Page 1

DCS800

Quick guide

DCS800 Drives (20 A to 5200 A)

Page 2

DCS800 QuiCk GuiDe

english Contents

DC Drives Worldwide Service Network .............................. 3

DCS800 Drive Manuals ......................................................4

DCS800 DC Drives ............................................................. 5

Brief instructions for CD and documents overview ............. 7

Notes on EMC .................................................................... 8

Standard function assignments for the terminals ...............10

Connection example .........................................................11

Fan power connection ...................................................... 13

Terminal locations on the converter ...................................14

Notes For North American Installations .............................15

Safety and operating instructions .....................................17

Installing the DCS800 PC tools on Your computer ............ 18

Commissioning .................................................................19

DCS800 Control Panel .....................................................20

Dimensions, drilling patterns and weights ........................ 77

Fault / Alarm list ............................................................... 79

Diagnosis messages.......................................... ...............88

Macro & Firmware structure ..............................................93

Declaration of conformity ................................................ 106

Certificate of manufacture ..............................................107

deutsch Inhalt

DC Drives Worldwide Service Network .............................. 3

DCS800 Drive Manuals ......................................................4

DCS800 Gleichstromantriebe ........................................... 21

Kurzanweisung CD und Documentations[bersicht ...........23

EMV Filter ......................................................................... 24

Digitaler und analoger E-A/Anschluss von SDCS-CON-4 ..26

Anschlussbeispiel .............................................................27

Lüfterkühlung ...................................................................29

Klemmen- und Steckeranordnung des Stromrichters ........ 30

Sicherheits- und Anwendungshinweise ............................. 31

Installation der DCS800 Programme auf dem PC ............. 32

Inbetriebnahme ................................................................33

DCS800 Steuertafel .......................................................... 34

Abmessungen, Bohrbild und Gewichte ............................ 77

Fehler- und Alarmliste ...................................................... 79

Diagnose.......................................... ................................ 88

Macro & Firmware Struktur ............................................... 93

Declaration of conformity ................................................ 106

Herstellerbescheinigung ................................................. 107

español Contenido

Red de atención mundial de convertidores de CC ..............3

Manuales de convertidores DCS800 ................................... 4

Convertidores de CC DCS800 ......................................... 49

Instrucciones para la descripción del CD y documentación 51

Notas acerca de EMC .....................................................52

Asignaciones de funciones estándar para los terminales ... 54

Ejemplo de conexión ....................................................... 55

Conexión de alimentación del ventilador ..........................57

Ubicación de los terminales en el convertidor ...................58

Instrucciones de seguridad ............................................... 59

Cómo instalar las herramientas para PC del DCS800 ......60

Puesta en funcionamiento ...............................................61

Panel de control del DCS800 ........................................... 62

Dimensiones, patrones de taladrado y pesos....................77

Lista de fallos/alarmas .....................................................79

Mensajes de diagnóstico .................................................88

Estructura del macro & firmware ....................................... 93

Declaración de conformidad ........................................... 106

Certificate of manufacture ............................................... 107

français Sommaire

DC Drives Worldwide Service Network .............................. 3

Manuels du DCS800 (originaux anglais) .............................. 4

Variateurs à courant continu DCS800 ............................... 63

Documentation technique ................................................ 65

Compatibilité électromagnétique (CEM) ............................ 66

Raccordement standard des signaux d’E/S ...................... 68

Exemple de schéma de câblage ....................................... 69

Câblage du ventilateur ...................................................... 71

Emplacement des bornes sur le convertisseur .................. 72

Consignes de sécurité et d’exploitation............................. 73

Installation des outils logiciels du DCS800 sur votre PC .... 74

Mise en service ................................................................. 75

Micro-console DCS800 .................................................... 76

Dimensions, perçages et poids ........................................ 77

Liste des défauts / alarmes .............................................. 79

Messages de diagnostic.......................................... ......... 88

Structure du logiciel macro & système .............................. 93

Déclaration de conformité ............................................... 106

Certificat du fabricant ....................................................107

italiano Indice

DC Drives Worldwide Service Network .............................. 3

DCS800 Drive Manuals / DCS800 Manuali Drive ................4

DCS800 DC Drives ........................................................... 35

Brevi istruzioni CD e documentazione ............................... 37

Note sulle EMC ................................................................. 38

Assegnazione funzioni standard per i morsetti ..................40

Esempi schemi di collegamento........................................41

Fan power connection ...................................................... 43

Terminal locations on the converter ................................... 44

Istruzioni per la sicurezza e il funzionamento ..................... 45

Installa i DCS800 PC tools sul Tuo computer .................... 46

Messa in servizio ..............................................................47

Descrizione display ........................................................... 48

Disegni dimensionali ........................................................77

Fault / Alarm list ............................................................... 79

Diagnosis messages.......................................... ............... 88

Struttura macro & firmware ............................................... 93

Dichiarazione di conformità ............................................. 106

Certificato del costruttore ..............................................107

2

3ADW000191R0500 DCS800 Quick guide edisf e

Page 3

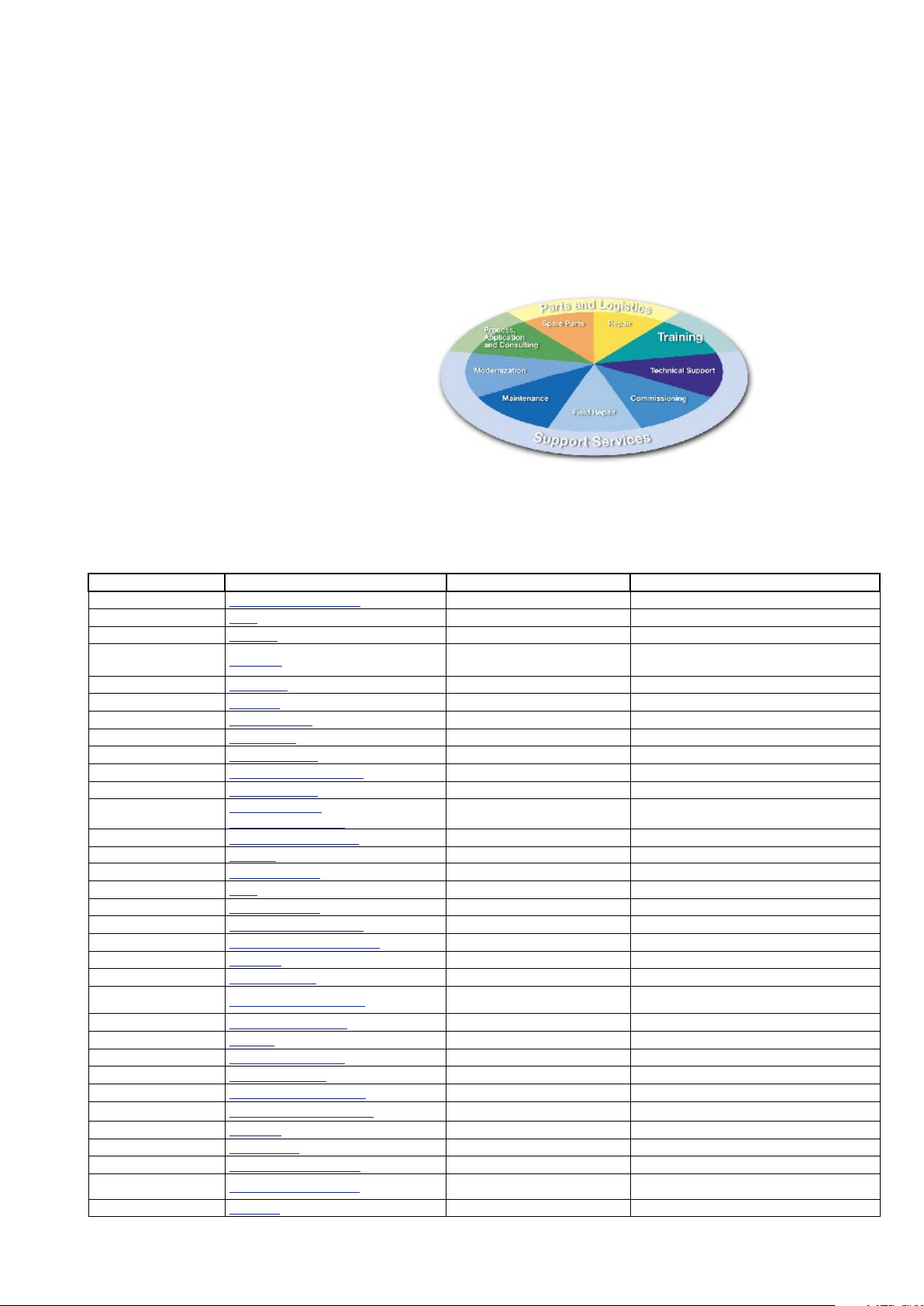

ABB Drive Service EN

In order to offer the same after sales

service to our customer around the

world, ABB has created the DRIVE

SERVICE CONCEPT.

ABB's after sales service is globally

consistent due to common targets,

rules, and the way of operation. This

means for our customers:

Please visit the ABB drive service

homepage

www.abb.com/drivesservices

ABB Drive Service FR

Pour offrir la même qualité de service

à tous nos clients, ABB a créé DRIVE

SERVICE CONCEPT.

Dans le monde entier, les équipes

de service proposent les mêmes

prestations aux mêmes conditions

avec les mêmes objectifs.

Pour en savoir plus, connectez-vous sur ABB drive service

homepage

www.abb.com/drivesservices

ABB Drive Service DE

Um jedem Kunden rund um die

Welt die gleiche Service Dienstleistung anbieten zu können, hat ABB

das DRIVE SERVICE CONCEPT

entwickelt.

Durch die Definition von einheitlichen

Zielen, Regeln, und Arbeitsvorschriften kann ABB die Dienstleitungs

Produkte weltweit auf gleichwertig

hohem Qualitätsniveau anbieten. Für

unsere Kunden bedeuted dies:

Bitte besuchen Sie die ABBHomepage Service für Antriebe

www.abb.com/drivesservices

ABB Drive Service IT

ABB ha creato il DRIVE SERVICE

CENCEPT, con lo scopo di offrire ai

nostri clienti lo stesso servizio post

vendita in tutto il mondo.

Attraverso la definizione di obbiettivi

comuni, ruoli e modo di operare, le

attività post vendita di ABB offrono

sevizi coerenti nella loro globalità. Per

i nostri clienti questo significa:

Vi invitiamo a visitare la homepage

ABB drive service

www.abb.com/drivesservices

ABB Drive Service ES

Para poder ofrecer el mismo servicio posventa a nuestros clientes

en todo el mundo, ABB ha creado

el CONCEPTO DE SERVICIO DE

CONVERTIDORES.

El servicio posventa de ABB está

mundialmente consolidado gracias

a unos objetivos y normas comunes,

así como a su funcionamiento. Esto

significa para nuestros clientes:

Visiten el portal de convertidores

de ABB

www.abb.com/drivesservices

DC Drives Worldwide Service Network

Country Local ABB Service Town Service Phone No.

