PSE – The efficient range

Description

Product description

• Wide rated operational voltage 208 – 600 V AC

•

Wide rated control supply voltage 100 – 250 V, 50/60 Hz

• Rated operational current 18 to 370 A

• Wide ambient temperature range, -25 to +60 ºC

(-13 to 140 ºF)

• Coated circuit boards for reliable operation in harsh

environment

• Built-in by-pass on all sizes, saving energy and

reducing installation time

• User friendly HMI with illuminated language neutral

display and four button keypad

• Optional external keypad, IP66

• Torque control for excellent control of pumps

• Current limit, adjustable between 1.5 – 7 x I

• Motor overload protection with classes 10A, 10,

20 and 30

•

Motor underload protection to detect pumps running dry

• Locked rotor protection, detecting jammed pumps

• Kick start to start jammed pumps or conveyor belts

• Analog output showing operational current, 4 – 20 mA

• Optional fieldbus communication using Profibus,

Modbus, Devicenet or CANopen

• Sophisticated algorithm eliminating the DC-compo-

nent and thereby providing excellent starting

performance.

e

The PSE softstarter range is the world’s first compact softstarters with Torque Control. This makes the PSE range an excellent

choice for pumping application where water hammering normally is a big problem. With its compact design and advanced

functionality, the PSE is also a very efficient solution for other

common applications such as compressors and fans.

Torque control

The most important function when stopping pumps is torque

control. Since the PSE softstarter is optimized for controlling

pumps, this feature is a must.

Built-in by-pass for energy saving

Using the built-in by-pass after reaching full voltage will greatly

reduce the power loss and thereby save energy. In the PSE

softstarter range, the by-pass is built-in on all sizes, which will

give the most compact starting solution and reduce the need

for wiring during installation.

Coated circuit boards

All circuit boards in the new PSE softstarter have a protective

coating to ensure a reliable operation even in tough environments like wastewater plants, where corrosive gases and acids

may exist.

Motor protection

The PSE softstarter is equipped with built-in electronic overload

protection, protecting the motor from overheating. Since no

additional overload device is needed, our efficient design saves

both space, installation time, and ultimately money.

Analog output

The analog output terminals can be connected to an analog

current meter to show the current during operation and thereby

eliminating the need for an additional current transformer. The

analog output signal can also be used as an analog input to a

PLC.

Display and keypad

The set-up of the PSE softstarter is done by using the four

button keypad and the illuminated display, providing a quick

and easy set-up. While operating, the display will also provide

important status information such as current and voltage.

External keypad

As an option the PSE softstarter can be equipped with an external keypad for easy set-up and monitoring of the unit without

opening the enclosure door. The keypad can also be used to

copy parameters between different softstarters.

14 | Softstarters Softstarters | 15

PSE – The efficient range

Description

The PSE Softstarter can be selected according to the rated motor power in normal duty

applications like pumps, compressors, elevators, escalators, short conveyor belts and

bow thrusters. See page 18.

For heavy duty applications like centrifugal

fans, crushers, mixers, mills, stirrers and long

conveyor belts, select a softstarter from page

19. The softstarter selection tool prosoft can

also be used for a more optimized selection.

