Page 1

Low Voltage Products

Power factor improvement

Application guide

Page 2

Table of contents

3 Basics of power factor

5 Options and solutions

6 Options and solutions, applications and installation

7 Applications and installation

9 Low voltage capacitor construction

11 Sizing capacitors

14 Harmonics

16 Harmonics filtering

17 Appendix

2 Table of contents | Power factor improvement

Page 3

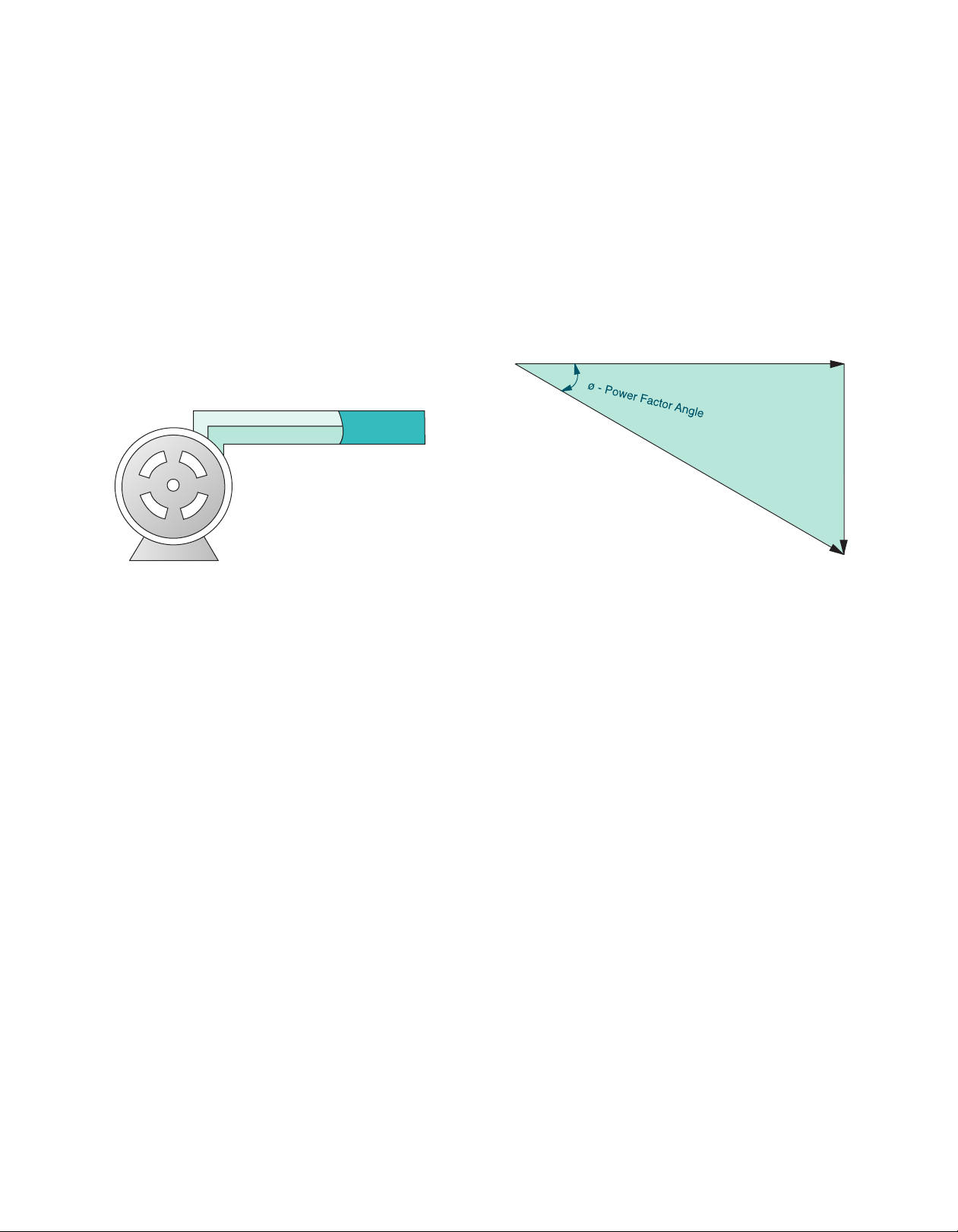

Basics of power factor

Motor

Basic concepts

Most load on an electrical distribution system can be

categorized into three types - resistive, inductive and capacitive.

On modern systems, the most common load is the inductive

type simply due to the nature of loads that consume electricity.

Typical examples include transformers, fluorescent lighting and

AC induction motors.

Active Power

Reactive Power

Figure 1

Apparent

Power

A common characteristic of all inductive loads from doorbells

to transformers is that they comprise a winding of some kind.

This winding creates an electromagnetic field that allows the

motor or transformer to function. A certain portion of electrical

power goes to maintain this electromagnetic field.

All inductive loads require two kinds of power to function

properly:

– Active power (kW) which actually performs the work

– Reactive power (kVAR) that sustains the electromagnetic field

One common example of reactive power can be seen in an

unloaded AC motor. When all load is removed from the motor,

one might expect the no-load current to drop near zero. In truth,

however, the no-load current will generally show a value between

25% and 30% of full load current. This is because of the continuous demand for magnetizing current by any inductive load.

Active power is the power indicated on a wattmeter. Apparent

power is simply the vector sum or geometrical sum of reactive

and active power (Fig. 2).

What is power factor?

Power factor (p.f.) is the relationship between working (active)

power and total power consumed (apparent power). Essentially,

power factor is a measurement of how effectively electrical

power is being used. The higher the power factor, the more

effectively electrical power is being used.

A distribution system’s operating power is composed of two

parts: Active (working) power and reactive (non-working

magnetizing) power. The active power performs the useful

work... the reactive power does not. It’s only function is to

develop magnetic fields required by inductive devices.

kW (active power)

kV

A

(apparent po

w

er)

kvar (reactive power)

Figure 2

Generally, power factor decreases (angle Φ increases) with

increased motor load. This geometric relationship of

apparent power to active power is traditionally expressed by

the right triangle (Fig 2) relationship of:

Cos Φ = p.f. = kW/kVA

Why improve low power factor?

Low p.f. simply means poor utilization efficiency. CosΦ varies

between 0 and 1, hence a value between 0.9 and 1.0 is

considered good power factor and essentially means that

metered power and used power are almost equal. From a

consumer’s perspective, it simply means you are using what

you paid for, with minimal wastage. When p.f. is low, the

utility must provide the non-productive reactive power in

addition to productive active power. For the utility that means

larger generators, transformers, conductors and other system

devices that pushes up their own capital expenditures and

operating costs, which they simply pass on to industrial users

in the form of power factor penalties. Hence, improved power

factor helps avoid those penalties.

Key advantage of improved power factor = $$$ savings!!

1. Good p.f. minimizes or eliminates utility p.f. penalties

2. Good p.f. helps improve operating life of equipment

3. Good p.f. expands system capacity, hence facilitating

partial deferrment of capital expenditures at plant level.

