ABB HygienicMaster FEH631, ProcessMaster FEP631, HygienicMaster FEH632, HygienicMaster FET632, ProcessMaster FEP632 Operating Instruction

...Page 1

—

ABB MEASUREMENT & ANALYTICS | OPERATING INSTRUCTION

ProcessMaster FEP630, HygienicMaster FEH630

Electromagnetic flowmeter

Devices-Firmware version: 01.07.00

Measurement made easy

—

FEP630

FEH630

FET630

Introduction

Intelligent design and extended functions for

efficient system operation at reduced costs and with

higher profitability.

ProcessMaster FEP630

The first choice for demanding applications in the

processing industry.

HygienicMaster FEH630

The first choice for demanding applications in the

food industry.

Additional Information

Additional documentation on FEP630, FEH630 is

available for download free of charge at

www.abb.com/flow.

Alternatively simply scan this code:

Page 2

2 FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D

Table of contents

Change from one to two columns

1 Safety .......................................................................... 4

General information and instructions .................................. 4

Warnings .................................................................................... 4

Intended use ............................................................................. 5

Improper use ............................................................................. 5

Use in Potentially Explosive Atmospheres .......................... 5

Notes on data safety ............................................................... 5

Warranty provisions ................................................................. 6

Manufacturer’s address .......................................................... 6

6 Electrical connections .............................................29

Safety instructions ................................................................ 29

Use in Potentially Explosive Atmospheres ................... 29

Sensor grounding .................................................................. 29

General information on grounding ................................ 29

Metal pipe with fixed flanges ......................................... 30

Metal pipe with loose flanges ......................................... 30

Plastic pipes, non-metallic pipes or pipes with

insulating liner ................................................................... 30

Sensor type HygienicMaster ............................................ 31

2 Design and function .................................................. 7

Overview .................................................................................... 7

ProcessMaster ..................................................................... 7

HygienicMaster .................................................................... 8

Transmitter .......................................................................... 9

Model variants ........................................................................ 10

Measuring principle ............................................................... 11

3 Product identification ............................................ 12

Name plate .............................................................................. 12

Additional warning plate ...................................................... 12

4 Transport and storage ............................................ 13

Inspection ................................................................................ 13

Transport ................................................................................. 13

Storing the device .................................................................. 14

Temperature data .................................................................. 14

Returning devices ................................................................... 14

Grounding with conductive PTFE grounding plate ..... 31

Devices with extended diagnostic functions ............... 31

Installation and grounding in piping with cathodic

corrosion protection ......................................................... 31

Power supply .......................................................................... 33

Cable entries ........................................................................... 34

Connection via cable conduit ......................................... 34

Installing the connection cables ......................................... 34

Connection with IP rating IP 68 ........................................... 35

Pin assignment ....................................................................... 37

Electrical data for inputs and outputs .......................... 38

Connection examples ....................................................... 42

Connection to integral mount design ........................... 44

Connection to remote mount design ........................... 46

Digital communication ......................................................... 49

HART® communication .................................................... 49

Modbus® communication ............................................... 49

Cable specification ........................................................... 50

5 Installation ............................................................... 15

PROFIBUS DP® communication ...................................... 50

Safety instructions ................................................................. 15

Use in Potentially Explosive Atmospheres ................... 15

Installation conditions .......................................................... 15

General ................................................................................ 15

Devices with extended diagnostic functions ............... 15

Brackets .............................................................................. 16

Gaskets................................................................................ 16

Devices with a wafer-type design .................................. 16

Flow direction .................................................................... 16

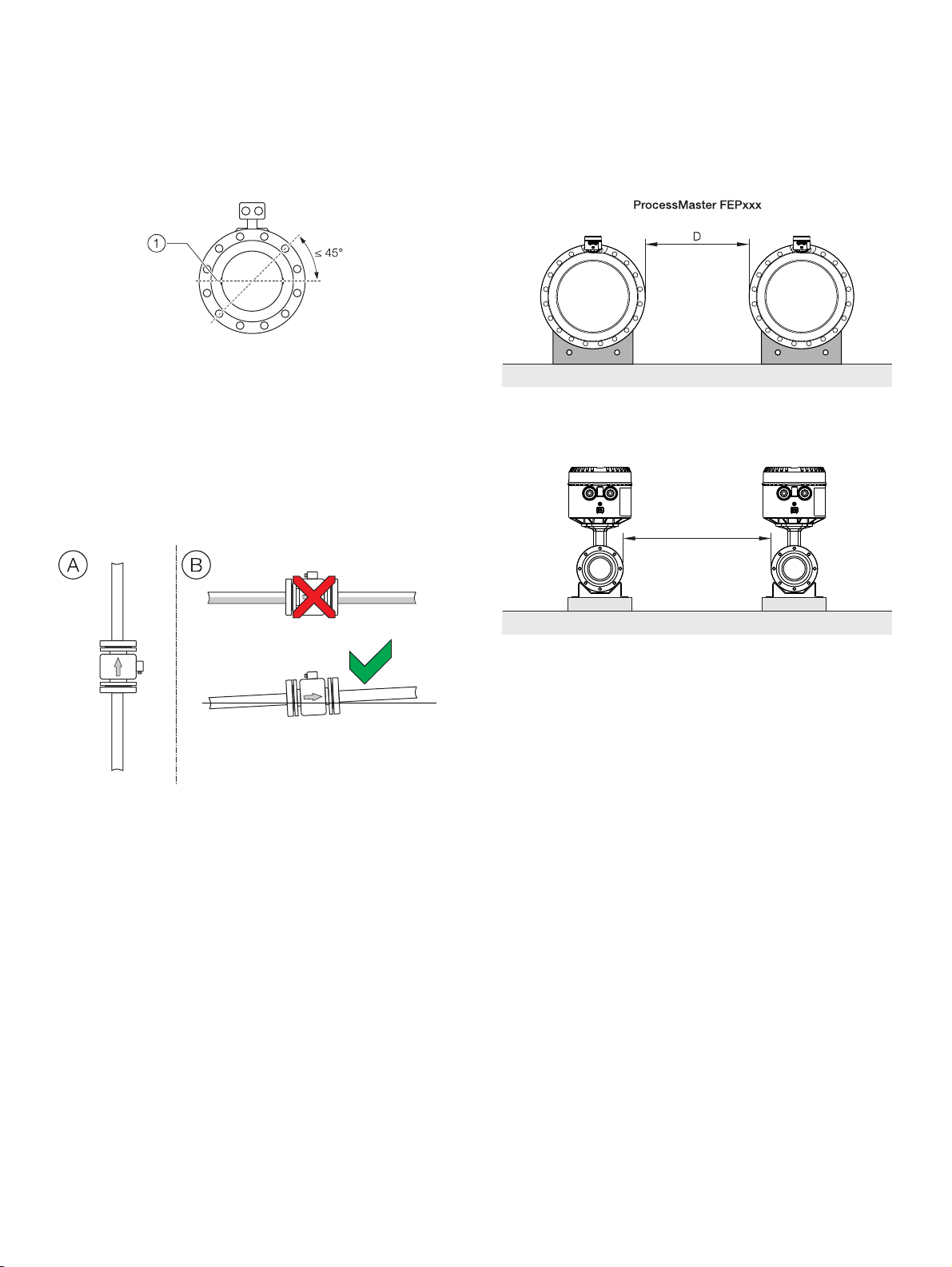

Electrode axis ..................................................................... 17

Mounting position............................................................. 17

Minimum spacing of the devices .................................... 17

Grounding ........................................................................... 18

Sensor insulation ............................................................... 18

Inlet and outlet sections .................................................. 18

Free inlet or outlet ............................................................. 19

Mounting with heavily contaminated measuring media

.............................................................................................. 19

7 Commissioning ........................................................ 52

Safety instructions ................................................................ 52

Use in Potentially Explosive Atmospheres ................... 52

Hardware settings ................................................................. 52

Dual- compartment housing ........................................... 52

Single-compartment housing ......................................... 53

Configuration of digital outputs V1 / V2 or V3 / V4 ... 53

Checks prior to commissioning .......................................... 54

Parameterization of the device ........................................... 54

Parameterization via the local operating interface .... 54

Parameterization via the infrared service port adapter

.............................................................................................. 55

Parameterization via HART® ........................................... 55

Factory settings ..................................................................... 56

Switching on the power supply ........................................... 56

Parameterization via the menu function Easy Setup ...... 56

Measuring range table .......................................................... 60

Mounting with pipe vibration ......................................... 19

Installation in piping with larger nominal diameter ... 20

Installation in 3A compliant installations ..................... 20

Installing the sensor .............................................................. 21

Installing the transmitter in the remote mount design .. 22

Opening and closing the housing ....................................... 23

Adjusting the transmitter position ..................................... 24

Installing the plug-in cards ................................................... 26

Page 3

FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D 3

8 Operation ................................................................. 61

Safety instructions ................................................................. 61

Menu navigation ..................................................................... 61

Menu levels .............................................................................. 62

Process display ....................................................................... 63

Switching to the information level ...................................... 63

Error messages on the LCD display .............................. 64

Switching to the configuration level

(parameterization) ................................................................ 64

Selecting and changing parameter .................................... 66

Entry from table................................................................ 66

Parameter overview .............................................................. 68

Parameter descriptions ........................................................ 78

Available units .................................................................... 78

Menu: Easy Setup .............................................................. 79

Menu: Device Info ............................................................. 80

Menu: Device Setup ........................................................... 82

Menu: Display ..................................................................... 87

Menu: Input/Output ........................................................ 88

Menu: Process Alarm ....................................................... 94

Menu: Communication ..................................................... 95

Menu: Diagnostics ............................................................. 97

Menu: Totalizer ................................................................ 104

Menu: Sensor Setup ........................................................ 107

Software history ................................................................... 107

Filling function ...................................................................... 108

Setup ................................................................................. 108

Brief overview of configurations ....................................... 108

9 Diagnosis / error messages ................................. 109

Calling up the error description ........................................ 109

Error messages ..................................................................... 110

Overview ................................................................................ 114

Extended diagnostic functions ......................................... 118

Overview ........................................................................... 118

Detection of partial filling .............................................. 118

Detection of gas bubbles............................................... 119

Monitoring the conductivity .......................................... 119

Monitoring the electrode impedance .......................... 120

Measurements on the flowmeter ................................. 120

Monitoring the grounding ............................................. 121

Verification ............................................................................ 121

Fingerprint database ...................................................... 121

11 Repair ...................................................................... 123

Safety instructions ............................................................... 123

Spare parts ........................................................................... 124

Replacing the fuse ............................................................... 124

Replacing the LCD indicator .............................................. 125

Replacing the frontend board ........................................... 126

Integral mount design ................................................... 126

Remote mount design ................................................... 128

Replacing the sensor ........................................................... 129

Returning devices ................................................................ 129

12 Recycling and disposal .......................................... 130

Dismounting ......................................................................... 130

Disposal ................................................................................. 130

13 Specification .......................................................... 131

Permitted pipe vibration ..................................................... 131

ProcessMaster – Temperature data .................................. 131

Maximum permissible cleaning temperature ............. 131

Maximum ambient temperature depending on

measuring medium temperature .................................. 132

ProcessMaster – Material load for process

connections .......................................................................... 136

Minimum permissible operating pressure ................. 136

Material load ..................................................................... 137

HygienicMaster - Temperature data ................................ 140

Maximum permissible cleaning temperature ............ 140

Maximum ambient temperature depending on

measuring medium temperature ................................. 140

HygienicMaster – Material load for process

connections ........................................................................... 141

14 Additional documents ........................................... 142

15 Appendix ................................................................. 143

Return form ........................................................................... 143

Torque information ............................................................. 144

Tightening torques for transducers with

design level ‘A’ ................................................................. 144

Tightening torques for transducers with

design level ‘B’ ................................................................. 149

Tightening torques for HygienicMaster with

variable process connections ........................................ 151

Parameterization overview (factory settings) ................ 151

10 Maintenance ........................................................... 122

Safety instructions ............................................................... 122

Sensor .................................................................................... 123

Gaskets.............................................................................. 123

Cleaning ............................................................................ 123

Page 4

4 FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D

‘

E

’

1 Safety

General information and instructions

These instructions are an important part of the product and

must be retained for future reference.

Installation, commissioning, and maintenance of the product

may only be performed by trained specialist personnel who have

been authorized by the plant operator accordingly. The specialist

personnel must have read and understood the manual and must

comply with its instructions.

For additional information or if specific problems occur that are

not discussed in these instructions, contact the manufacturer.

The content of these instructions is neither part of nor an

amendment to any previous or existing agreement, promise or

legal relationship.

Modifications and repairs to the product may only be performed

if expressly permitted by these instructions.

Information and symbols on the product must be observed.

These may not be removed and must be fully legible at all times.

The operating company must strictly observe the applicable

national regulations relating to the installation, function testing,

repair and maintenance of electrical products.

Warnings

The warnings in these instructions are structured as follows:

DANGER

The signal word ‘DANGER’ indicates an imminent danger.

Failure to observe this information will result in death or

severe injury.

WARNING

The signal word ‘WARNING’ indicates an imminent danger.

Failure to observe this information may result in death or

severe injury.

CAUTION

The signal word ‘CAUTION’ indicates an imminent danger.

Failure to observe this information may result in minor or

moderate injury.

NOTICE

The signal word

Note

‘Note’ indicates useful or important information about the

product.

NOTIC

indicates possible material damage.

Page 5

FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D 5

Intended use

This device is intended for the following uses:

• For the transmission of fluid, pulpy or pasty measuring

media with electrical conductivity.

• For volume flow measurement (in operating conditions).

• For mass flow measurement (based on a non-adjustable

density value).

The device has been designed for use exclusively within the

technical limit values indicated on the identification plate and in

the data sheets.

When using measuring media, the following points must be

observed:

• Wetted parts such as measuring electrodes, liner,

grounding electrodes, grounding plates or protection

plates must not be damaged by the chemical and physical

properties of the measuring medium during the

operating time.

• Measuring media with unknown properties or abrasive

measuring media may only be used if the operator is able

to perform regular and suitable tests to ensure the safe

condition of the device

• The indications on the name plate must be observed

• Before use of corrosive or abrasive measuring media, the

operator must clarify the level of resistance of wetted

parts.

ABB will gladly support you in the selection, but cannot

accept any liability in doing so.

Improper use

The following are considered to be instances of improper use of

the device:

• Operation as a flexible compensating adapter in piping,

for example for compensating pipe offsets, pipe

vibrations, pipe expansions, etc.

• For use as a climbing aid, for example for mounting

purposes.

• For use as a bracket for external loads, for example as a

support for piping, etc.

• Material application, for example by painting over the

housing, name plate or welding/soldering on parts.