Argentina Asea Brown Boveri S.A. BUENOS AIRES +54 (0) 12 29 55 00

Australia ABB NOTTING HILL +61 (0) 3 85 44 00 00

Austria ABB AG WIEN +43 1 60 10 90

Belgium ABB N.V. ZAVENTEM

Brazil ABB Ltda. OSASCO +55 (0) 11 70 84 91 11

Canada ABB Inc. SAINT-LAURENT +1800 865 7628

China ABB China Ltd BEIJING +86 40 08 10 88 85 - 24h service

Czech Republic ABB S.R.O. PRAHA +42 02 34 32 23 60

Finland ABB Oy Service KUUSANKOSKI +35 8 10 22 51 00

Finland ABB Oy Product Service HELSINKI +35 8 10 22 20 00

Finland ABB Oy Service NOKIA +35 8 10 22 51 40

France

Germany ABB Process Industries MANNHEIM +49 18 05 22 25 80

Greece ABB SA METAMORPHOSSIS +30 69 36 58 45 74

Ireland ABB Ireland Ltd. TALLAGHT +35 3 14 05 73 00

Italy ABB MILAN +39 02 90 34 73 91

Korea, Republic ABB Ltd., Korea CHONAN +82 (0) 4 15 29 22

Malaysia ABB Malaysia Sdn. Bhd. KUALA LUMPUR +60 3 56 28 42 65

Mexico ABB Sistemas S.A. DE C.V. TLALNEPANTLA +52 53 28 14 00

Netherlands ABB B.V. ROTTERDAM +31 1 04 07 88 66

New Zealand ABB Service ltd AUCKLAND +64 92 76 60 16

Poland ABB Centrum IT Sp.zo.o

Russia ABB Automation LLC MOSCOW +74 95 96 0

Switzerland ABB AG DÄTTWIL +41 5 85 86 87 86

Singapore ABB Industry Pte Ltd SINGAPORE +65 67 76 57 11

Slovakia ABB Elektro s.r.o. BANSKA BYSTRICA +42 19 05 58 12 78

South Africa ABB South Africa (Pty) Lt JOHANNESBURG +27 1 16 17 20 00

Spain ABB Automation Products BARCELONA +34 9 37 28 73 00

Taiwan ABB Ltd. TAIPEI 105 +88 62 25 77 60 90

Thailand ABB Limited SAMUTPRAKARN +66 27 09 33 46

Turkey ABB Elektirk Sanayi A.S ISTANBUL +90 2 16 36 52 90

USA ABB Industrial Products NEW BERLIN

Venezuela ABB S.A. CRCS +58 (0) 22 38 24 11 / 12

ABB Automation

ABB Process Industry

MONTLUEL from abroad

France

WROCLAW

LODZ

+32 27 18 64 86

+32 27 18 65 00 - 24h service

+33 1 34 40 25 81

+0810 02 00 00

+48 42 61 34 96 2

+48 42 29 93 91 39 5

+1 26 27 85 32 00

+1 262 435 7365

3ADW000191R0500 DCS800 Quick guide edisf e

3

Page 4

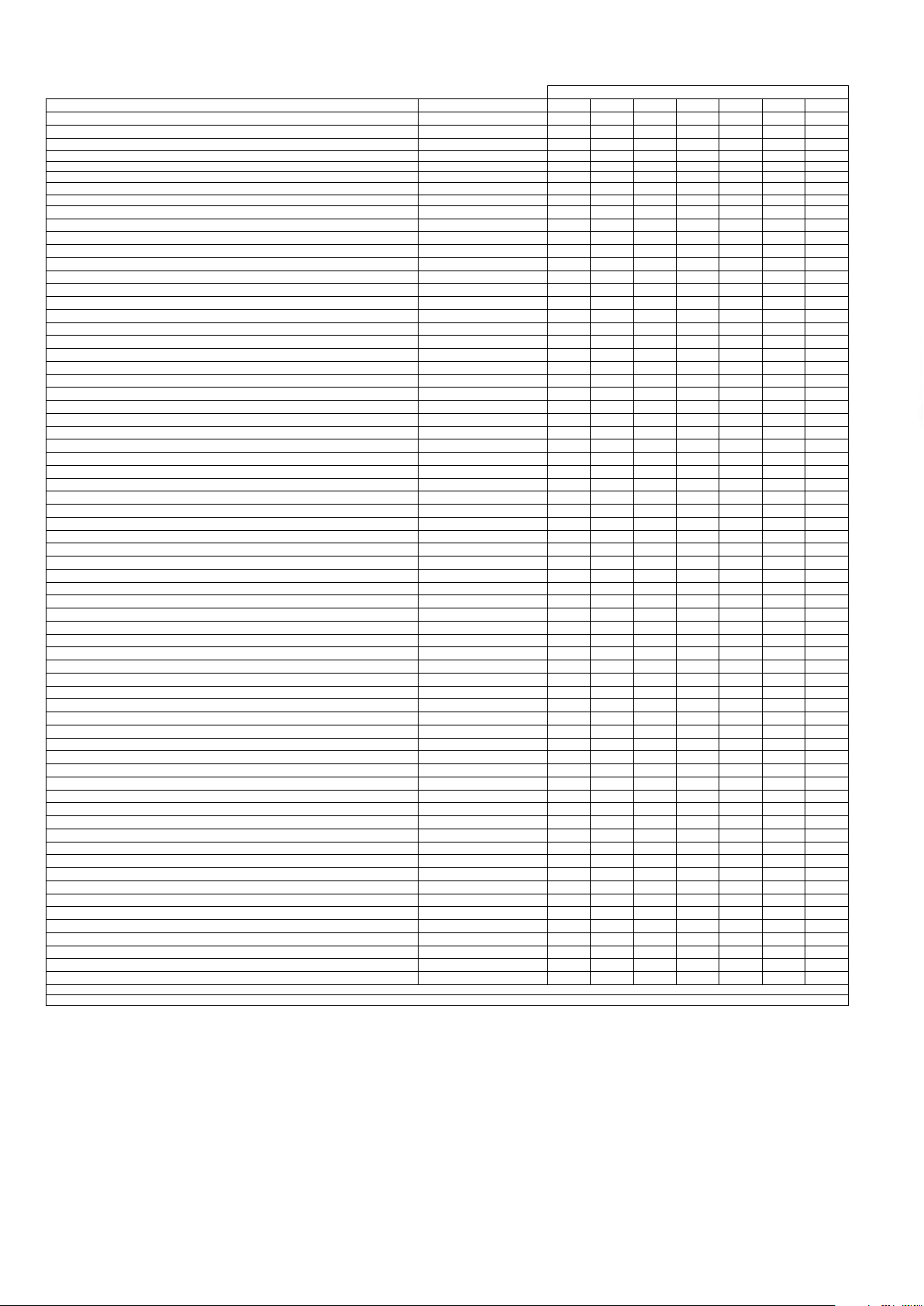

DCS800 Drive Manuals

DCS800 Quick Guide

DCS800 Tools & Documentation CD

DCS800 Converter module

Flyer DCS800 3ADW000190 x x x x x x x

Technical Catalogue DCS800 3ADW000192 x x x x x x x

Hardware Manual DCS800 3ADW000194 x x p x x x x

Hardware Manual DCS800 update DCF503B/DCF504B 3ADW000194Z0301 x

Firmware Manual DCS800 3ADW000193 x x p x p x x

Installation according to EMC 3ADW000032 x

Technical Guide 3ADW000163 x

Service Manual DCS800 3ADW000195 x x

12-Pulse Manual 3ADW000196 x

CMA-2 Board 3ADW000136 p

Flyer Hard - Parallel 3ADW000213 x

Drive Tools

DriveWindow 2.x - User's Manual 3BFE64560981 x

DriveOPC 2.x - User's Manual 3BFE00073846 x

Optical DDCS Communication Link 3AFE63988235 x

DDCS Branching Units - User´s Manual 3BFE64285513 x

DCS800 Applications

PLC Programming with CoDeSys CoDeSys_V23 x x x

61131 DCS800 target +tool description - Application Program 3ADW000199 x

DCS800 Crane Drive

DCS800 Crane Drive Manual suppl. 3AST004143 x

DCS800 Crane Drive Product note PDC5 EN REVA p

DCS800 Winder ITC

DCS800 Winder Product note PDC2 EN x

DCS800 Winder description ITC 3ADW000308 x

Winder Questionnaire 3ADW000253z x

DCS800-E Panel Solution

Flyer DCS800-E Panel solution 3ADW000210 x

Hardware Manual DCS800-E 3ADW000224 x

DCS800-A Enclosed Converters

Flyer DCS800-A 3ADW000213 x

Technical Catalogue DCS800-A 3ADW000198 x

Installation of DCS800-A 3ADW000091 p

DCS800-R Rebuild System

Flyer DCS800-R 3ADW000007 x x

DCS800-R Manual 3ADW000197 x

DCS500/DCS600 Size A5...A7, C2b, C3 and C4 Upgrade Kits 3ADW000256 x

Extension Modules

RAIO-01 Analogue IO Extension 3AFE64484567 x

RDIO-01 Digital IO Extension 3AFE64485733 x

AIMA R-slot extension 3AFE64661442 x

Serial Communication

Drive specific serial communication

NETA Remote diagnostic interface 3AFE64605062 x

Fieldbus Adapter with DC Drives RPBA- (PROFIBUS) 3AFE64504215 x

Fieldbus Adapter with DC Drives RCAN-02 (CANopen)

Fieldbus Adapter with DC Drives RCNA-01 (ControlNet) 3AFE64506005 x

Fieldbus Adapter with DC Drives RDNA- (DeviceNet) 3AFE64504223 x

Fieldbus Adapter with DC Drives RMBA (MODBUS) 3AFE64498851 x

Fieldbus Adapter with DC Drives RETA (Ethernet) 3AFE64539736 x

x -> existing p -> planned

Status 10.2008

DCS800 Drive Manuals-List_h.doc

Public. number E D I ES F CN RU

3ADW000191 x x x x x

3ADW000211 x

Language

4

3ADW000191R0500 DCS800 Quick guide edisf e

Page 5

english

Standard Features

• compact

• highest power ability

• simple operation

• comfortable assistants, e.g. for autotuning or commissioning

• scalable to all applications

• free programmable by means of integrated IEC61131-PLC

3ADW000191R0500 DCS800 Quick guide edisf e

5

Page 6

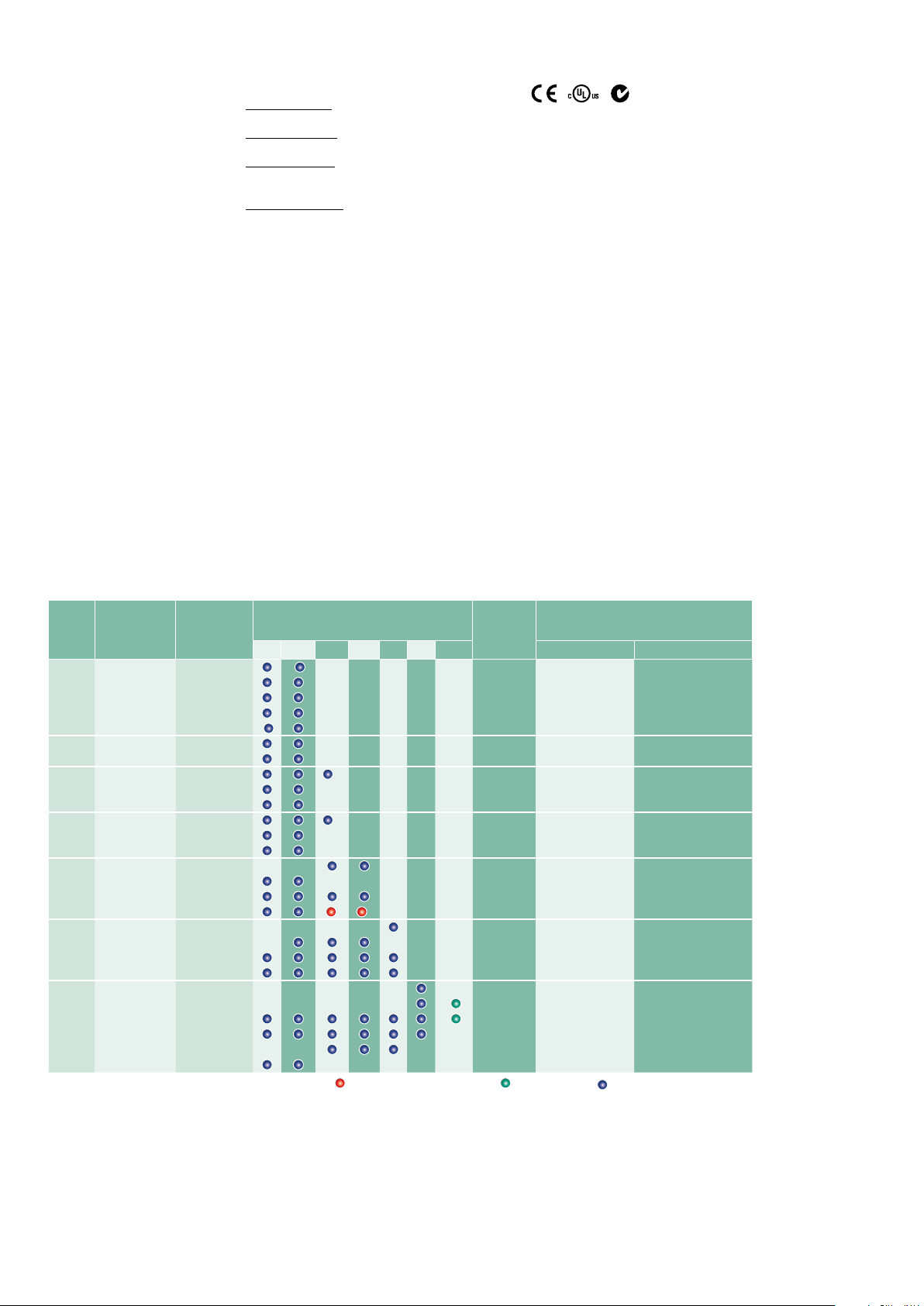

DCS800 DC Drives

Technical data

Mains supply volt. 230...1,200 V,

+/–10 %, 3~

Frequency 50...60 Hz, +/–5

Hz

Electronics supply 115...230 V,

–15 % / +10 %, 1~

DC Output current 20...5,200 A

Overload capability 200 %

Ambient conditions

Ambient temperat. 0° ... +40° C

40° ... 55°C with

reduction

Storage temperat. –40° ... +55° C

Transport temper. –40° ... +70° C

Relative humidity 5 ... 95 %, not

condensing

(max. 50 % betw.

0°...5° C)

Pollution degree Class 2

Protection class IP 00

Altitude < 1,000 m height

above sea level:

nominal Current

> 1,000 m height

above sea level:

with reduction

I/O

Digital inputs: 8 standard, up to

14 optional

Digital outputs: 8 standard, up

to 12 optional

Analog inputs: 4 standard +/–

10 V; 0/2…10 V, up to 8 optional

+/ 20 mA; 0/4…20 mA

Analog outputs: 3 standard (1x

I

) +/-10 V; 0/2…10 V, up to 7

act

optional –20 mA; 0/4…20 mA

PC-Tools

DriveWindow Light: free of

charge with every converter,

Standard RS232 PC-connection

DriveWindow: Real-time optical

connection

ControlBuilder DCS800:

IEC61131 programming tool

DriveSize: Converter- and motor

dimensioning

Maintenance / Diagnosis

Remote diagnosis with any

Internet-PC worldwide

• with internet browser / internet

explorer

• or with DriveWindow full drive

control via OPC

Approvals

Adaptive Programming

pre-defined drive-specific

function blocks, e.g.

