ABB DCS800 Technical Catalog

Low voltage DC drives

ABB DC Drives

DCS800, 10 to 4000 hp

Catalog

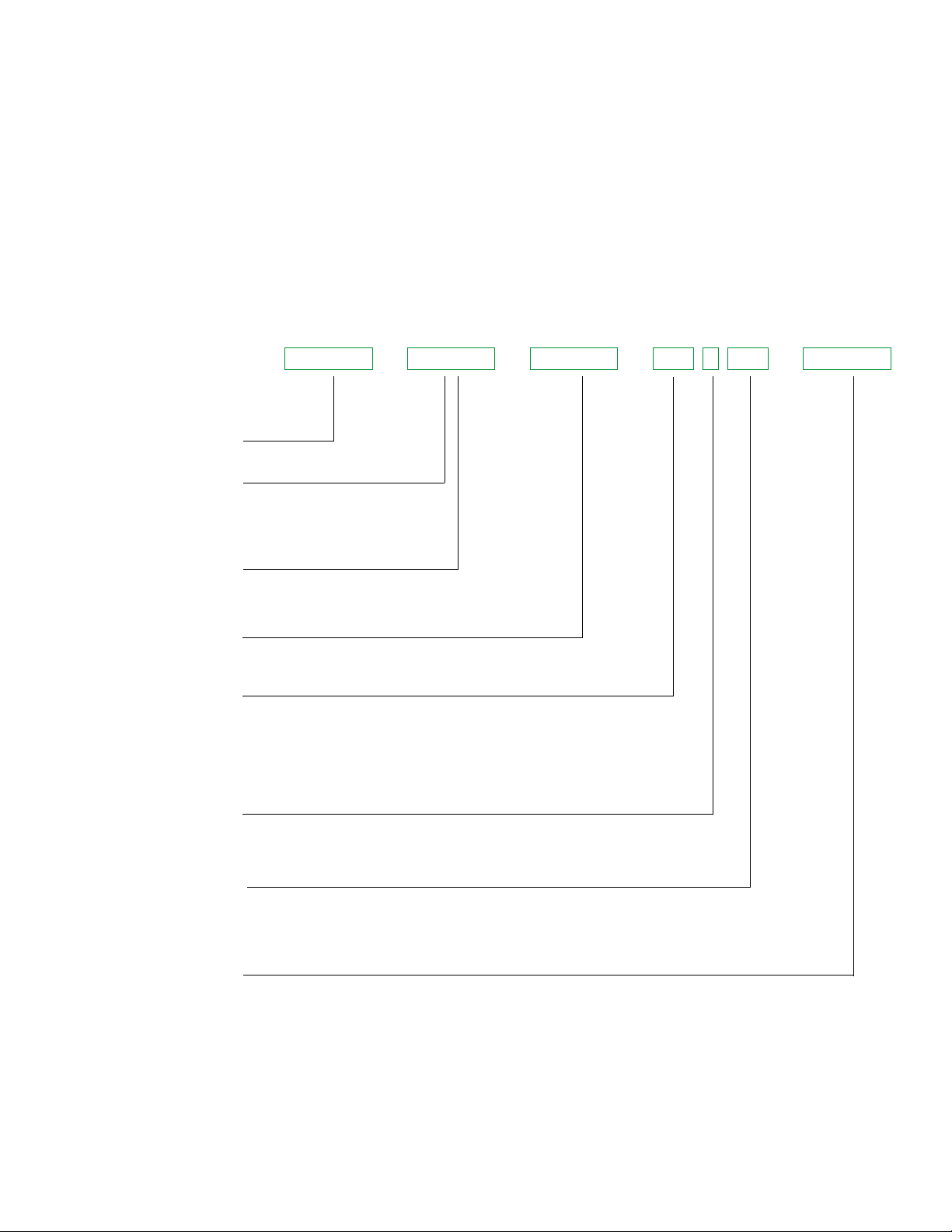

Selecting and ordering your drive

Type designation is a unique reference number that clearly

identifies the drive by construction, power and voltage

rating and selected options. Using the type designation

you can specify your drives from the wide range of options

available. Options are added to the type designation using the

corresponding “plus” (+) code.

Type designation:

Product series

Type

A0 = Cabinet drive (600+ HP)

EP = Panel mounted converter

PC = Cabinet drive (5-500 HP)

R0 = Rebuild kit

S0 = 3-phase converter module

Bridge type

1 = non-reversing (2-Q)

2 = reversing (4-Q)

DCS800 - S01 - 0680 - 05 + XXXX

Build up your own ordering code using the type designation

key below or contact your local ABB drives sales office and let

them know what you want.

Rated Current

Current rating of drive unit (Amps)

Rated Input Voltage

05 = 230...525 V AC

06 = 270...600 V AC

07 = 315...690 V AC

08 = 360...800 V AC

10 = 450...990 V AC

12 = 540...1200 V AC

Revision

Blank = No option (D1 - D4)

B = High Efficiency Fans (D5-D7)*

Power Terminal Connection

Blank = No option (D1 - D6)

