Page 1

Medium voltage products

HD4

Installation and service instructions

Index

1. Packing and transport 5

2. Checking on receipt 6

3. Storage 7

4. Handling 8

5. Description 10

6. Instructions for circuit-breaker operation 12

7. Installation 13

8. Putting into service 32

9. Periodical checking 34

10. Maintenance operations 34

11. Indications for handling apparatus with SF6 35

12. Spare parts and accessories 36

12-40.5 kV – 630-3600 A – 16-50 kA

Page 2

Page 3

3

• Make sure that the installation room (spaces, divisions

and ambient) are suitable for the electrical apparatus.

• Check that all the installation, putting into service and

maintenance operations are carried out by qualified

personnel with in-depth knowledge of the apparatus.

• Make sure that the standard and legal prescriptions

are complied with during installation, putting into

service and maintenance, so that installations

according to the rules of good working practice and

safety in the work place are constructed.

• Strictly follow the information given in this instruction

manual.

• Check that the rated performance of the apparatus is

not exceeded during service.

• Pay special attention to the danger notes indicated in

the manual by the following symbol:

• Check that the personnel operating the apparatus

have this instruction manual to hand as well as the

necessary information for correct intervention.

Responsible behaviour safeguards your own

and others’ safety!

For any requests, place contact the

ABB Assistance Service.

For your safety!

Page 4

4

I. Introduction

This publication contains the information necessary for

installation and putting into service of HD4 medium voltage

circuit-breakers.

For correct usage of the product, please read this manual

carefully.

For correct mounting of accessories and/or spare parts

please refer to the relevant instructions.

Like all the apparatus manufactured by us, the HD4 circuitbreakers are designed for different installation configurations.

They do, however, allow further technical-constructional

variations (at the customer’s request) to suit special

installation requirements.

For this reason, the information given below does not always

cover special configurations.

Apart from this booklet, it is therefore always necessary to

refer to the latest technical documentation available (circuit

diagram, wiring diagrams, assembly and installation drawings,

any studies of protection co-ordination, etc.), especially with

regard to any variations from standardized configurations

requested.

All the operations regarding installation, putting

into service, operation and maintenance must be

carried out by suitably qualified personnel with indepth knowledge of the apparatus.

Only use original spare parts for maintenance operations.

For further information, also see the technical catalogue of the

circuit-breaker and the spare parts catalogue.

II. Programme for the environmental

protection

The HD4 circuit-breakers comply with ISO 14000 Standards

(Guidelines for the Environmental Management).

The production system of the Medium Voltage factories

complies for the environmental protection in terms of energy

consumption, raw materials and waste.

The environmental impact of the product life cycle is assessed

by the LCA - Life Cycle Assessment procedure, which is also

the result of a well-focused project phase in the selection of

materials, processes and packaging.

The Product environmental declaration is available for the

HD4 circuit-breakers

Production techniques are carried out in order to achieve

an easy dismantling and separation of the components at

the end of the circuit-breaker life cycle, while optimizing the

recycling process.

Page 5

5

1. Packing and transport

The circuit-breaker is shipped in special packing in the open

position with the springs discharged and with absolute pole

pressure corresponding with the service value.

Each piece of apparatus is protected by a plastic film to

prevent any infiltration of water during the loading and

unloading stages and to keep the dust off during storage.

Handling and transport must only be carried out by expert

and properly trained personnel.

Do not remove or alter the switch identification contents and

labels.

Switches subject to UN3164 standards for transportation by

air and / or sea.

Safety data sheet: 1VCD850182

Page 6

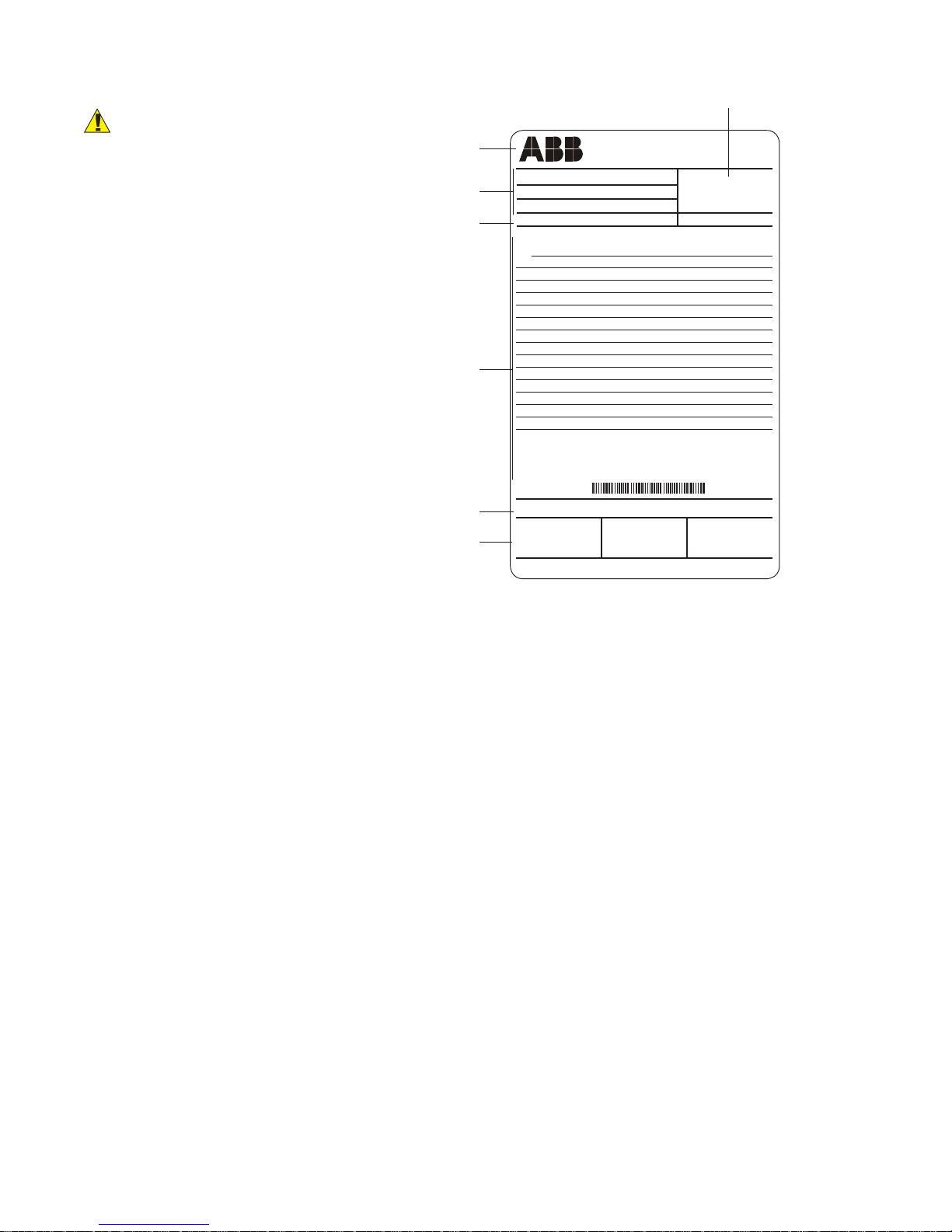

6

Caption

A Circuit-breaker nameplate

B Operating mechanism nameplate

1 Type of apparatus

2 Symbols and compliance with Standards

3 Serial number

4 Circuit-breaker characteristics

5 Characteristics of the operating auxiliaries

Nameplate

Fig. 1

A

B

3

4

2

CIRCUIT-BREAKER IEC 62271-100

HD4 ... ... ... CEI 17-1

CLASSIFICATION ... ... ...

SN ... ... ... PR. YEAR ......

M MASS ... Kg

Ur

m SF6 mass for circuit-breaker .... Kg

ELECTRIC DIAGRAM ... ... ... ...

FIG. ... ...

.. ... ... ... OPERATING MECHANISM

-MO1 ... ... ... V

Made by ABB

1

5

Before carrying out any operation, always make

sure that the operating mechanism dprings are

discharged and that the apparatus is in the open

position.

