Abbott APM and APM II Infusion Pumps - EPS-85656-005 Power Column From Hill-Rom Service Manual

Page 1

HOSPIRA

TECHNICAL SUPPORT OPERATIONS

TECHNICAL SUPPORT OPERATIONS

ELECTRONIC TECHNICAL SERVICE MANUAL

ELECTRONIC TECHNICAL SERVICE MANUAL

APM and APM II

Infusion Pumps

EPS-85656-005 (Rev. 03/05)

Page 2

®

A

For use with the following list numbers:

13960-04 All Codes

13965-04 All Codes

P

and

Technical Service Manual

430-85656-005 (Rev. 03/05)

Page 3

© 2005 Hospira, Inc.

This document and the subject matter disclosed herein are proprietary information. Hospira

retains all the exclusive rights of dissemination, reproduction, manufacture, and sale. Any party

using this document accepts it in confidence, and agrees not to duplicate it in whole or in part

nor disclose it to others without the written consent of Hospira.

430-85656-005 (Rev. 03/05) APM and APM II Infusion Pumps

Page 4

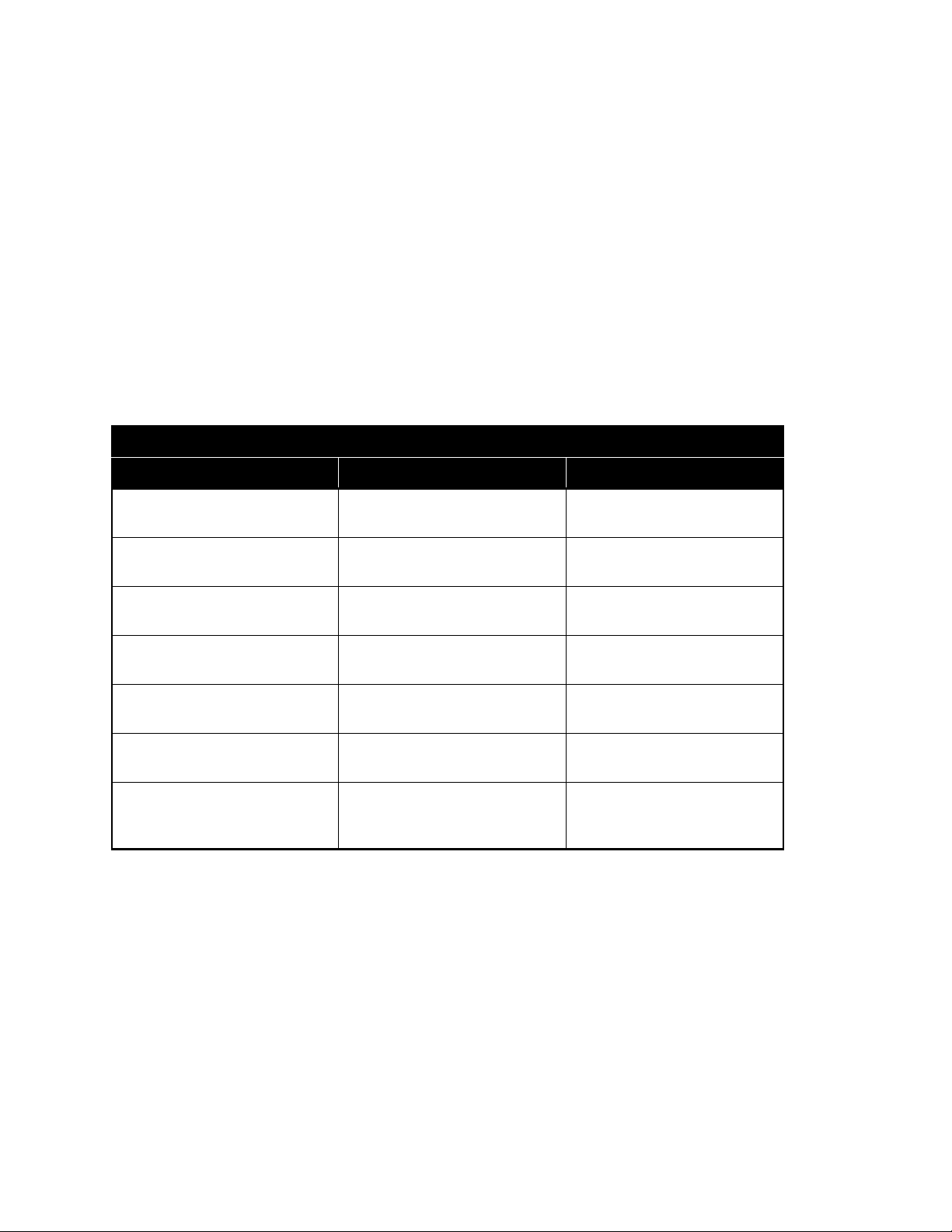

Change History

Part Number Description of Change

430-85656-001 (Rev. 02/94) Original issue

430-85656-002 (Rev. 06/94) Second issue

Added PVT Data Form and winged

bottom case in appropriate figures;

added international screens for global

use

430-85656-003 (Rev. 08/96) Third issue

Reformatted text and added APM II

pump information

430-85656-004 (Rev. 01/00) Fourth issue

Section 5:

1. Updated cleaning materials.

2. Added password protected entry to

PVT mode for APM II software version

7.005 and greater.

3. Deleted description of screen

messages not relevant to

performance of delivery test.

4. Added configuration mode

information for software 7.005 and

greater.

Section 6:

1. Added Year 2000 effect on Error

Code Event Log description

2. Revised APM II Malfunction Code 18

to specify not applicable to software

versions 7.005 and greater

3. Added section to troubleshooting

table for failure to power-on with AC

power supply

Section 7:

Defined motor repair/replacement

procedure using Portescap 22N motor

(motor installation differences also

noted in Section 4)

Section 9:

Added overvoltage protection to APM

PCA (see Figure 9-4 and Figure 9-5)

General:

Added Seiko DPU414 as compatible

printer

Technical Service Manual 430-85656-005 (Rev. 03/05)

Page 5

CHANGE HISTORY

430-85656-005 (Rev. 03/05) Fifth issue

Complete redesign and revision to

Hospira style

Removed unecessary equipment from

PVT in Section 5

Reorganized and simplified repair

procedures in Section 7

430-85656-005 (Rev. 03/05) APM and APM II Infusion Pumps

Page 6

Contents

Section 1

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 SCOPE . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 CONVENTIONS . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 ACRONYMS AND ABBREVIATIONS . . . . . . . . . . . . . . . . 1-3

1.4 APM AND APM II OVERVIEW . . . . . . . . . . . . . . . . . . 1-4

1.4.1 PUMP DESCRIPTION . . . . . . . . . . . . . . . . . . . 1-4

1.4.2 PUMP OPERATION . . . . . . . . . . . . . . . . . . . . 1-5

1.4.3 APM AND APM II HARDWARE DIFFERENCES. . . . . . . . . . 1-5

1.4.4 APM AND APM II SOFTWARE DIFFERENCES . . . . . . . . . . 1-6

1.5 USER QUALIFICATION . . . . . . . . . . . . . . . . . . . . . 1-7

1.6 ARTIFACTS . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.7 INSTRUMENT INSTALLATION PROCEDURE . . . . . . . . . . . . 1-8

1.7.1 UNPACKING . . . . . . . . . . . . . . . . . . . . . . 1-8

1.7.2 INSPECTION . . . . . . . . . . . . . . . . . . . . . . 1-8

1.7.3 SELF TEST. . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.7.4 SETTING THE TIME AND DATE . . . . . . . . . . . . . . . 1-10

Section 2

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Section 3

SYSTEM OPERATING MANUAL . . . . . . . . . . . . . . . . . . . . 3-1

Section 4

THEORY OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1 MOTOR FRAME . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.2 LATCH ASSEMBLY . . . . . . . . . . . . . . . . . . . . 4-3

4.1.3 MOTOR ASSEMBLY . . . . . . . . . . . . . . . . . . . . 4-4

4.1.3.1 MOTOR GEARBOX . . . . . . . . . . . . . . . . . 4-5

4.1.3.2 MOTOR TACHOMETER . . . . . . . . . . . . . . . 4-5

4.1.3.3 MOTOR SHAFT EXTENSION . . . . . . . . . . . . . 4-5

4.1.4 OPTICS ASSEMBLY . . . . . . . . . . . . . . . . . . . . 4-7

4.1.4.1 AIR IN LINE DETECTION. . . . . . . . . . . . . . . 4-7

4.1.4.2 OCCLUSION DETECTION . . . . . . . . . . . . . . 4-7

4.1.4.3 CARTRIDGE INSTALLATION . . . . . . . . . . . . . 4-7

4.2 ELECTRONIC SYSTEM OVERVIEW . . . . . . . . . . . . . . . . 4-9

4.2.1 PRINTED CIRCUIT BOARD . . . . . . . . . . . . . . . . . 4-9

4.2.1.1 MICROPROCESSOR AND EXTERNAL EPROM. . . . . . . 4-10

4.2.1.2 PORT EXPANDER . . . . . . . . . . . . . . . . . 4-10

4.2.1.3 EXTERNAL TIMER . . . . . . . . . . . . . . . . . 4-10

4.2.1.4 ALPHANUMERIC DISPLAY MODULE . . . . . . . . . . 4-10

4.2.1.5 POWER SUPPLY . . . . . . . . . . . . . . . . . . 4-11

4.2.1.6 TACHOMETER. . . . . . . . . . . . . . . . . . . 4-11

4.2.1.7 MOTOR DRIVE . . . . . . . . . . . . . . . . . . 4-11

4.2.1.8 D/A CONVERTER. . . . . . . . . . . . . . . . . . 4-11

4.2.1.9 OPTICS INTERFACE. . . . . . . . . . . . . . . . . 4-11

4.2.1.10 SERIAL EEPROM . . . . . . . . . . . . . . . . . . 4-12

4.2.1.11 ISOLATED PRINTER INTERFACE . . . . . . . . . . . 4-12

4.2.2 CIRCUIT DESCRIPTION . . . . . . . . . . . . . . . . . . 4-12

APM and APM II Infusion Pumps i 430-85656-005 (Rev. 03/05)

