Page 1

LifeCare®

and

HomeCare®

MODEL

INFUSION

For

use

with:

LifeCare

LifeCare

LifeCare

HomeCare

For

country

04,13,15,18,22,27,

29,

36,

Model

Model

Micro

42, 46,

4

4P

Model 4H List 22100,

codes:

54,

88

4

SERIES

PUMPS

List

1814,1914,1915

List 2505,

List

1815,1916,1917

2506

24000

Technical

Service

Manual

Abbott

North

USA

Laboratories

Chicago,

II,

60064

430-01858-003

(Rev.

5/95)

Page 2

.'•'3

-..;tv

d'-.

'""

^ttJfc

/.. 5t;.i"

a^xy...

ttfjbpfc-.LTU.

>riJ

:lo

L ?:?t;t7-j::,

©Copyright 1995

This

document

retains

all

document

others without

andthe

the

exclusive

acceptsitin

the

ho:-

^OLCEST

subject

matter

rights^qtatesemination,

confidence,

written

consent

of Abbott Laboratories.

'"J

:-7"l

•

Abbott

disclosed

reproduction,

and^agtises

Laboratories

herein

are

proprietary

manufacture

nottoduplicateitin

information.

andsale. Any

wholeorin

All

Rights^served

Abbott

Laboratories

party

part

nor

discloseitto

using

this

430-01858-003(Rev. 5/95)

9Lfe.T

bSJt;..

LifeCare

and

HomeCare Model 4 Series

Page 3

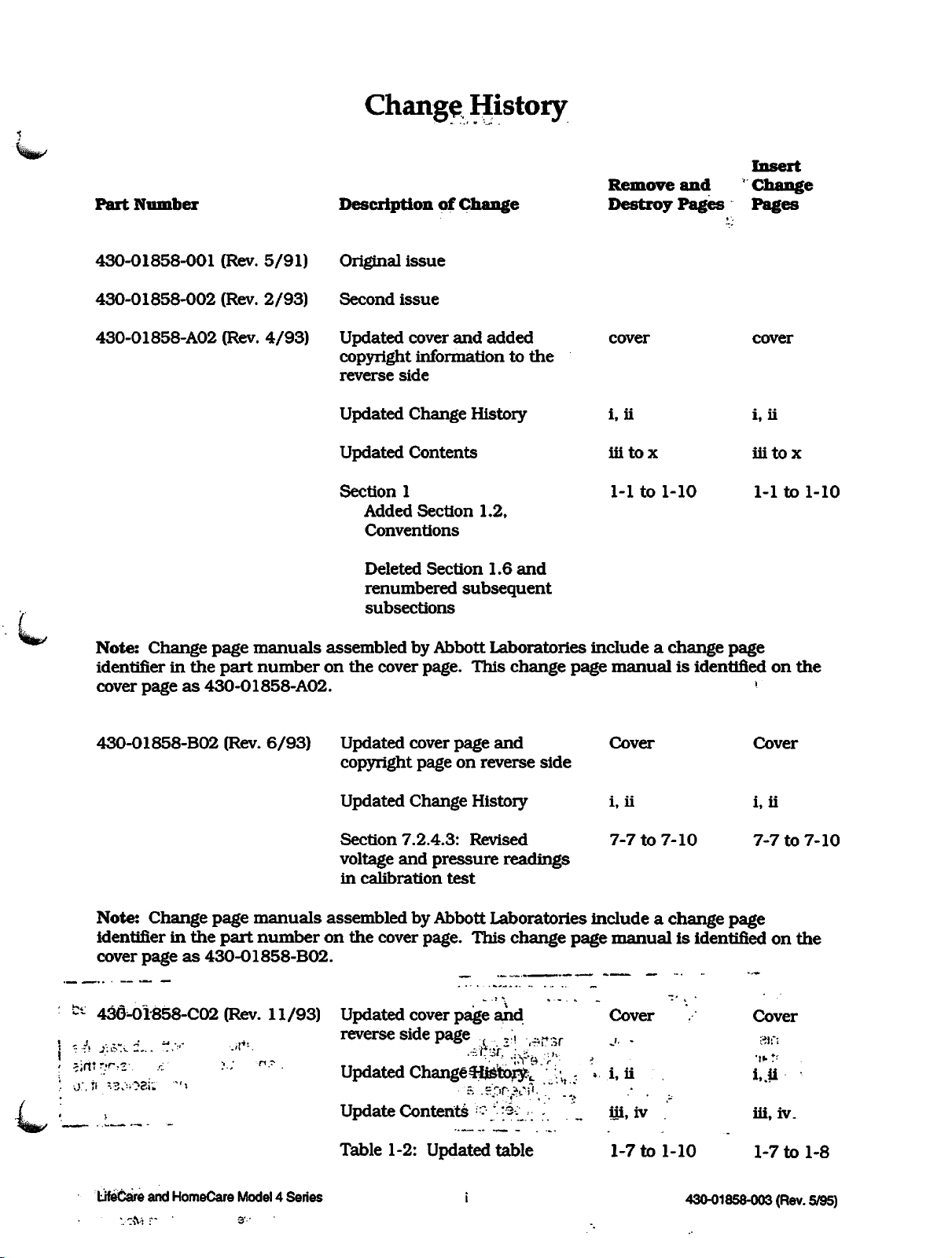

Part

Number

Change

Description

History

of

Change

Remove

Destroy

and

Pages

Insert

Change

Pages

430-01858-001

430-01858-002

430-01858-A02

(Rev.

(Rev.

(Rev.

5/91)

2/93)

4/93)

Original

Second

Updated

copyright

reverse

Updated

Updated

Section

Added

Conventions

Deleted

renumbered

subsections

issue

issue

cover

and

added

informationtothe

side

Change

History

Contents

1

Section

Section

1.2,

1.6

subsequent

and

cover

i,

iii

1-1

cover

ii

tox

to

1-10

i,

iii

1-1

ii

tox

to

1-10

(

Note:

identifierinthe

cover

Change

page

part

manuals

number

pageas430-01858-A02.

assembledbyAbbott

on

the

cover

page.

Laboratories

This

change

includeachange

page

manualisidentifiedonthe

page

"^jp/

430-01858-B02

Note: Change page

identifierinthe

cover

pageas430-01858-B02.

'*•-

436^01858-C02 (Rev.

s;ritr.r?2-..

LifeCare

vita

n

and

r '

HomeCare

(Rev.

6/93)

manuals

part

number

?.;

^-

Model4Series

3':'

11/93)

Updated

copyright

Updated

Section

voltage

in

calibration

cover

page

pageonreverse

Change

7.2.4.3:

and

History

Revised

pressure

test

and

readings

side

Cover

i, ii i, ii

7-7

to

assembled by Abbott Laboratories include a

on

the

cover page.

Updated cover

reverse

Updated

side

Changeiijfeto^

Update Contents -\'-;^V:

Table 1-2:

This

page

page

Updated

.,

change

and

",:,

table

...H.^

':[\

r.

page

manual

Cover

J,

-

i,

ii

iii.

iv

1-7

to

Cover

7-10

change

7-7to7-10

page

is identifiedonthe

Cover

31 f;

i..U

iii,

iv.

1-

-10

430-01858-003 (Rev.5/95)

1-7

to

1-8

Page 4

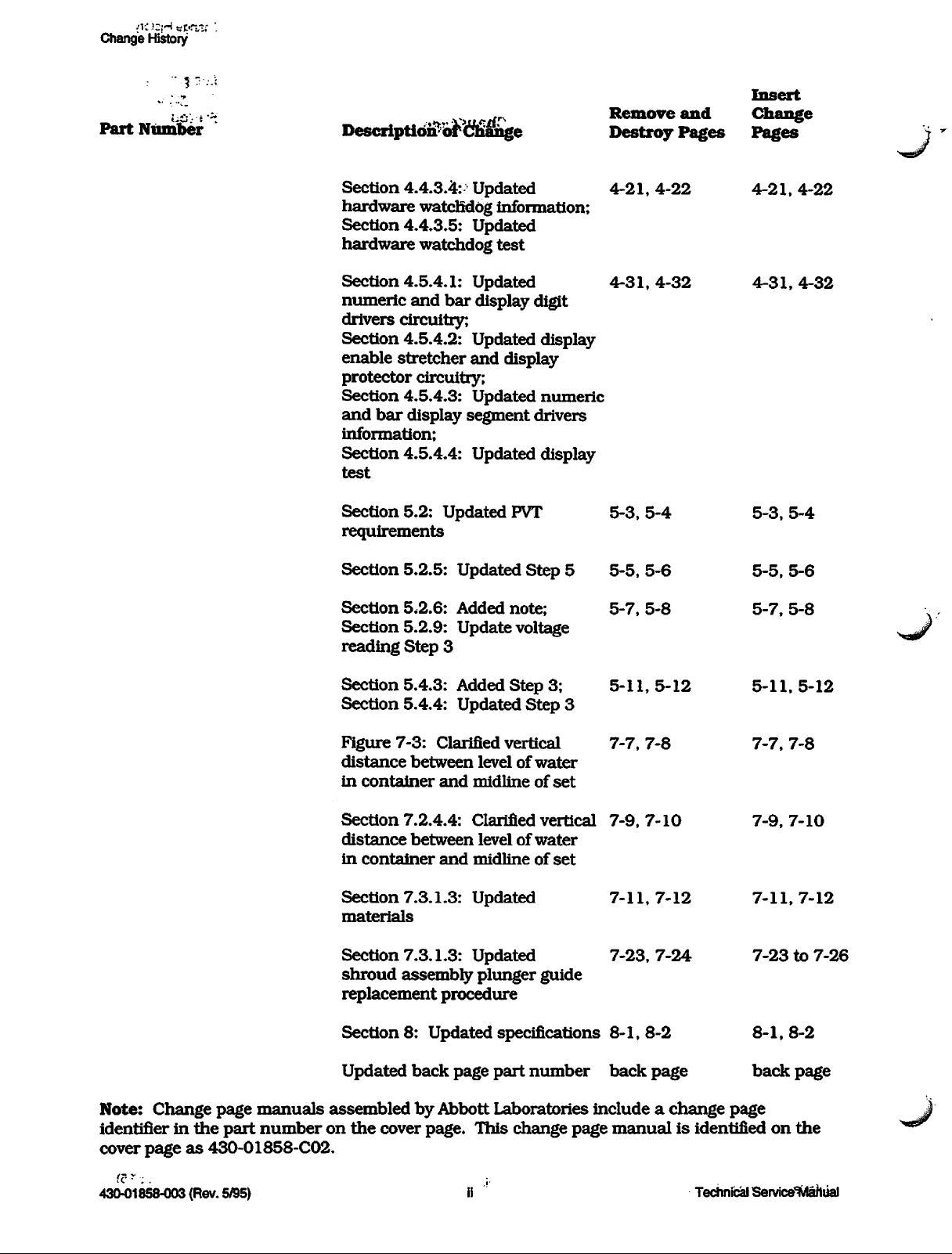

Change History

Part

Number

DesciiptiotfbF6naiige

Remove

Destroy

Insert

and

Change

Pages Pages

s^ssr

Section

4.4.3.4: Updated 4-21,

hardware

Section

4.4.3.5:

hardware

Section

numeric

drivers

Section

enable

protector

Section

and

information;

Section

test

Section

requirements

Section

Section

Section

reading

4.5.4.1:

and

circuitry;

4.5.4.2: Updated display

stretcher

circuitry;

4.5.4.3:

bar

display

4.5.4.4: Updated display

5.2:

5.2.5:

5,2.6:

5.2.9: Update voltage

Step

watchdog

Updated

watchdog

Updated

bar

display

and

Updated

segment

Updated

Updated

Added

3

information;

test

digit

display

numeric

drivers

PVT

Step

5

note;

4-31,

5-3,

5-5,

5-7,

4-22

4-32

5-4

5-6

5-8

4-21,

4-22

4-31,4-32

5-3,

5-4

5-5,

5-6

5-7,

5-8

Note:

identifierinthe

cover

Change

page

part

pageas430-01858-C02.

manuals

number

Section

Section

Figure

distance

in

Section

distance

in

Section

materials

Section

shroud

replacement

Section

Updated

5.4.3:

5.4.4:

7-3:

container

7.2.4.4:

container

7.3.1.3:

7.3.1.3:

assembly

8:

Clarified

between

and

between

and

procedure

Updated

back

Added

Updated

page

assembledbyAbbott

on

the

cover

page.

