Page 1

Relion® 650 series

Switchsync™ PWC600 Version 1.1

User manual

Page 2

Page 3

Document ID: 1MRK 511 463

Issued: February 2020

Revision: A

Product version: 1.1

© Copyright 2020 ABB. All rights reserved

Page 4

Copyright

This document and parts thereof must not be reproduced or copied without written

permission from ABB, and the contents thereof must not be imparted to a third party, nor

used for any unauthorized purpose.

The software and hardware described in this document is furnished under a license and may

be used or disclosed only in accordance with the terms of such license.

This product includes software developed by the OpenSSL Project for use in the OpenSSL

Toolkit (http://www.openssl.org/).

This product includes cryptographic software written/developed by: Eric Young

(eay@cryptsoft.com) and Tim Hudson (tjh@cryptsoft.com).

This product includes software provided by the jQuery Foundation (

the Flot project (http://www.flotcharts.org/).

http://jquery.org/) and by

Trademarks

ABB and Relion are registered trademarks of the ABB Group. Switchsync is a trademark of the

ABB PG Group. All other brand or product names mentioned in this document may be

trademarks or registered trademarks of their respective holders.

Warranty

Please inquire about the terms of warranty from your nearest ABB representative.

ABB Power Grids Sweden AB

Grid Automation Products

SE-721 59 Västerås

Sweden

Telephone: +46 (0) 21 32 50 00

Facsimile: +46 (0) 21 14 69 18

http://www.abb.com/substationautomation

Page 5

Disclaimer

The data, examples and diagrams in this manual are included solely for the concept or product

description and are not to be deemed as a statement of guaranteed properties. All persons

responsible for applying the equipment addressed in this manual must satisfy themselves that

each intended application is suitable and acceptable, including that any applicable safety or

other operational requirements are complied with. In particular, any risks in applications where

a system failure and/or product failure would create a risk for harm to property or persons

(including but not limited to personal injuries or death) shall be the sole responsibility of the

person or entity applying the equipment, and those so responsible are hereby requested to

ensure that all measures are taken to exclude or mitigate such risks.

This document has been carefully checked by ABB but deviations cannot be completely ruled

out. In case any errors are detected, the reader is kindly requested to notify the manufacturer.

Other than under explicit contractual commitments, in no event shall ABB be responsible or

liable for any loss or damage resulting from the use of this manual or the application of the

equipment.

Page 6

Conformity

This product complies with the directive of the Council of the European Communities on the

approximation of the laws of the Member States relating to electromagnetic compatibility

(EMC Directive 2004/108/EC) and concerning electrical equipment for use within specified

voltage limits (Low-voltage directive 2006/95/EC). This conformity is the result of tests

conducted by ABB in accordance with the product standard EN 60255-26 for the EMC directive,

and with the product standards EN 60255-1 and EN 60255-27 for the low voltage directive. The

product is designed in accordance with the international standards of the IEC 60255 series.

Page 7

Table of contents

Table of contents

Section 1 Introduction...................................................................................................11

1.1 This manual.................................................................................................................................. 11

1.2 Intended audience...................................................................................................................... 11

1.3 Product documentation.............................................................................................................11

1.3.1 Product documentation set....................................................................................................11

1.3.1.1 Related documents............................................................................................................. 11

1.3.2 Document revision history......................................................................................................12

1.4 Symbols and conventions......................................................................................................... 12

1.4.1 Symbols...................................................................................................................................... 12

1.4.2 Document conventions........................................................................................................... 12

Section 2 Safety information....................................................................................... 13

2.1 Safety information......................................................................................................................13

2.1.1 Symbols on the product.......................................................................................................... 13

2.1.2 Warnings.....................................................................................................................................13

2.1.3 Caution signs.............................................................................................................................14

Section 3 Switchsync PWC600 overview....................................................................17

3.1 Introduction................................................................................................................................. 17

3.2 Hardware overview.....................................................................................................................17

3.3 Functioning principle.................................................................................................................18

3.4 Application overview................................................................................................................. 20

3.4.1 Common applications.............................................................................................................20

3.4.2 Variable applications................................................................................................................21

3.5 User interfaces............................................................................................................................ 21

3.6 Communication...........................................................................................................................21

3.7 PCM600 tool................................................................................................................................ 22

3.7.1 Connectivity packages............................................................................................................ 22

3.8 Environmental aspects..............................................................................................................23

3.8.1 Sustainable development....................................................................................................... 23

3.8.2 Disposing of the IED................................................................................................................ 23

Section 4 Application.................................................................................................... 25

4.1 Introduction.................................................................................................................................25

4.2 Load applications....................................................................................................................... 25

4.2.1 Capacitor banks........................................................................................................................26

4.2.2 Shunt reactors.......................................................................................................................... 26

4.2.2.1 Re-ignition free window.................................................................................................... 26

4.2.3 Power transformers.................................................................................................................27

4.2.4 Discharged transmission lines and cables..........................................................................28

4.3 Switching targets.......................................................................................................................28

4.3.1 Target reference ......................................................................................................................29

User manual

1

© Copyright 2020 ABB. All rights reserved

Page 8

Table of contents

4.3.2 Target definition...................................................................................................................... 29

4.3.2.1 Controlled energization targets...................................................................................... 29

4.3.2.2 Controlled de-energization targets................................................................................30

4.3.3 Circuit breaker properties...................................................................................................... 32

4.4 Optimization of accuracy..........................................................................................................32

4.4.1 Parameter compensation....................................................................................................... 32

4.4.2 Adaptive correction................................................................................................................. 33

4.4.2.1 Adaptive correction for closing....................................................................................... 33

4.4.2.2 Adaptive correction for opening.....................................................................................34

4.4.3 Overall optimization................................................................................................................ 34

4.4.3.1 Optimization of closing operations................................................................................34

4.4.3.2 Optimization of opening operations..............................................................................35

4.5 Monitoring and supervision..................................................................................................... 36

4.5.1 Electrical operations monitoring.......................................................................................... 37

4.5.1.1 Circuit breaker electrical status.......................................................................................38

4.5.1.2 Detection of electrical switching instants.....................................................................39

4.5.1.3 Detection of re-ignitions/re-strikes...............................................................................40

4.5.1.4 Interrupter wear..................................................................................................................42

4.5.2 Mechanical operations monitoring...................................................................................... 43

4.5.3 Recommended alarms............................................................................................................ 44

4.5.4 Selection of feedback signals................................................................................................45

4.5.5 Trip circuit supervision........................................................................................................... 46

Section 5 Specific load applications .......................................................................... 47

5.1 Standard load applications...................................................................................................... 47

5.1.1 Grounded capacitor bank.......................................................................................................48

5.1.1.1 Controlled energization.................................................................................................... 48

5.1.1.2 Controlled de-energization.............................................................................................. 49

5.1.2 Ungrounded or delta connected capacitor bank.............................................................. 50

5.1.2.1 Controlled energization.....................................................................................................51

5.1.2.2 Controlled de-energization...............................................................................................52

5.1.3 Grounded non-coupled reactor............................................................................................. 53

5.1.3.1 Controlled energization.................................................................................................... 54

5.1.3.2 Controlled de-energization.............................................................................................. 54

5.1.4 Non-coupled ungrounded or delta connected reactor ....................................................55

5.1.4.1 Controlled energization.................................................................................................... 56

5.1.4.2 Controlled de-energization...............................................................................................57

5.1.5 Magnetically coupled grounded reactor............................................................................. 59

5.1.5.1 Controlled energization.................................................................................................... 59

5.1.5.2 Controlled de-energization.............................................................................................. 60