Page 7

CONTENTS

4.2.2.1 MICROPROCESSOR (CPU) . . . . . . . . . . . . . . 4-12

4.2.2.2 ADDRESS LATCH . . . . . . . . . . . . . . . . . 4-12

4.2.2.3 PROGRAM MEMORY . . . . . . . . . . . . . . . . 4-14

4.2.2.4 PORT EXPANDER . . . . . . . . . . . . . . . . . 4-14

4.2.2.5 EXTERNAL TIMER . . . . . . . . . . . . . . . . . 4-14

4.2.2.6 LCD ALPHANUMERIC DISPLAY MODULE . . . . . . . . 4-14

4.2.2.7 D/A CONVERTER . . . . . . . . . . . . . . . . . 4-15

4.2.2.8 KEYPAD . . . . . . . . . . . . . . . . . . . . . 4-15

4.2.2.9 BATTERY POWER CIRCUIT . . . . . . . . . . . . . . 4-16

4.2.2.10 LOW-VOLTAGE DETECTION AND RESET . . . . . . . . 4-16

4.2.2.11 TACHOMETER . . . . . . . . . . . . . . . . . . 4-17

4.2.2.12 MOTOR DRIVE AND SPEED CONTROL . . . . . . . . . 4-17

4.2.2.13 AIR AND OCCLUSION DETECTION OPTICS . . . . . . . 4-21

4.2.2.14 NONVOLATILE MEMORY . . . . . . . . . . . . . . 4-21

4.2.2.15 RS-232 SERIAL DATA INTERFACE FOR PRINTER . . . . . 4-21

Section 5

MAINTENANCE AND SERVICE TESTS . . . . . . . . . . . . . . . . . . 5-1

5.1 ROUTINE MAINTENANCE . . . . . . . . . . . . . . . . . . . 5-1

5.1.1 INSPECTION . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.2 CLEANING . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.3 SANITIZING THE INFUSION PUMP. . . . . . . . . . . . . . 5-3

5.2 PERFORMANCE VERIFICATION TEST . . . . . . . . . . . . . . . 5-3

5.2.1 EQUIPMENT REQUIRED . . . . . . . . . . . . . . . . . . 5-4

5.2.2 INSPECTION . . . . . . . . . . . . . . . . . . . . . . 5-4

5.2.2.1 PUMP INSPECTION. . . . . . . . . . . . . . . . . 5-4

5.2.2.2 ACCESSORIES INSPECTION . . . . . . . . . . . . . 5-5

5.2.3 DIAGNOSTIC TESTS . . . . . . . . . . . . . . . . . . . 5-6

5.2.3.1 ENTERING THE DIAGNOSTIC TEST MODE . . . . . . . 5-7

5.2.3.2 SETTING THE CLOCK . . . . . . . . . . . . . . . . 5-7

5.2.3.3 HIGH-SPEED MOTOR TEST . . . . . . . . . . . . . 5-8

5.2.3.4 LOW-SPEED MOTOR TEST . . . . . . . . . . . . . . 5-9

5.2.3.5 KEYPAD AND REMOTE BOLUS CHECK . . . . . . . . . 5-10

5.2.3.6 DISPLAY CHECK . . . . . . . . . . . . . . . . . . 5-10

5.2.3.7 PRINTER TEST . . . . . . . . . . . . . . . . . . 5-11

5.2.4 OPERATION TEST . . . . . . . . . . . . . . . . . . . . 5-12

5.2.4.1 EQUIPMENT REQUIRED . . . . . . . . . . . . . . . 5-12

5.2.4.2 TEST SETUP. . . . . . . . . . . . . . . . . . . . 5-12

5.2.4.3 SELF TEST . . . . . . . . . . . . . . . . . . . . 5-12

5.2.4.4 PROGRAM ENTRY TEST . . . . . . . . . . . . . . . 5-13

5.2.4.5 OCCLUSION TEST . . . . . . . . . . . . . . . . . 5-15

5.2.4.6 AIR IN LINE TEST . . . . . . . . . . . . . . . . . 5-16

5.2.4.7 PURGING FUNCTION TEST . . . . . . . . . . . . . 5-16

5.2.4.8 DELIVERY TEST . . . . . . . . . . . . . . . . . . 5-17

5.2.4.9 CLEARING PROGRAM AND TEST HISTORY . . . . . . . 5-18

5.2.5 PREPARATION FOR USE . . . . . . . . . . . . . . . . . . 5-19

5.2.5.1 INITIALIZE NVRAM . . . . . . . . . . . . . . . . 5-19

5.2.5.2 CLEAR ERROR LOGS . . . . . . . . . . . . . . . . 5-19

5.3 CONFIGURATION GUIDE FOR APM II . . . . . . . . . . . . . . . 5-20

5.3.1 ENTERING THE CONFIGURATION MODE . . . . . . . . . . . 5-20

5.3.2 CONFIGURATION PROGRAMMING . . . . . . . . . . . . . 5-21

5.3.2.1 MODES OF DELIVERY. . . . . . . . . . . . . . . . 5-21

5.3.2.2 UNITS OF DELIVERY . . . . . . . . . . . . . . . . 5-21

5.3.2.3 MAXIMUM CONTINUOUS RATE . . . . . . . . . . . 5-22

5.3.2.4 MAXIMUM VOLUME OF LOADING DOSE . . . . . . . . 5-22

5.3.2.5 ALARM AFTER LOADING DOSE COMPLETES . . . . . . 5-22

430-85656-005 (Rev. 03/05) ii APM and APM II Infusion Pumps

Page 8

CONTENTS

5.3.2.6 MAXIMUM VOLUME OF PCA/BOLUS DOSE . . . . . . . 5-23

5.3.2.7 SOFT OR HARD BOLUS/PCA LIMITS . . . . . . . . . . 5-23

5.3.2.8 SAVING CHANGES . . . . . . . . . . . . . . . . . 5-23

5.4 APM AND APM II PVT RECORD . . . . . . . . . . . . . . . . . 5-24

5.5 PERIODIC MAINTENANCE INSPECTION . . . . . . . . . . . . . . 5-25

Section 6

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 TECHNICAL ASSISTANCE. . . . . . . . . . . . . . . . . . . . 6-1

6.2 ALARM MESSAGES AND ERROR CODES . . . . . . . . . . . . . . 6-1

6.2.1 ALERTS AND ALARMS. . . . . . . . . . . . . . . . . . . 6-2

6.3 SYSTEM ERROR CODES . . . . . . . . . . . . . . . . . . . . 6-4

6.4 MALFUNCTION CODES . . . . . . . . . . . . . . . . . . . . 6-6

6.5 TROUBLESHOOTING PROBLEMS AND SOLUTIONS . . . . . . . . . 6-8

Section 7

REPLACEABLE PARTS AND REPAIRS . . . . . . . . . . . . . . . . . . 7-1

7.1 REPLACEABLE PARTS . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 REPLACEMENT PROCEDURES . . . . . . . . . . . . . . . . . . 7-3

7.2.1 SAFETY AND EQUIPMENT PRECAUTIONS . . . . . . . . . . . 7-3

7.2.2 REQUIRED TOOLS AND MATERIALS . . . . . . . . . . . . . 7-3

7.2.3 SEPARATING THE TOP AND BOTTOM CASES . . . . . . . . . 7-4

7.2.4 MOTOR AND MOTOR ASSEMBLY REPLACEMENT . . . . . . . . 7-7

7.2.4.1 PCB MODIFICATION FOR THE 22N MOTOR . . . . . . . 7-8

7.2.5 OPTICS ASSEMBLY REPLACEMENT. . . . . . . . . . . . . . 7-12

7.2.6 LATCH ASSEMBLY REPLACEMENT . . . . . . . . . . . . . . 7-14

7.2.7 PCB ASSEMBLY REPLACEMENT . . . . . . . . . . . . . . . 7-16

7.2.8 TOP CASE ASSEMBLY REPLACEMENT. . . . . . . . . . . . . 7-18

7.2.8.1 LCD WINDOW REPLACEMENT . . . . . . . . . . . . 7-19

Section 8

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Section 9

DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

APM and APM II Infusion Pumps iii 430-85656-005 (Rev. 03/05)

Page 9

FIGURES

Figures

Figure 4-1. Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Figure 4-2. Motor Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Figure 4-3. Latch Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Figure 4-4. Motor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Figure 4-5. Optics Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Figure 4-6. Circuit Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Figure 5-1. Cartridge Channel Detail . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Figure 5-2. Motor Test Display . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Figure 5-3. High-Speed Motor Test Display . . . . . . . . . . . . . . . . . . . . . 5-9

Figure 5-4. Low-Speed Motor Test Display. . . . . . . . . . . . . . . . . . . . . . 5-10

Figure 7-1. PCB Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Figure 7-2. Separating the Top and Bottom Cases . . . . . . . . . . . . . . . . . . . 7-6

Figure 7-3. Separating the Motor from the Motor Frame . . . . . . . . . . . . . . . . 7-8

Figure 7-4. Portescap 22N Motor Assembly with Encoder PCB/Insulator . . . . . . . . 7-10

Figure 7-5. Circuit Board Modification for the 22N Motor . . . . . . . . . . . . . . . 7-11

Figure 7-6. Optics Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . 7-13

Figure 7-7. Optics Carrier Detail . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Figure 7-8. Optics Wiring Details . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

Figure 7-9. Latch Assembly to Motor Frame . . . . . . . . . . . . . . . . . . . . . 7-15

Figure 7-10.PCB Back Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Figure 7-11.Top Case Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

Figure 7-12.LCD Window to Top Case . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Figure 9-1. Illustrated Parts Breakdown . . . . . . . . . . . . . . . . . . . . . . . 9-3

Figure 9-2. APM Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Figure 9-3. APM Motor Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Figure 9-4. APM Analog Schematic . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Figure 9-5. APM Microprocessor (CPU) Schematic . . . . . . . . . . . . . . . . . . 9-11

Figure 9-6. APM Power and Miscellaneous Circuitry Schematic . . . . . . . . . . . . 9-13

