ABB HygienicMaster FEH630, ProcessMaster FEP632, ProcessMaster FEP630, ProcessMaster FEP631, HygienicMaster FEH632 Operating Instruction

...Page 1

—

ABB MEASUREMENT & ANALYTICS | EX SAFETY INSTRUCTIONS

ProcessMaster FEP630, HygienicMaster FEH630

Electromagnetic flowmeter

Safety instructions FM / cFM Div. 1,

Div. 2

Measurement made easy

—

ProcessMaster FEP630

HygienicMaster FEH630

This document forms an integral part of the

following manuals:

• Operating instruction OI/FEP630/FEH630-EN

• Commissioning instruction

CI/FEP630/FEH630-EN

Additional Information

Additional documentation on ProcessMaster FEP630,

HygienicMaster FEH630 is available for download

free of charge at www.abb.com/flow.

Alternatively simply scan this code:

Page 2

2 ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A

Table of contents

Change from one to two columns

1 Safety .......................................................................... 3

General information and instructions .................................. 3

Warnings .................................................................................... 3

Improper use ............................................................................. 4

Notes on data safety ............................................................... 4

Warranty provisions ................................................................. 4

2 Device designs ........................................................... 5

Version in integral mount design .......................................... 6

DIV. 1 ...................................................................................... 6

DIV. 2 ...................................................................................... 7

Version with remote mount design ...................................... 8

DIV. 1 ...................................................................................... 8

Div. 2 ....................................................................................... 9

Overview: The fast track to explosion protection device

data ........................................................................................... 11

3 Name plate ................................................................ 11

Device identification – name plate ...................................... 11

4 Housing ..................................................................... 12

Opening and closing the housing ....................................... 12

Dual- compartment housing ........................................... 12

Single-compartment housing ......................................... 13

Rotating the transmitter housing and LCD display .... 13

Installation instructions ........................................................ 14

cFMus .................................................................................. 14

Use in areas exposed to combustible dust .................. 14

Electrical connections ........................................................... 15

Process sealing ....................................................................... 15

High temperature design ..................................................... 16

5 Installing the plug-in cards..................................... 17

6 Operation in Div. 1 ................................................... 18

Electrical connections ........................................................... 18

Electric data for operation in Div. 1 ..................................... 19

Devices with HART protocol ............................................ 19

Special connection conditions ........................................ 21

Protection against electrostatic discharges ................ 21

Repair ................................................................................... 21

Temperature data .................................................................. 22

Surface temperature......................................................... 22

Measuring medium temperature as a function of liner

and flange material ........................................................... 22

Measuring medium temperature (Ex Data) for

ProcessMaster Model FEP631 ......................................... 23

Measuring medium temperature (Ex Data) for

ProcessMaster Model FEP632 ......................................... 24

Measuring medium temperature (Ex Data) for

HygienicMaster Model FEH631 ....................................... 25

7 Operation in Div. 2 ................................................... 27

Electrical connections ........................................................... 27

Electric data for operation in Div. 2 .................................... 29

Devices with HART protocol ............................................ 29

Special connection conditions ........................................ 30

Protection against electrostatic discharges................ 30

Temperature data .................................................................. 30

Surface temperature ........................................................ 30

Measuring medium temperature as a function of liner

and flange material ........................................................... 31

Measuring medium temperature (Ex Data) for

ProcessMaster Model FEP631 ......................................... 32

Measuring medium temperature (Ex Data) for

ProcessMaster Model FEP632 ......................................... 34

Measuring medium temperature (Ex Data) for

HygienicMaster Model FEH631 ....................................... 35

Measuring medium temperature (Ex Data) for

HygienicMaster Model FEH632 ....................................... 37

8 Commissioning ........................................................ 38

Checks before commissioning ............................................ 38

Output configuration for NAMUR switching amplifier ... 38

Configuring the current output ...................................... 38

Configuring the digital outputs ..................................... 38

9 Changing the type of protection ........................... 40

10 Maintenance ............................................................ 41

Sensor ...................................................................................... 41

Cleaning ................................................................................... 41

11 Repair ........................................................................ 41

Safety instructions ................................................................ 41

Spare parts .............................................................................. 42

Replacing the fuse ................................................................. 42

Replacing the frontend board ............................................. 43

Integral mount design ...................................................... 43

Remote mount design ...................................................... 45

Replacing the sensor ............................................................. 46

Returning devices .................................................................. 46

12 Recycling and disposal ........................................... 47

Dismounting ........................................................................... 47

Disposal ................................................................................... 47

13 Additional documents ............................................ 47

14 Appendix .................................................................. 48

Return form ............................................................................. 48

Installation diagram 3KXF000061G0009 .......................... 49

Page 3

ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A 3

1 Safety

General information and instructions

These instructions are an important part of the product and

must be retained for future reference.

Installation, commissioning, and maintenance of the product

may only be performed by trained specialist personnel who have

been authorized by the plant operator accordingly. The specialist

personnel must have read and understood the manual and must

comply with its instructions.

For additional information or if specific problems occur that are

not discussed in these instructions, contact the manufacturer.

The content of these instructions is neither part of nor an

amendment to any previous or existing agreement, promise or

legal relationship.

Modifications and repairs to the product may only be performed

if expressly permitted by these instructions.

Information and symbols on the product must be observed.

These may not be removed and must be fully legible at all times.

The operating company must strictly observe the applicable

national regulations relating to the installation, function testing,

repair and maintenance of electrical products.

Warnings

The warnings in these instructions are structured as follows:

DANGER

The signal word ‘DANGER’ indicates an imminent danger.

Failure to observe this information will result in death or

severe injury.

WARNING

The signal word ‘WARNING’ indicates an imminent danger.

Failure to observe this information may result in death or

severe injury.

CAUTION

The signal word ‘CAUTION’ indicates an imminent danger.

Failure to observe this information may result in minor or

moderate injury.

NOTICE

The signal word

‘

NOTIC

E

’

indicates possible material damage.

Note

‘Note’ indicates useful or important information about the

product.

Page 4

4 ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A

… 1 Safety

… Warnings

The device has been designed for use exclusively within the

technical limit values indicated on the identification plate and in

the data sheets.

When using measuring media, the following points must be

observed:

• Wetted parts such as measuring electrodes, liner,

grounding electrodes, grounding plates or protection

plates must not be damaged by the chemical and physical

properties of the measuring medium during the operating

time.

• Measuring media with unknown properties or abrasive

measuring media may only be used if the operator is able

to perform regular and suitable tests to ensure the safe

condition of the device

• The indications on the name plate must be observed

• Before use of corrosive or abrasive measuring media, the

operator must clarify the level of resistance of wetted

parts.

ABB will gladly support you in the selection, but cannot

accept any liability in doing so.

Improper use

The following are considered to be instances of improper use of

the device:

• Operation as a flexible compensating adapter in piping,

for example for compensating pipe offsets, pipe

vibrations, pipe expansions, etc.

• For use as a climbing aid, for example for mounting

purposes.

• For use as a bracket for external loads, for example as a

support for piping, etc.

• Material application, for example by painting over the

housing, name plate or welding/soldering on parts.

• Material removal, for example by spot drilling the housing.

Notes on data safety

This product is designed to be connected to and to

communicate information and data via a network interface.

It is operator’s sole responsibility to provide and continuously

ensure a secure connection between the product and your

network or any other network (as the case may be).

Operator shall establish and maintain any appropriate measures

(such as but not limited to the installation of firewalls,

application of authentication measures, encryption of data,

installation of anti-virus programs, etc.) to protect the product,

the network, its system and the interface against any kind of

security breaches, unauthorized access, interference, intrusion,

leakage and / or theft of data or information.

ABB Automation Products GmbH and its affiliates are not liable

for damages and / or losses related to such security breaches,

any unauthorized access, interference, intrusion, leakage and / or

theft of data or information.

Warranty provisions

Using the device in a manner that does not fall within the scope

of its intended use, disregarding this manual, using

underqualified personnel, or making unauthorized alterations

releases the manufacturer from liability for any resulting

damage. This renders the manufacturer's warranty null and void.

Change from two to one column

Page 5

ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A 5

2 Device designs

Two device ranges are available in the 630 series. ProcessMaster 630 and HygienicMaster 630.

Two designs (integral mount / remote mount) are available within each device range.

This results in the following variants:

• ProcessMaster FEP631, integral mount device

• ProcessMaster FEP632, flow sensor remote mount design

• HygienicMaster FEH631, integral mount device

• HygienicMaster FEH632, flow sensor remote mount design

• Remote transmitter FET632 for ProcessMaster / HygienicMaster

Devices suitable for use in potentially explosive atmospheres feature the corresponding Ex mark on their name plates.

Moreover, each device design has a specific model number.

The parts of the model number relating to explosion protection are listed in the following table. The complete key to model numbers

is described in the device data sheet.

ProcessMaster FEP631, integral mount device

ProcessMaster FEP632, flow sensor remote mount design

HygienicMaster FEH631, integral mount device

HygienicMaster FEH632, flow sensor remote mount design

Remote transmitter for ProcessMaster / HygienicMaster

FEP631

FEP632

FEH631

FEH632

FET632

XX XX

Explosion protection

Without Y0

ATEX / IECEx (Zone 1 / 21) A1

ATEX / IECEx (Zone 2 / 22) A2

cFMus Class I, II, III Div. 1 (Zone 1 / 21)) F1

cFMus Class I, II, III Div. 2 (Zone 2 / 22) F2

NEPSI (Zone 1 / 21) S1

NEPSI (Zone 2 / 22) S2

Design / terminal box material / cable glands

Single-compartment / aluminum / M20 x 1.5 S1

Single-compartment / Aluminum / NPT ½ in S2

Dual-compartment / aluminum / M20 x 1.5 D1

Dual-compartment / Aluminum / NPT ½ in D2

Dual-compartment / stainless steel / M20 x 1.5 D3

Dual-compartment / stainless steel / NPT ½ in D4

Dual-compartment / aluminum / M20 x 1.5 (Ex ‘d’ cable gland) D6

Dual-compartment / stainless steel / M20 x 1.5 (Ex ‘d’ cable gland) D8

Remote mount / aluminum / M20 x 1.5 A1

Remote mount / Aluminum / NPT ½ in A2

Field mount housing / single-compartment / aluminum / M20 x 1.5 F1

Field mount housing / single-compartment / aluminum / NPT ½ in F2

Wall-mount housing / dual-compartment / aluminum / M20 x 1.5 W1

Wall-mount housing / dual-compartment / Aluminum / NPT ½ in W2

Wall-mount housing / dual-compartment / stainless steel / M20 x 1.5 W3

Wall-mount housing / dual-compartment / stainless steel / NPT ½ in W4

Wall-mount housing / dual-compartment / aluminum / M20 x 1.5 (Ex ‘d’ cable gland) W5

Wall-mount housing / dual-compartment / stainless steel / M20 x 1.5 (Ex ‘d’ cable gland) W7