Power factor improvement | Basics of power factor 3

Page 4

Basics of power factor

Capacitor

Motor

WITHOUT CAPACITORS

Reactive Power

r

Motor

% Current

5

Power Factor cos-phi

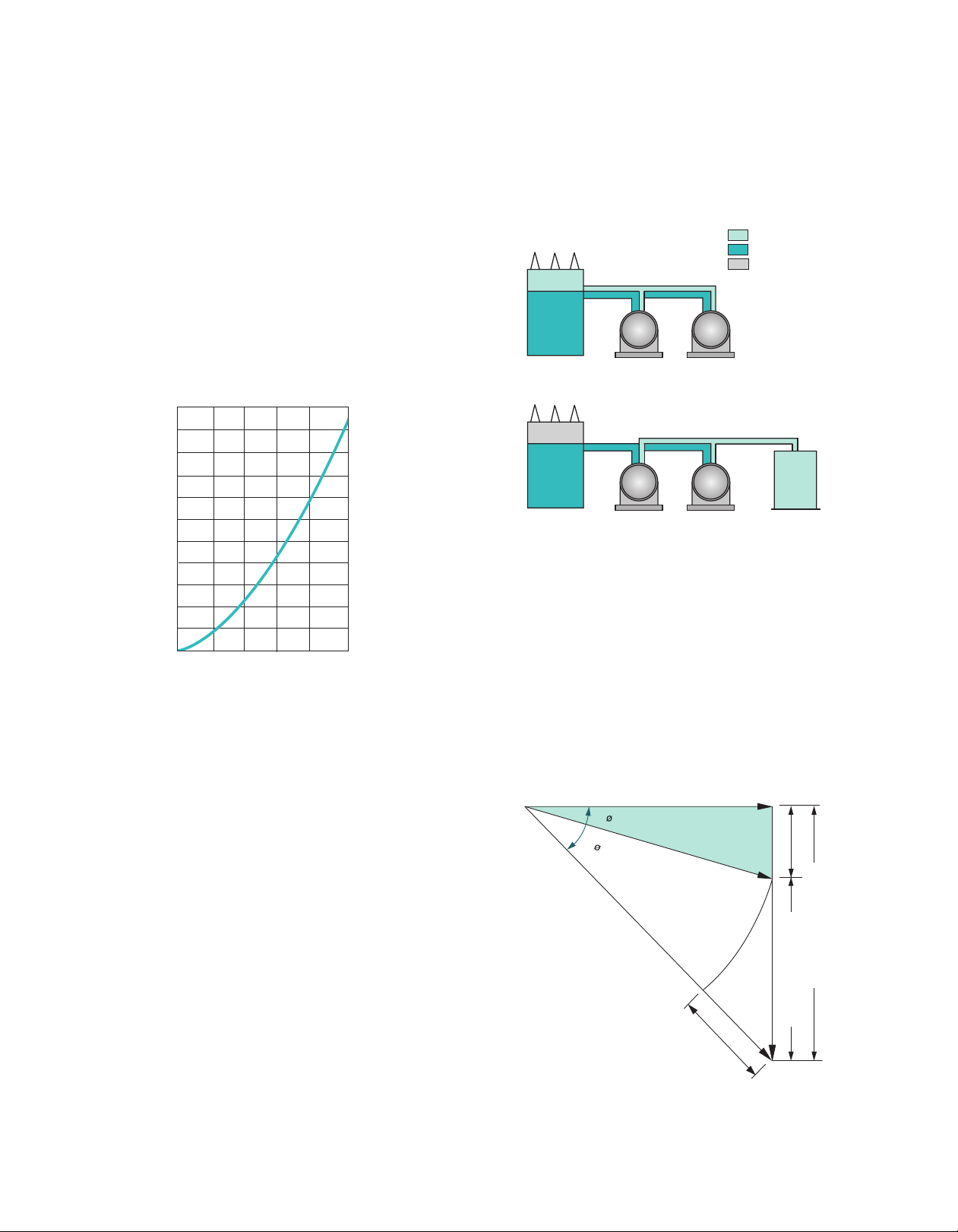

Figure 3 illustrates the relationship of power factor to total

current consumed. With a p.f. = 1.0 given a constant load,

the 100% figure represents the required useful current. As the

power factor drops from 1.0 to 0.9, power is used less

effectively. Therefore, 10% more current is required to handle

the same load. A power factor of 0.7 requires approximately

43% more current; and a power factor of 0.5 requires approximately 200% (twice as much!!) current to handle the same load.

200

150

100

1 0.9 0.8 0.7 0.6 0.

Fig. 3

How capacitors solve the problem of low p.f.

Low p.f. is a problem that can be solved by adding power factor

improvement (PFI) capacitors to the plant distribution system.

As illustrated in Fig. 4, capacitors work as reactive current

generators “supplying” reactive power (kVAR) to the system.

By generating their own reactive power, industrial users free the

utility from having to supply it; therefore, the total apparent

power (kVA) supplied by the utility will be less, which is

immediately reflected in proportionately smaller bills. Capacitors

also reduce the total current drawn from the distribution system

and subsequently increase system capacity.

Capacitor rating

Power factor correction capacitors are rated in electrical units

called “vars”. One VAR = one Volt Ampere of Reactive power.

VARs are units of measurement for indicating how much reactive

power the capacitor will supply. As reactive power is usually

measured in thousands of vars, the prefix “k” (for “kilo”) is added

to create the more familiar “kVAR” term. The capacitor kVAR

rating shows how much reactive power the capacitor will supply.

Each unit of kVAR supplied will decrease the inductive reactive

power demand by the same amount.

Active Power

Available Active Powe

Utility

Motor Motor

WITH CAPACITORS

Utility

Fig. 4

Example (Fig. 5):

A low voltage network requires 410 kW active power at full load,

and the power factor is measured to be 0.70. Therefore, the

system’s full load consumption of apparent power is 579.5 kVA.

If 300 kVAR of capacitive reactive power is installed, the power

factor will rise to 0.96 and the kVA demand will be reduced from

579.5 to 424.3 kVA. Thus, savings can vary from 20~30% or

even more in some cases, which cumulatively translates to

considerable money savings with the PFI equipment often

paying for itself in as little as 6 months.

410 kW

= 15° = .96 P

2

= 45° = .70 P

1

.F

.F

.

579.5 kV

A1

Fig. 5

.

424.3 kV

155.2 kV

Reduction

2

8.901

ravk

A

2

0

C 8.904 = 1ravk roticapa

C 03 = ravk roticapa

A

4 Basics of power factor | Power factor improvement

Page 5

Options and solutions

Options for improving power factor

The three main options for PFI are as follows:

– Individual capacitor units – One capacitor unit for each

inductive load (in most cases a motor)

– Banks of capacitor units – Several capacitors grouped

in an enclosure that is connected at a central point in the

distribution system. Fixed capacitor banks comprise

multiple capacitors racked in a common enclosure with

no switching while automatic capacitor banks, also called

“cap banks” have capacitors in a common enclosure with

contactor or thyristor (SCR) switched by a controller.

– Combination of above – Where individual capacitors are

installed on the larger inductive loads and banks are

installed on main feeders or switchboards, etc.

Advantages of individual capacitors

– Increased system capacity – When active power

compensation is closest to the load, it opens up system

capacity and also minimizes line losses.

– Cooler operation – Voltage drops cause the current to

increase, thereby cumulative heat losses occur due to

marginally higher current flow. When voltage drops are

corrected/addressed closest to the load itself, such

temperature issues are prevented right from the start.

– Simpler control – Motor and capacitor can be switched

ON and OFF together, which means simpler control logic

and fewer control parts.

– Precise compensation – Since the individual capacitor is

sized to the specific load and switches together with that

load, there is no chance of over compensation.

– Easier selection – Selection of individual capacitors is

simple and straight forward and requires no special

calculations. See relevant charts on pages 11 and 13.

Advantages of fixed or automatic bank systems

– More economical – Cap banks are more economical than

individual capacitor units when the key objective is to reduce

utility power bills and/or reduce the current in primary feeders

from a main generator or transformer. Being a single

installation for power factor compensation simply adds to the

convenience.

– Lower installation costs – The cost of installing one fixed or

automatic capacitor bank unit can be less than installing a

number of individual capacitors next to each inductive load.

– Switching – Automatic capacitor banks can switch all or part

of the capacitance automatically depending on load

requirements. This way, only as much power factor correction

as needed for the given load is provided. (This switching

capability is a primary advantage over fixed capacitor banks

where over-capacitance, leading power factor and resulting

overvoltages can occur should the load decrease.)

– Single point of control – It is easier to manage, monitor and

operate the process when the power factor inprovement (PFI)

equipment is in one physical location.

Low voltage capacitor construction

Combination of individual, fixed and automatic cap banks

A combination of individual and centralized cap banks is often

the best. Individual capacitors are installed on larger motors

and banks are installed on distribution systems. To determine

the total power factor correction required, then, you need to

know the total kVAR requirement for the facility and the desired

power factor. By referring to the Power Factor Correction Chart,

(Table 2), one can calculate the capacitance needed. See

selection instructions on the following pages for more details.