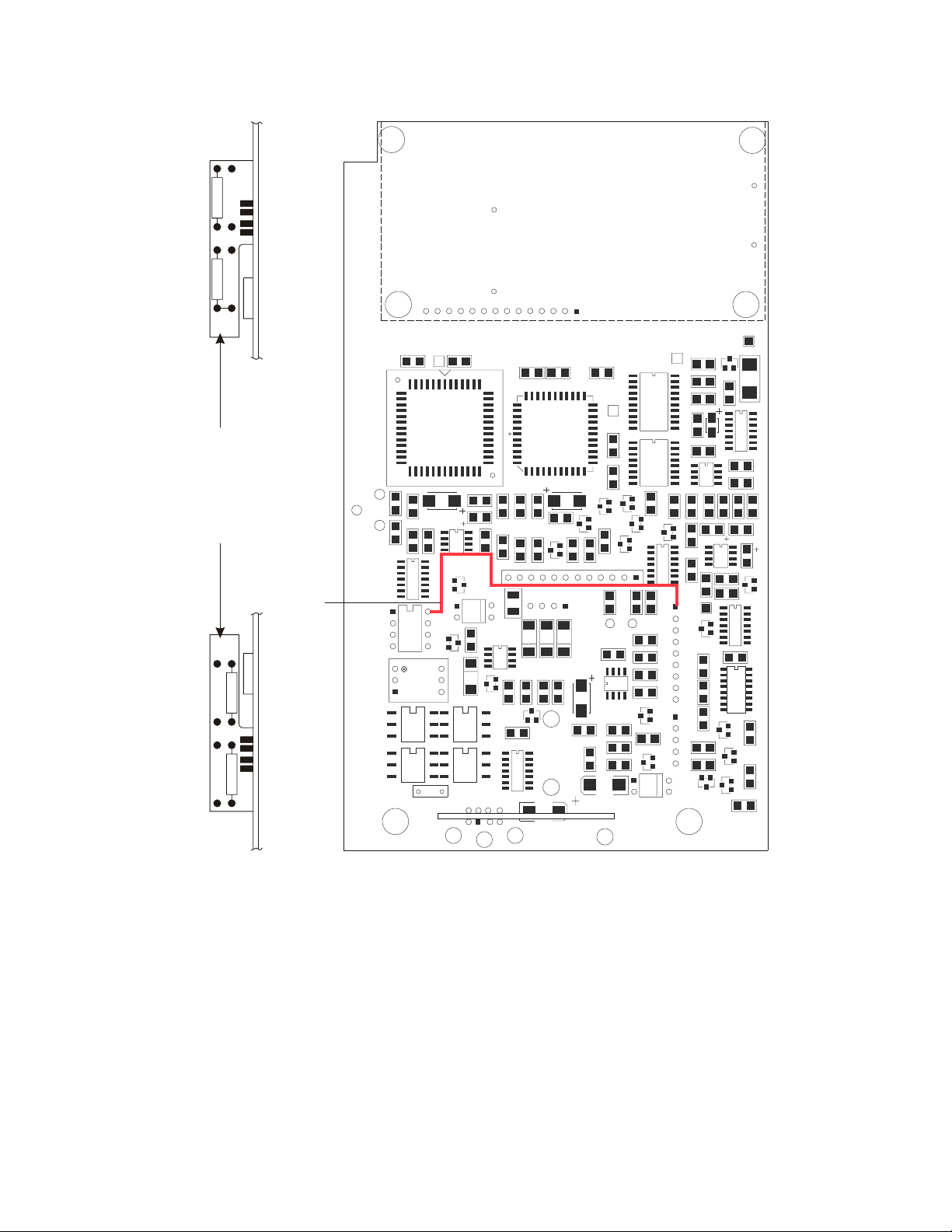

Figure 9-7. APM PC Board, Front Side . . . . . . . . . . . . . . . . . . . . . . . . 9-15

Figure 9-8. APM PC Board, Back Side . . . . . . . . . . . . . . . . . . . . . . . . 9-17

Figure 9-9. APM II Analog Schematic . . . . . . . . . . . . . . . . . . . . . . . . 9-19

Figure 9-10.APM II Microprocessor (CPU) Schematic . . . . . . . . . . . . . . . . . 9-21

Figure 9-11.APM II Power and Miscellaneous Circuitry Schematic . . . . . . . . . . . 9-23

Figure 9-12.APM II PC Board Front Side . . . . . . . . . . . . . . . . . . . . . . . 9-25

Figure 9-13.APM II PC Board Back Side . . . . . . . . . . . . . . . . . . . . . . . 9-27

430-85656-005 (Rev. 03/05) iv APM and APM II Infusion Pumps

Page 10

TA BL E S

Tables

Table 1-1. Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Table 1-2. APM and APM II Hardware Differences . . . . . . . . . . . . . . . . . . 1-5

Table 1-3. APM and APM II Software Differences . . . . . . . . . . . . . . . . . . 1-6

Table 4-1. PCB Reference Designators . . . . . . . . . . . . . . . . . . . . . . . 4-9

Table 5-1. Cleaning Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Table 5-2. Diagnostic Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Table 5-3. APM II Configurable Settings . . . . . . . . . . . . . . . . . . . . . 5-20

Table 5-4. APM/APM II PVT and Inspection Record . . . . . . . . . . . . . . . . 5-24

Table 6-1. Alerts and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Table 6-2. System Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Table 6-3. Malfunction Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Table 6-4. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Table 9-1. Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Table 9-2. IPB for the Infusion Pump . . . . . . . . . . . . . . . . . . . . . . . . 9-2

APM and APM II Infusion Pumps v 430-85656-005 (Rev. 03/05)

Page 11

CONTENTS

This page intentionally left blank.

430-85656-005 (Rev. 03/05) vi APM and APM II Infusion Pumps

Page 12

Section 1

INTRODUCTION

The APM® and APM™II infusion pumps are single-channel devices designed for epidural,

patient-controlled analgesia and other therapies requiring delivery rates at or below 25

mL/hr. The versatility, flexibility, and adaptability of the APM and APM II devices make

them ideal for all pain management protocols.

1.1

SCOPE

This manual is organized into 11 sections:

❏ Section 1 Introduction

❏ Section 2 Warranty

❏ Section 3 System Operating Manual

❏ Section 4 Theory of Operation

❏ Section 5 Maintenance and Service Tests

❏ Section 6 Troubleshooting

❏ Section 7 Replaceable Parts and Repairs

❏ Section 8 Specifications

❏ Section 9 Drawings

❏ Appendices

❏ Index

❏ Technical Service Bulletins

If a problem in device operation cannot be resolved using the information in this manual,

contact Hospira (see Section 6.1, Technical Assistance).

Specific instructions for operating the device are contained in the APM and APM II System

Operating Manuals. Provision is made for the inclusion of the system operating manuals

in Section 3 of this manual.

Note: Unless otherwise specified, the terms “device” and “pump” refer to all

configurations of both the APM and APM II.

Note: Non-English language keypad names and display text are not indicated in this

manual.

Note: Figures are rendered as graphic representations to approximate actual

product; therefore, figures may not exactly reflect the product. Display screens and

key labels may vary slightly, depending on the configuration of the pump in use.

Technical Service Manual 1 - 1 430-85656-005 (Rev. 03/05)

Page 13

SECTION 1 INTRODUCTION

1.2

CONVENTIONS

The conventions listed in Table 1-1, Conventions, are used throughout this manual.

Table 1-1. Conventions

Convention Application Example

Italic Reference to a section, figure,

table, or publication

[ALL CAPS] In-text references to keys are

described in all caps and

enclosed in brackets

ALL CAPS Screen displays INITIALIZE NVRAM OR USE

Bold Emphasis CAUTION: Do not use the

Throughout this manual, warnings, cautions, and notes are used to emphasize important

information, as follows:

(see Section 6.1, Technical

Assistance)

[1], [0], [YES/ENTER]

ARROWS

infusion pump if it appears

to be damaged. Should

damage be found, contact

Hospira.

WARNING: A WARNING CONTAINS SPECIAL SAFETY EMPHASIS AND

MUST BE OBSERVED AT ALL TIMES. FAILURE TO OBSERVE

A WARNING MAY RESULT IN PATIENT INJURY AND BE

LIFE-THREATENING.

CAUTION: A caution usually appears in front of a procedure or statement. It

contains information that could prevent hardware failure, irreversible equipment

damage or loss of data.

Note: A note highlights information that helps explain a concept or procedure.

430-85656-005 (Rev. 03/05) 1 - 2 APM and APM II Infusion Pumps

Page 14

1.3 ACRONYMS AND ABBREVIATIONS

1.3

ACRONYMS AND ABBREVIATIONS

Acronyms and abbreviations used in this manual are as follows:

A Ampere

AC Alternating current

A/D Analog-to-digital

CMOS Complementary metal-oxide semiconductor

CPU Central processing unit

DC Direct current

ECG Electrocardiograph

EEG Electroencephalogram

EMG Electromyogram

EMI Electromagnetic interference

EPROM Electrically programmable read-only memory

ESD Electrostatic discharge

ETO Ethylene oxide

FDA Food and Drug Administration

hr Hour

IC Integrated circuit

I/O Input/output

IPB Illustrated parts breakdown

KB Kilobytes

kHz Kilohertz

kPa Kilopascal

LCD Liquid crystal display

LED Light emitting diode

mA Milliampere

mg Milligram

MHz Megahertz

mL Milliliter

mL/hr Milliliter per hour

ms Millisecond

mV Millivolt

N/A Not applicable

NVRAM Nonvolatile random access memory

PCB Printed circuit board

PVT Performance verification test

RAM Random-access memory

Technical Service Manual 1 - 3 430-85656-005 (Rev. 03/05)

Page 15

SECTION 1 INTRODUCTION

ROM Read-only memory

V Volt

V

Volts AC

AC

V

Base to emitter voltage

BE

V

Collector supply voltage

CC

Volts DC

V

DC

V

Drain supply voltage

DD

V

Voltage in

IN

Offset voltage

V

OS

V

Volts peak-to-peak

PP

V

Voltage set point

SET

µA Microampere

µg Microgram

µV Microvolt

1.4

APM AND APM II OVERVIEW

The APM and APM II infusion pumps share the same design and functionality, other than

the hardware and software differences described in Section 1.4.3, APM and APM II

Hardware Differences.

1.4.1

PUMP DESCRIPTION

The APM and APM II infusion pumps are single-channel devices designed to deliver

analgesic drugs to patients in the hospital, in outpatient treatment centers, and at home.

Primarily designed for pain management protocols, the pumps may also be used for other

therapies that require infusion delivery schedules of continuous rates at or below 25 mL

per hour. The pumps provide accurate, pulsatile administration of single-fluid regimens

delivered via the following routes: epidural, intravenous, subcutaneous, or arterial. A

remote bolus switch allows for patient controlled analgesia (PCA).

Special safety features are integrated into the pump design, which include an occlusion

alarm, an air in line alarm, a motor watchdog circuit, motor parameter monitoring, and

numerous backup failure detection modes to prevent single-point failures from

endangering the patient.

The pump is microprocessor-based and is programmed through a 24-key keypad on the

front of the pump. The state of the pump is displayed using a 16-character-by-2-line

alphanumeric LCD module. Dedicated cartridges are required to deliver fluids through

rotary peristaltic pumping action. Power is supplied by two, 9 V alkaline batteries, an

optional nickel-cadmium rechargeable battery pack, or an external AC power supply.

APM and APM II system kits contain a pump, a remote bolus switch, a wall plug-in AC

power supply (110 V or 220 V), two 9 V alkaline batteries, and a System Operating Manual.

Some international configurations contain a tabletop 220 V AC power supply with a

separate power cord.

430-85656-005 (Rev. 03/05) 1 - 4 APM and APM II Infusion Pumps

Page 16

1.4 APM AND APM II OVERVIEW

1.4.2

PUMP OPERATION

The pump has several programming modes: Continuous, Bolus (PCA) only, or Continuous

and Bolus (PCA). The continuous mode delivers fluid in small doses spaced evenly over

time. Delivery rates and bolus dosage amounts are programmed in one of three units of

measure: milliliters (mL), milligrams (mg), or micrograms (µg). A loading dose is

programmable for immediate delivery or delayed delivery. Bolus doses can be programmed

to begin delivery on demand.

