Page 1

Section

7,

7.6

Replaceable

Parts

and

Repairs

Optics

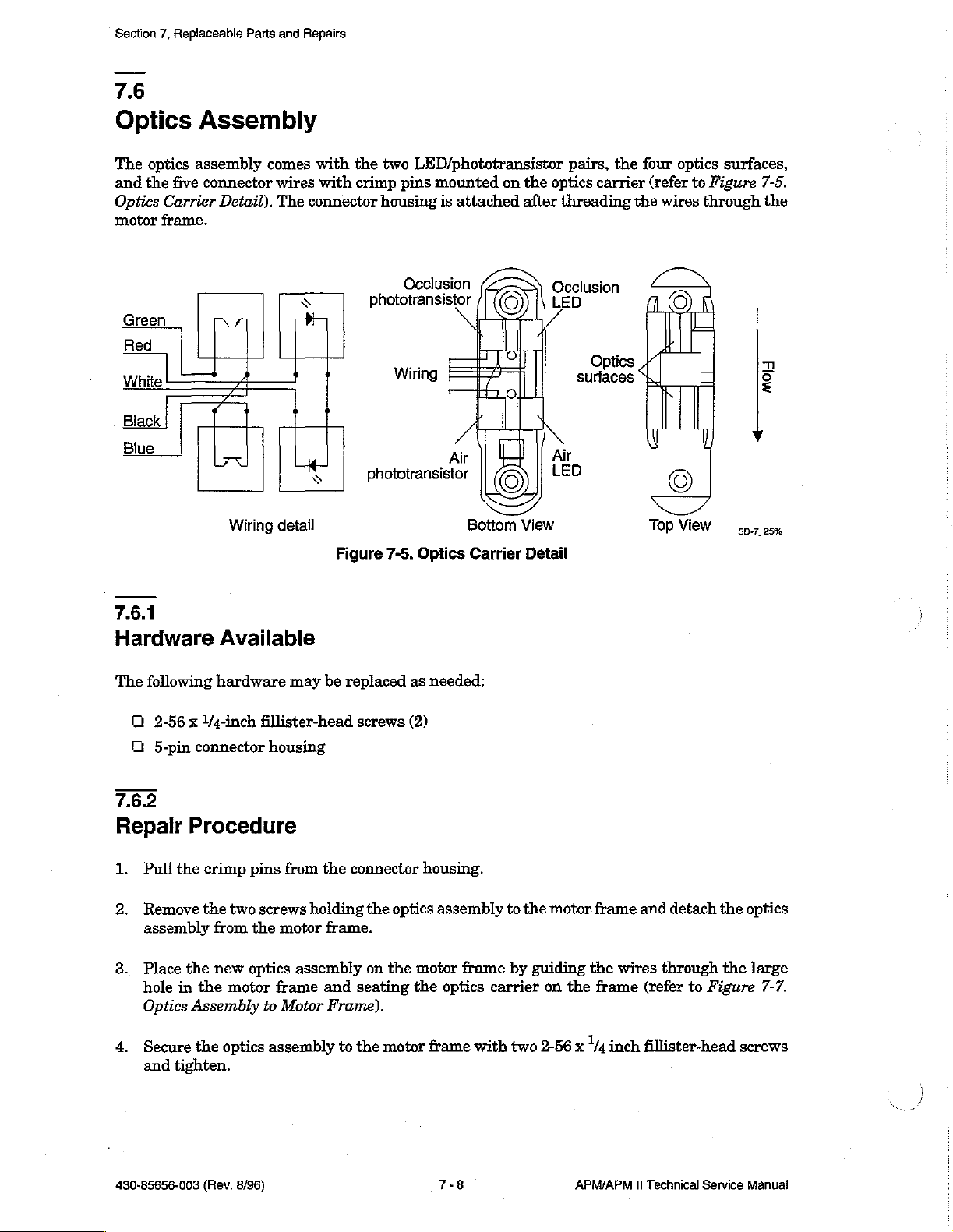

The

optics

and

the

five

Optics

motor

Green

Blue

frame.

Red

White

Black

Carrier

Assembly

assembly

connector

Detail).

Mí]

Wiring

comes

wires

The

detail

with

with

connector

<

Di

さ

Figure

the

two

LED/phototransistor

crimp

pins

mounted

housing

phototransistor

is

attached

Occlusion

Wiring

Air

phototransistor

Bottom

7-5.

Optics

Carrier

on

the

after

©

o

o

©

View

Detail

pairs,

optics

carrier

threading

Occlusion

Optics

surfaces

Air

LED

the

four

(refer

the

wires

y

T т

©

Top

optics

to

Figure

through

©

|

|

日

View

surfaces,

7-5.

the

n

2

725%

7.6.1

Hardware

The

following

Q

2-56 x l/4-inch

ロ

5-pin

connector

7.6.2

Repair

1.

2.

8.

4.