Power factor improvement | Options and solutions 5

Page 6

Options and solutions, applications and installation

Logic of mechanical protection in QCap

A low-impedence fault rapidly leading to a short-circuit, can be

protected by a fuse. A high-impedance fault on the other hand

may not lead to a current large enough to trip a fuse, it does

cause cumulative resistive heating which increases the pressure

in the sealed can, at a rate directly proportional to the rate of

heating. Likewise, cumulative heating caused by self-healing

action also slowly increases the pressure. Thereby the pressure

threshold can be reached either by the long-term accumulation

of gas released by self-healings (normal end of life) and/or by a

high-impedance fault as described above.

Capacitors special applications

Care should be taken when power factor correction capacitors

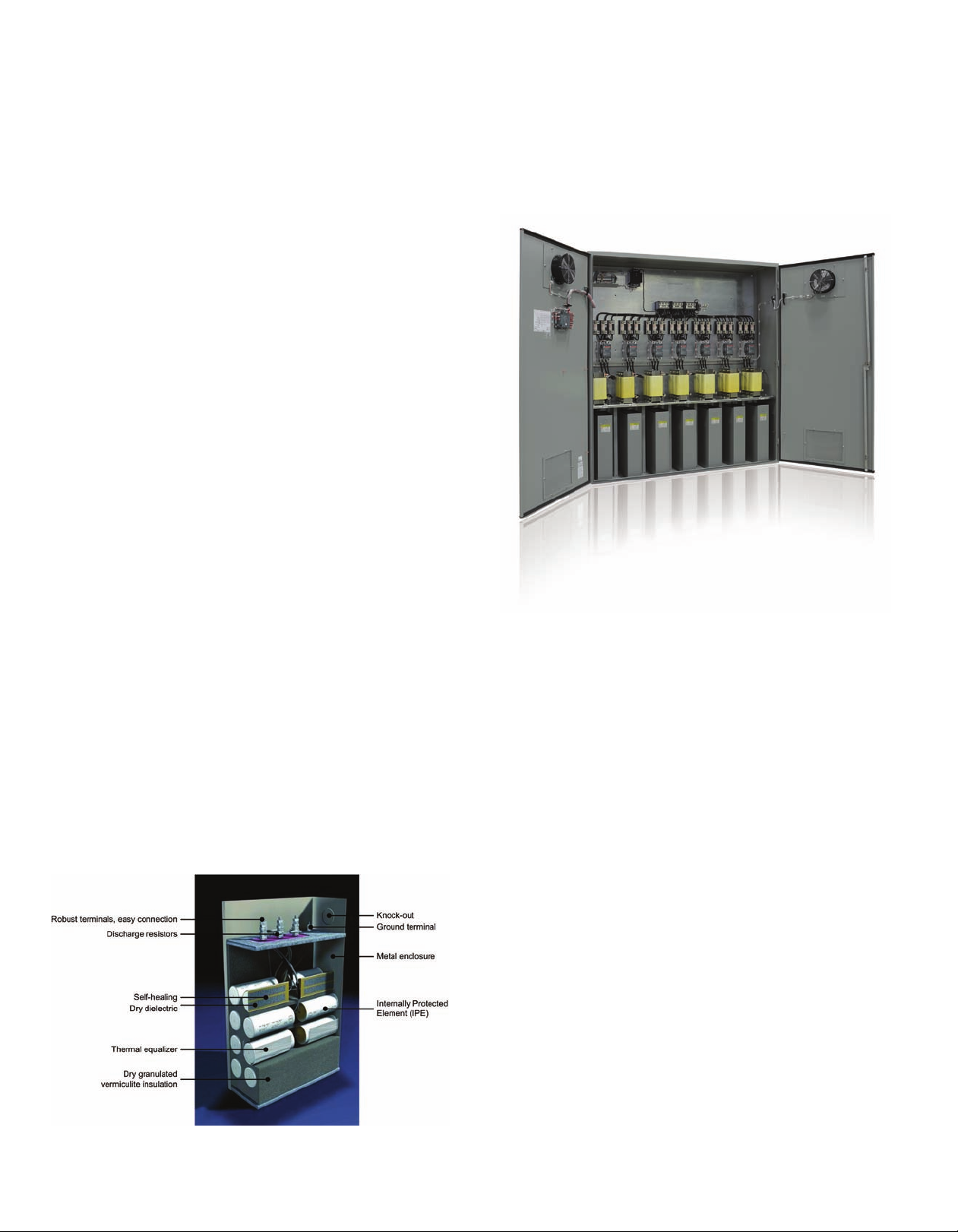

Cylindrical capacitors

Functionally very similar to enclosed capacitors (rectangular),

cylindrical capacitors are different in terms of physical dimensions and arrangement of internal parts. ABB cylindrical capacitors, also called QCap. Cylindrical capacitors are packaged

very conveniently and are best suited to plain and detuned cap

banks from 100 to 300 kVAR at 480V or 600V, 60Hz, standard

design for use in commercial market segments in Canada.

are used in the following applications:

– Frequent starts, plugging and jogging applications

– Regenerative loads where load may drive the motor (coasting,

etc.)

– Multi-speed motors

– Motors involving open-transition reduced-voltage starting

– Reversing starters that switch more than once per minute

– Electronic thyristor (SCR) controlled softstarters

QCap mechanical protection feature

A very simple but uniquely effective design feature provides

mechanical protection to each Qcap unit. The device terminals

are internally connected using three notched wires that break

together when the lid rises due to gas pressure. To ensure the

disconnection works reliably, the wires are indirectly anchored

to the lid at one end and to the can at the other. The groove is

designed to support this. The lid itself is has two stable

positions – normal and expanded. When pressure pushes up

the lid, all three wires break and the capacitor is entirely

disconnected.

SNAP on guard

Rigid connections

Locked by groove

SNAP actuated

Typical wiring diagram (detuned)

Plain autobanks are exactly the same as above, only without the reactors R1, R2

and so on.

6 Options and solutions, applications and installation | Power factor improvement

Page 7

Application and installation

Where should power factor correction capacitors be

installed in a distribution system?

Fig. 6 illustrates multiple options for locating PFI capacitors on

a low voltage distribution system.

Option A: Downstream of the overload relay

Advantages: this is the most efficient location since the

reactive power (kVAR) compensation is produced right where

it is consumed. Line losses and voltage drop are minimized.

The capacitor is switched automatically by the motor starter,

so it is only energized when the motor is running. No separate

switching device or overcurrent protection required. Also,

thermal overload needs to be set carefully, since the capacitor

will cause a reduction in amps through the overload, hence

lower trip setting for the same level of motor protection (see

Table1 for line current reduction as a percent of FLA).

Note: this works only with contactor starters. Special care

needs to be taken in cases where softstarters are used.

Option B: Between the contactor and the overload relay

Advantages: same as Option A except that the overload relay

can be set to the full load amps as per motor nameplate.

This location is often preferred by panel builders as overload trip

setting is simplified.

Option C: Between the circuit breaker and the contactor

Advantages: The capacitor can act as a central kVAR

source for multiple motors fed by the same circuit breaker.

Recommended for frequent jogging & reversing applications.

Disadvantage: as the capacitor stays energized even when the

motor(s) are not running, there is a risk of overcompensation

and leading p.f. at light load. Also, line losses are higher than

with Options A & B as the reactive current is carried further.

Option D: As a central compensation source (cap bank)

connected to the main distribution bus

Advantages: Of the four options,this is the most cost-effective as it

uses a few large kVAR capacitors rather than many small units.

Also, it is a single installation, hence easier to operate, monitor and

control. A power factor controller switches the capacitors in and

out to ensure the correct level of compensation on the network.

Main Feed

Motor

Feed

Fused

Safety Switch

or Breaker

Fused

Safety Switch

or Breaker

PFCC

D

Contactor

L1

L2

L3

Fused

Safety Switch

or Breaker

PFCC PFCCPFCC

Overload

Relay

T1

T2

T3

MOTOR

ACB

Locations for capacitors in motor circuits

Fig. 6

Temperature and ventilation

Low voltage capacitors should be located in adequately

o

ventilated areas with ambient temperature below 40

C. As

capacitors always operate at full load and generate heat of

their own, the better the heat dissipation, the longer the

operating life of the capacitor. Frequency and voltage are key

factors that can cause capacitor temperature to rise.