5.1.6 Transformers with different configurations...................................................................... 61

5.1.6.1 Controlled energization.................................................................................................... 65

5.1.6.2 Controlled de-energization.............................................................................................. 69

5.1.7 Transmission line and power cable...................................................................................... 70

5.1.7.1 Controlled energization..................................................................................................... 71

5.1.7.2 Controlled de-energization............................................................................................... 72

2

User manual

© Copyright 2020 ABB. All rights reserved

Page 9

Table of contents

5.2 Special load applications.......................................................................................................... 73

5.2.1 Impedance grounded reactor................................................................................................ 74

5.2.1.1 Controlled energization.....................................................................................................74

5.2.1.2 Controlled de-energization...............................................................................................78

5.2.2 Energization of ungrounded capacitor bank with three-pole operated circuit

breaker....................................................................................................................................... 80

5.2.3 Non-coupled Reactor energization and de-energization with L3 as lead phase.........82

5.2.3.1 Controlled energization.....................................................................................................82

5.2.3.2 Controlled de-energization...............................................................................................83

5.2.4 Variable applications...............................................................................................................84

5.2.5 Adaptive correction for coupled transformers using load voltage feedback............. 86

Section 6 Installation.................................................................................................... 89

6.1 Unpacking, inspecting and storing........................................................................................ 89

6.1.1 Removing transport packaging............................................................................................ 89

6.1.2 Inspecting the product........................................................................................................... 89

6.1.2.1 Identifying the product.....................................................................................................89

6.1.2.2 Checking delivery items.................................................................................................... 89

6.1.2.3 Inspecting the IED.............................................................................................................. 89

6.1.2.4 Returning an IED damaged in transit............................................................................. 89

6.1.3 Storing....................................................................................................................................... 90

6.2 Checking environmental conditions and mounting space................................................90

6.3 Rack mounting the IED..............................................................................................................90

6.4 Arranging ventilation................................................................................................................. 91

6.5 Safety against laser exposure..................................................................................................91

Section 7 Hardware interfaces.................................................................................... 93

7.1 Connectors.................................................................................................................................. 93

7.2 Physical connections................................................................................................................. 93

7.2.1 Connecting protective earthing............................................................................................93

7.2.2 Connecting wires .................................................................................................................... 94

7.2.2.1 Connecting to screw-compression type terminals..................................................... 94

7.3 Inputs............................................................................................................................................95

7.3.1 Measuring inputs..................................................................................................................... 95

7.3.2 Auxiliary supply voltage input............................................................................................... 96

7.3.3 Binary inputs............................................................................................................................. 96

7.4 Outputs........................................................................................................................................ 98

7.4.1 Outputs for circuit breaker control...................................................................................... 98

7.4.2 Outputs for signalling............................................................................................................. 98

7.4.3 IRF................................................................................................................................................99

7.5 Trip circuit supervision (TCS).................................................................................................. 99

7.5.1 TCS with external resistor....................................................................................................100

7.5.2 TCS without external resistor.............................................................................................. 101

7.6 Communication interfaces..................................................................................................... 101

7.6.1 Ethernet RJ-45 front connection......................................................................................... 101

7.6.2 Station communication rear connection ..........................................................................102

7.6.3 EIA-485 serial rear connection.............................................................................................102

User manual

3

© Copyright 2020 ABB. All rights reserved

Page 10

Table of contents

7.6.4 Process bus rear connection ...............................................................................................103

7.6.5 Recommended industrial Ethernet switches .................................................................. 103

7.7 Connection diagrams.............................................................................................................. 103

Section 8 Setting up a project in PCM600............................................................... 105

8.1 Protection and Control IED Manager PCM600...................................................................105

8.2 PCM600 projects...................................................................................................................... 105

8.3 Installing Connectivity packages.......................................................................................... 105

8.3.1 Installing IED Connectivity package from USB stick.......................................................106

8.3.2 Installing IED Connectivity package from Update Manager......................................... 106

8.4 Project handling in PCM600................................................................................................... 107

8.4.1 Creating a new project..........................................................................................................108

8.4.2 Importing a project................................................................................................................108

8.4.3 Opening a project.................................................................................................................. 109

8.4.4 Exporting a project................................................................................................................109

8.4.5 Backing up projects...............................................................................................................109

8.4.6 Exporting the substation to SCD file..................................................................................110

8.5 Building a plant structure........................................................................................................ 111

8.5.1 IEC 61850 naming conventions to identify an IED........................................................... 112

8.6 Inserting a PWC600 IED...........................................................................................................114

8.6.1 Inserting an IED from the template library........................................................................114

8.6.2 Inserting a configured IED.................................................................................................... 115

8.6.3 Setting an IED's IP address in the project..........................................................................116

8.7 Setting up communication between PCM600 and the IED.............................................. 118

8.7.1 Setting up IP addresses.........................................................................................................118

8.7.2 Setting up the PC or workstation for point-to-point access to IEDs front port....... 118

8.7.3 Setting up the PC to access the IED via a network.......................................................... 122

8.7.4 Security warning..................................................................................................................... 123

8.8 Setting technical key................................................................................................................ 123

8.9 Exporting an IED object...........................................................................................................126

Section 9 Application engineering............................................................................ 129

9.1 Engineering process overview .............................................................................................. 129

9.2 Using Switchsync Setting Tool.............................................................................................. 129

9.2.1 General description................................................................................................................129

9.2.2 Starting Switchsync Setting Tool....................................................................................... 130

9.2.3 Navigating between steps....................................................................................................132

9.2.4 Setting parameters overview...............................................................................................132

9.2.5 Description of setting parameters in SST.........................................................................135

9.2.5.1 Power system.................................................................................................................... 135

9.2.5.2 System time....................................................................................................................... 136

9.2.5.3 Breaker control.................................................................................................................. 136

9.2.5.4 Circuit breaker................................................................................................................... 137

9.2.5.5 Reference signals..............................................................................................................138

9.2.5.6 Controlled switching........................................................................................................140

9.2.5.7 Adaptive correction..........................................................................................................144

9.2.5.8 Compensation...................................................................................................................146

4

User manual

© Copyright 2020 ABB. All rights reserved

Page 11

Table of contents

9.2.5.9 Alarms enabling................................................................................................................ 150

9.2.5.10 Time synchronization.......................................................................................................154

9.2.5.11 Breaker times.....................................................................................................................155

9.2.6 Defining or editing a custom circuit breaker....................................................................157

9.2.6.1 Initiating of CB model creation or editing................................................................... 157

9.2.6.2 Editing the data ................................................................................................................157

9.2.6.3 Viewing the data .............................................................................................................. 157

9.2.6.4 Circuit breaker definition................................................................................................158

9.2.6.5 Transferring custom CB files..........................................................................................158

9.2.7 Intermediate saving...............................................................................................................159

9.2.8 Completing Switchsync Setting Tool.................................................................................160

9.3 Writing parameters to the IED...............................................................................................162

9.4 Modification of the default pre-configuration...................................................................164

9.4.1 Precautions..............................................................................................................................164

9.4.2 General information for working with PCM600...............................................................165

9.4.3 Working with the Application Configuration tool........................................................... 166

9.4.3.1 Adding application worksheets in the configuration............................................... 166

9.4.3.2 Function blocks.................................................................................................................168

9.4.3.3 Adding a function to the application............................................................................ 171

9.4.3.4 Function block execution parameters.......................................................................... 172

9.4.3.5 Signals and signal management....................................................................................173

9.4.3.6 Adding user-defined names............................................................................................174

9.4.3.7 Connections and variables..............................................................................................174