• Material removal, for example by spot drilling the

housing.

Use in Potentially Explosive Atmospheres

Note

• An additional document with Ex safety instructions is

available for measuring systems that are used in potentially

explosive atmospheres.

• Ex safety instructions are an integral part of this manual. As

a result, it is crucial that the installation guidelines and

connection values it lists are also observed.

The icon on the name plate indicates

the following:

Notes on data safety

This product is designed to be connected to and to

communicate information and data via a network interface.

It is operator’s sole responsibility to provide and continuously

ensure a secure connection between the product and your

network or any other network (as the case may be).

Operator shall establish and maintain any appropriate measures

(such as but not limited to the installation of firewalls,

application of authentication measures, encryption of data,

installation of anti-virus programs, etc.) to protect the product,

the network, its system and the interface against any kind of

security breaches, unauthorized access, interference, intrusion,

leakage and / or theft of data or information.

ABB Automation Products GmbH and its affiliates are not liable

for damages and / or losses related to such security breaches,

any unauthorized access, interference, intrusion, leakage and /

or theft of data or information.

Page 6

6 FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D

… 1 Safety

Warranty provisions

Using the device in a manner that does not fall within the scope

of its intended use, disregarding this manual, using

underqualified personnel, or making unauthorized alterations

releases the manufacturer from liability for any resulting

damage. This renders the manufacturer's warranty null and void.

Manufacturer’s address

ABB Automation Products GmbH

Measurement & Analytics

Dransfelder Str. 2

37079 Goettingen

Germany

Tel: +49 551 905-0

Fax: +49 551 905-777

Email: vertrieb.messtechnik-produkte@de.abb.com

ABB Automation Products GmbH

Measurement & Analytics

Dransfelder Str. 2

37079 Goettingen

Germany

Tel: +49 551 905-0

Fax: +49 551 905-777

Email: vertrieb.messtechnik-produkte@de.abb.com

ABB Inc.

Measurement & Analytics

125 E. County Line Road

Warminster, PA 18974

USA

Tel: +1 215 674 6000

Fax: +1 215 674 7183

ABB Engineering (Shanghai) Ltd.

Measurement & Analytics

No. 4528, Kangxin Highway, Pudong New District

Shanghai, 201319,

P.R. China

Tel: +86(0) 21 6105 6666

Fax: +86(0) 21 6105 6677

Email: china.instrumentation@cn.abb.com

Customer service center

Tel: +49 180 5 222 580

Email: automation.service@de.abb.com

Change from two to one column

Page 7

FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D 7

2 Design and function

Overview

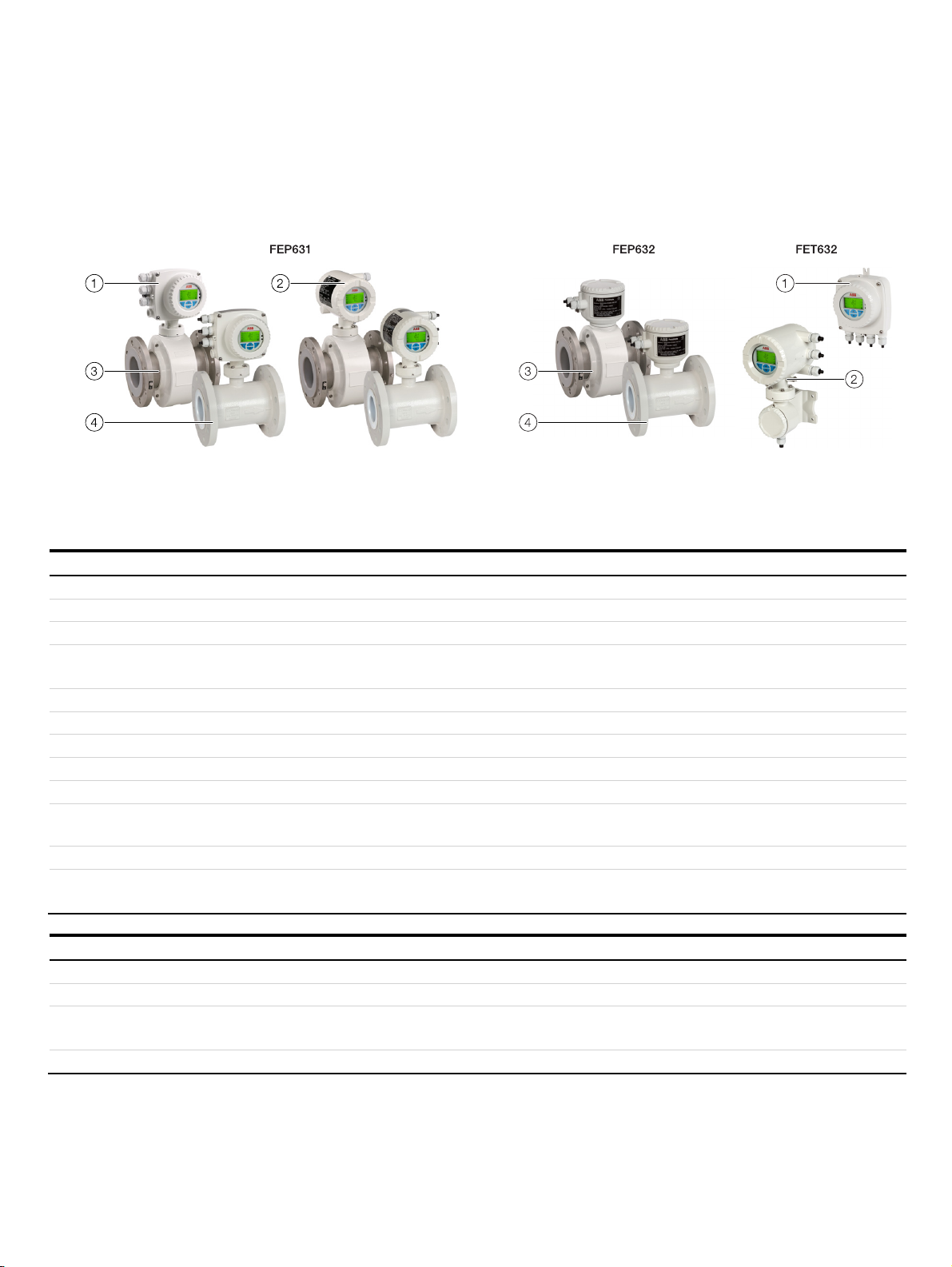

ProcessMaster

Integral mount design Remote mount design

1 Single-compartment transmitter housing

2 Dual-compartment transmitter housing

Figure 1: Designs

3 Flowmeter sensor, Design Level A (DN 3 to 2000)

4 Flowmeter sensor, Design Level B (DN 25 to 300)

Flowmeter sensor

Model ProcessMaster FEP631, FEP632, FET632

Housing Integral mount design, remote mount design

Measuring accuracy for liquids 0.4 % of the measured value, option for 0.3 % and 0.2 % of the measured value

Permissible measuring medium temperature

T

medium

Standard: −25 to 130 °C (−13 to 266 °F)

Option: −25 to 180 °C (−13 to 356 °F)

Minimum conductivity > 5 µS/cm, (20 µS/cm for demineralized water)

Nominal pressure rating PN 10 to 40; ASME CL 150, 300; JIS 5K, 10K, 20K

Nominal diameter DN 3 to 2000 (¹⁄₁₀ to 80 in)

Process connection Flange in accordance with DIN, ASME, JIS, AS2129 table D, E

Materials process connection Steel, cast iron, stainless steel

Lining material Hard rubber (DN 25 to 2000), soft rubber (DN 50 to 2000), PTFE (DN 10 to 600), PFA (DN 3 to 200),

ETFE (DN 25 to 600), Ceramic Carbide (DN 25 to 1000), Linatex® (DN 50 to 600)

Electrode material Stainless steel, Hastelloy B®, Hastelloy C®, platinum-iridium, tantalum, titanium, Double Layer, tungsten carbide

IP rating Integral mount design: IP 65 / IP 67, NEMA 4X

Remote mount design: IP 65 / IP 67 / IP 68 (sensor only), NEMA 4X

Approvals

Pressure Equipment Directive 2014/68/EU Conformity assessment in accordance with category III, fluid group 1

CRN (Canadian regulatory number) On request

Explosion protection (in preparation) ATEX / IECEx Zone 1, 2, 21, 22

Additional approvals At www.abb.com/flow or on request.

FM / cFM Cl 1 Div 1 (≤ DN 300), Cl 1 Div 2

Page 8

8 FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D

… 2 Design and function

… Overview

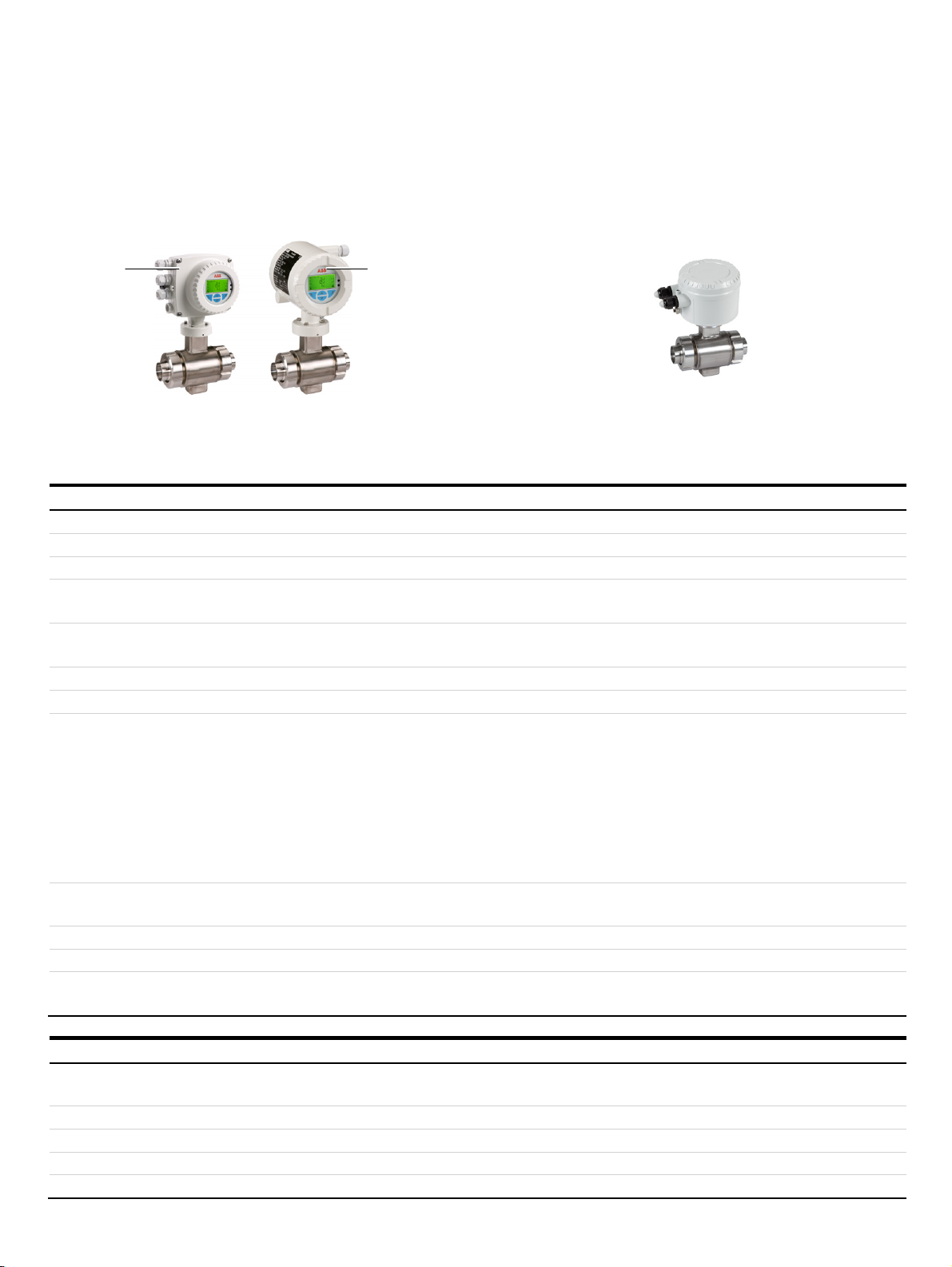

HygienicMaster

Integral mount design Remote mount design

FEH631 FEH632

1 2

G12161

1 Single-compartment transmitter housing

Figure 2: Designs (example, devices with variable process connections)

2 Dual-compartment transmitter housing

Flowmeter sensor

Model HygienicMaster FEH631, FEH632, FET632

Housing Integral mount design, remote mount design

Measuring accuracy for liquids 0.4 % of the measured value, option for 0.3 % and 0.2 % of the measured value

Permissible measuring medium

temperature T

medium

Standard: −25 to 130 °C (−13 to 266 °F), DN 1 to 2 limited to a maximum of 120 °C (248 °F)

Option: −25 to 180 °C (−13 to 356 °F), flange devices only

Minimum conductivity > 5 µS/cm, (> 20 µS/cm for demineralized water)

> 20 µS/cm for nominal diameter DN 1 to 2 (¹⁄₂₅ to ¹⁄₁₂in)

Nominal pressure PN 10 to 40, ASME CL 150, 300, JIS 10K

Nominal diameter DN 1 to 100 (¹⁄₂₅ to 4 in)

Process connection Wafer type design:

Flange in accordance with DIN, ASME or JIS

Screwed connections for the food industry in accordance

with DIN 11851:

Welded spuds:

Tri-clamp in accordance with DIN 32676

Tri-clamp in accordance with ASME BPE:

External thread in acc. with ISO 228 / DIN 2999

DN 3 to 100 (¹⁄₁₀ to 4 in)

DN 3 to 100 (¹⁄₁₀ to 4 in), PN 10 to 40

DN 3 to 100 (¹⁄₁₀ to 4 in), PN 10 to 40

DN 3 to 100 (¹⁄₁₀ to 4 in), PN 10 to 40

DN 3 to 100 (¹⁄₁₀ to 4 in), PN 10 to 16

DN 3 to 100 (¹⁄₁₀ to 4 in), PN 10

DN 3 to 25 (¹⁄₁₀ to 1 in), PN 16

Materials process connection Flange design: stainless steel, variable process connections: 1.4404;

devices with nominal diameter DN 1 to 2 (¹⁄₂₅ to ¹⁄₁₂ in): stainless steel 1.4571 (AISI 316 Ti), PVC, POM

Lining material PFA [vacuum-tight, from DN 3 (¹⁄₁₀ in)], PEEK [DN 1 to 2 (¹⁄₂₅ to ¹⁄₁₂ in)]

Electrode material Stainless steel 1.4571 (AISI 316Ti), 1.4539 [904L], Hastelloy B®, Hastelloy C®, platinum-iridium, tantalum, titanium

IP rating Integral mount design: IP 65 / IP 67, NEMA 4X

Remote mount design: IP 65 / IP 67 / IP 68 (sensor only), NEMA 4X

Approvals

Pressure Equipment Directive

2014/68/EU

CRN (Canadian regulatory number) On request

Hygiene design approvals 3A, FDA-approved materials

Explosion protection (in preparation) ATEX / IECEx Zone 1, 2, 21, 22; FM / cFM Cl 1 Div. 1, Cl 1 Div. 2

Additional approvals At www.abb.com/flow or on request.