– Line frequency – variations in mains frequency can result in

temperature stress in the capacitor, though modern power

system frequencies tend to be increasingly stable.

– Operating voltage – if operating voltage exceeds 110% of

the capacitor rating, then overheating and cumulative

damage can occur. In such a case, the voltage must be

corrected or the capacitor must be taken offline in the

shortest time possible.

Note: This overvoltage problem is exactly why it is always

recommended to “undersize” a capacitor’s kVAR rating

during selection. Too much capacitance causes overvoltage

and overvoltage in turn causes excessive heat, the

cumulative effects of which can result in damage to the

capacitor itself.

Discharging time

Low voltage capacitors need a full minute to discharge through

the resistors, but it is still recommended that the terminals be

short-circuited to ground after the 1-minute has elapsed and

prior to human contact.

Power factor improvement | Application and installation 7

Page 8

Application and installation

Recommended wiring schematics with starter combinations

Autotransformer

Wye-Delta

Part-winding

Softstarter

Note: for softstart wiring, see page 12

2 speed/ 2 winding

Note: standard applicable guidelines and practices shall be used for installation.

8 Application and installation | Power factor improvement

Page 9

Wire B

Wire B

Low voltage capacitor construction

Principal components of a 3-phase capacitor

The principal components of a 3-phase ABB capacitor include:

1. Sequential protection system:

– Self-healing capacitor elements

Self-healing means that in case of dielectric breakdown,

the fault is cleared by evaporation of the metalized layer.

– Modularity due to multiple elements

Since the average capacitor comprises multiple elements

wired in Y or Δ, the end-of-life failure of one element

does not affect the continued operation of the capacitor,

though the overall capacitance may be reduced slightly.

– Nonflammable dry vermiculite filler

Vermiculite is a dry, granular, inert and non-flammable

insulating material filled around the elements and

compacted down to displace oxygen in the enclosure.

2. Discharge resistors

Discharge resistors (one per phase) are sized for safe

capacitor discharge (<50V in <1 min), as per NEC.

3. Terminal studs

Large terminal studs are located inside the enclosure at the

top of the capacitor for quick and easy cable connections.

4. Enclosure

All ABB enclosures are made of welded heavy gauge steel.

Available enclosure types include Nema 1, 12 and 3R.

Wire A

Electrode

Dielectric

Electrode

Dielectric

Electrode

Dielectric

Electrode

Dielectric

Electrode

Fig. 12

Dielectric

Wire A

Dielectric

Electrode

Dielectric

Electrode

Dielectric

Partial cutaway view of

capacitive element layers

Fig. 13

More about self healing elements

“Self-healing” is a characteristic which is unique to metallized

electrode capacitors. All capacitor normally experience insulation

breakdown as a result of the accumulated effect of temperature,

voltage stress, impurities in the insulating medium, etc. When this

happens in a non-“metallized” design, the electrodes are shortcircuited and the capacitor ceases its production of reactive power.

What is a metallized-film element?

Zinc metallized polypropylene film comprises a very thin layer

of conducting material (electrode) vapour-coated onto a layer

of capacitor grade insulating film. The electrode thickness

averages ~0.01 microns while the film is 5~10 microns thick

depending on design voltage (higher the voltage rating,

thicker the film). The capacitance of an element is inversely

proportional to the separation between electrodes. Hence, if

the electrode separation is halved, the capacitance is doubled

and element size is halved. Two electrode layers separated by

one layer of insulating film are tightly wound around a core,

effectively forming thousands of layers, such that the edge of

one electrode is exposed on one side of the element and the

edge of the other electrode is exposed on the other side (Fig.

12 & 13). Wires are then connected to each side of the element.

The element is enclosed in a plastic canister and sealed.

Key advantages are:

1. Self-healing design (see Fig. 14 & 15)

2. Low internal losses (<0.5 Watt/kVAR including resistors)

3. Small element size but powerful capacitors

4. Smaller environmental footprint at end of life cycle

Dielectric

Electrode

Dielectric

Electrode

Dielectric

Figure 14. Two electrodes short circuit through a fault in a dielectric layer.

In an ABB metallized-film unit, however, these individual insulation

breakdowns do not mean the shutdown of the capacitor.

The faults self-heal themselves and the capacitor continues

operation. The conducting electrode is very thin; when a short

circuit develops as a result of a fault in the insulating dielectric,

the thin electrode vaporizes around the area of the fault. This

vaporization continues until sufficient separation exists between

the faulted electrodes to overcome the voltage level. Fig. 15

illustrates the process of self-healing. The entire process of selfhealing takes “microseconds” and the amount of electrode which

is lost is negligible in comparison to the total surface area of the

element. The result is the metallized-film unit may self-heal

hundreds of times during its long life and still retain virtually all of

its rated capacitance.

Power factor improvement | Low voltage capacitor construction 9

Page 10

Low voltage capacitor construction

DIELECTRIC

Dielectric

Electrode

Dielectric

Electrode

Dielectric

Figure 15 and the real picture illustrates “self-healing” where electrode layers

around the short circuit (<1μm) are vaporized, hence contained.