Table 1: Excerpt from ordering information

Page 6

6 ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A

… 2 Device designs

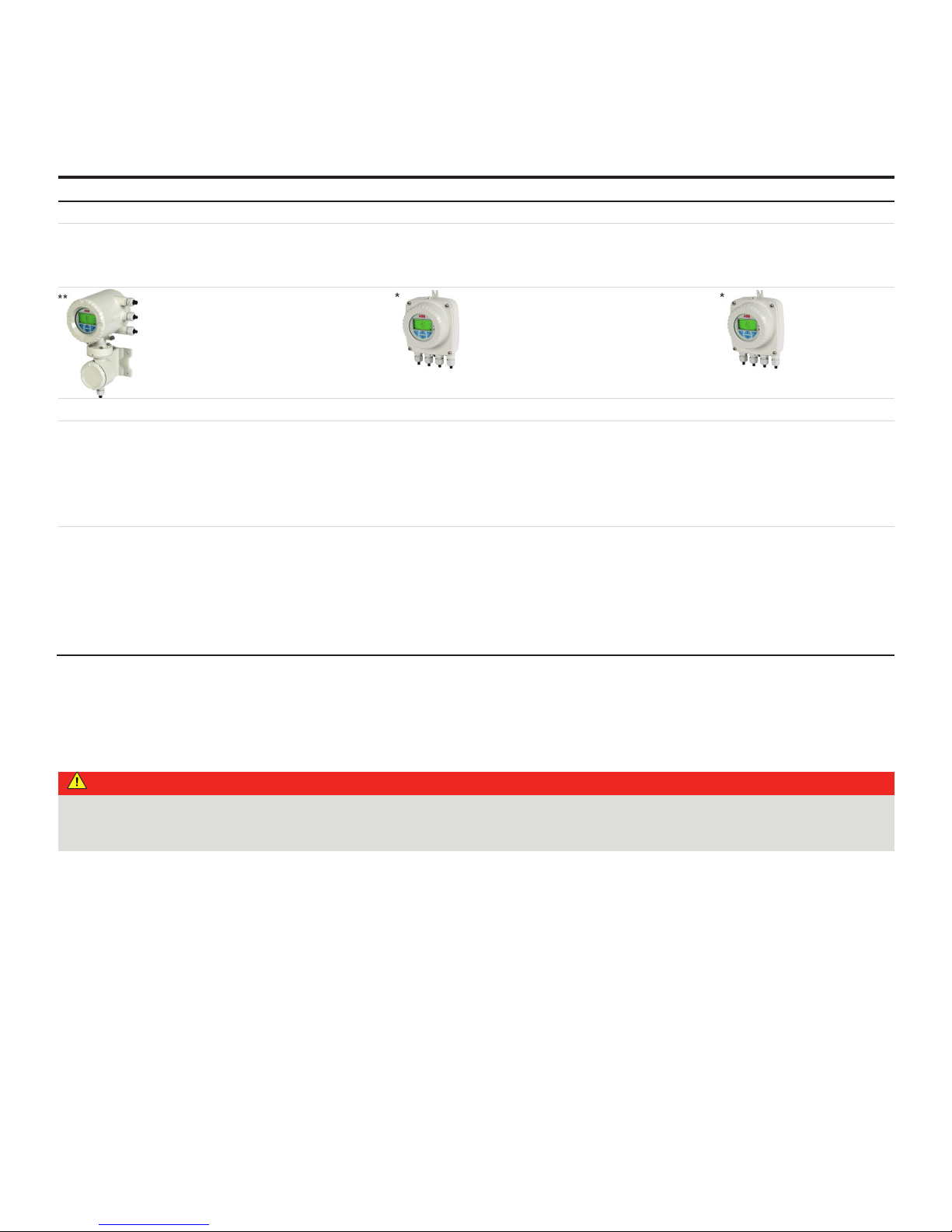

Version in integral mount design

The transmitter and the flowmeter sensor form a single mechanical entity.

The transmitter is available in two housing designs

• Single-compartment housing

This is suited for use in CI I Div. 2

In the single-compartment housing, the electronics chamber and the connection chamber in the transmitter are not separated

from each other.

• Dual- compartment housing:

This is suited for use in CI I Div. 1

In the dual-compartment housing, the electronics chamber and the connection chamber in the transmitter are separated from

each other.

Note

Further information on the Ex Approval of devices can be found in the type examination certificates or the relevant certificates at

www.abb.com/flow.

DIV. 1

Sensor

ProcessMaster 630 HygienicMaster 630

FEP631-F1 FEH631-F1

Div. 1 Div. 1

USA, FM approval USA, FM approval

Certificate: FM17US0062X Certificate: FM17US0062X

DN3-300:

S-XP-IS: CL I, Div 1, GPS ABCD T6...T1

DIP: CL II,III, Div 1, GPS EFG T6...T3B

>DN300:

CL I, ZN 1, AEx db eb mb [ia Ga] IIC T6…T1 Gb

DN3-100:

S-XP-IS: CL I, Div 1, GPS ABCD T6...T1

DIP: CL II,III, Div 1, GPS EFG T6...T3B

ZN 21, AEx tb [ia Da] IIIC T80°C...T165°C Db

Canada, FM approval Canada, cFM approval

Certificate: FM17CA0033X Certificate: FM17CA0033X

DN3-300:

S-XP-IS: CL I, Div 1, GPS BCD T6...T1

DIP: CL II,III, Div 1, GPS EFG T6...T3B

>DN300:

CL I, ZN 1, Ex db eb mb [ia Ga] IIC T6…T1 Gb

DN3-100:

S-XP-IS: CL I, Div 1, GPS BCD T6...T1

DIP: CL II,III, Div 1, GPS EFG T6...T3B

Ex tb [ia Da] IIIC T80°C...T165°C Db

Page 7

ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A 7

DIV. 2

Sensor

ProcessMaster 630 HygienicMaster 630

FEP631-F2 FEH631-F2

Div. 2 Div. 2

USA, FM approval USA, FM approval

Certificate: FM17US0062X Certificate: FM17US0062X

NI: CL I, Div 2, GPS ABCD T6...T1 NI: CL I, Div 2, GPS ABCD T6...T1

DIP: CL II,III, Div 2, GPS EFG T6…T3B

CL I, ZN 2, AEx ec IIC T6…T1

ZN 21, AEx tb IIIC T80°C...T165°C

DIP: CL II,III, Div 2, GPS EFG T6…T3B

CL I, ZN 2, AEx ec IIC T6…T1

ZN 21, AEx tb IIIC T80°C...T165°C

Canada, cFM approval Canada, cFM approval

Certificate: FM17CA0033X Certificate: FM17CA0033X

NI: CL I, Div 2, GPS ABCD T6...T1 NI: CL I, Div 2, GPS ABCD T6...T1

DIP: CL II,III, Div 2, GPS EFG T6…T3B

CL I, ZN 2, Ex ec IIC T6...T1 Gc

Ex tb IIIC T80°C...T165°C Db

DIP: CL II,III, Div 2, GPS EFG T6…T3B

CL I, ZN 2, Ex ec IIC T6...T1 Gc

Ex tb IIIC T80°C...T165°C Db

* Single-compartment housing

** Dual-compartment housing

Page 8

8 ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A

… 2 Device designs

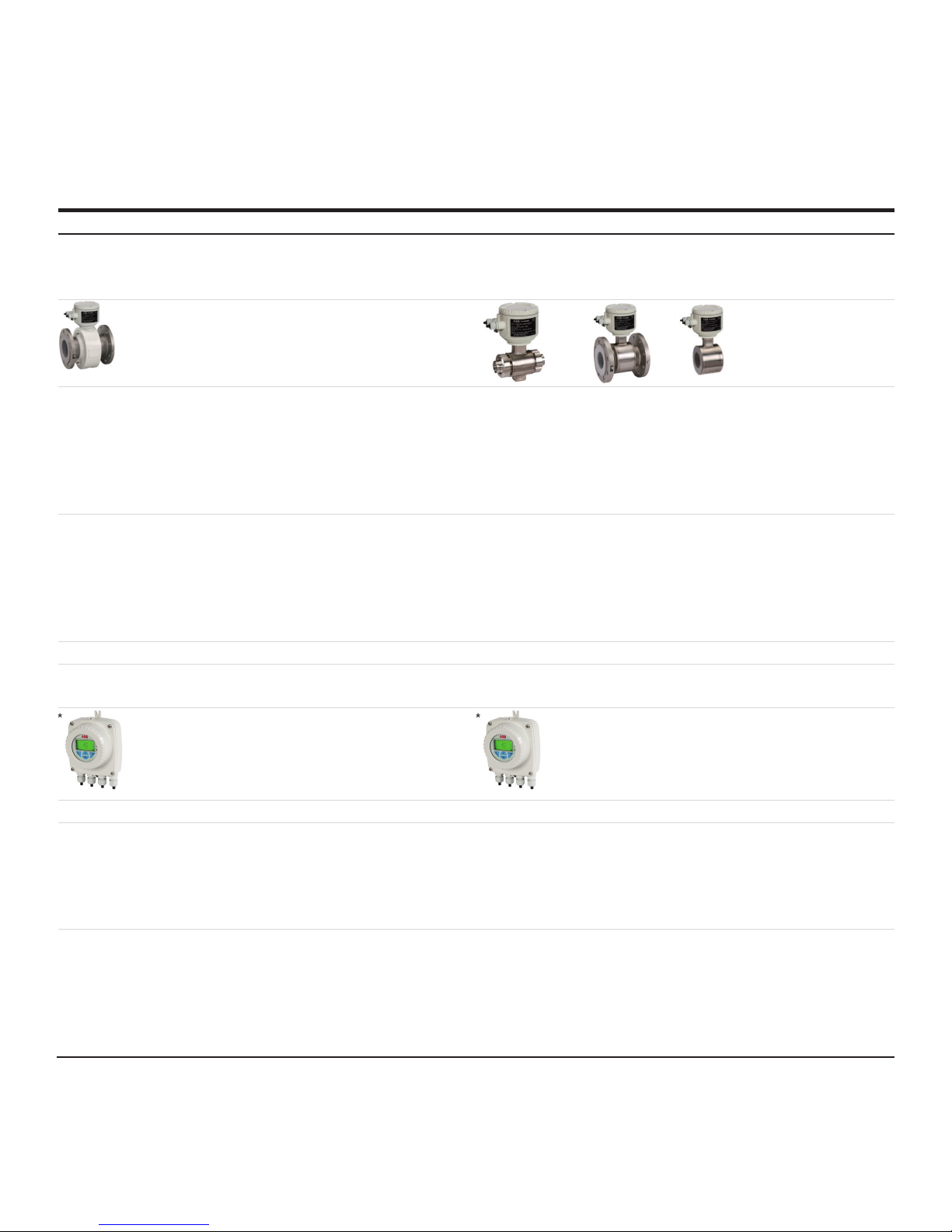

Version with remote mount design

The transmitter is mounted in a separate location from the flowmeter sensor. The electrical connection between the transmitter and

flowmeter sensor may only be established using the signal cable supplied.

A maximum signal cable length of 200 m (656 ft) is possible.

Note

Further information on the Ex Approval of devices can be found in the type examination certificates or the relevant certificates at

www.abb.com/flow.

DIV. 1

DANGER

Explosion hazard caused by incorrect transmitter installation

The FET632-Y0 transmitter does not have Ex Approval.

The FET632-Y0 transmitter may not be installed and operated in potentially explosive atmospheres.

The following table presents the combination of the FEP632, FEH632 sensor in explosion-proof design with the FET632 transmitter.

Sensor

ProcessMaster 630 HygienicMaster 630

FEP632-F1 FEH632-F1

in Ex area, Div. 1 in Ex area, Div. 1

USA, FM approval USA, FM approval

Certificate: FM17US0062X Certificate: FM17US0062X

DN3-300:

S-XP-IS: CL I, Div 1, GPS BCD T6...T1

DIP: CL II,III, Div 1, GPS EFG T6...T3B

DN3-100:

S-XP-IS: CL I, Div 1, GPS BCD T6...T1

DIP: CL II,III, Div 1, GPS EFG T6...T3B

>DN300:

CL I, ZN 1, AEx db eb mb [ia Ga] IIB+H2 T6…T1 Gb

ZN 21, AEx tb [ia Da] IIIC T80°C...T165°C Db

Canada, cFM approval Canada, cFM approval

Certificate: FM17CA0033X Certificate: FM17CA0033X

DN3-300:

S-XP: CL I, Div 1, GPS BCD T6...T1

DIP: CL II,III, Div 1, GPS EFG T6…T3B

DN3-100:

S-XP: CL I, Div 1, GPS BCD T6...T1

DIP: CL II,III, Div 1, GPS EFG T6…T3B

>DN300:

CL I, ZN 1, Ex db eb mb IIB+H2 T6…T1 Gb

Ex tb IIIC T80°C...T165°C Db

Page 9

ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A 9

Sensor

Transmitter

FET632-F1 FET632-F2 FET632-Y0

in Ex area, Div. 1 in Ex area, Div. 2 outside the potentially explosive

atmosphere

USA, FM approval USA, FM approval -

Certificate: FM17US0062X Certificate: FM17US0062X No Ex Approval!

