Page 1

DCS800

(

)

Service manual

DCS800 Drives

20 to 5200 A

Page 2

_

DCS800 Drive Manuals

Langu age

Public. number

DCS800 Quick Guide

DCS800 Tools & Documentation CD 3ADW000211 x

DCS800 Converter module

Flyer DCS800 3ADW000190 x x x x

Technical Catalogue DCS800 3ADW000192 x x x x x x x

Hardware Manual DCS800 3ADW000194 x x x x x x x x

Hardware Manua l DCS800 update DCF503B/DCF504 B 3ADW000194Z0301 x

Firmware Manual DCS8 00 3ADW000193 x x p x x x x x

Installation according to EMC 3ADW000032 x

Technical Guide 3ADW000163 x

Service Manual DCS800 3ADW000195 x x

12-Pulse Manual 3ADW000196 x

CMA-2 Board 3ADW000136 p

Flyer Hard - Parallel 3ADW000213 x

Drive Tools

DriveWindo w 2. x - Us er's Manu al 3BFE 64560 981 x

DriveOPC 2.x - User' s Manual 3BFE 00073 846 x

Optical D DCS Co mmunication Link 3AFE 63988 235 x

DDCS Branchin g Units - User’s Ma nual 3BFE 64285 513 x

DCS800 Applications

PLC Programming with CoDeSys CoDe Sys_V 23 x x x

61131 DCS800 target +tool descr iption - Application Prog ram 3ADW000 199 x

DCS800 Crane Drive

DCS80 0 Crane Drive Manual suppl. 3AST 00414 3 x

DCS80 0 Crane Drive Produc t note PDC5 E N REVA p

DCS800 Winder ITC

DCS80 0 Wi nder Product n ote PDC2 EN x

DCS80 0 Wi nder description IT C 3ADW000308 x

Wind er Questio nnaire 3ADW000253z x

DCS800-E Panel Solution

Flyer DCS800-E Panel solution 3ADW000210 x

Hardware Manua l DCS800-E 3 ADW000224 x

DCS800-A Enclose d Conver ters

Flyer DCS800-A 3ADW000213 x

Technical Catalogue DCS800-A 3ADW000198 x

Installation of DCS800 -A 3ADW000091 x x

DCS800-R Rebuild System

Flyer DCS8 00-R 3ADW000007 x x

DCS80 0-R Manual 3ADW000197 x

DCS50 0/DCS6 00 Si ze A5...A7, C2b, C3 and C4 Upgrade Kit s 3ADW000256 x

Extension Modules

RAIO-01 Analogue IO E xtension 3AFE64484567 x

RDIO-01 Digital IO Extension 3AFE64485733 x

RRIA -01 Resolver Interf ace Module 3AFE 68570 760 x

RTAC- 01 P ulse Encode r Interface 3AFE 64486 853 x

RTAC- 03 TTL Pulse Encode r Interface 3AFE 68650 500 x

AIMA R-slot e xtension 3AFE 64661 442 x

Serial Communication

Drive specific serial co mmunication

NETA Re mote diagnostic interface 3 AFE64 60506 2 x

Fieldbus Ada pter with DC Drives RPBA- (PROFIBUS) 3AFE 64504 215 x

Fieldbus Ada pter wi th DC Drives RCAN-02 (C ANopen)

Fieldbus Ada pter with DC Dr ives RCNA-01 (ControlNet) 3AFE 64506 005 x

Fieldbus Adapter with DC Drives RDNA- (DeviceNet) 3AFE64504223 x

Fieldbus Ada pter with DC Drives RMBA (MODBU S) 3AFE 64498 851 x

Fieldbus Ada pter with DC Drives RETA (Ethe rnet) 3AFE 64539 736 x

x -> existing p -> planned

Status 04.2010

DCS800 Drive Manuals-List

j.doc

3ADW000191 x x x x x

E D I ES F CN RU PL

Page 3

DCS800 Drives

20 to 5200 A

Service Manual

Code: 3ADW000195R0501 Rev E

DCS800 Service Manual e e.doc

EFFECTIVE: 03.2011

SUPERSEDES: Rev D 09.2009

2011 ABB Automation Products GmbH. All rights reserved.

Page 4

3ADW000195R0501 DCS800 Service Manual e e

3ADW000195R0101 DCS800 Service Manual e a

Page 5

Safety instructions

What this chapter contains

This chapter contains the safety instructions you must follow when installing,

operating and servicing the drive. If ignored, physical injury or death may follow, or

damage may occur to the drive, the motor or driven equipment. Read the safety

instructions before you work on the unit.

To which products this chapter applies

The information is valid for the whole range of the product DCS800, the converter

modules DCS800-S0x size D1 to D7, field exciter units DCF80x, etc. like the

Rebuild Kit DCS800-R00-9xxx.

Usage of warnings and notes

There are two types of safety instructions throughout this manual: warnings and

notes. Warnings caution you about conditions which can result in serious injury or

death and/or damage to the equipment, and advise on how to avoid the danger.

Notes draw attention to a particular condition or fact, or give information on a

subject. The warning symbols are used as follows:

Dangerous voltage warning warns of high voltage which can cause

physical injury or death and/or damage to the equipment.

5

General danger warning warns about conditions, other than those

caused by electricity, which can result in physical injury or death

and/or damage to the equipment.

Electrostatic sensitive devices warning warns of electrostatic

discharge which can damage the equipment.

Safety instructions

3ADW000195R0501 DCS800 Service Manual e e

Page 6

6

Installation and maintenance work

These warnings are intended for all who work on the drive, motor cable

or motor. Ignoring the instructions can cause physical injury or death

and/or damage to the equipment.

• Never work on the drive, motor cable or motor when main power is

• Do not work on the control cables when power is applied to the

• Do not make any insulation resistance or voltage withstand tests

• Isolate the motor cables from the drive when testing the insulation

• When reconnecting the motor cable, always check that the C+ and

• Depending on the external wiring, dangerous voltages (115 V,

• DCS800 with enclosure extension: Before working on the drive,

WARNING!

•

Only qualified electricians are allowed to install and maintain

the drive!

applied.

Always ensure by measuring with a multimeter (impedance at least

1 Mohm) that:

1. Voltage between drive input phases U1, V1 and W1 and

the frame is close to 0 V.

2. Voltage between terminals C+ and D- and the frame is

close to 0 V.

drive or to the external control circuits. Externally supplied control

circuits may cause dangerous voltages inside the drive even when

the main power on the drive is switched off.

on the drive or drive modules.

resistance or voltage withstand of the cables or the motor.

D- cables are connected with the proper terminal.

Note:

• The motor cable terminals on the drive are at a dangerously high

voltage when the main power is on, regardless of whether the

motor is running or not.

220 V or 230 V) may be present on the relay outputs of the drive

system (e.g. SDCS-IOB-2 and RDIO).

isolate the whole drive system from the supply.

Safety instructions

3ADW000195R0501 DCS800 Service Manual e e

Page 7

7

Grounding

These instructions are intended for all who are responsible for the

grounding of the drive. Incorrect grounding can cause physical injury,

death and/or equipment malfunction and increase electromagnetic

interference.

WARNING!

• Ground the drive, motor and adjoining equipment to ensure

personnel safety in all circumstances, and to reduce

electromagnetic emission and pick-up.

• Make sure that grounding conductors are adequately sized and

marked as required by safety regulations.

• In a multiple-drive installation, connect each drive separately to

protective earth (PE ).

• Minimize EMC emission and make a 360° high frequency

grounding (e.g. conductive sleeves) of screened cable entries at

the cabinet lead-through plate.

• Do not install a drive equipped with an EMC filter to an

ungrounded power system or a high resistance-grounded (over 30

ohms) power system.

Note:

• Power cable shields are suitable as equipment grounding

conductors only when adequately sized to meet safety regulations.

• As the normal leakage current of the drive is higher than 3.5 mA

AC or 10 mA DC (stated by EN 50178, 5.2.11.1), a fixed protective

earth connection is required.

Safety instructions

3ADW000195R0501 DCS800 Service Manual e e

3ADW000195R0101 DCS800 Service Manual e a

Page 8

8

Printed circuit boards and fiber optic cables

These instructions are intended for all who handle the circuit boards

and fiber optic cables. Ignoring the following instructions can cause

damage to the equipment.

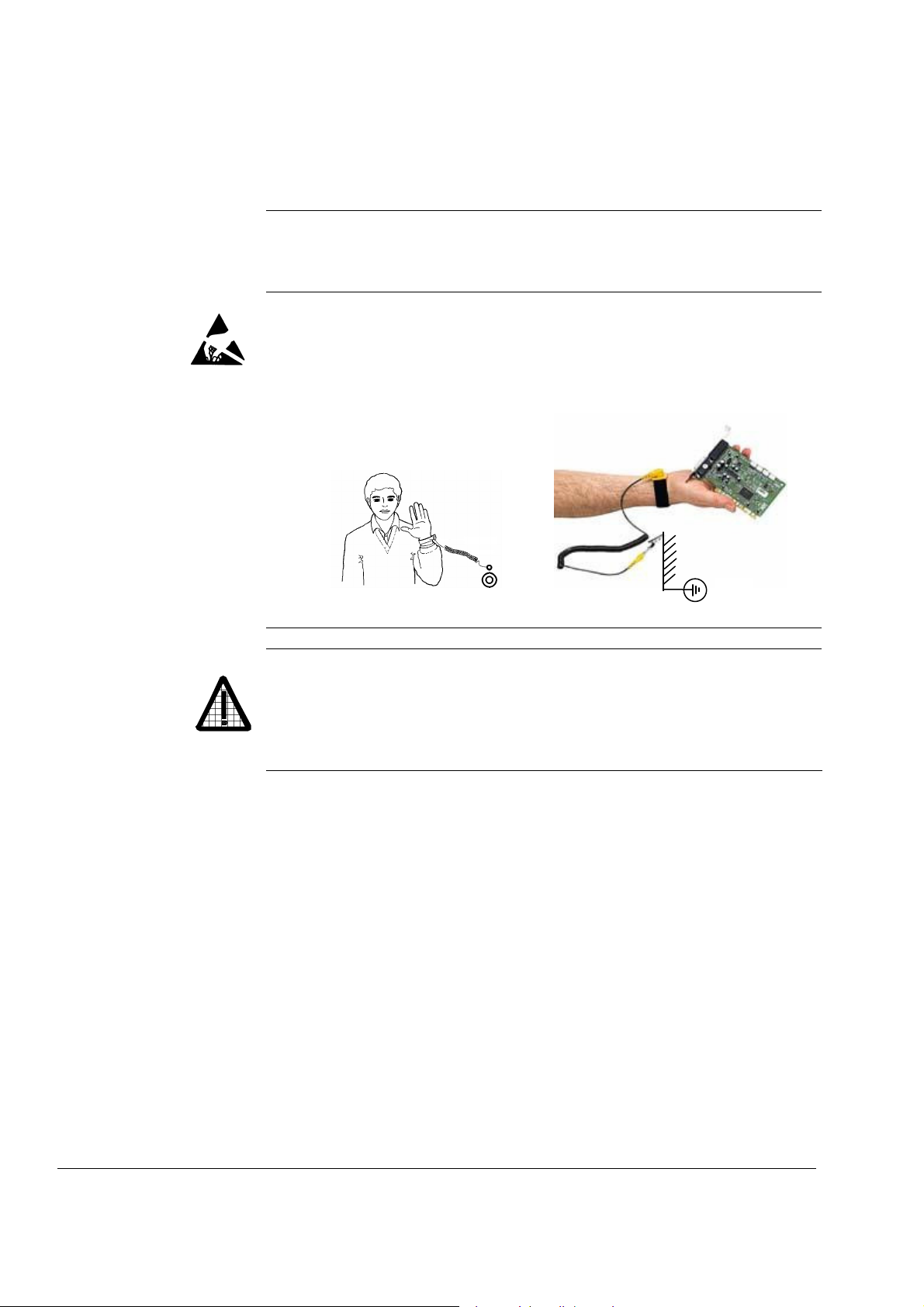

WARNING! The printed circuit boards contain components sensitive to

electrostatic discharge. Wear a grounding wrist band when handling

the boards. Do not touch the boards unnecessarily.