The operator programs the pump by selecting the mode (epidural or PCA), volume delivery

(mL) or mass delivery (mg or µg), concentration (only if mass delivery is selected), rate,

loading dose (if desired), and total amount to be delivered. If mass delivery is selected, the

pump automatically converts milligrams or micrograms to the closest number of

tenths-of-mL. The amount of fluid delivered is shown on the display. When a bolus is

programmed, a minimum lockout time between boluses must also be programmed. In

addition to the lockout time, the operator can also program the maximum total volume

that can be delivered in a selected period.

The pump contains a time-of-day clock and event history storage capability. The program

settings and significant events that take place while a protocol is running can be reviewed

on the liquid crystal display (LCD), along with time and date of occurrence. A printer jack

allows printout of this history information when a pump is connected to a compatible

printer. With proper communication software, a pump’s history can also be downloaded

to a personal computer as an ASCII file.

For specific instructions regarding pump operation, refer to the APM System Operating

Manual or the APM II System Operating Manual.

1.4.3

APM AND APM II HARDWARE DIFFERENCES

Table 1-2, APM and APM II Hardware Differences details the significant hardware

differences between the APM and the APM II infusion pumps.

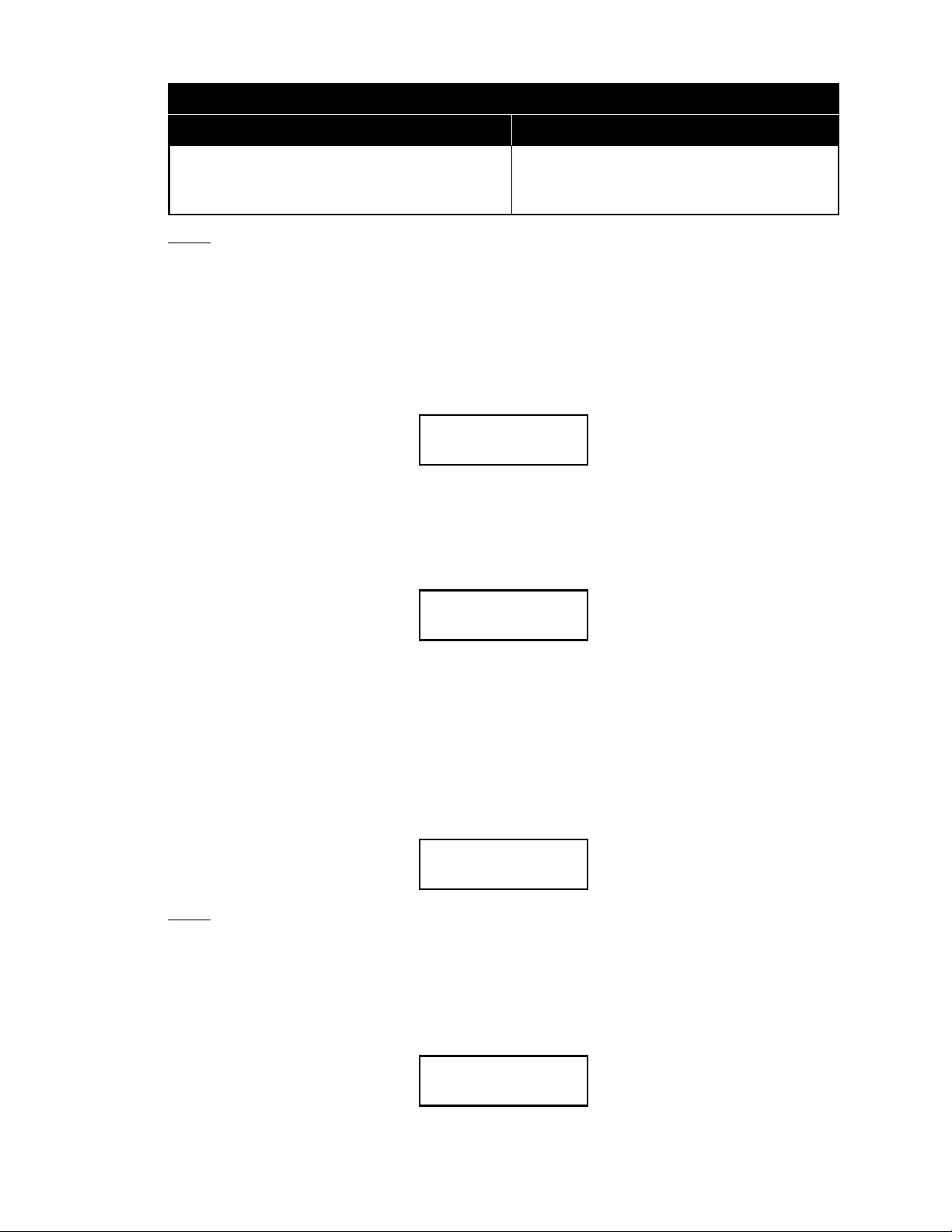

Table 1-2. APM and APM II Hardware Differences

Item APM APM II

Winged bottom case design

that stabilizes the motor if the

pump is dropped

Add-on PCBs (not

interchangeable)

This change has been

implemented for APM pumps,

but some earlier models may

not have this feature. All

replacement bottom case

assemblies have this feature

Surge suppressor board Add-on board

All APM II pumps are

manufactured with the winged

bottom case design

Technical Service Manual 1 - 5 430-85656-005 (Rev. 03/05)

Page 17

SECTION 1 INTRODUCTION

Table 1-2. APM and APM II Hardware Differences

Item APM APM II

External unit interface None External unit interface uses

two previously unused pins in

the printer port; a circuit was

added to interface pins with

the microprocessor. This

interface is not currently used

Circuit protection against

incorrect AC power supply

usage

None A transient voltage

suppressor was added to

prevent damage to the U35

comparator should an

incorrect AC adapter be used

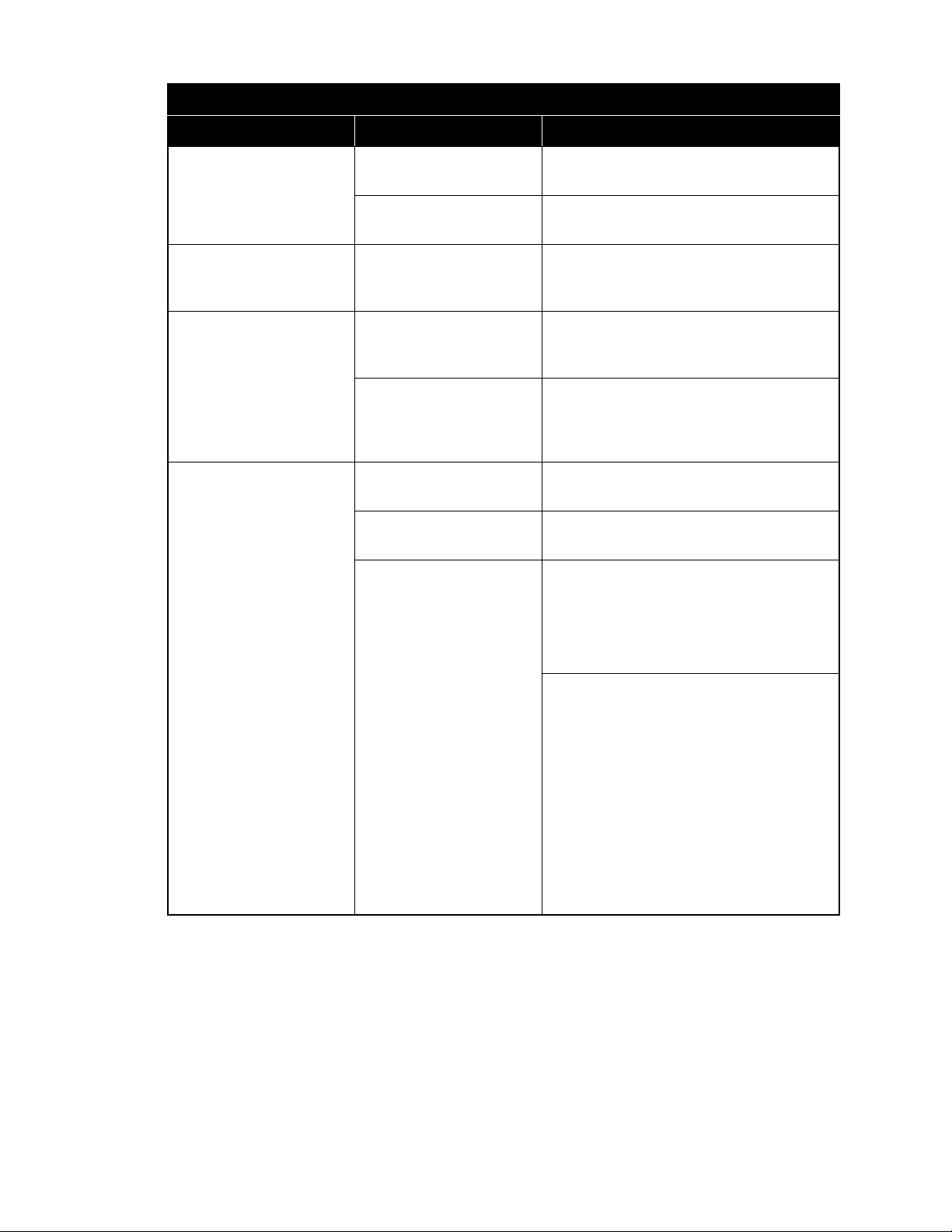

1.4.4

APM AND APM II SOFTWARE DIFFERENCES

Table 1-3, APM and APM II Software Differences details the significant software differences

between the APM and the APM II.

Table 1-3. APM and APM II Software Differences

Item APM APM II

Scrolling HISTORY key provides

forward-only scrolling

Volume History User can review entire history

event log only

Arrow keys provide back and

forth scrolling; HISTORY key

provides forward scrolling

User can review entire history

event log or shift and

container volume information

Bolus Counts Delivered and demand counts

logged to two places

(max. 99)

Program Totals Text GRAND

TO GO

Numeric Entries If entered value is too large or

too small, pump defaults to

maximum or minimum value

Micrograms Range 0.1 to 9999.9 µg 1 to 999,999 µg

Bolus Lockout Time 5 to 99 minutes 5 to 999 minutes

Volume Limits Four-hour limit available One-hour and four-hour limits

Container Size Pump requests TOTAL

AMOUNT for container

size entry

430-85656-005 (Rev. 03/05) 1 - 6 APM and APM II Infusion Pumps

Delivered and demand counts

logged to four places

(max. 9999)

VOLUME INFUSED

VTBI

If entered value is too large or

too small, pump defaults to

zero

available; epidural mode

defaults to one-hour, 25 mL

limit

Pump requests CONTAINER

SIZE

Page 18

1.5 USER QUALIFICATION

Table 1-3. APM and APM II Software Differences

Item APM APM II

Air Sensitivity Defaults to HIGH setting unless

keypad is locked at different

setting

Purging Two minute maximum; purging

available only after

programming complete

Loading Dose If stopped, cannot be

completed

Keypad Lock Full lock only Full lock or container lock,

Air in Line Alarm Cleared by unlocking pump and

pressing PURGE key

RESET Key Display 1. RESET SHIFT

2. RESET PROGRAM

Sensitivity setting selected

during programming

Four minute maximum;

purging available during

programming before delivery

of loading dose

Loading dose may be

completed after an

interruption

which allows user to reset

program and clear shift

amount

Cleared by pressing

SILENCE then STOP,

whether the pump is locked or

not

1. NEW SHIFT TOTL

2. NEW CONTAINER

CHANGE Key Functionality Units of delivery can be

changed through the CHANGE

key function

Units of delivery cannot be

changed without

programming

1.5

USER QUALIFICATION

The APM and APM II infusion pumps are intended for use at the direction or under the

supervision of licensed physicians or certified healthcare professionals who are trained in

the use of the pump. Training should emphasize preventing related IV complications,

including appropriate precautions to prevent accidental infusion of air.