On receipt, check the state of the apparatus, that the packing

is undamaged and that the nameplate data corresponds (see

fig. 1) with that specified in the order acknowledgement and

in the delivery note.

Also make sure that all the materials described in the shipping

note are included in the supply.

If any damage or irregularity is discovered on unpacking,

notify ABB (directly or through the agent or supplier) as soon

as possible and in any case within five days of receipt.

The apparatus is only supplied with the accessories

specified at the time of order and confirmed in the order

acknowledgement sent by ABB.

The following accompanying documents are inserted in the

shipping packing:

– Instruction manual (this document)

– Test certificate

– Identification tag

– Fiscal copy of shipping note

– Electrical diagram

These other documents are sent prior to shipment:

– Order acknowledgement

– Original copy of shipping note

– Any drawings or documents regarding special

configurations/conditions.

2. Checking on receipt

Page 7

7

3. Storage

In case a storage period is foreseen, on request our

workshops will provide a suitable packing to the specified

storage conditions.

On receipt, the apparatus must be carefully unpacked and

checked as described in chapter 2: Checkink on receipt.

If immediate installation is not possible and the circuit breaker

has to be re-stored again, it is necessary to restore the

packaging at least suitable for protection against dust.

Insert hygroscopic substances in the packaging in the

quantity of at least one standard pack per apparatus.

Therefore, store in a sheltered, well-ventilated area with a

dry, non-dusty, non-corrosive atmosphere away from highly

flammable materials, with a temperature between -5 °C and

+45 °C.

In any case, avoid accidental shocks or accommodations that

stress the structure of the circuit breaker.

Page 8

8

1

2

2

2

1

3

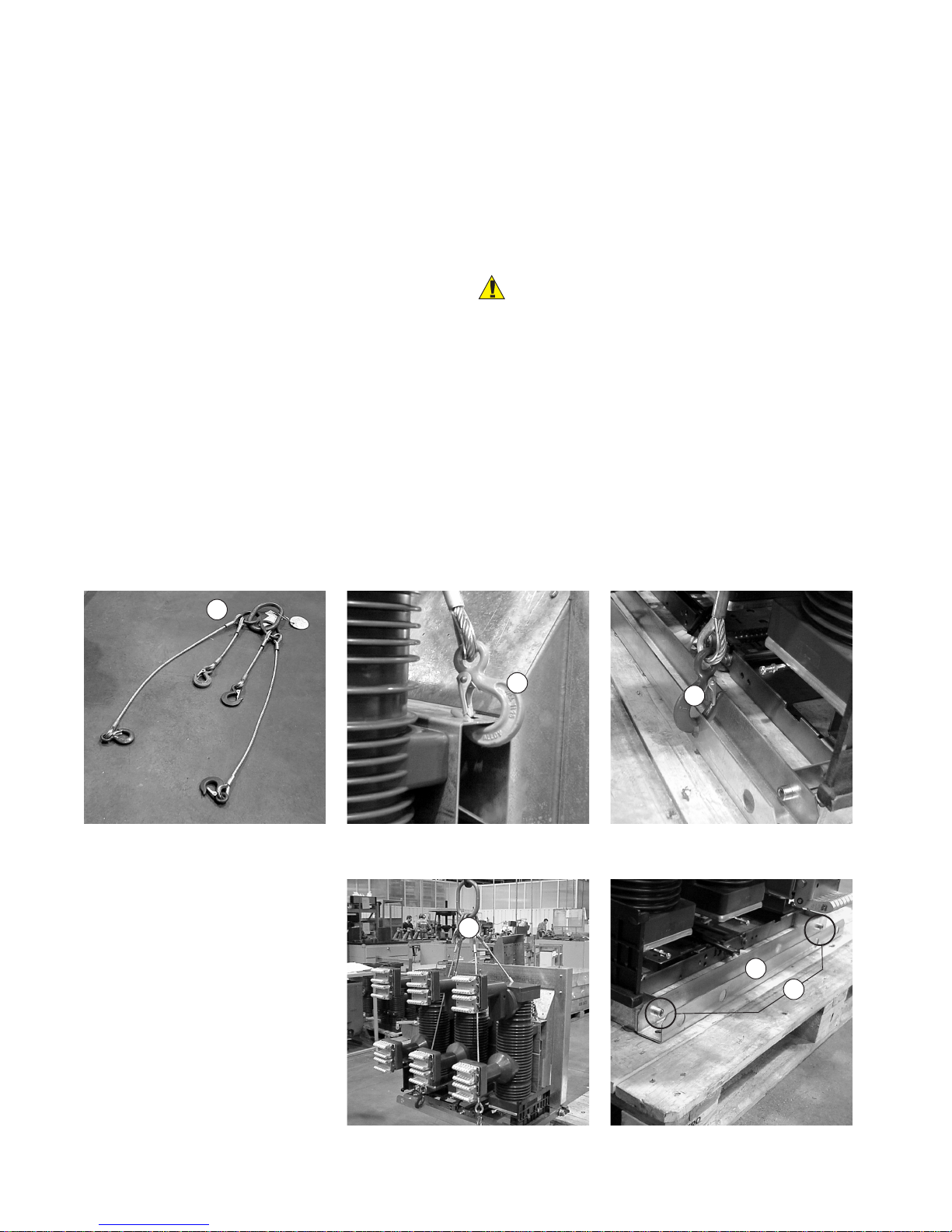

4. Handling

Before carrying out any operation, always check that the

operating mechanism springs are discharged and that the

apparatus is in the open position.

Circuit-breakers up to 24 kV

– To lift and handle the circuit-breaker, use the tool (1) (fig. 2a:

shortest hooks for circuit-breakers up to 17.5 kV; all hooks

for 24 kV circuit-breakers).

– Put the hooks (2) in the holes prepared in the circuit-breaker

frame and lift.

– On completion of the operation (and in any case before

putting into service) unhook the lifting tool (1) (fig. 2b) and

dismantle the crosspiece (2) by unscrewing the screws (3).

Fig. 2a

36 kV circuit-breakers

– Attach the tools (1) to lift and handle the circuit-breaker

(fig. 2c);

– Attach the hooks (2) as illustrated in fig. 2d and lift;

– On completion of the operation, remove the tools (1).

Always take great care during handling not to stress the

insulating parts and the circuit-breaker terminals.

The apparatus must not be handled by inserting

lifting devices directly under the apparatus itself.

Should it be necessary to use this method, place

the circuit-breaker on a sturdy supporting surface

(see fig. 3).

