Page 1

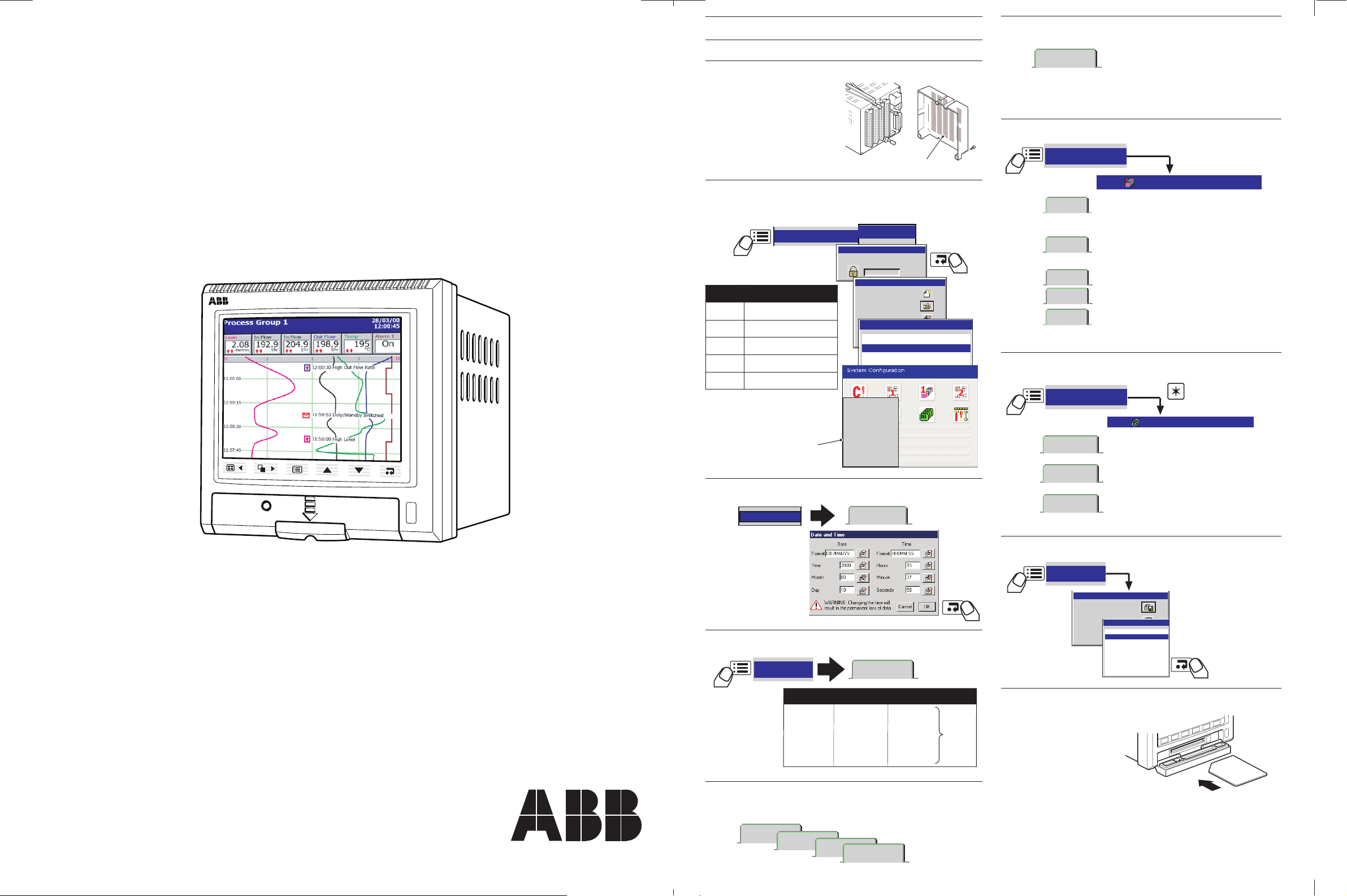

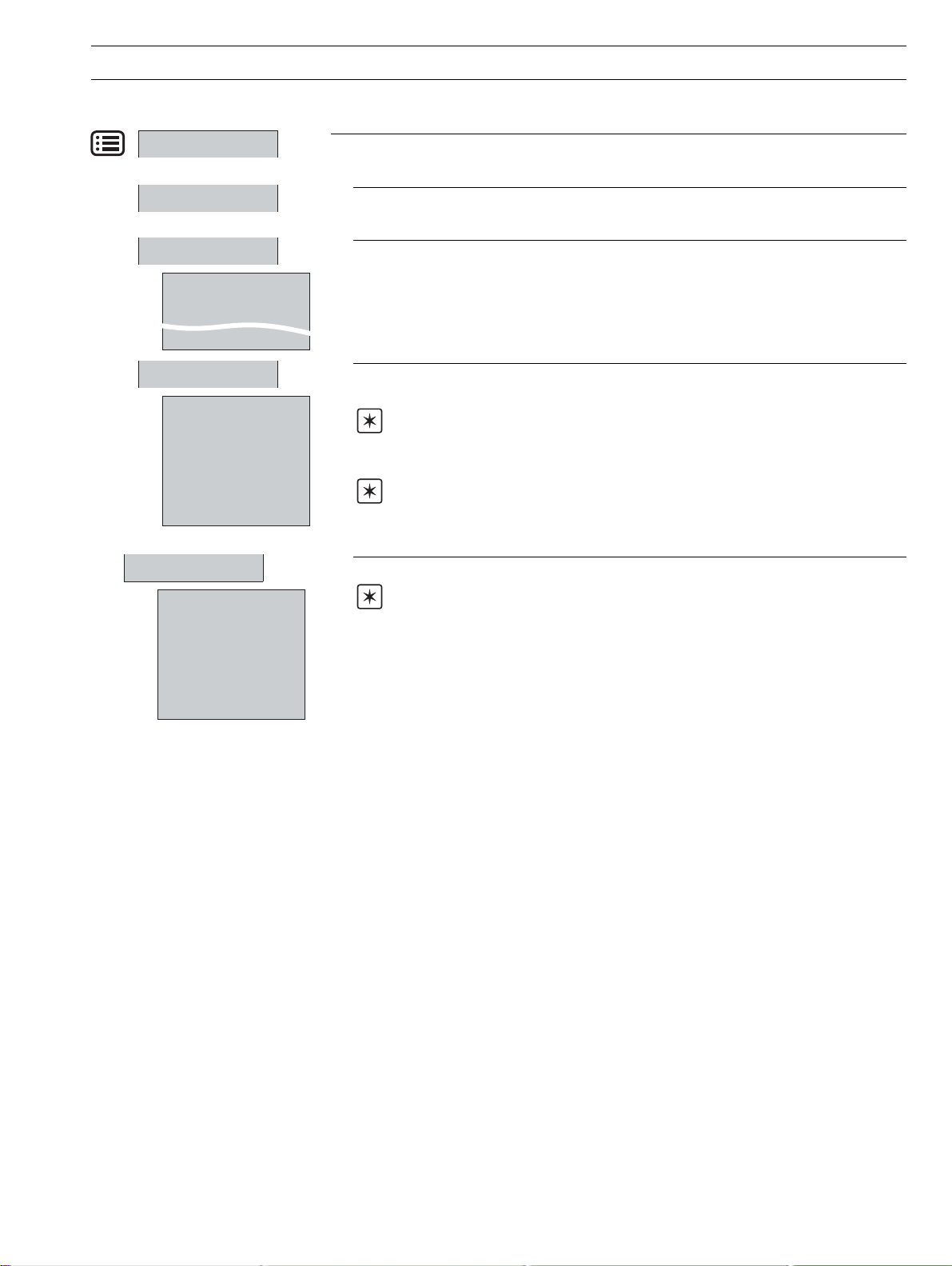

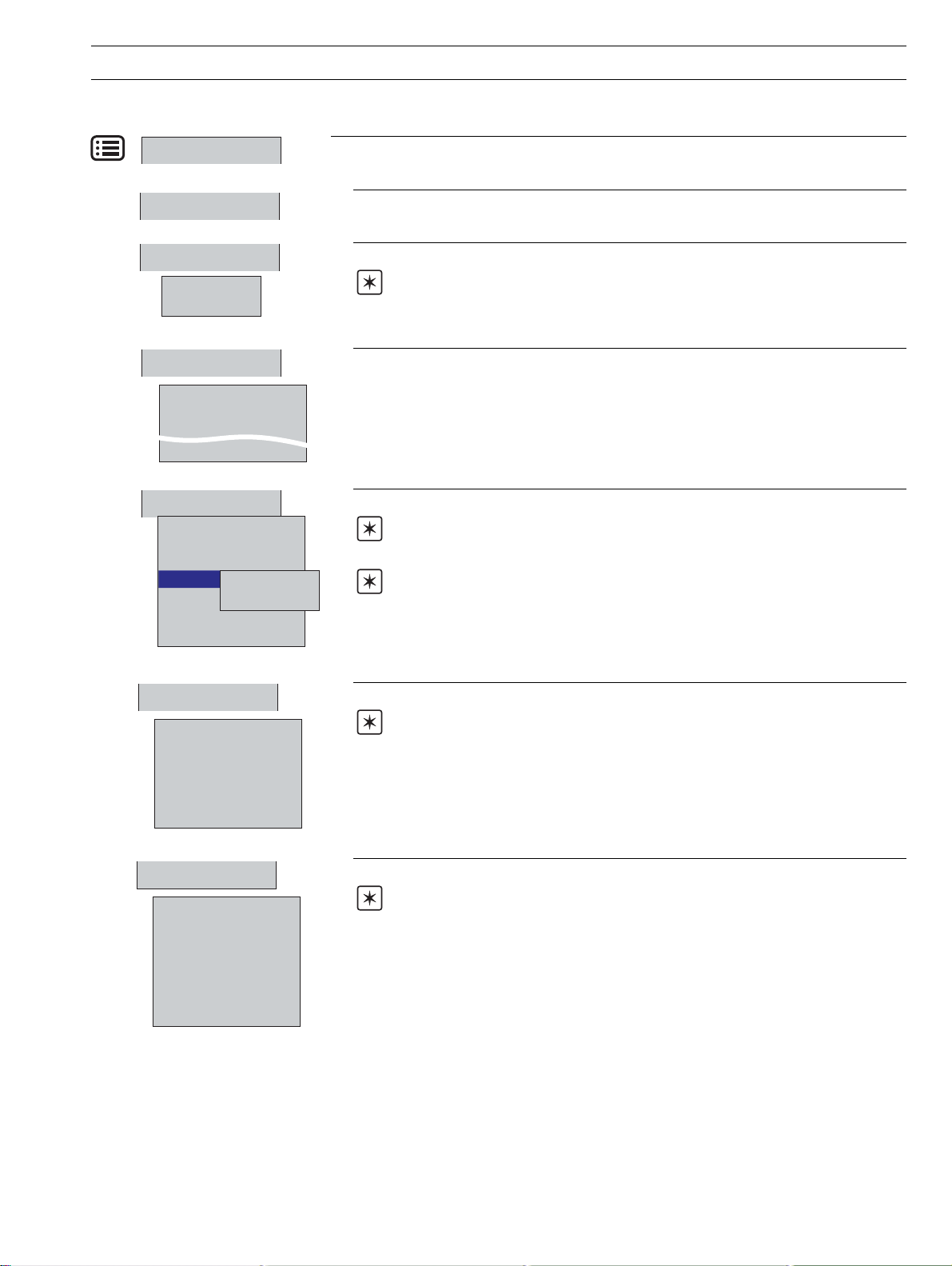

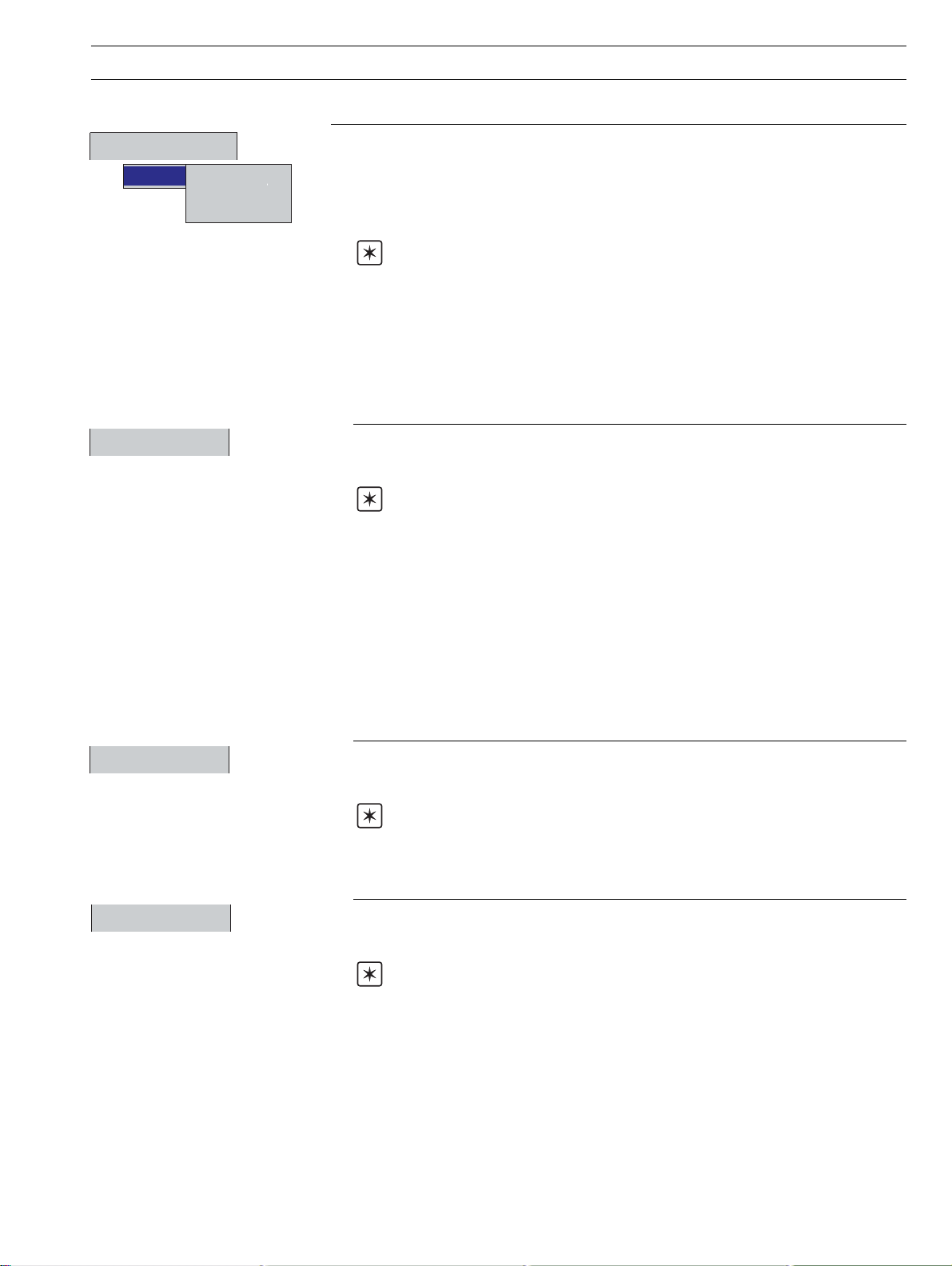

Chart

Digital

Bar

Process

Connection

Details

Insert media to start the archiving process automatically

Archive

• Set the Archive File Enables

– i.e. the files to be archived

• Set the Filename Tag

• Set the New File Interval

(hourly, monthly or none)

A:Analog i/p

• Set the Mains Rejection Frequency

• Select the Relay Source and the Relay

Polarity

• Select the Analog Output Source & Ranges

•Select the Digital Output Sources & Polarity

C:Relay

C:Hybrid

Note. Modules fitted

are detected automatically

I/O Modules

I/O Modules

<configuration filename>.cfg

Save as Current Configuration

Save Configuration

Cancel

Exit

<configuration filename>.cfg

Internal Storage

External Storage

Chart speed Sample Rate On board storage

10 mm/h 60s 12 months

20 mm/h 30s 6 months 6

60 mm/h 10s 2 months Channels

120 mm/h 5s 30 days Enabled

240 mm/h 2s 14 days

720 mm/h 1s 6 days

Recording

Group 1

Setup

Common

SM1000

Setup

Analog i/p

Totalizer

• Select the Channel Source

• Set the Input Filter Type: Instantanteous or Max.

and Min. Values during the sample interval.

• Select the input type, linearizer, ranges and

tag name

• Select the Alarm type, set the alarm trip points,

the tag and the hysteresis.

• Set the Count Rate, Preset & Predetermined

Count values

Alarm A

Alarm B

Channel n.n

Channels 1.1 - 1.6

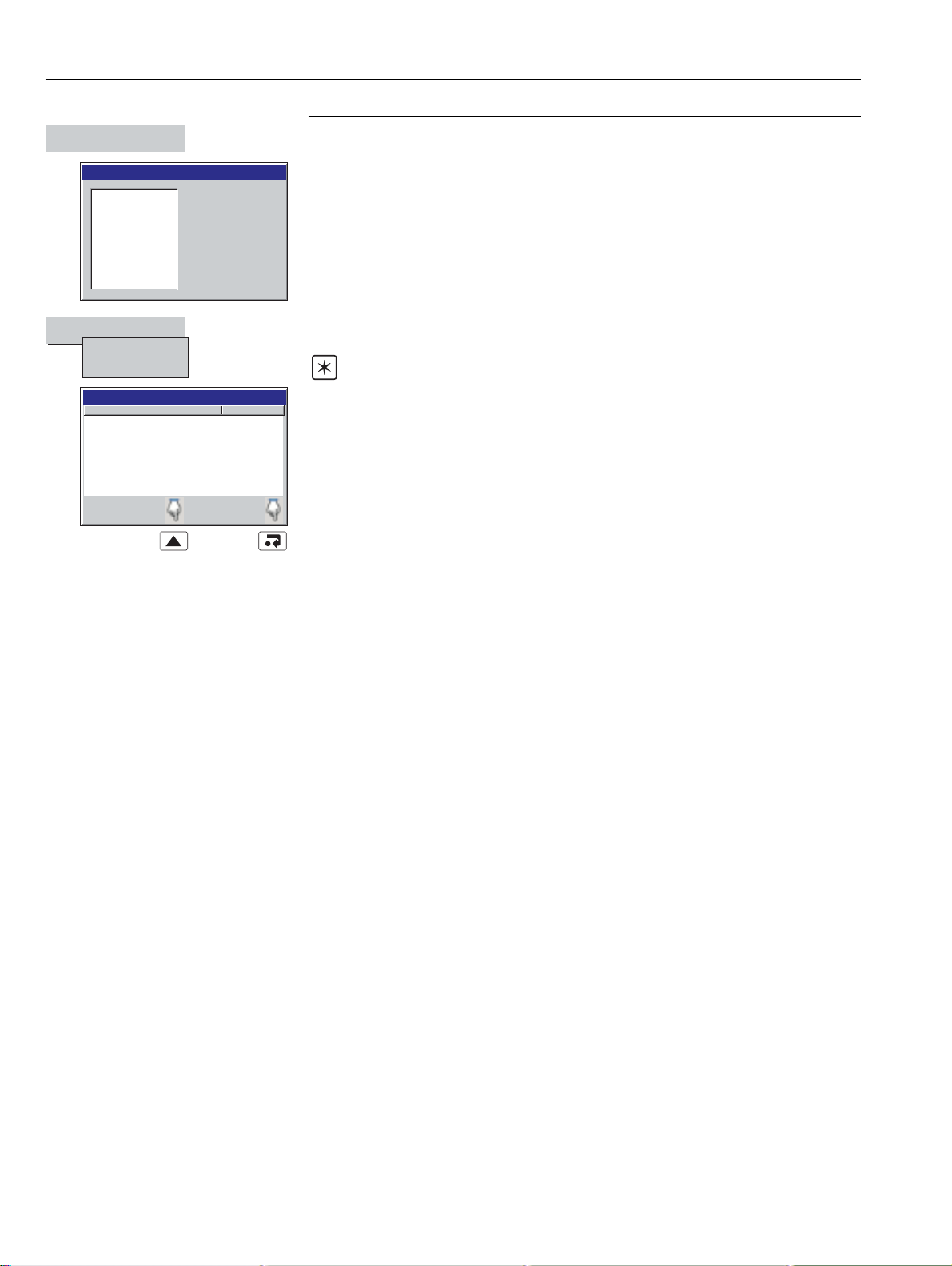

Configuration

Operator 1

Operator 2

Operator 3

Operator 4

Operator 1

Use the up and down keys to select your password.