Technical Service Manual 1 - 7 430-85656-005 (Rev. 03/05)

Page 19

SECTION 1 INTRODUCTION

1.6

ARTIFACTS

Nonhazardous, low-level electrical potentials are commonly observed when fluids are

administered using infusion devices. These potentials are well within accepted safety

standards, but may create artifacts on voltage-sensing equipment such as ECG, EMG,

and EEG machines. These artifacts vary at a rate that is associated with the infusion rate.

If the monitoring machine is not operating correctly or has loose or defective connections

to its sensing electrodes, these artifacts may be accentuated so as to simulate actual

physiological signals. To determine if the abnormality in the monitoring equipment is

caused by the pump instead of some other source in the environment, set the pump so

that it is temporarily not delivering fluid. Disappearance of the abnormality indicates that

it was probably caused by electronic noise generated by the pump. Proper setup and

maintenance of the monitoring equipment should eliminate the artifact. Refer to the

appropriate monitoring system documentation for setup and maintenance instructions.

1.7

INSTRUMENT INSTALLATION

PROCEDURE

CAUTION: Infusion pump damage may occur unless proper care is exercised during

product unpacking and installation. The battery may not be fully charged upon

receipt of the infusion pump. Do not place the infusion pump in service if it fails the

self test.

CAUTION: Infusion pump performance may be degraded by electromagnetic

interference (EMI) from devices such as electrosurgical units, cellular phones,

pagers, and two-way radios. Operation of the infusion pump under such conditions

should be avoided.

The instrument installation procedure consists of unpacking, inspection, and self test.

1.7.1

UNPACKING

Inspect the infusion pump shipping container as detailed in Section 1.7.2, Inspection. Use

care when unpacking the infusion pump. Retain the packing slip and save all packaging

material in the event it is necessary to return the infusion pump to the factory.Verify the

shipping container contains a copy of the system operating manual.

1.7.2

INSPECTION

Inspect the infusion pump container for shipping damage. Should any damage be found,

contact the delivering carrier immediately.

CAUTION: Do not use the infusion pump if it appears to be damaged. Should

damage be found, contact Hospira.

430-85656-005 (Rev. 03/05) 1 - 8 APM and APM II Infusion Pumps

Page 20

1.7 INSTRUMENT INSTALLATION PROCEDURE

Inspect the infusion pump for signs of defects, such as worn accessories, broken

connections or damaged cable assemblies. Also inspect the infusion pump after repair or

during cleaning. Replace any damaged or defective external parts (see

Section 5.1.1, Inspection).

1.7.3

SELF TEST

CAUTION: Do not place the infusion pump in service if the self test fails.

To perform the self test, proceed as follows:

1. Press [ON/OFF] to power on the pump.

2. Confirm the following display appears:

UNIT SELF-TEST

IN PROGRESS

3. Verify that the self test completes and that the backlight illuminates.

- A series of short beeps sounds.

4. The current program displays if it was not cleared before the pump was powered off:

PCA MODE

CONTINUOUS ONLY

5. The unit displays the current time for several seconds:

TIME IS 4:19 PM

MON, SEPT 29, 03

- If the time and date are incorrect, refer to Section 1.7.4 to change the settings.

6. If the history and the previous program have not been cleared, the following display

appears:

CLEAR HISTORY & Rx?

YES OR NO

7. Press [YES], and confirm the following display appears:

CLEARING HISTORY

AND Rx

- No response is required.

Technical Service Manual 1 - 9 430-85656-005 (Rev. 03/05)

Page 21

SECTION 1 INTRODUCTION

8. Confirm the following display appears:

HISTORY AND Rx

CLEARED

- The previous program and history are cleared. The pump automatically advances

to the next screen:

EPIDURAL MODE

YES OR NO

1.7.4

SETTING THE TIME AND DATE

The set the time and date, proceed as follows:

1. Confirm that the pump is in stop mode, and the following screen displays:

PRESS RUN/STOP

TO INFUSE

2. Press [ENTER], then [2], and confirm the following display appears:

12-HOUR CLOCK?

YES OR NO

- Press [YES] for the 12-hour clock or [NO] to choose the 24-hour clock.

- After selecting the appropriate clock, confirm the following display appears:

SET MONTH (arws)

AUG 6,04 9:05A

3. Use the [

4. Use the number or arrow keys as indicated to change the day, year, hour, minute,

AM/PM, and the day of the week. Press [ENTER] to accept each change.

5. When all changes are made, the changed time and date briefly display, then the

pump returns to the stop mode.

U] or [V] keys to select the month. Press [ENTER].

430-85656-005 (Rev. 03/05) 1 - 10 APM and APM II Infusion Pumps

Page 22

Section 2

WARRANTY

Subject to the terms and conditions herein, Hospira, Inc. herein referred to as Hospira,

warrants that (a) the product shall conform to Hospira's standard specifications and be

free from defects in material and workmanship under normal use and service for a period

of one year after purchase, and (b) the replaceable battery shall be free from defects in

material and workmanship under normal use and service for a period of 90 days after

purchase. Hospira makes no other warranties, express or implied, as to merchantability,

fitness for a particular purpose, or any other matter.

Purchaser’s exclusive remedy shall be, at Hospira’s option, the repair or replacement of

the product. In no event shall Hospira’s liability arising out of any cause whatsoever

(whether such cause be based in contract, negligence, strict liability, tort, or otherwise)

exceed the price of such product, and in no event shall Hospira be liable for incidental,

consequential, or special damages or losses or for lost business, revenue, or profits.

Warranty product returned to Hospira must be properly packaged.

The foregoing warranty shall be void in the event the product has been misused, damaged,

altered, or used other than in accordance with product manuals so as, in Hospira’s

judgment, to affect its stability or reliability, or in the event the serial or lot number has

been altered, defaced, or removed.

The foregoing warranty shall also be void in the event any person, including the Purchaser,

performs or attempts to perform any major repair or other service on the product without

having been trained by an authorized representative of Hospira and using Hospira

documentation and approved spare parts. For purposes of the preceding sentence, “major

repair or other service” means any repair or service other than the replacement of accessory

items such as batteries.

In providing any parts for repair or service of the product, Hospira shall have no

responsibility or liability for the actions or inactions of the person performing such repair

or service, regardless of whether such person has been trained to perform such repair or

service. It is understood and acknowledged that any person other than an Hospira

representative performing repair or service is not an authorized agent of Hospira.

Technical Service Manual 2 - 1 430-85656-005 (Rev. 03/05)

Page 23

SECTION 2 WARRANTY

This page intentionally left blank.

430-85656-005 (Rev. 03/05) 2 - 2 APM and APM II Infusion Pumps

Page 24

Section 3

SYSTEM OPERATING MANUAL

A System Operating Manual is included with every APM and APM II infusion pump. Insert

a copy here for convenient reference. If a copy of the System Operating Manual is not

available, contact Hospira Technical Support Operations (see Section 6.1, Technical

Assistance).

Technical Service Manual 3 - 1 430-85656-005 (Rev. 03/05)

Page 25

SECTION 3 SYSTEM OPERATING MANUAL

This page intentionally left blank.

430-85656-005 (Rev. 03/05) 3 - 2 APM and APM II Infusion Pumps

Page 26

Section 4

THEORY OF OPERATION

This section describes the APM and APM II theory of operation. Related drawings are

provided in Section 9, Drawings. The theory of operation details the general description,

circuit block diagram, and circuit description.

4.1

GENERAL DESCRIPTION

The pump has a modular construction that consists of top and bottom case assemblies;

a motor frame mounted with the latch, motor, and optics assemblies; and a printed circuit

board (PCB) with mounted display module assembly (see Figure 4-1, Assemblies).

The top case is constructed of durable, shock-resistant plastic that contains or is coated

with a conductive material to provide enhanced ESD and EMI protection for the pump

electronics. A clear plastic window protects the liquid crystal display (LCD) mounted on

the PCB. The keypad provides user interface with 24 membrane switches connected to

the PCB by a ribbon cable threaded through a slot in the top case. Refer to the pump’s

System Operating Manual for descriptions of key functionality.

The bottom case is constructed of the same durable, shock-resistant, ESD/EMI-protected

plastic as the top case. The battery door is removable to allow access to the battery

compartment. Battery terminals are constructed of spring clips that are insulated from

the conductive case. Positive and negative contacts are identified. Batteries are installed

in a diode-isolated parallel configuration. Wires housed in a crimp terminal connect the

four battery contacts to the PCB.

Technical Service Manual 4 - 1 430-85656-005 (Rev. 03/05)

Page 27

SECTION 4 THEORY OF OPERATION

TOP CASE ASSEMBLY

PCB ASSEMBLY

LATCH, OPTICS, AND MOTOR

ASSEMBLIES MOUNTED ON

MOTOR FRAME

BOTTOM CASE ASSEMBLY

01K04001

Figure 4-1. Assemblies

4.1.1

MOTOR FRAME

The motor frame aligns the cartridge to the drive motor and optical sensors, and completes

the outer part of the pumping mechanism (see Figure 4-2, Motor Frame). The alignment of

the cartridge is critical to the performance of the pump. Air in line and occlusion detection

systems require correct cartridge alignment to function properly.

430-85656-005 (Rev. 03/05) 4 - 2 APM and APM II Infusion Pumps

Page 28

4.1 GENERAL DESCRIPTION

The location, height, and perpendicularity of the dowel pins determine the location of the

cartridge within the motor frame. Dowel pin insertion into the motor frame is accomplished

by using specially designed equipment. Therefore, replacement of the motor frame must

be performed by Hospira.

DOWEL PINS

05K04033

Figure 4-2. Motor Frame

4.1.2

LATCH ASSEMBLY

The latch holds the cartridge in the motor frame with tabs at two points to keep it properly

aligned to the motor and the optics assembly. One capture point on the cartridge is the

indentation on the side of the cartridge near the rotor; the second point is a protruding

tab on the cartridge next to the blue foil.

