Page 1

DCS800

Firmware manual

DCS800 Drives (20 to 5200 A)

Page 2

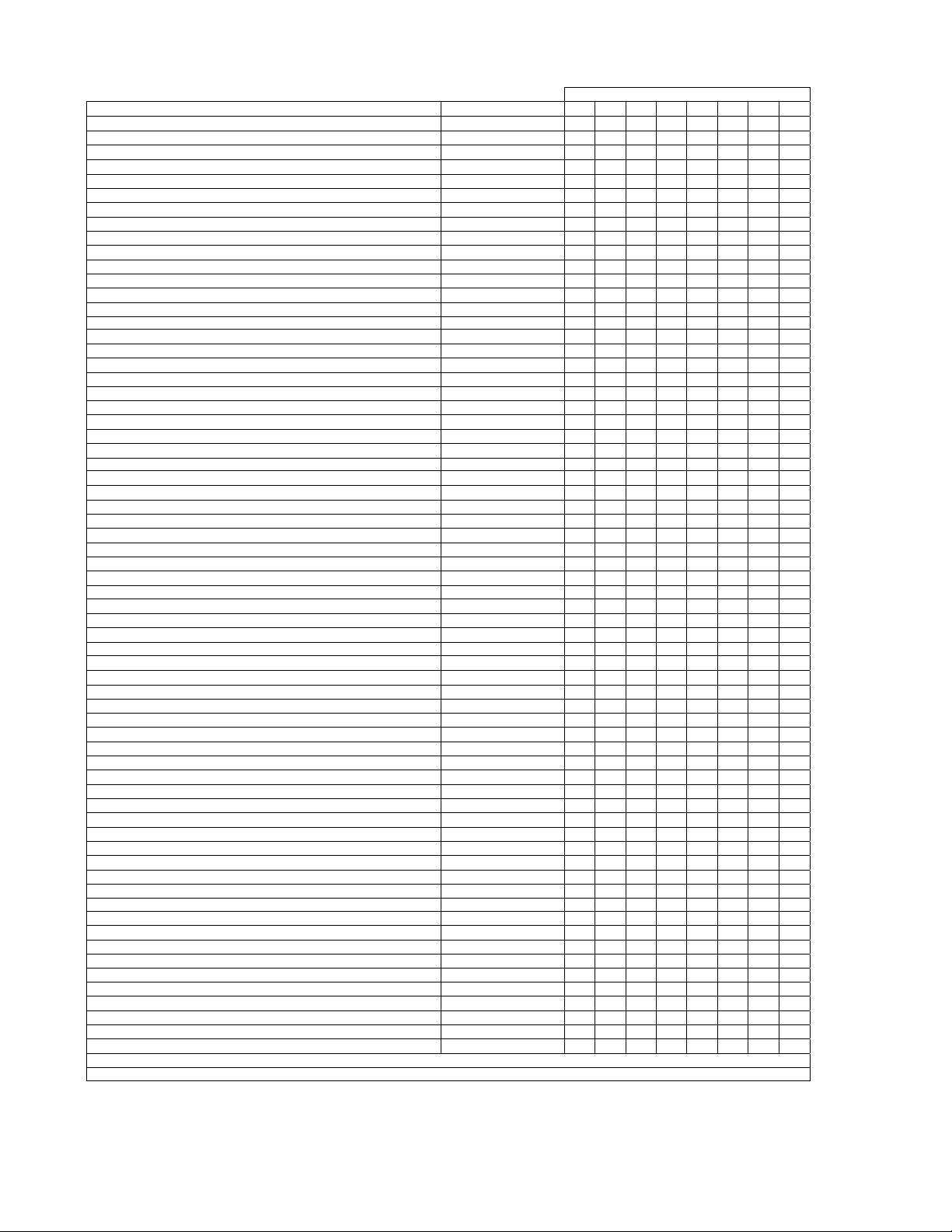

DCS800 Drive Manuals

All the documents available for the drive system DCS800 are listed below:

Language

Public. number

DCS800 Quick Guide

DCS800 Tools & Documentation CD

DCS800 Converter module

3ADW000191 x x x x x

3ADW000211 x

Flyer DCS800 3ADW000190 x x x x

Technical Catalogue DCS800 3ADW000192 x x x x x x x

Hardware Manual DCS800 3ADW000194 x x x x x x x x

Hardware Manual DCS800 update DCF503B/DCF504B 3ADW000194Z0301 x

Firmware Manual DCS800 3ADW000193 x x p x x x x x

Installation according to EMC 3ADW000032 x

Technical Guide 3ADW000163 x

Service Manual DCS800 3ADW000195 x x

12-Pulse Manual 3ADW000196 x

CMA-2 Board 3ADW000136 p

Flyer Hard - Parallel 3ADW000213 x

Drive Tools

DriveWindow 2.x - User's Manual 3BFE64560981 x

DriveOPC 2.x - User's Manual 3BFE00073846 x

Optical DDCS Communication Link 3AFE63988235 x

DDCS Branching Units - User’s Manual 3BFE64285513 x

DCS800 Applications

PLC Programming with CoDeSys CoDeSys_V23 x x x

61131 DCS800 target +tool description - Application Program 3ADW000199 x

DCS800 Crane Drive

DCS800 Crane Drive Manual suppl. 3AST004143 x

DCS800 Crane Drive Product note PDC5 EN REVA p

DCS800 Winder ITC

DCS800 Winder Product note PDC2 EN x

DCS800 Winder description ITC 3ADW000308 x

Winder Questionnaire 3ADW000253z x

DCS800-E Panel Solution

Flyer DCS800-E Panel solution 3ADW000210 x

Hardware Manual DCS800-E 3ADW000224 x

DCS800-A Enclosed Converters

Flyer DCS800-A 3ADW000213 x

Technical Catalogue DCS800-A 3ADW000198 x

Installation of DCS800-A 3ADW000091 x x

DCS800-R Rebuild System

Flyer DCS800-R 3ADW000007 x x

DCS800-R Manual 3ADW000197 x

DCS500/DCS600 Size A5...A7, C2b, C3 and C4 Upgrade Kits 3ADW000256 x

Extension Modules

RAIO-01 Analog IO Extension 3AFE64484567 x

RDIO-01 Digital IO Extension 3AFE64485733 x

RRIA-01 Resolver Interface Module 3AFE68570760 x

RTAC-01 Pulse Encoder Interface 3AFE64486853 x

RTAC-03 TTL Pulse Encoder Interface 3AFE68650500 x

AIMA R-slot extension 3AFE64661442 x

Serial Communication

Drive specific serial communication

NETA Remote diagnostic interface 3AFE64605062 x

Fieldbus Adapter with DC Drives RPBA- (PROFIBUS) 3AFE64504215 x

Fieldbus Adapter with DC Drives RCAN-02 (CANopen)

Fieldbus Adapter with DC Drives RCNA-01 (ControlNet) 3AFE64506005 x

Fieldbus Adapter with DC Drives RDNA- (DeviceNet) 3AFE64504223 x

Fieldbus Adapter with DC Drives RMBA (MODBUS) 3AFE64498851 x

Fieldbus Adapter with DC Drives RETA (Ethernet) 3AFE64539736 x

x -> existing p -> planned

Status 04.2010

DCS800 Drive Manuals-List_j.doc

E D I ES F CN RU PL

Page 3

Safety instructions

What this chapter contains

This chapter contains the safety instructions you must follow when installing,

operating and servicing the drive. If ignored, physical injury or death may follow, or

damage may occur to the drive, the motor or driven equipment. Read the safety

instructions before you work on the unit.

To which products this chapter applies

The information is valid for the whole range of the product DCS800, the converter

modules DCS800-S0x size D1 to D7, field exciter units DCF80x, etc. like the

Rebuild Kit DCS800-R00-9xxx.

Usage of warnings and notes

There are two types of safety instructions throughout this manual: warnings and

notes. Warnings caution you about conditions which can result in serious injury or

death and/or damage to the equipment, and advise on how to avoid the danger.

Notes draw attention to a particular condition or fact, or give information on a

subject. The warning symbols are used as follows:

Dangerous voltage warning warns of high voltage which can cause

physical injury or death and/or damage to the equipment.

3

General danger warning warns about conditions, other than those

caused by electricity, which can result in physical injury or death

and/or damage to the equipment.

Electrostatic sensitive devices warning warns of electrostatic

discharge which can damage the equipment.

Safety instructions

3ADW000193R0701 DCS800 Firmware Manual e g

Page 4

4

Installation and maintenance work

These warnings are intended for all who work on the drive, motor cable

or motor. Ignoring the instructions can cause physical injury or death

and/or damage to the equipment.

WARNING!

•

Only qualified electricians are allowed to install and maintain

the drive!

•

Never work on the drive, motor cable or motor when main power is

applied.

Always ensure by measuring with a multimeter (impedance at least

1 Mohm) that:

1. Voltage between drive input phases U1, V1 and W1 and

the frame is close to 0 V.

2. Voltage between terminals C+ and D- and the frame is

close to 0 V.

•

Do not work on the control cables when power is applied to the

drive or to the external control circuits. Externally supplied control

circuits may cause dangerous voltages inside the drive even when

the main power on the drive is switched off.

•

Do not make any insulation resistance or voltage withstand tests

on the drive or drive modules.

•

Isolate the motor cables from the drive when testing the insulation

resistance or voltage withstand of the cables or the motor.

•

When reconnecting the motor cable, always check that the C+ and

D- cables are connected with the proper terminal.

Note:

•

The motor cable terminals on the drive are at a dangerously high

voltage when the main power is on, regardless of whether the

motor is running or not.

•

Depending on the external wiring, dangerous voltages (115 V,

220 V or 230 V) may be present on the relay outputs of the drive

system (e.g. SDCS-IOB-2 and RDIO).

•

DCS800 with enclosure extension: Before working on the drive,

isolate the whole drive system from the supply.

Safety instructions

3ADW000193R0701 DCS800 Firmware Manual e g

Page 5

5

Grounding

These instructions are intended for all who are responsible for the

grounding of the drive. Incorrect grounding can cause physical injury,

death and/or equipment malfunction and increase electromagnetic

interference.

WARNING!

•

Ground the drive, motor and adjoining equipment to ensure

personnel safety in all circumstances, and to reduce

electromagnetic emission and pick-up.

•

Make sure that grounding conductors are adequately sized and

marked as required by safety regulations.

•

In a multiple-drive installation, connect each drive separately to

protective earth (PE ).

•

Minimize EMC emission and make a 360° high frequency

grounding (e.g. conductive sleeves) of screened cable entries at

the cabinet lead-through plate.

•

Do not install a drive equipped with an EMC filter to an

ungrounded power system or a high resistance-grounded (over 30

ohms) power system.

Note:

•

Power cable shields are suitable as equipment grounding

conductors only when adequately sized to meet safety regulations.

•

As the normal leakage current of the drive is higher than 3.5 mA

AC or 10 mA DC (stated by EN 50178, 5.2.11.1), a fixed protective

earth connection is required.