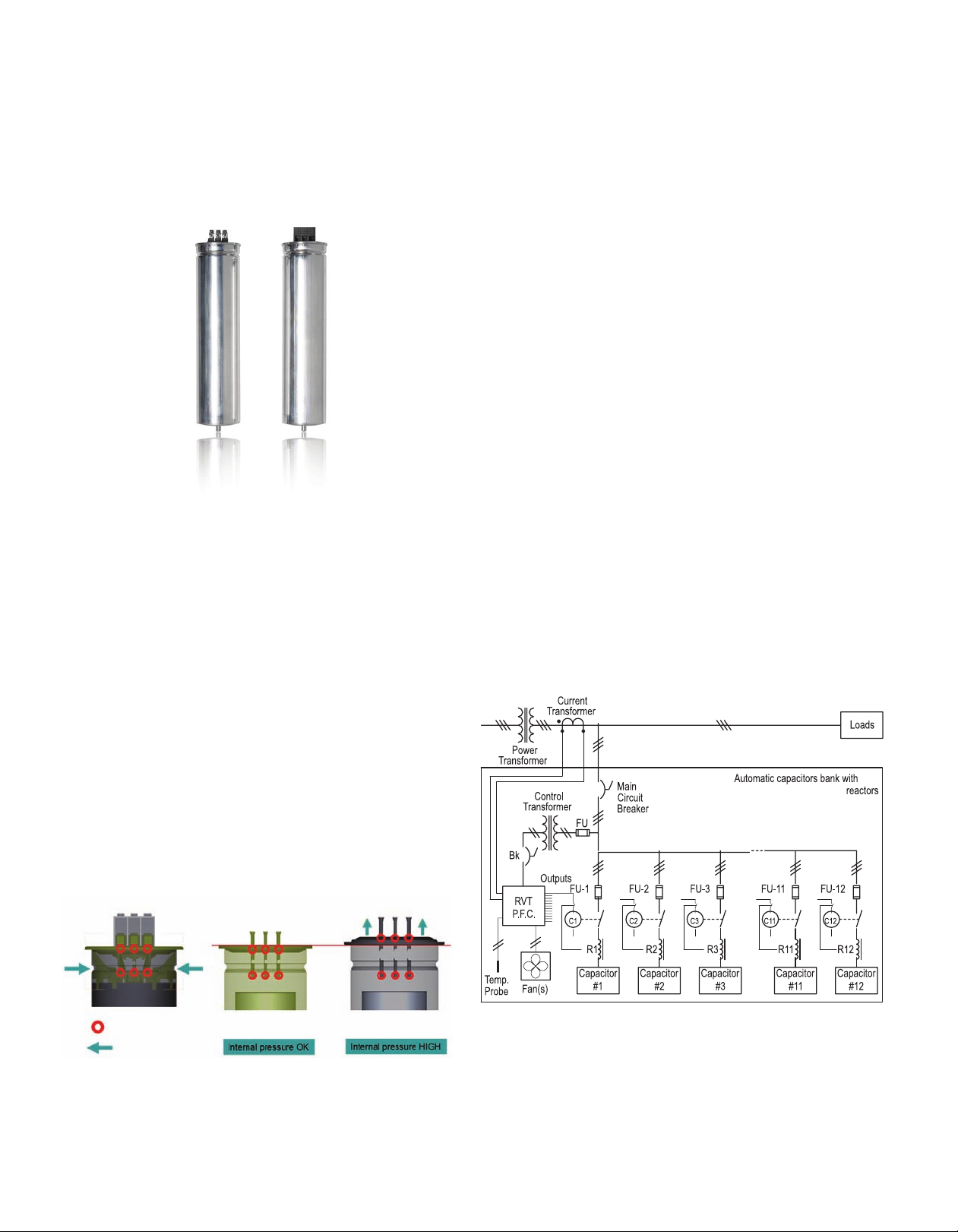

The IPE sequential protection system

ABB’s metallized-film self-healing capacitor elements have a

longer life than conventional foil design. However, the effects

of time, temperature, voltage stress and frequency, cumulatively

effect capacitor life. ABB’s sequential protection system with

patented Internally Protected Element (IPE) design provides the

highest possible protection to equipment and personnel. This

proven design ensures maximum reliable service and protection

in each element, which includes an internal fuse link (See Fig. 16)

for individual disconnection in short-circuit conditions.

ELECTRODE

Cylindrical capacitors design (QCap)

QCaps comprice 3 rolls of metallized film stacked vertically and

sealed off with a thermosetting plastic, much like the IPE

described earlier. The sealing not only protects from oxidation

of the electrode, but also provides mechanical rigidity to the

capacitor unit. Discharge resistors are integrated with the cageclamp terminals at the top. One fixing bolt at the bottom is

suitable for vertical or horizontal mounting.

•

•

FUSE LINK

•

•

•

•

•

Figure 16

What are discharge resistors?

As the capacitor elements store electrical charges like a battery,

the capacitor will maintain a near full charge even off power.

As this is a potential safety issue (dangerous on human contact),

discharge resistors are connected between all of the terminals.

When the capacitor is pulled off power, these resistors drain the

stored electrical charge, in the form of heat. It is recommended,

however, that capacitor terminals should always be shortcircuited

before touching the terminals.

What is the significance of dry type design?

ABB low voltage capacitors – both box type and cylindrical –

contain no free liquids. Environmental and personnel concerns

associated with leakage or flammability of conventional oil-filled

units are eliminated while kVAR for kVAR, dry-type units weigh

30% to 60% less than their oil filled counterparts.

•

Enclosed or QCap - which to select?

While both designs are functionally very similar, each is better

suited to certain applications primarily due to design and

construction, availability, etc.

Enclosed/rectangular capacitors are best suited to industrial

applications in Canada for the following reasons:

1. Fully customizable – 208~750V, 50/60 Hz, 2~100kVAR

2. Modular design – longer operating life under stress

3. Servicable, repairable

4. Standalone design, with options (fuse, indications, etc.)

5. Made in ABB Canada

Cylindrical capacitors are best suited to commercial

applications in Canada for the following reasons:

1. Single can size with 6 ratings, 12.5~30 kVAR

2. Suitable for detuned banks (660V available on request)

3. Compact design suitable for smaller cap banks

4. Easy to stock, hence ideal for integrators

5. Made in ABB Belgium

10 Low voltage capacitor construction | Power factor improvement

Page 11

Sizing capacitors

Selection chart based on motor HP and rpm

Table 1. Suggested maximum capacitor ratings for T-frame EEMAC class B motors (600V and below)

Induction

motor

rating

(HP)

3 1.5 14 1.5 23 2.5 28 3 38 3 40 4 40

5 2 14 2.5 22 3 26 4 31 4 40 5 40

7.5 2.5 14 3 20 4 21 5 28 5 38 6 45

10 4 14 4 18 5 21 6 27 7.5 36 8 38

15 5 12 5 18 6 20 7.5 24 8 32 10 34

20 6 12 6 17 7.5 19 9 23 12 25 18 30

25 7.5 12 7.5 17 8 19 10 23 12 25 18 30

30 8 11 8 16 10 19 14 22 15 24 22.5 30

40 12 12 13 15 16 19 18 21 22.5 24 25 30

50 15 12 18 15 20 19 22.5 21 24 24 30 30

60 18 12 21 14 22.5 17 26 20 30 22 35 28

75 20 12 23 14 25 15 28 17 33 14 40 19

100 22.5 11 30 14 30 12 35 16 40 15 45 17

125 25 10 36 12 35 12 42 14 45 15 50 17

150 30 10 42 12 40 12 52.5 14 52.5 14 60 17

200 35 10 50 11 50 10 65 13 68 13 90 17

250 40 11 60 10 62.5 10 82 13 87.5 13 100 17

300 45 11 68 10 75 12 100 14 100 13 120 17

350 50 12 75 8 90 12 120 13 120 13 135 15

400 75 10 80 8 100 12 130 13 140 13 150 15

450 80 8 90 8 120 10 140 12 160 14 160 15

500 100 8 120 9 120 12 160 12 180 13 180 15

3600 R/MIN 1800 R/MIN 1200 R/MIN 900 R/MIN 720 R/MIN 600 R/MIN

Capacitor

rating

(kVAR)

Line current

reduction

(%)

Capacitor

rating

(kVAR)

Line current

reduction

(%)

Capacitor

rating

(kVAR)

Enclosure type

Line current

reduction

(%)

Capacitor

rating

(kVAR)

Line current

reduction

(%)

Capacitor

rating

(kVAR)

Line current

reduction

(%)

Capacitor

rating

(kVAR)

Line current

reduction

(%)

WARNING

In order to avoid any complications with

the motor or capacitor, never oversize

capacitors or exceed 1.0 power factor.

Problems caused by overcompensation

Overcompensation causes p.f. to cross 1.0, also called as

leading power factor, which must be avoided at all costs.

The main issue is that leading power factor causes overvoltage,

which puts stress on the capacitor

eventually burn out. Also, power factor exceeding 0.95 leading

on generator supply can cause the genset to hunt, enough to

trip circuit breakers and also affect operation of other equipment on the network.

, causing it to heat up and

Example based on motor HP and rpm: A manufacturer needs

to determine the proper capacitors required for a 1200 RPM,

75HP T-Frame EEMAC class B motor.

1. First look up 75 in the horsepower column (Table 1)

2. Then locate the 1200 RPM capacitor rating (kVAR) column.

The result is 25 kVAR. That should improve the power factor

to around 0.95

3. Now refer to the appropriate brochure for capacitor part

number

Note: while selecting individual capacitors or fixed banks,

always select the calculated kVAR rating or a size lower.

On the other hand, for auto cap banks, selecting a size

higher than the calculated value helps to factor in future

expansions or load additions. That is because an auto cap

bank always has the flexibility to adjust its kVAR output

within its range, based on real-time demand.

Power factor improvement | Sizing capacitors 11

Page 12

Sizing capacitors

Selection methods and examples

Simple thumb-rule calculations based on motor data:

90% of no-load motor amps gives approximate kVAR Hence,

if no-load motor amps = 50A, then capacitor rating shall be

50 x 0.9 = 45 kVAR or less.

If only full-load motor amps is known, then no load amps can

be calculated as 30% of full load amps. Hence, if full load

motor amps = 100A, then no-load amps = 100 x 0.3 = 30A,

then capacitor rating shall be 30 x 0.9 = 27 kVAR or less.

A very rough estimation would be 30% of motor HP, hence for

a 100HP motor, 30 kVAR would be an approximate.

Calculation based on motor kW (see Table 2 next page)

– Starting p.f. = 0.75 and target p.f. = 0.90

– Corresponding factor from table = 0.398

– Motor HP = 100, hence 100 x 0.745 = 74.5 kW

– Required capacitor size = 74.5 x 0.398 = 29.65, rounded to

30 KVAR

– Part number for 600V, 3-ph network would be C603G30 if

installed inside a panel or C605G30 if standalone

What if existing power factor cannot be determined

because kVA is unknown?