Two pivot pins hold the latch assembly onto the motor frame. Once the pump is assembled,

tabs hold the pivot pins in place (see Figure 4-3, Latch Assembly).

The latch is opened by moving the thumb tab down and rotating it back. This action rotates

the lever arms outward from the motor frame and ejects a cartridge if one is installed. The

latch is closed and the cartridge locked into place by moving the thumb tab down, inward

and then upward.

Technical Service Manual 4 - 3 430-85656-005 (Rev. 03/05)

Page 29

SECTION 4 THEORY OF OPERATION

CARTRIDGE

HOLDING

TABS

EJECTION

LEVER

ARMS

EJECTOR PIVOT PIN

OPENING

THE LATCH

Figure 4-3. Latch Assembly

CLOSING

THE LATCH

05K04034

4.1.3

MOTOR ASSEMBLY

The motor assembly is attached to the motor frame with three locking screws. The motor

consists of a DC brush-type, iron-less core motor with attached gearbox and integral

tachometer built into the motor. An extension is attached to the motor shaft to mesh with

the cartridge rotor (see Figure 4-4, Motor Assembly).

All motors are tested at the factory and a resistor may or may not be added to make all

motors electrically interchangeable. If a resistor is installed, the white/red wire is attached

to the resistor lead and the yellow wire is not present.

Note: The Portescap 22N motor has replaced the 22C motor for use in the APM and

APM II. These motors are not interchangeable. Motor assemblies using 22N must

have an encoder PCB attached. To upgrade to a 22N motor, see Section 7.2.4.1, PCB

Modification for the 22N Motor.

430-85656-005 (Rev. 03/05) 4 - 4 APM and APM II Infusion Pumps

Page 30

4.1 GENERAL DESCRIPTION

4.1.3.1

MOTOR GEARBOX

The motor gearbox contains a 128:1 gear reduction to transform the relatively high speed,

low torque output of the motor to the slower speed, higher torque requirements necessary

to drive the rotary peristaltic cartridge pumping mechanism. The pump drive motor is

driven at various speeds, depending on the rate programmed.

4.1.3.2

MOTOR TACHOMETER

The tachometer consists of a disk mounted on the motor shaft on the end of the motor

opposite the gearbox. The flat surface of the disk is dark colored (not light-reflective) over

approximately 180 degrees of rotation and is light colored (light-reflective) over the

remaining 180 degrees of rotation. A side-by-side, light emitting diode (LED) and

phototransistor pair is mounted over the surface of the disk, such that the light beam

from the LED shines on the disk, and the phototransistor receives the reflected light from

the disk.

As the disk rotates, the phototransistor receives high and low levels of light reflected,

depending on whether the light or dark area of the disk is closest to the phototransistor.

The output of the phototransistor is connected to an electronic circuit that transforms the

light-to-dark-to-light transitions into pulses that correspond to motor turns. For each 128

pulses, or motor turns, the gearbox output shaft going to the cartridge completes one full

turn, resulting in a fluid delivery of approximately 0.0876 milliliters (mL). The pump’s

software keeps track of volume of fluid delivered by counting pulses.

4.1.3.3

MOTOR SHAFT EXTENSION

The motor shaft extension is cast with splines that mesh with the rotor in the cartridge

set. The motor shaft extension is attached to the motor with a set screw.

Technical Service Manual 4 - 5 430-85656-005 (Rev. 03/05)

Page 31

SECTION 4 THEORY OF OPERATION

SET SCREW

GEARBOX

MOTOR

TACHOMETER

1 = Black

1

2 = Wht/Rd

3 = Orange

WIRING DETAIL

*NOTE: YELLOW WIRE WILL NOT BE

PRESENT IF RESISTOR IS ON MOTOR

TYRAP®

9-PIN

CONNECTOR

HOUSING

6

4

5

6 = Red

2

3

5 = Green

4 = Yellow*

MOTOR SHAFT EXTENSION

Figure 4-4. Motor Assembly

2 = Yellow

3 = Wht/Rd

6 = Green

7 = Orange

8 = Red

9 = Black

1

2

3

4

5

6

7

8

9

05K04035

430-85656-005 (Rev. 03/05) 4 - 6 APM and APM II Infusion Pumps

Page 32

4.1 GENERAL DESCRIPTION

4.1.4

OPTICS ASSEMBLY

The optics assembly is attached to the motor frame with two screws. The optics assembly

consists of a carrier that holds two mounted LED/phototransistor pairs and four optics

surfaces (see Figure 4-5, Optics Assembly). The LED/phototransistor pairs detect air in

line and occlusion conditions by reflecting infrared light beams off a sensing chamber

within the cartridge. In order to function correctly, the optics surfaces must be kept clean

and free of scratches, which could impede light transmission, and the cartridge must be

inserted correctly so that the sensing chamber of the cartridge aligns properly with the

optics detectors.

The LED/phototransistor pairs, functioning properly with the cartridge sensing chamber,

perform the following functions.

4.1.4.1

AIR IN LINE DETECTION

When fluid is present in the cartridge it diffuses light from the LED, thus the air-detection

phototransistor receives relatively low levels of light and remains in the OFF state. When

air is present in the sensing chamber of the cartridge, however, the air behind the surface

of the sensing chamber makes the sensing chamber behave as a mirror, reflecting much

of the light from the LED to the phototransistor. Presence of air thus causes the

air-detection phototransistor to go further into conduction. In summary, air-detection

phototransistor ON = air in line condition.

4.1.4.2

OCCLUSION DETECTION

When no occlusion condition is present, light from the LED reaches the occlusion

phototransistor, driving it further into conduction. When a distal occlusion condition is

present, cartridge rotation causes fluid pressure to expand a small balloon segment within

the cartridge-sensing chamber. When the balloon expands sufficiently such that a

significant amount of the balloon surface touches the plastic on the inside of the sensing

chamber, the mirror surface becomes less reflective. An occlusion condition therefore

results in a decrease in occlusion phototransistor drive and causes the transistor to go

further out of conduction. In summary, occlusion phototransistor OFF = occlusion

condition.

4.1.4.3

CARTRIDGE INSTALLATION

When no cartridge is installed in the pump, or the cartridge is incorrectly installed or

defective, and the pump has been placed in the run mode, the occlusion-detection

phototransistor

occlusion alarm is displayed for any interruption of the light beam.

pair activates a check cartridge alarm. Once the pump is running, the

LED/

Technical Service Manual 4 - 7 430-85656-005 (Rev. 03/05)

Page 33

SECTION 4 THEORY OF OPERATION

OCCLUSION

PHOTOTRANSISTOR

TOP VIEWBOTTOM VIEW

WIRING

AIR

PHOTOTRANSISTOR

OCCLUSION

LED

OPTICS

SURFACES

AIR LED

Figure 4-5. Optics Assembly

FLOW DIRECTION

01K04012

430-85656-005 (Rev. 03/05) 4 - 8 APM and APM II Infusion Pumps

Page 34

4.2 ELECTRONIC SYSTEM OVERVIEW

4.2

ELECTRONIC SYSTEM OVERVIEW

The basic electronic system consists of the following components (see Figure 4-6, Circuit

Block Diagram).

❏ Microprocessor ❏ Tachometer

❏ External EPROM ❏ Motor Drive

❏ Port Expander ❏ D/A Converter

❏ External Timer ❏ Optics Interface

❏ Alphanumeric Display Module ❏ Serial EEPROM

❏ Power Supply ❏ Isolated Printer Interface

A particular pin of a component is identified by appending the pin number to the

component designator with a dash. For example, integrated circuit 10, pin 8 is written as

U10-8.

4.2.1

PRINTED CIRCUIT BOARD

Table 4-1, PCB Reference Designators, lists reference designators on the printed circuit

board (PCB) assembly.

Table 4-1. PCB Reference Designators

BT battery MOT motor

C capacitor PCB printed circuit board

D diode Q transistor

E enable test point R resistor

F fuse SP speaker or beeper

J jack T transformer or transducer

JP jumper TP test point

L inductor U integrated circuit

LED light emitting diode X crystal

Technical Service Manual 4 - 9 430-85656-005 (Rev. 03/05)

Page 35

SECTION 4 THEORY OF OPERATION

4.2.1.1

MICROPROCESSOR AND EXTERNAL EPROM

The CMOS microprocessor, with internal EEPROM, counter/timers, RAM, and A/D

converter, is configured in the expanded multiplexed mode, which utilizes an external

EPROM for program memory (64 KB x 8 bit). The address latch demultiplexes the

multiplexed lower eight bits of the address/data buss into address bits A0 through A7.

The microprocessor has a number of general-purpose I/O ports used to interface to the

motor control and monitoring circuits.

The major digital modules of the circuit are interfaced to the main address and data busses

of the microprocessor, and are thus considered to be memory mapped. Each digital

peripheral device has its unique address and is addressed just like external memory. The

microprocessor can be placed in two different low-power modes to extend battery life.

4.2.1.2

PORT EXPANDER

Because the number of port lines available on the microprocessor is not sufficient to

interface to the entire system, the port expander was added to increase the total number

of available ports. The port expander essentially replaces port lines that are lost to address

and data lines because the microprocessor is configured in the expanded multiplexed

mode. The 24-key keypad is interfaced to the system via the port expander ports. The

remote bolus switch jack is also interfaced to these ports.

4.2.1.3

EXTERNAL TIMER

An external timer is utilized (in addition to the timers internal to the microprocessor) to

maintain the current time and date and to generate timing interrupts to the

microprocessor. Because the timer operates on only a 32 kilohertz (kHz) crystal, and the

microprocessor on a 2 megahertz (MHz) crystal, the timer can operate at much lower

standby currents than the microprocessor to greatly extend battery life. The

microprocessor can be put in the stop mode without interrupting the external timer. The

timer automatically switches over to an internal backup battery when the 5.0 V supply

provided by the power circuit is no longer present.

4.2.1.4

ALPHANUMERIC DISPLAY MODULE

The alphanumeric display is a 16-character-by-2-line LCD module that interfaces to the

address and data busses and provides programming and operating status information to

the user. The module contains all I/O interface and LCD driver circuitry built in on its

own printed circuit board.

430-85656-005 (Rev. 03/05) 4 - 10 APM and APM II Infusion Pumps

Page 36

4.2 ELECTRONIC SYSTEM OVERVIEW

4.2.1.5

POWER SUPPLY

The power circuit provides regulated 5.0 V to most of the devices in the system and also

generates power-fail interrupts and reset signals to the microprocessor under certain

low-voltage operating conditions. Because some of the circuitry is utilized only part of the

time, the power-switching circuit was added to allow the microprocessor to cause power

to be applied to these low-duty cycle use circuits only when needed.