Conformity assessment in accordance with category III, fluid group 1

Page 9

FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D 9

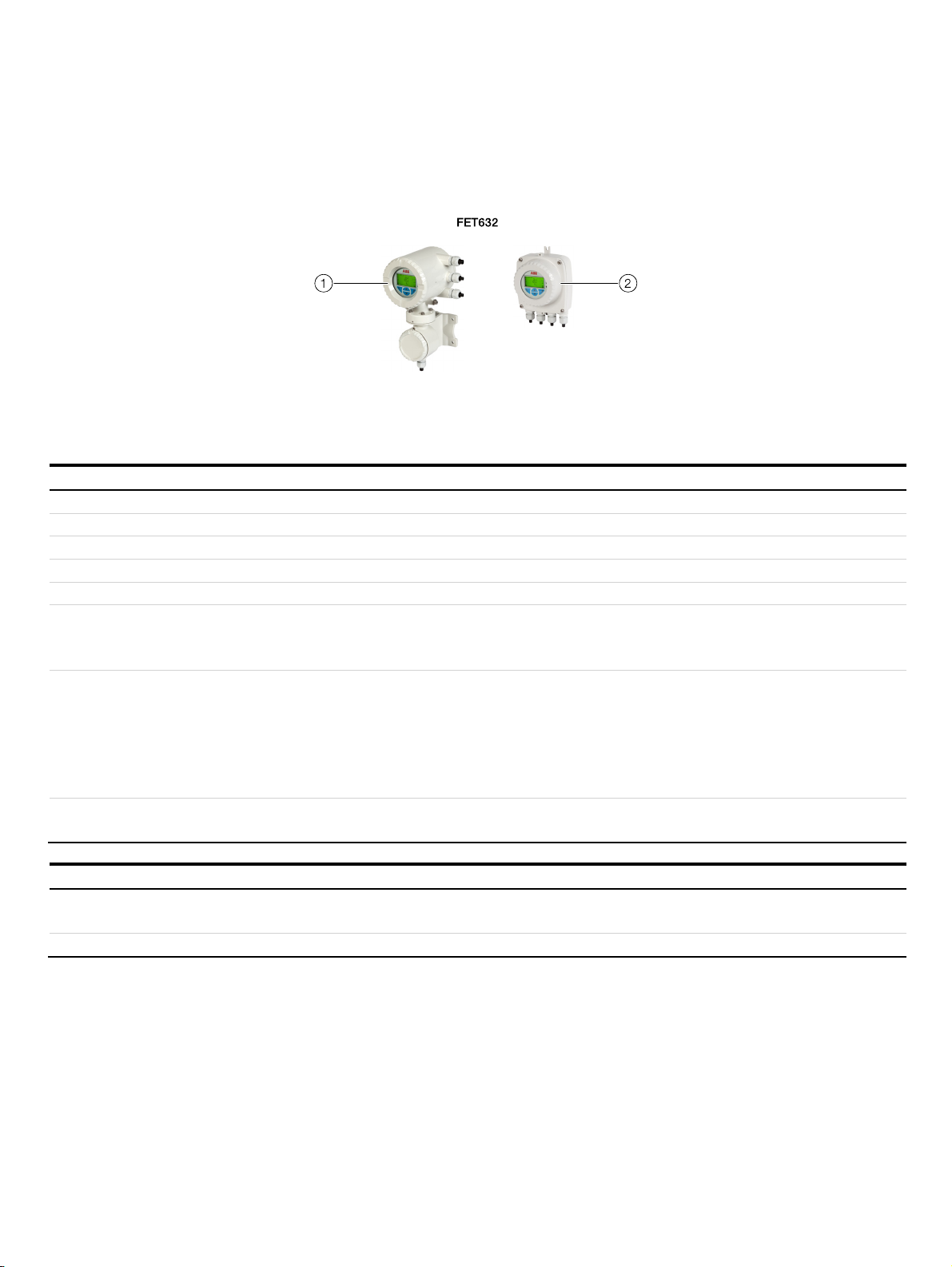

Transmitter

1 Dual-compartment transmitter housing

Figure 3: Designs

2 Single-compartment transmitter housing

Transmitter

Model FET632

Housing Integral mount design, remote mount design

IP rating IP 65 / IP 67 / NEMA 4X

Cable length Maximum 200 m (656 ft), remote mount design only

Power supply 100 to 240 V AC (−15 / +10 %) 50 / 60 Hz, 16.8 to 30 V DC

Outputs Current output: 4 to 20 mA active or passive (can be configured on-site)

Digital output 1: passive, configurable as pulse, frequency or switch output

Digital output 2: passive, configurable as pulse or switch output

Additional outputs The transmitter has two slots which can be used to insert plug-in cards to extend the outputs.

The following plug-in cards are available:

• Current output (passive)

• Digital output (passive)

• Digital input (passive):

• 24 V DC power supply for active outputs

Communication Standard: HART® 7.1

Option: PROFIBUS DP® / Modbus®

Approvals

Explosion protection (in preparation) ATEX / IECEx Zone 1, 2, 21, 22

Additional approvals At www.abb.com/flow or on request.

Change from one to two columns

FM / cFM Cl 1 Div 1, Cl 1 Div 2

Page 10

10 FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D

… 2 Design and function

Model variants

ProcessMaster / HygienicMaster is available in two product

series.

• FEP610 / FEH610 with base functionality

• FEP630 / FEH630 with extended functions and options

Characteristics / Functions ProcessMaster HygienicMaster

Measuring accuracy

0.4 % (option 0.2 %) of measured

value

0.5 % of measured value

Explosion protection

Option with approval for

potentially explosive atmosphere

Optional diagnosis functions

Detecting gas bubbles,

conductivity monitoring,

temperature monitoring

Grounding check

With noise check functions

Detection of partially filled pipe

With partial fill electrode

Liner and electrode material

optional

Ceramic carbide liner, tungsten

carbide electrodes, double-layer

electrodes

Batch functions

Presetting counter, overrun

correction, external start/stop,

batch end contact

Optional nominal diameter

DN 1 to DN 2

Fieldbus

PROFIBUS DP®, Modbus®

Verification

Optional

FEP610 FEP630 FEH610 FEH630

–

–

–

–

–

–

– – –

–

–

–

–

–

– –

– –

–

–

–

Integral mount design

For devices with an integral mount design, the transmitter and

flowmeter sensor form a single mechanical unit.

Remote mount design

For devices with a remote mount design, the transmitter and

flowmeter sensor are mounted in separate locations.

The electrical connection between the transmitter and the

flowmeter sensor is provided by a signal cable.

A maximum signal cable length of 200 m (656 ft) is possible.

Notes on the ProcessMaster

The flowmeter sensor of the ProcessMaster is available in two

designs, which are distinguished by the design level (A / B).

Notes on the transmitter housing

The transmitter is available in two housing designs:

• Single-compartment housing:

In the single-compartment housing, the electronics

chamber and the connection chamber in the transmitter

are not separated from each other.

• Dual-compartment housing:

In the dual-compartment housing, the electronics

chamber and the connection chamber in the transmitter

are separated from each other.

Page 11

FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D 11

Measuring principle

Measurements performed by the electromagnetic flowmeter are

based on Faraday’s law of induction. A voltage is generated in a

conductor when it moves through a magnetic field.

1 Magnet coil

2 Measuring tube in electrode plane

Figure 4: Electromagnetic flowmeter diagram

3 Measuring electrode

2

D

1

U1 Measuring span

B Magnetic induction

D Electrode spacing

vDBU

~

qv

v

4

v Average flow velocity

qv Volume flow rate

qvU

~

1

With the device-relevant application of this measuring principle,

a conductive measuring medium flows through a tube in which a

magnetic field is generated perpendicular to the flow direction

(see Figure 4).

The voltage induced in the measuring medium is tapped by two

diametrically opposed electrodes. This measurement voltage is

proportional to the magnetic induction, the electrode spacing

and the average medium velocity v.

Taking into account that the magnetic induction and the

electrode spacing are constant values results in a proportion

between the measurement voltage U

and the average medium

1

velocity.

From the calculation of the volume flow rate follows that the

measurement voltage is linear and proportional to the volume

flow rate

The induced voltage is converted by the transmitter to

standardized, analog and digital signals.

Page 12

12 FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D

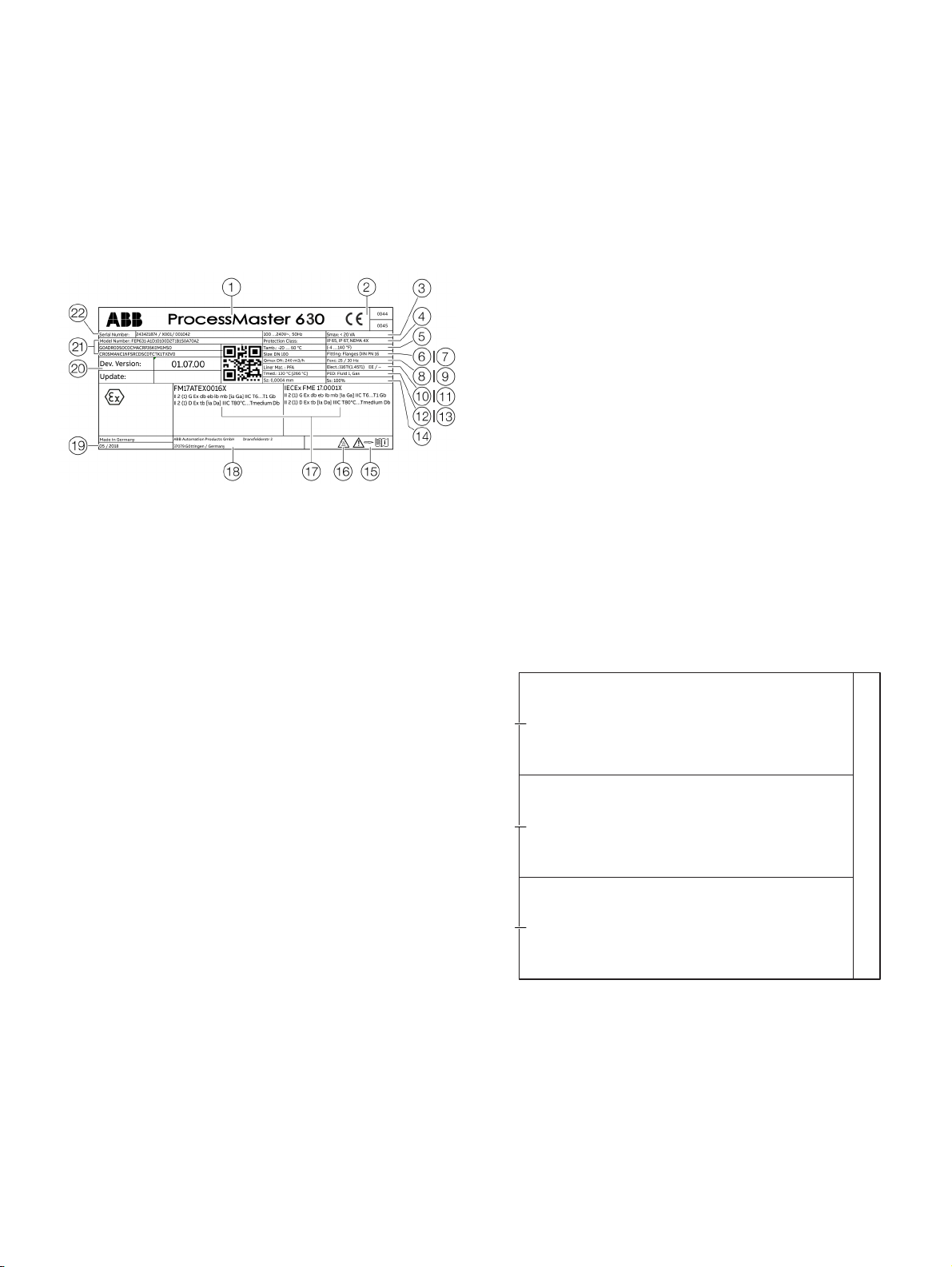

3 Product identification

Name plate

Note

The name plates displayed are examples. The device

identification plates affixed to the device can differ from this

representation.

1 Type designation

2 CE mark

3 Power supply

4 IP rating in accordance with

EN 60529

5 T

6 Nominal diameter

7 Process connection / pressure

8 Calibration value Q

9 Excitation frequency

0 Liner material

k Electrode material /

l T

m Label indicating whether the

Figure 5: Name plate (example)

= maximum permissible

amb

ambient temperature

rating

DN

max

Supplementary information:

EE = grounding electrodes,

TFE = partial filling electrode

= maximum permissible

med

measuring medium

temperature

pressure equipment is subject

to the Pressure Equipment

Directive.

n Calibration value Sz (zero point), Ss

(range)

o ‘Follow operating instruction’

symbol

p ‘Caution hot surface’ symbol

q Ex marking in accordance with

ATEX / IECEx (example)

r Manufacturer address

s Year of manufacture

t Software version

u Model number (for more detailed

information about the technical

design, refer to the data sheet or

the order confirmation)

v Order number / Serial number for

identification by the manufacturer

Note

Devices with 3A approval SIL are labeled with an additional plate.

Marking in accordance with Pressure Equipment Directive

2014/68/EU

Information on the relevant fluid group (Figure 5, Position

• PED: Fluid 1, Gas

Fluid group 1 = hazardous fluids, liquid, gaseous. (PED =

PressureEquipmentDirective).

• SEP

If the pressure equipment is not in the scope of the

Pressure Equipment Directive, it is classified in

accordance with SEP = Sound Engineering Practice

(‘sound engineering practice’) in accordance with Art. 4

para. 3 of the Pressure Equipment Directive.

If there is no such information at all, there is no compliance with

the requirements of the Pressure Equipment Directive.

Water supplies and connected equipment accessories are

classed as an exception in accordance with guideline 1/16 of

Art. 1 Para. 3.2 of the Pressure Equipment Directive.

Additional warning plate

Devices which are approved for use in potentially explosive

atmospheres have an additional warning plate.

Warnung!

