ABB DCS800 Brochure

ABB DC drives

DCS800, 10 to 4000 Hp

The practical requirements of a modern

DC drive are extremely diverse. A drive

should be full of features and easy to use

– not a simple task. The challenge is to

find an innovative solution which excels

in both - the solution is the DCS800.

The DCS800’s simple interface and rich

feature set allow you to commission your

drive quickly and adapt it easily to your

specific application. The DCS800 has the

widest power range in the industry, all

the way up to 2500 hp in a single module

package and solutions up to 1200 Volts

and 20,000 Amps.

The latest technology on a proven power

platform

The DCS800 has the most advanced digital

controller of any DC drive on our proven power platform. What does that mean for you?

It means 16-bit analog I/O; 5 msec response time to a step input; 2 msec response

time for overriding control; and integrated

speed, torque, PID, and voltage controls as

standard. It also means automatic tuning to

simplify commissioning, macros to simplify

setup, and Adaptive Programming feature that allows you to easily customize to

your needs. The latest digital technology

on a proven power platform – that is the

DCS800.

Commissioning made easy

Starting up the DCS800 is made easy with

these important features:

− Startup Assistant gives step-by-step

guidance

− Optimized automatic tuning

− Automatic phase sequence detection

− Automatic encoder adjustment

− Pre-defined macros for common applications

− Plain language user guide and help

functions

− Simplified fault diagnostics

− High resolution control panel

AP Programming adds Flexibility

Adaptive Programming (AP) gives you the

ability to customize the drive to your needs

without adding more hardware. Change

how a digital output works, add a PI controller, or filter an analog input – all these

things are possible. You program the drive

with the control panel or your PC using

DriveWindow Light (included with every

drive). Adaptive Programming gives you the

flexibility you need to make the drive work

to your specifications.

Adaptability second to none

The DCS800 functionality increases according to the requirements of the user. You

have the ability to include plug-in options

like field bus modules, I/O extension modules, and fiber-optic communication modules. ABB’s field bus alternatives give you full

access to drive control and status words

and to system diagnostics. This makes your

choice of automation system completely

independent from your decision to use firstclass ABB drives.

The DCS800 also offers the adaptability

of Control Builder, the tool that puts a fully

programmable PLC inside your drive. Con-

trol Builder can modify the drive operation,

interface, or create whole new functions

for your machine. Based on IEC61131, it is

easy to program in any one of six programming languages.

Accessibility through your PC

ABB offers a wide range of software for

your PC to make accessing, programming,

and diagnostics easier than ever before.

DriveWindow Light, included with every

drive, gives you a powerful tool to start up

and interface with your ABB drive. More

complex systems use the original highspeed DriveWindow tool. Its host of features, high speed data, and clear graphical

presentation of the operation make it a valuable addition to your system. For Control

Builder users, CoDeSys gives you all the

tools you need to create and modify your

applications. If that’s not enough, we can

even give your drive its own Web page with

full inter net access.