Procedure

Pull

the

Remove

assembly

Place

the

hole

in

the

Optics

Assembly

Secure

and

the

tighten.

Available

hardware

fillister-head

housing

crimp

pins

the

two

screws

from

the

motor

new

optics

motor

optics

frame

to

Motor

assembly

may

be

from

the

holding

frame.

assembly

and

Frame).

replaced

screws

connector

the

on

the

seating

to

the

motor

as

needed:

(2)

housing.

optics

motor

the

frame

assembly

frame

optics

carrier

with

to

by

two

the

guiding

2-56

motor frame

the

wires

on

the

frame

x 1/4

inch

and

detach

through

(refer

fillister-head

to

Figure

the

the

screws

optics

large

7-7.

430-85656-003

(Rev.

8/96)

7-8

APM/APM

II

Technical

Service

Manual

Page 2

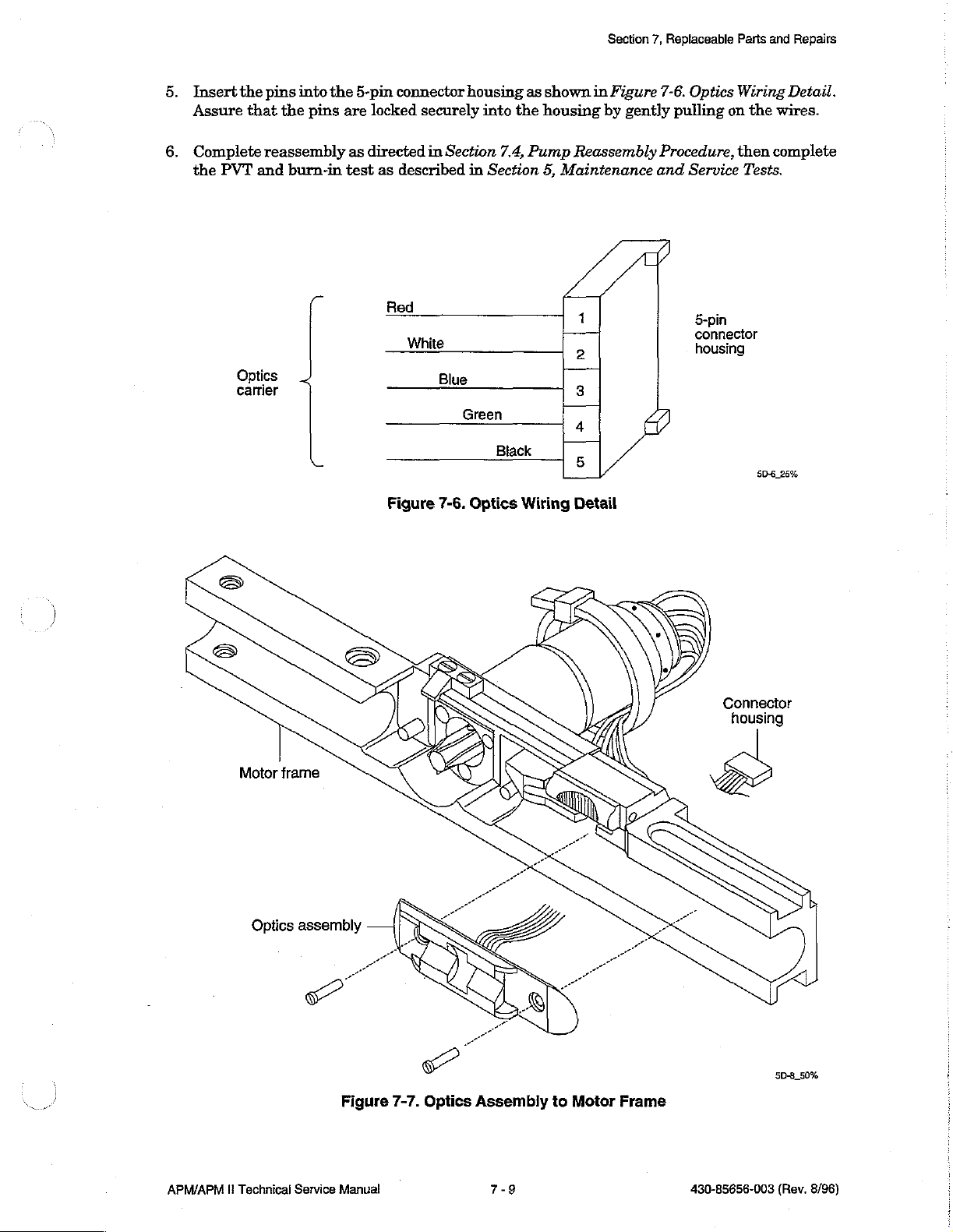

Insert

Assure

the

that

pins

the

into

pins

the

are

5-pin

locked

connector

securely

housing

into the

as

shown

housing

Section

in

Figure

by

7,

Replaceable

7-6.

gently

Optics

pulling

Parts

Wiring

on

the

and

Repairs

Detail.

wires.