Confirm with Enter key

0000

Operator 1

New Configuration

Open a Configuration

Edit Existing Configuration

Cancel

Disable Recording During Configuration

Main

Configuration

Menu

5.0

50.2

QSmilliamp

QSFlow

QSTHC_C

QSTHC_F

Configuration File

Common

Group 1

Channels 1.1 - 1.6

Group 2

Channels 2.1 - 2.6

Functions

I/O Modules

Exit

tratSkciuQ

etalpmeT

yrammuS

6.1ot1.1slennahC

pmAilliMSQ

,stupniAm02ot4

stinu0.001ot0

C_CHTSQ

F_CHTSQro

KepytelpuocomrehT

0001ot0 ° 0001ot0roC °F

C_DTRSQ

F_DTRSQro

stupni001tP

0001ot0 ° 0001ot0roC °F

wolFSQ

,rh/l081ot0,Am02ot4

delbanerezilatoT

yriaDSQ

mralAssecorPwoL/hgiHdeyaleD

09ot01–egnaRgnireenignE °C

User Guide

SM1000 QUICK START GUIDE

Set Up the Archive Files

6

Videographic Recorder

SM1000

Make Connections

1

& Power-up the

Instrument

Select the Configuration Level

2

and a Quick Start Template

Change the Channel Configurations

7

Set Up I/O

8

Set the Time and Date

3

Set the Sample Rate

4

Select the Views Required

5

and the Operator Menu Choices

Exit Configuration and Save Changes

9

Start Recording!

10

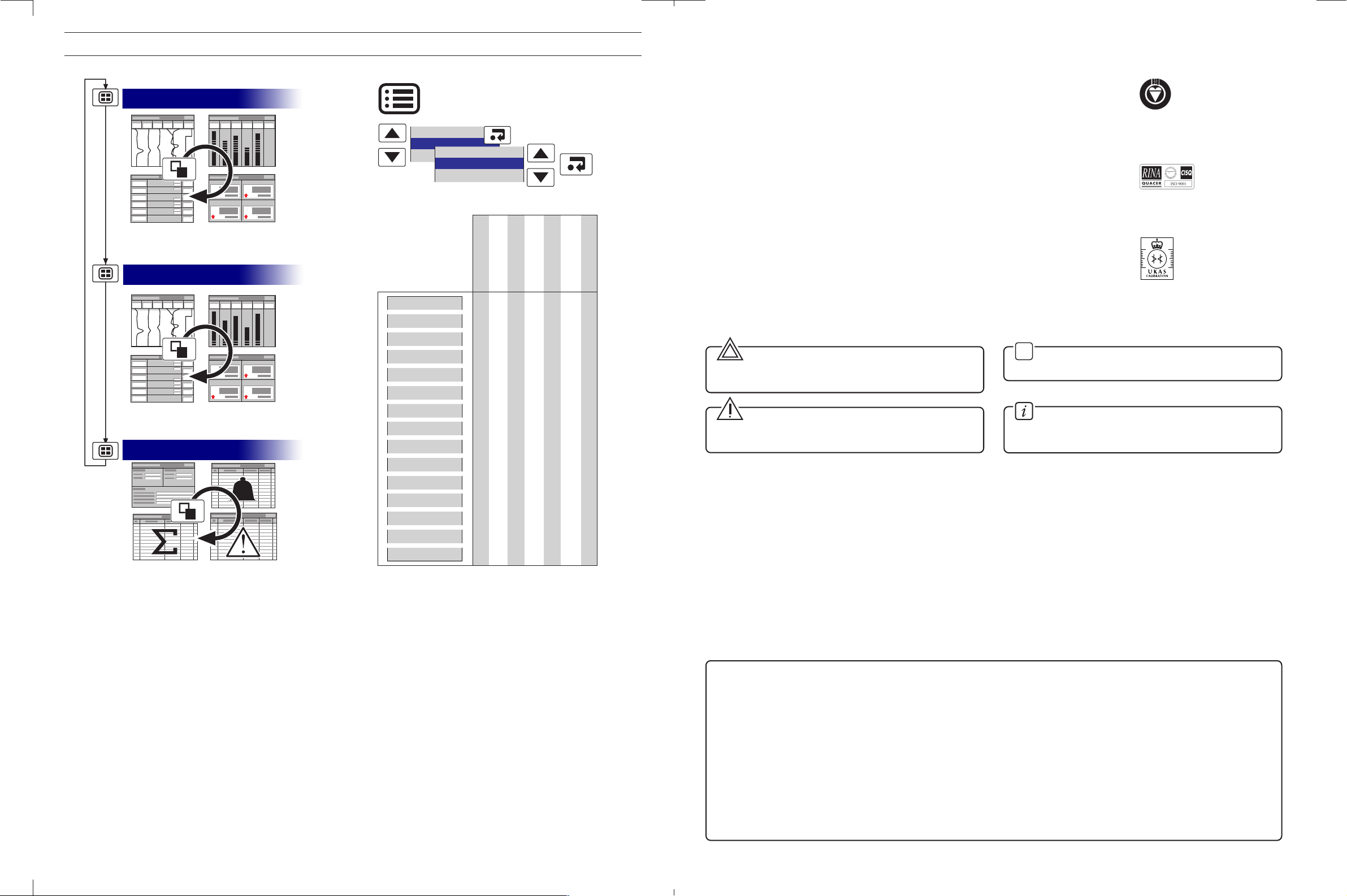

Page 2

Setup

Operator messages

Alarm acknowledge

Process Tune

Standby Switched

Day Shift

Chart View

Bar View

Indicator View

Process View

Alarm Event Log

Totalizer Log

Audit Log

Configuration

Set up

Historical review

View select

Operator messages

Chart annotation

Screen interval

Scales

Trace select

Channel select

Max/Min reset

Totalizer stop/Go

Totalizer reset

Filter

Alarm acknowledge

✔✔ ✔ ✔ ✔✔ ✔

✔✔ ✔ ✔ ✔✔ ✔

✔

✔

✔✔ ✔ ✔

✔

✔

✔

✔

✔

✔✔

✔✔

✔✔

✔✔

✔✔ ✔ ✔ ✔✔ ✔

Process Group 1

Process Group 2

Logs

Operator Functions

R

E

G

I

S

T

E

R

E

D

0255

ABB

The Company

We are an established world force in the design and manufacture of instrumentation for

industrial process control, flow measurement, gas and liquid analysis and environmental

applications.

As a part of ABB, a world leader in process automation technology, we offer customers

application expertise, service and support worldwide.

We are committed to teamwork, high quality manufacturing, advanced technology and

unrivalled service and support.

The quality, accuracy and performance of the Company’s products result from over 100 years

experience, combined with a continuous program of innovative design and development to

incorporate the latest technology.

The NAMAS Calibration Laboratory No. 0255 is just one of the ten flow calibration plants

operated by the Company, and is indicative of our dedication to quality

and accuracy.

Use of Instructions

Warning.

An instruction that draws attention to the risk of injury or

death.

✶

Note.

Clarification of an instruction or additional information.

BS EN ISO 9001

Cert. No. Q5907

EN 29001 (ISO 9001)

Lenno, Italy – Cert. No. 9/90A

Stonehouse, U.K.

Caution.

An instruction that draws attention to the risk of damage to

the product, process or surroundings.

Although

Warning hazards are related to personal injury, and Caution hazards are associated with equipment or property damage,

Information.

Further reference for more detailed information or

technical details.

it must be understood that operation of damaged equipment could, under certain operational conditions, result in degraded

process system performance leading to personal injury or death. Therefore, comply fully with all

Warning and Caution notices.

Information in this manual is intended only to assist our customers in the efficient operation of our equipment. Use of this manual

for any other purpose is specifically prohibited and its contents are not to be reproduced in full or part without prior approval of the

Marketing Communications Department.

Health and Safety

To ensure that our products are safe and without risk to health, the following points must be noted:

1. The relevant sections of these instructions must be read carefully before proceeding.

2. Warning labels on containers and packages must be observed.

3. Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel and in accordance with the

information given.

4. Normal safety precautions must be taken to avoid the possibility of an accident occurring when operating in conditions of high pressure

and/or temperature.

5. Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry. Normal safe handling procedures

must be used.

6. When disposing of chemicals ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual or any relevant hazard data sheets (where applicable) may be

obtained from the Company address on the back cover, together with servicing and spares information.

Page 3

CONTENTS

1 INTRODUCTION .............................................................. 2

2 OPERATION .....................................................................3

2.1 Powering Up the Instrument .............................................. 3

2.2 Displays and Controls ....................................................... 3

2.3 Chart Views (Horizontal and Vertical) ................................. 4

2.4 Bargraph Views (Horizontal and Vertical).......................... 10

2.5 Digital Indicator View ....................................................... 12

2.6 Process View .................................................................. 14

2.7 Alarm Event Log .............................................................. 16

2.8 Totalizer Log .................................................................... 18

2.9 Audit Log ........................................................................ 20

2.10 Status View ..................................................................... 21

3 SETUP............................................................................ 22

3.1 Introduction ..................................................................... 22

3.2 Accessing the Setup Level .............................................. 22

3.3 Setup Menu .................................................................... 23

3.4 Archiving ......................................................................... 25

3.4.1 SmartMedia Handling and Care .......................... 25

3.4.2 Media Status ...................................................... 25

3.4.3 Inserting and Removing Media ........................... 26

3.4.4 Archive File Types ............................................... 27

3.4.5 Channel Data Files .............................................. 27

3.4.6 Filename Example .............................................. 27

3.4.7 Log files .............................................................. 27

3.4.8 Online/Offline ...................................................... 27

3.4.9 Archiving Updates .............................................. 28

3.4.10 File Formats ........................................................ 28

3.4.11 Digital Signatures ................................................ 28

4 CONFIGURATION.......................................................... 30

4.1 Introduction ..................................................................... 30

4.1.1 Configuration Method ......................................... 30

4.1.2 Configuration Access ......................................... 30

4.2 Overview of Configuration ............................................... 32

4.2.1 Adjusting Screen Contrast .................................. 33

4.3 Making Changes to Parameters ...................................... 33

4.4 Common Configuration ................................................... 36

4.4.1 Setup ................................................................. 36

4.4.2 Security .............................................................. 37

4.4.3 Logs ................................................................... 38

4.4.4 Operator Messages ............................................ 38

4.5 Process Group Configuration .......................................... 39

4.5.1 Setting the Recording Parameters ...................... 39

4.5.2 Configuring the Chart Display ............................. 41

4.5.3 Configuring the Bargraph display ........................ 43

4.5.4 Configuring the Process View ............................. 44

4.5.5 Digital Indicator View .......................................... 45

4.5.6 Archiving ............................................................ 46

4.6 Channel Configuration ..................................................... 49

4.6.1 Recording Channel Setup ................................... 50

4.6.2 Analog Input Configuration ................................. 52

4.6.3 Digital Input Configuration ................................... 54

4.6.4 Alarm Configuration ............................................ 55

4.6.5 Totalizer Configuration ........................................ 60

4.7 I/O Module Configuration ................................................ 63

4.7.1 Analog Inputs ..................................................... 63

4.7.2 6-Relay Modules ................................................ 64

4.7.3 Hybrid Modules .................................................. 64

4.7.4 RS485 Modules .................................................. 65

4.7.5 Ethernet Modules ............................................... 66

4.8 Functions ........................................................................ 67

4.8.1 Custom Linearizers ............................................. 67

4.8.2 Real Time Alarms ............................................... 68

5INSTALLATION .............................................................. 69

5.1 Siting............................................................................... 69

5.2 Mounting ......................................................................... 70

5.3 Electrical Connections ..................................................... 71

5.4 Analog Inputs .................................................................. 72

5.5 RS422/485 Serial Communications ................................. 73

5.6 Mains Power Connections............................................... 74

5.7 Relay Output Board Connections .................................... 74

5.8 Hybrid I/O Module Connections ...................................... 74

5.8.1 Digital Output Connections ................................. 74

5.8.2 Digital Input Connections .................................... 74

5.8.3 Analog Output Connections ............................... 74

APPENDIX 1 – SIGNAL SOURCES ....................................75

APPENDIX 2 – MODBUS GUIDE ....................................... 76

A2.1 Introduction ..................................................................... 76

A2.2 Setting Up ....................................................................... 76

A2.3 Modbus Commands Supported ...................................... 76

A2.4 Modbus Exception Responses ........................................ 76

A2.5 Operating Mode Modbus Coils ........................................ 76

A2.6 Operating Mode Modbus Registers ................................. 79

A2.7 Comms Analog and Digital Inputs ................................... 81

APPENDIX 3 – STORAGE CAPACITY ................................ 81

A3.1 Internal Storage Capacity ................................................ 81

A3.2 Archive Storage Capacity ................................................ 82

APPENDIX 4 – DEFAULT SETTINGS .................................83

A4.1 Company Standard ......................................................... 83

A4.1.1 Common Configuration ...................................... 83

A4.1.2 Process Groups 1 and 2 ..................................... 83

A4.1.3 Recording Channels ........................................... 83

A4.1.4 I/O Modules........................................................ 84

A4.2 QuickStart Templates ...................................................... 84

A4.2.1 QSMilliAmp......................................................... 84

A4.2.2 QSFlow .............................................................. 84

A4.2.3 QSTHC_C .......................................................... 85

A4.2.4 QSTHC_F........................................................... 85

A4.2.5 QSRTD_C .......................................................... 85

A4.2.6 QSRTD_F ........................................................... 85

A4.2.7 QSDEMO ........................................................... 85

A4.2.8 QSDAIRY ........................................................... 85

APPENDIX 5 – SPARE PARTS & ACCESSORIES ............. 87

APPENDIX 6 – ERROR & DIAGNOSTICS INFORMATION 88

INDEX ..................................................................................89

Note.

For optional accessories, refer to

APPENDIX 5.

Keys

Mounting Clamps

Shunt Resistors

(1 per analog input)

Standard Accessories

1

Page 4

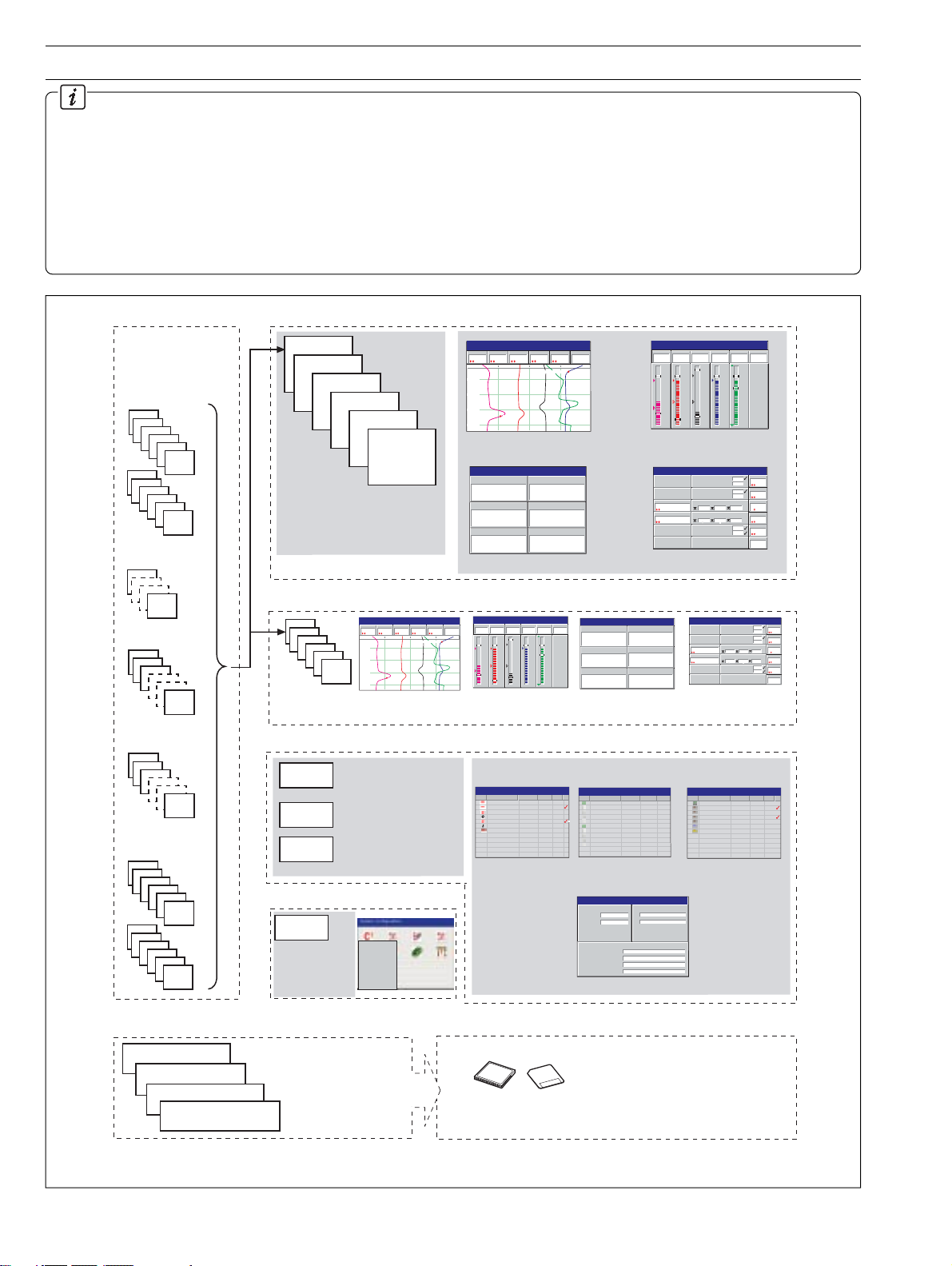

1 INTRODUCTION

Functional Overview – Fig. 1.1.

• 12 Recording Channels as standard, divided into 2

Process Groups, each with 6 Recording Channels.

•Two Alarms and one Totalizer are assigned to each

Recording Channel.

• Recording Channels 1.1 to 1.6 pre-assigned to Process

Group 1. Recording Channels 2.1 to 2.6 pre-assigned to

Process Group 2.

Sources

Note. Sources can be

assigned to any

recording channel in

either process group.

Analog Inputs

A1

A2

A3

A4

A5

A6

B1

B2

B3

B4

B5

B6

Internal sources –

see Appendix 1

Process Group 1

1.1

1.2

1.3

1.4

1.5

•Two process groups as

standard provide 12 recording

channels, irrespective of the

number of external inputs.

Recording

Channels

1.1 to 1.6

1.6

• Recording sources derived from universal analog inputs,

the Modbus serial link, optional digital inputs or internal

analog and digital signals.

• Any source can be assigned to any recording channel.

• Data from assigned sources can be displayed in Chart,

Bargraph, Indicator and Process formats.

• Three instrument logs record alarm events, totalizer

values and system/configuration changes.

Chart View

In Flow

Pressure

Level

204.9

4

2.08

bar

metres

010

12:00:00

11:59:00

11:58:00

High Level

11:57:00

28/03/00

14:52:00

Alarm 1

Temp

Out Flow

On

195

198.9

°C

l/hr

l/hr

High Out Flow Rate

Chart View (Section 2.3)

Digital Indicator

LevelLevel

2.08

In Flow

204.4

0005402801

Temp

195

Pressure

Out Flow

198.4

Alarm 1

4

0005402060

On

28/03

/00

Digital Indicator View (Section 2.5)

Vertical Bargraph

In Flow

Pressure

Level

204.9

4

2.08

bar

metres

5.0

5.0

300

2.5

2.5

150

0.0

0.0

0

Bargraph View (Section 2.4)

Process View

Tank 1 Low Level

Tank 1 High Level

Tank 1 Low Pressure

Tank 1 High Pressure

Total Daily In Flow

Storage Tank 1 In Flow

00054

225.4 110.9 201.0

02801

Total Daily Out Flow

litres

Storage Tank 1 Out Flow

00054

229.1 100.1 200.9

02060

litres

Tank 1 Low Temp

Tank 1 High Temp

Process View (Section 2.6)

28/03/00

14:52:00

Alarm 1

Temp

Out Flow

On

195

198.9

°C

l/hr

l/hr

300

250

150

125

0.0

0

28/03/

00

Level

1.2

2.0

4.