• Free process controller (PIController)

• I/O- and digital Operations

With control panel or PC-Tool, no

need for additional hardware

Speed Feedback

EMF

Analogue tacho

Encoder

2nd Encoder possible (RTAC)

Communication

Serial communication

• Ethernet • Profibus

• CANopen • DeviceNet

• ControlNet • DDCS

• Modbus

• CS31 • AF100

• Selma2

Industrial IT© enabled

DCSLink Peer-to-Peer

• up to 800 kBaud, < 2.5 ms

• Master-Follower

• Armature-fieldconverter

• Free selectable data

High Current Solutions

• 12-pulse up to 20,000 A, serial

and parallel

• Hard parallel and sequential

• up to 1,500 V

Protections

Speed feedback monitoring •

Temperature • Overload • Over

speed • Motor stalled • Motor

over current • Motor over voltage

• Field over current • Field over

voltage • Minimum field current

• Zero speed • Armature current

ripple • Mains over- and under

voltage

Integrated IEC 61131-PLC

• Open standard programming

tool ControlBuilder DCS800

• Support of all five IEC-

languages

• Drive-specific function blocks

• Saving of program and source

in Memory Card

• Online debugging and forcing

Current ratings, dimensions

Unit size 2-Q

rated Current

DCS800-01

IDC[A] IDC[A] 400 525 600 690 800 990 1200 [ADC] h x w x d [mm] h x w x d [inch]

D1 20 25

45 50

65 75

90 100

125 140

D2

180 200

230 260

D3 315 350

405 450

470 520

D4 610 680

740 820

900 1000

D5 900 900 25 1050 x 510 x 410 41.35 x 20.10 x 16.15

1200 1200

1500 1500

2000 2000

D6 1900 1900

2050 2050

2500 2500

3000 3000

D7 2050 2050

2600 2600

3300 3300

4000 4000

4800 4800

5200 5200

4-Q

rated Current

DCS800-02

Supply voltage

[V

]

AC

3)

3)

1)

1)

2)

1)

only available as 2-Q drive

2)

max. field

Dimensions

current

internal

6 370 x 270 x 200 14.56 x 10.65 x 7.90

15 370 x 270 x 270 14.56 x 10.65 x 10.65

20 459 x 270 x 310 18.07 x 10,65 x 12,25

25 644 x 270 x 345 25.35 x 10.65 x 13.60

external field

1750 x 460 x 410 68.90 x 18.15 x 16.15

35A, 1~/3~

50/60A, 1~

520A, 3~

external field

35A, 1~/3~

1750 x 760 x 570 68.90 x 29.95 x 22.45

50/60A, 1~

520A, 3~

2)

on request

3)

600V

2-Q -> 290 A / 590 A

4-Q -> 320 A / 650 A

6

3ADW000191R0500 DCS800 Quick guide edisf e

Page 7

Brief instructions for CD and documents overview

We appreciate that you purchased an ABB DC drive

power converter and thank you for the trust you put in our

products.

This brochure was put together to make sure that you continue

to be satisfied with our product. It is intended to provide you

with a brief overview of the product's key data, EMC notes,

typical applications, start-up and trouble-shooting.

If you need more information about the product you are

provided with a CD-ROM in addition to this brief documen-

tation. The CD-ROM is part of this document and features

the following contents:

System requirements to use the CD-ROM

• Operating system WINDOWS 2000, XP

• ACROBAT READER 4.0 is

sufficient (we recommend

8.0 - included on the CDROM)

In case the CD ROM does not start automatically please

double-click on Setup.exe.

english

Documentation

Our documentation is basically structured according to the

following system:

Technical catalogue (3ADW000192)

as comprehensive information to engineer complete DC

drive systems.

Hardware manual (3ADW000194)

as detailed information, with all important particulars about

the individual components, like module dimensions, electronic

boards, fans and auxiliary components.

Information for mechanical and electrical installation are

also included.

Firmware Manual (3ADW000193)

detailed information with all important issues about firmware

and setting of parameters. The manual includes information

for start-up and maintenance of the entire drive, in detailed

form.

This manual also includes Fault and Alarm codes and information for trouble shooting.

Service Manual (3ADW000195)

for maintenance and repair of the converters.

Further support

In addition we offer further support, since we can only be

satisfied when you, as our customer, are satisfied with us

and our products.

Internet

On the ABB homepage under

www.abb.com/dc

you'll find abundant information for

• DC products

• service support

• the latest updates

• tools

• downloads, etc.

Please don't hesitate to visit us.

Contacts

If you require any further information, please contact your

nearest ABB Drives office or send an email to:

DC-Drives@de.abb.com

Please give us your name, your company address and

phone number. We immediately put you in contact with our

specialist.

Applications

DCS800 DC Drive can include application software e.g.

cranes, winders. In such case following procedures and

assistants can be blocked or not completed. Please check

for further documentation and manuals (check parameter

4.03, 83.01).

Additional information about applications (e.g. 12-pulse)

and technical accessories (e.g. Hardware extension or

Field bus interfaces) are handled by separate manuals. See

table DCS800 Drive manuals.

3ADW000191R0500 DCS800 Quick guide edisf e

7

Page 8

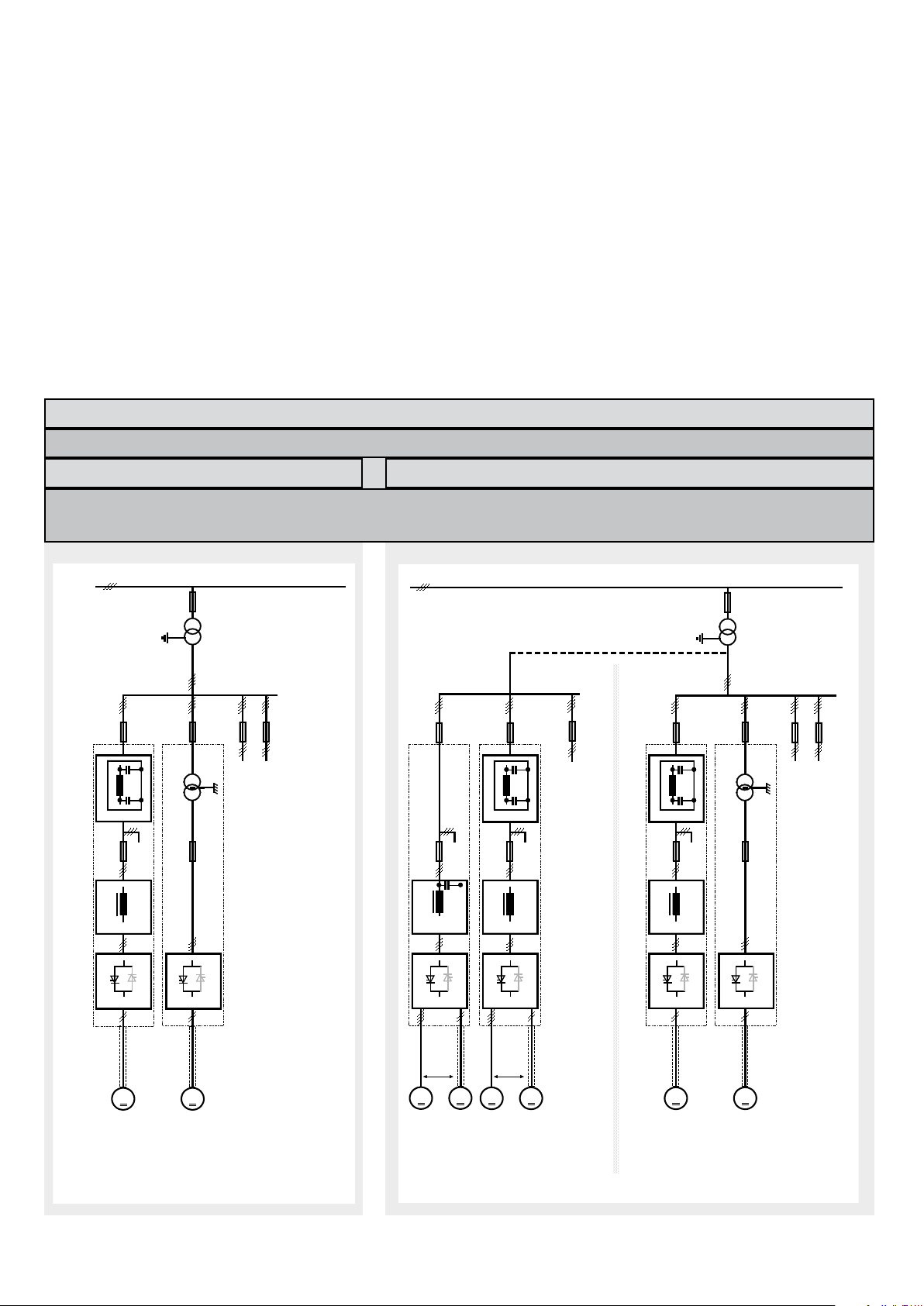

Notes on EMC

MM

Mains filter

Converter

Line reactor

Supply transformer for a residential

area (rating normally ≤ 1,2 MVA)

Earthed public 400-V

network with neutral

conductor

Medium-voltage network

Earthed

neutral

To other loads, e.g. drive systems

An isolating transformer

with an earthed screen

and earthed iron core

renders mains filter and

line reactor superfluous.

Operation at public

low-voltage network

together with other

loads of all kinds.

Residential area

To other loads which have to be protected from the system disturbances caused by

power converters (HF interference and commutation notches)

Converter

MM

MM

MM

alternative

alternative

Line reactor +

Y-capacitor

Medium-voltage network

Supply transformer for a residential

area (rating normally ≤ 1.2 MVA)

Earthed

neutral

Earthed public 400-V

network with neutral

conductor

To other loads, e.g. drive systems

Mains filter

Line reactor

Converter Converter

Mains filter

Line reactor

Converter Converter

An isolating transformer

with an earthed screen

and earthed iron core

renders mains filter and

line reactor superfluous.

Operation at public

low-voltage network

together with other

loads of all kinds.

To other loads, e.g. drive systems

To other loads which have to be protected from the system disturbances caused by

power converters (HF interference and commutation notches)

Earthed public 400-V

network with neutral

conductor

Operation at public

low-voltage network

together with other

loads of all kinds.

Light industry

Residential area

Commutaion notches < 20%

You will find further information in publication:

Technical Guide chapter:

EMC Compliant Installation and Configuration for

a Power Drive System

Not applicable

The paragraphs below describe selection of

the electrical components in conformity with

the EMC Guideline.

The aim of the EMC Guideline is, as the name

The EMC Guideline expects EMC to be taken

into account when a product is being developed;

however, EMC cannot be designed in, it can only

be quantitatively measured.

implies, to achieve electromagnetic compatibility with other products and systems. The

guideline ensures that the emissions from

the product concerned are so low that they

do not impair another product‘s interference

immunity.

In the context of the EMC Guideline, two

Note on EMC conformity

The conformity procedure is the responsibility of

both the power converter‘s supplier and the manu-

facturer of the machine or system concerned, in

proportion to their share in expanding the electrical

equipment involved.

aspects must be borne in mind:

• the product‘s interference immunity

• the product‘s actual emissions

First environment (residential area with light industry) with PDS category C2

Not applied, since category C1 (general distribution sales channel) excluded

satisfied

satisfied

8

3ADW000191R0500 DCS800 Quick guide edisf e

Page 9

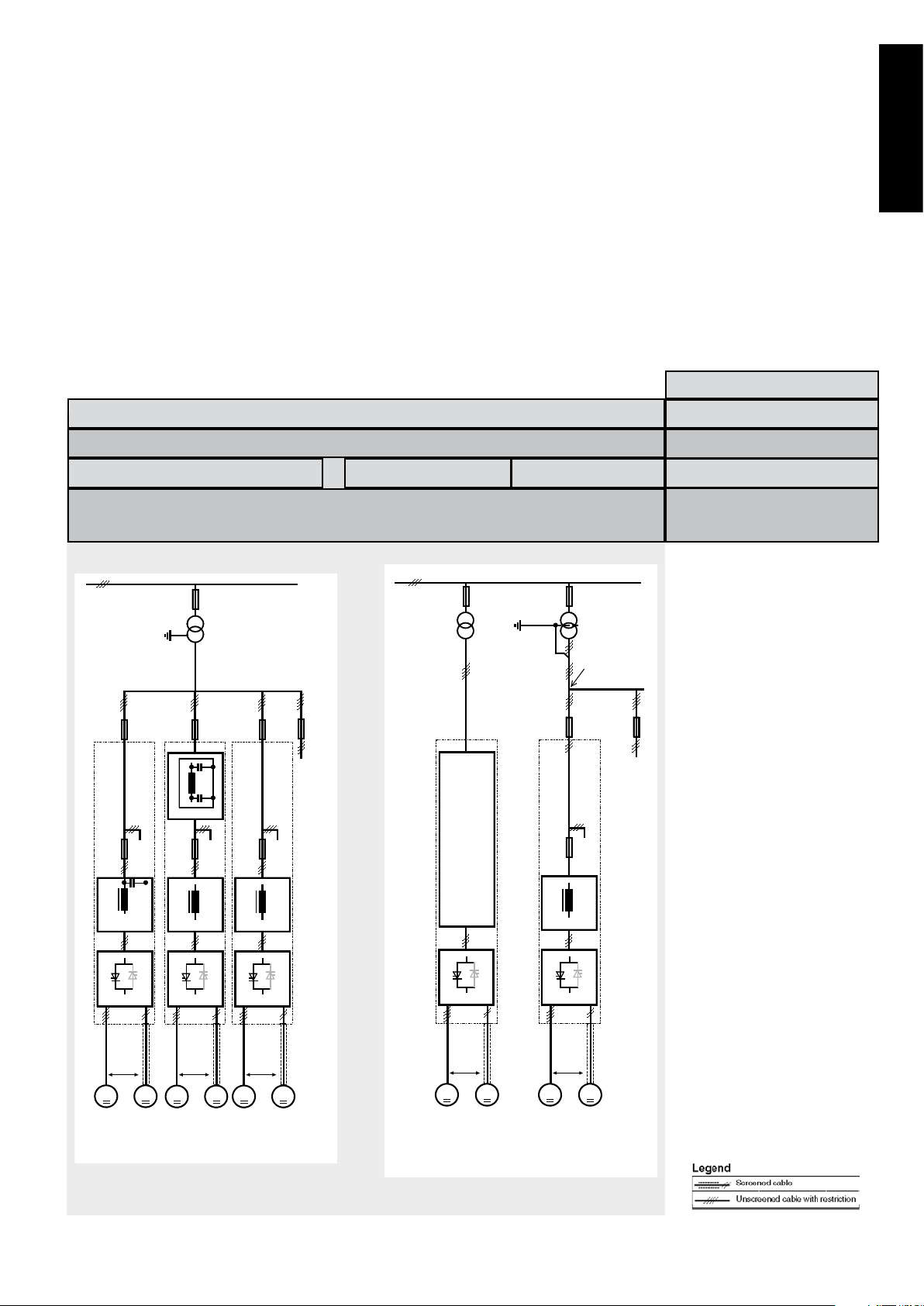

For compliance with the protection objectives

MMMM

emv_clssif_b.dsf

Converter

transformer

Case-referenced EMC analysis

alternative

Converter

transformer

with earthed

iron core

(and earthed

screen where

appropriate)

alternative

I > 400 A

and/or

U > 500 V

Operation with separate power converter transformer. If there

are other loads at the same secondary winding, these must be

able to cope with the commutation gaps caused by the power

converter. In some cases, commutating reactors will be

required.