9.4.3.8 Saving the configuration................................................................................................. 176

9.4.3.9 Single-phase reference signal.........................................................................................177

9.4.3.10 Validation............................................................................................................................177

9.4.4 Working with the Parameter Setting tool......................................................................... 179

9.4.4.1 Displaying options............................................................................................................179

9.4.4.2 Modifying settings............................................................................................................179

9.4.4.3 Enabling setting groups..................................................................................................180

9.4.4.4 Copying setting group values.........................................................................................181

9.4.5 Local HMI engineering...........................................................................................................182

9.4.5.1 Local HMI engineering process...................................................................................... 182

9.4.5.2 LEDs and function keys................................................................................................... 183

9.4.5.3 Single-line diagram engineering....................................................................................186

9.4.6 Configuration adjustments for coupled loads.................................................................195

9.4.6.1 Coupled load energized from YN end...........................................................................196

9.4.6.2 Ungrounded load.............................................................................................................. 197

9.4.6.3 Coupled transformer using load voltage feedback................................................... 198

9.4.7 Modification of event and waveform record signals...................................................... 199

9.4.8 Modification of alarm signals..............................................................................................201

9.4.9 Modification of operation log input...................................................................................202

9.4.10 Modification of binary inputs and outputs ..................................................................... 203

9.4.10.1 Adding binary inputs and outputs to Application Configuration.......................... 204

9.4.11 Generic IEC61850 function block configuration .............................................................205

9.4.12 Connection of GOOSE close and open commands.........................................................206

User manual

5

© Copyright 2020 ABB. All rights reserved

Page 12

Table of contents

9.4.13 Connection of compensation signals via analog GOOSE..............................................206

9.4.14 Implementing setting groups for controlled switching.................................................207

9.4.14.1 Hardware connections.................................................................................................... 208

9.4.14.2 Application configuration...............................................................................................209

9.4.14.3 Settings...............................................................................................................................210

9.4.15 Activating trip circuit supervision (TCS)............................................................................ 211

9.4.15.1 TCS with external resistor............................................................................................... 211

9.4.15.2 TCS without external resistor.........................................................................................211

9.5 Writing the configuration to the IED.................................................................................... 212

Section 10 Local HMI..................................................................................................... 215

10.1 Local HMI elements.................................................................................................................. 215

10.1.1 Display...................................................................................................................................... 216

10.1.2 LEDs.......................................................................................................................................... 218

10.1.3 Keypad...................................................................................................................................... 218

10.1.4 Local HMI functionality..........................................................................................................219

10.1.4.1 Status and alarm indication............................................................................................219

10.1.4.2 Parameter management ................................................................................................ 220

10.1.4.3 Front port communication............................................................................................. 220

10.2 Logging on................................................................................................................................. 221

10.3 Logging off................................................................................................................................ 223

10.4 Navigating in the menu...........................................................................................................224

10.4.1 Menu structure....................................................................................................................... 224

10.4.2 Scrolling the display.............................................................................................................. 224

10.4.3 Changing the default view....................................................................................................225

10.5 Identifying the device.............................................................................................................. 225

10.6 Changing the local HMI language......................................................................................... 226

10.7 Settings and configuration parameters..............................................................................226

10.7.1 Browsing setting values....................................................................................................... 226

10.7.2 Editing setting........................................................................................................................ 227

10.7.2.1 Editing numerical values................................................................................................. 227

10.7.2.2 Editing string values........................................................................................................ 229

10.7.2.3 Editing enumerated values.............................................................................................229

10.7.2.4 Changing system time.....................................................................................................229

10.7.3 Saving settings....................................................................................................................... 229

10.8 Monitoring ................................................................................................................................ 230

10.8.1 Measured and calculated values......................................................................................... 230

10.8.2 Recorded data........................................................................................................................ 230

10.8.2.1 Operation log.................................................................................................................... 230

10.8.2.2 Waveform records............................................................................................................ 232

10.8.2.3 Events................................................................................................................................. 234

10.8.3 Remote monitoring................................................................................................................235

10.8.3.1 Monitoring the IED remotely.......................................................................................... 235

10.8.4 Application indications.........................................................................................................236

10.8.5 Internal IED fault ....................................................................................................................236

10.9 Clearing status information................................................................................................... 237

6

User manual

© Copyright 2020 ABB. All rights reserved

Page 13

Table of contents

10.10 Using the local HMI help..........................................................................................................238

Section 11 Web HMI.......................................................................................................241

11.1 Logging in.................................................................................................................................. 241

11.2 Home page (Device information)..........................................................................................243

11.3 Menu structure......................................................................................................................... 244

11.4 Warning and error messages.................................................................................................245

11.5 Selecting a list view..................................................................................................................245

11.6 Navigating between pages.................................................................................................... 246

11.7 Operation records....................................................................................................................246

11.7.1 Viewing operation records...................................................................................................248

11.7.2 Downloading operation records.........................................................................................248

11.8 Waveform records....................................................................................................................248

11.8.1 List of waveform records..................................................................................................... 249

11.8.2 Waveform viewer................................................................................................................... 250

11.8.3 Viewing and managing waveform record graphs............................................................251

11.9 Alarms......................................................................................................................................... 252

11.9.1 Viewing and acknowledging alarms...................................................................................252

11.10 Events and internal events..................................................................................................... 253

11.11 Trend graphs............................................................................................................................. 253

11.11.1 Changing the range of data points in equidistant view................................................ 254

11.11.2 Changing the range of data points in time view............................................................. 255

11.12 Generating reports.................................................................................................................. 256

11.13 IED menu.................................................................................................................................... 257

11.14 Logging out...............................................................................................................................259

Section 12 Commissioning...........................................................................................261

12.1 Commissioning checklist........................................................................................................261

12.2 Preparations.............................................................................................................................. 261

12.3 Checking IED operation.......................................................................................................... 262

12.4 Checking CT circuits................................................................................................................ 262

12.5 Checking VT circuits................................................................................................................ 262

12.6 Checking binary input and output circuits..........................................................................263

12.6.1 Binary input circuits...............................................................................................................263

12.6.2 Binary output circuits............................................................................................................263

12.6.3 Circuit breaker control wiring............................................................................................ 263

12.7 Checking optical connections............................................................................................... 264

12.8 Circuit breaker operating times............................................................................................264

12.8.1 Entering operating times manually....................................................................................264

12.8.2 Circuit breaker timing test mode....................................................................................... 266

12.8.2.1 Electrical connections..................................................................................................... 266

12.8.2.2 LHMI navigation................................................................................................................ 267

12.8.2.3 Circuit breaker contact status....................................................................................... 270

12.8.2.4 Operation............................................................................................................................271

12.8.2.5 Concluding circuit breaker test mode..........................................................................272

12.8.2.6 Applying the acquired operating times from CB test mode....................................273

12.9 Live switching........................................................................................................................... 274

User manual

7

© Copyright 2020 ABB. All rights reserved

Page 14

Table of contents

12.9.1 Capacitor bank....................................................................................................................... 274

12.9.2 Shunt reactor.......................................................................................................................... 274

12.9.3 Power transformer.................................................................................................................275

12.9.4 Transmission line or power cable....................................................................................... 275

12.10 Concluding commissioning....................................................................................................276

Section 13 IED operation ..............................................................................................277

13.1 Start-up.......................................................................................................................................277

13.1.1 Checking IED operation.........................................................................................................277

13.1.2 IED start-up sequence .......................................................................................................... 277

13.2 Normal operation..................................................................................................................... 277

13.3 Controlled switching operations...........................................................................................277