Step

Step

vertical

levelofwater

midline

Clarified

levelofwater

midline

of

vertical

of

Updated

Updated

plunger

guide

specifications

part

number

Laboratories

This

change

3;

5-11,5-12

3

7-7,

set

7-9,

set

7-11,7-12

7-23,

8-1,8-2

back

includeachange

page

manualisidentifiedonthe

7-8

7-10

7-24

page

5-11,5-12

7-7,

7-9,

7-11,7-12

7-23

8-1,

back

page

7-8

7-10

to

8-2

page

7-26

430-01858-003 (Rev. 5/95)

Technical Sen/ice^Aaftiial

Page 5

'•i-j'

5/95)

(Rev.

430-01858-003

iii

4

Series

Model

and

HomeCare

JJeCare

:t«0.

..-,--•'•"l

/•^r.C

-•:

.3(V»v-

History

Change

Insert

Change

Pages Pages

and

Destroy

Remove

(Rev.

Third

issue

of

r

Change

Description

5/95)

430-01858-003

Part

Number

Page 6

Service

Manual.:.; j

Technical

IV

430-01858-003 (Rev. 5/95)

left

blank.

This

page

intentionally

>

i?3

J.A.~J

;>

Change-History

Page 7

Contents

Contents

.••o

^Il^/

Section

INTRODUCTION

1.1

1.2

1.3

1.4

1.5

1.6

1.7

Section

WARRANTY

Section

SYSTEM

Section

THEORY

4.1

43

1

SCOPE

CONVENTIONS

ACRONYMS

USER

ARTIFACTS

SERIES

INSTRUMENT

1.7.1

1.7.2

1.7.3

2

3

OPERATING

4

OF

GENERAL

4.1.1

4.1.2

4.1.3

4.1.4

EXTERNAL

4^.1

4^.2

4^.3

4.2.4

4.2.5

4.2.6

4.3

OPERATIONAL

4.3.1

43.2

4.33

4.4

MONITORS

4.4.1

AND

ABBREVIATIONS

QUALIFICATIONS

SPECIFIC

UNPACKING

INSPECTION

SELFTEST

OPERATION

FUNCTIONS

CASSETTE

FLOWDETECTOR

ALARMS

4.1.3.1

4.1.3.2

NUMERIC

ACC

FEATURES

INSTALLATION

MANUAL

AUDIBLEALARM

NURSE-CALL

AND

INTERFACE

CONNECTOR

NURSE-CALL

FLOW

RS-485

RS-232I/OPORT

20-MAI/OPORT

MODES

4.3.1.1

4.3.1.2

4.3.13

4.3.1.4

4.3.1.5

43.1.6

DETECTOR

DATAWAY

DESCRIPTION

OF

OPERATION

LOAD/OFF

SELFTESTMODE

LOCAL

REMOTE

BATTERY

SYSTEM

SILENCE/ASK

DATA

FLOW

4.4.1.1

4.4.1.2

4.4.1.3

4.4.1.4

RETENTION

AND

DETECTORS

MONITORING

FLOWDETECTOR

DROP

SIGNAL

CURRENT

SYNCHRONOUS

ALARM

BAR

DISPLAYS

PORTS

J23

JACK

J21

CONNECTOR

I/O

RECHARGE

CONTROL

CONTROL

DISCHARGED

FAILURE

FUNCTION

FUNCTION

AMPLITUDE

PROCEDURE

J22

CONNECTOR

MODE

MODE

MODE

MODE

MODE

SYSTEM

PROCESSOR

MODULATOR

DEMODULATOR

JlOl

,.,.

1-1

1-1

1-2

1-3

1-5

1-5

1-6

1-8

1-9

1-9

1-9

2-1

3-1

4-1

4-1

4-1

4-2

4-2

4-2

4-2

4-2

4-3

4-3

4-4

4-4

4-5

4-5

4-5

4-6

4-6

4-7

4-8

4-8

4-9

4-9

4-10

4-11

4-12

4-12

4-12

4-13

4-14

4-14

4-15

LifeCare

and

HomeCare

Model4Series

v

430-01858-003

(Rev.

5/95)

Page 8

Contents

4.4.2

4.43

4.5

ELECTRONICS

4.5.1

4.5.2

4.53

4.5.4

4.5.5

4.5.6

4.5.7

4.6

MECHANICAL

4.6.1

4.6.2

4.63

4.7

BATTERY

430-01858-003

4.4.1.5

4.4.1.6

4.4.1.7

PRESSURE

4.4.2.1

4.4.2.2

4.4.23

DROP

FLOW

FLOW

MEASURING

PRESSURE

PRESSURE

OCCLUSION

MALFUNCTION

4.43.1

4.4.3.2

4.43.3

4.43.4

4.4.3.5

4.4.3.6

4.43.7

INTERNAL

ROMTEST

POWER-UPTEST

HARDWARE

HARDWARE

SOFTWARE

MICROPROCESSOR

SUBSYSTEM

MPUPWA

4.5.1.1

4.5.1.2

4.5.1.3

4.5.1.4

4.5.1.5

MOTOR

4.5.2.1

4.5.2.2

4.5.2.3

4.5.2.4

DISPLAYPWA

DISPLAY

4.5.4.1

4.5.4.2

4.5.43

4.5.4.4

4.5.4.5

POWER

4.5.5.1

4.5.5.2

4.5.5.3

4.5.5.4

4.5.5.5

4.5.5.6

4.5.5.7

4.5.5.8

4.5.5.9

4.5.5.10

CURRENT

4.5.6.1

4.5.6.2

CONTROL

4.5.7.1

4.5.7.2

MICROPROCESSOR

MEMORY

MEMORY

MEMORY

I/O

PORTS

DRIVER

I/O

ADDRESS

INPUT

A/DCONVERTER

RS-485

DRIVER

HARDWARE

NUMERIC

DISPLAY

PROTECTOR

NUMERIC

DISPLAYTEST

SUPPLY

UNREGULATED

BATTERYPACK

BATTERY

DIODE

POWER

5

VDC

5

VDC

MOTOR

BATTERY

MEMORY

BOOST

AC

(MAINS)

DCOPERATION

SWITCHES

FRONT

REAR

SUBSYSTEM

CASSETTE

PUMPMECHANISM

MOTOR

AND

OPERATION

(Rev.

5/95)

AMPLITUDE

DETECTOR

ALGORITHM

SENSOR

SENSOR

ALARM

DETECTION

RAM

. . . . .

WATCHDOG

WATCHDOG

WATCHDOG

PRINCIPLES

CIRCUITRY

LATCH

PROTECTOR

PWA

DECODER

DATA

DATAWAY

POWER

REGULATOR

FAILURE

BUFFERS

PWA

WATCHDOG

AND

ENABLE

CIRCUITRY

AND

PWA

CHARGER

CONTROL

VOLTAGE

MONITOR

SUPPLY

CHARGER

BAR

BAR

SWITCH

DETECTOR

OPERATION

PANEL

PANEL

SWITCHES

SWITCHES

PRINCIPLES

MOTOR

OVERVIEW

THRESHOLD

PRESENCE

SYSTEM

PWA

PWA

ALGORITHM

CIRCUITRY

TEST

SANITY

CIRCUITRY

CIRCUITRY

...-.

PORT

DISPLAY

STRETCHER

DISPLAY

DC

POWER

CIRCUITRY

CIRCUITRY

CIRCUITRY

REGULATOR

CIRCUITRY

CIRCUITRY

PWA

. .

DRIVERS

DETECTION

(-004

AND

(-003

AND

TEST

CHECK

OF

OPERATION

.

CIRCUITRY

.

CIRCUITRY

DIGIT

AND

SEGMENT

SUPPLY

CIRCUITRY

CIRCUITRY

OF

OPERATION

vi

DETECTOR

HIGHER)

LOWER)

DRIVERS

DISPLAY

DRIVERS

CIRCUITRY

CIRCUITRY

...

Technical

Service

4-15

4-15

4-16

4-16

4-17

4-17

4-17

4-18

4-18

4-19

4-19

4-19

4-20

4-20

4-20

4-20

4-21

4-21

4-22

4-22

4-22

4-22

4-23

4-26

4-27

4-27

4-27

4-28

4-29

4-29

4-29

4-30

4-30

4-30

4-31

4-31

4-31

4-32

4-32

4-32

4-33

4-34

4-34

4-34

4-35

4-35

4-35

4-36

4-36

4-36

4-37

4-38

4-38

4-39

4-40

4-40

Manual

Page 9

Contents

\jjyjj~

Sections

MAINTENANCE

5.1 PREVENTIVE MAINTENANCE •'.'".'

5.1.1

5.1.2

5.1.3

5.2

PERFORMANCE

5.2.1

5.2.2

5.2.3

5.2.4

5.2.5

5.2.6

5.2.7

5.2.8

5.2.9

5.2.10

5.2.11

5.2.12

5.2.13

5.3

BATTERY

53.1

53.2

5.4

BATTERY

5.4.1

5.4^

5.4.3

5.4.4

5.5

PVTDATAFORM

AND

SERVICETESTS

INSPECTING THE PUMP

CLEANING

SANITIZING

EQUIPMENT

PUMP

DRY

CASSETTE

TEST

STARTUPTEST

PRESSURE

HIGH

AND

DELIVERY

PIGGYBACK

BATTERY

MALFUNCTION

ELECTRICAL

END

OF

MAINTENANCE

DEPTH

RECHARGING

CIRCUIT

TEST

LOW

BATTERY

BATTERY

THE

THE

VERIFICATION

AND

INSPECTION

SETUP

TEST

FLOW

AUDIBLE

EQUIPMENT

BATTERY

ALARM

ALARM

ACCURACY

TEST

CHARGING

SAFETY

PERFORMANCE

OF

DISCHARGE

ALARM

ALARM

SHUTDOWN

CHARGING

PUMP

PUMP

MATERIALS

TEST

AND

SILENCE

AND

(MODEL

TEST

SIMULATION

TEST

AND

REQUIRED

...];.

....."

....

....

TEST

LOW

TESTS

TEST

TEST

TEST

CIRCUIT

. . . .

4P

ONLY)

....

TEST

VERIFICATION

CHARGER

........

. . .

REQUIRED

SWITCH

FLOW

TEST

: ; .

. .

ALARM

.

TESTS

>:

:

:

TEST

TEST

\

.

(SIMULATED)

. . .

..:.......

.

. .

5-1

5-1

5-1

5-2

5-3

5-3

5-3

5-4

5-4

5-4

5-5

5-6

5-7

5-7

5-8

5-9

5-9

5-9

5-9

5-10

5-10

.

5-10

5-11

5-11

5-11

5-11

5-12

.

5-13

Section

TROUBLESHOOTING

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6.8

Section

6

TECHNICAL

AUDIBLEALARMS

ALARM

ALARM

OBTAINING

PUMP

FVTTROUBLESHOOTING

TEST

TROUBLESHOOTING

CONNECTOR

7

REPLACEABLE

7.1

REPLACEABLE

7.2

ADJUSTMENT

7.2.1

7.2.2

7.2.3

7.2.4

TOOLS

SHROUD

SHROUD

PRESSURE

7.2.4.1

7.2.4.2

7.2.4.3

ASSISTANCE

CONDITIONS

CODES

AN

PARTS

AND

PARTS

PROCEDURES

AND

TAB

REAR

PRESSURE

CALIBRATION

CAUBRATION

ALARM

REPAIRS

LIST

MATERIALS

CHECK

TAB

SENSOR

HISTORY

v .

: .

. .

.

REQUIRED

ADJUSTMENT

CALIBRATION

SENSOR

CALIBRATION

(PRESSURE

.

AND

SENSOR

TEST

(PRESSURE SENSOR PWA-004

SETUP

PWA-003

AND

LOWER)

AND

HIGHER) . .

...