To other loads, e.g. drive systems

Converter Converter

Line reactor

Medium-voltage network

Industrial

zone

MM

MM

MM

I

DC

< 100 A

I

DC

< 100 A

I

DC

>100 A

Supply transformer for a

residential area (rating

normally ≤ 1.2 MVA)

Earthed 400-V network

with neutral conductor

;

3~ ≤ 400 A

Operation at low-voltage network together with

other loads of all kinds, apart from some kinds

of sensitive communication equipment.

To other loads, e.g. drive systems

Line reactor +

Y-capacitor

Line reactor

Converter Converter

Mains filter

Earthed

neutral

Medium-voltage network

Industrial zone

alternative

alternative

Line reactor

Converter

alternative

Commutation notches < 40%

of the German EMC Act (EMVG) in systems and

machines, the following EMC standards must

be satisfied:

Product Standard EN 61800-3

EMC standard for drive systems (PowerDrive-

System), interference immunity and emissions

in residential areas, enterprise zones with light

industry and in industrial facilities.

This standard must be complied with in the EU

for satisfying the EMC requirements for systems

and machines!

Second environment (industry) with PDS categories C3, C4

For emitted interference, the following apply:

EN 61000-6-3 Specialised basic standard for emissions in light industry

can be satisfied with special features (mains filters, screened

power cables) in the lower rating range *(EN 50081-1).

EN 61000-6-4 Specialised basic standard for emissions in industry

*(EN 50081-2)

For interference immunity, the following apply:

EN 61000-6-1 Specialised basic standard for interference immunity in

residential areas *(EN 50082-1)

EN 61000-6-2 Specialised basic standard for interference immunity in in-

dustry. If this standard is satisfied, then the EN 61000-6-1

standard is automatically satisfied as well *(EN 50082-2).

* The generic standards are given in brackets

Standards

EN 61800-3

english

Not applicable

satisfied

on customer's request

satisfied

PDS category C3 PDS category C4

satisfied

EN 61000-6/3

EN 61000-6/3

EN 61000-6-2

EN 61000-6-1

Classification

The following overview utilises the

terminology and indicates the action required in accordance with

Product Standard

EN 61800-3

For the DCS800 series, the limit

values for emitted interference

are complied with, provided the

measure indicated is carried

out. PDS of category C2 (formerly restricted distribution in

first environment) is intended to

be installed and commissioned

only by a professional (person

or organization with necessary

skills in installing and/or commissioning PDS including their

EMC aspects).

For power converters without

additional components, the following warning applies:

This is a product of category C2

under IEC 61800-3:2004. In a

domestic/residential environment

this product may cause radio

interference in which case supplementary mitigation measures

my be required.

The field supply is not depicted

in this overview diagram. For the

field current cables, the same

rules apply as for the armaturecircuit cables.

3ADW000191R0500 DCS800 Quick guide edisf e

9

Page 10

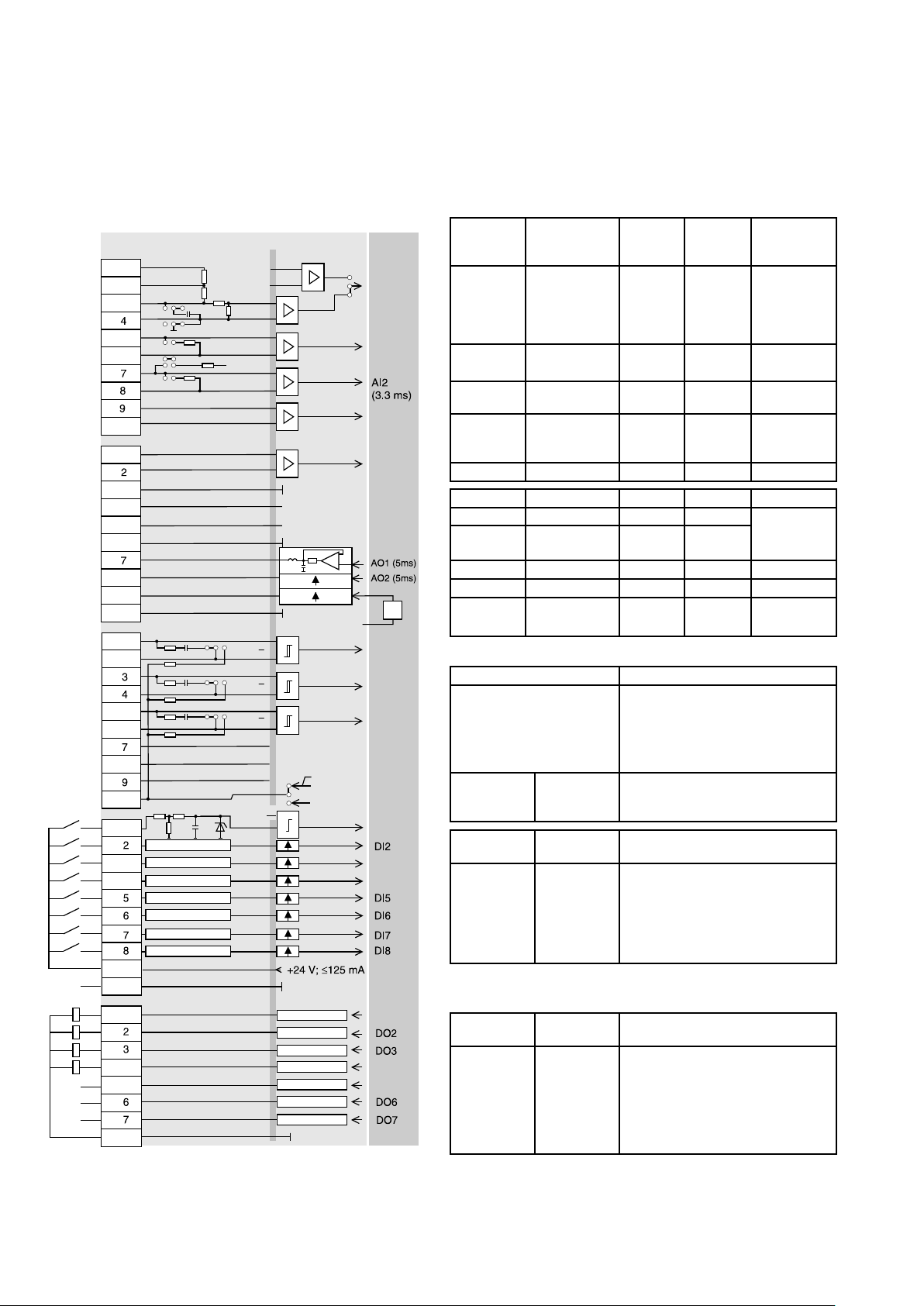

X2:

X1:

ATACH

±90...±270 V

±

30...±90 V

±

8...±30 V

AI4

(5 ms)

GND

GND

39k2

+10V

Power

Sense 0 V

Sense 5 V

AI3

(5 ms)

AI1

(3.3 ms)

+/- I-act

47.5

100

µ

100n

GND (AOx)

+10V

GND

-10V

DI1

DI3

DI4

DO4

DO5

DO1

4k75

3

4

5

6

9

X6:1

3

4

10

4

5

1

2

3

6

5

10

8

9

10

5

2

6

8

10

8

X3:1

X4:1

X5:1

X7:

SDCS-CON-4

Firmware

GND

1

3

S1

Con4_I_O-b.dsf

12k8

5k

1k66

+

-

4

6

S1

S2

3

4

250

S3

56

78

S3

3

4

250

+

-

SDCS-IOB-3

(PS5311)

9

8

7

ATACH1

ATACH2

S1

+

-

+

-

+

-

+

-

GND

1

3

S4

2

121

100nF

4

6

S4

5

121

100nF

7

10

S4

8

121

100nF

10k

10k

10k

+

-

+

-

+

-

PIN-4

= 5 V

S4

11

12

2k21 221k

4k75

47nF

Z15

+

-

5 V

Relay driver

Relay driver

Relay driver

Relay driver

Relay driver

Relay driver

Relay driver

X

9

τ

= 10 ms

τ

= 10 ms

τ

= 10 ms

τ

= 10 ms

τ

= 10 ms

τ

= 3.3 ms

τ

= 3.3 ms

ChA

ChB

ChZ

ChA

ChB

ChZ

POW-4

=

5V/

15V/24V

CON-4

= 24 V

Resolution

[bit]

Encoder supply

Input value

Signal

definition by

Output value

Signal

definition by

Standard function assignments for the terminals

10

3ADW000191R0500 DCS800 Quick guide edisf e

Input/output

values

Hardware

15 + sign ±90...270 V

±30...90 V

ScalingbyCommon

mode

range

①

±15 V

Firmware

Remarks

±8...30 V

15 + sign -10...0...+10 V Firmware ±15 V

15 + sign -10...0...+10 V Firmware ±15 V

15 + sign -10...0...+10 V Firmware ±15 V

15 + sign -10...0...+10 V Firmware ±15V

Power

+10 V ≤ 5 mA

-10 V ≤ 5 mA

for ext. use

e.g. refer. pot.

11 + sign -10...0...+10 V Firmware ≤ 5 mA

11 + sign -10...0...+10 V Firmware ≤ 5 mA

-10...0...+10 V Firmware+

Hardware

≤ 5 mA

8 V -> min. of

325% of [99.03] or

230% of [4.05]

Remarks

Inputs not isolated

Impedance = 120 W, if selected

max. frequence ≤ 300 kHz

5 V

24 V

≤ 250 mA

≤ 250 mA

Sense lines for GND and supply

to correct voltage drops on cable

(only if 5 V encoder is in use).

Remarks

0...7.3 V

7.5...50 V

Firmware

-> “0“ status

-> “1“ status

Remarks

50 * mA

22 V at no

load

Firmware

Current limit for all 7

outputs = 160 mA

Do not apply any reverse

voltages!

* short circuit protected

① gain can be varied in 15 steps between 1 and 4 by software parame-

ter

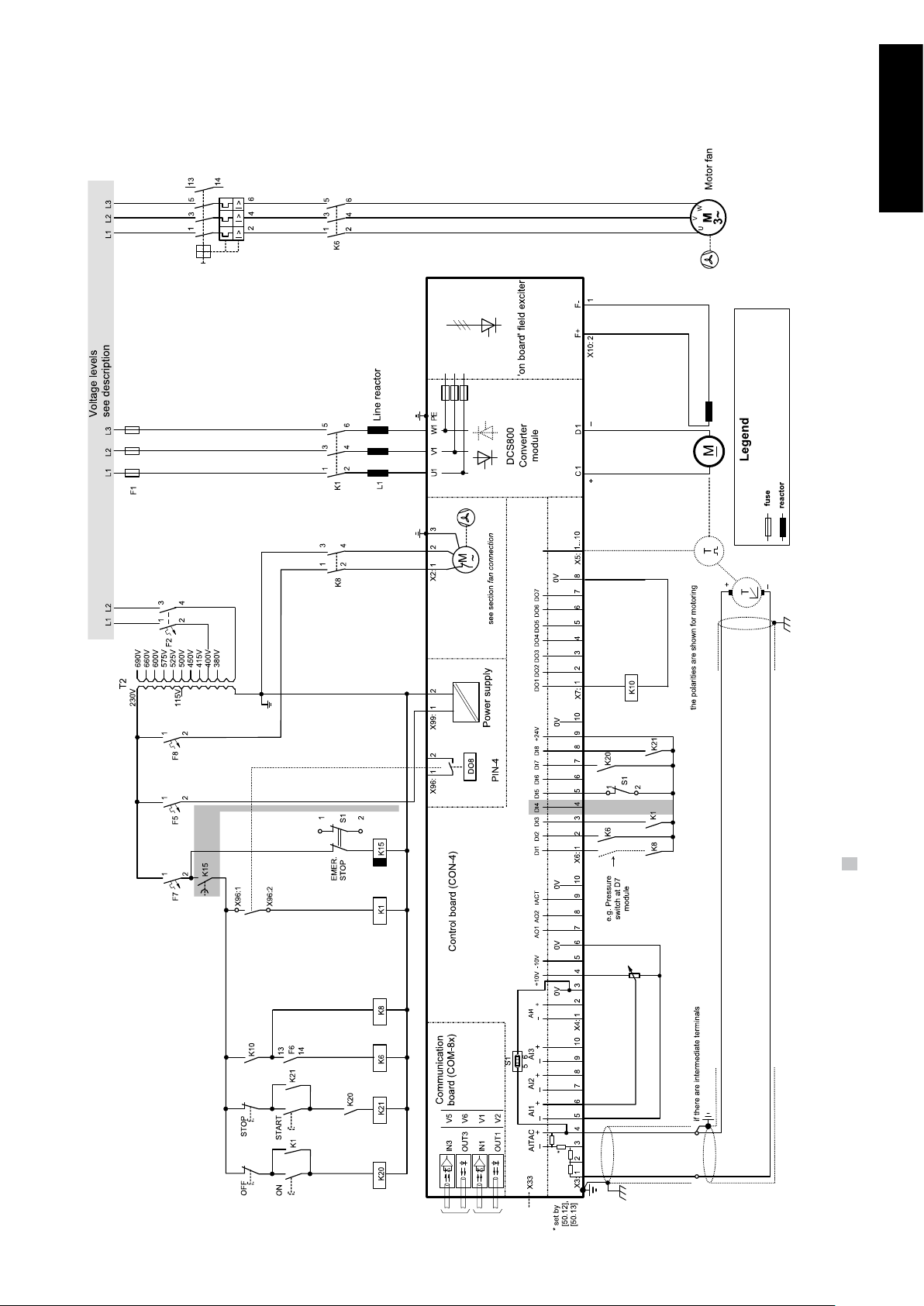

Page 11

F6

DCS8_ans_1_1d.dsf

Connection example

Converters D1...D4 drive configuration using ‘OnBoard‘ field exciter

Terminal selection according FACTORY macro (default)

english

3ADW000191R0500 DCS800 Quick guide edisf e

further information see the following page

11

Page 12

ON

RUN

RESET

MCW (7.01)

ON

RUN

RESET

ON

RUN

RESET

7.04

gen_ctrl_cmd_a.dsf

USED MCW

HW I/O

command

location (10.01)

PC tool or panel

local /

remote

used

Main Control Word

START, STOP and E-STOP control

K16

K15 K16

K15

DI4

K15

X6:9

CON-4

S1

1

2

Anschl_special_a.dsf

EMER.

