Page 1

ABBOTT

6

aim”

ABBOTT

aim

Technical

Service

Manual

For

use

with

the

following

13038-04,

13967-04,

Abbott

Abbott

AIM

AIM

list

Plus

plus

numbers:

ABBOTT

NORTH

USA

LABORATORIES

CHICAGO,

IL

60064

430-600035-002

(Rev.

11/99)

Page 2

©

Copyright

This

document

Laboratories

sale.

Any

whole

or

1999

party

in

part

and

retains

using

nor

the

subject

all

the

exclusive

this

document

disclose

it

to

matter

rights

accepis

others

Abbott

Laboratories

disclosed

of

dissemination,

it

in

without

herein

confidence,

the

written

are

proprietary

reproduction,

and

agrees

consent

of

Abbott

AllRights

information.

manufacture,

not

Reserved

to

duplicate

Laboratories.

Abbott

and

it

in

Page 3

List

of

Changes

Part

Number

Description

of

Change

Remove

Destroy

and

Pages

Insert

Change

Pages

430-600035-001

(Rev.

12/96)

430-600035-002

(Rev.

10/99)

Original

Second

Section

checklist

Added

performing

encoder

torque

alternate

Section

February

Section

RTV

General:

printer.

issue.

issue.

5:

(1)

Updated

to

match

alternate

the

motor

test,

and current

brake.

Revised

results.

6:

Added

29 on leap

7:

Added

sealing.

Added

pump

inspection

current service

PVT

procedures

test,

servo

supply

PVT

Data

procedure

years.

alternate

Seiko

for

instructions

DPU414

training.

for

calibration,

test

Form

setting

(2)

without

to

a

add

for

as

compatible

N/A

All

N/A

All

AIM/AIM

Plus

Technical

Service

Manual

i

430-600035-002

(Rev.

11/99)

Page 4

Changes

This

page

intentionally

left

blank.

430-600035-002

(Rev.

11/99)

AIM/AIM

Plus

Technical

Service

Manual

Page 5

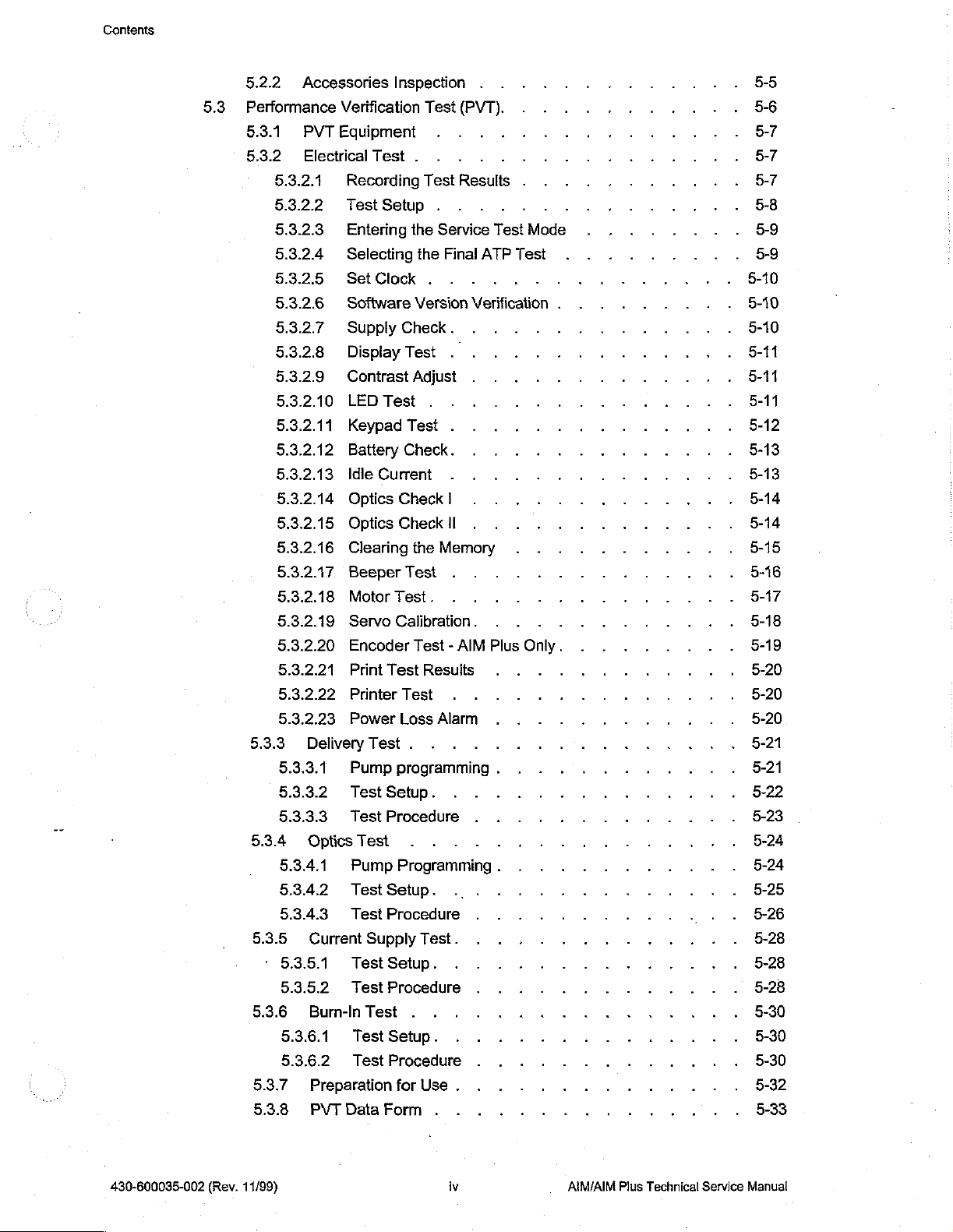

Table

of

Contents

Section

1

Introduction

1.1

1.2

1.3

Scope

AIM

1.2.1

1.2.2.

Conventions

Section 2 Warranty

Section 3 System

Section 4 Theory

4.1

General

4.2

Circuit

4.3

Detailed

4.3.1

4.3.2

.

and

AIM

Plus

Pump

Description

AIM

and

.

Operating

of

Operation.

Description

Block

Diagram

Circuit

CPU

System

4.3.1.1

4.3.1.2

4.3.1.3

4.3.1.4

4.3.1.5

4.3.1.6

4.3.1.7

4.3.1.8

4.3.1.9

4.3.1.10

4.3,1.11

4.3.21

4.3.2.2

4.3.2.3

4.3.2.4

Microprocessor

EPROM

Microprocessor

RAM

Time

Display

Encoder

Backup

Keypad

Bolus

Serial

Analog

Power

Audible

Air

Overview

AIM

Plus

Manual

.

Description

. . . . .

Of

Day

Interface

Microprocessor

Interface

Switch

Interface

Circuits

Circuits

Alarm

and

Occiusion

Motor

Drive

.

.

Differences

.

(CPU)

.

Supervisory

Clock

Circuit.

.

Interface

.

Optics

Circuit

.

.

.

.

.

.

Interface

.

o.

Circuit

. -

4-10

4-10

4-10

4-11

4-11

4-11

4-12

4-13

4-13

Section 5 Maintenance

5.1

Cleaning

5.2

Inspecting

5.2.1

AIM/AIM

Plus

Technical

Service

Manual

and

the

the

Pump

Service

Pump

.

Pump

and

Inspection

Tests

Accessories

.

. .

o.

.

430-600035-002

(Rev.

5-1

5-2

5-4

5-4

11/99)

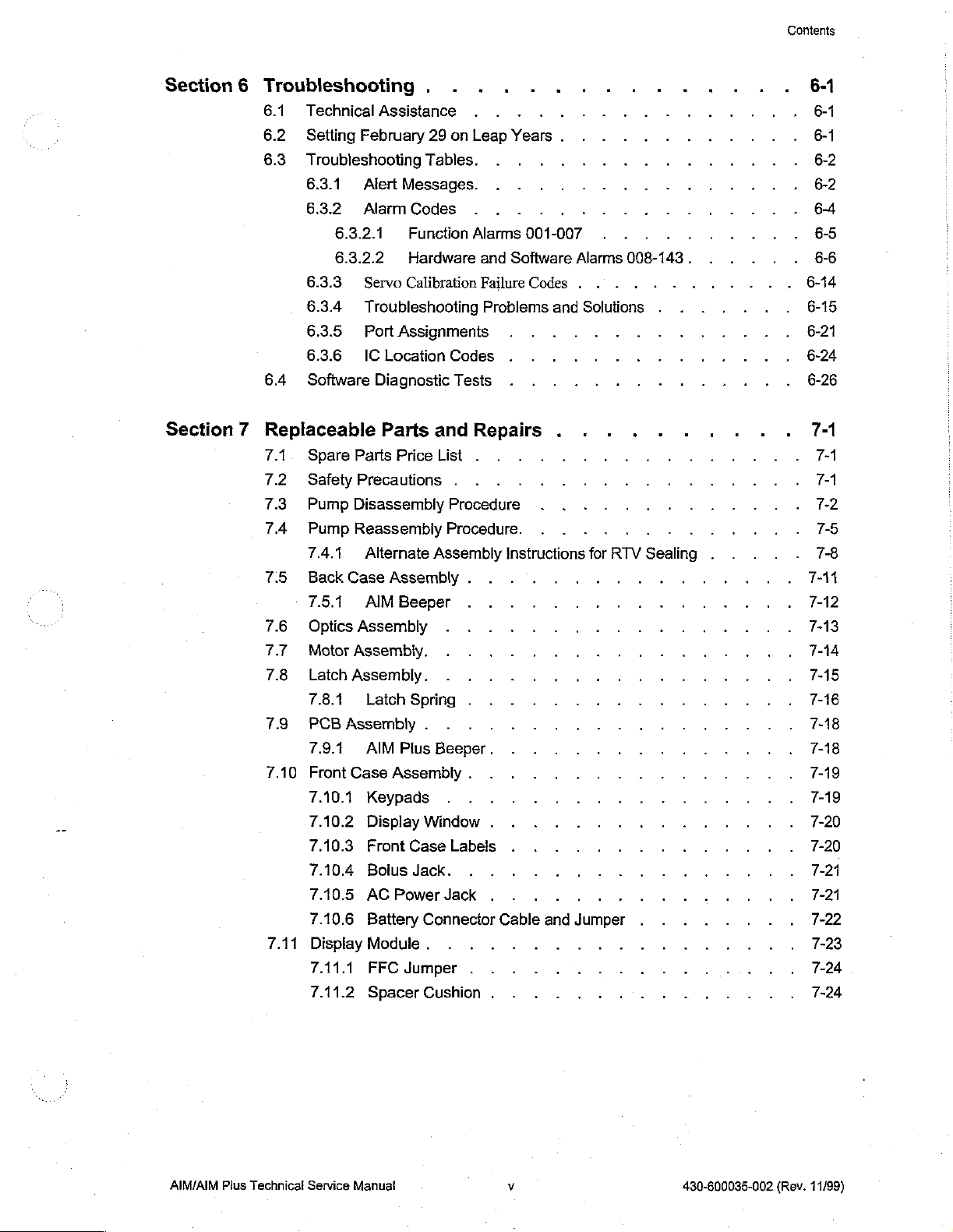

Page 6

Page 7

Contents

Section 6 Troubleshooting

6.1

Technical

6.2

Setting

6.3

Troubleshooting

6.3.1

6.3.2

6.3.3

6.3.4

6.3.5

6.3.6

64

Software

Section 7 Replaceable

7.1.

Spare

7.2

Safety

7.3.

Pump

74

Pump

7.4.1.

75

Back

7.5.1

7.6

Optics

7.7

Motor

7.8

Latch

7.8.1

7.9

PCB

7.9.1

7.10

Front

7.10.1

7.10.2

740.3

7.10.4

7.10.5

7.10.6

7.11

Display

7.11.1

7.11.2

Assistance

February

Alert

Alarm

6.3.2.1

6.3.2.2

Servo

Troubleshooting

Port

Assignments

IC

Location

Diagnostic

Parts

Parts

Price

Precautions

Disassembly

Reassembly

Alternate

Case

Assembly

AIM

Beeper

Assembly

Assembly.

Assembly.

Latch

Assembly

ALM

Plus

Case

Assembly

Keypads

Display

Front

Bolus

AC

Power

Battery

Module

FFC

Spacer

.

