

a power-down routine that gracefully stops the motor, saves current data, and powers off

the infuser.

430-600203-003 (Rev. 07/05) 4 - 4 GemStar

, U1 generates a system reset (/RST) that stops the computer and forces the

DC

drops below the

, imminent loss of 3.3 VCC power can

DC

PWR

PWR

) and

®

Page 27

4.1 ELECTRO-MECHANICAL SYSTEMS

4.1.2.2

POWER-ON RESET

During power-on or other reset conditions, the supervisory circuit holds the system in

reset for 140 ms after V

starting normal operation. During reset conditions, the reset signal interfaces with all

circuitry to assure conditions are held in a safe operational state (e.g., motor stopped).

4.1.2.3

reaches 2.6 VDC to assure the system has stable power prior to

CC

MEMORY AND TIME RETENTION

Whenever all power sources are disconnected from the infuser, an internal 3.0 V lithium

battery (BT201) provides power to retain memory and real-time clock operation.

The lithium battery provides approximately three years of backup power from the time

of infuser assembly. U1 monitors power, and whenever the supervisory circuit detects that

the logic power is low (approximately 2.6 V

appropriate circuits. A series 100 Ω resistor (R227) is used to measure the lithium current

during off conditions. Voltage across R227 is normally less than 0.6 V

4.1.2.4

), it switches the lithium battery power to the

DC

(6 µA).

DC

WATCHDOG FUNCTION

U1 has a built-in secondary watchdog detection circuit (WDT) that provides a secondary

check for proper CPU operation. The primary watchdog circuit is implemented using two

programmable integrated circuit (PIC) microcontrollers on the bottom board

(see Section 4.1.2.6, WDT PIC/Beeper PIC/Beeper Driver).

During normal operation, the CPU provides a one-second timing signal (WDTRIG) to the

supervisory circuit indicating proper operation. If the WDTRIG signal is greater than

approximately 1.6 seconds, the supervisory circuit will generate a system reset and stop

all infuser operations.

Each of the following signals are driven low during system reset:

- Motor on (MOTORON)

- Motor drive enable (MOTDRVEN)

- Motor speed control (MOTSPCTL)

4.1.2.5

CPU ERROR CHECKING/WATCHDOG CIRCUITRY

The CPU is the primary error detection and checking component. When error conditions

exist, the CPU generates an alarm, warning, or other action appropriate to the conditions.

For example, it stops delivery when out-of-tolerance conditions are sensed.

The watchdog (U202) PIC has been designed to monitor the CPU for error-free operation.

The CPU toggles the logic state of the watchdog trigger (WDTRIG). If the CPU becomes

unstable, this signal will either not be generated or will have incorrect timing. The PIC

processors monitor the WDTRIG signal for the correct timing. Whenever this signal is out

of tolerance (1 sec ± 25%), U202 stops the motor (using the WDFLT signal) and sounds

an alarm independent of the CPU.

Technical Service Manual 4 - 5 430-600203-003 (Rev. 07/05)

Page 28

SECTION 4 THEORY OF OPERATION

4.1.2.6

WDT PIC/BEEPER PIC/BEEPER DRIVER

The watchdog WDT PIC (U202) is clocked from an external 32 kHz oscillator and crystal

Y201 independent of the CPU clock. It monitors the WDTRIG signal for correct timing

(change of state once a second). If either clock is in error or if the WDTRIG from the CPU

is incorrect, the watchdog fault signal (WDFLT) goes low. This causes the beeper PIC (U201)

to generate an audible alarm and the motor servo switching current source (U102) to stop

the motor. When the infuser is turned off during normal power-down, the power-on

(POWERON) signal from the CPU inhibits a WDTRIG fault while the power supply supercap

discharges.

The beeper PIC (U201) can sound the beeper from the following two independent sources:

- Watchdog fault (WDFLT) signal from the WDT PIC (U202)

- Beeper control signal (BEEPCTL) from the CPU (U2)

When there is a watchdog fault, the WDFLT signal is activated and has the highest priority.

When this happens, the motor turns off and the infuser stops. This causes the beeper PIC

to produce an audible tone every five seconds.