Metered demand = 700kW. Ammeter reading indicates 900A.

Existing power factor and apparent power (kVA) are unknown.

How to calculate existing system power factor and capacitance

required to improve p.f. to 0.92 level?

1. kW is known (700kW) apparent power

kVA = ( VOLTS x AMPS x √3 ) ÷ 1000

2. The volts and amps of the distribution system are known so

for 600V and 900A, we have

(600 x 900 x 1.732) ÷ 1000 = 935.28 kVA

3. Now power factor is = 700kW/935.28kVA = 0.746 pf => 0.75

4. Look up Table 2 next page against existing p.f. of 0.75 and

target p.f. of 0.92. Hence multiplier = 0.398

5. Multiply this factor with the kW value.

Hence, 700 x 0.456 = 319.2 kVAR

The general rule as mentioned earlier in this document is to

select a rating below the calculated value if a fixed capacitor

bank is used and to select a rating above the calculated value

if an auto cap bank is uesd. Practically, the best option in this

particular case is an auto cap bank.

Note: in the last example, reactive power compensation of

319.2 kVAR is required to reach a target power factor of 0.92.

Fixed banks always carry the risk of overcompensation in light

load conditions so unless the capacitor is assigned to and

switched with a single load, it is recommended to use automatic

cap banks that can switch the capacitors in stages, especially

for larger values, that is 100 kVAR and above.

Note on using capacitors with softstarters

If individual power factor correction is to be provided to motors

controlled by softstarters, care muct be taken to use correct

interlocking in the control wiring such that the capacitor and

SCR’s are not in the circuit at the same time. Inappropriate

wiring or control logic may result in damage to the softstarter

and equipment. Please consider the following guidelines/logic

while designing the control circuit:

1. Capacitor shall always be located upstream of the

softstarter as indicated in the power schematic on page 8

2. Capacitor shall be switched by a contactor in order to

ensure isolation when required

3. Control logic shall ensure that the capacitor is isolated from

the circuit while the SCR’s in the softstarter are ramping up

as well as when ramping down. That means the capacitor

shall be active only when softstarter’s bypass contactor

is switched ON

4. Most ABB softstarters have a top-of-ramp (TOR) dry

contact that can be used to switch the capacitor contactor

12 Sizing capacitors | Power factor improvement

Page 13

Sizing capacitors

Selection based on existing and target cos phi values

Generic calculations

Step 1 – Know your starting power factor (cos

power factor (cos

)

Φ

2

Step 2 – Take inverse cosines of both cos

to obtain the angles

Φ

and

1

Φ

2

Step 3 – Take the tangents of the angles

subtract one from the other (tan

and cos

Φ

1

and cos

Φ

1

– tan

Φ

1

Φ

Step 4 – Finally, capacitor size in kVAR = P * (tan

) and Target

1

,

Φ

2

and

Φ

2

)

Φ

2

– tan

Φ

1

Φ

Using the tables

To make it easy, the (tan

Φ

1

– tan

) factors are already listed in

Φ

2

Table 2 below, so simply multiply that value with P (the actual

kW load) to directly obtain the kVAR value of the capacitor.

Note: As we normally use horse power values in North

America, the simple relationship is 1HP = 0.745kW

),

2

where P = load power in KW

Table 2: Power factor correction chart

Starting cos

Φ

0.85 0.90 0.91 0.92 0.93 0.94 0.95 0.96 0.97 0.98 0.99 1.00

0.60 0.714 0.849 0.878 0.907 0.938 0.970 1.005 1.042 1.083 1.130 1.191 1.333

0.61 0.679 0.815 0.843 0.873 0.904 0.936 0.970 1.007 1.048 1.096 1.157 1.299

0.62 0.646 0.781 0.810 0.839 0.870 0.903 0.937 0.974 1.015 1.062 1.123 1.265

0.63 0.613 0.748 0.777 0.807 0.837 0.870 0.904 0.941 0.982 1.030 1.090 1.233

0.64 0.581 0.716 0.745 0.775 0.805 0.838 0.872 0.909 0.95 0.998 1.058 1.201

0.65 0.549 0.685 0.714 0.743 0.774 0.806 0.840 0.877 0.919 0.966 1.027 1.169

0.66 0.519 0.654 0.683 0.712 0.743 0.775 0.810 0.847 0.888 0.935 0.996 1.138

0.67 0.488 0.624 0.652 0.682 0.713 0.745 0.779 0.816 0.857 0.905 0.966 1.108

0.68 0.459 0.594 0.623 0.652 0.683 0.715 0.750 0.787 0.828 0.875 0.936 1.078

0.69 0.429 0.565 0.593 0.623 0.654 0.686 0.720 0.757 0.798 0.846 0.907 1.049

0.70 0.400 0.536 0.565 0.594 0.625 0.657 0.692 0.729 0.770 0.817 0.878 1.020

0.71 0.372 0.508 0.536 0.566 0.597 0.629 0.663 0.700 0.741 0.789 0.849 0.992

0.72 0.344 0.480 0.508 0.538 0.569 0.601 0.635 0.672 0.713 0.761 0.821 0.964

0.73 0.316 0.452 0.481 0.510 0.541 0.573 0.608 0.645 0.686 0.733 0.794 0.936

0.74 0.289 0.425 0.453 0.483 0.514 0.546 0.580 0.617 0.658 0.706 0.766 0.909

0.75 0.262 0.398 0.426 0.456 0.487 0.519 0.553 0.590 0.631 0.679 0.739 0.882

0.76 0.235 0.371 0.400 0.429 0.460 0.492 0.526 0.563 0.605 0.652 0.713 0.855

0.77 0.209 0.344 0.373 0.403 0.433 0.466 0.500 0.537 0.578 0.626 0.686 0.829

0.78 0.183 0.318 0.347 0.376 0.407 0.439 0.474 0.511 0.552 0.599 0.660 0.802

0.79 0.156 0.292 0.320 0.350 0.381 0.413 0.447 0.484 0.525 0.573 0.634 0.776

0.80 0.130 0.266 0.294 0.324 0.355 0.387 0.421 0.458 0.499 0.547 0.608 0.750

0.81 0.104 0.240 0.268 0.298 0.329 0.361 0.395 0.432 0.473 0.521 0.581 0.724

0.82 0.078 0.214 0.242 0.272 0.303 0.335 0.369 0.406 0.447 0.495 0.556 0.698

0.83 0.052 0.188 0.216 0.246 0.277 0.309 0.343 0.380 0.421 0.469 0.530 0.672

0.84 0.026 0.162 0.190 0.220 0.251 0.283 0.317 0.354 0.395 0.443 0.503 0.646

0.85 – 0.135 0.164 0.194 0.225 0.257 0.291 0.328 0.369 0.417 0.477 0.620

0.86 – 0.109 0.138 0.167 0.198 0.230 0.265 0.302 0.343 0.390 0.451 0.593

0.87 – 0.082 0.111 0.141 0.172 0.204 0.238 0.275 0.316 0.364 0.424 0.567

0.88 – 0.055 0.084 0.114 0.145 0.177 0.211 0.248 0.289 0.337 0.397 0.540

0.89 – 0.028 0.057 0.086 0.117 0.149

0.90 – – 0.029 0.058 0.089 0.121 0.156 0.193 0.234 0.281 0.342 0.484

Target cos

Φ

0.184 0.221 0.262 0.309 0.370 0.512

Power factor improvement | Sizing capacitors 13

Page 14

Harmonics

Problems created by harmonics

– Excessive heating and failure of capacitors, capacitor fuses,

transformers, motors, fluorescent lighting ballasts, etc.

– Nuisance tripping of circuit breaker or blown fuses

– Presence of the third harmonic & multiples of the 3rd

harmonic in neutral grounding systems may require the

derating of neutral conductors

– Noise from harmonics that lead to erroneous operation of

control system components

– Damage to sensitive electronics (eg. ECG in hospitals)

– Electronic communications interference

Origins of harmonic distortion

Any device with non-linear operating characteristics can

produce harmonics. “Non-linear loads” are simply those where

the current does not follow the sinusoidal pattern of the voltage

waveform. An ever increasing demand for stability and precision

in electrical control and protection equipment has led to a

proliferation of diodes, diacs, triacs, thyristors (SCRs), IGBT’s

and similar semiconductor devices in power applications.