L = Left side power terminals

R = Right side power terminals

Additional Factory

Installed Options

* Standard after July 15, 2013

2 ABB DCS800 Technical Catalog

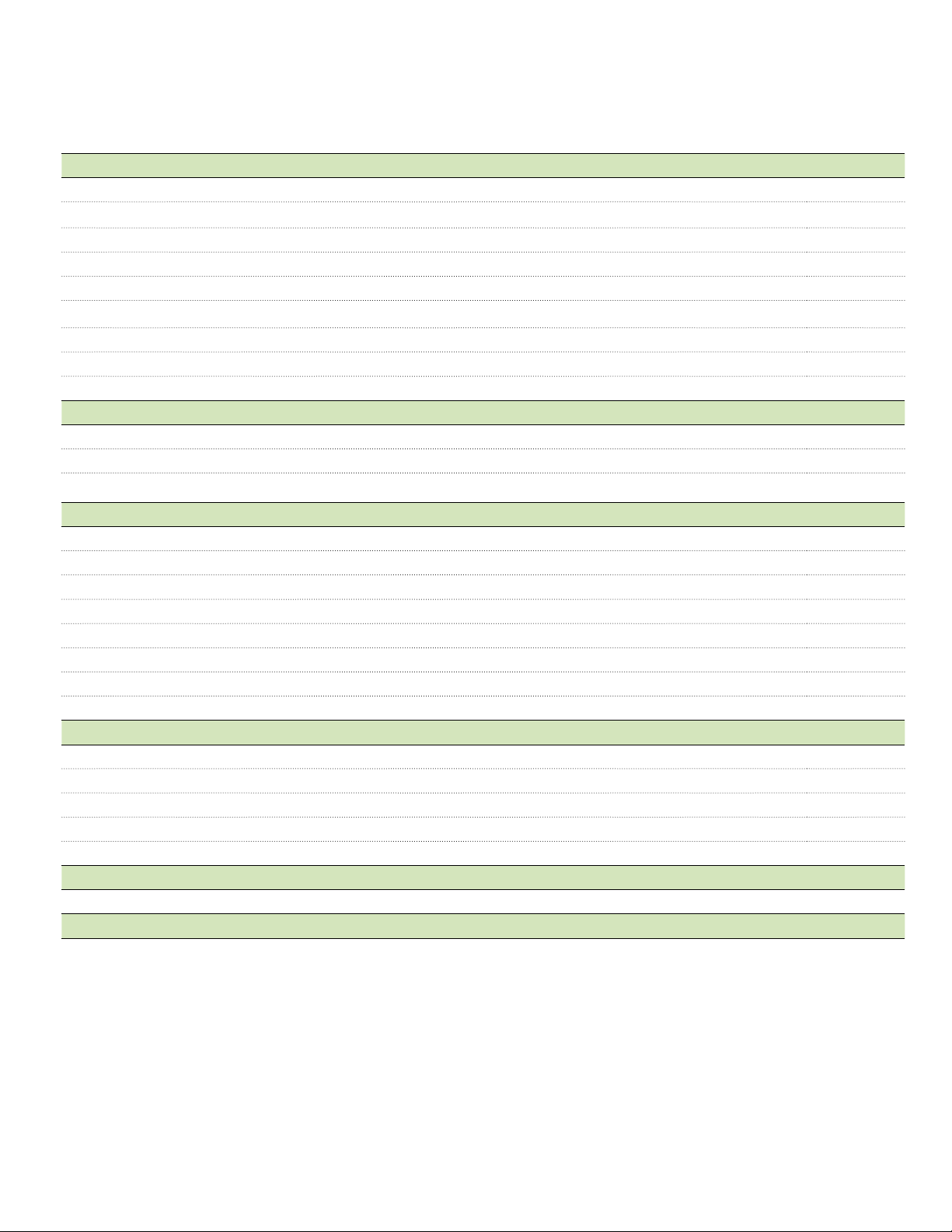

Contents

ABB low voltage DC drive, DCS800

ABB DCS800 drive 4

Overview 4

Power Converter Modules 5

Panel Drive 6

Cabinet Drive 7

Rebuild and Upgrade Kits 9

Adaptive Programming and Start-up Assistants 10

DriveWindow Light 11

Commissioning Macros 13

DCS800 Firmware 14

Ratings and Specications 15

Technical Specifications 15

Ratings 16

Dimensions and Weights 19

Hardware 20

Technical Diagram 20

Plug in Options 21

Feedback Options 22

Communication Options 23

External Field Supply 24

Fuse Connections 26

Line Reactors 27

Input and Output Contactors 28

Software Options / PC Tools 29

Control Builder 29

DriveWindow 30

DriveSize 31

DriveOPC and DriveBrowser 32

Remote Monitoring Tool 33

Drawings 34

Services and parts 36

Trademarks

DriveWindow is a registered trademark of ABB

Modbus is a trademark of Schneider Electric

Profibus is a trademark of Siemens

ControlNet is a trademark of ControlNet International, Ltd.

DeviceNet is a trademark of the Open DeviceNet Vendor Association.

Windows in a registered trademark of Microsoft Corp

Reliance Electric® and FlexPak® 3000 are registered trademarks of Rockwell Automation, Inc.

ABB DCS800 Technical Catalog 3

DC Industrial Drives Overview

ABB DC Industrial Drives

The DCS800 DC industrial drive from ABB combines a powerful

controller with a thyristor power platform that has been proven

in factories all over the world. The DCS800 boasts a wider

power range than any other DC drive on the market. The

hardware and software are designed with you, the user in mind.

Special features make installation and configuration simple and

allow you to customize the application to your needs.

Industrial Applications

The DCS800 can be used in a wide range of industrial

applications including:

− Metals

− Electrolysis

− Pulp & Paper

− Ski lifts

− Printing

− Magnets

− Material handling

− Food & Beverage

− Battery Chargers

− Test rigs

− Plastic & Rubber

− Mining

DCS800 DC Drive Promises

The drive meets the requirements of the most demanding drive

applications. Embedded software functions offer upgrades to all

classic installations like 12-pulse, double motor operation, and

field reversal.

PC Tool for ABB Drives

DriveWindow Light is an easy-to-use tool for your PC for start

up and maintenance of your ABB drive. It is included with every

DCS800 drive and has the following features:

− User interface tool to view and set parameters

− Startup Assistant tool

− Adaptive Programming (AP) tool

It supports a wide range of ABB industrial drives, including

ACS350, ACS550, ACS800, as well as the DCS800.

Main Features

− Basic control

− Transducer and transducerless operation

− Macros to simplify setup

− High-speed serial via Ethernet, ControlNet, etc.

− On/Off control with pulsed or maintained inputs

− Field heating

− Adaptive Programming

− Remembers two sets of motor parameters

− Drive position display

− Save parameter set to PC or keypad

− Motor Control

− Easily switches between local control via keypad and

remote control via digital I/O or high-speed serial

− Window speed control

− Flying start

− Field reversal, boost and opti-torque

− Motor pot up and down control

Highlights

− Reduced installation and commissioning work

− Internal three phase field power supply without additional

external hardware (D1-D5)

− Excellent control performance up to highest dynamic

application in field weakening operation

− All ACS800 PC tools (via DDCS) can be connected

− Able to be customized to your needs with Adaptive

Programming and with option Control Builder

− Flexible fieldbus system with numerous internally mountable

fieldbus adapters

− Virtually all DCS800 component parts are suitable for

recycling.