Complete

the

PVT

Optics

carrier

reassembly

and

burn-in

as

directed

test

as

—Nhite

in

described

Red

i

-一

Figure

Blue

7-6.

Section

in

Section

Green

Optics

7.4,

Black

Wiring

Pump

Reassembly

5,

Maintenance

|

人

4

Detail

1

2

3

5

Procedure,

and

Service

5-pin

connector

housing

then

Tests.

5D-6_25%

complete

Motor

frame

Optics

assembly

Figure

7-7.

Optics

Assembly

to

Motor

Frame

Connector

housing

5D-8_50%

APM/APM

li

Technical

Service

Manual

7-9

430-85656-003

(Rev.

8/96)

Page 3

Section

77

7,

Replaceable

Parts

and

Repairs

Motor

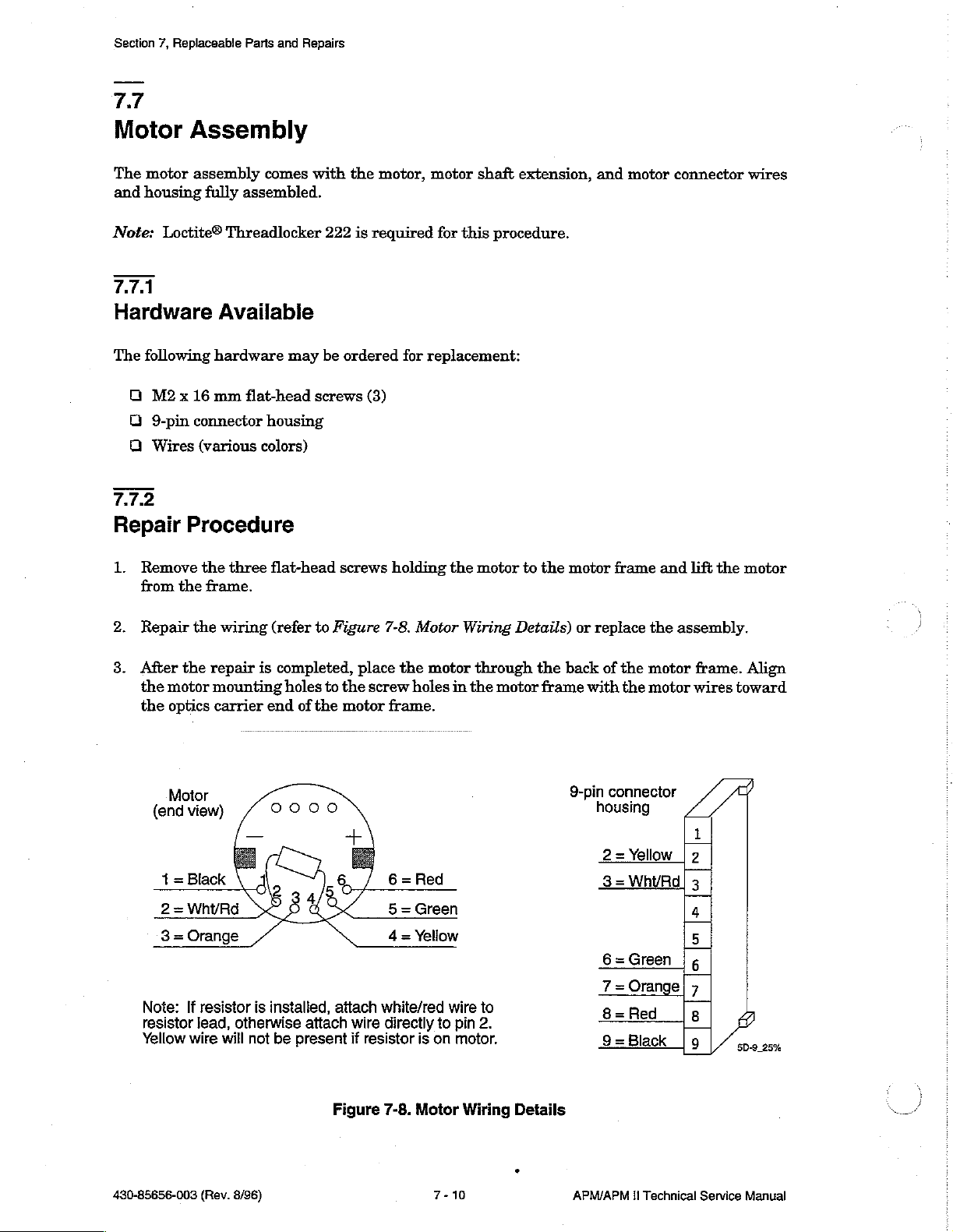

The

motor

and

housing

Note:

7.7.1

Hardware

The

7.7.2

Repair

1.

