Page 1

Horizontal and vertical induction motors

Operating Instructions

Manual

Motor type GP, SD, XP, LP, HP, HS

Low-Voltage NEMA motor.

50 A5E52711437A_AA

Edition

05/2023

Page 2

ENGLISH

Introduction 1

Safety information 2

Description 3

Storage and internal Handling 4

Preparing for use 5

Mounting and lifting of motor 6

Electrical Connection 7

Installation and start up 8

Operation 9

Maintenance 10

Spare Parts 11

Disposal 12

Technical Service 13

Unrestricted 51 A5E43486667A_AA

Page 3

Introduction 1

IMPORTANT

The information contained herein is general in nature and not intended for

specific application purposes. It does not relieve the user from responsibility to use

sound practices in application, installation, operation and maintenance of the

purchased motor. ABB reserves the right to make changes in the specifications

shown herein or to make improvements at any time without notice or obligations.

NOTE

These instructions do not purport to cover all details or variations in equipment,

nor provide information for every possible contingency to be met in installation,

operation, or maintenance. Should further information be desired about a specific

topic or inconvenience, contact the local ABB sales office. The contents of this

instruction manual shall not become part of or modify any prior or existing

agreement, commitment or relationship. The sales contract contains the entire

obligation of ABB. The warranty contained in the contract between the parties is

the sole warranty of ABB. Any statements contained herein do not create new

warranties or modify the existing warranty.

Configurator for drive technology

You can find product information on your motor according to ErP Directive

2019/1781 in the configurator for drive technology. If you enter the motor order

number (MLFB) you will find technical documentation such as data sheets,

characteristic curves, and CAD drawings for your motor.

https://new.abb.com/motors-generators/es-mx

IMPORTANT

The procedures described in this document must be carried out by qualified

personnel.

For the purpose of this manual a qualified person is one who is familiar with the

installation, construction and operation of the motor and the hazards involved. In

addition, this person has the following qualifications:

(a) Is trained and authorized to de-energize, energize, clear, ground, and tag

circuits and equipment in accordance with established safety practices.

(b) Is trained in the proper care and use of protective equipment such as rubber

gloves, hard hat, safety glasses or face shields, flash clothing, etc., in accordance

with established safety practices.

(c) Is trained in rendering first aid.

52 A5E52711437A_AA

Page 4

Safety Information 2

DANGER

WARNING

CAUTION

NOTICE

Philosophy in the signaling of warnings and dangers

This manual contains notices you have to observe in order to ensure your

personal safety, as well as to prevent damage to property. The notices referring to

your personal safety are highlighted in the manual by a safety alert symbol; notices

referring only to property damage have no safety alert symbol. These notices

shown below are graded according to the degree of danger

Indicates that death or severe personal injury will result if proper precautions

are not taken.

Indicates that death or severe personal injury may result if proper

precautions are not taken.

Indicates that minor personal injury can result if proper precautions are not

taken.

Indicates that property damage can result if proper precautions are not

taken.

If several levels of danger are present, the most strict safety instructions

are always used in each case. If in a safety instruction with alarm warning triangle

of possible personal injuries, the same password can also be a warning about

possible material damage.

53 A5E52711437A_AA

Page 5

Indications for motors for potentially explosive atmospheres.

WARNING

Qualified personnel

The product described in this documentation may be operated only by

personnel qualified for the specific task in accordance with the relevant

documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of

identifying risks and avoiding potential hazards when working with these

products/systems.

For proper use of ABB motors, consider the following.

ABB motors may only be used for the applications described in the

catalog and in the relevant technical documentation. If products and

components from other manufacturers are used, these must be

recommended or approved by ABB. Proper transport, storage, installation,

assembly, commissioning, operation and maintenance are required to

ensure that the products operate safely and without any problems. The

permissible ambient conditions must be complied with. The information in

the relevant documentation must be observed.

Trademarks:

All names identified by ® are registered trademarks of ABB. The

remaining trademarks in this publication may be trademarks whose use by third

parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

The content of this publication is reviewed periodically; if necessary,

possible corrections are included in the next edition.

54 A5E52711437A_AA

Page 6

WARNING

:

Dangerous voltages and rotating parts can cause serious personnel injury,

WARNING

equipment damage and even death. Always disconnect and properly ground

the motor before maintenance. Read and understand this instruction manual

before using the motor.

Maintenance should be performed only by qualified personnel. Use only

original ABB spare parts in the repair of the motor. Do not modify the motor

with non-original ABB spare parts. Follow all safety instructions contained in

this instruction manual.

Safe handling

Workplace safety depends on the attentiveness, care, and common

sense of the personnel who install, operate, and maintain the machine. In addition

to the safety measures cited, as a matter of principle, the use of caution is

necessary when you are near the machine. Always pay attention to your safety.

Also observe the following to prevent accidents:

● General safety regulations applicable in the country where the

machine is deployed.

● Manufacturer-specific and application-specific regulations

● Special agreements made with the operator

● Separate safety instructions supplied with the machine

● Safety symbols and instructions on the machine and its packaging

Live parts

Electric machines contain live parts.

Fatal or severe injuries and substantial material damage can occur if the

covers are removed or if the machine is not handled, operated, or maintained

properly.

● Always observe the “five safety rules" (Page 14) when carrying out

any work on the machine.

● Only remove the covers using the methods described by these

operating instructions.

● Operate the machine properly.

● Regularly and correctly maintain the machine.

PARTS UNDER ELECTRICAL TENSION

55 A5E52711437A_AA

Page 7

PARTS OR ROTARY ELEMENTS

WARNING

WARNING

CAUTION

Electric motors contain dangerous rotating parts.

Fatal or severe injuries and substantial material damage can occur if the

covers are removed or if the motor is not handled, operated, or maintained

properly.

● Only remove the covers using the methods described by these

operating instructions.

● Operate the motor properly.

● Perform regular maintenance on the motor.

● Secure free-standing shaft ends.

HOT SURFACES

Electric motors have hot surfaces. Do not touch these surfaces. They could

cause burns.

● Allow the motor to cool before starting work on the motor.

● Only remove the covers using the methods described by these

operating instructions.

● Operate the motor properly.

Chemical substances required for the setup, operation and maintenance

of motors can present a health risk.

Poisoning, skin damage, cauterization of the respiratory tract, and other

health damage may result.

UNHEALTHY SUBSTANCES

56 A5E52711437A_AA

Page 8

● Read the information in these operating instructions and the product

CAUTION

WARNING

information supplied by the manufacturer.

● Observe the relevant safety regulations and wear the personal

protective equipment specified.

Flammable substances

Chemical substances required for the setup, operation and maintenance

of motors may be flammable.

Burns and other damage to health and material may result.

● Read the information in these operating instructions and the product

information supplied by the manufacturer.

