Page 1

User Guide

IM/SM2000 Issue 13

Advanced Videographic Recorder

SM2000

Page 2

ABB

The Company

EN ISO 9001:2000

We are an established world force in the design and manufacture of instrumentation for

industrial process control, flow measurement, gas and liquid analysis and environmental

applications.

Cert. No. Q 05907

As a part of ABB, a world leader in process automation technology, we offer customers

application expertise, service and support worldwide.

EN 29001 (ISO 9001)

We are committed to teamwork, high quality manufacturing, advanced technology and

unrivalled service and support.

The quality, accuracy and performance of the Company's products result from over 100 years

experience, combined with a continuous program of innovative design and development to

Lenno, Italy – Cert. No. 9/90A

incorporate the latest technology.

The UKAS Calibration Laboratory No. 0255 is just one of the ten flow calibration plants operated

Stonehouse, U.K.

by the Company and is indicative of our dedication to quality and accuracy.

0255

Electrical Safety

This equipment complies with the requirements of CEI/IEC 61010-1:2001-2 'Safety Requirements for Electrical Equipment for

Measurement, Control and Laboratory Use'. If the equipment is used in a manner NOT specified by the Company, the protection

provided by the equipment may be impaired.

Symbols

One or more of the following symbols may appear on the equipment labelling:

Warning – Refer to the manual for instructions Direct current supply only

Caution – Risk of electric shock Alternating current supply only

Protective earth (ground) terminal Both direct and alternating current supply

Earth (ground) terminal

Information in this manual is intended only to assist our customers in the efficient operation of our equipment. Use of this manual for

any other purpose is specifically prohibited and its contents are not to be reproduced in full or part without prior approval of the

Technical Publications Department.

Health and Safety

To ensure that our products are safe and without risk to health, the following points must be noted:

1. The relevant sections of these instructions must be read carefully before proceeding.

2. Warning labels on containers and packages must be observed.

3. Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel and in accordance with the

information given.

4. Normal safety precautions must be taken to avoid the possibility of an accident occurring when operating in conditions of high pressure

and/or temperature.

5. Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry. Normal safe handling

procedures must be used.

6. When disposing of chemicals ensure that no two chemicals are mixed.

The equipment is protected

through double insulation

Safety advice concerning the use of the equipment described in this manual or any relevant hazard data sheets (where applicable) may be

obtained from the Company address on the back cover, together with servicing and spares information.

Page 3

Advanced Videographic Recorder

SM2000 Contents

Contents

1 Introduction .....................................................................3

2 Operation .........................................................................5

2.1 Powering up the Instrument .....................................5

2.2 Displays and Controls ..............................................5

2.3 Chart Views .............................................................7

2.3.1 Electronic Signatures ..................................14

2.4 Bargraph Views ......................................................15

2.5 Digital Indicator View ..............................................17

2.6 Process View .........................................................20

2.7 Alarm Event Log .....................................................23

2.8 Totalizer Log ..........................................................25

2.9 Audit Log ...............................................................27

2.10 Status View ............................................................28

3 Setup .............................................................................29

3.1 Introduction ............................................................29

3.2 Accessing the Setup Level .....................................29

3.3 Password Entry ......................................................31

3.4 Setup Menu ...........................................................32

3.5 Archiving ................................................................34

3.5.1 Card Compatibility ......................................34

3.5.2 SmartMedia Handling and Care .................. 34

3.5.3 Media Status ..............................................35

3.5.4 Inserting and Removing Media ....................35

3.5.5 Archive File Types .......................................36

3.6 Text Format Archive Files .......................................37

3.6.1 Text Format Channel Data Files .................. 37

3.6.2 Text Format Filename Examples ................. 38

3.6.3 Text Format Log files ..................................38

3.6.4 Text Format Data File Examples ..................39

3.6.5 Text Format Data File Digital Signatures ......39

3.6.6 Text Format Data Verification

and Integrity ................................................39

3.7 Binary Format Archive Files ....................................41

3.7.1 Binary Format Archive Filenames ................41

3.7.2 Binary Format Channel Data Files ...............41

3.7.3 Binary Format Log files ...............................41

3.7.4 Binary Format Data File Examples ...............41

3.7.5 Binary Format Data Verification

and Integrity ................................................41

3.8 Archiving Online/Offline ..........................................44

3.9 Backing-up Archived Data .....................................44

3.10 Archive Wrap .........................................................44

4 Configuration ................................................................ 45

4.1 Introduction ........................................................... 45

4.1.1 Configuration Modes .................................. 45

4.1.2 Configuration Level Security ....................... 45

4.1.3 Configuration Level Access ........................ 45

4.2 Overview of Configuration ...................................... 48

4.3 Making Changes to Parameters ............................. 49

4.4 Common Configuration ......................................... 52

4.4.1 Setup ......................................................... 52

4.4.2 Screen ....................................................... 53

4.4.3 Time ........................................................... 54

4.4.4 Security ...................................................... 56

4.4.5 Users ......................................................... 58

4.4.6 Logs ........................................................... 60

4.4.7 Operator Messages .................................... 60

4.4.8 RS485 (Modbus™) Communications ......... 61

4.4.9 Comms Analog Input ................................. 62

4.4.10 Comms Digital Input .................................. 63

4.5 Process Group Configuration ................................. 64

4.5.1 Setting the Recording Parameters .............. 64

4.5.2 Configuring the Chart View ......................... 67

4.5.3 Configuring the Bargraph View ................... 70

4.5.4 Configuring the Process View ..................... 71

4.5.5 Configuring the Digital Indicator View .......... 72

4.5.6 Archiving .................................................... 73

4.6 Channel Configuration ........................................... 76

4.6.1 Recording Channel Setup .......................... 77

4.6.2 Analog Input Configuration ......................... 81

4.6.3 Digital Input Configuration .......................... 84

4.6.4 Alarm Configuration .................................... 85

4.6.5 Totalizer Configuration ................................ 91

4.6.6 Scales ........................................................ 94

4.7 I/O Module Configuration ....................................... 95

4.7.1 Analog Inputs ............................................. 95

4.7.2 Relay Modules ........................................... 96

4.7.3 Hybrid Modules .......................................... 97

4.7.4 Ethernet Modules ....................................... 98

4.8 Modbus TCP ......................................................... 98

4.9 Functions .............................................................. 99

4.9.1 Custom Linearizers .................................... 99

4.9.2 Real-time Alarms ...................................... 100

IM/SM2000 Issue 13 1

Page 4

Advanced Videographic Recorder

SM2000 Contents

5 Installation ...................................................................101

5.1 Siting ....................................................................101

5.2 Mounting ..............................................................102

5.3 Electrical Connections ..........................................103

5.4 Analog Inputs .......................................................105

5.4.1 Current and Voltage ..................................105

5.4.2 Thermocouple ...........................................105

5.4.3 Resistance Thermometer (RTD) ................105

5.4.4 Transmitter Power Supply .........................105

5.5 RS422/485 Serial Communications ......................106

5.6 Mains Power Connections ....................................107

5.7 Relay Output Board Connections .........................107

5.8 Hybrid I/O Module Connections ............................108

5.8.1 Digital Output Connections .......................108

5.8.2 Digital Input Connections ..........................108

5.8.3 Analog Output Connections ......................108

Appendix A – Signal Sources ..........................................109

Appendix B – Modbus Guide ..........................................111

B.1 Introduction ..........................................................111

B.2 Setting Up ............................................................111

B.3 Modbus Commands Supported ...........................111

B.4 Modbus Exception Responses .............................111

B.5 Operating Mode Modbus Coils .............................111

B.6 Operating Mode Modbus Registers ......................117

B.7 Comms. Analog and Digital Inputs ........................119

Appendix C – Storage Capacity ..................................... 121

C.1 Internal Storage Capacity .....................................121

C.2 Archive Storage Capacity ..................................... 122

Appendix D – Default Settings .......................................124

D.1 Company Standard .............................................. 124

D.1.1 Common Configuration ............................ 124

D.1.2 Process Groups 1 to 6 .............................124

D.1.3 Recording Channels .................................125

D.1.4 I/O Modules ..............................................125

D.1.5 Functions .................................................126

D.2 QuickStart Templates ..........................................126

D.2.1 QSMilliAmp ............................................... 126

D.2.2 QSFlow .................................................... 126

D.2.3 QSTHC_C ................................................ 126

D.2.4 QSTHC_F .................................................126

D.2.5 QSRTD_C ................................................ 126

D.2.6 QSRTD_F .................................................126

D.2.7 QSDEMO ................................................. 127

D.2.8 QSDAIRY .................................................128

Appendix E – Spare Parts and Accessories .................. 129

Appendix F – Error & Diagnostics Information .............. 131

Appendix G – Symbols and Icons ..................................132

Index .................................................................................133

Notes .............................................................................. 136

2 IM/SM2000 Issue 13

Page 5

Advanced Videographic Recorder

SM2000 1Introduction

1Introduction

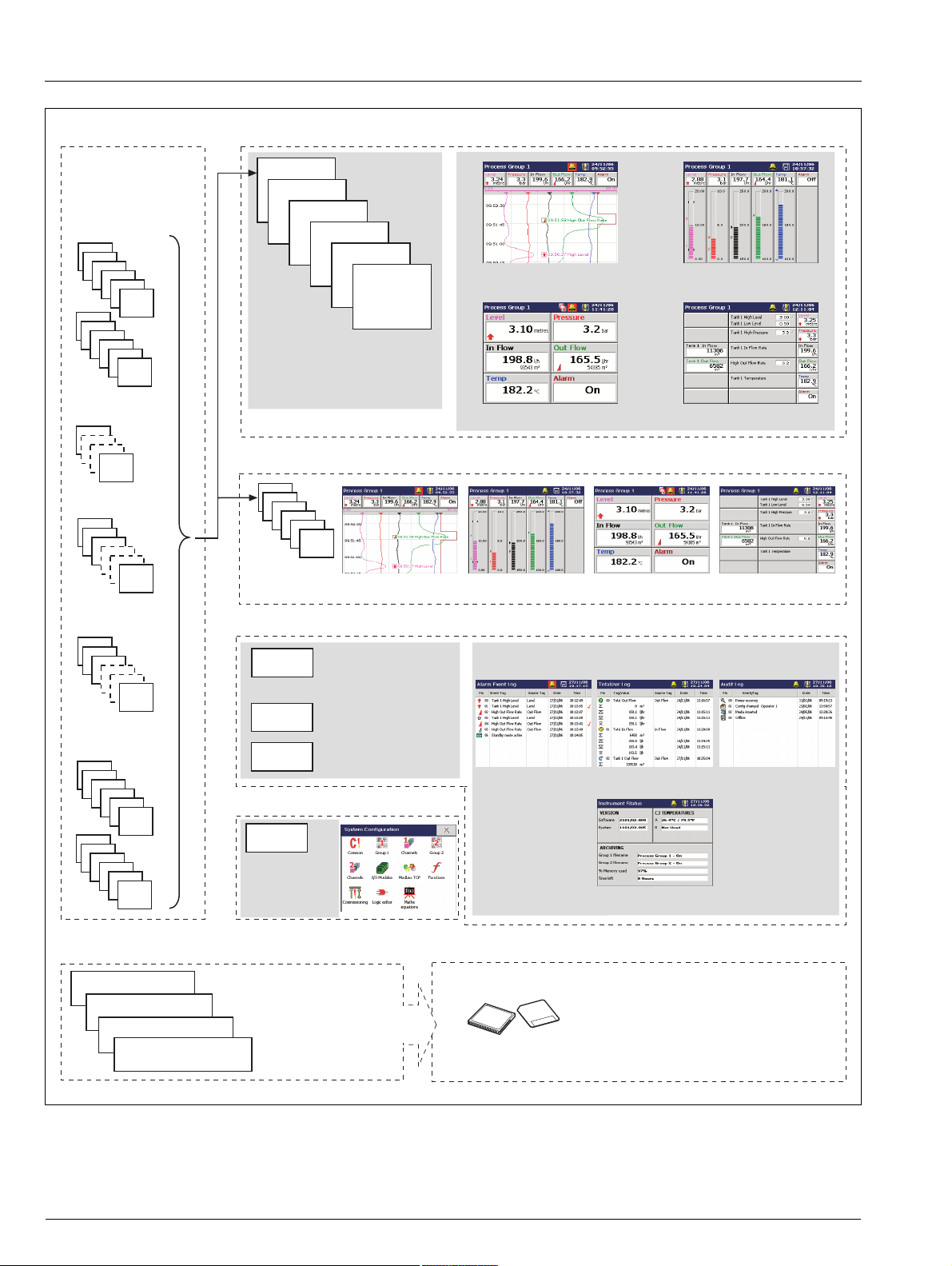

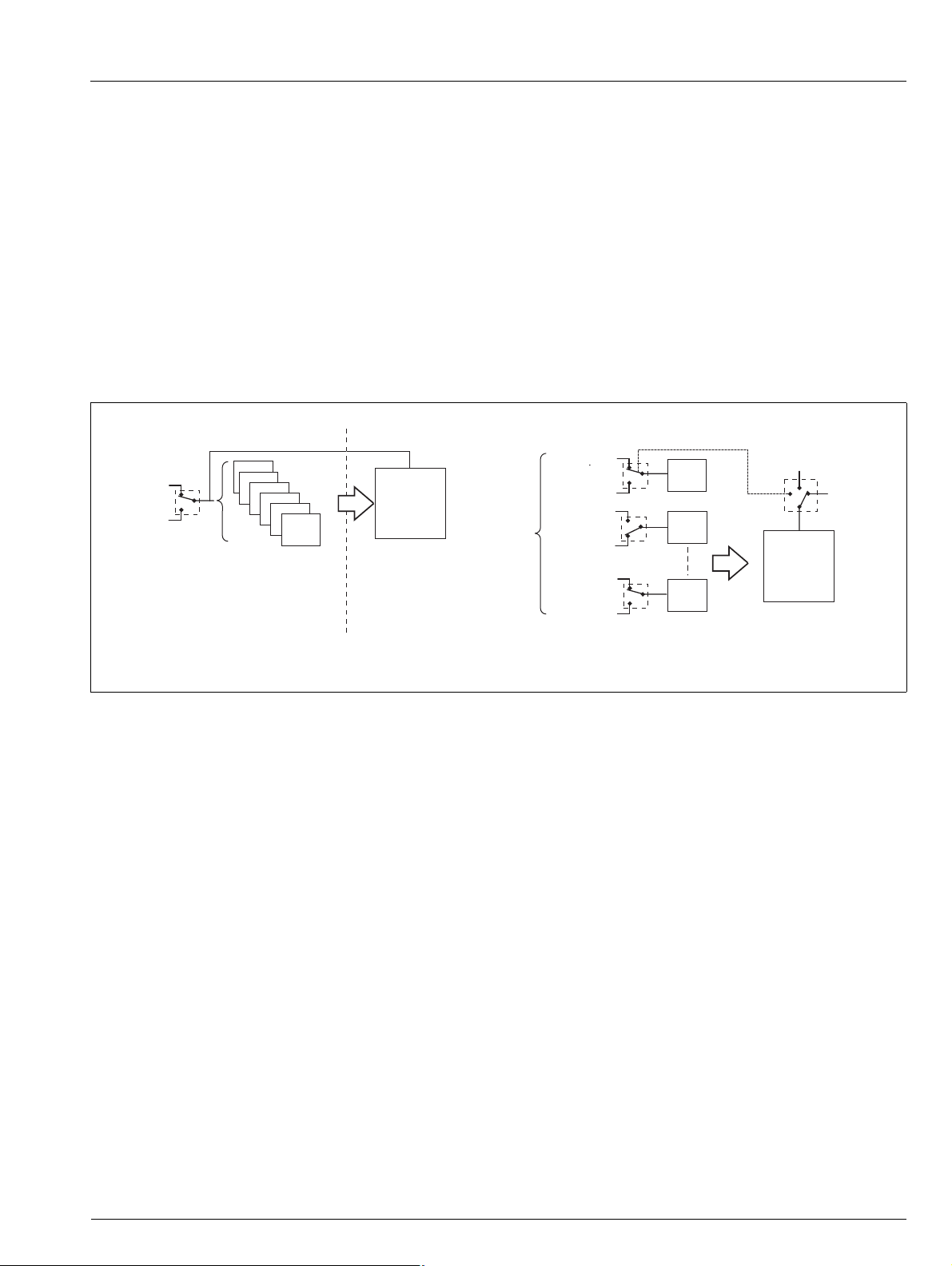

Functional Overview – Fig. 1.1

12 Recording Channels as standard, divided into 2 Process Groups, each with 6 Recording Channels.

Two Alarms and one Totalizer are assigned to each Recording Channel.

Signal sources derived from universal analog inputs, the Modbus serial link, optional digital inputs or internal analog and digital

signals.

Any source can be assigned to any recording channel.

Data from assigned sources can be displayed in:

– Vertical or Horizontal Chart view format

– Vertical or Horizontal Bargraph view format

– Digital Indicator view format

– Process view format

Three instrument logs record alarm events, totalizer values and system/configuration changes.

Screen Capture facility – saves an image of any of the operator views to external archive media provided external archive media

with sufficient free space is inserted in the instrument. It is not necessary for archiving to be 'online'.

Shunt Resistors

(1 per analog input)

Mounting Clamps

Keys

Standard Accessories

Note. For optional accessories, refer to Appendix E on

page 129.

Compact Flash Card

(If fitted with a compact flash drive)

IM/SM2000 Issue 13 3

Page 6

Advanced Videographic Recorder

SM2000 1Introduction

Signal Sources

Note. Signal sources

can be assigned to any

recording channel in

either process group.

Analog Inputs

A1

A2

A3

A4

A5

A6

B1

B2

B3

B4

B5

B6

Internal sources

see Appendix A

Comms.

Analog Inputs

1

2

3

24

Comms.

Digital Inputs

1

2

3

24

Digital Inputs

C1

C2

C3

C4

C5

C6

D1

D2

D3

D4

D5

D6

Process Group 1

1.1

1.2

1.3

1.4

1.5

Two process groups as

standard provide 12 recording

channels, irrespective of the

number of external inputs.

Process Group 2

2.1

2.2

2.3

2.4

2.5

2.6

Recording

Channels

2.1 to 2.6

Instrument Logs

Alarm/Event Log

Totalizer Log

Audit Log

Configuration Data

Configuration

Data

Stores all

instrument

configuration,

calibration and

user preferences

Records all alarm

transitions and all

operator messages

Records all totalizer

activity

Records all system

acfivity

Recording

Channels

1.1 to 1.6

1.6

Bargraph View (Section 2.4)Chart View (Section 2.3)

Digital Indicator View (Section 2.5) Process View (Section 2.6)

Chart View Bargraph View Digital Indicator View Process View

Alarm Event Log

(Section 2.7)

Totalizer Log

(Section 2.8)

Audit Log

(Section 2.9)

Views provide a window on the stored data.

Status View

Recorded Data

Recording Channels 1.1 to 1.6

(Process Group 1)

Recording Channels 2.1 to 2.6

(Process Group 2)

Instrument Logs

Configuration Data

Files stored in

instrument's on-board

flash memory. Newest

data overwrites oldest.

Archive Data

Data saved to archive storage media

Archive Media

Fig. 1.1 Functional Overview

4 IM/SM2000 Issue 13

Page 7

Advanced Videographic Recorder

SM2000 2Operation

2Operation

2.1 Powering up the Instrument

When power is first applied to the instrument, its processor carries out a number of self-tests and displays the start-up screen.

At the end of the start-up sequence the instrument displays the Operator View that was being displayed when the instrument was

powered down.

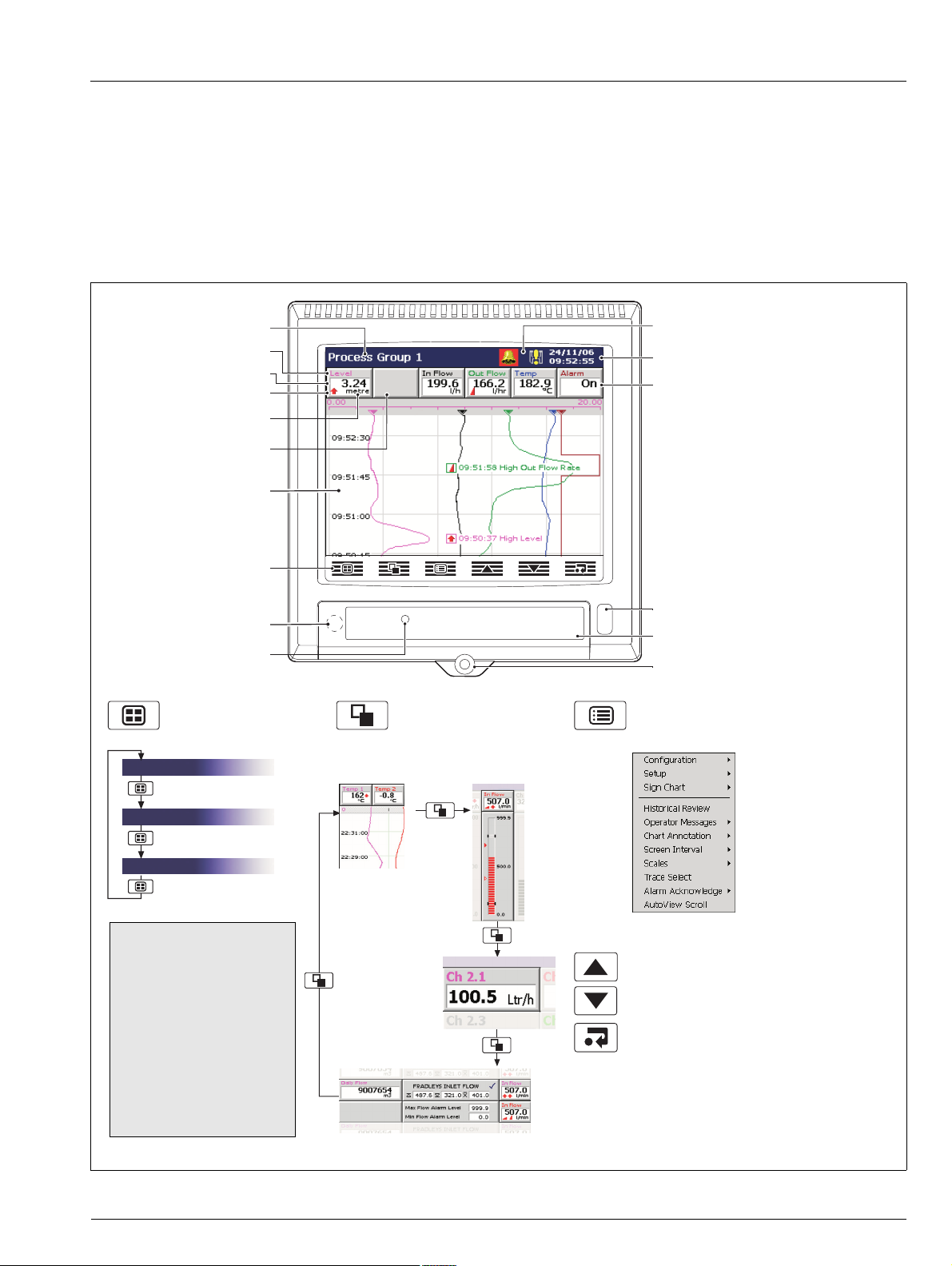

2.2 Displays and Controls – Figs. 2.1 and 2.2

In normal day-to-day use, the instrument is operated via the Operator Keys located along the bottom of the screen.

Process Group Name

Short Channel Tag

Current Value

Alarm Status

Engineering Units

Channel not enabled

Touch Screen

(Configuration Mode only)

Operator Keys

Programming Socket

(Inside Door)

Door Lock

Group Key

Selects a different

process group.

Process Group 1

View Key

Selects a different process

view or log.

Chart View

see Section 2.3

Status Icons – see Appendix G, page 132

Current Date and Time

Digital ON or OFF tag,

according to input status

Infrared Link

Media Door

Jacking Screw and Fitting for

Tamper-proof Seal

Menu Key

Displays or hides the context-sensitive operator

menu associated with each view.

Bargraph Views

see Section 2.4

Process Group 2

Instrument Status & Logs

Note.

Do not use sharp

objects such as

screwdrivers, pen

nibs etc. to operate

the touch screen.

Clean the touch

screen periodically

using a soft cloth

and mild detergent.

Digital Indicator

View see

Section 2.5

Process View

see Section 2.6

Also cancels the menu without making a change

or returns to the previous menu level.

Up/Down Keys

Highlights menu items and scrolls through

previously recorded data.

Enter Key

Selects the highlighted menu item.

If 'Screen capture' is set to 'Enabled' (see

Section 4.4.2, page 53) and external archive

media is inserted in the instrument, the operator

can save a snapshot of any operator view to the

external media, if pressed when the menu is not

open.

Fig. 2.1 Displays and Controls

IM/SM2000 Issue 13 5

Page 8

Advanced Videographic Recorder

SM2000 2Operation

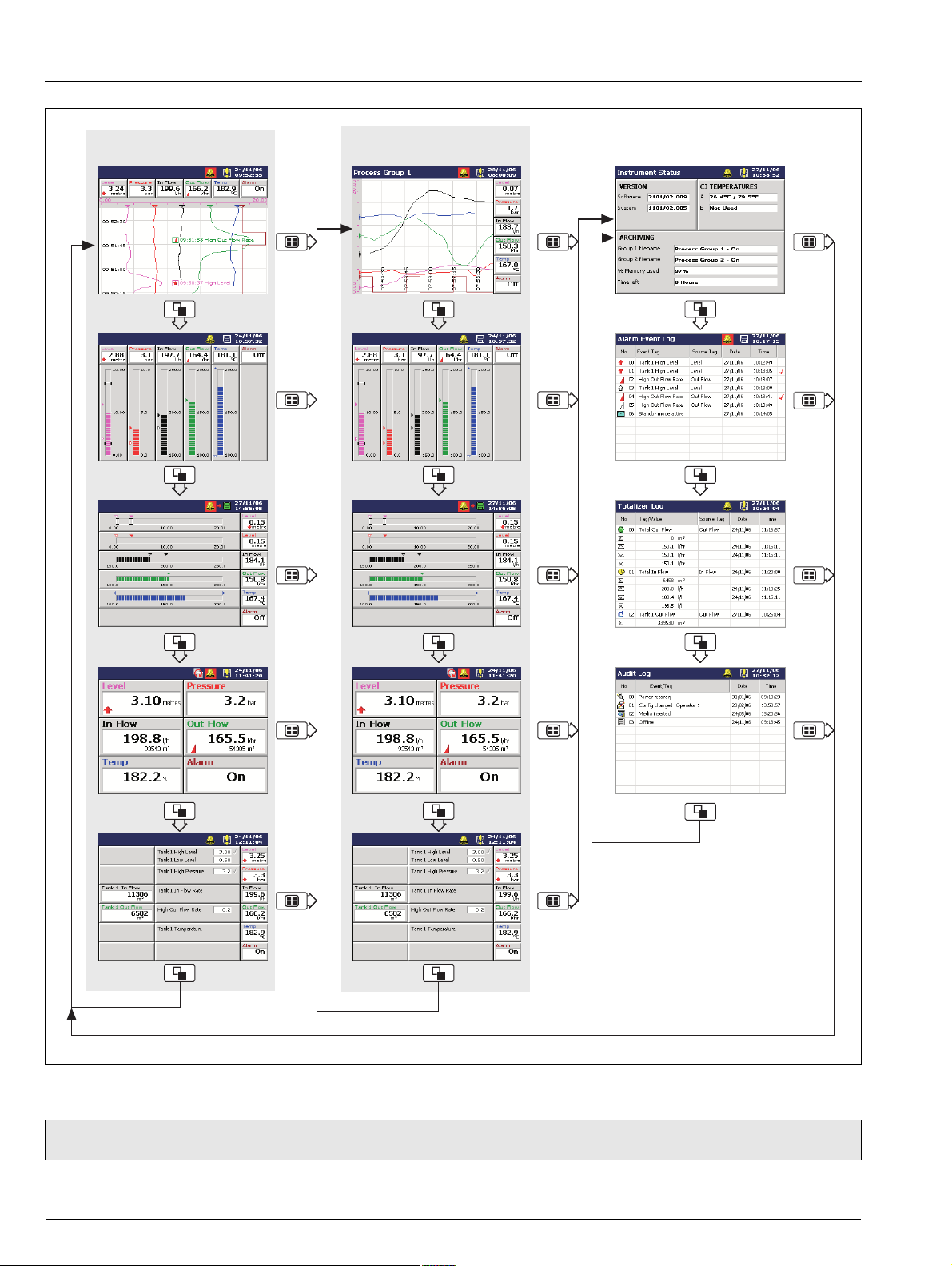

Process Group 1

(Recording Channels 1.1 to 1.6)

Chart View

Vertical Bargraph

Horizontal Bargraph

Process Group 2

(Recording Channels 2.1 to 2.6)

Vertical Bargraph

Horizontal Bargraph

Digital Indicator

Process View

Fig. 2.2 Overview of Operator Displays

Digital Indicator

Process View

Note. Only process groups and views that have been enabled are displayed – see Section 4.5, page 64.

6 IM/SM2000 Issue 13

Page 9

Advanced Videographic Recorder

SM2000 2Operation

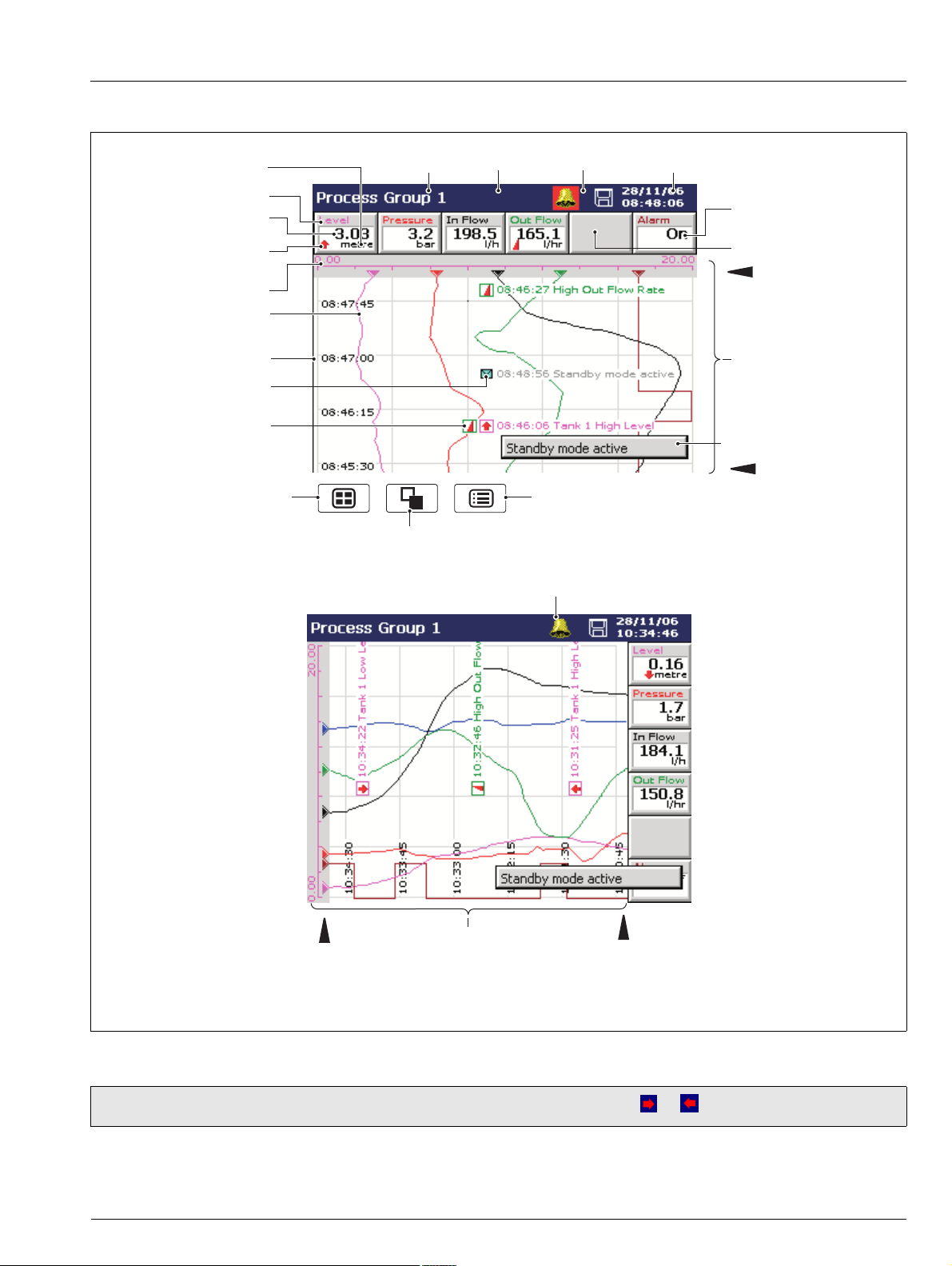

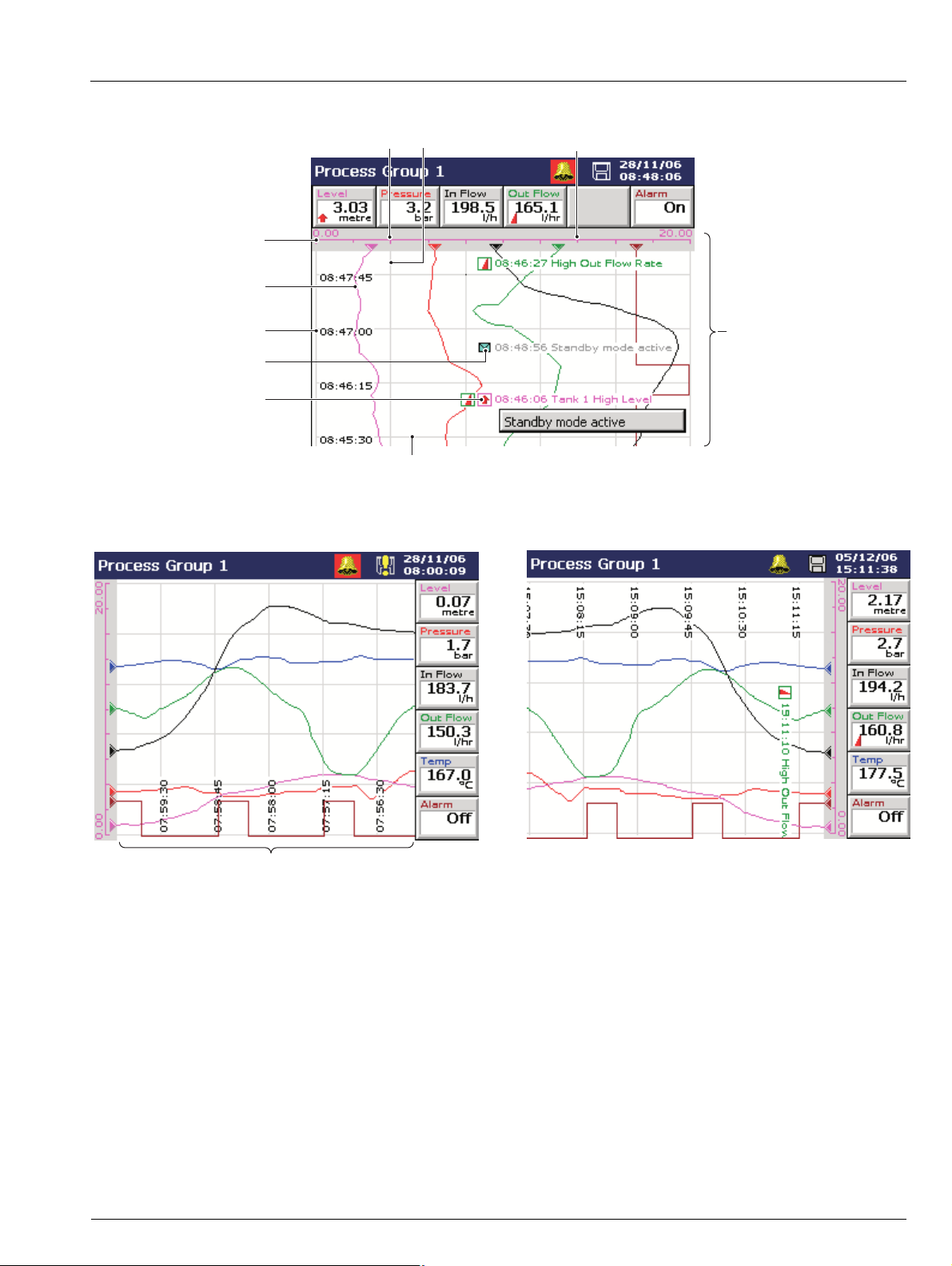

2.3 Chart Views – Fig. 2.3

Units

Short Channel Tag

Current Value

(see Note 1 on Page 8)

Alarm Event Icon

(see Note 2 on Page 8)

Scale Bar

Chart Trace

Time Stamp

Operator Message Annotation

(see Note 3 on Page 8)

Alarm Event Annotation

(see Note 3 on Page 8)

Selects next Process Group

(if enabled) or Status View

Group Tag

Selects the next enabled

view in the group

(Bar, Digital or Process)

Status Bar

Status Icons

Opens the Operator Menu for

the current view

Global Alarm Status Icon (see Note 2 on Page 8)

Current Date and Time

Digital On/Off Tag

Channel Not Used

Newest Data

Screen Interval

Operator Message

(appears for 1 second)

Oldest Data

Newest Data

For a description of the Status Icons (displayed in the Status Bar) and Alarm Event Icons

(displayed in the Bargraph, Digital Indicators, Process and Chart Views), see Appendix G, page 132.