Safety instructions

3ADW000193R0701 DCS800 Firmware Manual e g

Page 6

6

Printed circuit boards and fiber optic cables

These instructions are intended for all who handle the circuit boards

and fiber optic cables. Ignoring the following instructions can cause

damage to the equipment.

WARNING! The printed circuit boards contain components sensitive to

electrostatic discharge. Wear a grounding wrist band when handling

the boards. Do not touch the boards unnecessarily.

Use grounding strip:

ABB order no.: 3ADV050035P0001

WARNING! Handle the fiber optic cables with care. When unplugging

optic cables, always grab the connector, not the cable itself. Do not

touch the ends of the fibers with bare hands as the fiber is extremely

sensitive to dirt. The minimum allowed bend radius is 35 mm (1.38 in.).

Safety instructions

3ADW000193R0701 DCS800 Firmware Manual e g

Page 7

Mechanical installation

7

These notes are intended for all who install the drive. Handle the unit

carefully to avoid damage and injury.

WARNING!

•

DCS800 sizes D4 ... D7: The drive is heavy. Do not lift it alone. Do

not lift the unit by the front cover. Place units D4 and D5 only on its

back.

DCS800 sizes D5 ... D7: The drive is heavy. Lift the drive by the

lifting lugs only. Do not tilt the unit. The unit will overturn from a tilt

of about 6 degrees.

•

Make sure that dust from drilling does not enter the drive when

installing. Electrically conductive dust inside the unit may cause

damage or lead to malfunction.

•

•

Ensure sufficient cooling.

Do not fasten the drive by riveting or welding.

Safety instructions

3ADW000193R0701 DCS800 Firmware Manual e g

Page 8

8

Operation

These warnings are intended for all who plan the operation of the drive

or operate the drive. Ignoring the instructions can cause physical injury

or death and/or damage to the equipment.

WARNING!

•

Before adjusting the drive and putting it into service, make sure

that the motor and all driven equipment are suitable for operation

throughout the speed range provided by the drive. The drive can

be adjusted to operate the motor at speeds above and below the

base speed.

•

Do not control the motor with the disconnecting device

(disconnecting mains); instead, use the control panel keys

, or commands via the I/O board of the drive.

•

Mains connection

You can use a disconnect switch (with fuses) to disconnect the

electrical components of the drive from the mains for installation

and maintenance work. The type of disconnect switch used must

be as per EN 60947-3, Class B, so as to comply with EU

regulations, or a circuit-breaker type which switches off the load

circuit by means of an auxiliary contact causing the breaker's main

contacts to open. The mains disconnect must be locked in its

"OPEN" position during any installation and maintenance work.

•

EMERGENCY STOP buttons must be installed at each control

desk and at all other control panels requiring an emergency stop

function. Pressing the STOP button on the control panel of the

drive will neither cause an emergency stop of the motor, nor will

the drive be disconnected from any dangerous potential.

To avoid unintentional operating states, or to shut the unit down in

case of any imminent danger according to the standards in the

safety instructions it is not sufficient to merely shut down the drive

via signals "RUN", "drive OFF" or "Emergency Stop" respectively

"control panel" or "PC tool".

•

Intended use

The operating instructions cannot take into consideration every

possible case of configuration, operation or maintenance. Thus,

they mainly give such advice only, which is required by qualified

personnel for normal operation of the machines and devices in

industrial installations.

If in special cases the electrical machines and devices are intended for use in non-industrial installations - which may require

stricter safety regulations (e.g. protection against contact by

children or similar) - these additional safety measures for the

installation must be provided by the customer during assembly.

and

Safety instructions

3ADW000193R0701 DCS800 Firmware Manual e g

Page 9

9

Note:

•

When the control location is not set to Local (L not shown in the

status row of the display), the stop key on the control panel will not

stop the drive. To stop the drive using the control panel, press the

LOC/REM key and then the stop key

.

Safety instructions

3ADW000193R0701 DCS800 Firmware Manual e g

Page 10

10

Table of contents

Safety instructions 3

What this chapter contains......................................................................................................... 3

To which products this chapter applies ...................................................................................... 3

Usage of warnings and notes.....................................................................................................3

Installation and maintenance work............................................................................................. 4

Grounding.......................................................................................................................5

Mechanical installation ............................................................................................................... 7

Operation ................................................................................................................................... 8

Table of contents 10

Introduction 23

Chapter overview.......................................................................................................... 23

Before You Start ........................................................................................................... 23

What this manual contains ........................................................................................... 23

Start-up 24

Chapter overview.......................................................................................................... 24

General.........................................................................................................................24

Start-up procedure ................................................................................................................... 25

Tools............................................................................................................................. 25

Checking with the power switched off .......................................................................... 25

Checking with the power switched on .......................................................................... 27

Commissioning a DCS800 ....................................................................................................... 28