● Observe the relevant safety regulations and wear the personal

protective equipment specified.

Interference to electronic devices caused by electrical power

equipment

Electrical power equipment generates electric fields during operation.

Potentially lethal malfunctions can occur in medical implants, e.g.

pacemakers, in the vicinity of electrical power equipment. Data may be lost

on magnetic or electronic data carriers.

● It is forbidden for people with pacemakers to enter the vicinity of the

motor.

● Protect the personnel working in the plant by taking appropriate

measures, such as erecting identifying markings, safety barriers and

warning signs and giving safety talks.

● Observe the nationally applicable health and safety regulations.

● Do not carry any magnetic or electronic data media.

Safety instructions, explosion-proof motors

Note

Potentially explosive atmospheres are more dangerous, so it is necessary to

observe very carefully the indications indicated with the following symbol:

57 A5E52711437A_AA

Page 9

Description 3

Application area

The three-phase machines of this series are used as industrial drives.

They are designed for a wide range of drive applications both for line operation as

well as in conjunction with frequency converters. They are characterized by their

high-power density, extreme robustness, long service life and outstanding

reliability.

Intended use of the motors

These motors are intended for industrial installations and comply with the

harmonized standards of the series NEMA MG1. When used in a non-industrial

application, precautions must be put into place to provide safety to pedestrian

traffic. Consult with local governing agencies for minimum requirements.

Motors directive

Low-voltage motors are components designed for installation in machines

in accordance with the current Machinery Directive. Commissioning is prohibited

until it has been absolutely identified that the end product is in conformance with

this locals Directives.

Applicable standards

On the nameplate you will find the prescriptions and standards taken as

the basis for sizing and testing the motor and are based on the NEMA MG-1

standard.

Degree of protection

The machine has a type of protection to the degree indicated as stamped

on the rating plate and can be installed in dusty or humid environments to the

degree indicated.

58 A5E52711437A_AA

Page 10

Environmental conditions

CAU

TION

Limit values for the standard version

Relative humidity for ambient temperature Tamb 40 °C max. 55 %

Ambient temperature -20 °C a +40 °C

Installation altitude ≤ 1000 m

Air with normal oxygen content, usually 21% (V/V)

Note: The environmental conditions mentioned on the rating plate supersede this

table.

Degree of protection in XP motors

The motor has a type of protection as stamped on the rating plate and can

be installed in dusty or humid environments.

Storage and Internal Handling 4

Storage

Before any handling, make sure you have your personal safety

equipment such as shoes, gloves, girdle and lenses because if these

preventive measures are not taken, physical damage may occur.

If the motor will not be used immediately, it should be stored addressing

the following recommendations:

1. The storage location should be a clean, ventilated, free of vibrations.

Relative humidity must be lower than 60%, and temperature variation must

not be such that causes condensation in the windings. If the storage

conditions are conducive to condensation, the motor must be drained

regularly through the plug located in the lower part of both end-shields

minimum every 6 months. Precautions must be taken in order to

avoid entry of dust, insects or rodents into the motor. The motor must not

be exposed to corrosive atmosphere or substances. If the motor will be

59 A5E52711437A_AA

Page 11

stored for more than three months, please consult your local ABB sales

WARNING

Risk of dropping and swinging when transported suspended

office.

2. Prior to the shipment, motors are lubricated with the proper amount and

grade of grease to provide six months of satisfactory service under normal

operation and conditions. During storage, the motor shaft should be turned

by hand several (30RPM for 15 seconds) every 3 months to evenly

distribute the grease inside the bearings and avoiding marks in the

bearings, please refer to the long-term storage instructions for more details.

3. Prolonged storage periods reduce the useful life of the bearing grease.

In case of prolonged storage, the duration of use of bearing grease is

shortened and must be re-lubricated (See LUBRICATION chapter).

4. Measure and register the winding insulation every month (See

INSULATION RESISTANCE MEASUREMENT).

5. It should not be stored in open areas and without protection against rain,

breeze, and humidity.

6. To protect with greater importance the parts those are mechanized with

suitable lubricants to inhibit the oxidation of these.

7. Stack only if indicated and in the maximum quantities indicated on the

packaging. (Any deviations to the indicated pallets are possible causes of

damage to the user's account).

If you transport the motor suspended from cables or ropes, the cables or

ropes can break, e.g. as a result of damage. Further, if not adequately

attached, the motor can swing. This can result in death, serious injury, or

material damage.

Use additional eye bolts, suitable lifting equipment for transport and

during installation.

Two cables alone must be able to carry the complete load.

Prevent the lifting equipment from sliding by appropriately securing

it.

60 A5E52711437A_AA

Page 12

WARNING

Toppling over or slipping of the motor

The motor can slide or topple over if it is not correctly lifted or transported.

This can result in death, serious injury, or material damage.

Use all the lifting eyes on the machine.

When using the lifting eyes on the machine, do not attach any

additional loads or weight. The lifting eyes are only designed for the

weight of the machine itself.

Any eyes bolts that are screwed in must be tightly fastened.

Eyebolts must be screwed in right up to their supporting surface.

Comply with the permissible eyebolt loads.

When necessary, use suitably dimensioned transport equipment, for

example hoisting straps and load restraints.

Additional notes

When lifting the machines for transport, only lift them in a position that

corresponds to their basic construction type.

The motors are packed in different ways depending on how they are

transported and their size. If not otherwise contractually agreed, the packaging

corresponds to the packing guidelines according to ISPM (International Standards

for Phytosanitary Measures).

Comply with the images shown on the packaging. Their meaning is as follows:

61 A5E52711437A_AA

Page 13

Explosion hazard during start up, if stored

WARNING

incorrectly

Risk of explosion due to damaged sealing materials

Storing the motor at temperatures that do not fall within the specified

limits can damage the material of the seals and cause them to fail. As a result,

a potentially explosive gaseous atmosphere can enter the machine and be

ignited during start up. Explosions can occur. This can result in death, serious

injury or material damage.

The materials used are specially designed for the temperature range

required by the customer. Do not store the motor in conditions that lie outside

the specified temperature limits. The relevant temperature limits are specified

on the rating plate.

Storage temperature

Permissible temperature range: -20 °C to +50 °C

The relative humidity of the air should be less than 60 %.

In this case, refer to the machine rating plate for data on the coolant temperature

and installation altitude.

Preparing for Use 5

Actions are taken in the factory to ensure the motor arrives at its destination

in optimal conditions. If you detect packaging damage when receiving your motor,

immediately submit a claim to the carrier and notify your local ABB sales office.

Once the motor has been unpackaged, inspect it to make certain no damage has

occurred in conduit box, fan cover or any part of the equipment. Put special

attention in optional additional devices such as tachometers, brakes, blowers or

auxiliary conduit boxes.

