ABB RS85 Operating Instructions Manual

—

ABB MEASUREMENT & ANALYTICS | OPERATING INSTRUCTION | OI/RS85– EN REV. K

RS85

Vibrating fork level switch

K–TEK Level products

Measurement made easy

Introduction

This operating instruction manual provides the

following information:

• installation

• setup

• time delay

• troubleshooting

2

RS85 VIBRATING FORK LEVEL SWITCH | OI/RS85-EN REV. K

Contents

1 Description .................................3

2 Installation .................................5

3 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Time delay .................................13

5 Troubleshooting........................... 14

6 Warranty statement ........................15

7 ABB RMA form ..............................16

RS85 VIBRATING FORK LEVEL SWITCH | OI/RS85-EN REV. K

1 Description

3

Introduction

The RS85 switch is a vibrating fork switch designed for liquid

level detection. The robust sensor design and built–in

temperature compensation ensure reliable response even in

the presence of very extreme process conditions. The LED

indicators of the RS85 modular electronics allow for simple

set–up and status detection. Configuration is via

pushbuttons or a provided magnet. The rugged construction

allows it to withstand the rigors of just about any industrial

environment.

Theory of operation

The RS85 vibrating switch utilizes a piezoelectric driven

tuning fork that exhibits a change in resonant frequency

when the forks are immersed in any liquid. 'Smart'

microprocessor–based electronics keep the sensor in a

resonant state as it changes from dry to wet or wet to dry.

The resonant frequency is continuously monitored for

changes created by a wet or dry sensor and an alarm (change

in LED) is provided along with a DPDT relay. An important

feature of this device is that its resonant frequency is not

significantly affected by coating on the fork unless the space

between the forks is bridged. The RS85 ability to identify true

liquid level in viscous, coating or aerated liquid is

unparalleled. The self–test option continuously checks for

fault conditions such as a damaged sensor and under fault

conditions displays a blinking red LED visible through the

glass cover. Applications include high/low liquid level

detection and are unaffected by parameters such as specific

gravity, dielectric constant or mounting position of the

sensor.