13.3.1 Switching operation mode...................................................................................................278

Section 14 Requirements on external equipment..................................................... 281

14.1 Circuit breaker...........................................................................................................................281

14.2 Current transformers...............................................................................................................281

14.3 Voltage transformers...............................................................................................................281

14.4 Non-conventional instrument transformers and merging units.................................... 281

14.5 SNTP server................................................................................................................................282

Section 15 Maintenance................................................................................................283

15.1 IED maintenance.......................................................................................................................283

15.2 Optimizing accuracy for circuit breaker changes..............................................................283

Section 16 Troubleshooting ........................................................................................ 285

16.1 Application diagnostics ......................................................................................................... 285

16.1.1 Resetting persistent signals................................................................................................305

16.2 Fault tracing.............................................................................................................................. 305

16.2.1 Identifying hardware errors.................................................................................................305

16.2.2 Identifying runtime errors................................................................................................... 306

16.2.3 Identifying communication errors..................................................................................... 306

16.2.3.1 Checking communication link operation.................................................................... 306

16.2.3.2 Checking merging unit status....................................................................................... 307

16.2.3.3 Checking time synchronization..................................................................................... 307

16.2.4 Running the display test.......................................................................................................307

16.3 Indication messages............................................................................................................... 308

16.3.1 Internal faults......................................................................................................................... 308

16.3.2 Warnings..................................................................................................................................308

16.3.3 Additional indications...........................................................................................................309

16.4 Correction procedures............................................................................................................309

16.4.1 Changing and setting the password................................................................................. 309

16.4.2 Identifying IED application problems................................................................................309

16.4.2.1 Inspecting the wiring.......................................................................................................309

Section 17 Technical data............................................................................................. 313

17.1 Dimensions ............................................................................................................................... 313

17.2 Power supply............................................................................................................................. 313

8

User manual

© Copyright 2020 ABB. All rights reserved

Page 15

Table of contents

17.3 Measuring inputs ..................................................................................................................... 313

17.4 Binary inputs..............................................................................................................................314

17.5 Signal outputs .......................................................................................................................... 315

17.6 Power outputs .......................................................................................................................... 315

17.7 Data communication interfaces ........................................................................................... 316

17.8 Enclosure class ......................................................................................................................... 317

17.9 Ingress protection.................................................................................................................... 318

17.10 Environmental conditions and tests.................................................................................... 318

17.11 Electromagnetic compatibility tests....................................................................................319

17.12 Insulation tests.........................................................................................................................320

17.13 Mechanical tests....................................................................................................................... 321

17.14 Product safety .......................................................................................................................... 321

17.15 EMC compliance ....................................................................................................................... 321

Section 18 Glossary....................................................................................................... 323

User manual

9

© Copyright 2020 ABB. All rights reserved

Page 16

10

Page 17

1MRK 511 463 A Section 1

Introduction

Section 1 Introduction

1.1 This manual

The user manual provides basic instructions on how to install and use Switchsync PWC600.

The manual also describes setting up a secure system, including password procedures and

levels of access in the system. The manual provides instructions for engineering, mechanical

and electrical installing, commissioning and operating, to cover the common use cases of the

product.

1.2 Intended audience

This manual addresses new users as well as not frequent users of Switchsync PWC600,

providing an easy start or refresh on using the product. The manual offers quick assistance to

operators and field personnel as well as engineering and commissioning personnel.

1.3 Product documentation

1.3.1 Product documentation set

The user manual provides basic instructions on how to install and use Switchsync PWC600.

The manual provides instructions for engineering, mechanical and electrical installing,

commissioning and operating, to cover the common use cases of the product.

GUID-44873E8A-0624-49D3-AA84-4DA61C513D66 v3

GUID-0EFD9002-000E-43C2-A39F-D790486D43C1 v5

GUID-DBA0DD95-55A1-42D3-B161-8F1C487BA9AB v7

The communication protocol manual describes a communication protocol supported by the

IED. The manual concentrates on vendor-specific implementations.

The cyber security deployment guideline describes setting up a secure system, including

password procedures and levels of access in the system.

The technical manual contains application and functionality descriptions and lists function

blocks, logic diagrams, input and output signals, setting parameters and technical data sorted

per function. The manual can be used as a technical reference during the engineering phase,

installation and commissioning phase, and during normal service.

1.3.1.1 Related documents

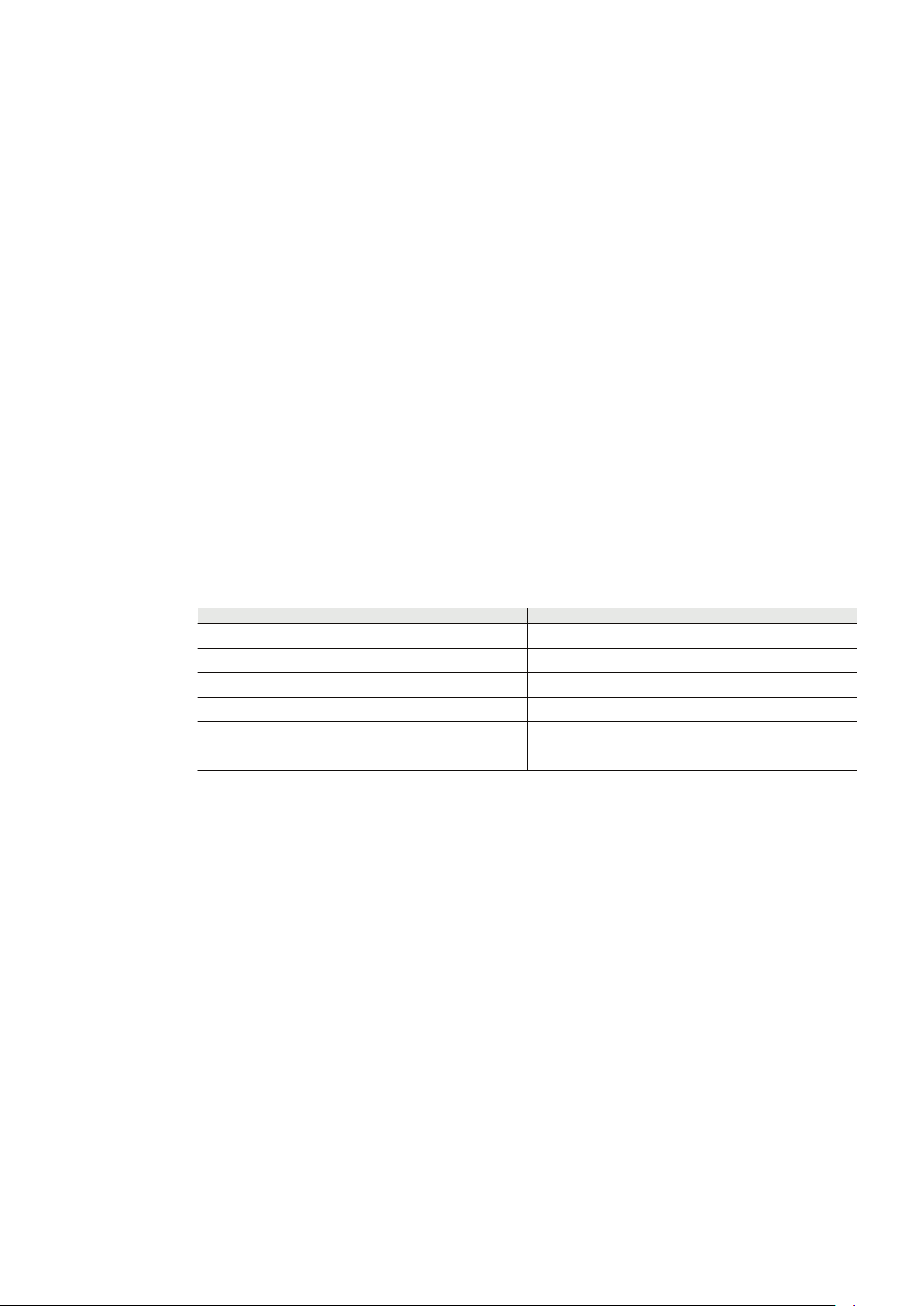

Documents related to Switchsync PWC600 Identity number

Communication protocol manual, IEC 61850 1MRK 511 464-UEN

Cyber Security deployment guidelines 1MRK 511 465-UEN

User Manual 1MRK 511 463-UEN

Technical manual 1MRK 511 462-UEN

MICS 1MRG 035 293

PICS 1MRG 035 460

PIXIT

TICS

GUID-42926503-028A-4885-96EA-39CE83211411 v6

1MRG 035 547

1MRG 035 548

1)