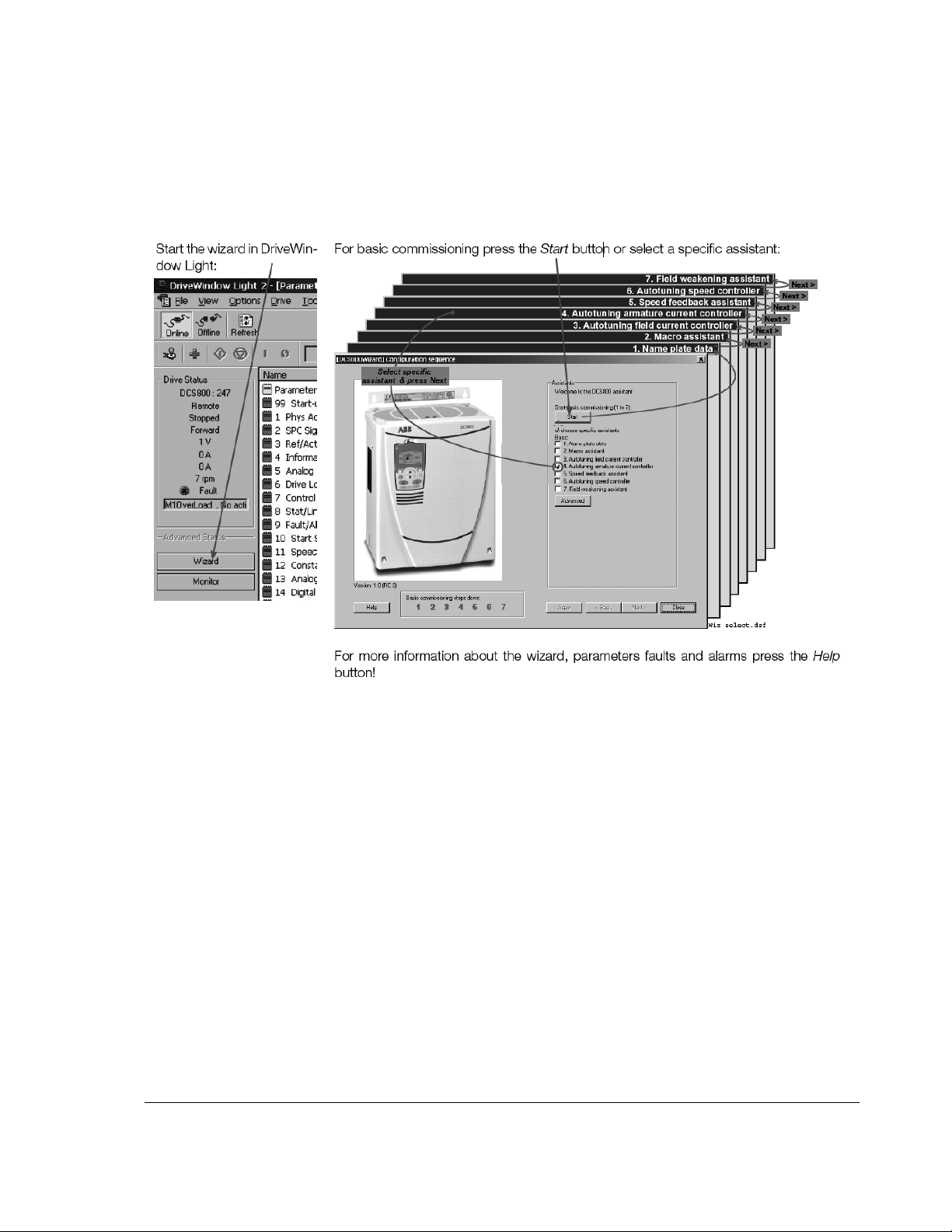

Connect DCS800 to PC with DriveWindow Light..................................................................... 28

Commissioning a DCS800 with the wizard .............................................................................. 29

Commissioning a DCS800 with DriveWindow.......................................................................... 30

Requirements ............................................................................................................... 30

01, 02 Macro assistant / Name plate data .................................................................... 30

03 Autotuning field current controller............................................................................ 31

04 Autotuning armature current controller .................................................................... 31

05 Speed feedback assistant ....................................................................................... 32

Analog tacho fine tune procedure ................................................................ 32

06 Autotuning speed controller..................................................................................... 32

07 Field weakening assistant ....................................................................................... 33

Manual tuning........................................................................................................................... 34

I/O configuration ........................................................................................................... 34

Field current controller.................................................................................................. 34

Armature current controller........................................................................................... 35

Control principle ........................................................................................... 35

Manual tuning............................................................................................... 36

Analog tacho................................................................................................................. 41

Manual tuning............................................................................................... 42

Speed controller ........................................................................................................... 42

Basics........................................................................................................... 42

Manual tuning............................................................................................... 43

EMF controller .............................................................................................................. 45

Table of contents

3ADW000193R0701 DCS800 Firmware Manual e g

Page 11

11

Basics............................................................................................................45

Manual tuning................................................................................................45

Flux linearization............................................................................................................47

Basics............................................................................................................47

Manual tuning................................................................................................48

Thyristor diagnosis ........................................................................................................50

Basics............................................................................................................50

Check all thyristors........................................................................................50

Check individual firing pulses........................................................................50

Firmware description 52

Chapter overview...........................................................................................................52

Identification of the firmware versions ...........................................................................52

Start / stop sequences ..............................................................................................................53

General..........................................................................................................................53

Switch on sequence ......................................................................................................53

Start the drive ................................................................................................................54

Stop the drive ................................................................................................................55

Field excitation ..........................................................................................................................58

General..........................................................................................................................58

Field Reversal................................................................................................................58

Field control...................................................................................................58

Field reference hysteresis .............................................................................59

Force field current direction...........................................................................59

Reversal time ................................................................................................59

Bumpless transition.......................................................................................59

Optitorque......................................................................................................................59

Field current reference gain ..........................................................................59

Field current monitoring.................................................................................................60

Field minimum trip.........................................................................................60

Flux reversal..................................................................................................60

Field reversal hysteresis................................................................................60

Field reversal active ......................................................................................60

Field Heating .................................................................................................................60

Overview .......................................................................................................60

Modes of operation........................................................................................61