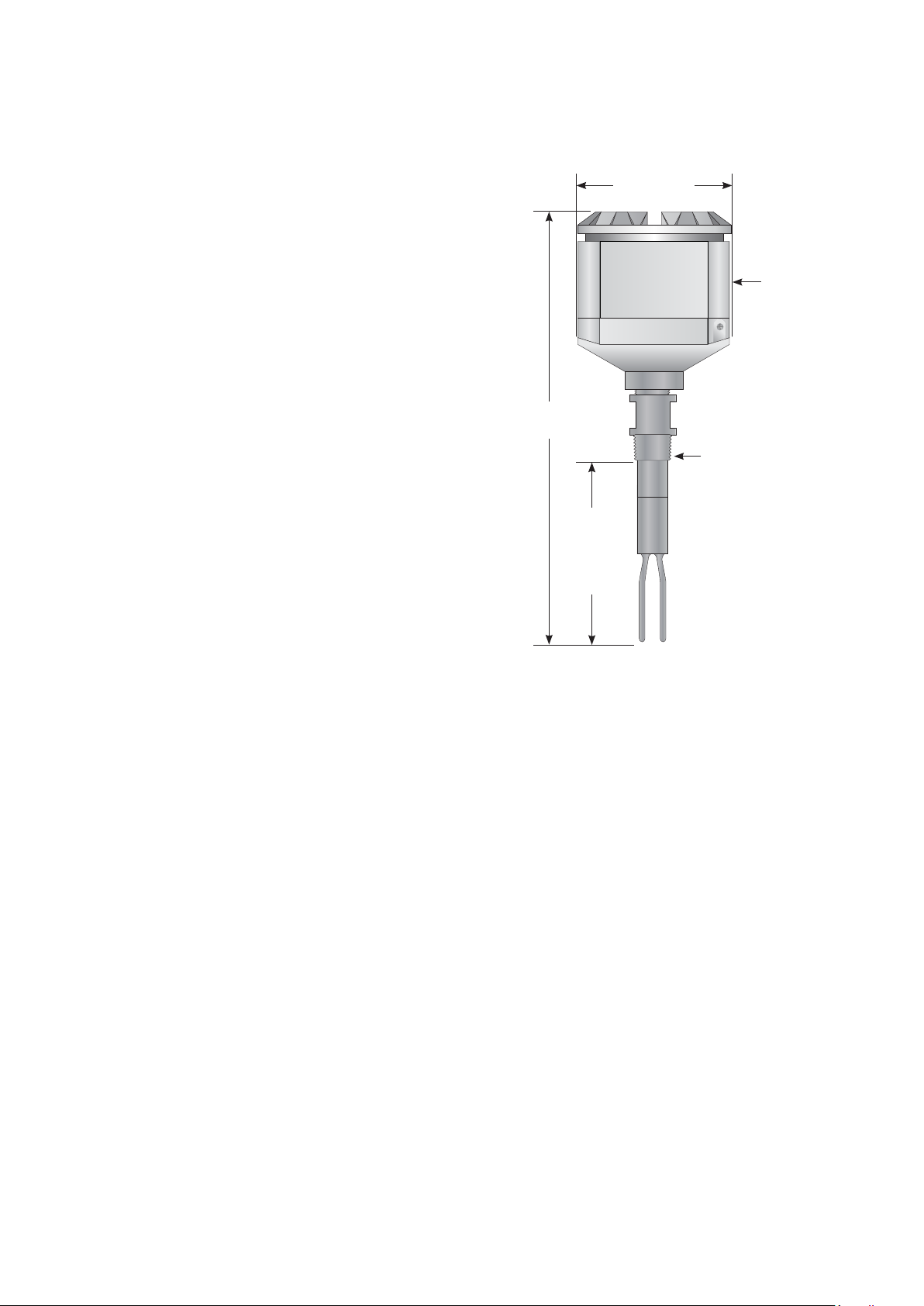

Dimensions

111 mm

19.05 mm (¾ in)

FNPT

cable entry

279 mm (11 in)

Standard

19.05 mm (¾ in)

MNPT standard

Standard

86 mm

PL*

*Trip point 19.05 mm (¾ in)

from end of probe type

Figure 1

Specification

For detailed specifications consult the RS85 data sheet (DS/

RS85–EN).