Screen Interval

Oldest Data

Fig. 2.3 Horizontal and Vertical Chart Views

Note. Do not remove media while either of the media update in progress status icons ( or ) are displayed.

IM/SM2000 Issue 13 7

Page 10

Advanced Videographic Recorder

SM2000 2Operation

Note.

1. Current Values

The Current Value, shown on the digital indicators at either the top (vertical chart view) or right hand side (horizontal chart

view) of the screen, is the latest instantaneous value and its update rate is not affected by the recording sample rate.

If the current value in the digital indicator is displayed in red, recording has been stopped for that channel – see Section 3.4,

page 32 and see Section 4.6.1, page 77.

Traces are shown only when that particular channel is being recorded. When a channel is set to Stop, its trace continues to

be shown for up to one sample period.

2. Alarm Status

– Flashing red alarm event icon – alarm active and unacknowledged

– Continuous red alarm event icon – alarm active and acknowledged

If

any alarm in any process group is active, the Global Alarm status icon ( ) is displayed in the status bar – see Fig. 2.3. If

any active alarm in any process group is unacknowledged, the icon is surrounded by a red flashing border ( ).

3. Alarm Event and Operator Message Annotations

Alarm Event and Operator Message annotations are not shown on the chart unless enabled – see 'Chart Annotation' on

page 11 and see Section 4.5.2, page 67.

If Alarm event annotation is enabled and an alarm becomes active, a red alarm event icon surrounded by a channel colored

box is displayed at the point at which the alarm occurred, together with the alarm time and tag, e.g.

11:58:00 1.1A High Level

If more than one alarm occurs in the same sample period:

– and the second alarm on a channel becomes active, its icon is added behind the first.

– and more than one operator message is active (max. six), a second icon is added behind the first.

– the new alarm event icons appear to the left of earlier icons.

– the time and tag of the oldest alarm (right-most icon) only is displayed.

4. Screen Capture

If 'Screen capture' is set to 'Enabled' in Common Configuration (see Section 4.4.1, page 52) and an external archive media

card is inserted in the instrument, an image of any Chart, Bargraph, Digital Indicator, Process, Instrument Status, Audit

Log, Alarm Log or Totalizer Log view can be saved to the external media by pressing the key whenever the Operator

Menu is not open.

8 IM/SM2000 Issue 13

Page 11

Advanced Videographic Recorder

SM2000 2Operation

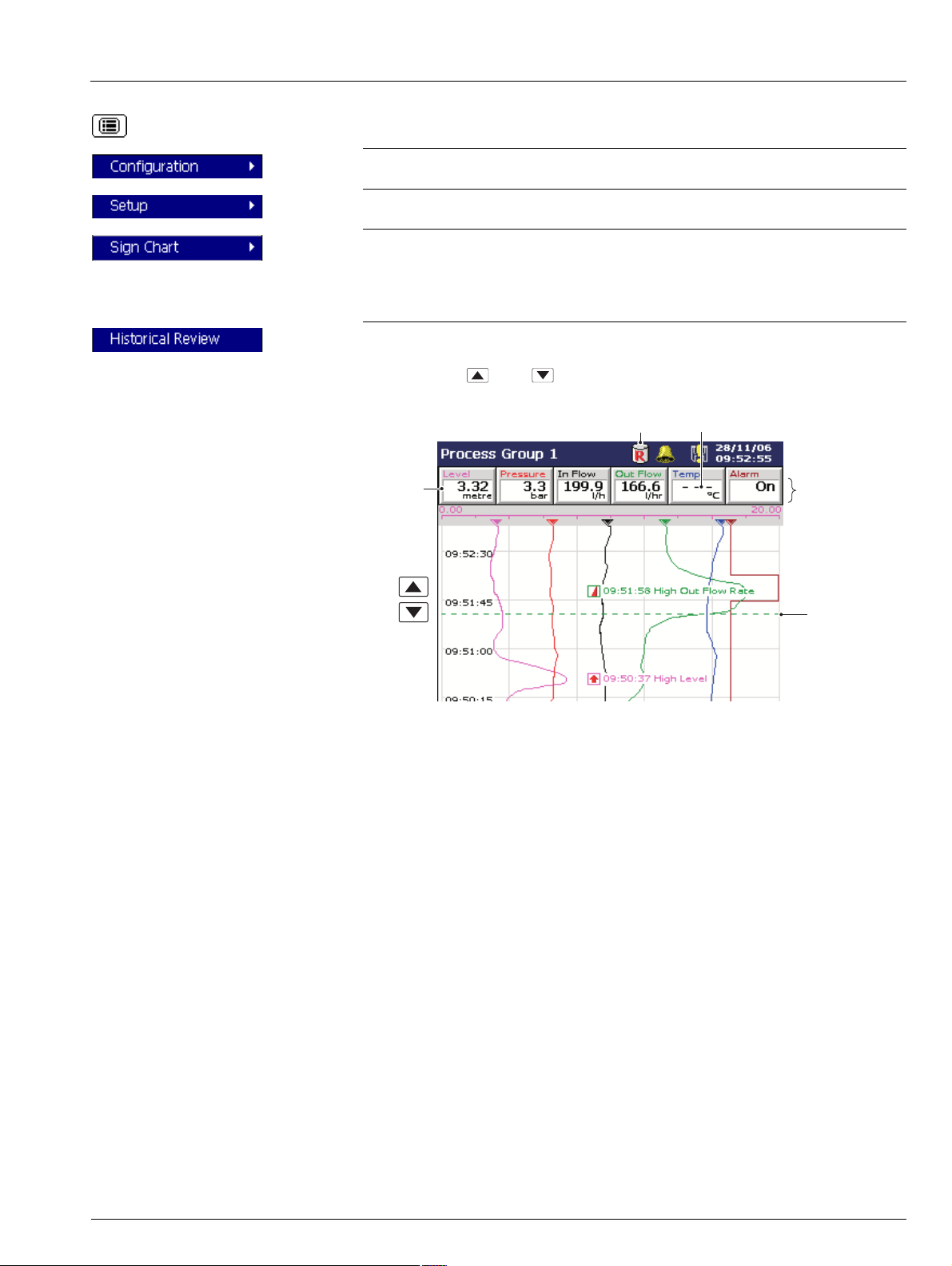

Select the Configuration Level – see Section 4, page 45.

Select the Setup Level – see Section 3, page 29.

Note. Available only if 'Security system' is set to 'Advanced' – see Section 4.4.4,

page 56.

Sign the chart electronically – see Section 2.3.1, page 14.

Select Historical Review to view previously recorded data stored in the instrument's

onboard memory.

Note. Use the and keys to move backwards and forwards through the

recorded data.

Historical Review Active Invalid data e.g. recording disabled

Digital

Indicators

Values displayed

indicate the

process status at

the cursor position

Cursor

IM/SM2000 Issue 13 9

Page 12

Advanced Videographic Recorder

SM2000 2Operation

Note.

While in Historical Review mode:

Recording of new data continues unless stopped from the Setup Menu – see

Section 3.4, page 32.

Invalid historical data (e.g. when recording has stopped) is denoted by '– – –' in the

digital indicator.

Where the trace at the cursor position represents more than one sample, the

indicators flash between the maximum and minimum values of those samples.

Menu options remain active – allowing the screen interval to be changed, different

scales and channels to be selected, etc.

Operator messages generated are added to the alarm event log at the present

time, not the time indicated by the cursor.

All data stored in the instrument's internal memory can be viewed.

The display can be scrolled back to the start of the oldest data.

Archiving to removable media does not occur but all data recorded in the internal

memory buffer during this time is archived on exiting Historical Review mode.

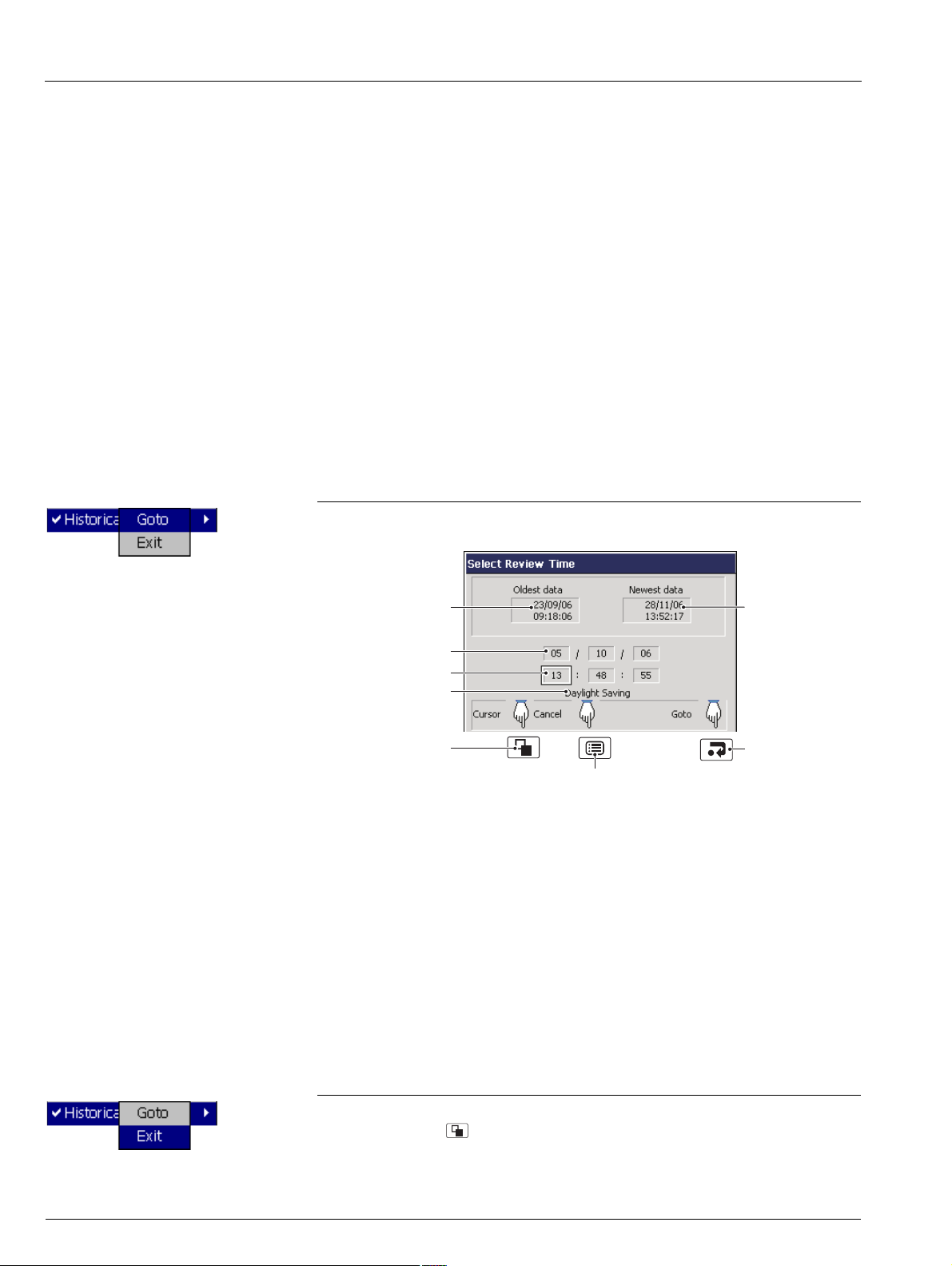

Select 'Goto' to move to data stored in the instrument's onboard memory that was

recorded at a specific date and time.

Oldest data in

internal memory

'Goto' target date

'Goto' target time

Selected 'goto' target

date/time is within

daylight saving period

Moves cursor between

'goto' target date and

time boxes

Returns to Menu

Newest data in

internal memory

Goes to the chart

view at the selected

'goto' target date

and time

Note.

If daylight saving is enabled (see Section 4.4.3, page 54) and the selected 'Goto'

target date/time is within the daylight saving period, 'Daylight Saving' is displayed

on the dialog box.

Once internal memory becomes full, oldest data is overwritten by newest data. If

historical review has been selected for some time, the oldest data present may no

longer be available.

If different sample rates have been selected for individual channels (Advanced

Configuration mode only – see Sections 4.4.1 and 4.6.1), earlier data from

channels with faster sample rates are overwritten before those with slower sample

rates.

The instrument exits Historical Review mode automatically after 15 minutes if no

key is pressed.

Select Exit to return to the real-time recording display.

Note. Pressing the key also exits Historical Review mode and displays the next

enabled view.

10 IM/SM2000 Issue 13

Page 13

Advanced Videographic Recorder

SM2000 2Operation

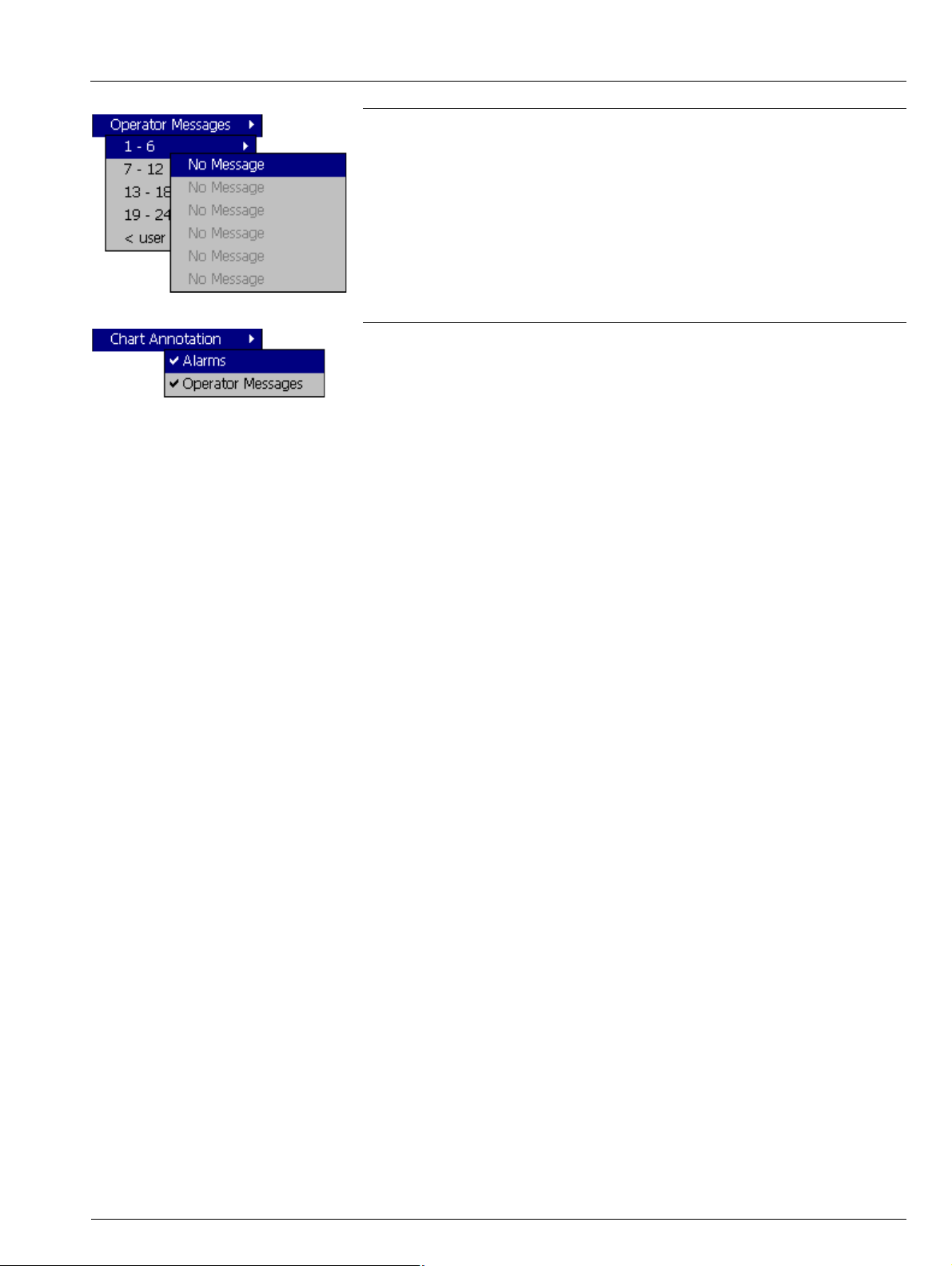

Add one of 24 predefined Operator Messages (see Section 4.4.7, page 60) or one UserDefined Message to the alarm event log.

If '< user defined >' is selected, a data entry keyboard appears to enable the message to

be entered (see Fig. 4.5, page 50).

The selected or user-defined message is displayed briefly on screen. If Operator

Message annotation is selected (see 'Chart Annotation' below) the message is also

added to the chart.

Note. When the instrument is in Historical Review mode, Operator Messages generated

are added at the current time, not the time indicated by the cursor.

If an alarm or operator message is obscuring part of a chart trace, use the Chart

Annotation option to hide or display alarms and messages on the screen. Select the

annotation required. indicates the annotations selected.

The possible combinations are:

No annotation (Alarms and Operator Messages both disabled)

Alarm annotation only

Alarms and Operator Message annotation

Operator Message annotation cannot be enabled unless Alarm annotation is also

enabled.

Note.

If more than 15 icons are present on the screen, chart annotation is disabled

automatically.

When chart annotation is disabled, new operator messages and alarms are still

added to the Alarm Event log – see Section 2.7, page 23.

IM/SM2000 Issue 13 11

Page 14

Advanced Videographic Recorder

SM2000 2Operation

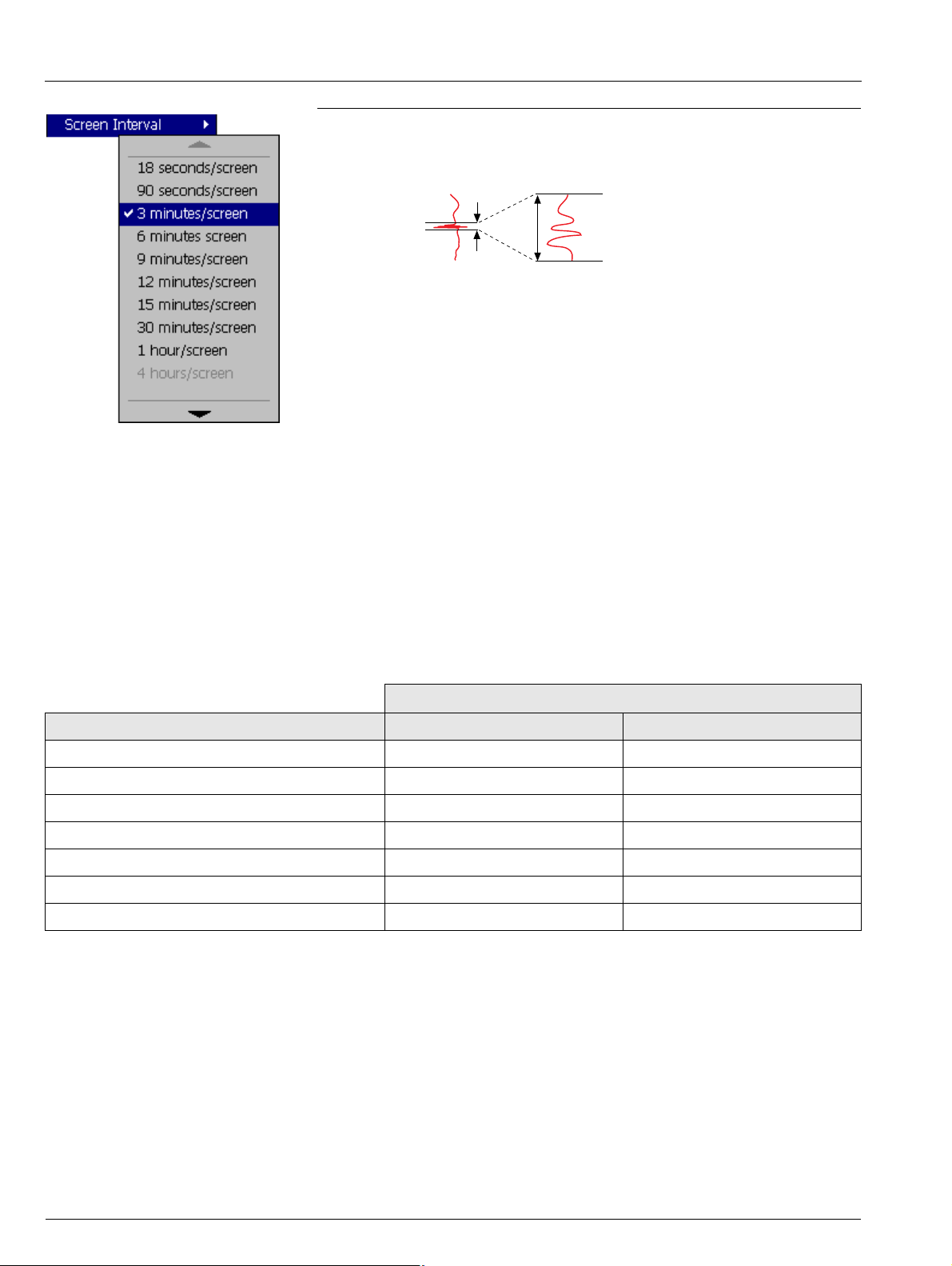

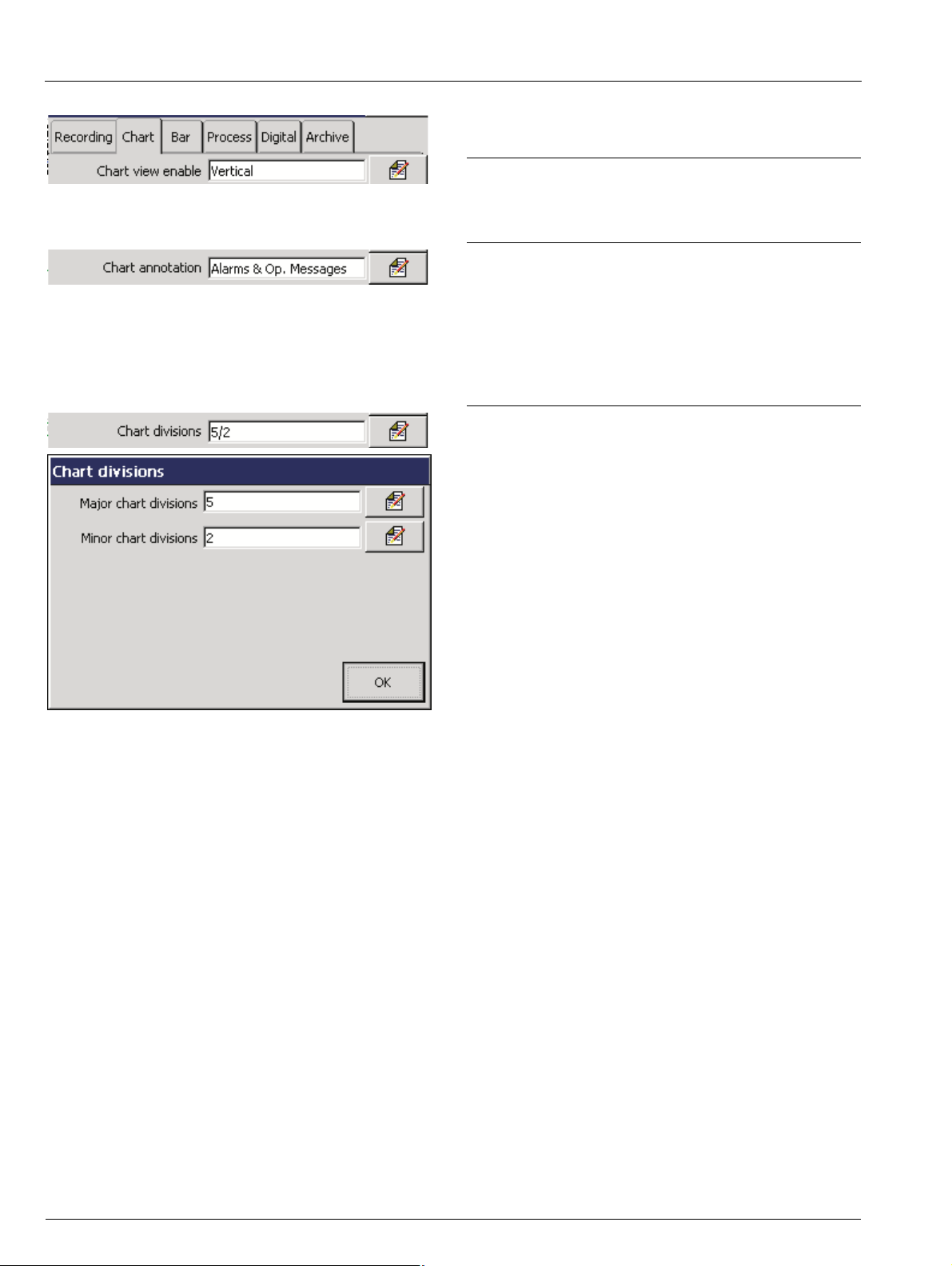

Use the 'Screen Interval' to change the amount of data displayed on the screen. A longer

screen interval displays more data, a shorter screen interval displays data over a shorter

time period, but in more detail. In both cases, the full trace is preserved by plotting the

maximum and minimum samples for each display point.

Longer interval =

better overview

Shorter interval

= more detail

When 'Configuration Type' is set to 'Basic' (see Section 4.4.1, page 52), the screen

intervals available in the menu are determined by the faster of the primary and secondary

sample rates set for the process group during configuration – see Section 4.5.1,

page 64. Unavailable screen intervals are greyed-out.

When 'Configuration Type' is set to 'Advanced' (see Section 4.4.1, page 52), all screen

intervals are available.

Note. The time taken for the screen to refresh after changing the screen interval setting

is dependent on the sample rate and screen interval selection, e.g. fast sample rate +

long screen interval = slow refresh rate.

Table 2.1 shows the relationship between sample rate and screen interval for the Vertical

and Horizontal Chart views.

Note.

A 'Please Wait' message appears in the status bar while the instrument retrieves

data from storage.

Selecting a different screen interval does not affect the rate at which data is

sampled.

When in historical review mode, changing the screen interval causes the time at

the cursor position to change.

Sample Rate Setting Vertical Chart View horizontal Chart View

Between 1 and 10 seconds Up to 1 hour/screen Up to 1.5 hours/screen

More than 10 seconds, less than 20 seconds Up to 12 hours/screen Up to 18 hours/screen

Between 20 and 40 seconds Up to 1 day/screen Up to 1.5 days/screen

Between 40 and 60 seconds Up to 2 days/screen Up to 3 days/screen

More than 60 seconds, less than 140 seconds Up to 3 days/screen Up to 4.5 days/screen

More than 140 seconds Up to 7 days/screen Up to 10 days/screen

Table 2.1 Sample Rates and Screen Intervals

Maximum Screen Interval

<1 second Up to 9 minutes/screen Up to 13 minutes/screen

12 IM/SM2000 Issue 13

Page 15

Advanced Videographic Recorder

SM2000 2Operation

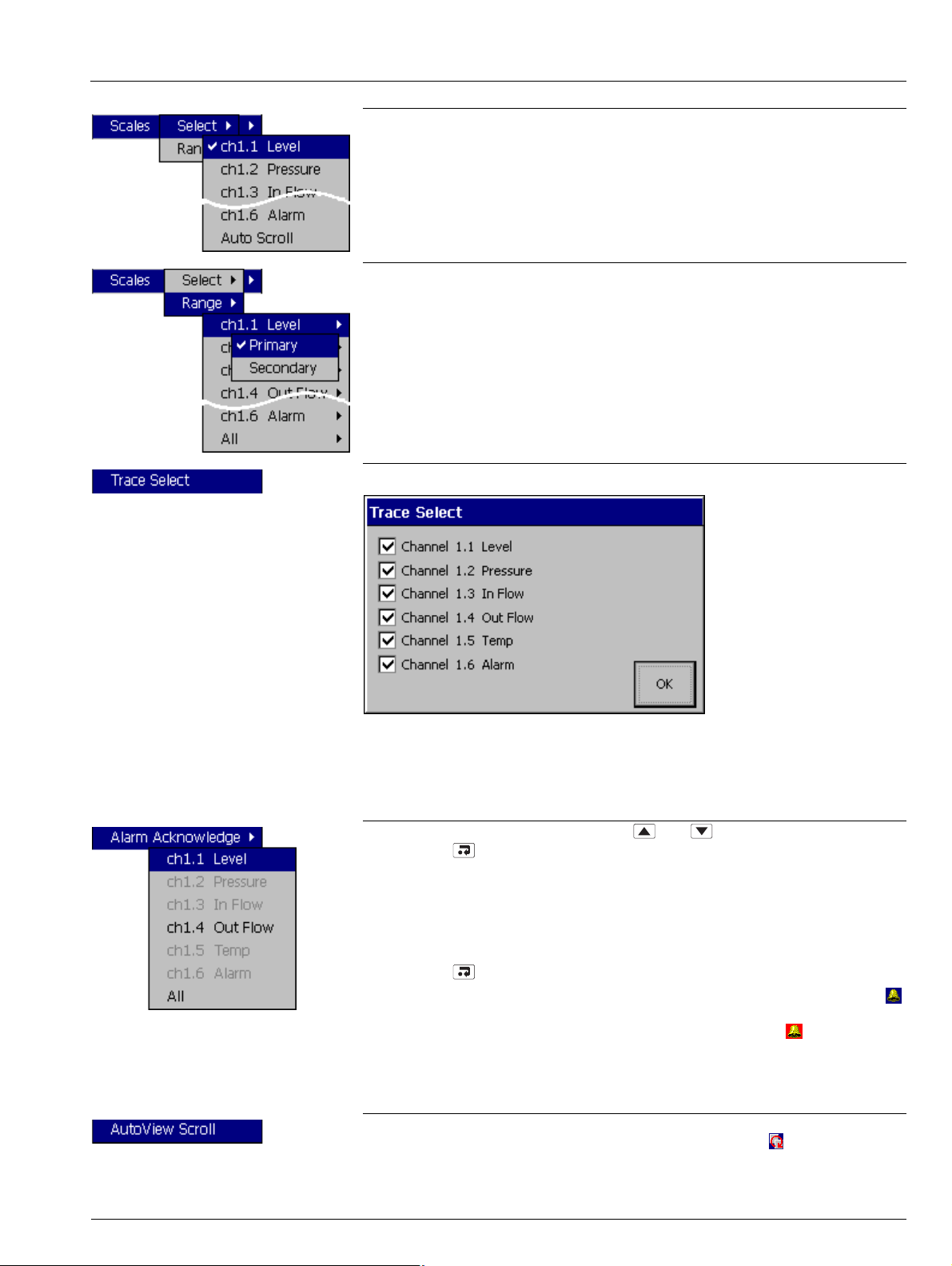

Select a channel scale to be displayed in the scale bar at the top of the chart window.

For digital channels, the On and Off tags are displayed at the corresponding position on

the scale bar.

Select 'Auto Scroll' to display the scale for each enabled channel in turn for 36 seconds.

Note. 'Range' is displayed only if 'Configuration Type' is set to 'Advanced' – see

Section 4.4.1, page 52.

Select a channel followed by either the Primary or Secondary scale range configured for

that channel (see Section 4.6.1, page 77). The channel's trace is plotted and displayed

accordingly.

Select 'All' followed by 'Primary' or 'Secondary' to display each enabled channel in the

selected scale range configured for that channel (see Section 4.6.1, page 77). Each

channel's trace is plotted and displayed accordingly.

Hide individual channel traces to improve chart clarity.

Traces are identified by the Channel Number (e.g. Ch1.1) and its short tag.

Note. The recording of a channel's data is not affected by this operation and the

instantaneous channel values are still shown on the indicators at the top of the screen.

To acknowledge a particular alarm, use the and keys to highlight it in the menu

and press the key.

Note. Active unacknowledged alarms in the current process group are identified by a

flashing red Alarm Event icon in the bottom left hand corner of the associated channel

indicator. Active acknowledged alarms are identified by a continuous red Alarm Event

icon in the bottom left hand corner of the indicator – see Fig. 2.3, page 7.

To acknowledge all active alarms in the current process group simultaneously, select 'All'

and press the key.

Note. If an alarm in

continues to be displayed in the status bar. If an active alarm in

the other process group is active, the Global Alarm status icon ( )

the other process group

is unacknowledged, the icon is surrounded by a red flashing border ( ).

If neither alarm on a particular channel is configured, the short channel tag is shown

greyed-out in the menu.

Select 'AutoView Scroll' to display the enabled chart view for each configured process

group, in turn for, 40 seconds. The AutoView Scroll status icon ( ) is displayed in the

status bar when AutoView Scroll is active. Press any key to cancel AutoView Scroll.

IM/SM2000 Issue 13 13

Page 16

Advanced Videographic Recorder

SM2000 2Operation

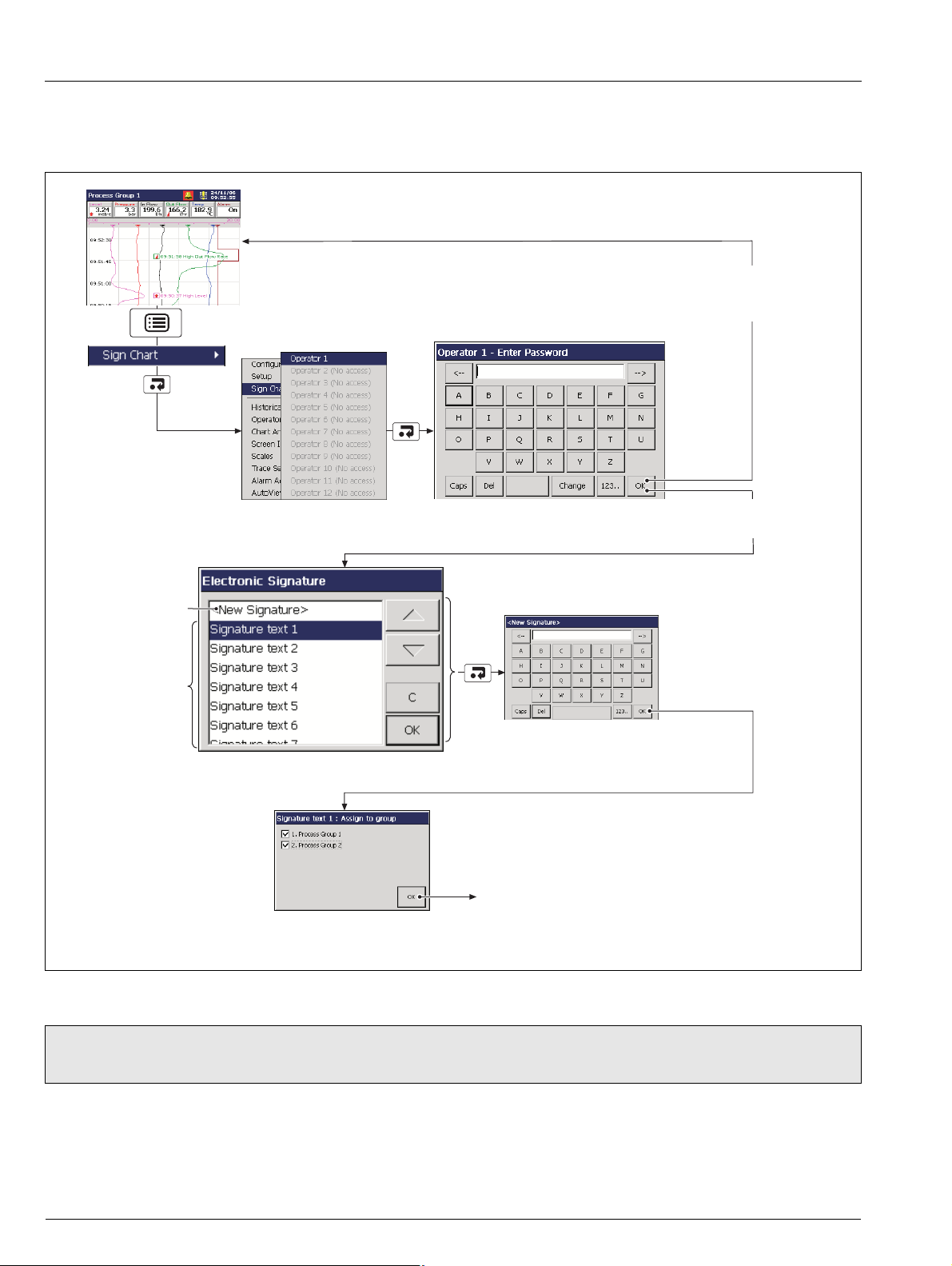

2.3.1 Electronic Signatures – Fig. 2.4

Entering an electronic signature is the equivalent to signing the chart of a conventional paper recorder. Local procedures may require

the approval of a record by an authorized signatory; for this reason, an electronic signature is password protected.