Loctite®

following

Q

M2 x 16

С

9-pin

Q

Wires

Remove

from

the

Procedure

Assembly

assembly

fully

Available

hardware

mm

connector

(various

the

frame.

comes

assembled.

Threadlocker

flat-head

housing

colors)

three

flat-head

may

with

the

222

be

ordered

screws

screws

motor,

is

required

(3)

holding

motor

for

this

for

replacement:

the

shaft

extension,

procedure.

motor

to

the

and

motor

motor

frame

connector

and

lift

the

wires

motor

2.

3.

Repair

After

the

the

Note:

resistor

Yellow

the

wiring

the

repair

motor

mounting

optics

carrier

Motor

view)

(end

Black

=

1

WhyRd

=

2

resistor

If

lead,

will

wire

(refer

is

completed,

holes

end

installed,

is

otherwise

be

not

to

Figure

to

of

the

attach

attach

present

place

the

screw

motor

wire

resistor

if

7-8.

Motor

the

motor

holes

frame.

white/red

is

to

on

directly

Wiring

through

in

the

wire

pin

motor.

motor

to

2.

Details)

the

back

frame

9-pin

or

replace

of

with

connector

housing

=

2

3=WhyRd|

6=Green

7=Orange|

=

8

TTT]

9=Black

the

the

Yellow

Red

the

assembly.

motor

motor

|

frame.

wires

1

2

3

4

5

is

7

8

|9

Align

toward

25%

SD

430-85656-003

(Rev.

8/96)

Figure

7-8.

Motor

7-10

Wiring

Details

APM/APM

il

Technical

Service

Manual

Page 4

Section

7,

Replaceable

Parts

and

Repairs

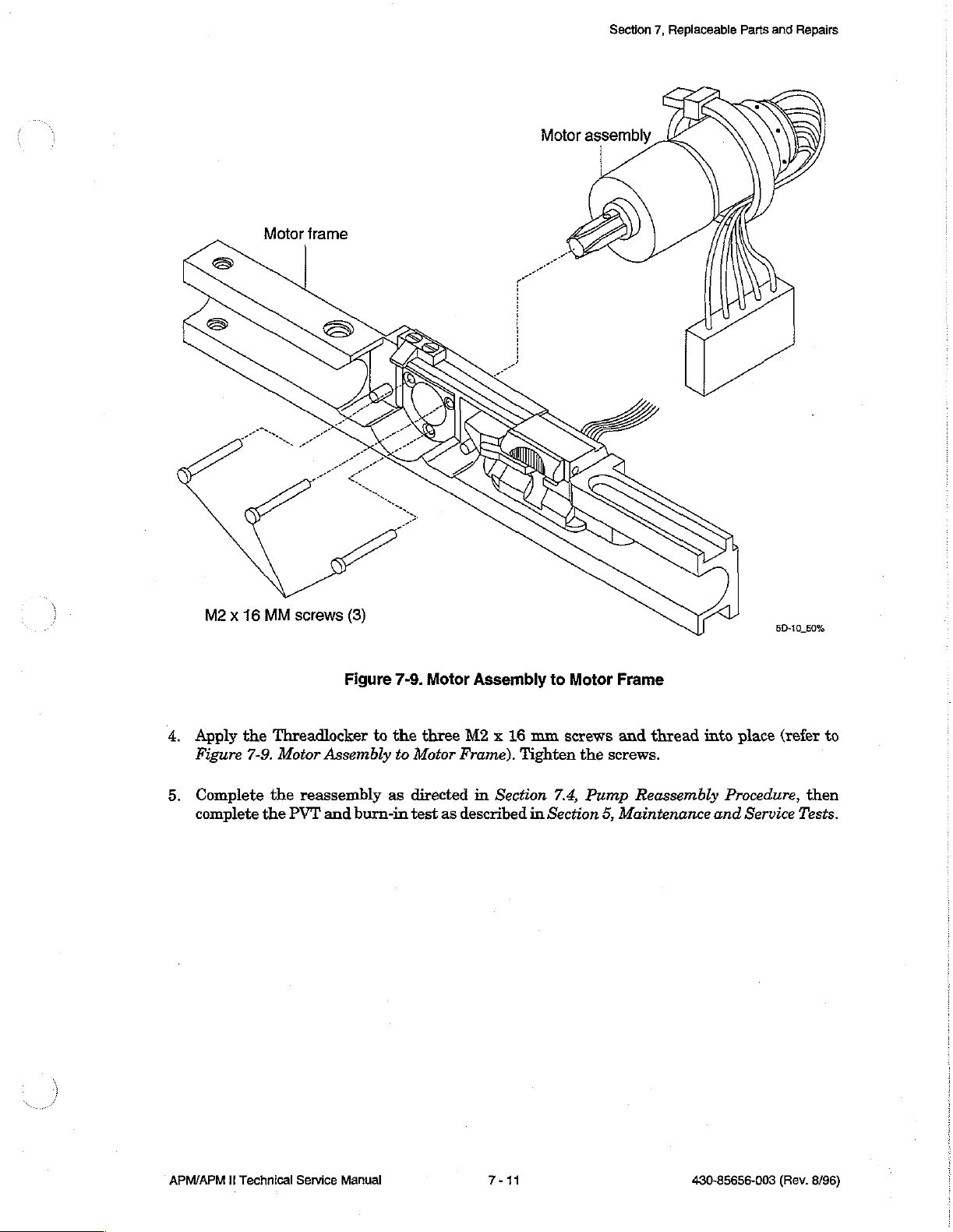

Motor frame

M2 x 16

MM

screws

(3)

5D-10

50%

4.

