Page 1

US User Manual

1116 554 , 1116 66 3

1116752 Rev. A 2018/09

Page 2

Dear Customer,

Congratulations on the purchase of your Anion™ 2 Analyzer.

Upon arrival of your Anion 2 Analyzer we recommend that the serial number along with the software version be recorded in the table provided below. The

additional rows in the table are to be utilized if a software upgrade is performed on your Anion 2 Analyzer. The recorded information will be of great value if and

when a question is reported, or the desire to add a new Anion Test to your analyzer arises.

Serial number

(for serial number (SN), see label on the rear side of the analyzer or on the transport container)

Software records

Date

Upon receipt

1. SW upgrade

2. SW upgrade

3. SW upgrade

4. SW upgrade

5. SW upgrade

* See start-up menu when you power on the analyzer (see “How to power on the analyzer”, page 11).

Software version* Anion™ Tests available

Notes

_________________________________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________________________________

Technical Support

Call 1.866.216.9505

2 | US

AFINION™ 2 User Manual

Page 3

Intended use of the AFINION™ 2 System

Anion 2 System, consisting of the Anion 2 Analyzer and the Anion Test Cartridges, is for in vitro diagnostic use only. Anion 2 Analyzer is a compact multi-assay

analyzer for point-of-care testing and is designed to analyze the Anion Test Cartridges.

CLIA Statements - Waived Anion™ Tests

Anion HbA1c is waived under the Clinical Laboratory Improvement Amendment of 1988 (CLIA`88). A CLIA Certicate of Waiver is needed to perform testing in a

waived setting.

If the laboratory does not have a Certicate of Waiver, the Application for Certication (Form CMS-116), can be obtained at

https://www.cms.gov/cmsforms/downloads/cms116.pdf.

The form should be mailed to the address of the local State Agency of the State in which the laboratory resides

(https://www.cms.gov/CLIA/12_State_Agency_&_Regional_Ofce_CLIA_Contacts.asp).

If the laboratory modies the Anion Test or Anion 2 Analyzer system instructions, the test no longer meets the requirements for waived categorization. A modied

test is considered to be highly complex and is subject to all applicable CLIA requirements.

Conformity to directives and standards

European IVD directive and RoHS 2 directive (CE marking)

The Anion 2 Analyzer meets all provisions in the Directive 98/79/EC on in vitro diagnostic (IVD) medical devices and in the Directive 2011/65/EU on the restriction

of the use of certain hazardous substances in electrical and electronic equipment (RoHS 2).

North American product safety standards (CNUS mark)

The Anion 2 Analyzer has been tested and found to be in conformity with North American safety standards. See list of safety standards below.

Safety standards

The Anion 2 Analyzer has been tested and found to be in conformity with standards for Safety requirements for electrical equipment for measurement, control, and

laboratory use (IEC 61010-1:2010 , UL 61010-1:2012, CAN/CSA-C22.2: 61010-1 -12) and standard for Particular requirements for in vitro diagnostic (IVD) medical

equipment (IEC 61010-2-101:2015).

EMC standards

The Anion 2 Analyzer has been tested and found to be in conformity with standards for Electrical equipment for measurement, control, and laboratory use

– EMC requirements (EN 61326-1:2013, EN 61326-2-6:2006, EN 61326-2-6:2013 and CFR 47 Telecommunications, Chapter I- FCC Part 15 – Radio Frequency

Devices – Subpart B: unintentional radiators).