Invalid Password

(see Note in Fig. 3.2, page 30)

Entered

Create a new signature

or

Select one of 7

previously

defined signatures

Note below)

(see

If more than one process group is

enabled (see Section 4.4.1, page 52),

assign the signature to one or more

groups

Enter Password

(see Section 3.3, page 31)

Create new signature or

edit an existing one.

Electronic signature is entered into alarm log.

If Operator Message annotation is enabled (see Page 11),

the electronic signature is also displayed on the chart.

Valid Password

Entered

Fig. 2.4 Entering an Electronic Signature

Note. Up to 7 electronic signatures can be stored in the instrument’s memory. If 7 signatures exist and a new one is created, the

oldest is overwritten.

14 IM/SM2000 Issue 13

Page 17

Advanced Videographic Recorder

SM2000 2Operation

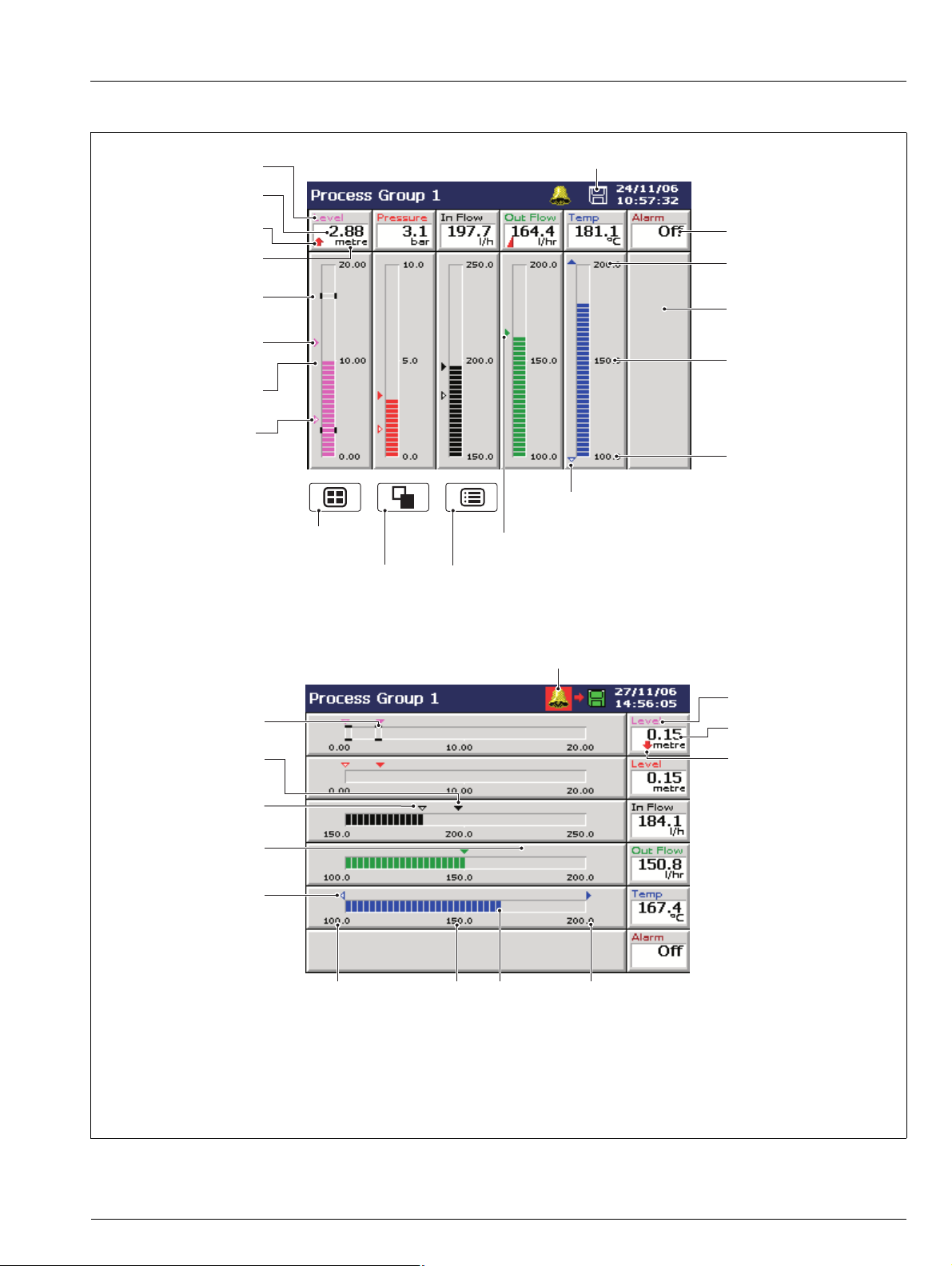

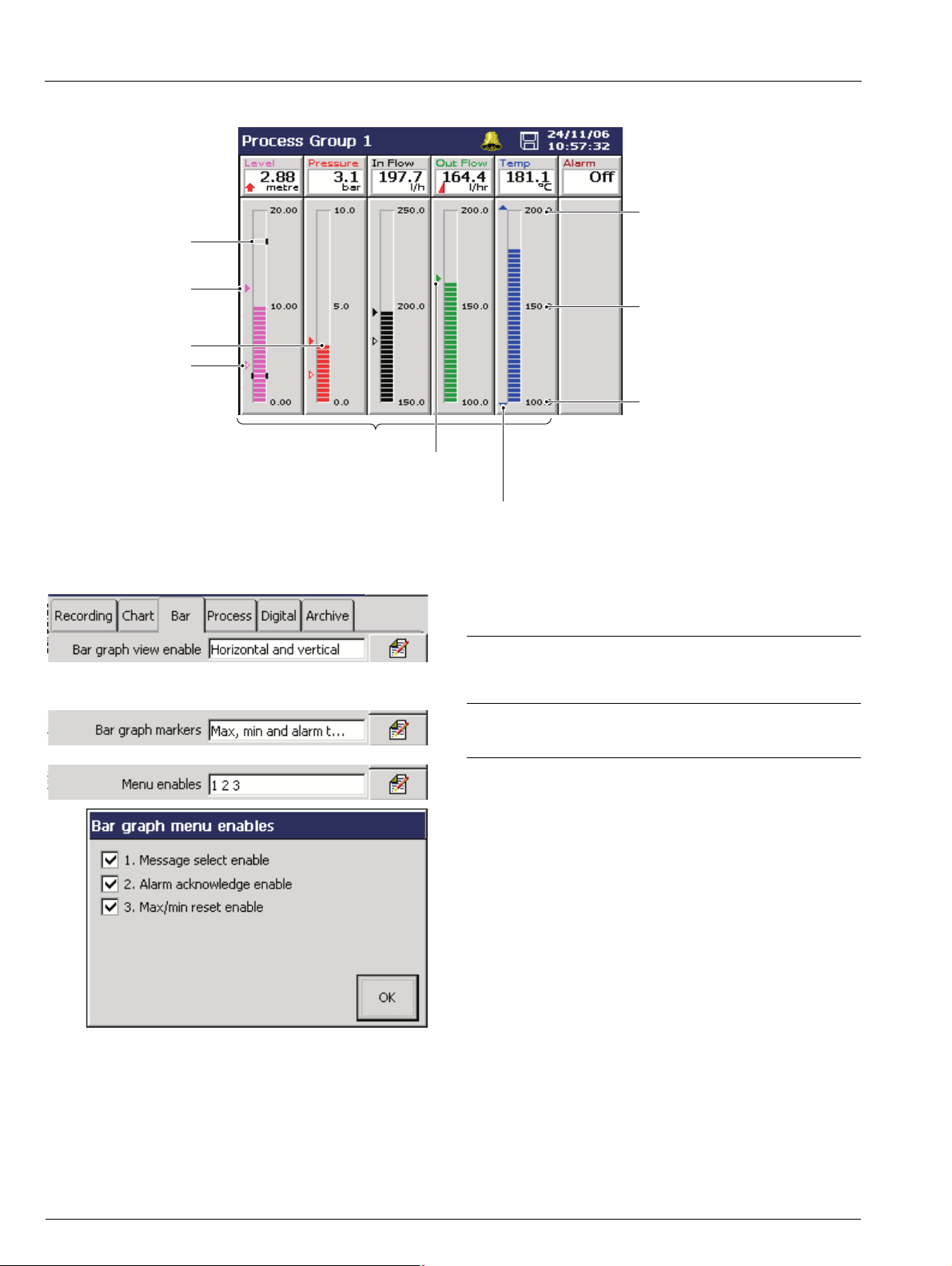

2.4 Bargraph Views – Fig. 2.5

Short Channel Tag

Current Value

Alarm Event Icon

see Rear fold-out

Engineering Units

Alarm Trip Level

(not shown for slow and

fast rate alarms)

Maximum Value

(solid color)

Instantaneous Value

Minimum Value

(white fill)

Selects the next Process Group

(if enabled) or Status View

Selects the next enabled view in the group

(Digital Indicator, Process or Chart)

Status Icons

Digital On or Off tag,

according to input status

Engineering Range

High Value

Digital Channel

Engineering Range

Middle Value

Engineering Range

Low Value

Minimum below engineering limit,

maximum above engineering limit

Identical Maximum and Minimum Values

Opens the Operator Menu for

the current view

A Vertical Bargraph View

Alarm Trip Level

(not shown for slow and

fast rate alarms)

Maximum Value

(solid color)

Minimum Value

(white fill)

Identical Maximum

and Minimum Values

Minimum below

engineering limit,

Maximum above

engineering limit

Engineering Range

(displayed in the Bargraph, Digital Indicators, Process and Chart Views), see Appendix G, page 132.

Global Alarm Status Icon

Low Value

Engineering Range

Middle Value

Instantaneous

Value

Engineering Range

High Value

B Horizontal Bargraph View

For a description of the Status Icons (displayed in the Status Bar) and Alarm Event Icons

Short Channel Tag

Current Value

Alarm Event Icon

Fig. 2.5 Bargraph Views

IM/SM2000 Issue 13 15

Page 18

Advanced Videographic Recorder

SM2000 2Operation

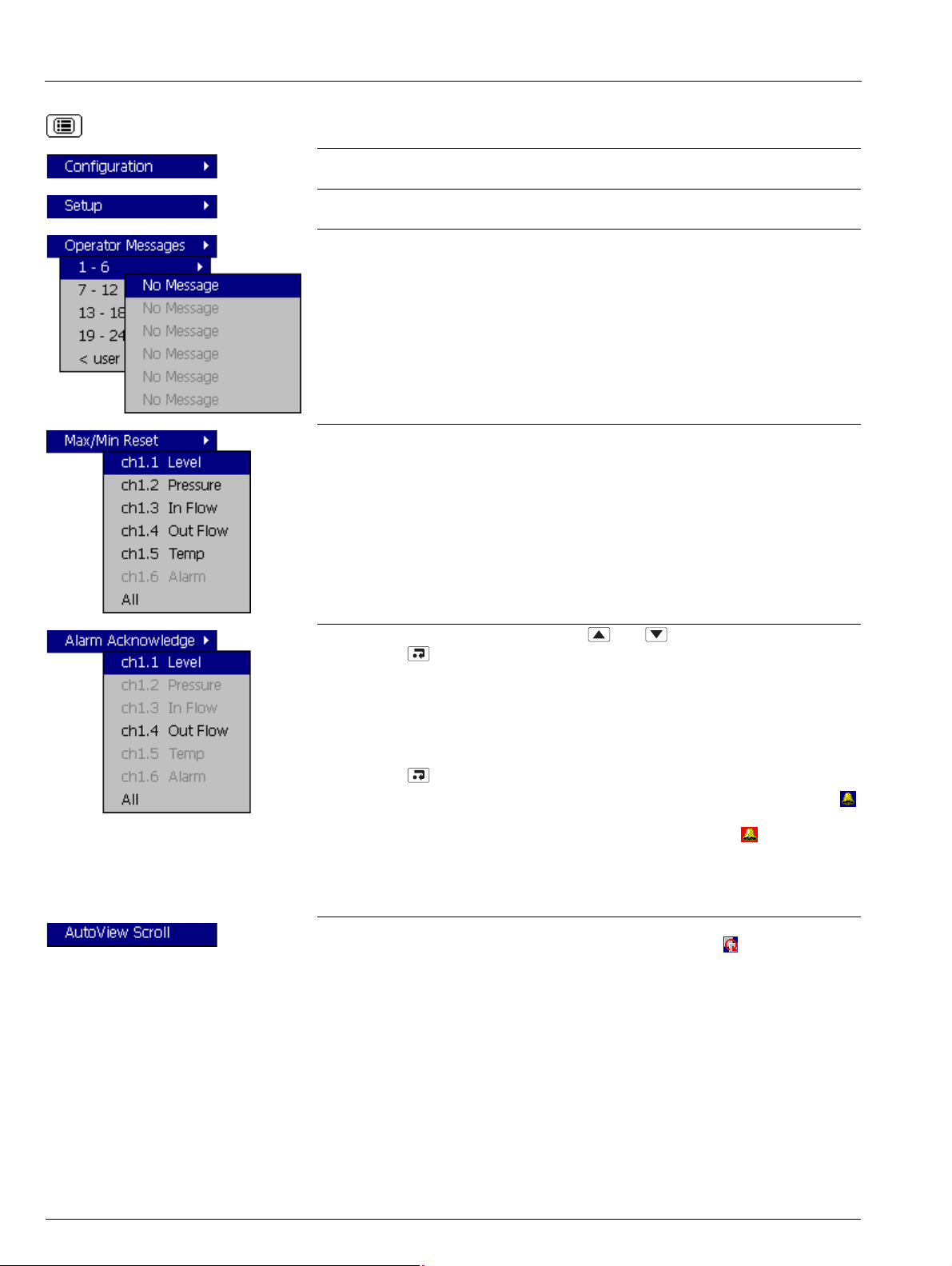

Select the Configuration Level – see Section 4, page 45.

Select the Setup Level – see Section 3, page 29.

Add one of 24 predefined Operator Messages (see Section 4.4.7, page 60) or one UserDefined Message to the alarm event log.

If '< user defined >' is selected, a data entry keyboard appears to enable the message to

be entered (see Fig. 4.5, page 50). The selected or user-defined message is displayed

briefly on-screen.

Reset the Maximum and Minimum value markers on one or all channels to the current

value.

Notes.

These Maximum and Minimum values are for display purposes only. They are not

saved or archived and are not connected to the Totalizer Maximum and Minimum

Values displayed in the Process View.

These Maximum and Minimum values are reset whenever the current configuration

has been changed or is re-saved.

To acknowledge a particular alarm, use the and keys to highlight it in the menu

and press the key.

Note. Active unacknowledged alarms in the current process group are identified by a

flashing red Alarm Event icon in the bottom left hand corner of the associated indicator.

Active acknowledged alarms are identified by a continuous red Alarm Event icon in the

bottom left hand corner of the indicator – see Fig. 2.5, page 15.

To acknowledge all active alarms in the current process group simultaneously, select 'All'

and press the key.

Note. If an alarm in

continues to be displayed in the status bar. If an active alarm in

the other process group is active, the Global Alarm status icon ( )

the other process group

is unacknowledged, the icon is surrounded by a red flashing border ( ).

If neither alarm on a particular channel is configured, the short channel tag is shown

greyed-out in the menu.

Select 'AutoView Scroll' to display the enabled bargraph for each configured process

group, in turn for, 40 seconds. The AutoView Scroll status icon ( ) is displayed in the

status bar when AutoView Scroll is active. Press any key to cancel AutoView Scroll.

16 IM/SM2000 Issue 13

Page 19

Advanced Videographic Recorder

SM2000 2Operation

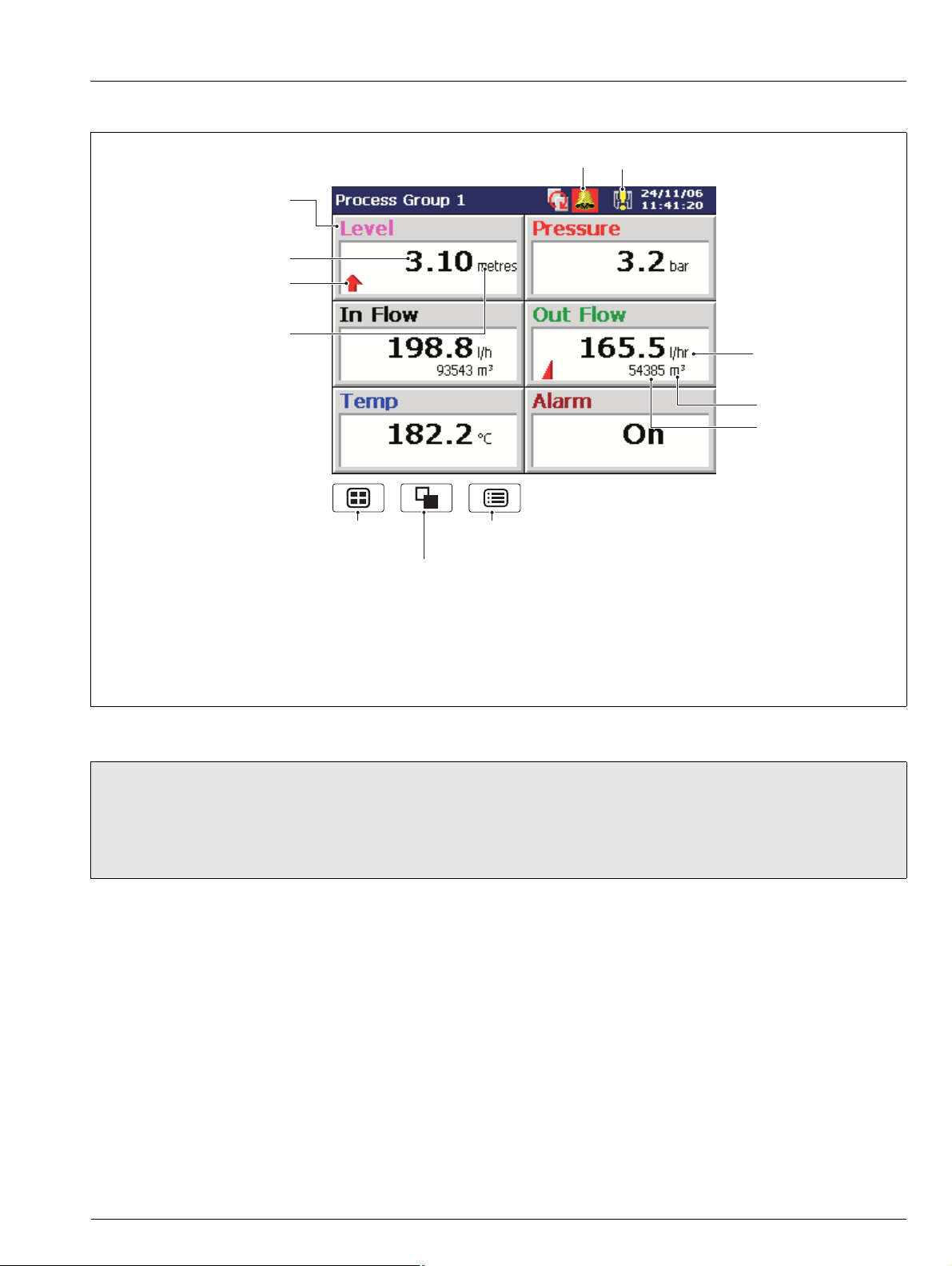

2.5 Digital Indicator View – Fig. 2.6

Short Channel Tag

Current Value

Alarm Event Icon

Engineering Units

Selects the next Process Group

(if enabled) or the Status View

Global Alarm Status Icon

Opens the Operator Menu for

the current view

Selects the next enabled

view in the group

(Process, Chart or Bargraph)

Status Icons

Channel Units

Totalizer Units

Totalizer Value

For a description of the Status Icons (displayed in the Status Bar) and Alarm Event Icons

(displayed in the Bargraph, Digital Indicators, Process and Chart Views), see Appendix G, page 132.

Fig. 2.6 Digital Indicator View

Note.

Digital indicators resize automatically according to the number of channels displayed.

Totalizers must be configured and enabled before they are displayed – see Section 4.6.5, page 91.

When a totalizer is not running (i.e. 'Stop' is selected), the corresponding totalizer value is shown in red.

IM/SM2000 Issue 13 17

Page 20

Advanced Videographic Recorder

SM2000 2Operation

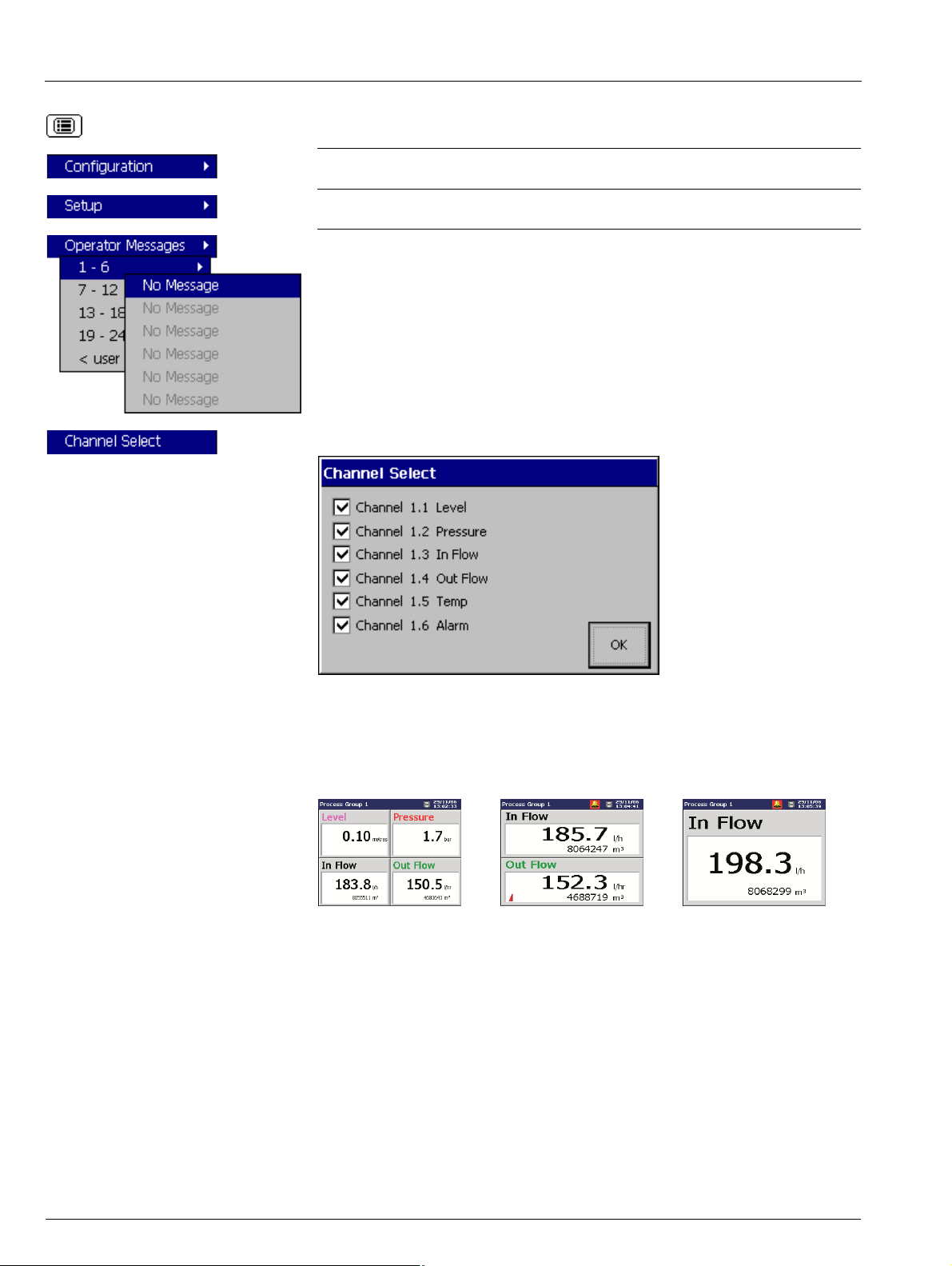

Select the Configuration Level – see Section 4, page 45.

Select the Setup Level – see Section 3, page 29.

Add one of 24 predefined Operator Messages (see Section 4.4.7, page 60) or one UserDefined Message to the alarm event log.

If '< user defined >' is selected, a data entry keyboard appears to enable the message to

be entered (see Fig. 4.5, page 50). The selected or user-defined message is displayed

briefly on-screen.

Hide or display individual channel indicators for the group currently displayed.

Notes.

The digital indicators displayed are sized equally depending on the number of

channels selected. This has no effect on the recording of the channel.

Channels that have not been configured are greyed-out in the menu.

Three or Four

Channels Selected

Two Channels Selected One Channel Selected

18 IM/SM2000 Issue 13

Page 21

Advanced Videographic Recorder

SM2000 2Operation

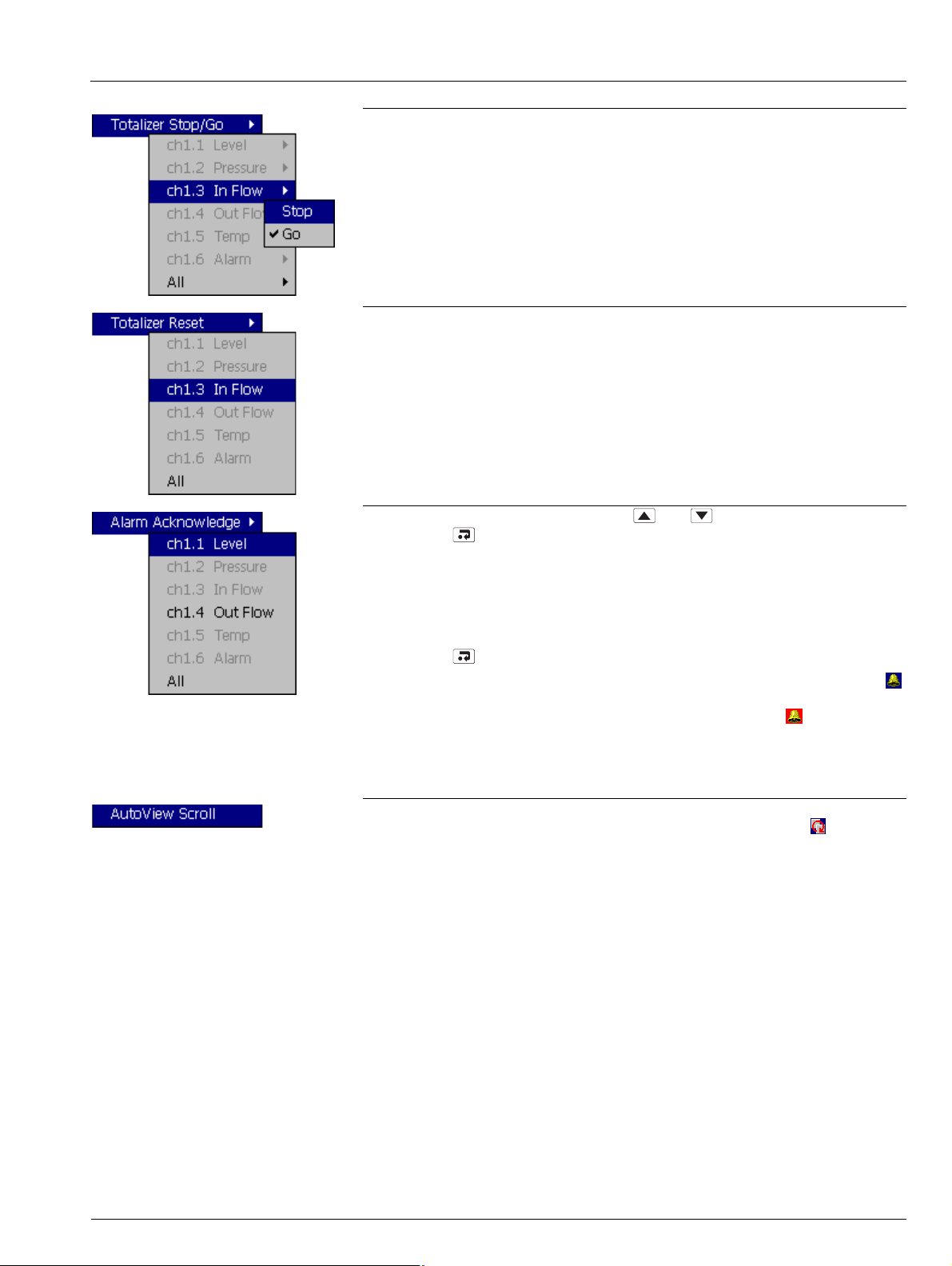

Stop and start individual totalizers.

Channel totalizers that have not been enabled in the Configuration level are greyed-out.

Note. When a totalizer is not running (i.e. 'Stop' is selected), the corresponding totalizer

value is shown in red.

Reset the totalizer value to the totalizer preset value.

Channel totalizers that have not been enabled in the Configuration level are greyed-out.

To acknowledge a particular alarm, use the and keys to highlight it in the menu

and press the key.

Note. Active unacknowledged alarms in the current process group are identified by a

flashing red Alarm Event icon in the bottom left hand corner of the associated indicator.

Active acknowledged alarms are identified by a continuous red Alarm Event icon in the

bottom left hand corner of the indicator – see Fig. 2.6, page 17.

To acknowledge all active alarms in the current process group simultaneously, select 'All'

and press the key.

Note. If an alarm in

continues to be displayed in the status bar. If an active alarm in

the other process group is active, the Global Alarm status icon ( )

the other process group

is unacknowledged, the icon is surrounded by a red flashing border ( ).

If neither alarm on a particular channel is configured, the short channel tag is shown

greyed-out in the menu.

Select 'AutoView Scroll' to display the enabled digital indicator for each configured

process group, in turn for, 40 seconds. The AutoView Scroll status icon ( ) is displayed

in the status bar when AutoView Scroll is active. Press any key to cancel AutoView

Scroll.

IM/SM2000 Issue 13 19

Page 22

Advanced Videographic Recorder

SM2000 2Operation

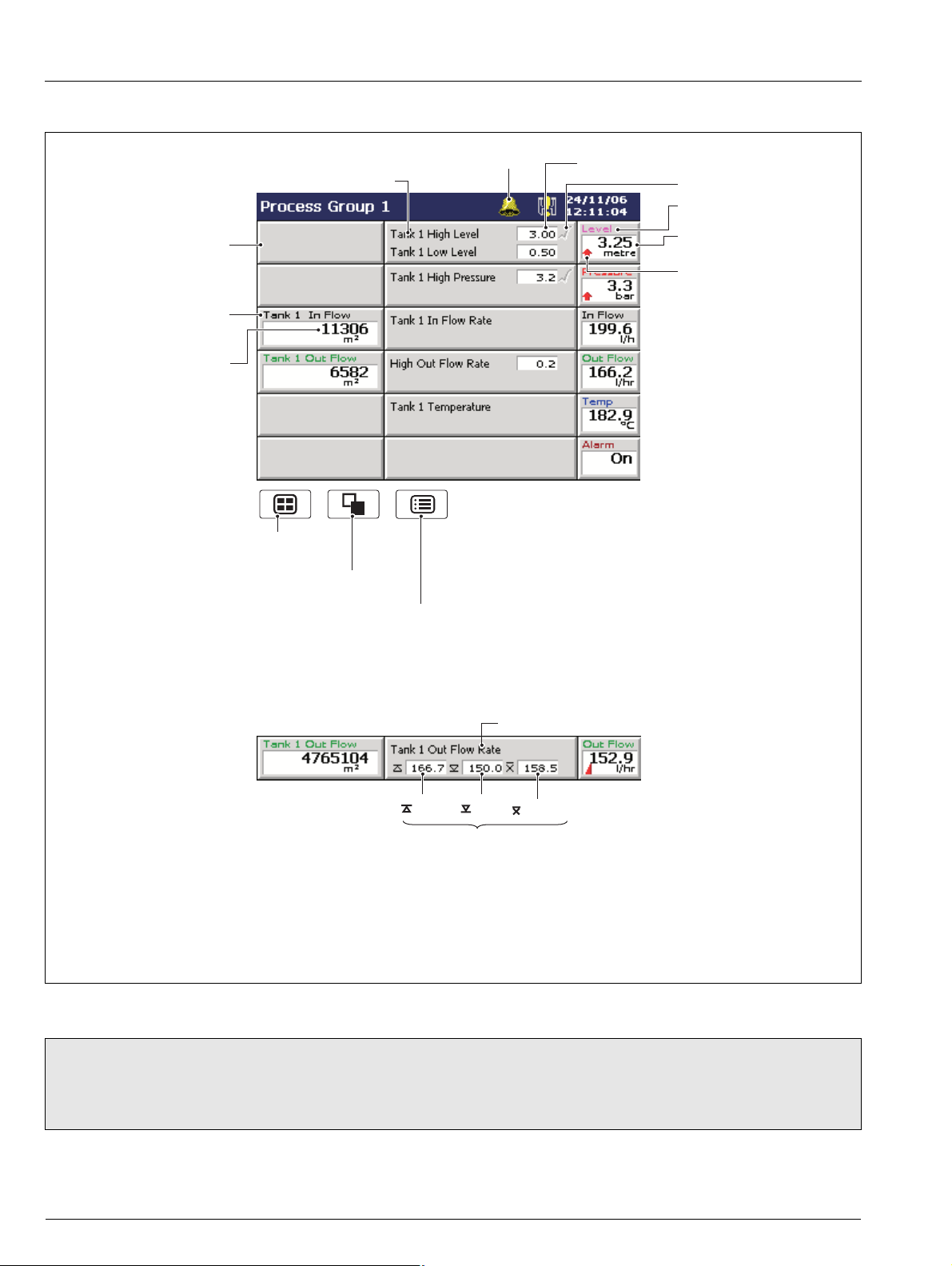

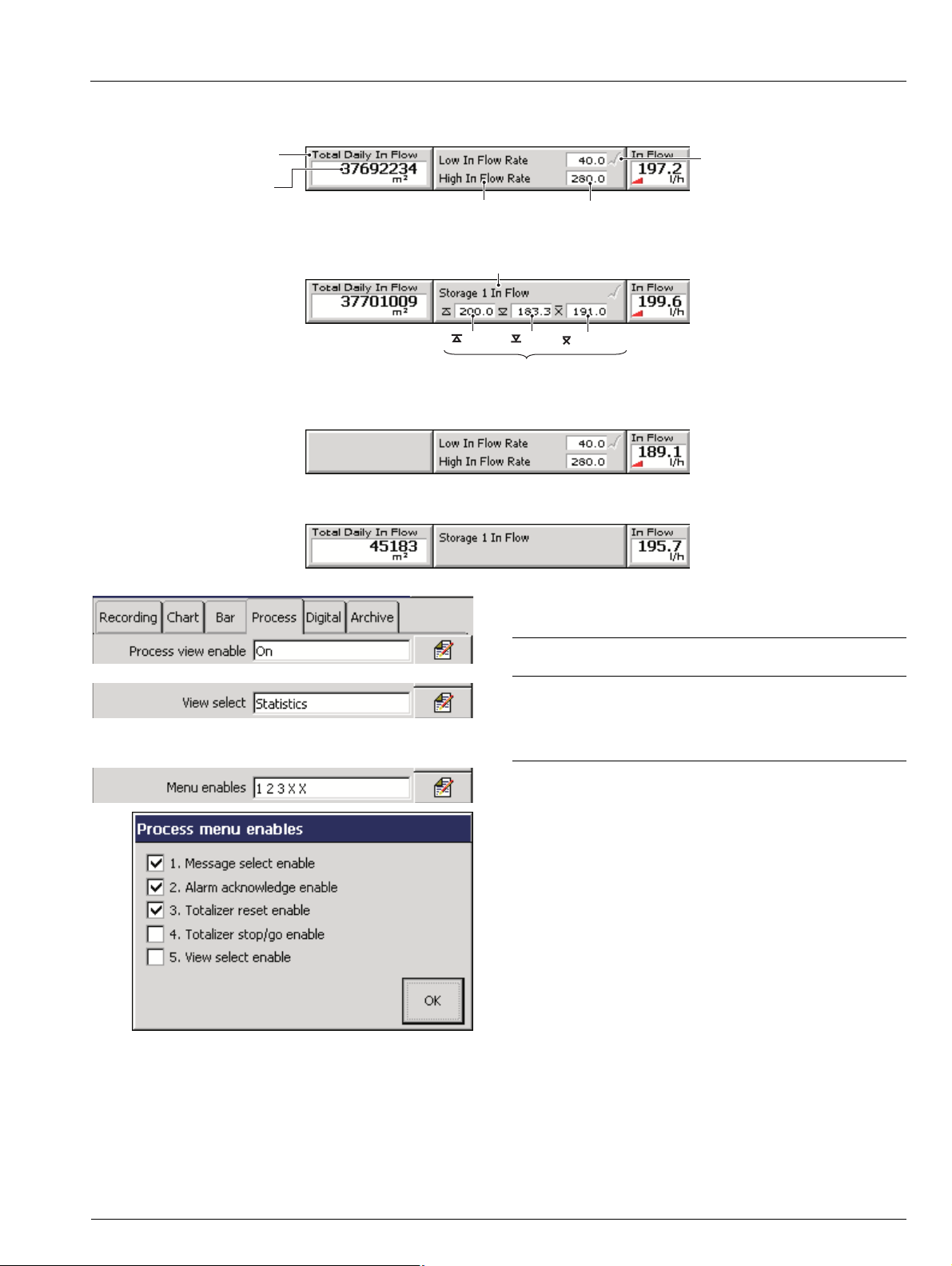

2.6 Process View – Fig. 2.7

Totalizer not enabled

in configuration level

Totalizer

Tag Name

Totalizer

Value

Selects the next Process Group

(if enabled) or the Status View

Selects the next enabled view

(Bargraph, Digital Indicator or Chart)

Global Alarm Status Icon

Alarm Tag

Opens the Operator Menu for

the current view

Alarm Trip Level

Alarm Acknowledged

Short Channel Tag

Instantaneous Value

Alarm Status

A Process View (Alarms)

Channel Source Long Tag

Max

Values since last totalizer reset or totalizer wrap. Calculated only while

the totalizer is enabled. Updated only while the totalizer is running.