1)

User manual

1) Switchsync PWC600 1.1 is based on Relion 650 series, version 1.3. So the PIXIT and TICS from Relion 650

series, version 1.3 are applicable for Switchsync PWC600 1.1 too.

11

© Copyright 2020 ABB. All rights reserved

Page 18

Section 1 1MRK 511 463 A

Introduction

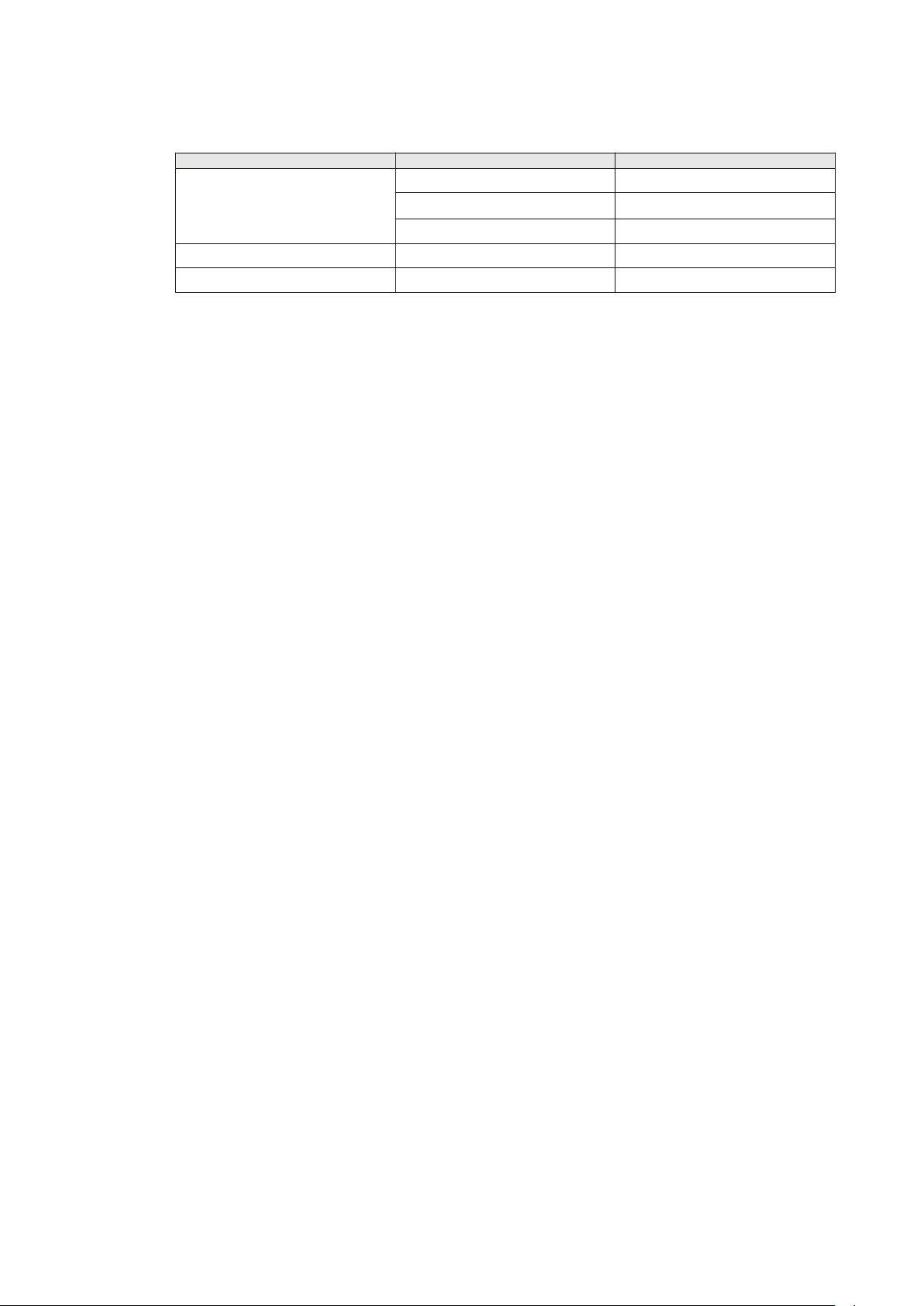

1.3.2 Document revision history

Document revision/date Product version History

A/2020-02 1.1 First release

1.4 Symbols and conventions

1.4.1 Symbols

The caution icon indicates important information or warning related to the

concept discussed in the text. It might indicate the presence of a hazard which

could result in corruption of software or damage to equipment or property.

The information icon alerts the reader of important facts and conditions.

The tip icon indicates advice on, for example, how to design your project or

how to use a certain function.

GUID-2FDA8977-F1F8-424B-B6E4-A68B78BD49C6 v9

D0E747T201305151541 v1

Although warning hazards are related to personal injury, it is necessary to understand that

under certain operational conditions, operation of damaged equipment may result in

degraded process performance leading to personal injury or death. It is important that the

user fully complies with all warning and cautionary notices.

1.4.2 Document conventions

• Abbreviations and acronyms in this manual are spelled out in the glossary. The glossary

also contains definitions of important terms.

• Push button navigation in the LHMI menu structure is presented by using the push button

icons.

For example, to navigate between the options, use

• HMI menu paths are presented in bold.

For example, select Main menu/Settings.

• LHMI messages are shown in Courier font.

For example, to save the changes in non-volatile memory, select Yes and press .

• Parameter names are shown in italics.

For example, the function can be enabled and disabled with the

and .

Operation

D0E809T201305141505 v3

setting.

12

User manual

© Copyright 2020 ABB. All rights reserved

Page 19

1MRK 511 463 A Section 2

Safety information

Section 2 Safety information

2.1 Safety information

2.1.1 Symbols on the product

All warnings must be observed.

Read the entire manual before doing installation or any maintenance work on

the product.

Class 1 Laser product. Take adequate measures to protect your eyes and do not

view directly with optical instruments.

2.1.2 Warnings

Observe the warnings during all types of work related to the product.

Only electrically skilled persons with the proper authorization and knowledge of

any safety hazards are allowed to carry out the electrical installation.

GUID-E48F2EC3-6AB8-4ECF-A77E-F16CE45CA5FD v4

IP1504-1 v2

GUID-C9B6638A-57E7-4E05-9A33-A60E359C54AF v1

M2366-2 v2

National and local electrical safety regulations must always be followed.

Working in a high voltage environment requires serious approach to avoid

human injuries and damage to equipment.