Fig. 2b

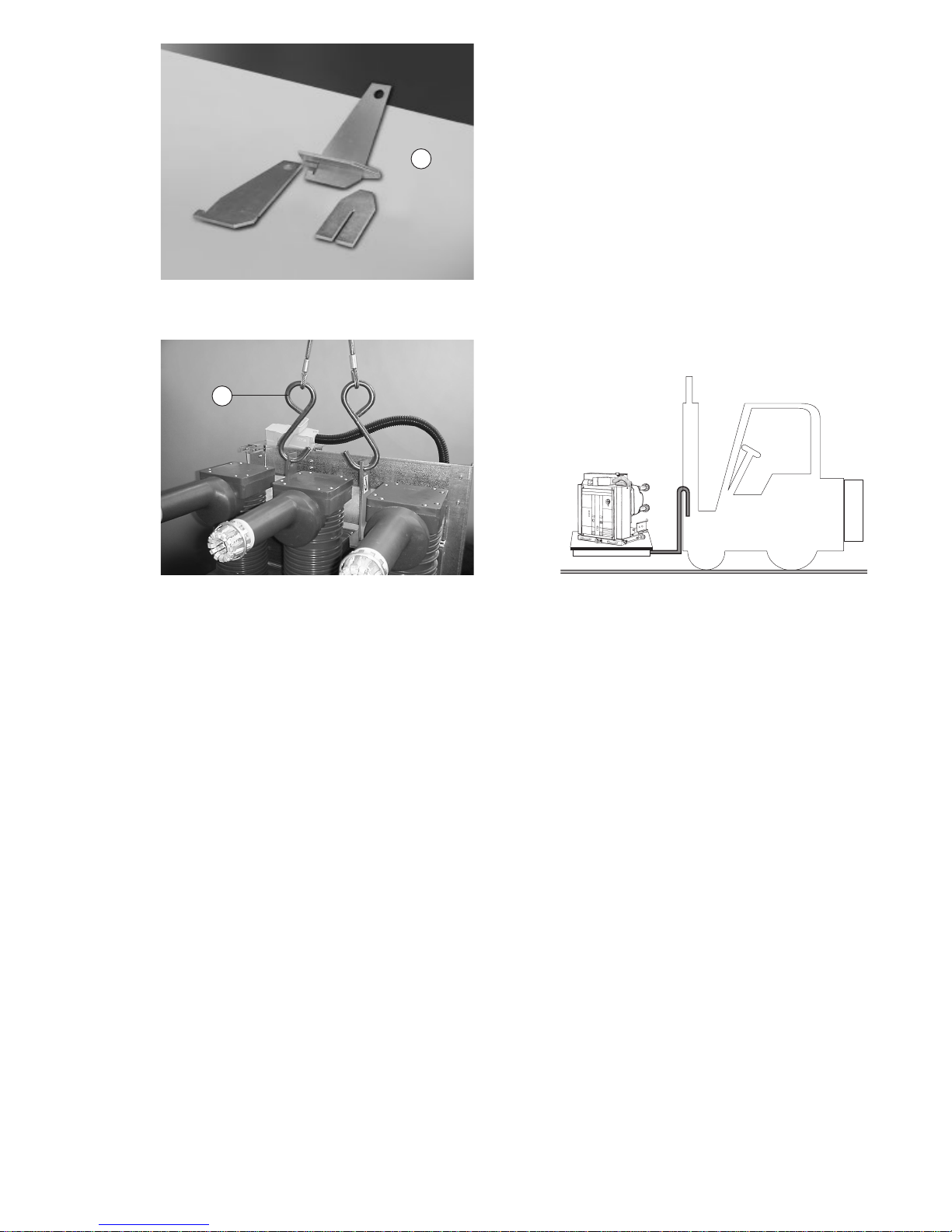

Page 9

9

1

2

Fig. 2c

Fig. 3 Fig. 2d

Page 10

10

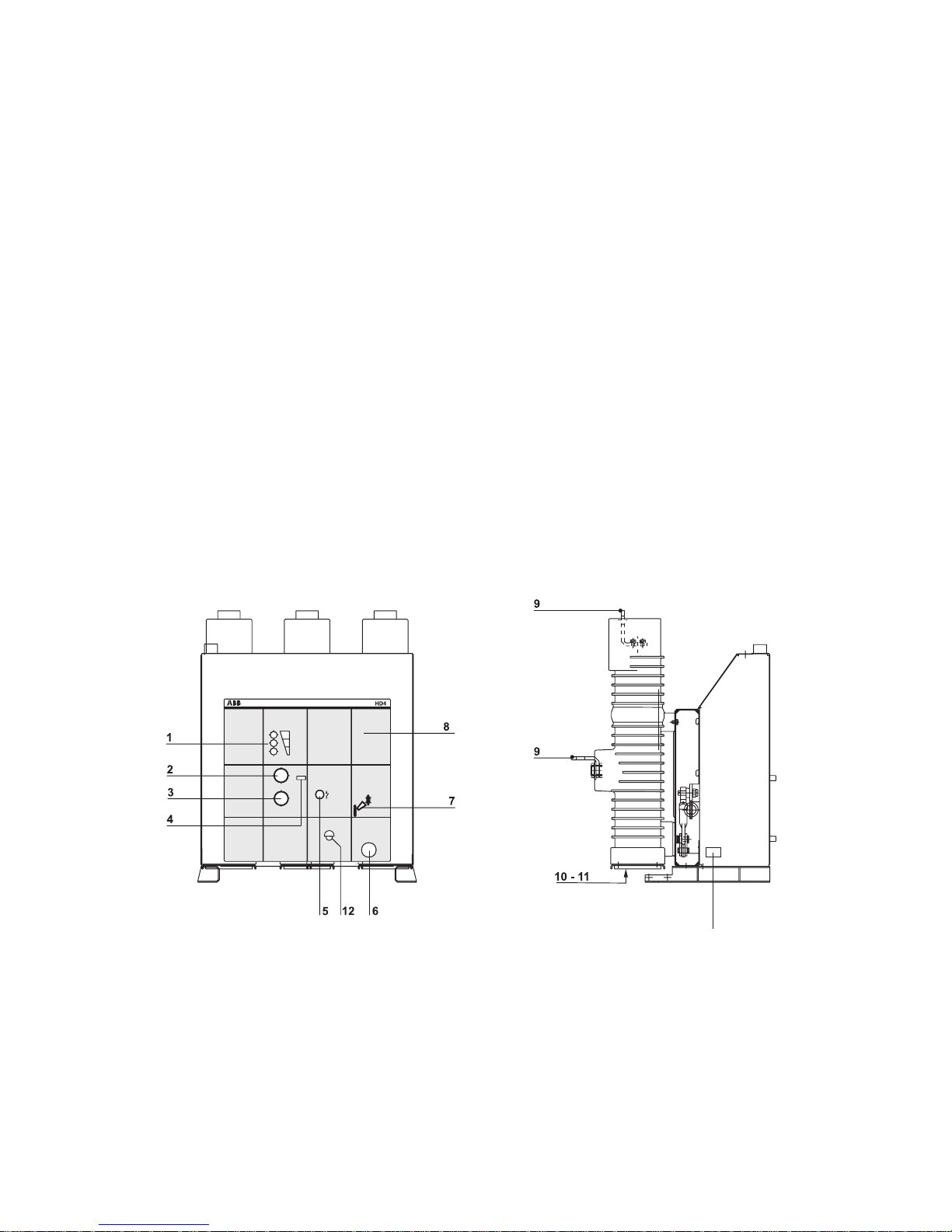

Fig. 4

Caption

1 Signalling device for state of SF6 pressure (on request)

2 Opening push button

3 Closing push button

4 Operator counter

5 Signalling device for circuit-breaker open/closed

6 Shaft for manual closing spring charging

5. Description

5.1. General features

The HD4 series are sulphur hexafluoride circuit-breakers for

indoor installation. For the electrical performance, please refer

to the corresponding technical catalogue code 1VCP000004.

For special installation conditions please ask ABB.

The following versions are available:

– fixed

– withdrawable for CBE, PowerCube enclosures and CBF

fixed parts

– withdrawable for switchgear: UniGear type ZS1, UniGear

type ZS2, UniGear type ZS3.2

– withdrawable for switchgear: UniSwitch, UniMix and

UniSec.

5.2. Reference Standards

The HD4 series circuit-breakers comply with the following

Standards:

– IEC 62271-100.

5.3. Fixed circuit-breaker

The fixed circuit-breaker (see fig. 4) corresponds to the basic

version complete with a front protection shield and frame.

The anchoring holes are drilled in the lower part of the frame.

The terminal box, fixed on the upper protection, is available

for connection of the circuit-breaker auxiliary circuits.

The earthing screw is located on the circuit-breaker side.

For further details, refer to the caption of fig. 4.

5.4. Withdrawable circuit-breaker

The withdrawable circuit-breakers (see fig. 5) are consist

of a truck on which the supporting structure of the circuitbreaker itself is fixed. The cord with the connector (plug) for

connection of the operating mechanism electrical accessories

comes out of the front protection of the circuit-breaker.