STOP

ELEC.

DISCONN.

Block

current

command

Timer K15

Timer K16

Stop-Mode_a.dsf

E-STOP

speed

Block current control

K1 main contactor

E-Stop ramp Coast

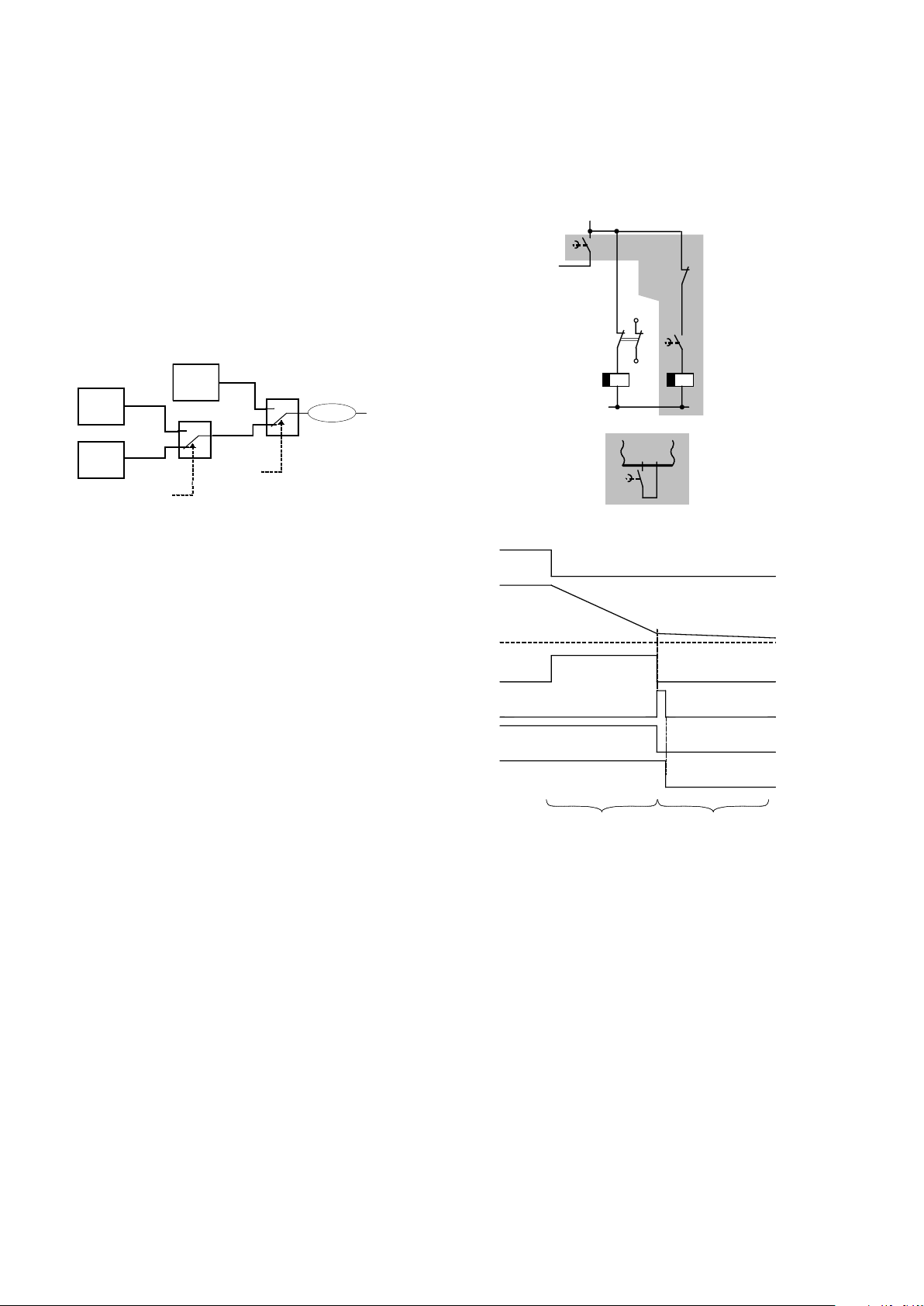

The relay logic can be split into three parts:

a: Generation of the ON/OFF and START/STOP com-

mand:

The commands represented by K20 and K21 (latching interface relay) can be e.g. generated by a PLC and transferred to

the terminals of the converter either by relays, using galvanic

isolation or directly via 24V signals.

These commands can be as well transferred via serial

communication. Even a mixed solution can be realized by

selecting different possibilities for the one or the other signal

(see parameter group 11).

b: Generation of control and monitoring signals:

The main contactor K1 for the armature circuit is controlled

by a dry contact (DO 8) located on the SDCS-PIN-4. Status

of fans and fans klixon can be monitored by means of fan

ack signals: MotFanAck (10.06) and ConvFanAck (10.20).

If the drive has not finished the function within the K15 timer

setting, the drive must get the command to switch OFF the

current via K16. After K16 timer set has elapsed the main

contactor is opened independent of the drives status.

c: OFF2, OFF3 Stop function:

Beside ON/OFF and START/STOP, the drive is equipped

with two additional stop functions, OFF2 and OFF3, according to Profibus standard. OFF3 is a scalable stop function

(rampstop, max torque stop, dynamic braking …) to perform

stop category 1. This function should be connected to the

E-STOP button without any time delay. In case of ramp stop

selection the, K 15 timer relay must be set longer than the

EStopRamp (22.04). For COAST selection, the drive opens

the main contactor immediately.

OFF2 switches off DC current as fast as possible and prepares the drive for opening main contactor or drop down

mains supply. For a normal DC motor load the time to switch

OFF the DC current is below 20 ms. This function should be

connected to all signals and safety functions opening the main

contactor. This function is important for 4-quadrant drives.

Do not open main contactor during regenerative current.

The correct sequence is

1. switch off regenerative current

2. then open the main contactor

In case of the E-STOP is hit, the information is transferred

to the converter via digital input 5. In case of rampstop, or

max torque selection the converter will decelerate the motor

and then open main contactor.

12

3ADW000191R0500 DCS800 Quick guide edisf e

E-Stop reaction

Page 13

Fan power connection

1 2 3

X2:

4 5

L

N

230 Vac

1 2 3

X2:

4 5

L

N

115 Vac

M

~

1 2 3

X2:

M

~

4 5

M55 M56

M

~

1 2 3

X2:

M

~

4 5

M55 M56

M

~

M

~

M57 M58

M55

M

~

1 2 3 4 5

X2:

L

N

L

N

1 2 3

X2:

4 5

L

N

230 Vac

1 2 3

X2:

4 5

L

N

115 Vac

ϑ

230 VAC

or

115 VAC with Pluscode +S171

DCS8 fan conn D1-D4.dsf

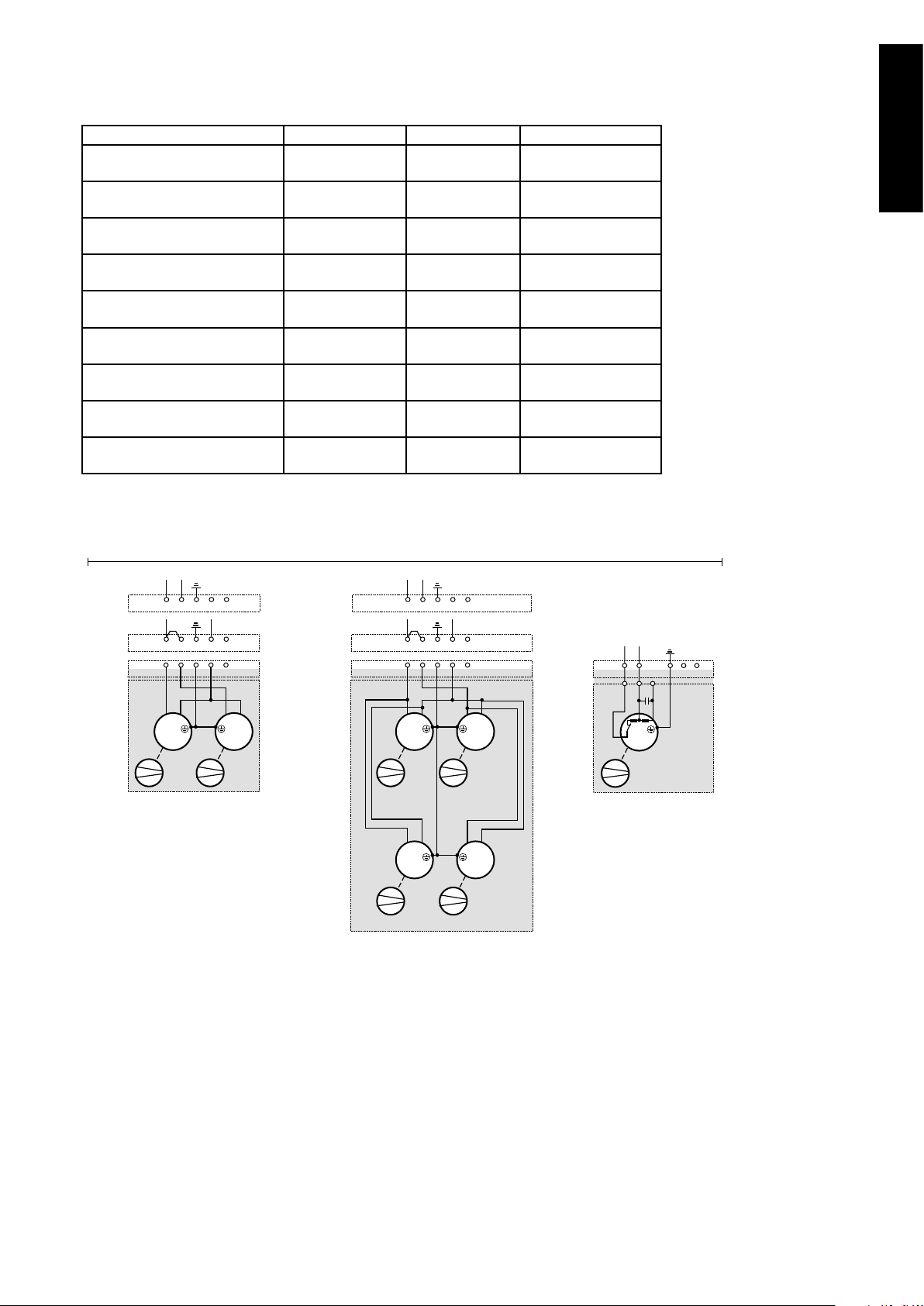

Fan assignment for DCS800

Converter type Model Configuration Fan voltage

DCS800-S01-0020-04/05...

DCS800-S02-0025-04/05

DCS800-S0x-0045-04/05...

DCS800-S0x-0140-04/05

DCS800-S0x-0180-04/05...

DCS800-S0x-0260-04/05

DCS800-S0x-0315-04/05...

DCS800-S0x-0350-04/05

DCS800-S0x-0405-04/05...

DCS800-S0x-0520-04/05

DCS800-S0x-0610-04/05...

DCS800-S0x-0820-04/05

DCS800-S0x-0610-04/05...

DCS800-S0x-0820-04/05

Pluscode S171

DCS800-S0x-0900-04/05...

DCS800-S0x-1000-04/05

DCS800-S0x-0900-04/05...