Min

Average

B Process View (Statistics)

For a description of the Status Icons (displayed in the Status Bar) and Alarm Event Icons

(displayed in the Bargraph, Digital Indicators, Process and Chart Views), see Appendix G, page 132.

Fig. 2.7 Process View

Note.

Only totalizers that have been configured and enabled in the Configuration level are displayed.

When a totalizer is not running (i.e. 'Stop' is selected), the corresponding totalizer value is shown in red.

20 IM/SM2000 Issue 13

Page 23

Advanced Videographic Recorder

SM2000 2Operation

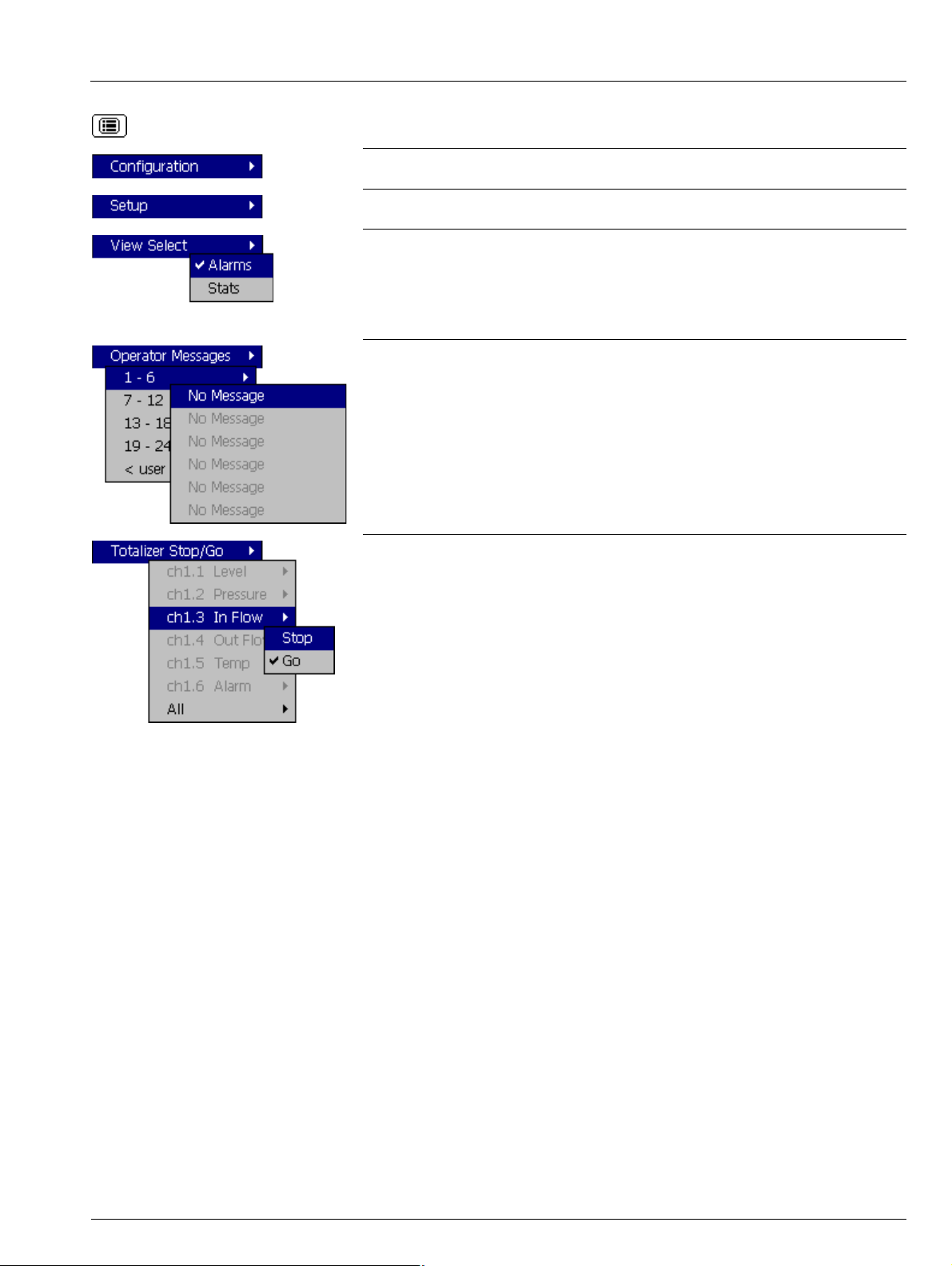

Select the Configuration Level – see Section 4, page 45.

Select the Setup Level – see Section 3, page 29.

Switch between the Alarm View and the Statistics View.

Note. If a channel's totalizer is not enabled in the Configuration level, Alarm trip levels

are shown in place of the channel statistics. If no alarms are enabled, the long tag for

that channel is displayed.

Add one of 24 predefined Operator Messages (see Section 4.4.7, page 60) or one UserDefined Message to the alarm event log.

If '< user defined >' is selected, a data entry keyboard appears to enable the message to

be entered (see Fig. 4.5, page 50). The selected or user-defined message is displayed

briefly on-screen.

Stop and start individual totalizers.

Channel totalizers that have not been enabled in the Configuration level are greyed-out.

Note. When a totalizer is not running (i.e. 'Stop' is selected), the corresponding totalizer

value is shown in red.

IM/SM2000 Issue 13 21

Page 24

Advanced Videographic Recorder

SM2000 2Operation

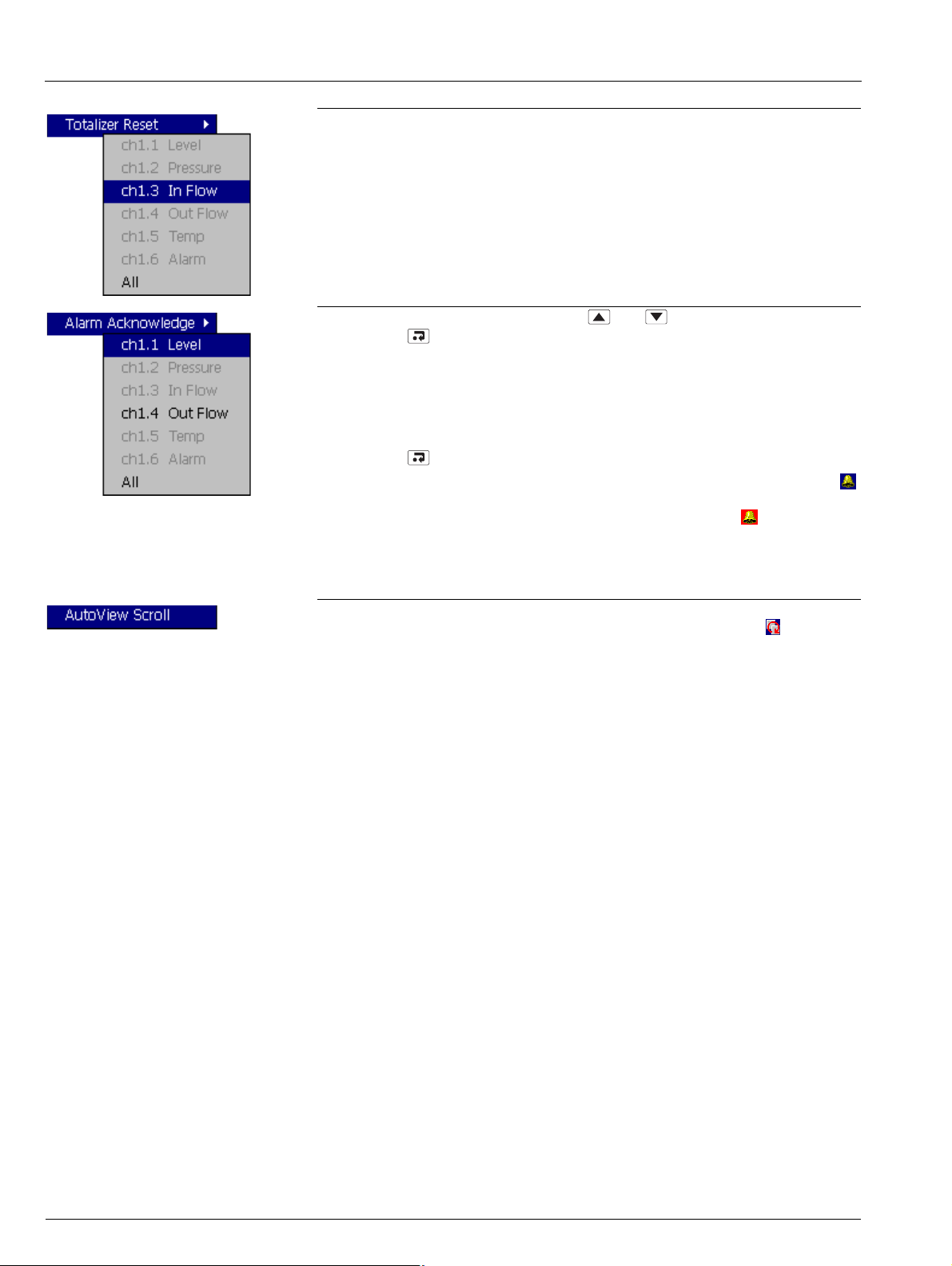

Reset the totalizer value to the totalizer preset value.

Channel totalizers that have not been enabled in the Configuration level are greyed-out.

To acknowledge a particular alarm, use the and keys to highlight it in the menu

and press the key.

Note. Active unacknowledged alarms in the current process group are identified by a

flashing red Alarm Event icon in the bottom left hand corner of the associated indicator.

Active acknowledged alarms are identified by a continuous red Alarm Event icon in the

bottom left hand corner of the indicator – see Fig. 2.7, page 20.

To acknowledge all active alarms in the current process group simultaneously, select 'All'

and press the key.

Note. If an alarm in

continues to be displayed in the status bar. If an active alarm in

the other process group is active, the Global Alarm status icon ( )

the other process group

is unacknowledged, the icon is surrounded by a red flashing border ( ).

If neither alarm on a particular channel is configured, the short channel tag is shown

greyed-out in the menu.

Select 'AutoView Scroll' to display the enabled process view for each configured

process group, in turn for, 40 seconds. The AutoView Scroll status icon ( ) is displayed

in the status bar when AutoView Scroll is active. Press any key to cancel AutoView

Scroll.

22 IM/SM2000 Issue 13

Page 25

Advanced Videographic Recorder

SM2000 2Operation

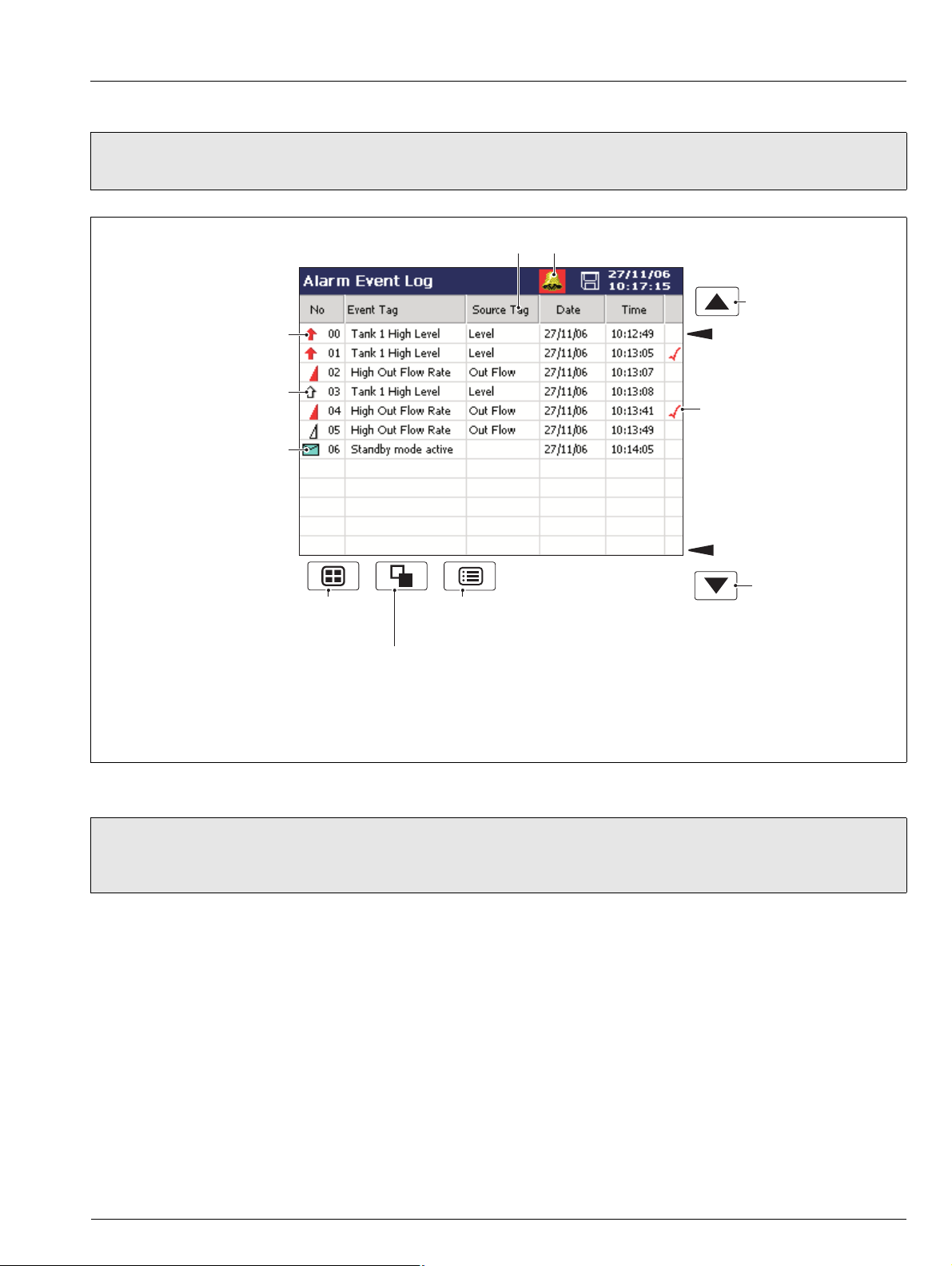

2.7 Alarm Event Log – Fig. 2.8

Note. The Alarm Event log view provides an historical log of all alarm events in the sequence in which they occurred. To view the

current status of all alarms, choose the Process View – see Section 2.6, page 20.

Alarm becomes active

(Active transition)

Alarm becomes inactive

(Inactive transition)

Operator Message

Short tag of the alarm's source

Selects

Process

Group 1

Selects the

Totalizer Log

For a description of the Alarm Event Icons (displayed in the Alarm Event Log

and the Bargraph, Digital Indicators, Process and Chart Views), see Appendix G, page 132.

Opens the

Operator Menu for

the current view

Global Alarm Status Icon

View previous

page of data

Oldest Data

Alarm Acknowledged

Newest Data

View next

page of data

Fig. 2.8 Alarm Event Log

Note. When the number of entries in the Alarm Event log has reached that defined in 'Alarm log size' (see Section 4.4.6,

page 60), the oldest data is overwritten by the newest. Entries are renumbered so that the number of the oldest entry is

always 00.

IM/SM2000 Issue 13 23

Page 26

Advanced Videographic Recorder

SM2000 2Operation

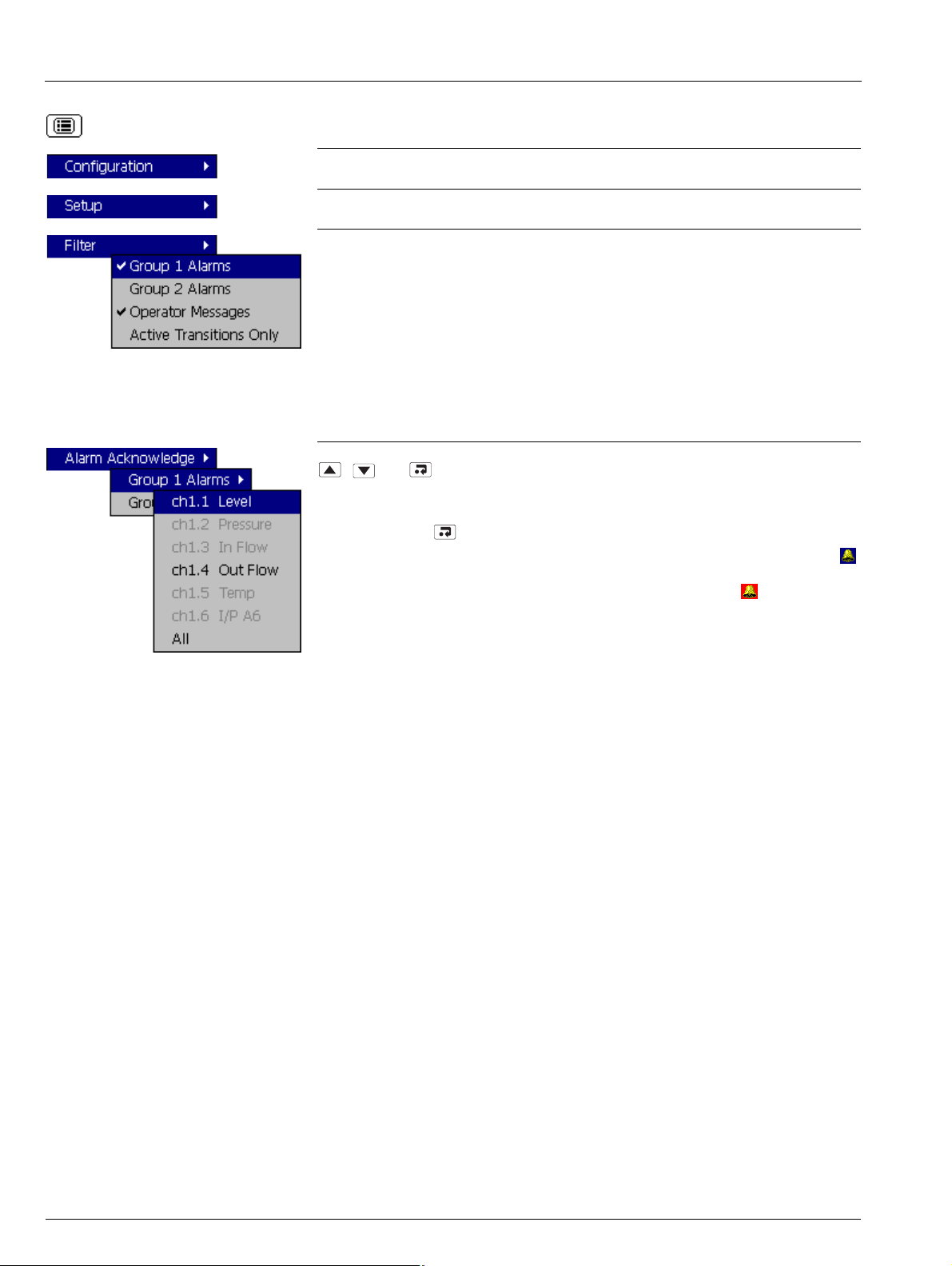

Select the Configuration Level – see Section 4, page 45.

Select the Setup Level – see Section 3, page 29.

Select the entries to be displayed in the log. Indicates entries currently displayed.

Note.

Hiding and displaying log entries does not affect the recording of events in the log.

All selected alarm event transitions (from inactive to active, from active to

acknowledged, from acknowledged to inactive, from active to inactive) appear in

the sequence in which they occurred.

Selecting 'Active Transitions Only' displays entries for alarms when made active

and hides all acknowledged & inactive transitions.

The Alarm Event log is not group specific. To acknowledge a particular alarm, use the

, and keys to first select the relevant process group, followed by the alarm

to be acknowledged.

To acknowledge all active alarms in the selected process group simultaneously, select

'All' and press the key.

Note. If an alarm in

continues to be displayed in the status bar. If an active alarm in

the other process group is active, the Global Alarm status icon ( )

the other process group

is unacknowledged, the icon is surrounded by a red flashing border ( ).

If neither alarm on a particular channel is configured, the short channel tag is shown

greyed-out in the menu.

24 IM/SM2000 Issue 13

Page 27

Advanced Videographic Recorder

SM2000 2Operation

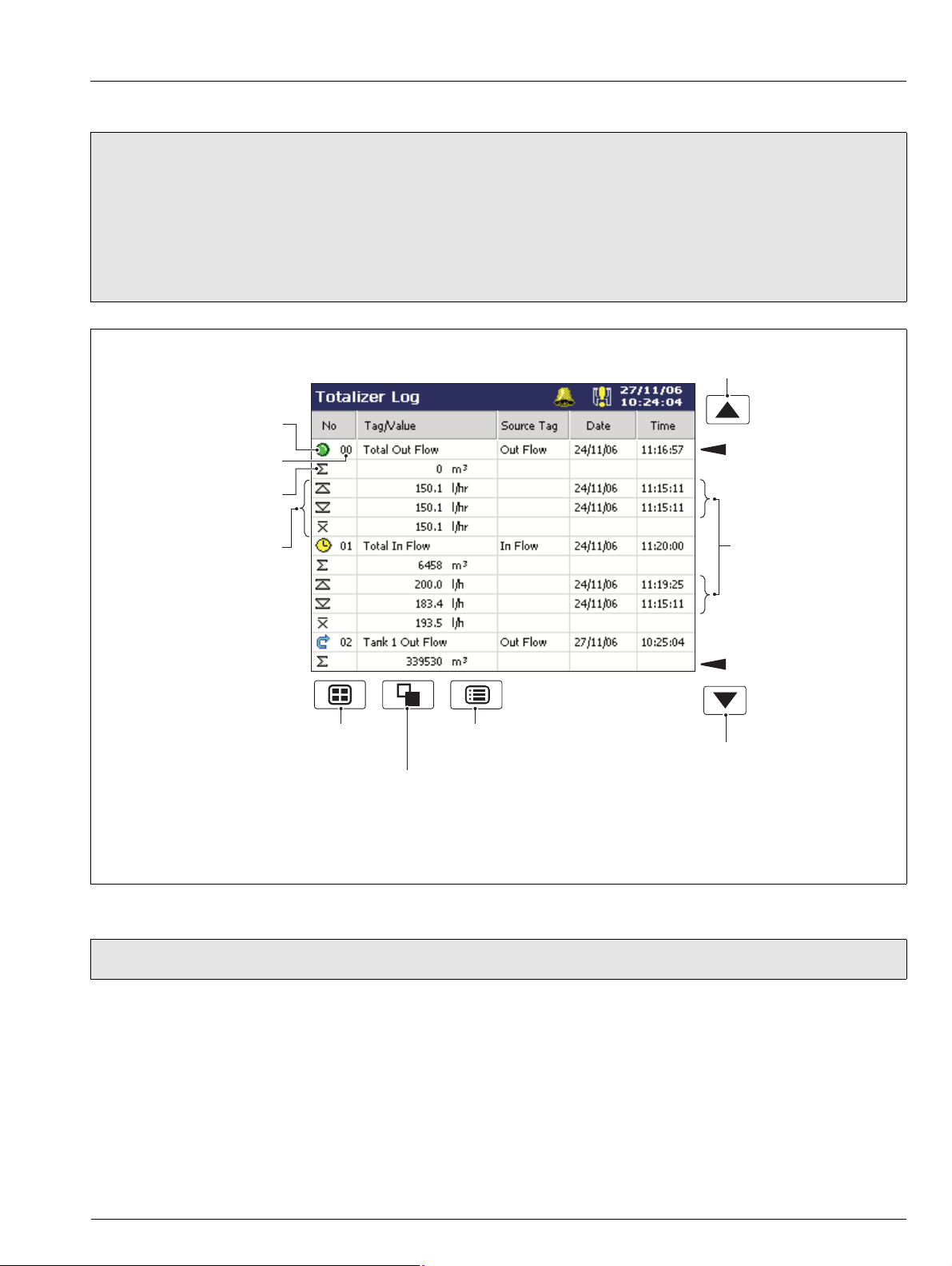

2.8 Totalizer Log – Fig. 2.9

Note.

The Totalizer log view provides an historical log of totalizer activity. To view the current totalizer status, choose the Process

or Digital View.

When the number of entries in the Totalizer log has reached that defined in 'Totalizer log size' (see Section 4.4.6, page 60),

the oldest data is overwritten by the newest. Entries are renumbered so that the number of the oldest entry is always 00.

The logging of totalizer values can be triggered at pre-determined intervals and/or by digital signal – see 'Log update time'

and 'Log update source' on page 92.

View previous

page of data

Totalizer Icon

Oldest

Log Entry Number

Batch total at the

time of the event

Max., min. and

average of the value

being totalized at the

time of the event

Data

Date/time at which

max. and min.

flowrates occured

Newest

Data

Selects

Process

Group 1

Selects the

Audit Log

For a description of the Totalizer Icons (displayed in the Totalizer Log

and the Process View), see Appendix G, page 132.

Opens the

Operator Menu for

the current view

View next page

of data

Fig. 2.9 Totalizer Log

Note. Maximum, Minimum and Average statistics are not shown unless enabled in the 'Filter' menu – see overleaf.

IM/SM2000 Issue 13 25

Page 28

Advanced Videographic Recorder

SM2000 2Operation

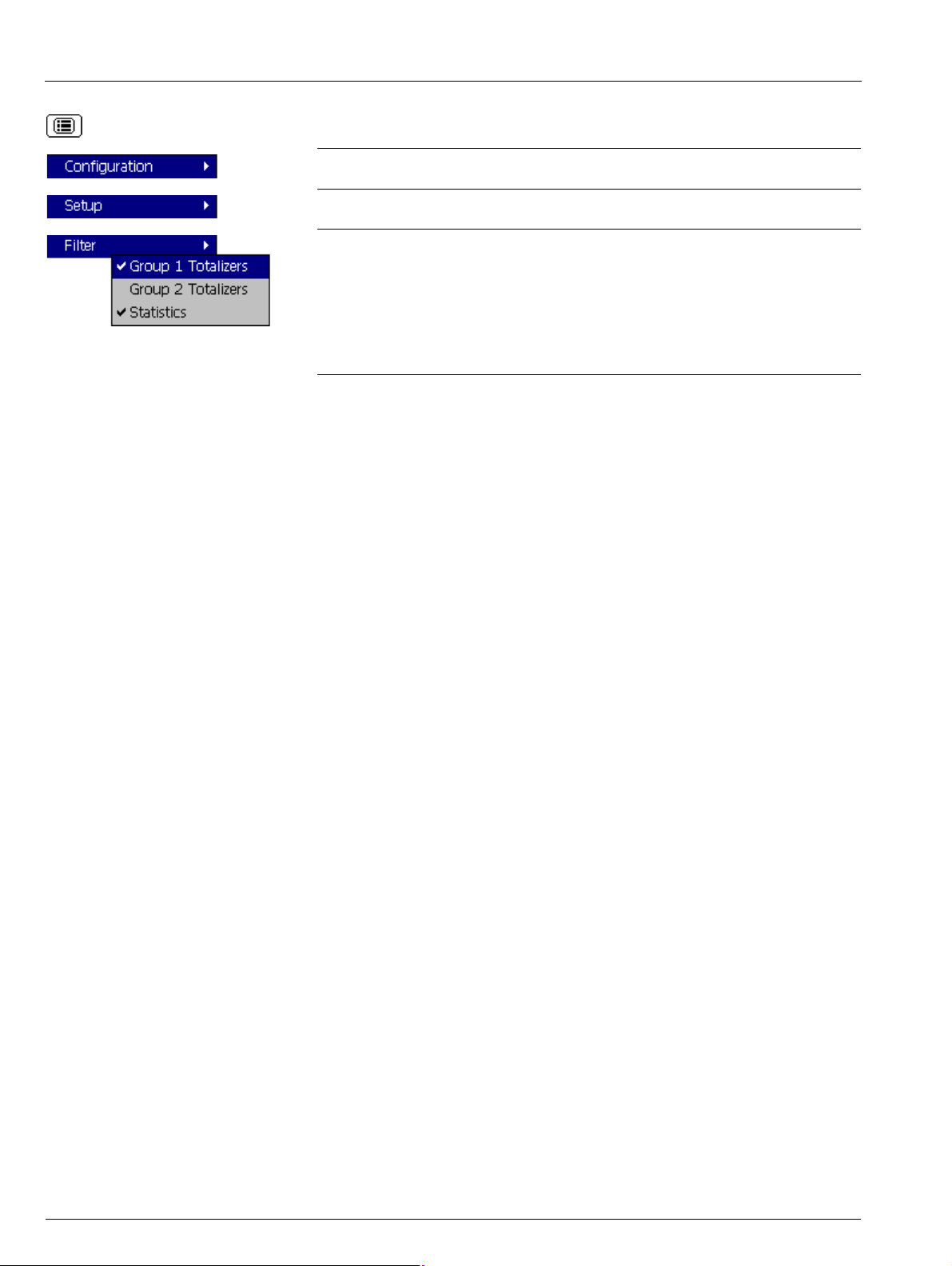

Select the Configuration Level – see Section 4, page 45.

Select the Setup Level – see Section 3, page 29.

Select the entries to be displayed in the log. Indicates entries currently displayed. This

does not affect which events are recorded in the log.

'Statistics' displays the maximum, minimum and average values of the analog value

being totalized, together with the dates and times at which all maximum and minimum

values occurred.

These values are reset when the totalizer is reset and are updated only when the totalizer

is running.

26 IM/SM2000 Issue 13

Page 29

Advanced Videographic Recorder

SM2000 2Operation

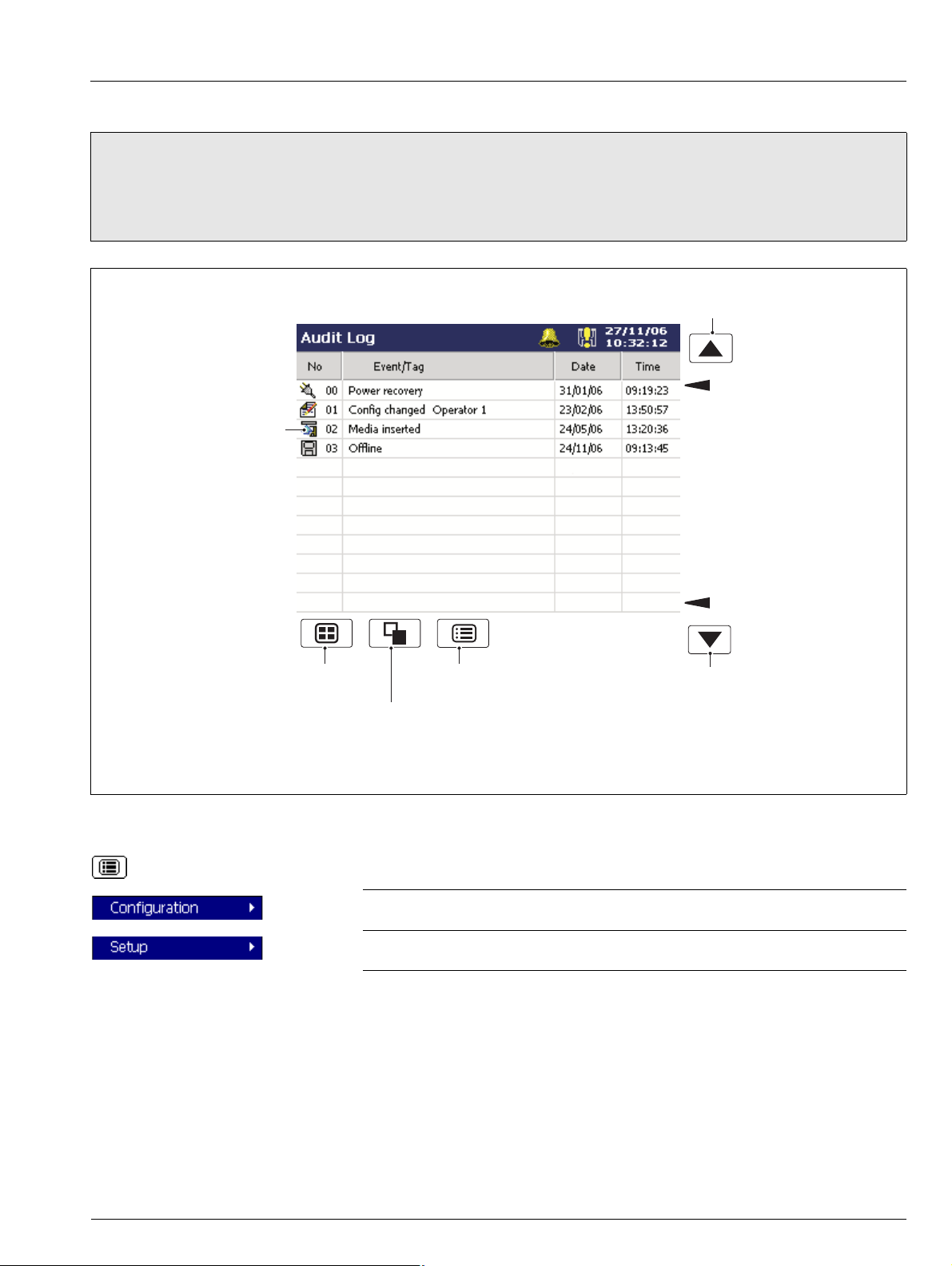

2.9 Audit Log– Fig. 2.10

Note.

The Audit log view provides an historical log of system activity.

When the number of entries in the Audit log has reached that defined in 'Audit log size' (see Section 4.4.6, page 60), the

oldest data is overwritten by the newest. Entries are renumbered so that the number of the oldest entry is always 00.

View previous

page of data

Oldest Data

Audit Log Icon

Fig. 2.10 Audit Log

Newest Data

Selects

Process

Group 1

Selects the

Status View

For a description of the Audit Log Icons (displayed in the Audit Log) see Appendix G, page 132.