Fixed circuit-breaker

7 Signalling device for closing springs charged/discharged

8 Characteristics nameplate

9 Terminals (only available for certain versions)

10 Pressure switch (on request)

11 Valve for checking the SF6 gas pressure

12 Resetting button for protection circuit-breaker of geared motor (on request)

10 - 11 (36 kV)

Page 11

11

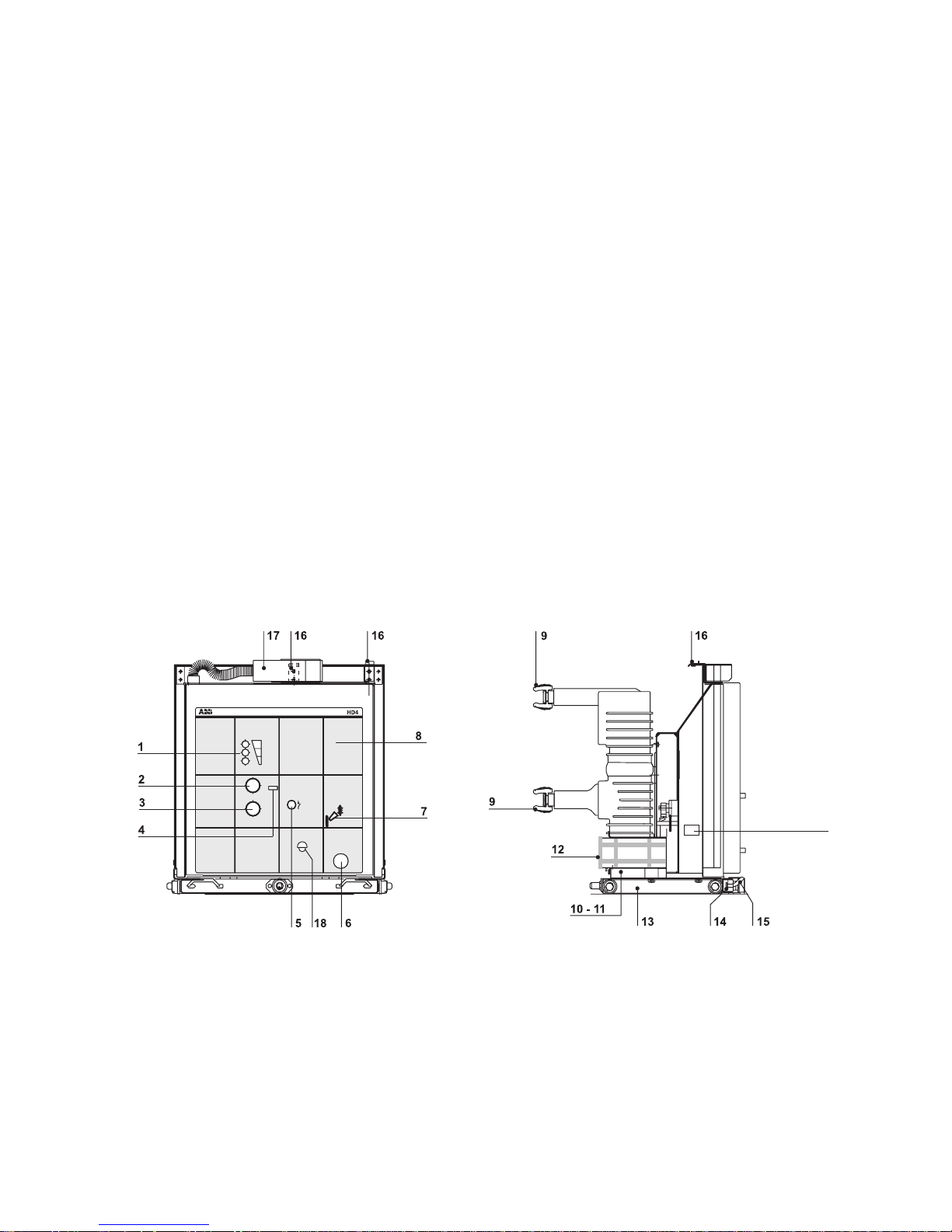

Withdrawable circuit-breaker

Caption

1 Signalling device for state of SF6 pressure (on request)

2 Opening push button

3 Closing push button

4 Operator counter

5 Signalling device for circuit-breaker open/closed

6 Shaft for manual closing spring charging

7 Signalling device for closing springs charged/discharged

8 Characteristics nameplate

9 Isolating contacts

Fig. 5

5.5. Enclosures and fixed parts

For information about the enclosures and fixed parts, please

consult the relative documentation.

The strikers for activating the contacts (connected/isolated),

located in the enclosure or in the switchgear, are fixed in the

top part of the circuit-breaker. The slides for activating the

segregation shutters of the medium voltage contacts of the

enclosure or switchgear are fixed on the sides of the circuitbreaker. The crosspiece for hooking the circuit-breaker for

the connection/isolation operation by means of the special

operating lever is mounted on the front part of the circuitbreaker truck.

The circuit-breaker is completed with the tulip isolating

contacts. The withdrawable circuit-breaker is fitted with

special locks, on the front crosspiece, which allow hooking

into the corresponding joints in the enclosure or fixed part.

The locks can only be activated by the handles with the truck

resting completely on the crosspiece.

The activating lever (connection/isolation) must be fully

inserted. A lock prevents the truck from advancing into the

enclosure or fixed part (for example when the earthing switch

is closed). With the truck in the middle position between

isolated and connected, the lock prevents closure of the

circuit-breaker (both mechanical and electrical).

On request, a locking magnet can be mounted on the truck

which, when de-energised, prevents truck operation.

10 Pressure switch (on request)

11 Valve for checking the SF6 gas pressure

12 Slide for activating the enclosure shutters

13 Truck

14 Locks for hooking into the fixed part

15 Lock activating handles (17)

16 Strikers for activating the contacts located in the enclosure

17 Connector (plug)

18 Resetting button for protection circuit-breaker of geared motor (on request)

10 - 11 (36 kV)

Page 12

12

7

6

8

3

5

4

1

2

6.1. Safety indications

HD4 circuit-breakers ensure a minimum degree

of protection IP2X if installed under the following

conditions:

– fixed version, with protection netting

– withdrawable version, installed in a switchgear.

Under these conditions, the operator is guaranteed

against accidental contact with moving parts.

Should any mechanical operations be carried out

on the circuit-breaker outside the switchgear or

with the protection netting removed, be very careful

of any moving parts.

If the operations are prevented, do not force the

mechanical interlocks and check that the operation

sequence is correct.

The racking-in and racking-out operations of

the circuit-breaker must be carried out gradually

to prevent any impacts which might deform the

mechanical interlocks.

6.2. Operating and signalling parts

Fig. 6

6.3. Circuit-breaker closing and opening

operations (fig. 6)

Circuit-breaker operation can be manual or electrical.

a) Manual operation for spring charging

To manually charge the closing springs, it is necessary fully

insert the charging lever into the seat (6) and turn it clockwise

until the yellow indicator (7) appears.

The force which can normally be applied to the charging lever

fitted is 130 N. In any case, the maximum force which can be

applied must not exceed 170 N.

b) Electrical operation for spring charging

On request the circuit-breaker can be fitted with the following

accessories for electrical operation:

– geared motor for automatic charging of the closing springs

– shunt closing release

– shunt opening release.

The geared motor automatically recharges the springs after

each closing operation until the yellow indicator (7) appears.

Should there be no voltage during charging, the geared motor

stops and then starts recharging the springs automatically

when the voltage is on again. It is, however, always possible

to complete the charging operation manually.

c) Circuit-breaker closing

This operation can only be carried out with the closing springs

completely charged.

For manual closing, push the push button (3).

When there is a shunt closing release, the operation can

also be carried out with remote control by means of a

control circuit. The indicator (4) shows that closing has been

accomplished.

In case of earthing truck with making capacity, activate

the key lock (in the closed position) and remove the key.

This is to prevent accidental opening operations during any

maintenance work on the installation.

d) Circuit-breaker opening

For manual opening, push the push button (2).

When there is a shunt opening release, the operation can

also be carried out with remote control by means of a control

circuit. The indicator (4) shows that opening has been

accomplished.

Caption

1 Signalling device for state of SF6 pressure (on request)

2 Opening push button

3 Closing push button

4 Operator counter

5 Signalling device for circuit-breaker open/closed

6 Shaft for manual closing spring charging

7 Signalling device for closing springs charged/discharged

8 Resetting button for protection circuit-breaker of geared motor (on request)

6. Instructions for circuit-breaker operation

Page 13

13

7. Installation

7.1. General

Correct installation is of prime importance. The

instructions given by the manufacturer must

be carefully studied and followed. It is good

practice to use gloves to handle the pieces during

installation.