4

RS85 VIBRATING FORK LEVEL SWITCH | OI/RS85-EN REV. K

... 1 Description

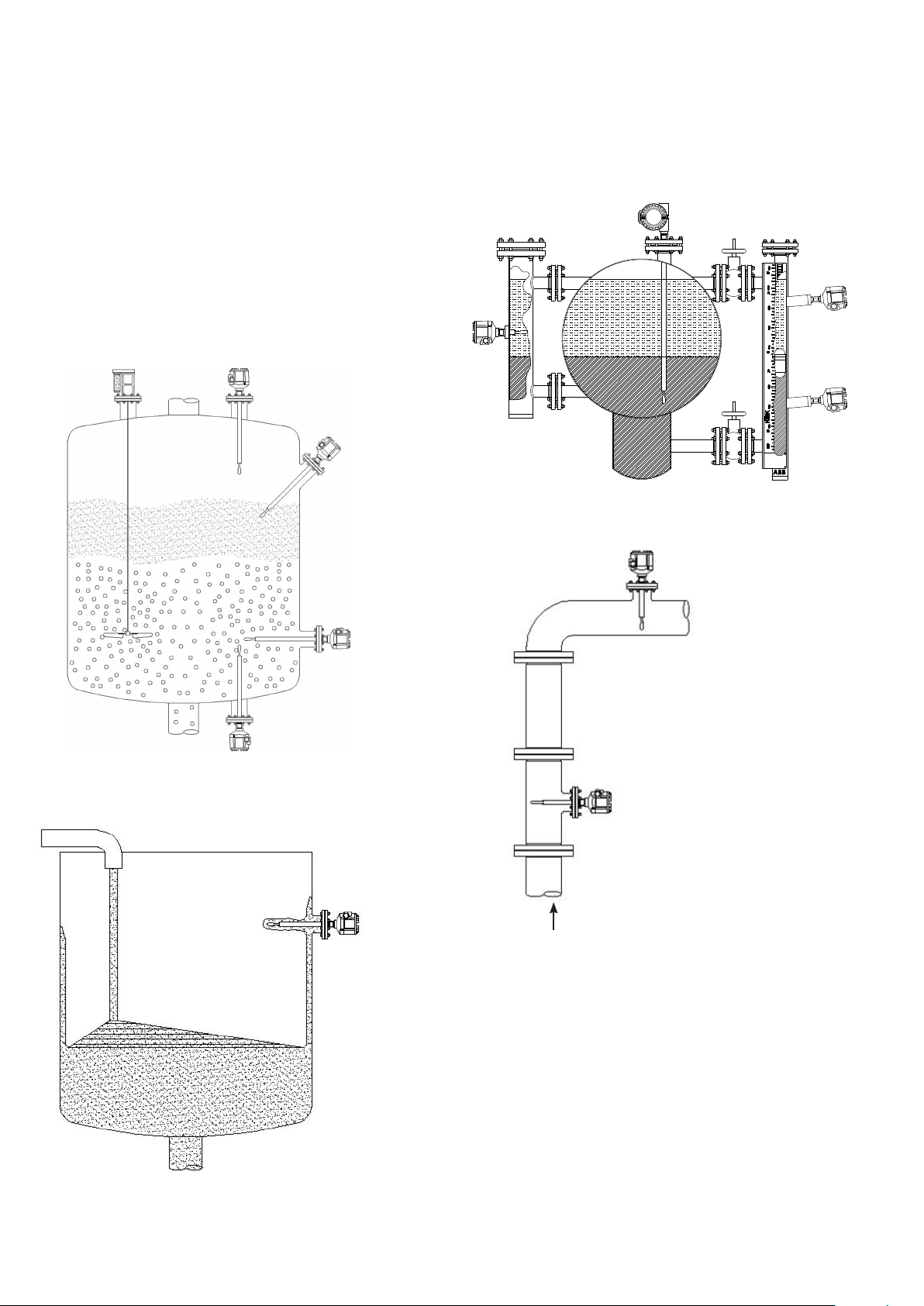

Sample applications

The RS85 can be used for level detection in tanks, vessels or

piping containing all types of hot or cold liquids and is

suitable for high/low level detection applications in

hazardous areas. The RS85 can be mounted in any

orientation. In vertical applications where room allows, the

unit can be extended into the vessel (up to 84 in) with an

extension tube. The RS85 is also available with Teflon

coatings or alloy wetted parts for use in corrosive fluid and

sticky applications.

RS85

switches

mounted in

external

chamber

Figure 4

RS85 dual compartment

housing and custom

insertion length

RS85

switches

mounted in KM26

magnetic level

gauge

.

.

.

.

2

.

.

Figure 2

Figure 3

Empty pipe detection, level in

vertical pipe

(not to be used as a flow

switch) maximum velocity

.5FPS

Figure 5

RS85 VIBRATING FORK LEVEL SWITCH | OI/RS85-EN REV. K

2 Installation

Mounting

After unpacking the unit, inspect it for any evidence of

shipping damage. Inspect the fork tines to insure that they

are not bent. Forks should be parallel to each other. Any

claims for damage due to shipping must be filed with the

carrier who handled the package (s).

• Select a mounting location for the switch and the sensor

probe. Your unit may be an integral mounting option or the

remote mounting option. The integral mounting unit

consists of a single enclosure that includes the electronic

module and the sensor probe. The remote mounting unit

consists of two enclosures, one containing the electronic

module and the other containing the sensor probe.

• Be sure that there is sufficient clearance around the

mounting position to allow for the turning radius of the

switch or remote sensor enclosure as the unit is screwed

into place. Allow sufficient room above the vessel entry to

be able to insert the probe into the opening of the vessel.

• The standard size of the threaded vessel coupling is ¾ in

NPT for most probes. Other size threaded connections or

flanges are also available.

• Install and tighten threaded process connection switches

with a spanner wrench on the wrench flats of the threaded

connection.