Opens the

Operator Menu for

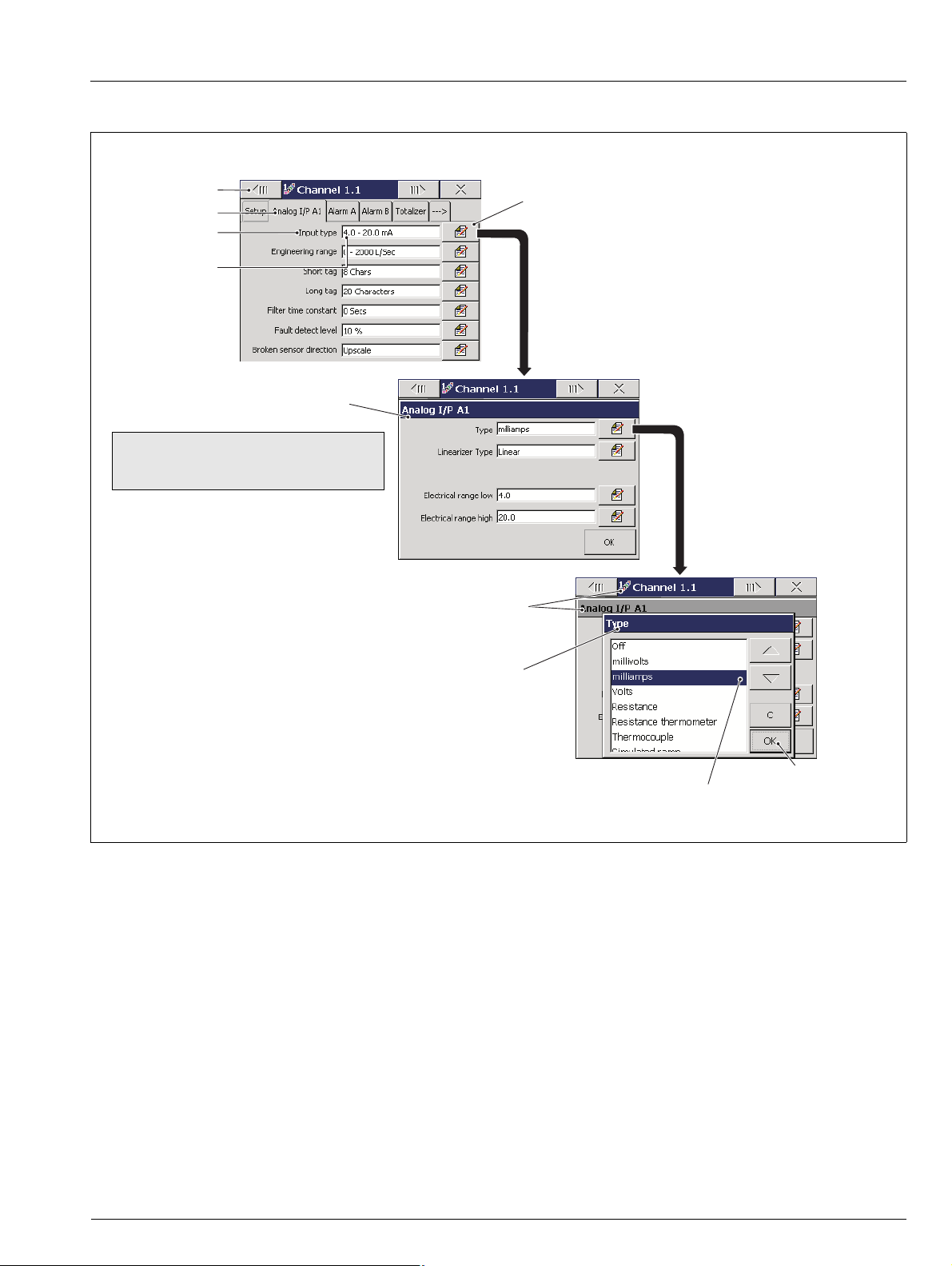

the current log

View next

page of data

Select the Configuration Level – see Section 4, page 45.

Select the Setup Level – see Section 3, page 29.

IM/SM2000 Issue 13 27

Page 30

Advanced Videographic Recorder

SM2000 2Operation

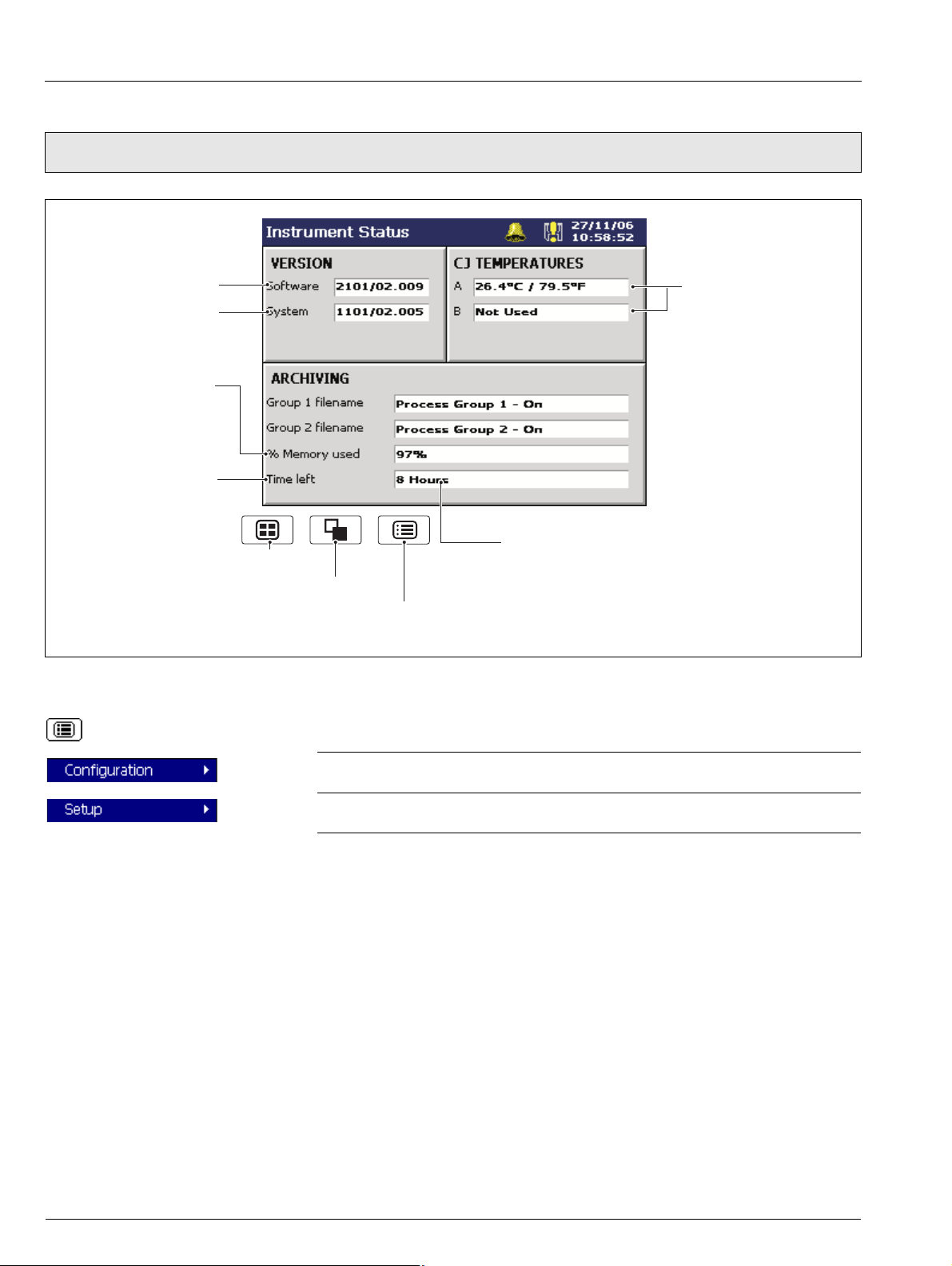

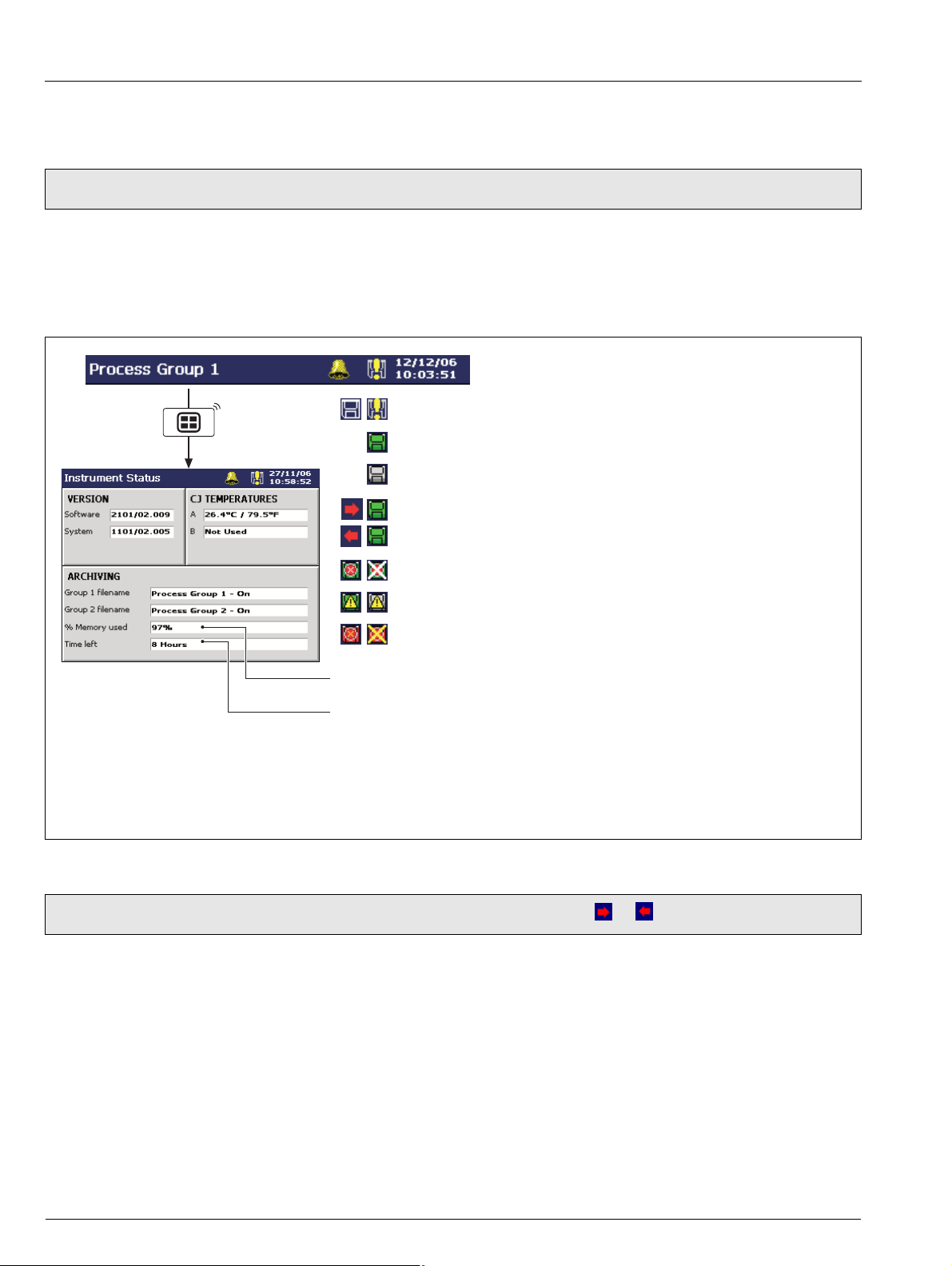

2.10 Status View – Fig. 2.11

Note. The Status view provides an overview of the instrument's status.

Instrument Software Version

Operating System Version

Amount of memory used

on the archive media

currently installed

Approximate time left

before the current archive

media is full, assuming the

amount of data recorded

remains the same

Selects Process Group 1

Fig. 2.11 Status View

Selects the Alarm Event Log

Opens the Operator Menu for

the current view

Cold junction temperatures

for Modules A & B; measured

by the built-in cold junction

circuitry.

'Not Used' is displayed if none

of the inputs on the module

are thermocouples.

Time Left Display Format

>=1 Day: Days, e.g. '5 Days'

>=1 Hour, <1 Day: Hours, e.g. '10 hours'

<1 Hour: Minutes, e.g. '25 minutes'

Select the Configuration Level – see Section 4, page 45.

Select the Setup Level – see Section 3, page 29.

28 IM/SM2000 Issue 13

Page 31

Advanced Videographic Recorder

SM2000 3Setup

3Setup

3.1 Introduction

Note. Users with Setup access can:

Start/Stop recording.

Switch between primary and secondary recording rates.

Set archiving 'on-line' and 'off-line'.

View internal and external archive media file directories and delete external archive media files.

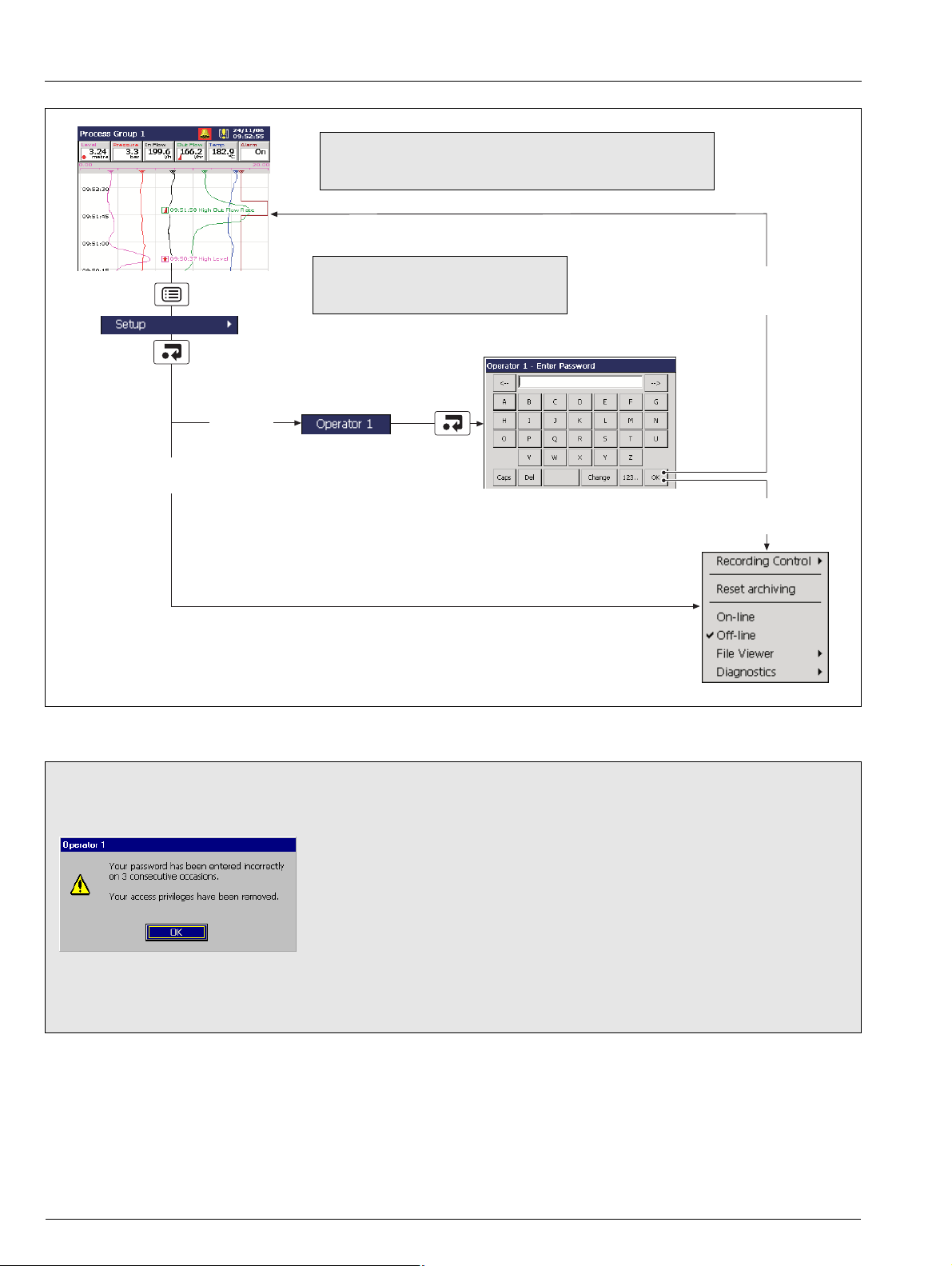

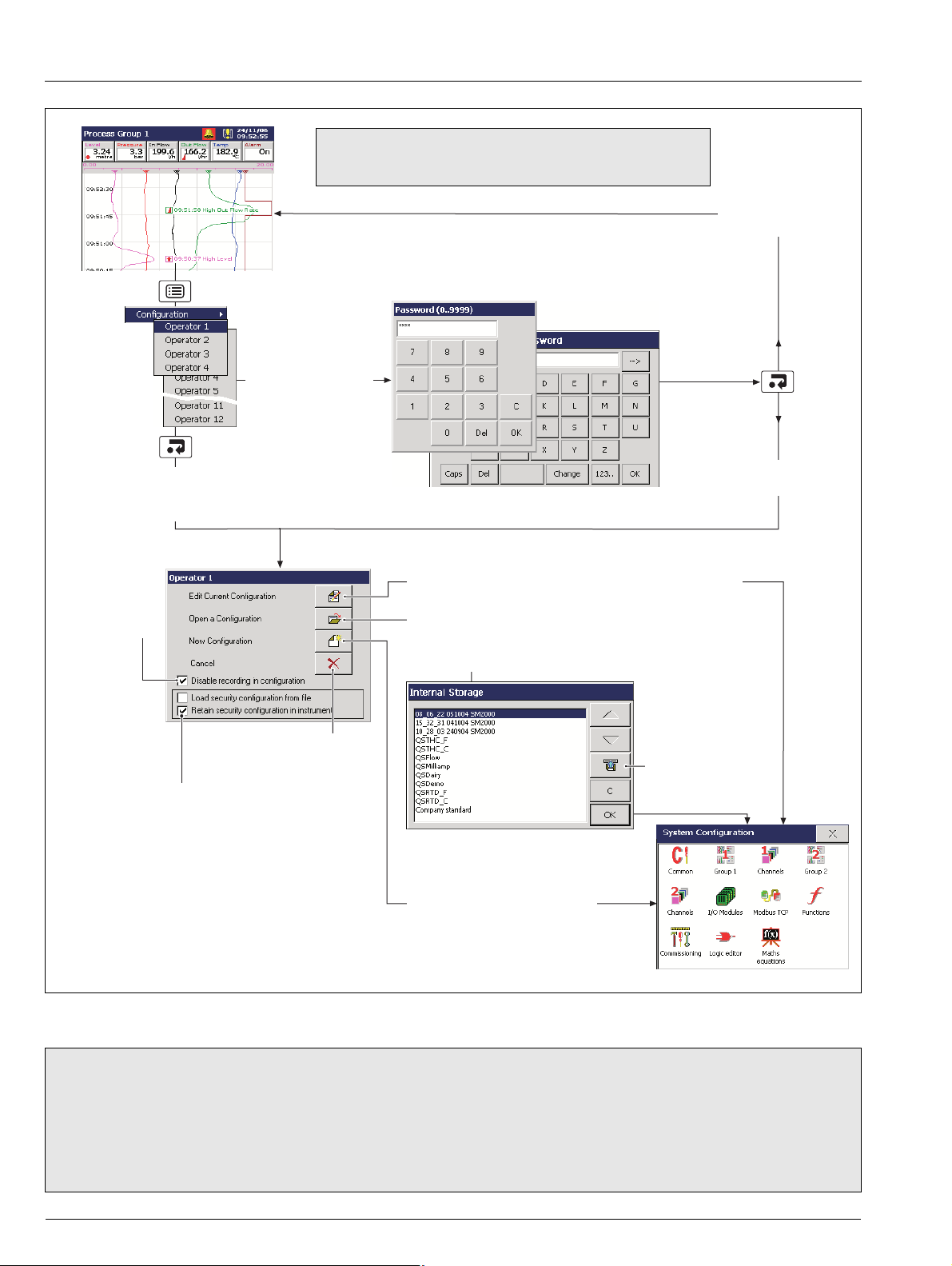

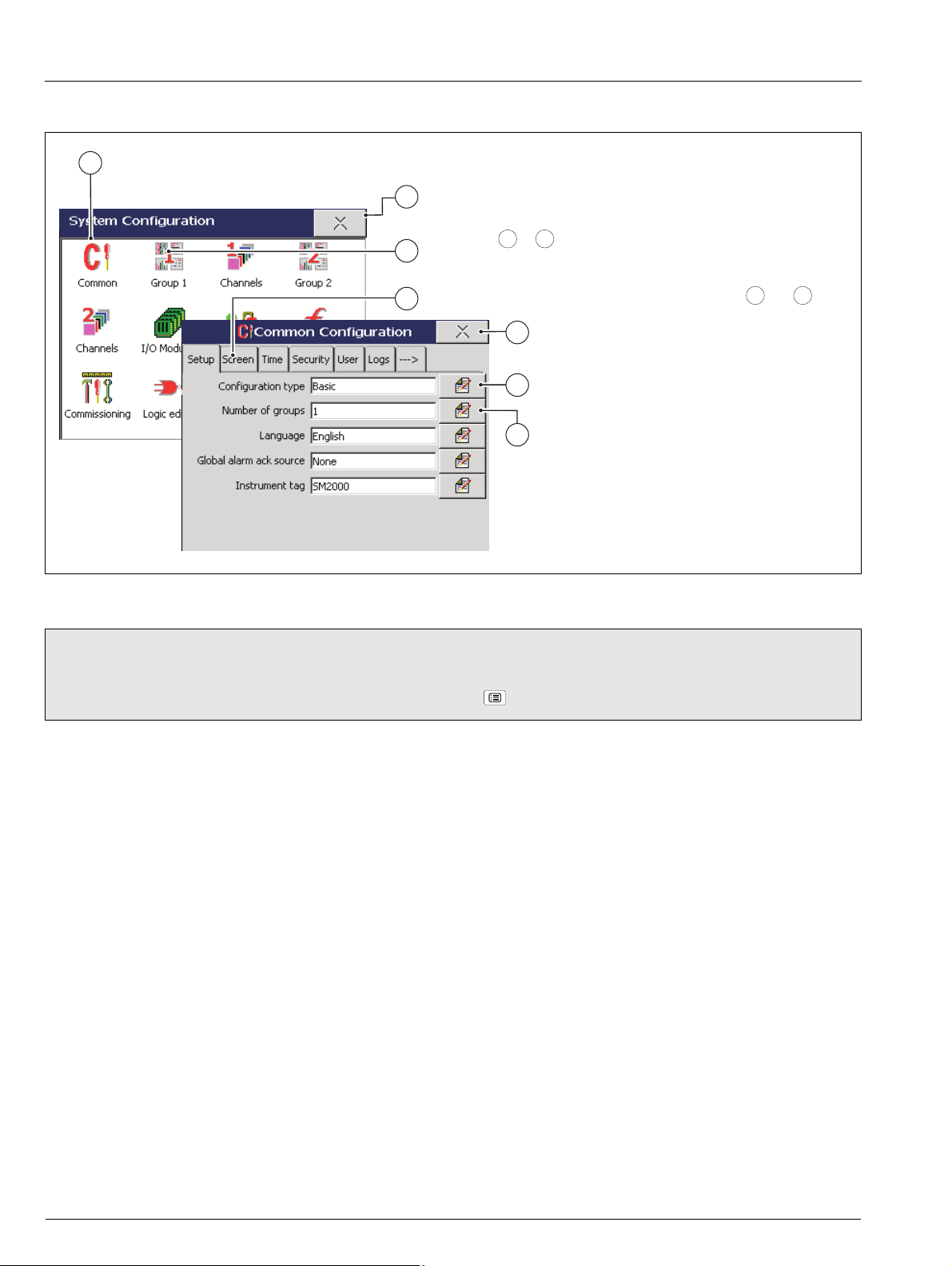

3.2 Accessing the Setup Level – Figs. 3.1 and 3.2

Access to the Setup Level is controlled by the instrument's Security System – see Section 4.4.4, page 56.

If 'Security System' is set to 'Basic' and 'Setup Level Security' is set to 'Off', access to the Setup Level is unrestricted.

If 'Security System' is set to 'Basic' and 'Setup Level Security' is set to 'On', access to the Setup Level is protected by a single

password for all users. Refer to Fig. 3.1 to access the Setup Level.

If 'Security System' is set to 'Advanced' and 'Setup Level Security' is set to 'On', access to the Setup Level is protected by a

unique password for each authorized user. Refer to Fig. 3.2 to access the Setup Level.

Setup Security

Not Enabled

Note. Do not use sharp objects such as screwdrivers, pen

nibs etc. to operate the touch screen.

Note. The Setup level can be

accessed from any operator screen.

Invalid Setup

Password

Setup

Security

Enabled

Valid Setup

Password

Fig. 3.1 Accessing the Setup Level – Basic Security

IM/SM2000 Issue 13 29

Page 32

Advanced Videographic Recorder

SM2000 3Setup

Note. Do not use sharp objects such as screwdrivers, pen

nibs etc. to operate the touch screen.

Note. The Setup level can be

accessed from any operator screen.

Setup

Security

Enabled

Setup Security

Not Enabled

Fig. 3.2 Accessing the Setup Level – Advanced Security

Enter Password

(see Section 3.3, page 31)

Invalid Password

Entered

(see Note Below)

Valid Password

Entered

Note. If an incorrect password is entered the display returns to the Operating view. However, if the maximum number of

consecutive incorrect password entries is exceeded, the user's access privileges are removed and the following message is

displayed:

If this occurs, access privileges can be reinstated only by the system administrator (User 1). If the system administrator's access

privileges have been removed, the security system must be disabled using the configuration security switch (Yellow switch) to

gain access to the configuration – see Section 4.1.3, page 45.

30 IM/SM2000 Issue 13

Page 33

Advanced Videographic Recorder

SM2000 3Setup

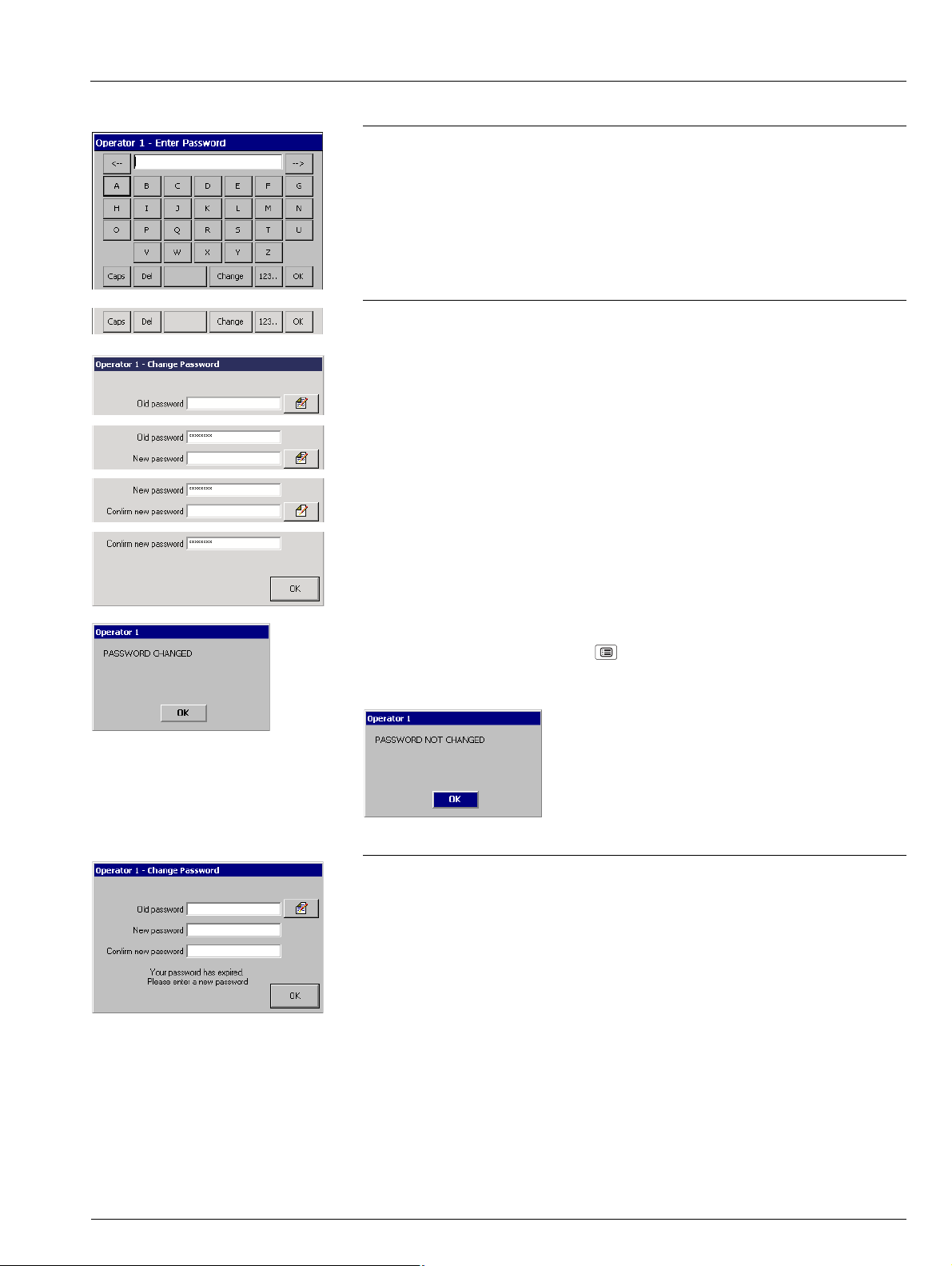

3.3 Password Entry

Enter Password

Enter the required password using the touchscreen and press 'OK'.

Note. For security, all characters are displayed as ''.

Change Password

1. Press the 'Change' button.

2. Enter the old password.

3. Enter the new password.

4. Enter the new password again to confirm it.

Password change successful.

Note. If either of the 'OK' button or key are pressed at any stage before the new

password is confirmed, the password change operation is cancelled and the following

message is displayed:

Password Expired

Passwords can be configured to expire at pre-determined intervals. If a password is time

expired, this screen is displayed automatically. Enter a new password as described

above.

IM/SM2000 Issue 13 31

Page 34

Advanced Videographic Recorder

SM2000 3Setup

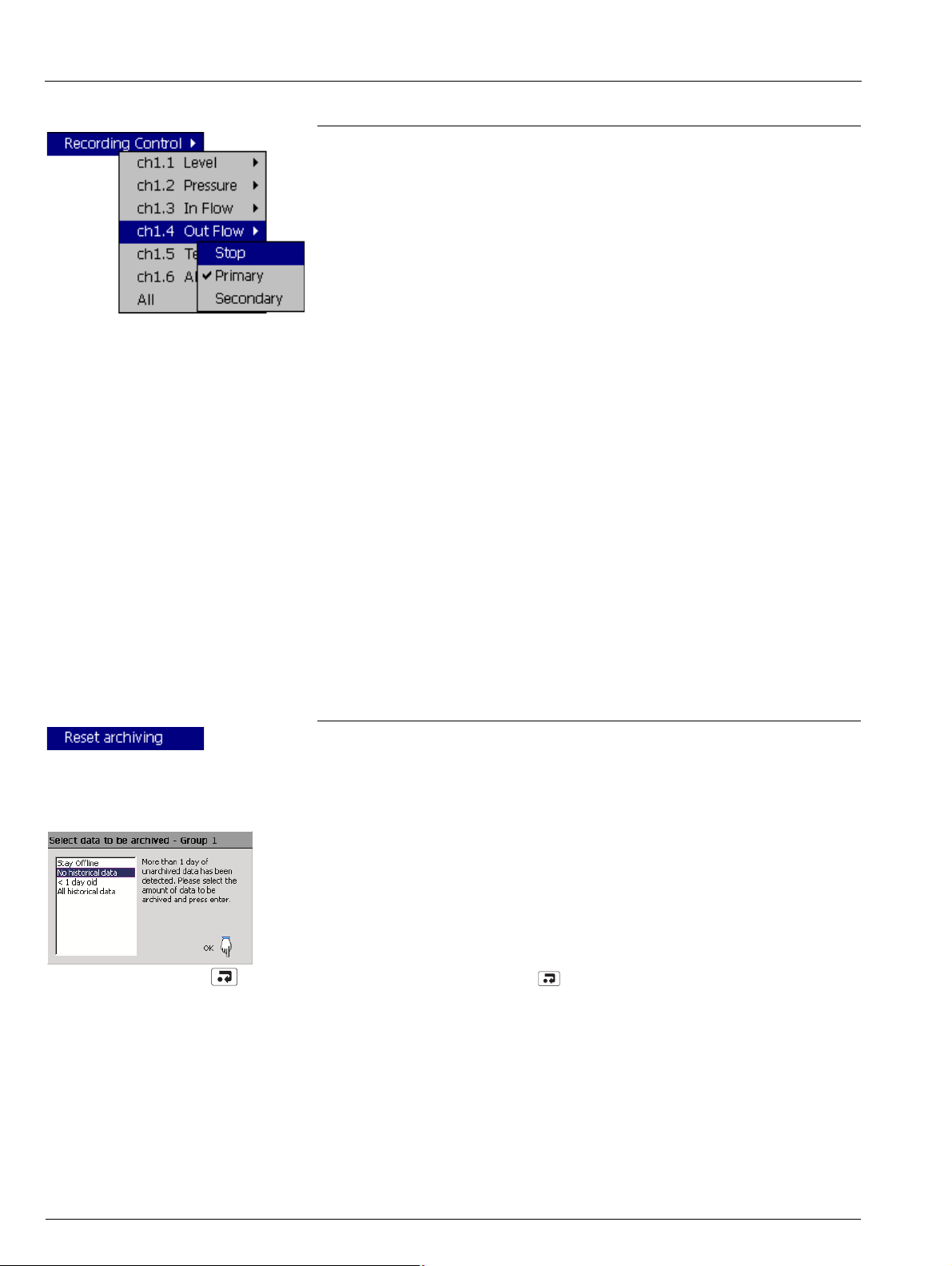

3.4 Setup Menu

Use this menu to stop and start recording or switch between the Primary and Secondary

sample rates on one or more channels in the current Process Group.

The Primary sample rate is set typically to a relatively slow rate (depending upon process

recording requirements) and is active during normal process operating conditions in

order to maximize internal memory and external archive media.

The Secondary sample rate is set typically to a faster rate than the Primary sample rate

and may be selected manually in order to record the maximum amount of detail during,

for example, an alarm condition.

The rates are set during configuration:

If 'Configuration type' is set to 'Basic' (see Section 4.4.1, page 52), the primary

and secondary sample rates apply to all enabled channels in each Process Group

– see Section 4.5.1, page 64. Therefore, individual channel selections are greyedout in the menu and the 'Stop', 'Primary' and 'Secondary' selections are applied to

all channels in the current process group simultaneously.

If 'Configuration type' is set to 'Advanced' (see Section 4.4.1, page 52), each

channel's sample rates are configured independently (see Section 4.6.1, page 77)

and the 'Stop', 'Primary' and 'Secondary' selections can be applied to individual or

all channels.

Note.

Switching between the primary and secondary sample rates does not affect the

screen interval in the Chart view.

When a channel is set to 'Stop' the instantaneous value in the associated indicator

is displayed in red and, after the end of the next sample period, no further samples

are plotted on the associated trace.

Digital recording channels can only be set to 'Stop' or 'Go'.

Recording control can also be implemented using digital sources – see Sections

4.5.1, page 64 and 4.6.1, page 77.

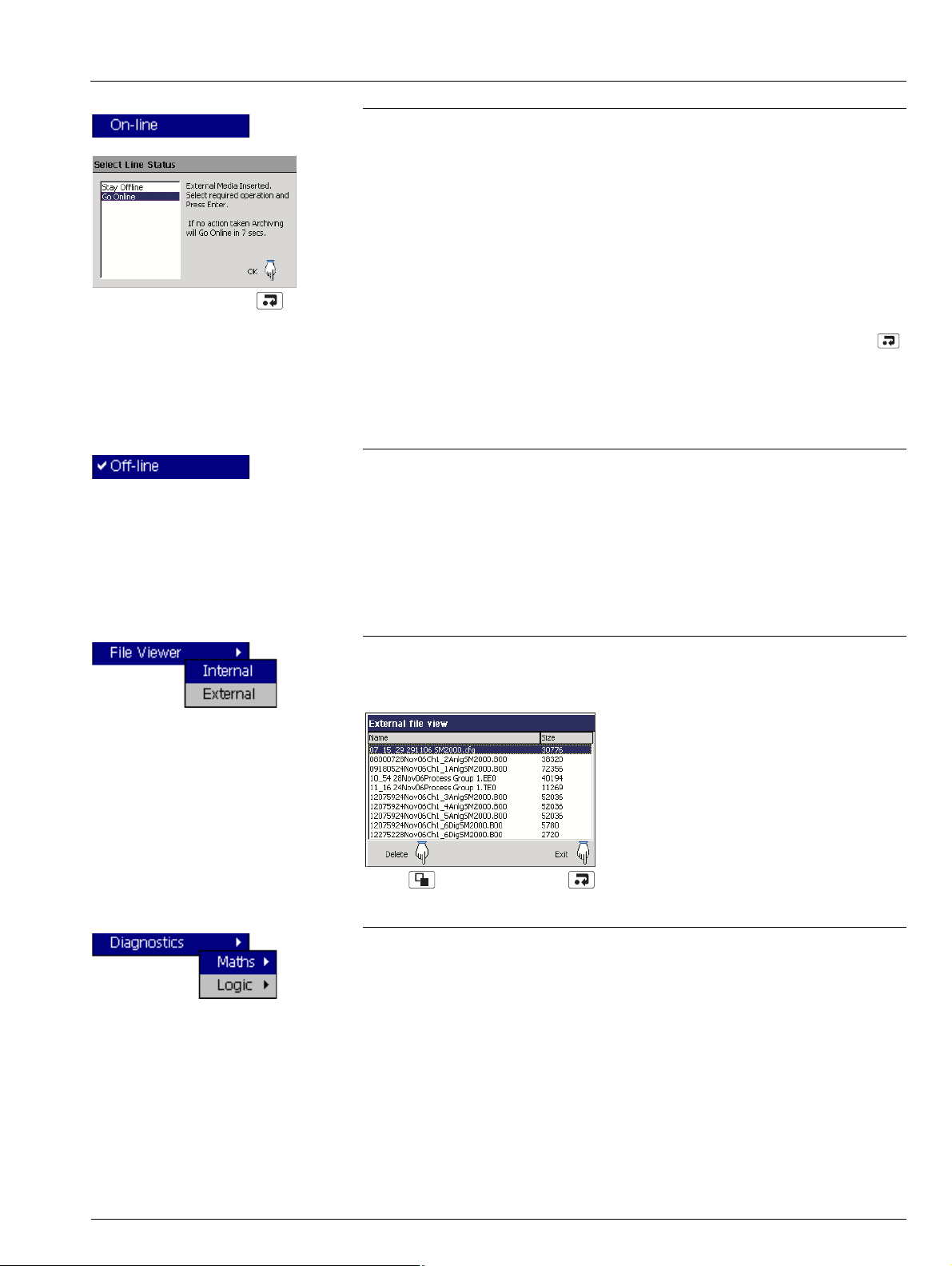

If selected, the date of the oldest unarchived data is set to that of the oldest data in the

internal flash memory. This allows all data in the internal memory to be re-archived to

external media.