29

on

Tables.

Messages.

Codes

Function

Hardware

Calibration

Codes

Tests

and

List

.

Procedure

Procedure.

Assembly

.

Spring

Case

Jack.

.

Jumper

.

.

Beeper.

.

Window

Labels

Jack

Connector

.

Cushion

. .

Leap

Years

Alarms

and

Software

Failure

001-007

Codes

Problems

Repairs

.

.

instructions

.

Cable

.

.

and

-

and

Alarms

.

008-143

Solutions

-

for

RTV

,

Jumper

.

.

o.

Sealing

6-1

6-1

6-1

6-2

6-2

64

6-5

6-6

6-14

6-15

6-21

6-24

6-26

7-1

7-1

7-1

7-2

7-5

7-8

7-14

7-12

7-13

7-14

7-15

7-16

7-18

7-18

7-19

7-19

7-20

7-20

7-21

7-21

7-22

7-23

7-24

7-24

AIM/AIM

Plus

Technical

Service

Manual

v

430-600035-002

(Rev.

11/99)

Page 8

Contents

Section 8 Specifications

Section9

Drawings

.

.

.

430-600035-002

(Rev.

11/99)

vi

AIM/AIM

Plus

Technical

Service

Manual

Page 9

List

of

Figures

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

4-1.

Assemblies

4-2.

Motor

4-3.

Motor

4-4.

Optics

4-5.

Latch

4-6.

Circuit

5-1.

Cartridge

5-2.

Basic

5-3.

Optics

7-1.

Back

7-2.

Front

7-3.

Motor,

7-4.

AIM

7-5.

Pump

7-6:

RTV

7-7.

RTV

7-8.

RTV

7-9.

Motor

7-10.

Back

7-11.

AIM

7-12.

Optics

7-13.

Motor

7-14.

Latch

7-15.

PCB

7-16.

Front

7-17.

Bolus

7-18.

Battery

7-19.

Display

9-1.

AIM

9-2.

AIM

9-3.

AIM

9-4.

AIM

9-5.

AIM

9-6.

AIM

9-7.

AIM

9-8.

AIM

9-9.

AIM

9-10.

AIM

.

Frame

Assembly

Assembly

Assembly

Block

Channel

Equipment

Test

Case

Case

Optics,

and

AlM

Assembly

Sealing

Sealing

Sealing

Frame

Case

Beeper

Carrier

Assembly

Assembly

Front

Case

and

Connections

Module

Analog

Microprocessor

Power

PC

Board,

PC

Board,

Plus

Analog

Plus

Microprocessor

Plus

Power

Plus

PC

Plus

Detail

Diagram

Detail

Setup

Block

Placement

Screws

Connections.

and

Plus

PCBs

for

Printer

for

Side,

for

Motor

Seal.

Labels

Installation

to

Motor

to

to

View

Keypads

AC

Power

Installation

Schematic

and

Miscellaneous

Front

Back

Schematic

and

Board,

PC

Board,

.

.

Beeper

Connections

to

Back

Port

Bottom

Frame

.

,

Frame

Motor

Frame

Motor

Frame

and

Labels

Jack

Installation.

.

(CPU)

Schematic.

Side

Side

.

(CPU)

Miscellaneous

Front

Side

Back

Side

.

o.

Cases

Case

.

.

.

.

Circuitry

Schematic

Circuitry

.

.

.

. . . .

Schematic.

.

.

. . .

Schematic

. .

..

. . .

.

.

4-1

4-2

4-3

4-3

4-4

46

5-3

5-8

5-14

7-2

7-3

7-4

7-5

7-6

7-8

7-8

7-9

.

7-9

7-11

7-12

7-13

7-14

7-15

7-17

7-20

7-21

7-22

7-23

Fold-out

Fold-out

Fold-out

Fold-out

Fold-out

Fold-out

Fold-out

Fold-out

Fold-out

Fold-out

AIM/AIM

Plus

Technical

Service

Manual

vii

430-600035-002

(Rev.

11/99)

Page 10

Figures

This

page

intentionally

left

blank.

430-600035-002

(Rev.

11/99)

viii

AIM/AIM

Plus

Technical

Service

Manual

Page 11

List

of

Tables

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

1-1.

AIM

and

1-2.

AIM

and

5-1.

Cleaning

6-1.

AIM/AIM

6-2.

AIM/AIM

6-3.

AIM/AIM

6-4.

Servo

Calibration

6-5.

Troubleshooting

6-6.

AIM/AIM

6-7.

AIM/AIM

AIM

Plus

AIM

Plus

Solutions.

Plus

Alert

Plus

Alarm

Plus

Alarm

Failure

.

Plus

Port

Plus

IC

Location

Hardware

Software

Differences

Messages

Codes

Codes

001 - 007.

008 - 143.

Codes

o

Assignments

Codes

Differences

..

.

.

.

.

.

.

1-3

1-3

5-2

6-3:

6-5

6-14

6-15

6-21

6-24

AIM/AIM

Plus

Technical

Service

Manual

ix

430-600035-002

(Rev.

11/99)

Page 12

Tables

This

page

intentionally

ieft

blank.

430-600035-002

(Rev.

11/99)

AIM/AIM

Plus

Technical

Service

Manual

Page 13

Po

ㄴㄴ

Section

1

Introduction

11

Scope

This

Technical

Infusion

pumps.

analog

It

is

Manager

It

is

and

organized

ロ

Section 1 Introduction

Section2

ロロ

Section 3 System

Section 4 Theory

Service

(AIM™)

intended

digital

microprocessor-based

into

Warranty

Manual

for

the

the

following

Operating

of

and

trained

Operation

presents

Abbott

technician

nine

sections:

Manual

technical

Ambulatory

experienced

equipment.

information

Infusion

Manager

in

analysis,

about

the

Abbott

Plus

(AIM®

troubleshooting

Ambulatory

Plus)

infusion

and

repair

of

ロロ

Section 5 Maintenance

Section 6 Troubleshooting

ロロ

Section 7 Replaceable

Section 8 Specifications

ロロ

Section9

Note:

In

AIM

Plus

Note:

figures

depending

Ifa

contact

Figures

may

problem

Abbott

this

unless

Drawings

manual,

otherwise

are

rendered

not

exactly

on

the

configuration

in

the

infusion

Laboratories

the

reflect

and

Parts

terms

“pump”

specified.

as

graphic

the

product.

of

system

operation

Technical

Service

and

Tests

Repairs

and

“pumps”

representations

Display

the

pump

in

use.

cannot

Support

Operations

refer

to

to

approximate

screens

be

and

resolved

(see

all

configurations

the

actual

touchswitch

using

Section

labels

the

information

6.1,

Technical

of

both

product;

may

vary

in

Assistance).

the

AIM

therefore,

slightly,

this

manual,

and

AIM/AIM

Plus

Technical

Service

Manual

1-1

430-600035-002

(Rev.

11/99)

Page 14

Section

12

1,

Introduction

AIM

The

noted

and

pumps

in

Section

AIM

share

1.2.1

Pump

The

intravenously

over-pressure

parameter

endangering

The

battery

through a 24-key

16-character

dedicated

and

Description

Abbott

pump

of

AIM

monitoring,

the

is

powered

packs,

by

cartridges

the

cartridge

or

(occlusion)

or

Plus

the

same

design

1.2.2,

AIM

and

AIM

epidurally.

alarm,

and

patient.

by

four

an

AC

power

keypad

4-line

alphanumeric

to

deliver

assure

Overview

and

and

AIM

Plus

are

Special

an

numerous

1.5V

AA

supply.

on

the

front of

fluids

accurate

functionality

Plus

Differences.

single-channel

other

safety features

air-in-line

failure

alkaline

The

liquid

through

fluid

alarm, a back-up

backup

batteries,

pump

the

unit.

crystal

rotary

delivery.

than

the

hardware

infusion

modes

optional

is

microprocessor-based

The

display

peristaltic

pumps

integrated

to

state

into

(safety)

prevent

nickel

of the

(LCD)

pumping

designed

metal

pump

module.

action.

and

software

to

deliver

the

design

microprocessor,

single

point

failures

hydride

and

is

rechargeable

is

programmed

displayed

The

unit

Control

differences

fluids

include

an

motor

from

using

a

requires

of the

pump

The

pump

detects

specification

the

cartridge

proceed

deactivated,

The

pump

Variable

The

pump

place

with

The

pump

pump

is

cables

For

specific

AIM

Plus

occlusion

exceeds.

until

the

refer

has

Time

contains a time-of-day

the

contains a printer

connected

(depending

instructions

System

occlusions

the

air

is

to

the

several

Delivery

pump

can

to

one

on

printer

Operating

and

air

alarm

pressure,

pre-set

cleared

pump’s

and

(the

System

programming

Continuous

be

reviewed

connector

of

the

two

choice)

regarding

Manual.

in

the fluid

the

sensitivity

air

sensitivity

cartridge.

instrument

limit,

Operating

modes:

Delivery.

clock

and

history

on

the

LCD

that

also

recommended

are

available

pump

operation,

sounds

the

pump

setting

Manual

TPN,

Pain

storing

display,

allows

printout

compatible

from

Abbott

refer

to

Ifthe

pressure

an

alarm

will

alarm,

is

variable,

for

more

Management,

capability.

along

with time

of

this

printers.

as

accessory

the

AIM

System

at

the

cartridge

and

stops

delivery.

stop

delivering

and

for

the

AIM

information).

Intermittent

Significant

and

history

Two

different

events

date

of

information

special

items.

Operating

exceeds

Plus

the

If

air

and

not

can

be

Delivery,

that

take

occurrence.

when

the

printer

Manual

or

the

in

430-600035-002

(Rev.

11/99)

1-2

AIM/AIM

Plus

Technical

Service

Manual

Page 15

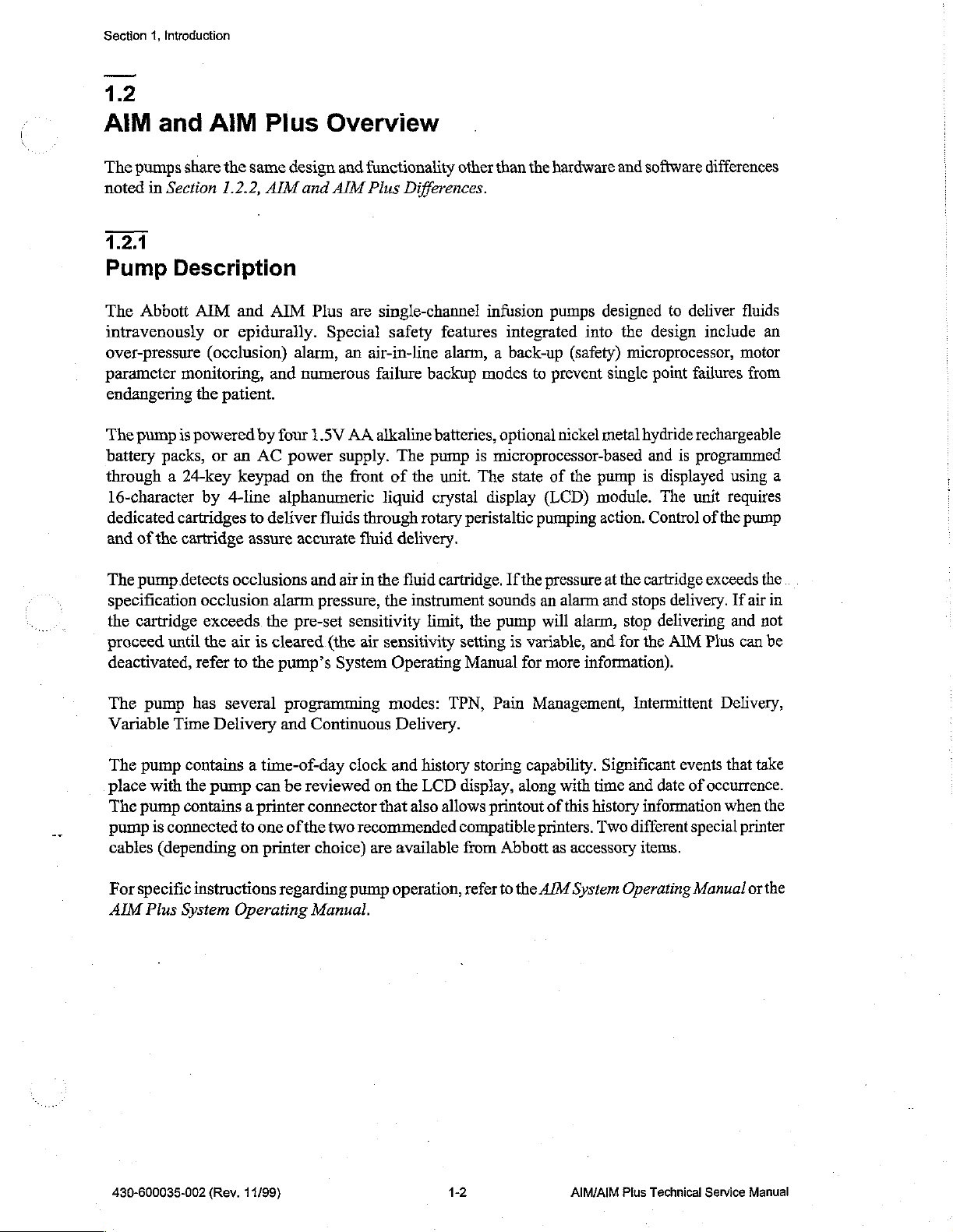

1.2.2

AIM

The

and

AIM

Beeper

Function

Bottom

AIM

and

Item

Keypad

Case

AIM

Plus

Plus

Differences

have

the

following

Table

1-1.