The beeper PIC uses an internal 4 MHz oscillator and generates a predefined frequency

and duty cycle for WDFLT faults. The CPU sends the BEEPCTL signal to generate audio

output, such as audible operator alarms or keypad feedback. The beeper PIC passes the

BEEPCTL signal frequency and duty cycle to the beeper. This allows different tones,

duration, and volumes.

If the 3.3 V

CPUs are reset. R201, R202, R203, D204, and Q203 (brownout detector) provide

a reset-generator, which nominally trips at 2.1 V

When power losses occur, such as an accidental disconnection of the AC adapter with no

battery backup, two .047 F capacitors (supercaps) maintain the 3.3 V supply for

approximately 10 seconds. This allows the CPU to execute an orderly shutdown, and

provides enough power to the watchdog circuit to sound an audible alarm every five

seconds after power loss (at least three audible beeps).

supply drops below the minimum PIC operating level of 2.5 VDC, the PIC

CC

.

DC

4.1.3

DISPLAY MODULE/BACKLIGHT

The display module is a 64-by-128 dot matrix LCD array with control and memory

circuitry. The CPU and FPGA generate the display control signals. Since the display

consumes only 1 mA, it is powered from a logic gate (U4A) that goes low when powered

off. This allows the display to clear within seconds after power-off.

Note: Display contrast can be factory adjusted.

An electroluminescent (EL) backlight illuminates the display. The CPU turns on the

backlight drive circuit (U10) when a key is pressed or when AC mains power is applied.

430-600203-003 (Rev. 07/05) 4 - 6 GemStar

®

Page 29

4.1 ELECTRO-MECHANICAL SYSTEMS

4.1.4

KEYPAD/LEDS

A 23-key keypad receives operator input. One of these keys is used for power on/off

(see Section 4.1.9, Infuser On/Off Control). Each of the other keys is at a distinct junction

of an array of four columns and six rows, strobed by the FPGA approximately every 30

milliseconds. Pressing a key connects a row to a column. As the FPGA energizes each row,

the columns are monitored and the FPGA determines which key has been pressed.

A software routine eliminates noise (debounce) when the keys are pressed.

Two signal LEDs are mounted on the keypad and driven under software control, via FPGA

outputs. The yellow LED illuminates when AC mains power is connected to the infuser.

The red LED illuminates during an alarm condition, and is accompanied by an audible

alarm and a display message, when applicable.

4.1.5

BOLUS SWITCHES

Patients can request a bolus dose for pain management and variable time protocols.

The bolus switch (SW101) is located on the top of the infuser and is protected by a rubber

end cap. The bolus switch signal (logic low) is buffered, inverted (U4C), and passed to the

FPGA (U9-11) as the bolus request (BOLUSREQ) signal. The bolus request is latched by

the FPGA and passed to the CPU as an interrupt.

An external (remote) bolus pendant can be connected to the bolus connector on the bottom

of the infuser. The remote bolus pendant is wired in parallel with SW101. There is no

distinction between the infuser bolus switch and the remote bolus switch. The buffering

provided for the bolus request signal (U4C) allows for electrostatic discharge (ESD)

rejection.

4.1.6

TIME-OF-DAY CLOCK

The infuser has a separate time-of-day clock (U3). The time is displayed at power-on

and can be reset by the operator. This clock is used to provide the following:

- Schedule deliveries

- Record infuser history and event timing

- Generate a precise one-second CPU interrupt for timing functions

The internal lithium battery (BT201) powers the clock when no other power source

is present.

Technical Service Manual 4 - 7 430-600203-003 (Rev. 07/05)

Page 30

SECTION 4 THEORY OF OPERATION

4.1.7

POWER INPUT SENSING/SELECTION CIRCUITRY

The infuser can be powered by two internal disposable AA batteries, or an external power

source connected to the 3.3 V connector on the bottom of the infuser (see Figure 4-3,

Power Input). Power is applied to the internal voltage-power (V

or disconnected when the infuser is powered on or off (see Section 4.1.9).

) line, which is connected

PWR

Battery power connects to V

through a fuse (F101) and a field effect transistor (FET)

PWR

switch (Q110 A and B) controlled by comparator U110. The FET switch has an intrinsic

forward diode, which allows sufficient battery current for the infuser to power-on when

only batteries are present.

