Page 1

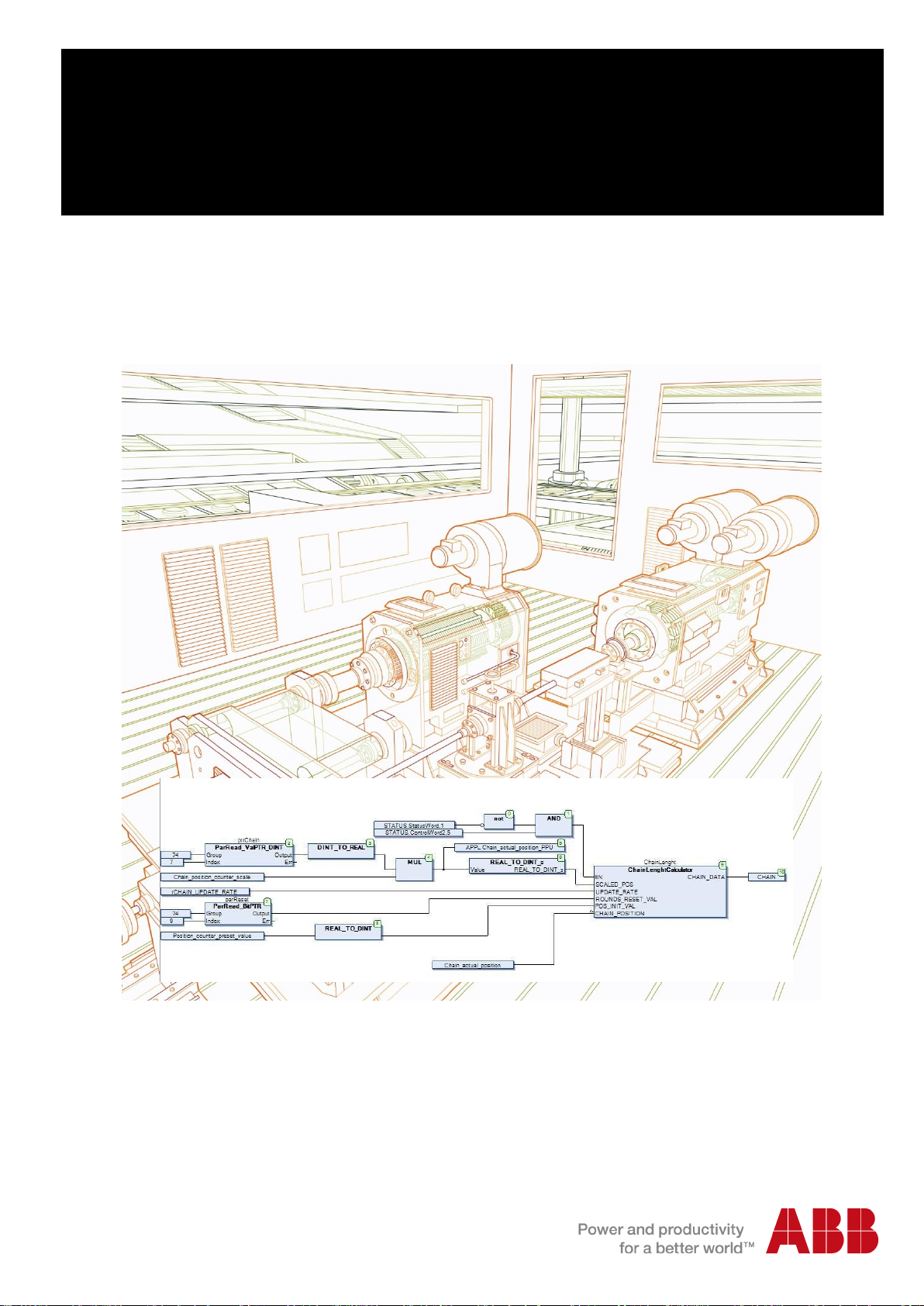

ABB industrial drives

Programming manual

Drive application programming (IEC 61131-3)

Page 2

Drive application and firmware manuals and

guides

Code (English)

Drive (IEC 61131-3) application programming manual

3AUA0000127808

ACS880 primary control program firmware manual

Drive composer start-up and maintenance PC tool

user’s manual

AC500 Control Builder PS501 Complete English

documentation

3AUA0000085967

3AUA0000094606

3ADR025078M02xx

List of related manuals

You can find manuals and other product documents in PDF format on the Internet. See

section Document library on the Internet on the inside of the back cover. For manuals not

available in the Document library, contact your local ABB representative.

Page 3

Programming manual

Drive application programming (IEC 61131-3)

3AUA0000127808 Rev C

EN

EFFECTIVE: 2015-04-03

© 2015 ABB Oy. All Rights Reserved

Page 4

Page 5

5

Continuous function chart (CFC) program ..................................................................... 35

Table of contents

List of related manuals ...................................................................................................... 2

Introduction to the manual .............................................................................................. 13

Contents of this chapter ..................................................................................................... 13

Compatibility ....................................................................................................................... 13

Target audience ................................................................................................................. 13

Safety instructions .............................................................................................................. 14

Purpose of the manual ....................................................................................................... 14

Contents of the manual ...................................................................................................... 14

Related documents ............................................................................................................ 14

Terms and abbreviations .................................................................................................... 15

Getting started .................................................................................................................. 17

Contents of this chapter ..................................................................................................... 17

Setting up the programming environment .......................................................................... 17

Overview of drive programming ..................................................................................... 21

Contents of this chapter ..................................................................................................... 21

Drive application programming ........................................................................................... 21

System diagram ................................................................................................................. 22

Programming work cycle .................................................................................................... 23

Special tasks ...................................................................................................................... 23

Programming languages and modules ............................................................................... 24

Libraries.............................................................................................................................. 24

Program execution ............................................................................................................. 24

DriveInterface ..................................................................................................................... 24

ApplicationParametersandEvents ...................................................................................... 25

Creating application program ......................................................................................... 26

Contents of this chapter ..................................................................................................... 26

Creating a new project ....................................................................................................... 27

Updating project information .............................................................................................. 29

Appending a new POU ....................................................................................................... 32

Writing a program code ...................................................................................................... 34

Page 6

6

Viewing device information ............................................................................................ 57

Upgrading or adding a new device ................................................................................. 59

Changing an existing device .......................................................................................... 60

Viewing software updates .............................................................................................. 61

Adding tasks ................................................................................................................... 68

Monitoring tasks ............................................................................................................. 71

Safe debugging .............................................................................................................. 77

Downloading loading package to a drive ....................................................................... 83

Preparing a project for download ........................................................................................ 43

Establishing online connection to the drive ......................................................................... 43

Downloading the program to the drive ................................................................................ 50

Executing the program ........................................................................................................ 52

Creating a boot project ....................................................................................................... 54

Features ............................................................................................................................. 56

Contents of this chapter ...................................................................................................... 56

Device handling .................................................................................................................. 56

Program organization units (POU) ...................................................................................... 63

Data types ........................................................................................................................... 64

Drive application programming license ............................................................................... 64

Application download options ............................................................................................. 65

Removing the application from the target ........................................................................... 66

Retain variables .................................................................................................................. 67

Task configuration .............................................................................................................. 67

Uploading and downloading source code ........................................................................... 73

Adding symbol configuration ............................................................................................... 75

Debugging and online changes .......................................................................................... 77

Reset options ...................................................................................................................... 78

Memory limits ...................................................................................................................... 79

CPU limitation ..................................................................................................................... 80

Application loading package ............................................................................................... 81

DriveInterface .................................................................................................................... 87

Contents of this chapter ...................................................................................................... 87

Implementing DriveInterface ............................................................................................... 87

Selecting the parameter set ................................................................................................ 89

Viewing parameter mapping report ..................................................................................... 90

Page 7

7

Mapping example .......................................................................................................... 91

Creating parameter groups .......................................................................................... 103

Creating parameters .................................................................................................... 104

Parameter settings ...................................................................................................... 106

Scaling ......................................................................................................................... 108

Linking parameter to application code ......................................................................... 109

Parameter types .......................................................................................................... 110

Parameter families ....................................................................................................... 113

Selection lists ............................................................................................................... 114

Units ............................................................................................................................ 115

Application events ....................................................................................................... 116

Question: What to do when scan network does not find any drives? .......................... 126

Question: What to do if communication fails while establishing online connection to the

drive? ........................................................................................................................... 127

Question: What to do if communication fails between Automation Builder/Drive composer

pro and drive? .............................................................................................................. 128

Updating drive parameters from installed device ............................................................... 94

Updating drive parameters from parameters file ................................................................ 96

Setting parameter view ....................................................................................................... 98

Application parameter and events ................................................................................ 100

Contents of this chapter ................................................................................................... 100

ApplicationParametersandEvents .................................................................................... 101

ParameterManager .......................................................................................................... 103

Libraries .......................................................................................................................... 117

Contents of this chapter ................................................................................................... 117

Library types ..................................................................................................................... 117

Adding a library to the project ........................................................................................... 118

Creating a new library ...................................................................................................... 121

Installing a new library ...................................................................................................... 123

Managing library versions ................................................................................................ 125

Practical examples and tips .......................................................................................... 126

Contents of this chapter ................................................................................................... 126

Solving communication problems ..................................................................................... 126