Piezo

element

bottom

approximately 4 KHz

Four

4-450z.

No

beeper

case;

raised

actuation

molded

sound

AIM

and

AIM

mounted

frequency

profile

switches

force

recess;

hole

significant

AIM

Plus

on

to

emit

hardware

Hardware

the

with

differences:

Differences

Audio

transducer

frequency

protection

(R135

resistor

transducer

100K,

Three

4-150z.

flat

Molded

installation

for

the

approximately 2 KHz;

diode

replaced

value

oscillator

1%

to

raised

actuation

profile

and

recess

of

beeper

(AIM

PCB)

AIM

Plus

mounted

added

with

15S353

changed

circuit

200K,

1%)

profile

switches

force;

6-200z.

(0.020

kapton

insulator;

Plus

beeper

Section

1,

Introduction

on

the

to

beeper

diode)

in

backup

(R95

from

with

STOP

key

actuation

inch)

force

aids

in

no

mounted

PCB;

circuit

and

audio

has

hole

on

The

AIM

and

AIM

Plus

have

the

Table

Air

Rate

End

Dose

interrupt

Program

Change

Lock

Number

Item

Alarm

Sensitivity | Air

Change

of

Frequency

Sequence

Lock

Infusion

Messages

Review

Mode

New

tates

END

Dose

Number

Intermittent

Program

unlocked

When

altered

AIM

1-2.

alarm

feature

to

be

OF

INFUSION

frequency

of

changes

are

is

13038,

following

AIM

and

can

be

turned

added

locked

increased

message

and

Variable

review

not

at

power-on

are

displayed

AIM

significant

AIM

Plus

Significant

completely

that

allows

in

Pain

Management

alert

added

from

screens

programs

required

without

being

made

Plus

is

13967

software

Software

AIM

Plus

off

if

air

programmable

programs

fo

TPN

and

24

to

96

hours

displayed

if

pump

program

for a program

is

off

review

to a program,

(product

differences:

Differences

Differences

eliminating

ranges

Intermittent

less

only

list

numbers)

filter

for

continuous

programs

in

Intermittent

interruption

than 5 minutes;

those

screens

in

use

programs

reduced

pump

that

and

can

can

bolus

in

be

be

AIM/AIM

Plus

Technical

Service

Manual

1-3

430-600035-002

(Rev.

11/99)

Page 16

Section

1,

Introduction

13

Conventions

The

following

С

Touchswitches

[ENTER]

Q

Screen

beeps

conventions

displays

sound

are

to

select a 100

referenced

and

the

are

used

described

mL

in

INITIALIZE

throughout

in

all

caps

and

container

the

text

size.”

are

NVRAM

this

manua!:

enclosed

in

all

OR

in

caps,

USE

brackets,

e.g.,

“When

ARROWS

e.g.,

“Press

resetting

display

[1], [0],

is

[0]

complete

returns.”

and

two

Throughout

as

follows:

this

WARNING:

A

warning

Failure

CAUTION:

damage

Note: A note

to

observe a warning

or

manual,

contains

A

caution

failure.

highlights

warnings,

special

cautions,

safety

is

contains

information

information

and

notes

emphasis

potentially

that

helps

explain a concept

are

used

and

life

threatening.

that

could

to

emphasize

-

must

be

prevent

or a procedure.

important

observed

irreversible

at

information

all

times.

equipment

430-600035-002

(Rev.

11/99)

1-4

AIM/AIM

Plus

Technical

Service

Manual

Page 17

|

ЗесНоп

2

Warranty

Subject

warrants

in

Abbott

purpose,

Purchaser’s

no

contract,

event

business,

The

used

or

to

the

that

the

material

and

makes

or

any

exclusive

event

shall

Abbott’s

negligence,

shall

Abbott

revenue,

foregoing

other

than

reliability,

or

terms

product

workmanship

no

other

other

matter.

remedy

strict

be

or

profits.

warranty

in

accordance

in

the

and

conditions

shall

conform

under

warranties,

shall

liability

liable

shall

event

arising

liability,

for

incidental,

Warranty

be

void

with

the

serial

herein,

to

Abbott’s

normal

express

be,

at

Abbott’s

out

tort,

or

product

in

the

product

or

lot

Abbott

Laboratories,

standard

use

and

service

or

implied,

as

option,

of

any

cause

whatsoever

otherwise)

consequential,

returned

event

manuals

number

the

product

so

exceed

as,

has

herein

specifications

for a period

to

merchantability,

the

repair

the

or

special

to

Abbott

has

been

in

Abbott’s

been

altered,

of

two

or

replacement

(whether

price

of

damages

must

be

misused,

judgment,

defaced,

referred

and

be

free

years

fitness

of the

such

cause

such

product,

or

losses

properly

damaged,

to

affect

or

to

as

Abbott,

from

defects

after

purchase.

for a particular

product.

be

and

or

packaged.

altered,

its

removed.

In

based

in

in

no

for

lost

or

stability

The

foregoing

or

attempts

by

an

For

purposes

other

In

providing

liability

whether

acknowledged

an

authorized

to

authorized

than

the

for

the

such

warranty

perform

representative

of

the

replacement

any

actions

person

that

agent

shall

any

preceding

parts

for

or

has

any

person

of

Abbott.

also

be

major

repair

of

Abbott

sentence,

of

accessory

repair

or

inactions

been

trained

other

than

void

in

or

other

and

“major

items

service

of

the

person

to

an

Abbott

the

event

service

using

Abbott

repair

such

of

the

product,

performing

perform

representative

any

person,

on

the

documentation

or

other

as

batteries.

such

repair

including

product

service”

Abbott

such

or

performing

the

without

and

means

shall

have

repair

or

service.

Purchaser,

having

approved

any

no

service,

It

repair

been

spare

repair

responsibility

regardless

is

understood

or

service

performs

trained

parts.

or

service

or

of

and

is

not

AIM/AIM

Plus

Technical

Service

Manual

2-1

430-600035-002

(Rev.

11/99)

Page 18

Section

3

System

A

System

binder’s

contact

Operating

pockets

Abbott

for

Laboratories

Operating

Manual

convenient

is

included

reference.

Technical

with

Ifa

Support

Manual

every

AIM

copy

of

the

Operations

and

AIM

System

(see

Section

Plus

kit.

Operating

Manual

6.1,

Technical

Insert a copy

is

not

available,

Assistance).

in

this

AIM/AIM

Plus

Technical

Service

Manual

3-1

430-600035-002

(Rev.

11/99)

Page 19

0

lå

Section

4

Theory

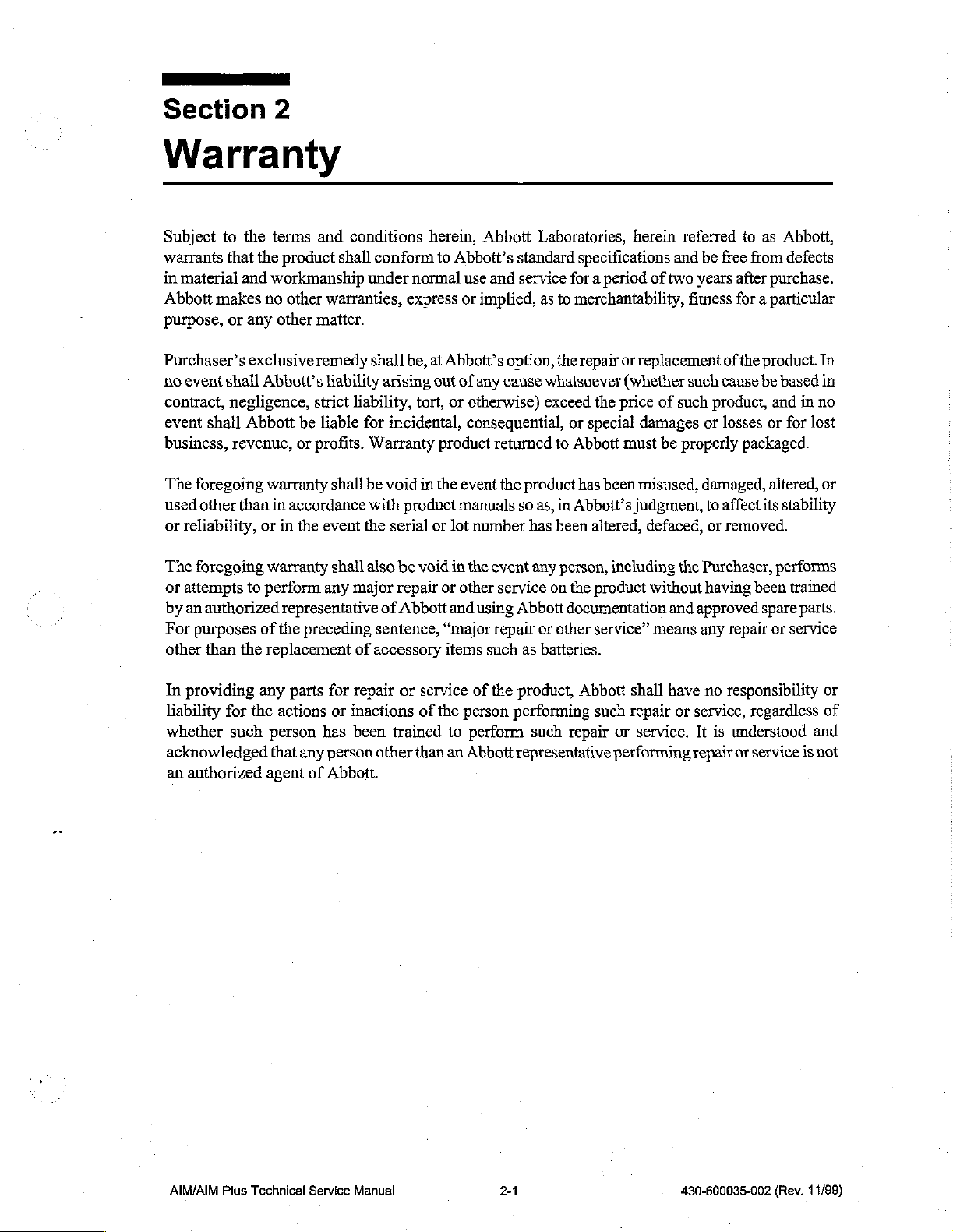

This section

construction

Front

assembly

case

Displa

module

Mylar

Washer

describes

as

shown

of

the

theory

in

Figure

Operation

of

operation

4-1,

Assemblies.

of

the

AIM/AIM

Plus.

The

pump

Battery door

Motor

has a modular

jack

power

AC

assembly

Bolus

jack

assembly

frame

seal

PCB

assembly

Back

case

assembly

.

Motor

optics

motor

latch

frame

with

assembly,

assembly,

assembly

and

(AIM

AIM/AIM

Plus

Plus

AIM

Assembly

beeper

Technical

is

mounted

Service

Manual

on

PCB)

Figure

4-1.

Assemblies

41

430-600035-002

5A-12a

(Rev.