DCS800-S0x-1000-04/05

Pluscode S171

Fan connection for DCS800

Terminals on top of converter housing

D1 - no fan

D1 1 115 or 230 VAC

D2 1 115 or 230 VAC

D3 1 115 or 230 VAC

D3 2 115 or 230 VAC

D4 3 230 VAC

D4

3 115 VAC

D4 3 230 VAC

D4

3 115 VAC

english

Configuration 1

D1- D3

Configuration 2

D3

3ADW000191R0500 DCS800 Quick guide edisf e

Configuration 3

D4

13

Page 14

DCS800 terminal alloc.dsf

X4X3 X5 X6 X7

1 1 1 1 1

2

S5

1

15

6 9

S3

S2

1

X1

X2

X17

2

25

26

1

2

25

26

S4

1

2

1

2

1

2

1

2

H2500

1

2

D2100

1

D2001

D2001

D1000

1 30

1

2

1

2

1

2

1

26

S1

1

42

1

2

3

10

11

12

1

82

1

42

1

2

3

7

8

9

Jumpers shown in default position

1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8

X8

1

42

S2

S1

1

2

3

X51 X52 X53 X54

24V

DCS Link

24V

0V

GND B

CANL

CANH

GND B

CANL

CANH

grey

grey

grey

grey

dark

grey

dark

grey

d

ark

grey

blue

blue

RxD

CH 1

TxD

RxD

CH 2

TxD

RxD

CH 3

TxD

RxD

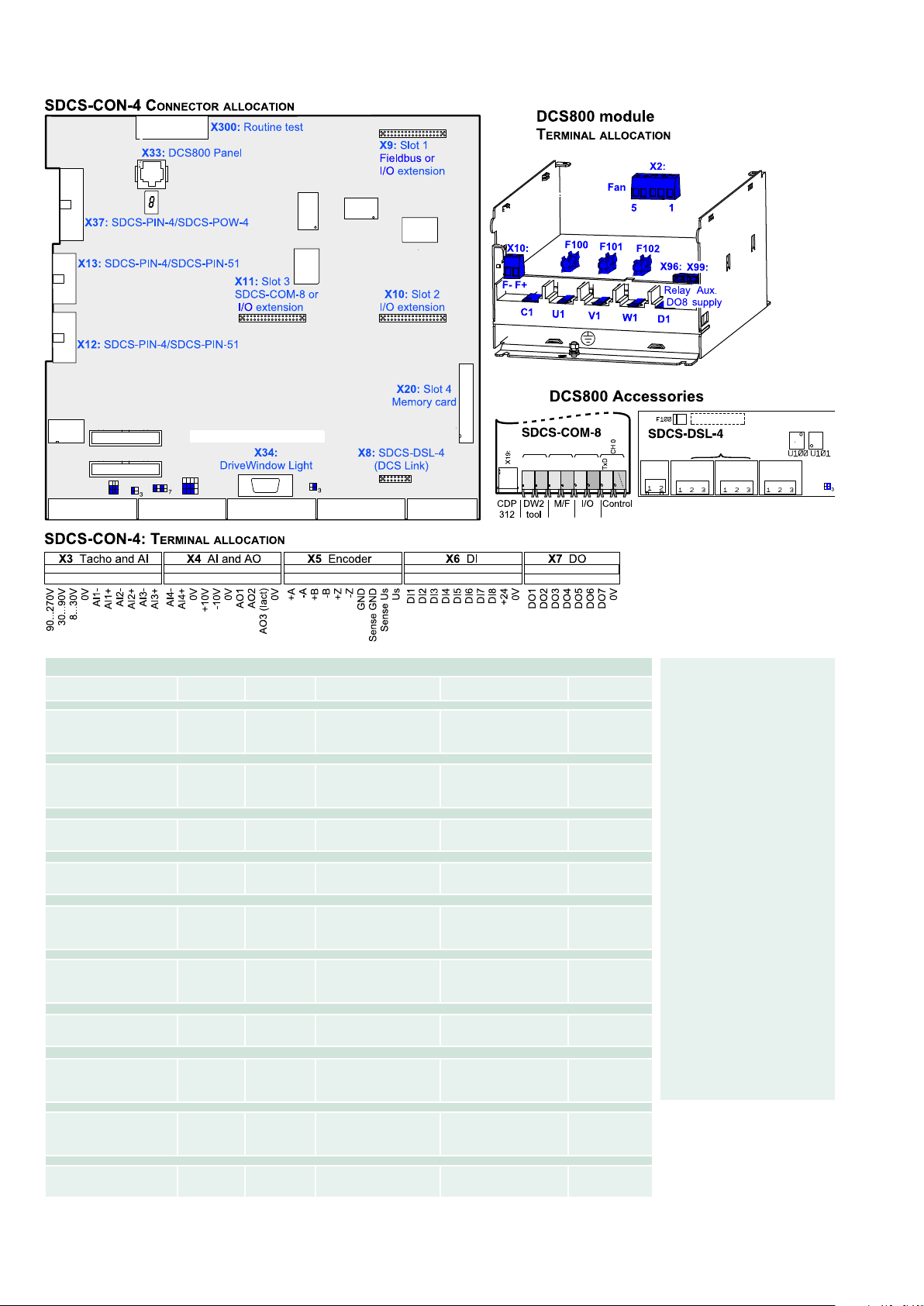

Terminal locations on the converter

Macro finder

DI function

Jog1 --> DI1

Jog2 --> DI2

Ext Fault --> DI 3

Ext Alarm --> DI4

Jog1 --> DI1

Jog2 --> DI2

Ext Fault --> DI 3

Main Cont Ack --> DI4

Fix speed1 --> DI1

Ext Fault --> DI 3

Main Cont Ack --> DI4

Fix speed1 --> DI1

Ext Fault --> DI 3

Ext Alarm --> DI4

Jog1 --> DI1

Jog2 --> DI2

Ext Fault --> DI 3

Ext Alarm --> DI4

Jog1 --> DI1

Jog2 --> DI2

Direction --> DI 3

SpC - KP, KI --> DI4

Control select --> DI2

Reference select --> DI2

Direction select --> DI 3

Motor pot up --> DI1

Motor pot down --> DI2

Direction select --> DI 3

Reference select --> DI4

Direction select --> DI 1

Motor pot up --> DI2

Motor pot down --> DI3

Motor pot minimum --> DI4

OFF2 (coast stop) --> DI1

Torque select --> DI2

Ext Fault --> DI 3

Standard

Macro name

Main

Contactor

ON / OFF

Start/Stop

AC Static

2-wire DC cont. US

DC Static

3-wire DC cont. US

DC Pulse

3-wire Standard

Torque limit

Manual / Const

AC Pulse

AC Static

AC Pulse

Hand / Auto

AC Static

Hand / Mot Pot

AC Pulse

AC Static

AC Static

Motor Pot

Torque Ctrl

Comment DI5 --> ESTOP

Hardware I/O control x

Hardware I/O control x

Hardware I/O control x

Hardware I/O control x

Hardware I/O control

+ Torque limit

Hardware I/O control

select gain

Hardware I/O control

or field bus control

Hardware I/O control

Reference hardware or Motor

potentiometer

Hardware I/O control

Reference Motor potentiometer

Hardware I/O control

Speed control or Torque

reference

DI6 --> Reset

x

x

x

x

x

x

Enabling a macro

Use the

[DCS800Wizard] 2. Macro

assistant of DriveWindow

Light or

Parameter browser, either

through the control panel,

DriveWindow, or DriveWindow

Light.

Use the following parameters:

ApplMacro (99.08) =

Macro selection

Applrestore (99.07) =

YES = execute selection

MacroSel (8.10) =

double check

NOTE

Functions and inputs defined

by macro can be changed later on without restrictions.

NOTE

Macro diagrams see page

93 ...

14

3ADW000191R0500 DCS800 Quick guide edisf e

Page 15

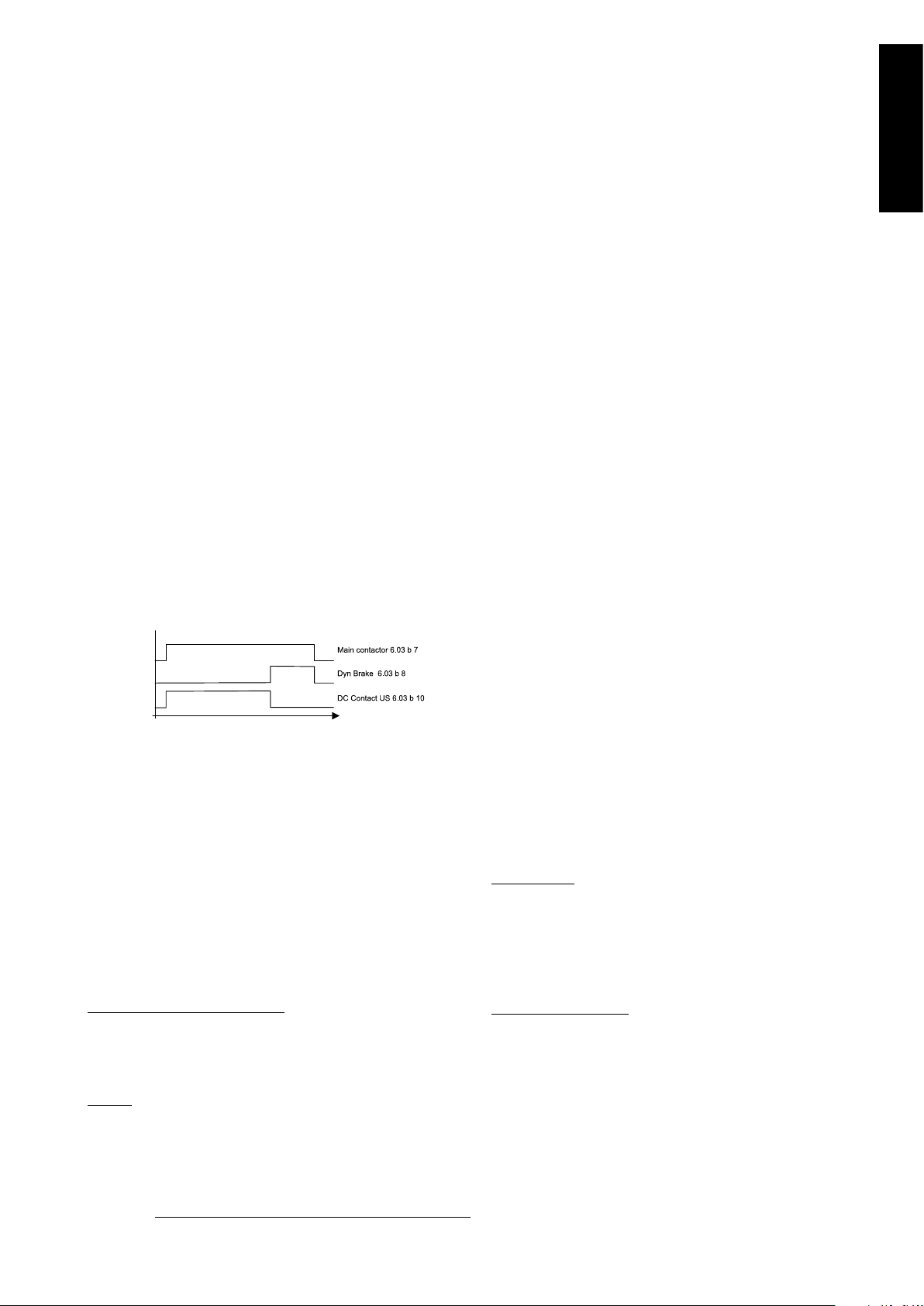

Notes For North American Installations

1. EMC conformity is not usually required in North America. In most cases, the section “Notes on EMC” can be

bypassed. In this manual, you will see references to DIN, EN

and VDE standards. These are European standards and,

generally, do not apply to North America. It is, however,

the responsibility of the user to determine which standards

need to be followed.

2. If using a DC contactor, you must connect an auxiliary

contact to a digital input of your choice and set para. Main-

ContAck accordingly. Set the following parameters:

MainContAck (10.21) = DI-1 (or any input you

choose for the DC cont.

auxiliary contact)

DO8BitNo (14.16) = 10

MainContCtrlMode (21.16) = DCcontact (3)

Set these parameters AFTER macros are loaded but BEFORE

the drive is commissioned.

Digital output 8 (DO-8) must be used to turn the DC

contactor on and off.

DC contactor US:

DC contactor US K1.1 is a special designed contactor with 2x

NO contacts for C1 and D1 connection and 1x NC contact for

connection of Dynamic Brake resistor RB.

The contactor should be controlled by signal 6.03 Bit 10.

The acknowledge can be connected to parameter:

10.21 MainContAck

10.23 DCBreakAck

3. If using Dynamic Braking, the drive allows you to select the stopping method under three different situations.

Parameters 21.02, 21.03 and 21.04 select the stopping

method for loss of

the OnOff, run command (StartStop, Jog1, Jog2, etc.), and

E-Stop input, respectively.

Each can be set to:

• RampStop • TorqueLimit

• CoastStop • DynBraking

In order to command the drive to perform a DB stop, one

or more of these parameters must be set to DynBraking.

Most users will want the drive to ramp stop when OnOff or a

run command (StartStop, Jog1, Jog2, etc.) input is cleared,

and dynamically brake when the E-Stop input is cleared. In

that case, use the following settings:

• Off1Mode (21.02) = RampStop

• StopMode (21.03) = RampStop

• E StopMode (21.04) = DynBraking

However, any case is allowed and the final decision is left

to the user.

Other parameters control stops during faults.

See:

LocalLossCtrl (30.27) ComLossCtrl (30.28)

FaultStopMode (30.30) SpeedFbFltMode (30.36)

If using EMF feedback with dynamic braking, set:

• DynBrakeDly (50.11) = t

Where: t = the time (sec) it normally takes the motor

to stop during dynamic braking

english

Overview of the Installation and Commissioning Process

Step 1:

Check converter for damage. Contact ABB Technical Support

if damage is found. In North America, call 1-800-435-7365

(1-800-HELP-365)

Step 2:

Select supporting hardware for the converter:

For specific recommendations for fuses, reactors, and

contactors, see the DCS800 hardware manual or technical

catalog.

Circuit breaker or disconnect:

Current rating = Idc * 0.816 * 1.25 (min)

= Idc * 0.816 * 2.50 (max)

Where: Idc = nominal DC motor current

Fuses:

AC Line Fuses: To properly protect the converter, semiconductor fuses on the incoming AC power line are required

in all cases.

DC Output Fuses: Fuses between the motor and the

converter are required for all regenerative (4-Q) converters.

This is to protect the motor and converter if a commutation

fault should occur. NOTE: DC output fuses are the same

type and size as AC line fuses.