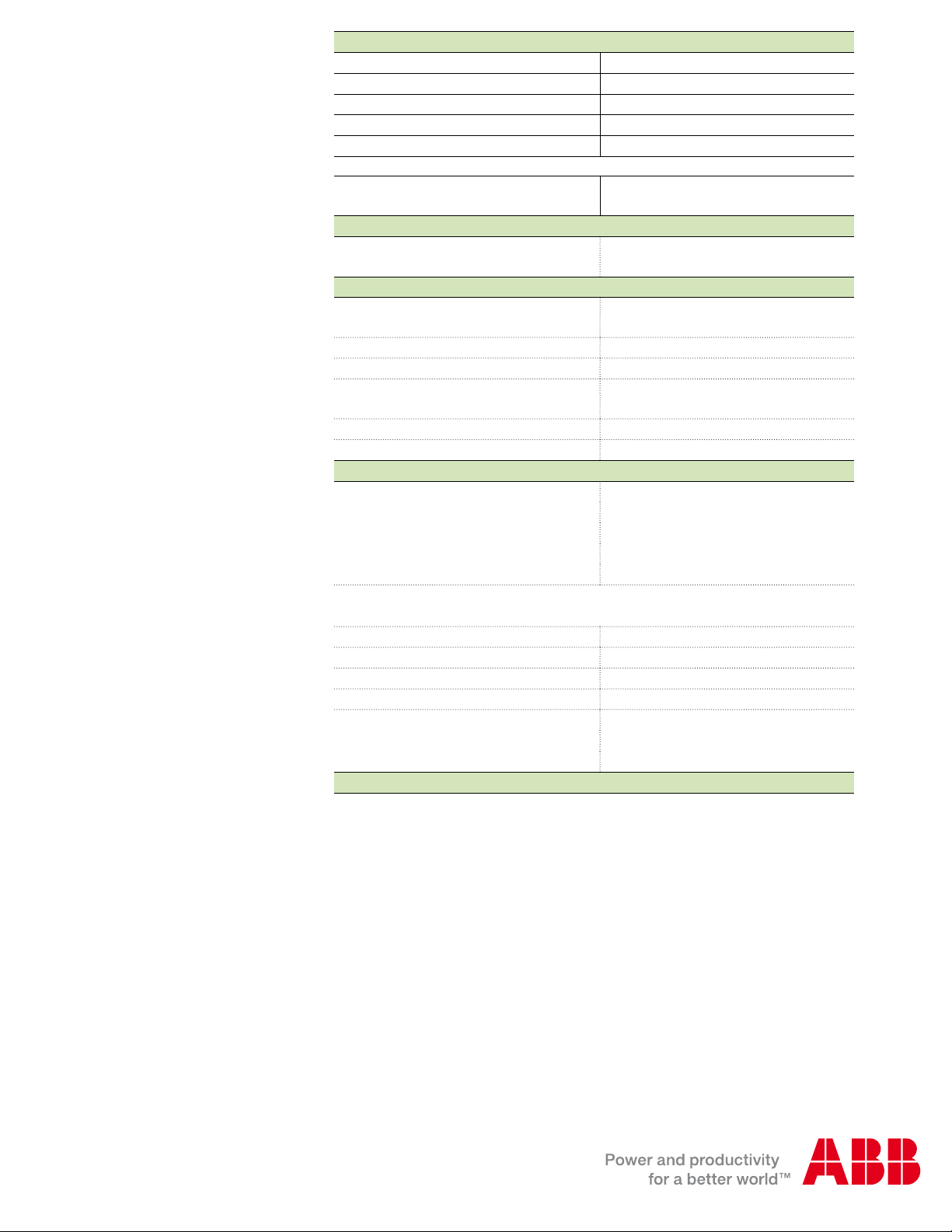

Product Highlights

Communication options

− Profibus-DP

− CANopen

− Modbus RTU

− DeviceNet

− ControlNet

− Ethernet/IP, Modbus TCP

Protections

− Temperature

− Motor stalled

− Motor over voltage

− Armature current ripple

− Mains over- and under-voltage

− Over speed

− Motor over current

− Field over voltage

− Zero speed

− Overload

− Field over current

− Minimum field current

− Speed feedback monitoring

Adaptive Programming

− Up to 16 function blocks from a library of

30 types

− Pre-defined drive-specific function blocks

examples include:

− Free process controller (PI-Controller)

− I/O and digital operations

− With control panel or PC-Tool there is no

need for additional hardware

System connection

Voltage, 3-phase 240 to 990 V acc. to IEC 60038

Voltage deviation ±10% continuous

Rated frequency 50 Hz or 60 Hz

Static frequency deviation 50 Hz ±2 %; 60 Hz ±2 %

Dynamic: frequency range 50 Hz: ±5 Hz; 60 Hz: ± 5 Hz

Please note: Special consideration must be taken for voltage deviation in re generat ive mod e.

Short Circuit Current Rating

(SCCR)

Protection Class

Converter module and options (line chokes,

fuse holder, fi eld supp ly u nit, etc .)

Speed Feedback / Accuracy

Speed resolution with encoder 0.005% of nominal speed, with

Cycle time, speed and current controller 2.77 ms at 60 Hz, 3.33 ms at 50 Hz

Step response, current controller 5 ms

Speed feedback EMF (transducerless), analog tach, encoder,

Analog tach voltage ±8-30 Vdc, ±30-90 Vdc, ±90-270 Vdc

Pulse encoder voltage 5, 12, 15, 24 Vdc

Environmental limit values

Permissible cooling air temperature.

- at converter module air inlet 0 to +55°C

with rated DC current 0 to +40°C

with different DC current +40 to +55°C derating (1%/1

- options 0 to +40°C

Relative humidity (at 5...+40°C): 5 to 95%, no condensation

Relative humidity (at 0...+5°C): 5 to 50%, no condensation

Change of the ambient temp.: < 0.5°C / minute

Storage temperature: -40 to +55°C

Transpo rt t empe ratu re: -40 to +70°C

Pollution de gree (IEC 60664-1, IEC 60439-1): 2

Site elevation

<1000 m above M.S.L.: 100%, without derating

1000 to 4000 m M.S.L.: with derating (1%/100m)

Product Compliance

UL, cUL, CE, C-TICK

D1-D4 = 65 kA

D5-D7 = 100 kA

UL Type Open

analog tach, 0.1% (16 bits)

2nd encoder with RTAC

o

C)

DCS800 -PHPB01 U-EN REVA Efefctive: 1/15/2010 Subject to change w ithout notice.

For more information please contact:

www.abb.us/drives

Copyright 2010 ABB. All rights reserved.

Specifications subject to change without notice.

Loading...

Loading...