Inspect all the screws and fittings that might have come loose during shipping.

Rotate the shaft by hand to be sure it rotates freely. If it is suspected that the motor

62 A5E52711437A_AA

Page 14

has not been transported with sufficient care, in such a way that it might have

CAUTION

ABB

6.-

WARNING

suffered structural damage; end-shields or motor covers must be removed to check

for internal damage.

1. - Before any handling, make sure you have your personal safety

equipment such as shoes, gloves, girdle and eyes protection. Failure to do

so could result in injury.

2. - Make sure before any handling that the motor to be prepared for its

use is of the appropriate environment and complies with the specifications

according to the installation area.

3. - Explosion proof motors are designed to comply with the U.L. label

service procedure manual, therefore the repair or maintenance work of this

type of motors must be performed only by technical personnel authorized by

ABB or in U.L. certified service centers. Violation of any of the above will

invalidate the U.L. certification as well as the

4.- Check the storage time of the equipment as well as verify the

conditions of the bearing grease and, if necessary, change or renew it before

starting the installation.

5. - Take care when removing the package because the packaging could

have staples, nails and screws with sharp parts that could physically hurt the

installer.

For the disposal of packaging materials, the laws of your area should

be consulted regarding the separation of materials and their final disposal.

7. - Check the free movement or rotation of the arrows before energizing

the motor.

warranty.

Explosion hazard in case of modifications to the machine

Substantial modifications to the motor are not permitted – or may only be

performed by the manufacturer. Otherwise an explosion can occur in an

explosive atmosphere. This can result in death, serious injury or material

damage.

Please contact the ABB Service Center, if necessary.

63 A5E52711437A_AA

Page 15

Note

WARNING

The increased level of danger in hazardous areas demands that you pay

particular attention to the notes marked with:

Motor for installation

Only use explosion-protected motors in appropriate areas in accordance

with directive applied in this location.

Indication for paint repairing the paint on

explosion-proof motors

In the repair of paint damage on explosion-proof motors, the following

warnings must be observed.

Explosion hazard caused by incorrect painting

The paint coat can become electrostatically charged where there is a thick

coat. Electrostatic discharges can occur. There is a risk of explosion if

potentially explosive mixtures are also present at this moment. This can

result in death, serious injury or material damage.

Electromagnetic compatibility verification

If the torque levels are very unequal (e.g. when a reciprocating compressor

is being driven), a non-sinusoidal machine current will be induced whose harmonics

can have an impermissible effect on the supply system and cause impermissible

interference emissions as a result.

64 A5E52711437A_AA

Page 16

Converter application

CAUTION

If operated with a frequency converter, the emitted interference varies in

strength, depending on the design of the converter (type, interference

suppression measures, and manufacturer).

Avoid that the specified limit values stipulated for the drive system

(consisting of the motor and converter) are exceeded.

You must observe the EMC information from the manufacturer of the

converter.

The most effective method of shielding is to conductively connect a

shielded motor supply cable to the metal terminal box of the machine (with

a metal screw connection) over a large surface area.

On motors with integrated sensors (e.g. PTC Thermistors), disturbance

voltages caused by the converter may occur on the sensor cable.

Immunity to interference

The motors in principle fulfill the requirements of interference immunity in

conformity with the standards applied in their location. If the motors with

integrated sensors (e.g. PTC thermistors) are used, the operating company must

ensure sufficient interference immunity by selecting a suitable sensor signal lead

(Possibly with shielding, connected in the same way as the motor feeder cable)

and a suitable evaluation unit.

Mounting motor and lifting 6

Before any handling, make sure you have your personal safety

equipment such as shoes, gloves, girdle and lenses because if these

preventive measures are not taken, physical damage may occur.

Although the motors are robust in construction, these must be handled

with care. Dropping or jarring a motor can seriously damage its components.

When lifting, use a device with sufficient load capacity.

65 A5E52711437A_AA

Page 17

WARNING

Instructions for lifting

1.- Before starting any activity of lifting, make sure the eye bolt or screw are

firmly held and fully in contact with the surface of the motor.

Correct Incorrect

2.- Motors must not be lifted by the shaft, but by the eyebolt, which has been

designed to lift only the motor.

3.- It is forbidden to move loads over the worker height, loads should be

transported closed to the floor.

4. - Before lifting check stability of load.

For horizontal motors with a lifting eyebolt

For these Motors, the maximum angle resulting in the lifting should NOT be

greater than 30 degrees relative to the vertical axis.

66 A5E52711437A_AA

Page 18

For vertical motors with two lifting hooks

DANGER

For vertical motors both lifting hooks must be used simultaneously, also a

device should be used to separate and keep in vertical sense the lifting element

(Like chains) to avoid possible motor damage.

For the proper lifting or lifting with safety of the motor, since due to its

weight and length it is very important to use special devices with the adequate

capacity (3 TN) to avoid a serious accident and / or that can go so far as to

produce death. (Check in data plate the weight).

These lifting devices called Joke (Separating steel bar) of an appropriate

length and steel chains or cable are VERY NECESSARY for a

SIMULTANEOUS lifting and safely for their lifting points. (See next figure).

Any other form of lifting or with other devices than those specified in this

manual will be incurring in a lack of SAFE MOTOR HANDLING and ABB will

not be responsible for non-compliance with these warnings.

67 A5E52711437A_AA

Page 19

Suitable lifting device (Yoke Type) for motors with two

WARNING

CAUTION

lifting points.

The equipment used to lift the motor must be in good condition. While lifting

the motor, keep at a safe distance in order to avoid personnel injuries.

If your motor is equipped with special devices such as tachometers, brakes,

blowers and/or auxiliary conduit boxes, these should never be used as an

anchoring point to lift the motor; otherwise the motor or such equipment can

suffer severe damage.

68 A5E52711437A_AA

Page 20

Electrical connection 7

DANGER

1.- The installation, operation and maintenance of the motor shall be carried

out by qualified personnel, who must be familiar with codes, guidelines and

applicable local regulations. Personnel must use the adequate tools and be

experienced in installation, operation and maintenance of electric motors.

2.- Before any handling, make sure you have your personal safety

equipment such as shoes, gloves, girdle and lenses because if these

preventive measures are not taken, physical damage may occur.

3.- Verify that electrical supply matches with motor specifications as printed

on the motor nameplate. Make connections for each lead as indicated in the

connections diagram on nameplate. Failure to comply these instructions

could result in severe damage to the motor, surrounding equipment or

personnel injury.

4. - To facilitate the electrical connection, the conduit box can be rotated in

90° degrees increments. Avoid having the wire output towards drive end.

5.- Check that the machine really is in a no-voltage condition.

6.- Establish a safe protective conductor connection before starting any work.

7.- Verify that the power lines are COMPLETELY DISCONNECTED when

making connections to the motor.

