ABB i-bus SA/S 2.16.2.1, i-bus SA/S 4.6.1.1, i-bus SA/S 2.16.6.1, i-bus SA/S 2.10.2.1, i-bus SA/S 4.10.2.1 Product Manual

...Page 1

ABB i-bus® KNX

SA/S Switch Actuators

Product Manual

Page 2

ABB i-bus KNX

General

SA/S | 2CDC 505 056 D0208 5

1 General

KNX systems provide an attractive solution that meets the most demanding residential, commercial and

public buildings requirements. H igh liv ing stan dard s, com fort and safety can be easi ly comb ined w ith cos teffectiveness and environmental awareness using KNX bus systems from ABB. KNX products cover the

entire range of buildings applications, from illumination and blind control to heating, ventilation, energy

management, security and surveillance. These requireme nts can be met cos t-effectively with minimal

planning and installation effort using the ABB KNX. Furthermore, flexible room usage and continuous

adaptation to changing requirements are simple to implement. SA/S Switch Actuators fulfill individual

requirements in industrial, commercial and public buildings as well as in the private sector for controlling

switchable loads, e.g.:

• Illumination

• Heating control

• Signaling equipment

Certain types of Switch Actuator can also detect and monitor load current via a threshold value function.

Based on the load current detected, responses can be triggered via KNX and the load can be switched off

directly or switched via KNX.

1.1 Using the product manual

This manual provides you with detailed technical information on the ABB i-bus® SA/S Switch Actuator

range, its installation and programming.

Application of the device is explained using examples.

This manual is subdivided into the following sections:

Section 1 General

Section 2 Device technology

Section 3 Commissioning

Section 4 Planning and application

Section A Appendix

Page 3

ABB i-bus KNX

General

6 2CDC 505 056 D0208 | SA/S

1.1.1 Structure of the product manual

All parameters are described in section 3.

Please note

This product manual describes all the current 2/4/8 and 12-fold Switch Actuators. However, as the

functions for all outputs are identical, only the functions of output A will be described.

Where information in the product manual refers to all outputs, the description output A...X is used. 2-fold

corresponds to outputs A...B, 4-fold corresponds to outputs A...D, 8-fold corresponds to outputs A...H

and 12-fold corresponds to outputs A...L.

Variants with current detection feature an additional parameter page as well as additional

communication objects for this function.

1.1.2 Notes

Notes and safety instructions are represented as follows in this product manual:

Please note

Tips for usage and operation

Example

Application examples, installation examples, programming examples

Important

These safety instructions are used as soon as there is danger of a malfunction without risk of damage

or injury.

Caution

These safety instructions are used if there is a danger of damage with inappropriate use.

Danger

These safety instructions are used if there is a danger to life and limb with inappropriate use.

Danger

These safety instructions are used if there is an extreme danger to life with inappropriate use.

Page 4

ABB i-bus KNX

General

SA/S | 2CDC 505 056 D0208 7

1.2 Product and functional overview

SA/S

12.16.6.1

ABB i-bus® KNX SA/S Switch Actuators are modular installation devices with module widths of

2/4/8/12 units in ProM design for installation in a distribution board.

Connection to the ABB i-bus® is established via a bus connection terminal on the front.

The Switch Actuators require no auxiliary voltage.

The assignment of the physical address as well as the parameterization is carried out with

Engineering Tool Software (ETS), version ETS2 V1.3a or higher. If using ETS3 or ETS4 you

will need to import the corresponding application program.

Please note

The illustrations of the parameter windows in this manual correspond to the ETS3 parameter

windows. The user program is optimized for ETS3.

In ETS2 the parameter page for any parameter being used may split automatically.

The Switch Actuators can switch 2 to 12 independent electrical AC or three-phase loads via

KNX with floating contacts. With SA/S x.16.6.1 types it is possible to detect the load current for

each output. The outputs of the 6 A, 10 A, 16 A and 16/20 A Switch Actuators can be switched

on and off manually.

Switch Actuators SA/S x.16.6.1 and SA/S 12.16.5.1, which have the highest switching capacity

(C-load), are particularly well-suited for switching loads with high peak inrush currents, e.g.

lighting equipment with compensation capacitors or fluorescent lamp loads (AX) to EN 60 669.

The following functions can be set individually for each output:

• Time and ON/OFF delay functions

• Staircase lighting function with warning and modifiable staircase lighting time

• Recall of scenes/presets via 8/1 bit command s

• Logical functions AND, OR, XOR, GATE function

• Status messages

• Forced operation and safety functions

• Response to threshold values

• Control of electro-thermal valve drives

• Selection of the default state on bus voltage failure and recovery

• Output inversion

SA/S

8.16.6.1

SA/S

4.16.2.1

SA/S

2.10.2.1

SA/S

8.6.2.1

SA/S

8.6.1.1

SA/S

4.6.1.1

Page 5

ABB i-bus KNX

General

8 2CDC 505 056 D0208 | SA/S

On Switch Actuators with current detection, SA/S x.16.6.1, each output also features the lo ad current

detection function with parameterizable response to two current threshold values. The current value can

be sent via the bus. Individual outputs in the Switch Actuators can be copied or exchanged to minimize

programming work.

The SA/S x.16.6.1 and SA/S x.16.5.1 are suitable for rated currents up to 20 A and have C-load switching

capacity.

In the following table you will find an overview of the ABB i-bus

®

Switch Actuators and their type

designations:

– SA/S 2.6.2.1 SA/S 2.10.2.1 SA/S 2.16.2.1 SA/S 2.16.5.1 SA/S 2.16.6.1

SA/S 4.6.1.1 SA/S 4.6.2.1 SA/S 4.10.2.1 SA/S 4.16.2.1 SA/S 4.16.5.1 SA/S 4.16.6.1

SA/S 8.6.1.1

SA/S 8.6.2.1

SA/S 8.10.2.1

SA/S 8.16.2.1

SA/S 8.16.5.1

SA/S 8.16.6.1

SA/S 12.6.1.1 SA/S 12.6.2.1 SA/S 12.10.2.1 SA/S 12.16.2.1 SA/S 12.16.5.1 SA/S 12.16.6.1

Please note

The codes represent the following:

SA/S x.y.z.w

x = number of outputs (2, 4, 8 or 12)

y = rated current in Amperes (6, 10, 16)

z = load type specification:

1 = type with no manual operation

2 = type with manual operation

5 = type with higher switch capacity, C-load (200 µF)

6 = type with higher C-load switching capacity and current detection

w = version number

Page 6

ABB i-bus KNX

Device technology

SA/S | 2CDC 505 056 D0208 9

2 Device technology

2.1 Switch Actuators SA/S x.6.1.1, 6 A, MDRC

SA/S

12.6.1.1

Switch Actuators SA/S

x.6.1.1 6 A are

modular installation devices in Pro

M

design for installation in the distribution

board. They are suitable for switching

resistive, inductive and capacit iv e loads.

The actuators can

switch up to

12

independent electrical loads via

floating contacts. The outputs are

connected using screw terminals in

groups of two

contacts for SA/S 8.6.1.1

and SA/S

12.6.1.1. SA/S 4.6.1.1 has one

terminal per output for power feed. Each

output is contr

olled separately via KNX,

regardless of the variant.

The device does not require an

additional power supply and is ready for

immediate use after the bus voltage

has been applied. The Switch Actuator

is parameterized via ETS. Connection

to KNX is implemented using the bus

connection terminal on the front.

2.1.1 Technical data

Supply

KNX bus voltage 21…32 V DC

Current consumption, bus < 12 mA

Power consumption

Maximum 250 mW

Rated output value

SA/S type 4.6.1.1 8.6.1.1 12.6.1.1

Current detection no no no

N

umber (floating contacts 2/group) 4 *) 8 12

U

n

rated voltage 250/440 V AC (50/60 Hz)

I

n

rated current (per output) 6 A 6 A 6 A

L

eakage loss per device at max. load 1.5 W 2.0 W 2.5 W

Output switching current

AC3

1)

operation (cos ϕ = 0.45)

To EN 60 947-4-1

6 A/230 V AC

AC3

1)

operation (cos ϕ = 0.8)

To EN 60 947-4-1

6 A/230 V AC

Fluorescent lighting load to EN 60 669-1 6 A/250 V AC (35 µF)2)

Minimum switching ca p acity 20 mA/5 V AC

10 mA/12 V AC

7 mA/24 V AC

Output service life

Mechanical service lif e

> 107

Electrical endurance

To IEC 60 947-4-1

A

C1

1)

(240 V/cos ϕ = 0.8)

> 10

5

AC31) (240 V/cos ϕ = 0.45)

> 1.5 x 104

AC5a1) (240 V/cos ϕ = 0.45)

> 1.5 x 104

*) Each output has one terminal for power feed.

2CDC 071 033 S0012

Page 7

ABB i-bus KNX

Device technology

10 2CDC 505 056 D0208 | SA/S

Output switching times 3)

Maximum output relay position change per

minute if all relays are switched simultane o usly.

The position changes should be distributed

equally within the minute.

4.6.1.1 8.6.1.1 12.6.1.1

60 30 20

Maximum output relay position change per

minute if only one relay is swit ched.

240 240 240

Connections

KNX

Loa

d circuits

Tightening torque

Operating and display elements

Programming button/LED

Degree of protection

IP 20

Protection class

II

Isolation category

Overvoltage category

Pol

lution degree

Via bus connection terminals,

0.8 mm Ø, solid

Universal head screw terminal (PZ 1)

0.2… 4 mm2 fine stranded, 2 x 0.2…2.5 mm2

0.2… 6 mm2 solid, 2 x 0.2…4 mm

2

max. 0.6 Nm

For assignment of physical address To EN 60

529

To EN 61 140

III to EN 60 664-1

2 to EN 60 664-1

KNX safety extra low voltage

SELV 24 V DC

Temperature range

Operation

Storage

Transport

- 5 °C…+45 °C

-25 °C…+55 °C

-25 °C…+70 °C

Ambient conditions

Maximum a ir humidity 95 %, no condensation allowed

Design

Modular installation device (MDRC) Modular installation device, ProM

SA/S t

ype 4.6.1.1 8.6.1.1 12.6.1.1

Di

mensions 90 x W x 64.5 mm (H x W x D)

Widt

h W in mm 72 108 144

Mou

nting width in units (18 mm modules) 4 6 8

Mounting depth in mm 64.5 64.5 64.5

Weight

in kg

0.13 0.24 0.3

Mounting

On 35 mm mounting rail

To EN 60 715

Mounting position

As required

Housing/color

Plastic housing, gray

Approvals

KNX to EN 50 090 -1, -2 Certification

CE mark

in accordance with the EMC guideline and

low voltage guideline

1)

Further information concerning electrical endurance to IEC 60 947-4-1 can be found at: AC1, AC3, AX, C-load specifications, p. 43

2)

The maximum inrush current peak may not be exceeded.

3)

The specifications apply only after the bus voltage has been applied to the device for at least 30 seconds. Typical relay delay is approx. 20 ms.

Page 8

ABB i-bus KNX

Device technology

SA/S | 2CDC 505 056 D0208 11

2.1.2 Lamp output load at 230 V AC

Lamps

Incande s cent lamp load 1,200 W

Fluorescent lamps T5/T8

Uncorrected

Parallel compensated

DUO circuit

800 W

300 W

350 W

Low-voltage halogen lamps

Inductive transform e r

Electronic transfor mer

Halogen lamps 230 V

800 W

1,000 W

1,000 W

Dulux lamp

Uncorrected

Parallel compensated

800 W

800 W

Mercury-vapor lamp

Uncorrected

Parallel compensated

1,000 W

800 W

Switching capacity (switchi ng conta c t )

Maximum peak inrush current Ip (150 µs)

Maximum peak inrush current I

p

(250 µs)

Maximum peak inrush current I

p

(600 µs)

200 A

160 A

100 A

Number of electronic ballasts (T5/T8, single

element)1)

18 W (ABB EVG 1 x 18 SF)

24 W (ABB EVG-T5 1 x 24 CY)

36 W (ABB EVG 1 x 36 CF)

58 W (ABB EVG 1 x 58 CF)

80 W (Helvar EL 1 x 80 SC)

10

10

7

5

3

1)

For multiple element lamps or other types, the number of electronic ballas ts mu s t be deter mined usi ng the peak inrush current of the electronic

ballasts, see Ballast calculation, p. 42

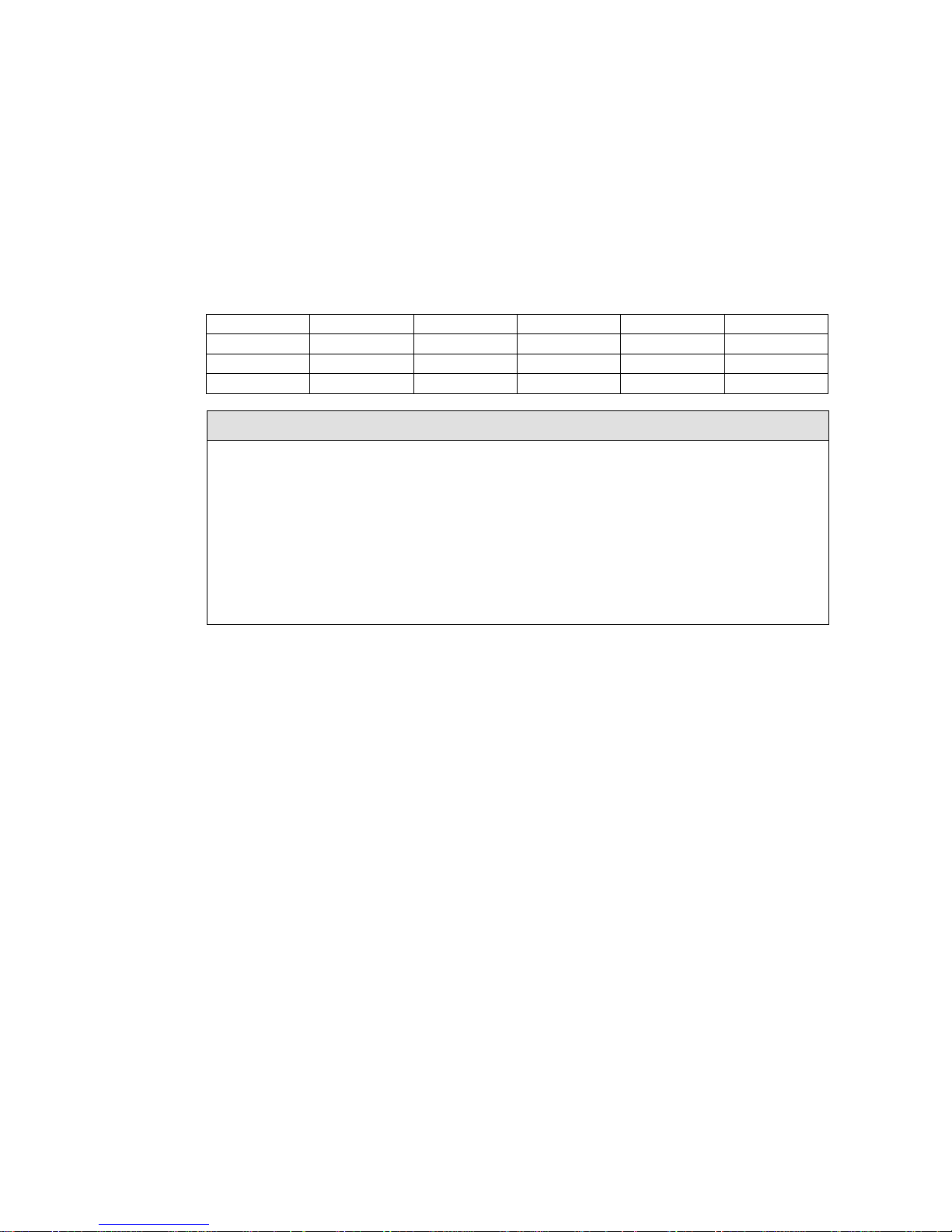

Device type Application program Maximum number of

communication objects

Maximum number of

group addresses

Maximum number of

associations

SA/S 4.6.1.1 Switch 4f 6A/…* 64 254 254

SA/S 8.6.1.1 Switch 8f 6A/…* 124 254 254

SA/S 12.6.1.1 Switch 12f 6A/…* 184 254 254

* … = current version number of the application program

Please note

ETS and the current version of the device application program are required for programming.