6-1

6-1

6-1

6-2

6-2

6-2

6-4

6-17

6-19

7-1

7-1

7-3

7-3

7-3

7-4

7-5

7-5

7-6

7-8

LifeCare

and

HomeCare

Model 4

Series

vii

430-01858-003 (Rev. 5/95)

Page 10

Contents

7.2.4.4

7.3

REPLACEMENT

7.3.1

7.3.2

7.3.2.1

7.3.2.2

7.3.2.3

7.33

7.3.4

7.3.4.1

7.3.4.2 FUSE

7.3.5

VELCRO

7.3.6

73.7

73.8

73.9

7.3.10

7.3.11

73.12

73.13

7.3.14

7.3.15

7.3.16

73.17

7.3.18

73.18.1

73.18.2

7.3.19

73.19.1

73.19.2

73.19.3

73.20

7.3.21

73.22

7.3.23

7.3.24

7.3.25

7.3.26

7.3.27

73.28

73.29

TOUCHSWTTCH

TRANSFORMER

7.330

7331

73.32

7.3.33

7.3.34

PRESSURE

SENSOR

TEST

PROCEDURES

SAFETY

REQUIRED

BATTERY

FUSE

AC

AC

NURSE-CALL

FLOW

FLOW

FEMALE

FLOW

CONNECTOR(S)

MAIN

POLE

POLE

AUDIBLE

SHROUD

ACCESSORY

CASE

PWA

AC

AC

AC

PIEZOELECTRIC

FEMALE

MAIN

MAIN

MAIN

FUSEHOLDERREPLACEMENT(115V~)

NURSE-CALL

PRESSURE

SET

RUBBER

MAINS

AND

EQUIPMENT

TOOLS

STANDARD

SPECIALTOOLS

MATERIALS

PACK

REPLACEMENT

FUSE

REPLACEMENT

AND

ANCHOR

POWER

POWER

CORD

CORD

CABLE

DETECTOR

DETECTOR

TERMINAL

DETECTOR

CONTROL

CLAMP

CLAMP

KNOB

SHAFT

ALARM

ASSEMBLY

(ACC)

REPLACEMENT

ONE-PIECE

CLAMSHELL

REPLACEMENT

POWER

DISPLAY

MOTOR

MOTHERBOARD

POWER

(MAINS)

POWER

CORD

POWER

CORD

TERMINAL

CONTROL

CONTROL

CONTROL

JACK

LEVEL

TYPE

SWITCH

FOOT

RECEPTACLE

AND

MATERIALS

HANDTOOLS

REPLACEMENT

FUSE

DRAWER

PAD

REPLACEMENT

STRAIN

PLUG

ASSEMBLY

ASSEMBLY

CONNECTOR

REPLACEMENT

KNOB

LEVEL

CASE

SUPPLY

PWA,

DRIVER

REPLACEMENT

RETAINER

PANEL

ALARM

CONNECTOR

SWITCH

SWITCH

SWITCH

REPLACEMENT

ASSEMBLY

REPLACEMENT

REPLACEMENT

REPLACEMENT

REPLACEMENT

SWITCH

PLUNGER

CONNECTOR

REPLACEMENT

CASE

PWA

DISPLAY

PWA

PWA

CORD

REPLACEMENT

REPLACEMENT

REPLACEMENT

REPLACEMENT

SELECT

REPLACEMENT

PAD

REPLACEMENT

ASSEMBLY

PRECAUTIONS

(115

RELIEF

REPLACEMENT

PLUG

REPLACEMENT

REPLACEMENT

REPLACEMENT

REPLACEMENT

REPLACEMENT

CLIP

SHAFT

SHAFT

WAFER

SWITCH

V~)

REPLACEMENT

BUSHING

REPLACEMENT

AND

CLOSED

HOUSING

REPLACEMENT

GUIDE

DRIVER

P10

REPLACEMENT

(OR

PINS)

PWA,

(115

V~)

REPLACEMENT

AND

CLOSED

ASSEMBLY

ASSEMBLY

REPLACEMENT

REPLACEMENT

(MICRO

REPLACEMENT

(100

V~,

REPLACEMENT

ENTRY

AND

MALE

REPLACEMENT

MPU

(100V-,

ENTRY

REPLACEMENT

LUBRICATION

ONLY)

PWA,

220

(115

(100

PIN

V~)

V~)

V~,

220

AND

220

V~)

(115

V~)

V~)

...

...

. .

7-10

7-11

7-11

7-11

7-12

7-12

7-12

7-13

7-14

7-14

7-15

7-15

7-16

7-16

7-17

7-17

7-18

7-19

7-20

7-20

7-21

7-22

7-23

7-24

7-26

7-26

7-28

7-30

7-30

7-31

7-33

7-34

7-35

7-36

7-36

7-38

7-39

7-40

7-43

7-44

7-45

7-46

7-46

7-47

7-48

7-49

Section

8

SPECIFICATIONS

430-01858-003

(Rev.

5/95)

viii

Technical

Service

8-1

Manual

Page 11

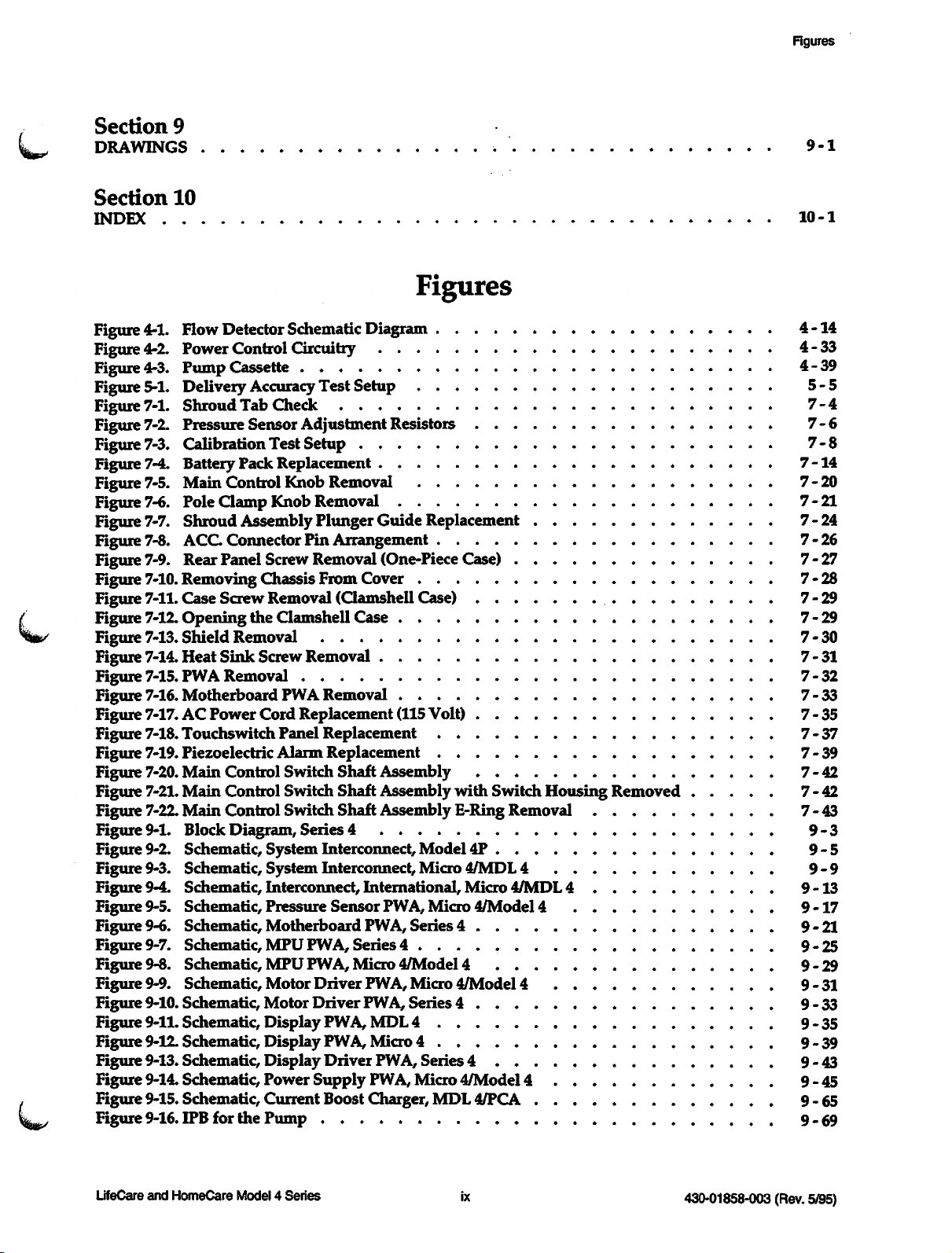

Rgures

^jjgs/

Section

DRAWINGS

Section

INDEX

9

10

Figures

Figure

Figure

Figure4-3. Pump Cassette

Figure5-1. DeliveryAccuracy Test Setup

Figure7-1. Shroud Tab Check

Figure7-2. Pressure Sensor AdjustmentResistors

Figure7-3. Calibration Test Setup

Figure7-4. Battery Pack Replacement

Figure

Figure

Figure

Figure 7-8. ACC.Connector Pin Arrangement

Figure7-9. Rear Panel Screw Removal (One-Piece Case)

Figure 7-10.

Figure

Figure

Figure

Figure

Figure 7-15.

Figure

Figure7-17.ACPower Cord Replacement

Figure7-18.Touchswitch Panel Replacement

Figure7-19.Piezoelectric AlarmReplacement

Figure

Figure 7-21.Main Control

Figure 7-22.Main Control Switch

Figure 9-1.

Figure 9-2. Schematic,

Figure 9-3. Schematic,

Figure 9-4. Schematic, Interconnect, International, Micro

Figure 9-5. Schematic, Pressure Sensor

Figure 9-6. Schematic, Motherboard

Figure 9-7. Schematic, MPU

Figure 9-8. Schematic, MPU

Figure 9-9. Schematic,

Figure 9-10. Schematic, Motor Driver PWA, Series 4

Figure 9-11.Schematic,

Figure 9-12.Schematic, Display

Figure 9-13. Schematic,

Figure 9-14.Schematic, Power

Figure 9-15.Schematic, Current Boost Charger,

Figure 9-16.IPB for

4-1.

FlowDetectorSchematicDiagram

4-2.

PowerControl Circuitry

7-5.

Main Control Knob Removal

7-6.

PoleClamp Knob Removal

7-7.

Shroud AssemblyPlunger Guide Replacement

Removing

7-11.

Case Screw Removal (Clamshell Case)

7-12.

Openingthe Clamshell Case

7-13.

Shield Removal

7-14.

Heat

PWA

7-16.

Motherboard PWA Removal

Chassis From Cover

Sink

Screw Removal

Removal

(115

7-20.

Main Control Switch Shaft Assembly

Block

Diagram, Series 4

the

Switch

System

System

Motor

Display

Display

Pump

Shaft

Assembly

Shaft

Assembly

Interconnect,

Interconnect, Micro 4/MDL4

PWA,

PWA,

Series 4

PWA,

Micro 4/Model4

Driver

Supply

PWA,

PWA,

Driver

PWA,

MDL

Micro 4

PWA, Micro

PWA,

PWA,

Model

Series 4 .

Micro

4

Series 4

Volt)

with

E-Ring Removal

4P

Micro

4/Model

4/Model

4/Model

MDL

4/PCA

Switch

4/MDL

4

4

Housing

4

4

Removed

9-1

10-1

4-14

4-33

4-39

5-5

7-4

7-6

7-8

7-14

7-20

7-21

7-24

7-26

7-27

7-28

7-29

7-29

7-30

7-31

7-32

7-33

7-35

7-37

7-39

7-42

7-42

7-43

9-3

9-5

9-9

9-13

9-17

9-21

9-25

9-29

9-31

9-33

9-35

9-39

9-43

9-45

9-65

9-69

LifeCare

and

HomeCare

Model4Series

ix

430-01858-003

(Rev.