5

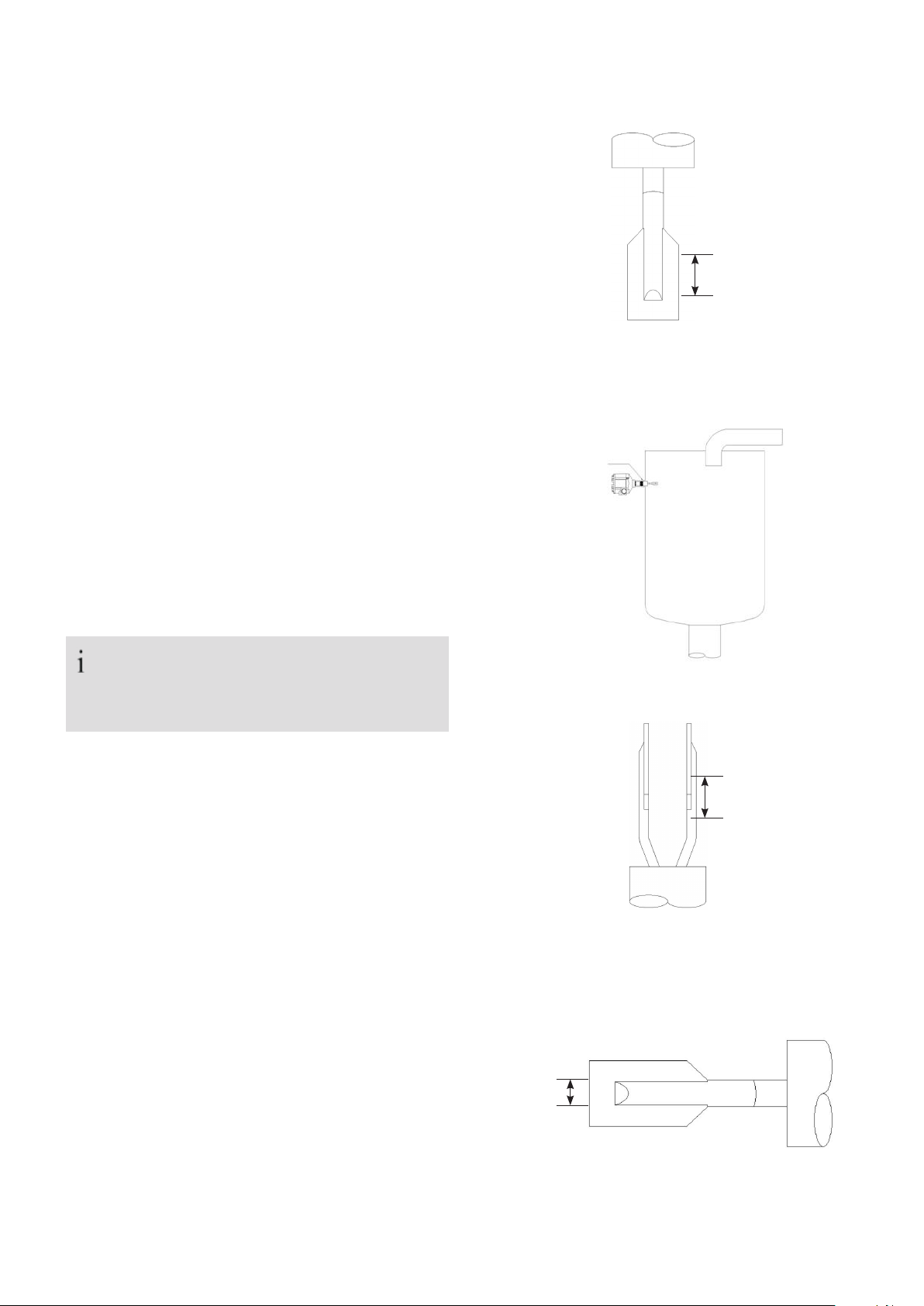

Switch point

Top mounted

Figure 6

RS85 mounted via

¾ in NPT

connector

NOTE

Do not rotate switch housing on process connection.

Switch performance may be affected.

• The information included on the enclosure label should be

visible. If necessary clean the label using a cloth soaked

with either water or isopropyl alcohol.

Tank mounting

The RS85 can be mounted for high or low level detection using

a flange or the standard ¾ in NPT connection.

Switch point and mounting position

Switch points on the sensor depend on the mounting

position. The switch point is determined by the position of

the tuning fork.

Figure 7

Switch point

Bottom mounted

Figure 8

Switch Point

Figure 9

Side mounted

6

RS85 VIBRATING FORK LEVEL SWITCH | OI/RS85-EN REV. K

2 ...Installation

Mounting for vessel wall build–up

If there is a potential for build–up on the vessel wall, mount

the RS85 with sufficient distance between the wall and the

fork assembly to prevent bridging.

*

Vertical top mounted

Figure 10

*Ensure that there is sufficient distance between the build–up

expected on the tank and the forks.