The current application program is available for download at www.abb.com/knx. After import into ETS

it can be found under ABB/Out put/Binary output xf 6A/…* (x = 4, 8 or 12).

The device does not support the locking function of a KNX device in ETS. If you inhibit access to all of

the project devices by using a BCU code, it has no effect on this device.

Data can still be read and programmed.

Page 9

ABB i-bus KNX

Device technology

12 2CDC 505 056 D0208 | SA/S

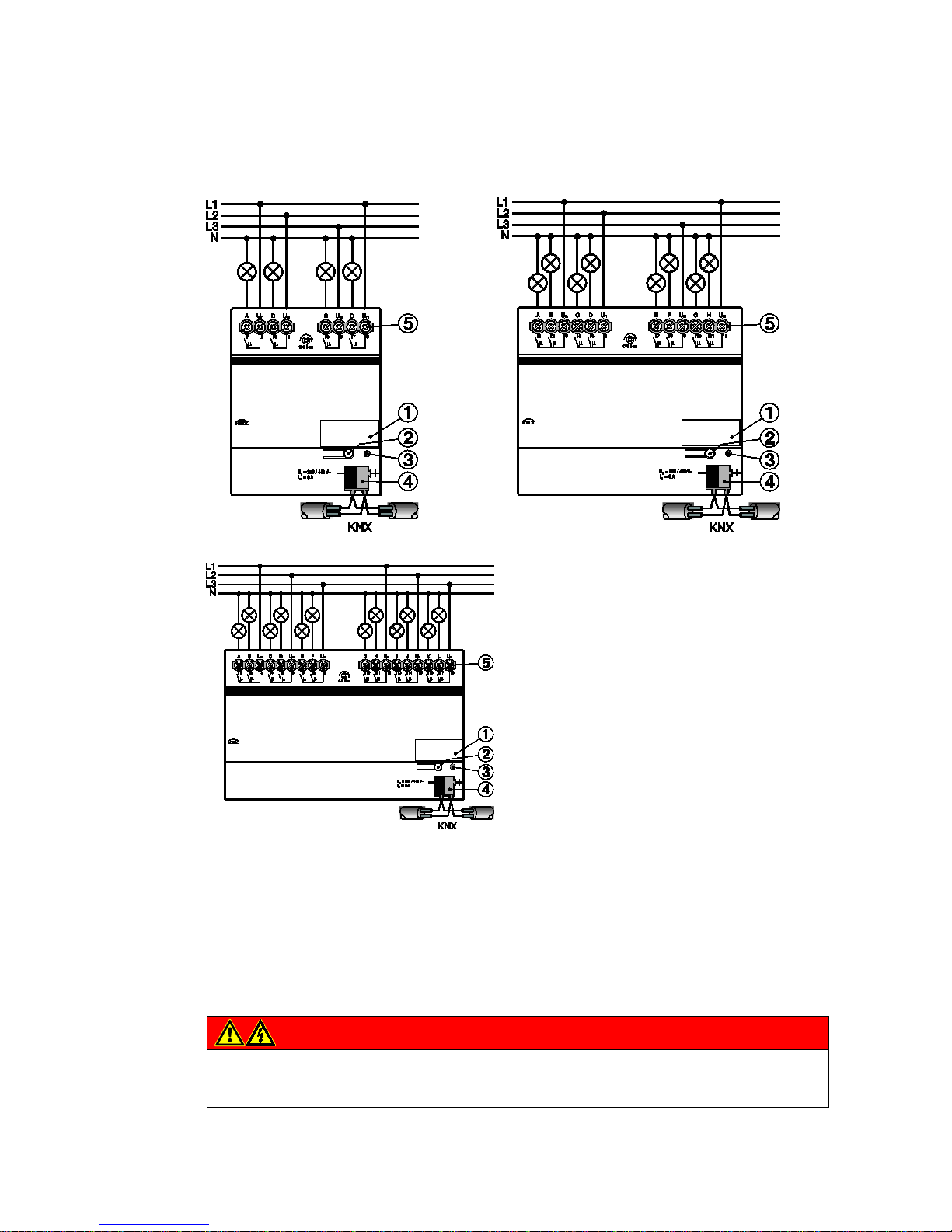

2.1.3 Connection schematic SA/S x.6.1.1

1 Label carrier

2 Programming button

3 Programming LED

4 Bus connection terminal

5 Load current circuits, one screw terminal for phase connection per contact

Danger

Touch voltages.

Danger of injury.

Observe all-pole disconnection.

2CDC 072 07x F0011

Page 10

ABB i-bus KNX

Device technology

SA/S | 2CDC 505 056 D0208 13

2.1.4 Dimension drawing SA/S x.6.1.1

SA/S 4.6.1.1

SA/S 8.6.1.1

SA/S 12.6.1.1

Width W

Mounting width

(18 mm modules)

72 mm

4 units

108 mm

6 units

144 mm

8 units

2CDC 072 077 F0011

Page 11

ABB i-bus KNX

Device technology

14 2CDC 505 056 D0208 | SA/S

2.2 Switch Actuators SA/S x.6.2.1, 6 A, manual, MDRC

SA/S

8.6.2.1

Switch Actuators SA/S

x.6.2.1, 6 A are

mod

ular installation devices in ProM

design for installation in the distribution

board. They are suitable for switching

resistive, inductive and capacit iv e loads as

well as fluorescent lamp loads (AX) to

EN

60 669.

The Switch Actuator can be actuated

manually

using a button. This

simultaneously indicates the contact

position.

The actuators can switch up to

12 independent electrical loads via

floating contacts. The connection of the

outputs is implemented using combohead screw terminals. Each output is

controlled separately via KNX.

The device does not require an

additional power supply and is ready for

immediate use after the bus voltage has

been applied.

The Switch Actuators are parameterized

via ETS. Connection to KNX is

implemented using the bus connection

terminal on the front.

2.2.1 Technical data

Supply

KNX bus voltage 21…31 V DC

Current consumption via bus < 12 mA

Power consumption via bus Maximum 250 mW

Rated output value

SA/S type 2.6.2.1 4.6.2.1 8.6.2.1 12.6.2.1

C

urrent detection no no no no

N

umber (floating contacts) 2 4 8 12

Un rated voltage

250/440 V AC (50/60 Hz)

In rated current

6 AX 6 AX 6 AX 6 AX

Leakage loss per device at max. load 0.9 W 1.2 W 1.5 W 3.9 W

Output switching current

AC3

1)

operation (cos ϕ = 0.45)

To EN 60 947-4-1

6 A/230 V AC

AC1

1)

operation (cos ϕ = 0.8)

To EN 60 947-4-1

6 A/230 V AC

Fluorescent lighting load to EN 60 669-1

6 AX/250 V AC (140 µF)2)

Minimum switching ca p acity 100 mA/12 V AC

100 mA/24 V AC

DC current switching capacity (resistive load) 6 A/24 V DC

Output service life

Mechanica l service life

> 3 x 106

Electrical endurance

To IEC 60 947-4-1

A

C1

1)

(240 V/cos ϕ = 0.8)

> 105

AC31) (240 V/cos ϕ = 0.45)

> 3 x 104

AC5a 1) (240 V/cos ϕ = 0.45)

> 3 x 104

2CDC 071 001 S0013

Page 12

ABB i-bus KNX

Device technology

SA/S | 2CDC 505 056 D0208 15

Output switching times3)

SA/S type

Maximum output relay position change per

minute if all relays are switche d simultaneo usly.

The position changes should be distributed

equally within the minute.

2.6.2.1 4.6.2.1 8.6.2.1 12.6.2.1

60 30 15 10

Maximum output relay position change per

minute if only one relay is switched.

120 120 120 120

Connections

KNX Via bus connection terminals,

0.8 mm Ø, solid

L

oad circuits Universal head screw terminal (PZ 1)

0.2… 4 mm

2

fine stranded, 2 x 0.2…2.5 mm2

0.2… 6 mm

2

solid, 2 x 0.2…4 mm2

F

errules without/with plastic sleeves

0.25…2.5/4 mm

2

T

WIN ferrules

0.5…2.5 mm

2

Contact pin length min. 10 mm

T

ightening torque max. 0.6 Nm

Operating and display elements

Programming button/LED For assignment of the physical address

Contact position display Relay operator

Degree of protection

IP 20

To EN 60 529

Protection class

II To EN 61 140

Isolation category

Overvoltage category III to EN 60 664-1

P

ollution degree 2 to EN 60 664-1

KNX safety extra low voltage

SELV 24 V DC

Temperature range

Operation

Storage

Transport

- 5 °C…+45 °C

-25 °C…+55 °C

-25 °C…+70 °C

Ambient conditions

Maximum a ir humidity

95 %, no condensation allowed

Design

Modular installation device (MDRC)

Modular installation device, ProM

SA/S type 2.6.2.1 4.6.2.1 8.6.2.1 12.6.2.1

D

imensions 90 x W x 64.5 mm (H x W x D)

W

idth W in mm 36 72 144 216

M

ounting width in units (18 mm modules) 2 4 8 12

M

ounting depth in mm 64.5 64.5 64.5 64.5

Weight

in kg 0.15 0.25 0.46 0.65

Mounting

On 35 mm mounting rail To EN 60 715

Mounting position

any

Housing/color

Plastic housing, gray

Approvals

KNX to EN 50 090-1, -2

Certification

CE mark

in accordance with the EMC guideline and

low voltage guideline

1)

Further information concerning electrica l endurance to IEC 60 94 7-4-1 can be found at: AC1, AC3, AX, C-load specifications, p. 43

2)

The maximum inrush current peak may not be exceeded.

3)

The specifications apply only after the bus voltage has been applied to the device for at least 30 seconds. Typical relay delay is approx. 20 ms.

Page 13

ABB i-bus KNX

Device technology

16 2CDC 505 056 D0208 | SA/S

2.2.2 Lamp output load, 6 A

Lamps

Incande s cent lamp load 1,380 W

Fluorescent lamps T5/T8

Uncorrected

Parallel compensated

DUO circuit

1,380 W

1,380 W

1,380 W

Low-voltage halogen lamps

Inductive transform e r

Electronic transfor mer

Halogen lamps 230 V

1,200 W

1,380 W

1,380 W

Dulux lamp

Uncorrected

Parallel compensated

1,100 W

1,100 W

Mercury-vapor lamp

Uncorrected

Parallel compensated

1,380 W

1,380 W

Switching capacity (switchi ng conta c t )

Maximum peak inrush current Ip (150 µs)

Maximum peak inrush current Ip (250 µs)

Maximum peak inrush current Ip (600 µs)

400 A

320 A

200 A

Number of electronic ballasts (T5/T8, single

element)1)

18 W (ABB EVG 1 x 18 SF)

24 W (ABB EVG-T5 1 x 24 CY)

36 W (ABB EVG 1 x 36 CF)

58 W (ABB EVG 1 x 58 CF)

80 W (Helvar EL 1 x 80 SC)

23

23

14

11

10

1)

For multiple element lamps or other types, the number of electronic ballas ts mu s t be deter mined usi ng the peak inrush current of the electronic

ballasts, see

Ballast calculation, p. 42.

Device type Application program Maximum number of

communication objects

Maximum number of

group addresses

Maximum number of

associations

SA/S 2.6.2.1 Switch 2f 6AM/…* 34 254 254

SA/S 4.6.2.1 Swit ch 4f 6AM/…* 64 254 254

SA/S 8.6.2.1 Switch 8f 6AM/…* 124 254 254

SA/S 12.6.2.1 Switch 12f 6AM/…* 184 254 254

* … = current version number of the application program

Please note

ETS and the current version of the device application program are required for programming.

The current application program is available for download at www.abb.com/knx. After import into ETS it

can be found under ABB/Output/Binary output xf 6AM/…* (x = 2, 4, 8 or 12).

The device does not support the locking function of a KNX device in ETS. If you inhibit access to all of

the project devices by using a BCU code, it has no effect on this device.

Data can still be read and programmed.