5/95)

Page 12

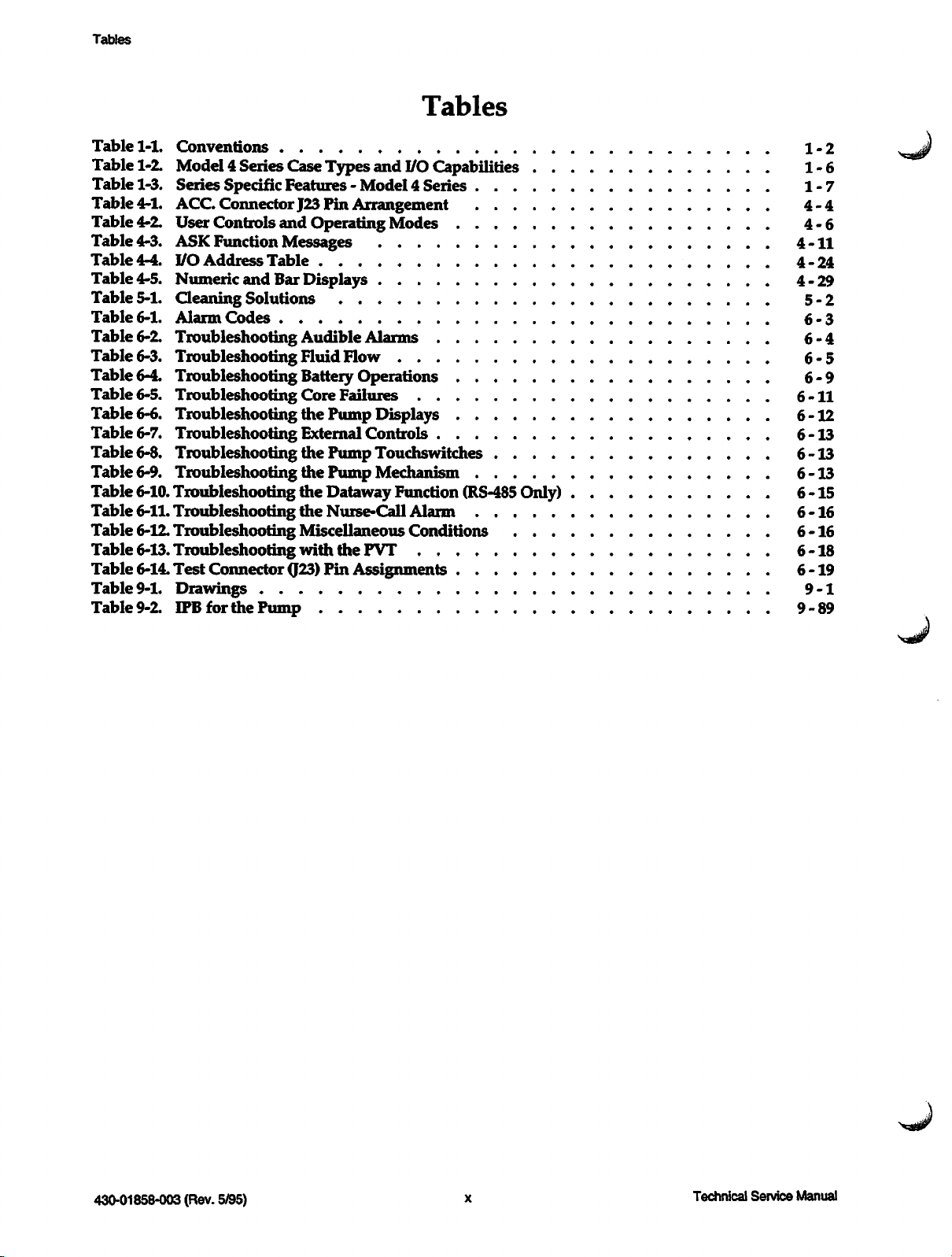

Tables

Tables

Table

1-1.

Conventions

Table

1-2.

Model 4 Series CaseTypes and I/O Capabilities

Table 1-3. Series Specific Features - Model 4 Series

Table 4-1. ACC. Connector

Table 4-2. User Controls and Operating Modes

Table 4-3.

Table

4-4.

ASK

Function Messages

I/O

Address

Table 4-5. Numeric and Bar Displays

Table 5-1. Cleaning Solutions

Table

6-1.

Alarm

Codes

Table 6-2. Troubleshooting

Table 6-3. Troubleshooting Fluid Flow

Table 6-4. Troubleshooting Battery Operations

Table

6-5.

Troubleshooting

Table 6-6. Troubleshootingthe Pump Displays

Table 6-7. TroubleshootingExternal Controls

Table 6-8. Troubleshooting the PumpTouchswitches

Table 6-9. Troubleshooting the Pump Mechanism

Table

6-10.

Troubleshooting the Dataway Function (RS-485 Only)

Table 6-11.Troubleshooting

Table

6-12.

Troubleshooting Miscellaneous Conditions

Table 6-13.Troubleshooting

Table 6-14.

Test

Connector

Table9-1. Drawings

Table9-2. IPB for

the

Table

(J23)

Pump

J23

Pin Arrangement

Audible

Alarms

Core Failures

the

Nurse-Call Alarm

with

the

PVT

Pin

Assignments

1-2

1-6

1-7

4-4

4-6

4-11

4-24

4-29

5-2

6-3

6-4

6-5

6-9

6-11

6-12

6-13

6-13

6-13

6-15

6-16

6-16

6-18

6-19

9-1

9-89

430-01858-003 (Rev. 5/95)

Technical

Service

Manual

Page 13

^ Section1

INTRODUCTION

LifeCare®

are

identifiedbythe

•

Q

•

•

The

Model4except

LifeCare Micro

and

LifeCare

LifeCare

LifeCare

HomeCare

LifeCare

HomeCare

Model

Model

Micro

Model

Model4isabaseline

that

features

Model4Hversionofthe

For

details

Features.

about

the

1.1

SCOPE

The

manualisorganized

Model

following

4

4P

4H

Dual

Rate

delivery

Model4

various

into

4 SeriesInfusionPumps, herein

model

11

designations:

infusion

automatic

rates

from

hasalimited

pump

configurations,

sections:

pump.

The

LifeCare Model 4Pissimilartothe

piggybackingisavailableonModel 4P.

0.1to99.9

delivery

milliliters

rate

range

refertoSection 1.6,

referred

per

for

home

to asthe pump,

hour

(ml/hr).

care

applications.

Series

The

The

Specific

•

Section

Q

Section2Warranty

•

Section3System

•

Section4TheoryofOperation

•

Section

Q

Section6Troubleshooting

•

Section7Replaceable

•

Section8Specifications

Q

Section9Drawings

•

Section

•

Technical

The

material in

testing,

adjustment

Specific

system

1

Introduction

5

Maintenance

10

Index

Service

this

various

Bulletins

manual

service

procedures, troubleshooting,

instructions

operating

for

manuals.

Operating

and

Parts

is limited to technical information necessary for

tests,

pump

Manual

Service

and

interpreting

Tests

Repairs

and

system

alarm

and

authorized repairsonthe

operation are providedinthe

status

LifeCare

messages,

pump.

and

HomeCare

battery

field

Technical

Service

Manual

1-1

430-01858-003

(Rev.

5/95)

Page 14

Section1INTRODUCTION

Ifa problem in

contact

Abbott

pump

operation cannot be resolvedusing the information in this manual,

Laboratories (see Section 6.1, Technical Assistance).

Note: Figures are rendered as graphic representations to approximate the actual product;

therefore, figures may

exactly reflect the product. Display screens

and

touchswitch

not

labels may vary slightly,depending on the configuration ofthe pump system in use.

1.2

CONVENTIONS

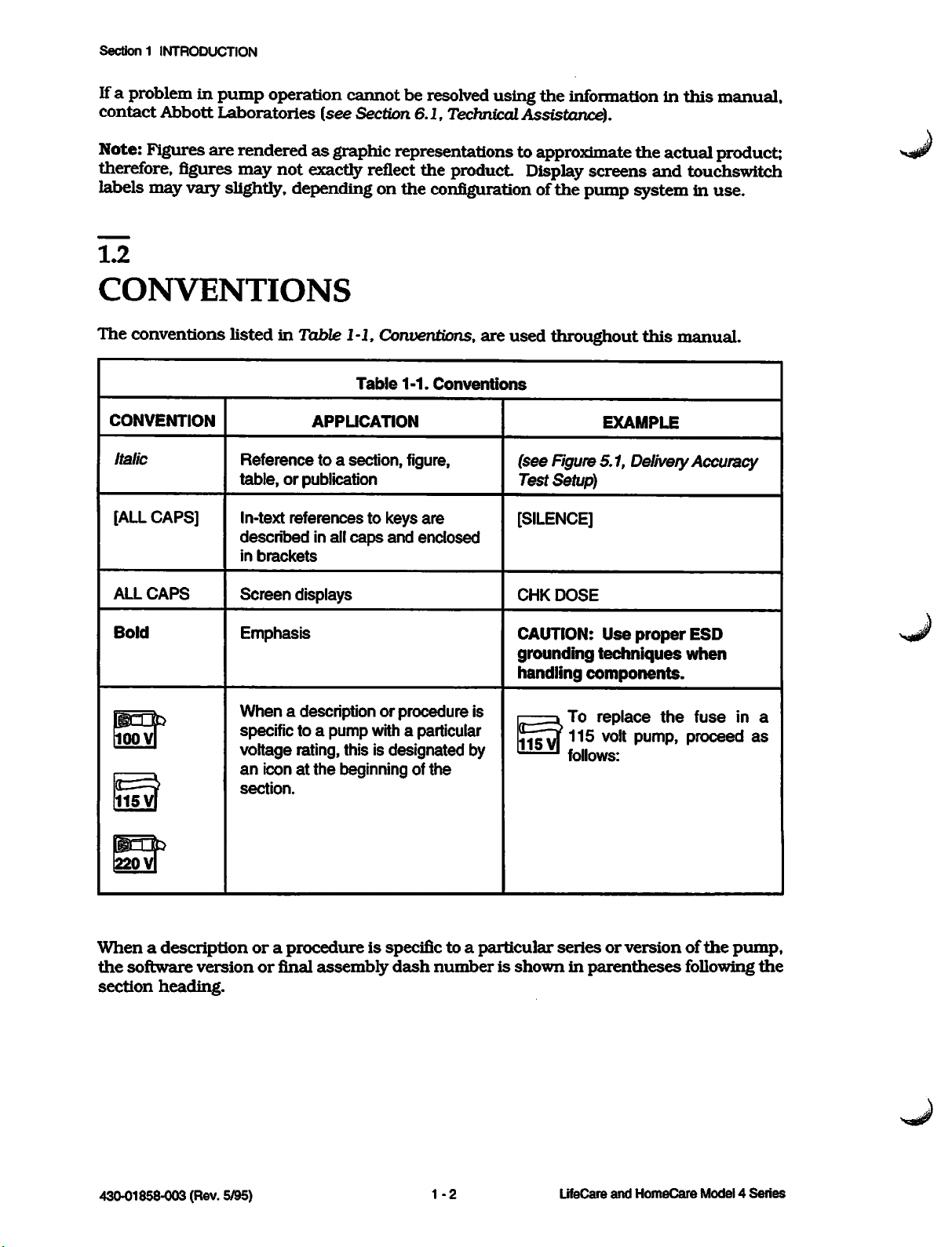

The conventions listed in Table 1-1, Conventions, are used throughout this manual.

Table

1-1.

Conventions

CONVENTION

Italic

[ALLCAPS]

Reference to a section, figure,

table,orpublication

In-text references to keys

described

in

brackets

APPLICATION

in all

caps

and

are

enclosed

EXAMPLE

(see

Figure5.1, DeliveryAccuracy

Test Setup)

[SILENCE]

ALL

Bold

loovl

115Vf

220

V|

CAPS

Screen

Emphasis

When

specific to a

voltage

an

iconatthe

section.

Whenadescriptionora

the

software

section

versionorfinal

heading.

displays

a description or procedure is

pump

with a particular

rating, this is

beginning of

designated

the

by

procedureisspecific to a

assembly

dash

numberisshowninparentheses

CHK

CAUTION:

grounding

handling

—d

j^vj

particular

DOSE

Use

proper

techniques

ESD

when

components.

To

115

'

follows:

replace

volt

the

pump,

fuse

proceed

seriesorversionofthe

following

in a

as

pump,

the

430-01858-003 (Rev. 5/95)

1-2

LifeCare

and

HomeCare

Mode!4Series

Page 15

1.3 ACRONYMS AND ABBREVIATIONS

Throughout

information

A

WARNING

ALL

this

as

TIMES.

follows:

THREATENING.

CAUTION:

contains

Note: A

1.3

A

CAUTION

information

note

highlights

ACRONYMS

Acronyms

and

abbreviations

ABSPRES

manual,

CONTAINS

FAILURE

that

warnings, cautions,

WARNING

SPECIAL

TO

usually

could

information

AND

usedinthis

A

Ampere

Absolute

SAFETY

OBSERVE

appears

prevent

that

ABBREVIATIONS

pressure

and

notes

EMPHASIS

A

WARNING

in

front

ofaprocedure

irreversible

helps

explainaconceptora

manual

areasfollows:

are

used

AND

MUST

IS

POTENTIALLY

equipment

to emphasize

BE

OBSERVED

or

statement.

damage

procedure.

important

AT

LIFE

or

failure.