4.2.1.6

TACHOMETER

Motor speed is indicated to the microprocessor via a tachometer and a tachometer interface

circuit. The circuit interfaces to either optical or magnetic Hall-effect type tachometers

and allows power to be pulsed on and off to minimize power consumption.

4.2.1.7

MOTOR DRIVE

The motor drive circuit allows the motor to be driven at various input speeds as determined

by the D/A outputs under microprocessor control. The motor driver provides analog (not

pulsed) DC drive to the permanent magnet DC motor. Because the drive signal is not

pulsed, the motor is driven with a relatively smooth, slowly varying level to maximize brush

and gearbox life. Switching regulator DC-to-DC step-down converter techniques are

utilized to convert the battery voltage to a lower voltage to the motor.

Motor speed is maintained relatively constant by a servo system that utilizes motor voltage

and current information to indicate the motor speed. The motor drive circuit contains

safety circuits to cause shutdown of the motor to prevent runaway in the event of any

single component failure.

4.2.1.8

D/A CONVERTER

To allow the motor to operate at various output speeds, a two-channel, D/A converter is

used to set the speed references for the motor drive circuit. The converter provides two

independent analog outputs to provide a high and low range of motor speed control, for

high (bolus or loading dose) or low rates, respectively.

4.2.1.9

OPTICS INTERFACE

The optics air-detection and occlusion-detection circuits interface to the separate

air-detection and occlusion-detection optics. Both air and occlusion circuits have been

modified to allow microprocessor control over the trip points. The optics interface allows

the optics to be pulsed on and off to minimize power consumption.

Technical Service Manual 4 - 11 430-85656-005 (Rev. 03/05)

Page 37

SECTION 4 THEORY OF OPERATION

4.2.1.10

SERIAL EEPROM

A serial EEPROM interfaces to the microprocessor via port lines and is utilized for

nonvolatile storage of history data that can be reviewed on the display or printed out.

4.2.1.11

ISOLATED PRINTER INTERFACE

An optically isolated RS-232 circuit interfaces the microprocessor port lines to a connector.

The circuit has provision for one serial data line in, one serial data line out, and an input

control line and an output control line.

4.2.2

CIRCUIT DESCRIPTION

This section describes the electronic circuitry, CPU system, and analog circuits. See

Section 9, Drawings, for schematics and PCB assembly drawings.

4.2.2.1

MICROPROCESSOR (CPU)

The heart of the CPU system is the Motorola 68HC11E1FN CMOS microprocessor (U2).

The microprocessor is configured in the expanded multiplexed mode through the pull-up

connections at MODA and MODB inputs. When the microprocessor is reset, both of these

inputs are read as “1’s,” which instructs the microprocessor to go into the expanded

multiplexed mode. Other modes can be initiated at reset by pulling one or both of these

lines low with a clip lead to digital ground. For troubleshooting the address decoder circuit,

initiate mode B testing by grounding TP2.

The oscillator circuit is formed via X1, R13, R11, and C1. The oscillator is a single inverter

parallel resonant type operating at a crystal frequency of 2.00 MHz. The resulting

microprocessor bus speed is 1/4 of the crystal frequency, or 500 kHz. Resistor R13 serves

to bias the single inverter in the 68HC11E1FN somewhere in the linear region of operation.

Resistor R11 acts to limit the drive energy to the relatively low power capacity X1. C1 helps

to establish the correct phase shift for stable oscillation to occur. Since this circuit is

especially vulnerable to even very small amounts of stray capacitance from other

components or runs, the layout of this circuit is extremely critical.

4.2.2.2

ADDRESS LATCH

The multiplexed address/data lines (A/D0 through A/D7) are available on PC0 through

PC7, and the upper address lines (A8 through A15) are available from PB0 through PB7.

Address latch U3 demultiplexes the lower address lines (A0 through A7) from the

multiplexed lines A/D0 through A/D7. The address latch U3 is clocked by the U2 address

strobe (AS) output connected to the G input of U3.

430-85656-005 (Rev. 03/05) 4 - 12 APM and APM II Infusion Pumps

Page 38

4.2 ELECTRONIC SYSTEM OVERVIEW

MOTOR

CKT

DRIVE

MOTOR

HIGH

RANGE

TAC H

_

+

A

CKT

DRIVE

MOTOR

LOW

RANGE

OUTPUT

ANALOG

D/A

2 CH

TAC H

CONV

CKT

SERIAL

EEPROM

ADDRESS

DECODING

AND CONTROL

JACK

PRINTER

RS-232

INTERFACE

OPTICS

OPTICS

PORT LINES

(ANGL & DIG)

INTERFACE

DEVICE

EXTERNAL

INTERFACE

NOT USED)

(APM ll ONLY,

EXT.PWR

DISPLAY

D0-7

PWR SWITCHED CIRCUIT

TO PWR PINS OF

D0-7

FROM

POWER

SWITCHING

POWER

CIRCUIT

9V

BATT

PORTS

FAIL

PWR

Figure 4-6. Circuit Block Diagram

A0-15

EPROM

A0-7

A8-15

D0-7

LATCH

ADDRESS\DATA

RES

A/D07

INT

ANALOG SUPPLY VOLTAGE SENSE

ADDRESS

CPU

D0-7

ADDRESS

INT

A8-15

TIMER

PORTS

BEEPER

BOLUS

SW. INTERFACE

PORT

D0-7

EXPANDER

A12-15

PORTS

JACK

BOLUS

REMOTE

KEYPAD

05K04026

Technical Service Manual 4 - 13 430-85656-005 (Rev. 03/05)

Page 39

SECTION 4 THEORY OF OPERATION

4.2.2.3

PROGRAM MEMORY

Program memory is stored in a 64 KB x 8 bit CMOS EPROM (27C512), U4. The address

decoding for U4 is accomplished by U17A and U14F. Any address of 1000 H or greater

enables gate U7B to cause the U4 chip enable input to pulse low when E clock and Read

are simultaneously high. Thus U4 is chip selected for any read operation whose address

is 1000 H through FFFF H.

4.2.2.4

PORT EXPANDER

The address decode for the port expander U1 consists of U14C and internal decoding from

A12 through A15. Following reset, U1 is addressed as 12XX, 13XX, 16XX, 17XX H, etc.,

but th e sof t wa r e r e p ro g ra m s U 1 to a n a d dr e ss of 02XX, 03XX, etc. The port expander adds

two extra 8-bit ports to the system as PC0 through PC7 and PB0 through PB7. Note that

reset on U1 is connected to the same reset as U2, so that both ICs are reset simultaneously.

4.2.2.5

EXTERNAL TIMER

U9, U7C, U8B, and associated inverters decode the address for the timer. U9 decodes the

address 08XX H, where U7 defines the lower two nibbles to be in the range of 00 H to 1

FH. U8 decodes the total address to thus be in the range of 0800 H to 081 FH. The RD

and WR control lines with proper timing are generated by summing the E clock from U2

with read or write, respectively, via U8C and U8D. 1M pull-up resistors such as R17, R15,

and R16 pull up control lines to maintain the U5 power consumption low when the 5.0 V

supply is not present. When the 5.0 V supply drops below a preset threshold, U5 contains

internal circuits that automatically switch the U5 ground circuit to the negative side of

the three volt lithium backup battery BT1. Address lines A0 to A4 are connected directly

to the multiplexed address/data bus, because U5 contains its own address latch clocked

by the U2 address strobe (AS) connected to the U5 ALE input.

The oscillator circuit for U5 consists of components X2, C7, and C8. C7 is an adjustable

trimmer capacitor to allow trimming the time base for minimal timing error. The oscillator

circuit is similar to the microprocessor oscillator (U2), except that the frequency and

resultant power consumption is much lower. The U5 oscillator circuit is also susceptible

to coupling from other components or traces. The effective ground for the U5 oscillator is

5.0 V. Interrupts to the microprocessor can be generated through pin 6 of U5 via an open

drain output pulled up by R12.

4.2.2.6

LCD ALPHANUMERIC DISPLAY MODULE

U6 and U7A perform address decoding for the LCD module. U6 combines the decode of

08XX from U9 with the decode of XX20 to XX23 to result in a decode of 0820 to 0823.

When this is ANDed with A1

0821 to the display from U8A. The ANDing of E clock with the address decode assures

that only stable address decode, glitch-free enable pulses are presented to the enable

display input. The display is configured to operate in a 4-bit mode with only the upper

four data bits being connected to the display — DB4 to DB7. U12 serves as a switch for

the bidirectional-directional AD4 to AD7 lines to allow these lines to be effectively

disconnected from the display when the display power is shut off.

via U7A and E clock, the final resultant decode is 0820 to

430-85656-005 (Rev. 03/05) 4 - 14 APM and APM II Infusion Pumps

Page 40

4.2 ELECTRONIC SYSTEM OVERVIEW

Display power is shut off by the microprocessor when the display is not needed in order

to minimize 5.0 V drain current. Power to the display can be turned on and off via PB5

(DISPLAY PWRON) from the microprocessor. When power to the display is shut off, gates

U13A to U13C cause the control lines to the display to go to zero volts. Transistor Q7

functions as the power switch to the display to turn the display’s V

power on and off.

DD

The RC and diode networks (C29, R49, D7; and C30, R50, and D6) function as time-delay

circuits to assure that all signal lines to the display are either at 0 V or floating before V

DD

to the display is shut off. When VDD is turned back on, the delay circuits allow VDD to be

applied to the display before signal lines become active. These delays are necessary to

prevent latchup in the display when switching display power on and off.

4.2.2.7

D/A CONVERTER

Address decoding for the D/A converter is the same as address decoding for the display

as described above, except that A1 is used in place of A1

0822-23 for the DAC. Address bit A0 determines whether the A or B section of the

two-channel D/A converter is addressed, thus 0822 addresses section A and 0823

addresses section B of the DAC. The WR

input clocks the DAC when WRITE and Eclock

are both high, with the same signal that clocks the WR

to give the resultant address of

of the timer.

4.2.2.8

KEYPAD

The keypad interfaces to the microprocessor via port expander ports PC0 to PC5 and PB0

to PB4. The four columns of the keypad are driven by output ports PB03, and the six rows

are read by input ports PC05. Diodes D20 through D23 are in series between the column

drive and the actual column of the keypad for isolation that prevents conflicts should two

or more keys in the same row be pressed simultaneously. PB4 is an extra output used

currently only to drive the bolus switch interface, but also serves as a spare column drive

for a fifth column to allow for potential keypad expansion.

Pull-down resistors R31 to R34, R40, and R57 keep the input ports at a 0 level until a key

is pressed and the column drive is pulsed. U15A allows generation of an interrupt to the

microprocessor on IRQ

in row 1, provided that the appropriate column drive for the on/off key is high. The

keyboard interrupt is used to allow the microprocessor to be removed from stop mode to

turn the system from off to on. U13D ORs the keyboard-generated interrupt with the

interrupt from the timer to cause an interrupt to the microprocessor on IRQ

keyboard or a timer interrupt.