Page 14

ABB i-bus KNX

Device technology

SA/S | 2CDC 505 056 D0208 17

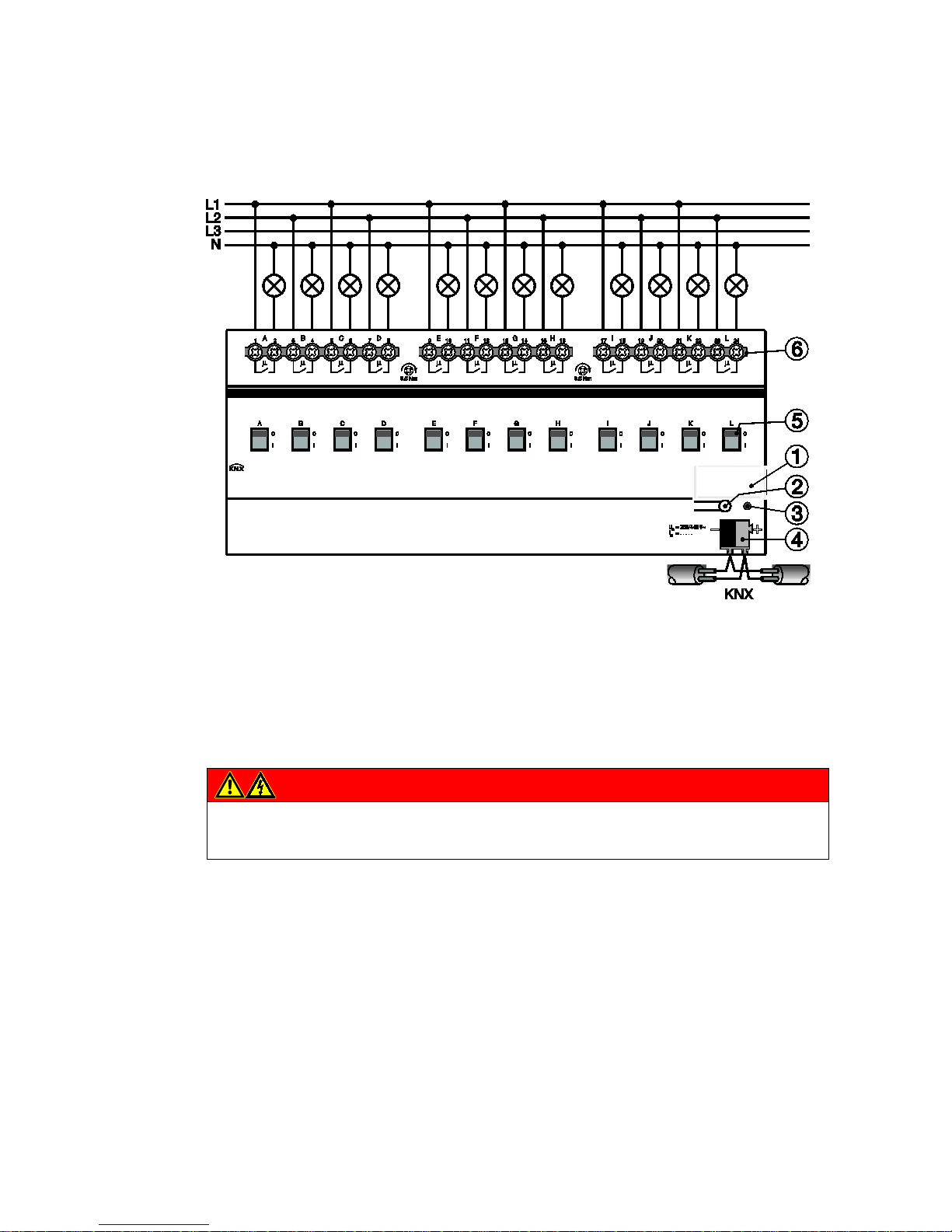

2.2.3 Connection schematic SA/S x.6.2.1

1 Label carrier

2 Programming button

3 Programming LED

4 Bus connection terminal

5 Contact position display and manual operation

6 Load current circuits, for every 2 connection terminals

Danger

Touch voltages.

Danger of injury.

Observe all-pole disconnection.

2CDC 072 086 F0011

Page 15

ABB i-bus KNX

Device technology

18 2CDC 505 056 D0208 | SA/S

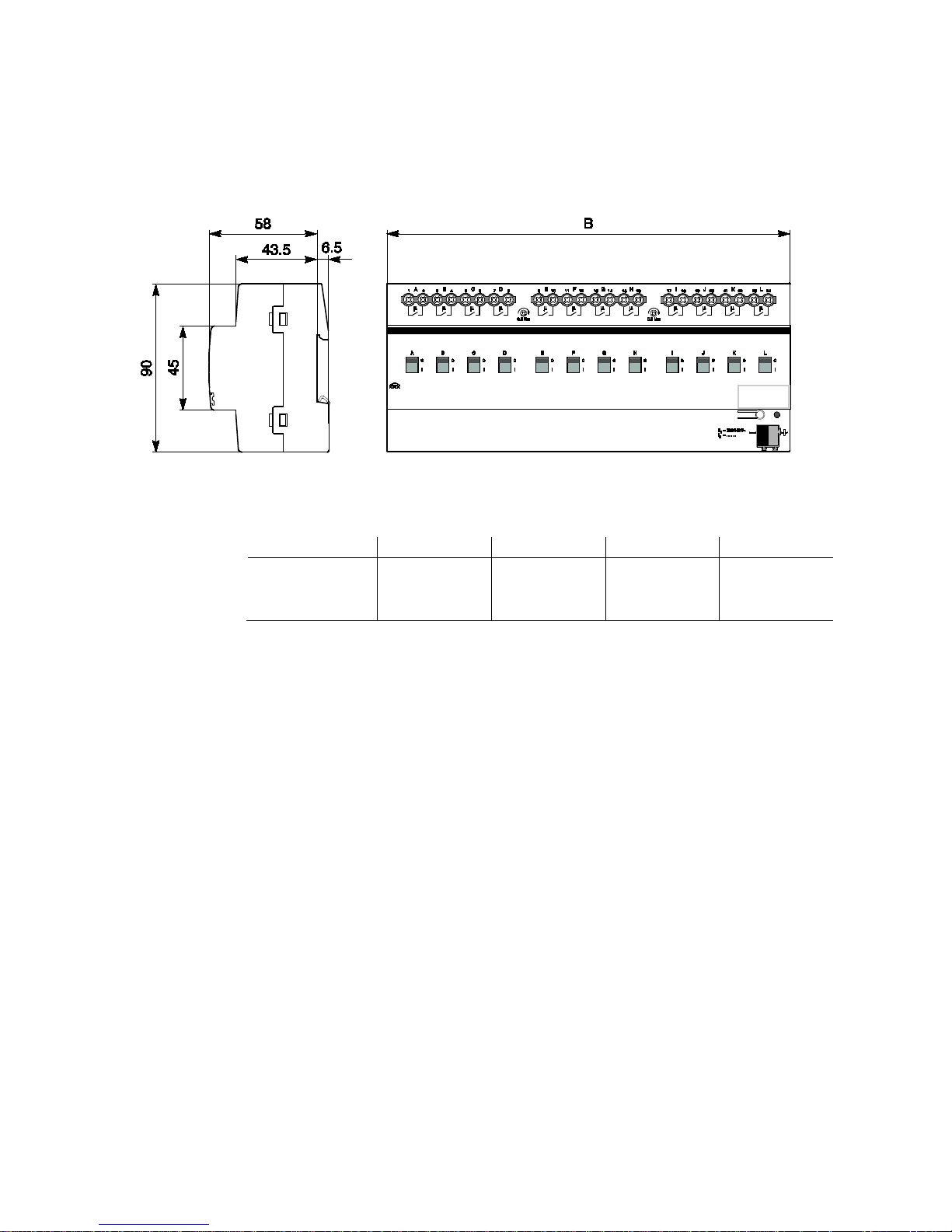

2.2.4 Dimension drawing SA/S x.6.2.1

SA/S 2.6.2.1 SA/S 4.6.2.1 SA/S 8.6.2.1 SA/S 12.6.2.1

Width W

Mounting width

(18 mm modules)

36 mm

2 units

72 mm

4 units

144 mm

8 units

216 mm

12 units

2CDC 072 019 F0013

Page 16

ABB i-bus KNX

Device technology

SA/S | 2CDC 505 056 D0208 19

2.3 Switch Actuators SA/S x.10.2.1, 10 A, MDRC

SA/S

8.10.2.1

Switch Actuators SA

/S x.6.2.1, 10 A are

modular installation devices in Pro

M

design for installation in the distribution

board. They are suitable for switching

resistive, inductive and capacit iv e loads as

well as fluorescent lamp loads (AX) to

EN

60 669.

The Switch Actuator

can be actuated

manually using a button. This

simultaneously indicates the contact

position.

The Switch Actuators can switch up to

12 independent electrical loads via

floating contacts. The connection of the

outputs is implemented using combohead screw terminals. Each output is

controlled separately via KNX.

The device does not require an

additional power supply and is ready for

immediate use, after the bus voltage has

been applied.

The Switch Actuators are parameterized

via ETS. Connection to KNX is

implemented using the bus connection

terminal on the front.

2.3.1 Technical data

Supply

KNX bus voltage 21…31 V

Current consumption via bus < 12 mA

Power consumption via bus Maximum 250 mW

Rated output value

SA/S type

2.10.2.1 4.10.2.1 8.10.2.1 12.10.2.1

Current detection

no no no no

Number (floating contacts 2/group) 2 4 8 12

Un rated voltage 250/440 V AC (50/60 Hz)

I

n

rated current 10 AX 10 AX 10 AX 10 AX

L

eakage loss per device at max. load 1.5 W 2.0 W 2.5 W 6.5 W

Output switching current

AC3

1)

operation (cos ϕ = 0.45)

To EN 60 947-4-1

8 A / 230 V AC

AC1

1)

operation (cos ϕ = 0.8)

To EN 60 947-4-1

10 A / 230 V AC

Fluorescent lighting load to EN 60 669-1

Minimum switching ca p acity

DC current switching capacity (resistive load)

Output service life

Mechanica l service life

10 AX/250 V AC (140 µF)

2)

100 mA/12 V AC

100 mA/24 V AC

10 A/24 V DC

> 3 x 106

Electrical endurance

To IEC 60 947-4-1

A

C1

1)

(240 V/cos ϕ = 0.8)

> 105

AC31) (240 V/cos ϕ = 0.45)

> 3 x 104

AC5a 1) (240 V/cos ϕ = 0.45)

> 3 x 104

2CDC 071 016 S0012

Page 17

ABB i-bus KNX

Device technology

20 2CDC 505 056 D0208 | SA/S

Output switching times3)

Maximum r elay position chan ge of output and

minute if all relays are switched simultane o usly.

The position changes should be distributed

equally within the minute.

2.10.2.1 4.10.2.1 8.10.2.1 12.10.2.1

60 30 15 10

Maximum output relay position change per

minute if only one relay is switched.

120 120 120 120

Connections

KNX

Via bus connection terminals,0.8 mm Ø, solid

Load current circuits (1 terminal per contact)

Universal head screw terminal (PZ 1)

0.2… 4 mm

2

fine stranded, 2 x 0.2…2.5 mm2

0.2… 6 mm

2

solid, 2 x 0.2…4 mm2

F

errules without/with plastic sleeves

0.25…2.5/4 mm

2

T

WIN ferrules

0.5…2.5 mm

2

Contact pin length min. 10 mm

Tightening torque max. 0.6 Nm

Operating and display elements

Programming button/LED For assignment of the physical address

Contact position display Relay operator

Degree of protection

IP 20 To EN 60 529

Protection class

II To EN 61 140

Isolation category

Overvoltage category III to EN 60 664-1

Pollution degree

2 to EN 60 664-1

KNX safety extra low voltage

SELV 24 V DC

Temperature range

Operation

Storage

Transport

- 5 °C…+45 °C

-25 °C…+55 °C

-25 °C…+70 °C

Ambient conditions

Maximum a ir humidity 95 %, no condensation allowed

Design

Modular installation device (MDRC) Modular installation device, ProM

SA

/S type 2.10.2.1 4.10.2.1 8.10.2.1 12.10.2.1

Dimensions

90 x W x 64.5 mm (H x W x D)

Width W in mm

36 72 144 216

Mounting width in units (18 mm modules) 2 4 8 12

Mounting depth in mm 64.5 64.5 64.5 64.5

Weight

in kg 0.15 0.25 0.46 0.65

Mounting

On 35 mm mounting rail To EN 60 715

Mounting position

As required

Housing/color

Plastic housing, gray

Approvals

KNX to EN 50 090-1, -2

Certification

CE mark

in accordance with the EMC guideline and

low voltage guideline

1)

Further information concerning electrical endurance to IEC 60 947-4-1 can be found at: AC1, AC3, AX, C-load specif ications, p. 43

2)

The maximum inrush current peak may not be exceeded.

3)

The specifications apply only after the bus voltage has been applied to the device for at least 30 seconds. Typical relay delay is approx. 20 ms.

Page 18

ABB i-bus KNX

Device technology

SA/S | 2CDC 505 056 D0208 21

2.3.2 Lamp output load 10 A

Lamps

Incande s cent lamp load 2,500 W

Fluorescent lamps T5/T8

Uncorrected

Parallel compensated

DUO circuit

2,500 W

1,500 W

1,500 W

Low-voltage halogen lamps

Inductive transform e r

Electronic transfor mer

Halogen lamps 230 V

1,200 W

1,500 W

2,500 W

Dulux lamp

Uncorrected

Parallel compensated

1,100 W

1,100 W

Mercury-vapor lamp

Uncorrected

Parallel compensated

2,000 W

2,000 W

Switching capacity (switchi ng conta c t )

Maximum peak inrush current I

p

(150 µs)

Maximum peak inrush current I

p

(250 µs)

Maximum peak inrush current I

p

(600 µs)

400 A

320 A

200 A

Number of electronic ballasts (T5/T8, single

element)1)

18 W (ABB EVG 1 x 18 SF)

24 W (ABB EVG-T5 1 x 24 CY)

36 W (ABB EVG 1 x 36 CF)

58 W (ABB EVG 1 x 58 CF)

80 W (Helvar EL 1 x 80 SC)

23

23

14

11

10

1)

For multiple element lamps or other types, the number of electronic ballas ts mu s t be deter mined usi ng the peak inrush current of the electronic

ballasts, see

Ballast calculation, p. 42.

Device type Application program Maximum number of

communication objects

Maximum number of

group addresses

Maximum number of

associations

SA/S 2.10.2.1 Switch 2f 10 A/…* 34 254 254

SA/S 4.10.2.1 Switch 4f 10 A/…* 64 254 254

SA/S 8.10.2.1 Switch 8f 10 A/…* 124 254 254

SA/S 12.10.2.1 Switch 12f 10A/…* 184 254 254

* … = current version number of the application program

Please note

ETS and the current version of the device application program are required for programming.

The current application program is available for download at www.abb.com/knx. After import into ETS,

it is available in ETS under ABB/Output/Binary output xf 10A/…* (x = 2, 4, 8 or 12).

The device does not support the locking function of a KNX device in ETS. If you inhibit access to all of

the project devices by using a BCU code, it has no effect on this device.

Data can still be read and programmed.