75

11/99)

Page 20

Section

41

4,

Theory

of

Operation

General

The

pump

case

conductive

front

motor

accomplished

access

constructed

connected

The

motor

part

detection

material

half

of

frame

is

accomplished

of

and

frame

of

the

pumping

systems

Description

is

constructed

to

provide

the

case

is

side

by

the

removal

spring

isolated

aligns

require

houses

mounted.

clips.

mechanism

by

Positive

from

the

cartridge

correct

the

of

removal

the

of

durable,

enhanced

Liquid

Access

retaining

of

and

optional

to

(refer

cartridge

shock

ESD

Crystal

to

screws

the

negative

power

the

drive

to

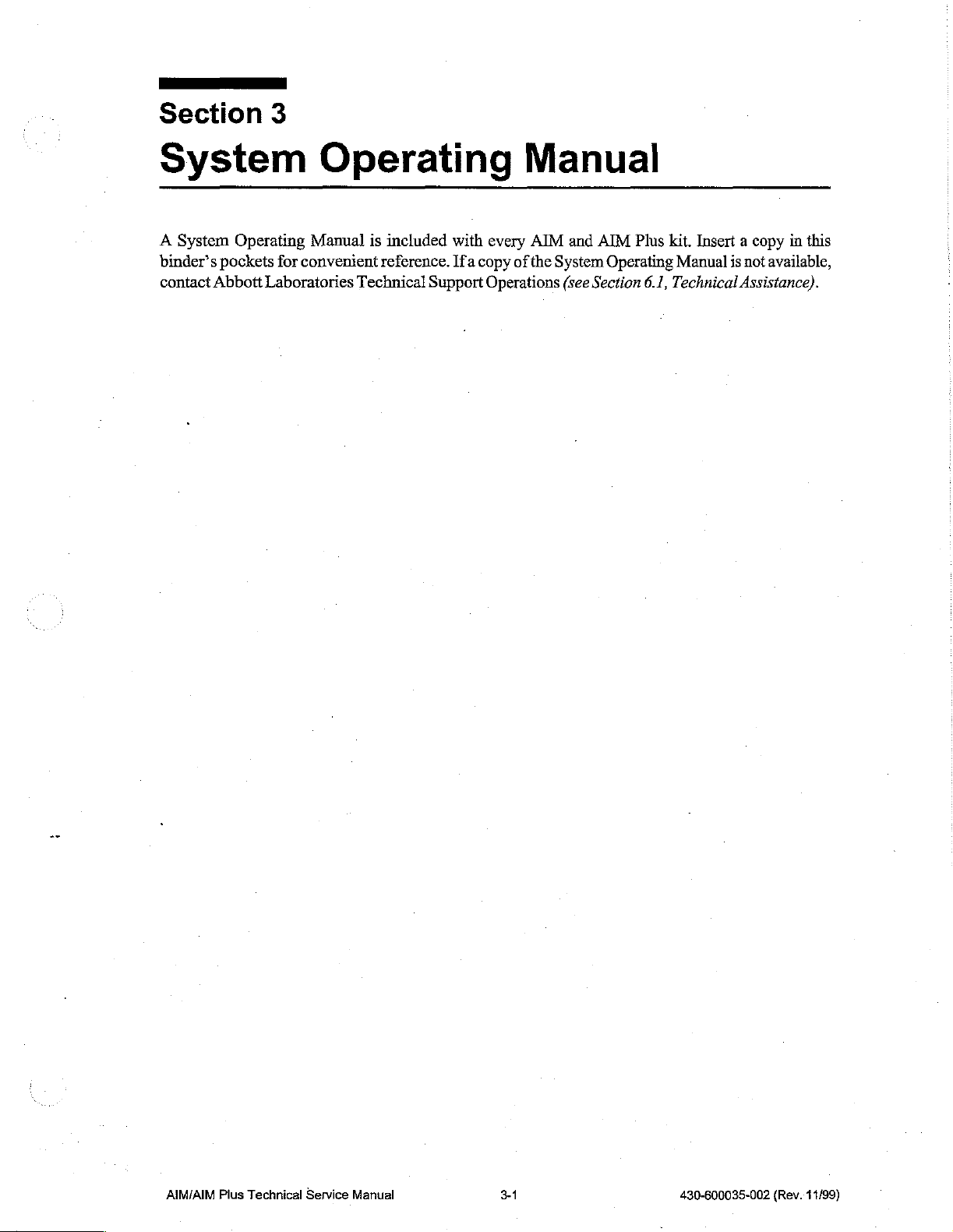

Figure

alignment

resistant

and

Display

the

electro-mechanical

located

battery

contacts

supply

motor

4-2,

EMI

door.

via

and

to

on

Motor

function

plastic

protection

(LCD)

the

Positive

are

diodes.

optical

that

contains

for

the

and

membrane

assembly

rear

case

half.

and

identified.

sensors,

Frame).

properly.

Air-in-line

or

is

pump

electronics.

contact

of

Battery

negative

The

batteries

and

completes

coated

terminals

and

with

The

keys.

The

the

pump

compartment

are

are

series

the

outer

occlusion

a

is

The

location,

within

the

equipment;

height,

motor

for

Laboratories.

The

mechanical

consists

encoder

to

torque

drive

The

mounted

magnetic

create

pulse,

gearbox

approximately

counting

of a DC

built

transform

requirements

motor

motor

assembly

on

pole

16

pulses

on

both

output

encoder

into

the

can

the

pairs.

phase 1 and

and

frame.

Dowel

that

reason,

drive

consists

brush

type,

the

motor.

relatively

necessary

be

driven

includes

motor

shaft

The

for

every

shaft

going

0.0876

mL.

pulses.

Figure

perpendicularity

pin

insertion

replacement

ofa

motor

assembly

iron-less

The

high

speed,

to

at

various

an

on

the

encoder

one

motor

gearbox

core

or

low

drive

the

speeds,

encoder,

end

of

the

contains

shaft

turn.

phase 2 outputs.

to

the

cartridge

The

pump’s

4-2.

of

the

into

of

motor

Motor

the

the

dowel

motor

motor

(refer

with

Frame

pins

transmission

torque

or

software

output

rotary

peristaltic

depending

tachometer.

motor

opposite

two

Hall

The

motor

For

each

completes

keeps

effect

64

one

determine

frame

is

frame

to

Figure

attached

of

the

motor

of

the

cartridge

on

the

rate

The

encoder

the

gearbox.

magnetic

encoder

by

16

full

turn,

track

the

location

made

by

using

must

be

4-3.

Motor

gearbox

and

contains a 64/1

motor

to

the

pumping

programmed.

consists

The

sensors,

outputs

tach

of

these

pulses

resulting

volume

50-19

of

the

specially

performed

Assembly).

integral

gear

slower

speed,

mechanism.

of a magnetic

disc

contains

in

quadrature,

16

pulses,

or

64

motor

in a fluid

of

fluid

delivered

25

cartridge

designed

by

Abbott

The

motor

Hall

effect

reduction

higher

The

disc

multiple

that

90°

out

of

turns,

the

delivery

of

by

430-600035-002

(Rev.

11/99)

4-2

AIM/AIM

Plus

Technical

Service

Manual

Page 21

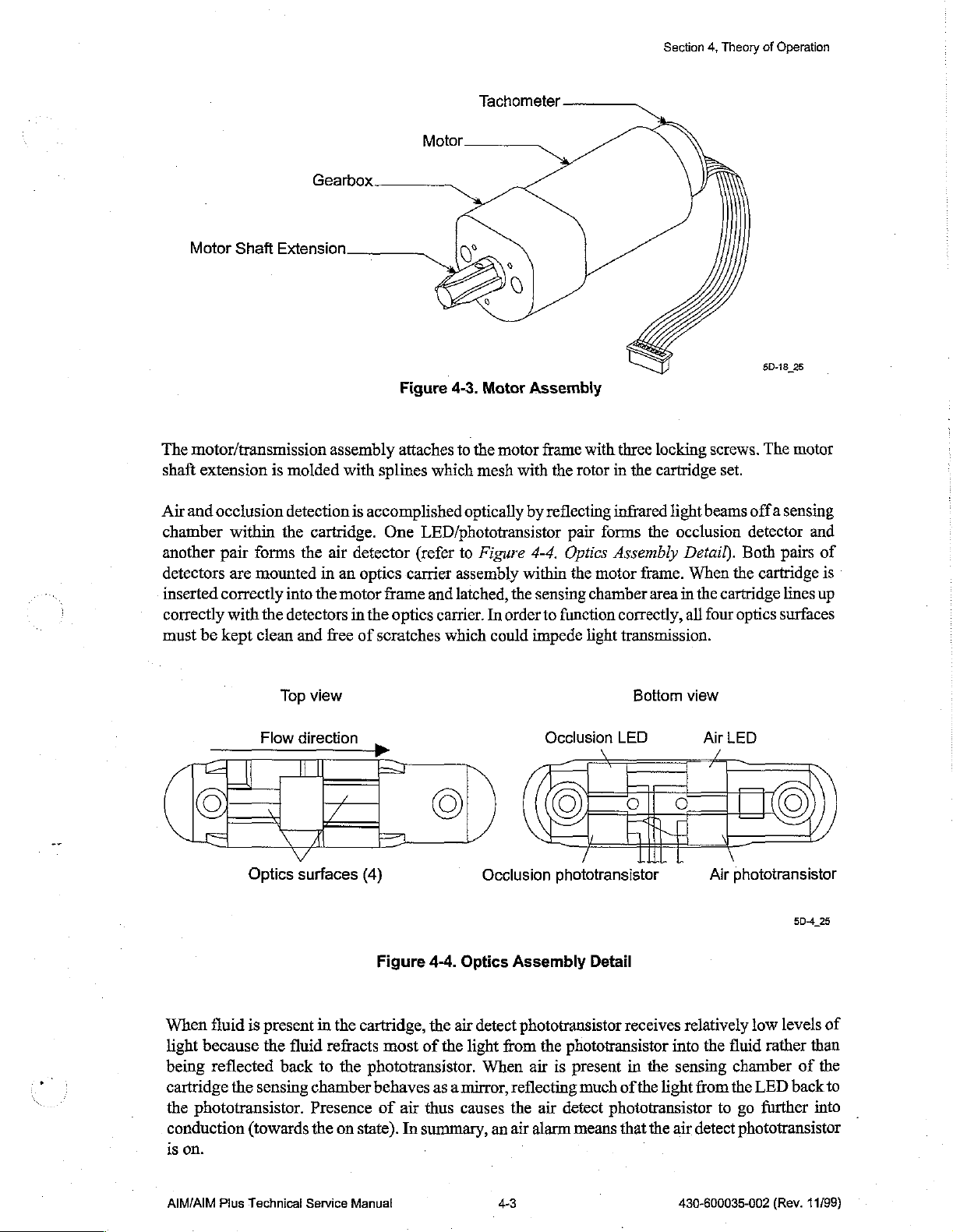

The

motor/transmission

shaft

extension

is

Gearbox

molded

assembly

with

splines

Figure

attaches

4-3.

to

which

Tachometer

Motor

Assembly

the

motor

mesh

with

frame

the

rotor

with

in

three

locking

the

cartridge

Section

4,

Theory

screws.

set.

