ABB circuit breaker Accessories Catalog

Accessories

Versions and types

Fixed circuit breaker

3

Tmax XT circuit breakers are available in the following versions:

n

FIXED. These have a current-interrupting part connected to the trip unit, to be installed on the

back plate of the box;

n

PLUG-IN. These have a moving part and a fixed part. The latter must be installed on the back

plate of the box. The moving part comes in the kit that converts the fixed version into a plug-in

version;

n

WITHDRAWABLE. These have a moving part and a fixed part, equipped with side runners to

allow easy racking in/out of the moving part. The fixed part is installed on the back plate of

the box. The moving part comes in the kit that converts the fixed version into a withdrawable

version. To create the withdrawable circuit breaker, it’s necessary to order a front accessory to

maintain the IP40 degree of protection over the circuit breaker’s entire isolation run.

If the plug-in circuit breaker is fitted with electrical accessories, appropriate connectors for

insulating the corresponding auxiliary circuits must also be ordered. For the withdrawable version,

there are dedicated accessories fitted with connectors enabling automatic disconnection when

racking-out. (Consult the “Connectors for electrical accessories” section of this chapter).

Using the fixed version as a base, SACE Tmax XT circuit breakers can easily be converted into

plug-in and withdrawable versions with the appropriate conversion kits. The moving part can

always be obtained in the required version, fully pre-engineered in the factory, by ordering the

fixed circuit breaker and the conversion kit at the same time.

Plug-in circuit breaker

Withdrawable circuit breaker

Version

Fixed Plug-in Withdrawable

XT1

XT2

XT3

XT4

n n

n n n

n n

n n n

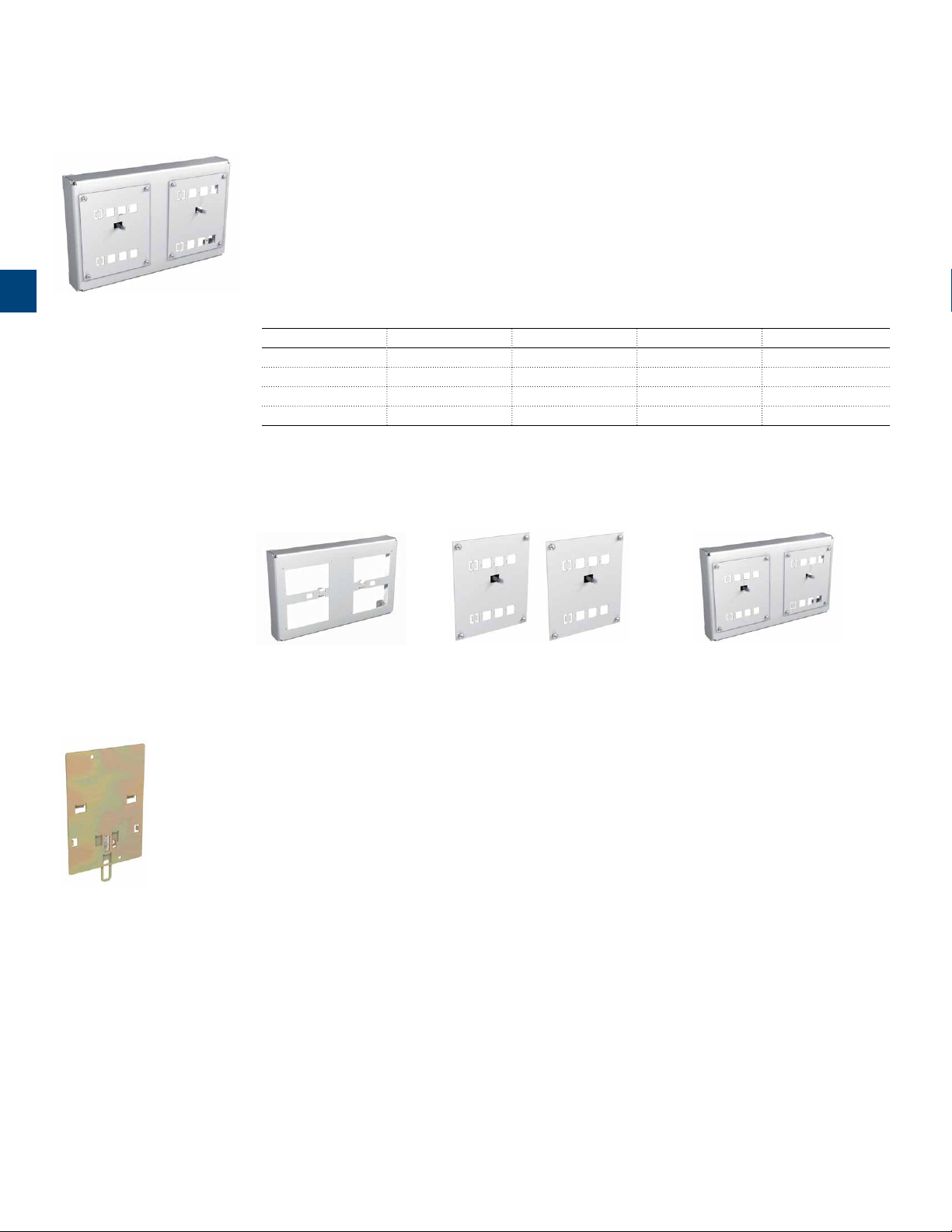

Fixed part of plug-in and withdrawable versions

The fixed parts of the plug-in/withdrawable versions are available with extended front terminals