Note. Ideally, a blank media storage card should be inserted prior to selecting this

function.

To re-archive data:

1. Insert archive media, with sufficient free space, into the instrument.

2. Select 'Off-line' in the Setup Menu.

3. Select 'Reset archiving' in the Setup Menu.

4. Select 'On-line' in the Setup Menu.

5. Select data to be archived if >1 hour (Text format) or >1 day (Binary format) of data

in internal memory and press .

32 IM/SM2000 Issue 13

Page 35

Advanced Videographic Recorder

SM2000 3Setup

Places the archive media on-line, starting the archiving process.

Note.

The On-line function is disabled (greyed-out in the Setup Menu) if no archive media

card is inserted or the instrument has been placed in Historical Review mode.

When an archive media card is inserted and there is <1 hour (Text format) or <1

day (Binary format), the 'Select Line Status' dialog box (left) is displayed, giving the

user the choice of placing archiving on-line or remaining off-line. Archiving is placed

automatically on-line in 10 seconds unless 'Stay Offline' is selected.

When an archive media card is inserted and there is >1 hour (Text format) or >1

day (Binary format) of data in internal memory, the 'Select data to be archived'

dialog box (previous page) is displayed. Select data to be archived and press .

Once selected, all data within the selected time frame is archived. Older unarchived data

remains in the internal memory buffer until overwritten by newer data but is not available

for archiving unless 'Reset archiving' is selected.

Places the archive media off-line. Recording of channel data into internal memory

continues uninterrupted but archiving to the removable media is suspended until it is put

on-line again.

Note.

Always set the external media Off-line before removing it.

The Off-line function is disabled (greyed-out in the Setup Menu) when in Historical

Review mode.

Use the file viewer to view a list of the files stored in internal memory and on external

archive media.

Note. Files stored in internal memory cannot be deleted.

The diagnostics features are available only on instruments with the Advanced Software

option enabled. To use the diagnostics features, refer to the Advanced Software Options

User Guide Supplement, IM/SM2000ADV.

IM/SM2000 Issue 13 33

Page 36

Advanced Videographic Recorder

SM2000 3Setup

3.5 Archiving

Recorded data, logs and configuration files stored on the instrument's internal memory can be archived to files created on removable

media. Parameters for archiving Process Groups 1 and 2 data are set up independently.

Note. To configure Archiving, refer to Section 4.5.6, page 73.

3.5.1 Card Compatibility

Our recorders comply with approved industry standards for memory cards. SanDisk Standard Grade memory cards have been fully

tested and are recommended for use with our recorders. Other brands may not be fully compatible with this device and therefore

may not function correctly.

3.5.2 Media Status – Fig. 3.3

External archive media not inserted (yellow flashing exclamation mark)

External archive media on-line (green icon, shaded area indicates % used)

External archive media off-line (grey icon, shaded area indicates % used)

External archive media update in progress (see

External media 100% full, archiving stopped (green/red icon, flashing white cross)

Warning! Too many files (green icon media online, grey icon media offline)

Too many files, archiving stopped (red icon, flashing yellow cross)

Amount of memory used on the external archive media currently installed

Approximate time left before the current external archive media is full,

assuming the amount of data recorded remains the same.

Time Left Display Format

>=1 Day: Days, e.g. '5 Days'

>=1 Hour, <1 Day: Hours, e.g. '10 hours'

<1 Hour: Minutes, e.g. '25 minutes'

Note below)

Fig. 3.3 Media Status Icons

Note. Do not remove media while either of the media update in progress status icons ( or ) are displayed.

34 IM/SM2000 Issue 13

Page 37

Advanced Videographic Recorder

SM2000 3Setup

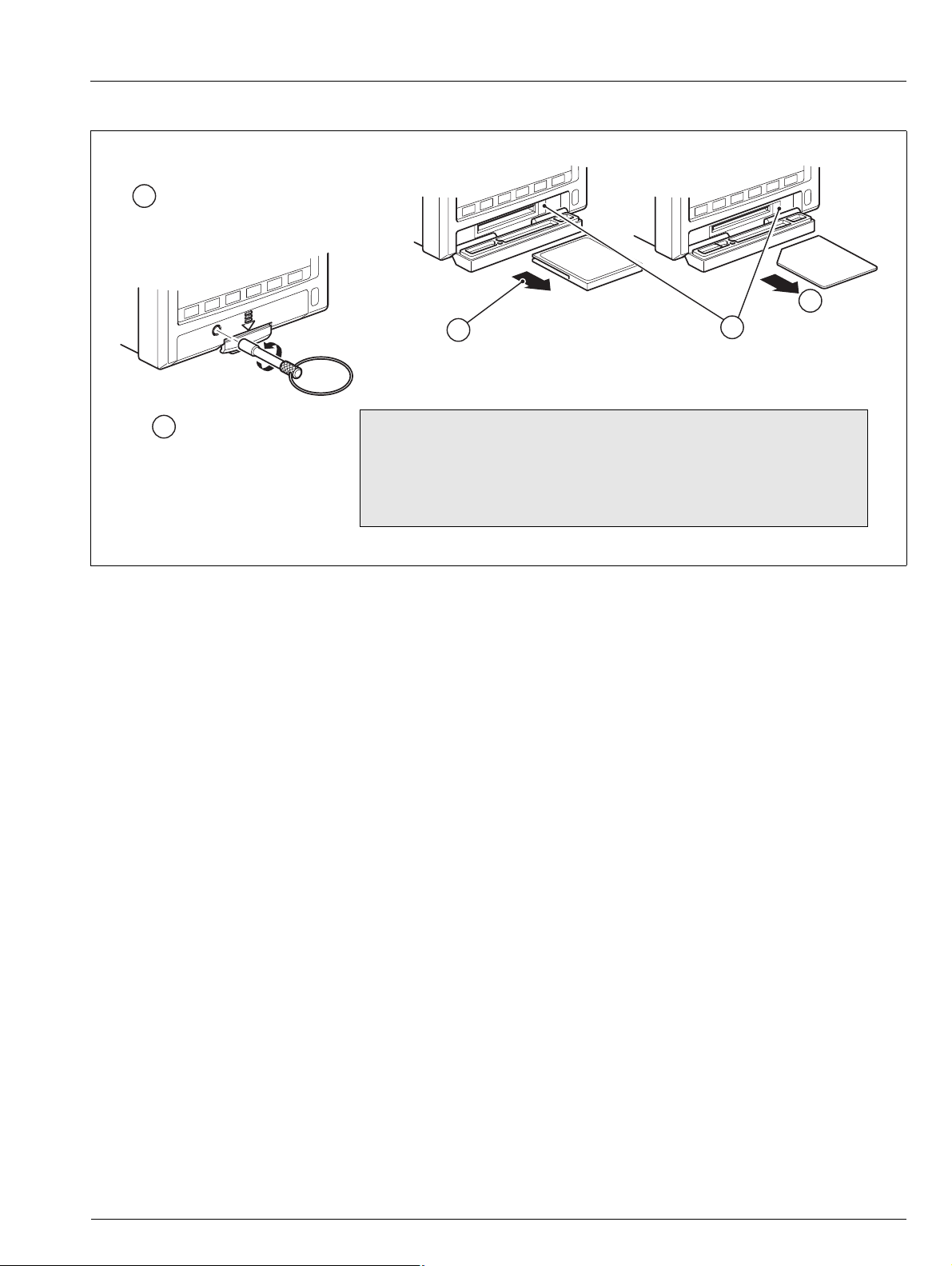

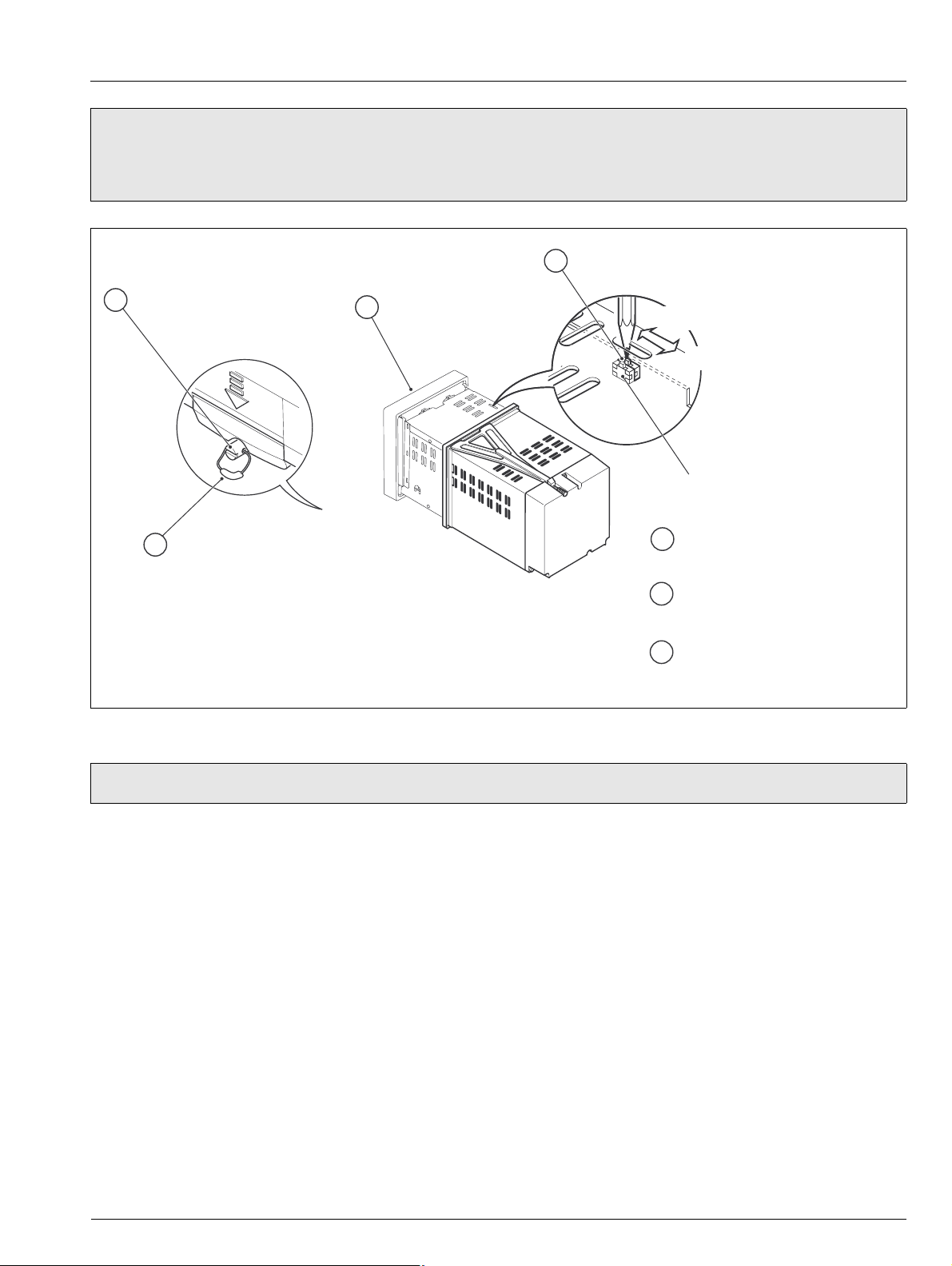

3.5.3 Inserting and Removing Media – Fig. 3.4

Set the archive media off-line –

see Section 3.4, page 32

1

4

4

Withdraw the media

Compact Flash Media SmartMedia

3

Press the eject button

Unlock the media door with

2

the key supplied and press the

release catch to open the door

Fig. 3.4 Inserting and Removing External Media

Note. When inserting the media into the instrument:

Ensure the media is the correct type for the instrument.

If SmartMedia option is fitted, ensure only 3.3 V SmartMedia cards used.

Do not use excessive force.

IM/SM2000 Issue 13 35

Page 38

Advanced Videographic Recorder

SM2000 3Setup

3.5.4 Archive File Types

Archive files are created in 1 of 2 user-selectable formats:

Text (comma separated values [.csv]) – see Section 3.6,

page 37

or

Secure binary encoded – see Section 3.7, page 41

All archive files created by the instrument are given filenames

automatically but each type of archived file is given a different file

extension depending on whether Text or Binary format has been

selected during archive configuration – see Section 4.5.6,

page 73. File types and extensions for Text files are shown in

Table 3.1. File types and extensions for Binary files are shown in

Ta bl e 3. 2 .

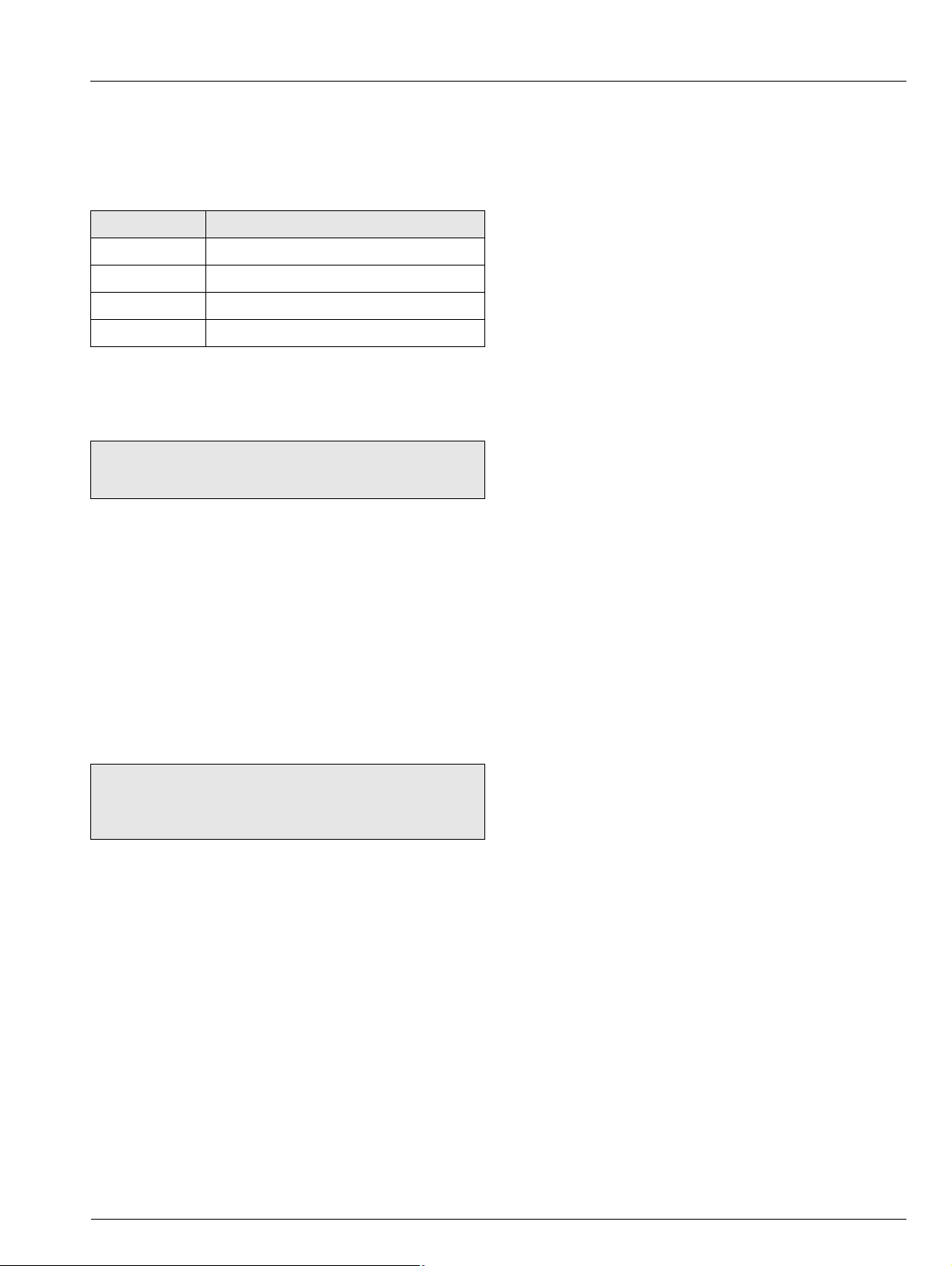

Ty pe Extension Contents

Channel

data files

Alarm

event log

files

Totalizer

log files

Audit log

files

Digital

signature

files

Batch

data files

Batch log

files

*.D**

*.E**

*.T**

*.A**

*.S**

*.V* Analog or digital recording channels in the

*.X* Historical record of the batches recorded.

Analog or digital recording channels in the

current process group.

The historical record of the alarm events

related to the group's channels plus the history

of any operator messages, electronic

signatures or real time alarms.

The historical record of all totalizer and

associated statistical values relating to the

group's recording channels.

The historical entries from the audit log.

(Note. The content of this file is the same for

all groups).

Digital signature file for the corresponding

channel data file.

current process group when the batch

function is active.

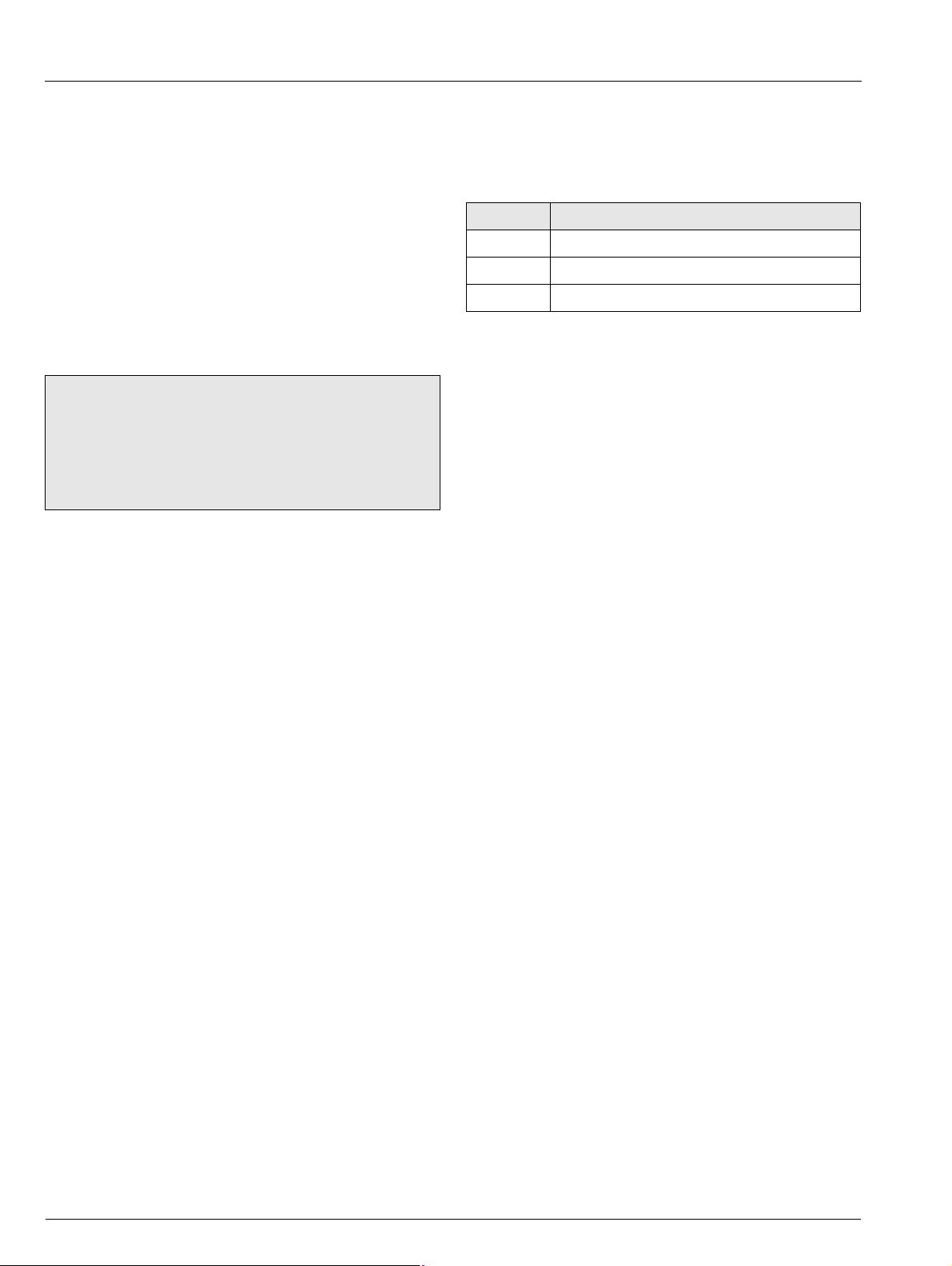

Ty pe Extension

Channel

data files

Batch

channel

data files

Alarm

event log

files

Totalizer

log files

Audit log

files

Batch log

files

*Batch files are created only if the Batch Recording software option is

enabled.

*.B00

*.V**

*.EE0

*.TE0

*.AE0

*.X**

Table 3.2 Binary Encoded Format File Types and Extensions

No. of

Files

One per

channel

One per

channel

One per

process

group

One per

process

group

One per

instrument

One per

process

group

Contents

Analog or digital recording

channel data

Batch recording channel data *.

The historical record of the alarm

events related to a particular

process group's channels plus the

history of any operator messages,

electronic signatures or real time

alarms.

The historical record of all totalizer

and associated statistical values

relating to a particular group's

recording channels.

The historical entries from the

audit log.

Batch information associated with

a process group *.

Table 3.1 Text Format File Types and Extensions

36 IM/SM2000 Issue 13

Page 39

Advanced Videographic Recorder

SM2000 3Setup

3.6 Text Format Archive Files

3.6.1 Text Format Channel Data Files

Text format channel data files can be configured to contain data

gathered over a predefined period of time using the 'New File

Interval' setting – see Table 3.3.

New File Interval Filename

Hourly <hour> <day, month, year>* <filename tag>

Daily <day, month, year>* <filename tag>

Monthly <month, year>* <filename tag>

None <filename tag>

* Formatted according to the date format set in Common

Configuration – see Section 4.4.3, page 54

Table 3.3 New Text File Intervals

Note. The 'New File Interval' is set in the Configuration level

– see Section 4.5.6, page 75.

In addition to new channel data files being created according to

the New File Interval selection, they are also created in the

following circumstances if automatic update is enabled and the

media is on-line or if a manually triggered update is in progress:

The instrument's power is lost then restored.

The instrument is taken offline and the archive media

removed, replaced or refitted.

The instrument's configuration is changed.

One of the current files exceeds the maximum permissible

size.

When the daylight saving period starts or ends.

Files containing data generated during the daylight saving period

(summertime) have '~DS' appended to the filename.

Example 1 – Start of daylight saving period:

A daily file is started at 00:00:00 on 30th March 2003 –

filename: 30Mar03ProcessGroup1.D00.

Summertime starts at 2:00am on 30th March 2003.

The clock changes automatically to 3:00am.

The existing file is closed and a new file is created –filename:

30Mar03ProcessGroup1~DS.D00.

The file '30Mar03ProcessGroup1.D00' contains data

generated from 00:00:00 to 01:59:59 (before summertime

starts).

The file '30Mar03ProcessGroup1~DS.D00' contains data

generated from 03:00:00 (after summertime starts).

Example 2 – End of daylight saving period:

A daily file is started at 00:00:00 on 26th October 2003 –

filename: 26Oct03ProcessGroup1~DS.D00

Summertime ends at 3:00am on 26th October 2003.

The clock changes automatically to 2:00am.

The existing file is closed and a new file is created –filename:

26Oct03ProcessGroup1.D00

The file '26Oct03ProcessGroup1~DS.D00' contains data

generated from 00:00:00 to 02:59:59 (before summertime

ends).

The file '26Oct03ProcessGroup1.D00' contains data

generated from 02:00:00 (after summertime ends)

Note. The instrument's internal clock can be configured to

adjust automatically at the start and end of Daylight Saving

Time (Summertime) periods – see Section 4.4.3, page 54.

When one of these conditions occurs, new channel data files

are created for each enabled group and the file extension index

on each new file is incremented by one from the previous file.

Example – if the original file had an extension of .D00, after

one of the above events a new file will be created with the

same filename but an extension of .D01.

IM/SM2000 Issue 13 37

Page 40

Advanced Videographic Recorder

SM2000 3Setup

3.6.2 Text Format Filename Examples

'New file interval' set to 'Hourly', 'Filename tag' set to 'Process

Group 1' (see Section 4.5.6, page 73); date is 10th October

2000; Channel data and alarm event log files only enabled:

9:00 amNew file created in which all channel data recorded

between 9:00 and 9:59:59 is archived in the following file:

09_00_10Oct00_Process_Group_1.d00

09:12amPower interrupt occurs

09:13amPower restored and new file created:

09_00_10Oct00_Process_Group_1.d01

10:00amNew file created in which all data recorded between

10:00 and 10:59:59 is archived.

10_00_10Oct00_Process_Group_1.d00

Note.

Hourly files start exactly on the hour.

Daily files start at 00:00:00.

Monthly files start at 00:00:00 on the first of the

month.

3.6.3 Text Format Log files

The Alarm Event and Totalizer Logs for each Process Group and

the Audit Log are archived into individual files. The filenames are

formatted as shown in Table 3.4 with the date and the time

indicating the first entry in the file.

Log File Filename

Alarm Event <hour min> <dd, mm, yy>* <process group tag>.e00

Totalizer <hour min> <dd, mm, yy>* <process group tag>.t00

Audit <hour min> <dd, mm, yy>* <instrument tag>.a00

* Formatted according to the date format set in Common

Configuration – see Section 4.4.3, page 54.

Table 3.4 Log File Formats

If one of the archive log files becomes full (>64000 entries) a

new file is created with an extension incremented by 1, e.g. a01,

e01 etc.

New text format log data files are also created when the daylight

saving period starts or ends.

Files containing log data generated during the daylight saving

period (summertime) have '~DS' appended to the filename.

38 IM/SM2000 Issue 13

Page 41

Advanced Videographic Recorder

SM2000 3Setup

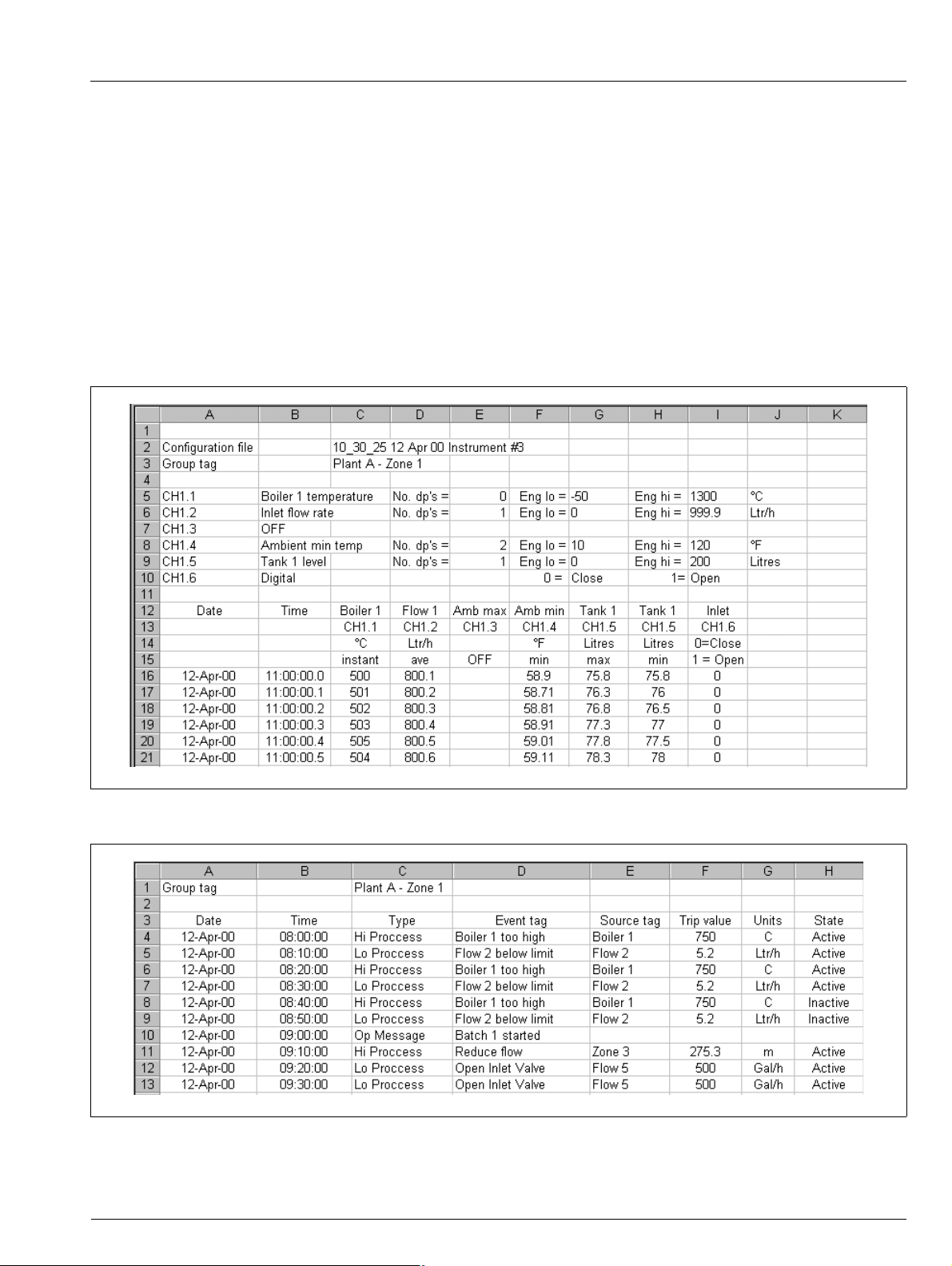

3.6.4 Text Format Data File Examples – Figs. 3.5 to 3.8

Text format archived data is stored in a comma separated value

(*.csv) format so that it can be imported directly into a standard

spreadsheet, e.g. Microsoft Excel™ and Lotus 1-2-3™. The

files can also be read as an ASCII text file by a text viewer. When

imported into a spreadsheet, the files appear as shown in Figs.

3.5 to 3.8.

Alternatively, detailed graphical analysis of the data can be

carried out on a PC using the Company's DataManager data

analysis software package.

3.6.5 Text Format Data File Digital Signatures – Fig. 3.5

A digital signature file is created for each channel data file using

the same filename but with a *.S** extension. The file contains a

unique 'fingerprint' of the contents of the data file that can be

used to prove if the data has been tampered with or corrupted.

Data validation can be carried out on a PC using the Company's

DataManager software package.

3.6.6 Text Format Data Verification and Integrity

When data is saved to the archive media it is checked

automatically to verify that the date value stored on the media

matches exactly the date value stored in the internal memory.

Fig. 3.5 Channel Data File Sample – Text Format

Fig. 3.6 Alarm Event Log Sample – Text Format

IM/SM2000 Issue 13 39

Page 42

Advanced Videographic Recorder

SM2000 3Setup

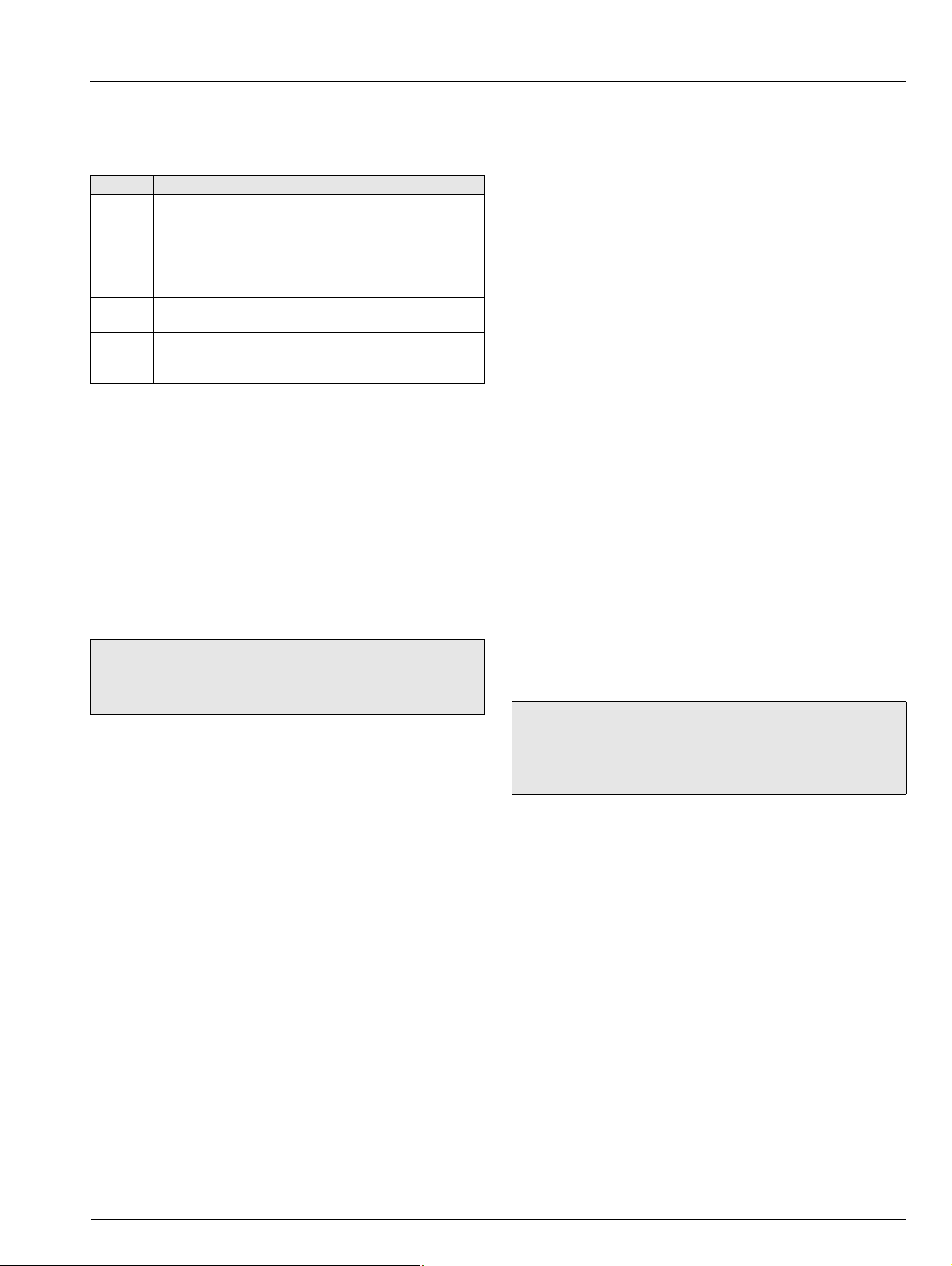

Fig. 3.7 Totalizer Log Sample – Text Format

Fig. 3.8 Audit Log Sample – Text Format

40 IM/SM2000 Issue 13

Page 43

Advanced Videographic Recorder

SM2000 3Setup

3.7 Binary Format Archive Files

3.7.1 Binary Format Archive Filenames

Examples of binary archive filenames are shown in Table 3.5.

Ty pe Format

Channel

data files

Alarm

event log

files

To ta li ze r

log files

Audit log

files

<Start Time HHMMSS><Start Date

DDMMMYY>Ch<Group>_<Channel><Instrument tag>

e.g. 14322719Dec03Ch1_2Boiler room3

<Start Time HH_MM><Start Date DDMMMYY><Process

Group Tag> e.g. 14_3219Dec03Boiler5

<Start Time HH_MM><Start Date DDMMMYY><Process

Group Tag> e.g. 14_3219Dec03Boiler5

<Start Time HH_MM><Start Date

DDMMMYY><Instrument Tag> e.g. 14_3219Dec03Boiler

room 3

Table 3.5 Binary Archive Filenames

3.7.2 Binary Format Channel Data Files

A new binary format channel data file is created under the

following conditions:

When the current file for a channel does not exist on the

media card.

When the maximum size (5 Mb) of the existing data file is

exceeded.

When the recording channel's configuration is changed.

When the daylight saving period starts or ends.