7.2. Normal installation conditions

Maximum ambient air temperature + 40 °C

Minimum ambient air temperature – 5 °C

Relative humidity % < 95

Altitude < 1000 m

It must be possible to ventilate the installation room.

For other installation conditions, please follow what is

indicated in the product Standards.

For special installation requirements please contact us.

The areas affected by the passage of power conductors or

auxiliary circuit conductors must be protected against the

possible access of animals which could cause damage or

anomalous service.

7.3. Preliminary operations

– Clean the insulating parts with clean dry rags.

– Check that the upper and lower terminals are clean and

free of any deformation caused by shocks received during

transport or storage.

7.4. Installation of fixed circuit-breaker

The circuit-breaker can be mounted directly on the supporting

frames provided by the customer.

The circuit-breaker, complete with supporting truck, must be

fixed to the floor of its compartment with special brackets.

The parts of the floor surface on which the truck wheels rest

must be perfectly level.

The areas on which the supporting frames or truck wheels

rest (if a truck is provided) must be on the same horizontal

plane to avoid any risk of distortion in the breaker frame.

Fit the isolating partitions if provided.

A minimum degree of protection (IP2X) must be guaranteed

from the front towards live parts.

7.5. Installation of withdrawable circuitbreaker

The withdrawable circuit-breakers are preset for insertion in

enclosures, in fixed parts or in the corresponding switchgears.

Insertion and racking-out of the circuit-breakers must

be gradual to avoid any shocks which could deform the

mechanical interlocks.

If the operations are prevented, do not force the interlocks

and check that the operating sequence is correct. The force

normally applicable to the insertion/racking-out lever is 250 N.

Please also refer to the technical documentation of the

enclosures and switchgears for the circuit-breaker installation

operations.

CAUTION!

The insertion and racking-out operations must always be carried

out with the circuit-breaker open.

Page 14

14

Mounting procedures

– Place the connections in contact with the circuit-breaker

terminals.

– Interpose a spring washer and a flat washer between the

head of the bolt and the connection.

– Tighten the bolt, taking care not to subject the insulating

parts to stress (see table tightening torque).

– Make sure that the connections do not exert force on the

terminals.

– In case of cable connections, carefully follow the

manufacturer’s instructions for terminating the cables.

7.6. Fixed circuit-breaker power circuit

connections

7.6.1. General directions

– The connections must be made using only the squares-

terminals supplied with the circuit-breaker.

– Select the conductor cross-section according to the

operating and short-circuit current of the installation.

– Near the terminals of fixed version circuit-breakers or

enclosure, provide suitable support insulators dimensioned

according to the electrodynamic stresses that may arise

from the short-circuit current of the installation.

– Fit the isolating partitions if provided.

7.6.2. Mounting the connections

– Check that the connection contact surfaces are perfectly

flat and have no burrs, oxidation traces, or deformations

due to drillings or impacts.

– Depending on the conductive material and surface

treatment used, carry out the operations indicated in the

table on the contact surface of the conductor.

Screw Tightening torque

M6 10 Nm

M8 30 Nm

M10 40 Nm

M12 70 Nm

Bare copper Silver-plated copper or aluminium Bare aluminium

– Clean with a fine file or emery cloth. – Clean with a rough dry rag. – Clean with a metallic brush or

emery cloth.

– Fully tighten and smear a film of industrial vaseline grease over the

contact surfaces.

– In case of tough oxidation traces

only, clean with a very fine emery

cloth, taking care not to remove

the surface layer.

– Immediately smear a film of

industrial vaseline grease over the

contact surfaces.

– Interpose the copper-aluminium bi-metal with restored surfaces

between the aluminium connection and the copper terminal (copper

side in contact with the terminal; aluminium side in contact with the

connection).

– If necessary, recondition the

surface treatment.

Table of tightening torque

Page 15

15

7.8. Auxiliary circuit connection

Notes

– The minimum cross-section of the wires used for the

auxiliary circuits must not be less than that used for

internal wirings.

– Before carrying out the connection of the auxiliary

circuits, it is advisable to check the selected type of

automatism provided for operation of the pressure

switch (if provided) referring to the latest technical

documentation supplied by ABB.

7.8.1. Fixed circuit-breaker

The connection of the circuit-breaker auxiliary circuits must

be made via the terminal box mounted on the circuit-breaker

structure.

Outside the circuit-breaker the wires must run inside

appropriately earthed metal tubes or ducts.

Before removing the operating mechanism cover

to access the terminal box, make sure that the

circuit-breaker is open and the closing springs

discharged.

7.8.2. Withdrawable circuit-breaker

The auxiliary circuits of the withdrawable circuit-breaker are

fully cabled in the factory as far as the connector. For the

external connections, please refer to the electric diagram of

the enclosure or of the switchgear.

7.7. Earthing

For fixed version circuit-breakers, use the screw marked with

the relative symbol to effect the earthing.

Clean and degrease the surrounding area for a diameter of

about 30 mm. After completion of the assembly, cover the

entire joint with vaseline.

Use a conductor (busbar or braid) with a cross-section as

indicated in the Standards in force.

Page 16

16

150

496

63 248,5

43

347

493

473

67,5

150

586

402

13

205 260,5

10,5

114,5

117

270

332

21,5

541,5

13,5 336,5

446

87

27 27

2XM8 depth 16

2XM8 depth 16

M12 depth 25

M12 depth 22

581

600

63 231,5

472

598

618

43

210 210

67,5

117

34 270

332

10,5

87 336,5

205 266,5

21,5

623

13,5

13

446

111,5

27

27

2XM8 depth 16

2XM8 depth 16

M12 depth 25

M12 depth 25

7.9. Overall dimensions

Fixed circuit-breakers

Fixed circuit-breakers

HD4

TN

1VCD000231

Ur 12 kV

17.5 kV

Ir 630 A

1250 A

Isc 16 kA

25 kA

31.5 kA

HD4

TN

1VCD000226

Ur 12 kV

Ir 630 A

1250 A

Isc 16 kA

25 kA

31.5 kA

Page 17

17

20

Ø 13

Ø 10.5

266.5

306.5

8

310

310

655

15.5

32

Ø182 x

80

2.5

35

322

385

561

8

28

622

600

210210

472

598

43

618

YU

YU

Q60

578

35

322

385

20

Ø13

Ø10.5

310

266.5

20

40

20

20

62

20 40

603

Ø18

4x

655

670 min.

420

min.

468.5

349.5

2

115

622

8

28

465

15

730

275275

137.

5 137.5

708

602

748

43

728

YU

YU

Fixed circuit-breakers

HD4

TN

7163

Ur 12 kV

17.5 kV

Ir 1600 A

Isc 40 kA

50 kA

HD4

TN

7163

Ur 12 kV

17.5 kV

Ir 2000 A

Isc 25 kA

31.5 kA

40 kA

50 kA

Fixed circuit-breakers

HD4

TN

7165

Ur 12 kV

17.5 kV

Ir 2500 A

3150 A

3600 A

Isc 25 kA

31.5 kA

40 kA

50 kA

HD4

TN

7165

Ur 24 kV

Ir 2500 A

3150 A

3600 A

Isc 25 kA

31.5 kA

40 kA

Insulating partitions (only for 24 kV)

to be provided by the customer

(a special kit is available on request).

Page 18

18

27 27

2XM8 depth 16

2XM8 depth 16

M12 depth 25

M12 depth 25

10,5

117

34 270

332

468

623

13,5

451,5

310 302,5

356,5

87

730

705

63 231

43

602

728

748

275 275

67,5

695

210 210

472

618

43

231 63

600

581

67,5

103,5 103,5

598

695

117

13

623

468

270

332

310

302,5

451,5

87 356,5 13,5

10,5

34

420

670

27

27

2XM8 depth 16

M12 depth 25

M12 depth 25

2XM8 depth 16

Fixed circuit-breakers

Fixed circuit-breakers

7.9. Overall dimensions

HD4

TN

1VCD000235

Ur 24 kV

Ir 630 A

1250 A

Isc 16 kA

20 kA

25 kA

HD4

TN

1VCD000237

Ur 24 kV

Ir 630 A

1250 A

Isc 16 kA

20 kA

25 kA

Insulating partitions to be provided by the customer

(a special kit is available on request).