M2362-2 v1

Do not touch circuitry during operation. Potentially lethal voltages and currents

are present.

M2364-2 v1

Always use suitable isolated test pins when measuring signals in open circuitry.

Potentially lethal voltages and currents are present.

M2370-2 v1

Never connect or disconnect a wire and/or a connector to or from a IED during

normal operation. Hazardous voltages and currents are present that may be

lethal. Operation may be disrupted and IED and measuring circuitry may be

damaged.

User manual

13

© Copyright 2020 ABB. All rights reserved

Page 20

Section 2 1MRK 511 463 A

Safety information

GUID-BEDD698E-356C-4CF9-9DAE-64DB3CEADEAD v1

Dangerous voltages can occur on the connectors, even though the auxiliary

voltage has been disconnected.

M2369-2 v3

Always connect the IED to protective earth, regardless of the operating

conditions. This also applies to special occasions such as bench testing,

demonstrations and off-site configuration. This is class 1 equipment that shall

be earthed.

M2372-2 v1

Never remove any screw from a powered IED or from a IED connected to

powered circuitry. Potentially lethal voltages and currents are present.

SEMOD168311-3 v1

Take adequate measures to protect the eyes. Never look into the laser beam.

2.1.3 Caution signs

Whenever changes are made in the IED, measures should be taken to avoid

inadvertent tripping.

The IED contains components which are sensitive to electrostatic discharge.

ESD precautions shall always be observed prior to touching components.

Always transport PCBs (modules) using certified conductive bags.

Do not connect live wires to the IED. Internal circuitry may be damaged

GUID-11CCF92B-E9E7-409C-84D0-DFDEA1DCBE85 v2

IP1503-1 v1

GUID-5D1412B8-8F9D-4D39-B6D1-60FB35797FD0 v2

GUID-F2A7BD77-80FB-48F0-AAE5-BE73DE520CC2 v1

M2695-2 v2

M2696-2 v1

M2697-2 v2

14

Always use a conductive wrist strap connected to protective earth when

replacing modules. Electrostatic discharge (ESD) may damage the module and

IED circuitry.

M2698-2 v2

Take care to avoid electrical shock during installation and commissioning.

User manual

© Copyright 2020 ABB. All rights reserved

Page 21

1MRK 511 463 A Section 2

Safety information

M2693-2 v2

Changing the active setting group will inevitably change the IED's operation. Be

careful and check regulations before making the change.

User manual

15

© Copyright 2020 ABB. All rights reserved

Page 22

16

Page 23

1

2

1MRK 511 463 A Section 3

Switchsync PWC600 overview

Section 3 Switchsync PWC600 overview

3.1 Introduction

Switchsync PWC600 is a point-on-wave controller for high-voltage circuit breakers. Its purpose

is to delay circuit breaker operation commands such that current inception or current

interruption occurs at a phase angle that minimizes stress on the switched load or the circuit

breaker. The PWC600 device (IED, intelligent electronic device) is usually installed in the

control room in the bay control cabinet, where all required signals are present.

3.2 Hardware overview

GUID-2D3D7A43-2A78-4159-8AB5-BA2CE19D03DD V1 EN-US

Figure 1: Switchsync PWC600 front view

GUID-B5FC3CED-4D7B-4F92-BA26-A9FAD91B0DDB v3

GUID-5E5B3CA8-3EC7-4C6B-87C2-4D76FEF5B56A v3

1 Enlosure

2 Local HMI

A label with the IED ordering number and serial number is attached to the local HMI.

17

User manual

© Copyright 2020 ABB. All rights reserved

Page 24

1

4

5

6

7

2

3

Section 3 1MRK 511 463 A

Switchsync PWC600 overview

GUID-0E37AEC8-5216-40B9-8046-7D390EE9A3C3 V1 EN-US

Figure 2: Switchsync PWC600 rear panel with hardware modules

1 PSM02/PSM03: Power supply module with options for 48...125 VDC or 110...250 VDC

2 TRM01: Instrument transformer module with 4 current and 6 voltage inputs

3 COM03 + CPU02: Communication and high performance processing module

4 and 5 Not used, slots are empty in Switchsync PWC600

6 BIO01: Binary input/output module

7 PIO01: Precision binary input/output module with event time resolution of 100 µs

For more information on connections, see Section 7.1.

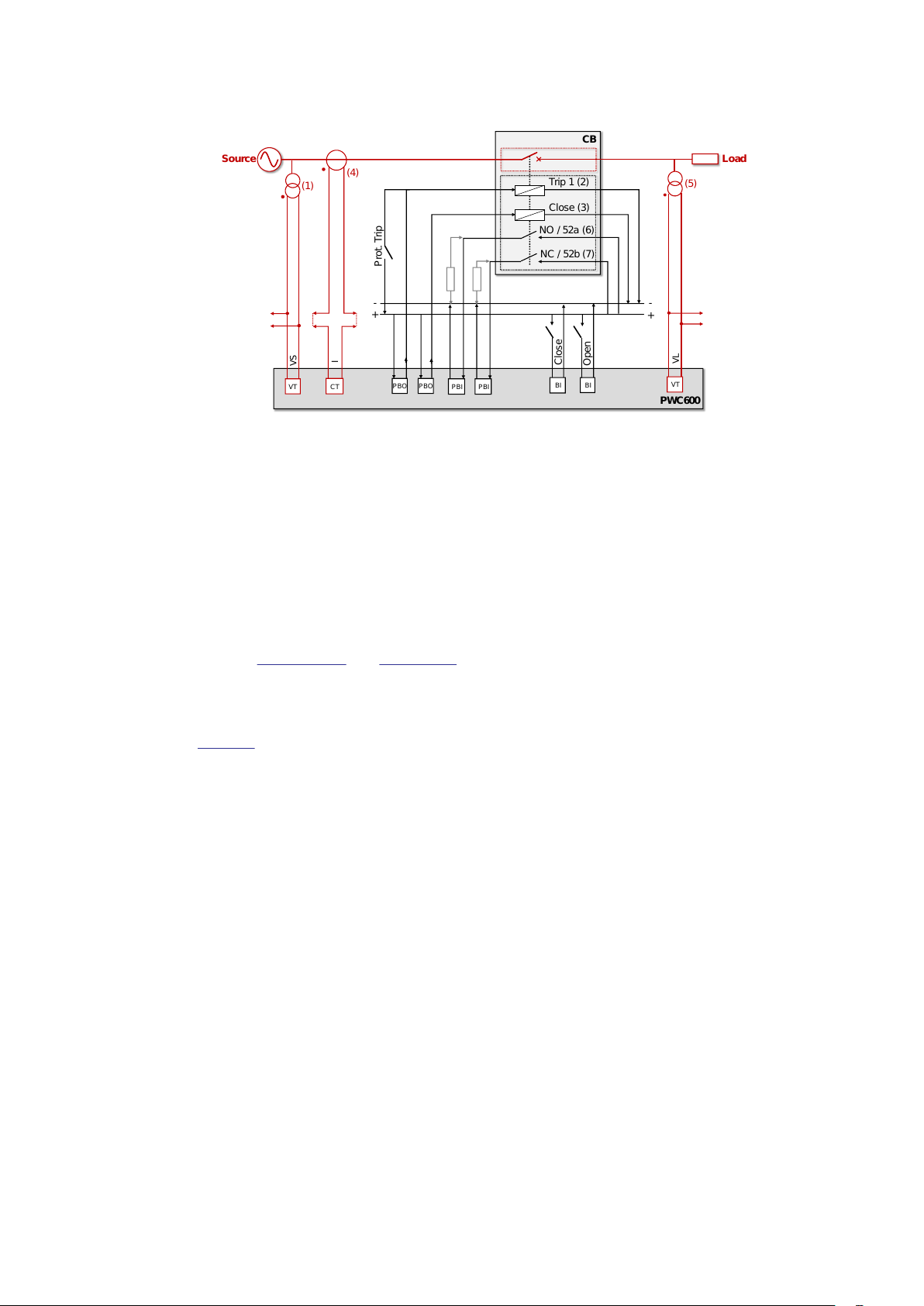

3.3 Functioning principle

The connection of PWC600 in a power system and its high-level functioning principle can be

understood from

optimal controlled switching instants for each phase from a primary reference signal. In most

cases, the reference is taken from a source side voltage transformer (1). The evaluation

considers the design and connection configuration of the load as well as the dielectric and

mechanical characteristics of the circuit breaker. Consequently, it issues a synchronized

opening or closing command to the respective operating coil (2 or 3) of each circuit breaker

pole.