E-stop............................................................................................................62

Field exciter mode.....................................................................................................................63

General..........................................................................................................................63

Large field exciter controlled by a DCS800 armature converter....................................63

Parameters to be set in the DCS800 armature converter: ............................64

Parameters to be set in large field exciters: ..................................................64

Field current autotuning for large field exciters: ............................................65

Stand alone field exciter ................................................................................................66

Parameters to be set in the stand alone field exciter: ...................................66

Field current autotuning for stand alone field exciter:....................................67

DC-breaker, DC-contactor ........................................................................................................68

General..........................................................................................................................68

HVCB controlled externally, DC-breaker controlled by the drive...................................68

DC-contactor US version ..........................................................................................................69

Table of contents

3ADW000193R0701 DCS800 Firmware Manual e g

Page 12

12

AC- and DC-breaker controlled by the drive................................................................. 71

No AC-breaker, DC-breaker controlled by the drive ..................................................... 72

AC-breaker controlled by the drive, DC-breaker controlled externally.......................... 73

No AC-breaker, DC-breaker controlled externally ........................................................ 74

Command Trip DC-breaker .......................................................................................... 74

Dynamic braking ...................................................................................................................... 75

General.........................................................................................................................75

Operation...................................................................................................................... 75

Activation...................................................................................................... 75

Function........................................................................................................ 75

Deactivation.................................................................................................. 76

Position counter ....................................................................................................................... 78

General.........................................................................................................................78

Counting procedure ...................................................................................................... 78

Synchronization ............................................................................................................ 78

I/O configuration 81

Chapter overview.......................................................................................................... 81

Digital inputs (DI’s) ................................................................................................................... 81

SDCS-CON-4 / SDCS-IOB-2........................................................................................ 81

st

and 2nd RDIO-01 ....................................................................................................... 81

1

Configuration ................................................................................................................ 82

Digital outputs (DO’s) ............................................................................................................... 84

SDCS-CON-4 / SDCS-IOB-2........................................................................................ 84

st

and 2nd RDIO-01 ....................................................................................................... 84

1

Configuration ................................................................................................................ 85

Analog inputs (AI’s) .................................................................................................................. 87

SDCS-CON-4 ............................................................................................................... 87

SDCS-IOB-3 ................................................................................................................. 87

st

RAIO-01 ................................................................................................................... 88

1

nd

RAIO-01................................................................................................................... 88

2

Configuration ................................................................................................................ 89

Scaling.......................................................................................................................... 89

Analog outputs (AO’s) .............................................................................................................. 91

SDCS-CON-4 / SDCS-IOB-3........................................................................................ 91

st

RAIO-01 ................................................................................................................... 91

1

nd

RAIO-01................................................................................................................... 92

2

Configuration ................................................................................................................ 92

Scaling.......................................................................................................................... 93

Communication 94

Chapter overview.......................................................................................................... 94

DCSLink with SDCS-DSL-4 ..................................................................................................... 94

General.........................................................................................................................94

Excitation, commissioning a FEX-4.......................................................................................... 94

Layout FEX-4................................................................................................................ 94

Layout SDCS-DSL-4 .................................................................................................... 94

Set the FEX-4 type ....................................................................................................... 95

Set the node numbers, transmission speed and the communication supervision........ 95

Set the DCSLink ........................................................................................................... 96

Table of contents

3ADW000193R0701 DCS800 Firmware Manual e g

Page 13

13

Set the supply of the FEX-4...........................................................................................97

Checking the FEX-4 ......................................................................................................97

Master-follower, commissioning................................................................................................98

Set the DCSLink hardware ............................................................................................98

Set the node ID numbers and transmission speed........................................................99

Activate the mailboxes...................................................................................................99

Activate the communication supervision .......................................................................99

Send and receive values .............................................................................................100

Firmware structure.......................................................................................................101

Additional settings .......................................................................................................102

Drive-to-drive communication .................................................................................................103

Set the DCSLink hardware ..........................................................................................103

Set the node ID numbers and transmission speed......................................................104

Activate the mailboxes.................................................................................................104

Activate the communication supervision .....................................................................104

Send and receive values .............................................................................................105

12-pulse ..................................................................................................................................106

Set the DCSLink hardware ..........................................................................................106

Set the node numbers, transmission speed and the communication supervision.......107

DDCS channels with SDCS-COM-8 .......................................................................................108

General........................................................................................................................108

Integer scaling on the DDCS link.................................................................................108

Ch0 communication to overriding control................................................................................109

ABB overriding control.................................................................................................109

Parameter setting example..........................................................................................109

Received data set table...............................................................................................110

Transmitted data set table...........................................................................................111

Fieldbus communication (N-type)................................................................................111

Ch1 I/O devices ......................................................................................................................112

Ch2 Master-follower link..........................................................................................................112

General........................................................................................................................112

Link configuration ........................................................................................................112

Master..........................................................................................................................112

Followers .....................................................................................................................113

Firmware structure.......................................................................................................113

Toggle between speed- and torque control.................................................................115

Follower diagnostics....................................................................................................115

Master-follower link specification.................................................................................115

Ch3 commissioning and maintenance tools............................................................................116

DriveWindow ...............................................................................................................116

Ethernet communication for monitoring with Ethernet adapter NETA-01 ...............................117

General........................................................................................................................117

NETA-01 - DCS800 .....................................................................................................117

Related documentation................................................................................................117

NETA-01 configuration ................................................................................................117

Mechanical and electrical installation ..........................................................................118

Drive configuration.......................................................................................................118

CANopen communication with fieldbus adapter RCAN-01 .....................................................119