External power (EXTPWR) connects to V

through an isolation diode D106. Comparator

PWR

U110 senses the external voltage and automatically switches to external power when the

external voltage (EXTPWR) is greater than approximately 1.8 V. When this happens,

transistors Q106 and Q104 turn off the FET switch (Q110 A and B) to disconnect the

internal batteries. The MAX965 (U110) has its own internal reference voltage at U110-6

of 1.235 V, which it uses to measure the switching point.

The external supply source may be from a DC supply connected to AC mains power or from

an external battery. If the source is derived from AC mains power, a separate signal line

is pulled high (to 3 volts). On external battery power, the signal line is low. The CPU

monitors this signal line through the multiplexer (U106-4) and the A/D converter.

The CPU uses this information when monitoring the external voltage to display

appropriate messages (e.g., ON BATTERIES; LOW BATTERIES) or to turn on the power

LED. The CPU monitors power source voltages. The internal (battery) and external voltages

are connected to the CPU A/D input port through the multiplexer, MUX U106 (U106-13

and U106-15).

430-600203-003 (Rev. 07/05) 4 - 8 GemStar

®

Page 31

EXT PWR IN

ALK

F101

4.1 ELECTRO-MECHANICAL SYSTEMS

D106

VPWR

Q110A Q110B

Vcc

EXT PWR IN

ALK

3.3V

100K

R152

Vcc

47.5K

Q106

R115

100K

U110

VREF (1.2V)

INPUT SOURCE POWER SWITCHING

R156

499K

R155

4.99K

R157

4.99K

SOURCES FOR SUPPLYING Vcc TO U110

Figure 4-3. Power Input

Q104

499K

47.5K

-5V

D108B

VPWR

D107B

D108A

02K02009

Technical Service Manual 4 - 9 430-600203-003 (Rev. 07/05)

Page 32

SECTION 4 THEORY OF OPERATION

4.1.8

INTERNAL POWER SUPPLIES

The input power at V

is converted to three operating voltages: +3.3 V, +5 V, and –5 V.

PWR

The 3.3 V supply is U109, a ML4875-3 outputting 3.3 V on pin 5. This switch-mode

regulator has internal FETs that ground inductor L103 and direct flyback current to the

output capacitor (C140). The value of coil L103 is chosen to optimize input power to achieve

3.3 V

output power during high loads, such as high motor torque, sensors on,

CC

or backlight activated.

The +5 V supply is U105, a ML4875-5. This circuit is similar to the 3.3 V regulator, except

for the output voltage. Both regulators have a tolerance of ± 3%.

The –5 V supply is U108, a MAX828 switched capacitor, +5 V to –5 V supply for high

efficiency at low currents. The –5 V is required at various points to allow FETs to turn on

with minimum resistance, which results in high efficiency and maximum battery life.

A separate –5 V supply is used in the motor drive servo amplifier circuitry. U101, a second

MAX828, provides –5 V to U103 A and B, and Q101.

The display backlight is an electroluminescent (EL) lamp that requires a symmetric,

®

low-frequency alternating voltage. This voltage is generated by U10, a Durel

D353 lamp

driver IC. This IC uses inductor L1 in switch mode inverter circuit to drive the EL lamp.

4.1.9

INFUSER ON/OFF CONTROL

Electronic hardware and software, in conjunction with a dedicated ON/OFF button on the

keypad, power the infuser on and off (see Figure 4-4, Power On/Off Circuitry). Flip-flop

U107A, and the 3.3 V and 5 V supplies (U109 and U105), form the core of the electronic

hardware. Pressing the keypad ON/OFF button grounds the on/off signal going to the

on-off control circuit. The following two other control lines are also used:

- Shutdown signal (SHUTDOWN): a signal from the ON/OFF hardware to the CPU

- Power switch off signal (PWRSWOFF): a signal from the CPU to the ON/OFF circuit

These signals allow power to be turned on and off while preserving all data and assuring

voltages are changed without damaging circuitry.