8

Press

metres

0.2

4

4.

bar

In

20

4.9

Out

l/hr

19

8.9

Temp

l/hr

15

19

25

5

Alarm

°C

On

Comms

Analog Inputs

1

2

3

24

Comms

Digital Inputs

1

2

3

24

Digital Inputs

C1

C2

C3

C4

C5

C6

D1

D2

D3

D4

D5

D6

Recorded Data

Recording Channels 1.1 to 1.6

(Process Group 1)

Recording Channels 2.1 to 2.6

(Process Group 2)

Instrument Logs

Configuration Data

Process Group 2

2.1

2.2

2.3

2.4

2.5

2.6

Recording

Channels

2.1 to 2.6

Instrument Logs

Alarm/Event Log

Totalizer Log

Audit Log

*if option fitted

Configuration Data

Configuration

Data

Stores all

instrument

configuration,

calibration and

user preferences

Files stored in instrument's

on-board flash memory.

Newest data overwrites

oldest.

28/03/00

Chart View

Pressure

Level

2.08

metres

010

12:00:00

11:59:00

11:58:00

11:57:00

Temp

Out Flow

In Flow

198.9

204.9

4

l/hr

l/hr

bar

High Out Flow Rate

High Level

Chart View

Records all alarm

transistions and all

operator messages

Records all totalizer

activity*

Records all system

acfivity

Common

Group 1

Channels 1.1 - 1.6

Group 2

Channels 2.1 - 2.6

Functions

I/O Modules

Exit

14:52:00

Alarm 1

On

195

°C

Vertical Bargraph

Level

2.08

metres

5.0

2.5

0.0

Bargraph View

Alarm Event Log

(Section 2.7)

Alarm Event Log

00 Tank 1 High Level Level 28/08/00 14:01

01 Tank 1 High Level Level 28/08/00 14:03

02 High Out Flow Rate Out Flow 28/08/00 14:09

03 Tank 1 High Level Level 28/08/00 14:11

04 High Out Flow Rate Out Flow 28/08/00 14:12

05 High Out Flow Rate Out Flow 28/08/00 14:15

06 Duty/Standby Change Out Flow 28/08/00 14:31

Archive Data

Pressure

204.9

4

bar

5.0

2.5

0.0

On

195

198.9

°C

l/hr

l/hr

300

300

250

150

150

125

0

0.0

0

LevelLevel

In Flow

Temp

2.08

204.4

0005402801

195

Pressure

Out Flow

Alarm 1

198.4

0005402060

On

4

28/03/00

14:52:00

Digital Indicator

Alarm 1

Temp

Out Flow

In Flow

Digital Indicator View

To ta lizer Log

(Section 2.8)

28/03/00

Totalizer Log

14:52:00

No Tag/Value Source Tag Date Time

Total Daily In Flow In Flow 28/03/00 14:52

0005402801 Litres

225.4 l/hr

110.9 l/hr

201.0 l/hr

Total Daily Out Flow Out Flow 28/03/00 14:52

0005402060 Litres

229.1 l/hr

100.1 l/hr

200.9 l/hr

•Views provide a window on the stored data.

Status View

VERSION

Software

System

ARCHIVING

Group 1 Filename

Group 2 Filename

% Memory used

Time left

SM 2001/1

1.0.130

Process Group 1

Process Group 2

80.5%

5 days

CJ TEMPERATURES

25°C / 77°F

A

25°C / 77°F

B

• Status View

Data saved to archive storage media

Archive Media

28/03

/00

Audit Log

(Section 2.9)

28/03/00

Audit Log

14:52:00

No Alarm Event Tag Source Tag Date Time

00 Power Restored 25/03/00 11:59

01 I/O Configuration JM 25/03/00 12:01

02 Common Configuration JM 25/03/00 12:05

03 Group 1 Configuration JM 25/03/00 12:09

04 Ch1.1 to 6 Config JM 25/03/00 12:10

05 AIN Cal, Module A JM 25/03/00 12:15

06 System Alarm

28/03/00

14:52:00

Process View

Total Daily In Flow

00054

02801

Total Daily Out Flow

litres

00054

02060

litres

Process View

Tank 1 Low Level

Tank 1 High Level

Tank 1 Low Pressure

Tank 1 High Pressure

Storage Tank 1 In Flow

225.4 110.9 201.0

Storage Tank 1 Out Flow

229.1 100.1 200.9

Tank 1 Low Temp

Tank 1 High Temp

28/03/

00

Level

1.2

2.0

4.

8

Press

metres

0.2

4

4.

bar

In

20

4.9

Out

l/hr

19

8.9

Temp

l/hr

15

19

25

5

Alarm

°C

On

28/03/00

14:52:00

Fig. 1.1 Functional Overview

2

Page 5

2 OPERATION

2.1 Powering Up the Instrument

When power is first applied to the instrument, its processor carries out a number of self-tests and displays the start up screen.

At the end of the start up sequence the instrument displays the Operator View that was being displayed when the instrument was

powered down.

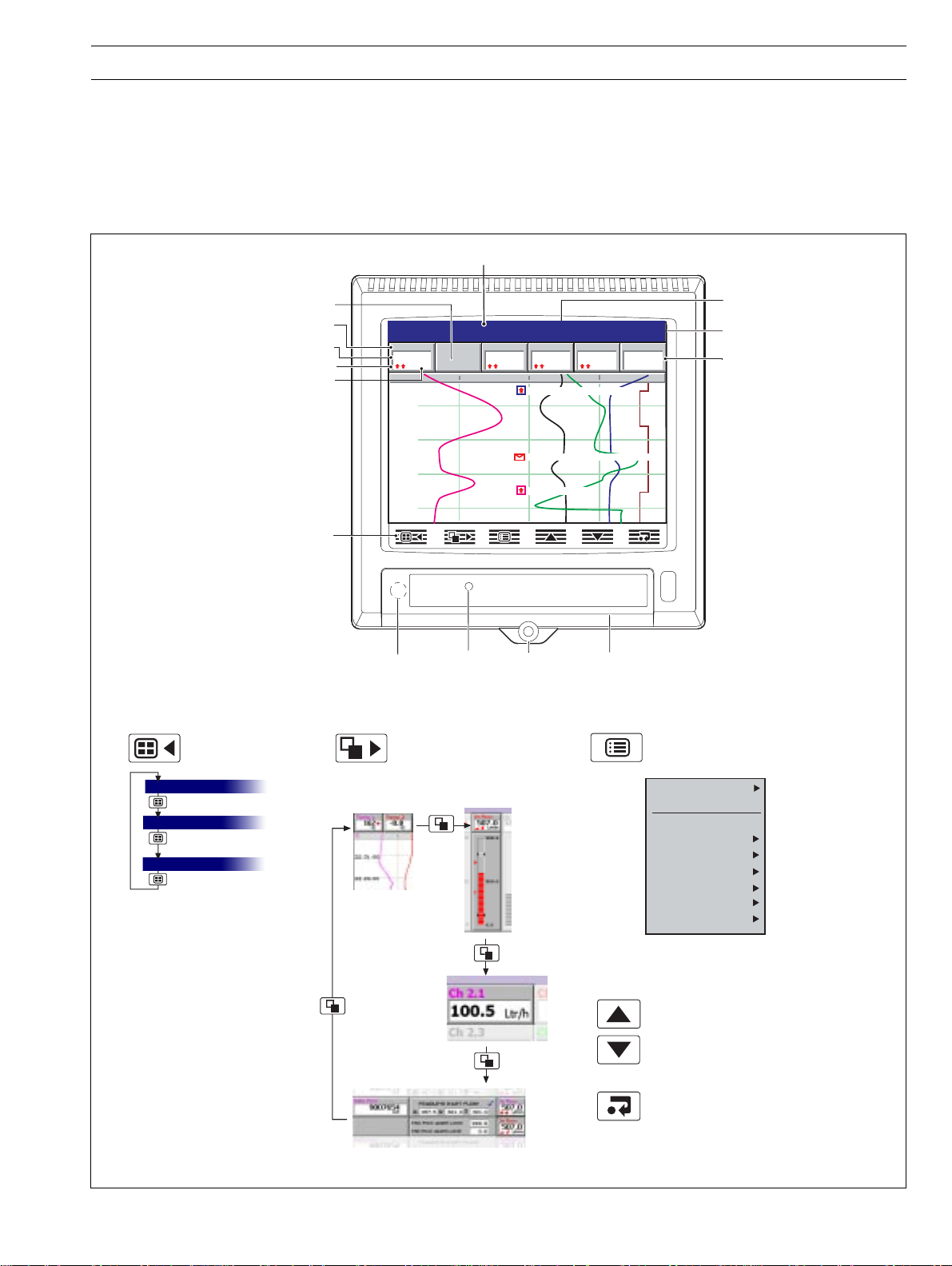

2.2 Displays and Controls – Figs. 2.1 and 2.2

In normal day-to-day use, the instrument is operated via the Operator Keys located along the bottom of the screen.

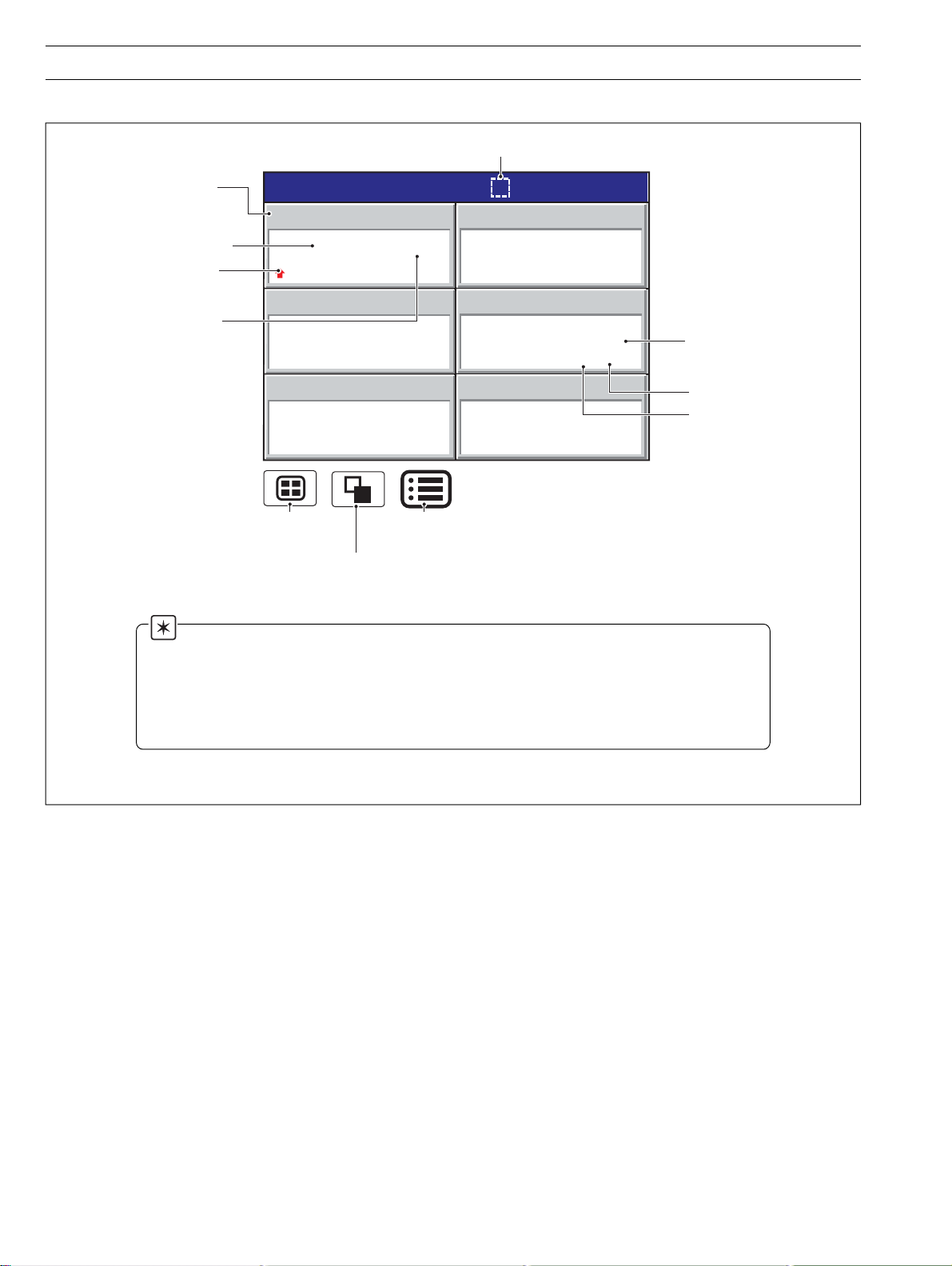

Process Group Name

Group Key

Selects a different

process group.

Process Group 1

Process Group 2

Instrument Status & Logs

Channel not enabled

Short Channel Tag

Current Value

Alarm Status

Engineering Units

Operator Keys

Process Group 1

Level

010

12:00:00

11:59:15

11:58:30

11:57:45

Programming

Socket

(Inside Door)

View Key

Selects a different process view

or log.

Chart View –

see Section 2.3

Digital Indicator

View – see

Section 2.5

2.08

metres

In Flow

204.9

l/hr

Door Lock

Bargraph Views –

see Section 2.4

Jacking

Screw and

Fitting for

Tamper-proof

Temp

Out Flow

198.9

l/hr

12:00:30 High Out Flow Rate

11:58:53 Duty/Standby Switched

11:58:00 High Level

Seal

195

Media

Door

Status Icons –

see inside rear fold-out

28/03/00

14:52:00

Alarm 1

On

°C

Menu Key

Displays or hides the context-sensitive operator

menu associated with each view:

Current

Date and Time

Digital ON or OFF tag,

according to input status

Configuration

Setup

Historical Review

Operator Messages

Chart Annotation

Screen Interval

Scales

Trace Select

Alarm Acknowledge

Also cancels the menu without making a

change or returns to the previous menu level.

Up/Down Keys

Highlights menu items and scrolls through

previously recorded data.

Process View – see Section 2.6

Fig. 2.1 Displays and Controls

Enter Key

Selects the highlighted menu item.

3

Page 6

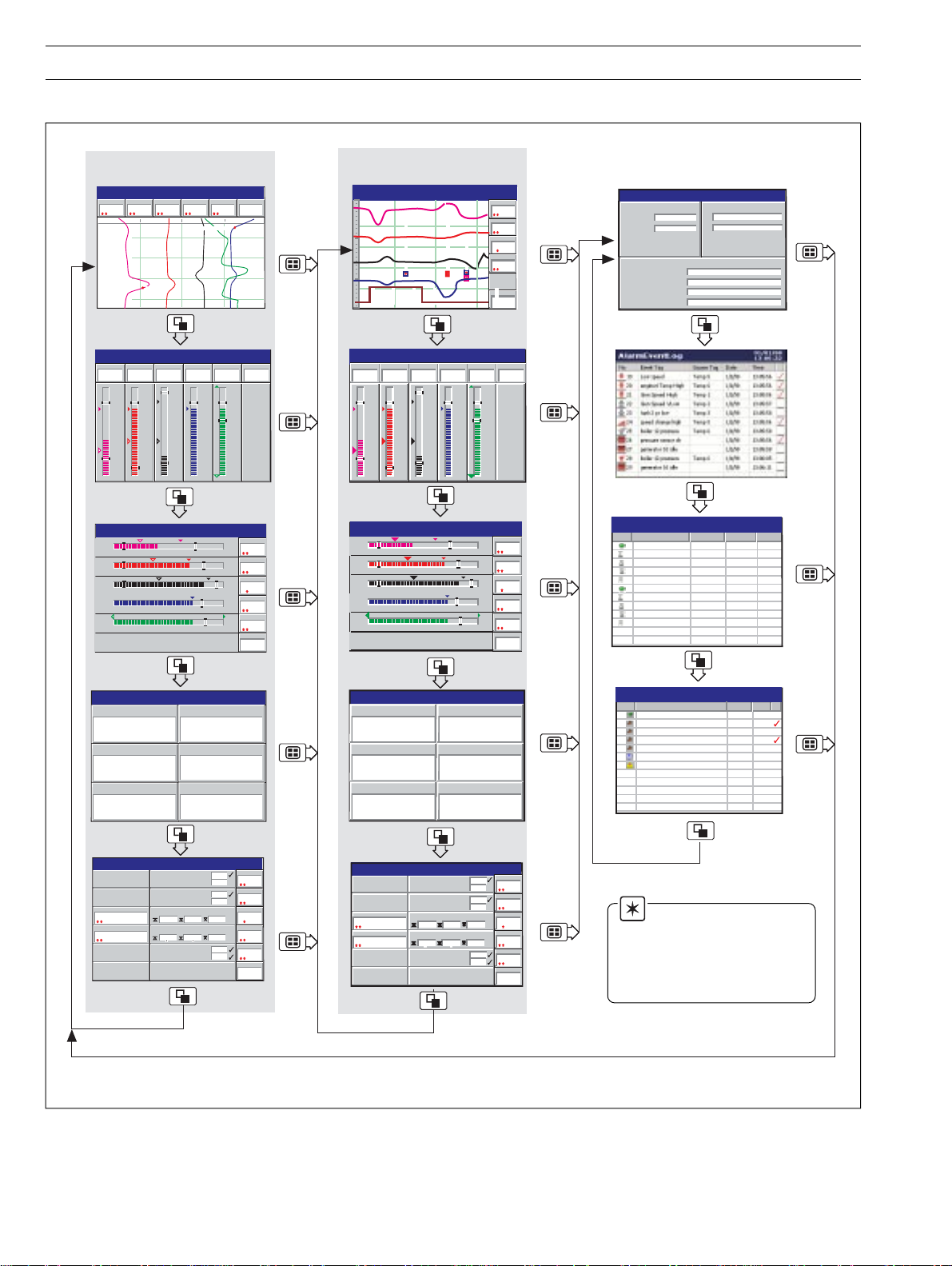

…2 OPERATION

…2.2 Displays and Controls

Process Group 1

(Recording Channels 1.1 to 1.6)

Chart View

Pressure

Level

2.08

metres

010

12:00:00

11:59:00

11:58:00

11:57:00

Vertical Bargraph

Pressure

Level

2.08

metres

5.0

2.5

0.0

Horizontal Bargraph

0.0

0.0

0

0

0

Out Flow

In Flow

198.9

204.9

4

l/hr

bar

High Level

Out Flow

In Flow

198.9

204.9

4

l/hr

bar

5.0

300

2.5

150

0.0

0

2.5

2.5

150

150

125

l/hr

High Out Flow Rate

l/hr

300

150

0.0

28/03/00

14:52:00

Alarm 1

Temp

On

195

°C

28/03/00

14:52:00

Alarm 1

Temp

On

195

°C

250

125

0

28/03/00

14:52:00

Level

2.08

5.0

metres

Pressure

4

5.0

bar

In Flow

204.9

300

l/hr

Out Flow

198.9

300

l/hr

Temp

195

250

°C

Alarm 1

On

Process Group 2

(Recording Channels 2.1 to 2.6)

Process Group 1

12:00:30 High Out Flow Rate

11:59:15

5.0

2.5

0.0

12:00:00

11:58:30

11:57:45

In Flow

204.9

4

l/hr

bar

300

150

0

2.5

2.5

150

150

125

12:00:00

010

Vertical Bargraph

Pressure

Level

2.08

metres

5.0

2.5

0.0

Horizontal Bargraph

0.0

0.0

0

0

0

11:58:00 High Level

11:58:53 Duty ON, Standby OFF

11:57:00

Out Flow

198.9

l/hr

300

150

0.0

28/03/00

12:00:45

Level

2.08

metres

Pressure

In Flow

204.9

l/hr

Out Flow

198.9

Alarm 1

On

11:56:15

11:57:45

28/03/00

14:52:00

Alarm 1

Temp

On

195

°C

250

125

0

28/03/00

14:52:00

Level

2.08

5.0

metres

Pressure

5.0

In Flow

204.9

300

Out Flow

198.9

300

Temp

195

250

Alarm 1

On

25°C / 77°F

25°C / 77°F

28/03/00

14:52:00

28/03/00

14:52:00

Instrument Status

VERSION

Software

4

bar

l/hr

4

bar

l/hr

l/hr

°C

SM 2001/1

System

1.0.130

ARCHIVING

Group 1 Filename

Group 2 Filename

% Memory used

Time left

Totalizer Log

No Tag/Value Source Tag Date Time

Total Daily In Flow In Flow 28/03/00 14:52

0005402801 Litres

225.4 l/hr

110.9 l/hr

201.0 l/hr

Total Daily Out Flow Out Flow 28/03/00 14:52

0005402060 Litres

229.1 l/hr

100.1 l/hr

200.9 l/hr

CJ TEMPERATURES

A

B

Process Group 1

Process Group 2

80.5%

5 days

Digital Indicator

Level

Level

In Flow

204.4

Temp

Process View

Total Daily In Flow

0005402801

Total Daily Out Flow

0005402060

2.08

578494

0005402801

195

Tank 1 Low Level

Tank 1 High Level

Tank 1 Low Pressure

Tank 1 High Pressure

litres

litres

Tank 1 Low Temp

Tank 1 High Temp

Pressure

Out Flow

Alarm 1

Storage Tank 1 In Flow

225.4 110.9 201.0

Storage Tank 1 Out Flow

229.1 100.1 200.9

198.4

On

1.25

4.75

0.25

4.75

150

250

28/03/00

14:52:00

578494

0005402060

28/03/00

14:52:00

Level

Pressure

In Flow

204.9

Out Flow

198.9

Temp

Alarm 1

2.08

On

Audit Log

No Alarm Event Tag Date Time

00 Power Restored 25/03/00 11:59

01 I/O Configuration 25/03/00 12:01

02 Common Configuration 25/03/00 12:05

03 Group 1 Configuration 25/03/00 12:09

04 Ch1.1 to 6 Config 25/03/00 12:10

05 AIN Cal, Module A 25/03/00 12:15

06 System Alarm

Note. Only process

groups and views that have

been enabled are displayed –

see Section 4.5, Process

Group Configuration.