Line reactor:

All thyristor-based dc converters cause notching in the AC

line due to motor commutation. A properly sized line reactor

will mitigate the effect on the line. Unless the converter uses

a dedicated isolation transformer, each converter requires

its own line reactor.

AC or DC contactor:

A contactor is required to safely disconnect the motor from

the incoming power when the converter is off. The contactor

can be installed between the line and the converter (an AC

contactor) or between the converter and the motor (a DC

contactor). Do not use both.

IMPORTANT: Other equipment may be necessary depending on application and local codes.

3ADW000191R0500 DCS800 Quick guide edisf e

15

Page 16

Step 3:

Mount and wire the converter and supporting hardware inside an industrial enclosure with adequate cooling (DCS800

modules have rating of NEMA type OPEN).

The following control and signal wiring is required:

o If using an AC contactor, we recommend wiring an auxi-

liary contact to the digital input you have designated as

MainContAck (10.21) or Start/Stop (10.16).

o If using a DC contactor, you must wire an auxiliary contact

from the contactor to the digital input you have designated

as MainContAck (10.21).

o Wire 115 or 230 Vac 1-phase power to terminal block 99

for converter control power.

o Wire 1-phase power to converter for cooling fans. See

table and wiring diagrams in this manual.

• D1 – D3 frames: 115/230 Vac selectable. Fan

terminal X2 is on top of the converter.

• D4 frame: If type code includes +S171, use 115

Vac; otherwise use 230 Vac. Fan terminal X2 is

on top of the converter.

o Wire tachometer or encoder to terminal block X3 (tacho)

or X5 (encoder).

o Wire analog inputs (e.g., speed reference) and outputs

(e.g., meters for motor voltage, current) to terminal block

X3 and/or X4.

o Wire high speed serial interface if needed. (Requires

optional fieldbus interface board.)

o The DCS800 allows you to choose the usage of each

digital and analog input and output. The converter has

factory default settings which can be changed by loading

a macro, but some designations are universal. They

include:

• Digital input 5: Estop

• Digital input 6: Fault reset

• Digital input 7: On/Off (maintained) or On-Start

(pulsed)

• *Digital input 8: Start/Stop (maintained) or Off-

Stop (pulsed)

• Digital output 8: Main Contactor On (3 Amps

max. at 115 – 230 Vac)

*except Hand/Auto macro

o Other signals may be required depending on your ap-

plication (e.g., motor fan acknowledge input, Off2 input,

fan-on output, brake output).

o You will select the macro and / or choose the configuration

for digital and analog inputs and outputs in step 2 of the

commissioning process, or by updating group 10 and 14

parameters.

o Check all wire terminations (with continuity tester) before

proceeding to the next step.

Step 4:

Connect the drive system to incoming power and the motor to

the converter (both field and armature) as well as accessory

equipment (motor fan, thermal switch, brake, etc.).

o See hardware manual for typical cable size and tightening

torque recommendations.

o IMPORTANT: Be sure all safety equipment is properly

sized for your application

Step 5:

Apply control power to the converter.

o IMPORTANT: See section “Safety and Operating

Instructions” in this manual before proceeding.

o Apply power to terminal block 99 and X2. The keypad

should light up and show the menu screen. The converter

fans should start to run (if converter has fans).

Step 6:

Commission the converter using Drive Windows Light

(preferred) or the control panel.

o IMPORTANT: See safety alerts and general instructions

in the section “Commissioning” before proceeding.

o Install the DCS800 PC tools on your computer. Instructions

are in this manual. Use DriveWindow Light to commission

your converter.

o If no PC is available, commission your drive using the

control panel as follows:

• On the control panel, press the softkey to select

MENU.

• Using the down arrow, select ASSISTANTS. Then

press ENTER.

• Starting with “name plate data,” press SEL.

Change the value with the arrow keys. Then press

SAVE.

• Repeat above with other parameters. Follow

directions on the screen.

Configuring and Displaying analog and digital I/O

HINT: To see if the drive is responding to an “on” or “run” command, view signal 8.08.

Control Panel:

o Digital Status: View signal 8.05 (DI’s) or 8.06 (DO’s).

Display is in hexadecimal.

o Configure digital inputs with Group 10.

o Analog Status: View signal 5.03 (AI1) or 5.11 (AO1).

Display is in Volts.

o Configure analog speed ref. with Group 11.

DriveWindow Light:

o Connect to the DCS800 and go on line by clicking on

File, then New Online Drive.

o Click on Wizard, at left side of the screen.

o Click on Advanced.

o Check the box for “I/O assistant,” then click on Next.

o Click on “edit parameters” in the appropriate section

(analog or digital inputs or outputs).

16

3ADW000191R0500 DCS800 Quick guide edisf e

Page 17

Safety and operating instructions

for drive converters DCS / DCF / DCR

(in conformity with the low-voltage directive 73/23/EEC)

1. General

In operation, drive converters, depending on their degree of

protection, may have live, uninsulated, and possibly also moving

or rotating parts, as well as hot surfaces.

In case of inadmissible removal of the required covers, of

improper use, wrong installation or maloperation, there is the

danger of serious personal injury and damage to property.

For further information, see documentation.

All operations serving transport, installation and commissioning

as well as maintenance are to be carried out by skilled technical personnel (Observe IEC 364 or CENELEC HD 384 or DIN

VDE 0100 and IEC 664 or DIN/VDE 0110 and national accident

prevention rules!).

For the purposes of these basic safety instructions, “skilled

technical personnel” means persons who are familiar with the

installation, mounting, commissioning and operation of the

product and have the qualifications needed for the performance

of their functions.

english

4. Installation

The installation and cooling of the appliances shall be in accordance with the specifications in the pertinent documentation.

The drive converters shall be protected against excessive

strains. In particular, no components must be bent or isolating

distances altered in the course of transportation or handling. No

contact shall be made with electronic components and contacts.

Drive converters contain electrostatic sensitive components

which are liable to damage through improper use. Electric

components must not be mechanically damaged or destroyed

(potential health risks).

5. Electrical connection

When working on live drive converters, the applicable national

accident prevention rules (e.g. VBG 4) must be complied with.

The electrical installation shall be carried out in accordance with

the relevant requirements (e.g. cross-sectional areas of conductors, fusing, PE connection). For further information, see documentation.

2. Intended use

Drive converters are components designed for inclusion in electrical installations or machinery.

In case of installation in machinery, commissioning of the drive

converter (i.e. the starting of normal operation) is prohibited until

the machinery has been proved to conform to the provisions of

the directive 89/392/EEC (Machinery Safety Directive - MSD).

Account is to be taken of EN 60204.

Commissioning (i.e. the starting of normal opertion) is admissible

only where conformity with the EMC directive (89/336/EEC) has

been established.

The drive converters meet the requirements of the low-voltage

directive 73/23/EEC. They are subject to the harmonized standards of the series prEN 50178/DIN VDE 0160 in conjunction with

EN 60439-1/ VDE 0660, part 500, and EN 60146/ VDE 0558.

The technical data as well as information concerning the supply conditions shall be taken from the rating plate and from the

documentation and shall be strictly observed.

3. Transport, storage

The instructions for transport, storage and proper use shall be

complied with.

Instructions for the installation in accordance with EMC requirements, like screening, earthing, location of filters and wiring,

are contained in the drive converter documentation. They must

always be complied with, also for drive converters bearing a

CE marking. Observance of the limit values required by EMC

law is the responsibility of the manufacturer of the installation or

machine.

6. Operation

Installations which include drive converters shall be equipped

with additional control and protective devices in accordance with

the relevant applicable safety requirements, e.g. Act respecting

technical equipment, accident prevention rules etc. Changes

to the drive converters by means of the operating software are

admissible.

After disconnection of the drive converter from the voltage

supply, live appliance parts and power terminals must not be

touched immediately because of possibly energized capacitors.

In this respect, the corresponding signs and markings on the

drive converter must be respected.

During operation, all covers and doors shall be kept closed.

7. Maintenance and servicing

The manufacturer’s documentation shall be followed.

The climatic conditions shall be in conformity with prEN 50178.

Keep safety instructions in a safe place!

3ADW000191R0500 DCS800 Quick guide edisf e

17

Page 18

Installing the DCS800 PC tools on Your computer

After inserting the DCS800 CD all programs and documentation

necessary to work with the DCS800 will be automatically installed.

This includes:

1. DriveWindow Light for parameterization, commissioning and

service

2. Hitachi FDT 2.2 for firmware download

3. Installation CD of DCS800 Drive for e.g. DWL Wizard, ABB

documents

4. CoDeSys for 61131 application programming

Attention:

If You do not want to install a certain program just skip it by using

Cancel at the beginning of the program’s wizard.

If the installation routine does not start automatically:

- Go to Start/Run and browse for setup.exe on the CD. Now start

the installation by confirming with OK

- Compact installtion for DriveWindow Light + Commsioning

Wizard + DriveWindow Light AP is reccomended

• Start DriveWindow Light PC tool

Check the communication setting of your COM port

If You use USB to COM port interface or PCMCIA / COM ad-

apters double check the active COM enabled

Start => Settings => Control Panel =>

System => Hardware

=> Device Manager

Steps to connect Drive to PC

• The documentation can be found under

C:\ABB\DCS800\Docu

• Remove design cover from the converter module

Remove the DCS800 Control Panel if Connect drive (X34) to your PC COM port

present. Depress the locks to remove

the cover

18

3ADW000191R0500 DCS800 Quick guide edisf e

COM address of USB interface can change after the next boot

procedure or after disconnecting and reconnecting of the USB

interface.

Note:

PCMCIA to COM Port provide a stable and faster drive interface.

Utilize DriveWindow Light or DCS800 Panel Wizard continue

with chapter Commissioning in this manual.

For commissioning by DriveWindow find a workspace description in the DCS800 Firmware manual.

Page 19

Commissioning

7. Field weakening assistant

6. Autotuning speed cont roller

5. Speed feedback assistant

4. Autotuning armature current controller

3. Autotuning field current controller

2. Macro assistant

1. Name plate data

Next >

Next >

Next >

Next >

Next >

Next >

Select specific

assistant & press Next

Wiz select.dsf

Danger! High voltage: this symbol warns of high

voltages which may result in injuries to persons

and/or damage to equipment. Where appropriate,

the text printed adjacent to this symbol describes

how risk of this kind may be avoided.

General warning: this symbol warns of non-electrical risks and dangers which may result in serious

or even fatal injuries to persons and/or damage to

equipment. Where appropriate, the text printed

adjacent to this symbol describes how risk of this

kind may be avoided.

Warning of electrostatic discharge: this symbol

warns you against electrostatic discharges which

may damage to unit. Where appropriate, the text

printed adjacent to this symbol describes how risk

of this kind may be avoided.

NEC motor overload protection

The DCS800 provides a solid-state motor overload

protection in accordance with the NEC. The overload

protection (e.g. protection level in percent of full-load

motor current) can be adjusted by parameters in

group 31 and group 99.

The instructions can be found in chapter Motor

thermal model of the DCS800 Firmware manual.

General instructions

• This short commissioning refers to Chapter 5 Connection examples of this publication.

• Safety and operating instructions - see chapter 6

of this publication.

• Recommendations for motor and field voltages see

Technical catalogue.

• In accordance with DIN 57 100 Part 727 / VDE 0100

Part 727, precautions must be taken to enable the

drive to be shut down, e.g. in the event of danger.

The unit’s digital inputs or the control panel are not

sufficient as the sole measure for this purpose!

Preparations

• Check unit for any damage!

• Install unit and wire it up

• Supply voltage level / Rated value correct for electronics and fan?

• Supply voltage level / Rated value correct for armature-circuit converter?

• Supply voltage level / Rated value correct for field

supply?

• Wiring / cross-sections, etc. correct?

• EMERGENCY STOP functioning properly?

• COAST STOP functioning properly?

english

Commissioning DriveWindow Light

Start the wizard in DriveWindow Light:

For basic commissioning press the Start button or select a specific assistant:

For more information about the wizard, parameters faults and alarms press the Help

button!

3ADW000191R0500 DCS800 Quick guide edisf e

19

Page 20

DCS800 Control Panel

DCS800 QG pan ov_a.dsf

The following table summarizes the button functions and displays of the

DCS800 Control Panel (DCS CP).

With USISel (16.09) it is possible to limit the amount of displayed parameters!