− Coated circuit boards as standard

4 ABB DCS800 Technical Catalog

− Drive Configurations

− Stand-alone

− Master-follower (up to 10 followers)

− 12-pulse operation

− Hard-parallel operation (D7 only)

− Inputs and outputs

− All user-designated inputs and outputs

− Relay output for AC or DC contactor control

− Motor brake control, including torque proving input

− Motor temperature sensor monitoring

− High speed DC breaker monitoring

− Faults and Diagnostics

− Fault logging with time and date stamp

− Diagnostic assistant activates when fault occurs

Power Converter Modules

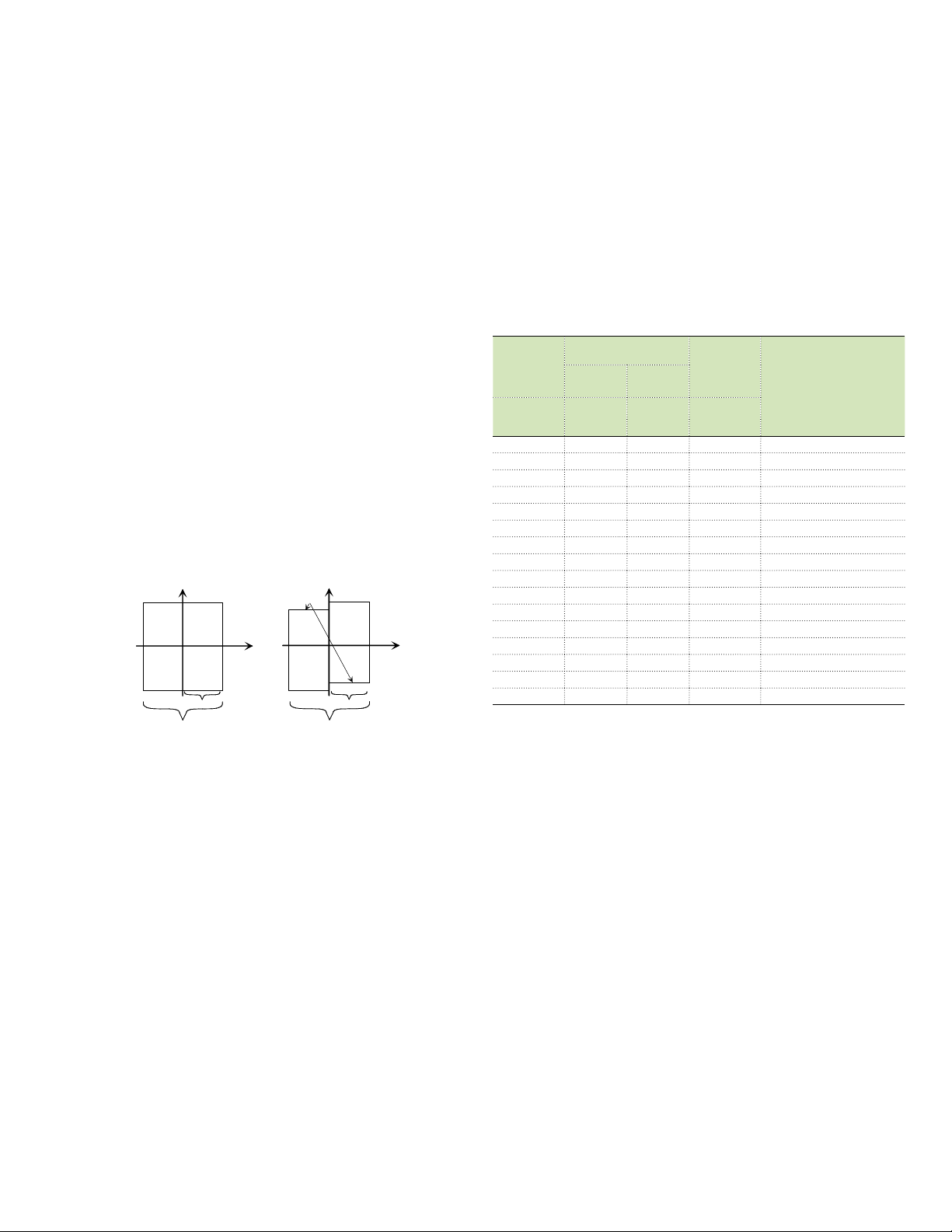

Speed

Torque

2-Q

4-Q

Motor

voltage

Current

max. regenerative

motor voltage

2-Q

4-Q

Enclosure Rating

The DCS800-S0x power converter module carries a NEMA

TYPE OPEN (IP00) rating and must be mounted in a protective

enclosure. There are seven different frame sizes, D1 through D7,

graduated in terms of current and voltage.

Reversing and Non-Reversing Drives

Non-reversing (2-Q) power converter modules are used when

motor torque and speed are always in the same direction and

when significant stopping power is not required.

This is ideal for applications such as:

− Fan or blower

− Mixer

− Pump

− Extruder

It is not possible for a 2-Q drive to slow down an inertial load.

The load will stop only due to friction, windage, or another

form of load resistance. It is also not possible for a 2-Q drive to

reverse direction unless field reversal is used.

needed for all 4-Q drives and are to be separately mounted.

See page 26 for fuse recommendations as well as specifications

for other external system components.

Voltage Selection

The output voltage of the drive depends on the incoming AC

line voltage and whether a 2-Q or 4-Q drive is selected. The

table below shows the maximum output voltage that will result

for various input voltages for both the 2-Q and 4-Q drives.

System

input AC

line voltage

1200 1380 1235 1590 12

DC voltage

(recommended)

2Q 4Q

U

VN

[V] [V] [V] [V]

230 265 240 310 05

380 440 395 510 05

400 465 415 540 05

415 480 430 560 05

440 510 455 590 05

460 530 480 620 05

480 555 500 640 05

500 580 520 670 05

525 610 545 700 05 (D1-D4), 06

575 670 600 770 06

600 700 625 810 06

660 765 685 890 07

690 800 720 930 07

800 915 820 1060 08

990 1160 1040 1350 10

U

dmax 2-Q

U

Ideal DC

voltage

without

load

dmax 4-Q

Recommended DCS800

voltage class type code

U

di0

Reversing (4-Q) power converter modules are used when motor

torque can occur in either direction. This is for applications such

as:

− Stop-start conveyor

− Draw Roll

− Rolling mill

− Unwinder

− Overhead crane hoist

A 4-Q drive is able to start and stop an inertial load in both

forward and reverse directions.

Field Power Supplies and Fusing

Converter modules sizes D1 through D5 are equipped with fused

internal field power supplies. Sizes D6 – D7 require an external

field power supply. See page 21 for details.

AC line fuses and DC armature fuses must be separately

mounted. See page 24 for fuse information as well as

information on other optional system components.

AC line fuses to be separately mounted on sizes D1 - D4.

They are included internally on D5 - D7. DC armature fuses are

The maximum output voltage of a 4-Q drive can be increased

up to the level of U

if the torque reversal time from

dmax 2-Q

motor to regenerative mode is set above 300 ms.

Low Mains Voltage - (30 to 120 V) SDCS-SUB-4 (+S186)

External DC Voltage Measurement - Measures Vdc at the

motor; (D1-D4) SDCS-UCM-1; (not needed D5-D7)

Analog, Digital and Encoder Interface

The drive is equipped with high-speed, high-resolution analog

inputs and outputs to interface with user signals. Analog inputs

are 16-bit resolution (15 plus one sign bit) which is the highest

resolution in the industry.