Page 19

ABB i-bus KNX

Device technology

22 2CDC 505 056 D0208 | SA/S

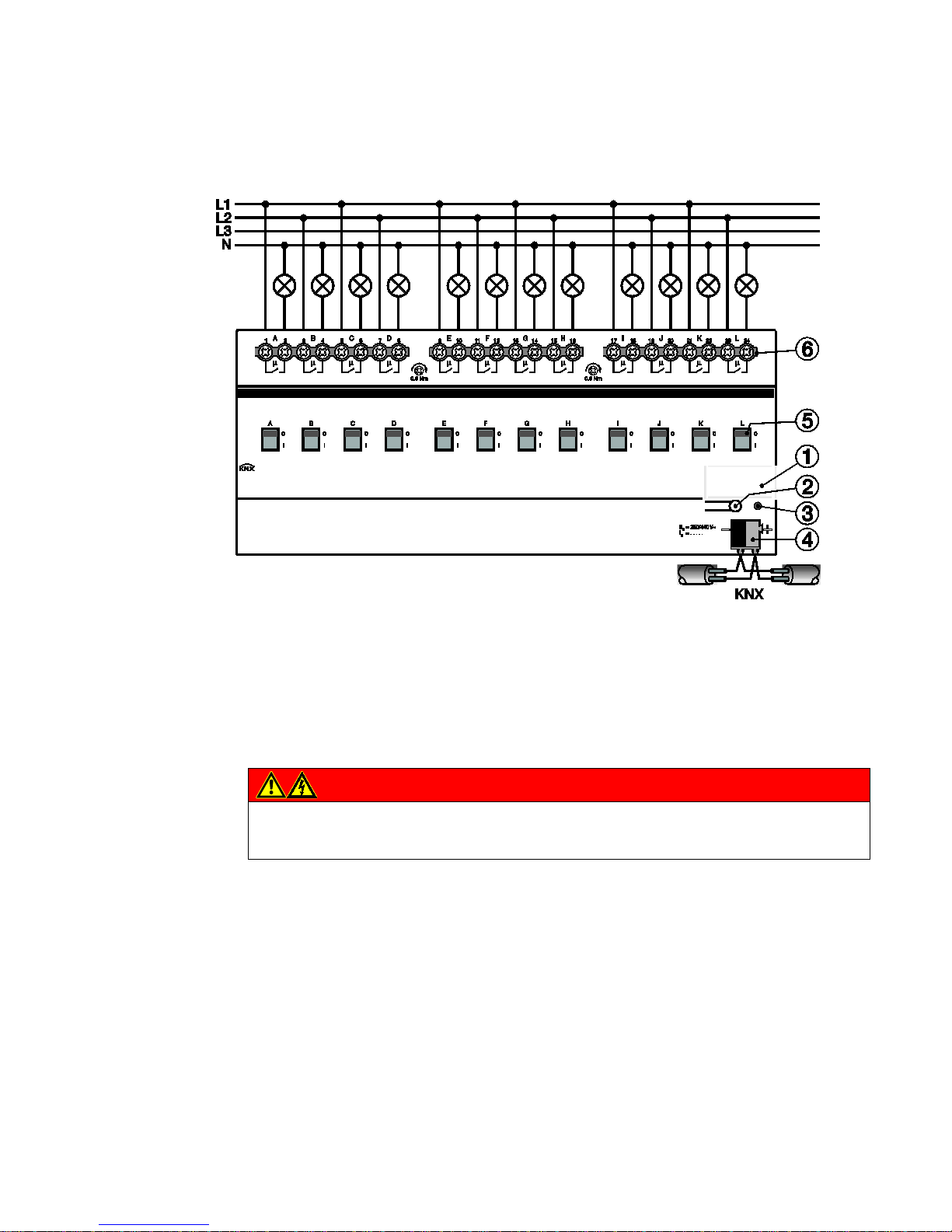

2.3.3 Connection schematic SA/S x.10.2.1

1 Label carrier

2 Programming button

3 Programming LED

4 Bus connection terminal

5 Contact position display and manual operation

6 Load current circuits, for every 2 connection terminals

Danger

Touch voltages.

Danger of injury.

Observe all-pole disconnection.

2CDC 072 086 F0011

Page 20

ABB i-bus KNX

Device technology

SA/S | 2CDC 505 056 D0208 23

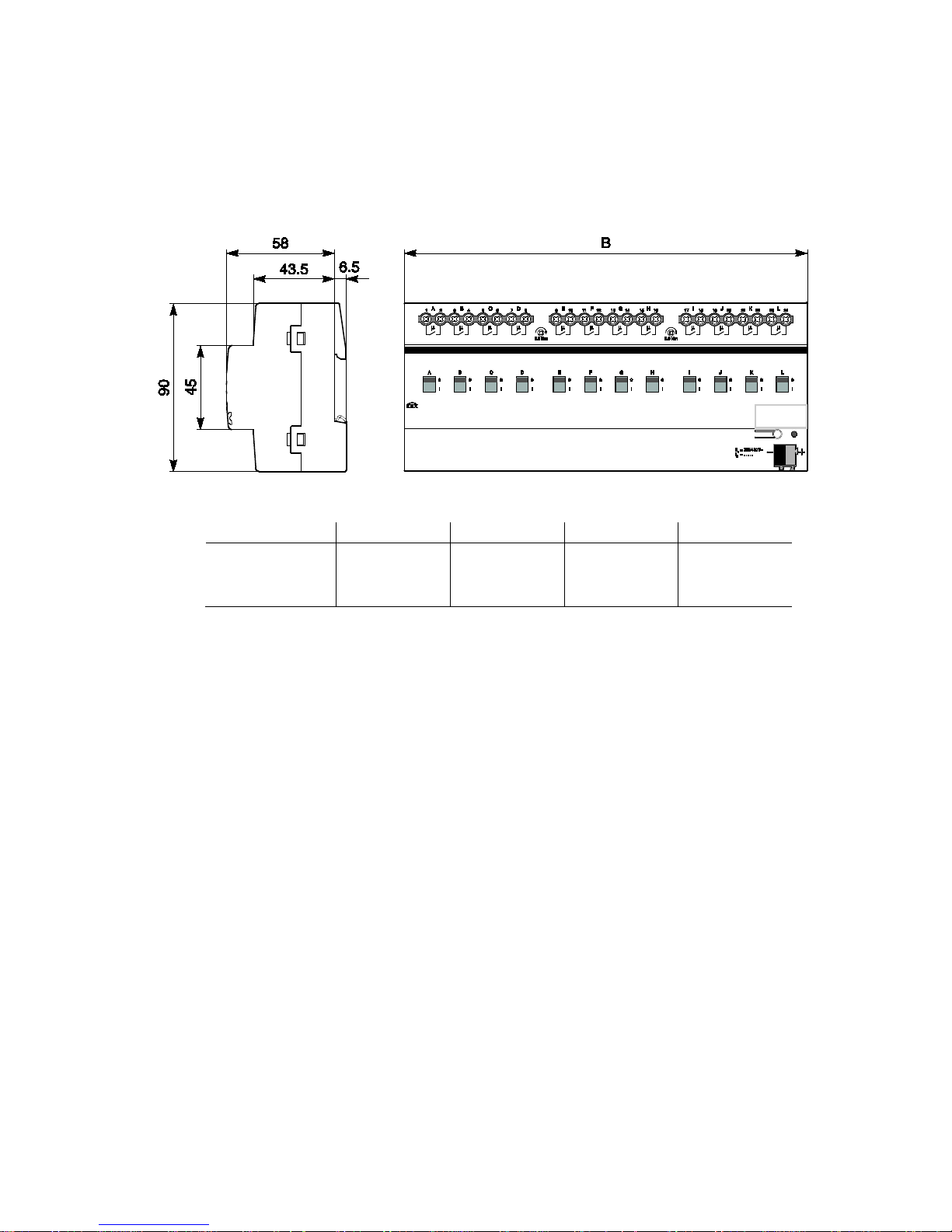

2.3.4 Dimension drawing SA/S x.10.2.1

SA/S 2.10.2.1

SA/S 4.10.2.1

SA/S 8.10.2.1

SA/S 12.10.2.1

Width W

Mounting width

(18 mm modules)

36 mm

2 units

72 mm

4 units

144 mm

8 units

216 mm

12 units

2CDC 072 019 F0013

Page 21

ABB i-bus KNX

Device technology

24 2CDC 505 056 D0208 | SA/S

2.4 Switch Actuators SA/S x.16.2.1, 16 A MDRC

SA/S

8.16.2.1

Switch Actuators SA/S x.16.2.1, 16 A are

modular installation devices in ProM

design for installation in the distribution

board. They are especially suitable for

switching resistive loads.

The Switch Actuator can be actuated

manually using a button. This

simultaneously indicates the c ont a ct

position.

The Switch Actuators can switch up to

12 independent electrical loads via

floating contacts. The connection of the

outputs is implemented using combohead screw terminals. Each output is

controlled separately via KNX.

The device does not require an

additional power supply and is ready for

immediate use, after the bus voltage has

been applied.

The Switch Actuators are parameterized

via ETS. Connection to KNX is

implemented using the bus connection

terminal on the front.

2.4.1 Technical data

Supply

KNX bus voltage 21…31 V DC

Current consumption via bus < 12 mA

Power consumption via bus Maximum 250 mW

Rated output value

SA/S type 2.16.2.1 4.16.2.1 8.16.2.1 12.16.2.1

Current detection

no no no no

Number (floating contacts 2/group)

2 4 8 12

Un rated voltage 250/440 V AC (50/60 Hz)

In rated current 16 A 16 A 16 A 16 A

L

eakage loss per device at max. load 2.0 W 4.0 W 8.0 W 12.0 W

Output switching current

AC3

1)

operation (cos ϕ = 0.45)

To EN 60 947-4-1

8 A / 230 V AC

AC1

1)

operation (cos ϕ = 0.8)

To EN 60 947-4-1

16 A/230 V AC

Fluorescent lighting load to EN 60 669-1

Minimum switching ca p acity

DC current switching capacity (resistive load)

Output service life

Mechanica l service life

16 AX/250 V AC (70 µF)

2)

100 mA/12 V AC

100 mA/24 V AC

16 A/24 V DC

> 3 x 106

Electrical endurance

To IEC 60 947-4-1

AC11) (240 V/cos ϕ = 0.8)

> 105

AC31) (240 V/cos ϕ = 0.45)

> 3 x 104

AC5a1) (240 V/cos ϕ = 0.45)

> 3 x 104

2CDC 071 017 S0012

Page 22

ABB i-bus KNX

Device technology

SA/S | 2CDC 505 056 D0208 25

Output switching times3)

Maximum r elay position chan ge of output and

minute if all relays are switched simultane o usly.

The position changes should be distributed

equally within the minute.

2.10.2.1 4.10.2.1 8.10.2.1 12.10.2.1

60 30 15 10

Maximum output relay position change per

minute if only one relay is switched.

120 120 120 120

Connections

KNX

Via bus connection terminals,0.8 mm Ø, solid

Load current circuits (1 terminal per contact)

Universal head screw terminal (PZ 1)

0.2… 4 mm

2

fine stranded, 2 x 0.2…2.5 mm2

0.2… 6 mm

2

solid, 2 x 0.2…4 mm2

F

errules without/with plastic sleeves

0.25…2.5/4 mm

2

T

WIN ferrules

0.5…2.5 mm

2

Contact pin length min. 10 mm

Tightening torque max. 0.6 Nm

Operating and display elements

Programming button/LED For assignment of the physical address

Contact position display Relay operator

Degree of protection

IP 20 To EN 60 529

Protection class

II To EN 61 140

Isolation category

Overvoltage category III to EN 60 664-1

Pollution degree

2 to EN 60 664-1

KNX safety extra low voltage

SELV 24 V DC

Temperature range

Operation

Storage

Transport

- 5 °C…+45 °C

-25 °C…+55 °C

-25 °C…+70 °C

Ambient conditions

Maximum a ir humidity 95 %, no condensation allowed

Design

Modular installation device (MDRC) Modular installation device, ProM

SA/

S type 2.10.2.1 4.10.2.1 8.10.2.1 12.10.2.1

Dimensions

90 x W x 64.5 mm (H x W x D)

Width W in mm

36 72 144 216

Mounting width in units (18 mm modules) 2 4 8 12

Mounting depth in mm 64.5 64.5 64.5 64.5

Weight

in kg 0.15 0.25 0.46 0.65

Mounting

On 35 mm mounting rail To EN 60 715

Mounting position

any

Housing/color

Plastic housing, gray

Approvals

KNX to EN 50 090-1, -2

Certification

CE mark

in accordance with the EMC guideline and

low voltage guideline

1)

Further information concerning electrical endurance to IEC 60 947-4-1 can be found at: AC1, AC3, AX, C-load specifications, p. 43

2)

The maximum inrush current peak may not be exceeded.

3)

The specifications apply only after the bus voltage has been applied to the device for at least 30 seconds. Typical relay delay is approx. 20 ms.

Page 23

ABB i-bus KNX

Device technology

26 2CDC 505 056 D0208 | SA/S

2.4.2 Lamp output load 16 A

Lamps

Incande s cent lamp load 2,500 W

Fluorescent lamps T5/T8

Uncorrected

Parallel compensated

DUO circuit

2,500 W

1,500 W

1,500 W

Low-voltage halogen lamps

Inductive transform e r

Electronic transfor mer

Halogen lamps 230 V

1,200 W

1,500 W

2,500 W

Dulux lamp

Uncorrected

Parallel compensated

1,100 W

1,100 W

Mercury-vapor lamp

Uncorrected

Parallel compensated

2,000 W

2,000 W

Switching capacity (switchi ng conta c t )

Maximum peak inrush current I

p

(150 µs)

Maximum p eak inrush curren t I

p

(250 µs)

Maximum peak inrush current I

p

(600 µs)

400 A

320 A

200 A

Number of electronic ballasts (T5/T8, single

element)1)

18 W (ABB EVG 1 x 18 SF)

24 W (ABB EVG-T5 1 x 24 CY)

36 W (ABB EVG 1 x 36 CF)

58 W (ABB EVG 1 x 58 CF)

80 W (Helvar EL 1 x 80 SC)

23

23

14

11

10

1)

For multiple element lamps or other types, the number of electronic ballas ts mu s t be deter mined usi ng the peak inrush

current of the electronic ballasts, see

Ballast calculation, p. 42

Device type

Application program

Maximum number of

communication objects

Maximum number of

group addresses

Maximum number of

associations

SA/S 2.10.2.1 Switch 2f 10 A/…* 34 254 254

SA/S 4.10.2.1

Switch 4f 10A/…*

64

254

254

SA/S 8.10.2.1

Switch 8f 10A/…*

124

254

254

SA/S 12.10.2.1 Switch 12f 10A/…* 184 254 254

* … = current version number of the application program

Please note

ETS and the current version of the device application program are required for programming.