Figure 3. Upon receiving an Open or Close command, PWC600 evaluates the

GUID-443A69F3-F594-406C-A808-ED266F45BA41 v1

18

© Copyright 2020 ABB. All rights reserved

User manual

Page 25

PWC600

Load

Source

I

CT

VL

VT

CB

-

-

Trip 1 (2)

Close (3)

Close

+

Open

BI

BI

+

Prot. Trip

VS

VT

PBO

PBI

PBO

PBI

NO / 52a (6)

NC / 52b (7)

(1)

(4)

(5)

1MRK 511 463 A Section 3

IEC19001157 V1 EN-US

Switchsync PWC600 overview

Figure 3: Overview of PWC600 integration in a power system

PWC600 also monitors the electrical and mechanical health of the circuit breaker as well as the

performance of controlled switching during the previous operation. This information is

obtained by detection the instants of inception or interruption of the primary feedback signal,

which can be load current (4) or load side voltage (5). If no suitable primary feedback signals

are available, monitoring is based on the changeover instants of CB auxiliary contacts 52a/NO

(6) and 52b/NC (7). From the available feedback signals, PWC600 calculates the target error

(difference between expected switching time and actual switching time from last operation)

and applies a timing correction in the next operation. This process is known as “adaptive

correction”.

Refer to

Section 4.4.2 and Section 4.5 for more details on adaptation and monitoring.

PWC600 also has a facility for measuring CB operating times during pre-commissioning

through temporarily connecting to the primary contacts of individual circuit breaker poles.

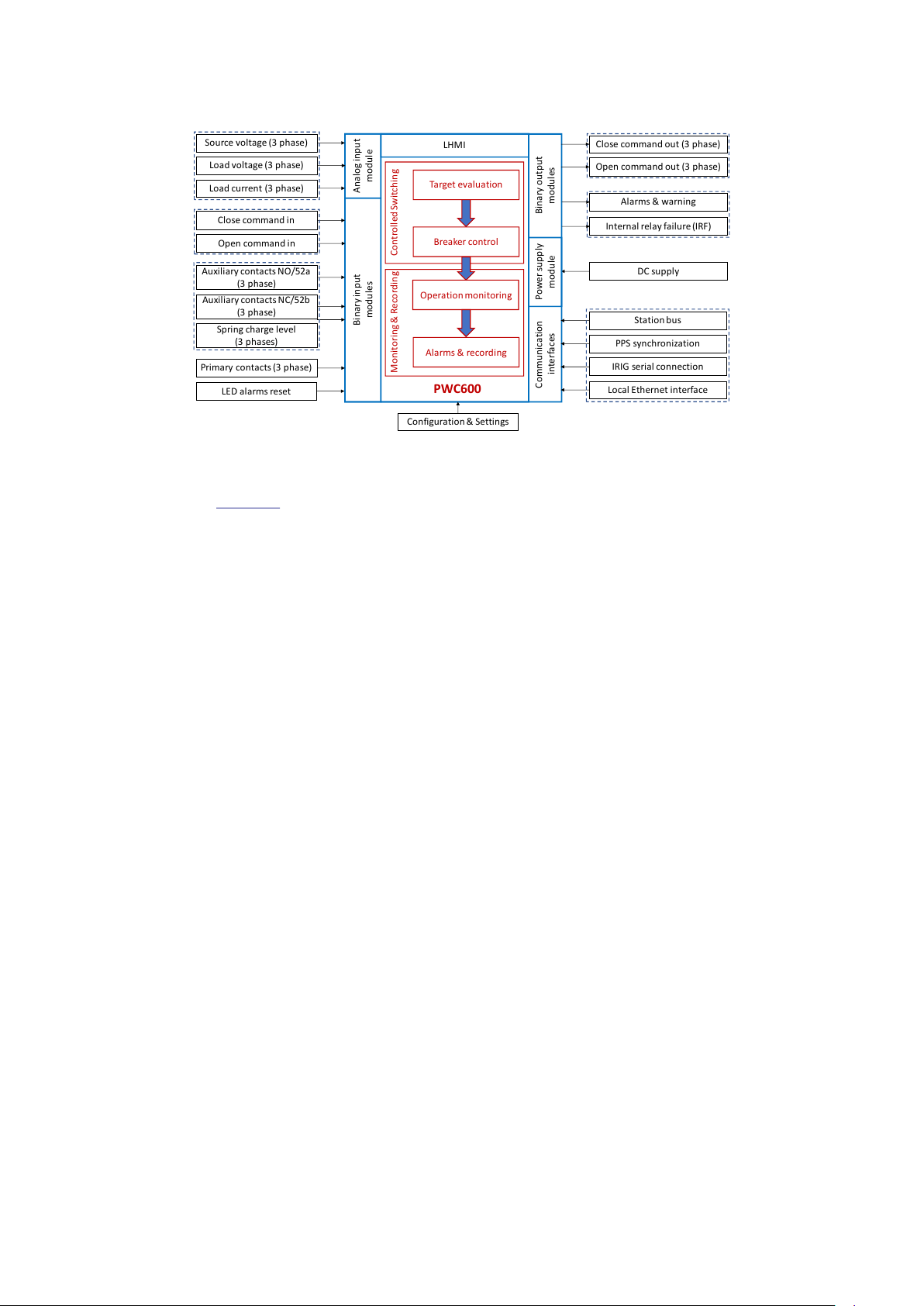

Figure 4 shows a block diagram of the interfaces to PWC600. The source side voltage, load

side voltage and load current are connected to the Analog input module (or alternatively

received on an IEC 61850-9-2(LE) compliant process bus). Incoming Open or Close commands

and output commands to the circuit breaker coils are connected to the binary input & output

modules. Also, the pole-wise auxiliary contacts and spring charge level (applicable for specific

drive designs) indicators are connected to binary input module. The power supply to the

PWC600 is provided through Power supply module. Alarms related to the health of the circuit

breaker as well as the performance of controlled switching operations can be generated by

relay contacts on the Binary output modules. The PWC600 IED continuously monitors itself

and in event of any internal failure, generates Internal relay failure (IRF) alarm. The user may

interact with PWC600 through the local user interface (LHMI) or through a web interface

(WHMI). Like for all ABB Relion IEDs, settings and configuration of PWC600 are prepared in

PCM600 tool.