Solving other problems ..................................................................................................... 129

Page 8

8

Question: How to prevent unauthorized access to an application that is running in the

drive? ........................................................................................................................... 129

Question: How to fix an unknown device in a project? ................................................. 129

Question: How to remove a boot application from the flash memory card? ................. 129

Question: What to do when I continuously receive “The project handle 0 is invalid” error

message? ..................................................................................................................... 129

Question: What to do when stack overflow fault 6487 occurs? .................................... 130

Question: How to optimize the memory usage of the drive application? ..................... 130

Question: How to solve the problem causing error message “Creating boot application

failed: Adding Application Parameters & Groups to UFF generator :

XmlDeserializationFailed“? .......................................................................................... 130

EVENT ......................................................................................................................... 137

ReadEventLog ............................................................................................................. 138

PAR_UNIT_SEL ........................................................................................................... 140

PAR_SCALE_CHG ...................................................................................................... 141

PAR_LIM_CHG_DINT ................................................................................................. 143

PAR_LIM_CHG_REAL ................................................................................................ 144

PAR_LIM_CHG_UDINT ............................................................................................... 145

PAR_DEF_CHG_DINT ................................................................................................ 146

PAR_DEF_CHG_REAL ............................................................................................... 147

PAR_DEF_CHG_UDINT .............................................................................................. 148

Appendix A: Incompatible features between ACS880 Drive and AC500 PLC IEC

programming ................................................................................................................... 131

Contents of this chapter .................................................................................................... 131

Incompatible features ....................................................................................................... 131

Appendix B: Unsupported features .............................................................................. 133

Appendix C: ABB drives system library ....................................................................... 134

Contents of this chapter .................................................................................................... 134

Introduction to ABB drives system library ......................................................................... 134

Function blocks of the system library ................................................................................ 135

Event function blocks ........................................................................................................ 137

Parameter change function blocks ................................................................................... 140

Parameter limit change ..................................................................................................... 143

Parameter default value change ................................ ....................................................... 146

Parameter decimal display ............................................................................................... 149

Page 9

9

PAR_DISP_DEC ......................................................................................................... 149

PAR_REFRESH .......................................................................................................... 150

PAR_PROT ................................................................................................................. 151

PAR_GRP_PROT ....................................................................................................... 152

ParReadBit .................................................................................................................. 153

ParRead_DINT ............................................................................................................ 154

ParRead_REAL ........................................................................................................... 155

ParRead_UDINT ......................................................................................................... 156

ParWriteBit .................................................................................................................. 157

ParWrite_DINT ............................................................................................................ 158

ParWrite_REAL ........................................................................................................... 159

ParWrite_UDINT .......................................................................................................... 160

ParRead_BitPTR ......................................................................................................... 161

ParRead_ValPTR_DINT .............................................................................................. 162

ParRead_ValPTR_REAL ............................................................................................. 163

ParRead_ValPTR_UDINT ........................................................................................... 164

ParSet_BitPTR_IEC .................................................................................................... 165

ParSet_ValPTR_IEC_DINT ......................................................................................... 166

ParSet_ValPTR_IEC_REAL ........................................................................................ 167

ParSet_ValPTR_IEC_UDINT ...................................................................................... 168

ParSet_BitPTR_Par ..................................................................................................... 169

ParSet_ValPTR_Par .................................................................................................... 170

UsedTimeLevel ............................................................................................................ 171

Parameter protection ........................................................................................................ 151

Parameter read function blocks ........................................................................................ 153

Parameter write function blocks ....................................................................................... 157

Pointer parameter read function block ............................................................................. 161

Set pointer parameter to IEC variable function blocks ..................................................... 165

Set pointer parameter to parameter function blocks ........................................................ 169

Task time level function block .......................................................................................... 171

Error codes ....................................................................................................................... 172

Appendix D: ABB D2D function blocks ........................................................................ 173

Contents of this chapter ................................................................................................... 173

Introduction to ABB D2D function blocks ......................................................................... 173

D2D function blocks of the system library ........................................................................ 174

Page 10

10

DS_ReadLocal ............................................................................................................. 175

DS_WriteLocal ............................................................................................................. 176

General ........................................................................................................................ 177

D2D_TRA ..................................................................................................................... 177

D2D_REC .................................................................................................................... 179

D2D_TRA_REC ........................................................................................................... 181

D2D_TRA_MC ............................................................................................................. 183

D2D_Conf .................................................................................................................... 185

D2D_Conf_Token ........................................................................................................ 187

D2D_Master_State ....................................................................................................... 189

Example 1: D2D_TRA / D2D_REC blocks ................................................................... 190

Example 2: Token send configuration blocks ............................................................... 191

BGET ........................................................................................................................... 195

BSET ............................................................................................................................ 196

DEMUX ........................................................................................................................ 197

DEMUXM ..................................................................................................................... 198

MUX ............................................................................................................................. 199

MUXM .......................................................................................................................... 200

PACK ........................................................................................................................... 201

SR_D ............................................................................................................................ 202

SWITCH ................................................................ ....................................................... 203

SWITCHC .................................................................................................................... 204

UNPACK ...................................................................................................................... 205

Data read/write blocks ...................................................................................................... 175

D2D communication blocks .............................................................................................. 177

D2D configuration blocks .................................................................................................. 185

Examples: D2D blocks ................................................................................................ ...... 190

Appendix E: ABB drives standard library .................................................................... 193

Contents of this chapter .................................................................................................... 193

Introduction to ABB drives standard library ...................................................................... 193

Basic functions .................................................................................................................. 195

Special functions ............................................................................................................... 206

Page 11

11

Drive control ................................................................................................................ 206

Filter ............................................................................................................................. 209

Function generator ...................................................................................................... 211

Integrator ..................................................................................................................... 213

Lead lag ....................................................................................................................... 215

Motor potentiometer .................................................................................................... 217

PID ............................................................................................................................... 219

Ramp ........................................................................................................................... 223

Further information ........................................................................................................ 225

Contact us ....................................................................................................................... 226

Page 12

12

Page 13

13

1

Introduction to the manual

Contents of this chapter

This chapter gives basic information on the manual.

Compatibility

This manual applies to the ABB drives equipped with the application programming functionality. For

example, ABB ACS880 and DCX880 industrial drives can be ordered with the application

programming functionality. The drive must be equipped with N8010 Application programming license

on ZMU-02.

This manual is compatible with the following product releases:

ABB Automation Builder 1.1

Drive composer pro 1.5 or later

For more details of compatibility information, refer the corresponding ACS880 or DCX880 drive

software release notes or contact your ABB representative.

Target audience

This manual is intended for a personnel performing drive application programming or for

understanding the programming environment capabilities. The reader of the manual is expected to

have basic knowledge of the drive technology and programmable devices (PLC, drive and PC) and

programming methods.

Page 14

14

WARNING! Ignoring the following instruction can cause physical injury or damage to

the equipment.

Do not make changes to drive in the online mode or download programs while the

drive is running to avoid damages to the drive.

Safety instructions

Follow all safety instructions delivered with the drive.

Read the complete safety instructions before you load and execute the application program

on the drive or modify the drive parameters. The complete safety instructions are delivered

with the drive as either part of the hardware manual, or, in the case of ACS880 multidrives,

as a separate document.

Read the firmware function-specific warnings and notes before changing parameter values.

These warnings and notes are included in the parameter descriptions presented in chapter

Parameters of the firmware manual.

Purpose of the manual

This manual gives basic instructions on the drive-based application programming using ABB

Automation Builder programming tool. The programming tool is the international IEC 61131-3

programming standard. The online help of Automation Builder contains more detailed information of

the IEC languages, programming methods, editors and tool commands.

Contents of the manual

The manual consists of the following chapters:

Getting started

Overview of drive programming

Creating application program

Features

DriveInterface

Application parameter and event creation

Libraries

Practical examples and tips

Appendix A: Incompatible features between ACS880 Drive and AC500 PLC IEC

programming

Appendix B: Unsupported features

Appendix C: ABB drives system library

Appendix D: ABB D2D function blocks

Appendix E: ABB drives standard library

Related documents

A list of related manuals is printed on the inside of the front cover.

Page 15

15

Term/

Abbreviation

Description

ACS-AP-x

ACS-AP-I or ACS-AP-S control panel used with ACS880 and DCX880 drives.

The control panel has an USB connector enabling a PC tool connection for

common architecture drives.

BCU

Type of control unit used in ACS880 and DCX880 drives

AB

ABB Automation Builder programming tool

CFC

Continuous function chart programming language

DI

Digital input

Drive composer pro

ABB Drive composer is a 32-bit Windows application for commissioning and

maintaining ABB common architecture drives.

The full version is called Drive composer pro.

DUT

Data type unit

FB

Function block, type of POU

FBD

Function block diagram programming language

FUN

Function, type of POU

IEC 61131-3

programming

Standardized programming language for industrial automation. Established by the

International Electro-technical Commission (IEC)

IL

Instruction list programming language

LD

Ladder diagram programming language

OPC server

OPC DA server interface for Drive composer pro that allows other programs, such

as Automation Builder, to communicate with the drive.

PIN

IEC variable of the block, which can be connected to other blocks.

PLC

Programmable logic controller

POU

Program organization unit. POU unit is a unit, object or area where you can write

the program code. Also called as Block.