U15B and U15C are added as interface buffers to either the bolus switch or the remote

bolus jack. R121, R56, R55, and C34 serve as a low-pass filter to attenuate potential noise

or ESD pickup from the remote bolus switch. U15B and U15C further isolate any ESD or

noise from the microprocessor port inputs. U15C will pulse high whenever the bolus switch

is pressed and Column 4 drive is pulsed simultaneously. Diode D4 prevents U15C from

holding row 4 drive in the low state when U15C is in its normally low-output state.

when the interrupt is enabled via PB7 and the on/off key is pressed

for either a

Technical Service Manual 4 - 15 430-85656-005 (Rev. 03/05)

Page 41

SECTION 4 THEORY OF OPERATION

4.2.2.9

BATTERY POWER CIRCUIT

Input power from the two 9 V alkaline batteries or rechargeable battery pack is routed

through diodes D1 and D2. These diodes prevent circuit damage in the event of an incorrect

battery polarity and also prevent one battery from loading down or shorting out the other

in case the two batteries are at different states of depletion and voltages (e.g., a new battery

being paired with a depleted battery). These are Schottky diodes for minimal voltage drop.

C20 provides low ESR filtering against fluctuations on the V_PWR line caused by such

loads as pulses from the motor drive circuits, tachometer or optics circuits, or display

LCD. R53, R54, and C65 form an attenuator and low-pass filter to allow the

microprocessor’s A/D port PE6 to sample the supply voltage. The attenuator attenuates

by a factor of 0.3651 so that a 13.7 V supply voltage results in a 5.0 V input to the A/D

(maximum input range). The low-pass filter serves to average out voltage fluctuations so

that the microprocessor reads a sample of the average battery voltage.

Power can also reach the V_PWR line from an external power supply coupled to D5. D1,

D2, and D5 provide isolation between the battery voltage and the external power supply.

Normally, the power supply voltage (typically 12 V) is higher than the battery voltage, thus

the power supply will override the batteries when it is plugged in and functioning. By

sampling the voltage at PE6, the microprocessor can determine when the pump is

operating on external (AC) power.

The supply voltage is regulated down to 5.0 V by the micropower voltage regulator U11.

C21 provides additional higher frequency regulation and noise suppression on the 5.0 V

bus. C22 provides energy storage and a 5.0 V bus loss-delay in the event of power failure

to allow the microprocessor to store certain information in its internal EEPROM prior to

being reset by the reset circuitry. C32 limits the rate of change of 5.0 V supply voltage

when power is removed and then reapplied to prevent false resets from being issued by

U16.

4.2.2.10

LOW-VOLTAGE DETECTION AND RESET

The dual low-voltage detect IC U16 functions as both a microprocessor reset and a power

fail interrupt to the microprocessor. The reset is generated when the 5.0 V supply is less

than approximately 3.3 V. R25, R26, and R27 form a voltage divider that attenuates the

5.0 V supply voltage down to a voltage to be compared with the approximately 1.3 V internal

reference of U16. C24 provides filtering to prevent any noise pulses on the 5.0 V supply

line from resetting the microprocessor. R58 adds hysteresis to the sensed input VS1 to

prevent ringing of the output at O1 during transitions. When the 5.0 V supply line is below

approximately 3.3 V, O1 will be high, causing transistor Q3 to be driven on, which drives

RESET

resets. It is important that RESET

voltage of approximately 1.0 V, or the point where the microprocessor crystal oscillator

stops running to assure that the microprocessor does not attempt to run at very low supply

voltages and cause corruption of its internal CONFIG register. At very low supply voltages,

the U16 output O1 floats high, resulting in Q3 remaining on down to approximately the

V

low. C37 provides additional filtering against noise pulses causing inadvertent

be held low to the microprocessor down to a supply

cut-in voltage of Q3, or approximately 0.6 V.

BE

Signal V BAT LOW

R23, and R24 function as voltage dividers, and C23 functions as a filter, while R120

provides hysteresis. V BAT LOW

indicate to the microprocessor that the supply power is failing, for example when the user

removes the 9 V batteries and no power supply is connected to the pump.

430-85656-005 (Rev. 03/05) 4 - 16 APM and APM II Infusion Pumps

goes low when the VBATT voltage drops below approximately 6 V. R59,

is connected to the microprocessor’s XIRQ input to

Page 42

4.2 ELECTRONIC SYSTEM OVERVIEW

4.2.2.11

TACHOMETER

The tachometer (encoder) circuit consists of U18 and associated components. This circuit

provides a continuous square wave output to be read by the microprocessor even though

the power supplied to the encoder is not continuous. This circuit allows use of either an

optical or a Hall-effect type encoder. When the LED tachometer is to be used, the LED

anode is connected to pin 6 and cathode to ground. When the Hall-effect sensor is used,

the Hall-effect sensor ground is connected to pin 4 and the Hall-effect supply to pin 5

(+5.0 V). R46 and C28 together determine the operating frequency of U18. R45, R47, and

R48 form a voltage divider to establish a set-point reference for operation of U18 at its SET

input (pin 3). R48 sets a hysteresis level (

operation. The collector output from the phototransistor in the encoder is pulled up by

R44 and connected to the V

approximately every 4 ms, turns on transistor Q8, and drives the tachometer LED ON.

Shortly after V

then the OUT pin will be low for the next cycle. If V

pulses high, U18 samples VIN. If VIN is higher than the SET input plus ∆,

PP

(pin 2) of U18. The VPP output of U18 pulses high

IN

∆) above and below this selected set point of

is lower than the SET input minus

IN

∆, then OUT will be high for the next cycle.

4.2.2.12

MOTOR DRIVE AND SPEED CONTROL

The following sections describe the functioning of the motor:

❏ D/A Converter Output ❏ Servo Error Amplifiers

❏ Motor Speed ❏ DC-to-DC Switching Regulator

❏ Current Sensing ❏ Runaway Prevention Circuits

4.2.2.12.1

D/A Converter Output

The current outputs of the D/A converter U20 are converted to voltages by U21A and

U21C, which work in conjunction with internal resistors in U20. The output voltages at

U21A and U21C are directly proportional to the value written to the D/A converter. Full

scale (FF) at the converter produces an output voltage of 5.0 V.

4.2.2.12.2

Motor Speed

The voltage applied to the motor at any given time is equal to the sum of the back EMF

generated by the motor plus the IR drop across the motor winding resistance. In other

words, the speed of the motor can be determined from the motor applied voltage and the

current through the motor, since the motor constant and motor resistance are known fixed

quantities. In this circuit, the set-point speed is established by the DA voltage outputs

from U21A or U21C. U21A is utilized to determine the high-speed range of the motor, while

U21B sets the low-speed range. This set-point speed is constantly compared to the

measured speed. The servo system raises or lowers the applied motor voltage to attempt

to maintain the speed at the set point. For example, if the motor current increases due to

increased torque loading, then voltage increases by the same amount as the resulting

increase in the IR drop.

Technical Service Manual 4 - 17 430-85656-005 (Rev. 03/05)

Page 43

SECTION 4 THEORY OF OPERATION

4.2.2.12.3

Current Sensing

Current sensing for the motor is accomplished by U34B and associated components. R71

serves as a current sensing resistor to convert motor current to a voltage (1 mA results in

1 mV of sensed voltage). Noninverting operational amplifier U34B amplifies this voltage

with a gain of 40, as determined by the ratio of R61/R60. Capacitor C40 and resistor R61

together act as a low-pass filter to smooth out fast fluctuations in motor current, which

results in a voltage proportional to an average motor current at U34 to U37. This output,

in addition to being used by the motor speed controller is also fed back to an A/D input

on the microprocessor for checks of motor current under software control.

4.2.2.12.4

Servo Error Amplifiers

Summing and inverting amplifier U34A sums the DA set-point voltage V

and motor

SET

current I, such that the output at U34A is as follows:

(high range) - (K1)(V

(low range) - (K1)(V

)(K2)(I) = -.411 V

set

)(K2)(I) = -.182 V

set

- 7.27 I

set

- 7.27 I

set

Assuming the total resistance in the motor circuit consisting of winding resistance plus

the Rds ON resistance of Q12 equals 24.2 Ω, then (24.2)(I) represents the IR drop across

the motor and drive transistor Q12. Note from the equation above that V-IR can be written

in terms of motor speed.

For the Portescap 12 V winding motor, and 128:1 gearbox, the relationship is as follows:

S= 4.88 (V-IR)

S= output speed (in RPM) at the output shaft of the gearbox

V= motor voltage

I= motor current

R= motor resistance

U21B inverts the normally negative voltage output signal from U34A to provide a positive

voltage to the negative input of U35A, or:

(high range) U35A = .411 V

(low range) U35A = .182 V

+ 7.27 I

SET

+ 7.27 I

SET

When the servo system is in regulation, the voltage at U35(2) will match the voltage at

U35(3). Considering just the high range:

.411 V

+ 7.27 I = .333 V + VOS where VOS is an offset voltage = .0699 V (from

SET

R98)

or, after rearranging:

.333 V - 7.27 I = .411 V

430-85656-005 (Rev. 03/05) 4 - 18 APM and APM II Infusion Pumps

SET

- .07

Page 44

4.2 ELECTRONIC SYSTEM OVERVIEW

14.65 (.333 V - 7.27 I) = 14.65 (.411 V

4.88 (V-21.8 I) = 6.02 V

SET

-1

SET

- .07)

Substitute S = (4.88)(V-IR) in the above equation set and assume R = 21.8 Ω, then:

(high) S = 6.02 V

- 1 where S = motor shaft speed in RPM and V

SET

= U21A D/A

SET

output voltage in volts,

or

(low) S = 1.95 V

The output of the D/A amplifier V

SET

-1

= 5 (D/255) V, where D is the decimal value written

SET

to the D/A converter, from 0 to 255 DEC. Therefore:

(high range) S = (.118)D - 1

(low range) S = (.0382)D - 1

4.2.2.12.5

DC-to-DC Switching Regulator

The voltage to the motor is generated by a DC-to-DC switching regulator converter

consisting of U35, Q11, L1, D10, and associated components. The switching regulator

technique minimizes power losses in the drive to the motor.

Q11 is driven into saturation or completely off by the output from U35A. The U35A output

pulses low whenever the negative input is greater than the positive input. When Q11 is

on, current flows from the power source (either battery or power supply), through L1 and

charges C43 to a higher voltage. When Q1 is on, L1 causes the current to ramp up

approximately linearly to its peak value. When the voltage at the motor reaches the desired

servo voltage, the positive (+) input to U35A will go higher than the negative (-) input, and

the U35A output will go to a high level near V_PWR, thus shutting off Q11. When Q11

shuts off, the current flow continues through the free-wheeling diode D10, and the current

begins to linearly ramp down to some minimum value.