of

Operation

5D-18

25

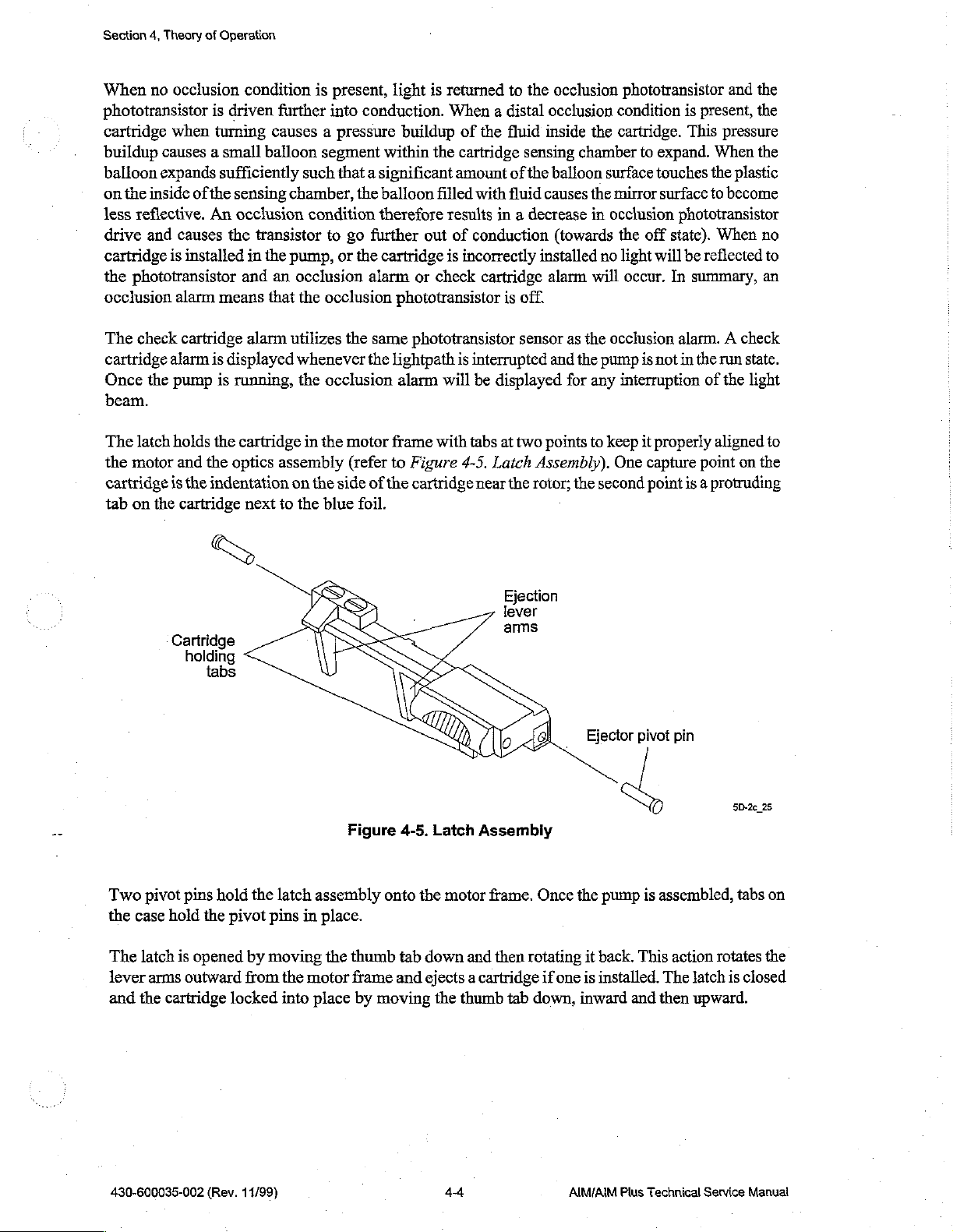

The

motor

Air

and

occlusion

chamber

another

detectors

inserted

correctly

must

within

pair

are

correctly

with

be

kept

detection

the

forms

the

mounted

into

the

detectors

clean

and

Top

Flow

direction

is

cartridge.

air

detector

in

an

the

motor

in

free

of

view

Optics

surfaces

accomplished

One

LED/phototransistor

(refer

optics

carrier

frame

and

the

optics

scratches

carrier.

which

©

(4)

Figure

4-4.

optically

to

Figure

assembly

latched,

In

order

the

could

Occlusion

Optics

Assembly

by

reflecting

pair

4-4.

Optics

within

the

sensing

to

function

impede

Occlusion

motor

chamber

light

gele

phototransistor

Detail

infrared

forms

Assembly

correctly,

light

the

occlusion

frame.

area

in

Detail).

When

all

transmission.

Bottom

LED

view

beams

offa

detector

Both

the

cartridge

the

cartridge

four

optics

Air

LED

Air

phototransistor

sensing

and

pairs

of

is

lines

up

surfaces

©

5D4

25

When

fluid

is

present

light

because

being

reflected

cartridge

the

phototransistor.

conduction

on.

is

AIM/AIM

the

Plus

Technical

the

sensing

(towards

fluid

back

chamber

Presence

the

Service

in

the

cartridge,

refracts

to

the

phototransistor.

on

state). In

Manual

most

of

behaves

of

air

thus

summary,

.

the

air

detect

the

light

from

When

as a mirror,

causes

an

4-3

phototransistor

the

phototransistor

air

is

present

reflecting

the

air

detect

air

alarm

means

receives

in

much

ofthe

phototransistor

that

relatively

into

the

sensing

light

from

the

air

detect

430-600035-002

low

the

fluid

rather

chamber

the

LED

to

go

further

phototransistor

(Rev.

levels

of

than

of

the

back

to

into

11/99)

Page 22

Section

4,

Theory

of

Operation

When

phototransistor

cartridge

buildup

balloon

on

less

drive

cartridge

the

occlusion

The

cartridge

Once

no

occlusion

is

when

causes a small

expands

the

inside

of

the

reflective.

and

An

causes

is

installed

phototransistor

alarm

check

cartridge

alarm

is

the

pump

beam.

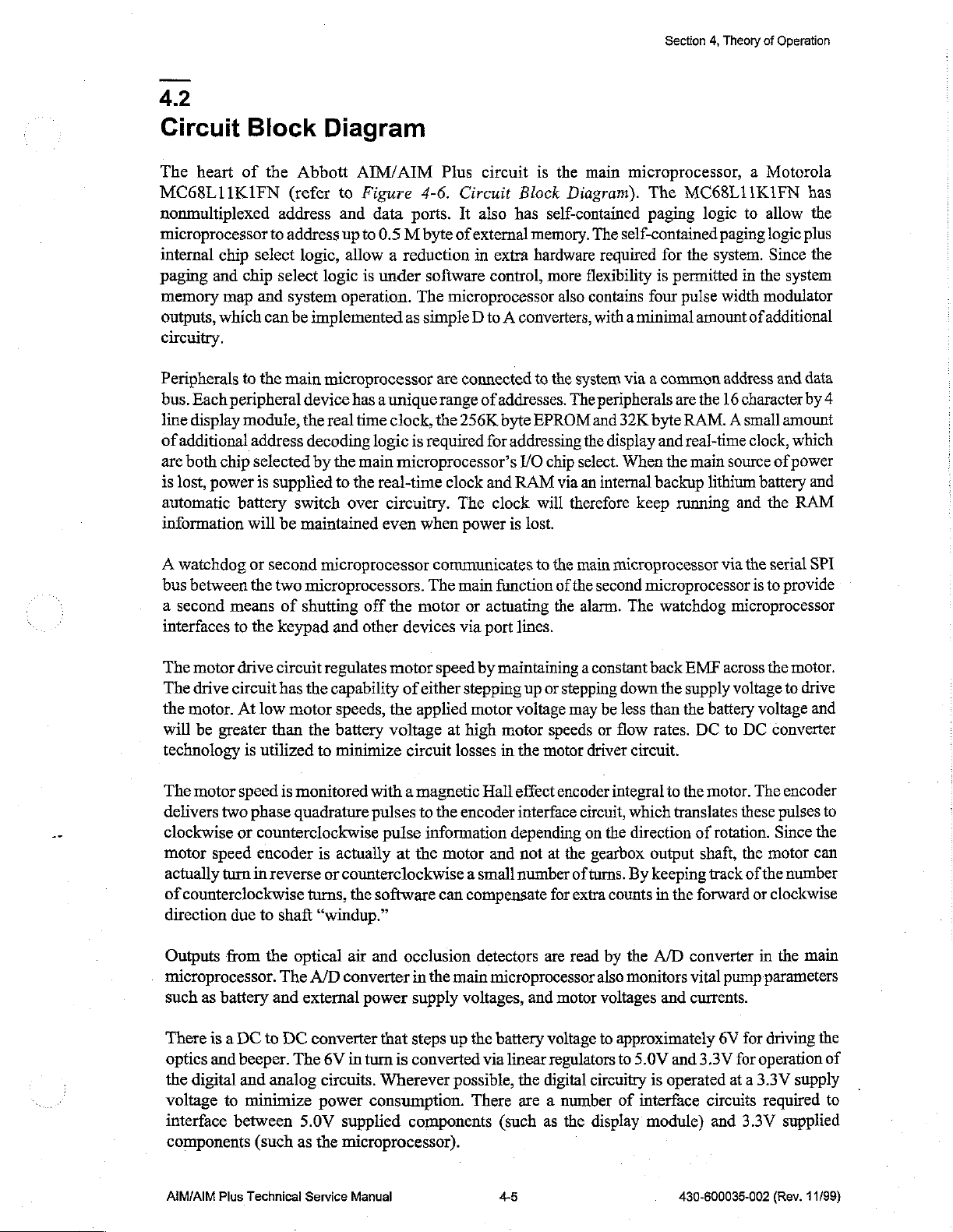

The

latch

holds

the

the

motor

and

the

cartridge

tab

on

is

the

the

indentation

cartridge next

condition

driven

turning

further

causes a pressure

balloon

sufficiently

sensing

occlusion

the

in

and

means

alarm

displayed

is

running,

cartridge

optics

such

chamber,

condition

transistor

the

pump,

an

occlusion

that

the

utilizes

whenever

the

in

assembly

on

to

the

is

present,

into

light

conduction.

buildup

segment

within

that a significant

the

balloon

therefore

to

go

further

or

the

cartridge

alarm

occlusion

the

the

occlusion

the

motor

(refer

the

side

of

blue

foil.

or

phototransistor

same

phototransistor

lightpath

alarm

frame

to

Figure

the

cartridge

is

returned

When a distal

of

the

the

cartridge

amount

filled

with

results

out

is

check

will

with

in a decrease

of

conduction

incorrectly

cartridge

is

interrupted

be

displayed

tabs

4-5.

Latch

near

to

the

fluid

inside

sensing

of

the

fluid

causes

installed

is

off.

sensor

at

two

points

Assembly).

the

rotor;

occlusion

occlusion

the

chamber

balloon

surface

the

mirror

in

occlusion

(towards

no

alarm

will

as

the

occlusion

and

the

pump

for

any

to

keep

One

the

second

phototransistor

condition

cartridge.

to

expand.

touches

surface

is

present,

This

pressure

When

the

to

become

and

plastic

phototransistor

the

off

state).

When

light

will

be

reflected

occur.

In

summary,

alarm. A check

is

not

in

the

run

interruption

it

properly

capture

point

of

the

aligned

point

is a protruding

the

the

the

no

to

an

state.

light

to

on

the

Two

the

case

The

latch

lever

and

the

Cartridge

holding

pivot

pins

hold

is

arms

outward

cartridge

tabs

hold

the

pivot

opened

locked

the

latch

pins

in

by

moving

from

the

motor

into

Figure

assembly

place.

the

thumb

frame

place

by

4-5.

onto

tab

and

moving

Ejection

Latch

Assembiy

the

motor

frame.

down

and

then

rotating

ejects a cartridge

the

thumb

tab

Once

if

one

down,

Sa

the

pump

it

back.

is

installed.

inward

is

assembled,

This

action

The

and

then

5D-2c_25

tabs

rotates

latch

is

upward.

on

the

closed

430-600035-002

(Rev.