The following interfaces are standard features:

− Analog DC tachometer

− Pulse encoder

− Motorized pot, speed pot and up to two analog meters

Optional modules are available to increase the number of

analog, digital, tachometer, and encoder interfaces and to add

isolated interfaces for temperature sensors and other devices.

ABB DCS800 Technical Catalog 5

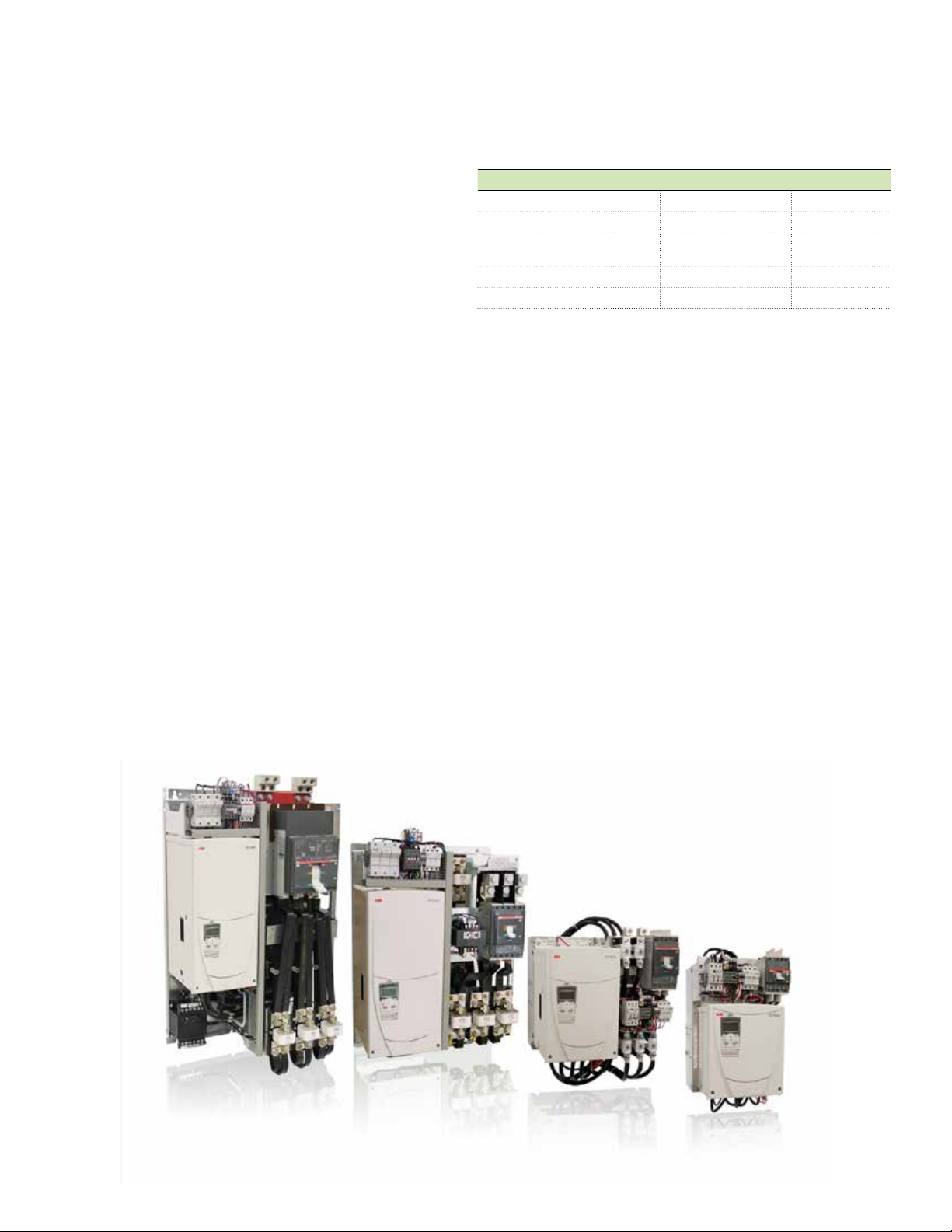

DCS800 Panel Drive

The DCS800-EPx Panel Drive is a DCS800 power module

and associated system components mounted and wired on a

sub-panel and ready to be installed into an industrial enclosure.

System components include AC input fuses, DC output fuses

(4-Q only), control transformer, AC contactor, plus optional

components. The drive is designed to easily replace a Reliance

Electric® FlexPak® 3000 drive.

Product Offering

− 460 Vac, factory or field convertible to 230 Vac

− 10 to 500 HP with heavy duty overload ratings (150 pct for

60 sec.)

− 600 HP with normal duty ratings (110 pct for 60 sec.)

− Integral ABB AC contactor

− UL Listed with 65 kA SCCR

Panel Drive Benefits

− Space efficient multilevel panel

− Easy to maintain

− Pre-wired, pre-tested solution for smooth start ups

− Greatly simplifies the procurement process

− Module can be replaced without replacing the entire panel

Optional Features

Option Size Option Code

Integral line reactor * Up to 150 hp +E213

ABB Tmax MCP circuit breaker +F278

ABB A-line blower motor

contactor & overload

Without AC contactor +0F250

230 Vac supply +S235

*Reactor or isolation transformer required!

Blower from 1/2 to

15 hp

+M611 +M641

DCS800 Power Module Benefits

− Highly reliable DCS800 module drive

− Integral field supply, including field weakening

− Control Panel with 5-line display and 2 soft keys

− DriveWindows Light PC tool included

Excellent Reliance® FlexPak® 3000 Retrofit Drive

− Same bolt pattern

− Similar features

− Fits within FlexPak® 3000 clearance area

− ABB’s Replacement Guide (DCS800-PHTG01U-EN) makes

conversions go smoothly

6 ABB DCS800 Technical Catalog

DCS800 Cabinet Drive

3 to 500 Hp

DCS800-PC cabinet drives, available from 3 to 500 horsepower

at 230 and 480 volt, feature field-proven DCS800 power

modules that are fully integrated into a robust drive system.

The DCS800-PC cabinet drive is packed with features that are

valued by American industry.

Those features include:

− UL listing; built in the USA

− Welded enclosures made of 12 gauge steel with multi-point

door latching mechanism

− Oversized forced air cooling system optimized by ABB engi-

neers to maximize heat removal

− Cabinet and drive fans that run only when needed

− Cabinet filter that can be changed from the outside; no need

to shut down the line

− Intelligent E-stop circuit that ensures power is shut off before

the contactor opens

− Fully documented; easy to integrate into your machine

DCS800 cabinet drives are ideal for a variety of industries

including metals, mining, rubber and plastics, material handling,

wood products and non-motoric. Applications include rolling

mills, piercing mills, mine hoists, extruders, rubber mixers,

cranes, veneer lines, and non-motoric applications such as

battery chargers, electromagnets, and electrolysis. The DCS800

is most frequently used with shunt-wound DC motors but can

also be used with specialty DC motors including permanent

magnet DC motors, series wound motors, traction motors, and

stab-shunt motors. Consult ABB Application Engineering when

a specialty motor is used.