Use grounding strip:

ABB order no.: 3ADV050035P0001

WARNING! Handle the fiber optic cables with care. When unplugging

optic cables, always grab the connector, not the cable itself. Do not

touch the ends of the fibers with bare hands as the fiber is extremely

sensitive to dirt. The minimum allowed bend radius is 35 mm (1.38 in.).

Safety instructions

3ADW000195R0501 DCS800 Service Manual e e

Page 9

9

Mechanical installation

These notes are intended for all who install the drive. Handle the unit

carefully to avoid damage and injury.

• Make sure that dust from drilling does not enter the drive when

• Ensure sufficient cooling.

• Do not fasten the drive by riveting or welding.

WARNING!

• DCS800 sizes D4 ... D7: The drive is heavy. Do not lift it alone. Do

not lift the unit by the front cover. Place units D4 and D5 only on its

back.

DCS800 sizes D5 ... D7: The drive is heavy. Lift the drive by the

lifting lugs only. Do not tilt the unit. The unit will overturn from a tilt

of about 6 degrees.

installing. Electrically conductive dust inside the unit may cause

damage or lead to malfunction.

Safety instructions

3ADW000195R0501 DCS800 Service Manual e e

3ADW000195R0101 DCS800 Service Manual e a

Page 10

10

Operation

These warnings are intended for all who plan the operation of the drive

or operate the drive. Ignoring the instructions can cause physical injury

or death and/or damage to the equipment.

WARNING!

• Before adjusting the drive and putting it into service, make sure

that the motor and all driven equipment are suitable for operation

throughout the speed range provided by the drive. The drive can

be adjusted to operate the motor at speeds above and below the

base speed.

• Do not control the motor with the disconnecting device

(disconnecting mains); instead, use the control panel keys

and

, or commands via the I/O board of the drive.

• Mains connection

You can use a disconnect switch (with fuses) to disconnect the

electrical components of the drive from the mains for installation

and maintenance work. The type of disconnect switch used must

be as per EN 60947-3, Class B, so as to comply with EU

regulations, or a circuit-breaker type which switches off the load

circuit by means of an auxiliary contact causing the breaker's main

contacts to open. The mains disconnect must be locked in its

"OPEN" position during any installation and maintenance work.

• EMERGENCY STOP buttons must be installed at each control

desk and at all other control panels requiring an emergency stop

function. Pressing the STOP button on the control panel of the

drive will neither cause an emergency stop of the motor, nor will

the drive be disconnected from any dangerous potential.

To avoid unintentional operating states, or to shut the unit down in

case of any imminent danger according to the standards in the

safety instructions it is not sufficient to merely shut down the drive

via signals "RUN", "drive OFF" or "Emergency Stop" respectively

"control panel" or "PC tool".

• Intended use

The operating instructions cannot take into consideration every

possible case of configuration, operation or maintenance. Thus,

they mainly give such advice only, which is required by qualified

personnel for normal operation of the machines and devices in

industrial installations.

If in special cases the electrical machines and devices are intended for use in non-industrial installations - which may require

stricter safety regulations (e.g. protection against contact by

children or similar) - these additional safety measures for the

installation must be provided by the customer during assembly.

Safety instructions

3ADW000195R0501 DCS800 Service Manual e e

Page 11

11

Note:

• When the control location is not set to Local (L not shown in the

status row of the display), the stop key on the control panel will not

stop the drive. To stop the drive using the control panel, press the

LOC/REM key and then the stop key

.

Safety instructions

3ADW000195R0501 DCS800 Service Manual e e

3ADW000195R0101 DCS800 Service Manual e a

Page 12

12

Safety instructions

3ADW000195R0501 DCS800 Service Manual e e

Page 13

13

Table of contents

Safety instructions 5

What this chapter contains..........................................................................................................5

To which products this chapter applies.......................................................................................5

Usage of warnings and notes .....................................................................................................5

Installation and maintenance work..............................................................................................6

Grounding........................................................................................................................7

Mechanical installation................................................................................................................9

Operation ..................................................................................................................................10

Table of contents 13

Introduction 16

How to use this manual.............................................................................................................16

Contents of this manual ............................................................................................................16

Target group .............................................................................................................................16

Associated publications ............................................................................................................16

Storage and transport ...............................................................................................................17

Name plate and type code ........................................................................................................17

Type code .................................................................................................................................18

Current and voltage ratings.......................................................................................................19

Fault Tracing Thyristors 21

Tools .........................................................................................................................................21

For commissioning and fault tracing..............................................................................21

Additionally for service and preventive maintenance ....................................................22

How to detect a faulty thyristor..................................................................................................22

A fuse is blown ..............................................................................................................22

DC-current pulses measured by an oscilloscope ..........................................................23

Thyristor diagnosis ........................................................................................................23

Ripple monitor ...............................................................................................................23

How to find a faulty thyristor......................................................................................................24

Converters size D1 to D4 (20...1000 A).........................................................................24

Blown fuses ...................................................................................................................24

Converters size D5, D6, and D7 (900...5200 A) ............................................................25

Blown fuses ...................................................................................................................25

Ripple monitor ...............................................................................................................25

Handling the Semiconductors 27

General Instruction how to handle the Semiconductors ...........................................................27

Exchange of Thyristors for Size D1 to D4 29

Installation of OnBoard bridge and thyristor modules in converters size D1 to D4

(20...1000 A) .............................................................................................................................29

Required Tools ..............................................................................................................29

Find faulty thyristor modules .........................................................................................29

Remove faulty thyristor modules ...................................................................................30

Install new thyristor modules .........................................................................................34

Table of contents

3ADW000195R0501 DCS800 Service Manual e e

Page 14

14

Remove faulty OnBoard bridge (V1) ............................................................................ 36

Install new OnBoard bridge (V1) .................................................................................. 36

OnBoard bridge (V1) and thyristor module location in DCS800-S01 (2-Q) units.......... 37

OnBoard bridge (V1) and thyristor module location in DCS800-S02 (4-Q) units.......... 38

OnBoard bridge and thyristor module terminals ........................................................... 39

Exchange of Thyristors for Size D5 41

Installation of "Disc Type" thyristor in converters size D5 (900...2000 A) ................................ 41

Required Tools ............................................................................................................. 41

Disk type thyristors ....................................................................................................... 42

Find faulty thyristor ....................................................................................................... 45

Remove faulty thyristor................................................................................................. 46

Install new thyristor....................................................................................................... 47

Exchange of Thyristors for Size D6 51

Installation of "Disc Type" thyristor in converters size D6 (1900...3000 A) .............................. 51

Required Tools ............................................................................................................. 51

Disk type thyristors ....................................................................................................... 52

BCT thyristors............................................................................................................... 53

Find faulty thyristor ....................................................................................................... 54

Remove faulty thyristor................................................................................................. 55

Install new thyristor....................................................................................................... 58

Exchange of Thyristors for Size D7 65

Installation of "Disc Type" thyristor in converters size D7 (2050...5200 A) .............................. 65

Required Tools ............................................................................................................. 65

Find faulty thyristor ....................................................................................................... 66

Install new thyristor....................................................................................................... 69

Exchange of SDCS-CON-4 75

General .................................................................................................................................... 75

Required Tools ............................................................................................................. 75

Overview SDCS-CON-4 exchange............................................................................... 75

Service 83

How to remove the converter fans in frames D1 to D3 (two fans) ........................................... 83

How to remove the converter fans in a frame D3 (four fans) ................................................... 87

How to remove the converter fan in a frame D6 ...................................................................... 92

How to remove the converter fan in a frame D7 ...................................................................... 93

DCS800 firmware download .................................................................................................... 94

General......................................................................................................................... 94

Download SDCS-CON-4 firmware................................................................................ 94

Add firmware or text files ............................................................................................ 107

Create a workspace.................................................................................................... 114

Download SDCS-COM-8 firmware ............................................................................. 129

Set type code ......................................................................................................................... 131

Type code table .......................................................................................................... 133

DC-Motor neutral zone adjustment ........................................................................................ 134

Types concerned ........................................................................................................ 134

Summary .................................................................................................................... 134

General....................................................................................................................... 134

Table of contents

3ADW000195R0501 DCS800 Service Manual e e

Page 15

15

Preventive Maintenance 135

Recommended regular maintenance......................................................................................136

Maintenance schedule ............................................................................................................136

Annual preventive maintenance..............................................................................................137

3 years preventive maintenance .............................................................................................140

6 years preventive maintenance .............................................................................................141

9 years preventive maintenance .............................................................................................143

Appendix A - Spare Parts List 145

Table of contents

3ADW000195R0501 DCS800 Service Manual e e

Page 16

16

Introduction

How to use this manual

The purpose of this service manual is to provide detailed information on how to

service power converters from the DCS800 series.

Contents of this manual

Safety instructions

This chapter is located at the beginning of this manual.

Introduction

This chapter informs about the contents and the use of this manual as well as the

boundary conditions applying and the thyristor power converter rating plate.

Fault Tracing Thyristors

This chapter describes how to detect and select a faulty thyristor.

Handling the Semiconductors

This chapter describes the handling of thyristors and thyristor modules.

Exchange of Thyristors of Sizes D1 to D4

This chapter describes the exchange of thyristors in converters sizes D1 to D4.

Exchange of Thyristors of Size D5

This chapter describes the exchange of thyristors in converters size D5.

Exchange of Thyristors of Size D6

This chapter describes the exchange of thyristors in converters size D6.

Exchange of Thyristors of Size D7

This chapter describes the exchange of thyristors in converters size D7

Exchange of SDCS-CON-4

This chapter describes the exchange of a SDCS-CON-4

Service

This chapter contains hardware information and technical hints.

Preventive Maintenance

This chapter describes the measures for preventive maintenance of the thyristor

converters.

Appendix A Spare Parts list

The Appendix A contains the spare parts list of the converters.

Target group

This manual is designed to help those responsible for planning, installing, starting

up and servicing the thyristor power converter.

These people should possess:

basic knowledge of physics and electrical engineering, electrical wiring

principles, components and symbols used in electrical engineering, and

basic experience with DC drives and products.

Associated publications

A list of associated publications is published on the inner page of this manual’s

cover, see DCS800 Drive Manuals

The DCS800 Hardware Manual (3ADW000194) describes all hardware

Introduction

3ADW000195R0501 DCS800 Service Manual e e

. Here is a list of the most important ones:

Page 17

17

R

components of the DCS800, their connections and settings (e.g. jumpers)

The DCS800 Firmware Description (3ADW000193) gives an overview of the

DCS800 firmware, describes all parameters, describes the function of the DCS

Control Panel, gives support in case of faults and alarms and gives information

about communication.

The above listed documentation can be found on the CD-ROM being attached to

the DCS800 Quick Guide (3ADW000191).

Storage and transport

If the unit has been in storage prior to installation or is transported to another

location, care must be taken to ensure that the environmental conditions are

complied with (see Hardware Manual).