Gefahr durch elektrostatische Entladung

Warning!

1

Danger by electrostatic unloading

AVERTISSEMENT!

Risque de d charge électrostatique

Warnung!

Nicht öffnen, wenn eine explosionsfähige Athmosphäre vorhanden ist.

Warning!

2

DO NOT OPEN WHEN AN EXLPOSIVE ATMOSPHERE IS PRESENT

AVERTISSEMENT!

Ne pas ouvrir en presence d'une atmosphere explosive

Achtung:

Heisse Oberfläche

Warning:

3

Hot Surface

Attention:

Surface tres chaude

1 WARNING - Danger due to

electrostatic discharge.

2 WARNING - Do not open if an

explosive atmosphere is

present.

Figure 6: Additional warning plate

3 WARNING - Hot surface.

4 Thread for cable glands

m):

4

Cable entries: M20 x 1,5

G12174

Page 13

FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D 13

4 Transport and storage

Inspection

Check the devices immediately after unpacking for possible

damage that may have occurred from improper transport.

Details of any damage that has occurred in transit must be

recorded on the transport documents.

All claims for damages must be submitted to the shipper

without delay and before installation.

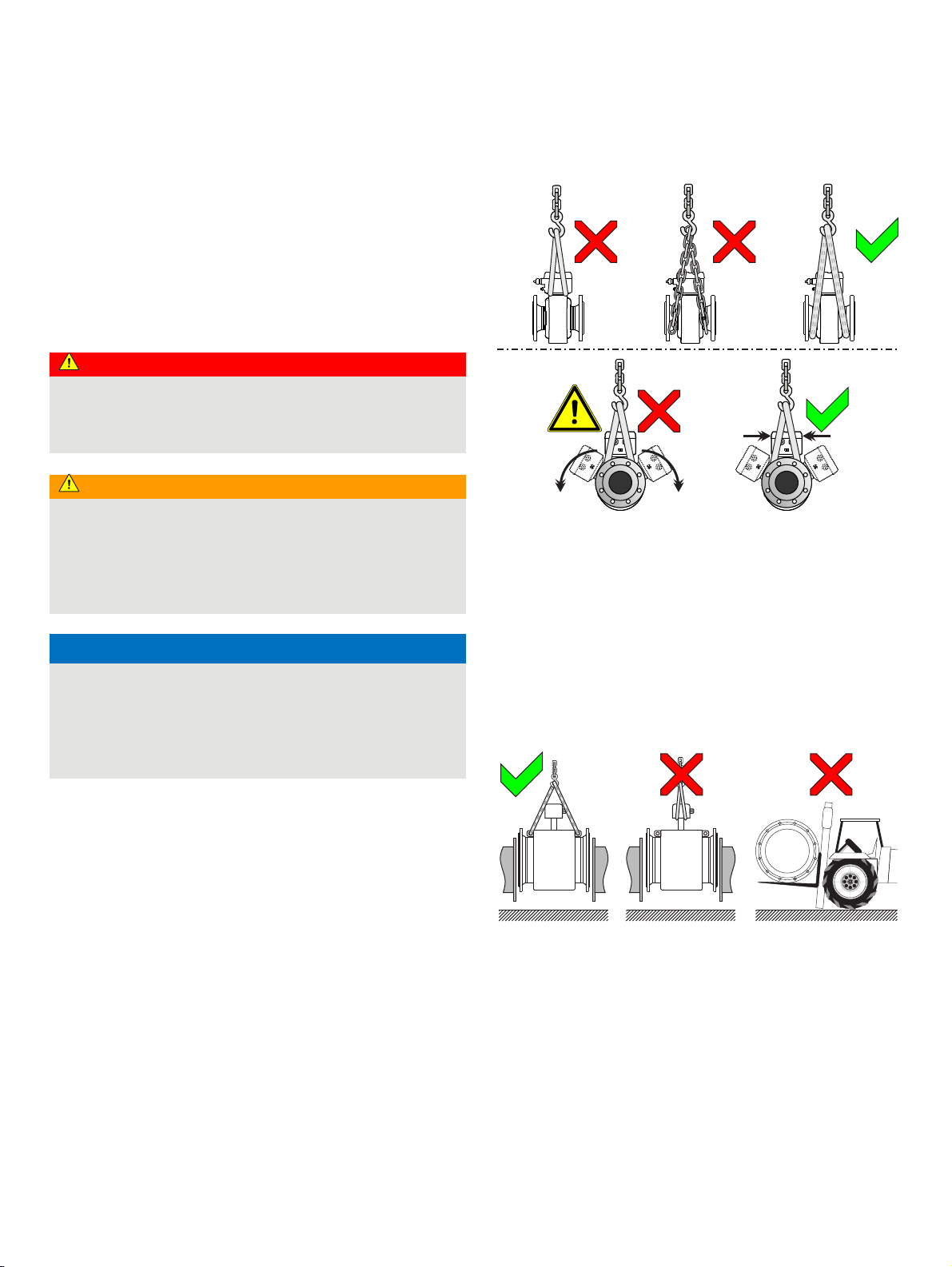

Transport

DANGER

Life-threatening danger due to suspended loads.

In the case of suspended loads, a danger of the load falling

exists.

• Standing under suspended loads is prohibited.

WARNING

Risk of injury due to device slipping.

The device's center of gravity may be higher than the harness

suspension points.

• Make sure that the device does not slip or turn during

transport.

• Support the device laterally during transport.

NOTICE

Potential damage to the device!

The protection plates or protection caps mounted at the

process connections on devices with PTFE / PFA liners may

only be removed immediately before installation.

• To prevent possible leakage, make sure that the liner on

the flange is not cut or damaged.

G12034

Figure 7: Transport instructions - ≤ DN 450

Flange devices ≤ DN 450

• Use carrying straps to transport flange designs smaller than

DN 450.

• Wrap the carrying straps around both process connections

when lifting the device.

• Chains should not be used, since these may damage the

housing.

Flange devices > DN 450

G10645

Figure 8: Transport instructions - > DN 450

• Using a forklift to transport flange device can dent the

housing.

• Flange devices must not be lifted by the center of the

housing when using a forklift for transport.

• Flange devices must not be lifted by the terminal box or by

the center of the housing.

• Only the transport lugs fitted to the device can be used to lift

the device and insert it into the piping.

Page 14

14 FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D

… 4 Transport and storage

Storing the device

Bear the following points in mind when storing devices:

• Store the device in its original packaging in a dry and

dust-free location.

• Observe the permitted ambient conditions for transport

and storage.

• Avoid storing the device in direct sunlight.

• In principle, the devices may be stored for an unlimited

period. However, the warranty conditions stipulated in

the order confirmation of the supplier apply.

Temperature data

Storage temperature range

−40 to 70 °C (−40 to 158 °F)

The ambient conditions for the transport and storage of the

device correspond to the ambient conditions for operation of

the device.

Adhere to the device data sheet!

Returning devices

For the return of devices, follow the instructions in Repair on

page 123.

Page 15

FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D 15

5 Installation

Safety instructions

WARNING

Risk of injury due to process conditions.

The process conditions, for example high pressures and

temperatures, toxic and aggressive measuring media, can

give rise to hazards when working on the device.

• Before working on the device, make sure that the process

conditions do not pose any hazards.

• If necessary, wear suited personal protective equipment

when working on the device.

• Depressurize and empty the device / piping, allow to cool

and purge if necessary.

WARNING

Risk of injury due to live parts!

When the housing is open, contact protection is not provided

and EMC protection is limited.

• Before opening the housing, switch off the power supply.

Use in Potentially Explosive Atmospheres

DANGER

Danger of explosion if the device is operated with the

transmitter housing or terminal box open!

While using the device in potentially explosive atmospheres

before opening the transmitter housing or the terminal box,

note the following points:

• A valid fire permit must be present.

• Make sure that no flammable or hazardous atmospheres

are present.

Note

• An additional document with Ex safety instructions is

available for measuring systems that are used in potentially

explosive atmospheres.

• Ex safety instructions are an integral part of this manual. As

a result, it is crucial that the installation guidelines and

connection values it lists are also observed.

The icon on the name plate indicates

the following:

Installation conditions

General

The following points must be observed during installation:

• The flow direction must correspond to the marking, if

present

• The maximum torque for all flange screws must be

complied with

• Secure flange screws and nuts against pipe vibration.

• The devices must be installed without mechanical tension

(torsion, bending)

• Install flange devices / wafer-type devices with plane

parallel counterflanges and use appropriate gaskets only

• Use gaskets made from a material that is compatible

with the measuring medium and measuring medium

temperature.

• Gaskets must not extend into the flow area, since

possible turbulence could influence the accuracy of the

device

• The piping may not exert any inadmissible forces or

torques on the device.

• Make sure that the temperature limits are not up-scaled

during operation of the device.

• Vacuum shocks in the piping should be avoided to

prevent damage to the liners (PTFE liner). Vacuum shocks

can destroy the device.

• Do not remove the sealing plugs in the cable glands until

you are ready to install the electrical cable

• Make sure the gaskets for the housing cover are seated

correctly. Carefully seal the cover. Tighten the cover

fittings

• The transmitter with a remote mount design must be

installed at a largely vibration-free location

• Do not expose the transmitter and sensor to direct

sunlight. Provide appropriate sun protection as necessary

If necessary, provide a suited means of sun protection.

• When installing the transmitter in a control cabinet, make

sure adequate cooling is provided

Devices with extended diagnostic functions

For devices with extended diagnostic functions different

installation conditions may be valid.

For additional information, see Extended diagnostic functions

on page 118.

Page 16

16 FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D

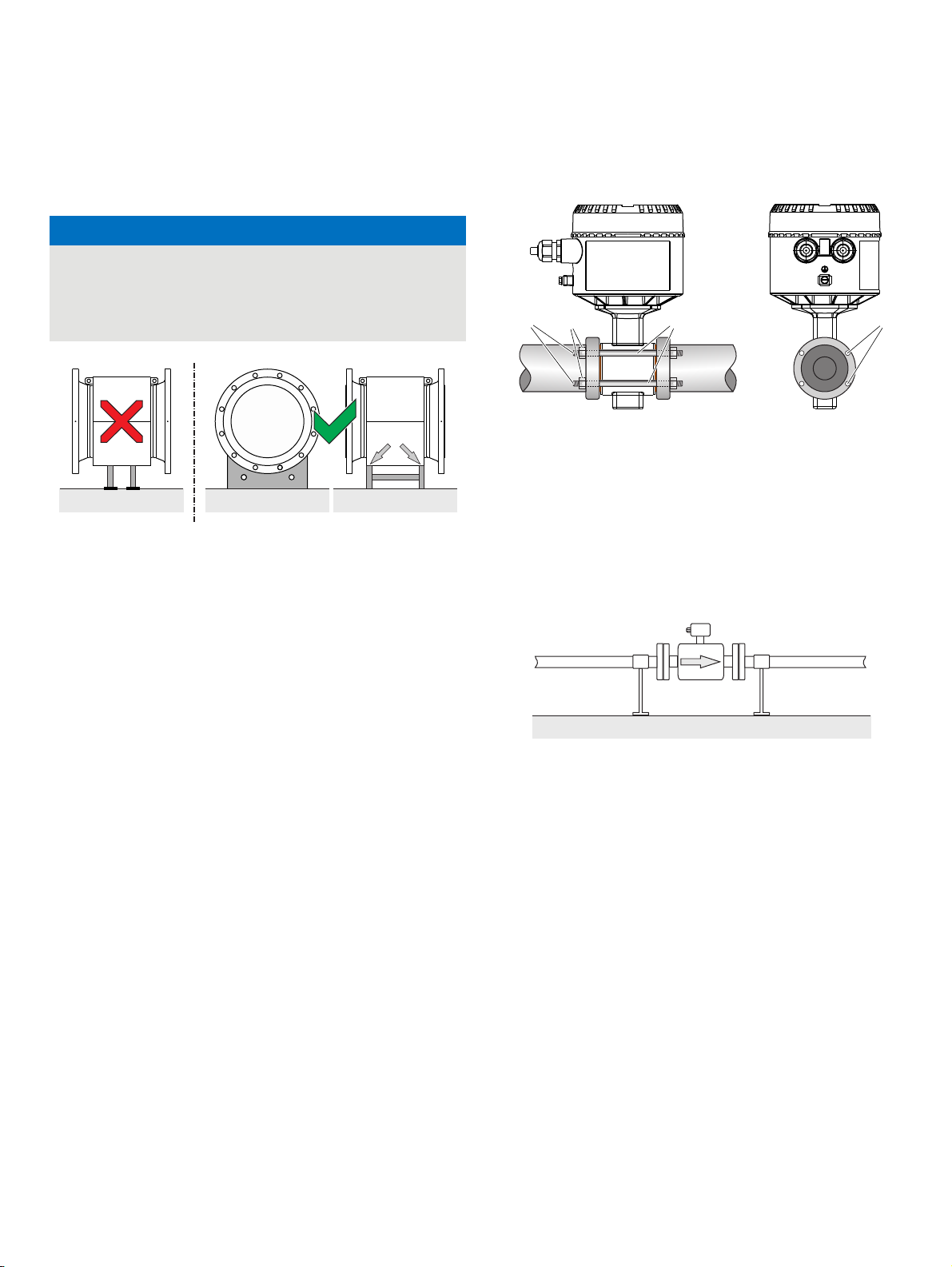

… 5 Installation

… Installation conditions

Brackets

NOTICE

Potential damage to the device!

Improper support for the device may result in a deformed

housing and damage to internal magnetic coils.

• Place the supports at the edge of the sensor housing (see

arrows in Figure 9).

Figure 9: Support for nominal diameters larger than DN 400

Devices with nominal diameters larger than DN 400 must be

mounted on a sufficiently strong foundation with support.

Gaskets

The following points must be observed when installing gaskets:

• To achieve the best results, make sure that the gaskets

and meter tube fit concentrically.

• To make sure that the flow profile is not distorted, the

gaskets may not intrude in the piping cross-section.

• The use of graphite with the flange or process connection

gaskets is prohibited. This is because, in some instances,

an electrically conductive coating may form on the inside

of the meter tube.

Devices with hard rubber or soft rubber liner

• Devices with a hard / soft rubber liner always require

additional gaskets

• ABB recommends using gaskets made from rubber or

rubber-like sealing materials

• When selecting the gaskets, make sure that the tightening

torques specified in chapter Torque information on page 144

are not up-scaled.

Devices with a PTFE, PFA or ETFE liner

• In principle, devices with a PTFE, PFA or ETFE liner do not

require additional gaskets.

Devices with a wafer-type design

1 2 3 3

1 Threaded rod

2 Nut with washer

Figure 10: Assembly set for wafer type assembly (example)

For devices with a wafer-type design, ABB offers an installation

set as an accessory that comprises threaded rods, nuts, washers

and centering sleeves for installation.