General........................................................................................................................119

RCAN-01 - DCS800 ....................................................................................................119

Table of contents

3ADW000193R0701 DCS800 Firmware Manual e g

Page 14

14

Related documentation............................................................................................... 119

Overriding control configuration.................................................................................. 119

EDS file....................................................................................................................... 119

Mechanical and electrical installation ......................................................................... 119

Drive configuration...................................................................................................... 119

Parameter setting example 1 using group 51............................................................. 119

Further information ..................................................................................................... 121

Parameter setting example 2 using groups 90 and 92 ............................................... 122

Switch on sequence ................................................................................................... 124

ControlNet communication with fieldbus adapter RCNA-01................................................... 125

General....................................................................................................................... 125

RCNA-01 - DCS800 ................................................................................................... 125

Related documentation............................................................................................... 125

Overriding control configuration.................................................................................. 125

EDS file....................................................................................................................... 125

Mechanical and electrical installation ......................................................................... 125

Drive configuration...................................................................................................... 125

Parameter setting example 1 using ABB Drives assembly......................................... 125

Parameter setting example 2 using Vendor specific assembly .................................. 127

Setting of parameter groups 51, 90 and 92 ................................................................ 128

Further information ..................................................................................................... 128

Switch on sequence ................................................................................................... 128

DeviceNet communication with fieldbus adapter RDNA-01 ................................................... 129

General....................................................................................................................... 129

RDNA-01 - DCS800 ................................................................................................... 129

Related documentation............................................................................................... 129

Overriding control configuration.................................................................................. 129

EDS file....................................................................................................................... 129

Mechanical and electrical installation ......................................................................... 129

Drive configuration...................................................................................................... 129

Parameter setting example 1 using ABB Drives assembly......................................... 129

Parameter setting example 2 using User specific assembly ...................................... 131

Setting of parameter groups 51, 90 and 92 ................................................................ 132

Further information ..................................................................................................... 132

Switch on sequence ................................................................................................... 132

Ethernet/IP communication with fieldbus adapter RETA-01 .................................................. 133

General....................................................................................................................... 133

RETA-01 - DCS800 .................................................................................................... 133

Related documentation............................................................................................... 133

EDS file....................................................................................................................... 133

Mechanical and electrical installation ......................................................................... 133

Drive configuration...................................................................................................... 133

Parameter setting example using Ethernet/IP ABB Drives communication profile..... 133

Up to 4 data words ..................................................................................................... 135

Up to 12 data words ................................................................................................... 135

Switch on sequence ................................................................................................... 138

Modbus (RTU) communication with fieldbus adapter RMBA-01 ............................................ 139

General....................................................................................................................... 139

RMBA-01 - DCS800 ................................................................................................... 139

Related documentation............................................................................................... 139

Table of contents

3ADW000193R0701 DCS800 Firmware Manual e g

Page 15

15

Mechanical and electrical installation ..........................................................................139

Drive configuration.......................................................................................................139

Parameter setting example ….....................................................................................139

… when controlling a drive ..........................................................................................139

… when used for monitoring only................................................................................141

Setting of PLC, parameter groups 90 and 92 ..............................................................143

Switch on sequence ....................................................................................................143

Modbus/TCP communication with fieldbus adapter RETA-01 ................................................144

General........................................................................................................................144

RETA-01 - DCS800 .....................................................................................................144

Related documentation................................................................................................144

Mechanical and electrical installation ..........................................................................144

Drive configuration.......................................................................................................144

Parameter setting example using Modbus/TCP ..........................................................144

Switch on sequence ....................................................................................................146

Profibus communication with fieldbus adapter RPBA-01........................................................147

General........................................................................................................................147

RPBA-01 - DCS800.....................................................................................................147

Related documentation................................................................................................147

Overriding control configuration...................................................................................147

Mechanical and electrical installation ..........................................................................147

Drive configuration.......................................................................................................147

Parameter setting example 1 using PPO Type 1 ........................................................147

Parameter setting example 2 using PPO types 2, 4 and 5..........................................148

Communication via group 51.......................................................................................149

Communication via group 90 and group 92.................................................................150

Switch on sequence ....................................................................................................151

Data set table..........................................................................................................................152

Adaptive Program (AP) 153

Chapter overview.........................................................................................................153

What is the Adaptive Program.....................................................................................153

Features ......................................................................................................................153

How to build the program ............................................................................................154

How to connect the Application Program with the firmware ........................................154

Block Parameter Set for block 1 ..................................................................................155

How to control the execution of the program...............................................................156

DWL AP ..................................................................................................................................157

General........................................................................................................................157

Important keys and buttons .........................................................................................157

Program modes...........................................................................................................157

Change to Edit mode...................................................................................................157

Insert function blocks...................................................................................................158

Connect function blocks ..............................................................................................159

Set the Time level........................................................................................................161

Saving AP applications................................................................................................161

Function blocks .......................................................................................................................162

General rules...............................................................................................................162

Block inputs .................................................................................................................162

Block input attributes...................................................................................163

Table of contents

3ADW000193R0701 DCS800 Firmware Manual e g

Page 16

16

Parameter value as an integer input .......................................................... 164

How the block handles the input ................................................................ 164

How to select the input ............................................................................... 164

Constant as an integer input ...................................................................... 165

How to set and connect the input ............................................................... 165

Parameter value as a boolean input........................................................... 166

How the block handles the input ................................................................ 166

Constant as a boolean input....................................................................... 167

How to set and connect the input ............................................................... 167

String input ................................................................................................. 167

How to select the input ............................................................................... 167