430-600203-003 (Rev. 07/05) 4 - 10 GemStar

®

Page 33

VPWR

4.1 ELECTRO-MECHANICAL SYSTEMS

ON

OFF

R123

47.5K

R122

47.5K

R136

47.5K

FROM

CPU

TO

CPU

U109

2

SHDN

4

DET RESET

PWRSWOFF

SHUTDOWN

U105

2

SHDN

4

DET

RESET

5V OUT

3.3V OUT

Q109

Vcc

5

D

3

CLK

1

Q

2

Q

POWER OFF

POWER ON

U107A

R137

47.5K

02G02011

Figure 4-4. Power On/Off Circuitry

Technical Service Manual 4 - 11 430-600203-003 (Rev. 07/05)

Page 34

SECTION 4 THEORY OF OPERATION

4.1.9.1

POWER ON

When power is first applied to the infuser, there is a voltage at V

and 5 V supplies are held in a shutdown mode. The voltage at V

. However, the 3.3 V

PWR

is applied through

PWR

resistor R136 to the shutdown inputs (U105-2 and U109-2). Meanwhile, the voltage at

pin 4 of U105 and U109 (ON/OFF) is held at one-half V

by resistor-divider R122 and

PWR

R123. When the ON/OFF key is pressed, the on/off signal line is pulled low, which causes

a comparator in U105-7 to go low and removes the shutdown signal on U105-4 and

U109-4. These switching regulators rapidly change their outputs (VOUT on pin 5) to 5 V

and 3.3 V respectively. This supplies power to flip-flop U107A where the clock is held low

by the reset output of U109-7. When the ON/OFF switch is released, the ON/OFF line

returns to one-half V

and the reset lines on U105-7 and U109-7 return high. This clock

PWR

flip-flops U107A. The Q-Bar output (U107-2) toggles high, switching the signal line

power-on (POWERON) high. It also turns on transistor Q109, which removes the shutdown

signal from power supplies U105-2 and U109-2. Simultaneously, the Q output (U107-1)

toggles low, switching POWEROFF low. As a result, power is established and maintained.

4.1.9.2

POWER OFF

Power is removed from the infuser under CPU control. When the ON/OFF switch is

pressed, it pulls pin 4 of the 3.3 V supply (U109-4) to ground. This causes the reset pin

(U109-7) to pull low and puts a low on the signal line SHUTDOWN\ to the CPU. When this

signal is received, the CPU begins its power-down sequence. First, it assures that

power-down is a viable choice. For example, if the infuser is in the delivery (RUN) mode,

the device will not power-off and a warning message will display. If power-down is a viable

choice, the CPU gracefully shuts down by saving data, history, and other required

housekeeping. When this is complete, the CPU changes the PWRSWOFF signal high. The

ON/O F F swi t ch mu s t be p r esse d and h e ld du r ing t h is pr o cess , whic h may t a ke up t o thr e e

seconds. After the PWRSWOFF signal is switched high, releasing the power switch will

change the signal ON/OFF and U109-4 back to one-half V

U109-7 and at the clock input of U107-A-3. The high on PWRSWOFF at the flip-flop data

input U107A-5 will be clocked to the Q output, and the Q output will go high. At the same

time, Q-bar (U107-2) will go low and Q109 will shut down both U109 and U105. This

removes power from the circuits.

. This will raise the signal at

PWR

4.1.10

MOTOR DRIVE CIRCUITS

A high efficiency moving coil permanent magnet DC motor operates a plunger to deliver

fluid. The motor includes a 27:1 speed reduction transmission and an integral,

dual-channel, quadrature-encoded tachometer. The speed of the motor is set by the CPU.

A hardware servo control circuit maintains the selected speed while compensating

for variations in load torque, motor losses, and power source voltage. The CPU monitors

the servo circuit by reading the motor voltage, motor current, and motor turns

(encoder counts). The CPU also monitors the activation of the cassette (via output shaft

encoder) to verify that motor turns are correctly converted into fluid delivery actions.

See Figure 4-5, Motor Control Circuit, and Figure 4-6, Detail of Motor Circuit.