8.- Before starting up, check that the electrical connections are in accordance

with the instructions on the wiring diagram located on the motor nameplate.

Explosion-protected motors are equipped with terminal boxes with type of

protection to explosion proof or flame. Please note in this regard design,

connection options and spare parts. Have authorized ABB workshops perform

any repairs.

.

69 A5E52711437A_AA

Page 21

Connecting converters

WARNING

Machine overheating

Operating explosion-protected machines at the converter without using

the appropriate protective equipment can result in death or severe injury.

Always use Thermal Protectors monitoring when operating explosion-

protected machines at the converter. Tripping units according to

directive 94/9/EC are always necessary when using Thermal

Protectors monitoring.

IMPORTANT

Some motors can be manufactured with six leads, in three pairs. However, this

does not indicate that the motor is suitable for "Delta-Wye” connection. If it is, it will

be indicated in the nameplate.

A motor with six leads shall be connected as follows:

1. Leads marked with the same number must be

connected to each other 1-1, 2-2 & 3-3.

2. Three pairs will be obtained. Each one shall be

connected to a different phase of the electrical supply.

IMPORTANT

If the motor was requested with a special connection, do not connect the motor

as described above. For further information and/or technical support, please

contact your local ABB sales office.

Note: All motor leads are marked according to NEMA MG1 standard, connections

must be done as diagram shown in nameplate, take in account that phases 1, 2

and 3 correspond to phases U, V and W respectively.

70 A5E52711437A_AA

Page 22

The motor might be supplied with an internal device protecting the windings

CAUTION

DANGER

against overheating and/or overload. The type of the protection device is specified

in the nameplate. A RTD (Resistance Temperature Detector) is placed on or inside

the windings to record its temperature. Leads of this device must be connected to

another device capable of interpreting the RTD signal to shut down the electrical

supply in case of overheating.

Overload protection devices act directly on the power circuit. They use

bimetallic materials which deform when a high and constant current passes through

them. E.g: The KLIXON's.

If the motor is equipped with an electrical heating element, it must have: an

adequate power supply, overload protection, and switching devices that ensure

that the heating element ONLY OPERATES WHEN THE MOTOR IS NOT

ENERGIZED.

If the motor is equipped with tachometer, safety and connection instructions

from the tachometer manufacturer shall be addressed before starting the motor

for the first time.

Installation and Start Up 8

1.- The installation, operation and maintenance of the motor shall be carried

out by qualified personnel, who must be familiar with codes, guidelines and

applicable local regulations. Personnel must use the adequate tools and be

experienced in installation, operation and maintenance of electric motor.

2.- Before any handling, make sure you have your personal safety

equipment such as shoes, gloves, girdle and lenses because if these

preventive measures are not taken, physical damage may occur.

3.- When working with voltage levels up to 600 V.A.C. and moving parts

(even at low speeds) there is the possibility to suffer serious injuries or death.

71 A5E52711437A_AA

Page 23

Before any repair or maintenance service, use electrical or mechanical locks

CAUTION

to prevent a sudden or unwanted startup of the motor.

1.- The motor shall be installed in an environment adequate for its design

and application features. Otherwise, the motor will have a deficient

performance and a reduced life. For further information please consult your

local ABB sales office.

2.- The motor foundation must rigidly support (Screwed) all four feet in the

same plane in order to avoid vibrations and maintain a correct alignment

between the motor shaft and the load. Shims can be used under the motor

feet. For direct drive, accurate alignment is 0.004 inch/ft. (radius to dial

indicator = one foot). Any change in shims requires rechecking alignment.

3.- When installing flat belt pulley, V-belt sheave, spur or helical pinion or

chain drives, be certain that they are within NEMA-MG1 limitations. Refer to

NEMA-MG1, Section II part 14.7 and Section II part 14.42. Protective covers

must be installed to prevent unwanted contact between moving parts and

other objects or personnel.

4.- Ensure that any optional supplementary motor monitoring equipment has

been connected correctly and is functioning as it should.

5.- It ensures a long life of the bearings maintaining proper alignment,

adequate tension in the band or chain and good lubrication at all times.

6.- Ensure that the cooling airflow is not obstructed or diminished in any

way and have enough free space for the correct operation of the motor.

7.- Prevent the air expelled by neighboring equipment from being

immediately sucked in again.

8.- For motors with a vertical type construction with air entry from above,

prevent the ingress of foreign bodies and water in the air entry openings.

72 A5E52711437A_AA

Page 24

CAUTION

Nominal

Danger caused by inappropriate fasteners material

If screws of an incorrect property class have been selected or if have

been fastened to an incorrect tightening, they may break or become loose.

This will cause the motor to move, which could damage the bearing. The

motor could smash into de motor enclosure and motor parts could be flung

out of place. This can result in death, serious injury or material damage

• Comply with the required property classes for screws connections.

• Tighten the screwed connections to de specified tightening torques.

Tightening torques in motors

All screws tightening torques for screws in threaded joints of

bearing shields, housing and bearing caps should have the following

torques according to the size of the screw.

Hexagonal screw head grade 5

Diameter

(Inches)

5/32" 32 3.1 3.5 3.8

3/16" 24 4.4 4.9 5.4

1/4" 20 10.7 11.9 14.2

5/16" 18 21.7 24.2 29.2

3/8" 16 38.2 42.5 47.0

7/16" 14 61.0 67.9 75.0

1/2" 13 92.0 103.0 114.0

5/8" 11 184.0 204.0 224.4

3/4" 10 322.0 358.0 393.0

7/8" 9 450.0 490.0 520.0

Threads per inch

73 A5E52711437A_AA

Minimum

(Nm)

(Nm)

Maximum

(Nm)

Page 25

Torque values for fan covers and deflector assembly

Nominal

Nominal

Hexagonal screw head grade 5

Diameter

(Inches)

3/16" 24 3.0 3.5 3.8

3/16" 24 3.0 3.5 3.8

3/16" 24 3.5 4.0 4.5

1/4" 20 8.0 10.0 13.0

3/8" 16 20.0 24.0 28.0

3/8" 16 25.0 30.0 35.0

7/16" 14 50.0 55.0 60.0

7/16" 14 55.0 60.0 65.0

3/8" 16 18.0 22.0 26.0

3/8" 16 20.0 24.0 28.0

3/8" 16 25.0 30.0 35.0

Threads per

inch

Minimum

(Nm)

(Nm)

Maximum

(Nm)

Torque values for terminal boxes assembly

Hexagonal screw head grade 5

Diameter

(Inches)

1/4" 20 5.0 7.5 10.5

5/16" 18 11.0 14.0 17.0

3/8" 16 16.0 20.0 24.0

1/2" 13 21.0 26.0 30.0

Threads per

inch

Minimum

(Nm)

(Nm)

Maximum

(Nm)

74 A5E52711437A_AA

Page 26

Cooling and Air Guidance

INCORRECT CORRECT

Minimum dimension X=5” for the distance between neighboring modules and the

air intake of the motor.