AFINION™ 2 User Manual

US | 3

Page 4

4 | US

AFINION™ 2 User Manual

Page 5

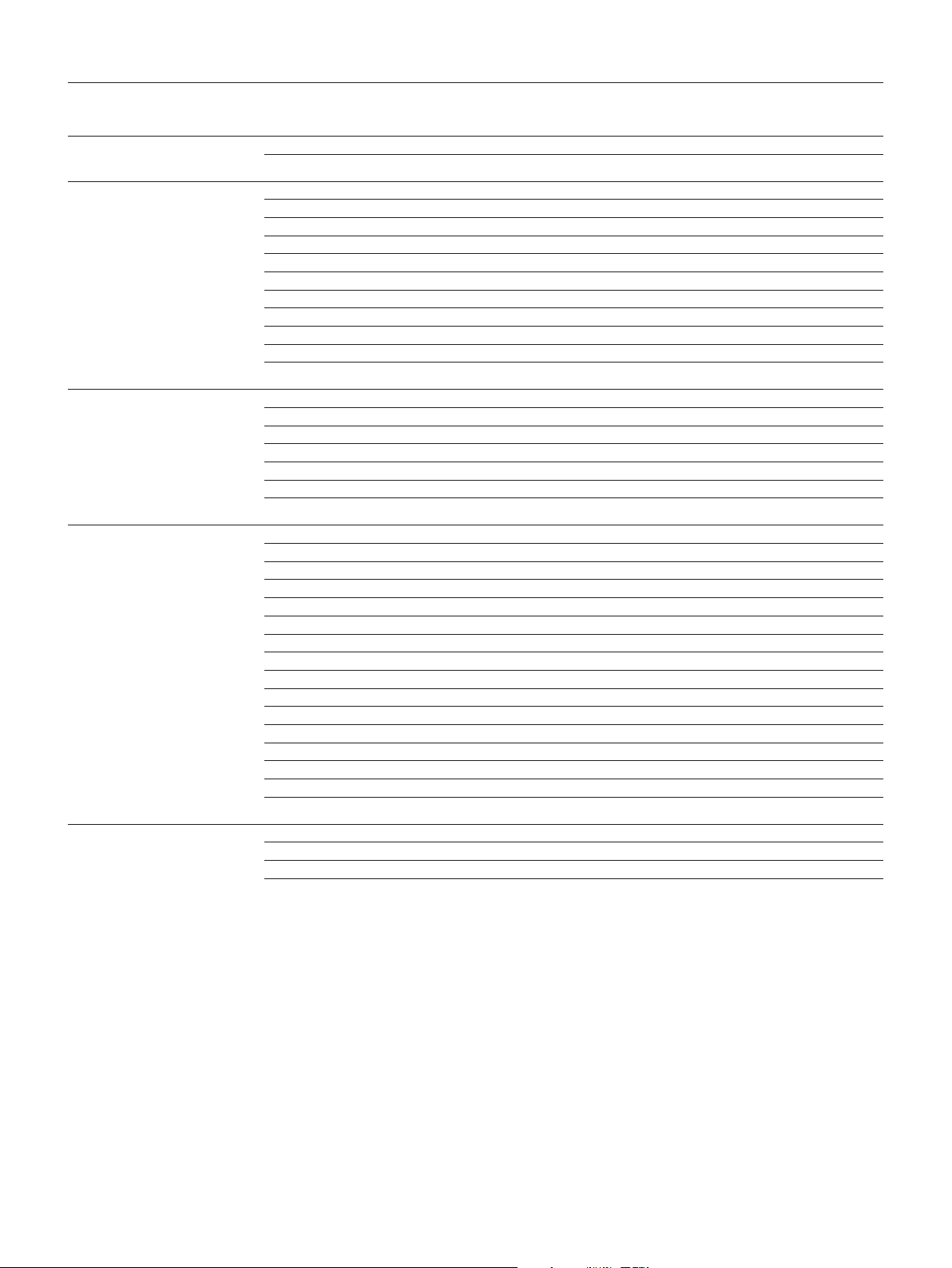

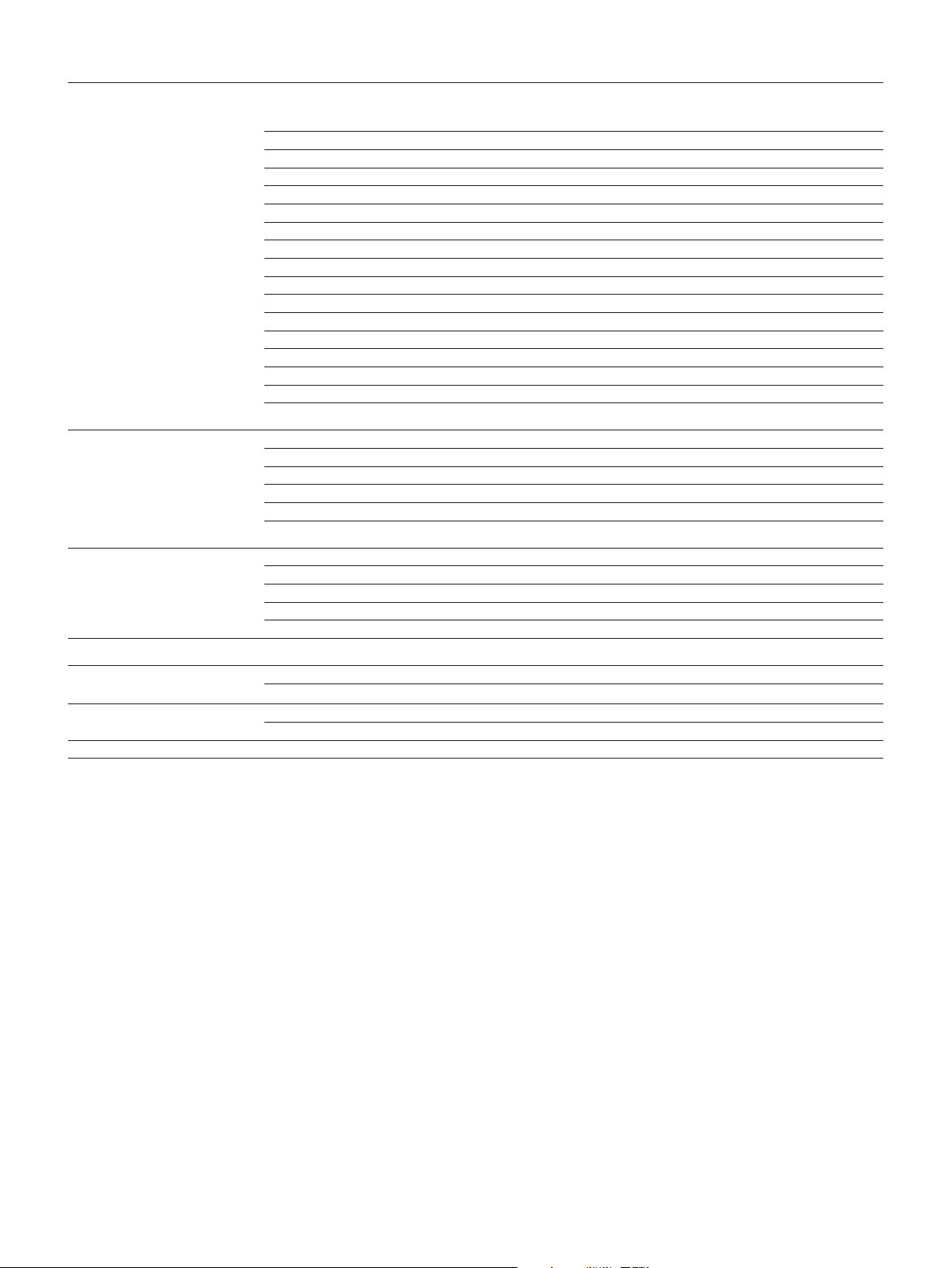

Table of Contents

Table of contents

Introduction About this user manual 7

Examining the package contents 7

Analyzer System Description Description of the AFINION™ 2 Analyzer 8

Description of the Anion™ Test Cartridge 8

How the AFINION™ 2 System works 9

Internal process control 9

The analyzer self-test 9

The fail-safe mechanisms 9

External process control 9

Patients ID 9

Operator ID 9

Quality Control lockout 9

Calibration 9

Getting Started Installing your analyzer 10

Connecting power supply 10

Connecting additional equipment 10

Connectivity 10

How to power ON the analyzer 11

How to power OFF the analyzer 11

How to operate the analyzer 11

Conguration The AFINION™ 2 menus 12

Setting the conguration 13

Patient ID conguration 13

Patient ID enable/disable 13

Operator conguration 14

Operator ID enable/disable 14

Operator login expiration 14

Operator list management 14

Choosing language 15

Adjusting screen/beeper settings 15

Setting date and time 15

QC lockout conguration 16

General settings 17

Erase all contents and conguration 17

Analyzer network settings 17

Connectivity settings 18

Quality Control Why quality control testing? 19

Choosing control material 19

Handling and testing controls 19

Frequency of control testing 19

Table of contents continues on next page

AFINION™ 2 User Manual

US | 5

Page 6

Table of Contents

Testing Procedures Operating precautions 20

When operating the analyzer 20

When handling the test cartridge 20

Preparing for an AFINION™ 2 Analysis 20

Collecting a sample 21

Analysing a patient/control sample 21

Using the operator ID function 22

Entering operator ID 22

Using the patient ID function 22

Entering patient ID 22

Using the control ID function 23

Entering control ID 23

Using the QC lockout function 23

QC lockout status 23

Running controls with enabled QC lockout function 24

Patient and control results records 25

View, print and export patient and control results 25

Information Codes and

Troubleshooting

Maintenance Cleaning and maintenance 29

Warranty 30

Technical Specications AFINION™ 2 Analyzer 31

Gallery of Icons The touch buttons and their function 32

Symbols and Abbrevations 35

When an information code appears 26

Information codes caused by test-specic limitations 26

Information codes caused by sample or test cartridge 27

Information codes and messages caused by analyzer failure 27

Other information codes 28

Service information 28

Cleaning the exterior 29

Cleaning the cartridge chamber 29

Disposal of the analyzer 29

Software upgrade 29

Additional equipment 31

Other symbols and signs 34

6 | US

AFINION™ 2 User Manual

Page 7

Introduction

About this user manual

This user manual will guide you through installation, operation and maintenance of your Anion 2 Analyzer. The user manual also explains how the analyzer works,

describes the quality assurance system and assists you in troubleshooting.

For analysing patient samples or controls, please also read the test specic information given in the package inserts following the Anion Test Kits. The quick

reference guides, available from your local Anion supplier, highlight the main steps of the test procedures.

It is recommended that you become familiar with these user instructions before you start operating the Anion 2 Analyzer.

Some of the information in this user manual is accompanied with a symbol that points you to the following particulars:

Warnings and precautions

References to the package inserts for the specic Anion Tests and control kits

Examining the package contents

When unpacking, check the contents against the list below and examine the components for signs of shipping damage.

The Anion 2 package unit includes:

• Anion 2 Analyzer

• Power cable

• Power supply, 24 VDC

• User manual

• Quick guides for the available Anion Tests

If the package unit is found incomplete, please report missing items or shipping damage to your supplier. It is recommended to keep the shipping box in case of

later transportation of the analyzer.

AFINION™ 2 User Manual

US | 7

Page 8

Analyzer System Description

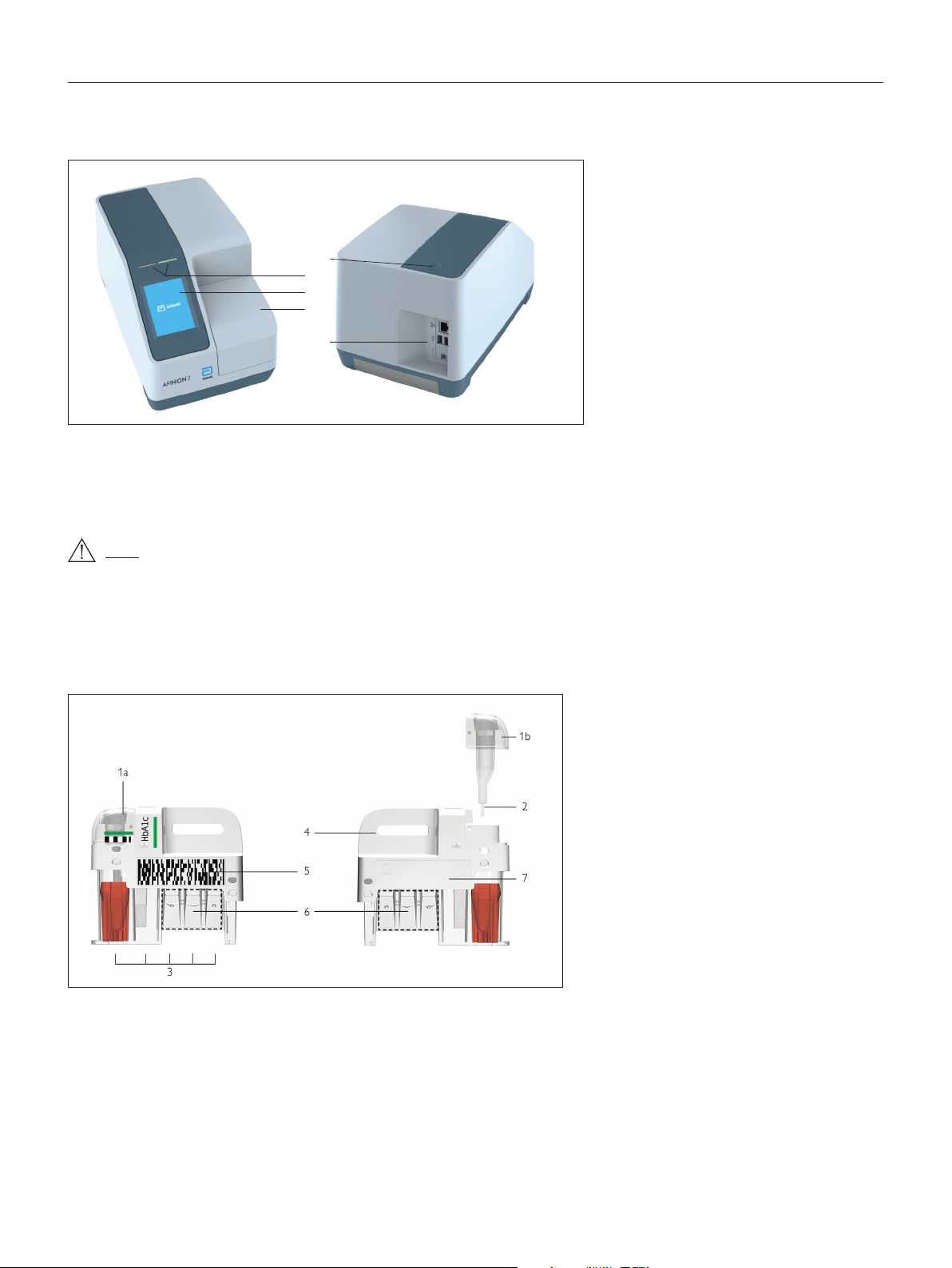

Description of the AFINION™ 2 Analyzer

Figure 1 shows the main exterior parts of the Anion 2 Analyzer.

1

2

3

4

5

Figure 1

1 ON/OFF button: Turns the power to the analyzer on and off.

2 Red and green LEDs: Light emitting diodes (LEDs) that indicates whether the analyzer is busy or not.

3 Touch screen: Allows you to communicate with the analyzer through touch buttons and messages.

4 The lid: Covers and protects the cartridge chamber.

5 Connectors: For connecting to mains power supply. Options for printer, barcode reader and/or LIS/HIS/EMR.

Do not open the lid manually.

Description of the Anion™ Test Cartridge

The Anion Test Cartridge is unique for each analyte to be measured, as the reagent composition, reagent volumes and the integrated devices are test specic.

The test cartridge label has a colour unique for the test. The test cartridges are separately packed in foil pouches to protect the reagents and plastic devices from

light, dirt and humidity. A single test cartridge contains all necessary reagents for one test and is ready to use. An integrated sampling device is used for collection

of the patient sample or control. The test cartridge cannot be reused. Figure 2 illustrates an Anion Test Cartridge with its functional parts:

Left side Right side

Figure 2

1 Sampling device: For collection of patient sample or control (1a - closed position, 1b - lifted position).

2 Capillary: Capillary to be lled with sample material.

3 Reaction wells: Contain all necessary reagents for one test.

4 Handle: For correct nger grip.

5 Barcode label: Contains assay and lot-specic information for the analyzer.

6 Optical reading area: Area for transmission measurement.

7 ID area: Space for written or labelled sample identication.

8 | US

AFINION™ 2 User Manual

Page 9

Analyzer System Description

How the AFINION™ 2 System works

The Anion 2 System uses different chemical and mechanical assay methods combined with advanced, computerized processing and measuring technology.