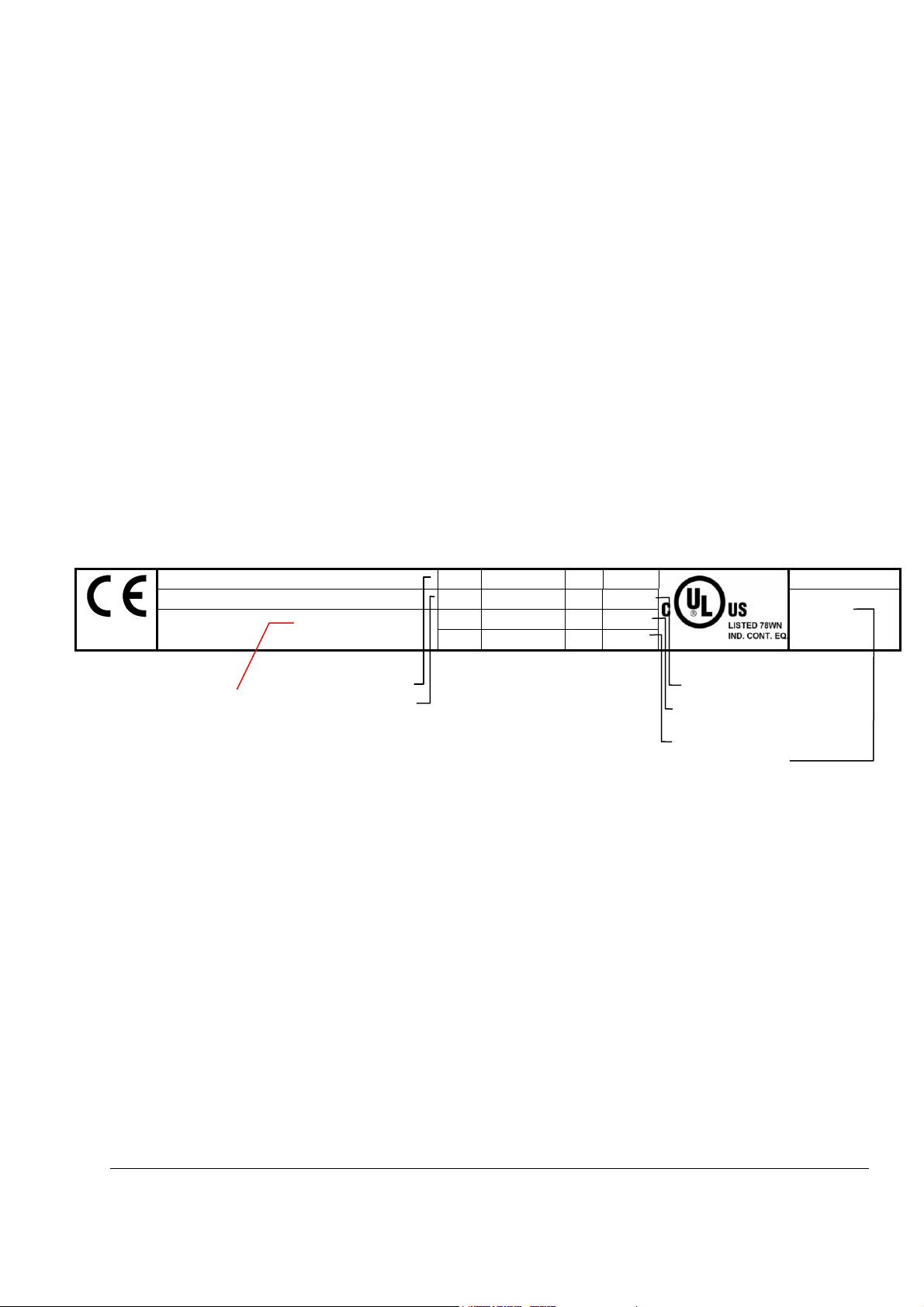

Name plate and type code

For purposes of identification, each thyristor power converter is fitted with name

plates, stating the type code and the serial number, which serve for each unit's

individual identification.

The type code contains information about the characteristics and the configuration

of the unit.

ABB Automation Products

Type: DCS800-S02-0025-05

Ser No: 0025421A06294264

Production year

2006 and week 29

Example of a name plate

Rated input voltage

Rated input current

U

1

I

1

f

1

SCC

3 525 V

20 A I

50/60 Hz If 6 A

65 kA

U2 610 V

25 A

2

Fan

----

Rated output current

Rated internal field

exciter current

Rated fan voltage

Plus code

Made in Germany

+K454

+J409

Introduction

3ADW000195R0501 DCS800 Service Manual e e

Page 18

18

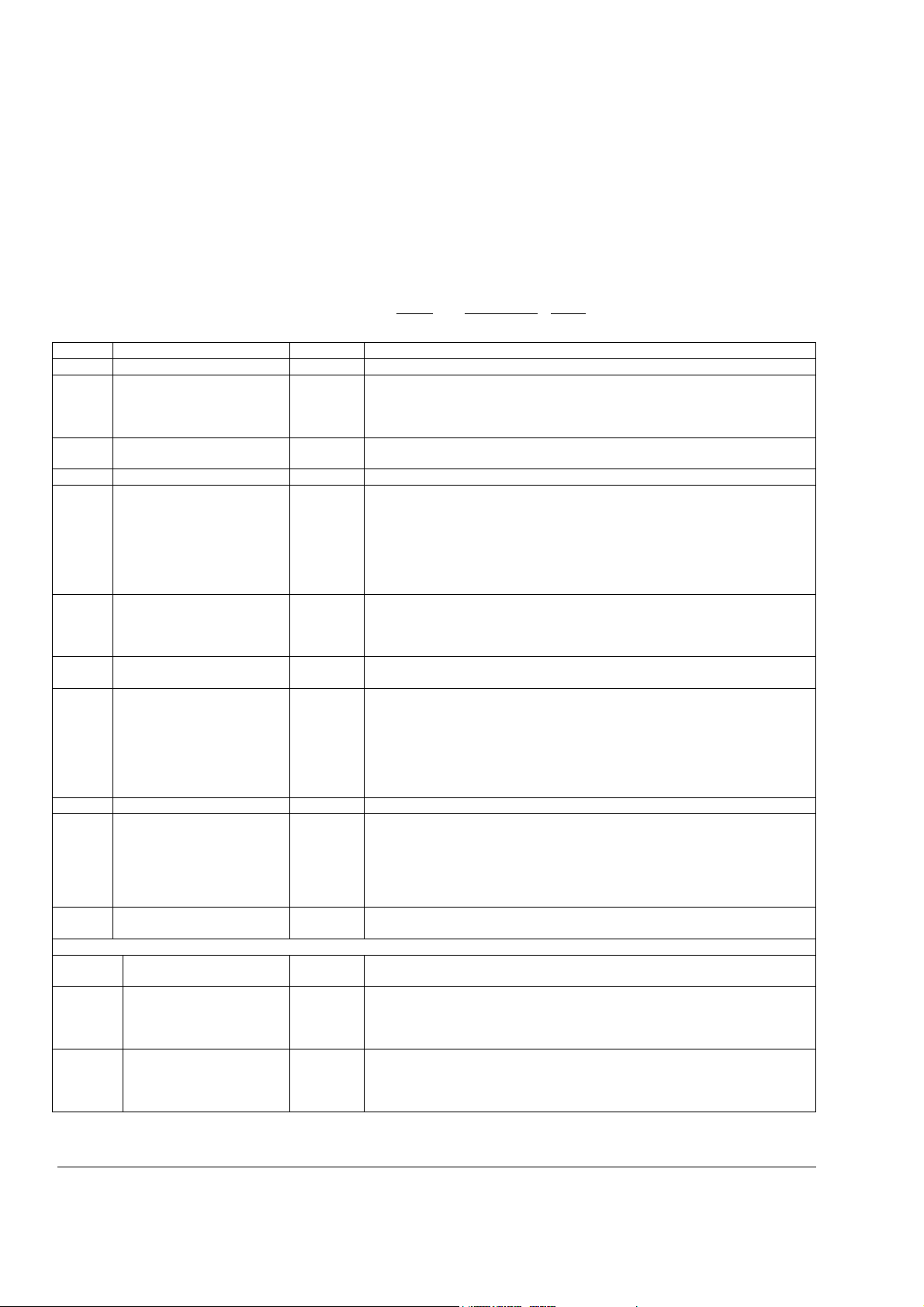

Type code

The type code contains information on the specifications and configuration of the

drive. The first digits from left express the basic configuration (e.g. DCS800-S01-

2005). The optional selections are given thereafter, on the name plate by plus

code. The main selections are described below. Not all selections are available for

Position Plus code

Product series DCS800

A Type S0 = Standard converter module IP00

X Bridge type 1 = Single bridge (2-Q)

Y Rated DC current YYYY = Rated current (e.g. 0025 = 25 ADC)

ZZ Rated AC voltage 04 = 400 VAC

B Power connection - = Standard D1 ... D6

Internal field exciter

configuration

Fan voltage

Current measurement +S175 SDCS-CMA-2 for sizes D5 to D7

Voltage measurement +S186

SDCS-DSL-4 +S199

+ plug-in options

DCS Control Panel

Fieldbus

I/O and DDCS L500

all types.

Type code D C S 8 0 0 -AAX-YYYY-ZZ- plus code

Position A X Y Z B

R0 = Rebuild system

E0 = Panel solution

A0 = Enclosed converter

2 = 2 anti parallel bridges (4-Q)

05 = 525 VAC

06 = 600 VAC

07 = 690 VAC

08 = 800 VAC

10 = 990 VAC

12 = 1200 VAC

L = Left side D7

R = Right side D7

a = Second thyristor type D5, D6

+S164

+0S163

+S171

+S172

+S180

+S181

+S182

+S183

+S189

+0S199

0J400

J409

K454

K451

K466

K458

L501

L508

L509

With internal field exciter, external supply (only D5:25 A, Rebuild kit: 25 A/16 A)

Without internal field exciter (only D1 ... D4)

Size D4

Standard fan voltage: 230 V / 1-ph

Additional fan voltage: 115 V / 1-ph

Size D6

Standard fan voltage for 400 V / 500 V / 800 V units: 400-500 V / 3-ph

Standard fan voltage for 600 V / 690 V units: 525-690 V / 3-ph

Additional fan voltage for 600-690 V units: 400-500 V / 3-ph

120 V SDCS-SUB-4 for sizes D1 ... D4

600 V for sizes D6 and D7

690 V for sizes D6 and D7

800 V for sizes D6 and D7.

990 V for sizes D6 and D7.

Galvanic isolation for sizes D6 and D7

With SDCS-DSL-4

Without SDCS-DSL-4

Without DCS Control Panel

Door mounting Kit (cable length 3 m)

Profibus RPBA

DeviceNet RDNA

Ethernet IP + Modbus TCP RETA

Modbus RMBA

Analogue Extension RAIO

Digital Extension RDIO

DDCS Communication board (10 Mbaud CH0) SDCS-COM-81

DDCS Communication board (5 Mbaud CH0) SDCS-COM-82

Introduction

3ADW000195R0501 DCS800 Service Manual e e

Page 19

19

The technical data and specifications are valid as of going to press. ABB reserves

the right to make subsequent alterations.

If you have any questions concerning your drive system, please contact your local

ABB agent.

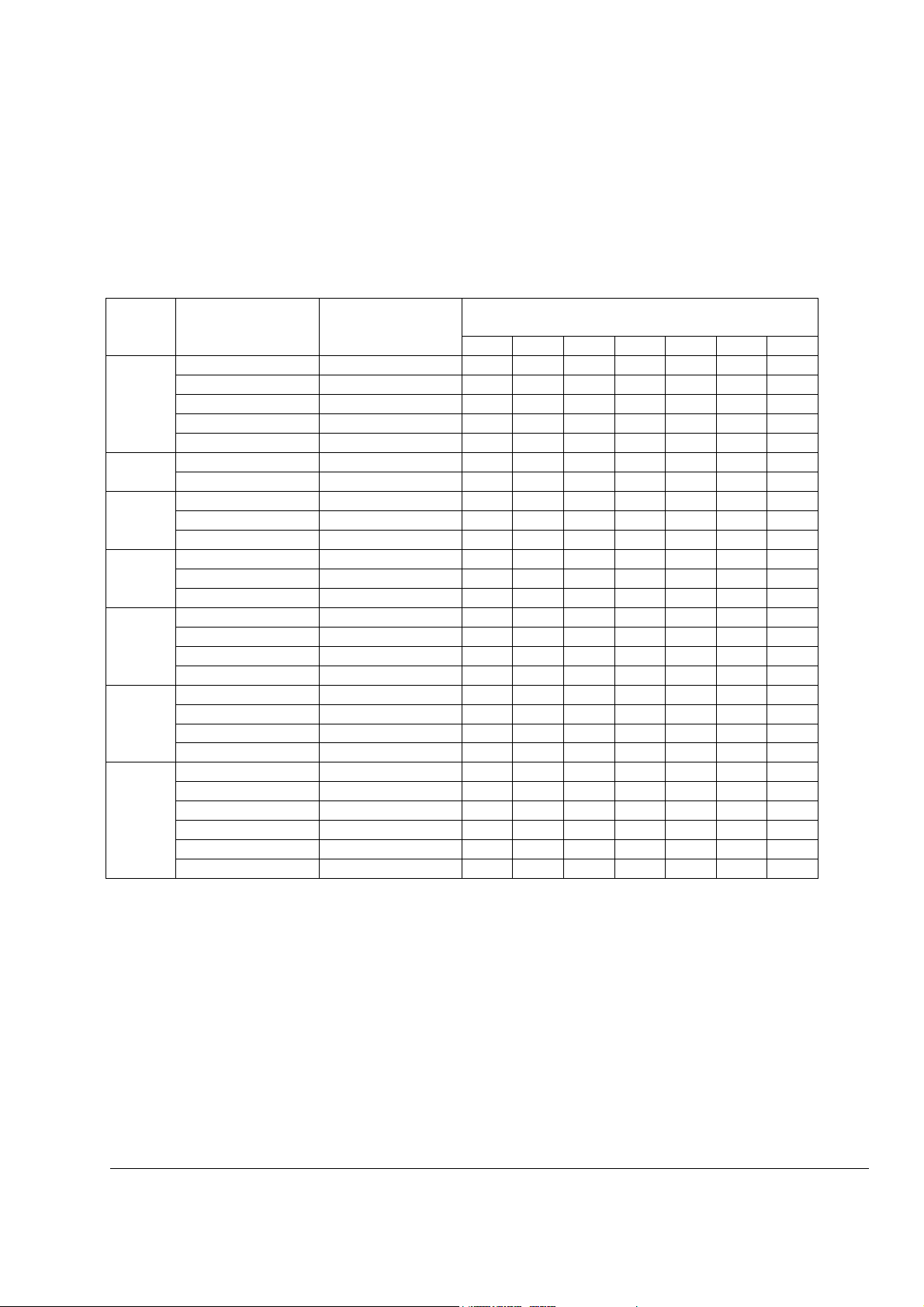

Current and voltage ratings

Unit size 2-Q rated current

DCS800-01 [ADC]