75 A5E52711437A_AA

Page 27

CAUTION

All wiring to the motor, size of the conductors, drivers, protection devices,

WARNING

motor starters, grounding devices and any other electrical equipment must be in

accordance with NOM-001-SEDE, NEC and the National Electrical Code and all

local regulations.

Electrical supply must meet the values of voltage and frequency described in

the motor nameplate. The motor will operate successfully under running

conditions at rated load with a variation in the voltage or the frequency up to the

following:

1. When the variation in the voltage value does not exceed 10% above or

below the specified in the motor nameplate, with all phases balanced.

2. When the variation in the frequency value does not exceed 5% above

or below the specified in the motor nameplate.

3. When the sum of the voltage and the frequency values does not exceed

10% above or below the specified in the motor nameplate (provided

frequency value variation does not exceed the 5%).

However, performance within these voltage and frequency variations will not

necessarily be in accordance with the standards established for operation at

rated voltage and frequency.

Any electrical maneuver must be carried out by qualified personnel, taking

the following warnings into consideration:

1. The electrical supply shall be disconnected and preventive action

against accidental connection must be taken.

2. The motor shall be properly connected to a grounding circuit. Refer to

the NOM-001-SEDE and NEC or any other local electrical code.

76 A5E52711437A_AA

Page 28

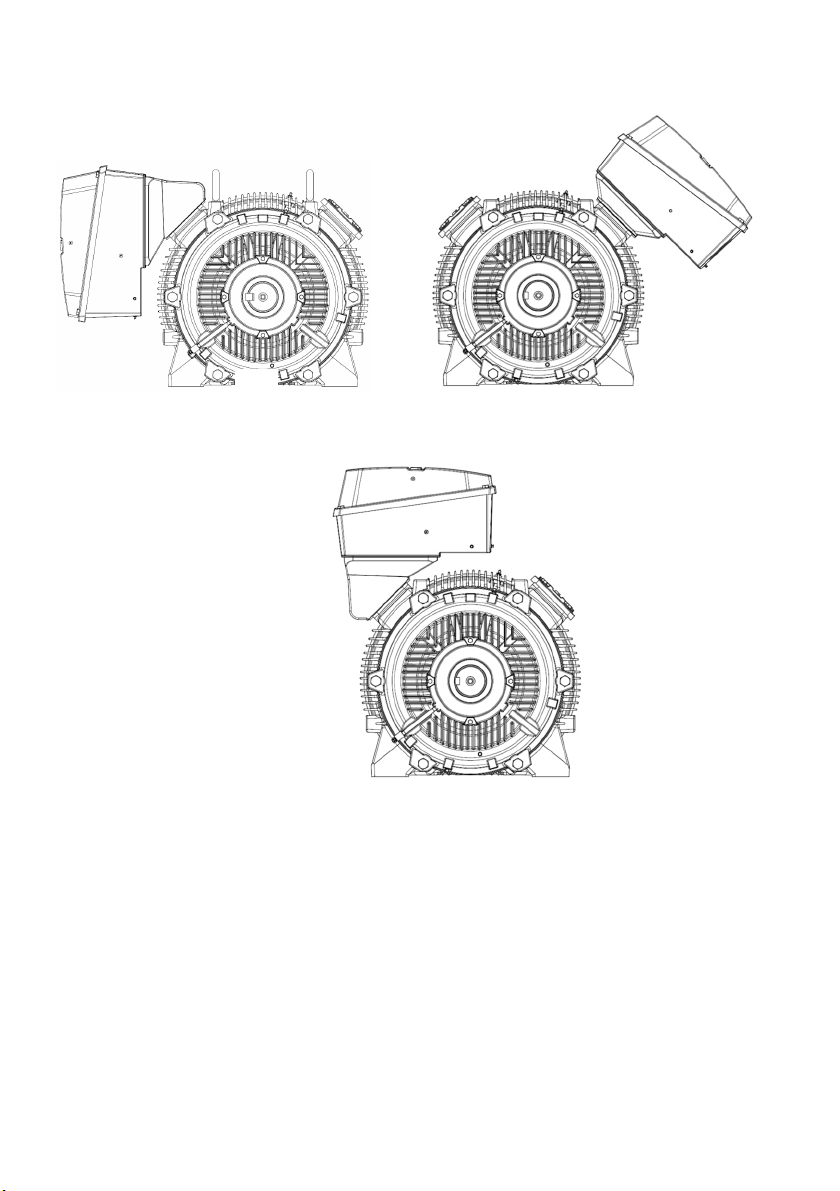

Mounting options for terminal box in motors type SD200

Top mounting on motor

Standard mounting Mounting to 45°

77 A5E52711437A_AA

Page 29

WARNING

Danger of falling components in the change of mounting

type F1 to F2 either box on the motor or box at 45 °

To change the configuration from F1 to F2 in frame 500 and given the

weight of the components to be moved, the following safety instructions

must be carried out.

Connection box base

2.1.- Remove the two lateral plastic plugs that are on the sides of the

connection box base where the threaded holes are for this purpose.

2.2.- Place a 3/8 "-16 NC eye bolt on each side of the connection base.

(See the following figure)

2.1.- Once the two eyebolts are in place, proceed to slightly tighten the

lifting system by slings and / or chains. (Optional).

2.2.- Proceed to remove all the fixing screws of the base with the

housing until its complete release and move slowly to the other side of the

motor for its placement and proceed to fix in its new position.

2.3.- Once the base has been placed in its new location remove the two

eyebolts and replace the protective plastic plugs.

Use eyebolts in placed laterally to the terminal base for

removal and change of position F1 to F2.

78 A5E52711437A_AA

Page 30

CAUTION

Do not insert screwdrivers or wedges between the base and the cover of the

CAUTION

explosion proof conduit box. Doing so could affect the tight fit between the base

and the cover which may compromise the explosion proof properties of the

motor.

To remove the cover of the explosion proof conduit box, first loosen

the screws, but do not remove them completely in order to prevent the

cover from sliding or falling. Then use a couple levers in the notches

provided, as shown in the illustration. Failure to follow these instructions

might result in serious injuries and/or damage to the motor and its

surroundings.

If the operation of the motor with a variable frequency drive (VFD) is

necessary, the readings listed in the standard NEMA-MG1 Section 4 Part 31, or

in the NEMA MG2-Section 6 must be addressed. In addition:

79 A5E52711437A_AA

Page 31

1. Variable frequency drive must be properly selected, according to the

WARNING

NEMA

NEMA

power of the motor and the conditions of the electrical supply (such as

number of phases, voltage, and current capacity).