It

CMOS

DIFPRES

DMM

DPM

DSPLN

ECG

EEG

EMG

EMI

ESD

ETO

AC

ACC

A/D

ADC

Ah

AS

dB

DS

Hz

IC

Alternating

current

Accessory

Analog-to-digital

Analog-to-digital

converter

Ampere-hour

Address

Complementary

Decibel

Differential

Digital

Digital

Data

Display

strobe

pressure

multimeter

pressure

strobe

enable

metal

meter

oxide

Electrocardiogram

Electroencephalogram

Electromyogram

Electromagnetic interference

Electrostatic discharge

Ethylene

Hertz

Integrated

oxide

circuit

semiconductor

Technical Service Manual

1 _ o

430-01858-003

(Rev.

5/95)

Page 16

Section 1

INTRODUCTION

MAL

LEDCATH

ALM

CODE

MFULL

INIT

IOA

IOD

EPB

IRQ

kHz

kPa

KVO

LED

LSB

mA

I/O

IV

Initiate

Input/output

Input/output

Input/output

Illustrated

Interrupt

Intravenous

Kilohertz

Kilopascal

Keep

Light

LED

Least

Milliampere

Malfunction

Message

request

vein

emitting

cathode

significant

full

parts

open

alarm

address

data

breakdown

diode

bit

code

MHz

ml/hr

MPU

MSB

NCALL

OKBATT

ml

ms

mV

N/A

NC

NO

No.

P/N

psi

psig

Megahertz

Milliliter

Milliliter

per

Microprocessor

Millisecond

Most

significant

Millivolt

Not

applicable

Normally

Nurse

Normally

Number

OK

Part

Pounds

Pounds

call

battery

number

closed

open

per

per

square

square

hour

unit

bit

inch

inch

gauge

i.nn'a

(Do\i

PVC

PVT

PWA

PWB

PWRCTL

PWRUP

c,iQx,\

Polyvinyl

Performance

Printed

Printed

Power

Power

wiring

wiring

control

up

chloride

verification

assembly

board

1

.4

test

LifeCareand HomeCare

Model

4 Series

Page 17

1.4

USER

QUALIFICATIONS

\|§py

SFTWRREV

UART

VMEM

VMOT

WDSTB

RAM

ROM

RST

RTS

TRE

VDC

SD

SW

HA

V

jiF

Random

Read

Reset

Requesttosend

Serial

Software

Switch

Transmit

Universal

Volt

Volt

Voltage

Motor

Watchdog

Microampere

Microfarad

access

only

Data

revision

enable

asynchronous

direct

memory

voltage

memory

current

strobe

memory

receiver/transmitter

requester

Microsecond

\xs

1.4

USER

The

Model 4 Series

of

licensed

in

the

QUALIFICATIONS

physicians,

useofthe

infusion

andbylicensedorcertified

pump

pumps

andinthe

are

administration

1.5

ARTIFACTS

Nonhazardous,

administered

standards,

EEG

machines.

the

monitoring

its

sensing

physiological signals. To determine if

causedbythe

thatitis temporarily

it

was

probably

maintenance

appropriate

low-level

using

but

may

create

These

machineisnot

electrodes,

pump

caused

of

the

monitoring

electrical

potentials

infusion devices. These potentials

artifactsonvoltage-sensing

artifacts

varyata

operating

these

instead

not

deliveringfluid.

artifacts

of some

by electronic noise generated by

monitoring

system

equipment

documentation

for

useatthe

healthcare

of

intravenous

are

commonly

equipment

rate

thatisassociated

correctlyorhas

may

be

accentuated

the

abnormalityinthe

other

sourceinthe

Disappearanceofthe

should

for

eliminate

setup

directionorunder

professionals

(IV)

fluids.

observed

are

well

within

suchasECG,

with

the

looseordefective

so

as

to

monitoring

environment,

abnormality

the

pump.

the

artifact

and

maintenance

the

supervision

who

are

trained

when

fluids

accepted safety

EMG,

infusion

rate.

connections

simulate

actual

equipment

set

the

pump

indicates

Proper

setup

Refer to

instructions.

are

and

If

to

is

so

that

and

the

Nj|^j^

Technical

Service

Manual

1-5

430-01858-003 (Rev. 5/95)

Page 18

Section1INTRODUCTION

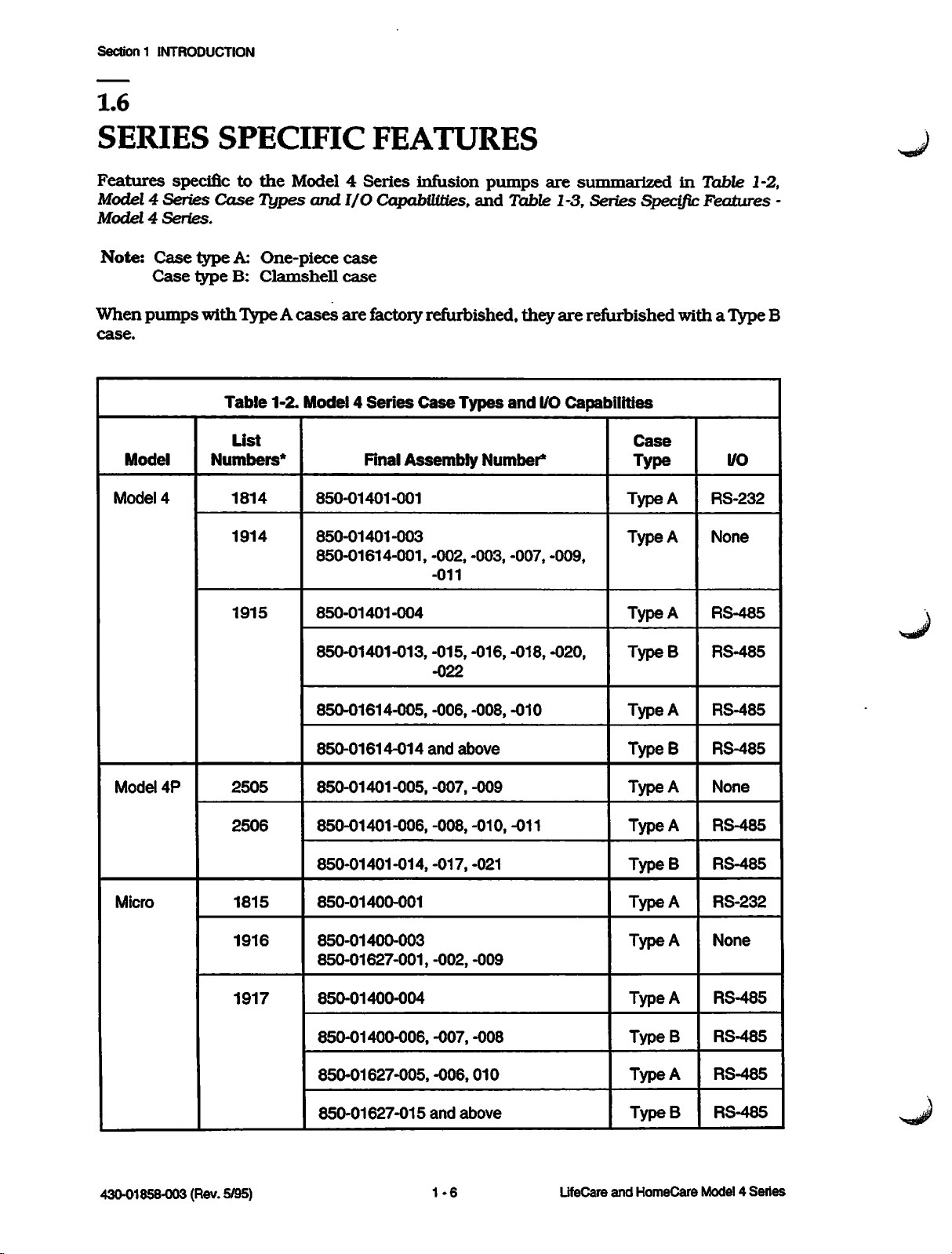

1.6

SERIES

Features

Model 4 Series

Model4Series.

Note:

When

case.

Model

Model

specific to

Case

Case

pumps

4

SPECIFIC

the

Case

Types

type

A:

One-piece

type

B:

Clamshell

with

Type A

Table

Numbers*

1-2.

List

1814

1914

FEATURES

Model 4

and

cases

Model4Series

Series

I/O

Capabilities,

case

case

are

factory refurbished,

Final

850-01401-001

850-01401-003

850-01614-001,-002,

infusion

Case

Types

Assembly

-011

pumps

and

Number*

-003,

are

summarized

in

Table 1-3, Series Specific Features -

they

are

and

-007,

refurbished

I/O

Capabilities

-009,

Type

Type

with

Case

Type

A

A

Table 1-2,

a Type B

I/O

RS-232

None

Model

Micro

4P

1915

2505

2506

1815

1916

1917

850-01401-004

850-01401-013,

850-01614-005,

850-01614-014

850-01401-005,

850-01401-006,

850-01401-014,-017,-021

850-01400-001

850-01400-003

850-01627-001,

850-01400-004

850-01400-006,

-015,

-022

-006,

and

-007,

-008,

-002,

-007,

above

-016,

-008,

-009

-010,

-009

-008

-018,

-010

-011

-020,

Type

TypeB

Type

TypeB

Type

Type

TypeB

Type

Type

Type

TypeB

A

RS-485

RS-485

A

RS-485

RS-485

A

None

RS-485

A

RS-485

RS-232

A

None

A

RS-485

A

RS-485

430-01858-003 (Rev. 5/95)

850-01627-005,

850-01627-015

-006,

and

1-6

010

above

LifeCare

and

Type

TypeB

HomeCare

A

Mode!4Series

RS-485

RS-485

Page 19

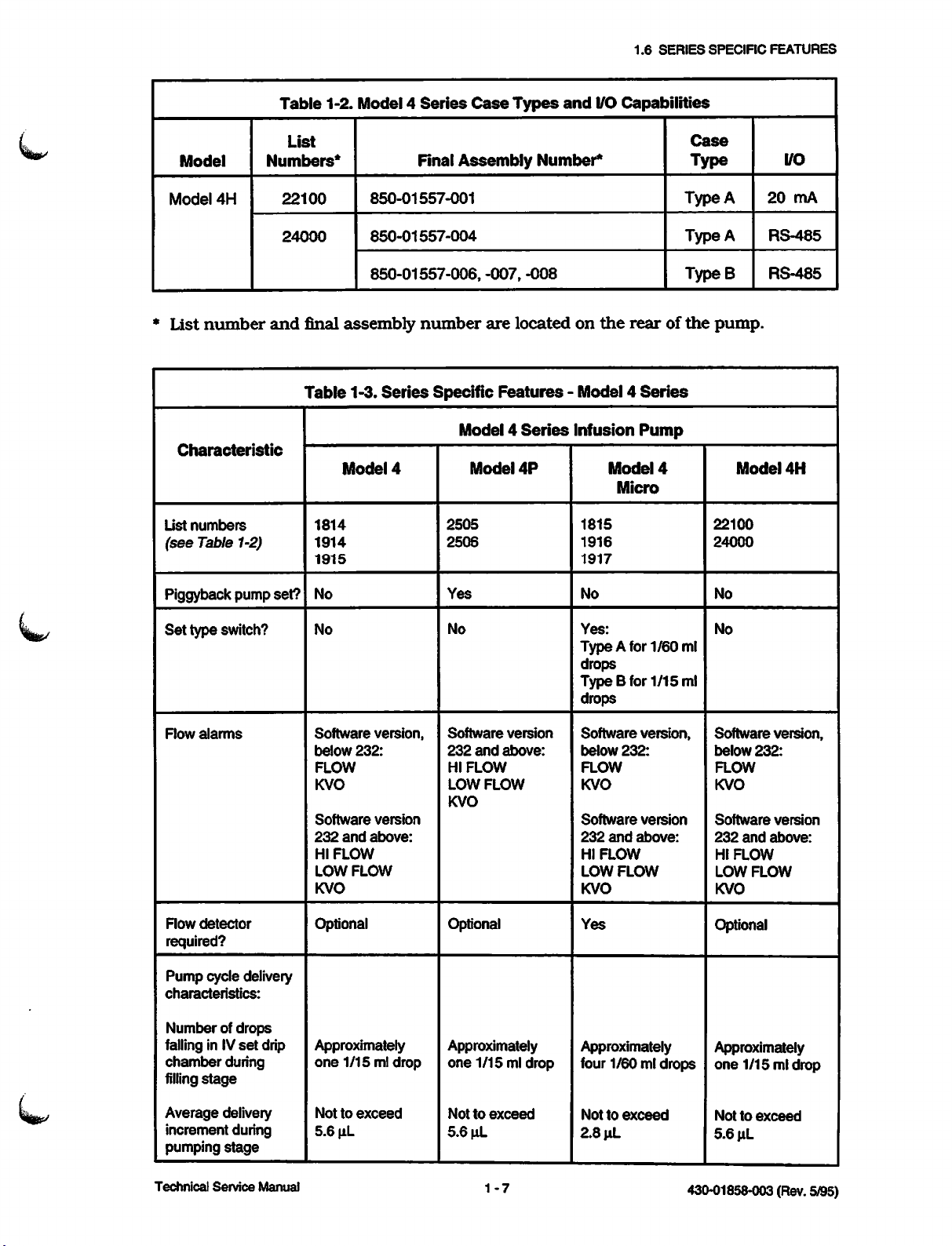

Table

1-2.