The current application program is available for download at www.abb.com/knx. After import into ETS,

it is available in ETS under ABB/Output/Binary output xf 10A/…* (x = 2, 4, 8 or 12).

The device does not support the locking function of a KNX device in ETS. If you inhibit access to all

devices of the project with a BCU code, it has no effect on this device.

Data can still be read and programmed.

Page 24

ABB i-bus KNX

Device technology

SA/S | 2CDC 505 056 D0208 27

2.4.3 Connection schematic SA/S x.16.2.1

1 Label carrier

2 Programming button

3 Programming LED

4 Bus connection terminal

5 Contact position display and manual operation

6 Load current circuits, for every 2 connection terminals

Danger

Touch voltages.

Danger of injury.

Observe all-pole disconnection.

2CDC 072 086 F0011

Page 25

ABB i-bus KNX

Device technology

28 2CDC 505 056 D0208 | SA/S

2.4.4 Dimension drawing SA/S x.16.2.1

SA/S 2.16.2.1

SA/S 4.16.2.1

SA/S 8.16.2.1

SA/S 12.16.2.1

Width W

Mounting width

(18 mm modules)

36 mm

2 units

72 mm

4 units

144 mm

8 units

216 mm

12 units

2CDC 072 019 F0013

Page 26

ABB i-bus KNX

Device technology

SA/S | 2CDC 505 056 D0208 29

2.5 Switch Actuator SA/S 16.5.1, 16/20 A, MDRC

SA/S

12.16.5.1

Switch Actuat

ors SA/S x.16.5.1, 16/20 A

are modular installation devices in Pro

M

design for installation in the distribution

board. They are especially suitable for

switching loads with high peak inrush

currents such as lighting equipment with

compensation capacitors o

r fluorescent

lamp loads (AX) to EN

60 669.

Manual actuation of the Switch Actuator is

possible using a button. This

simultaneously indicates the contact

position.

The Switch Actuators can switch up to

12 independent electrical loads via

floating contacts. The maximum load

current per output is 20 A. The

connection of the outputs is implemented

using combo-

head screw terminals. Each

output is controlled separately via KNX.

The devices do not require an additional

power supply and are ready for

immediate use, after the bus voltage

has

been applied.

The Switch Actuators are parameterized

via ETS. Connection to KNX is

implemented using the bus connection

terminal on the front.

2.5.1 Technical data

Supply

KNX bus voltage 21…31 V DC

Current consumption via bus

< 12 mA

Power consumption via bus

Maximum 250 mW

Rated output value

SA/S type 2.16.5.1 4.16.5.1 8.16.5.1 12.16.5.1

Current detection no no no no

N

umber (floating contacts) 2 4 8 12

U

n

rated voltage 250/440 V AC (50/60 Hz)

I

n

rated current 16/20 AX, C-load

L

eakage loss per device at max. load 16 A 2.0 W 4.0 W 8.0 W 12 W

L

eakage loss per device at max. load 20 A 3.0 W 5.5 W 11.0 W 16 W

Output switching current

AC3

1)

operation (cos ϕ = 0.45)

To EN 60 947-4-1

16 A/230 V AC

AC1

1)

operation (cos ϕ = 0.8)

To EN 60 947-4-1

16/20 A/230 V AC

Fluorescent lighting load to EN 60 669-1 16/20 AX/250 V AC (200 µF)2)

Minimum switching ca p acity 100 mA/12 V AC

100 mA/24 V AC

DC current switching capacity (resistive load) 20 A/24 V DC

Output service life

Mechanical service life > 106

E

lectrical endurance to IEC 60 947-4-1

AC11) (240 V/cos ϕ = 0.8)

> 105

AC31) (240 V/cos ϕ = 0.45)

> 3 x 104

A

C5a

1)

(240 V/cos ϕ = 0.45)

> 3 x 104

2CDC 071 001 S0011

Page 27

ABB i-bus KNX

Device technology

30 2CDC 505 056 D0208 | SA/S

Output switching times3)

Maximum r elay position chan ges

per output per minute if all

relays are switched simultaneously.

Position changes should be

distributed equally within the minute.

2.16.5.1 4.16.5.1 8.16.5.1 12.16.5.1

30 15 7 5

Maximum r elay position chan ges

per output per minute if only

one relay is switched.

60 60 60 60

Connections

KNX Via bus connection terminals,

0.8 mm Ø, solid

L

oad circuits Universal head screw terminal (PZ 1)

0.2… 4 mm

2

fine stranded, 2 x 0.2…2.5 mm2

0.2… 6 mm

2

solid, 2 x 0.2…4 mm2

F

errules without/with plastic sleeves

0.25…2.5/4 mm

2

TWIN ferrules

0.5…2.5 mm

2

Contact pin length min. 10 mm

T

ightening torque max. 0.6 Nm

Operating and display elements

Programming button/LED For assignment of the physical address

Contact position display Relay operator

Degree of protection

IP 20

To EN 60 529

Protection class

II

To EN 61 140

Isolation category

Overvoltage category III to EN 60 664-1

P

ollution degree 2 to EN 60 664-1

KNX safety extra low voltage

SELV 24 V DC

Temperature range

Operation

Storage

Transport

- 5 °C…+45 °C

-25…+55 °C

-25…+70 °C

Ambient conditions

Maximum a ir humidity

95 %, no condensation allowed

Design

Modular installation device (MDRC) 2.16.5.1 4.16.5.1 8.16.5.1 12.16.5.1

Dimensions 90 x W x 64.5 mm (H x W x D)

W

idth W in mm 36 72 144 216

M

ounting width in units (18 mm modules) 2 4 8 12

M

ounting depth in mm 64.5 64.5 64.5 64.5

Weight

in kg 0.2 0.34 0.64 0.75

Mounting

On 35 mm mounting rail

To EN 60 715

Mounting position

any

Housing/color

Plastic housing, gray

Approvals

KNX to EN 50 090-1, -2 Certification

CE mark

in accordance with the EMC guideline and

low voltage guideline

1)

Further information concerning electrical endurance to IEC 60 947-4-1 can be found at: AC1, AC3, AX, C-load specifications, p. 43

2)

The maximum inrush current peak may not be exceeded.

3)

The specifications apply only after the bus voltage has been applied to the device for at least 30 seconds. Typical relay delay is approx. 20 ms.

Page 28

ABB i-bus KNX

Device technology

SA/S | 2CDC 505 056 D0208 31

2.5.2 Lamp output load 16/20 A

Lamps

Incande s cent lamp load 3,680 W

Fluorescent lamps T5/T8

Uncorrected

Parallel compensated

DUO circuit

3,680 W

2,500 W

3,680 W

Low-voltage halogen lamps

Inductive transformer

Electronic transfor mer

Halogen lamps 230 V

2,000 W

2,500 W

3,680 W

Dulux lamp

Uncorrected

Parallel compensated

3,680 W

3,000 W

Mercury-vapor lamp

Uncorrected

Parallel compensated

3,680 W

3,680 W

Switching capacity (switchi ng conta c t )

Maximum peak inrush current I

p

(150 µs)

Maximum peak inrush current I

p

(250 µs)

Maximum peak inrush current I

p

(600 µs)

600 A

480 A

300 A

Number of electronic ballasts (T5/T8, single

element)1)

18 W (ABB EVG 1 x 18 SF)

24 W (ABB EVG-T5 1 x 24 CY)

36 W (ABB EVG 1 x 36 CF)

58 W (ABB EVG 1 x 58 CF)

80 W (Helvar EL 1 x 80 SC)

26

2)

26

2)

22

12

2)

102)

1)

For multiple element lamps or other types, the number of electronic ballas ts mu s t be deter mined usi ng the peak inrush current of the electronic

ballasts, see

Ballast calculation, p. 42.

2)

The number of ballasts is limited by protection with B16 circuit-breakers.

Device type

Application program

Maximum number of

communication objects

Maximum number of

group addresses

Maximum number of

associations

SA/S 2.16.5.1 Switch 2f 16C/…* 34 254 254

SA/S 4.16.5.1

Switch 4f 16C/…*

64

254

254

SA/S 8.16.5.1

Switch 8f 16C/…*

124

254

254

SA/S 12.16.5.1 Switch 12f 16C/…* 184 254 254

* … = current version number of the application program

Please note

ETS and the current version of the device application program are required for programming.

The current application program is available for download at www.abb.com/knx. After import into ETS,

it is available in ETS under ABB/Output/Binary output xf 16C/…* (x = 2, 4, 8 or 12).

The device does not support the locking function of a KNX device in ETS. If you inhibit access to all of

the project devices by using a BCU code, it has no effect on this device.

Data can still be read and programmed.

Page 29

ABB i-bus KNX

Device technology

32 2CDC 505 056 D0208 | SA/S

2CDC 072 177 F0009

2.5.3 Connection schematic SA/S 12.16.5.1

1 Label carrier

2 Programming button

3 Programming LED

4 Bus connection terminal

5 Contact position display and manual operation

6 Load current circuits, for every 2 connection terminals

Danger

Touch voltages.

Danger of injury.

Observe all-pole disconnection.

Page 30

ABB i-bus KNX

Device technology

SA/S | 2CDC 505 056 D0208 33

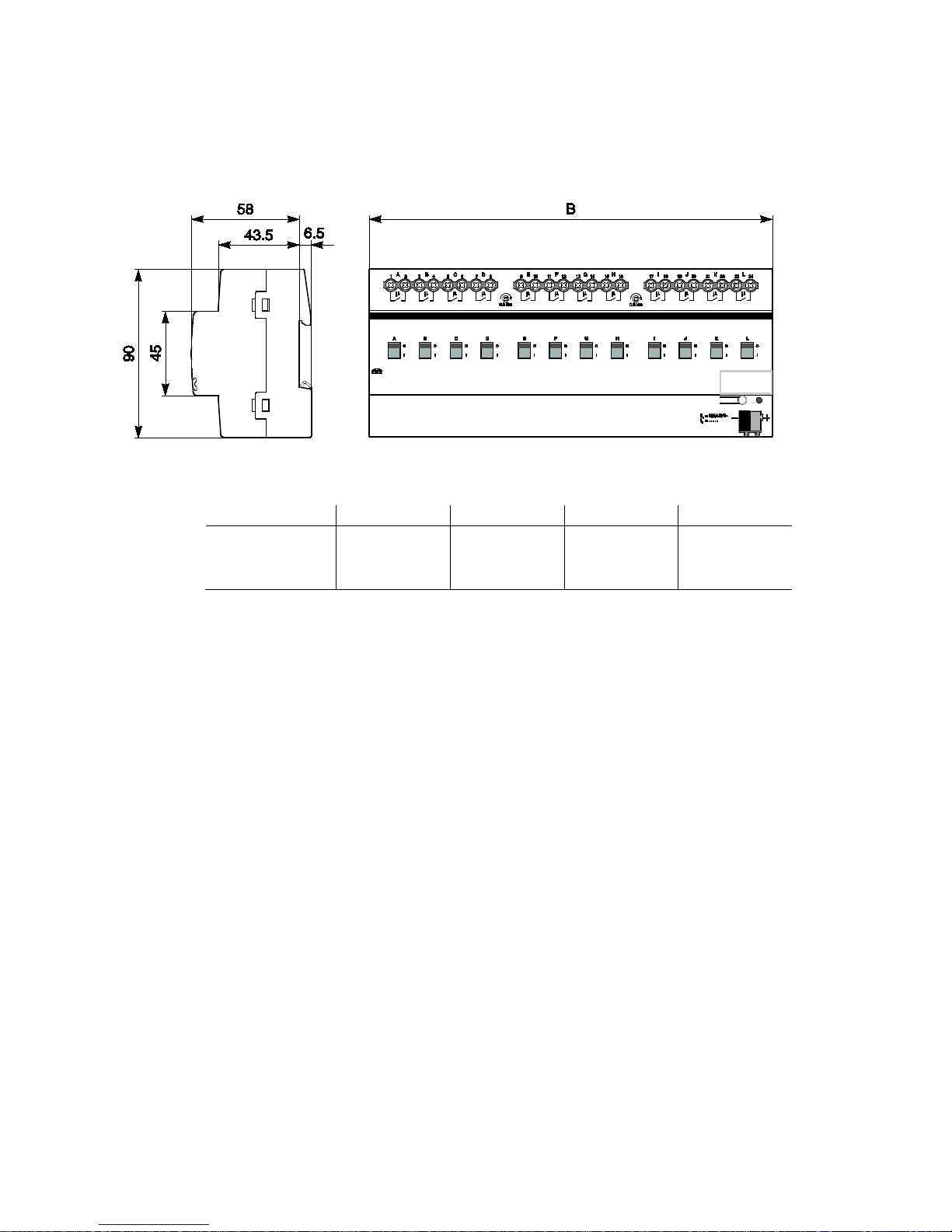

2.5.4 Dimension drawing SA/S 12.16.5.1

SA/S 2.16.5.1 SA/S 4.16.5.1 SA/S 8.16.5.1 SA/S 12.16.5.1

Width W

Mounting width

(18 mm modules)

36 mm

2 units

72 mm

4 units

144 mm

8 units

216 mm

12 units

2CDC 072 019 F0013

Page 31

ABB i-bus KNX

Device technology

34 2CDC 505 056 D0208 | SA/S

2.6 Switch Actuators SA/S x.16.6.1, 16/20 A, MDRC

SA/S

8.16.6.1

Switch Actuators SA/S

x.16.6.1, 16/20 A

are modular installation devices in Pro

M

design for installation in the distribution

board. They a

re especially suitable for

switching loads with high peak inrush

currents such as lighting equipment with

compensation capacitors or fluores cent

lamp loads (AX) to EN

60 669.

The Switch Actuators feature one load

current detection per output.

The maximum l

oad current per output is

20 A.

The Switch Actuator can be actuated

manually using a button. This

simultaneously indicates the contact

position.

The Switch Actuators can switch up to

12 independent electrical loads via

floating contacts. The maximum load

current per output is 20 A. The

connection of the outputs is implemented

using combo-

head screw terminals. Each

output is controlled separately via KNX.

Individual outputs on SA/S x.16.6.1

devices can be copied or exchanged to

minimize programming work.

The device does not require an

additional power supply and is ready for

immediate use, after the bus voltage has

been applied.

The Switch Actuators are parameterized

via ETS. Connection to KNX is

implemented using the bus connection

terminal on the front.