A test cartridge with patient sample or control is placed in the cartridge chamber of the analyzer. By manually closing the lid, the test cartridge is transported

into the analysis compartment of the analyzer. Test and lot-specic information is obtained from the barcode label (Figure 2). When the test cartridge enters the

analyzer, the integrated camera reads the barcode which then initiates the processing of the test cartridge. The sample and reagents are automatically transferred

between the wells. An internal camera monitors the entire process. Light-emitting diodes (LEDs) illuminate the reaction area, which can be either a coloured

membrane or a reaction well. The camera detects the reected or transmitted light, which is converted to a test result and displayed on the touch screen. When the

user accepts the result, the lid covering the cartridge chamber opens automatically and the used test cartridge can be removed and discarded. The analyzer is then

ready for the next run.

Internal process control

The analyzer self-test

A self-test is performed during start-up of the analyzer to ensure that the instrument is operating according to established specications. The self-test validates:

• Hardware and software integrity

• Test cartridge transport system

• Liquid transport system

• Camera vision system

If the self-test fails at any point, the red LED will start ashing and an information code will be displayed on the touch screen

(see “Information codes and troubleshooting”, page 26-28).

When the analyzer is powered on for a longer period, it will automatically restart once a day to ensure that a self-test is done regularly. This procedure does not

interrupt any analysis of the test cartridge.

The fail-safe mechanisms

Fail-safe mechanisms are included to secure safe processing. The integrated camera inspects the test cartridges initially before the process starts and during the

assay. If defects are detected (e.g. broken capillary, the cartridge is used past its expiry date), the test cartridge is rejected and an information code is displayed.

During processing vital functions and components (e.g. pumps, heater) are supervised. When problems are detected by the built-in safety mechanism, the process

will be aborted and an information code will be displayed.

External process control

Patient ID

The Anion 2 patient ID functionality will, if congured, allow up to four patient ID elds to be entered. The patient ID will be stored with each patient test result in

the result records.

Operator ID

The Anion 2 operator functionality will, if congured, require the operators to login before testing. The functionality may also prevent unauthorized operators to

login, perform tests and conguration. The operator ID will be stored with each test result in the result records.

Quality Control lockout

The Anion 2 QC lockout function allows you to congure the instrument to automatically enforce your local required frequency of control testing. If the required control

test has not been performed or the control result is outside the acceptable range, the instrument will disable patient testing for this assay. For manufacturer recommendations (see “Frequency of control testing” page 19).

For more information regarding these functionalities, see “Conguration” page 12–18.

Calibration

The Anion 2 Analyzer has been manufactured to deliver reliable and accurate results. During manufacturing, the analyzers are calibrated against a reference system. This procedure has been established to ensure that all analyzers operate within identical tolerance limits.

Test specic calibration data are established for each lot of test cartridges and then stored in the barcode label (Figure 2). When the test cartridge enters the

analyzer, the integrated camera reads the barcode. The calibration data for the actual lot are transferred to the instrument and used for calculating the results.

Calibration by the operator is thus not required.

AFINION™ 2 User Manual

US | 9

Page 10

Getting Started

Installing your analyzer

Place your Anion 2 Analyzer on a dry, clean, stable and horizontal surface. Make sure that the analyzer is located with sufcient surrounding airspace, at least 5

inches on each side. Placement of Anion 2 Analyzer should allow easy disconnection from the wall outlet at any time. Acclimate the analyzer to ambient operating

temperature (15-32°C, 59-89°F) before use.

The analyzer might be impaired by:

• Condensing humidity and water

• Heat and large temperature variations

• Direct sunlight

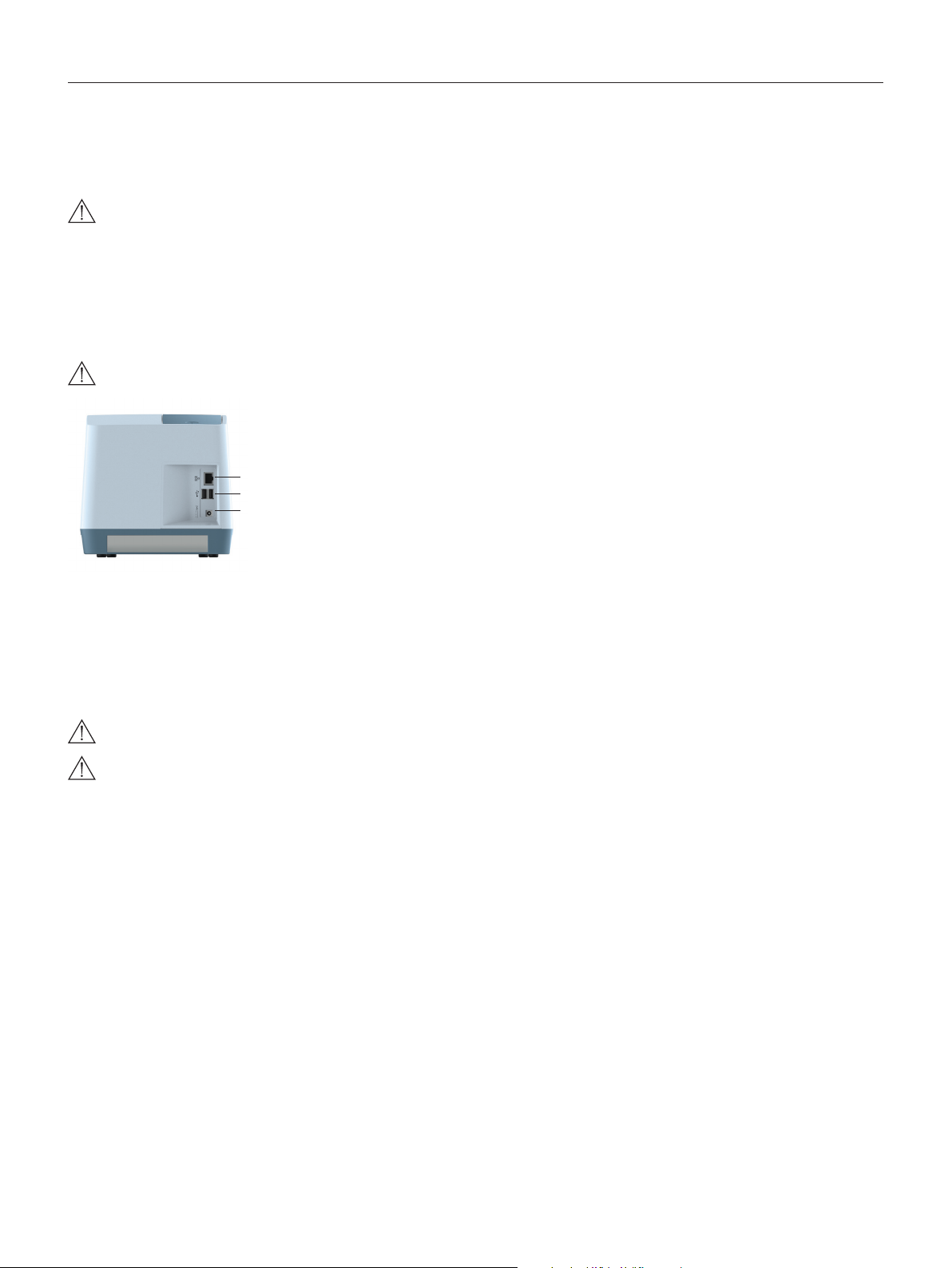

Connecting power supply

- Connect the power cable to the power supply.

- Insert the plug from the power supply into the power socket (Figure 3) in the back of the analyzer.

- Plug in the power supply to a wall outlet.

Only use the power supply and cable supplied with Anion 2 Analyzer. Any other power supplies or cables can damage the analyzer and may cause possible hazards.

Figure 3

1

1 Ethernet port for connection to LIS/HIS/EMR systems. Use shielded cable.

2

2 USB-A connectors for printer, USB ash and barcode reader.

3

3 Power input for power supply connection

• Vibrations (e.g. from centrifuges and dishwashers)

• Electromagnetic radiation

• Movement of the analyzer during processing of a test cartridge

Connecting additional equipment

Optional equipment, not provided with your Anion 2 Analyzer are:

• External barcode reader – for reading barcoded sample or operator identication.

• Printer – for optional print out of test results.

For additional information regarding barcode reader and printer specications, please contact your local Anion 2 supplier.

Connecting the equipment should be done while the analyzer is powered off.

All equipment connected to the USB and/or Ethernet ports must have double or reinforced insulation from mains to prevent the risk of electric shock.

Connectivity

Anion 2 Analyzer can reliably transfer test information to an information system. Use the Ethernet cable to interface the Anion 2 Analyzer to an information system.

Anion 2 Analyzer automatically transfers patient and control results to a connected LIS/HIS/EMR system via TCP/IP networking using the protocols POCT1-A,

HL7, ASTM 1381-85 (low level) or ASTM 1394-97 (high level), selectable by conguration. ASTM and HL7 protocols support the transfer of patient and QC

results. POCT1-A protocol supports in addition functions such as device lockout and operator list management. Operator conguration allows for protection of

connectivity settings. When operator conguration is set to operator ID with verication, the conguration of connectivity will only be available for operators at

supervisor level. For relevant information, see chapter “Operator conguration”, page 14.

When you export data that contains patient information, it is your responsibility to comply with your local regulations on protection of personal health information.

Anion 2 Analyzer POCT1-A, ASTM and HL7 communication protocols are available at www.alere.com or by contacting your local Anion 2 supplier.