Note. The instrument's internal clock can be configured to

adjust automatically at the start and end of Daylight Saving

Time (Summertime) periods – see Section 4.4.3, page 54.

Example 2 – End of daylight saving period:

Archiving is started at 00:15:00 on 26th October 2003 –

filename: 00150026Oct03Ch1_1AnlgSM2000~DS.B00.

Summertime ends at 3:00am on 26th October 2003.

The clock changes automatically to 2:00am.

The existing file is closed and a new file is created –filename:

02000026Oct03Ch1_1AnlgSM2000.B00.

The file '00150026Oct03Ch1_1AnlgSM2000~DS.D00'

contains data generated from 00:15:00 to 02:59:59 (before

summertime ends).

The file '02000026Oct03Ch1_1AnlgSM2000' contains data

generated from 02:00:00 (after summertime ends).

3.7.3 Binary Format Log files

A new binary log file is created under the following conditions:

When an existing valid binary log file does not exist on the

media card.

When the maximum size (64000 entries) is exceeded.

When the daylight saving period starts or ends.

Files containing log data generated during the daylight saving

period (summertime) have “~DS” appended to the filename.

3.7.4 Binary Format Data File Examples – Figs. 3.9 to 3.12

Binary format archived data is stored in a secure binary encoded

format. A separate file is created for each recording channel.

The log data is stored in an encrypted text format. The files can

be read on a PC using the Company's DataManager data

analysis software package.

Files containing channel data generated during the daylight

saving period (summertime) have '~DS' appended to the

filename.

Example 1 – Start of daylight saving period:

Archiving is started at 01:45:00 on 30th March 2003 –

filename: 01450030Mar03Ch1_1AnlgSM2000.B00.

Summertime starts at 2:00am on 30th March 2003.

The clock changes automatically to 3:00am.

The existing file is closed and a new file is created –filename:

03000030Mar03Ch1_1AnlgSM2000~DS.B00.

The file '01450330Mar03Ch1_1AnlgSM2000.B00' contains

data generated from 01:45:00 to 01:59:59 (before

summertime starts).

The file '03000030Mar03Ch1_1AnlgSM2000~DS.B00'