2.08

578494

198.4

0005402060

On

1.25

4.75

0.25

4.75

150

250

28/03/00

14:52:00

4

28/03/00

14:52:00

Level

Pressure

In Flow

204.9

Out Flow

198.9

Temp

Alarm 1

2.08

On

metres

3

m

metres

4

bar

l/hr

l/hr

195

°C

Digtial Indicator

metres

m

Pressure

3

Out Flow

Alarm 1

Level

Level

2.08

4

2.08

578494

In Flow

204.4

0005402801

Temp

195

metres

4

bar

l/hr

l/hr

195

°C

Process View

Total Daily In Flow

0005402801

Total Daily Out Flow

0005402060

litres

litres

Tank 1 Low Level

Tank 1 High Level

Tank 1 Low Pressure

Tank 1 High Pressure

Tank 1 Low Temp

Tank 1 High Temp

Storage Tank 1 In Flow

225.4 110.9 201.0

Storage Tank 1 Out Flow

229.1 100.1 200.9

28/03/00

14:52:00

Fig. 2.2 Overview of Operator Displays

4

Page 7

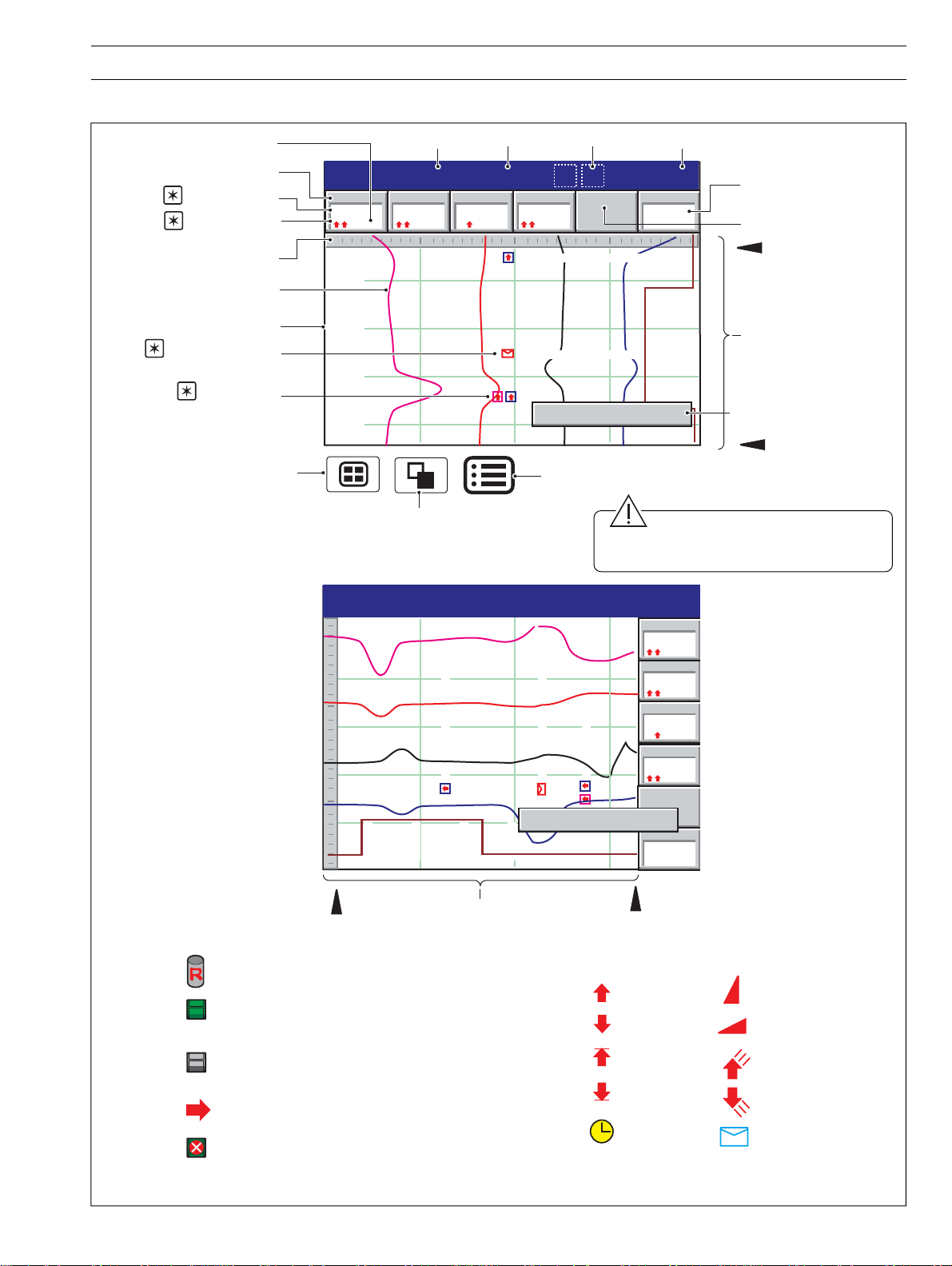

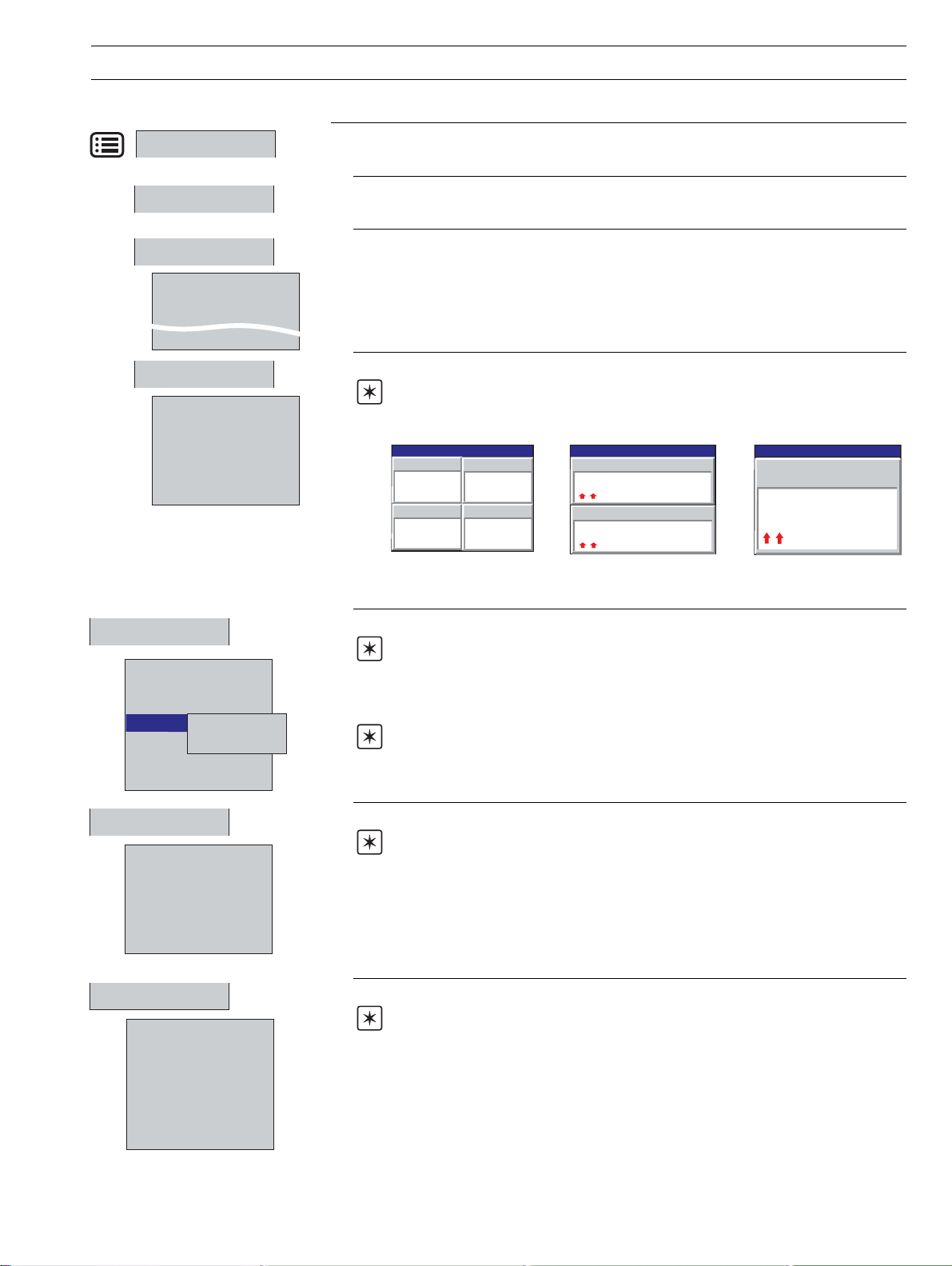

2.3 Chart Views (Horizontal and Vertical) – Fig. 2.3

2 OPERATION…

Units

Short Channel Tag

1

Current Value

2

Alarm Status

Scale Bar

Chart Trace

Time Stamp

3

Operator Message

Annotation

3

Alarm Event

Annotation

Selects next Process Group

(if enabled) or Status View

In Flow

204.9

Title Bar

Out Flow

198.9

l/hr

l/hr

12:00:30 High Out Flow Rate

11:58:53 Duty ON, Standby OFF

11:58:00 High Level

Duty/Standby Change

Status Icons

28/03/00

Current Date and Time

12:00:45

Alarm 1

On

Digital On/Off Tag

Channel Not Used

Newest Data

Screen Interval

Operator Message

(appears for 1 second)

Group Tag

Process Group 1

metres

Pressure

4

bar

Level

2.08

010

12:00:00

11:59:15

11:58:30

11:57:45

Oldest Data

Opens the Operator Menu for

the current view

Selects the next enabled

view in the group

(Bar, Digital or Process)

Caution. Do not remove media

while the external media update icon is

displayed.

Process Group 1

12:00:30 High Out Flow Rate

11:58:53 Duty ON, Standby OFF

28/03/00

12:00:45

Level

Pressure

In Flow

204.9

Out Flow

11:58:00 High Level

198.9

2.08

metres

4

bar

l/hr

l/hr

010

Newest Data

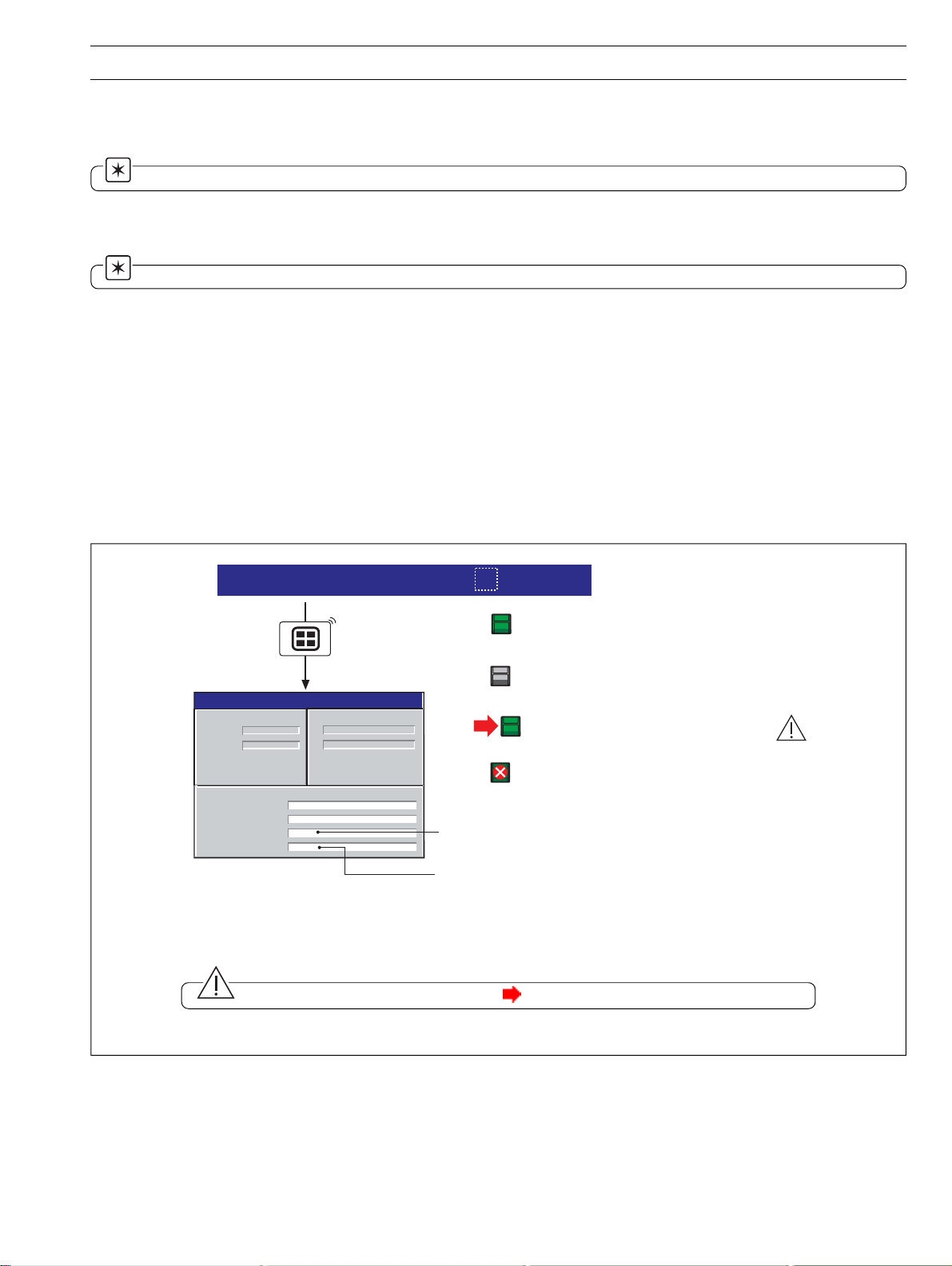

Status Icons

Historical Review active – see overleaf

External archive media on-line

(green icon – shaded area indicates % used)

External archive media off-line

(grey icon – shaded area indicates % used)

External archive media update in progress.

Media 100% full, archiving stopped (white

cross on red background)

12:00:00

11:59:15

11:58:30

Screen Interval

Fig. 2.3 Chart View

Duty/Standby Change

12:00:00

11:57:00

11:57:45

Alarm Event Icons

Digital Indicators and Chart View

Alarm 1

11:56:15

Oldest Data

High Process

Low Process

High Latch

Low Latch

Real time

On

Fast Rate

Slow Rate

High Annunciate

Low Annunicate

Operator Message

5

Page 8

…2 OPERATION

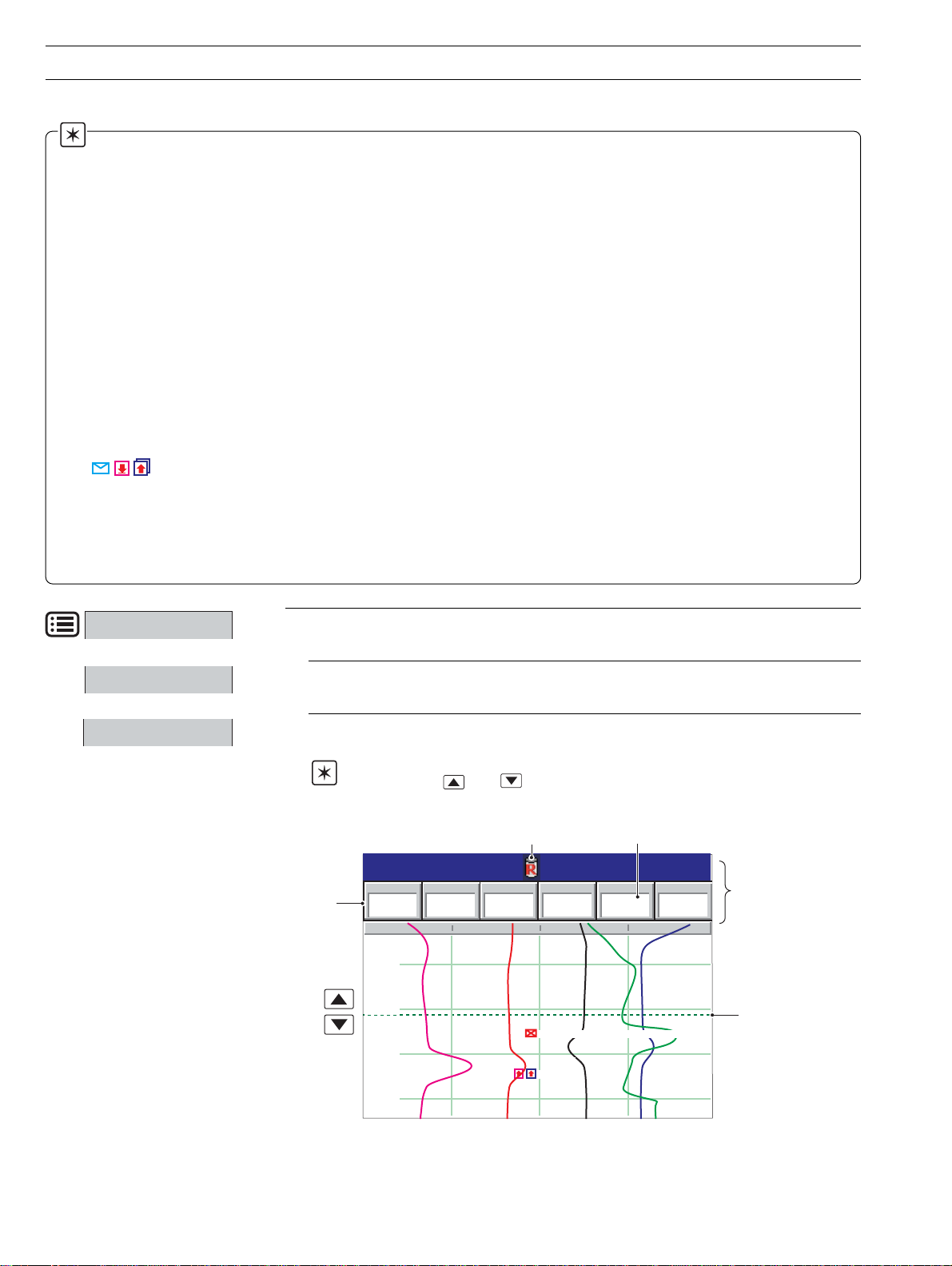

…2.3 Chart View

Notes.

1. Current Values

The Current Value, shown on the digital indicators at the top of the screen, is the latest instantaneous value and its update

rate is not affected by the recording sample rate.

If the current value in the digital indicator is displayed in red, recording has been stopped for that channel – see Section 4.5.1,

Setting the Recording Parameters.