11/99)

4-4

AIM/AIM

Plus

Technical

Service

Manual

Page 23

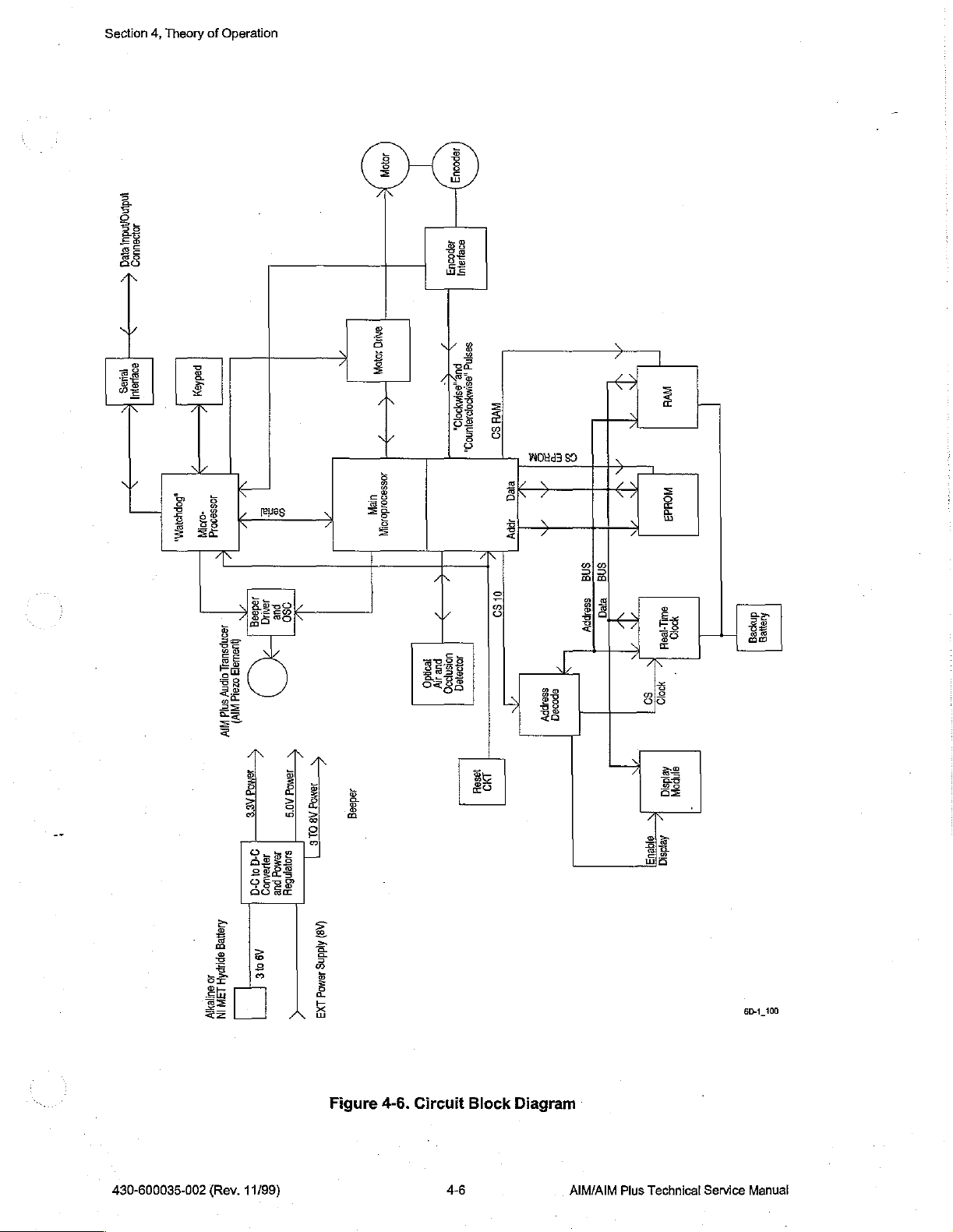

4.2

Section

4,

Theory

of

Operation

Circuit

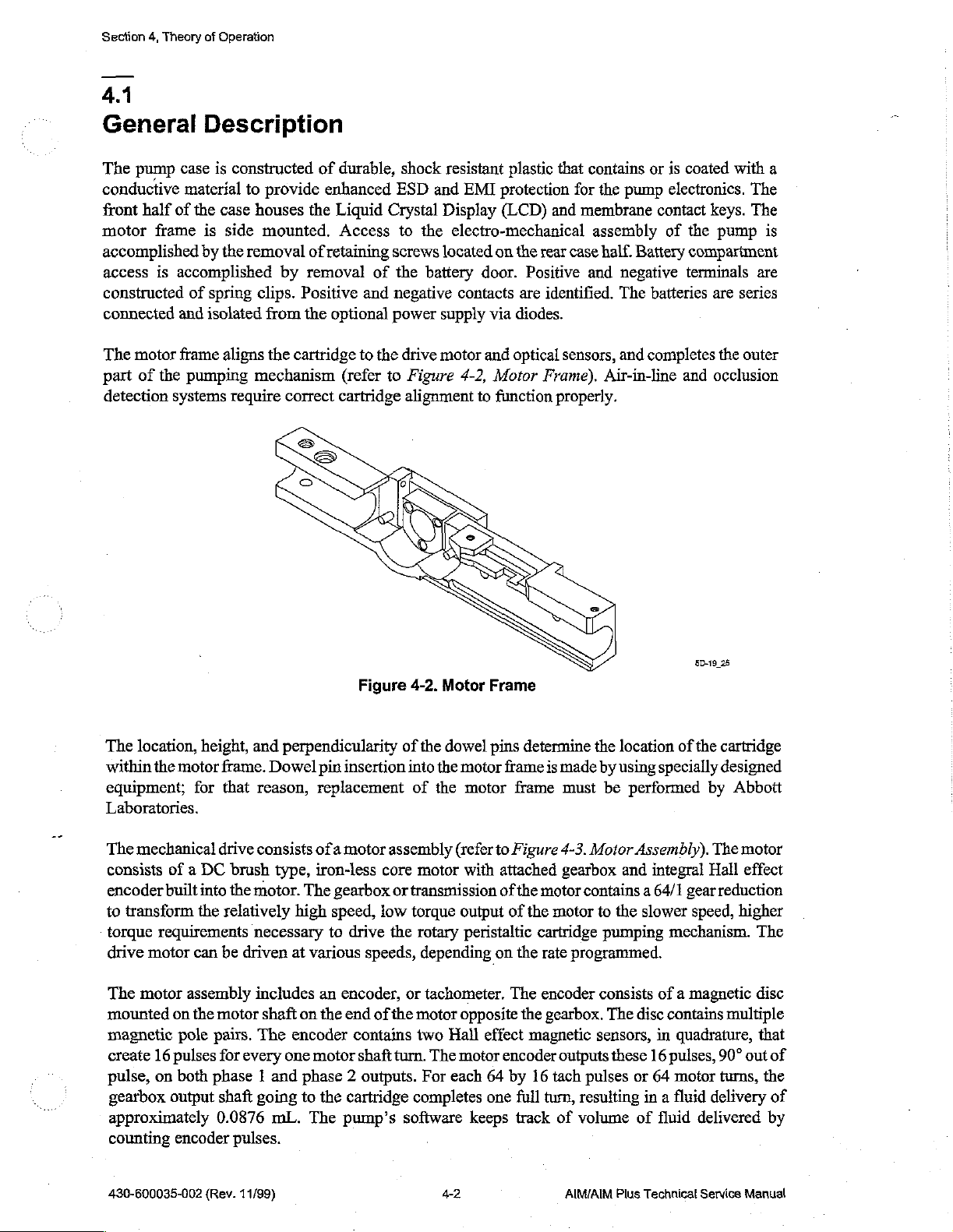

The

heart

MC68L1IKIFN

nonmultiplexed

microprocessor

internal

paging

memory

outputs,

circuitry.

Peripherals

bus.

Each

line

display

of

additional

are

both

is

lost,

automatic

information

A

watchdog

bus

between

a

second

interfaces

Block

of

chip

select

and

chip

map

and

which

to

the

peripheral

module,

address

chip

selected

power

is

battery

will

or

the

means

to

the

Diagram

the

Abbott

(refer

address

to

address

logic,

select

system

can

be

main

device

the

decoding

supplied

switch

be

maintained

second

two

microprocessors.

of

shutting

keypad

AIM/AIM

to

and

up

allow a reduction

logic

operation.

implemented

microprocessor

has a unique

real

time

by

the

to

the

over

microprocessor

and

Plus

Figure

data

to

is

4-6.

ports.

0.5 M byte

under

software

The

as

simple D to A converters,

are

range

clock,

the

logic

is

required

main

microprocessor’s

real-time

circuitry.

even

when

communicates

The

off the

other

motor

devices

circuit

Circuit

It

also

of

external

in

microprocessor

connected

of

256K

for

clock and

The

power

main

or

actuating

via

port

is

Block

has

self-contained

memory.

extra

hardware

control,

more

te

addresses.

byte

EPROM

addressing

I/O

chip

RAM

clock

will

is

lost.

to

function

lines.

the

main

Diagram).

The

required

flexibility

also

contains

with a minimal

the

system

The

peripherals

and

the

select.

via

an

internal

therefore

the

main

of the

second

the

alarm.

microprocessor, a Motorola

The

MC68L11K1FN

paging

self-contained

four

via a common

32K

byte

display and

When

backup

keep

microprocessor

microprocessor

The

logic

paging

for

the

system.

is

permitted

pulse

amount

are the

RAM.

real-time

the

main

lithium

running

watchdog

to

allow

logic

Since

in

the

width

modulator

of

additional

address and

16

character

A small

clock,

source

of

battery and

and

the

via the

serial

is

to

microprocessor

has

the

plus

the

system

data

by

4

amount

which

power

RAM

SPI

provide

The

motor

drive

The

drive

circuit

the

motor.

will

technology

The

delivers

clockwise

motor

actually

of

counterclockwise

direction

Outputs

microprocessor.

such

There

optics

the

voltage

interface

components

At

be

greater

is

motor

speed

two

or

speed

turn

due

from

as

battery

is a DC

and

beeper.

digital

and

io

minimize

between

low

than

utilized

phase

counterclockwise

encoder

in

reverse

to

the

and

to

analog

(such

circuit

regulates

has

the

capability

motor

the

to

is

monitored

quadrature

is

or

turns,

shaft

“windup.”

optical

The

A/D

external

DC

converter

The

6V

circuits.

power

5.0V

as

the

motor

speeds,

battery

minimize

the

voltage

with a magnetic

pulses

pulse

actually

speed

of

either

applied

circuit

to

the

information

at

the

motor

by

stepping

motor

at

high

losses

Hall

encoder

and

maintaining a constant

motor

in

counterclockwise a small

the

software

air

and

converter

power

that

in

turn

Wherever

consumption.

supplied

can

compensate

occlusion

in

the

main

supply

steps

is

converted

voltages,

up

possible,

components

detectors

microprocessor

the

battery voltage

via

There

(such

microprocessor).

up

or

stepping

voltage

the

effect

interface

depending

not

number

linear

the

may

speeds

motor

encoder

circuit,

at

the

of

for

extra

are

read

and

motor

regulators

digital

are a number

as

the

back

down

be

less

than

or

flow

driver

circuit.

integral

which

on

the

direction

gearbox

turns.

output

By

keeping

counts

by

the

also

monitors

voltages

to

approximately

to

5.0V

circuitry

display

is

of

interface

module)

EMF

the

supply

the

rates.

DC

to

the

motor.

translates

of

shaft,

in

the

forward

A/D

converter

vital

and

currents.

and

3.3V

operated

circuits

across

the

voltage

battery

voltage

to

DC

The

these

rotation.

the

track

of

the

or

in

pump

parameters

6V

for

driving

for

operation

at a 3.3V

required

and

3.3V

motor.

to

drive

and

converter

encoder

pulses

to

Since

the

motor

can

number

clockwise

the

main

the

of

supply

to

supplied

AIM/AIM

Plus

Technical

Service

Manual

4-5

430-600035-002

(Rev.

11/99)

Page 24

Section

4,

Theory

of

Operation

indingAndu

201094105)

eed

ETTİ

Ris

sBOpyoeM,

pedian

105589014

00

LI

769005464

use

0000

Ozal

9010

NIV)

NR

Аден

эру

A

ta

AN

の

g

E

100008

79040

pue

PC)

воле

|

VAT

JBMO

Ji9AU0O

PUR

Asa

ç

290

|

Jewod

TROIE

A09

DIE

siojenbay

(98)

Addng

Alddng

Jamo,

4emog

1x3

JON

ANO

ION

jedesg

MTT

jepoou3

po

UB,

=

OSC,

“ee

VOSSO

1098181

pur

tendo

dy

вера

зала

‚евмрораииоо,

AVE

SO

8

Е

med

IPY

ES)

Î

1996H

DI

a

5

sna

SSOPPY

звалрру

орооеа

sna

era

Wi

[|

moud3

eur

1684

1000

so

fejdsia

ferdsia

EE

Woo

:

旨

lnpo

内

dmpeg

heyeg

È

2

430-600035-002

(Rev.