Page 19

19

35

322

385

3

115

20

13

10.5

266 .5

306 .5

8

310

310

182x

80

15.5

32

655

561

8

28

622

730

602

728

748

43

275 275

708

YU

YU

Q60

Ø

Ø

Ø

22

22

10

342 .5

362

729 .

5

37

270

363.5

3

358

400

10

639. 5

120

10.52x

348

*

200

*

4.9

*

516.4

*

85

*

355

*

695.4

28

21

539

887

*

302.5

13

13

13

*

*

*

40

*

880

350350

50

901

881

755

43

712

106 0

*

855

*

915

*

955

*

4

*

Ø

Ø

Ø

Ø

Ø

Ø

Fixed circuit-breakers

Fixed circuit-breakers

HD4

with truck (on request)

TN

7241

Ur 36 kV

Ir 630 A

1250 A

1600 A

Isc 16 kA

20 kA

* Distance with truck

(if provided).

HD4

TN

7174

Ur 24 kV

Ir 1600 A

Isc 31,5 kA

40 kA

HD4

TN

7174

Ur 24 kV

Ir 2000 A

Isc 25 kA

31,5 kA

40 kA

Page 20

20

730

708

7.9. Overall dimensions

Insulating partitions to be provided by the customer

(a special kit is available on request).

* Distance with truck (if provided).

Fixed circuit-breakers

HD4

with truck (on request)

TN

7268

Ur 36 kV

Ir 1250 A

1600 A

Isc 25 kA

31.5 kA

HD4

with truck (on request)

TN

7268

Ir 2000 A

Isc 20 kA

25 kA

31.5 kA

Insulating partitions to be provided by the customer

(a special kit is available on request).

* Distance with truck (if provided).

Fixed circuit-breakers

HD4

with truck (on request)

TN

7315

Ur 36 kV

Ir 2500 A

Isc 20 kA

25 kA

31.5 kA

Page 21

21

531

503

340

496

30

203

622,5

4

619

98,5

205

±1

10

19,5

25

320

370

416

437

+

2

0

558

661

53

9

35

4

586

260

±1

619

±2

154

±1

21,5

4

541

119

125

150 150

55

608

456

±2

501

492

HD4/P withdrawable circuit-breakers for UniGear type ZS1 switchgears

Also suitable for PowerCube PB1

HD4/P

TN

1VCD000227

Ur 12 kV

17.5 A

Ir 630 A

1250 A

Isc 16 kA

25 kA

31.5 kA

Page 22

22

550

653

682

626

±2

210 ±1

210 ±1

310 ±1280 ±1

164.5 ±1

44

636

272

579

67.5

691

686

640

119

20

68

40

53.5

17

111. 5

36

21

551

±1.5

359

416

4

29

53

4

63245

688

89

21.5

543

10

Ø

122

Ø

79

668.54

4

Ø

19.5

550

653

682

626

±2

210 ±1

210 ±1

310 ±1280 ±1

164.5 ±1

44

636

272

579

67.5

691

686

640

119

20

68

40

53.5

17

111. 5

36

21

551

±1.5

359

416

4

29

53

4

63245

688

89

21.5

543

10

Ø

122

Ø

79

669

4

4

Ø

19.5

7.9. Overall dimensions

(*) Also suitable for

PowerCube PB2.

HD4/P withdrawable circuit-breakers for UniGear type ZS1 switchgears

HD4/P

TN

7350

Ur 12 kV

17.5 kV

Ir 1250 A

Isc 40 kA

HD4/P

TN

7350

Ur 12 kV

17.5 kV

Ir 1600 A

Isc 25 kA

31.5 kA

40 kA (*)

50 kA (*)

(*) Also suitable for

PowerCube PB2.

HD4/P withdrawable circuit-breakers for UniGear type ZS1 switchgears

HD4/P

TN 7351

Ur 12 kV

17.5 kV

Ir 2000 A

Isc 25 kA

31.5 kA

40 kA (*)

50 kA (*)

Page 23

23

750

853

882

806

±2

275 ±1

275 ±1

310 ±1280 ±1

164.5 ±1

375

842

708

67.5

144

691

686

643

58

30

43.5

17111. 5

119

36

21

554

±1.5

359

416

4

29

53

4

4

4

63245

688

89

21.5

10

Ø

152

Ø

109

668.5

Ø

19.5

750

853

882

806

±2

275 ±1

275 ±1

310 ±1

280 ±1

164.5 ±1

375

842

708

67.5

730

643

58

30

43.5

17

96.5

36

21

554

±1.5

359

416

4

29

53

4

63245

732

89

21.5

10

Ø

152

Ø

109

730

Ø

19.5

(*) Also suitable for

PowerCube PB3.

HD4/P

TN

7352

Ur 12 kV (*)

17.5 kV

Ir 2500 A

Isc 25 kA

31.5 kA

40 kA

50 kA

HD4/P withdrawable circuit-breakers for UniGear type ZS1 switchgears

(*) 3150 A with forced

switchgear ventilation

(consult the UniGear

type ZS1 switchgear

technical catalogue).

HD4/P withdrawable circuit-breakers for UniGear type ZS1 switchgears

HD4/P

TN

7371

Ur 12 kV

17.5 kV

Ir 3150 A (*)

Isc 25 kA

31.5 kA

40 kA

50 kA

Page 24

24

610

±2

681

653

636

772,5

766,5

63 254,5

210

±1

210

±1

44

276

310

±1

125

461

±1

119 24

20

697

746

±1,5

53

4 717

198

±2

645

768

35

325

±1

653

682

550

610

±2

210 ±1 210 ±1

310 ±1

329 ±1

202 ±1

641

272

578

67.5

21.5

776

293

23

25.5

8

799

36

28

10

710

±1.5

460

4

53

63

792

682

125

20

Ø

35

Ø

19.5

Ø

92.6

718

44

7.9. Overall dimensions

HD4/P withdrawable circuit-breakers for UniGear type ZS1 switchgears

HD4/P

TN 1VCD00236

Ur 24 kV

Ir 630 A

1250 A

Isc 16 kA (*)

20 kA

25 kA

(*) 630 A only.

HD4/P withdrawable circuit-breakers for UniGear type ZS1 switchgears

HD4/P

TN 1VCD000099

Ur 24 kV

Ir 1250 A

Isc 31.5 kA

Page 25

25

853

882

806

±2

275 ±1275 ±1

310 ±1

345 ±1

198 ±1

144

842

232

708

67.5

817.5

807

310

23

43.5

30

19

119

788

36

58

11

699

±1.5

457

4

53

4

4

4

63

814

700

125

20

Ø

79

Ø

122

733

853

882

750

806

±2

275 ±1275 ±1

310 ±1

345 ±1

198 ±1

144

842

232

708

817.5

807

310

23

43.5

30

19

119

788

36

58

11

699

±1

457

4

53

4

4

4

63

814

700

125

20

Ø

79

Ø

122

21.5

Ø

19.5

733

67.5

(*) Also suitable for

PowerCube PB5.

HD4/P withdrawable circuit-breakers for UniGear type ZS1 switchgears

HD4/P

TN

7355

(*)

Ur 24 kV

Ir 1600 A

Isc 16 kA

20 kA

25 kA

31.5 kA

(*) 2500 A with forced

ventilation; 2300 A

with natural ventilation.

(**) Also suitable for

PowerCube PB5.