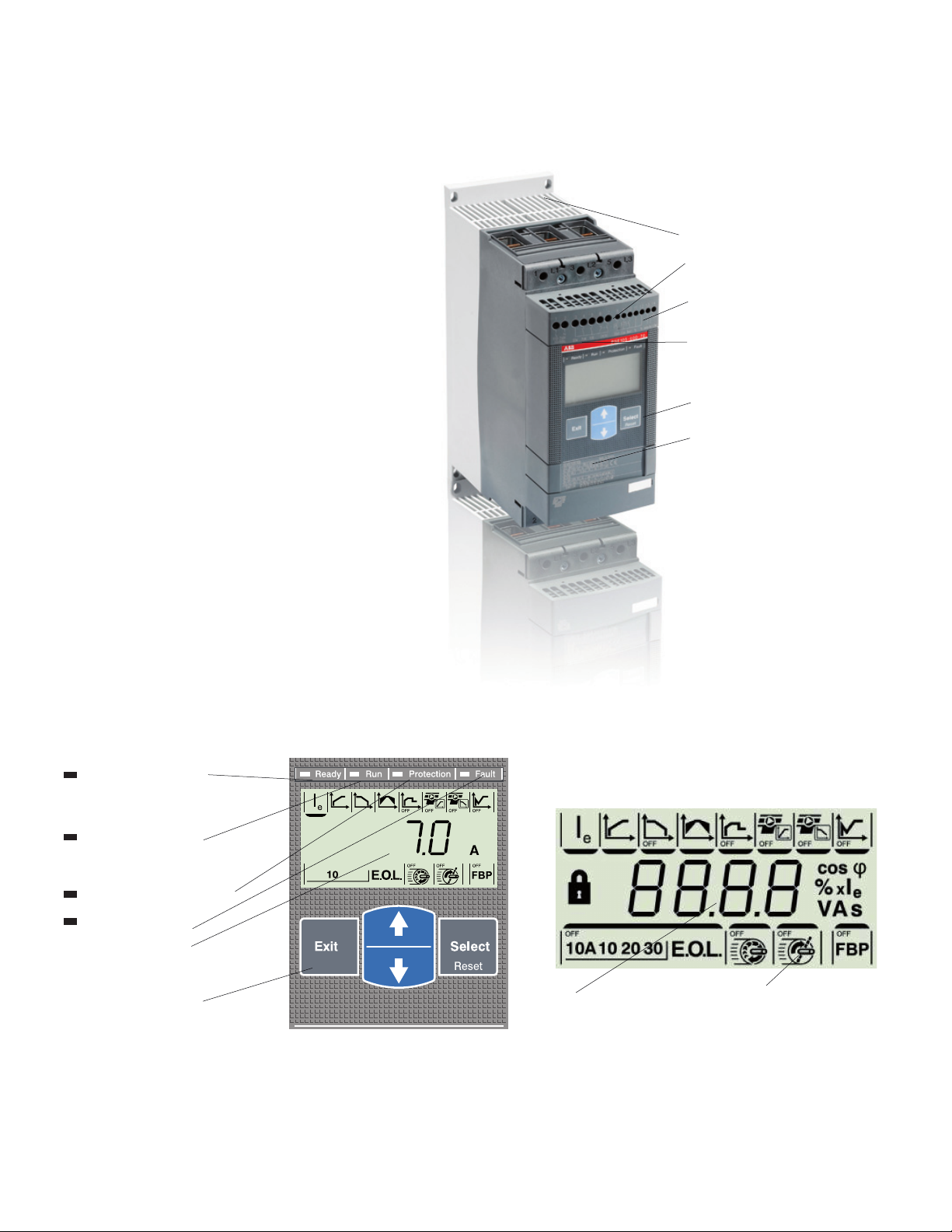

Screw mounting

Input for reset of faults

Analog output

3 output signal relays

(RUN, TOR, Event)

Built-in by-pass

All data available

on the front

Settings

Green ready LED

Flashing - Suppy available

Steady - Main available

Green run LED

Flashing - Ramping up/down

Steady - TOR

Yellow protection LED

Red fault LED

Back-lit display

User friendly keypad

Similar as for PST(B)

Four digits showing

values and messages

Icon’s for showing functions.

Language neutral

PSE – The efficient range

Overview

Softstarter

Normal start

In-line connected

(480 V) hp 10 15 20 25 30 40 50 60 75

(600 V) hp 15 20 25 30 40 50 60 75 100

UL/CSA, Max FLA 18 25 28 34 42 60 68 80 104

PSE18 PSE25 PSE30 PSE37 PSE45 PSE60 PSE72 PSE85 PSE105

PSE18 ... PSE105

Using MCCB only, type 1

coordination will be achieved

Max rating

Using J fuses, type 1

coordination will be

achieved

175% rating

Max rating 40 A 50 A 60 A 80 A 100 A 125 A 150 A 175 A 225 A

Minimum enclosure size

Fusible disconnect switch

for the above J fuses

The line contactor is not

required for the softstarter

itself but often used to open

if OL trips

Overload protection is used

to protect the motor from

over heating

The by-pass will reduce the

power loss of the softstarter

1)

Enclosure that has two latching points minimum. For use in pollution degree 2 environment.