11/99)

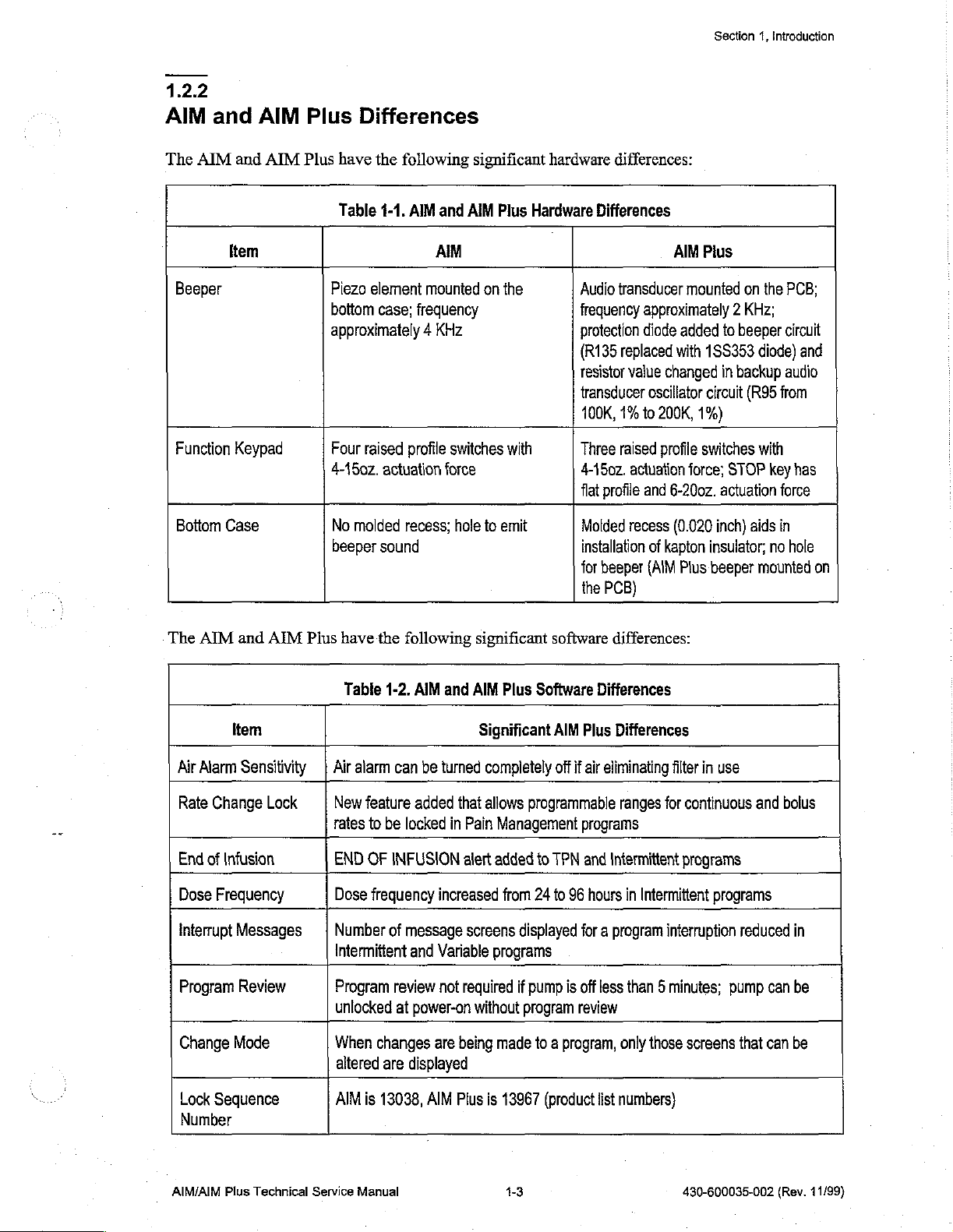

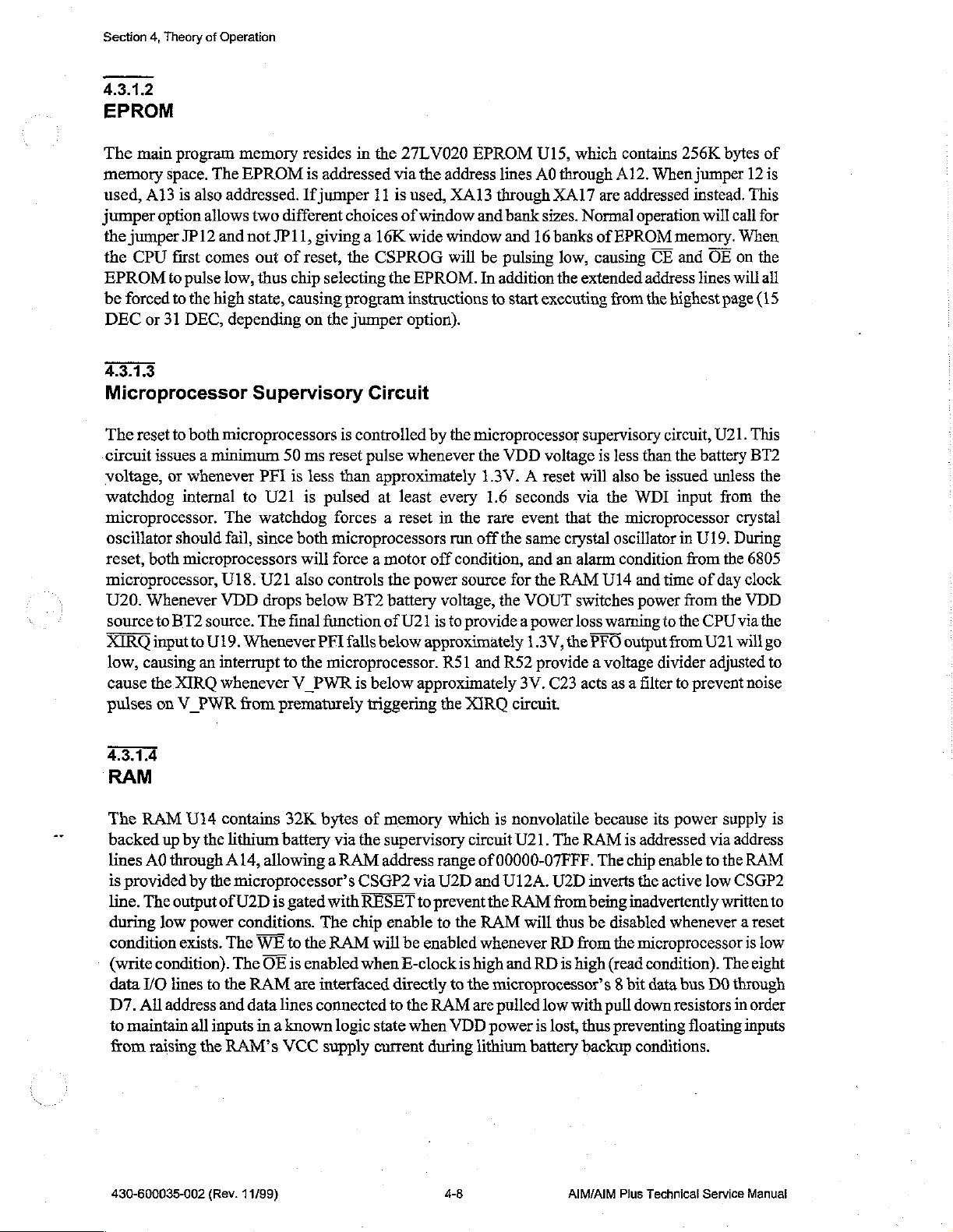

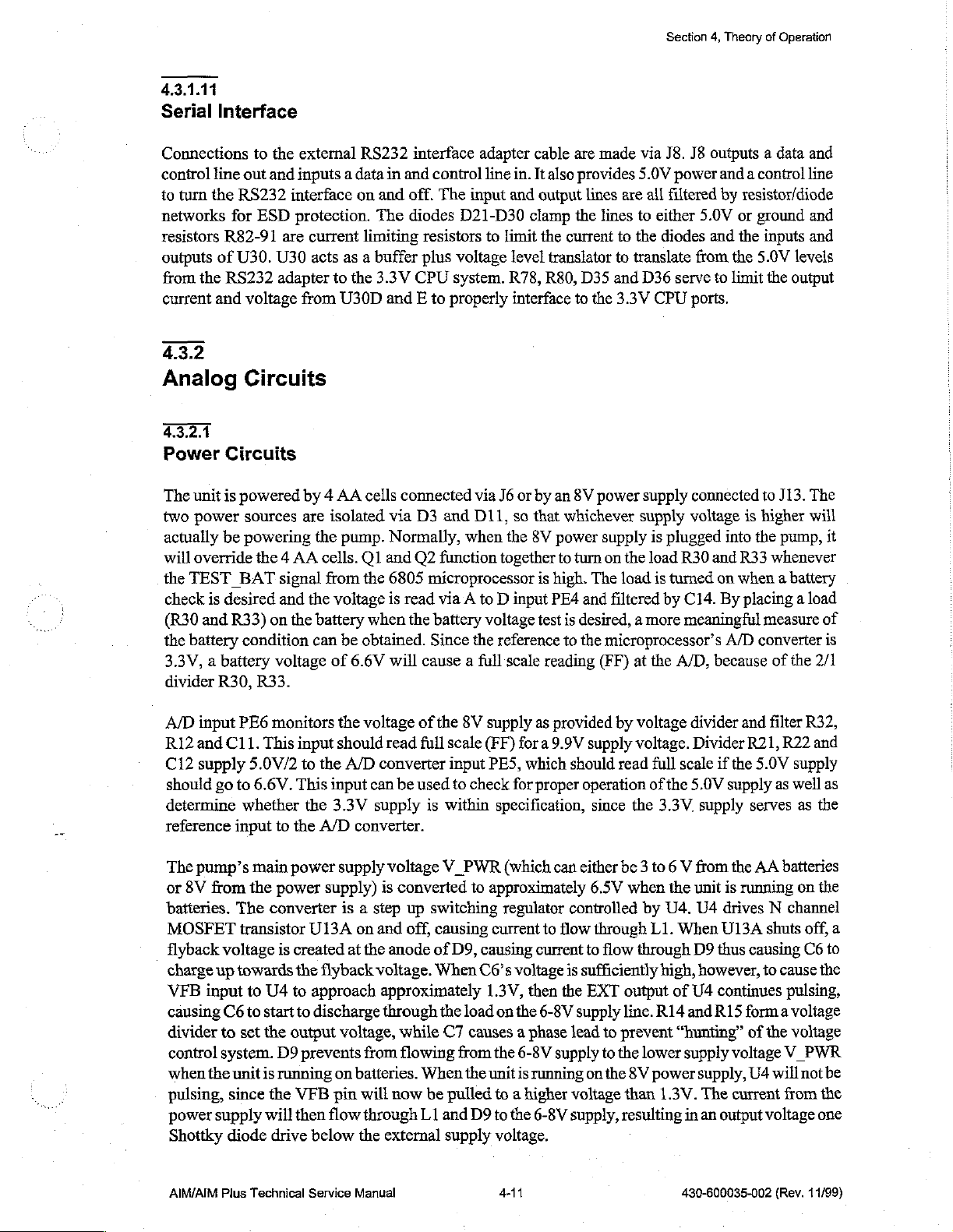

Figure

4-6.

Circuit

48

Block

Diagram

AIM/AIM

Plus

Technical

Service

Manual

Page 25

43

Section

4,

Theory

of

Operation

Detailed

Refer

to

Section

Figure

ロロ

Figure

Figure

Figure

ロロ

Figure

Figure

Figure

ロロ ロロ

Figure

Figure

ロロ

Figure

4.3.1

CPU

9-1,

9-2,

9-3,

9-4,

9-5,

9-6,

System

Circuit

9,

Drawings,

AIM

AIM

AIM

AIM

AIM

AIM

9-7,

AIM

9-8,

AIM

9-9,

AIM

9-10,

AIM

Description

for

the

following

Analog

Microprocessor

Power

PC

PC

Plus

Plus

Plus

Plus

Plus

Schematic

and

Miscellaneous

Board,

Board,

Front

Back

Analog

Microprocessor

Power

PC

PC

Schematic

and

Board,

Board,

fold-out

(CPU)

Miscellaneous

Front

Side

Side

Back

Schematic

Circuitry

(CPU)

Schematic

Side

Side

schematics

Schematic

Circuitry

Schematic

and

PCB

drawings:

43.11

Microprocessor

The

Motorola

attached

The

68L11

utilized

range

and

operation.

Resistors

microprocessor

form a low-pass

the

microprocessor.

microprocessor

that

allow

through

The

microprocessor

can

be

microprocessor

crystal.

peripherals.