Apply

Figure

5.

Complete

complete

the

Threadlocker

7-9.

Motor

the

reassembly

the

PVT

Figure

to

Assembly

and

burn-in

7-9.

the

three

to

Motor

as

directed

test

Motor

Frame).

as

described

Assembly

M2 x 16

Tighten

in

Section

to

mm

7.4,

in

Section

Motor

serews

the

Pump

5,

Frame

and

thread

screws.

Reassembly

Maintenance

into

place

Procedure,

and

Service

(refer

then

Tests.

to

APM/APM

1!

Technical

Service

Manual

7-11

430-85656-003

(Rev.

8/96)

Page 5

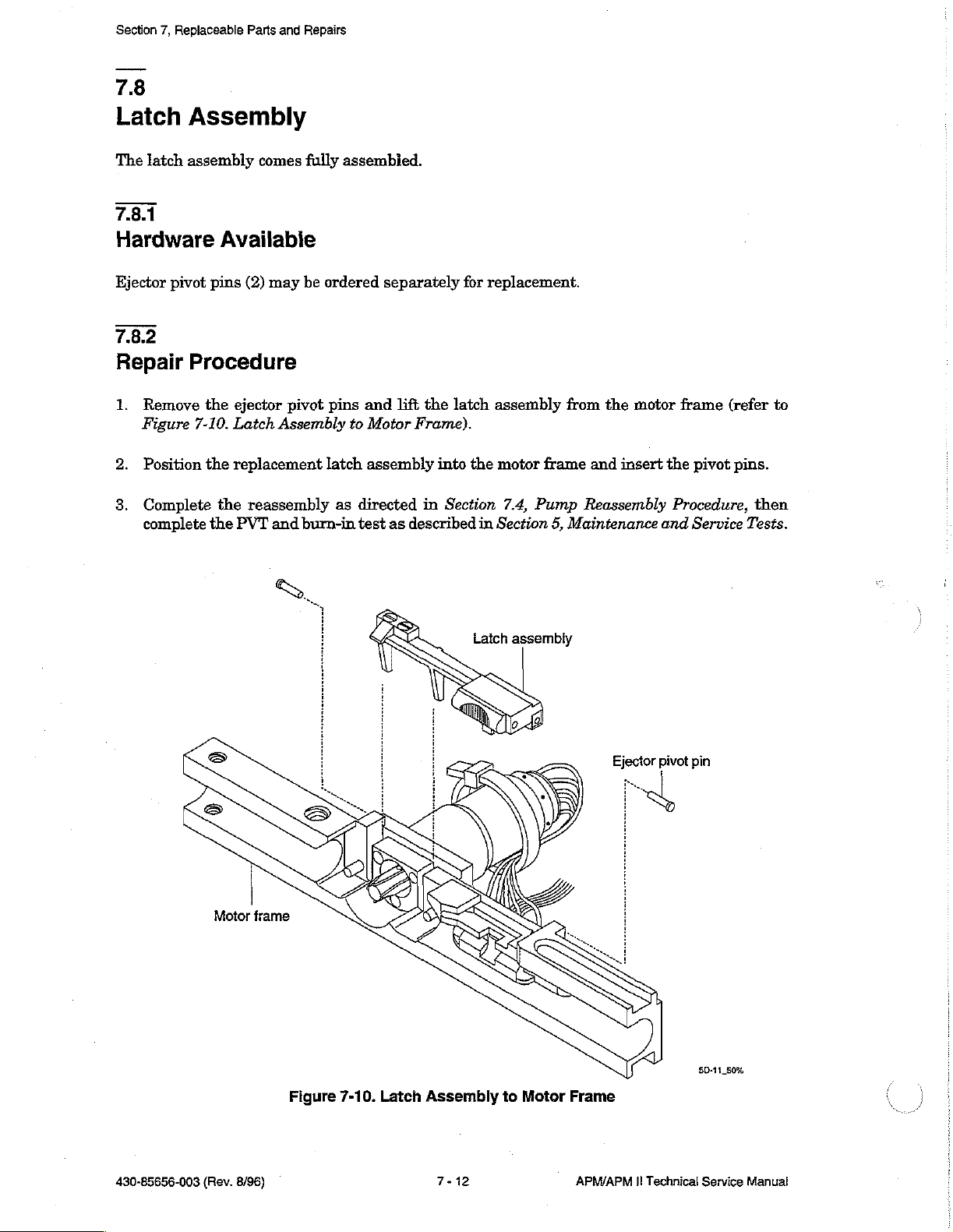

Section

7.8

7,

Replaceable

Parts

and

Repairs

Latch

The

7.8.1

Assembly

latch

assembly

Hardware

Ejector

7.8.2

Repair

1.