MCCB (25 kA/600 V, 35 kA/480 V, 40 ºC)

Ts3L070TW Ts3L100TW Ts3L125TW Ts3L150TW Ts3L150TW T4S250TW T5S300TW T5S300BW

J type fuse protection (85 kA)

30 A 40 A 45 A 50 A 70 A 100 A 110 A 125 A 175 A

1)

610 x 508 x 305 mm / 24 x 20 x 12 in

Fusible disconnect switch

OS30 OS60 OS100 OS200

Line contactor

AF26 AF30 AF50 AF63 AF75 AF95 AF110

Electronic overload relay

By-pass

Built-in

Built-in

16 | Softstarters Softstarters | 17

PSE – The efficient range

Overview

PSE142 ... PSE170 PSE210 ... PSE370

Softstarter

Normal start

In-line connected

(480 V) hp

(600 V) hp

UL/CSA, Max FLA

PSE142 PSE170 PSE210 PSE250 PSE300 PSE370

100 125 150 200 250 300

125 150 200 250 300 350

130 169 192 248 302 361

Using MCCB only, type 1

coordination will be achieved

Max rating

Using J fuses, type 1

coordination will be

achieved

175% rating 225 A 250 A 300 A 400 A 500 A 600 A

Max rating 300 A 350 A 450 A 500 A 600 A 600 A

Minimum enclosure size

Fusible disconnect switch

for the above J fuses

The line contactor is not

required for the softstarter

itself but often used to open

if OL trips

Overload protection is used

to protect the motor from

over heating

The by-pass will reduce the

power loss of the softstarter

1)

Enclosure that has two latching points minimum. For use in pollution degree 2 environment.

MCCB (25 kA/600 V, 35 kA/480 V, 40 ºC) MCCB (25 kA/600 V, 50 kA/480 V, 40 ºC)

T5S400BW T6S600BW T6S800BW

J type fuse protection (85 kA)

1)

Fusible disconnect switch

Line contactor

Electronic overload relay

By-pass

915 x 762 x 305 mm /

36 x 30 x 12 in

OS400 OS600

AF145 AF185 AF210 AF260 AF300 AF400

1220 x 915 x 407 mm / 48 x 36 x 16 in

Built-in

Built-in

How to select correct size

By using the guide here, you can quickly

select a suitable softstarter for the most

common applications.

Quick guide for selection

Normal start Class 10 Heavy duty start class 30

Ordering - see page 18 Ordering - see page 19

Typical applications

• Bow thruster • Centrifugal pump • Centrifugal fan • Conveyor belt (long)

• Compressor • Conveyor belt (short) • Crusher • Mill

• Elevator • Escalator • Mixer • Stirrer

If more than 10 starts/h

Select one size larger than the standard selection

!

PSE – The efficient range

Normal starts, class 10, In-Line, ordering details

PSE18 ... PSE370

Rated operational voltage, Ue, 208 - 600 V AC

Rated control supply voltage, Us, 100 - 250 V AC, 50/60 Hz

UL/CSA

Max

rated

operational

current I

A

PSE18 ... PSE105

PSE142 ... PSE170

230 VkW400 VkW500 VkW208 Vhp230 Vhp480 Vhp600 V

hp

4 7.5 11 5 5 10 15 18 PSE18-600-70 2.4 (5.29)

5.5 11 15 7.5 7.5 15 20 25 PSE25-600-70 2.4 (5.29)

7.5 15 18.5 7.5 10 20 25 28 PSE30-600-70 2.4 (5.29)