Flow direction

Figure 11: Flow direction

The device measures the flow rate in both flow directions.

Forward flow is the factory setting, as shown in Figure 11.

3 Centering sleeve

G12060

Page 17

FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D 17

Electrode axis

1 Electrode axis

Figure 12: Orientation of the electrode axis

The flowmeter sensor should be mounted in the piping in such a

manner that the electrode axis is oriented as horizontally as

possible.

A maximum deviation of 45° from the horizontal position is

permissible.

Mounting position

Minimum spacing of the devices

Spacing D: ≥ 1.0 m (3.3 ft) for Design Level ‘A’,

≥ 0.7 m (2.3 ft) for Design Level ‘B’

HygienicMaster xxxFEH

D

Figure 13: Mounting position

A Vertical installation for measuring abrasive materials,

preferably with flow in upward direction.

B For a horizontal installation, the meter tube must always be

completely filled with the measuring medium.

Provide for a slight incline of the connection for degassing.

Note

For hygienic applications, the vertical mounting position is

preferred.

For a horizontal mounting position, make sure that the sensor is

installed to be self-draining.

Spacing D: ≥ 1.0 m (≥ 3.3 ft)

Figure 14: Minimum spacing

• In order to prevent the devices from interfering with each

other, a minimum distance as presented in Minimum spacing

of the devices must be maintained between the devices.

• The sensor must not be operated in the vicinity of powerful

electromagnetic fields, e.g., motors, pumps, transformers,

etc. A minimum spacing of approx. 1 m (3.28 ft) must be

maintained.

• For installation on or to steel parts (e.g. steel brackets), a

minimum spacing of 100 mm (3.94 in

) must be maintained.

These values have been calculated on the basis of IEC 801-2

or IEC TC77B

G12063

Page 18

18 FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D

… 5 Installation

… Installation conditions

Grounding

The flowmeter sensor must be connected to ground potential.

For technical reasons, this potential must be identical to the

potential of the measuring medium.

In piping made of plastic or with insulating liner, grounding of

the measuring medium is done by installing grounding plates.

If stray potential is present in the piping, adding a grounding

plate on both ends of the flowmeter sensor is recommended.

Sensor insulation

1 Insulation

Figure 15: Insulation of the flowmeter sensor

In the high temperature design, the flowmeter sensor can be

completely thermally insulated. After the unit is installed, the

piping and sensor must be insulated in accordance with the

figure.

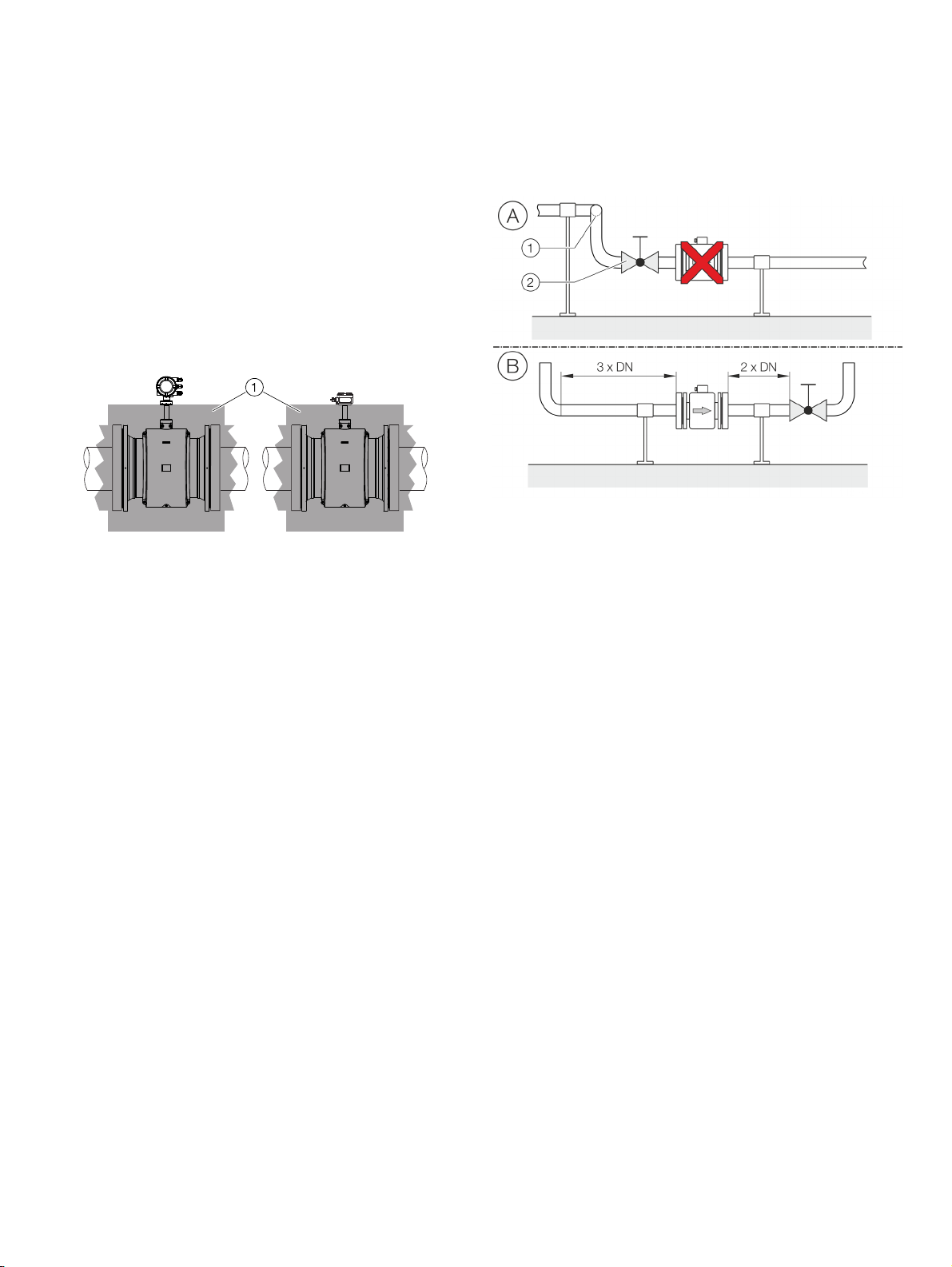

Inlet and outlet sections

1 Double manifold 2 Turn-off device

Figure 16: Inlet and outlet section, turn-off devices

The measuring principle is independent of the flow profile as

long as standing eddies do not extend into the measured value

formation, such as may for example occur after double

manifolds, in the event of tangential inflow, or where half-open

gate valves are located upstream of the sensor. In such cases,

measures must be put in place to normalize the flow profile.

A Do not install fittings, manifolds, valves, etc., right before the

flowmeter sensor.

B Inlet / outlet sections: length of the straight piping upstream

and downstream on the sensor.

Experience has shown that, in most installations, straight

inlet sections 3 × DN long and straight outlet sections 2 × DN

long are sufficient (DN = nominal diameter of the flowmeter

sensor).

For test stands, the reference conditions of 10 × DN straight

inlet and 5 × DN straight outlet must be provided, in

accordance with EN 29104 / ISO 9104.

Valves or other turn-off devices should be installed in the

outlet section.

Valve flaps must be installed so that the valve damper plate

does not extend into the flowmeter sensor.

Page 19

FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D 19

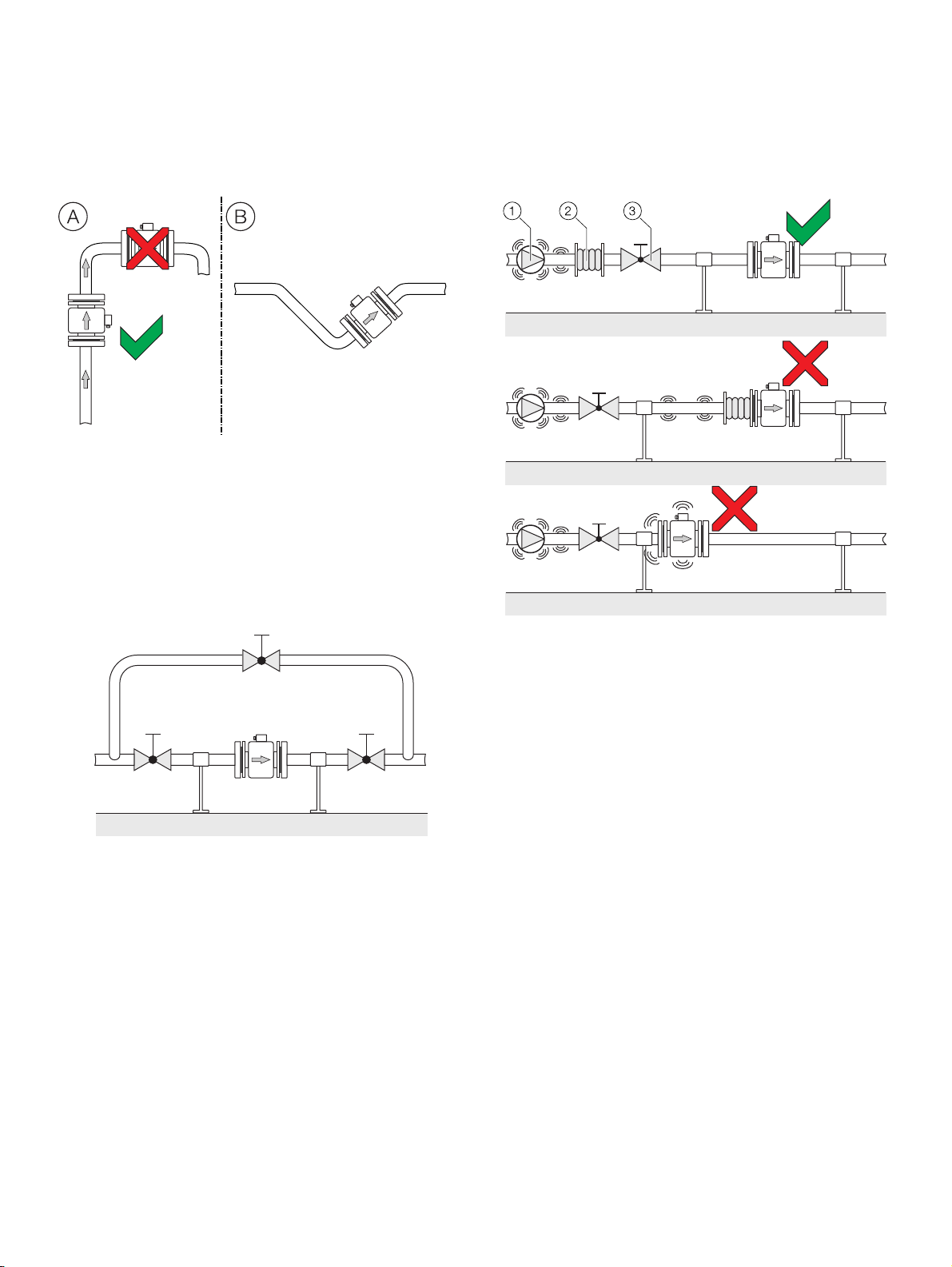

Free inlet or outlet

Figure 17: Free inflow and outflow

A For a free outflow, do not install flowmeter at the highest

point of the piping or on its outflow side, since the

measuring tube may run empty, creating air bubbles.

B For free inflow/outflow, provide an invert to make sure that

the piping is always full

Mounting with heavily contaminated measuring media

Mounting with pipe vibration

1 Pump

2 Damping device

3 Turn-off device

Figure 18: Bypass line

For strongly contaminated measuring media, a bypass line in

accordance with the figure is recommended so that operation of

the system can continue to run without interruption during

mechanical cleaning.

Figure 19: Vibration damping

If pipe vibration occurs, it needs to be damped using damping

devices.

The damping devices must be installed outside the support

section and outside of the piping section between the turn-off

devices.

Avoid connecting damping devices directly to the flowmeter

sensor.

Page 20

20 FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D

… 5 Installation

… Installation conditions

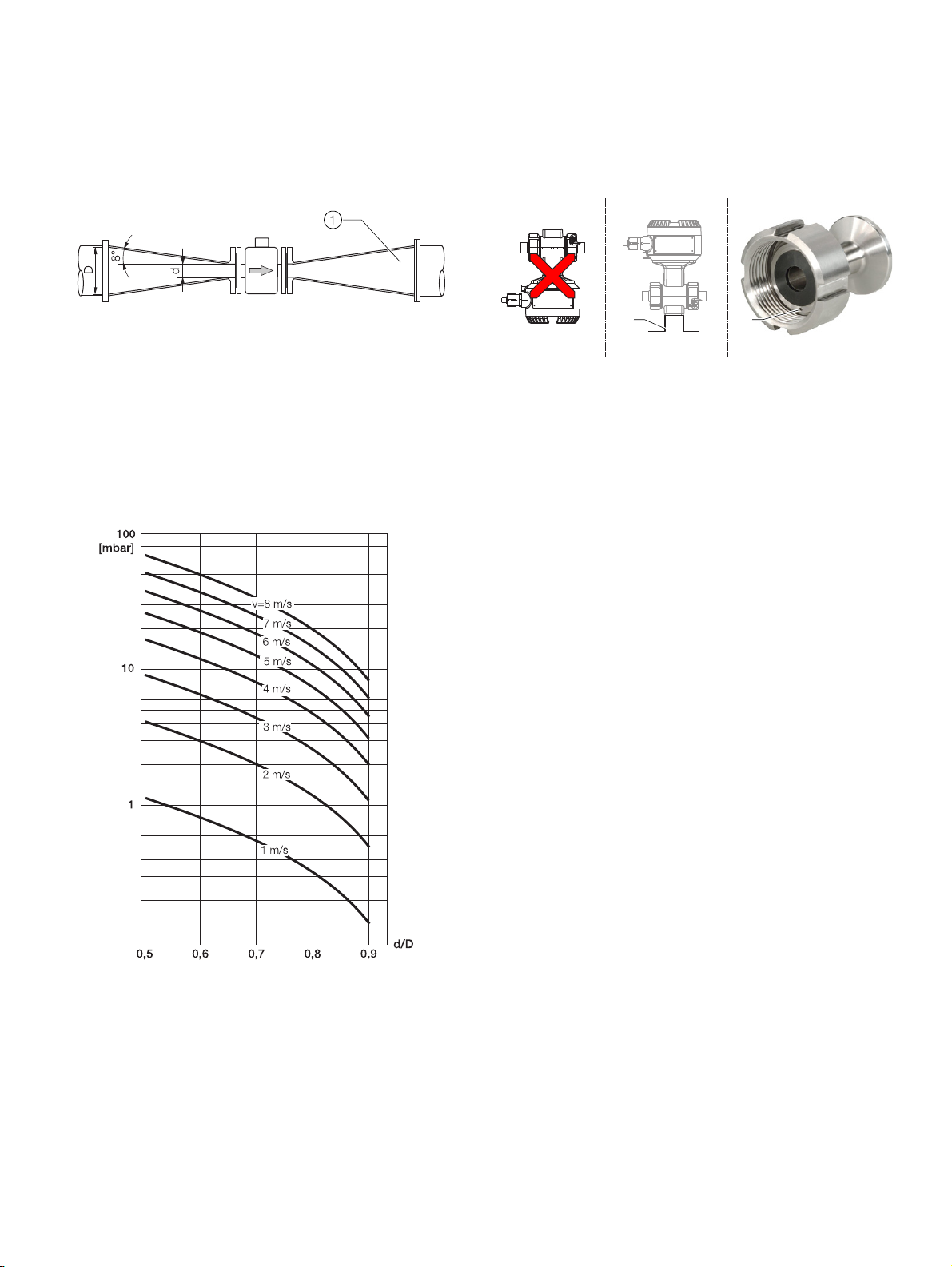

Installation in piping with larger nominal diameter

1 Reducer

Figure 20: Using reducers

Determine the resulting pressure loss when using reducers:

1. Determine diameter ratios d/D.

2. .Determine the flow velocity based on the flow rate

nomogram (Figure 21).