2. Connect the motor, the VFD, metal conduit and any metal part to an

independent grounding circuit. The VFD must be mounted as close as

possible to the motor.

3. Use conductor with the appropriate gauge, the shortest possible length

and canalized through metal conduits. In addition, the conductors can

be shielded to reduce electromagnetic interference with electronic

equipment.

4. The operation of a motor with a VFD causes an increase in operating

temperature which in turn leads to the deterioration of the insulation on

the windings.

Always attend the safety instructions of the VFD manufacturer. High AC and

DC voltages are present in a VFD even after the VFD is de-energized. See VFD

operation manual to avoid personnel injury.

In order not to affect the optimal functioning of the motor-VFD system and to

ensure proper insulation; the length of the power leads from the VFD to the motor

shall not exceed those listed in Table 1.1. Maximum power leads length from

VFD output to motor.

Frame Size 230 V 460V 575V

143-320

360-449

Table 1.1 Maximum power lead length from VFD output to motor.

80 A5E52711437A_AA

600 ft.

100 ft.

125 ft. 40 ft.

225 ft. 60 ft.

Page 32

CAUTION

A proper programming of the parameters of the VFD is of the utmost

WARNING

importance. Please read and understand the VFD manufacturer's instructions

manual. Use the data on the motor nameplate. VFD Programming should be

performed by qualified personnel only. For further information and/or technical

support, please consult your local ABB sales office.

If the motor is equipped with tachometer, safety and connection instructions

from the tachometer manufacturer shall be addressed before starting the motor

for the first time.

Measures to take when commissioning

explosion-proof motors

After installation or inspections, the following measures are recommended for

normal start-up of the machines:

● Start the machine without a load; to do this, close the motor starter

protector and do not switch the machine off prematurely.

● You should limit how often you switch the machine off while it is starting

up and still running at a slow speed, for checking the direction of rotation or the

required dimensions, for example.

● Allow machines to reach a standstill before switching them back on.

Operation 9

Before starting the motor for the first time make sure that all the previously

stated recommendations are fulfilled.

Before starting the motor, check that all the screws and rotating parts are

correctly positioned and tightened. The use of protective covers in rotating parts

is suggested. Make sure that the electrical connections are correct, and that

81 A5E52711437A_AA

Page 33

leads are firmly attached and sufficiently insulated for the operating voltage

WARNING

levels.

If a reduced voltage start method is to be used, it is important to consider

that the torque output will be lower in the same proportion. For further information

and/or technical support on our motor starting solutions, please consult your local

ABB sales office.

Before starting the motor for the first time, make sure that the

recommendations mentioned above are complied with.

1.- The first startup of the motor must be done without any load or mechanism

connected to motor’s shaft. Parameters such as current, voltage, power

consumption and temperature shall be measured and compared against

nameplate data. Check direction of rotation. If the motor is energized, but

this does not start or if vibration, noise or excessive current draw are present,

immediately switch off electrical supply. Investigate and correct the failure. If

the motor is equipped with roller bearings on the drive end this first startup

must be brief in order to avoid damage to the bearings.

2.- The use of electronic devices to achieve soft starts is recommended to

avoid high values of current during startup.

3.- If a reduced voltage start method is to be used, it is important to consider

that the torque output will be lower in the same proportion. For further

information and/or technical support on our motor starting solutions, please

consult your local ABB sales office.

4.- Check the mechanical operation for noises or vibrations at the bearings

and bearing end shields.

5.- Monitoring the electrical and temperature values during initial and

subsequent operation to verify correct operation.

6.- Verify in a reasonable period the voltages values of the line (High / Low)

and evaluate those conditions.

7.- Verify that the protective guards and hoppers of the parts in movement

are well insured to avoid accidents.

82 A5E52711437A_AA

Page 34

CAUTION

Repeated trial starts can overheat the motor and may result in motor

WARNING

burnout (particularly for across the line starting). If repeated trial starts are made,

allow sufficient time between trials to allow heat to dissipate from windings and

rotor to prevent overheating.

Hot surfaces

Electric machines have hot surfaces. Do not touch these surfaces. They

could cause burns.

• Allow the machine to cool before starting work on the machine.

• Only remove the covers using the methods described by these operating

instructions.

Danger of explosion

If the anti-condensation heating is switched on directly after the motor

is switched off, the temperature class or the maximum surface temperature

of the motor can be exceeded.

In an explosive atmosphere, there is a high risk of an explosion. This

can result in death, serious injury or material damage.

Do not switch on the anti-condensation heating for at least one hour

after the motor has been switched.

WARNING

83 A5E52711437A_AA

Page 35

WARNING

Risk of explosion due to excessive bearing temperature

WARNING

The surface temperature cannot be maintained within the maximum

permissible limits if the bearings become too hot. The dust can ignite,

resulting in an explosion. This can result in death, serious injury or material

damage.

• Always check the bearing temperature.

• In addition to the current-dependent overload protection device

located in the three phases of the connecting cable, we recommend that you

also monitor the temperature rise in the motor with the aid of the

temperature sensors integrated built into the stator winding.

Overheating of roller bearing

If roller bearings are not regularly re-greased, local overheating may be

possible, and, as a consequence, an explosion in an explosive atmosphere.

This can result in death, serious injury or material damage.

• Re-grease the roller bearings regularly according to the lubrication table.

• Implement bearing temperature monitoring if not yet in existence.

Operation temperature

The electric motors still operating under normal conditions reach high

temperatures. This is why motors are designed to withstand high temperatures, and

although some places may feel hot to the touch, the motor may be operating within

the limits. Use a thermocouple to measure the temperature in the winding when

there is any concern about it.

The total temperature, not the temperature rise, is the measure of safe

operation. Investigate the winding operating conditions. The total temperature

should not exceed of:

84 A5E52711437A_AA

Page 36

WARNING

230°F (110°C) for class “B” insulation

275°F (135°C) for class “F” insulation

302°F (150°C) for class “H” insulation

Safety information for explosion-protected

motors in operation

Explosion hazard

These explosion-protected machines are not suitable for hybrid explosive

environments.

This can result in death, serious injury or material damage.

Use in atmospheres where there is a risk of explosion caused by both gas

and dust simultaneously is absolutely prohibited.

Only install motors for Zone 2 in hazardous areas, according to the

regulations laid down by the responsible regulatory body. They are responsible

for determining the hazard level of each area (division 2 zones).

● If there are no other specifications examination certificates or on the

rating plate regarding operating mode and tolerance, electrical machines are

designed for continuous duty and normal starting procedures that are performed

infrequently and do not result in excessive temperature rise. Only use these

machines for the operating mode specified on the rating plate.

Safety instructions for cleaning

To ensure problem-free machine cooling, the air ducts (ventilation grilles,

channels, cooling fins, tubes) must be free of pollution.