9 18.5 22 10 10 25 30 34 PSE37-600-70 2.4 (5.29)

11 22 30 10 15 30 40 42 PSE45-600-70 2.4 (5.29)

15 30 37 20 20 40 50 60 PSE60-600-70 2.4 (5.29)

18.5 37 45 20 25 50 60 68 PSE72-600-70 2.5 (5.51)

22 45 55 25 30 60 75 80 PSE85-600-70 2.5 (5.51)

30 55 75 30 40 75 100 104 PSE105-600-70 2.5 (5.51)

40 75 90 40 50 100 125 130 PSE142-600-70 4.2 (9.26)

45 90 110 60 60 125 150 169 PSE170-600-70 4.2 (9.26)

59 110 132 60 75 150 200 192 PSE210-600-70 12.4 (27.34)

75 132 160 75 100 200 250 248 PSE250-600-70 13.9 (30.64)

90 160 200 100 100 250 300 302 PSE300-600-70 13.9 (30.64)

110 200 250 125 150 300 350 361 PSE370-600-70 13.9 (30.64)

e

Part number

Weight

kg (lb)

PSE210 ... PSE370

18 | Softstarters Softstarters | 19

PSE – The efficient range

Heavy duty starts, class 30, In-Line, ordering details

PSE18 ... PSE370

Rated operational voltage, Ue, 208 - 600 V AC

Rated control supply voltage, Us, 100 - 250 V AC, 50/60 Hz

UL/CSA

Max

rated

operational

current I

A

e

Part number

PSE18 ... PSE105

PSE142 ... PSE170

230 VkW400 VkW500 VkW208 Vhp230 Vhp480 Vhp600 V

hp

3 5.5 7.5 3 3 7.5 10 11 PSE18-600-70 2.4 (5.29)

4 7.5 11 5 5 10 15 18 PSE25-600-70 2.4 (5.29)

5.5 11 15 7.5 7.5 15 20 25 PSE30-600-70 2.4 (5.29)

7.5 15 18.5 7.5 7.5 20 25 28 PSE37-600-70 2.4 (5.29)

9 18.5 22 10 10 25 30 34 PSE45-600-70 2.4 (5.29)

11 22 30 15 15 30 40 42 PSE60-600-70 2.4 (5.29)

15 30 37 20 20 40 50 60 PSE72-600-70 2.5 (5.51)

18.5 37 45 25 25 50 60 68 PSE85-600-70 2.5 (5.51)

22 45 55 30 30 60 75 80 PSE105-600-70 2.5 (5.51)

30 55 75 40 40 75 100 104 PSE142-600-70 4.2 (9.26)

40 75 90 50 50 100 125 130 PSE170-600-70 4.2 (9.26)

45 90 110 60 60 125 150 169 PSE210-600-70 12.4 (27.34)

59 110 132 75 75 150 200 192 PSE250-600-70 13.9 (30.64)

75 132 160 75 75 200 250 248 PSE300-600-70 13.9 (30.64)

90 160 200 125 125 250 300 302 PSE370-600-70 13.9 (30.64)

Heavy duty

Weight

kg (lb)

PSE210 ... PSE370

PSE – The efficient range

Accessories

ATK...

LW...

LE185

LT ... -AL

Cable connectors for Al and Cu cables

For

softstarter type

PSE142 …170

PSE210 … 370

PSE210 … 370

Wire range

mm2 (AWG)

25-150

(4 AWG - 300 MCM)

25-185

(4 AWG - 400 MCM)

2 x 25-240

(2 x 4 AWG - 500 MCM)

Tightening

torque max. Nm (lb-in) Part number

1) 2)

Pack

piece

ing

13.5 (275 lb-in) ATK185 3

43 (375 lb-in) ATK300 3 0.168 (0.370)

43 (375 lb-in) ATK300/2 3 0.434 (0.957)

Weight

kg (lb)

1 piece

0.100 (0.220)