XP-IS: CL I, Div 1, GPS BCD T6 NI: CL I, Div 2, GPS ABCD T6

DIP: CL II,III, Div 1, GPS EFG T6

CL I, ZN 1, AEx db [ia Ga] IIB+H2 T6 Gb

ZN 21, AEx tb [ia Da] IIIC T80°C Db

DIP: CL II,III, Div 2, GPS EFG T6

CL I, ZN 2, AEx ec IIC T6

ZN 21, AEx tb IIIC T80°C

Canada, cFM approval Canada, cFM approval

Certificate: FM17CA0033X Certificate: FM17CA0033X

XP-IS: CL I, Div 1, GPS BCD T6 NI: CL I, Div 2, GPS ABCD T6

DIP: CL II,III, Div 1, GPS EFG T6

CL I, ZN 1, Ex db [ia Ga] IIB+H2 T6 Gb

Ex tb [ia Da] IIIC T80°C Db

DIP: CL II,III, Div 2, GPS EFG T6

Ex ec IIC T6 Gc

Ex tb IIIC T80°C Db

* Single-compartment housing

** Dual-compartment housing

Div. 2

DANGER

Explosion hazard caused by incorrect transmitter installation

The FET632-Y0 transmitter does not have Ex Approval.

The FET632-Y0 transmitter may not be installed and operated in potentially explosive atmospheres.

Page 10

10 ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A

… 2 Device designs

… Version with remote mount design

The following table presents the combination of the FEP632, FEH632 sensor in explosion-proof design with the FET632 transmitter.

Sensor

ProcessMaster 630 HygienicMaster 630

FEP632-F2 FEH632-F2

in Ex area, Div. 2 in Ex area, Div. 2

USA, FM approval USA, FM approval

Certificate: FM17US0062X Certificate: FM17US0062X

NI: CL I, Div 2, GPS ABCD T6...T1 NI: CL I, Div 2, GPS ABCD T6...T1

DIP: CL II,III, Div 2, GPS EFG T6…T6…T3B

CL I, ZN 2, AEx ec IIC T6…T1

ZN 21, AEx tb IIIC T80°C...T165°C

DIP: CL II,III, Div 2, GPS EFG T6…T6…T3B

CL I, ZN 2, AEx ec IIC T6…T1

ZN 21, AEx tb IIIC T80°C...T165°C

Canada, cFM approval Canada, cFM approval

Certificate: FM17CA0033X Certificate: FM17CA0033X

NI: CL I, Div 2, GPS ABCD T6...T1 NI: CL I, Div 2, GPS ABCD T6...T1

DIP: CL II,III, Div 2, GPS EFG T6…T3B

CL I, ZN 2, Ex ec IIC T6...T1 Gc

Ex tb IIIC T80°C...T165°C Db

DIP: CL II,III, Div 2, GPS EFG T6…T3B

CL I, ZN 2, Ex ec IIC T6...T1 Gc

Ex tb IIIC T80°C...T165°C Db

Transmitter

FET632-F2 FET632-Y0

In Ex area, Zone 2, 22 outside the potentially explosive atmosphere

USA, FM approval -

Certificate: FM17US0062X No Ex Approval!

NI: CL I, Div 2, GPS ABCD T6

DIP: CL II,III, Div 2, GPS EFG T6

CL I, ZN 2, AEx ec IIC T6

ZN 21, AEx tb IIIC T80°C

Canada, cFM approval

Certificate: FM17CA0033X

NI: CL I, Div 2, GPS ABCD T6

DIP: CL II,III, Div 2, GPS EFG T6

Ex ec IIC T6 Gc

Ex tb IIIC T80°C Db

* Single-compartment housing

** Dual-compartment housing

Change from one to two columns

Page 11

ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A 11

Overview: The fast track to explosion

protection device data

These safety instructions related to explosion protection are

valid in conjunction with the following test documentation and

certificates:

Table 2: Validity range

Model Operation in

zone

Electrical connection and

explosion protection

data

Chapter

ProcessMaster 630

FEP631-F1 Div. 1 Operation in Div. 1

FEP631-F2 Div. 2 Operation in Div. 2

FEP632-F1 and FET632-F1 Div. 1 Operation in Div. 1

FEP632-F1 and FET632-Y0 Div. 1 Operation in Div. 1

FEP632-F2 and FET632-F2 Div. 2 Operation in Div. 2

FEP632-F2 and FET632-Y0 Div. 2 Operation in Div. 2

HygienicMaster 630

FEH631-F1 Div. 1 Operation in Div. 1

FEH631-F2 Div. 2 Operation in Div. 2

FEH632-F1 and FET632-F1 Div. 1 Operation in Div. 1

FEH632-F1 and FET632-Y0 Div. 1 Operation in Div. 1

FEH632-F2 and FET632-F2 Div. 2 Operation in Div. 2

FEH632-F2 and FET632-Y0 Div. 2 Operation in Div. 2

Table 3: Overview

Note

All documentation, declarations of conformity, and certificates

are available in ABB's download area.

www.abb.com/flow

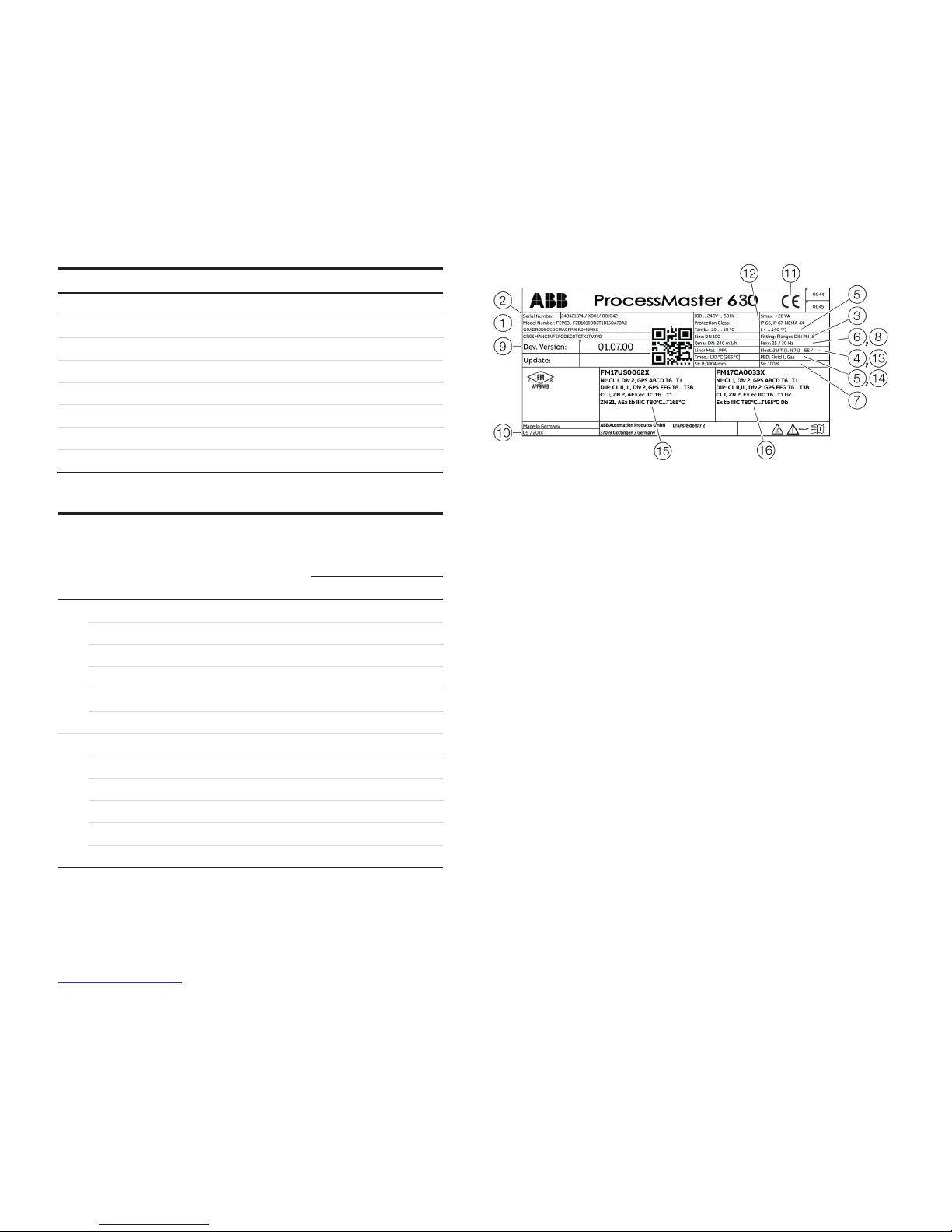

3 Name plate

Device identification – name plate

Note

The name plate shown is an example.

The name plate attached to the device can differ from this

representation.

1Model number (for more detailed

information about the technical

design, refer to the data sheet or

the order confirmation)

2 Order number / Serial number

for identification by the

manufacturer

3Meter size and nominal pressure

rating

4 Material: Flange / liner /

electrode

5 T

med

= maximum permissible

measuring medium temperature

T

amb

= maximum permissible

ambient temperature

6 Calibration value Q

max.

DN

7Calibration value Ss (span)

Calibration value Sz (zero point)

8 Excitation frequency of the

sensor

9Software version

j Year of manufacture

k CE mark

l IP rating in accordance with

EN 60529

m Supplementary information: EE =

grounding electrodes,

TFE = partial filling electrode

n Marking indicating whether the

pressure equipment is in the

scope of the Pressure Equipment

Directive.

Information on the relevant fluid

group.

Fluid group 1 = hazardous fluids,

liquid, gaseous. (Pressure

Equipment Directive = PED).

If the pressure equipment is not in

the scope of the Pressure

Equipment Directive 2014/68/EC,

it is classified in accordance with

SEP (= sound engineering

practice) in accordance with Art. 3

para. 3 of the PED.

If no such information is present,

it means that the device does not

claim to be in accordance with the

requirements of the Pressure

Equipment Directive 2014/68/EC.

Water supplies and connected

equipment accessories are

classed as an exception in

accordance with guideline 1/16 of

Art. 1 Para. 3.2 of the Pressure

Equipment Directive.

o Ex marking in accordance with

ATEX (example)

p Ex marking in accordance with

IECEx (example)

Figure 1: Name plate (example)

Note

Devices with 3A approval, EHEDG certificate, SIL are identified

with an additional plate.

Scope Certificate

ATEX Zone 1 / 21 FM17ATEX0016X

ATEX Zone 2 / 22 FM17ATEX 0017X

IEC Ex Zone 1 / 21 IECEx FME 17.0001X

IEC Ex Zone 2 / 22 IECEx FME 17.0001X

FMus Div 1 (USA) FM17US0062X

FMus Div 2 (USA) FM17US0062X

cFM Div 1 (Canada) FM17CA0033X

cFM Div 2 (Canada) FM17CA0033X

Page 12

12 ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A

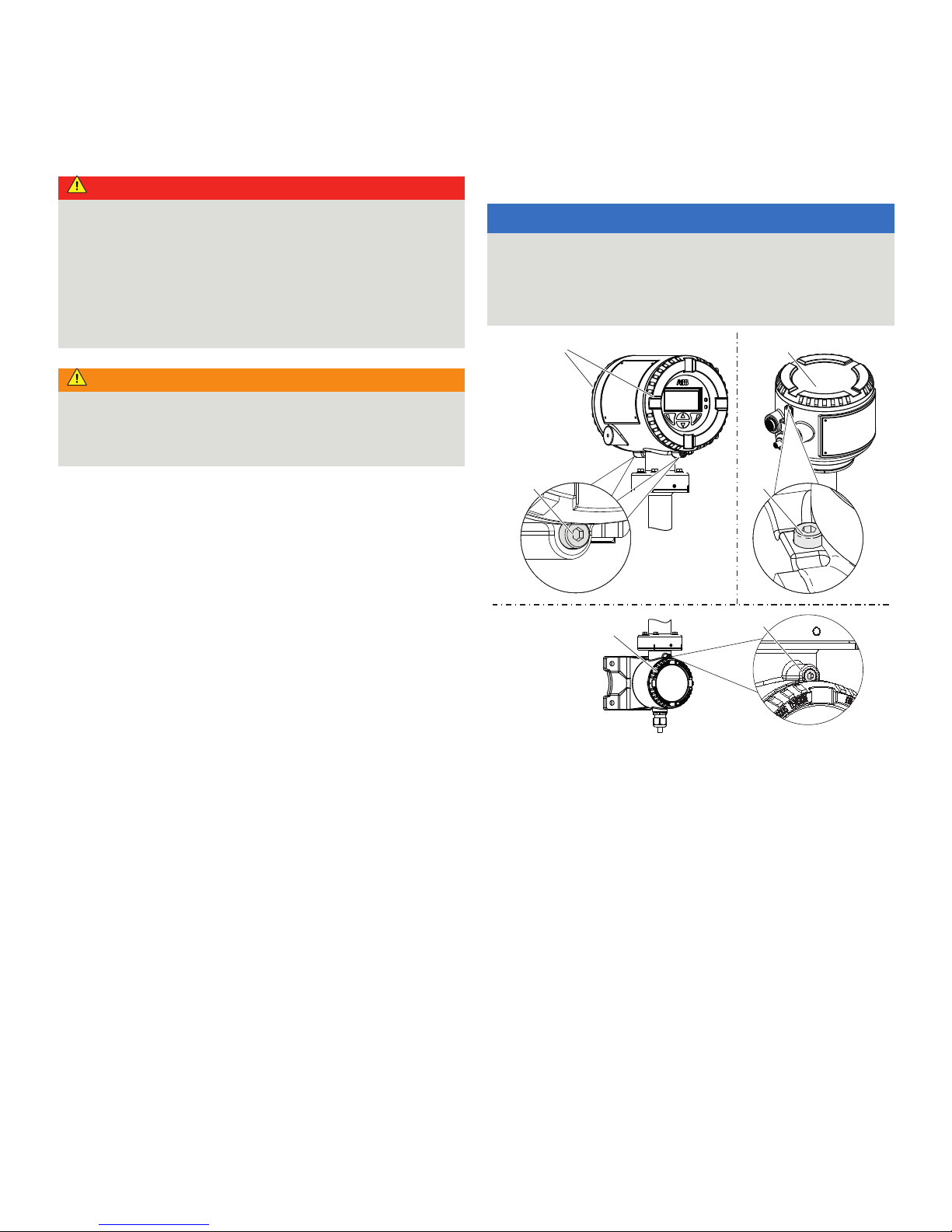

4 Housing

Opening and closing the housing

DANGER

Danger of explosion if the device is operated with the

transmitter housing or terminal box open!