Traces are shown only when that particular channel is being recorded. When channels are set to stop, the trace continues

to be shown for up to one sample period.

2. Alarm Status

•Flashing Red – Alarm Active and Unacknowledged

•Continuous Red – Alarm Active and Acknowledged

3. Alarm Event and Operator Message Annotations

Alarm Event and Operator Message annotations are not shown on the chart unless enabled –

see 'Chart Annotation' on Page 8 and Section 4.5.2.

If Alarm event annotation is enabled and an alarm becomes active, a red alarm icon surrounded by a channel-colored box is

displayed at the point at which the alarm occured, together with the alarm time and tag.

11:58:00 1.1A High Level

If more than one alarm occurs in the same sample period:

• If the second alarm on a channel becomes active its icon is added behind the first.

• If more than one operator messages is active (max. six) a second icon is added behind the first.

• New alarm icons appear to the left of earlier icons.

• The time and tag of the oldest alarm (right-most icon) only is displayed.

Configuration

Setup

Historical Review

Select the Configuration Level – see Section 4.

Select the Setup Level – see Section 3.

Select Historical Review to view previously recorded data stored in the instrument's

onboard memory.

Note. Use the and keys to move backwards and forwards through the

recorded data.

Digital

Indicators

Historical

Review Active

Process Group 1

In Flow

204.9

4

bar

2.08

metres

Pressure

Level

010

12:00:00

11:59:00

11:58:00

11:57:00

Out Flow

198.9

l/hr

11:58:23 Duty/Standby Pumps Switched

11:57:30 High Level

Invalid data – e.g.

recording disabled

Temp

- - - -

l/hr

°C

28/03/00

11:59:30

Alarm 1

On

Values displayed

indicate the process

status at the cursor

position

Cursor

6

Page 9

…2.3 Chart View

2 OPERATION…

Notes.

While in Historical Review mode:

• Recording of new data continues unless stopped from the Setup Menu – see

Section 3.3.

• Invalid historical data (e.g. when recording has stopped) is denoted by '– – – –' in the

digital indicator.

• Where the trace at the cursor position represents more than one sample, the indicators

flash between the maximum and minimum values of those samples.

• Menu options remain active, allowing the screen interval to be changed, different

scales and channels to be selected, etc.

• Operator messages are added to the alarm event log at the present time, not historical

time.

• All data stored in the instrument's internal memory can be viewed.

• The display can be scrolled back to the start of the oldest data.

•Archiving to removeable media does not occur but all data recorded in the internal

memory buffer during this time is archived on exiting Historical Review mode.

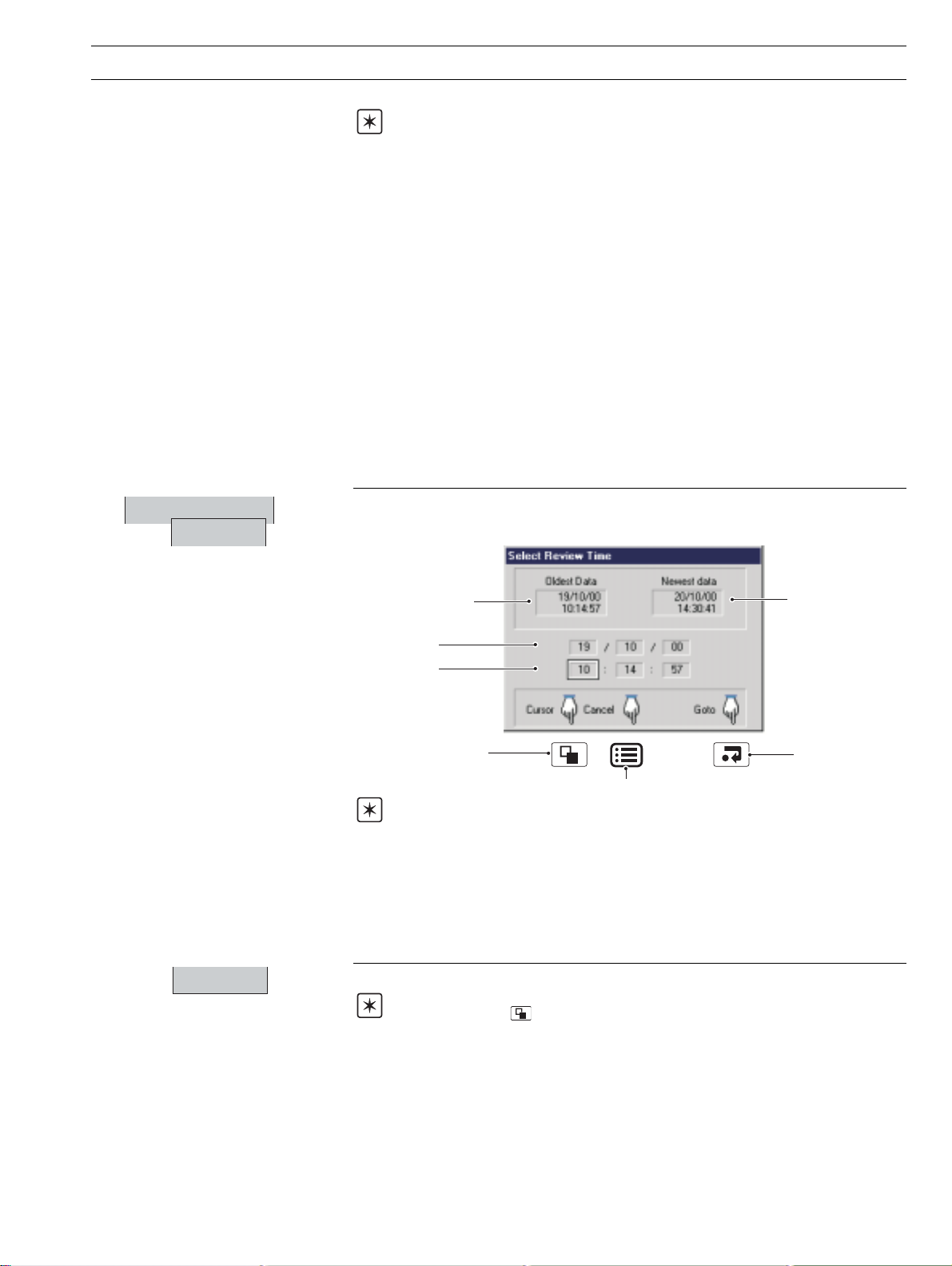

✔ Historical Review

Goto

Select Goto to move to data stored in the instrument's onboard memory that was

recorded at a specific date and time.

Oldest data in

internal memory

Ta rget date

Ta rg et time

Moves cursor between

target day, month, year,

hours, minutes & seconds

Returns to Menu

Newest data in

internal memory

Goes to the chart

view display, at the

selected date and

time.

Notes.

• Once internal memory becomes full, oldest data is overwritten by newest data. If

historical review has been selected for some time, the oldest data present may no longer

be available.

• The instrument exits historical review mode automatically after 3 hours or when the

oldest channel data file start time (which changes as files wrap) is earlier than the time

that historical review mode was selected.

Exit

Select Exit to return to the real-time recording display.

Note. Pressing the key also exits Historical Review mode and displays the next

enabled view.

7

Page 10

…2 OPERATION

…2.3 Chart View

Operator Messages

Message 1

Duty/Stby Switched

Message 3

Message 6

Chart Annotation

✓ Alarms

✓ Operator Messages

Screen Interval

18 Seconds/Screen

90 Seconds/Screen

1 Minute/Screen

✔3 Minutes/Screen

7 Days/Screen

Add one of six preset Operator Messages to the alarm event log. The selected message

is displayed briefly in a dialog box. If Operator Message annotation is selected (see Chart

Annotation below) the message is also added to the chart.

Note. When the instrument is in Historical Review mode, Operator Messages

generated are added at the current time, not the time indicated by the cursor.

If an alarm or operator message is obscuring part of a chart trace, use the Chart

Annotation option to hide or display alarms and messages on the screen.

Select the annotation required. ✓ indicates the annotations selected.

The possible combinations are: No annotation (Alarms and Operator Messages both

disabled); Alarm annotation only or Alarms and Operator Message annotation. Operator

Message Annotation cannot be enabled unless Alarm Annotation is also enabled.

Notes.

• If more than 15 icons are present on the screen, chart annotation is disabled

automatically.

• When chart annotation is disabled, new operator messages and alarms are still added

to the Alarm event log – see Section 2.7

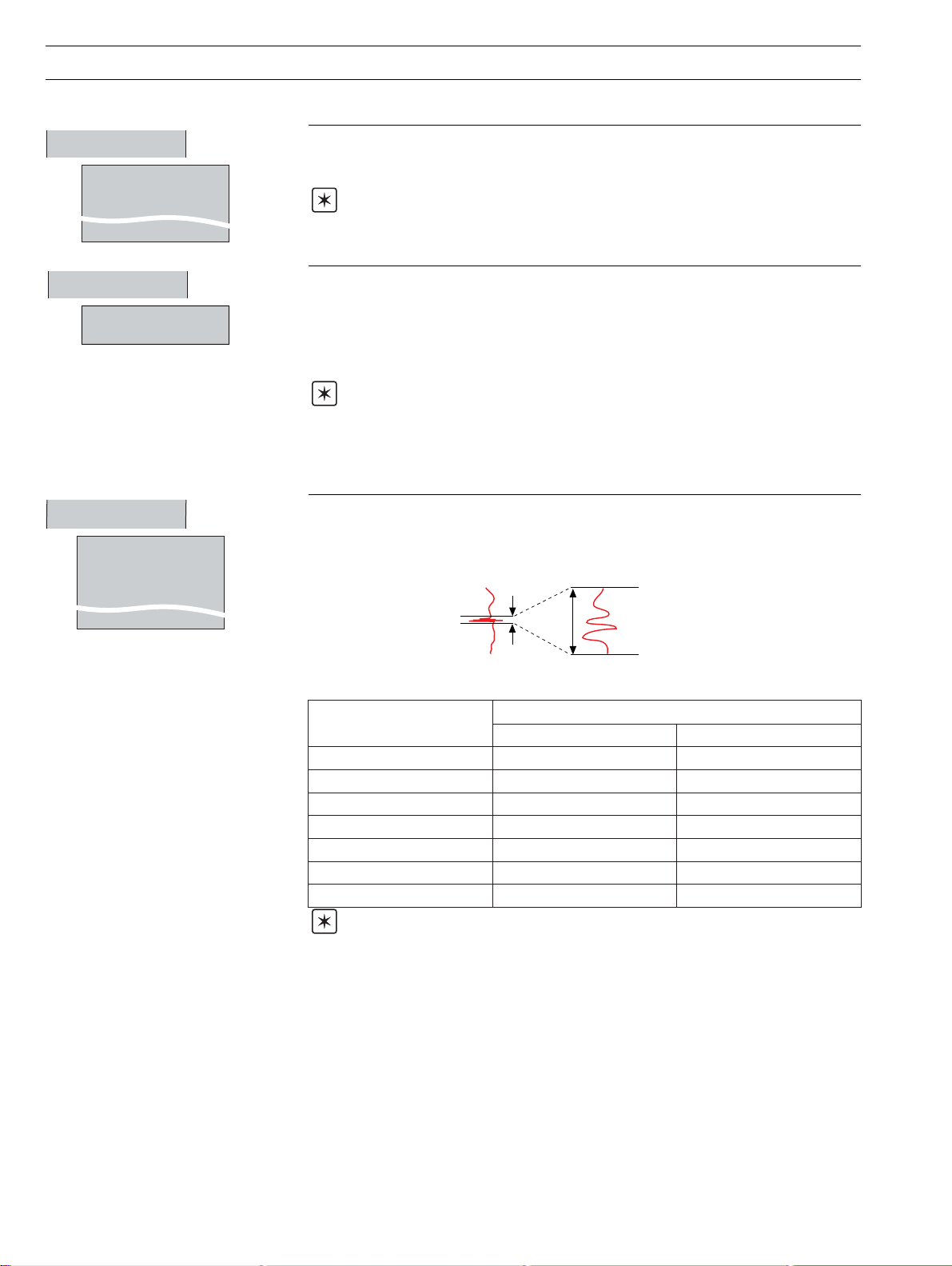

Use the Screen Interval to change the amount of data displayed on the screen. A longer

screen interval displays more data, a shorter screen interval displays data over a shorter

time period, but in more detail. In both cases, the full trace is preserved by plotting the

maxiumum and minimum samples for each display point.

Longer interval =

better overview

Shorter interval

= more detail

The maximum screen interval is determined by the sample rate.

gnitteSetaRelpmaS

s1<neercs/setunim9otpUneercs/setunim31otpU

s01dna1neewteBneercs/ruoh1otpUneercs/sruoh5.1otpU

s02nahtssel,s01nahteroMneercs/sruoh21otpUneercs/sruoh81otpU

s04dna02neewteBneercs/yad1otpUneercs/syad5.1otpU

s06dna04neewteBneercs/yad2otpUneercs/syad3otpU

s041nahtssel,s06nahteroMneercs/syad3otpUneercs/syad5.4otpU

s041nahteroMneercs/syad7otpUneercs/syad01otpU

weiVtrahClacitreVweiVtrahClatnoziroH

lavretnIneercSxaM

Notes.

•A 'Please Wait' dialog box appears while the instrument retrieves data from storage.

• Selecting a different screen interval does not affect the rate at which data is sampled.

• When in historical review mode, changing the scan interval may cause the time at the

cursor position to change slightly.

8

Page 11

…2.3 Chart View

2 OPERATION…

Scales

Select

✔ Ch 1.1 Level

Ch 1.2 Pressure

Auto Scroll

Trace Select

✔ Ch 1.1 Level

✔ Ch 1.2 Pressure

✔ Ch 1.3 In Flow

✔ Ch 1.4 Out Flow

Ch 1.5 Temp

✔ Ch 1.6 Alarm 1

Show all

Alarm Acknowledge

Ch 1.1 Level

Ch 1.2 Pressure

Ch 1.3 In Flow

Ch 1.4 Out Flow

Ch 1.5 Temp

Ch 1.6 Alarm 1

All

Scales

Select

Select the scale displayed in the scale bar at the top of the chart window. For digital

channels, the On and Off tags are displayed at the corresponding position on the scale bar.

Select Auto Scroll to display the scale for each channel in turn for a few seconds.

Note. If Auto Scroll is selected, only enabled and selected channels' scales are

displayed.

Hide individual channel traces to improve chart clarity.

Traces are identified by the Channel Number (e.g. Ch1.1) and its short tag. In this example,

the trace for Channel 5 is not shown.

Note. The recording of a channel's data is not affected by this operation and the

instantaneous channel values are still shown on the indicators at the top of the screen.

Used to acknowledge active alarms in the current process group either individually or

globally.

Note. Active alarms are identified by a flashing red 'Alarm Status' icon in the bottom

left hand corner of the associated channel indicator – see Fig. 2.4.

If neither alarm on a particular channel is configured, the short channel tag is shown

greyed-out in the menu.

9

Page 12

…2 OPERATION

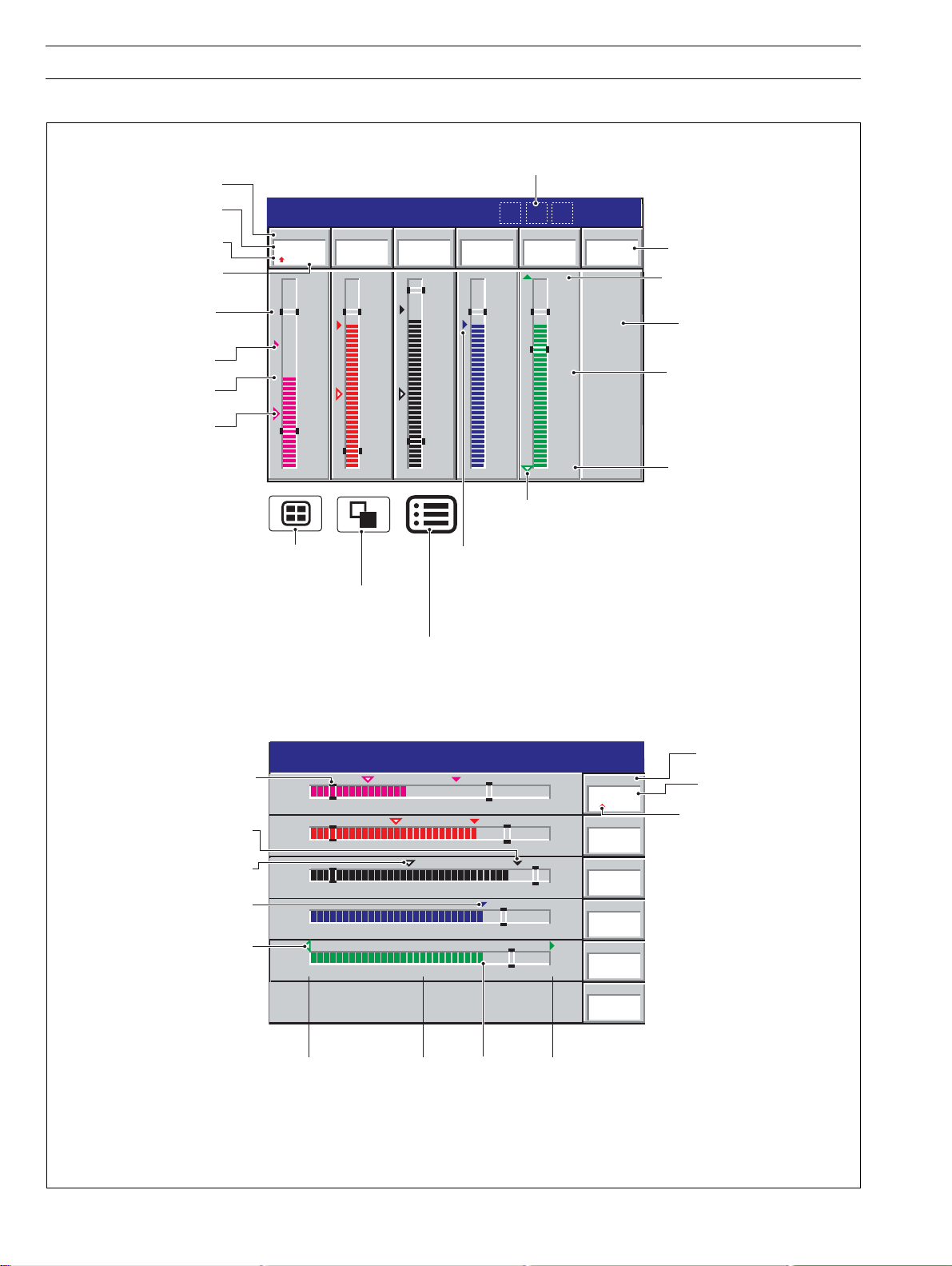

2.4 Bargraph Views (Horizontal and Vertical)

Short Channel Tag

Current Value

Alarm Status –

see Rear fold-out

Engineering Units

Alarm Trip Level

(not shown for slow and

fast rate alarms)

Maximum Value

(solid color)

Instantaneous Value

Minimum Value

(white fill)

Process Group 1

metres

5.0

2.5

Pressure

5.0

2.5

Level

2.08

Status Icons –

see Rear Foldout

28/03/00

14:52:00

195

250

125

Alarm 1

On

°C

Digital On or Off tag,

according to input status

Engineering Range High Value

Digital

Channel

Engineering Range

Middle Value

Temp

l/hr

300

150

300

150

Out Flow

198.9

l/hr

In Flow

204.9

4

bar

0.0

Selects the next Process Group

(if enabled) or Status View

Selects the next enabled view in the group

(Digital Indicator, Process or Chart)

Opens the Operator Menu for

Alarm Trip Level

Process Group 1

(not shown for slow and

fast rate alarms)

Maximum Value

(solid color)

Minimum Value

(white fill)

Identical Maximum

and Minimum Values

Minimum below

engineering limit,

Maximum above

engineering limit

0.0

0.0

0

0

0

0.0

0

0.0

Identical Maximum and Minimum Values

the current view

A – Vertical Bargraph View

2.5

2.5

150

150

125

0

Minimum below engineering

limit, maximum above

engineering limit

28/03/00

14:52:00

Level

5.0

5.0

300

300

250

2.08

metres

Pressure

In Flow

204.9

Out Flow

198.9

Temp

195

Alarm 1

4

bar

l/hr

l/hr

°C

On

Engineering Range Low Value

Short Channel Tag

Current Value

Alarm Status – see

Rear Fold-out

10

Engineering

Range

Low Value

Engineering

Range

Middle Value

Instantaneous

Value

Engineering

Range High

Value

B – Horizontal Bargraph View

Fig. 2.4 Bargraph Views

Page 13

…2.4 Bargraph Views (Horizontal and Vertical)