Model4Series

Case

Types

and

1.6

I/O

Capabilities

SERIES

SPECIFIC

FEATURES

N||^/

Model

*

Model

List

List

(see

4H

number

Characteristic

numbers

Table 1-2)

Piggyback pump

List

Numbers*

22100

24000

and

final

Table

set?

1814

1914

1915

No

850-01557-001

850-01557-004

850-01557-006,

assembly

1-3.

Series

Model

4

Final

Assembly

number

Specific

Model 4

2505

2506

Yes

Number*

-007,

-008

are locatedonthe

Model4Series

•

Infusion

Model

Features

Series

4P

Case

Type

Type

Type

TypeB

rearofthe

pump.

Pump

Model

1815

1916

1917

No No

4

Micro

22100

24000

A

A

Model

I/O

20

mA

RS-485

RS-485

4H

Set

type switch?

Row

alarms

Row

detector

required?

Pump

cycle delivery

characteristics:

Numberofdrops

falling in IV

chamber

filling

set

during

stage

drip

No

Software

below

FLOW

KVO

Software

232

HI

LOW

KVO

and

FLOW

FLOW

version,

232:

version

above:

Optional

Approximately

one

1/15

ml drop

No

Software

232

HI

LOW

KVO

and

FLOW

FLOW

version

above:

Optional

Approximately

one

1/15 ml drop

Yes:

Type A for 1/60ml

drops

TypeB

for

1/15

ml

drops

Software

below

FLOW

KVO

Software

232

HI

LOW

KVO

Yes

232:

and

FLOW

FLOW

version,

version

above:

Approximately

four 1/60 mldrops

No

Software

below

FLOW

KVO

Software

232

HI

LOW

KVO

232:

and

FLOW

FLOW

version,

version

above:

Optional

Approximately

one

1/15 ml drop

Average delivery

increment during

pumping

Technical

stage

Service

Manual

Nottoexceed

5.6

u.L

Nottoexceed

5.6

uL

1-7

Nottoexceed

2.8

\iL

Nottoexceed

5.6

^L

430-01858-003 (Rev. 5/95)

Page 20

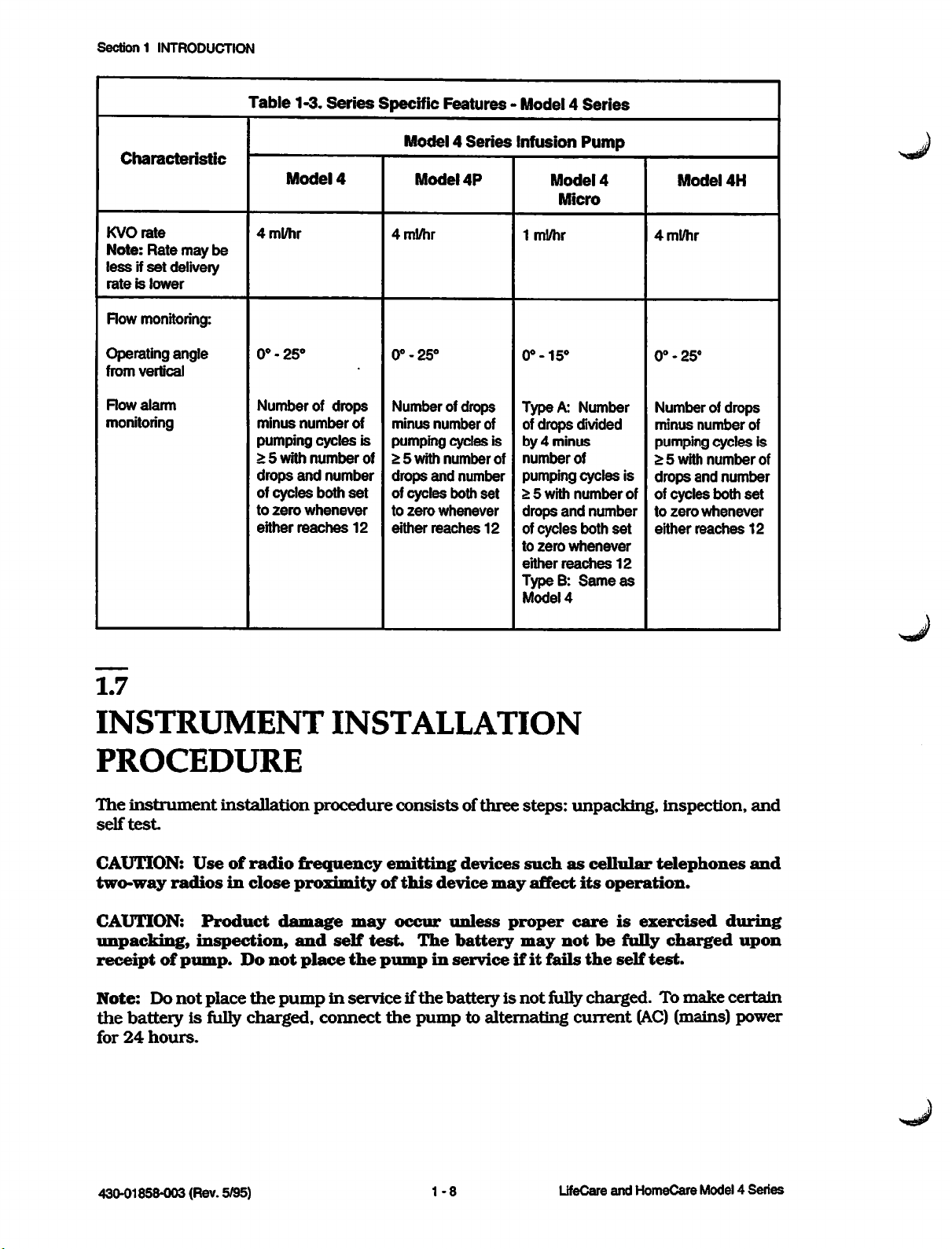

Sectionl

INTRODUCTION

Characteristic

KVO

rate

Note: Rate may be

lessifset

rateislower

delivery

Flow monitoring:

Operating angle

from

vertical

Row

alarm

monitoring

Table

1-3.

Model

4ml/hr

0°-25°

Number of

minus

number

Series

4

drops

pumping cycles is

> 5

with

number

drops

and

number

of

cycles

both

to

zero

whenever

either

reaches

Specific

4ml/hr

0°-25°

Number of drops

of

minus

pumping cycles is

of

> 5

drops

set

of cycles both

to

12

either

Features - Model 4

Model 4

Model

with

zero

number

number

and

number

whenever

reaches

Series

4P

of

set

12

Infusion

Model

Micro

1

ml/hr

0°-15°

Type A: Number

ofdrops divided

by 4 minus

number

of

pumping cycles is

> 5

with

drops

and

ofcycles both

to

zero

either

reaches

TypeB:

Model

Series

Pump

4

of

number

number

whenever

Same

4

4

0°-25°

Numberof drops

minus

pumping cycles is

> 5

drops

of

of

to

set

either

12

as

Model

ml/hr

with

cycles

zero

number

number

and

number

both

whenever

reaches

4H

of

of

set

12

1.7

INSTRUMENT

PROCEDURE

The

instrument

self

test.

CAUTION:

two-way

CAUTION:

unpacking,

receipt

Note:

the

for

of

Do

battery

24

hours.

radiosinclose

installation

Useofradio

Product

inspection,

pump.

not

Do

place

is fully charged,

INSTALLATION

procedure

frequency

proximity

damage

and

self

not

place

the

pumpinserviceif

connect

may

the

consistsofthree

emitting

of

this

device

occur

test.

pump

the

unless

The

in

the

batteryisnot

pump

steps:

devices

may

such

affect

proper

battery

may

serviceifit

to alternating

unpacking,

as

cellular

its

operation.

care

is

not

be

fully

fails

the

self

fully

charged.Tomake

current

inspection,

telephones

exercised

charged

test.

(AC)

(mains) power

and

and

during

upon

certain

430-01858-003 (Rev. 5/95)

1-8

LifeCare

and

HomeCare

Model4Series

Page 21

mjy-y

1.7.1

UNPACKING

Use

care

when

for

returning

container

1.7.2

the

also

INSPECTION

unpacking

pumptothe

the

pump.

factoryincaseitis

containsacopyofthe

Retain

system

1.7

INSTRUMENT

the

packing

damagedorfails

operating

manual.

slip

and

INSTALLATION

save

all

the

self

packing

test.

The

PROCEDURE

material

shipping

Inspect

the

the

delivering

CAUTION:

damaged;

1.7.3

SELF

contact

TEST

Note:Donot

the

self

test,

1.

Connect

2.

Connect

3.

Set

the

medium,

4.

Turn

5.

The

operations:

-

Initializes

been

packing

carrier

Inspect

place

proceed

the

the

AUD. ALM.

or

the

main

pump

reached

container

immediately.

the

pump

Abbott

the

power

flow

Laboratories

pumpinservice

as

follows:

cord

detectortothe

switchonthe

high.

control

switch

automatically

all

data

except

for

shipping

for

damage.

to a

properly

enters

historyifthe

damage.

(see

until

FLOW DET.

backofthe

to

LOCK/ON.

the

Should

Do

not

Section

the

self

grounded

pumptothe

self-test

four-hour

any

use

the

6.1,

Technical

test

has

AC

(mains)

receptacle

mode

data

damagebefound,

pumpifit

Assistance).

been

conducted.

outlet.

on

the

backofthe

desired

and

retention

volume

performs

interval

appears

To

level: low,

the

following

contact

to

be

conduct

pump.

has

-

-

-

-

-

If

the

Section

Technical

Tests

Checks

Illuminates

legends

Activates

Checks

pump

6.1,

Service

fails

Technical

random

failure

audible

critical

the

Manual

access

monitor

all

numeric

alarm

data

self

test,donot

Assistance).

memory

test

elements,

integrity

(RAM)

status

message

placeitin

1-9

and

read

display

service;

only

contact

memory

elements,

Abbott

(ROM)

and

front

Laboratories

430-01858-003

panel

(Rev.

(see

5/95)

Page 22

4

Series

Model

and

HomeCare

UfeCare

1-10

430-01858-003 (Rev. 5/95)

left

blank.

This

page intentionally

Section

1 INTRODUCTION

Page 23

^ Section 2

WARRANTY

Subject

Abbott,

and

periodofone

a

in

purchase.

fitness

Purchaser's

product

such

the

to

the

terms

warrants

be

free

from

year

material

causebebasedincontract,

price

and

Abbott

for a

particular

exclusive

Innoevent

of

workmanship

such

and

that

(a)

defectsinmaterial

after

makes

purpose,orany

remedy

shall

product,

consequential, or special

Warranty

The

altered,

judgment,

been

The

performs or

having

documentation

repairor

items

product

foregoing

or

to

altered,

foregoing

been

other

used

returnedtoAbbott

warranty

other

affect

effaced,

its

or

warranty

attempts

to perform

trained

and

approved spare parts. For purposesofthe

service"

means

stabilityorreliability,orin

by

suchasbatteries, flow detectors, detachable AC power cords,

conditions

the

product

purchase,

under

no

other

shall

Abbott's

and

herein,

shall

and

workmanship

and

(b)

the

normal

warranties,

other

be,atAbbott's

liability

negligence,

in

no

event

arising

damagesorlosses

mustbeproperly

shallbevoidinthe

than

in

accordance

removed.

event

shallalsobevoidinthe

any

majorrepair or

an

authorized

any

repairor service

representative

Abbott

Laboratories,

conformtoAbbott's

under

replaceable

use

and

service

expressorimplied,asto

matter.

option,

outofany

strict

liability,

shall

Abbott

or for

lost

packaged

the

product

with

product

the

event

event

any

other

normal

battery

the

shallbefree from

for a

repairorreplacementofthe

cause

other

tortorotherwise)

be

business,

and

has

been

manuals

the

serialorlot

person,

including

serviceonthe

of

Abbott

preceding sentence, "major

other

than

the

replacementofaccessory

herein

standard

use

and

periodof90

merchantability,

whatsoever

liable

for

revenues,

sent

freight prepaid.

misused,

so

as,

the

product

and

and

patient

referredtoas

specifications

service

days

incidental,

for

defects

after

(whether

exceed

or profits.

damaged,

in

Abbott's

number

has

Purchaser,

without

using

Abbott

pendants.