contains data generated from 03:00:00 (after summertime

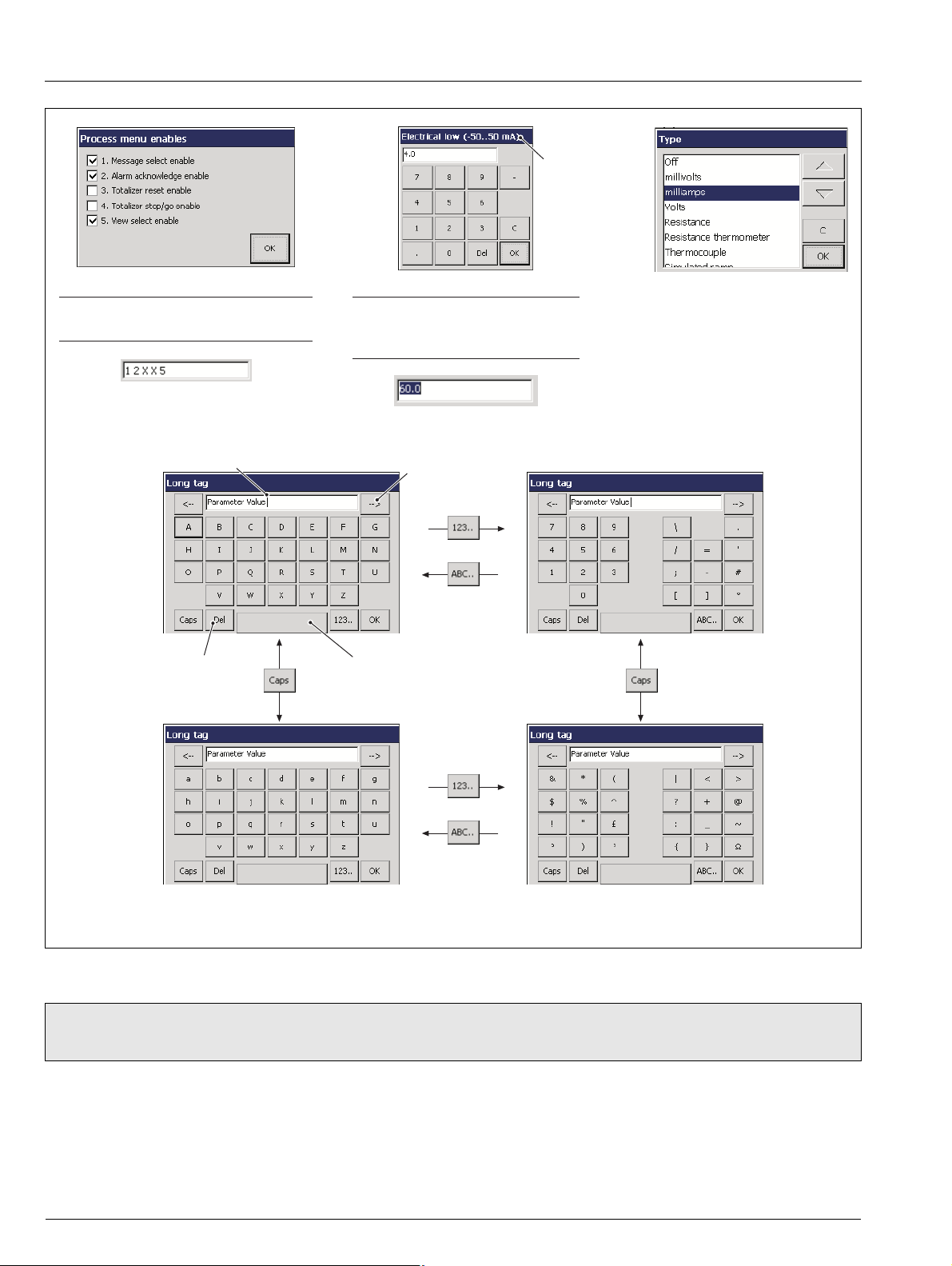

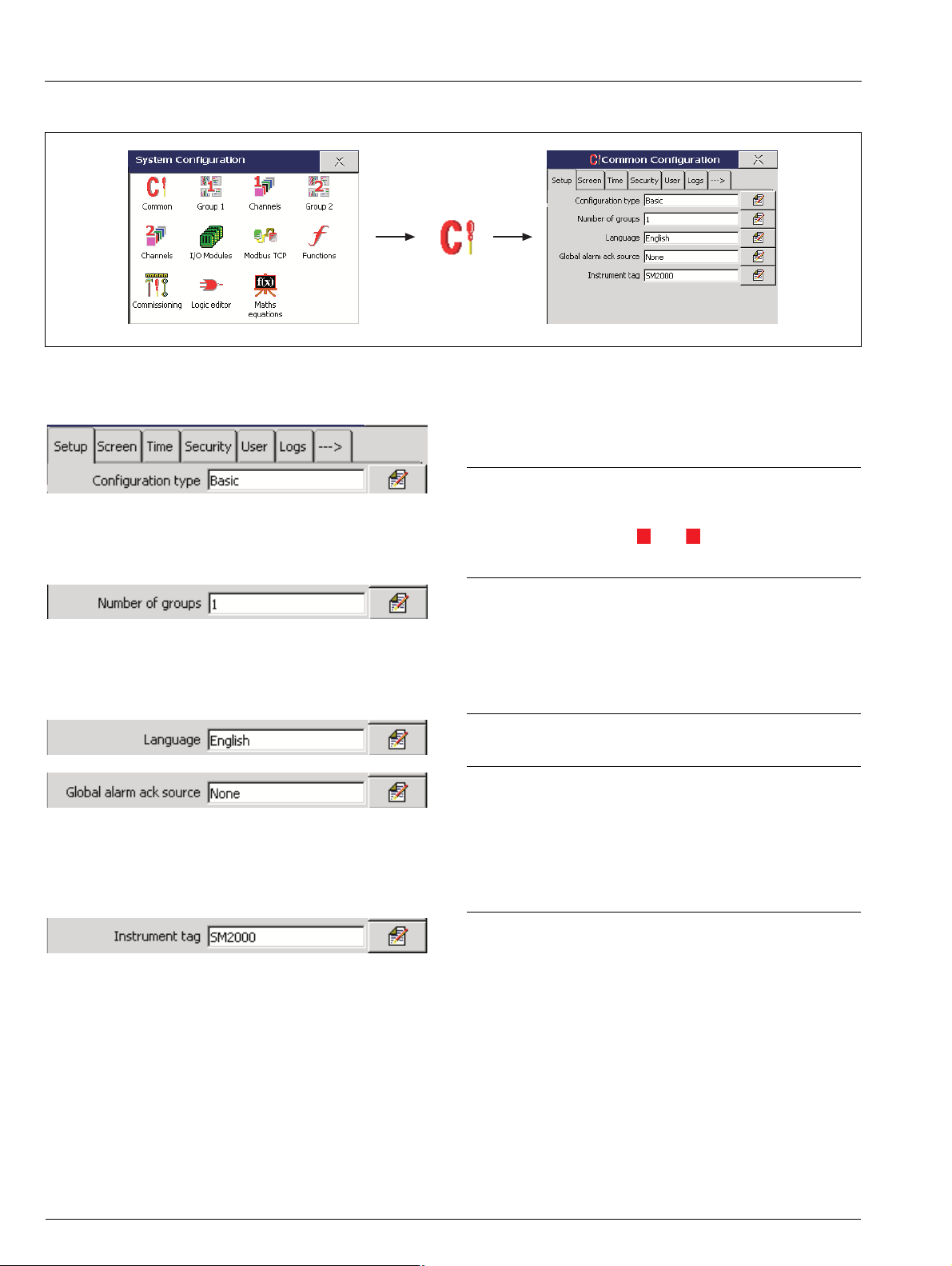

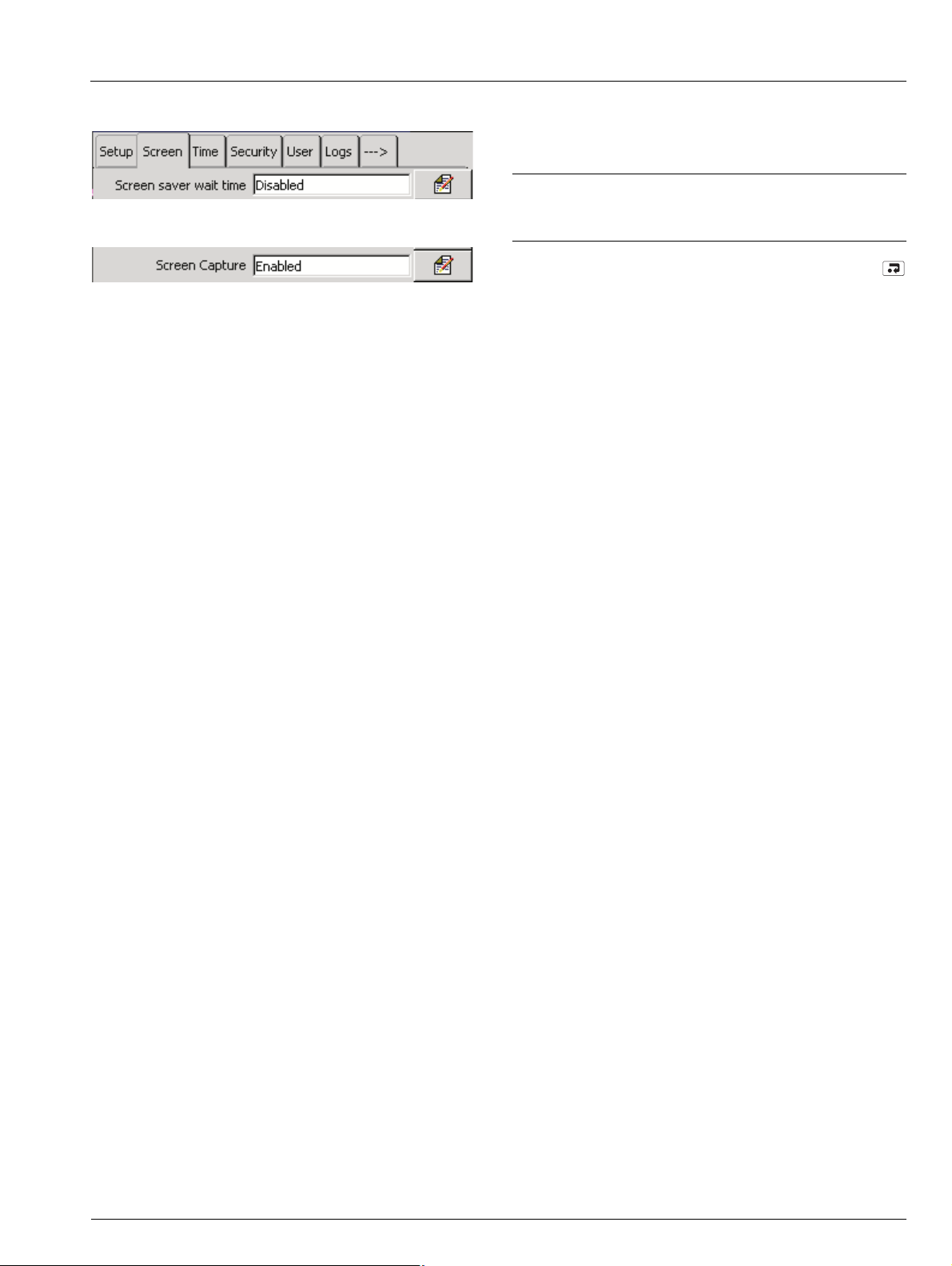

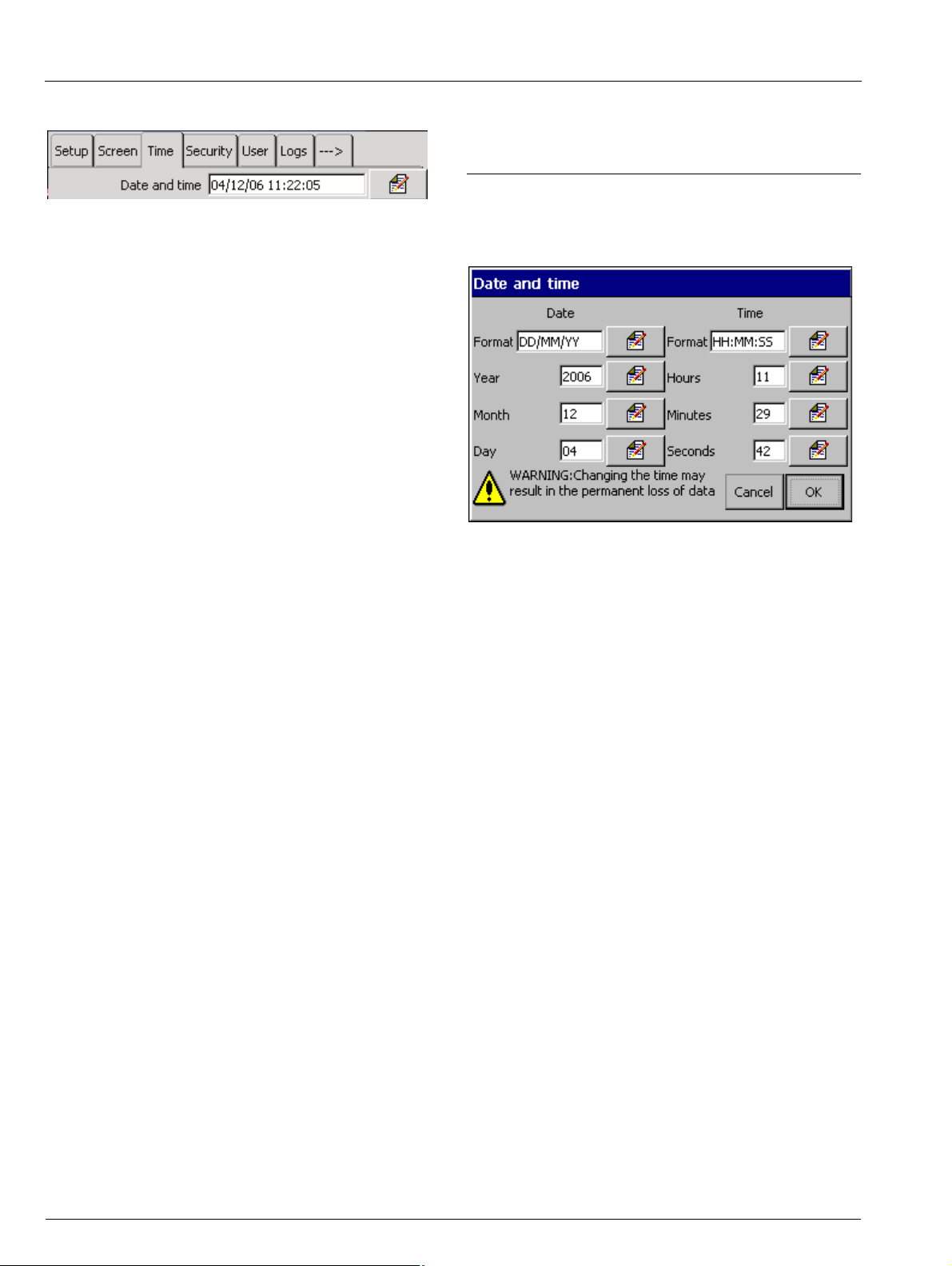

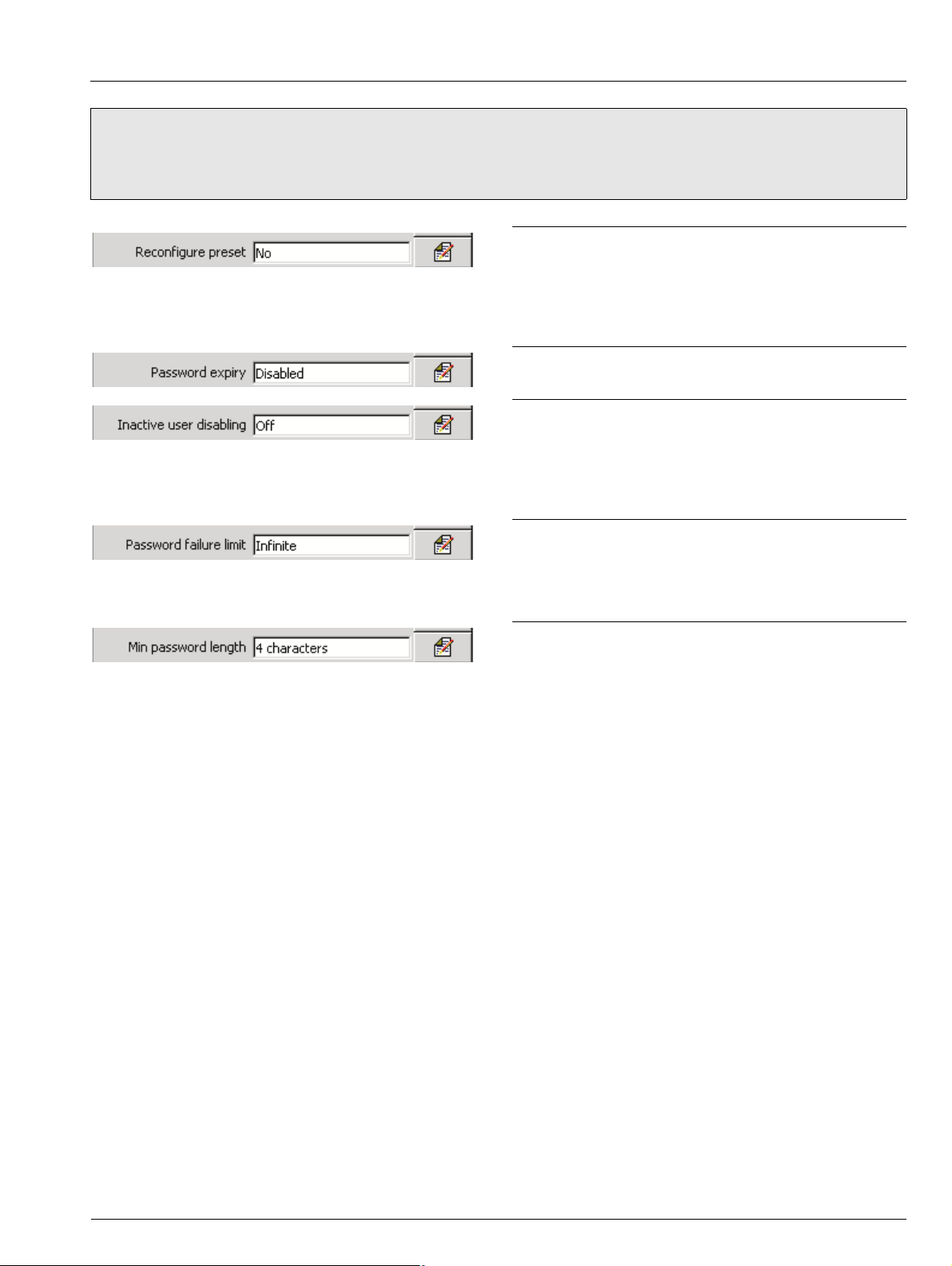

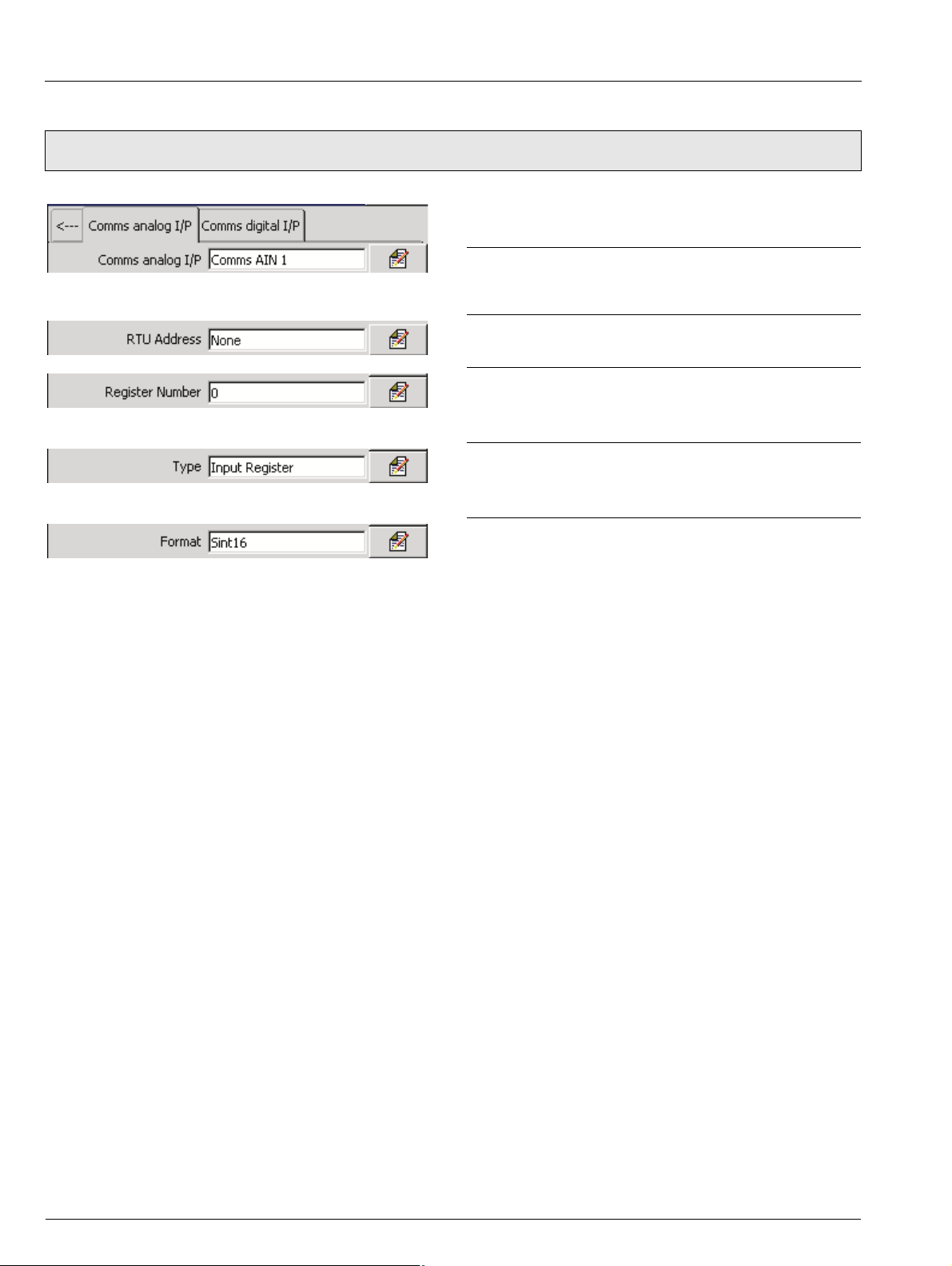

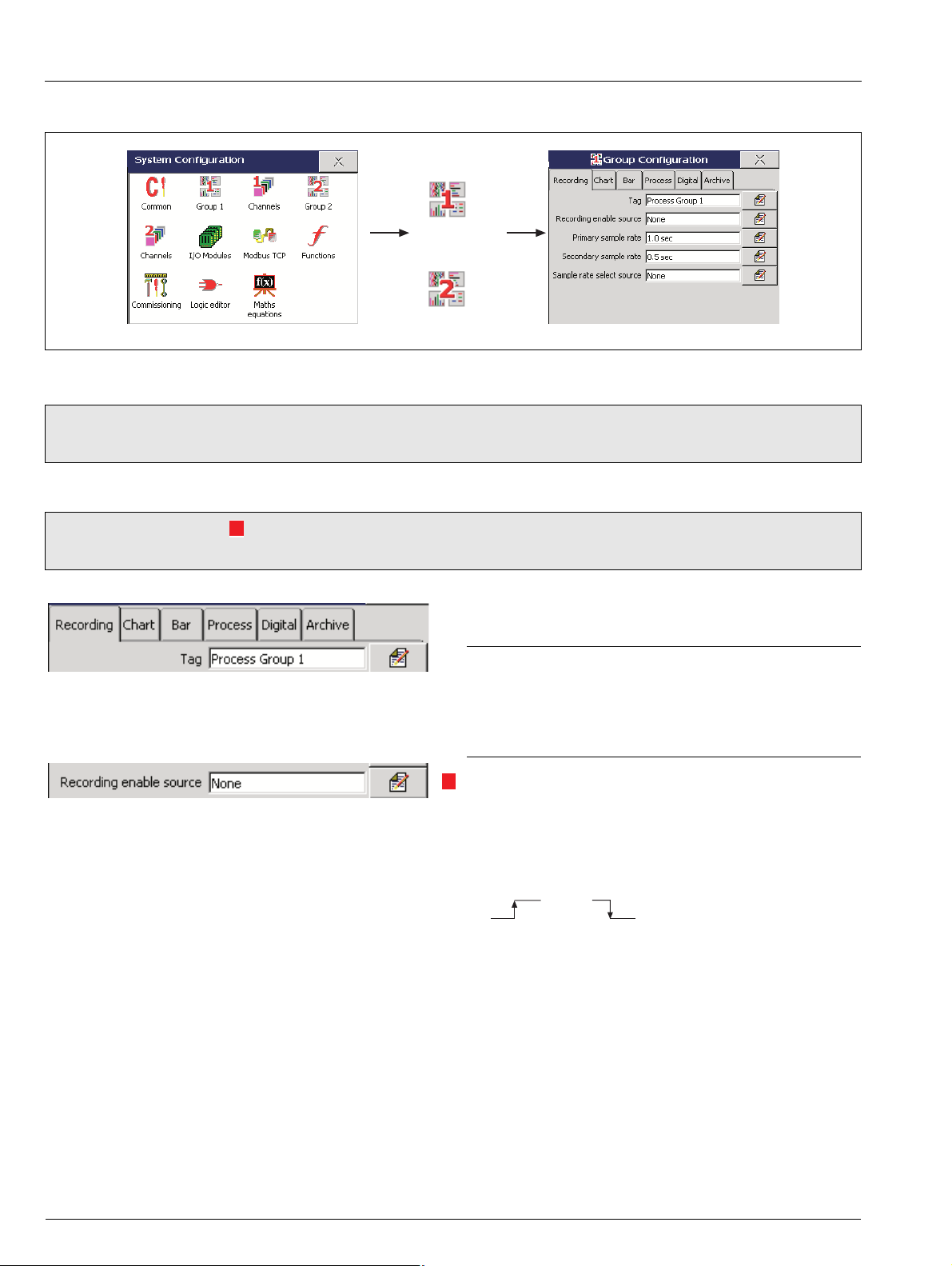

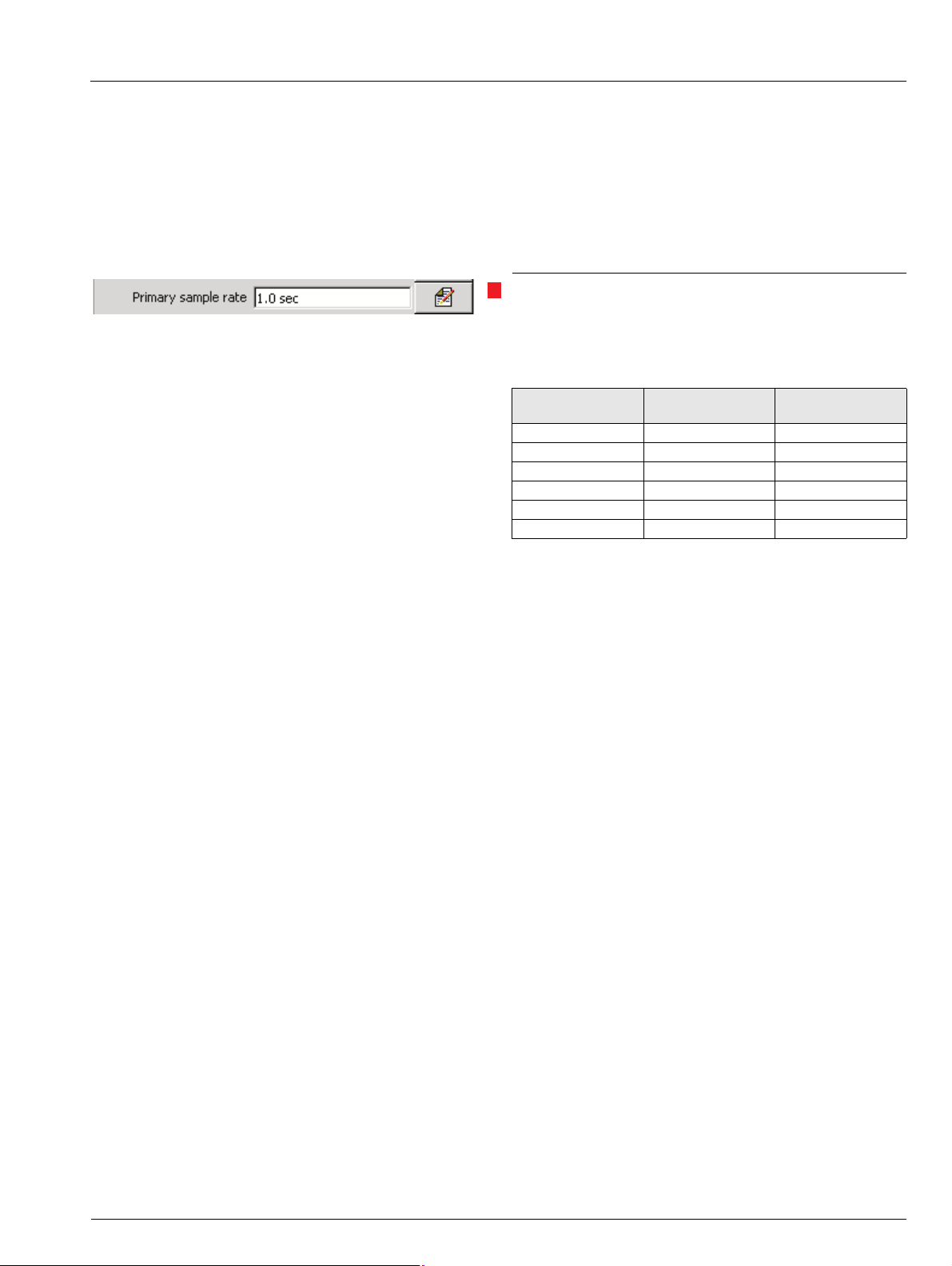

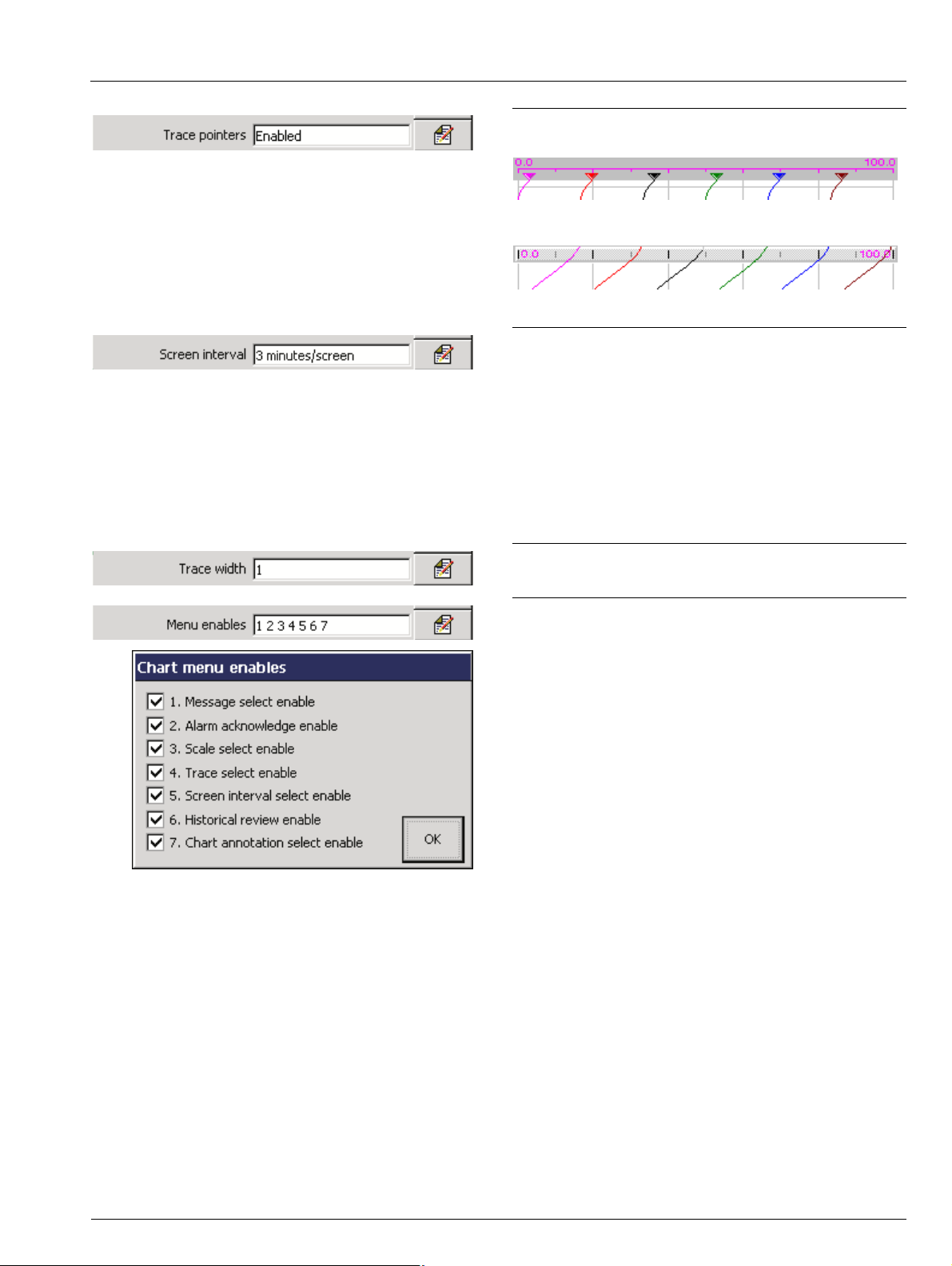

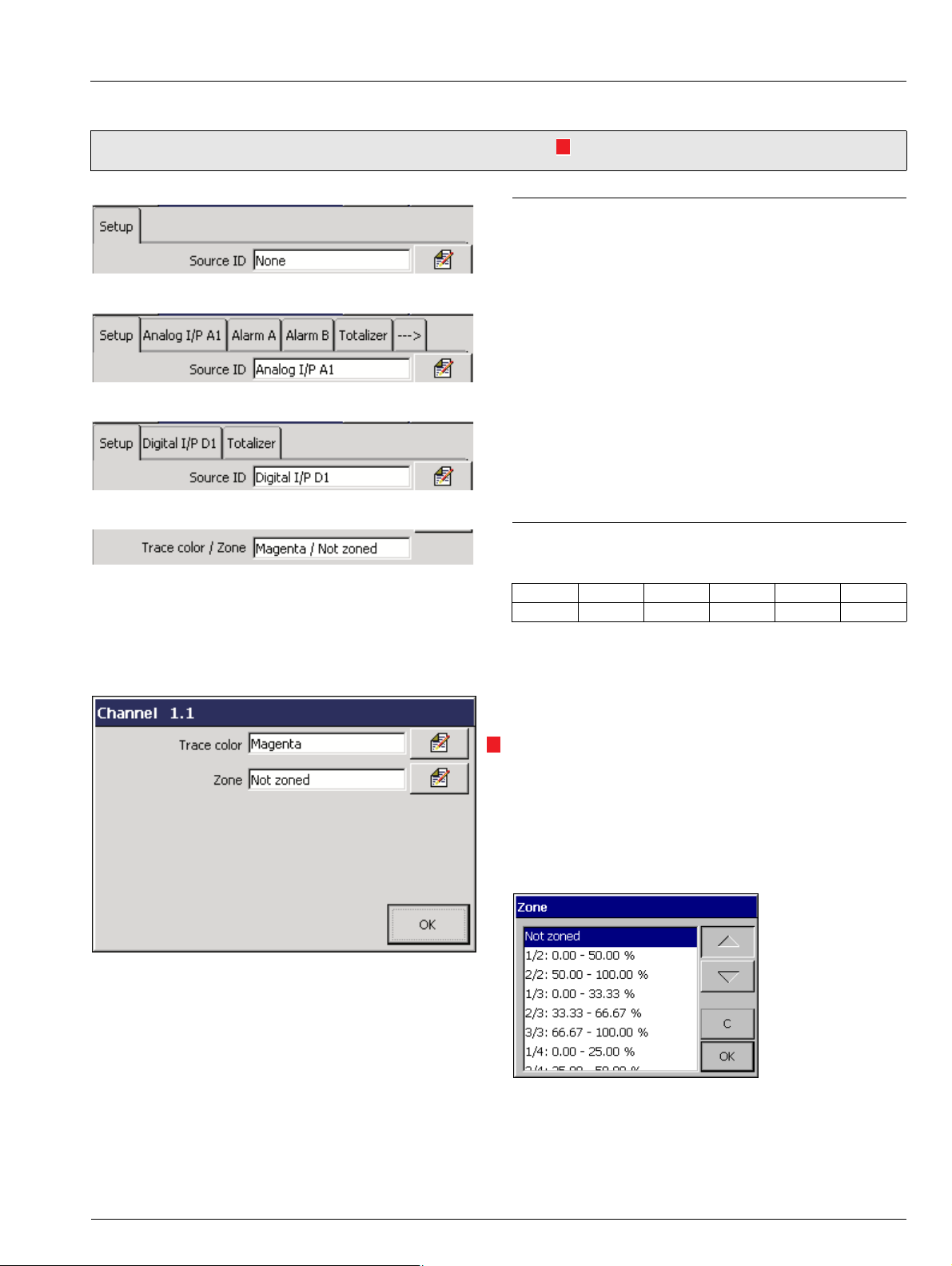

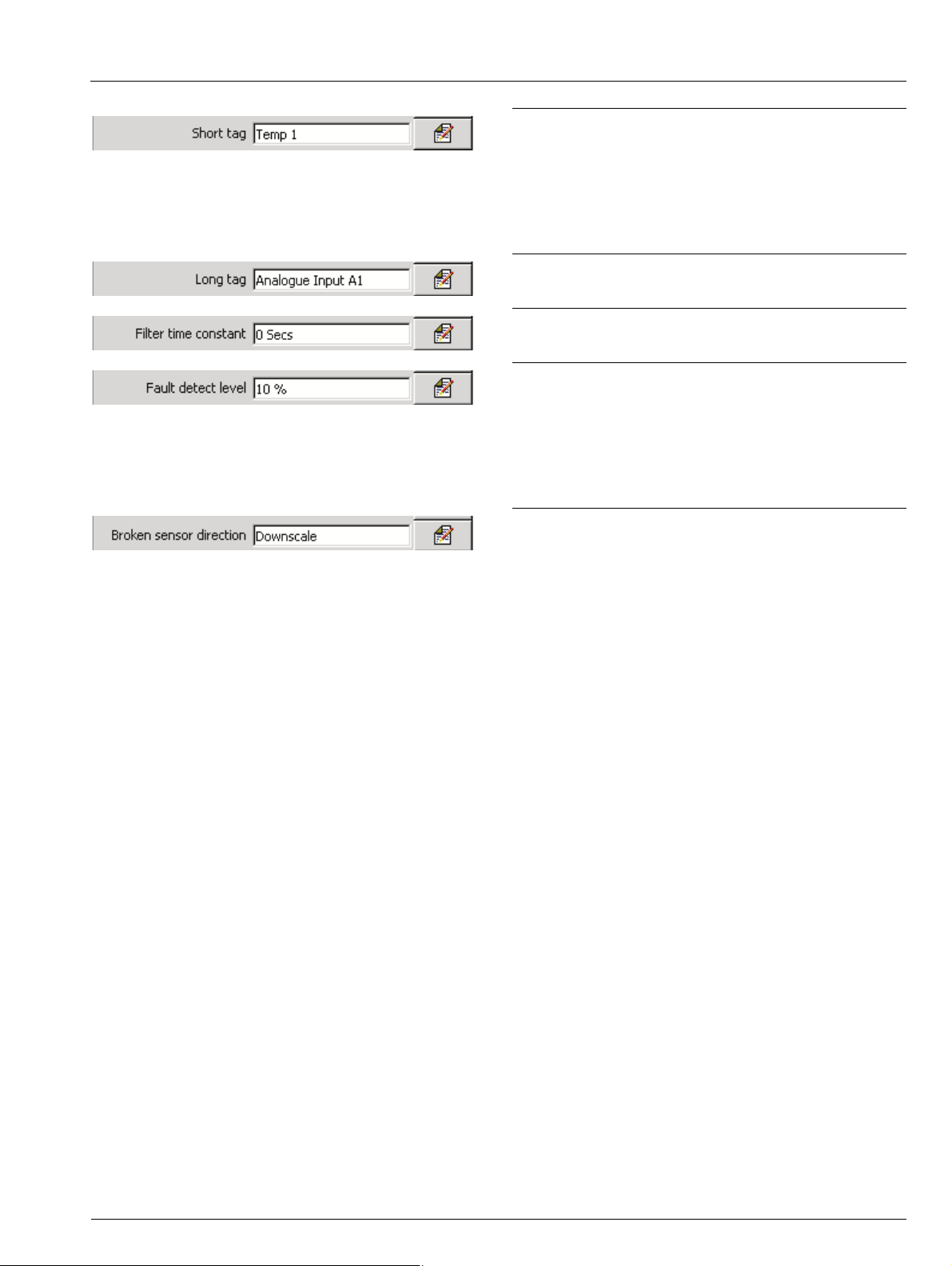

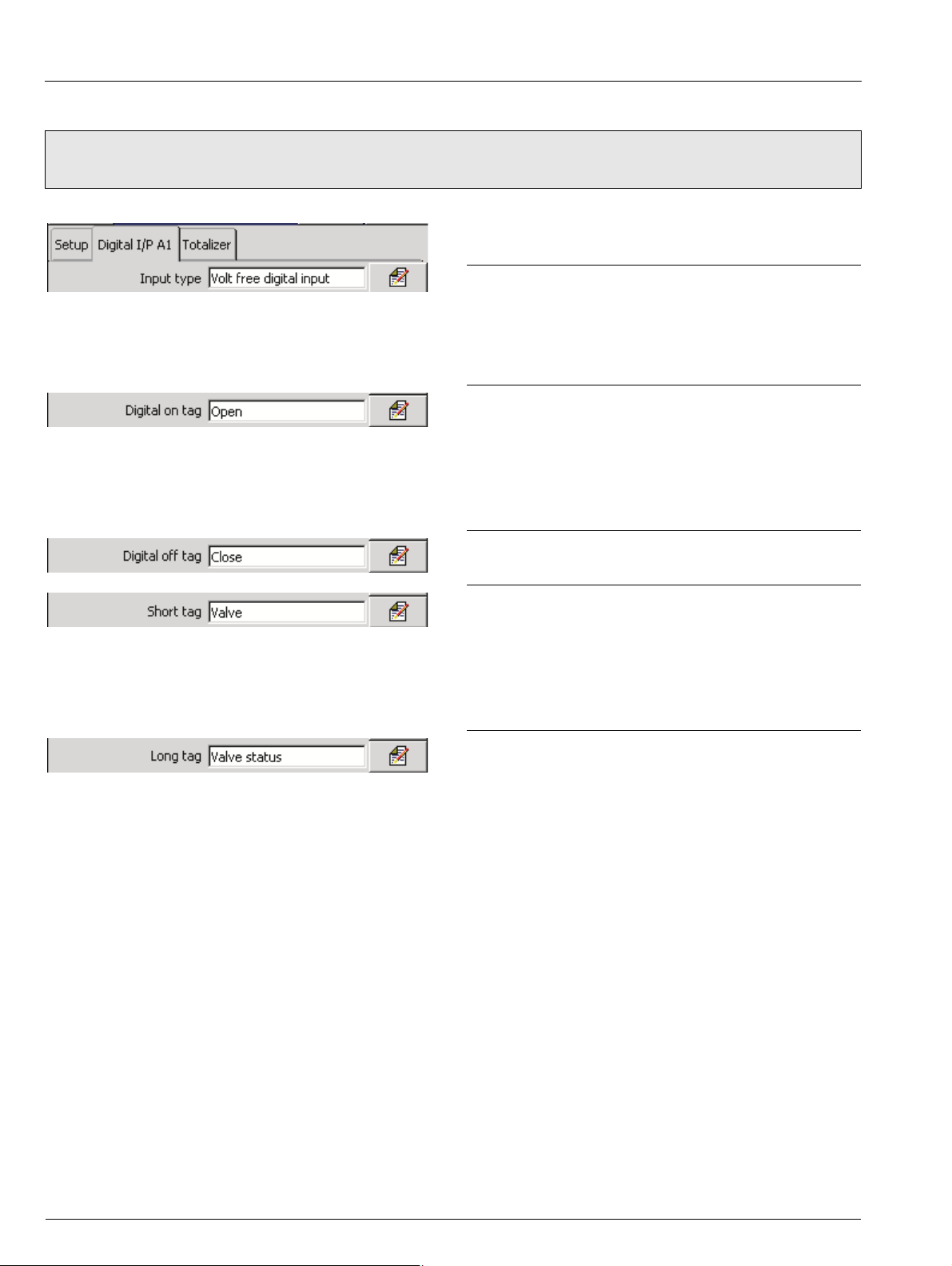

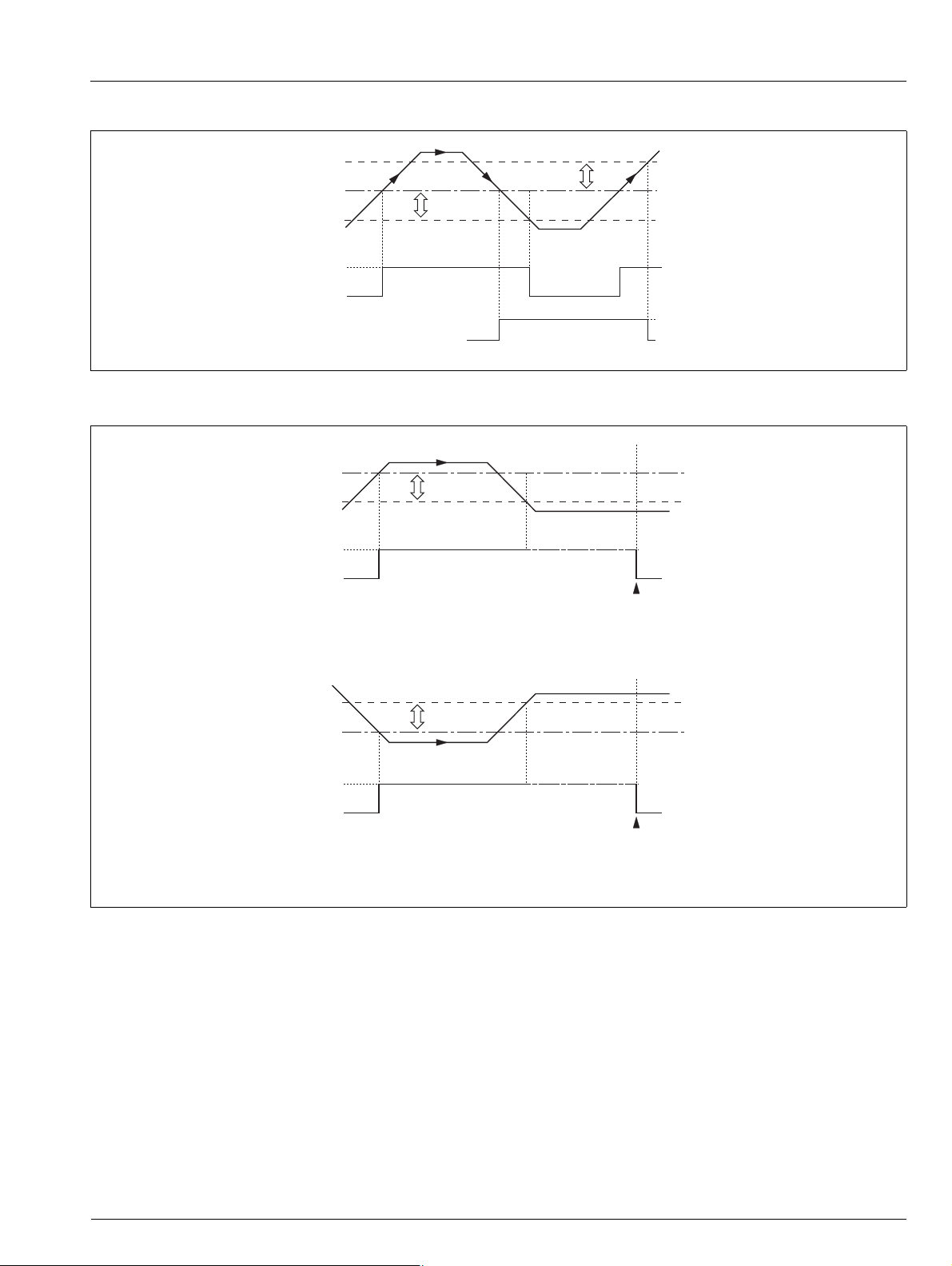

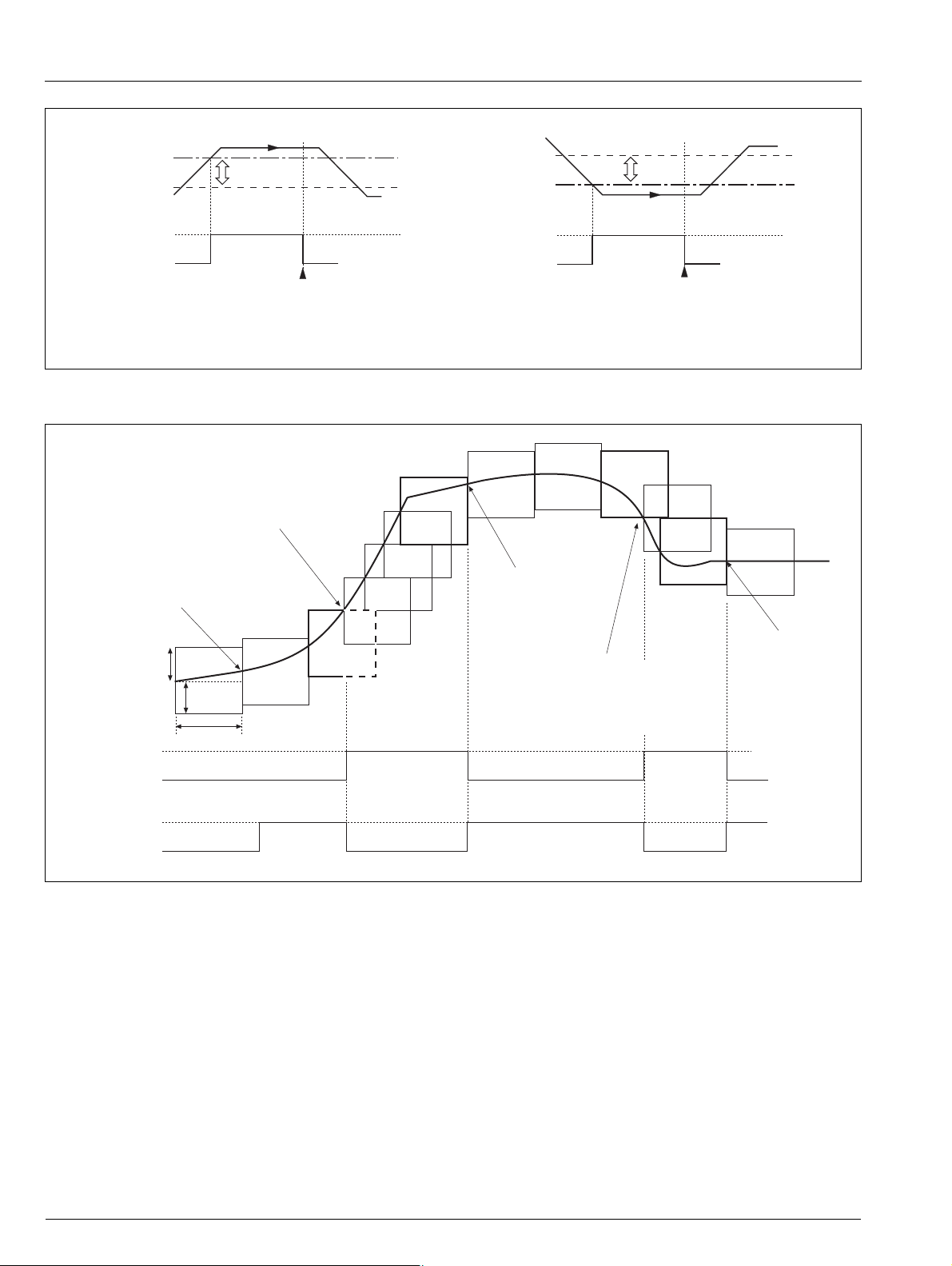

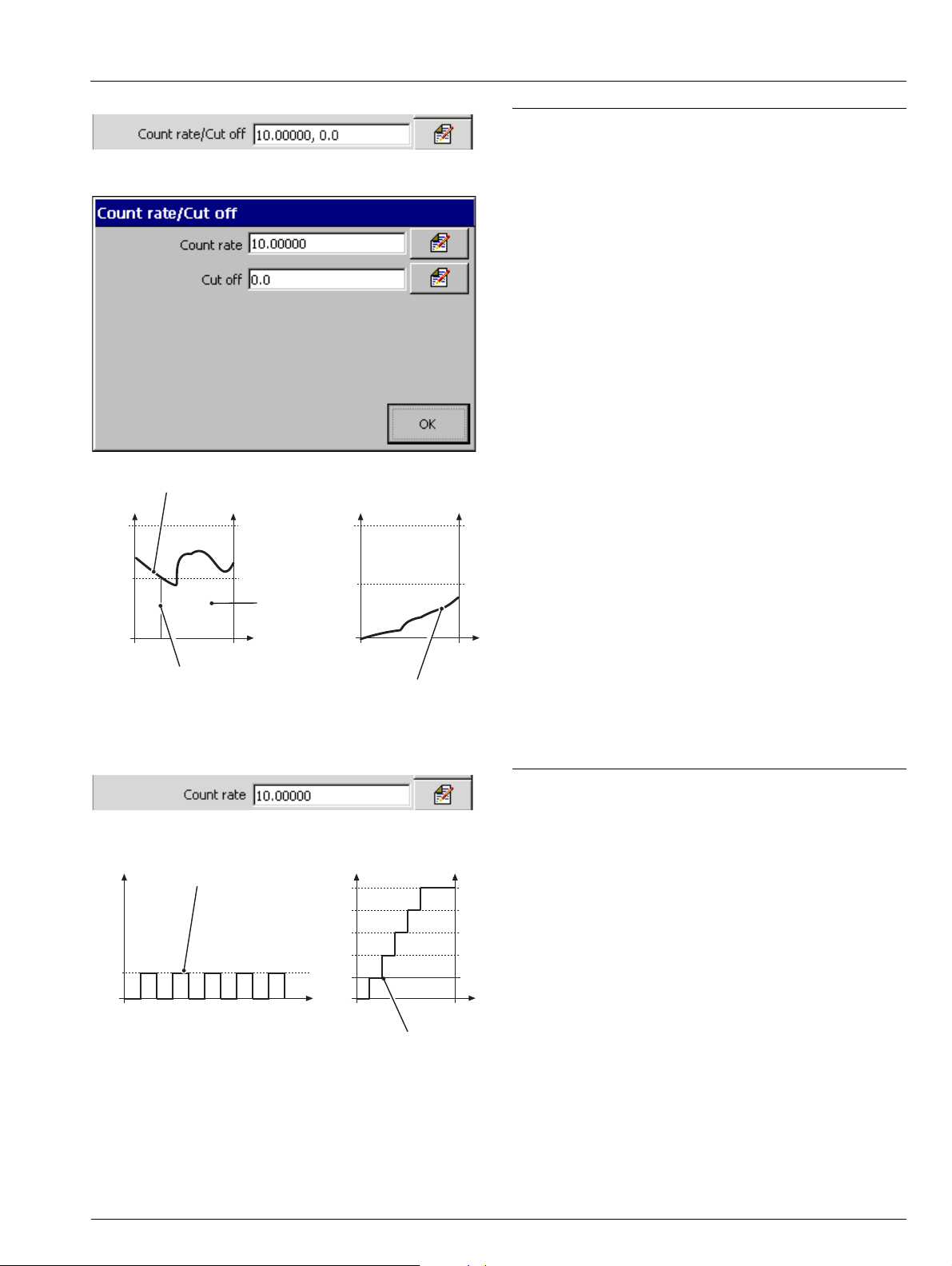

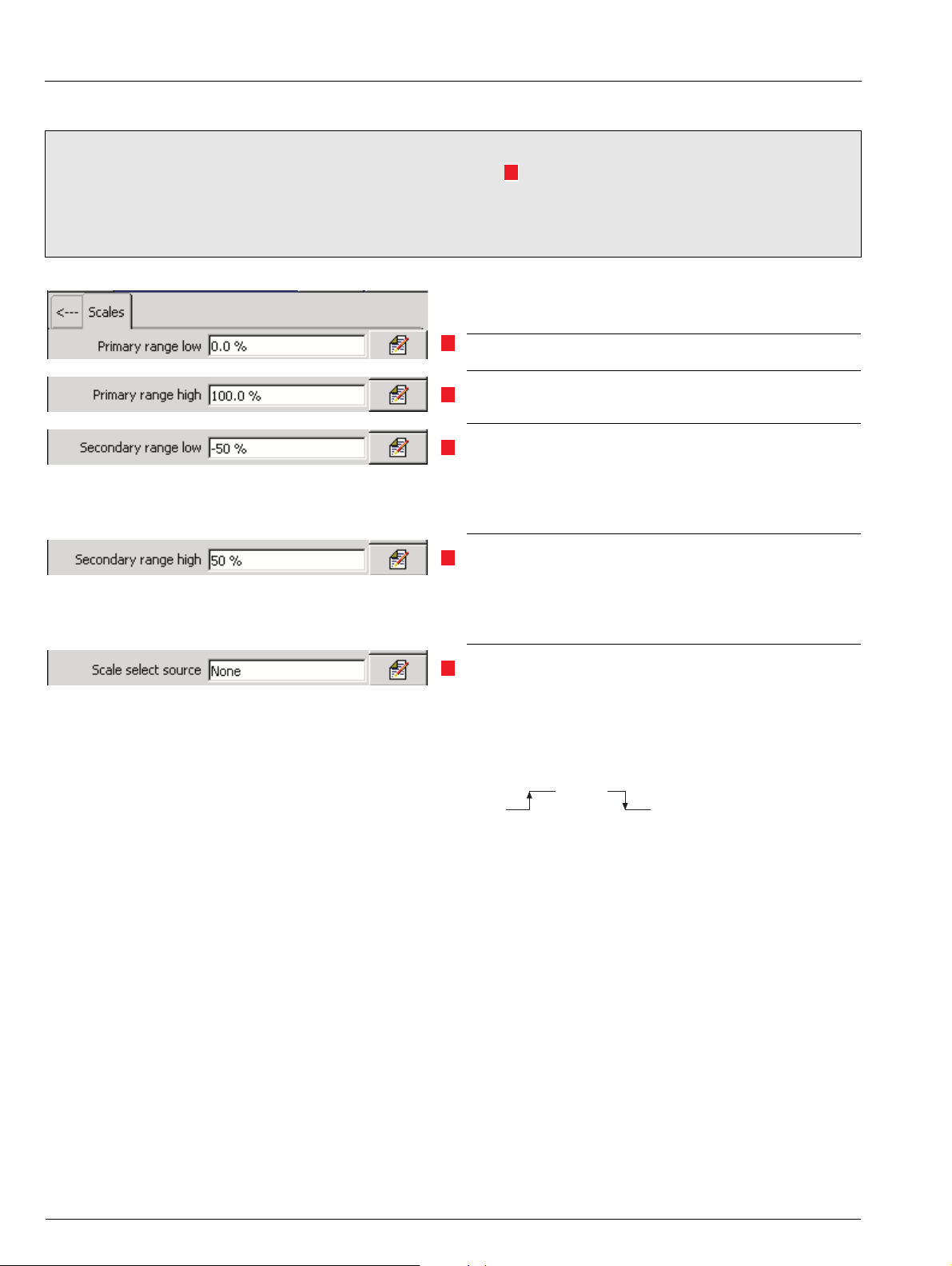

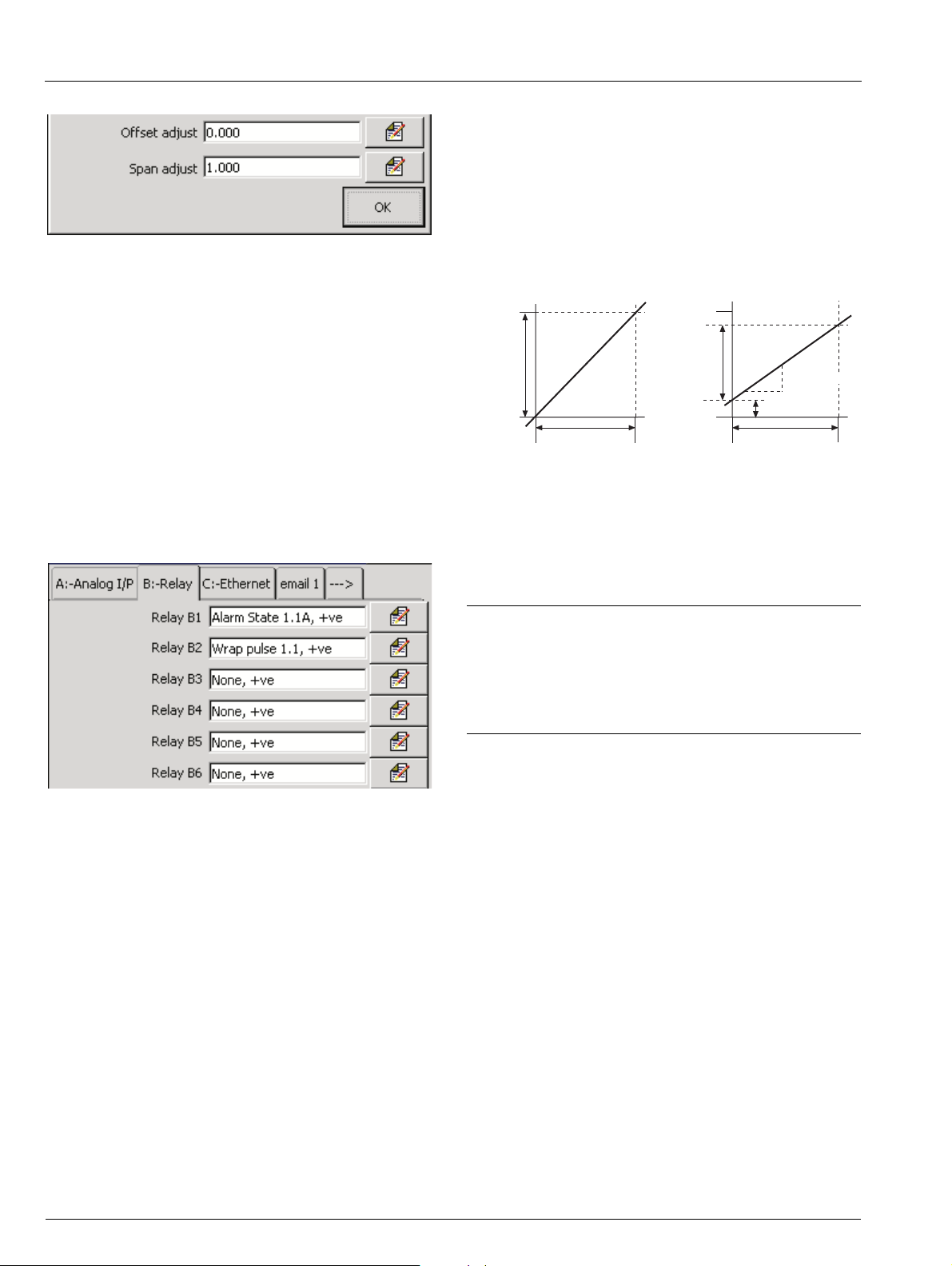

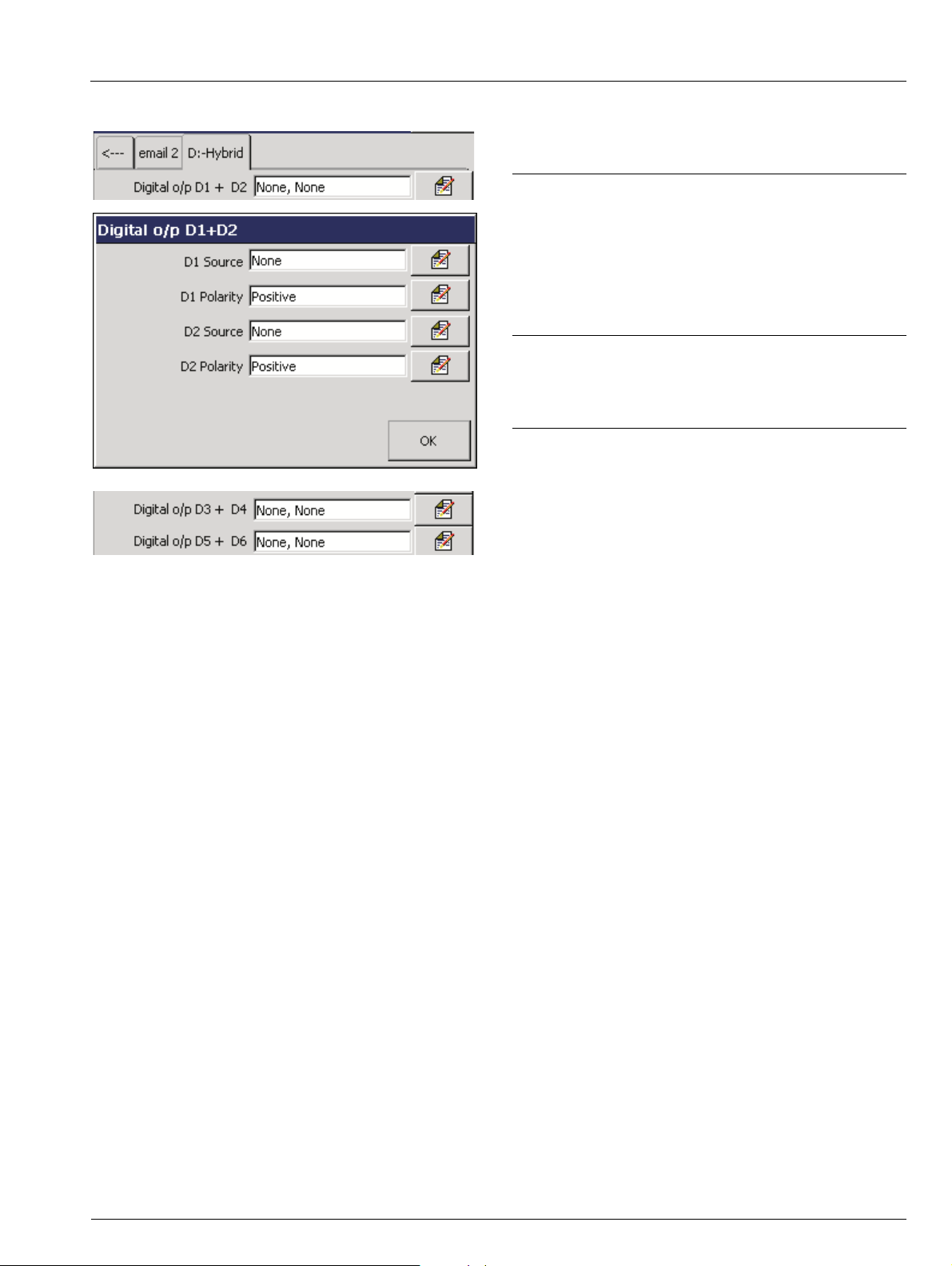

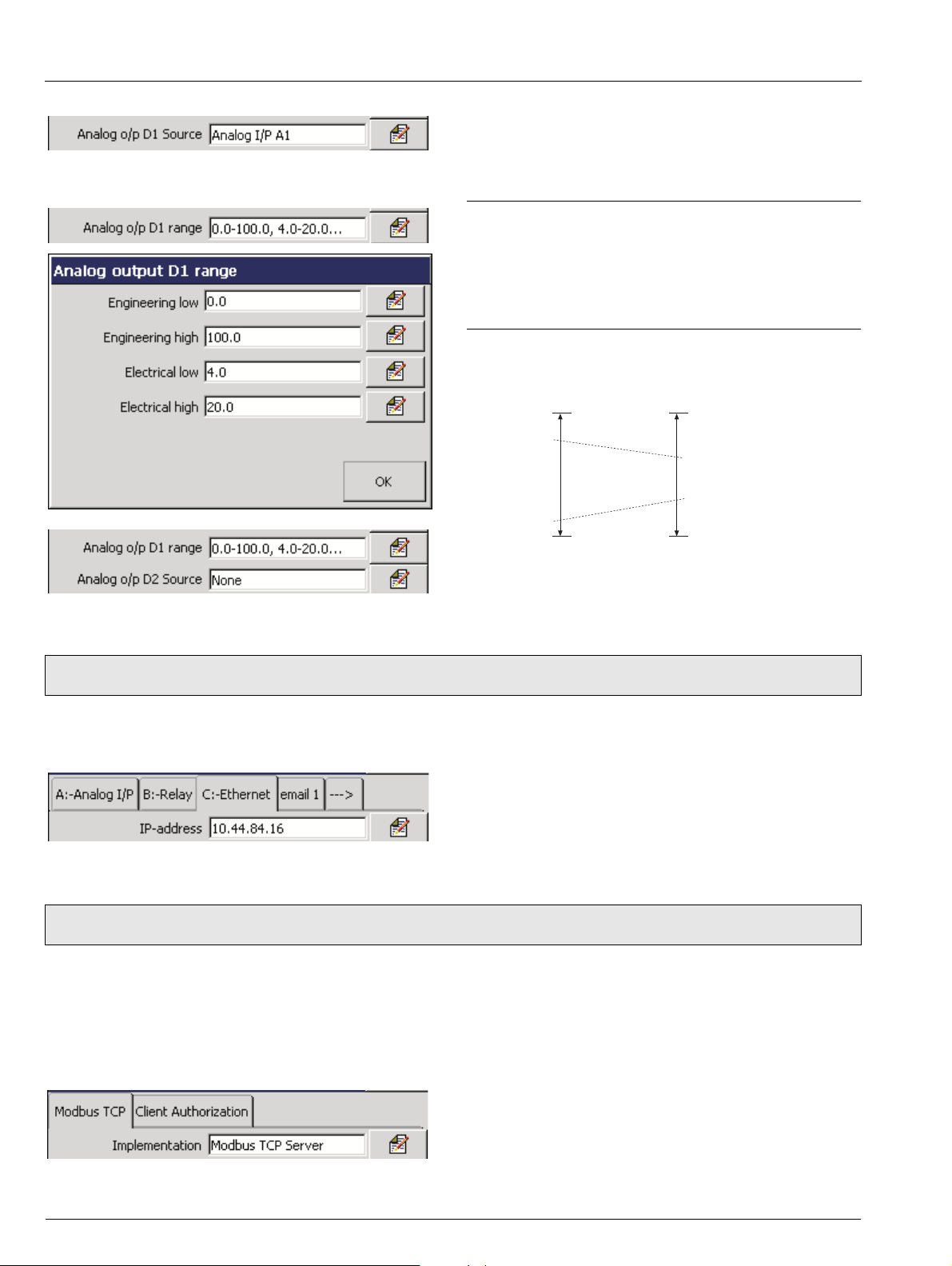

starts).