3. Read the pressure loss on the Y-axis in Figure 21.

Installation in 3A compliant installations

AB C

1 Angel bracket 2 Leakage hole

Figure 22: 3A compliant installation

Please observe the following points:

A Do not install the device vertically with the terminal box

or transmitter housing pointing downward.

B The ‘angel bracket’ option is not 3A compliant.

C Please make sure that the leakage hole of the process

connection is located at the lowest point of the installed

device.

• A vertical mounting position is preferred. For a horizontal

mounting position, make sure that the sensor is installed

to be self-draining.

• Make sure that the cover of terminal box and / or

transmitter housing is properly sealed. There can be no

gaps between the housing and the cover.

Only devices with the following process connections fulfill 3A

compliance.

• Welded spuds

• Tri-clamp

1 2

G12016

Figure 21: Flow rate nomogram for flange transition piece at α/2 = 8°

Page 21

FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D 21

Installing the sensor

NOTICE

Damage to the device

Damage to the device due to improper assembly.

• The use of graphite with the flange or process connection

gaskets is prohibited. This is because, in some instances,

an electrically conductive coating may form on the inside

of the meter tube.

• Vacuum shocks in the piping should be avoided to prevent

damage to the liners (PTFE liner). Vacuum shocks can

destroy the device.

The flowmeter sensor can be installed at any location in the

piping while taking the installation conditions into account.

1. Remove protective plates, if present, to the right and left of

the meter tube. To prevent possible leakage, make sure that

the liner on the flange is not cut or damaged.

2. Position the flowmeter sensor plane parallel and centered

between the piping.

3. Install gaskets between the surfaces, see Gaskets on

page 16.

Note

For achieve the best results, ensure the gaskets fit concentrically

with the meter tube

To ensure that the flow profile is not distorted, the gaskets must

not protrude into the piping.

4. Use the appropriate screws for the holes in accordance with

Torque information on page 144.

5. Slightly grease the threaded nuts.

6. Tighten the nuts in a crosswise manner as shown in the

figure. Observe the tightening torques in accordance with

Torque information on page 144!

First tighten the nuts to approx. 50 % of the maximum

torque, then to 80 %, and finally a third time to the maximum

torque. Do not exceed the max. torque.

1

3

8

4

4

Figure 23: Tightening sequence for the flange screws

2

1

6

5

3

7

2

G11726

Page 22

22 FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D

… 5 Installation

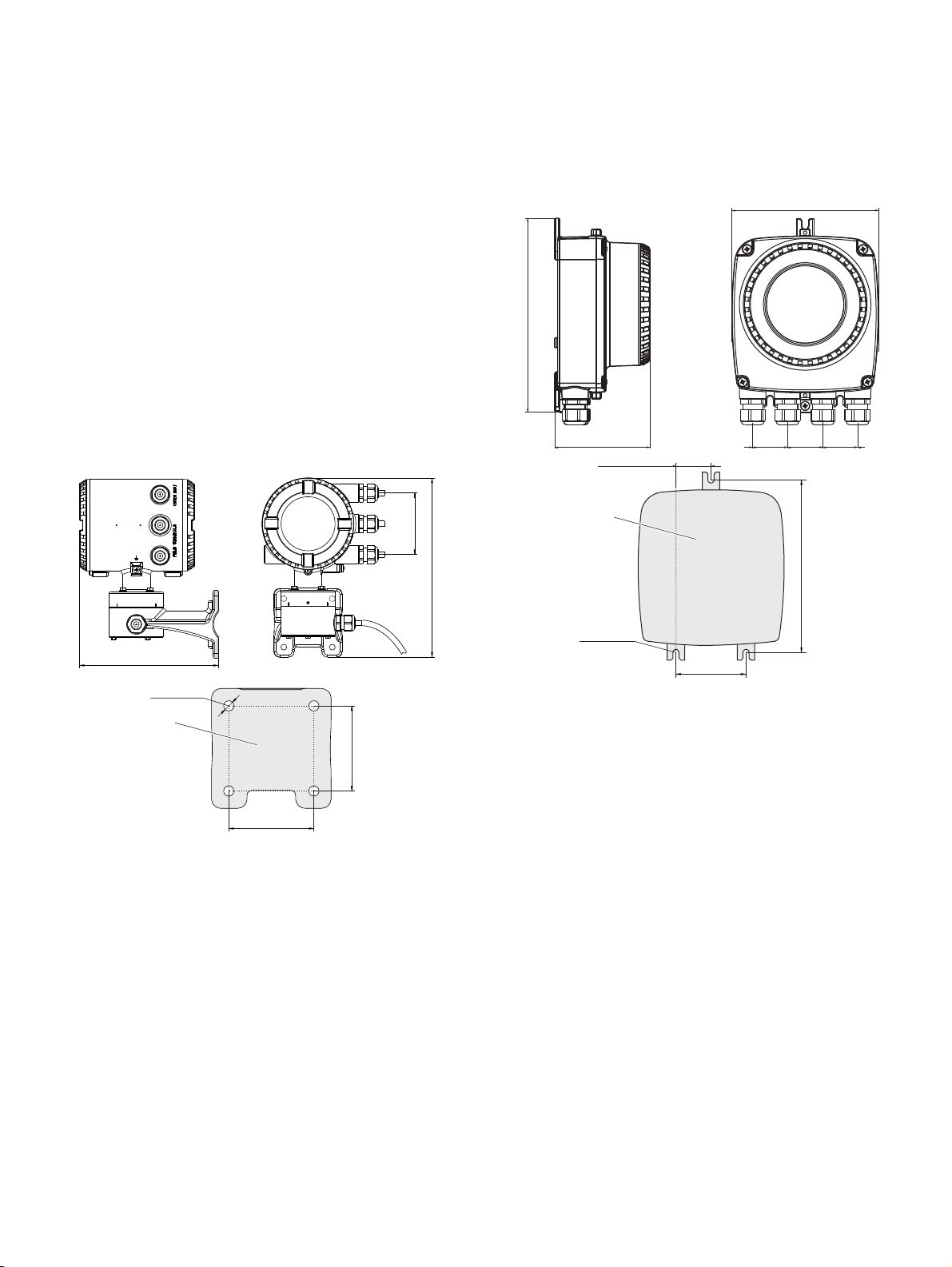

Installing the transmitter in the remote

mount design

When selecting a location for the transmitter, consider the

following points:

• Observe the information concerning maximum ambient

temperature and IP rating on the name plate

• The location must be mostly free from vibration.

• The location must not be exposed to direct sunlight. If

necessary provide a sun screen on site.

• Do not up-scale the maximum signal cable length

between the transmitter and the sensor.

1. Drill mounting holes at mounting location.

2. Attach transmitter securely to the mounting location using

suited fasteners for the base material.

2x45 = 90

(2x1.77 = 3.54)

150 (5.91)

200 (7.87)

98,1 (3.86)

36,5 (1.44)

36,3 (1.43)

1

205 (8.07)

Ø 7 (0.28)

1

71 (2.8)

1 Hole pattern for mounting holes

Figure 24: Mounting dimensions dual-compartment housing

71 (2.8)

G11567

262 (10.31)

Ø 6,4 (0.25)

72,5 (2.85)

1 Hole pattern for mounting holes

Figure 25: Mounting dimensions single-compartment housing

180 (7,1)

G11568

Page 23

FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D 23

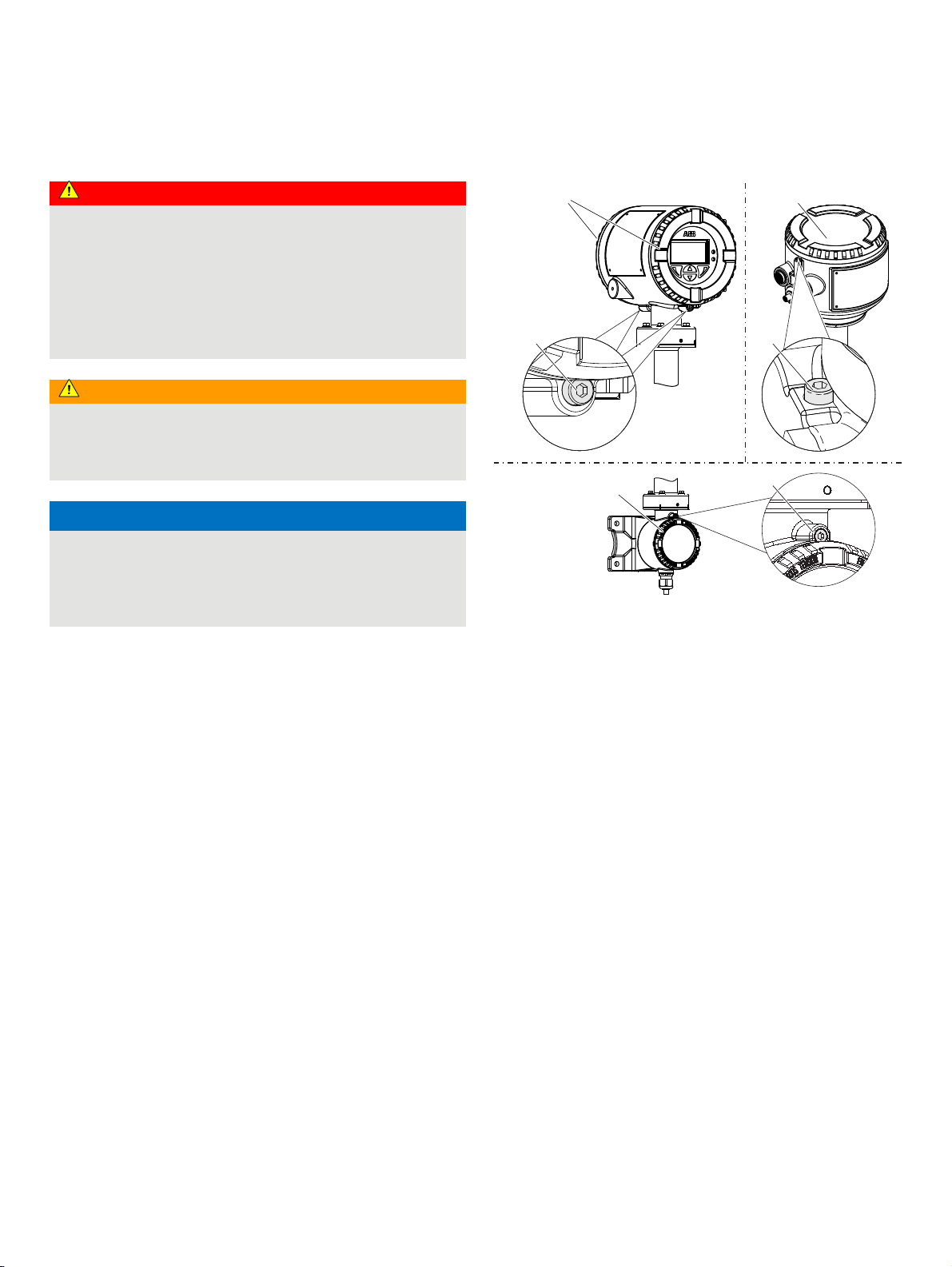

Opening and closing the housing

DANGER

Danger of explosion if the device is operated with the

transmitter housing or terminal box open!

While using the device in potentially explosive atmospheres

before opening the transmitter housing or the terminal box,

note the following points:

• A valid fire permit must be present.

• Make sure that no flammable or hazardous atmospheres

are present.

WARNING

Risk of injury due to live parts!

When the housing is open, contact protection is not provided

and EMC protection is limited.

• Before opening the housing, switch off the power supply.

NOTICE

Potential adverse effect on the IP rating

• Check the O-ring gasket for damage and replace it if

necessary before closing the housing cover.

• Check that the O-ring gasket is properly seated when

closing the housing cover.

AB

C

A Integral mount design

B Remote mount design

Abbildung 26: Deckelsicherung (Beispiel)

Figure 27: Cover lock (example)

Open the housing:

Close the housing:

1 1

2

1

C Transmitter, terminal space,

1. Release the cover lock by screwing in the Allen screw

2. Unscrew cover

1. Screw on the cover

1.

1.

2

2

G11738-01

signal cable

2.

2. After closing the housing, lock the cover by unscrewing

the Allen screw 2.

Page 24

24 FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D

… 5 Installation

… Opening and closing the housing

NOTICE

Potential adverse effect on the IP rating

• Check the gasket for damage and replace it if necessary

before closing the housing cover.

• Check that the gaskets are properly seated when closing

the housing cover.

1

AA

Adjusting the transmitter position

Depending on the installation position, the transmitter housing

or LCD display can be rotated to enable horizontal readings.

In addition, the display in the LCD indicator can be rotated by

180° using the parameter ‘Display Rotation’ (see Menu: Display

on page 87).

Transmitter housing

DANGER

Damaging the device carries a risk of explosion!

When the screws for the transmitter housing are loosened,

the explosion protection is suspended.

Tighten all screws prior to commissioning.

Never disconnect the transmitter housing from the sensor.

Only loosen the screws shown when rotating the transmitter

housing!

Rotate transmitter housing: Perform steps

A to C.

C

2 3

B

D

1 Cover screws

2 Transmitter housing cover

Figure 28: Open / close single-compartment housing

3 Gasket

Open transmitter housing: Perform steps

Close transmitter housing: Perform steps

A and B.