2.6.1 Technical data

Supply

KNX bus voltage 21…31 V DC

Current consumption via bus

< 12 mA

Power consumption via bus

Maximum 250 mW

Rated output value

SA/S type 2.16.6.1 4.16.6.1 8.16.6.1 12.16.6.1

C

urrent detection yes yes yes yes

N

umber (floating contacts 2/group) 2 4 8 12

U

n

rated voltage 250/440 V AC (50/60 Hz)

I

n

rated current 16/20 AX, C-load

L

eakage loss per device at max. load 16 A 2.0 W 4.0 W 8.0 W 12.0 W

Leakage loss per device at max. load 20 A

3.0 W 5.5 W 11.0 W 16.0 W

Output switching current

AC3

1)

operation (cos ϕ = 0.45)

To EN 60 947-4-1

16 A/230 V AC

AC1

1)

operation (cos ϕ = 0.8)

To EN 60 947-4-1

16/20 A/230 V AC

Fluorescent lighting load to EN 60 669-1 16/20 AX/250 V AC (200 µF)2)

Minimum switching ca p acity 100 mA/12 V AC

100 mA/24 V AC

DC current switching capacity (resistive load) 20 A/24 V DC

2CDC 071 006 S0010

Page 32

ABB i-bus KNX

Device technology

SA/S | 2CDC 505 056 D0208 35

Output service life

Mechanica l service life

> 106

Electrical endurance

To IEC 60 947-4-1

AC11) (240 V/cos ϕ = 0.8)

> 105

AC31) (240 V/cos ϕ = 0.45)

> 3 x 104

AC5a1) (240 V/cos ϕ = 0.45)

> 3 x 104

Current detection (load current )

Detection range (sine effective value)

0.02…20 A

Accuracy +/- 2 % of actual current value (sine) and

+/- 20 mA

Frequency 50/60 Hz

2 byte representation (figure value, DTP 7.012)

or 4 byte representation (floating value, DTP

14.019)

in mA

M

easurement speed:

– Low-pass filter transient response with τ

– Scanning frequency of the current value

3

00 ms

320 ms

Output switching times3)

Maximum r elay position chan ges

per output per minute if all

relays are switched simultaneously.

The position changes should be distributed

equally within the minute.

2.16.6.1 4.16.6.1 8.16.6.1 12.16.6.1

30 15 7 5

Maximum r elay position chan ges

per output per minute if only

one relay is switched.

60 60 60 60

Connections

KNX Via bus connection terminals,

0.8 mm Ø, solid

Load circuits Universal head screw terminal (PZ 1)

0.2… 4 mm

2

fine stranded, 2 x 0.2…2.5 mm2

0.2… 6 mm

2

solid, 2 x 0.2…4 mm2

F

errules without/with plastic sleeves

0.25…2.5/4 mm

2

T

WIN ferrules

0.5…2.5 mm

2

Contact pin length min. 10 mm

Operating and display elements

Programming button/LED For assignment of the physical address

Contact position display Relay operator

Degree of protection

IP 20 To EN 60 529

Protection class

II To EN 61 140

Isolation category

Overvoltage category

III to EN 60 664-1

Pollution degree

2 to EN 60 664-1

KNX safety extra low voltage

SELV 24 V DC

Temperature range

Operation

Storage

Transport

- 5 °C…+45 °C

-25 °C…+55 °C

-25 °C…+70 °C

Page 33

ABB i-bus KNX

Device technology

36 2CDC 505 056 D0208 | SA/S

Ambient conditions

Maximum a ir humidity

95 %, no condensation allowed

Design

Modular installation device (MDRC) Modular installation device, ProM

SA/S type 2.16.6.1 4.16.6.1 8.16.6.1 12.16.6.1

D

imensions 90 x W x 64.5 mm (H x W x D)

W

idth W in mm 36 72 144 216

M

ounting width in units (18 mm modules) 2 4 8 12

M

ounting depth in mm 64.5 64.5 64.5 64.5

Weight

in kg

0.2 0.34 0.64 0.83

Mounting

On 35 mm mounting rail

To EN 60 715

Mounting position

As required

Housing/color

Plastic housing, gray

Approvals

KNX to EN 50 090-1, -2 Certification

CE mark

in accordance with the EMC guideline and

low voltage guideline

1)

Further information concerning electrical endurance to IEC 60 947-4-1 can be found at:AC1, AC3, AX, C-load specifications, p. 43

2)

The maximum inrush current peak may not be exceeded.

3)

The specifications apply only after the bus voltage has been applied to the device for at least 30 seconds. Typical relay delay is approx. 20 ms.

2.6.2 Lamp output load 16/20 A

Lamps

Incande s cent lamp load 3,680 W

Fluorescent lamps T5/T8

Uncorrected

Parallel compensated

DUO circuit

3,680 W

2,500 W

3,680 W

Low-voltage halogen lamps

Inductive transform e r

Electronic transfor mer

Halogen lamps 230 V

2,000 W

2,500 W

3,680 W

Dulux lamp

Uncorrected

Parallel compensated

3,680 W

3,000 W

Mercury-vapor lamp

Uncorrected

Parallel compensated

3,680 W

3,680 W

Switching capacity (switchi ng conta c t )

Maximum peak inrush current Ip (150 µs)

Maximum peak inrush current I

p

(250 µs)

Maximum peak inrush current I

p

(600 µs)

600 A

480 A

300 A

Number of electronic ballasts (T5/T8, single

element)1)

18 W (ABB EVG 1 x 18 SF)

24 W (ABB EVG-T5 1 x 24 CY)

36 W (ABB EVG 1 x 36 CF)

58 W (ABB EVG 1 x 58 CF)

80 W (Helvar EL 1 x 80 SC)

26

2)

26

2)

22

12

2)

102)

1)

For multiple element lamps or other types, the number of electronic ballas ts mu s t be deter mined usi ng the peak inrush current of the electronic

ballasts, see Ballast calculation, p. 42

.

2)

The number of ballasts is limited by protection with B16 circuit-breakers.

Page 34

ABB i-bus KNX

Device technology

SA/S | 2CDC 505 056 D0208 37

Device type

Application program

Maximum number of

communication objects

Maximum number of

group addresses

Maximum number of

associations

SA/S 2.16.6.1 Switch 2f 16CS/…* 40 254 254

SA/S 4.16.6.1

Switch 4f 16CS/…*

76

254

254

SA/S 8.16.6.1

Switch 8f 16CS/…*

148

254

254

SA/S 12.16.6.1 Switch 12f 16CS/…* 220 254 254

* … = current version number of the application program

Please note

ETS and the current version of the device application program are required for programming.

The current application program is available for download at www.abb.com/knx. After import into ETS

it can be found under ABB/O u t put/B in ary outp ut xf 16CS/…* (x = 2, 4, 8 or 12).

The device does not support the locking function of a KNX device in ETS. If you inhibit access to all of

the project devices by using a BCU code, it has no effect on this device.

Data can still be read and programmed.

Important

The Switch Actuator types SA/S x.16.6.1 differentiate from the predecessor types SA/S x.16.5S by new

hardware and software.

While there have been few changes to the functions of the software, the hardware has been redesigned

for load currents up to 20 A. Furthermore, the current detection has been optimized and its accuracy

has been enhanced by a factor of four.

Existing projects can be converted to ensure operation with the new hardware / software.

For further information see: Conversion of previous application program versions, p. 53.

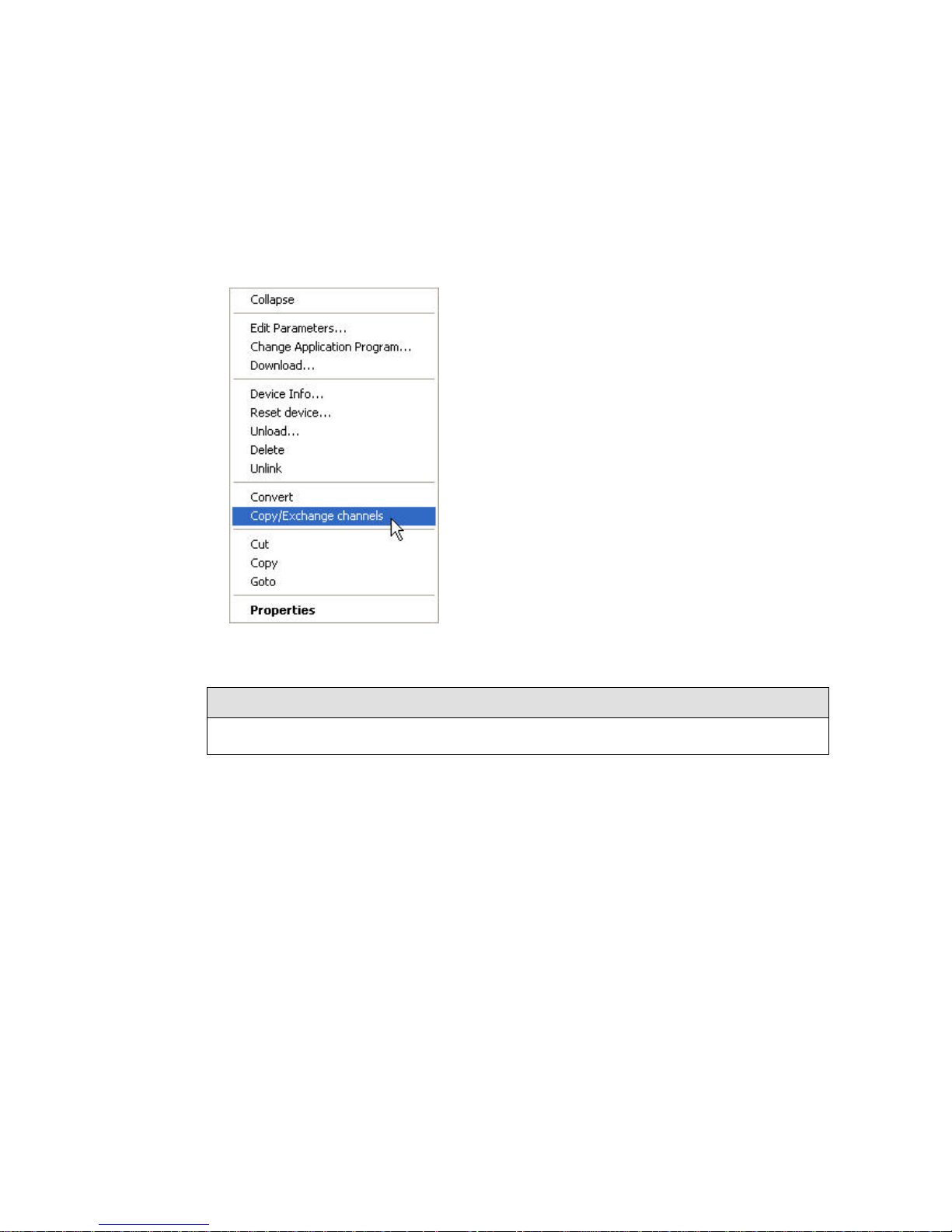

For faster and simpler commissioning, it is also possible to copy the parameter settings of the outputs to

others or to exchange them with another output.

For further information see: Copying and e x c hangi ng par amet er set ti ngs , p. 57.

Page 35

ABB i-bus KNX

Device technology

38 2CDC 505 056 D0208 | SA/S

Please note

Only load currents with a sine wave characteristic can be detected correctly. On other signal types, e.g.

phase angle or inverse phase angle control signals, the detected current value is distorted. In this case,

the measured value is meaningless.

Current values less than 20 mA are indicated as a 0 mA value via KNX. For small load currents that are

just above the minimum detection threshold of 20 mA, it is possible that a value of 0 mA is displayed due

to the inaccuracies, even though a current is flowing.

Example

A current of 25 mA is flowing. The Switch Actuator detects 5 mA due to the tolerances. This value is less

than the minimum current detection limit of 20 mA and is thus sent as a 0 mA value via KNX.

Important

The current detection and mon itoring function should not be used for safety-related applications. The

Switch Actuator cannot assume the function of a circuit-breaker or RCD (earth-leakage circuit breaker).

If the load current detection is used for equipment fault dete c tion that only causes a slight change of

under 30 mA, mains voltage and current fluctuations due to ambient influences, e.g. temperature,

natural ageing of the device or a non-sinusoidal current, play a significant role. Even when the current

changes are detected by the Switch Actuator, the detected current changes do not necessarily mean

that a device has malfunctioned.

Page 36

ABB i-bus KNX

Device technology

SA/S | 2CDC 505 056 D0208 39

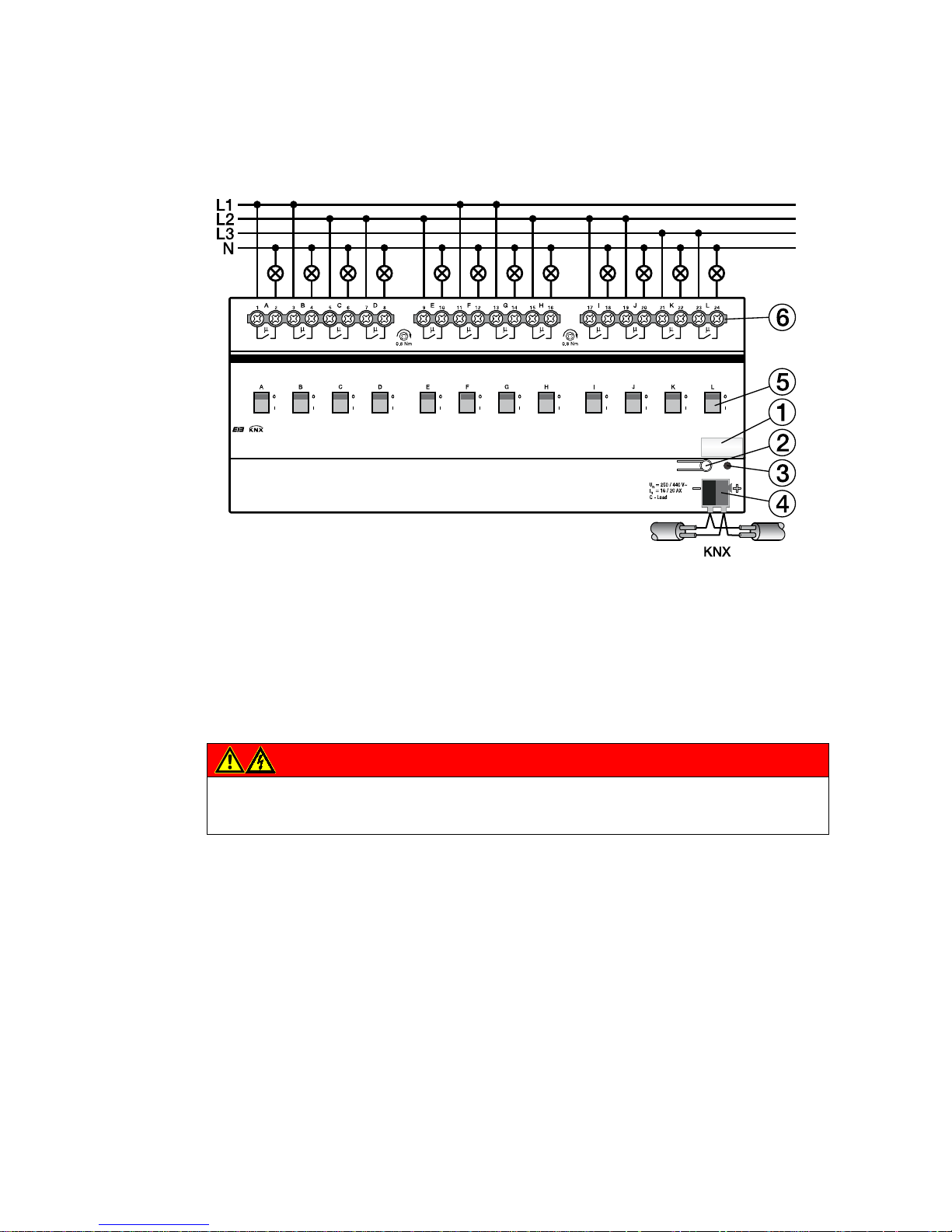

2.6.3 Connection schematic SA/S x.16.6.1

1 Label carrier

2 Programming button

3 Programming LED

4 Bus connection terminal

5 Contact position display and manual operation

6 Load current circuits, for every 2 connection terminals

Danger

Touch voltages.