10 | US

AFINION™ 2 User Manual

Page 11

GETTING STARTED

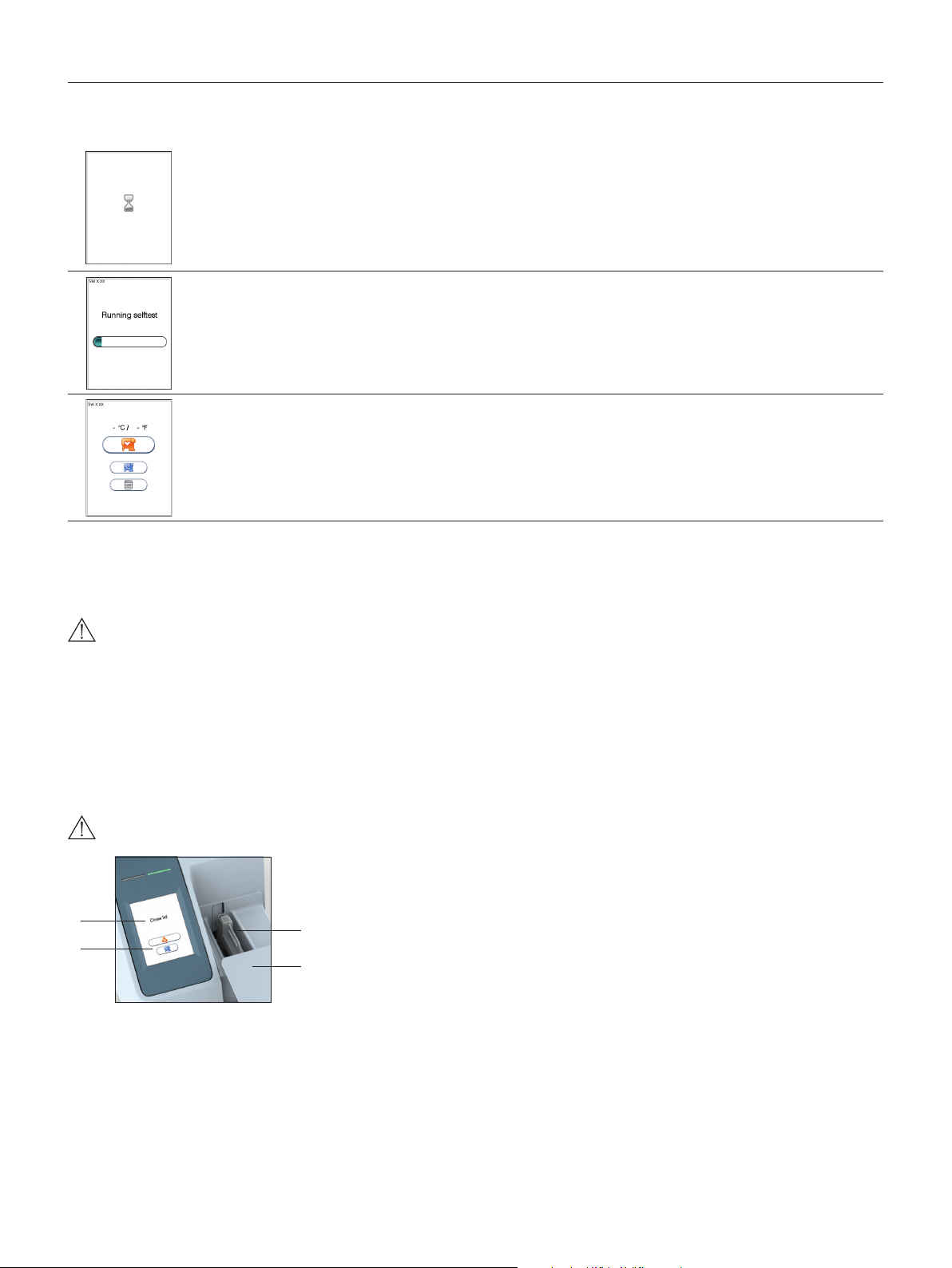

How to power ON the analyzer

1

Power on the analyzer by pressing the ON/OFF button (Figure1). An automatic start-up procedure will be initiated. Please wait.

Do not open the lid manually.

Getting Started

2

3

The automatic start-up procedure will be initiated shortly after the analyzer has been powered on. The red light on the top of the analyzer will

turn on, indicating that the analyzer is busy. The analyzer is ready for use when the start-up menu is displayed and the green indicator light

turns on.

Start-up menu

The analyzer’s software version (SW X.XX) will appear in the upper left corner of the Start-up menu screen. The temperature displayed in the

Start-up menu is the operating analyzer temperature. Make sure that the operating temperature is within the recommended range for your

Anion Test (see the package insert for the Anion Test).

If the analyzer fails during the start-up procedure, an information code will appear referring to a message given in the section “Information

codes and troubleshooting”, page 26-28.

How to power OFF the analyzer

Switch off the analyzer by pressing the ON/OFF button (Figure 1). The analyzer should be powered off after the end of a working day.

The analyzer can only be powered off when the cartridge chamber is empty and the lid is closed. If the ON/OFF button is pressed and the lid is open, the

message ”Close lid” will appear on the screen.

How to operate the analyzer

The Anion 2 Analyzer has two main user interfaces, the touch screen and the cartridge chamber. The analyzer is easily operated using the touch buttons that appear

on the screen. When a button is touched, its function will be activated. Text messages that appear on the screen will help guide you through the testing procedure.

The functions of the touch buttons are explained in the section “Gallery of icons”, page 32–34.

The other main operative part of the Anion 2 Analyzer is the cartridge chamber. The cartridge chamber is designed to receive the test cartridge in one orientation

only. The lid must be manually closed, but opens automatically. When a new test cartridge is placed in the chamber, manually closing the lid will initiate the analysis.

When the analysis is complete the lid will open automatically. The lid protects the cartridge chamber from dust, dirt, light and humidity during processing and when

the analyzer is not in use.

• The lid must be manually closed, but opens automatically. Do not open the lid manually.

• Use the ngertips only on the touch screen. Do not use pens or other sharp instruments.

Figure 4

1

2

Screen saver

The screen saver will turn on after 3 minutes, if the touch screen is not in use. To reactivate, touch the screen.

Light signals (the red and green LEDs)

The red diode is illuminated when the analyzer is busy. A ashing red light is seen when an information code is displayed. The green diode is illuminated when the

analyzer is ready for use. A ashing green light indicates completion of an analysis.

Sound signals

A short beep indicates completion of an analysis. Two beeps mean that an information code or message is displayed.

1 Text message

2 Touch buttons

3

3 The cartridge chamber

with a test cartridge

4

4 The lid in open position

AFINION™ 2 User Manual

US | 11

Page 12

Conguration

The AFINION™ 2 menus

Main menuStart-up menu

Patient ID conguration

menu

Language setting

Date/Time

menu

Conguration menu

Operator conguration

menu

Screen/beeper

menu

QC lockout conguration

menu

12 | US

General settings

menu

AFINION™ 2 User Manual

Page 13

Conguration

Setting the conguration

Before using your Anion 2 Analyzer you should set the conguration according to your needs. To enter the Conguration menu, do the following:

1

Start-up menu

Touch to enter Main menu.

2

3

Main menu

Touch to enter Conguration menu.

Conguration menu

Select an item for conguration (see following pages).

Patient ID conguration

Patient ID enable/disable

The patient identication (ID) function can be enabled or disabled. The patient ID function is enabled as a default setting by the manufacturer. When the patient

ID function is enabled, the patient ID must be entered for each test cartridge to be analyzed. If the patient ID function is disabled, a run number will automatically

replace the patient ID and be displayed in the upper left corner of the screen. This numbering is reset each day at midnight.

Touch

in the conguration menu to enter the patient ID on/off option.

Select to disable the patient ID function.

Select to enable the patient ID function.

Touch to accept and return to the Conguration menu.

AFINION™ 2 User Manual

US | 13

Page 14

Conguration

Operator conguration

The operator ID function is disabled as a default setting by the manufacturer.

Touch

Operator ID enable/disable

Touch

Operator login expiration

Touch

in the Conguration menu to enter the Operator conguration menu.

in Operator conguration menu to enable/disable operator ID.

Select to disable the operator ID function.

Select to enable operator ID. Any operator ID is accepted.

Select to enable operator ID with verication.

· To enable this function at least one supervisor is required to be present in the operator list.

· When operator ID with verication is enabled, analyzer conguration will only be available to the supervisors.

· To log in, the operator ID entered is required to be present in the operator list. See “Operator list management”, page 14.

Touch to accept and return to the Conguration menu.

in the Operator conguration menu to set automatic logout of the operator.

Enter the number of minutes before automatic logout of operator.

The operator will automatically be logged out after the congured number of minutes after ended test.

Touch to conrm and return to previous view.

Operator list management

Touch

1

2

3

in Operator conguration menu to enter operator list.

Touch to add new operator.

Touch desired operator ID and touch to delete or to edit the highlighted operator.

Copy operator list

It is possible to copy an existing operator lists between analyzers using a USB ash drive. Insert USB ash in the analyzer USB port.

Touch to export operator list from instrument to USB ash. Move USB to the new analyzer and touch

existing operator list on the analyzer will be deleted.

Enter new/edit operator ID

Enter new/edit operator ID and touch to enter. Both letters and numbers can be entered (maximum 16 characters).

If a barcode reader is connected to the analyzer, a barcoded operator ID can be entered.

Congure the operator level

Select USER to congure user access.

Select SUPERVISOR to congure supervisor access.

Congure tests accessible:

Select the test accessible for this operator.

Touch to return and edit the operator ID.

Touch to accept and store new operator in the operator list. The operator list can store 1000 operator IDs.

Supervisors will be marked with * in the operator list. When analyzer is congured to Operator ID with verication, conguration of the

analyzer will only be available to the supervisors.

to import operator list. Any

14 | US

AFINION™ 2 User Manual

Page 15

Conguration

Choosing language

Touch in the Conguration menu to enter the language setting. The default setting by manufacturer is English. Other languages are available.

1

Touch the arrow in the window to view other options. Scroll down until you nd the preferred language.

Touch to accept and return to the Conguration menu.

Adjusting screen/beeper settings

Touch in the Conguration menu to enter the Screen/beeper menu.

Touch to enter the Screen alignment setting.

Touch to enter the Beeper volume setting.

A + sign is shown. Use a blunt pencil and tap the center of the +. Repeat tapping the center of the + each time it is shown. When the

process is nished, the previous screen will return.

Adjust the beeper volume by touching or

Touch to conrm and return to the previous view.