430-600203-003 (Rev. 07/05) 4 - 12 GemStar

®

Page 35

MOTCNTRL

R106

100K

1.24V

REFERENCE

Figure 4-5. Motor Control Circuit

R105

301K

+

AMPLIFIER

-

4.1 ELECTRO-MECHANICAL SYSTEMS

U102, Q101, Q102

Q103, Q108, D101

MOT+

02K02013

MOT DREN

MOT+

MOTOR

R125

1

W

MOT SPCTL

R105

R121

57.6K

R120

1M

+

-

+5

-5

R112

150K

R111

U103A

-5V

+

-

R114

R110

200K

U103B

R106

TO U102-3

02K02005

Figure 4-6. Detail of Motor Circuit

Technical Service Manual 4 - 13 430-600203-003 (Rev. 07/05)

Page 36

SECTION 4 THEORY OF OPERATION

4.1.10.1

SPEED CONTROL

The CPU sets a desired speed. A summing amplifier (U103B) combines this speed setting,

the motor speed (voltage across the motor), and the motor load (current through the motor)

to establish a motor drive set point. This is converted into a drive voltage using a step-up

DC-DC controller (U102). The CPU sets the motor speed as a pulse-width (duty-cycle)

modulated signal (MOTSPCTL). Zero pulse width indicates a speed of zero, while full pulse

width (100% duty cycle) is maximum speed resulting in approximately 1150 mL/hr

delivery rate. A two pole RC filter (R117, C119, R118, C120) converts the duty cycle into

a DC voltage (MSPEED). This voltage is fed to the summing amplifier U103B. Other inputs

to this amplifier represent motor current and an offset reference current to assure the

motor is off when the CPU sets a zero speed.

The motor current is sensed as the voltage across R125, amplified by U103A

(gain approximately 18.4), and input to U103B via resistor R111. The motor current

is sensed by the CPU A/D converter by monitoring the voltage at the output of U103A

through R119 (MOTCUR).

The motor voltage and current range from approximately 1.5 V to 6.0 V, and 15 mA

to 150 mA depending upon speed and load torque. This wide range of power must be

delivered over the full range of input voltage (V

the motor servo output is a switch-mode up/down (buck/boost) voltage regulator (U102;

Q108B; Q102 A and B; L102; D101; and D102). It receives a DC signal (MOTCNTRL) from

the summing amplifier U103B and converts this to the required rate of current pulses to

equal the necessary output power to the motor.

) of 1.3 V to 3.2 V. To accomplish this,

PWR

U102 is a step-up DC-DC controller that adjusts the output pulses at pin 1 to maintain

a constant voltage of 1.24 V at the feedback pin 3. IC U102 and its associated switching

circuitry may be considered part of high gain op-amp circuit with input resistor R106 and

feedback resistor R105. The junction of R105 and R106, and U102-3 is a current summing

point maintained by U102. The ratio of R105 to R106 sets the gain at –3. As the motor

control signal (MOTCNTRL) at U103B-7 ranges from 1.65 V to –1.24 V, the motor voltage,

MOT+, will range from zero to 8.68 V. If the voltage MOT+ at the right side of R105 begins

to dip, U102-3 will dip, causing the output, U102-1, to output more control pulses. These

are amplified, and become higher output DC after filtering. Individual components have

been selected to make the servo circuit operate properly. U102 does not provide enough

current, or the required negative voltage, to drive Q108B efficiently, so Q103 and Q101

are used in the classic complementary CMOS output configuration. The low side of this

totem pole combination is tied to minus 5 V (MD-5V). This reduces the switching time of

the FETs and hence minimizes current consumption. L101 has been selected to deliver

approximately 1 V at the maximum frequency of output pulses from U102.

Peak current in L101 (22 _H) must be limited, or coil saturation may adversely affect

efficiency. Based on the voltage drop across R103 (0.05 Ω), U102 automatically terminates

the coil charging ramps at 1.6 amperes.

430-600203-003 (Rev. 07/05) 4 - 14 GemStar

®

Page 37

4.1 ELECTRO-MECHANICAL SYSTEMS

4.1.10.2

POWER CONSERVATION

To conserve power, the 5 V supply is disconnected when the motor circuit is not operating.