D1

D3

D4

D5

D6

D7

1

only available as 2-Q drive

20 25 X X

45 50 X X

65 75 X X

90 100 X X

125 140 X X

180 200 X X D2

230 260 X X

315 350 X X X

405 450 X X

470 520 X X

610 680 X X X

740 820 X X

900 1000 X X

900 900 X X

1200 1200 X X

1500 1500 X X X X

2000 2000 X X X

1900 1900 X

2050 2050 X X X

2500 2500 X X X X X

3000 3000 X X X X X

2050 2050 X

2600 2600 X X

3300 3300 X X X X X X X

4000 4000 X X X X X X X

4800 4800 X X X

5200 5200 X X

4-Q rated current

DCS800-02 [ADC]

400 525 600 690 800 990 1200

Supply voltage [VAC]

1

X1

Introduction

3ADW000195R0501 DCS800 Service Manual e e

Page 20

20

Introduction

3ADW000195R0501 DCS800 Service Manual e e

Page 21

21

Fault Tracing Thyristors

Tools

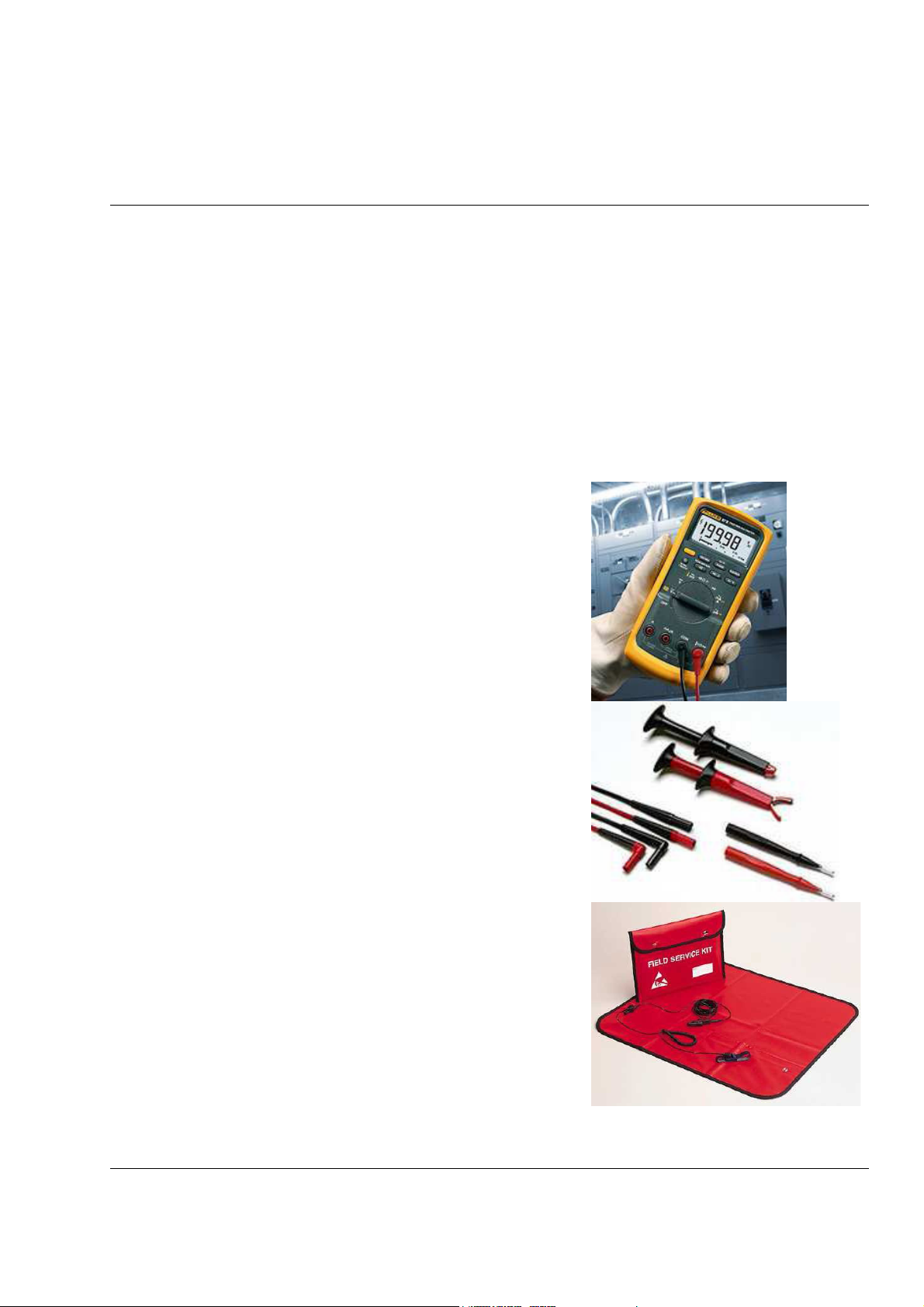

For commissioning and fault tracing

Following software tools are mandatory:

DriveWindow Light including commissioning wizard and DWL AP for Adaptive

Program and

DriveWindow for fast drive monitoring using SDCS-COM-8.

Following tools are mandatory in addition to standard tools:

An oscilloscope including memory function with either galvanically isolating

transformer or isolating amplifier (probe) for safe measurements. It can also be

a hand held (portable) oscilloscope.

A clamp on current probe. In case the scaling of the DC load current needs to

be checked it must be a DC clamp on current probe.

A voltmeter (at least CAT III 1000 V):

Make sure that all equipment in use is suitable for the voltage level applied to the

Fault Tracing Thyristors

1000 V probes and test leads:

An ESD-field service kit (ABB Service

Finland code 0001ESD / MS-Antistatic):

power part!

3ADW000195R0501 DCS800 Service Manual e e

3ADW000195R0501 DCS800 Service Manual e e

Page 22

22

Additionally for service and preventive maintenance

Following additional tools are mandatory for cleaning:

An ESD safe blower / ESD vacuum

cleaner (ABB Service Finland code

0006ESD / MUNTZ 555-ESD-S-E):

How to detect a faulty thyristor

Thyristor problems can be noticed differently:

A fuse is blown

This is an indication, that a strong overcurrent has happened due to one of the

following reasons:

An internal short circuit between the phases (line side) because of a defective

thyristor (short circuit inside a thyristor from anode to cathode).

An internal short circuit between the phases (line side) because of circulating

current in a 4-Q converter (malfunction of the control electronics, no thyristor

defective).

An external short circuit at the DC terminals of the converter without sufficient

impedance.

A commutation fault during generating (active braking with high current, high

EMF and with low AC voltage) of a 4-Q converter.

Note:

In case of parallel fuses: If one of the parallel fuses is blown, all parallel fuses have

to be changed. The ‘undamaged’ fuses might be ‘half-blown’ and will blow with the

next high current.

Fault Tracing Thyristors

3ADW000195R0501 DCS800 Service Manual e e

Page 23

23

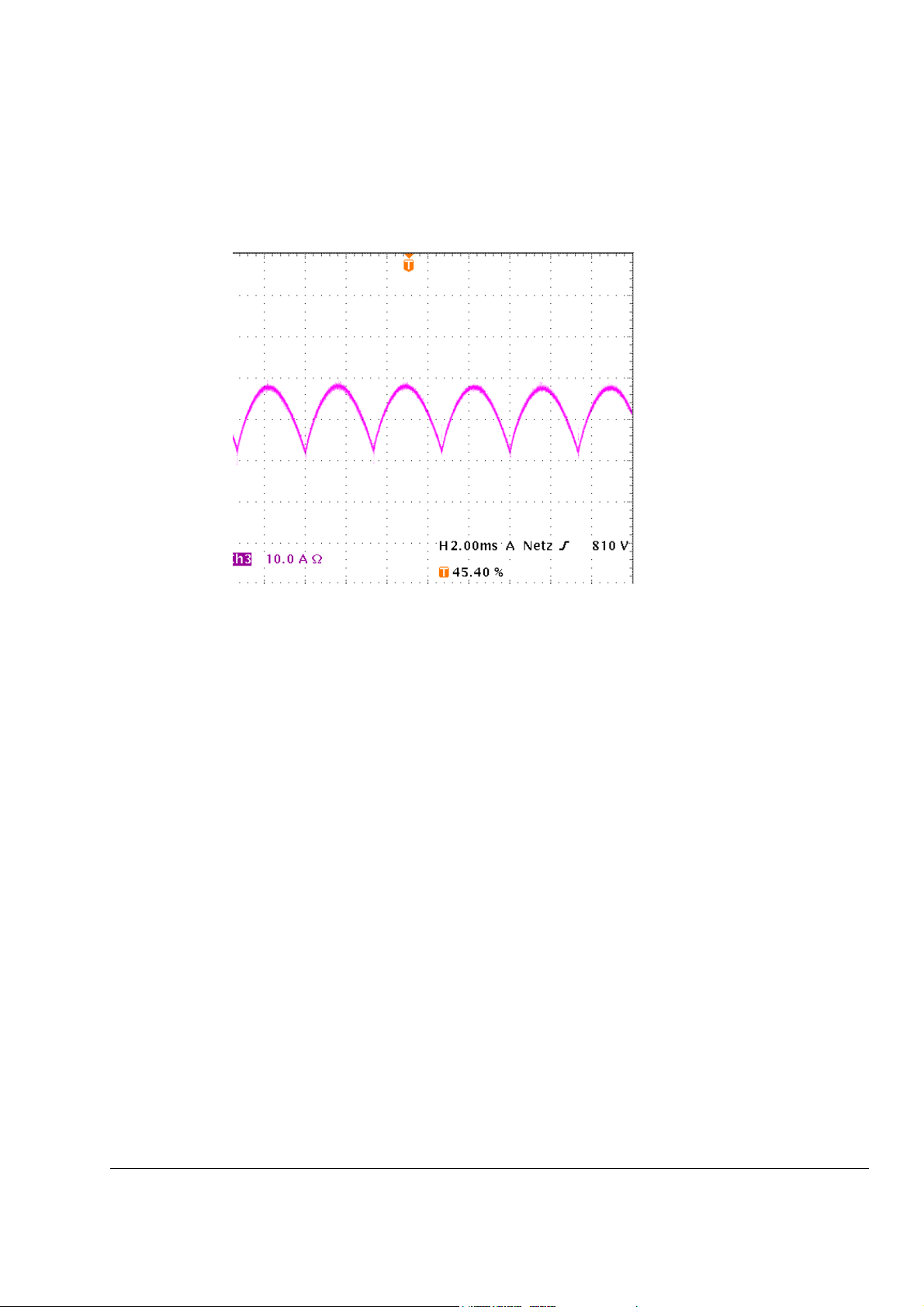

DC-current pulses measured by an oscilloscope

Connect an oscilloscope to the fixed AO I-act (X4:9/10 on the SDCS-CON-4 or

X4:5/6 on the SDCS-IOB-3) and check for the proper amount of current pulses:

Six current pulses in positive direction

There should be six current pulses in positive direction.

In case of a 4-Q converter also the six current pulses for the negative direction

have to be checked.