2 OPERATION…

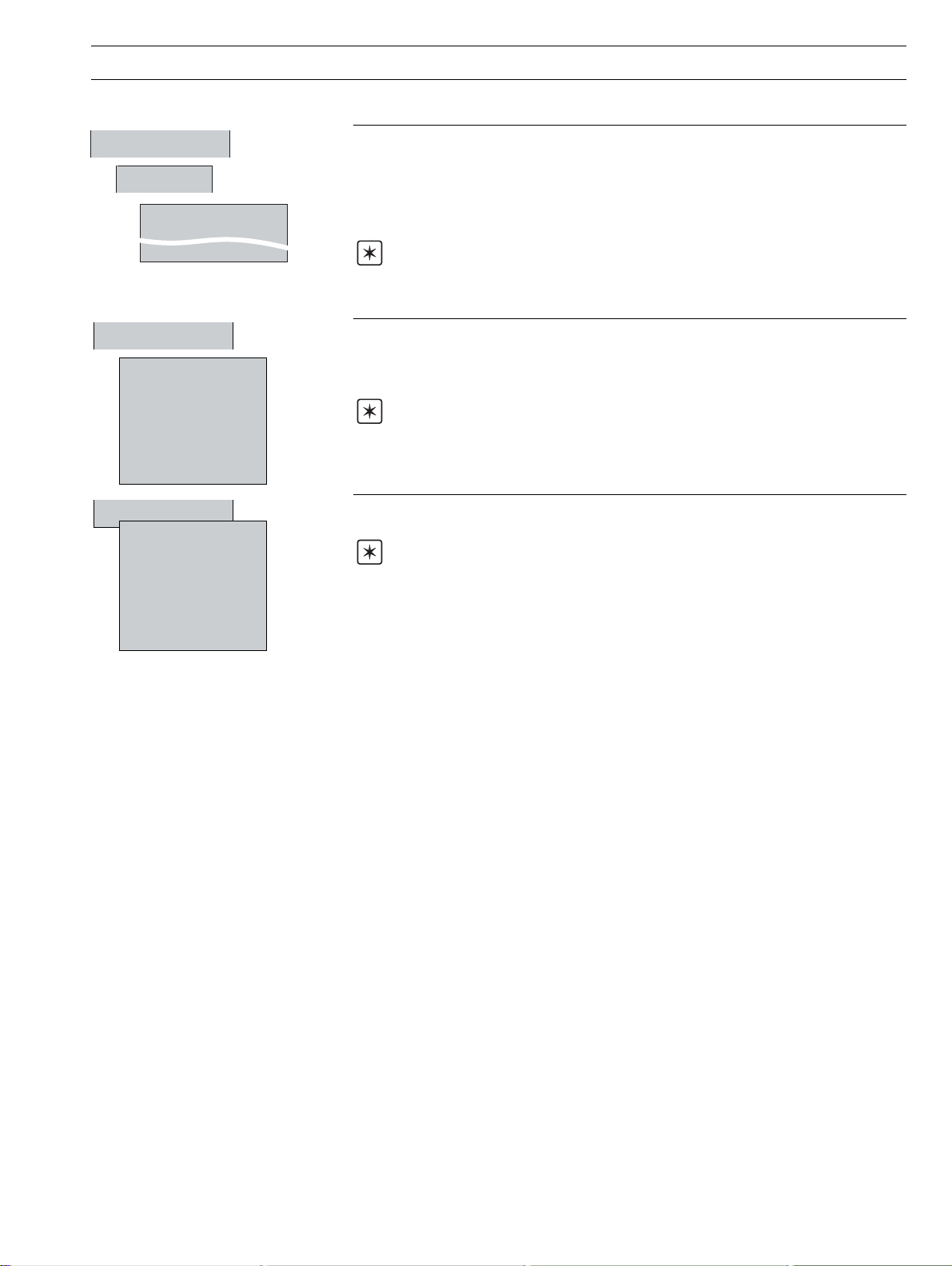

Configuration

Setup

Operator Messages

Message 1

Duty/Stby Switched

Message 3

Message 6

Max/Min Reset

Ch 1.1 Level

Ch 1.2 Pressure

Ch 1.3 In Flow

Ch 1.4 Out Flow

Ch 1.5 Temp

Ch 1.6 Alarm 1

All

Alarm Acknowledge

Ch 1.1 Level

Ch 1.2 Pressure

Ch 1.3 In Flow

Ch 1.4 Out Flow

Ch 1.5 Temp

Ch 1.6 Alarm 1

All

Select the Configuration level – See Section 4.

Select the Setup level – see Section 3.

Add one of six preset messages to the alarm event log. The selected operator message is

displayed on-screen briefly.

Reset the Maximum and Minimum value markers on one or all channels to the current

value.

Note. These Maximum and Minimum values are for display purposes only. They are

not saved or archived and are not connected to the Totalizer Maximum and Minimum

Values displayed in the Process View.

Note. These Maximum and Minimum values are reset whenever the current

configuration has been changed or is re-saved.

Acknowledge active alarms in the current process group either individually or globally.

Note. Active alarms are identified by a flashing red 'Alarm Status' icon in the bottom

left hand corner of the associated channel indicator – see Fig. 2.4.

If neither alarm on a particular channel is configured, the short channel tag appears

greyed-out in the menu.

11

Page 14

…2 OPERATION

2.5 Digital Indicator View – Fig. 2.5

Status Icons

4

578494

28/03/00

14:52:00

metres

bar

3

m

litre/h

3

m

Short Channel Tag

Current Value

Alarm Status –

see Rear Fold-out

Engineering Units

Selects the next Process Group

(if enabled) or the Status View

Notes.

• Indicators resize automatically according to the number of channels displayed.

•Totalizer option must be fitted and Totalizers must be configured and enabled before they can be

displayed – see Section 4.6.5.

•Totalizer values are shown in red if the totalizer is not running.

Process Group 1

Level

Level

2.08

2.08

578494

In Flow

204.4

0005402801

Temp

195

Selects the next enabled

view in the group

(Process, Chart or Bargraph)

Pressure

metres

metres

3

m

2.08

Out Flow

litre/h

m

3

198.4

0005402060

Alarm 1

°C

Opens the Operator Menu for

the current view

On

Channel Units

To talizer Units

To ta lizer Value

12

Fig. 2.5 Digital Indicator View

Page 15

…2.5 Digital Indicator View

2 OPERATION…

Configuration

Setup

Operator message

Message 1

Duty/Stby Switched

Message 3

Message 6

Channel select

✔ Ch 1.1 Level

✔ Ch 1.2 Pressure

✔ Ch 1.3 In Flow

✔ Ch 1.4 Out Flow

✔ Ch 1.5 Temp

✔ Ch 1.6 Alarm 1

Select the Configuration level – see Section 4.

Select the Setup level – see Section 3.

Add one of six preset operator messages to the alarm event log. The selected message is

displayed on screen briefly.

Hide or display individual channel indicators.

Note. The display is re-adjusted according to the number of channels selected. This

has no effect on the recording of the channel.

Process Group 1

Level

26.78

Out Flow

198.4

0005402060

metres

m

gal/hr

3

In Flow

204.4

Temp

28/03/00

14:52:00

0005402801

m

195

°C

Process Group 1

In Flow

gal/hr

3

204.4

Out Flow

0005402801

198.4

m

m

28/03/00

gal/hr

3

gal/hr

3

14:52:00

Process Group 1

In Flow

204.4

0005402801

28/03/00

14:52:00

gal/hr

3

m

One Channel SelectedTwo Channels SelectedThree or Four

Channels Selected

Totalizer stop/go

Ch 1.1 Level

Ch 1.2 Pressure

Ch 1.3 In Flow

Ch 1.4 Out Flow

✔ Stop

Ch 1.5 Temp

Ch 1.6 Alarm 1

All

Totalizer reset

Ch 1.1 Level

Ch 1.2 Pressure

Ch 1.3 In Flow

Ch 1.4 Out Flow

Ch 1.5 Temp

Ch 1.6 Alarm 1

Alarm acknowledge

Ch 1.1 Level

Ch 1.2 Pressure

Ch 1.3 In Flow

Ch 1.4 Out Flow

Ch 1.5 Temp

Ch 1.6 Alarm 1

All

Go

Stop and start individual totalizers.

Note. Displayed only if Totalizer option fitted.

Channel totalizers that have not been enabled in the configuration level are shown greyed

out.

Note. When a totalizer is not running (i.e. Stop is selected), the corresponding

totalizer value is shown in red.

Reset the totalizer value to the totalizer preset value.

Notes.

• Displayed only if Totalizer option fitted.

• Channel totalizers that have not been enabled in the Configuration level are shown

greyed out

Acknowledge active alarms individually, in the current process group or globally.

Note. Active alarms are identified by a flashing red 'Alarm Status' icon in the bottom

left hand corner of the associated channel indicator.

If neither alarm on a particular channel is configured, the short channel tag is greyed-out in

the menu.

13

Page 16

…2 OPERATION

2.6 Process View – Fig. 2.6

Note. This view is available only if the Totalizer option is fitted.

To ta lizer not

enabled in

configuration level

To ta lizer

Tag Name

To ta lizer

Value

Selects the next Process Group

(if enabled) or the Status View

Selects the next enabled view

(Bargraph, Digital Indicator or Chart)

Opens the Operator Menu for

Alarm Tag

Process Group 1

Total Daily In Flow

0005402801

Total Daily Out Flow

0005402060

the current view

Tank 1 Low Level

Tank 1 High Level

Tank 1 Low Pressure

Tank 1 High Pressure

Low In Flow Rate

High In Flow Rate

litres

High Out Flow Rate

litres

Tank 1 Low Temp

Tank 1 High Temp

Alarm Trip Level

1.25

4.75

0.25

4.75

280

250

150

200

40

Alarm Acknowledged

28/03/00

14:52:00

Level

2.08

metres

Pressure

4

bar

In Flow

204.9

l/hr

Out Flow

198.9

l/hr

Temp

195

°C

Alarm 1

On

Short Channel Tag

Instantaneous Value

Alarm Status

A – Process View (Alarms)

Channel Source Long Tag

Total Daily In Flow

0005402801

litres

Storage Tank 1 In Flow

225.4 110.9 201.0

Max

Min

Average

In Flow

204.9

l/hr

Values since last totalizer reset or totalizer wrap. Calculated only while

the totalizer is enabled. Updated only while the totalizer is running.

B – Process View (Statistics)

Notes.

• Only totalizers that have been enabled in the configuration level are displayed.

• When a totalizer is not running (i.e. Stop is selected), the corresponding totalizer value is shown

in red.

Fig. 2.6 Process View

14

Page 17

…2.6 Process View

2 OPERATION…

Configuration

Setup

View Select

✔ Alarms

Statistics

Operator Messages

Message 1

Duty/Stby Switched

Message 3

Message 6

Totalizer Stop/Go

Ch 1.1 Level

Ch 1.2 Pressure

Ch 1.3 In Flow

Ch 1.4 Out Flow

✔ Stop

Ch 1.5 Temp

Ch 1.6 Alarm 1

All

Go

Select the Configuration level – see Section 4.

Select the Setup level – see Section 3.

Switch between the Alarm View and Statistics View.

Note. If a channel's totalizer has not been enabled in the Configuration level, Alarm

trip levels are shown in place of the channels statistics. If no alarms are enabled, the

channel long tag is displayed for that channel.

Add one of six preset messages to the alarm event log. The selected message is displayed

on screen briefly. Messages are set in the Configuration level – see Section 4.

Stop and start individual totalizers.

Note. Channel totalizers that have not been enabled in the Configuration level are

shown greyed out.

Note. When a totalizer is not running (i.e. Stop is selected), the corresponding

totalizer value is shown in red.

Totalizer Reset

Ch 1.1 Level

Ch 1.2 Pressure

Ch 1.3 In Flow

Ch 1.4 Out Flow

Ch 1.5 Temp

Ch 1.6 Alarm 1

Alarm Acknowledge

Ch 1.1 Level

Ch 1.2 Pressure

Ch 1.3 In Flow

Ch 1.4 Out Flow

Ch 1.5 Temp

Ch 1.6 Alarm 1

All

Reset the totalizer value to the totalizer preset value.

Note. Channel totalizers that have not been enabled in the Configuration level are

shown greyed out.

Acknowledge active alarms in the current process group, either individually or globally.

Note. Active alarms are identified by a flashing red 'Alarm Status' icon in the bottom

left hand corner of the associated channel indicator – see Fig. 2.6.

If neither alarm on a particular channel is configured, the channel short tag is greyed out in

the menu.