In

providing

responsibility or liability for

or service, regardlessofwhether

service. It

representative performingrepair or service is

Technical Service Manual 2 -1 430-01858-003(Rev.5/95)

any

is

understood

parts

for repair or service

the

actions or inactionsofthe

such

person

and

acknowledged

notanauthorized

has

of

been

that

the

product,

person performing

trained to perform

any

person

agentofAbbott.

Abbott

other

shall

such

than

have

such

repair or

an

no

repair

Abbott

Page 24

LifeCareand HomeCare Model4 Series

2-2

430-01858-003 (Rev. 5/95)

left

blank.

This

page

intentionally

2

WARRANTY

Section

Page 25

430-01858-003 (Rev. 5/95)

-1

Technical Service Manual 3

the

of

Operating

Assistance).

(see

Section 6.1,

a copy

insert

System

Laboratories

reference,

Abbott

contact

here.

For

convenient

MANUAL

available,

manual

pump.

every

HomeCare Model 4 Series Infusion Pumps

and

OPERATING

is

not

manual

operating

with

LifeCare

system

included

of

the

Technical

If

an

operating

appropriate

Manual is

A

copy

SYSTEM

^ Section 3

Page 26

Series

(Rev.

and

Model 4

HomeCare

3 - 2 LifeCare

5/95)

430-01858-003

left

blank.

This

page

intentionally

MANUAL

OPERATING

3

SYSTEM

Section

Page 27

Section

4

THEORY

This

section

Related

general

operation,

mechanical

Note:

an

Whenasignal

active

4.1

GENERAL

The

Model4Series

housed

mechanical

include

driver

The

pumping

(one

1/15

mechanism.

pumping

motor

milliliter

describes

drawings

functionsofthe

monitors

low

positive

printed

are

subsystem

signal.

displacement

subassemblies

wiring

mechanism

volumeiscalculatedasa

revolution

(ml)offluidina

OF

the

providedinSection 9, Drawings.

pump

and

detectors,

principlesofoperation.

nameisfollowedbyan

OPERATION

theory

of

operation

and

providesabrief

electronics

for

subsystem

asterisk,

FUNCTIONS

infusion

assemblies

pump

pump.

used

for

operation

(PWA),

contains

The

motor

the

electromechanical

driverishoused

and

controlofthe

battery

is stepper-motor driven to

functionofthe

equals

one

primed

pump

pump

stroke

chamber).

the

Model4Series

The

theoryofoperation

overviewofexternal

principles

suchasINIT ,

with

pump.

pack,

the

display

enableasimple

numberofstepsofthe

which

equals

the

drivers

all

The

panel,

control

of

asterisk

the

displacement

infusion

interface

operation,

withacassette

electrical

subassemblies

and

pump.

describes

ports,

and

indicates

and

the

pump

logic. The

stepper

motor

of

N^ggi/

The

flow

detector

to

the

numberofmotor

motor

number

revolutions

of

drops

DELIVERED

4.1.1

CASSETTE

The

cassetteisdesigned

An

air-trap

trappedinthe

chamber.

open,

resultinginno

pumpedtothe

The

cassette

compression

be

carried

pump

on

the

chamber

The

into

operation

model

monitors

fluid drops. The control logic

revolutions.

by

more

than

by

more

light

emitting

holds

chamber,anair

compressibilityofthe

deliveryofsolution.

patient.

must

be

than

diode

withanoutlet

air

bubble

correctly

chamberorfails to

the

compression

stops

and

a flow/KVO

and

versionofthe

When

four,

four, a flow

(LED)

bubblesoroutgassing

the

or

the

display

valve

that

numberofdrops

number

alarm

indicates

requires

maybecarried

air

primed.

clear

sufficient

chamber.

pump.

bubble

alarm

prevents

This

outlet

Incorrect

air

from

In

either

or low flow/KVO

compares

of

motor

is

generated

the

natureofthe

hydraulic

from

solution.

through

the

outlet

valve

feature

cassette

the

air

case,ifthe

the

exceeds

revolutions

pressuretooperate.

the

cassettetothe

valve

prevents

priming

trap,

permitting

flow

detectorisattached,

alarm

numberofdrops

the

number

exceeds

and

the

VOLUME

flow problem.

If

too

much

pumping

from

being

air

from

leaves

air

in

the

sounds,

depending

the

air

forced

being

the

air

to

of

is

Technical Service Manual

4-1

430-01858-003 (Rev. 5/95)

Page 28

Section4THEORY

4.1.2

OF

OPERATION

FLOW DETECTOR

The

flow

detector

providesacomparative

rateiscorrect

clean,

often

Useofthe

Table 1-3,

4.1.3

dry,

and

tracedtodirtyorimproperly

flow

Series

ALARMS

The

operational

messages

pump.

4.1.3.1

AUDIBLE

are

performs

The

flow

correctly

detectorismandatory

Specific

failures

displayed

ALARM

dual

valuetothe

detectorisphotoelectric.Itis

mounted

Features

described

on

functions:itindicates

control

on

theIVset

placed

-Model 4 Series).

throughout

the

VOLUME DELIVERED

logicsothe

flow detectors.

in

some

thereisfluid flowinthe

essential

drip

chamber

applications

Section 4

pump

cause

display

can

determineifthe

that

the

flow

assembly.

and

optionalinothers

an

alarmtosound.

on

the

Flow

front

line,

and

flow

detector

alarms

panelofthe

be

are

{see

Alarm

^J

RefertoFigure 9-14,

is

generatedbythe

The

piezoelectricalarm

Q6isactivated.

Power

Supply

piezoelectric

transducer

Q6isturned

PWA Schematic, Micro

alarm

producesa

on

by

piezoelectric alarm transducer signals

by

interrupt

RECHARGE position.

ALM.

alarm

4.1.3.2

NURSE-CALL

Referto Figure9-14,

is

activated

switchisin

and

initiate

actively

low de-energizes

4.1.4

NUMERIC

request

level

whenever

the

LOCK/ON

(INTT*).

high

RSTatpin5of

switch

ALARM

Power

The

the

Kl

AND

(IRQ)

The

whenever

piezoelectricalarm

on

the

backofthe

SupplyPWASchematic, Micro

the

Kl

nurse-call

position.

purposeofIN1T*

U7B oranactively

nurse-call

BAR

relay,

DISPLAYS

transducer,

the

signals

AUDIO,

the

locatedonthe

2.7

kilohertz(kHz) frequency after

TONE

AUDIO

main

2, and AUDIO 1. Q6 is turned

control switch is

transducer

pump.

relayisde-energized

Kl

is controlledbysignals

is to drive

Kl

high

NCALLatpin6of

causinganalarm.

4/Model4.The

sideofthe

or

reset

(RST)

volume

4/Model4.The

when

is controlledbythe

while

nurse

the

power is

audible

clamp

transistor

to

produce

in

the

LOAD/OFF

nurse-call

the

master

call (NCALL),

turned

U7B

while

alarm

casting.

the

off

AUD.

alarm

control

RST,

on.

An

INTT*

is

^J

RefertoFigure

Micro 4.

DELIVERED,

seven-segment,

430-01858-003 (Rev. 5/95) 4 - 2 LifeCare and HomeCare Model4 Series

There

9-11,

Display

are

VOLUME

plus

decimal, LED display.

PWA Schematic, MDL4,orFigure

four

numeric

DELIVERED,

displays

and

9-12,

Display

used

in

the

pump:

DELIVERY

The

LifeCare Micro LED display

RATE.

PWASchematic,

DOSE

Each

LIMIT,

display

DOSE

contains

is

an

a

Page 29

extra

receive

The

bar

are

backlighted

The

legends

only)

DET.

4.2

digit

for

input/output

display

REMOTE,

are

each

contains

displaying

data0(IODO)

provides

by

two

backlighted

four

LEDs

decimal

points.

Each

through

colored

LED

bars,

backlighting.

yellow

and

OPERATING (Model 4

byayellow

andisbacklighted

bar

LED

display

IOD7.

The

red,

respectively,

and

4H

containing

byared

legends

only),

four

bar.

4.2

EXTERNAL

INTERFACE

sharesacommon

BATT

LEDs.

(DS4)

and

contain

and

PIGGYBACK

The

and

two

legend

PORTS

data

bus

LOW

(DS5)

LEDs

each.

(Model 4P

NO FLOW

to

EXTERNAL

External

the

System

Micro

(ACC.)

Additionally,

(I/O)

Series

interface

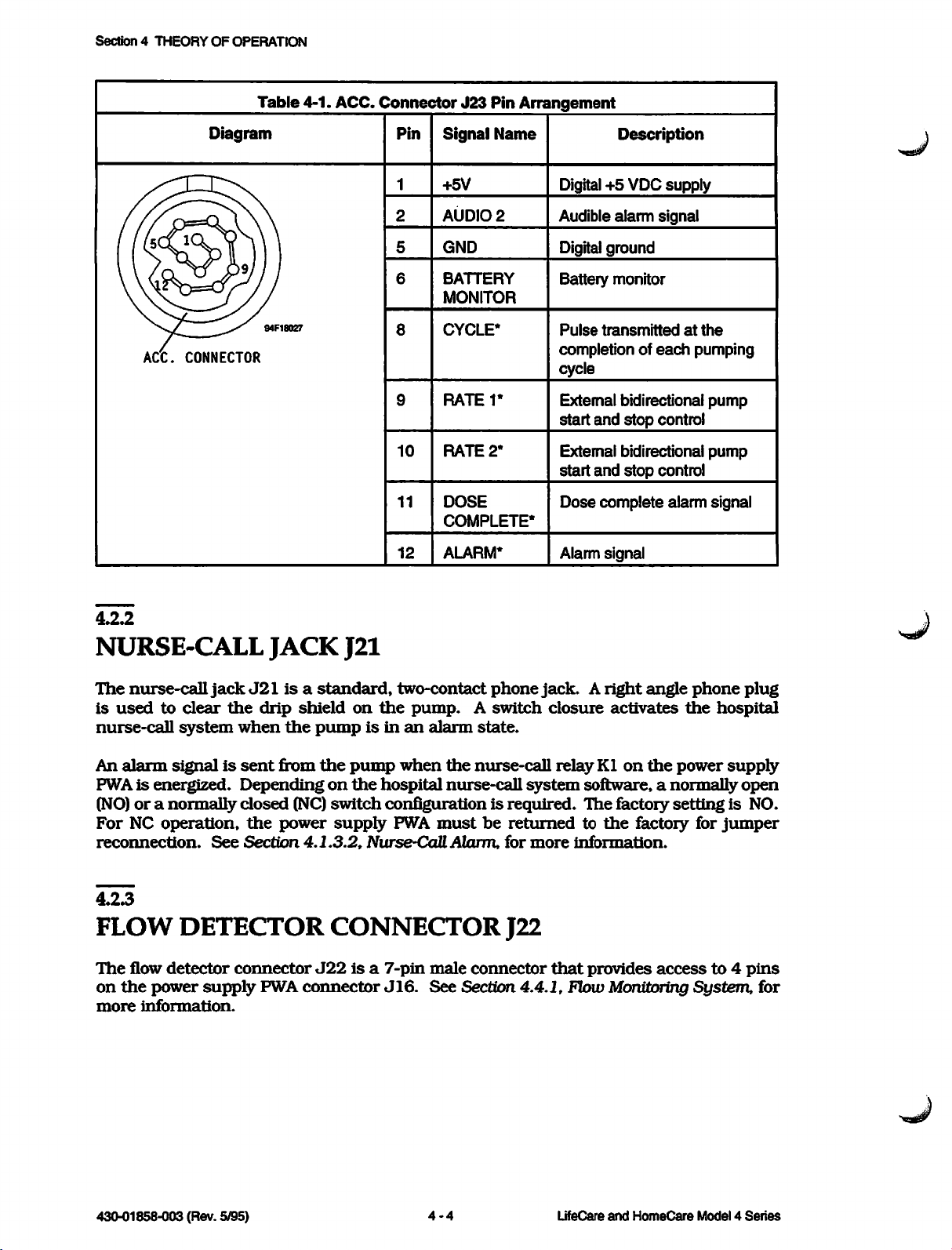

4.2.1

ACC

ACC.

supply

of

the

names,

The

stopping

that

stage.

pumpingisinhibited.

pump

interface

pump

and

are

Interconnect

4/MDL

4 (International).

connector

certain

connector

Case

ports

JlOl,

Types

follows.