Setting date and time

The correct date and time should always be set because the date and time for the analyses are stored and displayed in the patient and control records. The

date format is YYYY:MM:DD, where YYYY is the year, MM is the month (01 to 12), and DD is the day (01 to 31). The time format is hh:mm, where hh is the hour

from 00 to 23 and mm is minutes from 00 to 59.

Touch in the Conguration menu to enter Date/time menu.

1

2

Touch to enter Date setting.

Touch to enter Time setting.

Enter today’s date or time.

Touch to conrm and return to the previous view.

AFINION™ 2 User Manual

US | 15

Page 16

Conguration

QC lockout conguration

Touch in the Conguration menu to enter the QC lockout conguration menu.

Touch to congure QC lockout for the assay selected.

Touch to congure QC lockout interval.

Touch to view/add/delete stored control lots in the control lot database.

1

HbA1c

ACR

2

3

4

Select assay for QC lockout conguration

Touch the arrow in the window to open the drop down menu.

Touch the assay to select.

QC lockout

Select to disable the QC lockout function. No QC runs will be required for this assay.

Select to enable the QC lockout function. It is required to run ONE passed control,

control level C I OR C II, to reset the QC lockout interval.

Select to enable the QC lockout function. It is required to run TWO passed controls,

both control level C I AND C II, to reset the QC lockout interval.

Touch

QC lockout interval

Select

Select to congure QC lockout interval by hours.

Touch

Touch

Control lot database

To add a control to the control lot database the Anion Control Data is required.

The Anion Control Data is a numeric data string which contains all lot specic data:

• Anion Control lot number

• Control type (assay)

• Control level (C I or C II)

to conrm and return to the previous view.

to congure QC lockout interval by number of runs.

to enter/edit number of runs/hours to QC lockout.

displays the number of runs/hours congured in the QC lockout interval.

to conrm and return to the previous view.

• Control expiry date

• Acceptable control range

• CRC (check sum to validate the previous data)

16 | US

The Anion Control Data and its accompanying barcode is found in the Anion Control Package Insert. If the Anion Control Data is not

available, contact your local supplier.

Touch and either manually enter the Control Data or if a barcode reader is connected to the analyzer (recommended), scan the

barcode.

The Anion Control Data may also be entered before, during or after a control run. The control lot will automatically be stored in the

database. See page 25.

Select lot number and touch to delete a control from the list.

When a control lot has reached its expiry date, the control will automatically be deleted from the instrument control database. The control

lot database can store 100 control lots.

AFINION™ 2 User Manual

Page 17

General settings

Touch

in the Conguration menu to enter the General settings menu.

Conguration

Touch

Touch

Touch

to erase all content and congurations.

to enter Instrument network settings.

to enter Connectivity settings.

Erase all contents and congurations

Touch

in General settings menu to erase all contents and congurations.

Touch

Touch

to erase all content and congurations.

to cancel and return to General settings menu.

Analyzer network settings

See Table 1 for description of the available analyzer network settings.

Touch

to enter Instrument network settings view.

Touch

to congure the network.

Enter the IP Address. Touch

Enter the Gateway. Touch

Enter the Network mask. Touch

Enter the Hostname. Touch to conrm and return to Instrument network settings view.

Touch

Table 1 Description of the available analyzer network settings

Consult your network administrator and LIS/HIS/EMR administrator for required network settings.

DHCP DHCP is turned on/off by selecting “DHCP”.

IP address Insert xed IP address [0-255/0-255/0-255/1-254]

Gateway Insert Gateway [0-255/0-255/0-255/1-254]

Network Mask Insert Network mask [0-255/0-255/0-255/0-255]

Host name Insert Host name. Valid characters are [A-Z], [0-9], [-]. The length can be from 1-16 characters

to accept and return to the General settings menu.

When using DHCP the instrument’s IP address will be assigned by the DHCP Server.

No other network settings are necessary.

NB! If DHCP is activated, only the hostname setting can be edited.

to conrm and continue to Gateway.

to conrm and continue to Network mask.

to conrm and return to Hostname.

AFINION™ 2 User Manual

US | 17

Page 18

Conguration

Connectivity settings

See Table 2 for description of the available Connectivity settings.

Touch

Touch to enter page 2 of the conguration or to return to the General settings menu

Touch to enter Server IP and Port number, Receiving application (available for ASTM HL, ASTM LL and HL7 only) and Receiving facility (available

for HL7 only).

Enter the server IP address: Press

Enter the server port number setting: Touch

Enter the Receiving application setting: Press

Use the button to select Patient ID as (available for HL7 only):

HIS Patient ID

Visit Number

in General settings to enter Connectivity settings

Select appropriate communication protocol

ASTM HL

ASTM LL

HL7

POCT1-A

Communication protocol is disabled as default.

Select which results to be transferred to LIS/HIS/EMR by selecting the appropriate button

Patient results only

Patient and control results

Select “New results only” and previous obtained results will not be transferred to the LIS/HIS/EMR

to continue to the Port number setting.

to continue to the Receiving application setting or to close the text input.

to continue to the Receiving facility setting or to close the text input.

Touch

Table 2 Connectivity settings

Consult your network administrator and LIS/HIS/EMR administrator for required connectivity settings.

Protocol ASTM HL ASTM High Level: The communication protocol is based on ASTM E 1394 - 97

Results Patient results only Only patient results will be transferred to the LIS/HIS/EMR

Server IP Insert the IP address of the receiving system [0-255.0-255.0-255.1-254]

Port [0-65535] (0 = not set)

Receiving

Application

Receiving Facility (HL7 only)

Patient ID As HIS Patient ID (HL7 only)

For further information about the connectivity settings, see the Anion 2 data sheets for POCT1-A, ASTM and HL7 which can be obtained at www.Alere.com or

through your local Anion supplier.

to return to the General Settings menu

ASTM LL ASTM Low Level: The communication protocol is based on ASTM E 1381 - 95

HL7 HL7: The communication protocol is based on HL7 version 2.4

POCT1-A POCT1-A: The communication protocol is based on CLSI: POCT01-A2 Point-of-Care Connectivity; Approved

Disabled Data connectivity is disabled

Patient and quality

control

Visit Number (HL7 only)

Standard – Second Edition

Both patient and QC results will be transferred to the LIS/HIS/EMR

(ASTM HL, ASTM LL and HL7 only)

Receiving application name (0 – 30 characters)

Receiving facility name (0-30 characters)

18 | US

AFINION™ 2 User Manual

Page 19

Quality Control

Why quality control testing?

Quality control testing should be done to conrm that your Anion 2 System is working properly and provides reliable results. Accurate results for patient samples

can only be assured when controls are used routinely and the values are within the acceptable ranges.

Choosing control material

Controls supplied by Alere Technologies AS are recommended for use with the Anion 2 System. These control kits contain control materials with established

acceptable ranges for the Anion 2 System.

If you decide to use controls from another supplier, you will need to determine their precision and to establish acceptable control ranges for the Anion 2 System.

Handling and testing controls

Consult the package insert that comes with each control kit for detailed instructions on handling and storage of the control material.

To run a control, follow the procedure in the section “Testing procedures”, page 20-25.

The measured value should be within the acceptable range stated on the control vial label or in the control package insert. If the control results are within the

acceptable ranges, patient samples may be tested and results reported.

If the result obtained for a control is out of range, make sure that:

- The control vial has not passed its expiration date.

- The control vial has not passed the declared stability for opened vials.

- The control vial and Anion Test Cartridges have been stored according to recommendations.

- There is no evidence of bacterial or fungal contamination of the control vial.

Correct any procedural error and retest the control material. If no procedural errors are detected, it is recommended to examine the laboratory’s quality control

record to investigate the frequency of control failures. Ensure that there is no trend in out-of-range quality control results. Retest the control material using a new

control vial.

Patient results must be declared invalid when controls do not perform as expected. Contact your Technical service representative (1.866.216.9505) for

advice before analyzing patient samples.

Frequency of control testing

It is recommended that controls are analyzed:

• When starting up an Anion 2 Analyzer for the rst time.

• With each new shipment of Anion Test Kits.

• With each new lot of Anion Test Kits.

• Anytime an unexpected patient test result is obtained.

• When training new personnel in the correct use of the Anion 2 System.

• If national or local regulations require more frequent testing of control materials, perform quality control in compliance with the regulations for your facility.

• Users with a low frequency of testing should analyze controls at least every 30 days.

The controls should always be analyzed if an unexpected test result is obtained (see the Anion Test Package Insert, section Test result reporting). If

local, state and/or federal regulations require more frequent testing of control materials, then quality control should be performed in compliance with these

regulations. Each laboratory site can benet from establishing a quality control plan. The laboratory director should determine whether additional testing is

appropriate for their laboratory.

AFINION™ 2 User Manual

US | 19

Page 20

Testing Procedures

Operating precautions

When operating the analyzer:

• Use your ngertip to operate the touch screen. Do not use pens or other objects that may scratch or damage the screen. Exception: If the screen

alignment function is required, you will need to use a blunt pencil.

• The lid opens automatically, but must be closed manually. Do not try to open the lid manually.

• The lid protects the cartridge chamber from dust, dirt, light and humidity. Empty the cartridge chamber and keep the lid closed when the analyzer

is not in use.

• If an information code appears on the screen during the analysis, please consult the “Information codes and troubleshooting” section, page 26-28.

• Do not move the analyzer when a test cartridge is being processed.

When handling the test cartridge:

• Do not use test cartridges after the expiration date, or if the test cartridges are not stored in accordance with the recommendations.

• Do not touch the test cartridge optical reading area. Hold the test cartridge by the handle. (Figure 2).

• Do not use the test cartridge if the foil pouch, the desiccant bag or the test cartridge itself is damaged.

• The test cartridges must reach recommended operating temperature before use.

• Do not open the foil pouch until just before use. Once opened, the test cartridge has limited stability.

• Handle and dispose the test cartridges and sample collection equipment as potential biohazardous materials. Use gloves.

• Do not reuse any part of the test cartridge.

Consult the package insert that comes with each Anion Test Kit for assay specic information.

Preparing for an AFINION™ 2 analysis

- Allow the Anion Test Cartridges to reach the recommended operating temperature before use.

- Power on your Anion 2 Analyzer so it is ready for the day’s rst analysis.