Although these solid state devices have brought significant

improvements in control design and efficiency, they do produce

harmonic currents due to their high switching frequency in

operation. Such rapid switching breaks the current waveform

down to a point where it is no longer sinusoidal. Such currents

not only cause a disturbance on the supply network but also

adversely affect the operation of other equipment on the

network, including PFI equipment and capacitors. While we

focus our discussions on harmonics sources associated with

solid-state power electronics, there are other sources of

harmonic currents as well, grouped as follows:

1. Power electronic equipment: Variable Frequency Drives

(AC VFD’s, DC drives, PWM drives, etc.), UPS’s, rectifiers,

switched power supplies, static converters, SCR systems,

diode bridges, IGBT controlled systems, etc.

2. Arcing equipment: furnaces, welding, lighting (CFL, etc.)

3. Saturable devices: Transformers, motors, generators, etc.

The harmonics from such devices are relatively insignificant

compared to power electronics and arcing equipment.

Waveform

Harmonics are defined as integer multiples of the fundamental

60 Hz waveform (i.e., 3rd harmonic = 180 Hz; 5th harmonic =

300 Hz, etc). Multiple waveforms at various frequencies result in

a non-sinusoidal, distorted waveform. Harmonics are continuous

(steady-state) disturbances on the electrical network and very

different from transient disturbances like surges, spikes, sags,

impulses, etc.

Transient problems are usually solved by installing surge

capacitors, isolation transformers or MOVs. These devices help

solve the transient problems but will not affect the mitigation of

low order harmonics or solve harmonic resonance problems.

Harmonic content

IGBT/SCR based converters are often identified by the number

of DC current pulses they produce per cycle. The most common

ones are 6 and 12 pulse types. Several factors influence harmonic

content but some significant harmonic currents, shown as a

percentage of the fundamental current, are listed below (Fig 7).

Order

harmonic

Typical percentage

of

1 100 100

5 35 -

7 14 -

11 9 9

13 8 8

17 6 -

19 5 -

23 4 4

25 4 4

of harmonic

current

6 Pulse 12 Pulse

Figure 7

14 Harmonics | Power factor improvement

Page 15

Harmonic overloading of capacitors

X

fhz

r

L1

L2 L3

L1

L2 L3

The impedance of a circuit dictates the current flow in that

circuit. As supply impedance is generally considered to be

inductive, the network impedance increases proportionally with

frequency while the capacitor impedance decreases, hence

varying inversely. This causes most of the higher frequency

currents to be absorbed by the capacitor, and other equipment

associated with the capacitor. In certain cases, harmonic currents

can exceed the fundamental (60 Hz) capacitor current. They

can also cause an increased voltage across the dielectric of

the capacitor which could exceed its voltage rating, resulting in

premature capacitor failure.

Harmonic resonance

The circuit or selective resonant frequency is reached when the

capacitor reactance and the supply reactance are equal.

Whenever power factor correction capacitors are applied to a

distribution network, which combines capacitance and

inductance, there will always be at least one frequency at which

the capacitors are in parallel resonance with the supply. If this

condition occurs at, or very close to, one of the significant

harmonics generated, then large currents can oscillate between

the supply network and capacitors. These currents are limited

only by the damping resistance in the circuit. Such currents will

add to the harmonic voltage disturbance in the network causing

increased voltage distortion. This results in a higher voltage

across the capacitor and excessive current through all capacitor

components. Resonance can occur on any frequency, but the

common ones are 5th, 7th, 11th and 13th harmonics or close to

that, for 6 pulse systems. See Fig.8.

High Voltage

X

L

Network

Avoiding resonance

In older systems it used to help to install capacitors in a part

of the system (Fig. 9) with the least probablility of parallel

resonance with supply. Realistically though, with harmonics

increasingly prevalent on most networks these days, avoiding

resonance is not an option anymore as opposed to overcoming it.

Preventing resonance conditions

Ther

e are several ways to overcome resonance. The simplest

solution to overcome resonance is to connect a reactor in series

with each capacitor to ensure the reactance is inductive at the

critical resonant frequencies but capacitive at the fundamental

frequency. For this, the capacitor and reactor must have a tuning

frequency below the lowest critical order of harmonic, which is

usually the 5th, which translates to the 175 Hz to 270 Hz range,

depending on the magnitude and order of harmonics present.

The addition of a reactor in the capacitor circuit increases the

fundamental voltage across the capacitor, hence the voltage

rating of the capacitor needs to be higher. See Fig. 10.

Delta Wye

Detuned Capacitor/Reactor Systems

Fig. 10

X

+X

L

•

f

o

C

Low Voltage

Network

Eliminating harmonic distortion

Harmonic currents can be reduced by using a basic passive

harmonic filter, often packaged with VFD’s mainly to address the

X

fhz– Frequency

C

XL– Supply reactance

XC– Capacitor reactance

f

– Resonant frequency

o

Fig. 8

Motor

Loads

Motor

Loads

Fig. 9

Harmonic

Generator

Capacito

5th harmonic. In order to eliminate harmonics however, it is

necessary to employ more sophisticated filter technology,

especially active harmonic filtering as described on the next page.

Power factor improvement | Harmonics 15

Page 16

Harmonics filtering

11th5th 7th

Types of filters

Filtering technology has evolved to address harmonics caused by

a proliferation of semiconductor based, electronically switched

devices. Filters in the past involved precisely calculated LC circuits

tuned to different frequencies (see Fig.11) that addressed a limited

number of harmonic orders. Such combinations were almost

always a precarious balance, so any change in load would

necessitate a re-design and modification to the existing filter.

Also, increasingly complex non-linear loads on modern

networks result in higher order harmonics which are beyond

the capabilities of older, reactor based technologies.

Shunt Filters

Fig. 11

ABB solutions for harmonics mitigation

While old filters primarily depended on reactors, newer Insulated

Gate Bipolar Transistor-based (IGBT) solutions are best suited

to actively eliminate harmonics with far greater precision, which

is why ABB only promotes active filtering technology.

Active harmonic filters (AHF) are recommended where harmonic

distortion already exists or if the harmonic distortion is above the

5% limits recommended in IEEE 519-1992, “Guide for Harmonic

Control and Reactive Compensation of Static Power Converters”.

AHF are IGBT-based and can be used in conjunction with tuned

filters and are specifically designed to eliminate harmonics up to

the 50th, thereby improving power quality across the entire network. ABB has a full range of cULus approved active harmonic

filters (PQFM and PQFI versions) for a variety of applications and

environments - commercial, industrial and even marine. PQFI

and PQFM both, have the additional capability of load balancing

as well providing a limited amount of reactive compensation to

augment the power factor correction of standard fixed or

automatic PFI equipment. Full support is provided on request for

product sizing and selection based on the specific requirements

of every application. For more information

Harmonic studies

The first step in solving harmonic related problems is to perform

an analysis to determine the specific needs of the network.

To determine capacitor and filter requirements, it is necessary to

establish the impedance of the supply network and the value of

each harmonic current.