PRG

Program, type of POU

RTS

Run-time system

SFC

Sequential function chart programming language

ST

Structured text programming language

ZCU

Type of control unit used in ACS880 and DCX880 drives that consists of a ZCON

board built into a plastic housing.

The control unit may be fitted onto the drive/inverter module, or installed

separately.

Terms and abbreviations

Page 16

16

For more detailed descriptions, see Automation Builder online help.

Page 17

17

2

Getting started

Contents of this chapter

This chapter includes the following information required for programming ACS880 and DCX880

drives using ABB Automation Builder tool:

Quick steps for Setting up the programming environment.

Procedure for Upgrading a new device, Changing an existing device and Viewing device

information.

Setting up the programming environment

The following software installations are required for programming ACS880 and DCX880 drives. For

details of version, refer the corresponding ACS880 or DCX880 drive software release notes or

contact your ABB representative.

ACS880 drive or DCX880 converter with Drive application programming license (N8010)

ABB Automation Builder 1.1

ACS-AP-x control panel and micro USB cable

Drive composer pro 1.5 or later

The Drive composer pro enables setting and monitoring of the drive parameters and signals. The

control panel acts as a USB/RS485 converter between Automation Builder, Drive composer pro and

the drive.

Page 18

18

To setup ACS880 or DCX880 drive programming environment follow the pre-requisites and

installation steps listed below.

Pre-requisites:

The ABB Automation Builder supports Windows XP and Windows 7 (32-bit and 64-bit

versions) operating systems.

You must have Administrator user rights to install Automation Builder.

Installation steps:

1. Install Drive composer pro to enable communication with the target drive. For more details, see

Drive composer user’s manual (3AUA0000094606 [English]).

2. In the Drive composer pro System info -> Products/Licenses, check that the ACS880 or

DCX880 drive has an active IEC programming license and the drive firmware version is correct.

For details of version, refer the corresponding ACS880 or DCX880 drive software release notes

or contact your ABB representative.

Install ABB Automation Builder version 1.1 according to the instruction guide included in the

installation media of Automation Builder. All drive application programming related components are

automatically installed as well.

In Automation Builder, select Install Software Packages for -> Programmable Drive.

Figure 1: Automation Builder – Selecting software packages for installation

Page 19

19

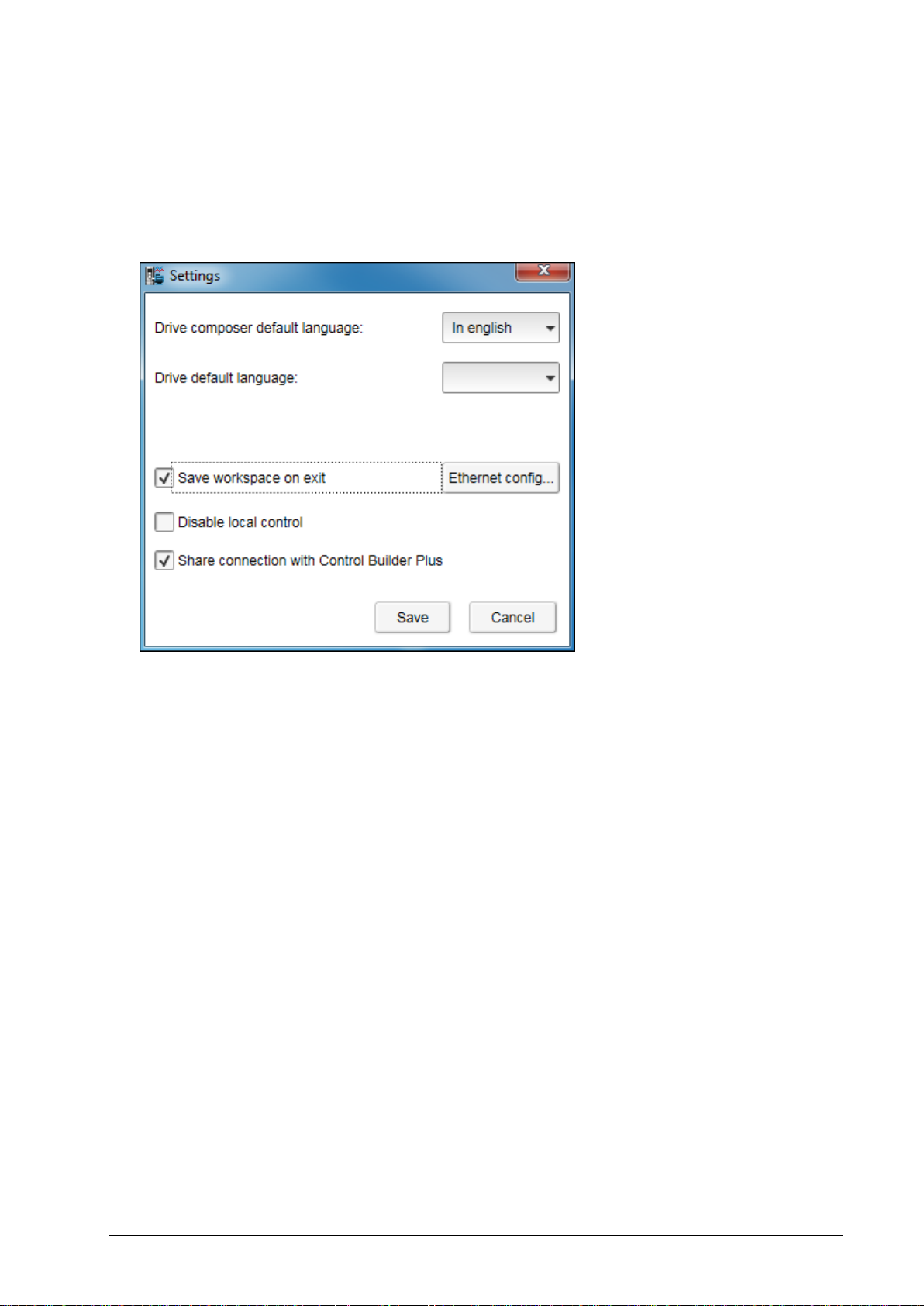

To allow parallel communication with Automation Builder and Drive composer pro, follow these

steps:

1. In the main menu of Drive composer pro, click View and then click Settings.

2. In the Settings window, select Share connection with Control Builder Plus check box and

click Save.

Figure 2: Drive Composer Pro settings

After configuring the settings, restart Drive composer pro.

Drive composer now connects to the drive and allows opening the Automation Builder.

Now you can create an application program. See section, Creating application program.

Page 20

20

Page 21

21

Note: For using ABB Automation Builder online with the drive, enable the drive application

programming license in the target drive. See section, Establishing online connection to the

drive.

3

Overview of drive programming

Contents of this chapter

This chapter provides an overview of ACS880 and DCX880 drive programming environment and a

typical work cycle of drive application programming.

Drive application programming

ABB ACS880 and DCX880 industrial drives can be ordered with the application programming

functionality. It allows you to add your own program code to the drive using the ABB Automation

Builder programming tool (version 1.1). The programming method and languages are based on the

IEC 61131-3 programming standard. ABB Automation Builder is also used for configuring and

programming the ABB AC500 PLC family devices.

With the drive application programming, you can create application specific features on top of the

drive firmware functionality. You can utilize the standard and extension I/O and communication

interfaces of the drive along with the appropriate firmware signals. Your program is executed in

parallel with the drive control tasks using the same hardware resources.

In addition, you can create your own parameters and events (faults and warnings) that are visible on

the ACS-AP-x control panel and in the Drive composer pro/entry commissioning tools.