Standard Features

− UL type 1 cabinet construction

− Forced air cooling

− Top or bottom AC line entry and DC motor exit

− Through-the-door rotary handle disconnect

− Line reactor

− AC line contactor

− Field power supply

− Door-mounted:

− Control panel

− Emergency stop pushbutton

− Armature current and voltage meters

− Isolated digital inputs and outputs, 120 Vac

− Isolated analog inputs and outputs, ± 10 Vdc

− Tachometer and encoder interface

− Wire labels that simplify troubleshooting

Optional features

− UL type 12 filtered cabinet construction

− Motor blower starter

− Extensive variety of fieldbus network adapters including

Ethernet IP, Profibus, ControlNet, etc.

− Analog and digital input/output extensions

− Feedback adapters for encoders and resolvers

− High speed network adapter for DDCS fiber optic and

drive-to-drive communications

The emergency stop circuit can be adapted to provide safety

functions Safe-Torque-Off (STO) or Safe-Stop 1 (SS1) if one

or both standard relays is replaced with safety relays. This is

possible because the standard e-stop circuit first commands

the drive to decelerate (Off3) and then cuts off the power in

two ways, by sending a signal to the drive (Off2) and then by

opening the input contactor. This will provide compliance with

SIL2 / PLd of IEC 62061 and IEC13849-2. Contact ABB for

more information.

ABB DCS800 Technical Catalog 7

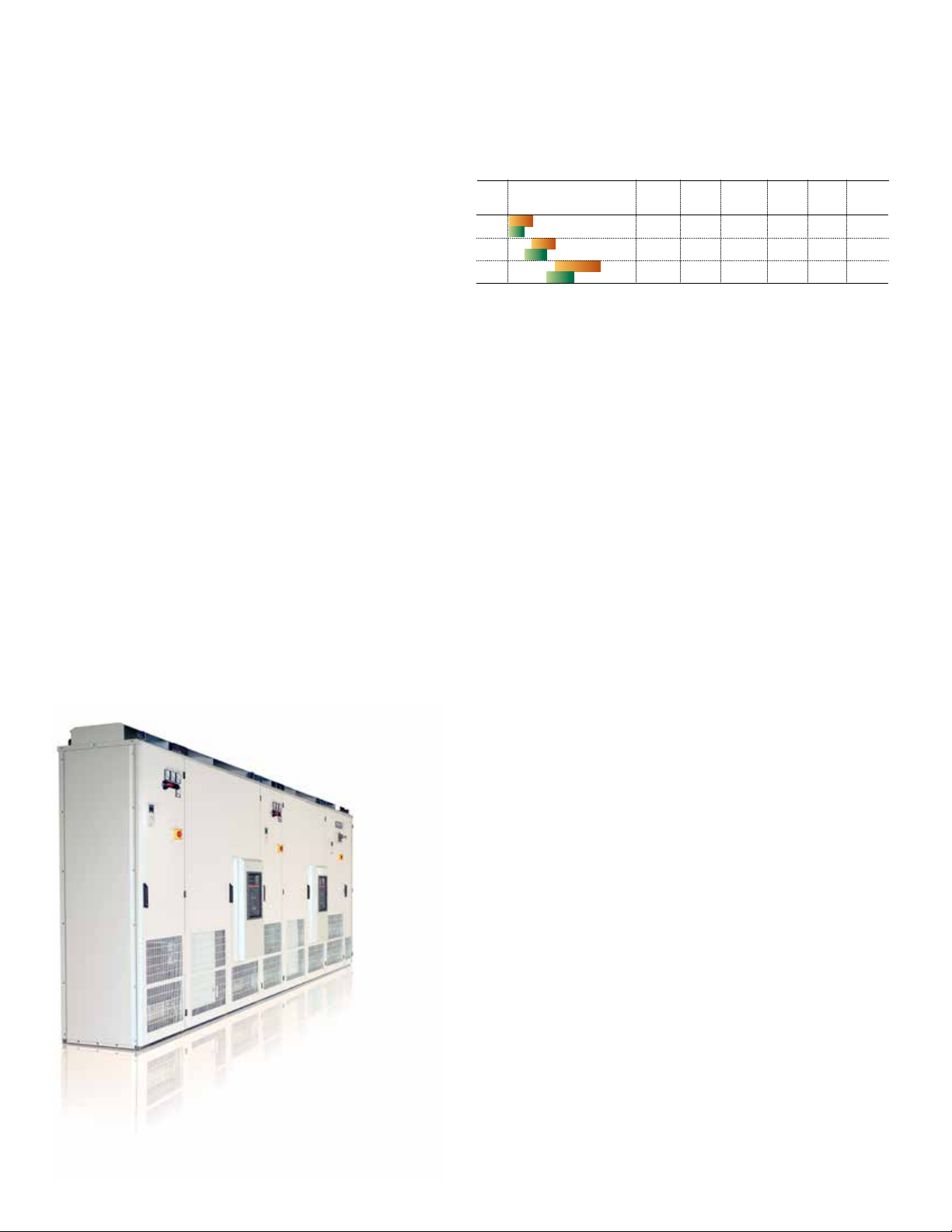

DCS800 Cabinet Drive

ND

ND

ND

SD

SD

SD

1100 hp

900 hp

1750 hp

1500 hp

3000 hp

2250 hp

D5

D6

D7

Frame Power Rating

ND - Normal Duty (110% OL)

SD - Standard Duty (150% OL)

UL Listed

Circuit

Breaker

Line

Contactor

Line

Reactor

Internal

Field

Supply *

External

Field

Supply *

Option

Option

Option

Option

#

#

#

# Circuit breaker can be electrically opened and closed to operate like a line contactor.

* Internal field supply located inside the drive modue. External supply located elsewhere within the cabinet.

Standard

Standard

Standard Option

600 to 3,000 Hp

DCS800-A0 cabinet drives, available from 600 to 3000 horsepower and beyond at voltages up to 1200 Vdc, provide optimal

flexibility in a DC system for a wide variety of applications.

Standard 480 Vac drive cabinets that include features common

to US industries can be ordered from our catalog.

Custom drive cabinets, available upon request, provide maximum flexibility for the most demanding applications, including

12-pulse parallel, serial and sequential and hard parallel configurations. Contact ABB for a custom quotation.