CONNECTOR

connector

PWA

pump.

and

RATE1*and

and

correspond

As

enters

J23isa

connector

Table

descriptions.

starting

inputs,

the

ports

showninFigure

J23,

and

4-1,ACC. Connector

RATE

with

when

failure

INTERFACE

on

the

Model4Series

9-2,

Schematic,

Micro

External

nurse-call

pump

versions

an

RS-232

I/O

Capabilities). A

I/O

J23

12-pin,

J16.

2*

the

each

RATE1*and

When

mode.

male

The

ACC.

signals

pump.

As

incremental

only

System

4/MDL4;and

Interconnect

interface

connector

are

equipped

port,ora

descriptionofModel4infusion

connector

connector

J23

PinArrangement,

are

bidirectional

outputs,

RATE1*and

delivery

RATE2*are

oneofthese

PORTS

infusion

J21,

withanRS-485

20-mA

that

allows

step

held

rate

pump

Figure

ports

include

and

I/O

provides

external

and

(32

below

signalsisheld

are

Schematic,

9-4,

Interconnect

the

flow

detector

Dataway

port

(refer to

accessto7

monitoring

provides

provide

an

RATE2*are

per

cycle)

0.5

volt

located

Model

following:

Table

pinsonthe

pin

external

low-going

during

direct

below

on

the

4P; Figure

Schematic,

accessory

connector

input/output

1-2,

pump

and

numbers,

means

the

pumping

current

0.5

VDC,

back

of

9-3,

J22.

Model

external

power

control

signal

for

pulses

(VDC)

the

4

The

CYCLE* signalistransmittedatthe

The

ALARM*

Technical

signal

Service

Manual 4 - 3

goes

low

when

completionofeach

the

pump

enters

the

alarm

pumping

stateorthe

cycle.

failure

430-01858-003

mode.

(Rev. 5/95)

Page 30

Section4THEORYOFOPERATION

Table

4-1.

ACC.

Connector

J23

Pin

Arrangement

ACC.

Diagram

7^"

~~^S

CONNECTOR

94F18027

Pin

1

2

5

6

8

9

10

11

12

Signal

+5V

AUDIO

GND

BATTERY

MONITOR

CYCLE*

RATET

RATE

DOSE

COMPLETE*

ALARM*

Name

2

2*

Description

Digital +5 VDC

supply

Audible alarm signal

Digitalground

Battery

Pulse

completion of

monitor

transmitted

at

each

cycle

External bidirectional

start

and

stop

control

External bidirectional

start

and

stop

control

Dose

complete alarm signal

Alarm signal

the

pumping

pump

pump

4.2.2

NURSE-CALL

The

nurse-call

is

used

to

nurse-call

An

alarm

PWAisenergized.

(NO)ora

For NC

reconnection.

4.2.3

operation,

FLOW

The

flow

on

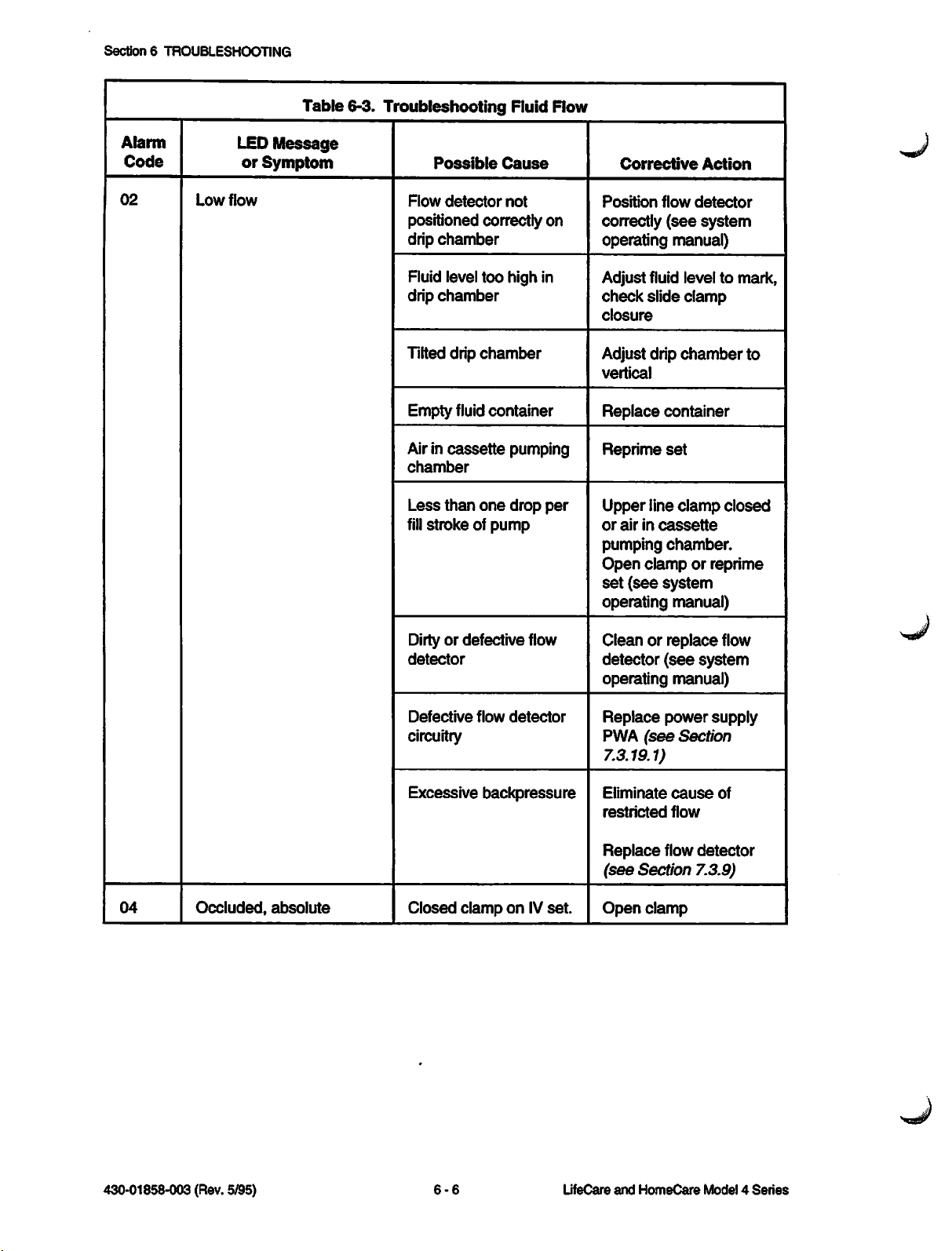

the

power

more

information.

jack

clear

the

system

signalissent

normally

See

DETECTOR

detector

connector

supply

JACK

J21isa

drip

when

the

from

J21

standard,

shield

on

pumpisinanalarm

the

pump

Dependingonthe

closed

Section

the

(NC)

power

4.1.3.2,

switch

supply

CONNECTOR

J22isa

PWA

connector

two-contact

the

pump.

A

phone

switch

state.

when

the

nurse-call

hospital

nurse-call

system

configurationisrequired.

PWA

must

be

returnedtothe

Nurse-CaR

Alarm,

for

J22

7-pin

male

connector

J16.

See

Section

4.4.1,

jack.Aright

closure

relayKlon

software,anormally

The

more

information.

that

provides

Flow

angle

activates

the

factory

settingisNO.

factory for

accessto4

Monitoring

phone

the

power

System,

plug

hospital

supply

open

jumper

pins

for

430-01858-003 (Rev. 5/95)

4-4

LifeCare

and

HomeCare

Model4Series

Page 31

4.2.4

4.2

EXTERNAL

INTERFACE

PORTS

>|$g^/

RS-485

Certain

Dataway

Capabilities, for a

capability.

The

RS

and

receive information between a

external

nurse

canbeobtained

limits

A

universal

driver

Section

To

use

modeisaccessed

mode,aDataway

withoutacommand

command,

makes

be

disabled.

remote

DATAWAY

versions

I/O

connector

485

Dataway

host

device

station

can

PWA.

4.5.2,

the

certain

operations.

console.

be

transmitted

asynchronous

Foradetailed

Motor DriverPWA,

Dataway

or

any

that

See

of

the

listofthe

I/O

suchasa

from

the

interface,

from

timerinthe

to

other

continued

Section

I/O

Model 4

JlOl.

connectorisa

Information

pump

to

transmit/receive

the

external

the

pump.

command

4.3.1,

Series

See

Model 4 Series

hospital

through

the

pump

description

and

the

pump

pump

fromaremote

interactive

ModesofOperation,

CONNECTOR

infusion

Table 1-2, Model 4

bidirectional,

maximum

patient

such

as

the

from

the

(UART) device,

of

Section

mustbeoperatinginthe

device

through

producesaDataway

Each

time

communications

pump

infusion

serial

of 31 electrically

data

management

status,

I/O

the

4.5.2.4,

alarm

port.

host

device.

operation

RS-485

the

the

pump

device,

for

JlOl

are

equipped

Series

pumps

data

history,ormalfunction

Information

Ul,ismounted

Dataway

I/O

alarmifone

receives a

the

timerisreset

with

additional

Case

with

interface

connected

systemora

suchasratesordose

of

the

remote

interface.

the

external

information

Dataway

Port

reset

with

an

RS-485

Types

RS-485

usedtotransmit

pumps

and

Dataway

and

computerized

on

the

UART,

mode.

When

minute

The

in

remote

remote

passes

Dataway

This

function

device

on

cannot

local

I/O

an

codes

motor

see

timer

and

Note:

and

number

to

4.2.5

For

Interface Manual,

430-01761

any

external

RS-232

This

technical

4.2.6

20-MA

This

technical

detailed

device.

I/O

PORT

service

I/O

PORT

service

Dataway

UfeCare

-XXX.

manual

manual

This

technical

information,

Model 4 Series Infusion

manual

does

does

shouldberead

not

support

not

support

the

the

see

the

Pumps

before

RS-232

20-mA

Technical Specification Guide

RS-485

connecting

I/O

port.

I/O

port.

Dataway,

the

Dataway

Manual

port

V%r>

Technical

Service

Manual 4 • 5

430-01858-003

(Rev. 5/95)

Page 32

Section4THEORY

4.3

OF

OPERATION

OPERATIONAL

This

section

the

data

4.3.1

MODES

The

Model4Series

1.

2.

3.

4.

5.

6.

Certain

by

the

pump.

describes

retention

function.

OF

OPERATION

infusion

Load/Off

Self

Local

Remote

Battery

System

recharge

test

control

control

discharged

failure

modesofoperation

See

Table4-2, User Controls

the

DESCRIPTION

six

modesofpump

pump

are

has

user

six

controlled.

and

operation,

the

silence/ASK

modesofoperationasfollows:

Other

OperatingModes, for

modesofoperation

additional

function,

are

controlled

information.

and

User

Control

LOAD/LOCK

control

DELIVERY

RATE

set

switch

volume

delivered

CLEAR

switch

DOSE

LIMIT

set

switch

Dose

LIMIT

ON/OFF

CLEAR

switch

Table

Load/

Off

Self

Test

X X X

4-2.

Reset

X

X

D

X

User

Local

Controls

and

ModeofOperation

Control

Operate

X X

Alarm

Operating

Remote

Control

Modes

Battery

Discharged

X X

System

Failure

X

START

switch

RESET

switch

430-01858-003 (Rev. 5/95)

X R X

X X X

4-6

LifeCare

and

HomeCare

Model4Series

Page 33

User

Control

Load/

Off

Table

Self

Test

4-2.

Reset

User

Local

Controls

and

ModeofOperation