Page 22

22

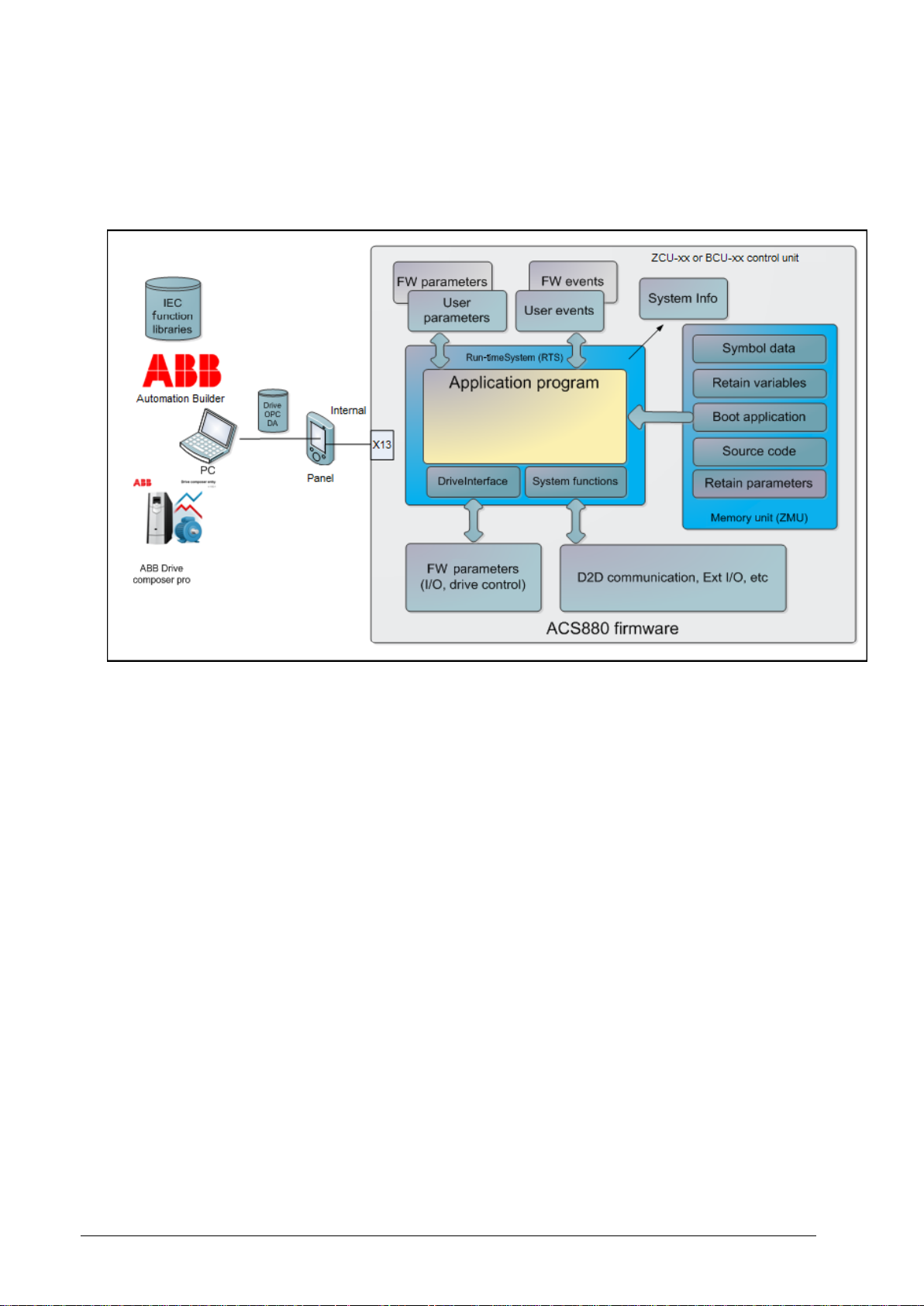

System diagram

The following simplified system diagram shows the application programming environment in the

same control unit as the drive firmware.

Figure 3: Application programming environment – System diagram

The following list describes the main components for application programming.

Drive control unit:

Run-time system (RTS) executes the application program.

DriveInterface allows input/output mapping between the application program and drive

firmware parameters.

System function library enables access to the drive system services (parameters/ events/

drive-to-drive communication, extension I/O).

User made parameters.

User made events (fault, warnings).

Drive System info includes version information of the application program.

Drive firmware parameters with I/O controls.

D2D function blocks enable drive to drive communication, I/O extension modules, and so on

for application programming.

Drive memory unit:

Creates a permanent version of the application program (Boot application).

Retains values of the application program variables .

Consists of application source code (Note that the size of the memory is limited).

Page 23

23

Includes symbol and address information of the application program variables for monitoring

purposes.

PC tool programs:

ABB Automation Builder for application program development and online operations.

ABB Drive composer pro for drive parameter, signal, event log monitoring and settings.

Application program function libraries (for example, ABB standard library).

The USB/ACS-AP-x control panel enables communication between the Automation Builder,

Drive composer pro and the drive.

Programming work cycle

The following steps describes a typical work cycle of the drive application programming tasks of

performing the module:

1. Creating a new project, adding objects, defining the target and first program module in the

Devices tree.

2. Defining the interface to drive firmware parameters (I/O access, drive control) in the

DriveInterface object.

3. Defining user parameters and events (ApplicationParametersandEvents) module in the Devices

tree.

4. Developing the program structure and coding program units.

5. Defining the program execution task configuration editor.

6. Compiling and loading the code using Build menu.

7. Creating boot applications if new parameters, mappings, events or task configuration are added

in the Online menu.

8. Debugging the program code (stepping, forcing variables and breakpoints) in the Online menu.

9. Monitoring program variables in Automation Builder and Drive composer pro from the watch

windows of the View menu.

10. Repeating the cycle from step 2 to 8 for testing the program.

Special tasks

The following special tasks are part of the drive application programming tasks:

1. Saving or restoring the source code to the permanent memory of the drive using the Online

menu.

2. Saving the drive IEC symbol data to permanent memory of the drive from the Devices tree using

the option Add Symbol configuration object to the tree.

3. Naming and versioning the application from the Application properties window or Project

information.

4. Removing the application from the target using Reset origin window on the Online menu.

Page 24

24

Programming languages and modules

The programming environment supports programming languages as specified in the IEC 61131-3

standard with some useful extensions. The following programming languages are supported:

Ladder diagram (LD)

Function block diagram (FBD)

Structured text (ST)

Instruction list (IL)

Sequential function chart (SFC)

Continuous function chart (CFC), normal and page-oriented CFC editor

A program can be composed of multiple modules like functions, function blocks and programs. Each

module can be implemented independently with the above mentioned languages. Each language

has its own dedicated editors. For more information of the programming languages, see

Automation Builder online help and chapter Features.

Libraries

Program modules can be implemented in projects or imported into libraries. A library manager is

used to install and access the libraries.

The two main types of libraries are:

Local libraries (IEC language source code, for example, AS1LB_Standard_ACS880_V3_5)

External libraries (external implementation and source code, for example,

AY1LB_System_ACS880_V3_5)

Local libraries include source code or can be compiled. If the library is compiled, source code is not

included in the library.

External libraries include AC500 PLC libraries used with the drive target by opening the library

project in Windows as Automation Builder project files (before V3.0).

For more information on compatibility, see chapter Libraries.

Program execution

The program is executed on the same central processing unit (CPU) as the other drive control tasks.

In real time applications, programs are typically executed periodically as cyclic tasks. The

programmer can define the cyclic task interval. For more information, see chapter Features.

DriveInterface

The DriveInterface object enables input and output mapping between the application program and

the drive firmware using the drive firmware parameters used in the application program. This list of

parameters may be different for each drive firmware versions. For more details on implementing the

DriveInterface and updating parameter list, see section DriveInterface.

Page 25

25

ApplicationParametersandEvents

The ApplicationParameterandEvents Manager (APEM) object allows creating application parameter

groups, parameters, parameter types, parameter families, units and application events for the drive

in Automation Builder environment. For more details on how to create parameter related tasks and

application events, see section ApplicationParametersandEvents.

Page 26

26

4

Creating application program

Contents of this chapter

This chapter describes the procedure to create application program.

For details of instructions and further development steps see chapters DriveInterface, Application

parameter and event creation, Features and Libraries. For more detailed descriptions, see also the

Automation Builder online help.

Page 27

27

Creating a new project

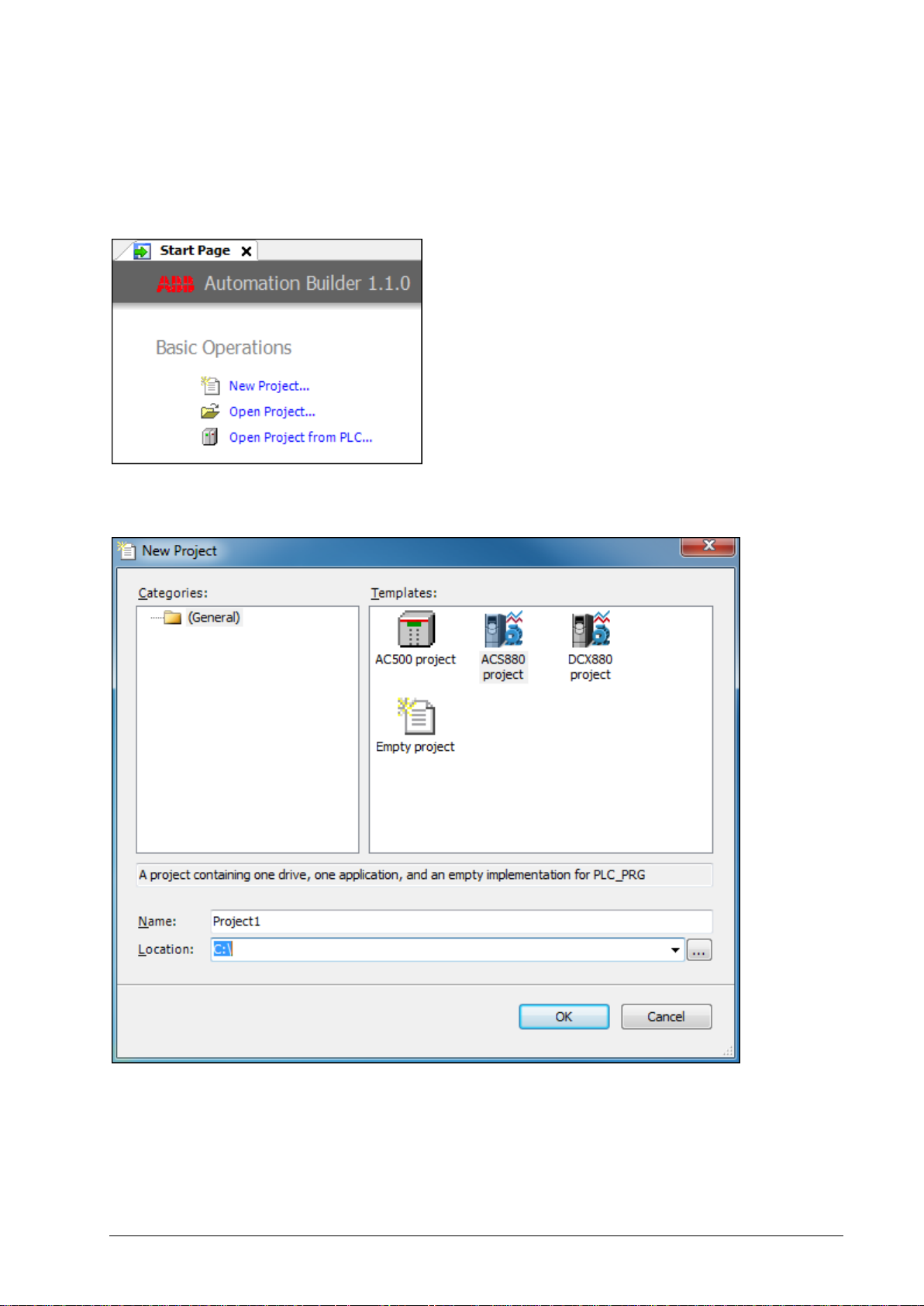

After starting ABB Automation Builder programming environment, you can create a new project.