C and D.

G12149

AB

90°

90°

C

G11569

Figure 29: Rotate transmitter housing

Page 25

FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D 25

Rotate LCD indicator – dual-compartment housing

The LCD indicator can be rotated in three increments of 90°

each. To open and close the housing, refer to Opening and

closing the housing on page 23.

Turn the LCD indicator:

Perform steps

A to F.

Rotate LCD indicator – single-compartment housing

The LCD indicator can be rotated in three increments of 90°

each. To open and close the housing, refer to Opening and

closing the housing on page 23.

Turn the LCD indicator:

Perform steps

A to F.

Figure 30: Rotating the LCD indicator

Change from two to one column

Figure 31: Rotating the LCD indicator

Page 26

26 FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D

… 5 Installation

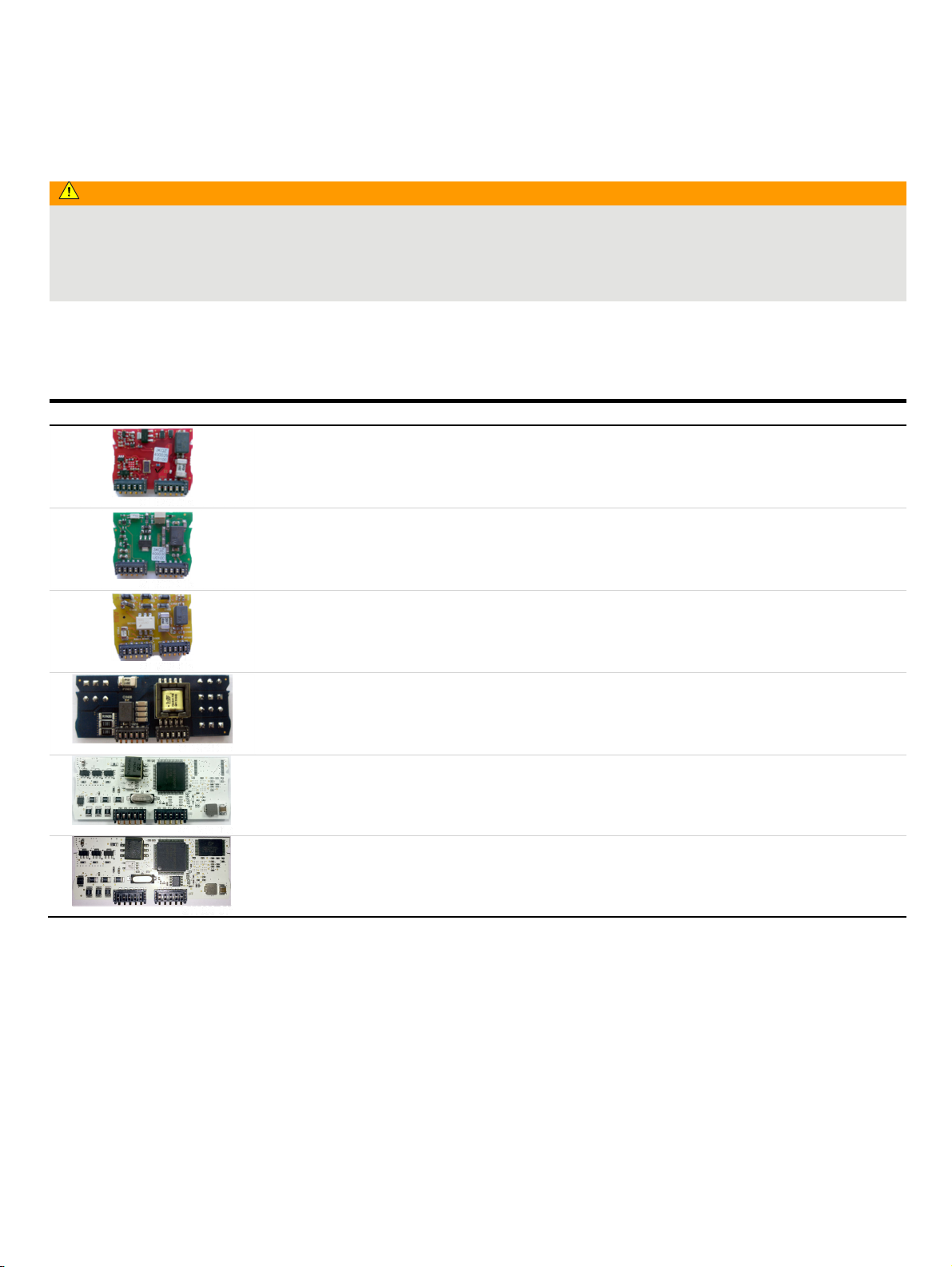

Installing the plug-in cards

WARNING

Loss of Ex Approval!

Loss of Ex Approval due to retrofitting of plug-in cards on devices for use in potentially explosive atmospheres.

• Devices for use in potentially explosive atmospheres may not be retrofitted with plug-in cards.

• If devices are to be used in potentially explosive atmospheres, the required plug-in cards must be specified when the order is

placed.

Optional plug-in cards

The transmitter has two slots (OC1, OC2) into which plug-in cards can be inserted to extend inputs and outputs. The slots are located

on the transmitter motherboard and can be accessed after removing the front housing cover.

Plug-in card Description Quantity*

Current output, 4 to 20 mA passive (red)

Order no.: 3KQZ400029U0100

Maximum of two plug-in cards

Passive digital output (green)

Order no.: 3KQZ400030U0100

Passive digital input (yellow)

Order no.: 3KQZ400032U0100

Loop power supply 24 V DC (blue)

Order no.: 3KQZ400031U0100

Modbus RTU RS485 (white)

Order no.: 3KQZ400028U0100

Profibus DP (white)

Order no.: 3KQZ400027U0100

* The ‘Number’ column indicates the maximum number of plug-in cards of the same type that can be used.

Maximum of one plug-in card

Maximum of one plug-in card

Maximum of one plug-in card

Maximum of one plug-in card

Maximum of one plug-in card

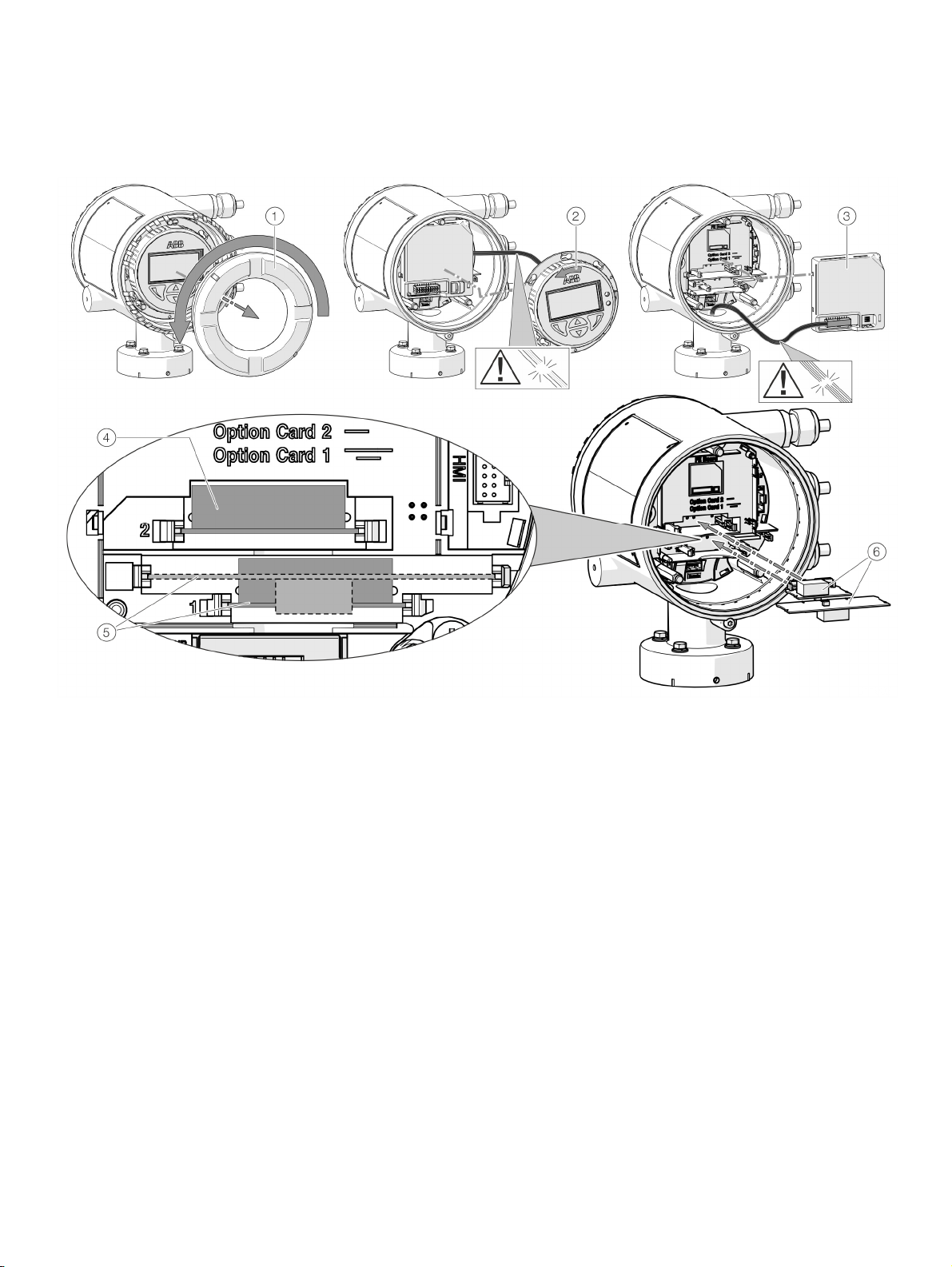

Page 27

FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D 27

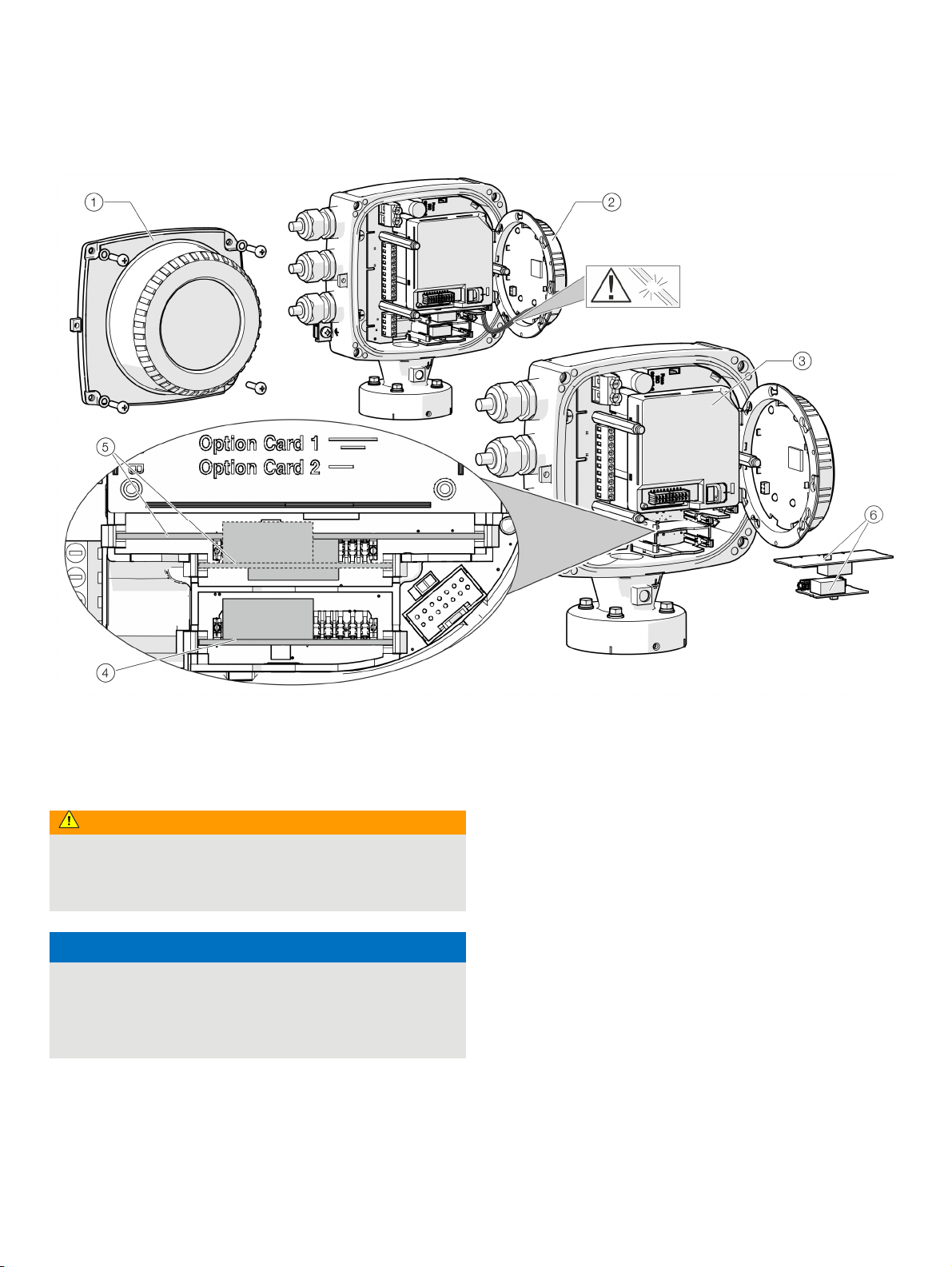

1 Cover

2 LCD indicator

3 Frontend board (FEB, with integral mount design only)

Figure 32: Installation of plug-in cards (example, dual-compartment housing)

4 Slot OC2

5 Slot OC1

6 Plug-in cards

Page 28

28 FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D

… 5 Installation

… Installing the plug-in cards

1 Cover

2 LCD indicator

3 Slot OC1

Figure 33: Installation of plug-in cards (example, single-compartment housing)

Change from one to two columns

WARNING

Risk of injury due to live parts!

When the housing is open, contact protection is not provided

and EMC protection is limited.

• Before opening the housing, switch off the power supply.

NOTICE

Damage to components!

The electronic components of the printed circuit board can be

damaged by static electricity (observe ESD guidelines).

• Make sure that the static electricity in your body is

discharged before touching electronic components.

4 Slot OC2

5 Plug-in cards

1. Switch off the power supply.

2. Unscrew / remove the cover.

3. Remove the LCD indicator. Ensure that the cable harness is

not damaged.

Insert the LCD indicator into the bracket

(only for single-compartment housings)

4. Remove frontend board (only in integral mount design and

dual-compartment housing). Ensure that the cable harness is

not damaged.