Before opening the transmitter housing or the terminal box,

note the following points:

• A valid fire permit must be present.

• Make sure that there is no explosion hazard.

• Switch off the power supply and wait for t > 20 minutes

before opening.

WARNING

Risk of injury due to live parts!

When the housing is open, explosion protection and contact

protection is not provided and EMC protection is limited.

• Before opening the housing, switch off the power supply.

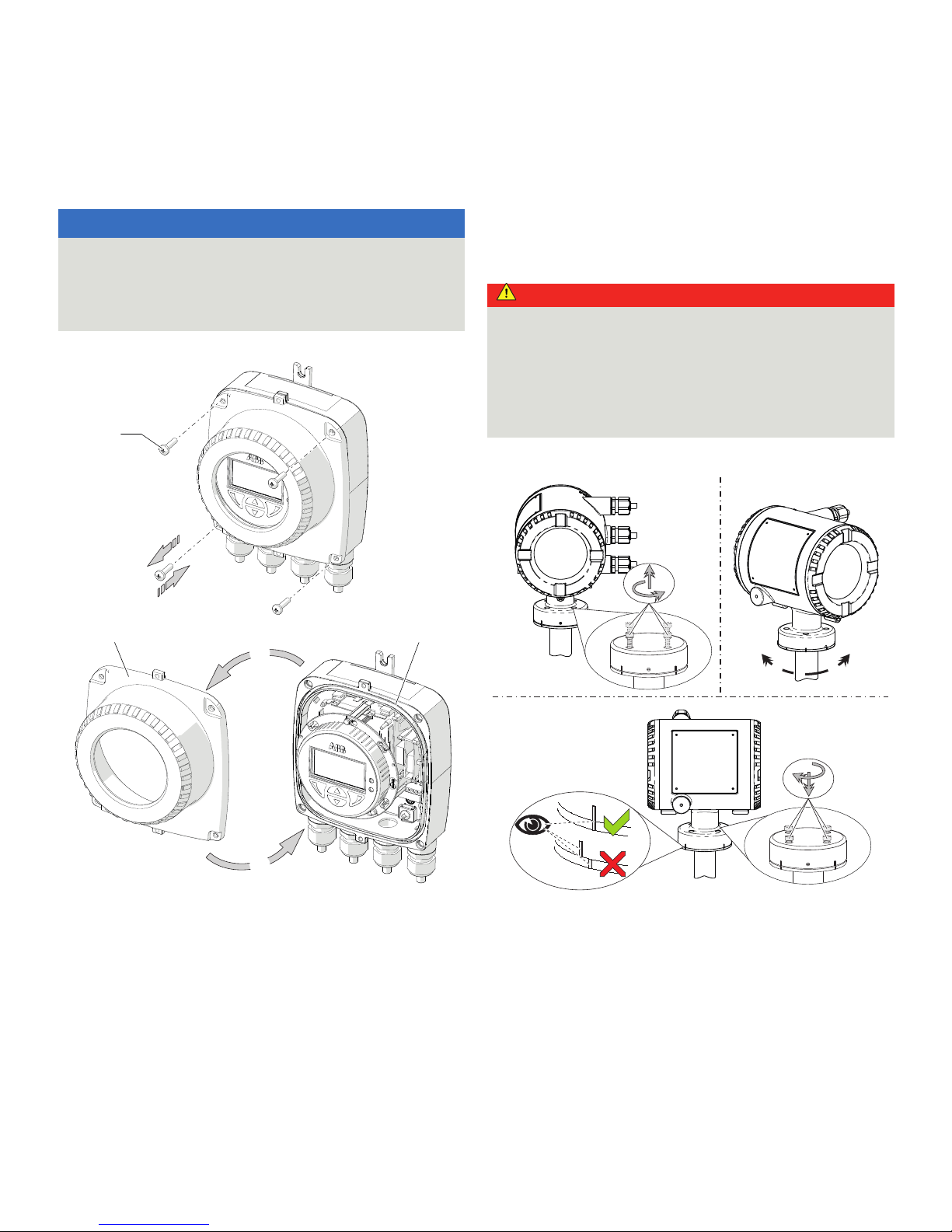

Dual- compartment housing

NOTICE

Potential adverse effect on the IP rating

• Check the O-ring gasket for damage and replace it if

necessary before closing the housing cover.

• Check that the O-ring gasket is properly seated when

closing the housing cover.

G11738-01

AB

C

1 1

2

1

2

2

A Integral mount design

B Remote mount design

C Transmitter, terminal space,

signal cable

Figure 2: Cover lock (example)

Open the housing:

1. Release the cover lock by screwing in the Allen screw

2.

2. Unscrew cover

1.

Close the housing:

1. Screw on the cover

1.

2. After closing the housing, lock the cover by unscrewing

the Allen screw

2.

Page 13

ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A 13

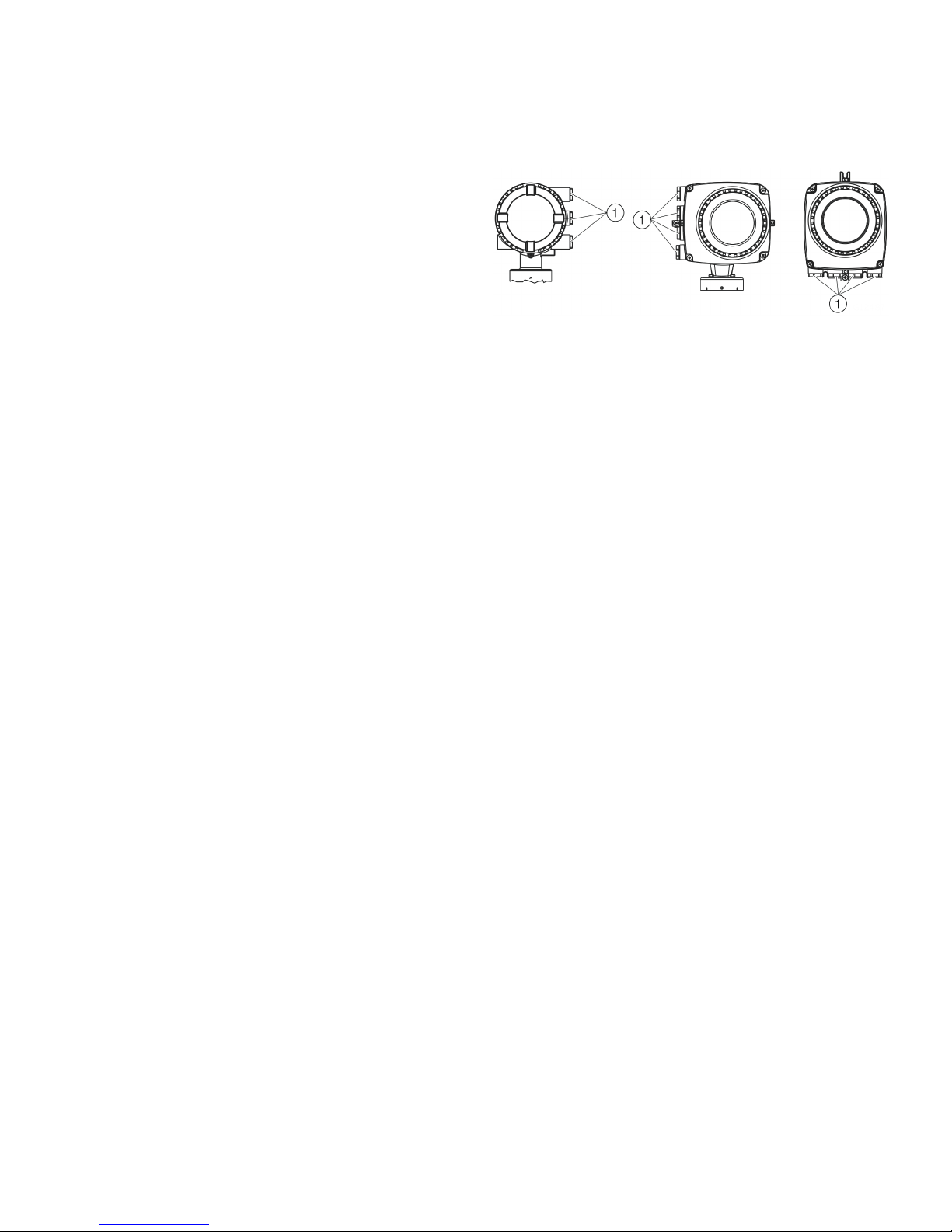

Single-compartment housing

NOTICE

Potential adverse effect on the IP rating

• Check the gasket for damage and replace it if necessary

before closing the housing cover.

• Check that the gaskets are properly seated when closing

the housing cover.

G12149

C

AA

B

D

1

2 3

1 Cover screws

2 Transmitter housing cover

3 Gasket

Figure 3: Open / close single-compartment housing

Open transmitter housing: Perform steps

A and B.

Close transmitter housing: Perform steps

C and D.

Rotating the transmitter housing and LCD display

Depending on the installation position, the transmitter housing

or LCD display can be rotated to enable horizontal readings.

Transmitter housing

DANGER

Damaging the device carries a risk of explosion!

When the screws for the transmitter housing are loosened, the

explosion protection is suspended.

Tighten all screws prior to commissioning.

Never disconnect the transmitter housing from the sensor.

Only loosen the screws shown when rotating the transmitter

housing!

Rotate transmitter housing: Perform steps

A to C.

G11569

AB

90°

90°

C

Figure 4: Rotate transmitter housing

Page 14

14 ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A

… 4 Housing

Installation instructions

cFMus

The installation, commissioning, maintenance and repair of

devices in areas with explosion hazard must only be carried out

by appropriately trained personnel.

The operator must strictly observe the applicable national

regulations with regard to installation, function tests, repairs,

and maintenance of electrical devices. (for example, NEC, CEC).

Use in areas exposed to combustible dust

When using the device in areas exposed to combustible dusts

(dust ignition), the following points must be observed:

• The maximum surface temperature of the device may not

up-scale the following values.

FEP631, FEH631 80 °C (176 °F)

FEP632, FEH632 80 °C (176 °F)

FET632 80 °C (176 °F)

• The process temperature of the attached piping may upscale 80 °C (176 °F).

• Approved dust-proof cable glands must be used when

operating in Zone 21, 22 or in Class II, Class III.