1. In the Start Page, click New Project or in the main menu, click File and then click New Project.

Figure 4: Automation Builder – Create a new project

2. In the New Project dialog box, select ACS880 or DCX880 project and click OK.

Figure 5: Select a project

Note: If required, rename the project in Name field and select the desired Location in the file

system.

Page 28

28

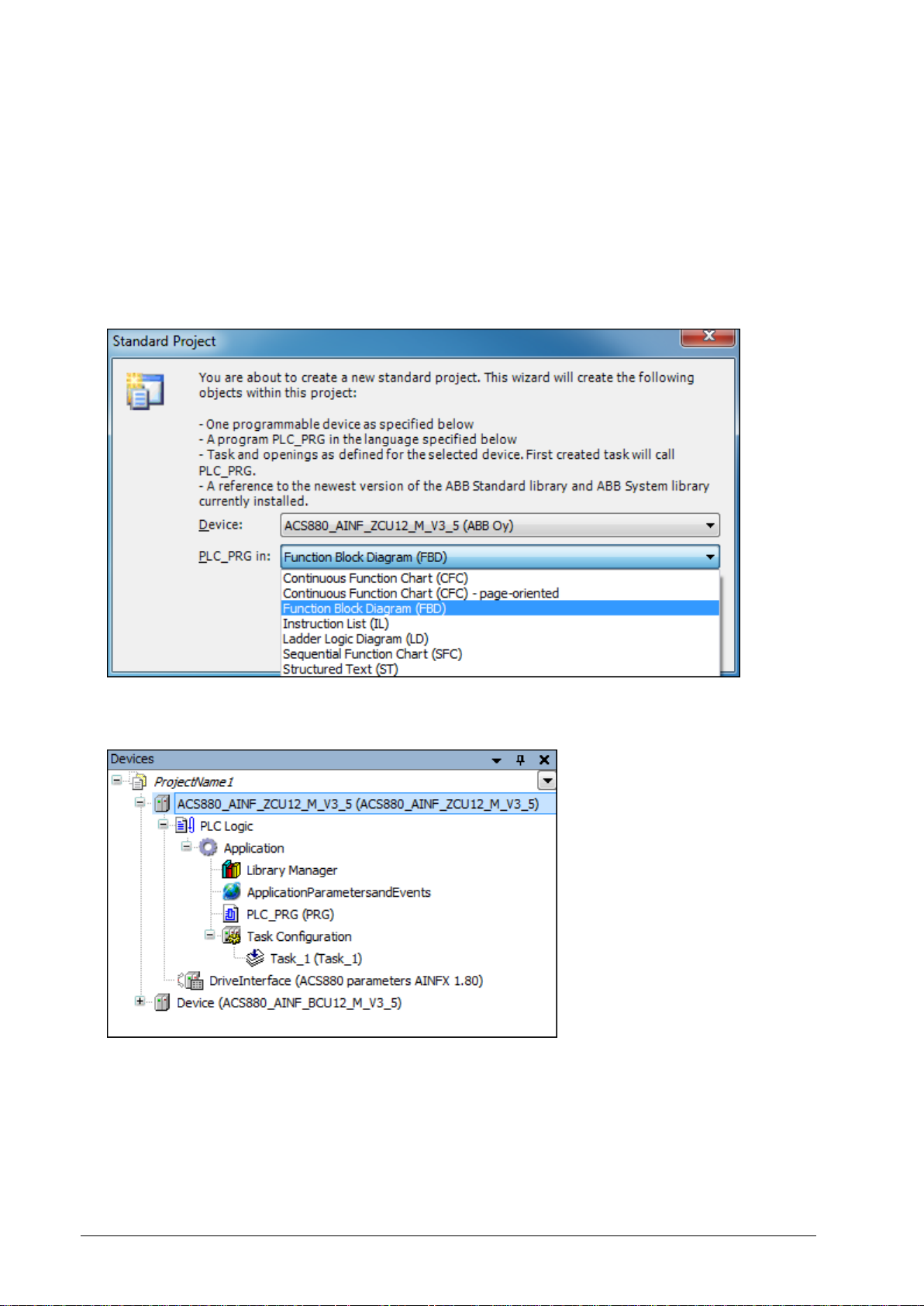

3. In the Standard Project dialog box, select the type of control unit in Device drop-down list.

ACS880_AINF_ZCU12_M_V3_5 for ZCU-xx control unit

ACS880_AINF_BCU12_M_V3_5 for BCU-xx control units

Check the control unit type of the target drive either from the unit itself, from the hardware

manual of drives or contact your local ABB representative.

4. In the PLC_PRG in drop-down list, select a programming language and click OK.

You can later add program modules made with other languages to the project.

Figure 6: Select a programming language

A simple project for an ACS880 target drive is created in the Devices tree.

Figure 7: New project created in the Devices tree

Page 29

29

The Devices tree includes:

PLC Logic

DriveInterface for firmware signal and parameter mapping

Application (for example, you can add the following objects under Application)

o Library Manager for installing function libraries

o ApplicationParametersandEvents for creating user parameters and events

o Program organization units (POUs)

o Task Configuration module for defining in which task the POUs are executed

o Text list

o Symbol configuration

o Global variable list

o Data type units (DUT)

For changing the device type, see section Changing an existing device.

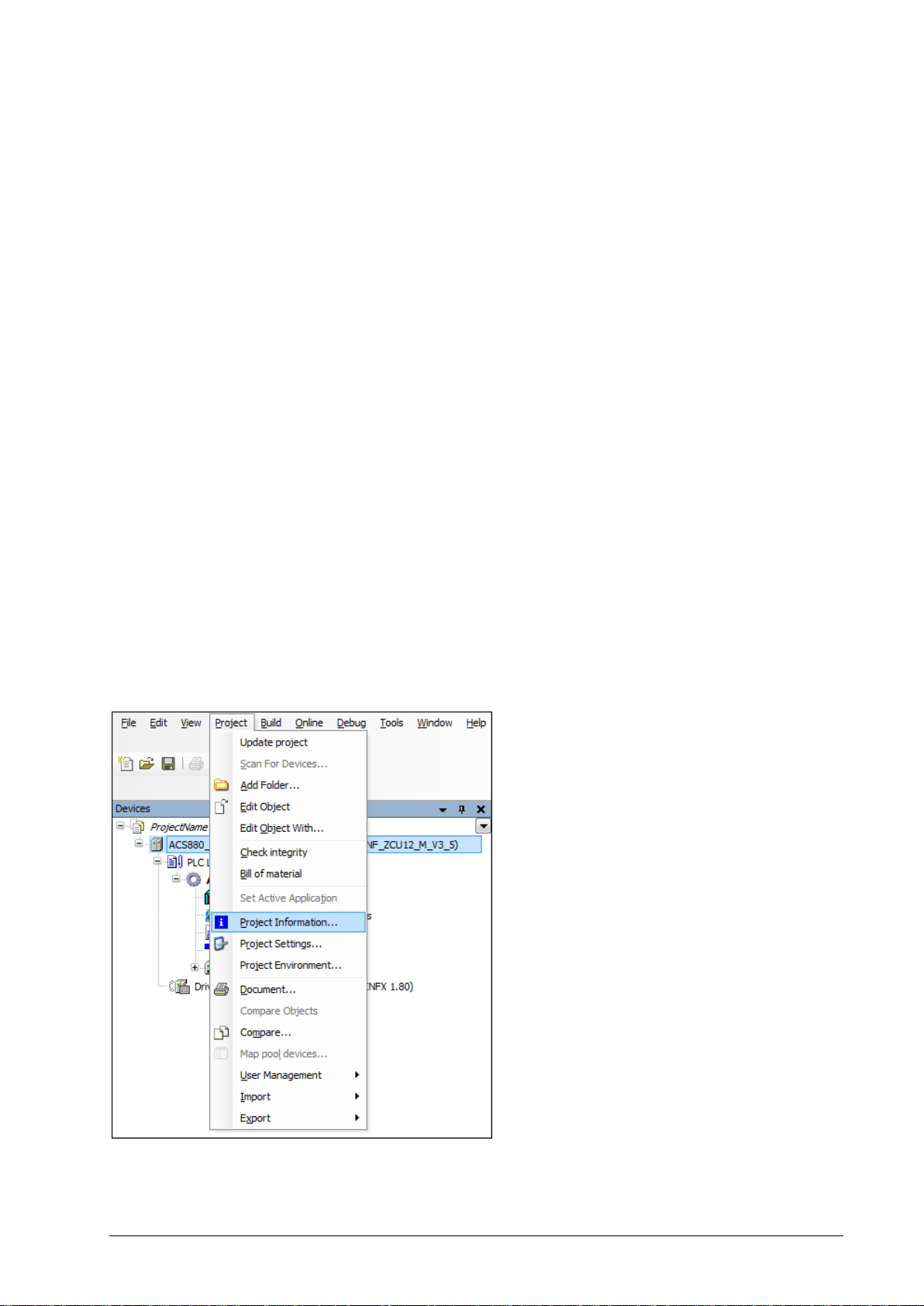

Updating project information

You can update a Company name and Version number for the application program in the Project

Information window. This information is visible in Drive composer tool and ACS-AP-x control panel in

the System info display. It also helps to identify the loaded application without the Automation

Builder tool. You can also name the application from the application tool.