- Enter the operator ID (optional). See procedure on page 22.

- The patient ID, control ID or Anion Control Data can be entered before or during processing of the test cartridge in the analyzer.

See procedures on page 22-25.

Consult the package insert that comes with each Anion Test Kit for assay specic information.

Tear strip

1

Open the foil pouch. Grip the handle and remove

the test cartridge from the pouch.

Discard the desiccant bag and foil pouch in

suitable waste containers.

When rst opened, the test cartridge has limited

stability.

If a barcode reader is connected to the analyzer, a barcoded patient ID, control ID or Anion Control Data can be entered.

2 3

Inspect the cartridge. Do not use the test

cartridgeif it is damaged or if loose desiccant

particles are found on the test cartridge.

Use the handle to avoid

touching the optical reading area.

Mark the test cartridge with the patient

or control ID. Use the ID area on the test

cartridge. An ID label can also be used.

Do not write on the barcode label or allow

it to become wet, dirty or scratched.

If an ID label is used, this must t into the

ID area.

20 | US

AFINION™ 2 User Manual

Page 21

Testing Procedures

Collecting a sample

• The patient sample material and control material to be used is specic for each Anion Test.

• The length of the capillary in the sampling device, and thereby the sample volume, might also vary for the different Anion Tests.

• The time from lling the capillary until analysing the test cartridge must be as short as possible.

• Do not use the test cartridge if dropped on the bench or oor after the sample has been collected.

Consult the package insert that comes with each Anion Test Kit for assay specic information.

Examples:

1 2 3

Remove the sampling device from the test

cartridge.

Use the handle to keep the test cartridge steady

against the table and pull the sampling device

straight up.

Fill the capillary; hold the sampling device almost

horizontally and bring the tip of the capillary in

surface contact with the sample. Make sure that

the capillary lls completely. It is not possible to

overll.

Do not wipe off the capillary.

Avoid air bubbles and excess sample on the

outside of the capillary.

Immediately and carefully replace the

sampling device into the test cartridge.

The time from lling the capillary until

analysing the test cartridge must be as

short as possible.

Analysing a patient/control sample

1 2 3

Touch to enter the patient sample mode.

Touch to enter the control mode.

The lid opens automatically.

Insert the test cartridge with the barcode label

facing left.

Be sure that the test cartridge is correctly placed in

the cartridge chamber.

A “C” in the upper left corner indicates that the

analyzer is in the control mode.

4 5 6

Touch and enter the patient ID.

Touch to conrm.

Touch and enter the control ID or Anion

Control Data.

Touch to conrm.

Entering the patient ID, control ID or Anion Control

Data will not interrupt the processing.

Record the result, then touch to accept.

If a printer is connected, touch to print

the result.

The lid opens automatically.

The result will be saved in the result records.

Close the lid manually.The analyzer will start

processing the test cartridge.

The processing time depends on the test

in use.

Remove the used test cartridge from the

cartridge chamber and discard it in a

suitable waste container.

Insert a new test cartridge or close the lid

manually.

Keep the lid closed to protect the cartridge

chamber when the analyzer is not in use.

Consult the package insert that comes with each Anion Test Kit for assay specic information.

AFINION™ 2 User Manual

US | 21

Page 22

Testing Procedures

Using the operator ID function

Entering operator ID

If enabled, the operator’s identication (ID) is required before processing an Anion Test Cartridge (see “Operator conguration”, page 14).

Both letters and numbers can be entered (maximum 16 characters). The operator ID will be displayed with the result and stored along with the other specic data

for this run (see “Patient and control results records”, page 25).

If congured to “enabled with verication” the operator ID entered is required to be present in the operator ID list (see “Operator conguration”, page 14).

Enter the operator ID by numbers and/or touch to enter letters. If a barcode reader is connected to the analyzer, a bar coded

operator ID can be entered.

Touch to conrm and return to previous view.

The operator will be automatically logged out according to the conguration (see “Operator conguration” page 14).

The operator may also manually logout by using the operator logout button displayed in the Start-up menu.

Using the patient ID function

The patient ID function is enabled as a default setting. As long as this function is enabled, the patient ID must be entered for each patient sample to be analyzed. The

patient ID function can be disabled (see “Patient ID conguration”, page 13).

Entering patient ID

It is recommended to enter the patient ID during processing of the test cartridge in the analyzer. Entering the patient ID will not interrupt the processing. It is also

possible to enter the patient ID before the processing.

1

2

3

The P-ID 1 will be stored in the memory and displayed along with the other specic data for this run (see “Patient ID conguration” page 13). Patient ID 2-4 will not

be displayed in the result records but will be stored in the memory and appear on printouts and data transferred to data management systems.

Touch to enter the patient ID option.

It is possible to enter up to four patient ID entries for each patient, P-ID 1 to 4. When enabled, P-ID 1 is required to be entered. Scrolling

between the patient IDs is done with the and .

Enter patient ID by numbers and/or touch to enter letters (maximum 16 characters).

If a barcode reader is connected to the analyzer, a barcoded patient ID can be entered.

Touch to conrm and return to previous view.

The entered P-ID 1 will appear on the screen.

The patient ID touch button will remain in the view and it is possible to make corrections.

22 | US

AFINION™ 2 User Manual

Page 23

Testing Procedures

Using the control ID function

In quality control testing, a suitable control ID must always be entered. The lot number of the control material is recommended as a suitable control ID. The control

ID function cannot be disabled.

Entering Control ID

It is recommended to enter the control ID during processing of the test cartridge in the analyzer. Entering the control ID will not interrupt the processing. It is also

possible to enter the control ID before processing. Both letters and numbers can be entered (maximum 16 characters). The control ID will be stored in the memory

and displayed along with the other specic data for this run.

To enter the control ID during processing, do the following:

1

2

3

Touch to enter the control ID option.

Enter control ID by numbers and/or touch to enter letters.

Touch to conrm and return to the previous view.

The entered control ID will appear on the screen.

The control ID touch button will remain in the view and make corrections possible.

Using the QC lockout function

When the QC lockout function is enabled for one or more assays, approved control testing is required within the congured interval. If the interval expires, patient

testing for the assay will be locked. A passed control run must be performed according to conguration to reset the interval or to unlock the assay for patient testing.

A failed control run will disable patient testing (see “QC lockout conguration”, page 16).

QC lockout status

The status of the active QC lockouts is presented with a QC lockout status button (padlock symbol) visible in the Start-up menu. This gives the operator the status

of QC lockout before he attempts to run any tests.

The padlock symbol will only be visible if QC lockout function is enabled for one or more assay types.

The padlock symbols used are:

Enabled-unlocked

All controls are within the congured interval. It is possible to run patient tests for all assays.

Warning-unlocked

All controls are within the congured interval. When one or more of the assays has 10 % or less of the congured interval remaining the

warning icon will be displayed. It is possible to run patient tests for all assays.

Expired-locked

One or more controls have expired according to the congured interval. Patient testing on the expired assay has been locked.

AFINION™ 2 User Manual

US | 23

Page 24

Testing Procedures

Touch the QC lockout status button (padlock symbol) in the Start-up menu to enter the QC lockout status view.

Status

The information is displayed as a list.

Only the assays with QC lockout activated are displayed in this window.

Red text indicates expired assays and orange text indicates assays within warning period.

Control level

How to reset QC lockout interval and/or unlock expired assays.

If no control level is specied, it is required to run ONE passed control, control level C I OR C II, to reset the QC lockout interval and unlock

the assay for patient testing.

E.g.

HbA1c: #0

If the control level is specied it is required to run TWO passed controls, both control level C I AND C II, to reset the QC lockout interval

and unlock the assay for patient testing.

E.g.

ACR C I: 00.00.00

ACR C II: 00.00.00

Remaining time/runs

Remaining time (dd:hh:mm) or number of runs for each assay with active QC lockout is shown. dd is the number of days, hh is the number

of hours, and mm is the number of minutes until the assay will be locked. # is number of patient tests.

Running controls with enabled QC lockout function

When running controls with the QC lockout function enabled, the Anion Control Data is required to be entered or previously stored in the instrument control lot

database. See “QC lockout conguration”, page 16.

1) The Anion Control Data is entered before, during or after the control run. If a barcode scanner is connected (recommended) the control data barcode may be

scanned. The control lot will automatically be stored in the instrument control database.

2) If the Anion Control Data is previously stored in the instrument control database, the operator will simply need to enter the 8 digit control lot number before,

during or after the control run.

If the instrument is congured to QC lockout and the control lot number is not found in the Anion Control database or the Anion Control Data entered is not valid,

the instrument will present an option to retry the input or discard the control run result. If discarded, the result will not be stored in the instrument result records.

Passed (result within the acceptable control range)

The result of the control is checked against the acceptable ranges for the corresponding lot number.

If the result is within the limits, a pass symbol is displayed on the screen and the QC lockout interval is reset according to the QC lockout conguration.

If QC lockout is congured to require two control levels (C I and C II), both levels must pass to reset the

lockout interval. Only the interval for the control level used in the test is reset.

Failed (result above or below the acceptable control range)

When a control result is not within the acceptable ranges specied for the control lot, a failed symbol is shown on the screen. The result

is stored in the instrument and is sent to the data management system if connected. The QC lockout interval will not be reset.

The arrow symbol will specify whether the result is above or below the acceptable ranges.

See “Handling and testing controls”, page 19.

24 | US

AFINION™ 2 User Manual

Page 25

Testing Procedures

Patient and control results records

The patient and control results are stored in the memory of the Anion 2 Analyzer. The last 500 patient results and the last 500 control results are saved in separate

records. When exceeding the capacity of 500 results, the oldest result will be deleted. The following parameters are listed for each run: Date and time, run number,

patient ID/control ID, operator ID, lot number of test cartridge and the test result.

View, print and export patient and control results

1

Main menu

Touch to enter patient results.

Touch to enter control results.

2

Result records may be exported if an USB ash (FAT 32 formatted) is inserted to the Anion 2 USB port.

Touch to export the results. The results will be stored on the USB in a .txt le for each assay tested on the Anion 2 Analyzer. These

les may be opened in e.g. Microsoft Excel for further processing.