• In potentially explosive atmospheres, the signal cable

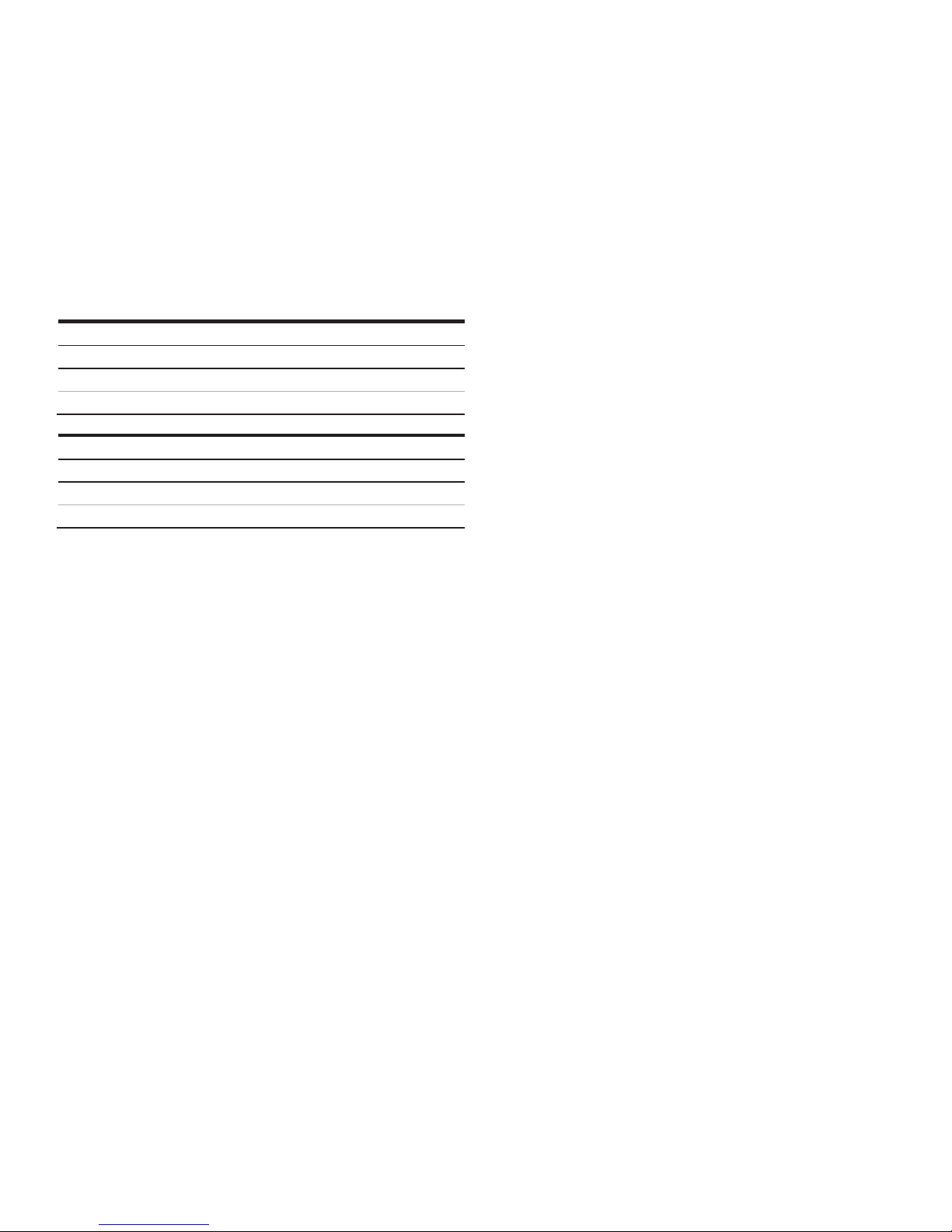

must measure at least 5 m (16.40 ft).

Cable entry

1 Transport protection plugs

Figure 5: Cable entry

The devices are delivered with ½ in NPT or PF ½ in threads with

transport protection plugs.

Unused cable entries must be sealed off prior to commissioning

using either approved pipe fittings or cable glands in accordance

with national regulations (NEC, CEC).

Make sure that the pipe fittings, cable glands and, if applicable,

sealing plugs are installed properly and tight.

If the device is to be operated in areas with combustible dusts, a

threaded pipe connection or cable gland with suitable approval

must be used.

The use of standard cable glands and seals is prohibited.

Any unused cable entries must be sealed before commissioning

in accordance with the applicable standards.

Note

Devices which are certified for use in North America are supplied

with a ½ in. NPT thread only and without cable glands.

Page 15

ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A 15

Electrical connections

Temperature resistance for the connecting cable

The temperature at the cable entries of the device is dependent

on the measuring medium temperature T

medium

and the ambient

temperature T

amb

.

For the electrical connection of the device, use only cables with

sufficient temperature resistance in accordance with the

following table.

Device in integral mount design

T

amb

Temperature resistance

á 50 °C (á 122 °F) â 60 °C (â 140 °F)

á 60 °C (á 140 °F) â 70 °C (â 158 °F)

Model in remote mount design

T

amb

Temperature resistance

á 50 °C (á 122 °F) â 70 °C (â 158 °F)

á 60 °C (á 140 °F) â 80 °C (â 176 °F)

Grounding

The sensor must be grounded in accordance with the applicable

international standards.

Perform grounding of the device in accordance with Electrical

connections on page 18.

In accordance with NEC standards, an internal ground

connection is present in the device between the sensor and the

transmitter.

Perform grounding of the device in accordance with Electrical

connections on page 18.

Process sealing

In accordance with the ‘North American Requirements for

Process Sealing between Electrical Systems and Flammable or

Combustible Process Fluids’.

Note

The device is suitable for use in Canada.

A maximum surface temperature of 165 °C (329 °F) must not be

up-scaled when used in Class II, Groups E, F and G.

All cable conduits should be sealed from the device within a

distance of 18 in (457 mm).

Among other things, devices with cable conduits are connected

to the electrical installation which makes it possible for

measuring media to reach the electric system.

To prevent process media from seeping into the electrical

installation, the instruments are equipped with process seals

which meet the requirements of ANSI / ISA 12.27.01.

The flow measurement devices are designed as ‘single seal

devices’ and are suited for the measurement of non-flammable

fluids.

In accordance with the requirements of standard ANSI/ISA

12.27.01, the existing operating limits of temperature, pressure

and pressure bearing parts must be reduced to the following

limit values:

Page 16

16 ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A

… 4 Housing

… Process sealing

Max. permissible operating temperature in acc. with ISA12.27.01

Liner material Nominal diameter Max. operating temperature in

acc. with ISA12.27.01

Hard rubber DN15 to 400 0 °C to 90 °C (32 °F to 194 °F)

DN450 to 2000 Max. 90 °C (194 °F)

Soft rubber DN50 to 400 0 °C to 60 °C (32 °F to 140 °F)

DN450 to 2000 0 °C to 60°C (140 °F)

PTFE DN10 to 400 Æ40 °C to 170 °C (Æ40 °F to 338 °F)

DN450 to 1000 Max. 130 °C (266 °F)

Thick PTFE DN10 to 400 Æ40 °C to 170 °C (Æ40 °F to 338 °F)

PFA DN3 to 200 Æ40 °C to 170 °C (Æ40 °F to 338 °F)

ETFE DN25 to 400 Æ40 °C to 150 °C (Æ40 °F to 302 °F)

DN450 to 1000 Max. 130 °C (266 °F)

Ceramic carbide DN25 to 400 0 °C to 80 °C (32 °F to 176 °F)

DN450 to 1000 0 °C to 80 °C (32 °F to 176 °F)

Max. permissible nominal pressure rating in acc. with

ISA12.27.01

Model Nominal diameter Max. nominal

pressure

Lining material

FEH DN10 to DN40 Class 150 All

DN50 to DN100 Class 150 All

FEP DN10 to DN50 Class 150 All

DN65 to DN400 Class 300 All

DN65 to DN400 Class 600 Hard rubber

DN450 to DN2600 Class 300 All

The operating temperature of the devices is determined by the

fluid temperature and the ambient temperature.

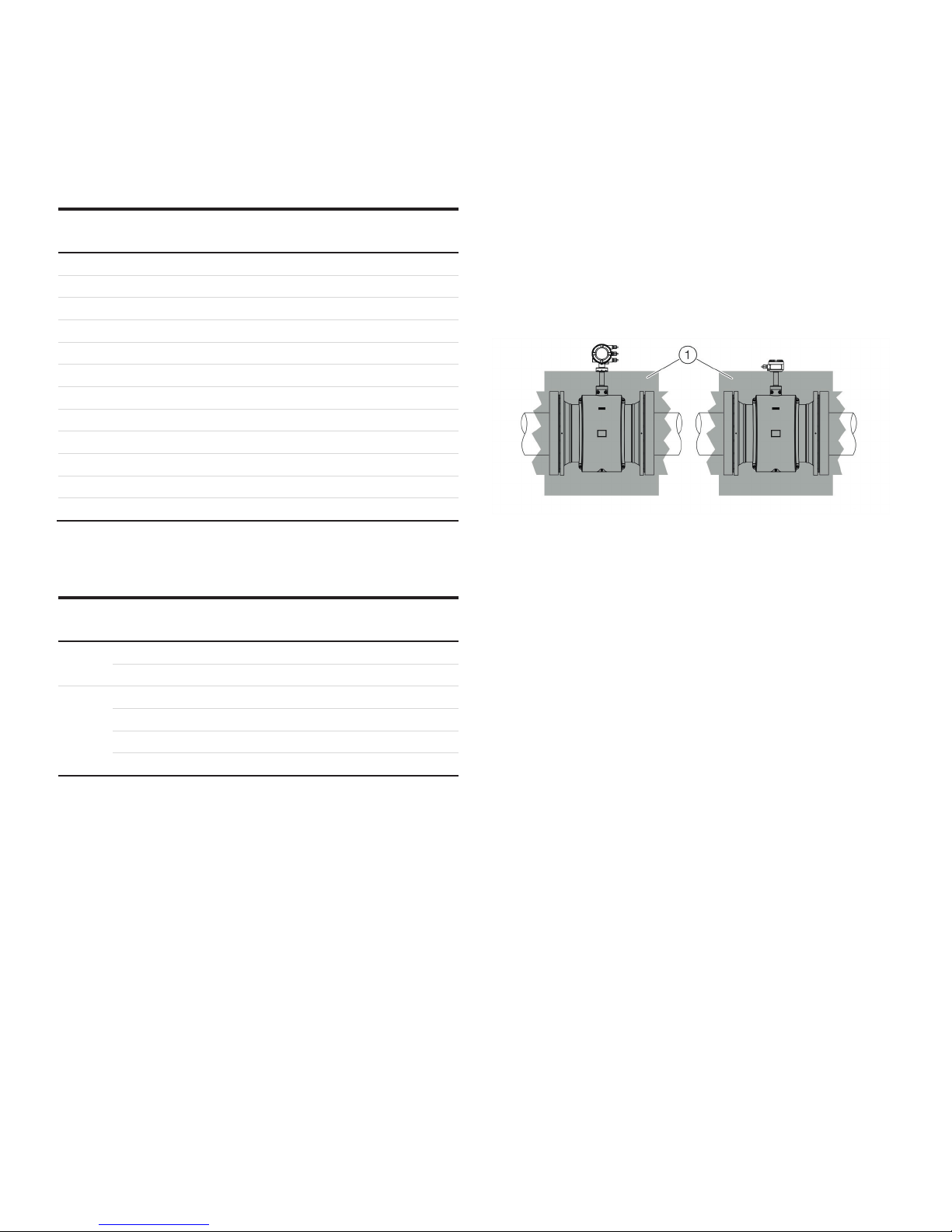

High temperature design

The high temperature design allows for complete thermal

insulation of the sensor, up to the maximum illustrated device

height.

The pipeline and sensor must be insulated after installing the

unit according to the following illustration.

The thermal resistance of the insulation may not up-scale

θ = 0.036 W/(mK); if it does, the thickness of the insulation must

be reduced accordingly.

1 Insulation

Figure 6: Insulation

Change from two to one column

Page 17

ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A 17

5 Installing the plug-in cards

WARNING

Loss of Ex Approval!

Loss of Ex Approval due to retrofitting of plug-in cards on devices for use in potentially explosive atmospheres.

• Devices for use in potentially explosive atmospheres may not be retrofitted with plug-in cards.

• If devices are to be used in potentially explosive atmospheres, the required plug-in cards must be specified when the order is

placed.

Note

The AS plug-in card (24 V DC loop power supply) may only be used to power the internal inputs and outputs on the device.