85 A5E52711437A_AA

Page 37

WARNING

Risk of explosion when cleaning with compressed air

CAUTION

If you clean the machine with compressed air, plastic components may

become statically charged and ignite a potentially explosive atmosphere; an

explosion can occur. This can result in death, serious injury or material

damage.

• Do not use compressed air to clean motors when installed in hazardous

zones!

Maintenance 10

Failure to properly maintain the equipment can result in severe personal

injury and product failure. The instructions contained herein should be carefully

reviewed, understood and followed. If the corrrect tools are not available or a

major maintenance is required, it must be carried out only by personnel

authorized by ABB. Please contact your local ABB sales office for more

information our comprehensive maintenance solutions.

Following maintenance procedures must be performed regularly:

1. Bearing lubrication.

2. Winding insulation resistance check.

3. Cleaning.

This checklist does not represent an exhaustive survey of maintenance steps

necessary to ensure safe operation of the equipment. Particular applications

may require further procedures. Should further information be desired or should

particular problems arise which are not covered sufficiently for the purchaser’s

purposes, the matter should be referred to the local ABB sales office.

86 A5E52711437A_AA

Page 38

WARNING

Dangerous voltages are present in the motor which can cause severe personnel

CAUTION

injuries. Always disconnect and ground the equipment before maintenance.

Maintenance should be performed only by qualified personnel

The use of unauthorized parts in the repair of the equipment, tampering by

unqualified personnel, or removal or alteration of guards or conduit covers will

result in dangerous conditions which can cause severe personal injury or

equipment damage. Follow all safety instructions contained herein.

Lubrication

Prior to shipment, motor bearings are lubricated with the proper amount and

grade of grease to provide six months of satisfactory service under normal

operation and conditions.

After that period, the motor must be lubricated as recommended in Table 1.2:

Lubrication frequencies, where, in a general way, time intervals have been

established according to the service and atmosphere in which the motor operates.

For further information, please consult your local ABB sales office.

Lubrication

frequency

6 Months Moderate service/ Clean and dry atmosphere

3 Months

Table 1.2 Lubrication frequencies.

Note: General purpose motors (up to FS250) and low maintenance motors are

provided with lubricated for life bearings, these bearings should be replaced at the

end of the grease service life.

Service/ Operation Atmosphere

Severe service/ Adverse atmospheres, dust,

moisture and vibrations

87 A5E52711437A_AA

Page 39

Grease

CAUTION

For standard motors, grease should be compounded from a Polyurea base and

a good grade of petroleum oil. It should be of No. 2 consistency and stabilized

against oxidation. Operating temperature range should be from -15°F to +250°F for

class “B” insulation, and to +300°F for class “F” and “H”. Most leading oil companies

have special bearing greases that are satisfactory.

Insert the new grease to be placed is equivalent and above all, compatible

with the original grease.

Lubrication procedure

The motor can be lubricated while running or stopped. It is advisable to do so while

the motor is stopped, for which the following procedure must be followed:

1. Take the necessary actions to prevent unexpected starts. (DISCONNECT

THE SYSTEM). Clean the grease fitting and remove the drain plug from

the grease outlet.

2. Remove the old hardened grease from inlets and outlets. Use a stiff wire

or rod.

3. If necessary, remove the nipples and fittings, clean, and reinstall.

4. With a low pressure grease gun, add half the required amount of new

grease.

5. Run the motor for 5 minutes to distribute the grease. Then stop it and add

the rest of the lubricant.

6. Install the drain plug in the grease outlet and wipe away the excess of

grease.

Verify motor grease type and only re-lubricate with compatible type of

grease. Mixing greases of different bases (lithium, clay, polyurea, etc.) will cause

bearing failure or malfunction and should not be done. All non-compatible grease

must be removed from the bearings and housings when making a grease

change. Excess grease in the motor can cause damage to the bearings; check

Table 1.3 of Grease Quantities, for the necessary grease quantities according to

the motor frame size.

88 A5E52711437A_AA

Page 40

Grease Quantity per End

-

Shield

side

(oz)

NEMA Frame Drive End.

Opp. Drive

End.

1400.20.2

1800.50.5

2100.60.6

250

1.1

1.1

280

1.5

1.5

320

2.5

2.5

360

3.7

3.7

400

5.6

5.6

440

9.4

8.7

S449

9.4

8.7

50016.4

16.4

Table 1.3 Grease Quantities.

Vertical motors thrust bearings

Top bearings

High external thrust from the driven unit is usually carried by the top bearing

or bearings. If replacement is necessary, the new bearing must be the same size

and type as the original.

Duplex bearings must also be the same type and mounted in an identical manner.

When angular contact type bearings are replaced, the new bearing must have the

same thrust capacity.

Bottom bearings

For an adequate lubrication It is important to maintain the lower cavity full of

grease at all times.

The re-lubricating procedure for vertical motors is the same as outlined above

under “Lubrication procedure”.

The correct replacement bearings are given on the nameplate by AFBMA

(Anti-Friction Bearing Manufacturers Association) number.

89 A5E52711437A_AA

Page 41

Insulation resistance measurement

WARNING

CAUTION

Measure insulation resistance and register it periodically (approx. every

5000 operating hours). A portable insulation meter (Megger) for 500 DCV is the

most convenient and safest method. According to IEEE (Institute of Electrical and

Electronics Engineers) standards, the insulation resistance at 75°C measured at

500 V.D.C. after one minute should be not less than:

Nominal motor voltage + 1000=Insulation resistance in Mega ohms

1000

This formula is satisfactory for most of the checks. For more information see

IEEE standard No. 43 “Recommended Practice for Insulation Resistance Testing

of AC Rotating Machinery”.

High DC voltage levels are used during this test. Therefore, severe injuries

can be caused if tests are not carried out by qualified personnel with adequate

tools.

Cleaning and draining

All surfaces of the motor must stay free of oil, dust, dirt, moisture, chemical

agents, or any other accumulation that would provoke a faulty cooling of the

equipment. For fan cooled motors, it is particularly important to keep the air

intake openings free of foreign material. Do not block air outlet or inlet. The motor

(excluding explosion proof models) has a removable plug, in the low part of the

housing, which allows draining accumulated humidity. Drain regularly.

Additional painting

Please contact your local ABB sales office for information about additional painting.

90 A5E52711437A_AA

Page 42

Motor disposition

WARNING

WARNING

Your motor has materials that can be recovered or recycled. The right

separation of materials helps with an easy recycling of important materials. Leave

your equipment or electrical product at a collection point. Contact your local

authorities for more information on disposal of electrical equipment.

Repair of paint damage

Note

Contact the Service Center before you repair any paint damage. They will

provide you with more information about the correct paint system and methods of

repairing paint damage.