To activate the motor circuitry, the CPU switches the motor drive on signal (MOTDRVON)

high. This is inverted by U104A, turns transistor Q105A on, and connects 5 V to the motor

drive 5 V line (MD5V). When positive 5 V is available on MD5V, U101, a MAX828 voltage

inverter, generates a -5 V (MD5V) for the negative rail of the op-amps and for FET switching.

4.1.10.3

MOTOR

The drive motor is a combined gear motor with integral quadrature tachometer.

The gearbox following the motor divides the motor speed by 27.0. The motor speed

constant is chosen such that with the maximum voltage available from the servo, the motor

output shaft will turn at a speed sufficient to provide approximately 1000 mL/hr.

The motor speed constant is 0.75 V

revolutions to in-out strokes for the cassette. One revolution equals one stroke to cassette.

The motor resistance is 15 Ω +/- 8% (16.2 Ω maximum). At 120 mA, the motor voltage loss

may be as high as 15.1 x 0.12 = 1.81 V

adjusted for by the servo to keep the motor speed constant. The servo adds this lost voltage

to the applied voltage to the motor. A 1 Ω resistor in series with the low side of the motor

provides for the required motor current sensing.

per 1000 RPM. The mechanism converts rotary

DC

. This internal motor drop is automatically

DC

To get 1000 mL/hr requires 220 RPM at the output shaft. With a 27:1 gearbox, the motor

is turning 6000 RPM. At 0.75 V/1000 RPM, the basic drive voltage is 4.5 V. The total

maximum required drive voltage is then: 4.50 + 1.81 + 0.12 = 6.43 V.

4.1.10.4

TACHOMETER

A digital tachometer keeps precise track of motor rotations. The tachometer is integrally

mounted on the motor, and has a two-channel output (PHASE A, PHASE B). Each channel

uses a Hall-effect sensor to generate a digital square wave of 16 pulses for each revolution.

The pulses on one channel follow the other by a one-fourth pulse. This quadrature phase

shift allows the direction of motor movement to be detected. Counting the pulses is an

indication of motor movement and is converted into volume delivered. Play in the

mechanism may result in backward motor movement. The tachometer allows the CPU to

keep track of this and correct for reverse motion.

4.1.10.5

REDUNDANT MOTOR CONTROL

Note that when the microcontroller detects an error or out of tolerance condition, it can

inhibit motor motion with any one of three commands. A logic low on MOTORON,

MOTDRVEN, or MOTSPCTL will stop the motor. All three being a logic low adds triple

redundancy for overdelivery protection.

Technical Service Manual 4 - 15 430-600203-003 (Rev. 07/05)

Page 38

SECTION 4 THEORY OF OPERATION

4.1.11

MOTOR TACHOMETER POWER CONSERVATION

The motor tachometer is used to monitor motor speed. To minimize power consumption,

the motor tachometer (encoder) is turned off whenever the motor is not running.

In addition, when the motor is running, the tachometer is strobed. This means that at

fixed intervals, the tachometer output is read into the computer. When it is not being read,

it uses less power.

The tachometer is turned on just before the motor is turned on and remains on a short

time after the motor turns off. It is switched on by the motor enable control signal

(MOTENCON) from the CPU which turns on transistor Q108A to supply power to the

tachometer on the motor (TACHVCC). The tachometer uses Hall-effect devices that switch

on rapidly. A second line from the CPU, motor enable strobe (MOTENSTB), is buffered by

U104E to become the tachometer strobe signal (STRB). This enables the Hall-effect devices

to output the PHASE A and PHASE B signals. The strobe sampling rate is 31.25 kHz.

This is fast enough to assure that no tachometer signals are missed, yet slow enough to

conserve power. There are 16 tachometer pulses generated on each channel when the

motor makes one revolution. The motor gear box has a gear ratio of twenty seven to one

(27:1). This makes the output shaft turn once for every 27 motor turns. The drive shaft

operates the pumping plunger once per revolution. As a result, there are 432 (16 x 27)

tachometer pulses per pumping stroke.

The tach operates at 5 V (TACHVCC). To reduce the output signals to the 3.3 V levels

required by the CPU system, resistors R145, R146, R107, and R108 divide the PHASE A

and PHASE B signals.