It must not be used to power external circuits!

Optional plug-in cards

The transmitter has two slots (OC1, OC2) into which plug-in cards can be inserted to extend inputs and outputs. The slots are located

on the transmitter motherboard and can be accessed after removing the front housing cover.

Plug-in card Description Number

*

Current output, 4 to 20 mA passive (red)

Order no.: 3KQZ400029U0100

Maximum of two plug-in cards

Passive digital output (green)

Order no.: 3KQZ400030U0100

Maximum of one plug-in card

Passive digital input (yellow)

Order no.: 3KQZ400032U0100

Maximum of one plug-in card

Loop power supply 24 V DC (blue)

Order no.: 3KQZ400031U0100

Maximum of one plug-in card

* The ‘Number’ column indicates the maximum number of plug-in cards of the same type that can be used.

Page 18

18 ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A

6 Operation in Div. 1

Electrical connections

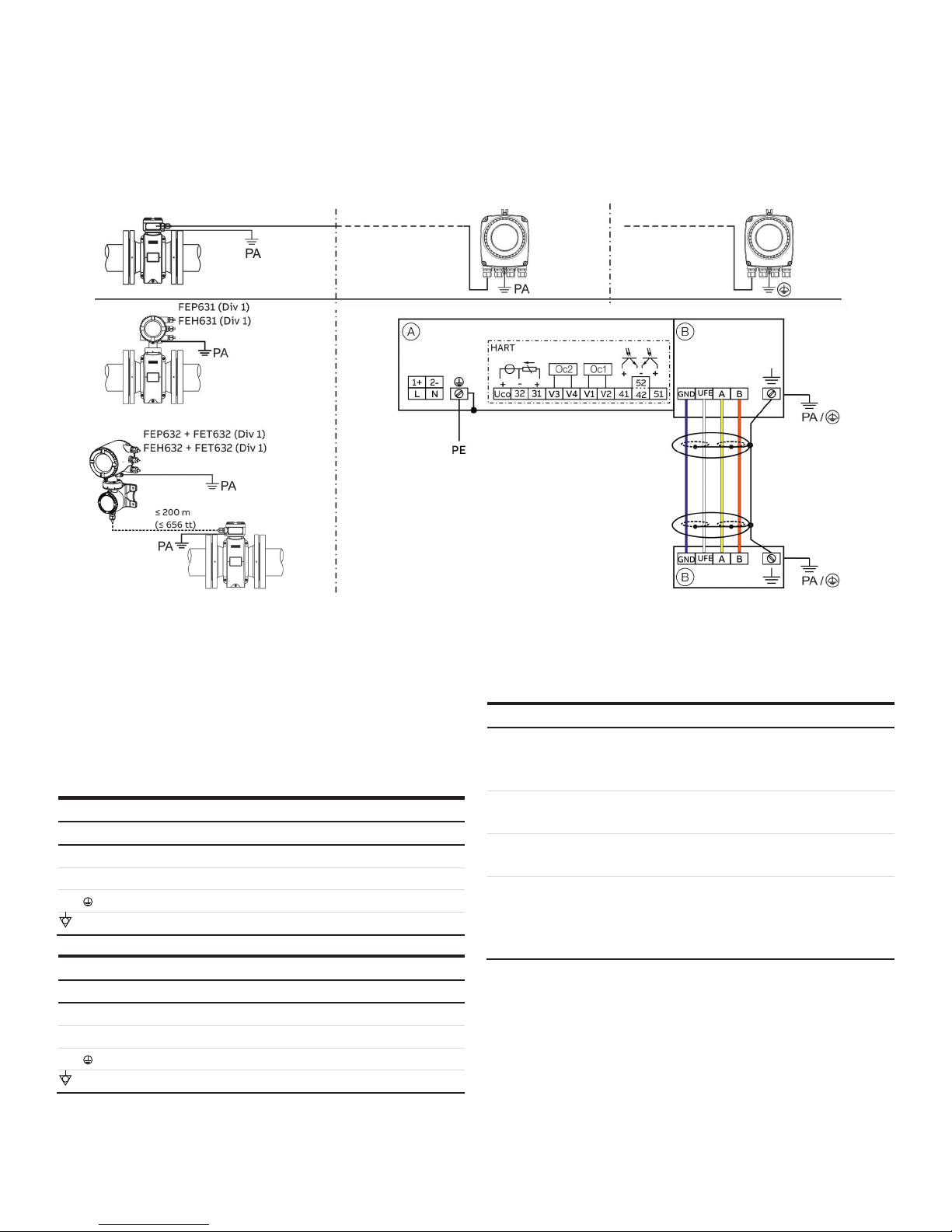

FEP632 sensor (Div 1) FET632 transmitter (Div 2) FET632 transmitter outside the hazardous area

A Transmitter

B Sensor

Figure 7: Electrical connections

Change from one to two columns

Note

For detailed information on grounding the transmitter and the

sensor, please refer to the operating or commissioning

instruction!

Connections for the power supply

AC power supply

Terminal Function / comments

L Phase

N Neutral conductor

PE / Protective earth (PE)

/ PA Potential equalization

DC voltage supply

Terminal Function / comments

1+ +

2Æ Æ

PE / Protective earth (PE)

/ PA Potential equalization

Connections for inputs and outputs

Terminal Function / comments

Uco / 32

31 / 32

Current output 4 to 20 mA- / HART output, active

or

Current output 4 to 20 mA- / HART output, passive

41 / 42 Passive digital output DO1

51 / 52 Passive digital output DO2

V1 / V2

V3 / V4

Plug-in card, slot OC1

Plug-in card, slot OC2

Plug-in cards may not be retrofitted in devices with explosion

protection on-site – loss of Ex Approval.

Page 19

ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A 19

Connecting the signal cable

Only for remote mount design.

The sensor housing and transmitter housing must be connected

to potential equalization.

Terminal Function / comments

UFE Sensor power supply

GND Ground

A Data line

B Data line

Functional earth / Shielding

Change from two to one column

Electric data for operation in Div. 1

Devices with HART protocol

When operating in potentially explosive areas, observe the following electrical data for the signal inputs and outputs of the

transmitter.

Current output terminals 31 / 32 / Uco can be operated on-site in active or passive mode through appropriate switching.

Model: FEP631, FEH631 or FET632 Type of protection

Outputs on basic device ‘e’ / ‘XP’ ‘ia’ / ‘IS’

U

M

[V]

I

M

[A]

U

O

U

I

[V]

I

O

[mA]

I

I

[mA]

P

O

[mW]

P

I

[mW]

C

O

[nF]

C

I

[nF]

C

OPA

[nF]

C

IPA

[nF]

L

O

[mH] L

I

[mH]

Current / HART output 31 / UCO, active

Terminals 31 / U

CO

30 0.2 30 30 115 115 815 815 10 10 5 5 0.08 0.08

Current / HART output 31 / 32, passive

Terminals 31 / 32

30 0.2 — 30 — 115

—

815 — 27 — 5 0.08 0.08

Digital output 41 / 42, active*

Terminals 41 / 42 and V1 / V2*

30 0.1 27.8 30 119 30 826 225 20 20 29 29 0.22 0.22

Digital output 41 / 42, passive

Terminals 41 / 42

30 0.1 — 30 — 30

—

225 — 27 — 5

—

0.08

Digital output 51 / 52, active*

Terminals 51 / 52 and V1 / V2*

30 0.1 27.8 30 119 30 826 225 20 20 29 29 0.22 0.22

Digital output 51 / 52, passive

Terminals 51 / 52

30 0.1 — 30 — 30

—

225 — 27 — 5

—

0.08

All outputs are electrically isolated from each other and from the power supply.

Digital outputs 41 / 42 and 51 / 52 are not electrically isolated from each other. Terminals 42 / 52 have the same potential.

Page 20

20 ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A

… 6 Operation in Div. 1

… Electric data for operation in Div. 1

Model: FEP631, FEH631 or FET632 Type of protection

Inputs and outputs with optional plug-in

cards

‘e’ / ‘XP’ ‘ia’ / ‘IS’

U

M

[V]

I

M

[A]

U

O

U

I

[V]

I

O

[mA]

I

I

[mA]

P

O

[mW]

P

I

[mW]

C

O

[nF]

C

I

[nF]

C

OPA

[nF]

C

IP

A

[nF]

L

O

[mH] L

I

[mH]

Current output V3 / V4, active*

Terminals V3 / V4 and V1 / V2*

30 0.1 27.8 30 119 30 826 225 29 29 117 117 0.4 0.4

Current output V1 / V2, passive**

Current output V3 / V4, passive**

Terminals V1 / V2** or V3 / V4**

30 0.1 — 30 — 68 — 510

—

45 — 59 — 0.27

Digital output V3 / V4, active*

Terminals V3 / V4 and V1 / V2*

30 0.1 27.8 30 119 68 826 225 17 17 31 31 0.4 0.4

Digital output V1 / V2, passive**

Digital output V3 / V4, passive**

Terminals V1 / V2** or V3 / V4**

30 0.1 — 30 — 30 — 225

—

13 — 16 — 0.27

Digital input V3 / V4, active*

Terminals V3 / V4 and V1 / V2

30 0.1 27.8 30 119 3.45 826 25.8 17 17 31 31 0.4 0.4

Digital input V1 / V2, passive*

Digital input V3 / V4, passive*

Terminals V1 / V2** or V3 / V4**

30 0.1 — 30 — 3.45 — 25.8

—

13 — 16 — 0.27

* Only in conjunction with additional ‘24 V DC loop power supply (blue)’ plug-in card in slot OC1.

** The terminal assignment depends on the model number or the slot assignments. For connection examples, refer to Installation in the operating instruction.

Change from one to two columns

Page 21

ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A 21

Special connection conditions

Note

The AS plug-in card (24 V DC loop power supply) may only be

used to power the internal inputs and outputs on the device.

It must not be used to power external circuits!

Note

If the protective earth (PE) is connected in the flowmeter's

terminal box, you must ensure that no dangerous potential

difference can arise between the protective earth (PE) and the

potential equalization (PA) in areas with explosion risk.

Note

For devices with a power supply of 16 to 30 V DC, on-site external

overvoltage protection must be provided.

It must be ensured that the overvoltage is limited to 140 % (=

42 V DC) of the maximum operating voltage.

The output circuits are designed so that they can be connected

to both intrinsically-safe and non-intrinsically-safe circuits.

• Combining intrinsically safe and non-intrinsically safe circuits

is not permitted.

• On intrinsically safe circuits, potential equalization should be

established along the entire length of the cable used for the

signal outputs.

• The rated voltage of the non-intrinsically safe circuits is

U

M

= 30 V.

• Intrinsic safety is preserved If the rated voltage U

M

= 30 V is

not up-scaled when connections are established to nonintrinsically safe external circuits.

• The information in Changing the type of protection on

page 40 must be observed when changing the type of

protection.

The concept of intrinsic safety allows several approved

intrinsically safe devices to be interconnected without additional

intrinsic safety installation checks, if the relevant installation

standards are observed.

Devices connected to the relevant equipment must not be

operated at over 250 V

rms

AC or 250 V DC to ground.

Installation in the USA or Canada must comply with ANSI / ISA

RP 12.6, ‘Installation of intrinsically safe systems for hazardous

(classified) locations’, the ‘National Electrical Code (ANSI / NFPA

70), sections 504, 505’ and the ‘Canadian electrical code (C22.1-

02)’.

Protection against electrostatic discharges

DANGER

Risk of explosion!

The painted surface of the device can store electrostatic

charges.

As a result, the housing can form an ignition source due to

electrostatic discharges in the following conditions:

• The device is operated in environments with a relative

humidity of á 30 %.

• The painted surface of the device is thereby relatively free

from impurities such as dirt, dust or oil.

• Instructions on avoiding ignition in potentially explosive

environments due to electrostatic discharges in

accordance with EN TR50404 and IEC 60079-32-1 must be

observed!

Instructions on cleaning

The painted surface of the device may be cleaned only using a

moist cloth.

Repair

Devices of type of protection ‘d’ are equipped with flameproof

joints in the housing. Contact ABB before commencing repair

work.

Page 22

22 ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A

… 6 Operation in Div. 1

Temperature data

Surface temperature

Model name Surface temperature

FEP632, FEH632 T 80 °C (176 °F)

FEP631 EH631 T 80 °C (176 °F)

FET632 T 80 °C (176 °F)

The surface temperature depends on the fluid temperature.