To update project information in Automation Builder, follow these steps:

1. In the main menu, click Project and then click Project Information.

Figure 8 Updating project information

Page 30

30

2. In the Project Information window, select Summary tab, update the desired information and click

OK.

Figure 9: Project information

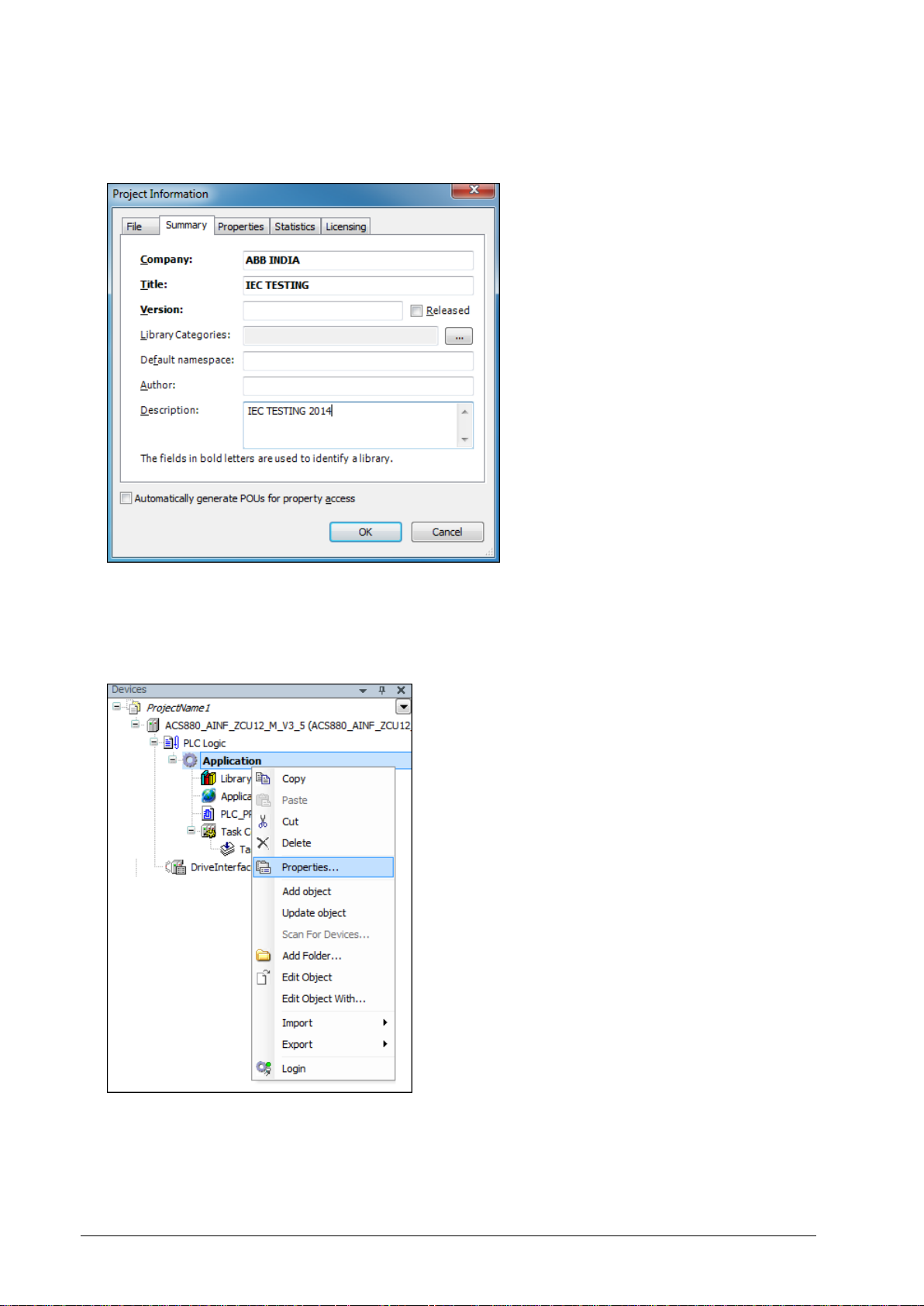

The updated project information is not loaded to the target application. Further steps explain how

to copy this information to the application information fields.

3. In the Devices tree, right click Applications and select Properties.

Figure 10 Application properties

Page 31

31

4. In Properties window, click Information tab and then click Reset to values from project

information and click OK.

Figure 11: Copy information to application information fields

The Automation Builder tool version and project identification code are registered automatically.

Page 32

32

Appending a new POU

To append a new POU, follow these steps:

1. In the Devices tree, right-click Application and select Add object.

Figure 12 Application add object

2. Select POU and click Add object.

Figure 13 Add POU object

Page 33

33

3. In the Add POU window, Name the POU, select the Type of the POU and the used

implementation language and then click Add.

Figure 14: Add POU

The appended POU, xxx (PRG) is added to the Devices tree under application and the POU

window is displayed with the declaration part and the program code.

Figure 15 POU page

Page 34

34

Writing a program code

A program organization unit (POU) is a unit, object or area where you can write the program code.

The units can be created either directly under the Applications in the Devices tree or in a separate

POUs window (View ->POUs or click POUs in the lower left corner).

The POU includes a declaration part (the upper window) and a program code part (the lower

window).

Figure 16: POU window

There are two different types of views for declaration part: a textual view and tabular view . You

can switch between these views by clicking the buttons.

Figure 17 POU view type

Page 35

35

Continuous function chart (CFC) program

This example shows how to create a new project in the CFC implementation language.

Adding elements

1. In the Devices tree, select the xxx (PRG) under the Application.

Figure 18 PLC PRG

2. In the View menu, select ToolBox.

Figure 19 ToolBox

Page 36

36

ToolBox components are displayed and are used to add a CFC scheme.

Figure 20: CFC scheme

If an empty ToolBox list is already displayed on the right side of the window, double-click the xxx

(PRG) to display the Toolbox and the POU window. You can add, for example, SEL and AND

elements (logic operators, functions), use the Box element in the ToolBox list.

3. In the ToolBox list, drag the Box and drop in the program code area.

Figure 21: ToolBox: Box element

Page 37

37

Note: The number in the upper right corner of the white box indicates the execution order

of the function.

4. Enter the name of the function or operand in the ??? field.

You can also use Input Assistant to find the function, keyword, and operator. To start

Input Assistant, click or press F2.

Figure 22: Input assistant

5. Right-click on input or output element and select Negate to invert.

Figure 23: Invert input/ouput

Page 38

38

Setting the execution order of the elements

Each element has its own execution order. The number in the upper right corner of the element

indicates the sequence in which the elements in a CFC network are executed in the online mode.

Processing starts from the element with the lowest number, that is 0. Note that the sequence

influences the result and are changed in certain cases.

To set execution order of the elements, follow these steps:

1. Right-click on element and then click Execution Order and select Set Execution Order.

Figure 24: Execution order

2. In the Set Execution Order window, type New Execution Order number and click OK.

Figure 25 Set execution order

The block execution order is changed.

Page 39

39

Adding comments to a CFC program

In the ToolBox, select Comment and drag to desired point in the program code area and enter the

comment text.

Figure 26: Add comment to a CFC program

Declaring variables

To create a new variable, you can either declare it in the declaration part of the editor window or use

Auto declaration.

Depending on the type of the declaration view (textual or tabular) add a new variable by writing its

properties to a new text row (textual view) or use the TAB button (tabular view). For changing

between the views, see section Writing a program code.

1. In the program code area, select the required object.

2. In the main menu, click Edit and then click Browse and select Auto Declare.

Figure 27 Auto declare option

Page 40

40

The Auto Declare window is displayed.

Figure 28 Auto declare variables

If you enable the option to declare unknown variables automatically (Tools -> Options ->

SmartCoding), the Auto Declare window opens every time you use an unknown variable in your

program and you can declare the variable instantly.

3. Define the Scope, Name and Type of the variable (mandatory).

Scope defines the type of variable (global, input, output, etc.).