Thyristor diagnosis

Also the thyristor diagnosis provided by the firmware can be used:

Switch the drive to local mode (DriveWindow, DriveWindow Light, DCS Control

Panel or local I/O).

Start the thyristor diagnosis by means of ServiceMode (99.06) = ThyDiagnosis

and set On and Run within 20 s.

During the thyristor diagnosis the main contactor will be closed and the

thyristors are checked. The field current is not released while the thyristor

diagnosis is active and thus the motor should not turn.

When the thyristor diagnosis is finished check Diagnosis (9.11) for details.

Ripple monitor

The ripple monitor indicates that the ripple of the DC current is much higher than

normal. In such a case, most often one thyristor does not work. It’s missing current

contribution causes a deep dip in the direct current.

The structure of the current loop (current controller) will force the other thyristors to

compensate the dip by a certain overcurrent in order to keep the average current

constant. Such a compensation results in a ripple monitoring fault during motoring

mode operation with 90°.

The reason for a current less thyristor may be:

Fault Tracing Thyristors

Page 24

24

A fuse has disconnected one of the six thyristors. This is possible only for

converters with 900 ... 5200 A (six internal branch fuses). A converter with

three external fuses stops working completely at once when one of the three

AC input fuses interrupts a phase input of the converter.

A thyristor does not get firing pulses or does not react to firing pulses.

The current controller may be totally mismatched to the DC load.

The AC mains network is causing that fault message. In this case,

asymmetrical phase shift, uneven phase voltage or critical designed power

factor correction equipment or harmonic reduction equipment can be the

reason.

How to find a faulty thyristor

If a blown fuse is suspected in the converter, the problem is caused most often by

a faulty thyristor. To make sure, that a thyristor is the reason and needs to be

exchanged fault tracing must be done in two different ways, depending on the size

of the converter.

In general, make sure, that all safety instructions, given within this manual or

within the safety instructions, related to the machine or the application itself,

are obeyed.

Converters size D1 to D4 (20...1000 A)

These converters require semiconductor fuses in the 3 AC lines.

The converter must be disconnected from the mains.

One motor armature cable should be disconnected from the converter.

Blown fuses

Using the OHM function of a normal multimeter, measurements must be made

from each AC terminal to each DC terminal (U1 to C1, V1 to C1, W1 to C1, U1

to D1, V1 to D1 and W1 to D1; see picture Anti-parallel B6-bridges with

branching fuses on page 45). Normally, every measurement should show high

resistance (> 1 k).

Target: find a short circuit, indicated by low resistance ( <1 ) (destroyed

thyristor).

If the converter is designed with half-bridge thyristor modules, then a module

consists of two anti-parallel thyristors. In this case it is sufficient to know which

thyristor pair or module has a defective thyristor because the complete module

must be replaced.

After a thyristor module is replaced, the above mentioned measurement should

be done another time to make sure that all faulty thyristors have been detected!

Note:

The RC circuit could also cause 0 result for a short time.

The measurement, showing less resistance than 1 should be made a second

time with test leads applied to the terminals with opposite polarity; if this

measurement shows the same result, one or two thyristors located in that path are

faulty; they need to be replaced.

Fault Tracing Thyristors

3ADW000195R0501 DCS800 Service Manual e e

Page 25

25

Converters size D5, D6, and D7 (900...5200 A)

These converters are equipped with fuses in the branches of the

power part.

The converter must be disconnected from the mains.

Blown fuses

In case of a blown fuse, the faulty thyristor or the faulty pair of

thyristors are already isolated at one side from the others and

therefore the faulty branch is known (see picture Anti-parallel

B6-bridges with branching fuses on page 45).

The OHM test should be performed, when the thyristor is still

clamped. Outside the converter a special thyristor clamping

device is needed.

For 4-Q converters with anti-parallel thyristors or BCT’s:

The selection of a forward or reverse thyristor or BCT

(Bidirectional-Controlled-Thyristor) is done during the

disassembly. Continue with related part Exchange of Thyristors

for Size D5

After a thyristor was replaced, the OHM test should be done

another time to make sure that all faulty thyristors have been

detected! If the motor is still connected to the converter the

result of the measurement may be wrong.

, D6 or D7 section Find faulty thyristor.

Ripple monitor

If the ripple monitor fault occurred, a fault tracing as described

above must be carried out:

Check the fuses and the thyristors, according to the statements

before.

If the power section seems to be ok, but still one or more

thyristors don’t take current, something went wrong in between

the firing pulse generation and the thyristor’s gate; in this case

check:

Is a firing pulse present on the primary side of the firing

pulse transformer?

Is a firing pulse present on the secondary side of the

firing pulse transformer?

Is the firing pulse transferred to the gate of the thyristor?

Are there all electrical connections still healthy?

Can the thyristor be fired with the applied firing pulse? Is

the pulse form of the firing pulse identical at all

measuring positions?

Check the settings of the current controller.

Check the AC mains network by taking recordings of the line

voltage and current at all 3 phases at the same time.

Fault Tracing Thyristors

Page 26

26

Fault Tracing Thyristors

3ADW000195R0501 DCS800 Service Manual e e

Page 27

27

Handling the Semiconductors

General Instruction how to handle the Semiconductors

Thyristor modules, busbars and fuses have to be mounted with the correct torque

using a torque screw driver or torque wrench.

In converters sizes D5 (900 ... 2000 A), D6 (1900 ... 3000 A) and D7 (2050 ... 5200

A) the mounting force is indicated by an indicating spring welded to the mounting

clamp, which is inside the unit.

Always mark suspected damaged components clearly after removing them from

the circuit, to avoid confusion with "good" components.

When removing a damaged semiconductor, write down how and where it was

installed (direction, location, connected gate leads and with BCT’s the position of

the gate connectors).

Check that the new and old components have the same type designation or that

the new component can replace the old one. A semiconductor can be replaced by

different compatible semiconductor according to the codes in the manufacturers'

table.

Semiconductor components are high-precision products. All unnecessary used

tools and objects might damage the easily dented and scratched surfaces of the

semiconductors.

1. Keep new semiconductors as long as possible in their original packages.

2. Use protective gloves if possible.

3. Clean work area and hands frequently.

4. Use good illumination.

Handling the Semiconductors

3ADW000195R0501 DCS800 Service Manual e e

Page 28

28

Handling the Semiconductors

3ADW000195R0501 DCS800 Service Manual e e

Page 29

29

Exchange of Thyristors for Size D1 to D4

Installation of OnBoard bridge and thyristor modules in converters size

D1 to D4

All DCS800 size D1 to D4 are equipped with an OnBoard bridge (excitation) and

(20...1000 A)

thyristor modules. In order to keep the operating temperature of the semiconductor

module low, the joint between the heat sink and the module should have a good

heat conducting ability. The electrical conductivity of the connectors must also be

good. For this reason the following instructions must be observed with particular

care.

Required Tools

Special tools or material needed in addition to standard tools for the exchange of

thyristor modules:

Torx screwdrivers: TX10, TX20, TX25

Torque spanner: mounting torques for the OnBoard bridge and the

thyristor modules to heat sink and electrical

connections see table Nominal mounting torque for

OnBoard bridge and thyristor modules on page 35

Screws are metric type; use appropriate nuts

Tissue paper

Solvent (e.g. ethanol)

Thermal joint compound:

(grease)

Manufacturer: Carl Bechem GmbH, 58089 Hagen

ABB Service: GHSN 390 011 P 0051

or

thermal joint compound: type WLPF 20 (10 ml)

ABB Service: GHSN 390 011 P 10

Before the work is started, disconnect the converter from the power supply

completely, then check the voltage free condition and make sure, everything

is located in an electrical and mechanical safe condition!

type Berulub FZ1 E3

Find faulty thyristor modules

See Fault Tracing Thyristors

of this publication.

Exchange of Thyristors for Size D1 to D4

3ADW000195R0501 DCS800 Service Manual e e

Page 30

30

Remove faulty thyristor modules

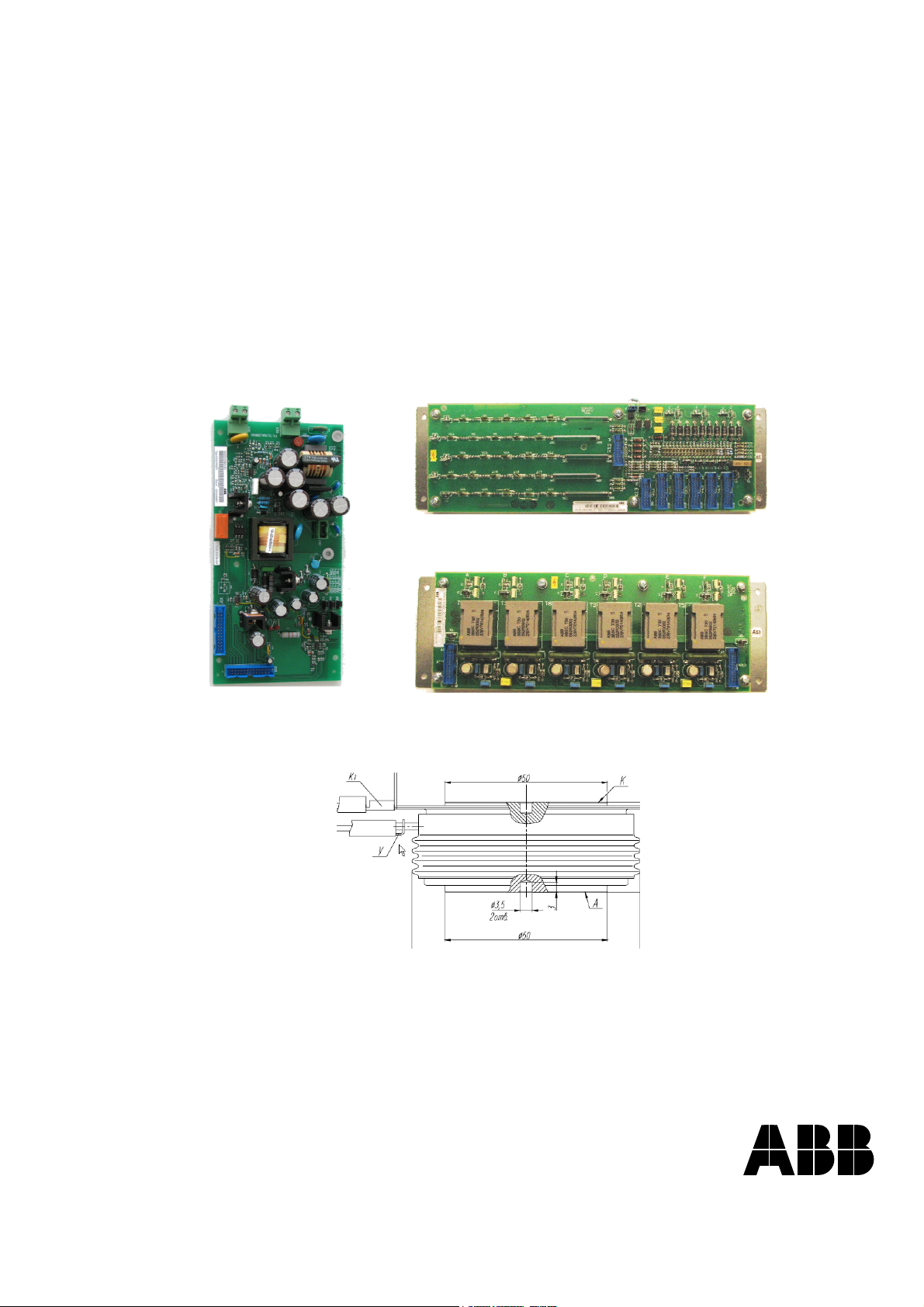

1. Remove the DCS Control Panel and design cover:

Remove DCS Control Panel

Depress the locks by means of a

screwdriver to remove the design

Remove design cover

2. Remove all plug in options on the intermediate cover e.g.:

serial communication modules (R-type),

extension I/O modules (RAIO, RDIO),

extension modules for second encoder (RTAC) or resolver (RRIA),

communication board (SDCS-COM-8),

isolated I/O (SDCS-IOB-2x, SDCS-IOB-3) and

SDCS-MEM-8 (Memory Card).