DCS800 cabinet drives are ideal for a variety of industries

including metals, mining, rubber and plastics, material handling,

wood products and non-motoric. Applications include rolling mills, piercing mills, mine hoists, extruders, rubber mixers,

cranes, veneer lines, and non-motoric applications such as

battery chargers, electromagnets, and electrolysis. The DCS800

is most frequently used with shunt-wound DC motors but can

also be used with specialty DC motors including permanent

magnet DC motors, series wound motors, traction motors, and

stab-shunt motors. Consult ABB Application Engineering when

a specialty motor is used.

DC drive systems excel at applications where full torque is

needed at zero speed, when high-impact loads require heavy

and frequent overloads, and on very large applications where

other alternatives become cost-prohibitive.

Standard Drive Cabinet – Features

− Circuit breaker, reactor and contactors on some cabi-

nets as shown in the chart

− Cabinet with 16 gauge steel panels covering 12 gauge

steel frame

− IP21 construction (like UL type 1)

− Forced air cooling

− Bottom AC line entry, bottom DC motor exit

− Built to UL specifications but not UL-listed

− Through-the-door rotary handle disconnect

− Isolated digital inputs and outputs, 120 Vac

− Isolated analog inputs and outputs, ± 10 Vdc

− Tachometer and encoder interface

− Door-mounted:

− Control panel

− Emergency stop pushbutton

− Armature current and voltage meters

− Documentation binder including AutoCAD drawings on

CD-ROM

Standard Drive Cabinet - Options

− IP42 cabinet construction (like UL type 12)

− Cabinet lighting

− Additional meter on door

− Class A2 plus or class B1 cable marking

− Motor blower starter

− Extensive variety of fieldbus network adapters including

Ethernet IP, Profibus, ControlNet, etc.

− Analog and digital input/output extensions

− Feedback adapters for encoders and resolvers

− High speed network adapter for DDCS fiber optic and

drive-to-drive communications

8 ABB DCS800 Technical Catalog

Custom Drive Cabinet

Solutions up to 20,000 Amps and 1200 Vdc. Features and

options vary widely. Contact your ABB representative for a

custom quotation.

DCS800 Rebuild and Upgrade Kits

The DCS800-R Rebuild or Upgrade Kit from ABB allows you to

update the controls on your existing DC drive and continue to

utilize the existing power section.

ABB, with the help of our channel partners, can make your

existing drive look and act like a new DCS800 drive. Gain the

benefits of having the latest motor control technology and

high speed serial connectivity without having to replace the

power section. This is an engineered solution which can have

significant cost advantages over complete drive replacement,

especially on large systems.

General Purpose Rebuild Kit

The DC800-R Rebuild Kit is recommended for thyristor-based

power sections that are:

− 500 horsepower (800 Amps) and above

− Originally manufactured by ABB or another drive company

− Reversing (4-quadrant) or non-reversing (2-quadrant)

− From 1, up to 4 parallel bridges

In order to determine if your existing drive can be rebuilt,

consider the following:

− Is the power section healthy?

Replacing the controls usually does not reduce the

occurrence of blown fuses or over-current faults. These

conditions commonly indicate that there is a malfunction

in the power section. Carefully consider the benefits of

upgrading compared to replacing with a full drive with a

brand new warranty.

− What data is available on the existing power section?

An accurate, up-to-date schematic is essential. The

schematic needs to include any changes that occurred over

the years.

− Is there space to mount the retrofit components?

A panel layout diagram, along with visual inspection of the

panel is needed.

− Are there any special features in the existing controller?

The DCS800 has functions to run most any application but

it is important to be sure that the new controller has the

functionality of the existing controller, or if other modifications

will be required.

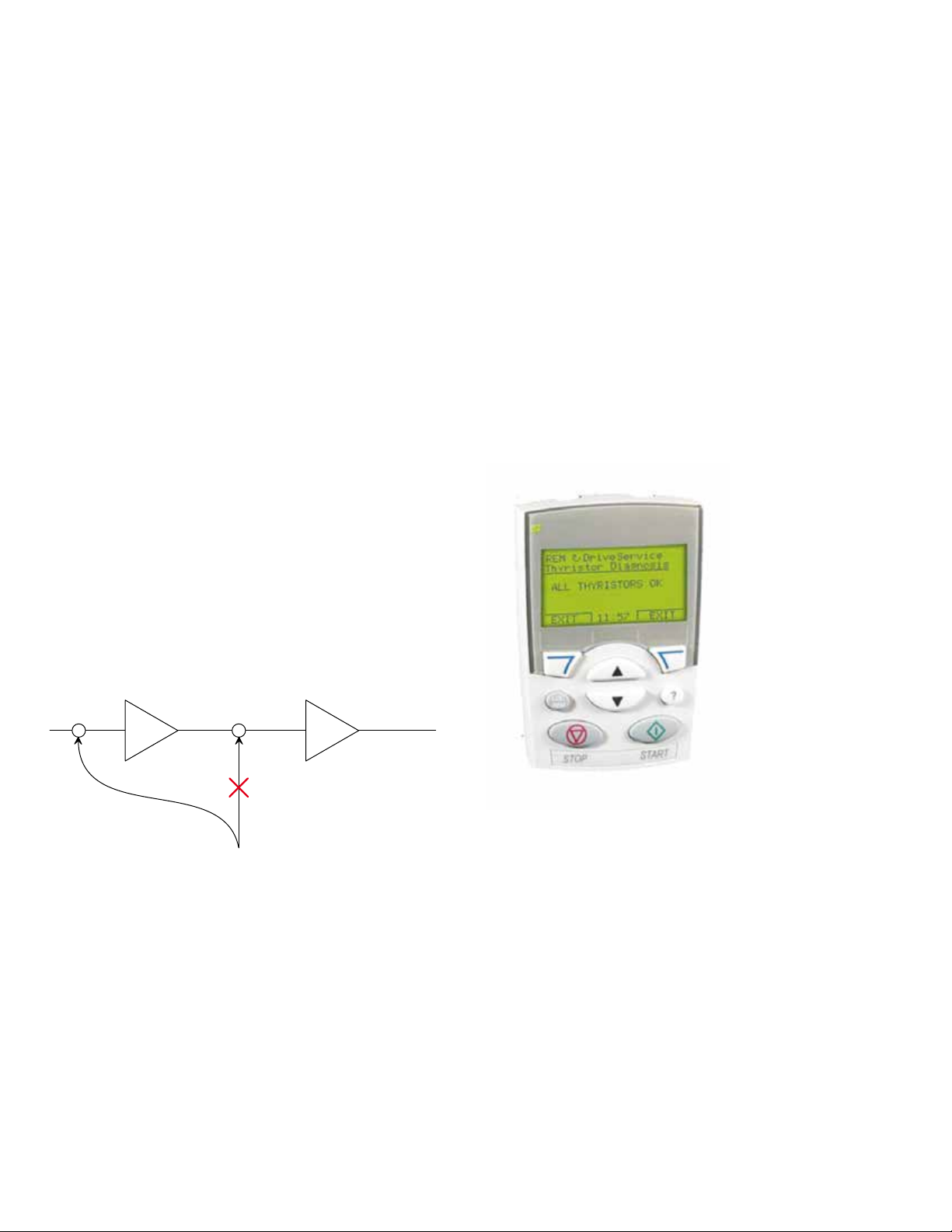

How it Works

A modern drive can be subdivided into two major sections, the

power section and the controller. The power section transfers

a measured amount of voltage and current from the incoming

lines to the motor. The computer-based controller controls the

power section, along with several other functions. The rebuild/

upgrade kit replaces the existing controller with a DCS800

controller.