When you export data that contains patient information, it is your responsibility to comply with your local regulations on protection

of personal health information.

The last patient result or control is displayed

To view more results touch

If a printer is connected, touch

or

to print the result.

AFINION™ 2 User Manual

US | 25

Page 26

Information Codes and Troubleshooting

When an information code appears

Information codes that might appear during use of the Anion 2 Analyzer refer to specic information or error messages. The code numbers, the possible causes and

actions to take are listed below.

If the analyzer detects a problem during processing of a test cartridge, the test will automatically be aborted and the test cartridge will be safely moved to the

cartridge chamber. Proceed as follows:

1

2

3

Do not reuse a test cartridge that has been rejected by the analyzer. Collect a new sample and repeat the test with a new test cartridge.

Record the code number (#) and touch to accept.

The lid opens automatically.

Remove the test cartridge.

If the test cartridge is not ejected, restart the analyzer.

Do not reuse the test cartridge.

Look up the possible cause from the table below, and take actions to solve the problem.

If the problem persists, contact your local Anion supplier (see “Service information” page 28).

Information codes caused by test-specic limitations

[#] Cause Action to take

103 Hemoglobin too low Consult the Anion HbA1c Package Insert.

104 Hemoglobin too high Consult the Anion HbA1c Package Insert.

105 HbA1c too low Consult the Anion HbA1c Package Insert.

106 HbA1c too high Consult the Anion HbA1c Package Insert.

107 Creatine too high Consult the Anion ACR Package Insert.

108 Blood in urine Consult the Anion ACR Package Insert.

26 | US

AFINION™ 2 User Manual

Page 27

Information Codes and Troubleshooting

Information codes caused by sample or test cartridge

[#] Cause Action to take

201 Insufcient sample volume:

- Empty capillary

- Air bubble in capillary

- Capillary incompletely lled

202 Excess sample on the sampling

device exterior

203 Wrong sample material Repeat the test with a new sample and test cartridge. Ensure that proper sample material is used (see package insert

204 Coagulated sample Repeat the test with a new sample and test cartridge.

Hemolysed blood sample or

poor sample quality

Test cartridge or analyzer failure Repeat the test with a new sample and test cartridge.

205 Capillary cracked or damaged Repeat the test with a new sample and test cartridge.

206 Barcode label not readable

(dirty or damaged)

207 - No sampling device inserted Repeat the test with a new sample and test cartridge. Ensure that the correct sampling device is in place and that the

- Sampling device belongs to

another Anion Test

- Label on sampling device not

readable (dirty or damaged)

208 Test cartridge previously used Repeat the test with a new sample and test cartridge.

209 Test cartridge has passed

expiration date

The date in the analyzer is

incorrectly set

210 Test cartridge temperature

too low

211 Test cartridge temperature

too high

212 Software upgrade is required

to run this test.

213

Test cartridge or analyzer failure Repeat the test with a new sample and test cartridge. If the problem persists, restart the analyzer and run controls.

214

215 Test cartridge or analyzer failure Repeat the test with a new sample and test cartridge. If the problem persists, restart the analyzer and run controls.

Hemolysed blood sample or

poor sample quality

(Anion HbA1c)

217 Hemolysed blood sample or

poor sample quality

(Anion HbA1c)

218 Condensation detected on

cartridge

Repeat the test with a new sample and test cartridge.

Ensure that the capillary is completely lled with no air bubbles (see package insert for the Anion Test in use).

Repeat the test with a new sample and test cartridge. Ensure that only the tip of the capillary is in contact with the

sample (see package insert for the Anion Test in use).

for the Anion Test in use, section “Specimen collection and storage”).

The time from lling the capillary until analyzing the test cartridge should be as short as possible.

Consult the Anion Package Insert.

Repeat the test with a new sample and test cartridge.

If the problem persists, restart the analyzer and run controls.

Inspect the sampling device before use and handle with care.

Repeat the test with a new sample and test cartridge.

If the problem persists, restart the analyzer and run controls.

sampling device label is clean.

Check expiry date on the foil pouch or kit container. Repeat the test using a new sample and a new test cartridge

fromanother lot.

Check the date in the analyzer to make sure it is set correctly. Repeat the test with a new sample and test cartridge.

Repeat the test with a new sample and a new test cartridge.

Ensure that the operating temperature is within acceptable range (see package insert for the Anion Test in use).

Repeat the test with a new sample and a new test cartridge.

Ensure that the operating temperature is within acceptable range (see package insert for the Anion Test in use).

Contact your local supplier for assistance.

Consult the Anion HbA1c Package Insert. Repeat the test with a new sample and test cartridge.

Consult the Anion HbA1c Package Insert. Repeat the test with a new sample and test cartridge.

Run a new test cartridge. Ensure that the cartridge is equilibrated to room temperature before the foil pouch is opened.

Information codes and messages caused by analyzer failure

[#] Cause Action to take

27

2829Start-up procedure failed Contact your local supplier for assistance.

Self-test

error.

Analyzer

in non-

operative

mode

Analyzer failure Restart analyzer. If the problem persists, contact your local Anion 2 supplier.

301 Self-test failed Restart the analyzer.

302 Analyzer failure Restart the analyzer and run controls. Repeat the test with a new sample and test cartridge.

303 Analyzer temperature is too

high

304 Analyzer temperature is

too low

Ensure that the operating temperature is within recommended range (15-32ºC, 59-89 °F).

Wait until the analyzer has cooled down. Repeat the test with a new sample and test cartridge.

Ensure that the operating temperature is within recommended range for the Anion Test in use (see package insert).

The analyzer temperature is displayed in the Start-Up menu (see page 11). Repeat the test with a new sample and test

cartridge.

AFINION™ 2 User Manual

US | 27

Page 28

Information Codes and Troubleshooting

[#] Cause Action to take

305 Printer improperly connected

Malfunction of the printer

Touch

screen

error

Touch screen failure/ Touch

screen buttons do not

respond accurately

Other information codes

[#] Cause Action to take

401 No registered supervisors in

operator list

402 Cannot delete last

supervisor

403 This assay type is not

accessible to the operator

404 Operator ID is not found in

operator list

[#] Cause Action to take

501 The control lot has passed

expiration date

502 Anion Control Data is not

recognised and is not stored

in control lot database

503 Control verication aborted. The Anion Control Data entered was not recognised. The control test was aborted by the operator. Test result was

504 Required control test interval

has expired. Patient testing

is disabled for this assay.

Switch off the analyzer, reconnect the printer and restart the analyzer.

If the message persists, see the printer user manual.

Restart analyzer and realign screen.

At least one supervisor is required in the operator list when the analyzer is congured to operator ID veried,

(see page 14).

At least one supervisor is required in the operator list when the analyzer is congured to operator ID veried,

(see page 14).

The operator logged in does not have access to run this assay type. Please contact your supervisor.

When Operator ID with verication is enabled, operator ID entered is required to be present in the operator list,

(see page 14). Please contact your supervisor.

Check the expiration date on the control lot package insert or kit box.

Repeat the test using a sample from a new control lot.

Reenter the Anion Control Data, (see page 16).

not stored. Run new control test to reset QC lockout interval.

A passed control run must be performed according to conguration to unlock this assay for patient testing.

[#] Cause Action to take

601 Operator list or control lot

database is full

The operator list can store 1000 operators and the control lot database can store 100 control lots. Delete an operator

or control lot to enter a new item

Service information

The laboratory must notify the manufacturer of this test system of any performance, perceived or validated, that does not meet the performance

specications as outlined in the instructions.

The manufacturer provides a toll free line for technical support: 1.866.216.9505

The toll free number is available for use only in the United States of America.

Before asking for assistance, please record the following information:

• Anion 2 serial number (SN) – see label on the backside of the analyzer

• Software version number – see Start-up menu.

• Anion Test type

• Test cartridge or kit lot number – see foil pouch or kit container

• Control identication and lot number – see vial label

• Control results obtained

• Description of the problem with reference to information codes or messages

28 | US

AFINION™ 2 User Manual

Page 29

Maintenance

Cleaning and maintenance

No maintenance of the Anion 2 Analyzer is required other than cleaning the exterior and cartridge chamber.

Cleaning the exterior

Cleaning the exterior of the Anion 2 Analyzer should be performed whenever necessary. Most spills and stains can be removed with water or a mild detergent.

- Power off the analyzer. Unplug the power supply when the shut down procedure is completed.

- Clean the outside of the analyzer and the touch display with a clean, lint-free and non-abrasive cloth dampened in water or a mild detergent.

- To disinfect the exterior of the analyzer use a 1:10 solution of household bleach (i.e., 0.5% sodium hypochlorite), 2% glutaraldehyde solution or 70% alcohol

solution. The surface of the analyzer should be exposed to the disinfectant for at least 10 minutes.

- Allow the analyzer to air dry.

- Plug in the power supply and power on the analyzer.

• The analyzer must be powered off and unplugged before cleaning.

• Do not use any cleaning liquid or equipment other than those recommended above.

• Do not immerse the analyzer in water or other liquids.

Cleaning the cartridge chamber

The Cleaning Kit (

The cartridge chamber should be cleaned immediately if materials or liquids are spilled in the cartridge chamber. For regular maintenance (removal of dust

particles etc.), the cartridge chamber should be cleaned every 30 days.

- Touch to open the lid.

- Unplug the power supply.

- Wet a Cleaning Swab with 3 drops of water and gently rinse the cartridge chamber. To disinfect the surface, use a 1:10 solution of household bleach (i.e., 0.5%

sodium hypochlorite), 2% glutaraldehyde solution or 70% alcohol solution). Do not soak.

- Carefully remove spills and particles from the cartridge chamber using the moistened swab.

- To disinfect the cartridge chamber, the surface of the chamber should be exposed to the disinfectant for at least 10 minutes1.

- Wipe off any residual liquid from the cartridge chamber using a new, dry Cleaning Swab.

- Plug in the power supply, and power on the analyzer by pressing the on/off button.

- The lid will close automatically during the self-test. If it doesn’t, then close it manually and restart the analyzer.

1116048) should always be used for cleaning the cartridge chamber.

• The analyzer must be unplugged before cleaning.

• Do not use any cleaning liquid or equipment other than those recommended above.