Explosion hazard caused by incorrect painting

The paint coat can become electrostatically charged where there is a thick

coat. Electrostatic discharges can occur. There is a risk of explosion if

potentially explosive mixtures are also present at this moment. This can result

in death, serious injury or material damage.

Repair work

Take into account, in all work carried out on the motor, the general safety

instructions.

Explosion hazard when carrying out repair work

Repairs are only permissible within the scope of the work described in

these operating instructions. Otherwise an explosion can occur in an

explosive atmosphere. This can result in death, serious injury or material

damage.

91 A5E52711437A_AA

Page 43

For repairs to go beyond this scope, please contact the Service Center.

Fan cover

Explosion hazard due to high temperature at surface

Components within the motor may be hotter than the maximum

permissible surface temperature for the enclosure. In an explosive

atmosphere, dust can ignite, and an explosion occurs. This can result in

death, serious injury or material damage.

• Do not open the motor in an explosive and dusty atmosphere when it is still

at normal operating temperature.

• Allow the machine to cool down before opening it.

Replacing bearings

Before to place single shielded bearings, take care to put shielded side of

bearings at opposite side of greasing hole. This to ensure the right lubrication of

the bearing.

Replacing bearings in explosion-proof motors

● When changing the bearings, renew the sealing rings and only use

original ABB spare parts.

● For radial sealing rings with dust protection lip (DIN 3760-AS),

completely fill the spaces (100%) in the sealing ring as well as in the bearing

shield hub with a suitable grease.

Note

For explosion-proof motors, only use spare parts and original repair parts.

WARNING

Danger of falling parts while changing bearings

In large frames and due to the weight of the components to be extracted,

the following safety instructions must be carried out.

1.-

It is necessary to use synthetic flat slings with a capacity

92 A5E52711437A_AA

Page 44

greater than 150 kilograms for the adequate lifting of the fan cover.

1.1.- Remove the protective cover from the fan cover and proceed to

pass the flat sling so that it completely supports the fan cover.

1.2.- Lightly tighten the lifting system with the sling and proceed to

remove the fastening screws of the cap until its complete release.

2.- Endshields For the safe extraction of the end shields or C flanges, it

will be carried out in the following way:

2.1.- Slightly loosen all the fastening screws with the housing in such a

way that when removing one of the upper screws it can be replaced by an

eyebolt which will be placed in the hole of the eye using a nut on the

opposite side of the eye bolt and fixed.

2.2.- Lightly tighten the lifting system and proceed with the extraction of

the rest of the screws with the housing and slowly move the shield outwards

until it is completely removed (be careful not to hit the shaft in the

extraction).

Spare parts 11

For ordering parts

1. - For orders of spare parts or parts for repair, the following information is

needed:

● Name of the piece

● Motor reference and serial number, (It is indicated on the name plate of

the motor).

2. - Contact any of our distributors in Mexico, USA and Canada, they are

authorized and trained to process your requirement of the parts that need your

motor.

3. - Additionally, you can also contact our customer service and support in

replacement parts and / or spare parts.

Disposal 12

Introduction

Protecting the environment and preserving its resources are corporate goals

of the highest priority for us. Our worldwide environmental management system to

ISO 14001 ensures compliance with legislation and sets high standards in this

93 A5E52711437A_AA

Page 45

regard. Environmentally friendly design, technical safety and health protection are

always firm goals even at the product development stage.

Recommendations for the environmentally friendly disposal of the machine

and its components are given in the following section. Be sure to comply with

local disposal regulations.

Preparing for disassembly

Disassembly of the machine must be carried out and/or supervised by

qualified personnel with appropriate expert knowledge.

1. Contact a certified waste disposal organization in your vicinity. Clarify what is

expected in terms of the quality of dismantling the machine and provision of the

components.

2. Follow the five safety rules.

2.1.- Disconnect the system. Also disconnect the auxiliary circuits, for

example, anti-condensation heating.

2.2.- Secure against reconnection.

2.3.- Verify absence of operating voltage.

2.4.- Ground and short-circuit.

2.5.- Provide protection against adjacent live parts.

To energize the system, apply the measures in reverse order.

3. Disconnect all electrical connections and remove all cables.

4. Remove all liquids such as oil and cooling liquids. Collect the liquids separately

and dispose of them in a professional manner.

5. Detach the machine fixings.

6. Transport the machine to a suitable location for disassembly.

Motor disassembly

Disassemble the motor using the general procedures commonly used in

mechanical engineering.

94 A5E52711437A_AA

Page 46

WARNING

Machine parts can fall

1.- The machine is made up of heavy parts. These parts are liable to fall

during dismantling. This can result in death, serious injury or material damage.

2.- Before you release any machine parts, secure them so that they cannot

fall.

3.- Take care when disassembling the motor since there are sharp parts that

can cause bodily injury.

Disposal of components

Components

The machines consist mainly of steel and various proportions of copper and

aluminum. Metals are generally considered to be unlimitedly recyclable.

Sort the components for recycling according to whether they are:

● Iron and steel

● Aluminum

● Non-ferrous metal, e.g. windings, the winding insulation is

incinerated during copper recycling.

● Insulating materials

● Cables and wires

● Electronic waste

Process materials and chemicals

Sort the process materials and chemicals for recycling according to whether they

are for example:

● Oil

● Grease

● Cleaning substances and solvents

● Paint residues

● Anti-corrosion agent

● Coolant additives such as inhibitors, antifreeze or biocides

Dispose of the separated components according to local regulations or via

a specialist disposal company. The same applies for cloths and cleaning

substances which have been used while working on the motor.

95 A5E52711437A_AA

Page 47

Information according to article 33 of the Reach

regulation

This product contains one or several sub products in which the following

substance – belonging to the "list of candidates" – exists in a concentration

exceeding 0.1 percent by weight.

CAS No. 7439-92-1, Lead.

Based on the currently available information, we assume that this substance

does not represent any risk when correctly used, including its disposal.

Packaging material

If necessary, contact a suitable specialist disposal company.

Wooden packaging for sea transport consists of impregnated wood.

(Observe the local regulations).

Motor disposition once productive life finished

Your motor has materials that can be recovered or recycled. The right

separation of materials helps with an easy recycling of important materials. Leave

your equipment or electrical product at a collection point. Contact your local

authorities for more information on disposal of electrical equipment.

DO NOT PUT IN TRASH CONTAINERS

96 A5E52711437A_AA

Page 48

Technical Service 13

For questions or technical support, contact your local technical support team

https://new.abb.com/contact-centers

Visit our website to learn more about products and services.

https://new.abb.com/motors-generators

For this, have the following data available:

● Type

● Serial number

This information is described on the name plate.

Notes

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

97 A5E52711437A_AA

Loading...

Loading...