15

Page 18

…2 OPERATION

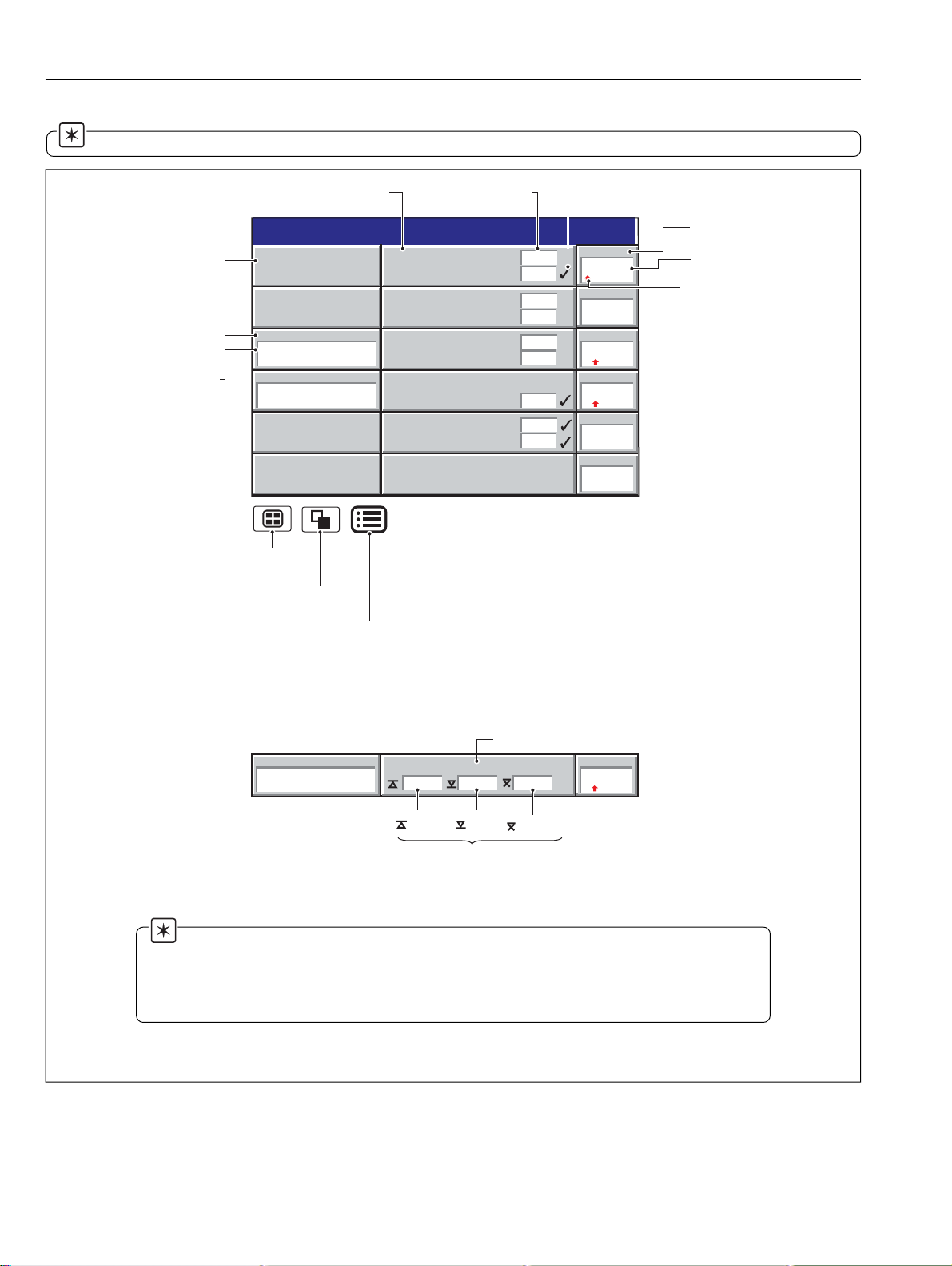

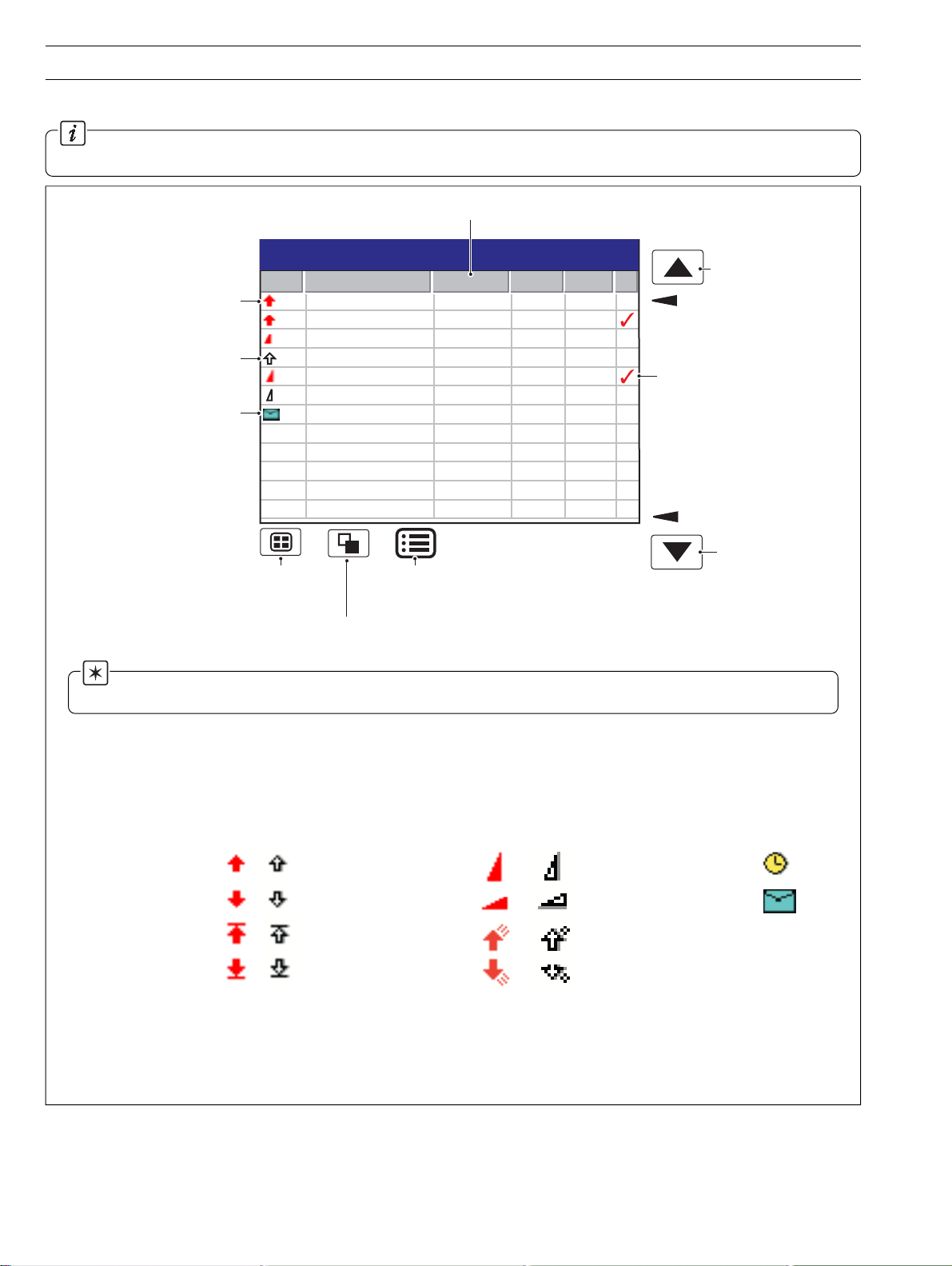

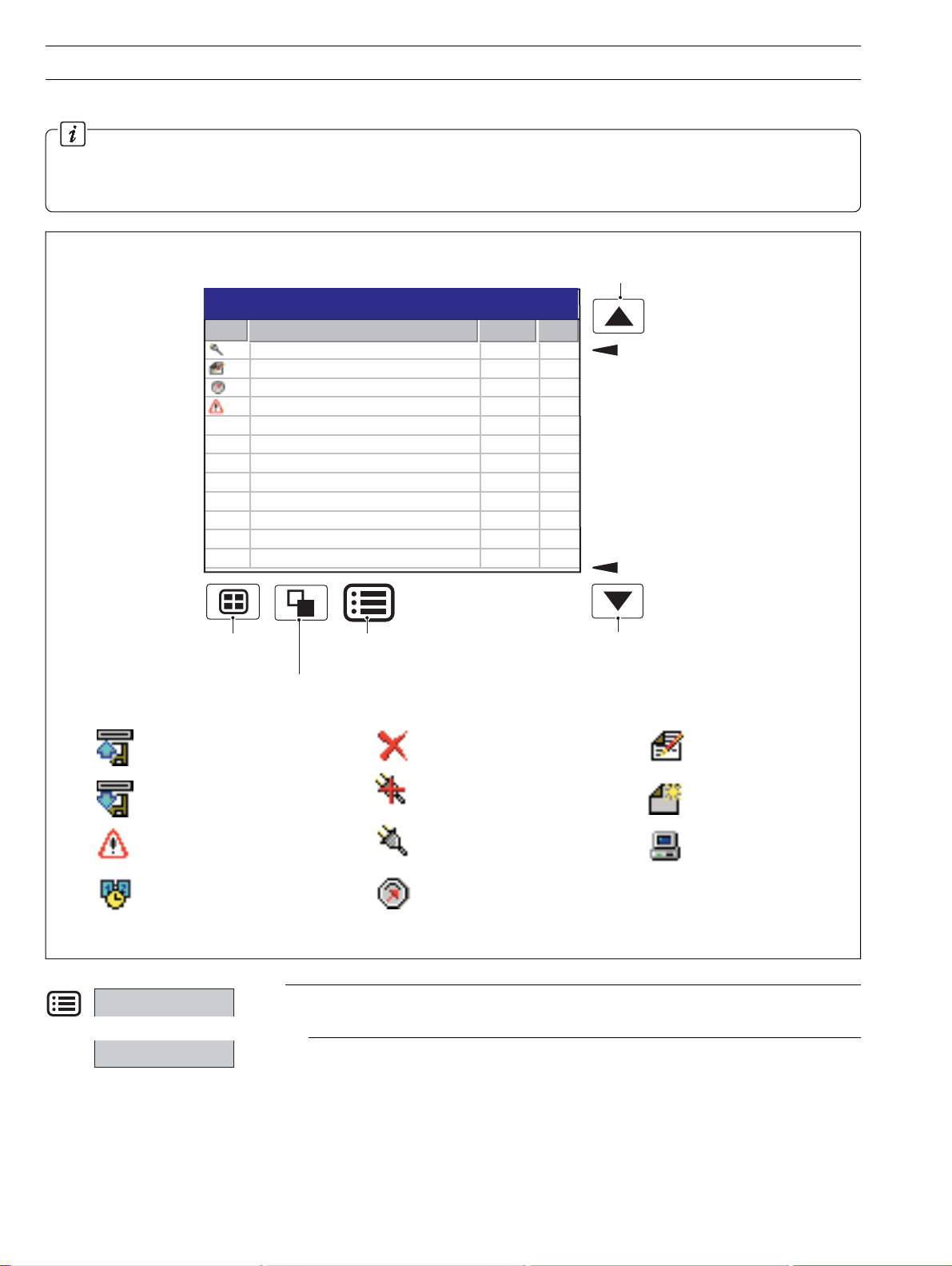

2.7 Alarm Event Log – Fig. 2.7

Information. This view provides an historical log of all alarm events in the sequence in which they occurred. To view the

current status of all alarms, choose the Process View – see Section 2.6.

Short tag of the alarm's source

28/03/00

14:52:00

View previous

page of data

Oldest Data

Alarm Acknowledged

Newest Data

View next

page of data

Alarm becomes active

(Active transition)

Alarm becomes inactive

(Inactive transition)

Operator Message

Alarm Event Log

No Alarm Event Tag Source Tag Date Time

00 Tank 1 High Level Level 28/08/00 14:01:22

01 Tank 1 High Level Level 28/08/00 14:03:51

02 High Out Flow Rate Out Flow 28/08/00 14:09:09

03 Tank 1 High Level Level 28/08/00 14:11:33

04 High Out Flow Rate Out Flow 28/08/00 14:12:47

05 High Out Flow Rate Out Flow 28/08/00 14:15:01

06 Duty/Standby Change Out Flow 28/08/00 14:31:19

Selects

Process

Group 1

Selects the

Totalizer Log

Opens the

Operator Menu for

the current view

Note. When the alarm event log has reached the maximum number of entries, the oldest data is overwritten by the

newest. Entries are renumbered so that the number of the oldest entry is always 00.

High Process Alarm

Low Process Alarm

High Latch Alarm

Low Latch Alarm

Active

Inactive

A – Alarm Event View

Active

Fast Rate Alarm

Slow Rate Alarm

High Annunciate Alarm

Low Annunicate Alarm

B – Alarm Event Icons

Fig. 2.7 Alarm Event Log

Inactive

Real time alarm

Operator Message

16

Page 19

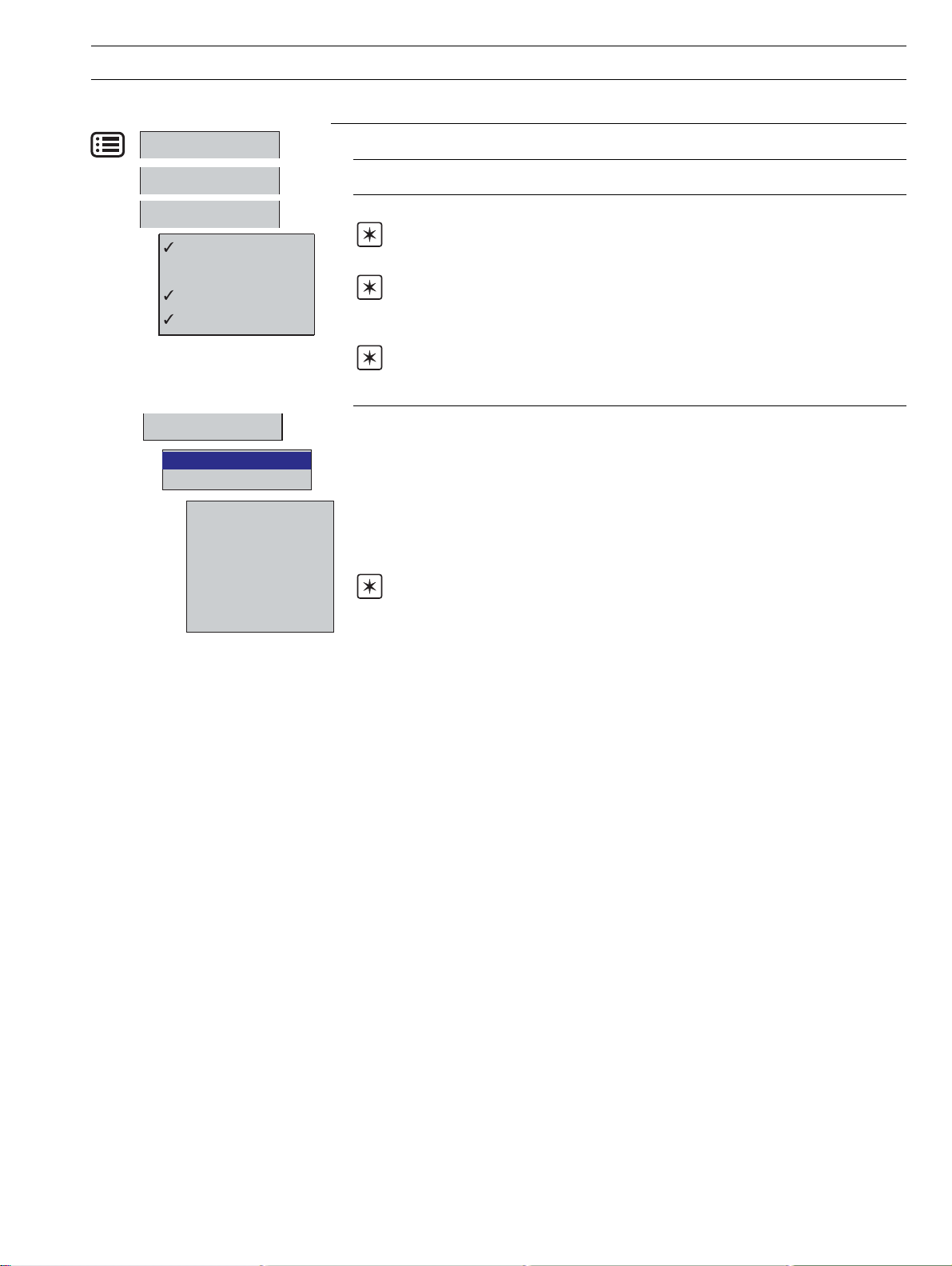

…2.7 Alarm Event Log

2 OPERATION…

Configuration

Setup

Filter

Group 1 Alarms

Group 2 Alarms

Operator Messages

Active Transitions Only

Alarm Acknowledge

Group 1 Alarms

Group 2 Alarms

Ch 1.1 Level

Ch 1.2 Pressure

Ch 1.3 In Flow

Ch 1.4 Out Flow

Ch 1.5 Temp

Ch 1.6 Alarm 1

All

Select the Configuration level – see Section 4.

Select the Setup level – see Section 3.

Select the entries displayed in the log. 4 Indicates categories currently displayed.

Note. Hiding and displaying log entries does not affect the recording of events in the

log.

Note. All selected alarm event transitions (from inactive to active, from active to

acknowledged, from acknowledged to inactive, from active to inactive) appear in the

sequence in which they occurred.

Note. Selecting 'Active Transitions Only' displays entries for alarms when made

active and hides all acknowledged & inactive transistions.

Used to acknowledge active alarms in each of the process groups, either individuallly or

globally.

Note. If neither alarm on a particular channel is configured, the short channel tag is

greyed-out in the menu.

17

Page 20

…2 OPERATION

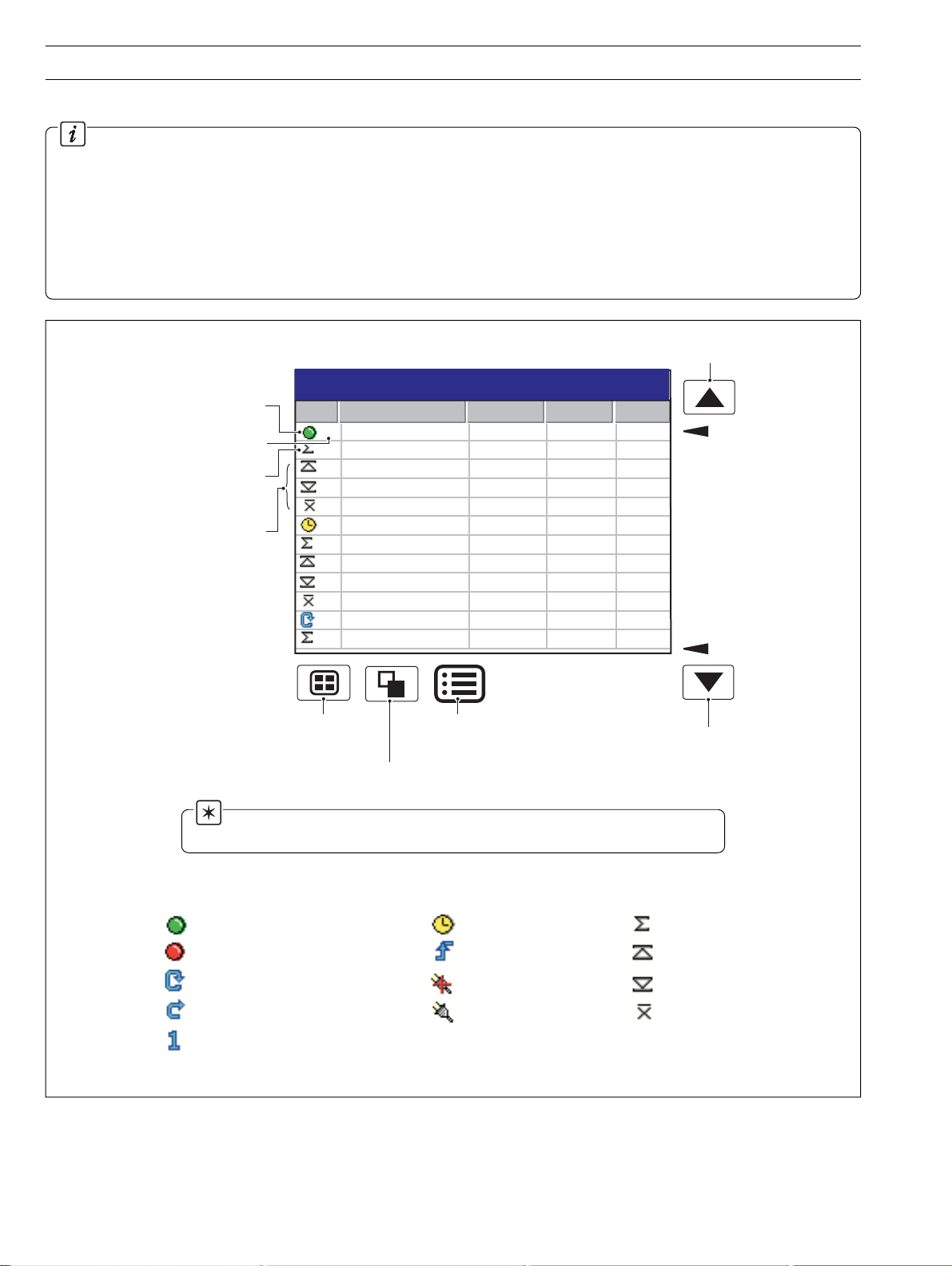

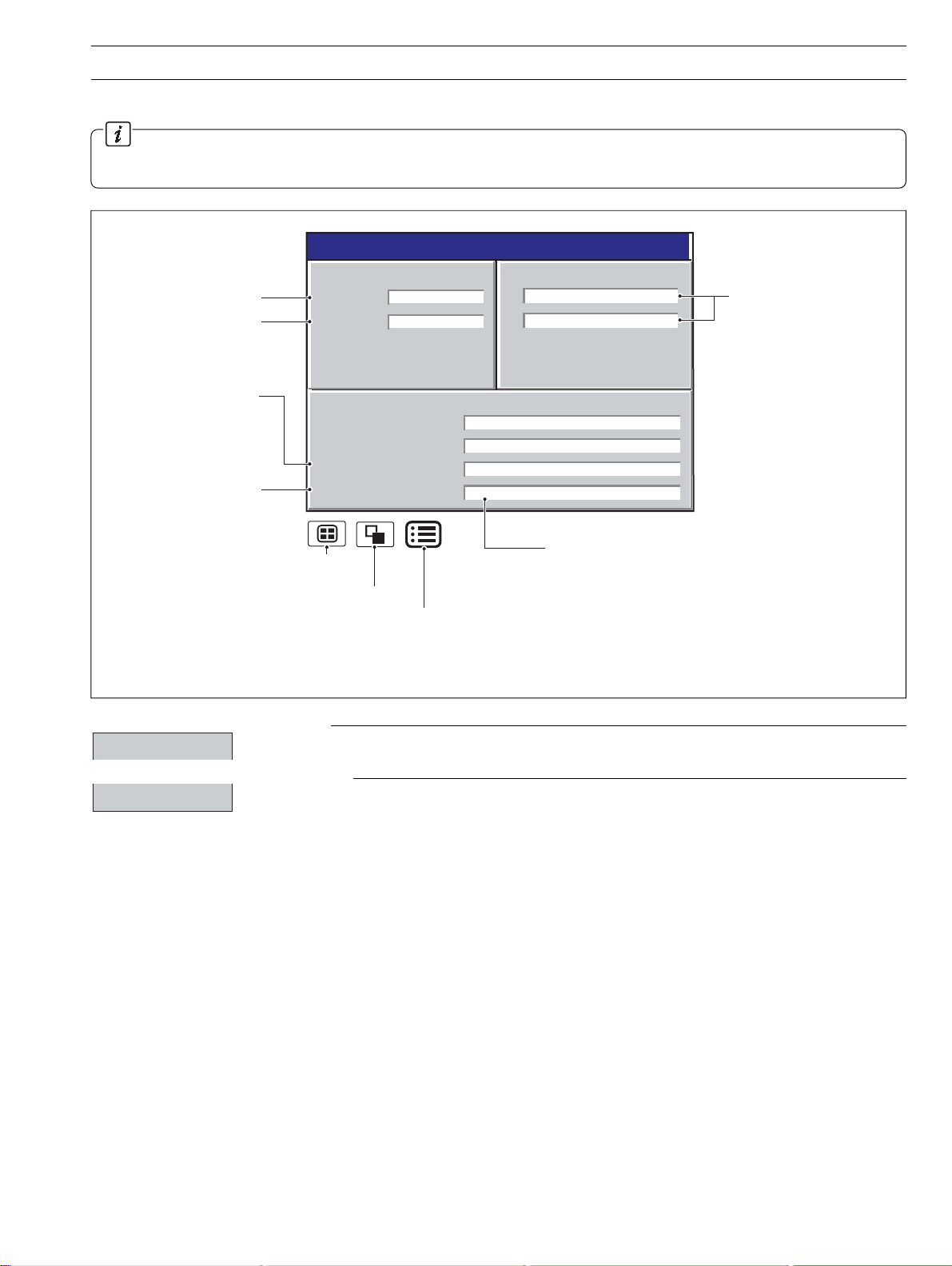

2.8 Totalizer Log – Fig. 2.8

Information.

• This view is displayed only if the Totalizer option is fitted.

• This view provides an historical log of totalizer activity. To view the current totalizer status, choose the Process or Digital View.

• When the totalizer log has reached the maximum number of entries defined in the Configuration level (see Section 4.4.3), the

oldest data is overwritten by the newest.

• The logging of totalizer values can be triggered at pre-determined intervals or by a digital signal assigned to the Totalizer Log

Source – see Section 4.6.5.

View previous

page of data

Icon –

see list below

Log Entry Number

Batch total at the

time of the event

Max., min. and

average of the value

being totalized at the

time of the event

Note. Maximum, Minimum and Average statistics are not shown unless

enabled in the Filters menu – see overleaf.

Totalizer Log

No Tag/Value Source Tag Date Time

00 Total Daily In Flow In Flow 28/03/00 14:52

0005402801 Litres

225.4 l/hr

110.9 l/hr

201.0 l/hr

01 Total Daily Out Flow Out Flow 28/03/00 14:52

0005403191 Litres

235.8 l/hr

110.9 l/hr

210.0 l/hr

02 Total Daily Out Flow Out Flow 28/03/00 15:01

0005403120 Litres

Selects

Process

Group 1

Selects the

Audit Log

Opens the

Operator Menu for

the current view

28/03/00

14:52:00

Oldest

Data

Newest

Data

View next page

of data

18

Totalizer Started

Totalizer Stopped

Totalizer Wrapped

Totalizer Reset

Intermediate Value Reached

Timed Event

Triggered Event

Power Failed

Power Restored

Fig. 2.8 Totalizer Log

Batch Total

Maximum input

Minimum input

Average input

Page 21

…2.8 Totalizer Log

2 OPERATION…

Configuration

Setup

Filter

Group 1 Totalizers

Group 2 Totalizers

Statistics

Select the Configuration level – see Section 4.

Select the Setup level – see Section 3.

Select the log entries that are displayed. This does not affect which events are recorded in

the log.

Note. ✔ indicates entries displayed.

'Statistics' displays the maximum, minimum and average values of the analog value being

totalized.

These values are reset when the totalizer is reset and are updated only when the totalizer

is running.

19

Page 22

…2 OPERATION

2.9 Audit Log – Fig. 2.9

Information.

• This view provides an historical log of system activity.

• When the audit log has reached the maximum number of entries, the oldest data is overwritten by the newest.