4.1.12

OUTPUT SHAFT ENCODER

The motor output shaft turns the drive mechanism which drives the pumping plunger.

A flag is attached to the end of the drive mechanism. Monitoring this flag allows the three

following functions:

- A positive indication that the mechanism is operating when the motor is operating

- An indicator when the pumping plunger is in the home (fully retracted) position

- An indication of pumping speed

The flag is monitored using a reflective optical encoder (U208). The encoder LED emits an

infrared beam of light. When the encoder flag enters the beam, it reflects light back to a

photo detector which generates an output signal (SHFTSIGNAL). This signal is squared

up by two inverters (U4D and E) before being input to the FPGA (U9-57) as shaft encoder

check (SHFTENCH).

When the signal transitions low to high, this event is latched by the FPGA, which presents

it to the CPU as an interrupt. In responding to this interrupt, the CPU polls

a memory-mapped location in the FPGA to determine which external event caused the

interrupt.

To assure correct motor operation, the shaft encoder looks for the flag every 8.2 ms

whenever the infuser is on. This assures that the motor is only running when it should

be. Any unauthorized motor movement or missing motor movement will be detected.

To minimize power consumption, the shaft encoder is enabled for only 140 µs for a 2 %

duty cycle. The shaft-on (SHFT-ON) control signal is generated at the FPGA (U9-30), passes

through connectors J3, J103, J105, and J205 to R224 and U208.

430-600203-003 (Rev. 07/05) 4 - 16 GemStar

®

Page 39

4.1 ELECTRO-MECHANICAL SYSTEMS

4.1.13

AIR-IN-LINE SENSING

The GemStar® uses an ultrasonic air detection system. The mechanism holds a pulse

generator on one side of the IV tubing and a receiver on the opposite side. If there is fluid

inside the tubing, the sound pulse is conducted to the receiver and a strong signal results.

Air in the tubing gives only a weak signal. The pulse generator (transmitter) and the receiver

are made of piezo-electric crystals. These convert electrical energy into mechanical motion

or mechanical motion into an electric signal. Sending an electrical pulse to a transmitting

crystal generates an ultrasonic pulse. When the pulse is transmitted to the receiving

crystal, the pulse energy acting on the crystal generates an electrical output signal. This

signal is amplified, filtered, and converted into a digital signal for processing by the CPU.

When the cassette is inserted into the infuser, the transmit and receive crystals are

clamped to opposite sides of the IV tubing. The transmit crystal is driven by U207 and

connected to J204. The receive crystal is connected to amplifier U206 through J203. To

check for air, the CPU first applies power to the ultrasonic circuits (AIRON) by turning

Q204 on. This activates power to the ultrasonic transmitter and receiver. After the U5V

supply is stable (about 10 µs), and before transmitting, the CPU measures the receive

signal to establish background noise levels. Next, a signal is transmitted. The signal toggle

air (TOGLAIR) switches from low to high. This is buffered by U207D and causes one side

of the transmit piezo to receive an out-of-phase signal from the other. The piezo deflects,

and rings slightly to generate approximately a 700 kHz burst. Approximately 12 ms later,

TOGLAIR returns to low. This causes the crystal to transmit a second signal. The CPU

measures the AIR reading immediately after this transmitted pulse.

The receiver is a differential amplifier, U206, which rejects low frequency interference,

such as 50-60 Hz, and triples the received signal. Inter-stage capacitor C219 is a high-pass

filter that rejects frequencies up to approximately 100 kHz. The second-stage amplifier is

Q205 with an AC gain of approximately 14. L20 and C215 tune the amplifier frequency

response to optimize only the range of piezo ringing frequencies. Total AC gain is

approximately 45. The amplified output is rectified and filtered by D201 and C206 and

converted to a digital value by the CPU’s A/D. The CPU records the signal value and the

baseline values to determine whether air is present.