Function blocks ...................................................................................................................... 168

ABS ............................................................................................................................ 168

ADD ............................................................................................................................ 169

AND ............................................................................................................................ 169

Bitwise ........................................................................................................................ 170

Bset ............................................................................................................................ 171

Compare..................................................................................................................... 171

Count .......................................................................................................................... 172

D-Pot .......................................................................................................................... 172

Event .......................................................................................................................... 173

Filter............................................................................................................................ 173

Limit ............................................................................................................................ 174

MaskSet...................................................................................................................... 174

Max............................................................................................................................. 175

Min.............................................................................................................................. 175

MulDiv......................................................................................................................... 175

NotUsed...................................................................................................................... 176

OR .............................................................................................................................. 176

ParRead ..................................................................................................................... 176

ParWrite...................................................................................................................... 177

PI ................................................................................................................................ 177

PI-Bal.......................................................................................................................... 178

Ramp .......................................................................................................................... 178

Sqrt ............................................................................................................................. 179

SqWav ........................................................................................................................ 179

SR............................................................................................................................... 180

Switch-B ..................................................................................................................... 180

Switch-I....................................................................................................................... 181

TOFF .......................................................................................................................... 181

TON ............................................................................................................................ 182

Trigg ........................................................................................................................... 182

XOR............................................................................................................................ 183

Diagram.................................................................................................................................. 184

Signal and parameter list 185

Signals and parameters ......................................................................................................... 185

Signal groups list.................................................................................................................... 185

Parameter groups list ............................................................................................................. 187

Signal and parameter list ....................................................................................................... 190

Table of contents

3ADW000193R0701 DCS800 Firmware Manual e g

Page 17

17

Group 1........................................................................................................................190

Physical actual values.................................................................................190

Group 2........................................................................................................................194

Speed controller signals..............................................................................194

Group 3........................................................................................................................198

Reference actual values..............................................................................198

Group 4........................................................................................................................201

Information ..................................................................................................201

Group 5........................................................................................................................209

Analog I/O ...................................................................................................209

Group 6........................................................................................................................210

Drive logic signals .......................................................................................210

Group 7........................................................................................................................216

Control words ..............................................................................................216

Group 8........................................................................................................................222

Status / limit words ......................................................................................222

Group 9........................................................................................................................228

Fault / alarm words......................................................................................228

Group 10......................................................................................................................244

Start / stop select ........................................................................................244

Group 11......................................................................................................................257

Speed reference inputs ...............................................................................257

Group 12......................................................................................................................264

Constant speeds .........................................................................................264

Group 13......................................................................................................................265

Analog inputs ..............................................................................................265

Group 14......................................................................................................................269

Digital outputs .............................................................................................269

Group 15......................................................................................................................271

Analog outputs ............................................................................................271

Group 16......................................................................................................................273

System control inputs..................................................................................273

Group 19......................................................................................................................276

Data storage................................................................................................276

Group 20......................................................................................................................278

Limits...........................................................................................................278

Group 21......................................................................................................................282

Start / stop...................................................................................................282

Group 22......................................................................................................................286

Speed ramp.................................................................................................286

Group 23......................................................................................................................289

Speed reference..........................................................................................289

Group 24......................................................................................................................294

Speed control ..............................................................................................294

Group 25......................................................................................................................299

Torque reference.........................................................................................299

Group 26......................................................................................................................300

Torque reference handling ..........................................................................300

Group 30......................................................................................................................304

Fault functions.............................................................................................304

Table of contents

3ADW000193R0701 DCS800 Firmware Manual e g

Page 18

18

Group 31..................................................................................................................... 315

Motor 1 temperature................................................................................... 315

Group 34..................................................................................................................... 317

DCS800 Control Panel display................................................................... 317

Group 40..................................................................................................................... 318

PID control.................................................................................................. 318

Group 42..................................................................................................................... 321

Brake control .............................................................................................. 321

Group 43..................................................................................................................... 327

Current control............................................................................................ 327

Group 44..................................................................................................................... 333

Field excitation ........................................................................................... 333

Group 45..................................................................................................................... 340

Field converter settings .............................................................................. 340

Group 47..................................................................................................................... 347

12-pulse operation...................................................................................... 347

Group 49..................................................................................................................... 348

Shared motion ............................................................................................ 348

Group 50..................................................................................................................... 360

Speed measurement .................................................................................. 360

Group 51..................................................................................................................... 367

Fieldbus...................................................................................................... 367

Group 52..................................................................................................................... 368

Modbus....................................................................................................... 368

Group 60, …, 69 ......................................................................................................... 369

Application program parameters ................................................................ 369

Group 70..................................................................................................................... 370

DDCS control ............................................................................................. 370

Group 71..................................................................................................................... 375

Drivebus ..................................................................................................... 375

Group 83..................................................................................................................... 375

Adaptive Program control........................................................................... 375

Group 84..................................................................................................................... 377

Adaptive Program....................................................................................... 377

Group 85..................................................................................................................... 380

User constants ........................................................................................... 380

Group 86..................................................................................................................... 382

Adaptive Program outputs.......................................................................... 382

Group 88..................................................................................................................... 383

Internal ....................................................................................................... 383

Group 90..................................................................................................................... 385

Receiving data sets addresses 1 ............................................................... 385

Group 91..................................................................................................................... 387

Receiving data sets addresses 2 ............................................................... 387

Group 92..................................................................................................................... 388

Transmit data sets addresses 1 ................................................................. 388

Group 93..................................................................................................................... 390

Transmit data sets addresses 2 ................................................................. 390