View previous

page of data

Audit Log

No Alarm Event Tag Date Time

00 Power Restored 25/03/00 11:59

01 Configuration Change, Oper 1 25/03/00 12:01

02 Input Calibration 25/03/00 12:15

03 System Alarm 25/03/00 13:17

28/03/00

14:52:00

Oldest Data

Media Inserted

Media Removed

System Error

Time/date Changed

Configuration

Selects

Process

Group 1

Opens the

Operator Menu for

Selects the

Status View

the current log

File Deleted

Power Failed

Power Restored

Calibration Change

Fig. 2.9 Audit Log

Select the Configuration level – see Section 4.

Newest Data

View next

page of data

Configuration Change

File Created

FTP Logon

20

Setup

Select the Setup level – see Section 3.

Page 23

2.10 Status View – Fig. 2.10

Information.

• This view provides an overview of the instrument's status.

2 OPERATION

Instrument Software Version

Operating System Version

Amount of memory used

on the archive media

currently installed

Approximate time left

before the current archive

media is full, assuming the

amount of data recorded

remains the same

Selects Process Group 1

Selects the Alarm Event Log

Instrument Status

VERSION

Software

System

ARCHIVING

Group 1 Filename

Group 2 Filename

% Memory used

Time left

Opens the Operator Menu for

the current view

SM 2001/01

1001/1

CJ TEMPERATURES

25°C / 77°F

A

25°C / 77°F

B

Process Group 1

Process Group 2

80.5%

5 days

Time Left Display Format

>=1 Day: Days, e.g. '5 Days'

>=1 Hour, <1 Day: Hours, e.g. '10 hours'

<1 Hour: Minutes, e.g. '25 minutes'

Fig. 2.10 Status View

28/03/00

14:52:00

Cold junction temperatures

for Modules A & B; measured

by the built-in cold junction

circuitry.

'Not Used' is displayed if none

of the inputs on the module

are thermocouples.

Configuration

Setup

Select the Configuration level – see Section 4.

Select the Setup level – see Section 3.

21

Page 24

3 SETUP

3.1 Introduction

Information.

Users with Setup access can:

• Start/Stop recording.

• Switch between primary and secondary recording rates.

• Set archiving 'on-line' and 'off-line'.

•View internal and external archive media file directories and delete files

3.2 Accessing the Setup Level – Fig. 3.1

l/hr

High Out Flow Rate

28/03/00

Alarm 1

Temp

On

195

°C

Process Group 1

Pressure

Level

2.08

metres

010

12:00:00

11:59:00

11:58:00

11:57:00

bar

4

High Level

In Flow

204.9

Out Flow

198.9

l/hr

Note. Can be

activated from any

operator screen.

Setup

Setup

Setup

Security

Enabled

Setup Security

Not Enabled

Use the up and down keys to select your password.

Confirm with Enter key

0000

Invalid Setup

Password

Valid Setup

Password

Recording Control

Reset archiving

On-Line

Off-Line

Update

File Viewer

22

Fig. 3.1 Accessing the Setup Level

Page 25

3.3 Setup Menu

3 SETUP…

Recording Control

All

✔ Primary

Reset archiving

Stop

Secondary

Use this menu to stop and start recording or change the sample rate for the channels in the

current Process Group.

The Primary and Secondary sample rates allow a slow rate to be selected for normal

conditions and a faster rate for abnormal alarm conditions in order to record the maximum

amount of detail. The rates are set during configuration – see Section 4.5.1.

Notes.

• Switching between primary & secondary sample rates does not affect the screen

interval on the Chart View.

• When the channels are set to 'Stop' the instantaneous values in the associated

indicator are displayed in red and, after the end of the next sample period, no further

samples are plotted on the associated traces.

• Digital recording channels can only be set to 'Stop' or 'Go'.

• Recording control can also be implemented using digital sources – see Sections 4.5.1

and 4.6.1.

If selected, the date of the oldest unarchived data is set to that of the oldest data in the

internal flash memory. This allows all data in the internal memory to be re-archived to

external media.

Note. Ideally, a blank media storage card should be inserted prior to selecting this

function. If the original archive files are still present on the inserted card after Reset

acrchiving, the new, re-archived files are annotated '_1' to distinguish them from the

original archive files, e.g.

original archive file: 10_00 25Feb02 Zone abc.d00

re-archived file: 10_00 25Feb02 Zone abc_1.d00

On-line

Off-line

To re-archive data:

Insert archive media, with sufficient free space, into the instrument.

Select 'Off-line' in the Setup Menu

Select 'Reset archiving' in the Setup Menu

Select 'On-line' in the Setup Menu

Select amount of data to be archived (if >1 hour of data in internal memory)

Places the archive media on-line, starting the archiving process. Any un-archived data is

stored automatically to the removeable media. If there is un-archived data more than one

day old, a selection box is displayed – see 'Update' overleaf.

Notes.

• When an archive media card/disk is inserted, it is placed automatically on line.

• The On-line function is disabled (greyed out) in the Setup Menu when in Historical

Review mode.

Places the archive media off-line. Recording of channel data into internal memory

continues uninterrupted but archiving to the removeable media is suspended until it is put

on-line again.

Notes.

• Always set the external media Off-line before removing it.

• The Off-line function is disabled (greyed out) in the Setup Menu when in Historical

Review mode.

23

Page 26

…3 SETUP

…3.3 Setup Menu

Update

Select the amount of data to archive

No historical data

< 1 day old

< 2 days old

< 3 days old

< 4 days old

< 5 days old

< 6 days old

< 7 days old

< 2 weeks old

All historical data

More than 1 day of

unarchived data has been

detected. Please select the

amount of data to be

archived and press enter.

Saves any unarchived data to the removeable media.

Any unarchived data less than one day old is saved automatically to removeable

media. If there is any un-archived data more than one day old, a selection box is

displayed, allowing the user to determine which data is archived to external

memory.

Once selected, all data within the selected time frame is archived. Older unarchived data remains in the internal memory buffer until overwritten by newer

data, but is not available for archiving to removeable media.

File Viewer

Internal

External

External File Viewer

Name Size

SM2000.cfg 17848

12_10_59 011100 SM2000.cfg 17848

13_09_48 311200 SM2000.cfg 17848

13_59_37 280800 SM2000.cfg 17848

21_49_58 010100 SM2000.cfg 17848

Delete

Use the file viewer to view a list of the files stored in internal memory and on external archive

media.

Note. Files stored in internal memory cannot be deleted.

Exit

24

Page 27

3 SETUP…

3.4 Archiving

Recorded data, logs and configuration files stored on the instrument's internal memory can be archived to files created on removeable

media. Parameters for archiving Process Groups 1 and 2 data are setup independently.

Note. For further information on Archiving refer to Section 4.5.6 – Archiving Configuration.

3.4.1 SmartMedia Handling and Care

Note. The instrument is designed to work only with 3.3V SmartMedia cards.

Follow the manufacturers' recommendations.

1) Avoid touching the gold connectors on SmartMedia cards to prevent damage to the card from static electricity. Before touching

a memory card, ensure that you are discharged of static electricity by touching a grounded metal object.

2) Keep the gold contacts on the card clean to prevent card corruption on insertion of the card. Clean the contacts using a soft, clean

cloth before re-insertion in the instrument.

3) Do not bend the card or subject it to impacts.

4) Keep the card in an anti-static film case when not in use.

5) Do not place the card in direct sunlight.

3.4.2 Media Status – Fig. 3.2

Process Group 1

28/03/00

External archive media on-line

(green icon, shaded area indicates % used)

External archive media off-line

(grey icon, shaded area indicates % used)

Instrument Status

VERSION

CJ TEMPERATURES

°°

°°

28/03/00

External archive media update in progress.

External media 100% full, archiving stopped

ARCHIVING

Amount of memory used on the external archive

media currently installed

(white cross on red background)

Approximate time left before the current external

archive media is full, assuming the amount of data

recorded remains the same.

Time Left Display Format

>=1 Day: Days, e.g. '5 Days'

>=1 Hour, <1 Day: Hours, e.g. '10 hours'

<1 Hour: Minutes, e.g. '25 minutes'

Caution. Do not remove media while the icon (media update in progress) is displayed.

Fig. 3.2 Media Status Icons

25

Page 28

…3 SETUP

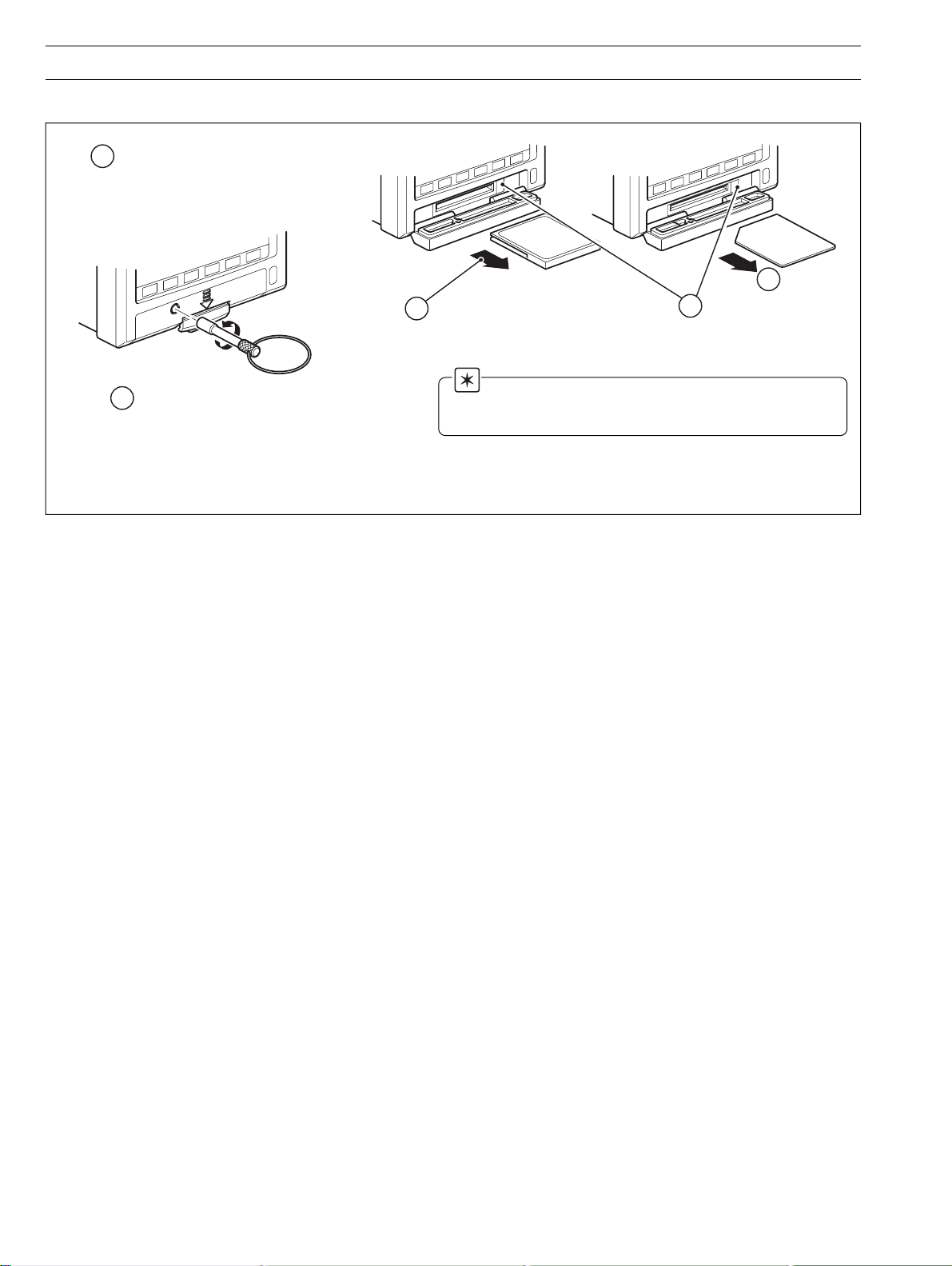

3.4.3 Inserting and Removing Media – Fig. 3.3

1

Ensure that the media is put off-line –

see Section 3.3

4

Withdraw the media

Compact Flash Media SmartMedia

3

Press the eject button

4

Unlock the media door with the key supplied

2

and press the release catch to open the door

Fig. 3.3 Inserting and Removing External Media

Note. When inserting the media into the instrument:

• Ensure that the media is the correct type for the instrument.

• Do not use excessive force.

26

Page 29

3 SETUP…

3.4.4 Archive File Types

Archive files created by the instrument are given filenames

automatically. Each type of archived file is given a different file

extension:

noisnetxE/epyTstnetnoC

/selifatadlennahC

**D.*

/selifgoltnevemralA

**E.*

/selifgolrezilatoT

**T.*

/selifgoltiduA

**A.*

erutangislatigiD

**S.*/selif

)spuorg

.elifatad

puorgssecorptnerruc

.slennahcgnidrocers’puorg

ehtnislennahcgnidrocerlatigidrogolanA

,stnevemralaehtfodrocerlacirotsihehT

.smralaemitlaerrosegassemrotarepoynafo

dnarezilatotllafodrocerlacirotsihehT

ehtotgnitalerseulavlacitsitatsdetaicossa

.goltiduaehtmorfseirtnelacirotsihehT

Note. Totalizer files are created only if the totalizer

option is fitted.

3.4.5 Channel Data Files

Channel data files can be configured to contain data gathered over

a predefined period of time using the 'New File Interval' setting.

lavretnielifweNemaneliF

ylruoH>emanelif<*>raey,htnom,yad<>sruoh<

yliaD.>gatemanelif<*>raey,htnom,yad<

ylhtnoM>gatemanelif<*>raey,htnom<

enoN>gatemanelif<

*nommoCnites'tamrofetaD'ehtotgnidroccadettamroF

Note. The New File Interval is set in the Configuration

level – see Section 4.5.6.

In addition to new files being created according to the New File

Interval selection, they are also created in the following

circumstances if automatic update is enabled and the media is

on-line or if a manually triggered update is in progress:

• The instrument's power is lost then restored.

• The instrument is taken offline and the archive media

removed, replaced or refitted.

• The instrument's configuration is changed.

• One of the current files exceeds the maximum

permissible size.

When one of these conditions occurs, new channel data files are

created for each enabled group and the file extension index on

each new file is incremented by one from the previous file.

Example – if the original file had an extension of .*D00, after one

of the above events a new file will be created with the same

filename but an extension of .D01.

.1.4.4noitceSees–noitarugifnoC

3.4.6 Filename Example

'New file interval' set to hourly, filename tag set to 'Process

Group 1'; date is 10th October 2000; Channel data and alarm

event log files only enabled:

9:00 am New file created in which all channel data recorded

between 9:00 and 9:59:59 is archived in the following

file:

09_00_10Oct00_Process_Group_1.d00

yrotsihehtsulpslennahcs’puorgehtotdetaler

09:12am Power interrupt occurs

09:13am Power restored and new file created:

09_00_10Oct00_Process_Group_1.d01

10:00am New file created in which all data recorded between

llarofemasehtsielifsihtfotnetnoceht:etoN(

10:00 and 10:59:59 is archived.

10_00_10Oct00_Process_Group_1.d01

lennahcgnidnopserrocehtroferutangislatigiD

Note.

• Hourly files start exactly on the hour.

• Daily files start at 00:00:01.

• Monthly files start at 00:00:01 on the first of the month.

3.4.7 Log files

The Alarm Event, Totalizer and Audit Logs are each archived into

one file. The filenames have the following formats, with the date

and the time indicating the first entry in the file:

eliFgoLemaneliF

tnevEmralA00e.>emanelif<*>yy,mm,dd<>nimruoh<

rezilatoT00t.>emanelif<*>yy,mm,dd<>nimruoh<

tiduA00a.>gattnemurtsni<*>yy,mm,dd<>nimruoh<

If one of the archive log files becomes full (>64000 entries) a new

file is created with an extension incremented by 1, e.g. a01, e01

etc.

Note. Totalizer logs are created only if the totalizer

option is fitted.

3.4.8 Online/Offline

Before data can be archived to external media, the external

media must be placed on-line and one or more archive file

enables must be set.

• External archive media is placed on-line automatically

when inserted.

• External archive media is set on-line and off-line in the Set

up menu – see Section 3.3.

•To avoid loss of data, external media must be set off-line

before removal.

Note. Data stored in the internal memory buffer can

still be stored to the archive media when the archive media

is placed on-line again (providing it is not off-line so long that

the un-archived data in the internal memory is overwritten).

noitarugifnoCnommoCnites'tamrofetaD'ehtotgnidroccadettamroF*

27

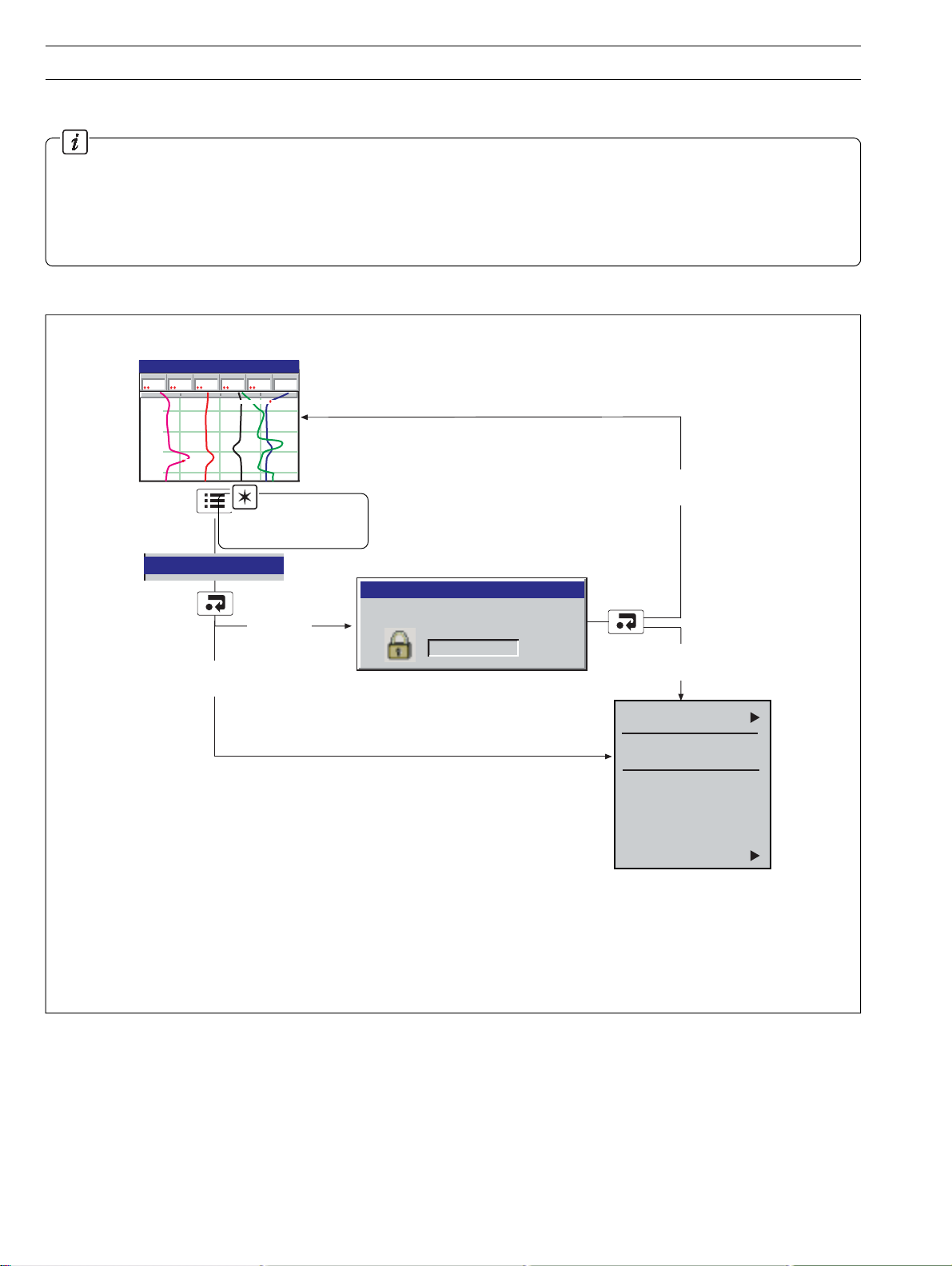

Page 30