In addition to controlling the power section, the DCS800-R will

also provide user interface (via keypad or DriveWindow Light)

and encoder and/or tachometer interface, if present. After the

drive is rebuilt, the complete drive system will operate like a

DCS800, which may include communicating with your PLC

via Ethernet, ControlNet, etc, receiving signals from switches,

push-buttons and pots, and sending signals to lamps and

meters.

DCS800-R Rebuild Kit

DCS500 to DCS800 Upgrade Kit

The DCS800-R Upgrade Kit is specifically designed to upgrade

the controls of existing DCS500 drives.

− For frame sizes A5, A6, A7, C2b, C3, & C4

− For drives approx. 350 HP and above

− Replaces existing door, control tray and keypad

ABB DCS800 Technical Catalog 9

Adaptive Programming and Start-up Assistants

Adaptive Programming

Optimal Adaptability

Adaptive Programming gives you the ability to customize the

drive to your needs without adding more hardware. Change how

a digital output works, modify speed or torque reference, or

filter an analog input - all these things are possible. You program

the drive with the control panel or your PC using DriveWindow

Light. Adaptive programming gives you the flexibility you need to

make the drive work to your specifications.

Features

− 16 programmable function blocks

− 31 Available functions:

− Logical: AND, OR and XOR

− Mathematical: add, mul, div, abs, max and min

− Other: timer, switch, comparator, filter, SR, PI and user-

defined warnings or faults

− Freely definable execution order

− Easy documentation

− Similar to the ACS800 AC Drives

The DCS800 DC drive offers you all this as standard features.

If more function blocks are required, ControlBuilder, which

uses compact flash memory, is available with expanded

capacity. See page 29 for details.

Start-Up Assistants

Faster and Easier Commissioning

The Startup Assistant is part of the standard DCS800 DC

Drives software package. It guides you actively through the

commissioning procedure either through the control panel

or with your PC using DriveWindow Light. It is multilingual,

requests data with clear and plain text messages, and sets the

required parameters to your needs.

On-line Info System

To make it easier and more informative, “info system” is

available at each step, helping to set the correct values for each

parameter and troubleshoot the problems. It also provides you

with a step-by-step reference to the printed manuals.

10 ABB DCS800 Technical Catalog

Features

− Easy and fast commissioning procedure

− Intelligent guide to assist you through the commissioning

− Available in 8 languages, including Spanish and French

− Info system always available

− Auto detection of connected hardware

The DCS800 DC drive offers you all this as standard features.

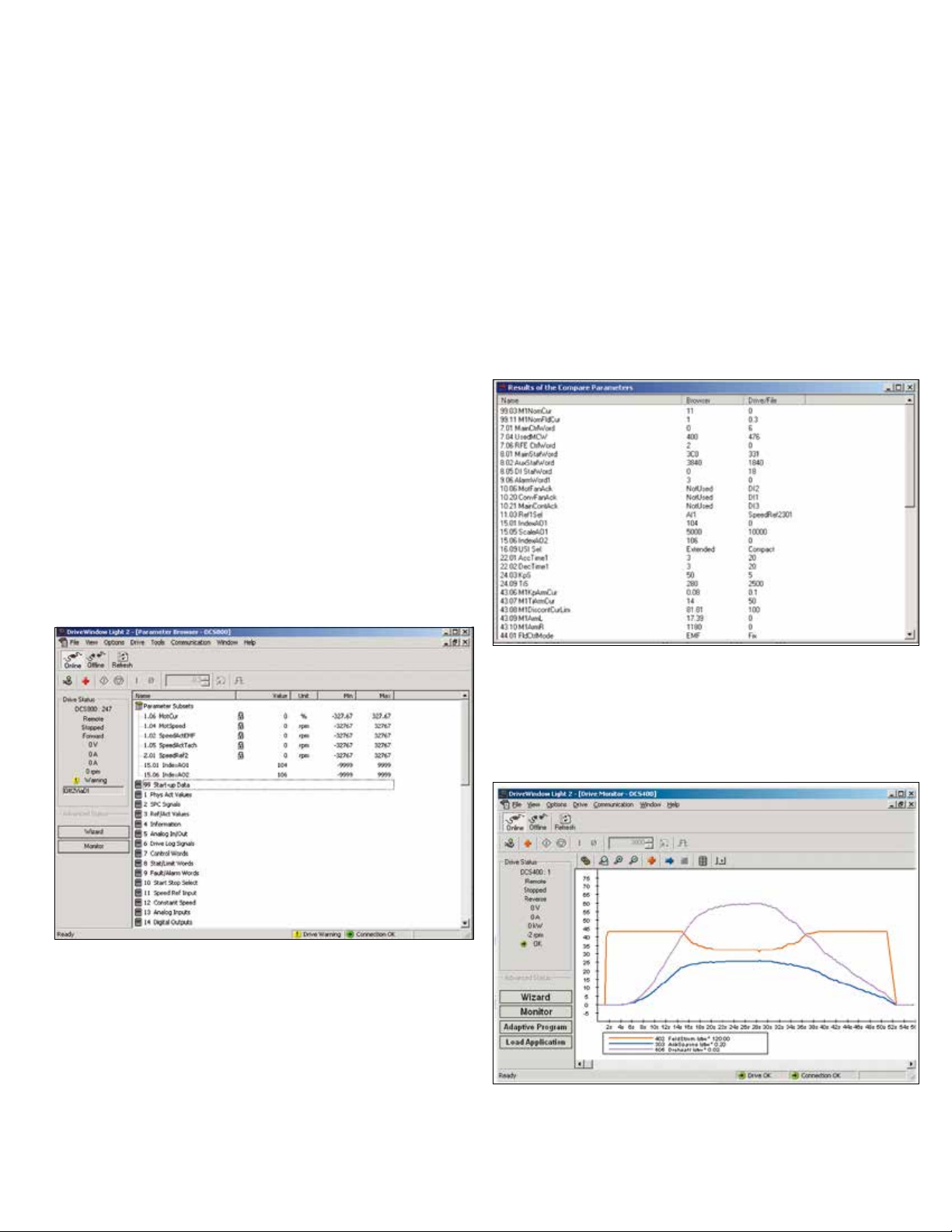

DriveWindow Light

Startup and Maintenance Tool

PC tool for ABB drives

DriveWindow Light is an easy-to-use tool for PC-based start

up and maintenance of your ABB drive. It is included with every

DCS800 drive and has the following features:

− User interface tool to view and set parameters

− Startup Assistant tool

− Adaptive Programming (AP) tool

− Fault Logging/Troubleshooting

It supports a wide range of ABB industrial drives, including

ACS350, ACS550, ACS800, as well as the DCS800.