2.

8.

pivot

Procedure

Remove

Figure

Position

Complete

complete

7-10.

comes

Available

pins

(2)

may

the

ejector

Latch

the

replacement

the

the

PVT

pivot

Assembly

reassembly

and burn-in

fully

be

ordered

pins

latch

as

assembied.

separately

and

lift

to

Motor

Frame).

assembly

directed

test

as

described

for

the latch

into the

in

Section

in

replacement.

assembly

motor frame

7.4,

Section

from

Pump

5,

Maintenance

the

motor

and

insert

Reassembly

frame

the

pivot

Procedure,

and

Service

(refer

pins.

then

Tests.

to

430-85656-003

Motor

(Rev.

frame

8/96)

Figure

7-10.

Latch

Assembly

7-12

to

Motor

Frame

APM/APM

Ejector

Il

Technical

pivot

pin

$D-11

50%

Service

Manual

Page 6

7.9

Section

7,

Replaceable

Parts

and

Repairs

PCB

The

schematics

7.9.1

Assembly

PCB

assembly

and

Components

The

following

O

Beeper

O

Bolus

O

12-VDC

Q

Lithium

A

LCD

components

Jack

Power

Battery

Module

7.9.2

Materials

Soldering

RTV

is

used

Required

iron

and

to

comes

drawings

Available

Jack

solder

reattach

the

fully

assembled

of

the

may

are

used

resonator

APM

be

replaced

to

replace

and

and

APM

individually:

bolus

to

the

PCB

tested.

II

printed

jack,

when

Refer

to

circuit

power

replacing

Section

boards.

jack,

lithium

the

9,

Drawings,

battery,

beeper.

for

detailed

and

beeper.

7.9.3

Repair

CAUTION:

methods

Replace

PCB

Pump

5,

7.9.3.1

Beeper

1.

2.

8.

4.

individual

assembly

Reassembly

Maintenance

Remove

Remove

Place

Apply

Procedure

The

PCB assembly

while

working

components

or

any

Procedure,

and

Service

resonator

solder

replacement

RTV

and

to

resonator.

is

with

the

as

individual

then

Tests.

from

around

lift

beeper

beeper

on

PCB

Replace

electrostatic

PCB.

described

component,

complete

beeper.

off

of

and

the

in

the

Clean

the

PCB.

solder

resonator

sensitive.

the

following

complete

PVT

and

off

old

in

place

around

Use

ESD

sections.

reassembly

burn-in

adhesive

(refer

to

Figure

the

beeper

safety

After

as

test

from

and

replacing

directed

as

described

around

7-11.

PCB

then

seat

precautionary

the

entire

in

Section

resonator.

Back

on

the

in

Section

Detail).

board.

7.4,

APM/APM

II

Technical

Service

Manual

7-13

430-85656-003

(Rev.

8/96)

Page 7

Section

7,

Replaceable

Parts

and

Repairs

(6P)

Moe[

Jemod

(LdS)

Jedeeg

(kr)

Jonoeuuoo

Aepeg

토로

5

O

(80)

HERE

αμ

ln

hi

O

Lo

απ.»

Or

L

KA

Lo

OÙ

a

qu

m

co

Nr

al.

圖

ММ

№

за

m

aw

o

o

o

9

o|o

9

fa

E

o

o

o

o

.

ΟΟΟΟΝΙΙΟΟΟΟΟΟΟΟΝΣ

sr

/

7

e

D

(Sp)

Joloeuuoo

soldo

(Ef)

Jojosuuoo

T+

ュー

ン

9

JoJo

ue

(ia)

xoel

snjog

[Fear

=

М

|-

ших

o

圖

IT

-ν

=

GE

a

a

EN

|

ии

=

yul

È

„=

ala

圖

圖

ml

me

o

ο

fc

ниниии

o

ms

a

LI]

8

Figure

η

а

“EE

[E]

인비

=

=

=

=

=

=

|

an

Pon

7-11.

88

a

=

ΗΝ

PCB

Μα

om

TEE

απ.

ea

mun

Back

ши

Calata)

ow

м

sus

a

Detail

ma

ll

画面

Mo

vin

SS

Ce

πι

|

min

3

ği

Tm

1180

"n

슨

자타

EM

gia

圖

13

加

Idi

LIL

on

b

©

SE-3

Aspeg

100%

430-85656-003

(Rev.