4.1.14

PROXIMAL PRESSURE MEASUREMENT

Proximal and distal pressures in the set are obtained by using strain gauges to measure

forces on pins that contact the cassette diaphragm. The proximal pressure sensor pin

contacts the cassette diaphragm at the inlet chamber. When proximal pressure decreases,

the chamber deflates slightly and as a result, the pressure pin moves with the chamber

wall. A resistive strain gauge connected to the pin deflects and changes its electrical output

in proportion to the applied pressure. The signal from the strain gauge (J202) is filtered

(R240; R241; C226; C227; C228) and then amplified by instrumentation amplifier U204

with a gain of 1000. Gain is established via gain resistor R211. The resultant signal,

proximal pressure (PROXPRES), is converted to a digital signal by the analog-to-digital

converter in the CPU (U2-48). The result is a signal with a range of 0 to 255. The normal

proximal pressure range is from 2 psi to –8 psi. This pressure range results in a strain

gauge signal change of approximately 1.75 mV

has full range reference voltage of 3.3 V (i.e., 3.3 V = 255 counts). As a result, the proximal

pressure gauge has a range change of 135 counts (1.75 mV x 1000 x 255 counts/3.3 V).

. The gain of U204 is 1000 and the ADC

DC

Initial offset voltages of the strain gauge circuit are adjusted to zero during production test

and calibration. During calibration, the CPU adjusts a digital potentiometer (U203)

to cancel the offset voltage. The setting is stored as calibration data in the

battery-backed-up RAM. The offset adjustment can be 6.75 mV.

Technical Service Manual 4 - 17 430-600203-003 (Rev. 07/05)

Page 40

SECTION 4 THEORY OF OPERATION

4.1.15

DISTAL PRESSURE MEASUREMENT

The distal pressure measurement is very similar to the proximal. Rather than the pressure

pin contacting the diaphragm directly, however, it contacts the cassette at the flow stop.

The flow stop makes direct contact with the diaphragm. The opposite end of the pin

contacts the strain gauge. The strain gauge connects at jack J201 and is filtered and

amplified by U204 and the associated circuitry. Distal pressures are higher than proximal

pressures (-5 to 40 psi). As a result, output voltages are larger (up to 6.75 mV) so the

amplifier gain (U205) is smaller. Gain is set at 301 via gain resistor R212. The distal

pressure gauge has a range change of 157 ADC counts (6.75 mV x 301 x 255 counts/3.3 V).

The distal pressure amplifier uses the same offset potentiometer that is used for proximal

measurements. The CPU selects the appropriate value before taking a pressure reading.

Because they share the same offset resistor, distal and proximal pressures cannot be

measured at the same time.

To conserve power, the pressure measurement circuits are turned off between readings.

The control signal from the CPU is called pressure sense on (PRSENSON). Transistors

Q201 and Q202 connect + 5 V (5V-B) to the sensors (P5V) while transistors Q207 and

Q208 connect - 5 V (-5 V-B) to the sensors (P-5V).

4.1.16

RS-232 INTERFACE SYSTEM

The infuser has an RS-232 interface to allow connection to a multiple of RS-232 devices.

This allows printing reports, downloading new software, remote monitoring, and modem

interfacing. The circuitry uses an RS-232 transceiver/receiver (U5) to buffer the signals.

To input data, U5 receives the RS-232 logic level signals, serial data in [SDATIN] and serial

control in [SCTLIN], converts them to 3.3 V

UART serial port. For output, U5 receives 3.3 V

serial data out (SDATOUT), and serial data control out (SCTLOUT) and converts them to

RS-232 logic levels for external transmission from the infuser at J109.

U5 provides ohmic isolation between the infuser circuitry, and the RS-232 inputs and

outputs. This isolation is good to several thousand volts, giving the infuser the ability to

withstand electrostatic discharges on th e seri a l por t pins . When t he se r ial p o rt is n ot be i n g

used, the IC is switched to a low-power mode. The logic line serial-on (SERIALON) (U9-29)

connects to U5-13, disables the charge pump, and switches the outputs to high-impedance

output states.

logic level signals, and connects to the CPU

DC

logic level signals from the CPU UART

DC

4.2

CASSETTE SYSTEM

The GemStar® cassette is a small, low cost, sterile pumping chamber that snaps into the

infuser to deliver fluid to the patient. The cassette snaps and locks into the infuser without

the need for a separate door. When the cassette release button on the top of the infuser

is depressed, the cassette is released. When released, the cassette is automatically