MC68L11K1FN

peripherals

microprocessor

in

conjunction

C17

and

R116

and

into

filter

has

the

microprocessor

A15).

set

up

via

is

The

E-clock,

(CPU)

are

supplied

contains

with

C16

provide

R117

the

expanded

to

supply a low

The

microprocessor

internal

also

software

typically

paging

contains

however,

microprocessor

by a 3.3V

an

internal

the

2MHz

pull

the

correct

up

the

memory

crystal,

noise

logic

controlled

to

access

memory

internal

to

issue

chip

the

crystal

can

frequency

be

U19

VDD

supply

single

Y1.

R37

loading

MODA

mode

and

of

reference

has

separate

by

beyond

chip

selects

selects

stretched

for

divided

forms

the

to

achieve

inverter

biases

and

phase

MODB

operation

to

the

internal

address

extended

its

normal

(CSPROG,

certain

by

under

software

basis

of the

minimal

(parallel

the

inverter

shift

inputs

coming

A/D

and

address

64K

CSGP2,

address

4,

or

500KHz

control

main

CPU

power

resonant)

for

operation

to

maintain

to

VDD

out

of

reset.

converter

data

lines.

lines

XA13

limitation

CSGP1

ranges.

in

The

the

to

system.

It

consumption.

oscillator

circuit

in a linear

stable

oscillator

to

program

R115

and

C43

via

VRH

input

In

addition,

through

(controlled

and

E-clock

case

allow

XA18

by

CSI0)

on

of a 2MHz

for

slower

and

the

to

the

AO

that

the

ΑΙΜ/ΑΙΜ

Plus

Technical

Service

Manual

4-7

430-600035-002

(Rev.

11/99)

Page 26

Section

4,

Theory

of

Operation

4.3.1.2

EPROM

The

main

program

memory

used,

jumper

the

the

EPROM

be

DEC

4.3.1.3

Microprocessor

The

circuit

voltage,

watchdog

microprocessor.

oscillator

reset,

microprocessor,

U20.

source

XIRQ

low,

cause

pulses

space.

A13

is

also

option

jumper

CPU

forced

JP12

first

to

pulse

to

the

or

31

DEC,

reset

to

both

issues a minimum

or

whenever

internal

should

both

microprocessors

Whenever

to

BT2

input

to

causing

the

XIRQ

on

V_PWR

The

allows

and

comes

low, thus chip

high

microprocessors

The

fail,

U18.

VDD

source.

U19.

an

interrupt

whenever

memory

EPROM

addressed.

two

not

state,

depending

different

JP11,

out

of

causing

resides

is

If

reset,

on

Supervisory

50

ms

PFI

is

to

U21

is

watchdog

since

both

will

U21

also

drops

below

The

final

Whenever

to

the

V_PWR

from

prematurely

in

the

27LV020

addressed

jumper

choices

giving a 16K

selecting

program

the

11

the

CSPROG

jumper

via

is

used,

of

wide

the

EPROM.

instructions

option).

Circuit

is

controlled

reset

pulse

whenever

less

than

approximately

pulsed

microprocessors

controls

function

PFI

microprocessor.

at

least

forces a reset

force a motor

the

power

BT2

battery

of

U21

falls

below

is

below

triggering

EPROM

the

address

XA13

window

window

will

by

the

every

in

run

off

voltage,

is

to

approximately

R51

approximately

the

lines

through

and

bank

and

be

pulsing

In

addition

to

start

microprocessor

the

VDD

1.3V. A reset

1.6

seconds

the

rare

event

off

the

same

condition,

source

and

for the

the

VOUT

provide a power

1.3V,

and

R52

3V.

XIRQ

circuit.

U15,

which

A0

through

XA17

sizes.

16

banks

low,

the

executing

voltage

that

crystal

an

RAM

the

contains

A12,

are

addressed

Normal

extended

supervisory

will

via

alarm

switches

loss

PFO

operation

of

EPROM

causing

is

the

U14

CE

address

from

the

less

than

also

be

the

WDI

microprocessor

oscillator

condition

and

power

warning

output

When

provide a voltage

C23

acts

as a filter

256K

jumper

instead.

will

memory.

and

OE

lines

highest

circuit,

the

battery

issued

unless

input

in

U19.

from

time

of

from

to

the

CPU

from

U21

divider

to

prevent

adjusted

bytes

call

When

on

will

page

U21.

from

crystal

During

the

day

clock

the

VDD

via

will

noise

of

12

is

This

for

the

all

(15

This

BT2

the

the

6805

the

go

to

4.3.1.4

RAM

The

RAM

backed

lines

is

line.

during

condition

(write

data

D7.

to

from

430-600035-002

up

A0

through A 14,

provided

The

output

low

exists.

condition).

I/O

lines

All

address

maintain

raising

by

Ul4

the

by

the

power

to

all

inputs

the

(Rev.

contains

lithium

microprocessor’s

of

U2D

conditions.

The

The

the

and

RAM’s

32K

battery

allowing a RAM

is

gated

WE

to

the

OE

is

enabled

RAM

are

data

lines

in a known

VCC

11/99)

bytes

The

interfaced

connected

supply

of

via the

CSGP2

with

RESET

chip

RAM

when

logic

memory

supervisory

address

enable

will

via

to

prevent

be

enabled

range

U2D

to

E-clock

directly

to

the

RAM

state

when

current

during

4-8 AIM/AIM

which

is

nonvolatile

circuit

U21.

The

of

00000-07FFF.

and

U12A.

the

the

RAM

whenever

is

high

to

the

microprocessor’s 8 bit

are

pulled

VDD

power

lithium

RAM

will

and

RD

battery

U2D

from

thus

RD

low

is

lost,

is

because

RAM

The

inverts

being

be

from

high

with

thus

backup

its

power

is

addressed

chip

enable

the

active

inadvertently

disabled

the

(read

pull

preventing

Plus

whenever a reset

microprocessor

condition).

data

bus

down

resistors

conditions.

Technical

supply

via

address

to

the

low

CSGP2

written

is

The

DO

through

in

floating

inputs

Service

is

RAM

to

low

eight

order

Manuat

Page 27

4.3.1.5

Time

U20

battery

reliable

by

power

enabled

by

does

for

U20,

allow

Ul2

insuring

inadvertent

4.3.1.6

Of

Day

contains a separate

backup

oscillator

the

RAM.

U16.

not

U20

so

For

loss

conditions,

by a combination

When

exist.

CSIO

then

becomes

that

U20

ANDing

is

also

powered

valid

access

Display

Clock

32.768

conditions.

function.

the

timer,

otherwise

of

A5-A11

of

the

logic

are

can

be

1000-101F.

cannot

E-clock

by

level

or

high

be

the

KHz

C20

and

C21

The

VDD

supply

it

is

also

important

lithium

the

microprocessor

low

and

CSIO

set

active

The

written

with

same

“1”

backup

during

RD

battery

conditions

battery

crystal

provide

for

battery

is

in

the

range

NAND

low

and

RD

backed

to

current

oscillator

U20

that

CSIO

low,

gate

power

signals

the

circuit

the

necessary

is

the

all

inputs

current

line

U20

is

of

1000-1FFF

U12B

conditions.

to

U20

supply

control

during

power

for

same

battery

be

pulled

drains

and

additional

chip

selected,

via

allows

in

the

as

the

inputs

loss

Section

low

power

additional

phase

backed

to a known

will

be

high.

address

provided a reset

software.

reset

to

disable

U12C

and

proper

RAM

of

and

these

time

time

devices

conditions.

4,

Theory

of

consumption

shift

to

maintain

VDD

supply

logic

state

The

CS

to

decoding

The

effective

the

U12D

sequence.

of

provided

condition

chip

NAND

Note

day

clock,

and

preventing

Operation

during

utilized

during

U20

is

address

select

to

gates

that

thus

The

display

buffers

the

nominal

display

effective

on.

U9A

resistance.

Q12,

U10A,

of

the

software.

to

average

U11B

display.

level

of

the

display

is a separate

the

data

3.3V

is

enabled

address

serves

The

and

display.

This

the

and

Q3

act

The

maximum

Q3

will

and

lines

bus

of

as a 3.3V

two

Q13.

The

pulse

pulses

together

reduce

prevent

4317

Encoder

The

encoder

phasel

decoding

counterclockwise.

Interface

integral

and

phase2.

the

pattern

self-contained

D4-D7,

system

via

U17

1020-1021

to

LED’s

that

U2A,

PW4

output

train

is

into a dc

to

display

the

contrast

oscillations.

Circuit

to

the

These

of

the

two

AO,

and

to

the

when

CSIO

for the

5.0V

are

part

U9B,

U1

is a pulse

applied

level

function

contrast

AIM

Plus

outputs

outputs,

module

EN_DISP

5.0V

bus

levels

is

low,

display.

translator

of

1B,

to a low

that

as a unity

to

the

motor

are

approximately

The

to

the

display

Q3

and

train

pass

is

directly

is

achieved

display.

contains a Hall

itis

possible

that

is

interfaced

(U17-13)

required

AS

is

high

backlight

drive

the

gate

module

associated

output

filter

gain

C56

with

and

proportional

buffer,

when

functions

90

to

determine

to

the

and

provides a logic

by

the

display

and

A6

through

to

the

display

of

O6

at a full

are

driven

components

variable

divider

to

driving

the

drain

R27,

the

the

of

as a filter

effect

encoder

degrees

out

if

the

main

board

level

for

proper

A11

are

is

enabled

5.0V

in a similar

work

to

control

duty

cycle,

R28

and

C13

duty

cycle

contrast

Q3

of

motor

is

at

to

smooth

with

phase

is

terminal

ground.

quadrature

with

turning

via

U32.

translation

from

operation.

low,

giving

by

driving

to

insure

low

manner

of

by

U9D,

the

contrast

controllable

which

function

the

waveform.

(V0)

of

Raising

out

pulses

outputs,

each

other.

clockwise

U32

The

an

Q6

on

by

the

the

from

By

or

PW2

generates a normally

buffer and

when

high.

a

lower

AIM/AIM

level

PW2

goes

Strobing

power

Plus

Technical

the

translator

low, and

encader

state

when

Service

high,

U10B

the

state

helps

its

Manual

low

and

of

reduce

strobe

going

pulse

simultaneously

both

phases

power

input

is

consumption

is

low.

4-9

that

generates a strobe

clocks

U7A

latched

into

U7A

from

and

and

the

encoder,

pulse

U7B.

The

U7B

430-600035-002

to

encoder

when

since

the

PW2

the

encoder

is

strobed

pulse

encoder

(Rev.

via

goes

is

in

11/99)

Page 28

Section

USA

pulse

U31B

4,

Theory

of

Operation

and

U8B

detect

the

CLKWISE

rises

whenever

CTRCLKWISE

direction.

counterclockwise

gearbox.

software

flow

rates.

line

followed

phase2

line

Normally

rotation,

By

subtracting

can

make

4318

Backup

U18

under

where

U18.

TCAP

frequency

circuitry

peripherals

disabled

microprocessor.

backup

Microprocessor

functions

fault

PD4

The

input

as a backup

conditions,

is

the

clock

oscillator

to

U18

can

be

to

detect

such

as

via

PAX4,

Note

microprocessor.

most

that

the

encoder

at

the

rate

of

by

at

the

the

phase2

pulse

pulse

rises

encoder

motor

usually

the

small

corrections

for the

system

U18

communicates

line,

PD2

input

to

U18

originates

independently

compared

the

keypad

and

that

with

encoder

the

alarm

the X is

or

and

is

turning

the

encoder

rising.

followed

pulse

does

as

the

number

motor

or

CPU

is

the

serial

monitors

software

circuit

serial

can

used

in

in a clockwise

pulses.

Clockwise

Counterclockwise

by

phasel

rate

whenever

turn

clockwise

motor

of

counterclockwise

“backlash”

watchdog

to

the

data

from

the

the

to

the

failures.

RS232

be

enabled

the

port

interface

the

is

stopping

to

help

main

microprocessor

output

from

main

tach

frequency

“clockwise”

Most

of

via

line

bus

(normal)

direction

rotation

rotation

pulse

rising.

motor

turns

except

due

to

counts

and

help

improve

prevent

U18

and

microprocessor

from

pulse

the

port

lines

circuit.

PAXO,

Most

totally

names

to

is

Pulses

counterclockwise

for

very

“backlash”

from

the

pump

U19

PD3

U19

phase]

from

are

importantly,

independently

signify

and

is

decoded

detected

will