HD4/P withdrawable circuit-breakers for UniGear type ZS1 switchgears

HD4/P

TN

7356

(**)

Ur 24 kV

Ir 2000 A

Isc 16 kA

20 kA

25 kA

31.5 kA

HD4/P

TN

7356

(**)

Ur 24 kV

Ir 2500 A (*)

Isc 20 kA

25 kA

31.5 kA

Page 26

26

636

44

228

4 688

681

653

626

550

310 ±1

89

53

587 ±1,50

539

119

15 63

19,5

416

359

+

2

0

4

280 ±1

691

111,5

640

692

01

35

165 ±1

21,5

28

210 ±1 210 ±1

55

586,5

7.9. Overall dimensions

HD4/W withdrawable circuit-breakers for PowerCube modules

HD4/W

TN

1VCD000228

Ur 12 kV

17.5 kV

Ir 630 A

1250 A

Isc 16 kA

25 kA

31.5 kA

Page 27

27

682

653

626

±2

210 ±1

210 ±1

310 ±1

280 ±1

165 ±1

691

44

636

578

67.5

228

688

63245

56

15

63

36

29

53

40

16

640

28

416

551

±1.5

4

4

4

688

636

89

10

Ø

79

Ø

35

Ø

19.5

21.5

359

682

550

653

626

±2

210 ±1

210 ±1

310 ±1

280 ±1

165 ±1

691

44

636

578

67.5

272

668.5

63245

56

1563

36

53

40

8

640

28

29

551

±1.5

4

4

4

4

698

635.5

89

10

Ø

79

Ø

122

Ø

20

21.5

359

HD4/W withdrawable circuit-breakers for PowerCube modules

HD4/W

TN

7421

Ur 12 kV

17.5 kV

Ir 1250 A

Isc 40 kA

50 kA

HD4/W withdrawable circuit-breakers for PowerCube modules

HD4/W

TN

7239

Ur 12 kV

17.5 kV

Ir 1600 A

2000 A

Isc 16 kA

25 kA

31.5 kA

Page 28

28

882

750

853

806

±2

275 ±1

275 ±1

310 ±1

280 ±1

164.5 ±1

730

144

375

842

67.5

63

730

245

742

112 16

643

36

53

30

21

43.5

416

58

29

554

±1.5

4

4

732

89

10

Ø

109

Ø

152

Ø

19.5

21.5

359

708

7.9. Overall dimensions

HD4/W withdrawable circuit-breakers for PowerCube modules

HD4/W

TN 1VCD000053

Ur 12 kV

17.5 kV

Ir 3150 A

Isc 31.5 kA

40 kA

50 kA

Page 29

29

836

805

882

853

275

275

480

198

380

232

144

708

842

67.5

63

952

345

941.5

119 23

788

36

53

4

44

10

60

78

699

19

4

949

833

125

198

20

Ø

35

4

457

202

125

973

4

956

953

484

380

456

18

23

275 275

706

730

842

836

853

882

805

35

Ø

701

30

57

Withdrawable circuit-breakers HD4/W for UniGear type ZS2 switchgear and for PowerCube module

HD4/W

TN

7402

Ur 36 kV

Ir 1250 A

Isc 20 kA

25 kA

Withdrawable circuit-breakers HD4/W for UniGear type ZS2 switchgear and for PowerCube module

HD4/W

TN

7316

Ur 36 kV

Ir 1250 A

Isc 31.5 kA

Page 30

30

836

805

882

853

750

275

275

480

21.5

903.5

380

232

144

708

842

67.5

63

952

345

941.5

119 23

788

36

53

4

44

10

60

78

699

19

4

949

833

125

198

20

Ø

122

Ø

79

Ø

20

4

457

Ø A

1250-1600 A 35 mm

2000-2500 A (*) 79 mm

280

32.5

760

100

718

45

23

43

25

103

150140

230

503

200

582

4030

27

245

385

2 ÷ 5

840

280

23

43

22

1575

15

550

50

100

Ø 18

Ø 16

Ø A

Ø 20

120

85

80

485

900

1288.5

328

7.9. Overall dimensions

Withdrawable circuit-breakers HD4/W for UniGear type ZS2 switchgear and for PowerCube module

(*) With forced

ventilation.

HD4/W

TN

7317

Ur 36 kV

Ir 1600 A

2000 A

2500 A (*)

Isc 20 kA

25 kA

31.5 kA

HD4/Z/40.5 kV

TN

7227

Ur 40.5 kV

Ir 1250 A

1600 A

2000 A

2500 A (*)

Isc 25 kA

31.5 kA

(*) With natural ventilation

in loose enclosure

type Powerbloc; with

forced ventilation in

switchgear type

ZS3.2.

HD4/Z withdrawable circuit-breakers for UniGear type ZS3.2 - 40.5 kV switchgears

Page 31

31

681

653

63

254

604

625 ±1

37

19

255

68

A

53

4

121,5 ±1

25

740

320

25

307

229

370

382

414

149

40

79

310 ±1

687 ±1,5

36

35

45°

1

8

435,5 ±2

739

325 ±1

734,5

4

644,5

55

210 ±1 210 ±1

650

19,5

25

36,3

DETAIL A

SCALE 1 : 2

HD4/SEC withdrawable circuit-breakers for UniSec switchgears

HD4/SEC 24 kV

TN 1VCD000220

Ur 24 kV

Ir 630 A

1250 A

Isc 16 KA

20 kA

Page 32

32

8.1. General procedures

All the operations regarding putting into service

must be carried out by ABB personnel or customer

personnel who are suitably qualified and have

an in-depth knowledge of the apparatus and

installation.

If the operations are prevented, do not force the

mechanical interlocks, but check that the operation

sequence is correct.

The operating forces which can be applied are

indicated in paragraph 6.3.

Subject of the inspection Procedure Positive check

1 Insulation resistance.

Medium voltage circuits

With a 2500 V Megger, measure the insulation resistance

between phases and exposed conductive part of the circuit.

The insulation resistance should be at least 50 MΩ

and, in any case, constant in time.

Auxiliary circuits

With a 500 V Megger (installed equipment permitting)

measure the insulation resistance between the auxiliary

circuits and the exposed conductive part.

The insulation resistance should be a few MΩ and,

in any case, constant in time.

2 Auxiliary circuits. Check that the connections to the control circuit are

correct; proceed with relative supply.

Normal switchings and signallings

3 Manual operating

mechanism.

Carry out a few closing and opening operations (see chap.

6). N.B. Supply the u/v release and the locking magnet on

the operating mechanism at the relative rated voltage (if

provided).

The operations and relative signals occur correctly.

4 Motor operator (if

provided)

Supply the geared motor for spring charging at the relative

rated voltage.

The springs are charged correctly.

The signals are correct.

The geared motor cuts off when the springs are

charged.

Carry out a few closing and opening operations.

N.B. Supply the undervoltage release and the locking

magnet on the operating mechanism at the relative rated

voltage (if provided).

The geared motor recharges the springs after each

closing operation.

5 Undervoltage release (if

provided).

Supply the undervoltage release at the relative rated voltage

and carry out the circuit-breaker closing operation.

The circuit-breaker closes correctly.

The signals are correct.

Disconnect the power supply to the release. The circuit-breaker opens.

The signal changes over.

6 Shunt opening release

and additional shunt

opening release (if

provided).

Close the circuit-breaker.

Supply the shunt opening release at the relative rated

voltage.

The circuit-breaker opens correctly.

The signals are correct.

7 Shunt closing release (if

provided).

Open the circuit-breaker. Supply the shunt closing release

at the relative rated voltage.

The circuit-breaker closes correctly.

The signals are correct.

8 Key lock (if provided). Open the circuit-breaker.

Turn the key and remove it.

Attempt the circuit-breaker closing operation.

Neither manual nor electric closing takes place.

Insert the key again and turn it 90°.

Carry out the closing operation.

Both electric and manual closing take place

correctly; in this position the key cannot be

removed.

9 Locking electromagnet

(YL1) (if provided).

With the circuit-breaker open, springs charged and locking

electromagnet not supplied, attempt to close the circuitbreaker both manually and electrically.

Closing is not possible.

10 Auxiliary contacts in the

operating mechanism.

Insert the auxiliary contacts into suitable signalling circuits.

Carry out a few closing and opening operations.

Signals occur correctly.

Before putting the circuit-breaker into service carry out the

following operations:

– check the tightness of the power connections on the circuit-

breaker terminals;

– establish the setting of the direct solid-state overcurrent

release (if provided);

– check that the value of the supply voltage for the auxiliary

circuits is within 85% and 110% of the rated voltage of the

electrical devices;

– check that no foreign body, such as packaging, has got into

the moving parts;

– check that air circulation in the circuit-breaker installation

site is adequate so that there is no danger of overheating;

– carry out the checks indicated in the following table:

8. Putting into service

Page 33

33

Subject of the inspection Procedure Positive check

11

Locking electromagnet on

the circuit-breaker truck

(YL2) (if provided).