8/96)

7-14

APM/APM

II

Technical

Service

Manual

Page 8

7.9.3.2

Bolus

1.

2.

7.9.3.3

12-VDC

1.

2.

Jack

Remove

Place

Detail).

Remove

Place

PCB

7934

Lithium

solder

replacement

Power

the

the

Back

and

Jack

solder

replacement

Detail).

Battery

lift

bolus

bolus

and

lift

12-VDC

jack

jack

the

off

on-PCB

12-VDC

power

of

the

and

power

jack

PCB.

solder

jack

on the

leads

off

PCB

the

and

Section

(refer

PCB.

solder

7,

Replaceable

to

Figure

leads

7-11.

(refer

Parts

to

Figure

and

PCB

Repairs

Back

7-11.

1.

Remove

2.

Place

PCB

7.9.3.5

LCD

1.

Gently

pins.

2.

Assurgtha&the

the

the

replacement

Back

Detail).

solder

and

|

lift

lithium

C

Module — 2720602.

pull

the

LCD

module

connectors

then

snap

the

the

lithium

battery

up

of

the

display

battery

on

the

and

off

of

the

replacement

securely

off

PCB

-

PCB,

LCD

into

of

the

and

uns

being

module

place

PCB.

solder

*

careful

are

(refer

leads

(refer

5342/32

not

to

damage

aligned

to

Figure

with

7-12.

to

Figure

the

LCD

the

guide

guide

Module

7-11.

pins

APM/APM

Guide

(PCB

II

Technical

pins

detail

not

shown)

SE2

(Rev.

259

8/96)

Service

Figure

Manual

7-12.

LCD

Module

7-15

Mounted

on

PCB

430-85656-003

Page 9

Section

7,

Replaceable

7.10

Parts

and

Repairs

Front

The

front

Case

case

7.10.1

Component

Assembly

assembly

Available

comes

fully

Figure

assembled

7-13.

Front

(refer

Case

to

Figure

Assembly

7-13.

,

Front

Case

Assembly).

5B-2

25%

The

LCD

Case).

7.10.2

Repair

After

replacing

directed

as

described

To

replace

1.

Detach

2.

If

necessary,

completely.

8.

Remove

inside

4.

Rub

case.

window

may

Procedure

the

in

Section

in

Section

the

LCD

the

LCD

clean

the

paper

the

front

the

back

of

be

entire

7.4,

Pump

5,

Maintenance

window,

window

the

adhesive

case

facing

the

window

replaced

front

case

Reassembly

proceed

from

the

inner

front

protector

the

to

assure a complete

individually

assembly

Procedure,

and

Service

as

follows:

front

case,

case

surface

from

front.

(refer

or

being

the

to

Figure

the

LCD

window,

then

complete

Tests.

careful

with isopropyl

matte

sealing

not

surface

of

the

7-14.

complete

the

to

damage

alcohol

of

the

window

LCD

PVT

the

LCD

adhesive

Window

reassembly

and

burn-in

case

and

allow

window

to

to

Front

or

keypad.

to

and

the

as

test

dry

place

front

5.

Remove

430-85656-003

the

(Rev.

clear

8/96)

protective

cover

from

the

7-16

smooth

surface

of

the

APM/APM

window.

II

Technical

Service

Manual

Page 10

Section

7,

Replaceable

Bare

front

Parts

case

and

Repairs

Figure.7-14.

LCD

Window

to

Front

Case

5B-1

50%

APM/APM

II

Technical

Service

Manual

7-17

430-85656-003

(Rev.

8/96)

Page 11

Section

7,

Replaceable

Parts

and

Repairs

This

page

intentionally

left

blank.

430-85656-003

(Rev.

8/96)

APM/APM

El

Technical

Service

Manual

Page 12

n

Section

8

Specifications

Physical

Pump

Time

Dimensions:

Weight:

Functional

Mechanism:

Display:

of

Day

Clock:

17.1

(H) x 10

Approximately

One

microcomputer-controlled

Two-line,

On

AC

power:

On

battery

program

backlight

seconds

does

12-hour

clock

after

not

activate

clock

without

(W) x 5.8

1.0

kg

liquid

crystal

continuously

power:

continuously

review, and

is

activated

the

keystroke.

the

with

AM/PM

AM/PM

(D)

cm

(6.75 x 4.0 x 2.3

(2

pounds)

display

backlit

history

by

display.

keystrokes

Pressing

backlight

displayed

displayed

inches)

eccentric-rotor

(LCD)

with

backlit

At

and

the

peristaltic

backlight

during

other

remains

remote

adjustable

motor

programming,

times,

on

for

bolus

to

24-hour

the

three

switch

Operating

Printer

Memory

Protection:

Electrical

Environmental

Temperature

Relative

Atmospheric

Controls:

interface:

Safety:

Ranges:

Humidity:

Pressure:

Accuracy:

Keypad:

ON/OFF:

Remote

Jack

Printers:

Printer

Bolus:

and

Port:

+3

24

One

isolated

Kodak

Nonvolatile

batteries

Meets

are

CSA

standards

Operating:

Shipping

10

to

0

to

and

90

percent

10,000

minutes/month

membrane-type

electromechanical

Jack

for

remote

interface

Diconix

RS232C

memory

removed

(NRTL)

+10

to

Storage:

feet

(0

to

150

serial

of

up

from

guidelines

+40

degrees

-20

3,000

or

better

switches

switch

circuit

Plus

interface

to

256

events

pump

and

Celsius

to

+60

m)

equivalent

switch

connection

or

180si,

port

IEC

601-1-1 and

degrees

or

Seiko

for

up

to

Celsius

pressure

DPU411

one

year

601-1-2

when

APM/APM

II

Technical

Service

Manual

8-1

430-85656-003

(Rev.

8/96)

Page 13

Section

8,

Specifications

Power

Disposable

Sources

AC

Power:

Batteries:

AC

power

international

not

indicate

Use

cord

Power

13036-04

(domestic)

13036-24

(int'

13036-36

(int'l

plug-in)

Two

Capacity:

indicator:

Abbott

and

molded

Supply

table

or

UK

9-V

Duracell

Approximately

if

List

top)

or

wall

plug

the

18036

plug

-54

Amber

icon

on

voltage

AC

115

60

0.18

220-240

50

12

230

50

12

alkaline

four

colored

the

keypad;

is

correct

Power

Hz

Hz

VA

Hz

VA

batteries

Adapter

Input

VAC

А

УАС

VAC

or0.10A

days

LED

next

illuminated

with

at

6.0

mL/hr

to

the

LED

3.6 m (12

Output

12

VDC

0.4

À

12

VDC

0.3A

12

VDC

0.4

or

0.5

does

ft)

A

Rechargeable

Occlusion

Occlusion Alarm

Maximum

{Audible

and

Pack:

Pressure

Pressure:

Delivery

Pressure:

Alarms

Visual)

Attachable

Recharge

Capacity:

45

psi

45

psi

Low

Limit

End

Check

Amount

System

time:

(310

(310

batteries

exceeded

ofinfusion

cartridge

too

error

separate

Approximately

kPa)

Full

battery

recharge

kPa)

On

Callback

Empty

Air-in-line

small

Amount

Internal

pack

requires

five

days

batteries

alert

container

too

large

malfunction

at

up

6.0

to

six

mL/hr

Change

Purge

Check

Occlusion

hours

batteries

overuse

printer

430-85656-003

(Rev.

8/96)

APM/APM

II

Technical

Service

Manual

Page 14

Section

8,

Specifications

Programmable

Ranges

Concentration

Delivery

Bolus

Doses

Flow

Bolus

Delivery

Entry

Rate

and

Loading

rate:

125

Lockout

Limit

mL/hr

Time

0.1 - 50.0

0.1 - 1000

0.1 - 25

0.1 - 9999.9

0.1 - 9999.9

mg

and

equivalent

0.1 - 25

0.1 - 9999.9

0.1 - 9999.9

mg

and

equivalent

5 - 99

min.

5 - 999

4

hour

APM APM

mg/mL

pg/mL

mL/hr

ug

entries

mL

yg

entries

(dom)

min.

limit

mg/hr

ug/hr

mg

Lg

(int!)

0.1 - 50.0

0.1 - 25

0.1 - 9999.9

cannot

0.1

0.1 - 9999.9

cannot

5 - 999

1 -

1000

1 -

999999

exceed

-25

1 -

999999

exceed

1

or 4 hour

min.

Il

mg/mL

pg/mL.

mL/hr

mg/hr

ug/hr

25

mL/hr

mL

mg

ug

25

mL

limit

Container

(Volume)

Air

Sensitivity

Size

0.4 - 1000

mL

0.1 - 9999.9 mg

0.1 - 9999.9

Cont/Cont+Bolus:

continuous

Bolus

0.1 - 1000

0.1 - 9999.9

0.1 - 9999.9

mg

and

equivalent

High

(pump

Low

(pump

Off

(air

Only:

mL

pg

alarm

ug

delivery

must

mg

ug

entries

alarms

alarms

off)

0.1 - 1000

0.1 - 9999.9

1 - 999999

must

be

greater

over

limit

be

at

least

0.1 - 1000

0.1 - 9999.9

1 -

999999

cannot

at

at

approx.

approx.

exceed

period

one

bolus

1000

100

ul)

300

pL)

mL

than

mg

pg

dose

mL

mg

ug

mL

APM/APM U Technical

Service

Manual

8-3

430-85656-003

(Rev.

8/96)

Page 15

Section

8,

Specifications

This

page

intentionally

left

blank.

430-85656-003

(Rev.

8/96)

APM/APM

II

Technical

Service

Manual

Loading...

Loading...