5. Insert the plug-in card in the corresponding slot and engage.

Ensure that the contacts are aligned correctly.

6. Attach the frontend board, insert the LCD indicator and

screw on / replace the cover.

7. Connect outputs V1 / V2 and V3 / V4 in accordance with

Electrical connections on page 29.

8. After powering up the power supply, configure the plug-in

card functions.

Page 29

FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D 29

6 Electrical connections

Safety instructions

WARNING

Risk of injury due to live parts.

Improper work on the electrical connections can result in

electric shock.

• Connect the device only with the power supply switched

off.

• Observe the applicable standards and regulations for the

electrical connection.

The electrical connection may only be established by authorized

specialist personnel and in accordance with the connection

diagrams.

The electrical connection information in this manual must be

observed; otherwise, the IP rating may be adversely affected.

Ground the measurement system according to requirements.

Use in Potentially Explosive Atmospheres

Note

• An additional document with Ex safety instructions is

available for measuring systems that are used in potentially

explosive atmospheres.

• Ex safety instructions are an integral part of this manual. As

a result, it is crucial that the installation guidelines and

connection values it lists are also observed.

The icon on the name plate indicates

the following:

Sensor grounding

General information on grounding

Observe the following items when grounding the device:

• For plastic piping or piping with insulating liner, the

ground is provided by the grounding plate or grounding

electrodes.

• When stray potentials are present, install a grounding

plate upstream and downstream of the sensor.

• For measurement-related reasons, the potential in the

station ground and in the piping should be identical.

Note

If the sensor is installed in plastic or earthenware pipelines, or in

pipelines with an insulating liner, compensating currents may

flow through the grounding electrode in special cases (e.g. with

corrosive measuring media, acids and bases)

In the long term, this may destroy the sensor, since the ground

electrode will in turn degrade electrochemically.

In these special cases, the connection to the ground must be

performed using grounding plates. Install a grounding plate

upstream and downstream of the device in this case.

Page 30

30 FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D

… 6 Electrical connections

… Sensor grounding

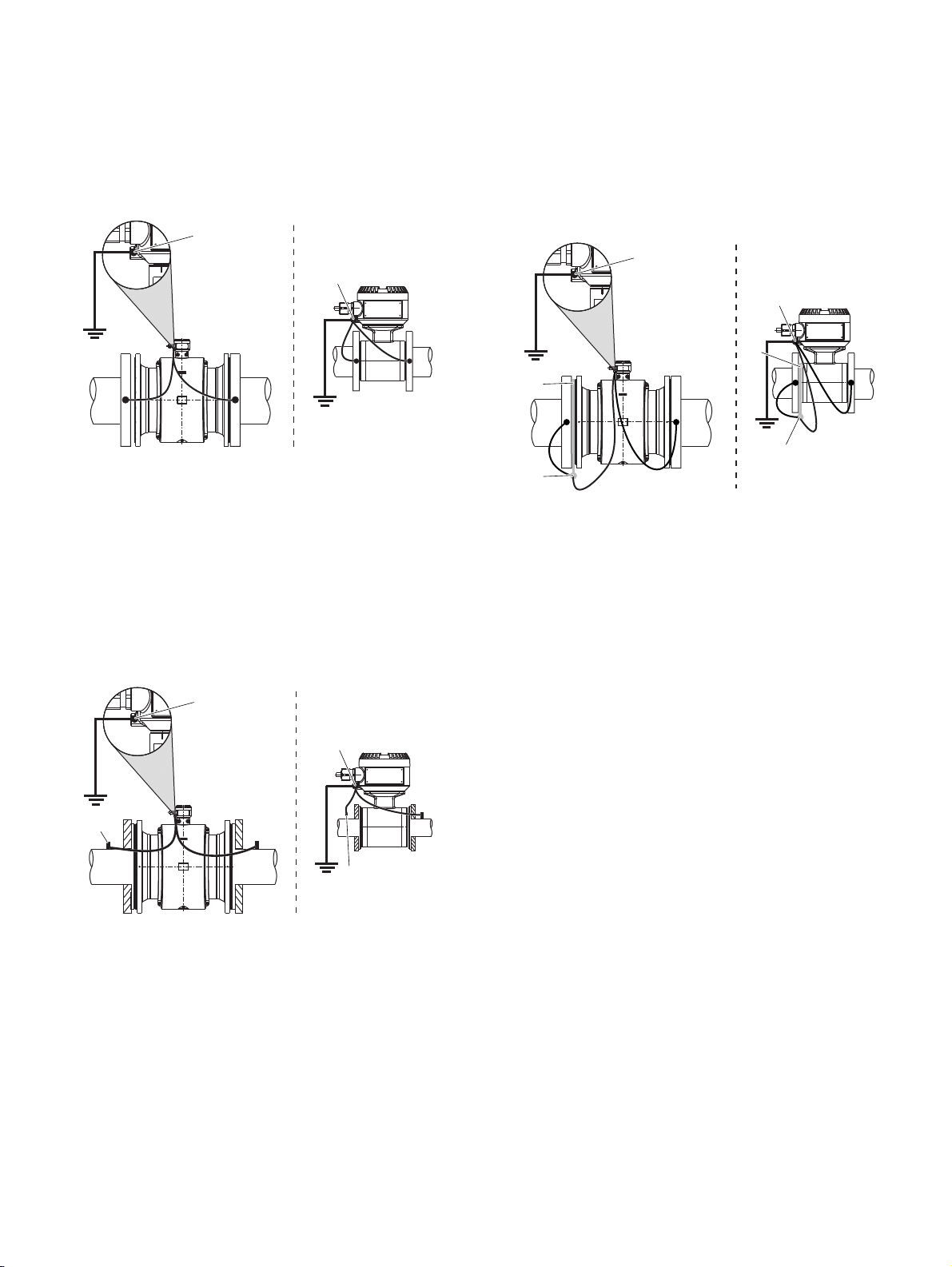

Metal pipe with fixed flanges

AB

A Flange design

B Wafer type design

Figure 34: Metal pipe, without liner (example)

1

1

G12021

1 Ground terminal

2

Use a copper wire [at least 2.5 mm

(14 AWG)] to establish the

connection between the ground terminal of the sensor, the

pipeline flanges and a suited grounding point in accordance with

the figure.

Metal pipe with loose flanges

AB

1

2

2

1

Plastic pipes, non-metallic pipes or pipes with insulating

liner

AB

3

2

A Flange design

B Wafer type design

1 Ground terminal

Figure 36: Plastic pipes, non-metallic pipes or pipes with insulating liner

For plastic pipes or pipes with insulating lining, the grounding of

the measuring medium is provided by the grounding plate as

shown in the figure below or via grounding electrodes that must

be installed in the device (option).

If grounding electrodes are used, the grounding plate is not

necessary.

1. Install the sensor with grounding plate in the piping.

2. Connect the terminal lug of the grounding plate and ground

connection on the sensor using the grounding strap.

3. Use a copper wire with at least 2.5 mm

establish a connection between the ground connection and a

suited grounding point.

1

1

3

2

2 Terminal lug

3 Grounding plate

2

(14 AWG)) to

G12023

G12022

A Flange design

B Wafer type design

Figure 35: Metal pipe, without liner (example)

1 Threaded bolts M6

2 Ground terminal

1. Solder the threaded bolts M6 to the piping and connect the

ground in accordance with the figure.

2

2. Use a copper wire [at least 2.5 mm

(14 AWG)] to establish

the connection between the ground terminal of the sensor

and a suited grounding point in accordance with the figure.

Page 31

FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D 31

Sensor type HygienicMaster

1

G12024

1 Process connection adapter

Figure 37: Sensor, type HygienicMaster

Perform grounding as shown in the figure. The measuring

medium is grounded via the process connection adapter, so

additional grounding is not required.

Grounding for devices with protective plates

The protection plates are used to protect the edges of the meter

tube liner, e.g. for abrasive media.

In addition, the protection plates function as a grounding plate.

• For plastic piping or piping with insulating liner, electrically

connect the protection plate in the same manner as a

grounding plate.

Grounding with conductive PTFE grounding plate

Grounding plates made of conductive PTFE are optionally

available for nominal diameter ranges of DN 10 to 250. These are

installed similar to conventional grounding plates.

Devices with extended diagnostic functions

For devices with extended diagnostic functions different

installation conditions may be valid.

For additional information, see Extended diagnostic functions

on page 118.

Installation and grounding in piping with cathodic

corrosion protection

The installation of electromagnetic flowmeters in systems with

cathodic corrosion protection must be made in compliance with

the corresponding system conditions. The following factors are

especially important:

1. Pipelines inside electrically conductive or insulating.

2. Piping consistently and widely on cathodic corrosion

protection potential. Or mixed systems with ranges on

cathodic corrosion protection potential and ranges on

functional ground potential.

• In the case of pipes free from stray current and

insulated on the inside with liner, the sensor should be

installed in the piping insulated with grounding plates

(upstream and downstream from the sensor). The

cathodic corrosion potential is bypassed around the

sensor. The grounding plates upstream and

downstream of the sensor are connected to

functional ground (Figure 38 / Figure 39).

• If the occurrence of external stray currents is to be

expected in piping with internal insulation (e.g. in the

case of long pipe sections in the vicinity of power

supply units), an uninsulated pipe of approx. ¼ × DN

of length should be provided upstream and

downstream of the sensor in order to deviate these

external stray currents away from the sensor

(Figure 40).

Page 32

32 FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D

… 6 Electrical connections

… Sensor grounding

Internally insulated piping with cathodic corrosion

potential

2 45

1066

3

1

8 7 6

1 Piping flange

2 Insulating plate

3 Gasket / insulating ring

4 Grounding plate

5 Insulating pipe

Figure 38: View Screw bolts

23

9

G11050

6 Flange

7 Liner

8 Insulation

9 Sensor

Install grounding plates on each side of the flowmeter sensor.

Insulate the grounding plates from the pipe flanges and connect

them to the flowmeter sensor and to functional ground.

The screw bolts for flange connections should be mounted with

insulation. The insulation plates and the insulation pipe are not

included in the delivery. They must be provided onsite by the

customer.

2

B

B

A Connection line corrosion

potential*

B Insulated screw bolts without

grounding plates

2

* ≥ 4 mm

Figure 39: sensor with grounding plate and functional ground

Cu, not included in the delivery, to be provided on-site

3

A

1 Insulated piping

2 Functional ground

3 Grounding plates

The corrosion protection potential must be diverted through a

connecting line

A away from the insulated installed sensor.

B

B

11

G11049

Page 33

FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D 33

Mixed system, piping with cathodic corrosion potential and

functional ground potential

Power supply

Note

• Adhere to the limit values of the power supply in accordance

with the information on the name plate.

• Observe the voltage drop for large cable lengths and small

conductor cross-sections. The voltage at the terminals of the

device may not down-scale the minimum value required in

accordance with the information on the name plate.

The power supply is connected to terminal L (phase), N (zero), or

B

2

3

121

B

1+, 2−, and PE.

A circuit breaker with a maximum rated current of 16 A must be

installed in the power supply line.

B

B

The wire cross-sectional area of the power supply cable and the

circuit breaker used must comply with VDE 0100 and must be

dimensioned in accordance with the current consumption of the

flowmeter measuring system. The cables must comply with

IEC 227 and/or IEC 245.

The circuit breaker must be located near the device and marked

as being associated with the device.

Connect the transmitter and sensor to functional earth.

A Connection line corrosion

potential*

B Insulated screw bolts without

grounding plates

2

* ≥ 4 mm

Figure 40: Sensor with functional ground

Cu, not included in the delivery, to be provided on-site

A

1 Insulated piping

2 Uninsulated metal piping

3 Functional ground

G11048

This mixed system has an insulated piping with corrosion

protection potential and an uninsulated metal pipe (L = ¼ × DN

sensor) with functional ground potential upstream and

downstream of the sensor.

Figure 40 shows the preferred installation for cathodic corrosion

protection.

Page 34

34 FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D

… 6 Electrical connections

Cable entries

The electrical connection is made via cable entries with a ½ inNPT or M20 × 1.5 thread.

Devices with a M20 × 1.5 or ½ in-NPT thread are equipped with

protective plugs.

The black protective plugs in the cable glands are intended to

provide protection during transport.

Any unused cable entries must be sealed with sealing plugs

before commissioning in accordance with the applicable

national standards.

• Observe maximum torque of 4.5 Nm (3.3 ft lb) when

tightening the M20 cable gland.

• Make sure that the cable outer dimension used will fit the

clamping range of the cable gland.

Connection via cable conduit

Installing the connection cables

General information on cable installation

Ensure that a drip loop (water trap) is used when installing the

connecting cables for the sensor.

When mounting the sensor vertically, position the cable entries

at the bottom.

If necessary, rotate the transmitter housing accordingly.

1

G12036

Figure 41: Installation set for cable conduit (Conduit)

NOTICE

Condensate formation in terminal box!

If the flowmeter sensor is permanently connected to cable

conduits, there is a possibility that moisture may get into the

terminal box as a result of condensate formation in the cable

conduit.

• Make sure that the cable conduits on the terminal box are

sealed.

An installation set for sealing the cable conduit is available

through order number 3KXF081300L0001 (Conduit).

1 Drip loop

Figure 42: Installation of the connection cable (example, integral mount design)

1

G12151

Page 35

FEP630, FEH630 ELECTROMAGNETIC FLOWMETER | OI/FEP630/FEH630-EN REV. D 35

Notes on signal cable installation

(only for remote mount design)

Observe the following points when installing the signal cable:

• The maximum signal cable length is 200 m (565 ft).

• Only used signal cable which is in accordance with the

following cable specifications.

• Avoid the vicinity of electrical equipment or switching

elements that can create stray fields, switching pulses

and induction. If this is not possible, run the signal /

magnet coil cable through a metal pipe and connect this

to the station ground.

• To shield against magnetic interspersion, the cable

contains outer shielding. This should be connected to the

SE clamp.

• Do not damage the sheathing of the cable during

installation.

The signal cable used for the connection of the transmitter and

sensor must fulfill at least the following technical specifications.

Cable specification

Impedance 100 to 200 Ω

Withstand voltage 120 V

Outer diameter 6 to 12 mm

(0.24 to 0.47 in)

Cable design Two wire pairs as a star-quad cable

Conductor cross-section Length-dependent

Shield Copper braid with

approximately 85 % coverage

Temperature range Depends on application.

Maximum signal cable length

0.25 mm2 (AWG 24) 50 m (164 ft)

0.34 mm2 (AWG 22) 100 m (328 ft)

0.5 mm2 (AWG 20) 150 m (492 ft)

0.75 mm2 (AWG 19) 200 m (656 ft)

Recommended cables