With the circuit-breaker open in the isolated for test position

and the locking electromagnet not supplied, attempt to

connect the circuit-breaker.

Connection is not possible.

Supply the locking electromagnet and carry out the

connection operation.

Connection takes place correctly.

12

Auxiliary transmitted

contacts for indicating

that the circuit-breaker

is connected, isolated

(CBE or PowerCube

enclosures).

Insert the auxiliary contacts into suitable signalling circuits.

With the circuit-breaker inside the enclosure carry out a few

translation operations from the isolated for test position to

the connected position.

Put the circuit-breaker in the withdrawn position.

The signals of the relative operations occur correctly.

13

Electromechanical locking

device (if provided)

(CBE or PowerCube

enclosures).

With no supply to the locking device try to rack-in the

circuit-breaker into the enclosure.

Supply the locking device at the relative rated voltage. Carry

out the racking-in operation.

Racking-in is not possible.

Racking-in is possible.

Page 34

34

Before carrying out any operation, make sure that

the operating mechanism springs are discharged

and that the apparatus is in the open position.

9.1. General

During normal service, the circuit-breakers are maintenancefree. The frequency and sort of inspections basically depend

on the service conditions. Various factors must be taken into

account: frequency of operations, interrupted current values,

relative power factor and the installation ambient.

The following paragraph gives the checking programme table,

showing the relevant time intervals.

As far as the time interval between these operations is

concerned, it is advisable to comply with specifications given

in the table, at least during the first check. On the basis of

the results obtained during the periodic inspections, set the

optimal time limits for carrying out the following operations.

9. Periodical checking

Checking operation Time interval Critera

1 Carry out five mechanical opening closing

operations.

1 year. The circuit-breaker must operate normally without stopping

in intermediate positions

2 Visual inspection of the poles (parts in

resin).

1 year or 5,000 operations. The parts in resin must be free of any accumulation of dust,

dirt, cracks, discharges or traces of surface discharges.

3 Visual inspection of the operating

mechanism and transmission.

1 year or 5,000 operations. The elements must be free of any deformation.

Screws, nuts, bolts, etc. must be tight.

4 Visual inspection of the isolating contacts. 5 year or 5,000 operations. The isolating contacts must be free of any deformation or

erosion.

Lubricate the contact elements with industrial vaseline

greaseindustriale.

5 Measuring the insulation resistance. 5 year or 5,000 operations. See para. 8.1. point 2.

6 Checking interlock operation. 5 year. The interlocks provided must operate correctly.

9.2. Checking programme

Maintenance must only be carried out by ABB

personnel or in any case by suitably qualified

customer personnel who have in-depth knowledge

of the apparatus (IEC 62271-1 para 10.4.2). Should

the maintenance by carried out by the customer’s

personnel, responsibility for any interventions lies

with the customer.

Replacement of any parts not included in the “List

of spare parts/accessories” must only be carried

out by ABB personnel.

In particular:

– Complete pole with bushings/connections

– Operating mechanism

– Closing spring unit

– Opening spring.

After 10,000 operations or after 10 years, for installation in

polluted and aggressive ambients, it is advisable to contact an

ABB service center to have the circuit-breaker checked.

10. Maintenance operations

Page 35

35

SF6 in its pure state is an odourless, colourless, non-toxic gas

with a density about six times higher than air. For this reason,

although it does not have any specific physiological effects, it

can produce the effects caused by lack of oxygen in ambients

saturated with SF6.

During the interruption phase of the circuit-breaker, an electric

arc is produced which decomposes a very small amount of

SF6. The decomposition products remain inside the poles and

are absorbed by special substances which act as molecular

sieves. The probability of contact with decomposed SF6 is

extremely remote, and its presence in small quantities (1-3

ppm) is immediately noticeable because of its sour and

unpleasant smell. In this case, the room must be aired before

anybody enters it.

The strong infrared absorption of SF6 and its long lifetime in

the environment are the reasons for its high Global Warming

Potential (GWP) which is 22.800 higher than CO2, according

to the Fourth Assessment Report.

The GWP is calculated over a time period of 100-years

warming potential of 1 kg of a gas referred to 1 kg of CO2. Its

overall contribution to the global greenhouse gas effect from

all applications amounts to approximately 0,2% overall.

However, the GWP of SF6 alone is not adequate to measure

the environmental impact of electric power equipment based

on SF6 technology.

The environmental impact of any specific application

should be evaluated and/or compared using the Life Cycle

Assessment – LCA approach as regulated by ISO 14040.

11. Indications for handling apparatus with SF6

The Electric Industry utilises SF6 in a closed cycle, banking

it e.g. in gas insulated substations (GIS), medium-voltage

and high-voltage gas circuit breakers (GCB), high-voltage

gas insulated lines (GIL), gas insulated voltage transformers

(GVT). In Asia, significant quantities of SF6 are banked in gas

insulated power transformers (GIT) as well.

The Electric Industry is reported as the most important user

of SF6, worldwide. In spite of being the most important

user of SF6, the Electric Industry is a low contributor to

the global emission of SF6, far below to other industries

or users with “open application” of the gas. However, its

importance as source substantially varies from region to

region and from country to country, depending on the SF6

handling procedures adopted, the tightness of the electric

power equipment and the amount of gas banked in electric

equipment.

For info about Life Cycle Assessment of apparatus, see

document (1VCP000264).

To dispose of the SF6 gas, please contact the ABB

Assistance Service (see contact persons at http://www.abb.

com/ServiceGuide/alphabetical.aspx) as this operation must

be done only by trained and qualified personal; on request are

available specific instructions for the evacuation of the SF6

gas from the apparatuses.

The volume of SF6 in each apparatus is indicated on the

nameplate.

Page 36

36

All assembly operations of spare parts/accessories

regarding installation, putting into service, service

and maintenance must be carried out by ABB

personnel or suitably qualified customer personnel

with in-depth knowledge of the apparatus (IEC

62271-1 para. 10.4.2). Should the maintenance

by carried out by the customer’s personnel,

responsibility for any interventions lies with the

customer.

Before carrying out any operation, check that the

circuit-breaker is open, the springs discharged and

that there is no voltage (medium voltage circuit and

auxiliary circuits).

To order accessories or spare parts, please refer to the

commercial ordering codes given in the technical catalogue

and always indicate:

– circuit-breaker type

– circuit-breaker rated voltage

– circuit-breaker rated thermal current

– circuit-breaker breaking capacity

– circuit-breaker serial number

– rated voltage of any electrical accessories.

For availability and ordering of spare parts please contact our

Service department.

12.1. List of spare parts

– Shunt opening release

– Additional shunt opening release

– Undervoltage release

– Contact signalling undervoltage release energised/de-

energised

– Undervoltage release delay device

– Mechanical exclusion device for undervoltage release

– Shunt closing release

– Spring charging geared motor with electric signalling of

springs charged

– Geared motor thermomagnetic protection circuit-breaker

– Contact signalling geared motor protection circuit-breaker

open/closed

– Contact signalling closing springs charged/discharged

– Transient contact with momentary closure during circuit-

breaker opening

– Auxiliary circuit-breaker contacts

– Locking electromagnet on operating mechanism

– Position contact of withdrawable truck

– Contacts signalling connected/isolated

– Opening solenoid

– Key lock in open position

– Isolation interlock with door

– Protection for opening pushbutton

– Protection for closing pushbutton

– Locking electromagnet on withdrawable truck

– Sliding earthing contact of withdrawable truck

– Opening/closing knob

– Set of six tulip contacts

– SF6 gas pressure monitoring device.

12. Spare parts and accessories

Page 37

37

Page 38

More product information:

abb.com/mediumvoltage

Your contact center:

abb.com/contactcenters

More service information:

abb.com/service

1VCD601246 - Rev. S - en Instruction Manual 2018.02 (HD4) (gs)

For more information please contact:

Data and illustration are not binding. We reserve the right to make

changes in the course of technical development.

© Copyright 2018 ABB. All rights reserved.

Loading...

Loading...