Extended into vessel,

side mounted

*

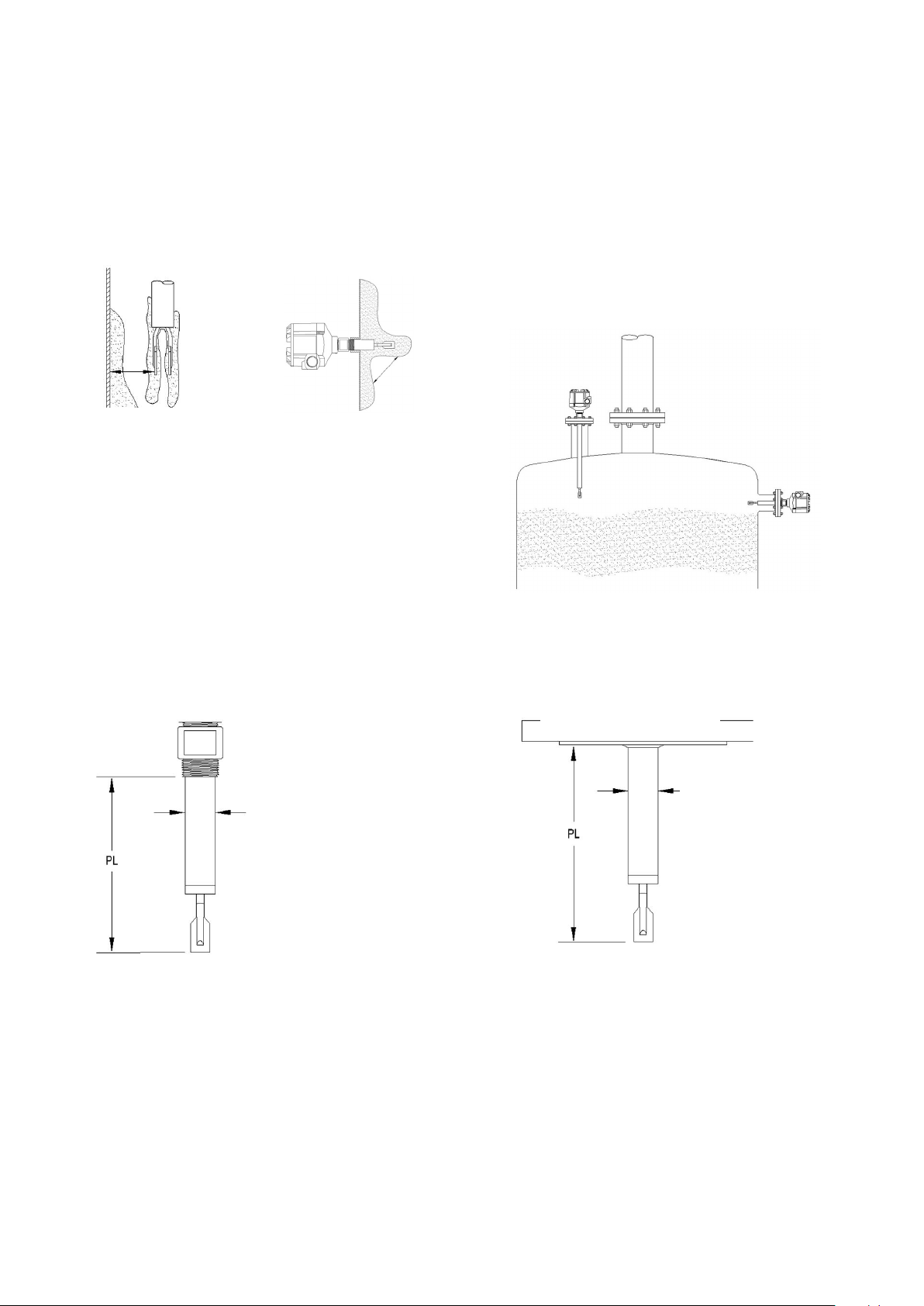

Extended Probe Lengths (PL)

The sensor length 'PL' for the RS85 will differ based on the

process connection. A threaded sensor PL is measured from

the bottom process thread to the tip of the fork tine. A

flanged sensor PL is measured from the face of the flange to

the tip of the fork tine.

Mounting position with extension tubes

If ordering the RS85 with an extended probe length, ensure

there is adequate space between outside walls or ceilings and

the vessel mounting point

A short extended probe length (up to 20 in) can be mounted

in any orientation. An RS85 with an extended probe length

over 20 in (up to 84 in) must be mounted vertically.

Figure 12

Figure 11

19.05 and 25.4 mm

(¾ In and 1 in)threaded

21.5 mm

(0.8500 in) dia.

From lower edge of thread

Flange connection

21.5 mm

(0.8500 in) dia.

Figure 13

Loading...

Loading...