• Do not allow liquid to drip off the Cleaning Swab into the analyzer. If liquid drips into the analyzer, optics can be destroyed.

• Do not immerse the analyzer in water or other liquids.

• Do not move or tilt the analyzer when cleaning the cartridge chamber.

Disposal of the analyzer

For correct disposal according to the Directive 2012/19/EU (WEEE), contact your local Anion 2 supplier.

Software upgrade

Consult the Anion USB Flash Drive Package Insert for software upgrade.

1

Clinical and Laboratory Standards Institute (CLSI) Guideline M29-A3: ”Protection of Laboratory Workers From Occupationally

Acquired Infections; Approved Guideline - Third Edition”. ISBN 1-56-238-567-4

AFINION™ 2 User Manual

US | 29

Page 30

Warranty

Alere Technologies AS warrants solely to the Buyer that the Anion 2 Analyzer will be free from defects in materials and workmanship, when given normal, proper

and intended usage, and will perform in accordance with Alere Technologies AS’s specications for a period of twelve months from the date of delivery.

At its expense, Alere Technologies AS agrees to repair, or at Alere Technologies AS’s option, replace with a new or reconditioned unit, any Anion 2 Analyzer which

is under warranty and not performing substantially in accordance with applicable product specications, provided that the Buyer has given Alere Technologies

AS notication of such warranty claim within the warranty period. If Alere Technologies AS is unable after reasonable efforts to repair or replace the Anion 2

Analyzer not performing substantially in accordance with applicable product specications, the Buyer’s sole remedy shall be the refund of an amount not to

exceed the actual purchase price paid by the Buyer for the Anion 2 Analyzer. All repairs will be done during normal working hours. All replaced parts shall become

Alere Technologies AS’s property. Alere Technologies AS may require the Buyer to ship the Anion 2 Analyzer to Alere Technologies AS or elsewhere at Alere

Technologies AS’s expense, for warranty service to be performed.

Notwithstanding the foregoing, Alere Technologies AS shall have no obligation to make repairs, replacements or corrections which result, in whole or in part, from

(i) an act of God or other unforeseen catastrophe, (ii) any error, omission or negligence of the Buyer, (iii) improper or unauthorized use of the Anion 2 Analyzer,

(iv)operating errors or the disregard of warnings and pre-cautions described in this Anion 2 Analyzer User Manual; (v) repairs performed to the Anion 2 Analyzer

by any person other than an authorized Alere Technologies AS service representative; (vi) use of the Anion 2 Analyzer in a manner for which it was not designed,

(vii) causes external to the Anion 2 Analyzer such as, but not limited to, power failure or electric power surges, or (viii) use of the Anion 2 Analyzer in combination

with equipment, components or software not supplied by Alere Technologies AS.

EXCEPT AS STATED IN THIS SECTION OF THE USER MANUAL, ALERE TECHNOLOGIES AS DISCLAIMS ALL WARRANTIES, WHETHER EXPRESS OR IMPLIED,

WRITTEN OR ORAL, WITH RESPECT TO THE AFINION 2 ANALYZER, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. ALERE TECHNOLOGIES AS’S MAXIMUM LIABILITY ARISING OUT OF THE SALE OF THE AFINION 2 ANALYZER OR ITS USE, WHETHER BASED

UPON WARRANTY, CONTRACT, TORT OR OTHERWISE, SHALL NOT EXCEED THE ACTUAL PURCHASE PRICE PAID BY THE BUYER FOR THE AFINION 2

ANALYZER. IN NO EVENT SHALL ALERE TECHNOLOGIES AS BE LIABLE FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING, BUT NOT

LIMITED TO, LOSS OF PROFITS, LOSS OF DATA OR LOSS OF USE DAMAGES, ARISING HEREUNDER OR FROM THE SALE OF THE AFINION 2 ANALYZER.

THIS WARRANTY MAY NOT BE TRANSFERRED BY THE BUYER.

The acknowledgement of claims shall be reported to your Technical Care Specialist at 1.866.216.9505

30 | US

AFINION™ 2 User Manual

Page 31

AFINIONTM 2 Analyzer

Analyzer

Size 200 mm W x 186 mm H x 328 mm D

Weight 3.4 kg

Display Standard LCD colour display with back light and integrated touch panel.

Resolution: 240 x 320 pixels. Visible area: 58 x 77 mm.

Camera 640 x 480 pixels

Capacity of result records 500 patient results and 500 control results

Capacity of operator list 1000 operators

Capacity of control lot database 100 control lots

SW update Via USB ash drive

Communication interface USB 2.0 High Speed, Ethernet 10/100 Mbps

Power supply

Power supply Separate AC to DC power supply. Double insulated.

Input 100-240 VAC, 50-60 Hz

Output 24 VDC ± 5% , 1.75 A, 42 W

Output connector 0.2 x 0.1 in. / 5.5 x 2.5 mm plug. Positive (+) on inner pin.

Operating conditions

Temperature 15-32°C (59-89°F)

Relative humidity 10-80%, non-condensing

Altitude Max 4000 MASL

Location Dry, clean, horizontal surface. Avoid direct sunlight.

Test cartridge temperature According to specications for the Anion Assay in use.

Storage and transport (in the original container)

Temperature -40 to 70ºC (-40 to 158°F)

Relative humidity 10-93 % at 40ºC

Technical Specications

Additional equipment

For information regarding recommended barcode reader, printer, the Anion Analyzer Cleaning Kit or USB ash drive, please call 1.866.216.9505.

AFINION™ 2 User Manual

US | 31

Page 32

Gallery of Icons

The touch buttons and their function

Touching a button on the screen will activate the function of this button. All the touch buttons that may appear during operation of the Anion 2 Analyzer are

explained below by their function.

Start-up menu

Main menu

Conguration

menu

Patient sample mode Select patient sample mode.

Control mode Select control mode.

Main menu Enter Main menu (operator ID, patient records, control records and conguration menu).

QC lockout status

QC lockout status

QC lockout status

Operator logout

button

Patient records View patient result records. View, print or export patient results.

Control records View control result records. View, print or export control results.

Conguration menu Enter conguration menu (language, patient ID on/off, date/time and screen/volume).

Patient ID

conguration menu

Operator

conguration menu

Language setting Enter language conguration.

Enabled-unlocked

All controls are within the congured interval. It is possible to run patient tests for all assays.

Warning-unlocked

All controls are within the congured interval. When one or more of the assays has 10 % or

less of the congured interval remaining the warning icon will be displayed. It is possible to

run patient tests for all assays.

Expired-locked

One or more controls have expired according to the congured interval. Patient testing on the

expired assay has been locked.

Manual operator logout button.

Congure patient ID function.

Congure operator function.

Patient ID

conguration

menu

Operator

conguration

menu

Patient and

control records

Universial

buttons

Screen/Volume menu Congure screen and volume settings (screen contrast, screen adjustment and beeper volume).

Date/Time menu Enter date/time settings (date and time).

QC lockout

conguration menu

General settings menu Enter the general settings menu.

Patient ID disabled Patient ID disabled.

Patient ID enabled Patient ID enabled and required.

Operator ID

conguration

Automatic operator

logout

Operator list Manage operator list. View, add, edit and delete operators.

Print Print result on connected printer.

Result records export Export result records to connected USB ash.

Patient ID Enter patient ID.

Control ID Enter control ID.

Enter Enter and return to previous view.

Backspace Delete previous character.

Congure QC lockout function.

Congure operator ID function.

Congure number of minutes before automatic logout of operator.

32 | US

Increase Increase contrast/volume.

AFINION™ 2 User Manual

Page 33

Menu Touch button Name Function

Decrease Decrease contrast/volume.

Scroll up View previous

Scroll down View next

Exit Exit current menu and return to previous screen view.

Accept Accept (a setting or a test result).

Abort Abort the test result or cancel operation.

Add button Add new operator or control lot.

Delete button Delete operator or control lot.

Edit button Edit QC lockout interval or operator ID.

Operator ID

conguration

Language

settings

Screen/Beeper

menu

Operator ID disabled Operator ID function is disabled.

Operator ID enabled Operator ID is required to be entered to run an Anion Test Cartridge

Operator ID enabled

with verication

Language Enter language conguration.

Screen alignment Enter screen alignment function.

Beeper volume Enter beeper volume setting.

Operator ID is required to be entered to run an Anion Test Cartridge. The operator ID is veried against the analyzer operator list.

Gallery of Icons

Date/Time menu

General settings

menu

QC lockout

conguration

menu

Operator list Operator list export Export operator list from analyzer to USB ash.

QC lockout QC lockout disabled QC lockout is disabled for this test.

QC lockout

interval

Date Enter date setting.

Time Enter time setting.

Erase Erase all content and congurations.

Instrument network

settings

Connectivity settings Enter connectivity settings

QC lockout Enable/disable QC lockout function.

QC lockout interval Congure QC warning and lockout interval.

Control lot information View, add or delete control lots stored on analyzer.

Operator list import Import operator list from USB ash to analyzer.

QC lockout enabled One passed control run of either C I or C II is required to reset QC lockout interval.

QC lockout enabled Two passed control runs, C I and C II are required to reset QC lockout interval.

Interval by number of

patient tests

Interval by number of

hours

Enter analyzer network settings

QC reminder and lockout active after a congured set of patient tests.

QC reminder and lockout active after a congured set of hours.

AFINION™ 2 User Manual

US | 33

Page 34

Gallery of Icons

Other symbols and signs

Other symbols, signs and abbreviations that may appear during operation of the Anion 2 Analyzer are explained below. These symbols or signs are only informative and can not be activated like the buttons.

Symbol Meaning Appears when?

Wait! Hour-glass icon that appears in the start-up procedure.

Information code

Operator ID Icon illustrates the operator ID.

Patient ID Icon illustrates the patient ID.

Control ID Icon illustrates the control ID.

Connected

Quality control pass Control result is within acceptable range.

Quality control failed Control result is outside acceptable range.

Result is above

acceptable range

Result is below

acceptable range

C Control The letter C will appear on the screen when the control mode is selected.

O-ID Operator ID Abbreviation used in the patient and control records.

P-ID Patient ID Abbreviation used in the patient records.