Group 94..................................................................................................................... 391

DCSLink control ......................................................................................... 391

Table of contents

3ADW000193R0701 DCS800 Firmware Manual e g

Page 19

19

Group 97......................................................................................................................399

Measurement ..............................................................................................399

Group 98......................................................................................................................407

Option modules ...........................................................................................407

Group 99......................................................................................................................415

Start-up data ...............................................................................................415

DCS800 Control Panel operation 420

Chapter overview.........................................................................................................420

Start-up........................................................................................................................420

DCS800 Control Panel ................................................................................................420

Display overview..........................................................................................................421

General display features..............................................................................................421

Output mode................................................................................................................422

Other modes................................................................................................................423

Maintenance................................................................................................................428

Fault tracing 429

Chapter overview.........................................................................................................429

General........................................................................................................................429

Fault modes ................................................................................................429

Converter protection ...............................................................................................................429

Auxiliary undervoltage .................................................................................................429

Armature overcurrent...................................................................................................429

Converter overtemperature .........................................................................................429

Auto-reclosing (mains undervoltage)...........................................................................430

Mains synchronism......................................................................................................431

Mains overvoltage .......................................................................................................431

Communication loss ....................................................................................................431

Fan, field and mains contactor acknowledge ..............................................................432

External fault................................................................................................................432

Bridge reversal ............................................................................................................433

Analog input monitor....................................................................................................433

Motor protection ......................................................................................................................435

Armature overvoltage ..................................................................................................435

Residual current detection...........................................................................................435

Measured motor temperature ......................................................................................435

Klixon...........................................................................................................................438

Motor thermal model....................................................................................................438

Field overcurrent..........................................................................................................441

Armature current ripple................................................................................................441

Speed feedback monitor..............................................................................................442

Stall protection.............................................................................................................443

Overspeed protection ..................................................................................................443

Current rise..................................................................................................................444

Field undercurrent .......................................................................................................444

Tacho / pulse encoder polarity ....................................................................................444

Tacho range ................................................................................................................444

Status messages ....................................................................................................................445

Display of status, fault and alarm signals ....................................................................445

Table of contents

3ADW000193R0701 DCS800 Firmware Manual e g

Page 20

20

Categories of signals and display options .................................................. 445

General messages ..................................................................................................... 446

Power-up errors (E) .................................................................................................... 446

Fault signals (F).......................................................................................................... 447

SDCS-COM-8 messages ........................................................................... 464

Alarm signals (A) ........................................................................................................ 465

Disappearing system alarm ........................................................................................ 475

User defined alarm by Adaptive Program................................................................... 475

Notices........................................................................................................................ 477

Appendix A: Firmware structure diagrams 479

Appendix B: SDCS-CON-4 Terminal Allocation 484

Appendix C: Index of signals and parameters 485

Table of contents

3ADW000193R0701 DCS800 Firmware Manual e g

Page 21

21

Chapters not yet available

3ADW000193R0701 DCS800 Firmware Manual e g

Page 22

22

3ADW000193R0701 DCS800 Firmware Manual e g

Page 23

Introduction

Chapter overview

Before You Start

What this manual contains

This chapter describes the purpose, contents and the intended use of this manual.

The purpose of this manual is to provide you with the information necessary to

control and program the drive.

Study carefully the Safety instructions at the beginning of this manual before

attempting any work on or with the drive. Read through this manual before starting-

up the drive. The installation and commissioning instructions given in the DCS800

Hardware Manual and DCS800 Quick Guide must also be read before proceeding.

This manual describes the standard DCS800 firmware.

The Safety instructions can be found at the beginning of this manual.

Introduction to this manual

to this manual.

Start-up

Firmware description

firmware.

I/O configuration

inputs and outputs with different hardware possibilities.

Communication

Adaptive Program (AP)

and instructs how to build a program.

Signal and parameter list

DCS800 Control Panel operation

DCS800 Control Panel.

Fault Tracing

Appendix A: Firmware structure diagram

Appendix B: SDCS-CON-4 Terminal Allocation

Appendix C: Index of signal and parameters

, this chapter describes the basic start-up procedure of the drive.

, this chapter describes the protections and fault tracing of the drive.

23

, the chapter you are currently reading, introduces you

, this chapter describes how to control the drive with standard

, this chapter describes the I/O configuration of digital and analog

, this chapter describes the communication capabilities of the drive.

, this chapter describes the basics of the Adaptive Program

, this chapter contains all signals and parameters.

, this chapter describes the handling of the

Introduction to this manual

3ADW000193R0701 DCS800 Firmware Manual e g

Page 24

24

Start-up

Chapter overview

General

This chapter describes the basic start-up procedure of the drive. A more detailed

description of the signals and parameters involved in the procedure can be found

in section Signal and parameter list.

The drive can be operated:

The following start-up procedure uses DriveWindow (for further information about

DriveWindow, consult its online help). However, parameters can also be changed

with DriveWindow Light or the DCS800 Control Panel.

The start-up procedure includes actions that need only be taken when powering up

the drive for the first time in a new installation (e.g. entering the motor data). After

the start-up, the drive can be powered up without using these start-up functions

again. The start-up procedure can be repeated later if the start-up data needs to be

altered.

Refer to section Fault tracing

problem, disconnect mains and wait for 5 minutes before attempting any work on

the drive, the motor, or the motor cables.

locally from DriveWindow, DriveWindow Light or DCS800 Control Panel

respectively remote from local I/O or overriding control.

in case problems should arise. In case of a major

Start-up

3ADW000193R0701 DCS800 Firmware Manual e g

Page 25