3. Remove the intermediate cover by depressing the two locks on the upper right

and left hand side of the cover:

cover

Depress the locks to remove the

design cover

Remove all o ptions, so that the

intermediate cover is empty

Remove plug in options

Exchange of Thyristors for Size D1 to D4

3ADW000195R0501 DCS800 Service Manual e e

Page 31

31

4. Disconnect all I/O plugs (X3 to X7) at the SDCS-CON-4 and the plugs at the

SDCS-DSL-4 board, if used (X51 to X54):

Disconnect all plugs from SDCS-

CON-4 and SDCS-DSL-4 boards

Disconnect all plugs

5. Remove the grounding plug and the holding screw at the electronic tray:

Remove the grounding plug and the

holding screw

Remove grounding and screws

Exchange of Thyristors for Size D1 to D4

3ADW000195R0501 DCS800 Service Manual e e

Page 32

32

6. To unhinge the electronic tray including the SDCS-CON-4 pull it up and then

out. Before remove tray completely unplug the flat cables (X12, X13, X37):

Electronic tray with SDCS-CON-4

Remove flat cables

Unhinge electronic tray

7. Remove all cables and plugs at the SDCS-PIN-4:

Keep winding direction and

amount of windings for T100

in mind.

How to handle X8:

use screw dr iver

X8

T100

Remove all cables

and plugs

Remove cables at the SDCS-PIN-4

Attention:

Write down the winding direction of the cable through T100!

D1: thread the wire 4 times through the hole in T100 (that equals 3 loops)

D2 - D4: thread the wire 1 time through the hole in T100 (that equals no loops)

Exchange of Thyristors for Size D1 to D4

3ADW000195R0501 DCS800 Service Manual e e

Page 33

33

8. Remove the SDCS-PIN-4 board:

OnBoard field exciter

bridge module

Thyristor modules

Snubber resistor

Current transformer Temperature sensor

Remove SDCS-PIN-4

9. Remove the gate leads from the faulty thyristor module and mark the

connectors clearly.

10. Remove the busbars necessary to get full access to the faulty thyristor module.

11. If a current transformer must be removed, mark its position and the

connections clearly.

Note:

Remove only as many parts as needed around the faulty thyristor module.

12. Remove the faulty thyristor module and mark it clearly as defective.

Exchange of Thyristors for Size D1 to D4

3ADW000195R0501 DCS800 Service Manual e e

Page 34

34

Install new thyristor modules

1. Ensure that the new thyristor module is of the correct type (see appendix A of

this manual).

2. Remove old heat conducting compound (grease) from the heat sink. Clean the

mounting surfaces (heat sink and thyristor module) with an appropriate solvent

(e.g. ethanol) by means of tissue paper. When the heat sink is clean, spread

out the heat conducting compound with a rubber spatula or by hand.

3. Apply a thin layer of heat conducting compound to the new thyristor module:

Application of heat conducting compound

4. Spread the heat conducting compound evenly by moving the thyristor module

forward and backward on the heat sink.

5. Tighten all clamping screws by hand until the screw heads touch the bottom of

the thyristor module. Then tighten the screws to 2.0 Nm torque.

Note:

If the thyristor module is mounted by means of four screws, tighten the screws

crosswise.

6. Tighten the screws to nominal torque according to table Nominal mounting

torque for OnBoard bridge and thyristor modules page 35.

Exchange of Thyristors for Size D1 to D4

3ADW000195R0501 DCS800 Service Manual e e

Page 35

35

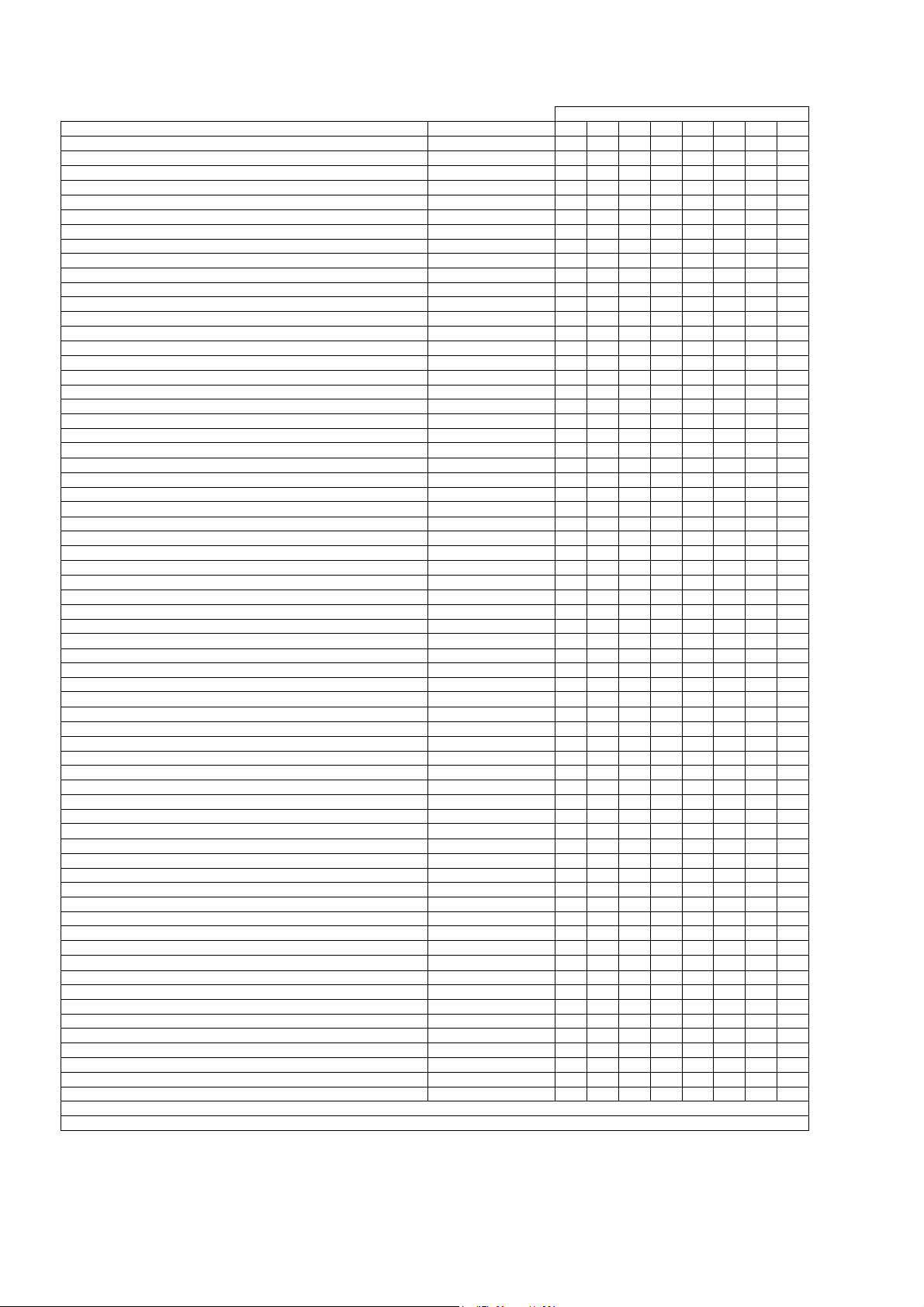

OnBoard bridge and thyristor modules

Size Type Electrical

29 mm bridge block VVZF 70-16 - 5 Nm

20 mm block SKKT 27, 42, 57, 106 3 Nm 5 Nm

20 mm block MCC 26, 44, 56, 95 2.5 ... 4 Nm 2.5 ... 4 Nm

34 mm block MCC 162 4.45 … 5.5 Nm 2.25 … 2.75 Nm

34 mm block SKKT 162 5 Nm 5 Nm

34 mm block TT 162 6 Nm 6 Nm

50 mm block MCC 255 11 … 13 Nm 4.5 … 7 Nm

50 mm block TT 250, 330 12 Nm 6 Nm

60 mm block TT 425, 570 12 Nm 6 Nm

Nominal mounting torque

Thyristor module

connections

to heat sink

Nominal mounting torque for OnBoard bridge and thyristor modules

7. Reinstall the current transformer, make sure, its position is correct.

8. Reinstall the busbars, make sure, the correct torque is applied according to

table Nominal mounting torque for OnBoard bridge and thyristor modules

on

page 35.

9. Reconnect all gate leads to the thyristor module.

10. Reinstall the SDCS-PIN-4 board.

11. Reconnect all cables and plugs at the SDCS-PIN-4:

snubber resistor (X30, X31),

temperature sensor (X22),

current transformers (X3, X4, X5),

OnBoard excitation (X8, X9, X11), use proper winding direction and amount

of windings for T100

gate leads (first X16, X18 then X15, X17),

OnBoard excitation line voltage (X1, X2, X7),

all plugs (X10, X96, X99) and

all flat cables (X12, X13, X37), use the lock connectors at the SDCS-PIN-4

12. Reconnect the flat cables at the SDCS-CON-4 (X12, X13, X37) and re-hinge

the electronic tray.

13. Reconnect the grounding plug and the holding screw at the electronic tray.

14. Reconnect all I/O plugs at the SDCS-CON-4 (X3 to X7) and the plugs at the

SDCS-DSL-4 (X51 to X54).

15. Reinstall the intermediate cover, all plug in options and the design cover.

Exchange of Thyristors for Size D1 to D4

3ADW000195R0501 DCS800 Service Manual e e

Page 36

36

Remove faulty OnBoard bridge (V1)

1. Follow the instructions Remove faulty thyristor modules until step 8 is done.

2. Remove all connectors from the faulty OnBoard bridge and mark the

connectors clearly.

3. Remove the faulty OnBoard bridge and mark it clearly as defective.

Install new OnBoard bridge (V1)

1. Ensure that the new OnBoard bridge is of the correct type (see appendix A of

this manual).

2. Remove old heat conducting compound (grease) from the heat sink. Clean the

mounting surfaces (heat sink and OnBoard bridge) with an appropriate solvent

(e.g. ethanol) by means of tissue paper. When the heat sink is clean, spread

out the heat conducting compound with a rubber spatula or by hand.

3. Apply a thin layer of heat conducting compound to the new OnBoard bridge.

4. Spread the heat conducting compound evenly by moving the OnBoard bridge

forward and backward on the heat sink.

5. Tighten all clamping screws by hand until the screw heads touch the bottom of

the thyristor module. Then tighten the screws to 2.0 Nm torque.

6. Tighten the screws to nominal torque according to table Nominal mounting

torque for OnBoard bridge and thyristor modules on page 35.

7. Reconnect all connectors to the OnBoard bridge.

8. Follow the instructions Install new thyristor modules

beginning with step 10.

Exchange of Thyristors for Size D1 to D4

3ADW000195R0501 DCS800 Service Manual e e

Page 37

37

OnBoard bridge (V1) and thyristor module location in DCS800-S01 (2-Q) units

V1 V1

DCS800-S01-0020 ... 0180

DCS800-S01-0230

V14/V11

1234 12

V14/V11

G1K1K2

G2

K

AK A

V16/V13

34

V1 V1

V16/V13 V12/V15

G2

KAK A

V12/V15

1234

G1K1K2

G1K1K2

G2

KAK A

V14/V11

K2 G2

K1 G1

V14/V11

A

K

AK

V16/V13 V12/V15

K2G2

K1G1

K2G2

DCS800-S01-0610 ... 0900DCS800-S01-0315 ... 0470

V16/V13 V12/V15

A K

AK

K1G1

A K AK

DCS800 loc of mod 1Q.dsf

Location of the OnBoard bridge and thyristor modules in DCS800-S01 (2-Q) units

Note:

This drawing is only showing the location of the OnBoard bridge and thyristor

modules, the actual converter module size is different!