With increasing measuring medium temperature > 60 °C (140 °F)

or > 80 °C (176 °F), the surface temperature also increases to the

level of the measuring medium temperature.

Note

The maximum permissible measuring medium temperature

depends on the liner and flange material, and is limited by the

operating values in the following tables.

Change from two to one column

Measuring medium temperature as a function of liner and flange material

Model FEP631, FEP632 Measuring medium temperature range (operating data)

Lining material Flange material Minimum Maximum

Hard rubber Steel Æ10 °C (14 °F)

Æ5 °C (23 °F)*

85 °C (185 °F)

80 °C (176 °F)*

Hard rubber Stainless steel Æ15 °C (5 °F)

Æ5 °C (23 °F)*

85 °C (185 °F)

80 °C (176 °F)*

Soft rubber Steel Æ10 °C (14 °F) 60 °C (140 °F)

Soft rubber Stainless steel Æ15 °C (5 °F) 60 °C (140 °F)

PTFE Steel Æ10 °C (14 °F) 130 °C (266 °F)

PTFE Stainless steel Æ25 °C (Æ13 °F) 130 °C (266 °F)

PFA Steel Æ10 °C (14 °F) 180 °C (356 °F)

PFA Stainless steel Æ25 °C (Æ13 °F) 180 °C (356 °F)

Thick PTFE Steel Æ10 °C (14 °F) 180 °C (356 °F)

Thick PTFE Stainless steel Æ25 °C (-13 °F) 180 °C (356 °F)

ETFE Steel Æ10 °C (14 °F) 130 °C (266 °F)

ETFE Stainless steel Æ25 °C (Æ13 °F) 130 °C (266 °F)

* Only for China production site

Model FEH631, FEH632 Fluid temperature (operating values)

Liner Process connection Material Minimum Maximum

PFA Flange Stainless steel Æ25 °C (Æ13 °F) 180 °C (356 °F)

PFA Wafer type — Æ25 °C (Æ13 °F) 130 °C (266 °F)

PFA Variable process connection Stainless steel Æ25 °C (Æ13 °F) 130 °C (266 °F)

Page 23

ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A 23

Measuring medium temperature (Ex Data) for ProcessMaster Model FEP631

Nominal diameter

Design

Temperature class

Ambient temperature

(Æ40 °C)* Æ20 °C to +40 °C

Ambient temperature

(Æ40 °C)* Æ20 °C to +50 °C

Ambient temperature

(Æ40 °C)* Æ20 °C to +60 °C

thermally uninsulated, thermally insulated thermally uninsulated, thermally insulated thermally uninsulated,

thermally insulated

Gas & dust Gas & dust Gas & dust

DN3 -2000

NT

T1

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T2

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T3

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T4

130°C 130°C 130°C

HT 130°C 130°C 130°C

NT

T5

95°C 95°C 95°C

HT 95°C 95°C 95°C

NT

T6

80°C 80°C 80°C

HT 80°C 80°C 80°C

* Low-temperature version (option)

NT standard version, T

medium

maximum 130 °C (266 °F)

HT high-temperature version, T

medium

maximum 180 °C (356 °F)

Thermally uninsulated: the sensor is not enclosed with pipe insulation material.

Thermally insulated: the sensor is enclosed with pipe insulation material.

Note

Cables for power supply, signal inputs and outputs must meet the following specifications:

• At an ambient temperature á 50 °C the cable must be suited for at least 60 °C

• At an ambient temperature á 60 °C the cable must be suited for at least 70 °C

Page 24

24 ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A

… 6 Operation in Div. 1

… Temperature data

Measuring medium temperature (Ex Data) for ProcessMaster Model FEP632

Nominal diameter

Design

Temperature class

Ambient temperature

(Æ40 °C)* Æ20 °C to +40 °C

Ambient temperature

(Æ40 °C)* Æ20 °C to +50 °C

Ambient temperature

(Æ40 °C)* Æ20 °C to +60 °C

thermally uninsulated, thermally insulated thermally uninsulated, thermally insulated thermally uninsulated,

thermally insulated

Gas & dust Gas & dust Gas & dust

DN3 -2000

NT

T1

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T2

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T3

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T4

130°C 130°C 130°C

HT 130°C 130°C 130°C

NT

T5

95°C 95°C 95°C

HT 95°C 95°C 95°C

NT

T6

80°C 80°C 80°C

HT 80°C 80°C 80°C

* Low-temperature version (option)

NT standard version, T

medium

maximum 130 °C (266 °F)

HT high-temperature version, T

medium

maximum 180 °C (356 °F)

Thermally uninsulated: the sensor is not enclosed with pipe insulation material.

Thermally insulated: the sensor is enclosed with pipe insulation material.

Note

Cables for power supply, signal inputs and outputs must meet the following specifications:

• At an ambient temperature á 50 °C the cable must be suited for at least 70 °C

• At an ambient temperature á 60 °C the cable must be suited for at least 80 °C

Page 25

ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A 25

Measuring medium temperature (Ex Data) for HygienicMaster Model FEH631

HT + NT design NT design onl

y

Nominal diameter

Design

Temperature class

Ambient temperature

(Æ40 °C)* Æ20 °C to +40 °C

Ambient temperature

(Æ40 °C)* Æ20 °C to +50 °C

Ambient temperature

(Æ40 °C)* Æ20 °C to +60 °C

thermally uninsulated, thermally insulated thermally uninsulated, thermally insulated thermally uninsulated,

thermally insulated

Gas & dust Gas & dust Gas & dust

DN3 -2000

NT

T1

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T2

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T3

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T4

130°C 130°C 130°C

HT 130°C 130°C 130°C

NT

T5

95°C 95°C 95°C

HT 95°C 95°C 95°C

NT

T6

80°C 80°C 80°C

HT 80°C 80°C 80°C

* Low-temperature version (option)

NT standard version, T

medium

maximum 130 °C (266 °F)

HT high-temperature version, T

medium

maximum 180 °C (356 °F)

Thermally uninsulated: the sensor is not enclosed with pipe insulation material.

Thermally insulated: the sensor is enclosed with pipe insulation material.

Note

Cables for power supply, signal inputs and outputs must meet the following specifications:

• At an ambient temperature á 50 °C the cable must be suited for at least 60 °C

• At an ambient temperature á 60 °C the cable must be suited for at least 70 °C

Page 26

26 ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A

… 6 Operation in Div. 1

… Temperature data

Measuring medium temperature (Ex Data) for HygienicMaster Model FEH632

HT + NT design NT design onl

y

Nominal diameter

Design

Temperature class

Ambient temperature

(Æ40 °C)* Æ20 °C to +40 °C

Ambient temperature

(Æ40 °C)* Æ20 °C to +50 °C

Ambient temperature

(Æ40 °C)* Æ20 °C to +60 °C

thermally uninsulated, thermally insulated thermally uninsulated, thermally insulated thermally uninsulated,

thermally insulated

Gas & dust Gas & dust Gas & dust

DN3 -2000

NT

T1

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T2

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T3

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T4

130°C 130°C 130°C

HT 130°C 130°C 130°C

NT

T5

95°C 95°C 95°C

HT 95°C 95°C 95°C

NT

T6

80°C 80°C 80°C

HT 80°C 80°C 80°C

* Low-temperature version (option)

NT standard version, T

medium

maximum 130 °C (266 °F)

HT high-temperature version, T

medium

maximum 180 °C (356 °F)

Thermally uninsulated: the sensor is not enclosed with pipe insulation material.

Thermally insulated: the sensor is enclosed with pipe insulation material.

Note

Cables for power supply, signal inputs and outputs must meet the following specifications:

• At an ambient temperature á 50 °C the cable must be suited for at least 70 °C

• At an ambient temperature á 60 °C the cable must be suited for at least 80 °C

Page 27

ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A 27

7 Operation in Div. 2

Electrical connections

FEP631, FEH631, FEP632, FEH632 sensor and FET632 transmitter (Div. 2) FET632 transmitter outside the

hazardous area

FEP631 FEH631 FEP632, FEH632 FET632 FET632

A Transmitter

B Sensor

Figure 8: Electrical connections

Change from one to two columns

Note

For detailed information on grounding the transmitter and the

sensor, please refer to the operating or commissioning

instruction!

Connections for the power supply

AC power supply

Terminal Function / comments

L Phase

N Neutral conductor

PE / Protective earth (PE)

/ PA Potential equalization

DC voltage supply

Terminal Function / comments

1+ +

2Æ Æ

PE / Protective earth (PE)

/ PA Potential equalization

Page 28

28 ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A

… 7 Operation in Div. 2

… Electrical connections

Connections for inputs and outputs

Terminal Function / comments

Uco / 32

31 / 32

Current output 4 to 20 mA- / HART output, active

or

Current output 4 to 20 mA- / HART output, passive

41 / 42 Passive digital output DO1

51 / 52 Passive digital output DO2

V1 / V2

V3 / V4

Plug-in card, slot OC1

Plug-in card, slot OC2

Plug-in cards may not be retrofitted in devices with explosion

protection on-site – loss of Ex Approval.

Connecting the signal cable

Only for remote mount design.

The sensor housing and transmitter housing must be connected

to potential equalization.

Terminal Function / comments

UFE Sensor power supply

GND Ground

A Data line

B Data line

Functional earth / Shielding

Change from two to one column

Page 29

ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A 29

Electric data for operation in Div. 2

Devices with HART protocol

When operating in potentially explosive areas, observe the following electrical data for the signal inputs and outputs of the

transmitter.

Current output terminals 31 / 32 / Uco can be operated on-site in active or passive mode through appropriate switching.

Change from two to one column

Model: FEP631, FEH631 or FET632

Outputs on basic device Operating values (general) Type of protection – ‘nA’ / ‘NI’

UN I

N

U

N

I

N

Current / HART output 31 / UCO, active

Terminals 31 / UCO

30 V 30 mA 30

V

30 mA

Current / HART output 31 / 32, passive

Terminals 31 / 32

30 V 30 mA 30

V

30 mA

Digital output 41 / 42, active*

Terminals 41 / 42 and V1 / V2*

30 V 30 mA 30

V

30 mA

Digital output 41 / 42, passive

Terminals 41 / 42

30 V 25 mA 30

V

25 mA

Digital output 51 / 52, active*

Terminals 51 / 52 and V1 / V2*

30 V 30 mA 30

V

30 mA

Digital output 51 / 52, passive

Terminals 51 / 52

30 V 30 mA 30

V

30 mA

All outputs are electrically isolated from each other and from the power supply.

Digital outputs 41 / 42 and 51 / 52 are not electrically isolated from each other. Terminals 42 / 52 have the same potential.

Model: FEP631, FEH631 or FET632

Plug-in cards Operating values (general) Type of protection – ‘nA’ / ‘NI’

UN I

N

U

N

I

N

Current output V3 / V4, active1)

Terminals V3 / V4 and V1 / V21)

30 V 30 mA 30

V

30 mA

Current output V1 / V2, passive2)

Current output V3 / V4, passive2)

Terminals V1 / V22) or V3 / V42)

30 V 30 mA 30

V

30 mA

Digital output V3 / V4, active1)

Terminals V3 / V4 and V1 / V21)

30 V 25 mA 30

V

25 mA

Digital output V1 / V2, passive2)

Digital output V3 / V4, passive2)

Terminals V1 / V22) or V3 / V42)

30 V 30 mA 30

V

30 mA

Digital input V3 / V4, active1)

Terminals V3 / V4 and V1 / V2

30 V 3.45 mA 30

V

3.45 mA

Digital input V1 / V2, passive2)

Digital input V3 / V4, passive2)

Terminals V1 / V22) or V3 / V42)

30 V 3.45 mA 30

V

3.45 mA

* Only in conjunction with additional ‘24 V DC loop power supply (blue)’ plug-in card in slot OC1.

** The terminal assignment depends on the model number or the slot assignments. For connection examples, refer to Installation in the operating instruction.

Page 30

30 ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A

Change from one to two columns

… 7 Operation in Div. 2

… Electric data for operation in Div. 2

Special connection conditions

Note

The AS plug-in card (24 V DC loop power supply) may only be

used to power the internal inputs and outputs on the device.

It must not be used to power external circuits!

Note

If the protective earth (PE) is connected in the flowmeter's

terminal box, you must ensure that no dangerous potential

difference can arise between the protective earth (PE) and the

potential equalization (PA) in areas with explosion risk.