Danger of injury.

Observe all-pole disconnection.

2CDC 072 177 F0009

Page 37

ABB i-bus KNX

Device technology

40 2CDC 505 056 D0208 | SA/S

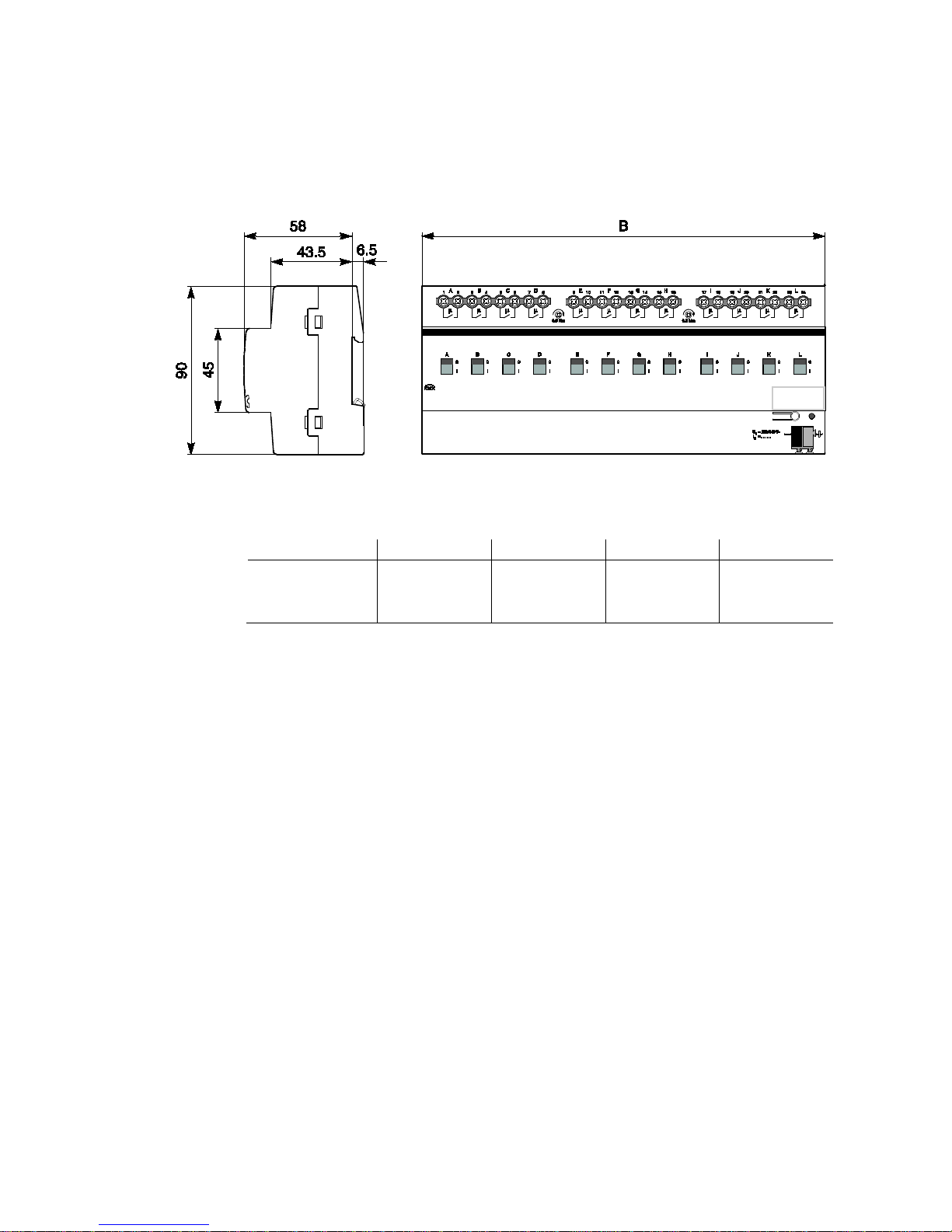

2.6.4 Dimension drawing SA/S x.16.6.1

SA/S 2.16.6.1

SA/S 4.16.6.1

SA/S 8.16.6.1

SA/S 12.16.6.1

Width W

Mounting width

(18 mm modules)

36 mm

2 units

72 mm

4 units

144 mm

8 units

216 mm

12 units

2CDC 072 019 F0013

Page 38

ABB i-bus KNX

Device technology

SA/S | 2CDC 505 056 D0208 41

2.7 Overview of switching performance

The following table shows the switching capacities, lamp loads and/or the number of lamps that can be

connected to each contact.

SA/S 4.6.1.1

SA/S 8.6.1.1

SA/S 12.6.1.1

SA/S 2.6.2.1

SA/S 4.6.2.1

SA/S 8.6.2.1

SA/S 12.6.2.1

SA/S 2.10.2.1

SA/S 4.10.2.1

SA/S 8.10.2.1

SA/S 12.10.2.1

SA/S 2.16.2.1

SA/S 4.16.2.1

SA/S 8.16.2.1

SA/S 12.16.2.1

SA/S 2.16.5.1

SA/S 4.16.5.1

SA/S 8.16.5.1

SA/S 12.16.5.1

SA/S 2.16.6.1

SA/S 4.16.6.1

SA/S 8.16.6.1

SA/S 12.16.6.1

In rated current ( A)

6 A 6 AX 10 AX 16 A

16/20 AX Cload

16/20 AX Cload

Un rated voltage (V)

250/440 V AC

250/440 V AC

250/440 V AC

250/440 V AC

250/440 V AC

250/440 V AC

AC1 operation (cos ϕ = 0.8) EN 60 947-4-1

6 A 6 A 10 A 16 A 20 A 20 A

AC3 operation (cos ϕ = 0.45) EN 60 947-4-1

6 A 6 A 8 A –4) 16 A 16 A

C-load switching capacity

– – – – 20 A 20 A

Fluorescent lighting load AX to EN 60 669-1

6 A (35

µF)3)

6 AX (140 µF)

3)

10 AX (140 µF)

3)

16 A (70 µF)

3)

20 AX (200 µF)

3)

20 AX (200 µF)

3)

Minimum switc hi ng capacity

10 mA/12 V

100 mA/12 V

100 mA/12 V

100 mA/12 V

100 mA/12 V

100 mA/12 V

DC current switching capacity

(ohmic load)

7 A/24 V = 6 A/24 V = 10 A/24 V = 16 A/24 V = 20 A/24 V = 20 A/24 V =

Mechanical lifetime

> 107 > 3 x 106 > 3 x 106 > 3 x 106 > 106 > 106

Electrical endurance to

IEC 60947-4-1:

– Rated current AC1 (240V/ 0.8)

– Rated current AC3 (240V/ 0.45)

– Rated current AC5a (240V/ 0. 4 5)

100,000

15,000

15,000

100,000

30,000

30,000

100,000

30,000

30,000

100,000

30,000

30,000

100,000

30,000

30,000

100,000

30,000

30,000

Incandescent lamp load at 230 V AC

1,200 W 1,380 W 2,500 W 2,500 W 3,680 W 3,680 W

Fluorescent lamps T5/T8:

– Uncompensated

– Parallel compensat ed

– DUO circuit

800 W

300 W

350 W

1,380 W

1,380 W

1,380 W

2,500 W

1,500 W

1,500 W

2,500 W

1,500 W

1,500 W

3,680 W

2,500 W

3,680 W

3,680 W

2,500 W

3,680 W

Low-voltage halogen lamps

– inductive transformer

– electronic transform er

800 W

1,000 W

1,200 W

1,380 W

1,200 W

1,500 W

1,200 W

1,500 W

2,000 W

2,500 W

2,000 W

2,500 W

Halogen lamps 230 V

1,000 W 1,380 W 2,500 W 2,500 W 3,680 W 3,680 W

Dulux lamps (energy-saving lamps):

– Uncompensated

– Parallel compensat ed

800 W

800 W

1,100 W

1,100 W

1,100 W

1,100 W

1,100 W

1,100 W

3,680 W

3,000 W

3,680 W

3,000 W

Mercury-vapor lamps:

– Uncompensated

– Parallel compensat ed

1,000 W

800 W

1,380 W

1,380 W

2,000 W

2,000 W

2,000 W

2,000 W

3,680 W

3,000 W

3,680 W

3,000 W

Sodium vapor lamps:

– Uncompensated

– Parallel compensat ed

1,000 W

800 W

1,380 W

1,380 W

2,000 W

2,000 W

2,000 W

2,000 W

3,680 W

3,000 W

3,680 W

3,000 W

Max. peak inrush current Ip (150 µs)

Max. peak inrush current Ip (250 µs)

Max. peak inrush current Ip (600 µs)

200 A

160 A

100 A

400 A

320 A

200 A

400 A

320 A

200 A

400 A

320 A

200 A

600 A

480 A

300 A

600 A

480 A

300 A

Number of electronic ballasts

(T5/T8, single element):

2)

18 W (ABB EVG 1 x 18 CF)

24 W (ABB EVG 1 x 24 CY)

36 W (ABB EVG 1 x 36 CF)

58 W (ABB EVG 1 x 58 CF)

80 W (Helvar EL 1 x 80 SC)

10 EBUs

10 EBUs

7 EBUs

5 EBUs

3 EBUs

23 EBUs

23 EBUs

14 EBUs

11 EBUs

10 EBUs

23 EBUs

23 EBUs

14 EBUs

11 EBUs

10 EBUs

23 EBUs

23 EBUs

14 EBUs

11 EBUs

10 EBUs

26

1)

EBUs

26

1)

EBUs

22 EBUs

12

1)

EBUs

12

1)

EBUs

26

1)

EBUs

26

1)

EBUs

22 EBUs

12

1)

EBUs

12

1)

EBUs

1)

The number of ballasts (EBUs) is limited by protection with B16/20 A circuit-breakers.

2)

For multiple element lamps or other types the number of electronic ballasts must be determined using the peak inrush current of the ballasts.

3)

The maximum inrush current peak may not be exceeded.

4)

Not intended for AC3 operation; maximum AC3 current see Technical data, from p. 9.

Page 39

ABB i-bus KNX

Device technology

42 2CDC 505 056 D0208 | SA/S

2.8 Ballast calculation

The electronic ballast is a device for operating gas discharge lamps, e.g. fluorescent lamps. During normal

operation, it converts the mains voltage to an optimum operating voltage for gas discharge lamps. It also

enables them to ignite (start) via capacitor circuitry.

With the original choke/starter circuitry the lamps switch on consecutively, with the electronic ballast all

fluorescent lamps switch on practically simultaneously. If switch-on occurs at the mains voltage peak, the

buffer capacitors of the electronic ballast cause a high but very short current pulse. When using several

ballasts on the same circuit, the simultaneous charging of the capacitors may result in very large system

inrush currents.

This peak inrush current I

p

is to be considered when designing the switch contacts as well as when

selecting the respective circuit protection. The effects of the electronic ballast peak inrush current and the

associated limitation of the number of electronic ballasts on the SA/S are examined below.

The inrush current of the electronic ballast depends not only on the wattage but also on the type,

the number of elements (lamps) and on the manufacturer. For this reason, the given maximum number

of connectible electronic ballasts per output can only relate to a defined type of electronic ballast.

For a different ballast type, this value can only represent an estimation.

In order to properly estimate the number of electronic ballasts, the peak inrush current I

p

and the

associated pulse width of the electronic ballast must be known. In the meantime, these values are stated

by manufacturers in the technical data or are available on request.

Typical values for single element electronic ballasts with T5/T8 lamps are:

Peak inrush current 15…50 A with a pulse time of 120…200 µs.

The Switch Actuator relays have the following maximum starting values:

SA/S 4.6.1.1

SA/S 8.6.1.1

SA/S 12.6.1.1

SA/S 2.6.2.1

SA/S 4.6.2.1

SA/S 8.6.2.1

SA/S 12.6.2.1

SA/S 2.10.2.1

SA/S 4.10.2.1

SA/S 8.10.2.1

SA/S 12.10.2.1

SA/S 2.16.2.1

SA/S 4.16.2.1

SA/S 8.16.2.1

SA/S 12.16.2.1

SA/S 2.16.5.1

SA/S 4.16.5.1

SA/S 8.16.5.1

SA/S 12.16.5.1

SA/S 2.16.6.1

SA/S 4.16.6.1

SA/S 8.16.6.1

SA/S 12.16.6.1

Max. peak inrush current Ip (150 µs)

Max. peak inrush current Ip (250 µs)

Max. peak inrush current Ip (600 µs)

200 A

160 A

100 A

400 A

320 A

200 A

400 A

320 A

200 A

400 A

320 A

200 A

600 A

480 A

300 A

600 A

480 A

300 A

*) x = 5 or 6, C-load types with and without load current detection

Caution

Do not exceed the threshold values.