Name is a unique identifier of the variable and represents the purpose of the variable.

Type is the IEC data type of the variable.

Optionally, you can also define the Initialization value, Address, Comment or Flags for the

variable.

Flags have the following meaning:

CONSTANT means that the variable value cannot be changed and the variable maintains

its initial value all the time.

RETAIN keeps its value over reboot and warm reset.

PERSISTENT is not supported.

Page 41

41

Adding inputs and outputs

You can add inputs and outputs by selecting ToolBox elements. See section Adding elements.

Figure 29: ToolBox for adding inputs and outputs

Another way to add inputs and outputs straight to a block is to select a pin of a block and start typing

the name of a variable.

1. In the program code area, select the pin of the block.

Figure 30 Naming inputs and outputs

2. Name the input or output by writing the variable name to the block or use input assistant as

described in Declaring variables.

3. To connect the input or output block to a pin, left-click the line connected to the block and drag it

to a pin of another block.

Page 42

42

Creating a block scheme

Example:

Create the following CFC program:

Figure 31: Example of CFC program

The following local variables are required in the block scheme.

Figure 32 Local variables

During block scheme programming, the already created variables are displayed in the Input

Assistant and new declarations are added to the variable declaration area.

For using the Input Assistant, see section Adding elements in Continuous function chart (CFC)

program.

Page 43

43

Preparing a project for download

To prepare a project for download, follow these steps:

1. In the main menu, click Build and select Build.

Figure 33 Build

2. In the View menu, select Messages. A Messages window is displayed.

Check that there are no errors or warnings. Otherwise, check and fix the application.

Figure 34: Build project message window

In the example, the process is successfully completed without any errors or warnings and the

project is ready for download.

Establishing online connection to the drive

The Automation Builder communication gateway handles communication between Automation

Builder and the drive. The gateway is a software component that starts automatically at the powerup of the PC after installing Automation Builder.

Before starting with the communication setup, follow the pre-requisites listed below.

Pre-requisites:

Page 44

44

1. Connect PC to a drive through USB port of the ACS-AP-x control panel using a standard USB

data cable (USB Type A <-> USB Type Mini-B). For information on making the control panel to

PC USB connection, see ACS-AP-x control panel user’s manual (3AUA0000085685 [English]).

2. Make sure the ACS-AP-x USB driver is installed. For installation procedure, refer Drive

composer user’s manual (3AUA0000094606 [English]).

3. Make sure the drive has application programming license N8010. To check license information in

Drive composer pro and in ACS-AP-x control panel, go to System info -> Licenses.

To establish online connection to the target drive after defining the device type, follow these steps:

1. In the Devices tree, double-click ACS880_AINF_ZCU12_M_V3_5 and then click

Communication Settings.

Gateway-1 is displayed by default.

Figure 35: Communication settings

Page 45

45

Note: If the gateway displays red , the CODESYS Gateway V3 is disabled in local

control panel settings.

Figure 36 Gateway disabled

2. Open Control panel -> Administrative Tools -> Services in the user PC.

3. In the Services window, double-click CODESYS Gateway V3.

Figure 37 Gateway services

A Properties window is displayed.

Page 46

46

4. In the Properties window, select the desired Startup type from the available drop-down list and

click OK.

Figure 38 Startup type

CODESYS Gateway V3 is enabled and turned to green .

Figure 39 Gateway enabled

Page 47

47

5. Ensure that the following default communication settings are correct.

Node Name: Gateway-1

Driver: TCP/IP

IP- Address: localhost (Remote gateways are not scanned)

Port: 1217

6. If Gateway-1 is not available, click Add gateway.

Figure 40 Add new gateway

7. In the Gateway window, select the appropriate settings and click OK.

Figure 41 Gateway settings

Page 48

48

8. Check that the USB cable is connected to the USB connector of the ACS-AP-x control panel and

the drive is powered.

For communication related problems, see practical examples and tips for Solving communication

problems.

9. Double-click Gateway-1 or click Scan network to search the target device.

Filter Target ID displays only devices that are of the same type as the device selected in

the Devices window.

The gateway device is added under Gateway-1.

Figure 42: Adding devices under Gateway

10. Under Gateway-1, double-click or right-click the device and select Set active path.

Figure 43: Activating devices under gateway

If the drive has appropriate license code, the selected device is set as active path and is

ready for downloading a program to the drive. See section Downloading the program to the

drive.

Page 49

49

Note: To see which port and node is used by each device, see the information in the

device name in brackets [GGGG.PPNN] where:

GGGG is the gateway number

PP is the OPC channel number

NN is the OPC node number

If the drive does not have the required license code, the selected device is displayed with no

license.

Figure 44: No license notification

Page 50

50

Downloading the program to the drive

After the project is ready for online communication with the drive, you can download and execute the

written program to the drive. Check that the active path to the target device is defined in the

communication settings. For more information, see section Establishing online connection to the

drive.

1. In the main menu, click Online and select Login.

Figure 45 Login

The following dialog is displayed if the program is not downloaded before. Click Yes.

Figure 46: Perform a download

Page 51

51

After the download is complete, the background color of the device name and the application

name in the Devices tree changes. The program is in stop mode and the status is shown in the

brackets [stop]. You can start the program by selecting Start in the Debug menu.

Figure 47 Program in stop mode

For more information on downloading program, see section Application download options in

chapter Features.

Page 52

52

Executing the program

To execute a program, follow these steps:

1. In the main menu, click Debug and select Start.

Figure 48: Debug menu

The application status changes to [run] and notifies that the program is executed successfully.

Figure 49 Executing a program

2. To set or change a value of an existing variable, double-click the cell in the Prepared value

column, type a new value and press Enter.

3. In the Debug menu select Write values to apply the prepared value to the variable.

4. In the Debug menu, select Force values to force the prepared value to the variable.

5. In the Debug menu, select Unforce values to unforce a forced value.

The variable value is changed. The current variable values are displayed in the Value column

and in the source code near the variable.

Page 53

53

WARNING! Ignoring the following instruction can cause physical injury or damage to

the equipment.

Do not debug or make changes to drive in the online mode or while the drive is

running to avoid damage to the drive.

6. In the Debug menu, click Stop and then in the Online menu, click Logout to logout.

Page 54

54

Creating a boot project

The regular downloading moves the application program to the RAM memory of the drive. Creating a

boot project copies the application to the non-volatile memory of the drive memory card and thus

retains the application after power cycle or reboot. For more details, see section Application

download options.

To create a boot project, follow these steps:

1. In the main menu, click Online and select Create boot application.

Figure 50: Create boot application

The following message is displayed. Click Yes to reboot the drive.

Figure 51: Reboot drive after boot project

The reset to default values is optional. If you select Reset application parameters to defaults

option, the next boot resets all the application parameters to their default values. The previously

set values are not restored from the permanent memory.

Page 55

55

Note: It is recommended to select the Reset application parameters to defaults

option whenever you load a new application to the drive or whenever you change

the parameter definitions of the existing application (APEM).

Select this option when a new application is loaded to drive or a reset origin has been performed

or when application parameters of the new application are different from the previously loaded

application.

After creating the boot application, the status changes from STOP to RUN.

2. System prompts to save the boot application, click Save.

Page 56

56

5

Features

Contents of this chapter

This chapter describes the device handling information and features supported by Automation

Builder.

Device handling

In the application programming environment, devices represent hardware. The device description file

contains information about the target device (drive) from the programming point of view like the

device identifier, compiler type and memory size. The ABB Automation Builder installation package

installs the device description files automatically.

The device description may be updated later and a new file can be installed. The system monitors

that a project with an incompatible device description file is not loaded to the drive.

The following topics describe device handling:

Viewing device information

Upgrading or adding a new device

Changing an existing device

Viewing software updates

Page 57

57

Viewing device information

To view the detailed device information, follow these steps:

In Devices tree, double-click device and click Information tab.

Figure 52: Device information

The Device ID (1612 0010), Drive FW name (AINFX) and application interface version (3.0.0.1) must

be identical in the project and drive target. In Drive composer pro, use the System info option to

check that the drive target has the corresponding application interface version and device type and

drive firmware name (displayed in parameter 7.04).

Page 58

58

You can also check if the drive target has the corresponding application interface version and device

ID.

In Drive composer pro, click System info -> Products -> More.

Figure 53: Checking drive compatible application and device

The name and version of the available system library is displayed. Make sure this information

matches with the installed system library of the Automation Builder project.

For more information, see parameter 7.23 for Application name and parameter 7.24 for version in

ACS880 FW.

For details of available functions, see chapter Libraries.

Page 59

59

Upgrading or adding a new device

You can upgrade or add a new device to the programming environment.

1. In the main menu of Automation Builder, click Tools and select Device Repository.

Figure 54 Automation Builder device repository

Device repository window is displayed.

2. Click Install to select device description file.

Figure 55: Device Repository window

Page 60

60

3. In the Install Device Description window, browse and select the device description file

(.devdesc.xml) in the file system.

Now you can add a new device to projects or upgrade currently existing devices in the project.

Changing an existing device

You can change an existing device in Automation Builder project.

1. In the Devices tree, right-click on Device and select Update object or in the main menu, click

Project and select Update project.

Figure 56: Update an object

The Update object window displays the available device types.