General display features

Following modes are available in the MAIN MENU:

1. Parameters mode

2. Start-up assistants mode

a. Name plate data

b. Macro assistant

c. Autotuning field current controller

d. Autotuning armature current controller

e. Speed feedback assistant

(Tacho fine tuning not available)

f. Autotuning speed controller

g. Field weakening assistant

(only used when maximum speed is higher than

base speed)

3. Macros mode (currently not used)

4. Changed parameters mode (compare to default and

display changed parameters)

5. Fault logger mode (Display fault history)

6. Clock set mode

7. Parameter backup mode

• copy active parameter set from the drive into the

DCS800 Control Panel (only in local mode)

• copy parameter set from DCS800 Control Panel into

the drive (only in local mode)

8. I/O settings mode (currently not used)

Parameters entered by assistant

99.02 Motor 1 nominal Voltage

99.03 Motor 1 nominal current

99.04 Motor 1 base speed

20.01

20.02

99.11 Motor 1 nominal field current

30.09 Armature over current level

30.16 Motor 1 over speed

99.10 Nominal mains voltage

99.12

20.05

20.06

20.12

20.13 Motor 1 current limit bridge 2

50.04 Motor 1 encoder pulse number, if selected

50.02

50.13 Motor 1 tacho volt, only DWL

50.12

20.03

22.01

22.02

30.12

44.01 Field control mode

Motor 1 minimum speed

Motor 1 maximum speed

Motor 1 used fex type

Torque maximum

Torque minimum

Motor 1 current limit bridge 1

Motor 1 encoder measured mode, if selected

Motor 1 tacho adapt, only DWL

Zero speed limit

Acceleration time 1

Deceleration time 1

Motor 1 field minimum trip

20

3ADW000191R0500 DCS800 Quick guide edisf e

Page 21

Dimensions, drilling patterns and weights — Abmessungen, Bohrbild und

S = 5 mm

S = 10 mm

S

S

H

A

B

A B C D E F G H

4x45=180

86

32.5

45

64.5

C1 U1 V1 W1 D1

10

270

225

48.5

for size D1

for size D2...D3

direction of air flow

screw M6

fan terminal

earthing

point

screw

Size Weight

D1toD3_dim_b.dsf

E

F

G

10.5

T2

T1

C

D

43.5

8.7

9

20

Power connection

Field and power

supply terminals

Signal terminals

Mounting direction

310 for size D1/D2

400 for size D3

Minimum

Bottom clearance

T2 = 100mm for size D1

T2 = 150mm for size D2/D3

Minimum

Top clearance

T1 = 150mm for size D1

T1 = 250mm for size D2/D3

Gewichte — Dimensioni, schemi di foratura e pesi — Dimensiones, patrones

de taladrado y pesos — Dimensions, perçages et poids

Module D1

DCS800-S01-0020

DCS800-S01-0045

DCS800-S01-0065

DCS800-S01-0090

DCS800-S01-0125

DCS800-S02-0025

DCS800-S02-0050

DCS800-S02-0075

DCS800-S02-0100

DCS800-S02-0140

Module D2

DCS800-S01-0180

DCS800-S01-0230

DCS800-S02-0200

DCS800-S02-0260

Module D3

DCS800-S01-0315

DCS800-S01-0405

DCS800-S01-0470

DCS800-S02-0350

DCS800-S02-0450

DCS800-S02-0520

600 V types

DCS800-S01-0290

DCS800-S02-0320

Dimensions in mm

Maße in mm

Dimensioni in mm

1

Dimensiones en mm

Dimensions en mm

Installation direction

1

Air direction

Montagerichtung

Luftrichtung

Direzione di installazione

Direzione aria

Modo de instalación

Dirección del aire

Sens de montage

Sens de circulation de

l‘air

Data for converters with

more than 1000 A (D5)

see Hardware manual

Daten für Stromrichter

mit mehr als 1000 A

(D5) siehe Hardware

Handbuch

Dati per convertitori di

potenza da oltre 1000

A (D5), si veda Hardware

manual

Datos para convertidores de más de 1.000 A

(D5), véase

Hardware manual

1

Données pour variateurs

supérieurs à 1000 A (D5),

cf. Manuel d’installation

3ADW000191R0500 DCS800 Quick guide edisf e

77

Page 22

Module D4

D4_dim_b.dsf

345

298

8.7

250

577

150

9

287.5(CON-4)

240(PIN-4)

195.5

147.5

25

20

42

fan terminal

min. Top clearance

min. Bottom clearance

Earthing

M12

Direction of air flow

S = 10 mm

S S

f. M6

48.5

270

225

644

625

107

52

40

80

80

80

f. M12

45

U1

V1

W1

C1

D1

for size D4

fan terminal

Power terminal: Busbar 40x5 mm

Weight appr. 38 kg

DCS800-S01-0610

DCS800-S01-0740

DCS800-S01-0900

DCS800-S02-0680

DCS800-S02-0820

DCS800-S02-1000

600 V types

DCS800-S01-0590

DCS800-S02-0650

Weight appr. 38 kg

1

Installation direction

1

Air direction

Montagerichtung

Luftrichtung

Direzione di installazione

Direzione aria

Modo de instalación

Dirección del aire

Sens de montage

Sens de circulation de

l‘air

Data for converters with

more than 1000 A (D5)

see Hardware manual

Daten für Stromrichter

mit mehr als 1000 A

(D5) siehe Hardware

Handbuch

Dati per convertitori di

potenza da oltre 1000

A (D5), si veda Hardware

manual

Datos para convertidores de más de 1.000 A

(D5), véase

Hardware manual

Données pour variateurs

supérieurs à 1000 A (D5),

cf. Manuel d’installation

78

3ADW000191R0500 DCS800 Quick guide edisf e

Page 23

Texto en el DCS800 Panel,

Texte dans la DCS800

Testo DCS800 Pannello,

FR

Description

DriveWindow

Microconsole,

DriveWindow Light et

AuxUnderVolt

Défaut tension auxiliaire

ArmOverCur

Surintensité, ArmOvrCurLev (30.09)

ArmOverVolt

Surtension d’induit (circuit c.c.),

ArmOvrVoltLev (30.08)

ConvOverTemp

Echauffement anormal du pont de

puissance, MaxBridgeTemp (4.17)

ResCurDetect

Défaut de terre (Σ I différent de

zéro), ResCurDetectSel (30.05)

M1OverTemp

Moteur 1 echauffement anormal,

M1FaultLimTemp (31.07)

M1OverLoad

Moteur 1 surcharge,

M1FaultLimLoad (31.04)

I/OBoardLoss

____________________________

M2OverTemp

Moteur 2 echauffement anormal,

M2FaultLimTemp (49.37)

M2OverLoad

Moteur 2 surcharge,

M2FaultLimLoad (49.34)

ConvFanCur

Courant du ventilateur du

convertisseur hors limites,

ConvTempDly (97.05)

MainsLowVolt

Sous-tension réseau (c.a.) ,

UnetMin1 (30.22)

SP

Definición

DriveWindow

DriveWindow Light y

AuxUnderVolt

Fallo de tensión auxiliar

(Subtensión auxil.)

ArmOverCur

Sobrecorriente (Sobreintensidad),

ArmOvrCurLev (30.09)

ArmOverVolt

Sobretensión de inducido (circuito

de C.C.), ArmOvrVoltLev (30.08)

ConvOverTemp

Sobretemperatura en la sección

de potencia, MaxBridgeTemp (4.17)

ResCurDetect

Fallo a tierra (Σ I distinto a cero),

ResCurDetectSel (30.05)

M1OverTemp

Motor 1 sobretemperatura,

M1FaultLimTemp (31.07)

M1OverLoad

Motor 1 sobrecarga,

M1FaultLimLoad (31.04)

I/OBoardLoss

Tarjetas E/S no encontradas o

faltan, comprobar parámetros gr.

94 y 98.________

M2OverTemp

Motor 2 sobretemperatura,

M2FaultLimTemp (49.37)

M2OverLoad

Motor 2 sobrecarga,

M2FaultLimLoad (49.34)

ConvFanCur

Intensidad en ventilador del

convertidor fuera de los límites,

ConvTempDly (97.05)

MainsLowVolt

Tensión Baja de red (C.A.),

UnetMin1 (30.22)

IT

Descrizione

DriveWindow

DriveWindow Light e

AuxUnderVolt

Guasto tensione ausiliaria

ArmOverCur

Sovracorrente, ArmOvrCurLev

(30.09)

ArmOverVolt

Sovratensione d’indotto (circuito in

c.c.), ArmOvrVoltLev (30.08)

ConvOverTemp

Sovratemperatura sezione di

potenza, MaxBridgeTemp (4.17)

ResCurDetect

Guasto a terra (Σ I diverso da zero),

ResCurDetectSel (30.05)

M1OverTemp

Motore 1 sovratemperatura,

M1FaultLimTemp (31.07)

M1OverLoad

Motore 1 sovraccarico,

M1FaultLimLoad (31.04)

I/OBoardLoss

______________________

M2OverTemp

Motore 2 sovratemperatura,

M2FaultLimTemp (49.37)

M2OverLoad

Motore 2 sovraccarico,

M2FaultLimLoad (49.34)

ConvFanCur

La corrente del ventilatore del

convertitore non rientra nei limiti,

ConvTempDly (97.05)

MainsLowVolt

Minima tensione di alimentazione

di rete (c.a.), UnetMin1 (30.22)

D

DriveWindow

Beschreibung

DriveWindow Light und

Text in DCS800 Panel,

AuxUnderVolt

Hilfs-Unterspannung, Klemme X99

auf SDCS-PIN-4 und SDCS-POW-4

ArmOverCur

Überstrom Anker, ArmOvrCurLev

(30.09)

ArmOverVolt

Überspannung Gleichstromkreis

(DC), ArmOvrVoltLev (30.08)

EN

Definition

DriveWindow

DriveWindow Light and

Text on DCS800 panel,

AuxUnderVolt

Auxiliary undervoltage, terminal X99

on SDCS-PIN-4 and SDCS-POW-4

Armature overcurrent,

ArmOvrCurLev (30.09)

Armature overvoltage (DC),

ArmOvrVoltLev (30.08)

Fault Word

Fault / Alarm list • Fehler- / Alarmliste / ital ??? / Diagrama de la estructura del firmware / Liste des défauts et alarmes

LED

F501 9.01 Bit 0

F502 9.01 Bit 1 ArmOverCur

F503 9.01 Bit 2 ArmOverVolt

ConvOverTemp

Übertemperatur Stromrichter,

MaxBridgeTemp (4.17)

ResCurDetect

Summenstromüberwachung (Σ I

ungleich Null), ResCurDetectSel

(30.05)

M1OverTemp

Motor 1 gemessene

Übertemperatur, M1FaultLimTemp

(31.07)

M1OverLoad

Motor 1 berechnete Überlast,

M1FaultLimLoad (31.04)

I/OBoardLoss

E/A-Karte nicht gefunden oder

fehlerhaft, s. Gruppe 94 und 98

M2OverTemp

Motor 2 gemessene

Übertemperatur, M2FaultLimTemp

(49.37)

M2OverLoad

Motor 2 berechnete Überlast,

M2FaultLimLoad (49.34)

ConvFanCur

Gerätelüfterstrom nicht innerhalb

der Grenzen, ConvTempDly (97.05)

MainsLowVolt

Netz-Unterspannung (AC), UnetMin1

(30.22)

Converter overtemperature,

MaxBridgeTemp (4.17)

Residual current detection (Σ I

differs from zero), ResCurDetectSel

(30.05)

Motor 1 measured overtemperature,

M1FaultLimTemp (31.07)

Motor 1 calculated overload,

M1FaultLimLoad (31.04)

I/O board not found or faulty, see

groups 94 and 98

Motor 2 measured overtemperature,

M2FaultLimTemp (49.37)

Motor 2 calculated overload,

M2FaultLimLoad (49.34)

Current converter fan not within

limits, ConvTempDly (97.05)

Mains low (under-) voltage (AC),

UnetMin1 (30.22)

F504 9.01 Bit 3 ConvOverTemp

F505 9.01 Bit 4 ResCurDetect

F506 9.01 Bit 5 M1OverTemp

F507 9.01 Bit 6 M1OverLoad

F508 9.01 Bit 7 I/OBoardLoss

3ADW000191R0500 DCS800 Quick guide edisf e

F509 9.01 Bit 8 M2OverTemp

F510 9.01 Bit 9 M2OverLoad

F511 9.01 Bit 10 ConvFanCur

F512 9.01 Bit 11 MainsLowVolt

Faults & Alarms / Diagnosis

79

Page 24

Texte dans la DCS800

Texto en el DCS800 Panel,

Testo DCS800 Pannello,

FR

Description

DriveWindow

Microconsole,

DriveWindow Light et

MainsOvrVolt

Surtension réseau (c.a.), > 1.3 *

NomMainsVolt (99.10)

MainsNotSync

Défaut de synchronisation (c.a.),

DevLimPLL (97.13)

M1FexOverCur

Moteur 1 Surintensité EXCITATION,

M1FldOvrCurLev (30.13)

M1FexCom

Moteur 1 Erreur de communication

EXCITATION, FexTimeOut (94.07)

ArmCurRipple

Ondulation courant d’induit,

CurRippleSel (30.18)

M2FexOverCur

Moteur 2 Surintensité EXCITATION,

M2FldOvrCurLev (49.09)

M2FexCom

Moteur 2 Erreur de communication

EXCITATION, FexTimeOut (94.07)

FieldAck

Absence de signal retour de

l’EXCITATION, Mot1FexStatus (6.12)

SpeedFb

Défaut retour vitesse (mesure),

M1SpeedFbSel (50.03)

ExtFanAck

Absence de signal retour du

VENTILATEUR du moteur,

MotFanAck (10.06)

MainContAck

Absence de signal retour du

contacteur principal, MainContAck

(10.21)

TypeCode

Erreur d’identification du type de

variateur, TypeCode (97.01)

ExternalDI

Défaut extérieur à l’entrée digitale,

ExtFaultSel (30.31)

SP

Definición

DriveWindow

DriveWindow Light y

MainsOvrVolt

Sobretensión de red (C.A.), > 1.3 *

NomMainsVolt (99.10)

MainsNotSync

Fallo de sincronización (C.A.),

DevLimPLL (97.13)

M1FexOverCur

Motor 1 Sobrecorriente de la

EXCITACIÓN, M1FldOvrCurLev

(30.13)

M1FexCom

Motor 1 Error de comunicación

con la excitación, FexTimeOut

(94.07)

ArmCurRipple

Rizado de la corriente (intensidad)

del inducido, CurRippleSel (30.18)

M2FexOverCur

Motor 2 Sobrecorriente de la

EXCITACIÓN, M2FldOvrCurLev

(49.09)

M2FexCom

Motor 2 Error de comunicación

con la excitación, FexTimeOut

(94.07)

FieldAck

EXCITACIÓN no detectada) ,

Mot1FexStatus (6.12)

SpeedFb

Fallo en la lectura de la velocidad,

M1SpeedFbSel (50.03)

ExtFanAck

Sin reconocimiento del

VENTILADOR del motor,

MotFanAck (10.06)

MainContAck

Falta reconocimiento contactor

principal, MainContAck (10.21)

TypeCode

Fallo de identificación de

Convertidor (Codificación de tipo)

, TypeCode (97.01)

ExternalDI