Exchange of Thyristors for Size D1 to D4

3ADW000195R0501 DCS800 Service Manual e e

Page 38

38

OnBoard bridge (V1) and thyristor module location in DCS800-S02 (4-Q) units

DCS800-S02-0025 ... 0200

V1 V1

V14/V21 V16/V23

1234 1234 123

V12/V25

4

DCS800-S02-0260

V14/V21

K2G2

K1G1

V16/V23 V12/V25

K2G 2

K1G 1

K2G 2

K1G 1

1234 1234 1234

V11/V24

V13/V26 V15/V22

K1G1

V11/V24

K2G 2

K2G2

K1G 1

V13/V26

K1G 1

V15/V22

K2G 2

DCS800-S01-0680 ... 1000DCS800-S02-0350 ... 0520

V26/V13 V22/V15

A K AK

AK

A K

V23/V16

DCS800 loc of mod 4Q.dsf

A K AK

AK

A K

V25/V12

V11

V24

V15

V22

V13

V26

V1

K1

G1

G2

K2

K1

G1

G2

K2

K1

G1

G2

K2

KAK A

AK

K

A

KAK A

KAK A

K

AK

KAK A

K2

G2

V14

G1

K1

V21

K2

V12

G2

A

G1

K1

V25

K2

V16

G2

G1

K1

V23

V1

V24/V11

A

K

AK

A K AK

V21/V14

Location of the OnBoard bridge and thyristor modules in DCS800-S02 (4-Q) units

Note:

This drawing is only showing the location of the OnBoard bridge and thyristor

modules, the actual converter module size is different!

Exchange of Thyristors for Size D1 to D4

3ADW000195R0501 DCS800 Service Manual e e

Page 39

39

)

)

OnBoard bridge and thyristor module terminals

The next figures show the terminals of the OnBoard bridge and all used thyristor

modules. The terminal description is also stamped or marked by a sticker on the

OnBoard bridge and all thyristor modules.

For all firing pulse cables is valid:

Yellow is gate lead.

Red is cathode lead.

VVZF 70-16

(K)

(AK)

1

2

4

5

1

7

2 3

MCC26, 44, 56, 95

6

7 G

6 K

5 K

4 G

(A

3

(AK)

1

2

5

4

2

1

7

6

3

(K)

SKKT 27, 42, 57, 106

6 G

7 K

4 K

5 G

(A

3

(A)

3

3

6 7

67

(AK)

1

(K)

2

5

4

1

6

7

2

4 5

MCC162

54

SKTT 162

Exchange of Thyristors for Size D1 to D4

3ADW000195R0501 DCS800 Service Manual e e

Page 40

40

A

A

A

A

A

A

K

K

K1

G1

K2 G2

K

K

TT 162

K2 G2

K1 G1

MCC255

(A)

K

K

K1

G1

AK A

K2

K

TT 250, 330

G2

K2

G2

G1

K1

3

6G

7K

3

TT 425, 570

(K)

4K5G

2

Terminals of the OnBoard bridge and all thyristor modules

2

(AK)

1

1

4K

5G

6G

7K

Exchange of Thyristors for Size D1 to D4

3ADW000195R0501 DCS800 Service Manual e e

Page 41

41

Exchange of Thyristors for Size D5

Installation of "Disc Type" thyristor in converters size D5 (900...2000 A)

All DCS800 converters sizes D5/D6/D7 are equipped with disk type thyristors. The

structure of the "Disc type" semiconductor component is such that it requires a

certain compression force to operate. The prevention of overheating of the

component essentially depends on a good heat dissipation between the

semiconductor and the conducted heat sink. It is thus important that all joints have

good thermal and electrical conduction.

Required Tools

Special tools or material needed in addition to standard tools for the exchange of

thyristor modules:

Torx screwdrivers: TX10, TX20, TX25

Torque spanner for electrical connections: 13 Nm (M8)

25 Nm (M10)

50 Nm (M12)

Screws are metric type; use appropriate nuts.

17 mm ring spanner for fuse and busbar connections.

17 mm ring spanner for press clamp.

Tissue paper / solvent (e.g. ethanol).

Thermal joint compound: type BECHEM-RHUS SU 2

(grease)

Manufacturer: Carl Bechem GmbH, 58089 Hagen

ABB Service: GHSN 390 001 P 0001

Disassembly tool 3ADT 621 023 P1

Note:

For more detailed information about the wiring of the power part, see Hardware

Manual.

Therefore strict observance of the build in instructions given below is of utmost

importance. Make sure that the new component can replace the old one in

accordance with the spare part list (see Appendix A

Semiconductors and heat sinks are to be handled carefully to avoid scratches and

other damage. Avoid touching the contact surfaces. Do not lift the semiconductor

with the gate wire. Do not lift the semiconductor by touching the current contact

surfaces. Do not damage the welding flange or the contact surface.

Before you start work, disconnect the converter completely from the power

supply then check the voltage free condition and make sure, everything is

located in an electrically and mechanically safe condition!

).

Exchange of Thyristors for Size D5

3ADW000195R0501 DCS800 Service Manual e e

Page 42

42

Disk type thyristors

Some converter modules size D5 are equipped with different disc type thyristors.

For easy identification the name plate of the converter module is marked with “a”

after the voltage identification:

Converter with original

thyristor type T459Nxxx

Id code: DCA0012007P0001

DCS800-S01-0900-06 3 ~ 600 VAC

DCS800-S02-0900-06 3 ~ 600 VAC

DCS800-S01-0900-07 3 ~ 690 VAC

DCS800-S02-0900-07 3 ~ 690 VAC

Converter with original

thyristor type T589Nxxx

Id code: DCA0012015P0001

DCS800-S01-1200-04 3 ~ 400 VAC

DCS800-S02-1200-04 3 ~ 400 VAC

DCS800-S01-1200-05 3 ~ 525 VAC

DCS800-S02-1200-05 3 ~ 525 VAC

Parts list

The current and voltage ratings of original and second thyristor type are the same,

but the sizes of gate and cathode terminals are different. Thus it is not possible to

interchange both thyristor types as spares.

Attention: Use always the correct spare thyristor!

Original thyristor type (900 A)

Converter with original thyristor type T459Nxxx Id code: DCA0012007P0001

U

Converter with second

1

thyristor type T460Nxxx

Id code: 3ADC340105P0001

DCS800-S01-0900-06a

DCS800-S02-0900-06a

DCS800-S01-0900-07a

DCS800-S02-0900-07a

U

Converter with second

1

thyristor type T590Nxxx

Id code: 3ADC340106P0001

DCS800-S01-1200-04a

DCS800-S02-1200-04a

DCS800-S01-1200-05a

DCS800-S02-1200-05a

Original thyristor type

Exchange of Thyristors for Size D5

3ADW000195R0501 DCS800 Service Manual e e

Page 43

43

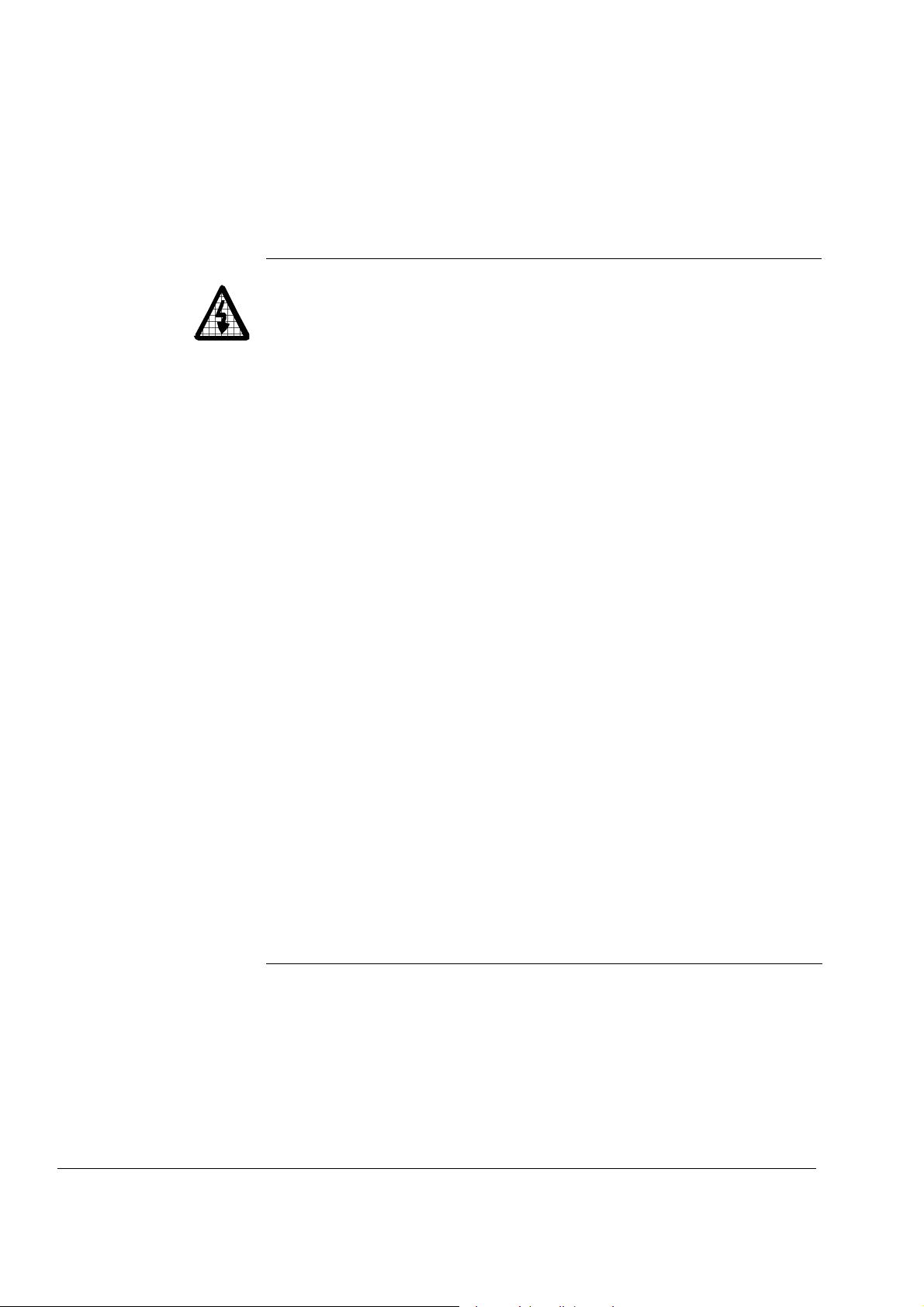

Gate (G): Faston 2.8 x 0.8 mm

Cathode (HK): Faston 4.8 x 0.8 mm

Conductive plate: Diameter 36 mm

Second thyristor type (900 A)

Converter with second thyristor type T460Nxxx Id code: 3ADC340105P0001

Second thyristor type

Gate (4): Round terminal D = 1.5 mm

Cathode (5): Faston 4.8 x 0.5 mm

Conductive plate: Diameter 36 mm

Original thyristor type (1200 A)

Converter with original thyristor type T589Nxxx Id code: DCA0012015P0001

Original thyristor type

3ADW000195R0501 DCS800 Service Manual e e

Exchange of Thyristors for Size D5

Page 44

44

Gate (G): Faston 2.8 x 0.8 mm

Cathode (HK): Faston 4.8 x 0.8 mm

Conductive plate: Diameter 36 mm

Second thyristor type (1200 A)

Converter with second thyristor type T590Nxxx Id code: 3ADC340106P0001

Second thyristor type

Gate (4): Round terminal D = 1.5 mm

Cathode (5): Faston 4.8 x 0.5 mm

Conductive plate: Diameter 36 mm

Exchange of Thyristors for Size D5

3ADW000195R0501 DCS800 Service Manual e e

Page 45

45

Find faulty thyristor

1. Find the defective branches by performing an OHM test (both polarities)

between U1, V1, W1 and C1, D1 (see fig. Anti-parallel B6-bridges with

branching fuses on page 45)

C1 (+)

V11 V13 V15V24 V26 V22

F11 F13 F15

U1

V1

W1

F14 F16 F12

V14 V16 V12V21 V23 V25

branching fuse

D1 (-)

princi ple_B6_a .dsf

Anti-parallel B6-bridges with branching fuses

2. Disconnect the branching fuses of the defective branches.

3. Find the defective thyristors by performing an OHM test (both polarities) over

their heat sinks.

4. In a 4-quadrant converter change both thyristors clamped between the same

heatsinks at once.

Note:

Because “Disc Type” semiconductors need a certain compression force to operate

properly, a measurement outside the clamped heat sinks might be wrong. To be

sure which thyristor is broken change only one thyristor, clamp the heat sinks

again and repeat step three.

branch

Exchange of Thyristors for Size D5

3ADW000195R0501 DCS800 Service Manual e e

Page 46

46

Remove faulty thyristor

1. Remove the screws of the DC – busbars and branch fuses preventing the

stack to be prized open.

Note:

It depends on the location of the defective thyristor which DC – busbar and

fuses have to be disconnected.