2. Select the required drive device and click Update object.

Page 61

61

Figure 57 Update object device

Viewing software updates

In the Automation Builder start page, click Automation Builder to download Automation Builder

update packages.

Figure 58: Automation Builder start page

Page 62

62

This link is the download center for low voltage products and systems (India). For example, you

can find Automation Builder Service Release 1 – Release note, Automation Builder update

packages, and so on.

Page 63

63

Program organization units (POU)

The POU types are:

A program (PRG) may have one or several inputs/outputs. A program may be called by another

POU but cannot be called in a function (FUN). It is not possible to create program instances.

A function (FUN) has always a return value and may have one or several inputs/outputs. The

functions contain no internal state information.

A function block (FB) has no return value but may have one or several outputs as declared in the

variable declaration area. A function block is always called using its instance and the instance

must be declared in a local or global scope.

A created project may have POUs with a specified implementation language. Each added POU

has its own implementation language.

For more detailed description of the POU types, see the IEC programming environment user manual

and the IEC 61131-3 open international standard.

Page 64

64

Data type

Size

(bits)

Range

Supported

by BCU-xx

Supported

by ZCU-xx

Notes

BOOL

8/16*

0, 1 (FALSE, TRUE)

Yes

Yes

8 bit BCU-xx

16 bit ZCU-xx

SINT

8

-128...127

Yes

No

INT

16

-215...215-1

Yes

Yes

DINT

32

-231...231-1

Yes

Yes

LINT

64

-263...263-1

No

Yes

USINT

8

0...255

Yes

No

UINT

16

0...65535

Yes

Yes

UDINT

32

0...2

32

Yes

Yes

ULINT

64

0...2

64

No

Yes

BYTE

8

0…255

Yes

No

WORD

16

0...65535

Yes

Yes

DWORD

32

0...232-1

Yes

Yes

LWORD

64

0...264-1

No

Yes

REAL

32

-1.2*10

-38

...3.4*1038

Yes

Yes

LREAL

64

-2.3*10

-308

...1.7*10

308

Yes

Yes

Slow. Do not use.

TIME

32

0 ms... 1193h2m47s295ms

Yes

Yes

LTIME

64

0 ns...~213503d

Yes

Yes

TOD

32

00:00:00...23:59:59

Yes

Yes

DATE

32

01.01.1970...~06.02.2106

Yes

Yes

DT

64

01.01.1970 00:00...

~06.02.2106 00:00

Yes

Yes

STRING[xx]

0...255 characters

Yes

No WSTRING[xx]

0...32767 characters

Yes

Yes

Data types

The ABB drives application programming does not support some of the standard IEC data types like

BYTE, SINT, USINT and STRING. The following list gives the standard IEC data types, sizes and

ranges.

Drive application programming license

The drive application programming license N8010 is required for downloading and executing the

program code on the ACS880 or DCX880 drives. To check license information in Drive composer

pro or in ACS-AP-x control panel, go to System info -> Licenses. If the required license code is not

available, contact your local ABB representative.

Page 65

65

Note: It is not recommended to download a program to the RAM memory when the drive

is in RUN mode. The drive must be in STOP mode and Start inhibits must be possible to

set.

Note:

Firmware parameter mapping, task configuration, application parameters

and event configuration are activated only after the boot application is

loaded and the drive is booted.

Start inhibition is not granted if the drive is running, disabled (DIL, Safety

function active) or faulted. Make sure that these conditions do not exist

before downloading the program.

Application download options

Before executing an application in the drive, download the application to the drive memory. After

downloading, the application software is embedded in the firmware of the drive and has access to

system resources.

Before download, ensure that there is no fieldbus device, M/F-link or D2D-link connected to the drive

and Drive composer is not running data monitoring or back-up/restore at same time.

There are two different download options:

Download – This is a regular download method that copies the compiled application to the

drive RAM memory. As a result, it is possible to execute the application, but after a power

cycle or reboot the memory is erased. This download method does not alter an application

that is located in the drive boot memory (ZMU) and the original application is available for

use after a reboot.

Create boot application – This download method copies the application to the non-volatile

memory of the drive memory card. This way the application remains intact after a power

cycle or reboot. You should be logged into the drive to perform this operation. Features that

can work only after restarting the drive should be downloaded with this method.

Create boot application command (Online -> Create boot application) also includes booting

the drive. Rebooting stops the execution of the complete drive firmware for some time. For

this reason, it is allowed only when the drive is stopped and start inhibition is granted to the

Automation Builder.

Page 66

66

Removing the application from the target

Use the Reset option if the application includes many changes like application parameter changes or

the application is replaced by another application. If the target already includes an application, use

the Reset origin selection in the Online tab before downloading a new application.

This command removes (clears all) old applications from the target and all the application related

references. Use this command at least once before the final version of application is loaded. The

command can be used only in the online mode. See also Reset options.

When you are prompted with the following message, click Yes.

Figure 59: Initiate reset origin

After you initiate the Reset origin option, the following message is displayed. Click Yes. The

command is executed only if Automation Builder receives the permission from the drive.

Figure 60: Confirm reset origin

Page 67

67

WARNING! In a function block, do not declare a local variable as RETAIN because the

complete instance of the function block is saved in the retain memory area and this large

function block instance may lead to running out of memory space.

Note: Declaring a local variable in a function as RETAIN has no effect and the variable

is not saved in the retain memory area.

The existing retain variables cannot be linked to application parameters.

Task

Time interval

Task_1

1 … 100 ms

Task_2

10 … 100 ms

Task_3

100 … 1000 ms

Note: The application program consists of its own quota of CPU resources. If the limit

exceeds, the drive tips to task overflow fault. For details, see ACS880 Firmware

manual.

Retain variables

Retain variables includes the RETAIN flag used to retain values throughout the drive reboot and

warm reset. A cold reset sets the retain variable to its initial value. The values of retain variables are

cyclically stored in the flash memory of the drive and restored to the stored value after the restart of

the program. The retain variables are stored in a separate 256-byte memory area which defines the

limits of their amount.

In firmware version 1.7 and later, the power control board works with the parameter settings:

If parameter 95.04 = Internal 24V, retain values are saved immediately at the time the drive

loses power, meaning it is not cyclical.

If parameter 95.04 = External 24V, retain values are saved at periodic intervals of 3 minutes.

So the recovered variable may not be the recent value.

Task configuration

The task configuration object handles call configuration of programs. A task is a project unit that

defines which program is called in the project and when it is called. The project can have more than

one task with different time levels.

There are two types of tasks:

Cyclic task (Task_1, Task_2 and Task_3) – These tasks are processed cyclically according

to the task cycle time interval. The following table lists the time intervals available for cyclic

application programs. The highest priority is given to the task with the shortest execution

interval.

Pre_task – This task is executed only once at start-up of the application program. This

feature is useful for one time initialization. POUs (blocks) assigned into this task are executed

before the start of cyclic tasks.

Page 68

68

Adding tasks

To add tasks to Task Configuration, follow these steps:

1. In the Devices tree, right-click Task Configuration and select Add Object.

Figure 61 Task configuration

2. Select Task and click Add object.

Figure 62 Task

Page 69

69

3. In the Task drop-down list, select a task and click Add.

Figure 63: Add tasks

The selected tasks are added in the Task Configuration object.

Figure 64: Tasks added

4. Click Add POU in the newly added Task_2 screen.

Page 70

70

5. In the Input Assistant window, click Categories and then select PLC_PRG and click OK.

Figure 65 Add POU input assistant

6. PLC_PRG is added to Task_2. Drag PLC_PRG to Task Configuration object.

Figure 66 New PLC PRG

Page 71

71

Monitoring tasks

Before adding the tasks for monitoring in Automation Builder, check parameter 7.21 Application

environment status in Drive composer pro.

Figure 67: Drive composer pro, parameter 7.21

The parameter bits 7.21.0, 7.21.1, 7.21.2, and 7.21.3 are used to monitor the application task related

execution. To check the continuous execution of tasks, write the specific task bit to 0. The executing

task bits are updated to 1, except the Pre task, which executes only once.

The calculation of tasks execution cycle (duration) is disabled by default. To view the tasks

execution monitoring in Automation Builder, change Bit 15 = Task monitoring to high.

Page 72

72

Note: The values in the task monitoring view are updated only setting the parameter

7.21.15 to high in Drive composer pro. This setting is configured again after the power

cycle or boot or control board.

To add task monitoring view in Automation Builder, follow these steps:

1. In the Devices tree, double click Task Configuration.

2. Click Monitor tab to check the status report of available tasks.

The status report of available tasks appears.

Figure 68: Task monitoring view

Page 73

73

Uploading and downloading source code

Optionally, the source code of the project can be saved in the drive. This feature is located in

Automation Builder main menu Online -> Source download to connected device and it ensures

that the files are easy to obtain if needed.

To retrieve the saved source code from the drive to a new project, follow these steps:

1. In the Devices tree, right-click Device and select Source upload.

Figure 69 Source upload

2. Select the drive and click OK.

Figure 70 Source upload device

Page 74

74

Note: If the source code is saved on the ZMU memory unit, you can retrieve the program

with another PC without the authors consent unless the project is password protected.

The size of the source code is limited to 500 KB. Check the archiving option to minimize the source

code size (File -> Project Archive -> Save/Send Archive…). Note that referenced devices and