Note

For devices with a power supply of 16 to 30 V DC, on-site external

overvoltage protection must be provided.

It must be ensured that the overvoltage is limited to 140 % (=

42 V DC) of the maximum operating voltage.

Installation in the USA or Canada must comply with ANSI / ISA

RP 12.6, ‘Installation of intrinsically safe systems for hazardous

(classified) locations’, the ‘National Electrical Code (ANSI / NFPA

70), sections 504, 505’ and the ‘Canadian electrical code (C22.1-

02)’.

Protection against electrostatic discharges

DANGER

Risk of explosion!

The painted surface of the device can store electrostatic

charges.

As a result, the housing can form an ignition source due to

electrostatic discharges in the following conditions:

• The device is operated in environments with a relative

humidity of á 30 %.

• The painted surface of the device is thereby relatively free

from impurities such as dirt, dust or oil.

• Instructions on avoiding ignition in potentially explosive

environments due to electrostatic discharges in

accordance with EN TR50404 and IEC 60079-32-1 must be

observed!

Instructions on cleaning

The painted surface of the device may be cleaned only using a

moist cloth.

Temperature data

Surface temperature

Model name Surface temperature

FEP632, FEH632 T 80 °C (176 °F)

FEP631 EH631 T 80 °C (176 °F)

FET632 T 80 °C (176 °F)

The surface temperature depends on the fluid temperature.

With increasing measuring medium temperature > 60 °C (140 °F)

or > 80 °C (176 °F), the surface temperature also increases to the

level of the measuring medium temperature.

Note

The maximum permissible measuring medium temperature

depends on the liner and flange material, and is limited by the

operating values in the following tables.

Change from two to one column

Page 31

ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A 31

Measuring medium temperature as a function of liner and flange material

Model FEP631, FEP632 Measuring medium temperature range (operating data)

Lining material Flange material Minimum Maximum

Hard rubber Steel Æ10 °C (14 °F)

Æ5 °C (23 °F)*

85 °C (185 °F)

80 °C (176 °F)*

Hard rubber Stainless steel Æ15 °C (5 °F)

Æ5 °C (23 °F)*

85 °C (185 °F)

80 °C (176 °F)*

Soft rubber Steel Æ10 °C (14 °F) 60 °C (140 °F)

Soft rubber Stainless steel Æ15 °C (5 °F) 60 °C (140 °F)

PTFE Steel Æ10 °C (14 °F) 130 °C (266 °F)

PTFE Stainless steel Æ25 °C (Æ13 °F) 130 °C (266 °F)

PFA Steel Æ10 °C (14 °F) 180 °C (356 °F)

PFA Stainless steel Æ25 °C (Æ13 °F) 180 °C (356 °F)

Thick PTFE Steel Æ10 °C (14 °F) 180 °C (356 °F)

Thick PTFE Stainless steel Æ25 °C (-13 °F) 180 °C (356 °F)

ETFE Steel Æ10 °C (14 °F) 130 °C (266 °F)

ETFE Stainless steel Æ25 °C (Æ13 °F) 130 °C (266 °F)

* Only for China production site

Model FEH631, FEH632 Fluid temperature (operating values)

Liner Process connection Material Minimum Maximum

PFA Flange Stainless steel Æ25 °C (Æ13 °F) 180 °C (356 °F)

PFA Wafer type — Æ25 °C (Æ13 °F) 130 °C (266 °F)

PFA Variable process connection Stainless steel Æ25 °C (Æ13 °F) 130 °C (266 °F)

Page 32

32 ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A

… 7 Operation in Div. 2

… Temperature data

Measuring medium temperature (Ex Data) for ProcessMaster Model FEP631

Single-compartment housing Dual- compartment housing

Nominal diameter

Design

Temperature class

Ambient temperature

(Æ40 °C)* Æ20 °C to +40 °C

Ambient temperature

(Æ40 °C)* Æ20 °C to +50 °C

Ambient temperature

(Æ40 °C)* Æ20 °C to +60 °C

thermally uninsulated, thermally insulated thermally uninsulated, thermally insulated thermally uninsulated, thermally insulated

Gas & dust Gas & dust Gas & dust

DN3 -2000

NT

T1

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T2

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T3

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T4

130°C 130°C 130°C

HT 130°C 130°C 130°C

NT

T5

95°C 95°C 40°C**

–***

HT 95°C 95°C

–

NT

T6

80°C –

–

HT 80°C –

–

* Low-temperature version (option)

** Single-compartment housing

*** Dual-compartment housing

Page 33

ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A 33

NT standard version, T

medium

maximum 130 °C (266 °F)

HT high-temperature version, T

medium

maximum 180 °C (356 °F)

Thermally uninsulated: the sensor is not enclosed with pipe insulation material.

Thermally insulated: the sensor is enclosed with pipe insulation material.

Note

Cables for power supply, signal inputs and outputs must meet the following specifications:

With single-compartment housing

• At an ambient temperature of 50 °C the cable must be suited for at least 80 °C

• At an ambient temperature of 60 °C the cable must be suited for at least 90 °C

With dual-compartment housing

• At an ambient temperature of 50 °C the cable must be suited for at least 70 °C

• At an ambient temperature of 60 °C the cable must be suited for at least 80 °C

Page 34

34 ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A

… 7 Operation in Div. 2

… Temperature data

Measuring medium temperature (Ex Data) for ProcessMaster Model FEP632

Nominal diameter

Design

Temperature class

Ambient temperature

(Æ40 °C)* Æ20 °C to +40 °C

Ambient temperature

(Æ40 °C)* Æ20 °C to +50 °C

Ambient temperature

(Æ40 °C)* Æ20 °C to +60 °C

thermally uninsulated, thermally insulated thermally uninsulated, thermally insulated thermally uninsulated, thermally insulated

Gas & dust Gas & dust Gas & dust

DN3 -2000

NT

T1

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T2

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T3

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T4

130°C 130°C 130°C

HT 130°C 130°C 130°C

NT

T5

95°C 95°C 95°C

HT 95°C 95°C 95°C

NT

T6

80°C 80°C 40°C

HT 80°C 80°C 20°C

* Low-temperature version (option)

NT standard version, T

medium

maximum 130 °C (266 °F)

HT high-temperature version, T

medium

maximum 180 °C (356 °F)

Thermally uninsulated: the sensor is not enclosed with pipe insulation material.

Thermally insulated: the sensor is enclosed with pipe insulation material.

Note

Cables for power supply, signal inputs and outputs must meet the following specifications:

• At an ambient temperature á 50 °C the cable must be suited for at least 70 °C

• At an ambient temperature á 60 °C the cable must be suited for at least 80 °C

Page 35

ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A 35

Measuring medium temperature (Ex Data) for HygienicMaster Model FEH631

Dual- compartment housing Single-compartment housing

Nominal diameter

Design

Temperature class

Ambient temperature

(Æ40 °C)* Æ20 °C to +40 °C

Ambient temperature

(Æ40 °C)* Æ20 °C to +50 °C

Ambient temperature

(Æ40 °C)* Æ20 °C to +60 °C

thermally uninsulated, thermally insulated thermally uninsulated, thermally insulated thermally uninsulated, thermally insulated

Gas & dust Gas & dust Gas & dust

DN3 -2000

NT

T1

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T2

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T3

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T4

130°C 130°C 130°C

HT 130°C 130°C 130°C

NT

T5

95°C 95°C 40°C**

–***

HT 95°C 95°C

–

NT

T6

80°C –

–

HT 80°C –

–

* Low-temperature version (option)

** Single-compartment housing

*** Dual-compartment housing

Page 36

36 ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A

… 7 Operation in Div. 2

… Temperature data

NT standard version, T

medium

maximum 130 °C (266 °F)

HT high-temperature version, T

medium

maximum 180 °C (356 °F)

Thermally uninsulated: the sensor is not enclosed with pipe insulation material.

Thermally insulated: the sensor is enclosed with pipe insulation material.

Note

Cables for power supply, signal inputs and outputs must meet the following specifications:

With single-compartment housing

• At an ambient temperature of 50 °C the cable must be suited for at least 80 °C

• At an ambient temperature of 60 °C the cable must be suited for at least 90 °C

With dual-compartment housing

• At an ambient temperature of 50 °C the cable must be suited for at least 70 °C

• At an ambient temperature of 60 °C the cable must be suited for at least 80 °C

Page 37

ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A 37

Measuring medium temperature (Ex Data) for HygienicMaster Model FEH632

Nominal diameter

Design

Temperature class

Ambient temperature

(Æ40 °C)* Æ20 °C to +40 °C

Ambient temperature

(Æ40 °C)* Æ20 °C to +50 °C

Ambient temperature

(Æ40 °C)* Æ20 °C to +60 °C

thermally uninsulated, thermally insulated thermally uninsulated, thermally insulated thermally uninsulated, thermally insulated

Gas & dust Gas & dust Gas & dust

DN3 -2000

NT

T1

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T2

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T3

130°C 130°C 130°C

HT 180°C 180°C 180°C

NT

T4

130°C 130°C 130°C

HT 130°C 130°C 130°C

NT

T5

95°C 95°C 95°C

HT 95°C 95°C 95°C

NT

T6

80°C 80°C 40°C

HT 80°C 80°C 20°C

* Low-temperature version (option)

NT standard version, T

medium

maximum 130 °C (266 °F)

HT high-temperature version, T

medium

maximum 180 °C (356 °F)

Thermally uninsulated: the sensor is not enclosed with pipe insulation material.

Thermally insulated: the sensor is enclosed with pipe insulation material.

Note

Cables for power supply, signal inputs and outputs must meet the following specifications:

• At an ambient temperature á 50 °C the cable must be suited for at least 70 °C

• At an ambient temperature á 60 °C the cable must be suited for at least 80 °C

Change from one to two columns

Page 38

38 ProcessMaster FEP630, HygienicMaster FEH630 ELECTROMAGNETIC FLOWMETER | SI/FEP630/FEH630/FM/CSA-EN REV. A

8 Commissioning

Checks before commissioning

The following items must be checked before commissioning:

• The power supply must be switched off.

• The power supply used must match the information on

the name plate.

• The connection assignment must be set up in accordance

with the electrical connection.

• Sensor and transmitter must be grounded properly.

• The temperature limit values must be observed.

• The transmitter must be installed at a location largely free

of vibrations.

• The housing cover and cover lock must be sealed before

powering-up the power supply.

• For devices with a remote mount design and a measuring

accuracy of 0.2 % of the measured value, make sure that

the sensor and the transmitter have been correctly

assigned.

• For this purpose, the final characters X1, X2, etc. are

printed on the name plates of the sensors. The final

characters Y1, Y2, etc. are printed on the transmitters.

• Devices with final characters X1 / Y1 or X2 / Y2 belong

together.

• Any unused glands should be sealed in accordance with

IEC 60079 prior to commissioning using the plugs

supplied. Also refer to Cable glands

Note

Commissioning and operation should be performed in

accordance with ATEX 137 or BetrSichV - German Industrial

Safety Regulation (EN60079-14). Only properly trained personnel

are authorized to carry out commissioning in Ex areas.

Output configuration for NAMUR switching

amplifier

Configuring the current output

Current output terminals 31 / 32 / Uco can be operated on-site in

active or passive mode through appropriate switching.

Terminal Uco / 32

Current output 4 to 20 mA- / HART

output, active

Terminal 31 / 32 Current output 4 to 20 mA- / HART

output, passive

.

Configuring the digital outputs

In the case of the device version suited for operation in Ex

Zone Div. 1 (dual-compartment housing), digital outputs DO1

(41 / 42) and DO2 (51 / 52) can be configured for connection to a

NAMUR switching amplifier.

On leaving the factory, the device is configured with the

standard wiring (non-NAMUR).

Note

The outputs' type of protection remains unaffected by this. The

devices connected to these outputs must conform to the

applicable regulations for explosion protection.

G11779

1

2

1 NAMUR DIP switch

2 Write protection DIP switch

Figure 9: Position of the DIP switches

Configuration of digital outputs 41 / 42 and 51 / 52

The configuration (NAMUR, optoelectronic coupler) for the

digital outputs on the basic device is set via DIP switches in the

transmitter.

Number Function

On Digital output 41 / 42 and 51 / 52 as NAMUR output.

Off Digital output 41 / 42 and 51 / 52 as optoelectronic coupler

output.

Page 39