2. Write down the direction and location of the thyristors to be removed and mark

their gate leads.

3. Remove the gate leads if possible.

4. Loosen the mounting clamp (see fig. Aluminum spring with welded indicating

spring on page 47) at the top of the thyristor stack.

Attention: While loosen the mounting clamp the indicating spring must be pulled

out a little, otherwise the spring will be damaged!

5. Attach the disassembly tool at the faulty thyristor and prize open the upper and

lower heat sinks (see fig. How to use the disassembly tool

page 46).

6. Remove the thyristors.

Attention: To centre the thyristors spring pins are used. The pins are inlayed into

all lower heat sinks. Open the gap wide enough that the thyristor and the pins are

not damaged while removing the thyristor!

Mounting clamp

View from

the left

Disassembly tool

mountc l_b.dsf

Front view

View from

the right

How to use the disassembly tool

Exchange of Thyristors for Size D5

3ADW000195R0501 DCS800 Service Manual e e

Page 47

47

Install new thyristor

1. Ensure that the new thyristor is of the correct type (see Appendix A). Keep the

semiconductor and its surroundings clean. If necessary clean them with a

piece of tissue paper moistened with solvent.

Note:

Do not touch the polished surfaces of the thyristor.

2. Clean the polished surfaces of the semiconductor with a piece of tissue paper

moistened with solvent. Dry all surfaces. Spread a thin layer of heat

conducting paste on both sides of the thyristor, if necessary use a rubber

spatula.

3. Connect the gate leads if possible.

4. Clean all parts with tissue paper moistened with solvent, which have had or will

have contact with the thyristor or each other (lower / upper heat sink). Do not

clean the surfaces of grease too thoroughly, because the aluminum surfaces

will oxidize in a few seconds. Dry all surfaces.

5. Centre the thyristors by means of the spring pins.

Note:

Be sure that the thyristor is installed in the right direction. Do not pinch or cut

the gate leads or any other cable.

6. Turn the thyristor so that the gate leads point in the right direction.

Loose

condition

TORQUE INDICATING SPRING

Insulating plate

In- sulating tube

Correct torque

Heatsink

Aluminum spring with welded indicating spring

Exchange of Thyristors for Size D5

3ADW000195R0501 DCS800 Service Manual e e

Page 48

48

7. Tighten the nuts of the mounting clamp by hand so that the clamp is in parallel

with the contact surface of the heat sinks.

Note:

The indicating spring is a very sensitive instrument and must be handled with

care.

8. Tighten each nut in turn, half a turn at a time with the help of a ring spanner

until the indicating spring clicks into position “correct torque” (see fig. Aluminum

spring with welded indicating spring

on page 47). Do not tighten the screws any

further.

Note:

The correct torque is indicated by means of the welded indicating spring.

9. Perform an OHM test to make sure the thyristor is ok.

10. Reconnect the DC – busbars, branch fuses and all other dismantled parts.

11. Perform an OHM test between U1, V1, W1 and C1, D1 to make sure the power

part is ok.

U1 V1 W1

left stack

rear front

V24 V11

V13 V26

V22 V15

View from the left Front view View from the right

Location of thyristors in frame D5 (4-Q bridge)

right stack

front rear

V14 V21

V23 V16

V12 V25

Exchange of Thyristors for Size D5

3ADW000195R0501 DCS800 Service Manual e e

Page 49

49

U1 V1 W1

left stack

rear front

V11

V13

V15

View from the left Front view View from the right

right stack

front rear

V14

V16

V12

Location of thyristors in frame D5 (2-Q bridge)

Exchange of Thyristors for Size D5

3ADW000195R0501 DCS800 Service Manual e e

Page 50

50

W1

V1

U1

D1 (-)

C1 (+)

Exchange of Thyristors for Size D5

Location of branch fuses frame D5

3ADW000195R0501 DCS800 Service Manual e e

Page 51

51

Exchange of Thyristors for Size D6

Installation of "Disc Type" thyristor in converters size D6 (1900...3000 A)

All DCS800 converters sizes D5/D6/D7 are equipped with disk type thyristors. The

structure of the "Disc type" semiconductor component is such that it requires a

certain compression force to operate. The prevention of overheating of the

component essentially depends on a good heat dissipation between the

semiconductor and the conducted heat sink. It is thus important that all joints have

good thermal and electrical conduction.

Required Tools

Special tools or material needed in addition to standard tools for the exchange of

thyristor modules:

Torx screwdrivers: TX10, TX20, TX25

Torque spanner for electrical connections: 13 Nm (M8)

25 Nm (M10)

50 Nm (M12)

Screws are metric type; use appropriate nuts.

17 mm ring spanner for fuse and busbar connections.

24 mm ring spanner for press clamp.

Tissue paper / solvent (e.g. ethanol).

Thermal joint compound: type BECHEM-RHUS SU 2

(grease)

Manufacturer: Carl Bechem GmbH, 58089 Hagen

ABB Service: GHSN 390 001 P 0001

Disassembly tool DCF 1066721 P1

Note:

For more detailed information about the wiring of the power part, see Hardware

Manual.

Therefore strict observance of the build in instructions given below is of utmost

importance. Make sure that the new component can replace the old one in

accordance with the spare part list (see Appendix A)

Semiconductors and heat sinks are to be handled carefully to avoid scratches and

other damage. Avoid touching the contact surfaces. Do not lift the semiconductor

with the gate wire. Do not lift the semiconductor by touching the current contact

surfaces. Do not damage the welding flange or the contact surface.

Before you start work, disconnect the converter completely from the power

supply then check the voltage free condition and make sure, everything is

located in an electrically and mechanically safe condition!

.

Exchange of Thyristors for Size D6

3ADW000195R0501 DCS800 Service Manual e e

Page 52

52

Disk type thyristors

Some converter modules size D6 are equipped with different disc type thyristors.

For easy identification the name plate of the converter module is marked with “a”

after the voltage identification:

Converter with original

thyristor type T 1329Nxxx

Id code: 3ADC340081P0001

DCS800-S01-1900-08 3 ~ 800 VAC

DCS800-S02-1900-08 3 ~ 800 VAC

DCS800-S01-2050-05 3 ~ 525 VAC

DCS800-S02-2050-05 3 ~ 525 VAC

DCS800-S01-2050-06 3 ~ 600 VAC

DCS800-S02-2050-06 3 ~ 600 VAC

DCS800-S01-2050-07 3 ~ 690 VAC

DCS800-S02-2050-07 3 ~ 690 VAC

Parts list

The current and voltage ratings of original and second thyristor type are the same,

but the sizes of gate and cathode terminals are different. Thus it is not possible to

interchange both thyristor types as spares.

Attention: Use always the correct spare thyristor!

Original thyristor type

Thyristor T 1329Nxxx with Id code 3ADC340081P0001

U

Converter with second

1

thyristor type T 1xxx-24

Id code: 3ADC340098P0001

DCS800-S01-1900-08a

DCS800-S02-1900-08a

DCS800-S01-2050-05a

DCS800-S02-2050-05a

DCS800-S01-2050-06a

DCS800-S02-2050-06a

DCS800-S01-2050-07a

DCS800-S02-2050-07a

Original thyristor type

Exchange of Thyristors for Size D6

3ADW000195R0501 DCS800 Service Manual e e

Page 53

53

Gate (4): Faston 2.8 x 0.8 mm

Cathode (5): Faston 4.8 x 0.8 mm

Conductive plate: Diameter 48 mm

Second thyristor type

Thyristor T 1xxx-24 with Id code 3ADC340098P0001

Second thyristor type

Gate (y): Round terminal D = 1.5 mm

Cathode (K

): Faston 4.8 x 0.5 mm

1

Conductive plate: Diameter 50 mm

BCT thyristors

Gates of BCT

In some converter modules size D6 so called BCT’s (Bidirectional-ControlledThyristors) are used. BCT’s are a pair of anti-parallel thyristors in one disk type

housing. They can easily identified by the second pair of gate leads. The second

gate is marked with Gate B on the thyristor.

Faston 4.8 x 0.5

Gate A

Faston 6.3 x 0.8

Gate B

Gate B

BCT.ds f

Gate A

Exchange of Thyristors for Size D6

3ADW000195R0501 DCS800 Service Manual e e

Page 54

54

Note:

The Faston connectors of the gates are of different size.

Gate A should always be in front of the clamped heat sinks due to cooling reasons.

Location of BCT’s gate A when built in

Find faulty thyristor

1. Find the defective branches by performing an OHM test (both polarities)

between U1, V1, W1 and C1, D1 (see picture Anti-parallel B6-bridges with

branching fuses on page 45).

2. Disconnect the branching fuses of the defective branches.

3. Find the defective thyristors by performing an OHM test (both polarities) over

their heat sinks.

4. In a 4 - quadrant converter with BCT’s change the BCT.

5. In a 4 - quadrant converter with 2 single thyristors change both thyristors

clamped between the same heatsinks at once.

Note:

Because “Disc Type” semiconductors need a certain compression force to operate

properly, a measurement outside the clamped heat sinks might be wrong. To be

sure which thyristor is broken change only one thyristor, clamp the heat sinks

again and repeat step three.

Exchange of Thyristors for Size D6

3ADW000195R0501 DCS800 Service Manual e e

Page 55

55

Remove faulty thyristor

1. Replace all blown fuses and reconnect all fuses taken out during search for the

faulty thyristor.

2. Remove the screws of the DC - busbar plates adjacent to the defective

thyristors

DCbusbar

plates

Location of the DC - busbar plates

Note:

It depends on the location of the defective thyristor which DC-busbar plates have

to be disconnected.

Exchange of Thyristors for Size D6

3ADW000195R0501 DCS800 Service Manual e e

Page 56

56

g

3. Write down the direction and location of the thyristors to be removed and mark

their gate leads. In case of BCT’s add the position of the gates.

4. Remove the gate leads if possible.

5. Loosen the mounting clamp at the top of the thyristor stack.

mounting clamp indicating sprin

Handling of indicating spring and mounting clamp

Attention: While loosen the mounting clamp the indicating spring must be pulled

out a little, otherwise the spring will be damaged!

Do not remove the nuts totally, otherwise the treaded rods will fall down!

6. Pull out both DC-busbar plates.

DCbusbar

plates

DC-busbar plates

Exchange of Thyristors for Size D6

3ADW000195R0501 DCS800 Service Manual e e

Page 57

57

7. Attach the disassembly tool at the faulty thyristor and prize open the upper and

lower heat sinks.

push

down

push

down

Use of disassembly tool

8. Remove the thyristors with e.g. a pair of pliers.

Attention: To centre the thyristors spring pins are used. The pins are inlayed into

all lower heat sinks. Open the gap wide enough that the thyristor and the pins are

not damaged while removing the thyristor!

Exchange of Thyristors for Size D6

3ADW000195R0501 DCS800 Service Manual e e

Page 58

58

Install new thyristor

1. Ensure that the new thyristor is of the correct type (see appendix A). Keep the

semiconductor and its surroundings clean. If necessary clean them with a

piece of tissue paper moistened with solvent.

Note:

Do not touch the polished surfaces of the thyristor.

2. Clean the polished surfaces of the semiconductor with a piece of tissue paper

moistened with solvent. Dry all surfaces. Spread a thin layer of heat

conducting paste on both sides of the thyristor, if necessary use a rubber

spatula.

Prepare disk type thyristor

3. Clean all parts with tissue paper moistened with solvent, which have had or will

have contact with the thyristor or each other (lower / upper heat sink). Do not

clean the surfaces of grease too thoroughly, because the aluminum surfaces

will oxidize in a few seconds. Dry all surfaces.

4. Centre the thyristors by means of the spring pins.

Note:

Be sure that the thyristor is installed in the right direction. Do not pinch or cut

the gate leads or any other cable.

5. Turn the thyristor so that the gate leads point in the right direction. When

changing BCT’s make sure, that gate A is in front (see fig. Gates of BCT

on

page 53).

6. Connect the gate leads if possible.

7. Insert first the top DC-busbar plate and then the bottom one.

Exchange of Thyristors for Size D6

3ADW000195R0501 DCS800 Service Manual e e

Page 59

59

DC-busbar

plates and

heatsinks

DC-busbar plates and adjacent heat sinks

Note:

The DC - busbar plates should line up with the adjacent heat sinks.

8. Reconnect the DC-busbars.