ABB Canada's full offering for low voltage power quality

– Individual capacitor units, fully assembled in Montreal

– Cylindrical capacitors, made in Belgium, with modules

and cap banks assembled in Montreal

– Fixed or automatic capacitor banks, plain or detuned as

required, fully assembled in Montreal

– Dynacomp SCR-switched detuned capacitor banks,

fully assembled in Montreal

– Active harmonic filters, made in Belgium

– All products above are fully cULus approved

– On-site power factor and harmonic studies

– On-site commissioning and startup offerred

– Complete pre-sales and after-sales support

16 Harmonics filtering | Power factor improvement

Page 17

Appendix

Typical recommended cable sizes and protection device ratings

1503- phase

capacitor

kVAR

240 Volt

480 Volt

2.5

3.5

5

7.5

10

15

20

25

30

40

50

60

75

100

125

150

200

250

300

1.5

2

2.5

3

3.5

4

5

6

6.5

7.5

10

15

20

25

30

35

40

45

50

60

70

75

80

90

100

150

200

250

300

350

400

500

Rated current

per phase (amps)

6

8.4

12

18

24

36

48

60

72

96

120

144

180

241

301

361

481

601

722

1.8

1.8

3

3.6

4.2

4.8

6

7.2

7.8

9

12

18

24

30

36

42

48

54

60

72

84

90

96

108

120

180

241

301

361

421

481

601

Minimum copper

cable size for

75 OC insulation

#14

#14

#12

#10

#8

#6

#6

#4

#3

#1

00

000

250 kcmil

400 kcmil

(2) - 0000

(2) - 250 kcmil

(2) - 400 kcmil

(3) - 300 kcmil

(3) - 400 kcmil

#14

#14

#14

#14

#14

#14

#14

#14

#14

#14

#12

#10

#8

#8

#6

#6

#6

#4

#4

#3

#2

#1

#1

0

00

350 kcmil

400 kcmil

(2) - 0000

(2) - 250 kcmil

(2) - 300 kcmil

(2) - 400 kcmil

(3) - 300 kcmil

Minimum copper

cable size for

90 OC insulation

#14

#14

#12

#10

#8

#6

#6

#4

#3

#1

00

000

250 kcmil

400 kcmil

(2) - 000

(2) - 250 kcmil

(2) - 350 kcmil

(3) - 300 kcmil

(3) - 350 kcmil

#14

#14

#14

#14

#14

#14

#14

#14

#14

#14

#12

#10

#8

#8

#6

#6

#6

#4

#4

#3

#2

#1

#1

0

00

350 kcmil

400 kcmil

(2) - 000

(2) - 250 kcmil

(2) - 300 kcmil

(2) - 350 kcmil

(3) - 300 kcmil

Recommended

fuse amps

10

15

20

30

40

60

80

100

125

175

200

250

300

400

500

600

800

1000

1200

3

3

6

6

10

10

10

15

15

15

20

30

40

50

60

70

80

90

100

125

150

150

175

200

200

300

400

500

600

700

800

1000

Recommended

disc switch amps

30

30

30

30

60

60

100

100

200

200

200

400

400

400

600

600

800

1000

1200

30

30

30

30

30

30

30

30

30

30

30

30

60

60

60

100

100

100

100

200

200

200

200

200

200

400

400

600

600

800

800

1000

Recommended

MCCB trip amps

15

15

20

30

40

60

80

90

110

150

200

225

300

400

500

600

750

900

1100

15

15

15

15

15

15

15

15

15

15

20

30

40

50

60

70

80

90

90

110

150

150

150

175

200

300

400

500

600

650

750

900

Power factor improvement | Appendix 17

Page 18

Appendix

Typical recommended cable sizes and protection device ratings

3- phase

capacitor

600 Volt

kVAR

2

3

4

5

7.5

10

15

20

25

30

35

40

45

50

60

70

80

90

100

150

200

250

300

350

400

500

Rated current

per phase (amps)

2

3

4

5

7

10

14

19

24

29

34

38

43

48

58

67

77

87

96

144

192

241

289

337

385

481

Minimum copper

cable size for

75 OC insulation

#14

#14

#14

#14

#14

#14

#12

#10

#8

#8

#6

#6

#6

#6

#4

#3

#2

#1

#1

3/0

300 kcmil

400 kcmil

(2) - 3/0

(2) - 4/0

(2) - 300 kcmil

(2) - 400 kcmil

Minimum copper

cable size for

90 OC insulation

#14

#14

#14

#14

#14

#14

#12

#10

#8

#8

#6

#6

#6

#6

#4

#3

#3

#2

#1

3/0

250 kcmil

400 kcmil

500 kcmil

(2) - 4/0

(2) - 250 kcmil

(2) - 350 kcmil

Recommended

fuse amps

3

6

6

10

15

20

25

35

40

50

60

70

80

80

100

125

150

150

175

250

350

400

500

600

600

800

Recommended

disc switch amps

30

30

30

30

30

30

30

60

60

60

60

100

100

100

100

200

200

200

200

400

400

400

600

600

600

800

Recommended

MCCB trip amps

15

15

15

15

15

15

25

30

40

50

60

60

70

80

90

110

125

150

150

225

300

400

450

550

600

750

The above table gives recommended ratings of cables,

disconnect switches, and/or molded case circuit breakers for

use with capacitor loads. For requirements not covered in the

table, the following application guidelines may be used for

capacitor switching duty:

– Power cable sizing 135% of capacitor current

– Disconnect switch 150% of capacitor current

– Molded case circuit breaker 150% of capacitor current

The above ratings are based on the CE code handbook.

ABB assumes no responsibility for inappropriate ratings.

18 Appendix | Power factor improvement

Wire connection

Metal end spray

In-house metallised

polypropylene film (unique profile)

Secondary foil winding

Biaxially oriented

polypropylene dielectric

Thermo-setting encapsulation

Fuse link

Plastic case

Cut-away view of an Internally Protected Element

Page 19

Installation requirements

For any installation requirements on capacitors, refer to

section 26-200 to 26-222 of the Canadian Electrical Code,

or consult ABB Control’s technical support department.

Separate overcurrent protection

A separate overcurrent device is not necessary when an ABB

capacitor is electrically connected on the load side of the motor

starter fused safety switch or breaker. Personnel and facility

short circuit protection is provided within the capacitor by ABB’s

patented Sequential Protection System. Short circuit protection

between the main feed and the capacitor is provided by the

motor starter fused safety switch or breaker. A disconnect

switch can be provided when the capacitor is connected as

illustrated in Option C (See Fig. 6, page 7). When the capacitor

is connected as in Option C, it remains energized even when the

motor is off. The optional disconnect helps avoid this condition.

Additional information

1. Improved voltage @ transformer due to capacitor addition:

kVAR

% voltage rise =

kVA of transformer

of capacitors x % reactance of transformer

Note: System reactance should be added to the transformer

reactance if available.

2. Reduced power losses in the distribution system due to

capacitor addition:

% reduction of losses = 100 – 100

improved power factor

3. Reduced kVAR when operating 60 Hz unit @ 50 Hz

Actual kVAR = rated kVAR

60

4. Reduced kVAR when operating @ below rated voltage

Actual kVAR = rated kVAR

i.e.

240 V @ 208V = .751 rated kVAR

rated voltage

i.e.

660 V @ 600V = .826 rated kVAR

rated voltage

50

(

original power factor

(

) = .83 rated kVAR

operating voltage)

(

operating voltage)

(

2

)

2

2

Common formulae:

cos Φ = cos Φ (average) =

kVAR = kW

kVA = kVAR =

I

line

Abbreviations and notations:

V = voltage, I = current in Amps, kW = real power

kVA = apparent power, kVAR = reactive power

C = capacitance in microFarad, f = frequency in Hertz

HP = horsepower, k = kilo, π = 3.14159

kW

kVA

tanΦ = kW * tan (cos

*

√

3

V * l

*

1000

1000

kVA

= kW =

√

3

*

V

*

–1

V

1000000/ 1000

√

√

(kWh

)

Φ

2

* 2 * π

3

V * l

*

1000

kWh

2

+ kVARh2)

f

C

*

*

cos

*

Φ

Power factor improvement | Appendix 19

Page 20

Contact us

ABB Inc.

Low Voltage Products

Note

The information contained in this document is for general

information purposes only. While ABB strives to keep

the information up to date and correct, it makes no

representations or warranties of any kind, express or

implied, about the completeness, accuracy, reliability,

suitability or availability with respect to the information,

products, services, or related graphics contained in the

document for any purpose. Any reliance placed on

such information is therefore strictly at your own risk.

ABB reserves the right to discontinue any product or

service at any time. For additional information on products

or related technical information, please consult with ABB.

The sizing, selection, installation and use of ABB products

shall conform to applicable local codes and/or industry

standards and best practices. Installation or use that is not

in accordance with these codes and standards may be

hazardous to personnel and/or equipment.

© Copyright 2015 ABB Inc. All rights reserved.

1SXP984000M0200 / June 2015

Loading...

Loading...