Exceeding the value leads to destruction of the relay, e.g. due to welding.

Page 40

ABB i-bus KNX

Device technology

SA/S | 2CDC 505 056 D0208 43

Example

ABB i-bus® ballast 1 x 58 CF

Peak inrush current Ip = 33.9 A (147.1 µs)

For Switch Actuator SA/S 4.16.6.1 this results in:

maximum number of electronic ballasts/output = 600 A/34 A = 17 electronic ballasts

This number has been limited to 12 electronic ballasts in conjunction with a B16 miniature circuit

breaker. If more electronic ballasts are connected, the miniature circuit breaker may trip dur ing sw it ch

on.

For Switch Actuator SA/S 4.6.1.1 this results in:

maximum number of electronic ballasts/output = 200 A/34 A = 5 electronic ballasts

2.9 AC1, AC3, AX, C-load specifications

In Intelligent Building Control, different switching capabilities and performance specifications, required by

special applications, have become established in industrial and residential systems. These performance

specifications are rooted in the respective national and international standards. The tests are defined to

simulate typical applications, e.g. motor loads (industrial) or fluorescent lamps (residential).

Specifications AC1 and AC3 are switching performance specifications which have become established in

the industrial field.

Typical application:

AC1 – Non-inductive or slightly inductive loads, resistance furnaces

(relates to switching of resistive loads, cos = 0.8)

AC3 – Squirrel-cage motors: starting or switching off during running

(relates to (inductive) motor load, cos = 0.45)

AC5a – Switching of electric discharge lamps

These switching performances are defined in standard EN 60 947-4-1 Cont act or s and motor-starters –

Electromechanical contactors and motor -starters.

The standard describes starters and/or contactors that were originally used primarily in ind ustrial

applications.

The designation AX has established itself in the field of building services technology.

AX relates to a (capacitive) fluorescent lighting load.

Switchable capacitive loads (200 µF, 140 µF, 70 µF or 35 µF) are referred to in conjunction with fluorescent

lamp loads.

This switching capacity refers to standard EN 60 669 Switches for household and simil ar fix ed electr ica l

installations – General requirements, which deals primarily with applications in building services

engineering. For 6 A devices, a test with 70 µF is required and for devices exceeding 6 A, a test with

140 µF.

Page 41

ABB i-bus KNX

Device technology

44 2CDC 505 056 D0208 | SA/S

The switching capacity specifications AC and AX are not directly comparable. However, the following

switching capacity capability can still be determined:

The lowest switching capacity corresponds with the specification

AC1 – mainly for ohmic loads.

The following switching capacity should be rated higher

AX – fluorescent lamp loads, under the standard: 70 µF (6 A), 140 µF (10 A, 16 A).

The highest switching capacity is designated by

AC3 – motor loads,

C-load – fluorescent lamp loads (200 µF).

Both specifications are almost equivalent. This means that a device which has met the test for AC3 under

EN 60 947 will most probably meet those under EN 60 669 with 200 µF.

In conclusion, generally speaking:

• Users or customers primarily involved with industrial applications will tend to refer to AC3 switching

capacities.

• Users involved with building or lighting technology will more often than not refer to an AX switching

capacity or C-load (200 µF loads).

The switching capacity differences must be considered when selecting a Switch Actuator.

2.10 Current detection specifications

The Switch Actuators with current detection are recognizable by a number 6 as the third number of the

type designation, e.g. SA/S 2.16.6.1.

This is a Switch Actuator with integrated load current detection.

Each output features its own current detection with evaluation electronics, which can be parameterized

separately.

For further information see: Parameter window A: Current Detection, p. 101

The current recognition detects sinusoidal load currents with a 45-60 Hz frequency range. Non-sinusoidal

currents, e.g. phase angle varied or distorted currents, cause a measurement error depending on the

curve type. If a DC current is superimposed, the measurement error is again considerably larger. Phase

angle varied currents are generated, for example, by a current rectifier.

The current detection principle in the Switch Actuator is based on the conversion of sinusoidal load

currents by a transformer. On the secondary side of the transformer, the transferred value is rectified and

smoothed by an RC element. The resulting value is multiplied with the fixed factor 1/√2, produc ing an RMS

value. The factor 1/√2 is derived from the crest factor Û/U

rms

= √2 for a sinusoidal curve type.

Page 42

ABB i-bus KNX

Device technology

SA/S | 2CDC 505 056 D0208 45

For a non-sinusoidal curve type, the resulting values can diverge significantly from the real RMS value.

This measurement method is used in most commercia lly available analog and digital multimeters that are

calibrated for sinusoidal curve types.

In this case, a true RMS meter or a “non-true RMS meter” are frequently referred to, e.g. METRAHit 13S.

Please note

With non-sinusoidal currents, there are considerable differences between a high-quality true RMS meter

and the displayed values of the SA/S. For this reason, comparative measurements should be taken

using a meter that is also calibrated for sinusoidal AC currents.

For technical reasons, only currents exceeding 20 mA can be displayed. Interference is suppressed by an

RC element, and the displayed value is stabilized. The RC element has a time constant τ of around

300 ms. The current values are scanned cyclically with a scanning frequency of 320 ms. Thus a change in

the current can be safely detected every 320 ms and sent via the bus if required. The near exact value is

displayed after 5 τ ≈ 1.5 s.

The following technical specifications apply for current detection:

Detection range: 0.02…20 A

Accuracy: +/- 2 % of actual current value +/- 20 mA

Time constant: 300 ms

Scanning rate: 320 ms

Load current I

Load

AC: 0…20 A, sinusoidal

Load current I

Load

DC: Is not detected

Frequency range: 45…65 Hz

Ambient temperature: -5 °C…+40 °C

Examples

Detected current value Max. inaccuracy

300 mA +/- 26 mA

2 A +/- 60 mA

16 A +/- 340 mA

20 A +/- 420 mA

For every output, the determined current values can be represented via a 2 or 4 byte value output object.

The currents are represented in mA as counter values (2 byte, DTP 7.012) or floating values (4 byte,

DTP 14.019).

Page 43

ABB i-bus KNX

Device technology

46 2CDC 505 056 D0208 | SA/S

It is possible to program two threshold values for each output. With an overshoot or undershoot of the

current threshold value a 1 bit telegram is sent via the bus. Thus for example, the failure of equipment can

be detected and displayed.

With relatively small current values (< 30 mA), natural deviations in the electrical system will be

immediately noticeable, e.g. natural ageing of the equipment, voltage fluctuations through differing load

levels during the day as well as distortions of the sinusoidal load current, e.g. through switching actions or

frequency inverters.

The ideal observation, i.e. where the current consumption of the equipment does not change with

temperature fluctuations, operating voltage deviations and ageing, should always be inspected in the

actual system. The changes of the ambient conditions in practice and the associated changes in current

consumption and the monitored equipment must be considered. As ambient influences cannot be

eliminated in practice, detection via a current thresh old model is only viable if a current change caused by

tolerances and ambient influences in normal operation is less than the current change caused by

equipment failure.

Recommended approach when monitoring loads that are close to the detection tolerances of the SA/S

current detection:

• Connect the complete circuit to the SA/S output.

• Close the circuit and operate loads in the typical operating range.

• In ETS, set the data point types of the communication object and start the ETS project group monitor

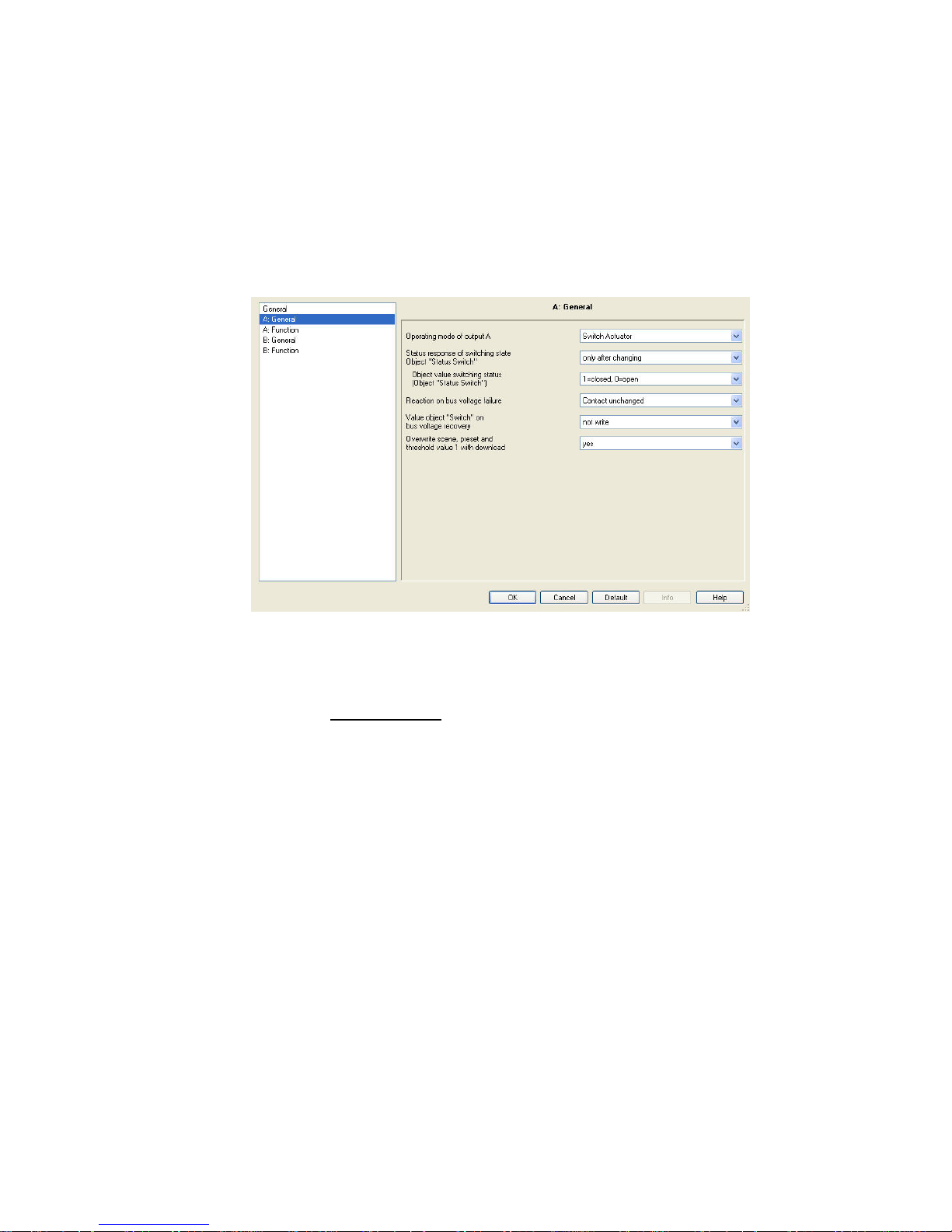

in order to display the current value.

• Observe current value I

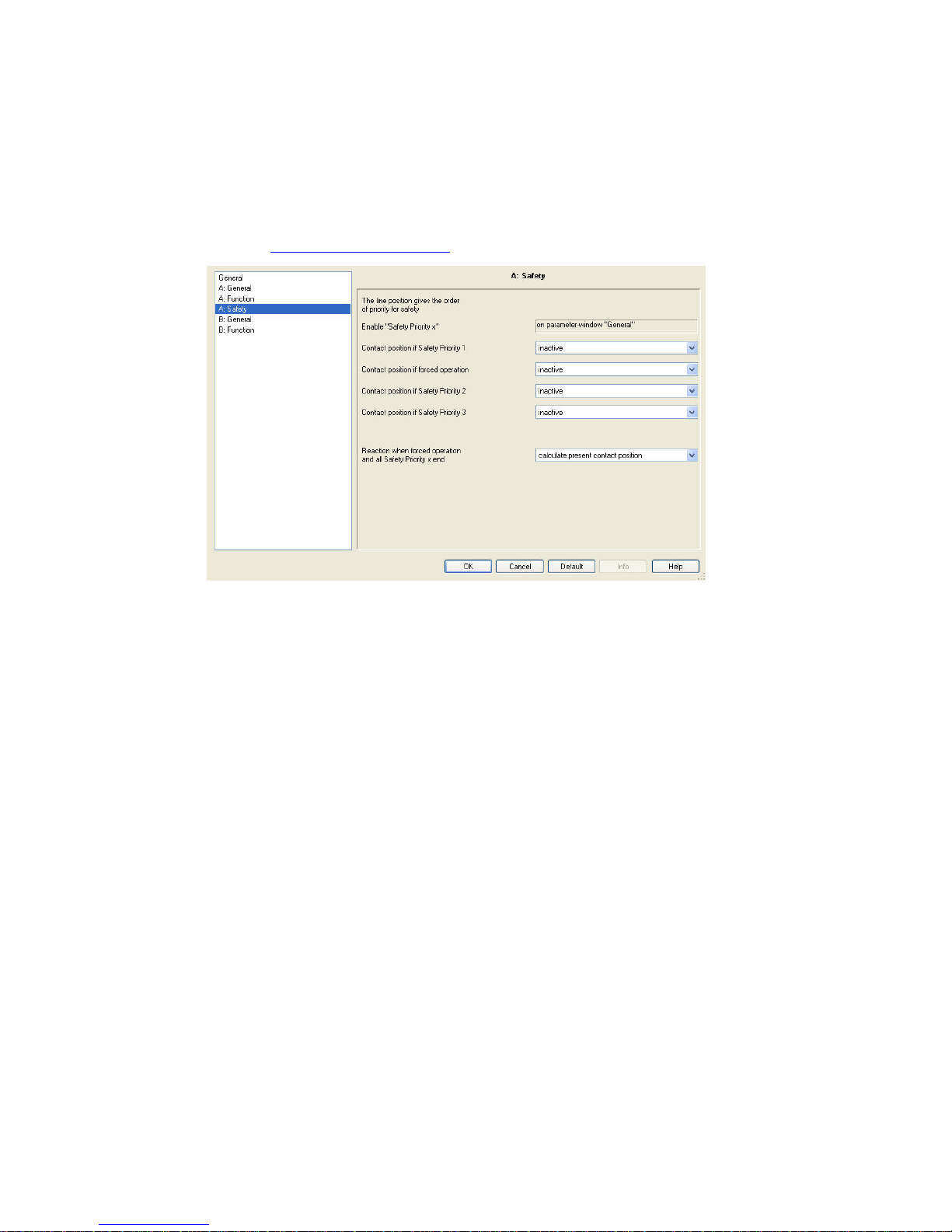

A