Highlights

− Viewing and setting parameters in offline and online modes

− Editing, saving and downloading parameters

− Comparing parameters

− Graphical and numerical signal monitoring

− Drive control

− Start-up assistants

− DWL AP tool for DCS800 (for Adaptive Programming)

− All DCS800 DC drives are equipped with DriveWindow Light

Light Software with Heavy Features

DriveWindow Light offers many functions in an easy-to-use

package. It can be used in an offline mode, which enables

parameter setting at the office even before going to the actual

site. The parameter browser enables viewing, editing and saving

of parameters. The parameter comparison feature makes it

possible to compare parameter values between the drive and

the file. With the parameter subset you can create your own

parameter sets. Controlling of the drive is naturally one of the

features in DriveWindow Light. Drive status and fault information

keeps commissioning time low.

With DriveWindow Light, you can monitor up to four signals

simultaneously. This can be done in both graphical and numerical

format. Any signal can be set to start the monitoring from a predefined level.

ABB DCS800 Technical Catalog 11

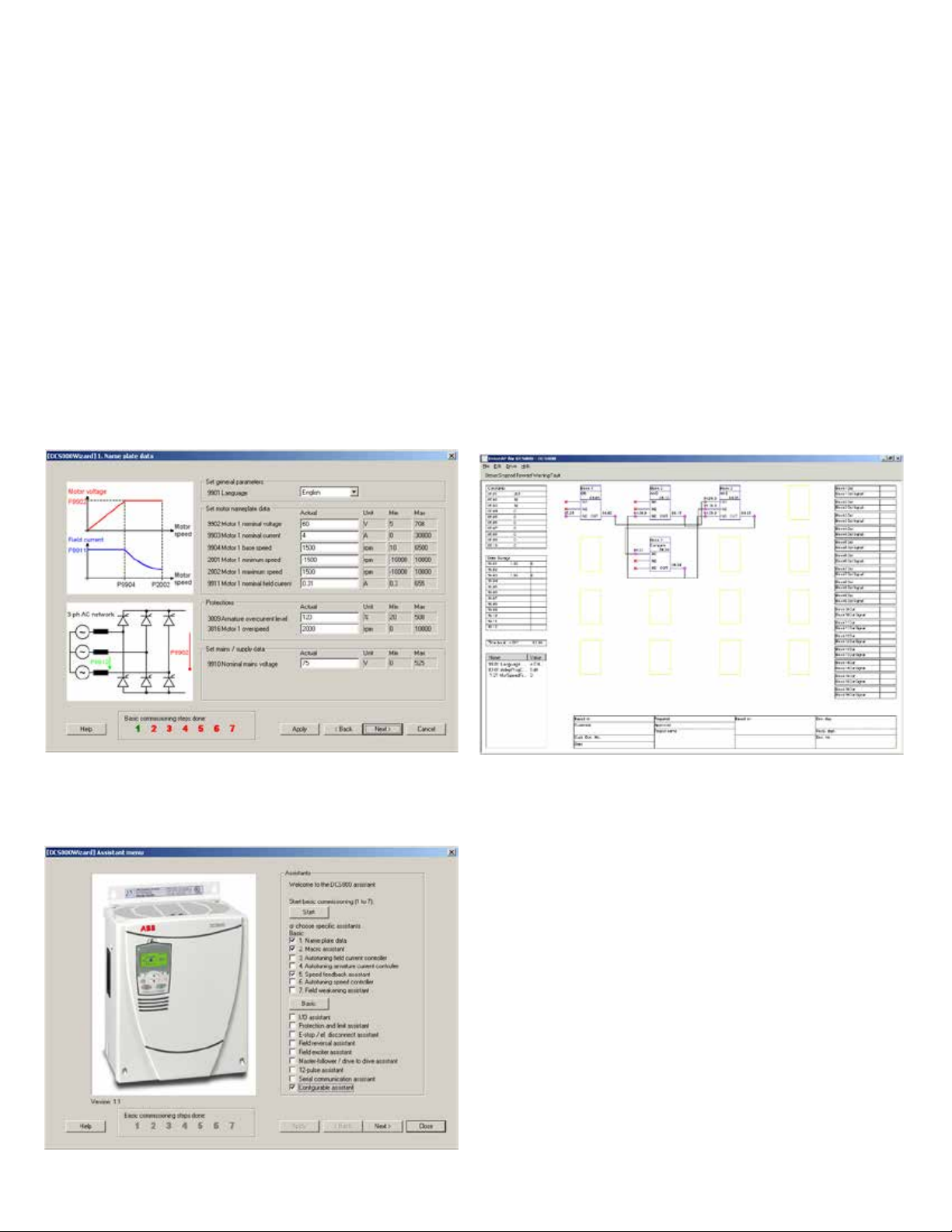

DriveWindow Light

Startup and Maintenance Tool

DWL Start-Up Assistant

DWL Start-Up Assistant for DCS800 gives important assistance

for commissioning by interactive dialog. The commissioning

steps are presented in correct sequence and necessary

parameters are preselected.

− The basic assistant collects motor and connection data and

executes controller auto tunings

− Advanced assistants provide guidance for 12-pulse

operation, field reversal, network communication (fieldbus)

and master-follower configuration.

− A context-sensitive help function is present during the whole

sequence

Adaptive Programming (AP) Tool

DWL AP is a graphical PC tool to create, document, edit and

download Adaptive Programs. Adaptive Program tools contain 16

function blocks and are available in standard firmware. DWL AP

offers a clear and easy way to develop, test and document these

programs with a PC.

It is a user-friendly tool to modify function blocks and their

connections. No special programming skills are required; basic

knowledge about block programming is sufficient.

Adaptive Programs are easy to document as hard copies are store

as PC files. All related information is saved directly to the drive by

parameter.

One page is freely configurable by the user. An individual

commissioning sequence or parameter selection can be setup

to application, machine or motor demands.

12 ABB DCS800 Technical Catalog

Loading...

Loading...