User manual

19

© Copyright 2020 ABB. All rights reserved

Page 26

Analog input

module

Binary input

modules

Binary output

modules

Communication

interfaces

LED alarms reset

Source voltage (3 phase)

Load voltage (3 phase)

Load current (3 phase)

Close command in

Open command in

Auxiliary contacts NC/52b

(3 phase)

Spring charge level

(3 phases)

Auxiliary contacts NO/52a

(3 phase)

Primary contacts (3 phase)

Local Ethernet interface

Station bus

PPS synchronization

IRIG serial connection

DC supply

Power supply

module

Close command out (3 phase)

Open command out (3 phase)

Alarms & warning

Internal relay failure (IRF)

Target evaluation

Breaker control

Operation monitoring

Alarms & recording

Controlled SwitchingMonitoring & Recording

LHMI

PWC600

Configuration & Settings

Section 3 1MRK 511 463 A

Switchsync PWC600 overview

IEC19001158 V1 EN-US

Figure 4: External interfaces of PWC600 device

Refer Section 7 for more details on hardware interfaces of PWC600.

3.4 Application overview

Controlled switching, provided by Switchsync PWC600, is used for minimizing harmful

electrical transients upon planned switching of loads such as capacitor banks, shunt reactors,

power transformers, and power cables. The method is also gaining acceptance for reenergizing of EHV transmission lines, and replacing traditional pre-insertion resistors.

3.4.1 Common applications

The most common applications of controlled switching are listed below. Note that PWC600 is

intended only for intentional switching operations, not for protection trips.

Shunt capacitor banks

Basic aim is to control energization to minimize the voltage transients as well as inrush

currents. To improve interrupting performance, controlled opening can also be utilized.

Shunt reactors

Basic aim is to control de-energization to ensure reignition-free current interruption. In

addition, controlled closing also serves as a useful method for minimizing inrush currents.

D0E1353T201305141628 v2

GUID-AFC0A8F0-28AC-4E13-8513-78FF52B53283 v3

20

Power transformers

Basic aim is to control energization to minimize inrush currents. This is enabled by controlled

de-energization, to set a repeatable residual flux pattern, which is taken into account for the

subsequent energization.

Unloaded transmission lines and power cables

Basic aim is to control energization to minimize overvoltage transients and to prevent missing

current zeroes on fully compensated cables. To improve interrupting performance, controlled

opening can also be utilized.

© Copyright 2020 ABB. All rights reserved

User manual

Page 27

1MRK 511 463 A Section 3

Switchsync PWC600 overview

3.4.2 Variable applications

In a 1½ circuit breakers arrangement, the middle (tie) breaker is connected to a load on each

end. The same is applicable to every breaker in a ring layout. These two loads may be of the

same type but more often they are different.

The traditional approach to optimize controlled switching of both loads is to install two pointon-wave (POW) controllers for the breaker, together with a hardware logic for transferring

control to the appropriate POW controller. PWC600 1.1 and higher can accommodate these

functionalities in a single device through a feature called Setting Groups, which allows

automatic selection of different parameter sets based on external signals or conditions.

Variable applications, where setting groups are beneficial, include:

• For the tie breaker in 1½-CB or ring arrangements, select the appropriate reference source

and switching strategy depending on the status of adjacent switches and/or voltage

sources.

• In a double-busbar arrangement, select the appropriate busbar VT as reference, without

the need for external circuits for switching the VT signals.

• For power transformers, apply a fallback strategy for closing (assuming zero residual flux)

whenever the CB was opened not by PWC600.

• For loads with variable electrical configuration, e.g. switchable earthing of neutral point,

apply the optimal switching strategy in all cases.

• For any application, bypass the controlled switching functionality whenever an external or

internal binary signal is asserted.

• For FAT or similar situations, where the actual CB is switching low voltage, provide a set of

alternate CB settings (e.g. RDDS) that does not interfere with the original settings to be

applied in the high-voltage grid.

GUID-10FB53BF-40D7-45DA-A44C-9F4523D178F9 v1

3.5 User interfaces

The user can interact with Switchsync PWC600 in several ways.

• Local Human-Machine Interface (LHMI) on the front panel of the IED, featuring LCD screen,

pushbuttons and status LEDs

• Web interface via web browser

• Various tools in Protection and Control Manager PCM600, installed on a PC

3.6 Communication

The IED supports communication protocols IEC61850-8-1 and HTTPS over Ethernet, and IEC

61850-9-2(LE) over separate Ethernet process bus.

All operational information and controls are available through these protocols. However, some

communication functionality, for example, horizontal communication (GOOSE) between the

IEDs, is only enabled by the IEC 61850-8-1 communication protocol.

Waveform (disturbance) files are accessed using IEC 61850 or the Web interface. Disturbance

files are also available to any Ethernet based application in the standard COMTRADE format.

The IED can send binary signals to other IEDs (so called horizontal communication) using the

IEC 61850-8-1 GOOSE (Generic Object Oriented Substation Event) profile. Binary GOOSE

messaging can, for example, be employed for protection and interlocking-based protection

schemes. The IED meets the GOOSE performance requirements for tripping applications in

distribution substations, as defined by the IEC 61850 standard. Furthermore, the IED supports

GUID-DA31E614-A7EA-45DE-B496-B7AA88A308AC v3

D0E864T201305141540 v4

User manual

21

© Copyright 2020 ABB. All rights reserved

Page 28

Section 3 1MRK 511 463 A

Switchsync PWC600 overview

the sending and receiving of analog values using GOOSE messaging. Analog GOOSE

messaging enables fast transfer of analog measurement values over the station. The IED

interoperates with other IEC 61850 compliant IEDs, tools and systems and simultaneously

reports events to five different clients on the IEC 61850 station bus. IEC 61850-9-2(LE) is

supported for subscribing to current and voltage signals in digital sampled value format.

All communication connectors, except for the front port connector, are placed on the

integrated communication module. The IED is connected to Ethernet-based communication

systems via the RJ-45 connector (10/100BASE-TX) or the fibre-optic multimode LC connector

(100BASE-FX).

The IED supports the following time synchronization methods with a timestamping resolution

of 1 ms:

Ethernet communication based:

• SNTP (simple network time protocol)

With special time synchronization wiring:

• IRIG-B

• PPS (pulse per second)

PPS signals are used for IEC 61850-9-2(LE) process synchronisation with accuracy of 4 µs.

3.7 PCM600 tool

Protection and Control IED Manager PCM600 offers all the necessary functionality to work

throughout all stages of the IED life cycle.

• Planning

• Engineering

• Commissioning

• Operation and disturbance handling

• Functional analysis

When using PCM600 for writing to the IED, ensure that the LHMI or WHMI is not

in a menu position where settings can be changed. Only one active writing

transaction, from LHMI, WHMI, or PCM600, is allowed at a time.

With the individual tool components, you can perform different tasks and functions. PCM600

can operate with various topologies, depending on the customer needs.

For more information, see PCM600 documentation.

D0E808T201305141540 v3

3.7.1 Connectivity packages

A connectivity package is a software component that consists of executable code and data

which enable system tools to communicate with a specific type of IED. Connectivity packages

are used to create configuration structures in PCM600.

22

© Copyright 2020 ABB. All rights reserved

D0E811T201305141540 v2

User manual

Page 29

1MRK 511 463 A Section 3

Switchsync PWC600 overview

A connectivity package with its associated IED Module(s) includes all of the data which is used

to describe the IED. For example it contains a list of what parameters exist, which data format

is used, the units, the setting range, the access rights and visibility of the parameter. In

addition it contains code which allows software packages in PCM600 to properly

communicate with the IED. It also allows for localization of text even when it is read from the

IED in a standard format such as COMTRADE.

The connectivity package for PWC600 includes a product specific tool, Switchsync Setting

Tool (SST), for entering the required settings for the application. SST comes with a library of

ABB circuit breakers that can be used for controlled switching.