Terminal enlargements

For

softstarter type

Dimensions

hole ø

mm (in)

bar

mm (in) Part number

Pack

piece

ing

PSE142...170 10.5 (0.413) 20 x 5 (0.787 x 0.197) LW185 1 0.450 (0.992)

PSE210...370 13 (0.512) 40 x 6 (1.575 x 0.236) LW300 1 1.230 (2.712)

Terminal nut washer kits

For

softstarter type Req. qty Part number

1)

ing

Pack

piece

PSE142...170 2 LE185 2 0.200 (0.441)

PSE210...370 2 LE300 2 0.300 (0.661)

Weight

kg (lb)

1 piece

Weight

kg (lb)

1 piece

Terminal shrouds

For

softstarter type Suitable for Req. qty Part number

PSE142...170

PSE210...370

Compression lugs

Compression lugs

2 LT185-AL 2 0.220 (0.485)

2 LT300-AL 2 0.280 (0.617)

ing

Pack

3)

piece

Weight

kg (lb)

1 piece

External keypad including a 3m cable

For

softstarter type Part number

Pack

piece

ing

PSE18...370 PSEEK 1 –

Weight

kg (lb)

1 piece

PSEEK

Fieldbus plug connection accessory

For

softstarter type Part number

Pack

piece

ing

Weight

kg (lb)

1 piece

The same accessory for all sizes PS-FBPA 1 0.060 (0.132)

ABB Field Bus Plug suitable for all sizes. See page 38-41

1)

The terminal nut washer kits come standard with the PSE unit.

2)

Two lug sets are needed per PSE.

3)

The LT300-AL is not compatible with ATK300/2 cable connector.

PS-FBPA

20 | Softstarters Softstarters | 21

PSE – The efficient range

Class 30

Class 20

Class 10

Class 10

A

87

6

5

4

3

21

10 000

1000

100

10

1

0

0

Time (s)

Current (x Ie)

Technical data

Rated insulation voltage U

Rated operational voltage U

i

e

Rated control supply voltage Us

Rated control circuit voltage U

600 V Analog output

208 ... 600 V +10 %/-15 % Output signal reference 4 ... 20 mA

100 ... 250 V +10 %/-15 %, 50/60 Hz ±5 %

Internal 24 V DC

c

Type of output signal I Amp

Scaling Fixed at 1.2 x I

e

Starting capacity 4xIe for 10 sec. Control circuit

Number of starts per hour 10

1)

Number of inputs 3 (start, stop, reset of faults)

Overload capability, Signal indication LED’s

Overload Class 10 On / Ready Green ashing / steady

Ambient temperature Run / TOR Green ashing / steady

During operation -25 … +60 °C (-13 to 140 ºF)

2)

Protection Yellow

During storage -40 … +70 °C (-40 to 158 ºF) Fault Red

Maximum Altitude 4000 m (13123 ft)

3)

Protections

Degree of protection Electronic overload Yes (Class 10A, 10, 20, 30)

Main circuit IP00 Locked rotor protection Ye s

Supply and Control circuit IP20 Underload protection Ye s

Main circuit

Built-in By-pass Yes Field bus connection

Cooling system - Fan cooled Connection for

(thermostat controlled)

Yes ABB FieldBusPlug Yes (option)

HMI for settings External keypad

Display 4 7-segments and icons. Illuminated Display LCD type

Keypad 2 selection keys and 2 navigation keys Ambient temperature

Main settings during operation -25 … +60 °C (-13 to 140 ºF)

Setting current Size dependent during storage -40 … +70 °C (-40 to 158 ºF)

Ramp time during start 1-30 sec Degree of protection IP66

Ramp time during stop 0-30 sec

Initial / end voltage 30-70%

Current limit 1,5-7xI

e

Torque control for start Yes / No

Torque control for stop Yes / No

Kick start Off, 30-100%

Signal relays

Number of signal relays 3

K2 Run signal

K3 TOR (By-pass) signal

K1 Event signal

Rated operational voltage Ue 250 V AC / 24 V DC

Rated thermal current I

th

Rated operational current I

e

3 A

4)

Tripping curves for electronic overload protection (Cold)

at AC-15 (Ue = 250 V) 1.5 A

1)

Valid for 50 % on time and 50 % off time, with 3.5 x Ie for 7 seconds. If other data is required, please contact your sales ofce

2)

Above 40 ºC (104 ºF) up to max. 60 ºC (140 ºF) reduce the rated current with 0.6 % per ºC (0.33 % per ºF).

3)

When used at high altitudes above 1000 meters (3281 ft) up to 4000 meters (13123 ft) you need to derate the rated current using the following formula.

[ % of Ie = 100 150

[ % of Ie = 100 497

4)

A common voltage needs to be used for all 3 signal relays.

x - 1000

] x = actual altitude for the softstarter in meter

x - 3280

] x = actual altitude for the softstarter in feet

PSE – The efficient range

E1858D

17.5

ø 8.5

5

E1859D

20

ø 10.2

5

Technical data

Cross section of connection cables

Softstarter

PSE18 ... PSE105 PSE142 ... PSE170 PSE210 ... PSE370

Main circuit

Connection clamp

Solid/stranded 1 x mm2 (AWG) 2.5...70 (12...2/0) See accessories

Solid/stranded 2 x mm

Tightening torque

(recommended)

Connection bar

2

(AWG) 2.5...70 (12...2/0) See accessories

Nm (lb-in) 9 (79.66) See accessories

Width and thickness mm (in)

13 (0.512) x 3 (0.118)

Hole diameter mm (in) 6.5 (0.256)

Tightening torque

(recommended)

Nm (lb-in) 9 (79.66)

17.5 (0.689) x 5 (0.197) 20 (0.787) x 5 (0.197)

8.5 (0.335) 10.2 (0.402)

18 (159.31) 28 (247.82)

Supply and control circuit

Connection clamp

Solid/stranded 1 x mm

2

(AWG) 0.2...2.5 (24...14) 0.2...2.5 (24...14)

Solid/stranded 2 x mm2 (AWG) 0.2...1.5 (24...16) 0.2...1.5 (24...16)

Tightening torque

(recommended)

Nm (lb-in) 0.5 (4.43) 0.5 (4.43) 0.5 (4.43)

0.2...2.5 (24...14)

0.2...1.5 (24...16)

Semi-conductor fuse ratings and power losses

Overload protection

For

Softstarter

Current

range

Type Type A W A Type Size VA/VA pull in

PSE

PSE18 Integrated 5.4-18 0.2 40 170M1563 000 16

PSE25 Integrated 7.5-25 0.4 50 170M1564 000 16

PSE30 Integrated 9-30 0.5 80 170M1566 000 16

PSE37 Integrated 11.1-37 0.8 100 170M1567 000 16

PSE45 Integrated 13.5-45 1.2 125 170M1568 000 16

PSE60 Integrated 18-60 2.2 160 170M1569 000 16

PSE72 Integrated 21.6-72 3.1 250 170M1571 000 16

PSE85 Integrated 25.5-85 4.3 315 170M1572 000 16

PSE105 Integrated 31.8-106 6.6 400 170M3819 1 16

PSE142 Integrated 42.9-143 12.1 450 170M5809 2 16

PSE170 Integrated 51.3-171 17.6 500 170M5810 2 16

PSE210 Integrated 63-210 8.8 630 170M5812 2 23/350

PSE250 Integrated 75-250 12.5 700 170M5813 2 23/350

PSE300 Integrated 90.6-302 18 800 170M6812 3 23/350

PSE370 Integrated 111-370 27.4 900 170M6813 3 23/350

1)

For the supply circuit use a maximum 6 A time-delay fuse or an MCB with type C characteristics.

22 | Softstarters Softstarters | 23

Max

power loss

at rated Ie

(Internal by-pass)

Max semi-conductor fuse raiting - main circuit

Coordination type 2 (85 kA)

Bussman Fuses, DIN43 620

Supply circuit

power

requirements

1)

Loading...

Loading...