(EF). The fixed parts can be equipped with some of the same terminal, terminal-cover and phase

barrier kits used for the fixed circuit breakers, by using the proper adapter.

The fixed parts of a plug-in/withdrawable circuit breaker can be installed at a distance of

50mm/1.97in from the back of the panel or at 70mm/2.76in as shown in the picture.

3/2 SACE Tmax XT UL/CSA | US Technical Catalog

Installing at 50mm/1.97in

Installing at 70mm/2.76in

Conversion kit for turning a fixed

circuit breaker into the moving

part of a plug-in circuit breaker

Conversion kit for turning a fixed

circuit breaker into the moving

part of a withdrawable circuit

breaker

Conversion kit for turning a fixed

part of plug-in version into the

fixed part of a withdrawable

version

Conversion kits

The following conversion kits can be obtained in order to create the different versions:

n

Kit for converting the fixed circuit breaker into the moving part of plug-in/withdrawable

versions. When withdrawable versions are made, it is essential to order an accessory to apply

to the front of the circuit breaker in order to maintain the IP40 degree of protection over the

entire isolation run. This accessory can be chosen from:

– front for lever operating mechanism (FLD);

– motor operator (MOE);

– direct or extended rotary handle operating mechanisms (RHD or RHE).

If no accessory is indicated, the front for lever operating mechanism (FLD) is automatically

included in the order.

n

Kit for converting the fixed part of plug-in versions into the fixed part of withdrawable

versions. The kit comprises:

– a guide for turning the fixed part of the plug-in circuit breaker into the fixed part of the

withdrawable circuit breaker;

– a racking-out rotary handle that allows the moving part to be inserted and withdrawn. The

mechanism allows the circuit breaker to be set to the isolated position (with the power

and auxiliary circuits disconnected) with the compartment door closed, for operator safety.

The rotary handle can only be inserted when the circuit breaker is open. Once it has been

removed or withdrawn, the circuit breaker can be set to the open/closed position;

– a flange for the compartment door, which replaces the one supplied with the fixed version of

the circuit breaker.

n

Kit for converting fixed type into the plug-in version for RC Sel residual current devices

for XT2-XT4. RC Sel four-pole residual current devices for XT2 and XT4 can be converted from

the fixed version into the plug-in version using the special kit.

n

Kit for converting plug-in types into the withdrawable version for RC Sel residual current

devices for XT2-XT4. RC Sel four-pole residual current devices for XT2 and XT4 can be

converted from the plug-in version to the withdrawable version using the special kit, which

comprises a bellows to apply to the front of the residual current device so as to allow it and

the residual current part to be withdrawn when the panel door is closed. This kit can also

be assembled on fixed circuit breakers fitted with the front part for locks or the direct rotary

handle, thus adding to the range of uses for residual current devices.

In the plug-in to withdrawable conversion kit, there is also a 6-pin connector to be applied onto

the right side of the circuit breaker to facilitate disconnecting the auxiliary circuits connected to

the residual current device.

This kit contains also the shunt opening release of the residual current device dedicated to the

withdrawable version, which is fitted with a connector for the fixed part and the moving part.

3

US Technical Catalog | SACE Tmax XT UL/CSA 3/3

Accessories

Versions and types

Plug-in version

+ + =

3

Fixed part of

plug-in

Withdrawable version

1st solution

Fixed part of

withdrawable

2nd solution

Fixed

circuit breaker

+ + =

Fixed

circuit breaker

Conversion kit for turning a fixed

circuit breaker into the moving

part of a plug-in

circuit breaker

Conversion kit for turning a

fixed circuit breaker into the

moving part of a withdrawable

circuit breaker

Plug-in

circuit breaker

+

Frontal

accessory

(1)

Withdrawable

circuit breaker

+ + +

Fixed part

of plug-in

(1)

Frontal accessory is mandatory. If not specified in the order, the FLD is supplied automatically

3/4 SACE Tmax XT UL/CSA | US Technical Catalog

Conversion kit for turning a

fixed part of plug-in version

into the fixed part of a

withdrawable version

Fixed

circuit breaker

Conversion kit for turning a

fixed circuit breaker into the

moving part of a withdrawable

circuit breaker

+

Frontal

accessory

=

Withdrawable

(1)

circuit breaker

Accessories

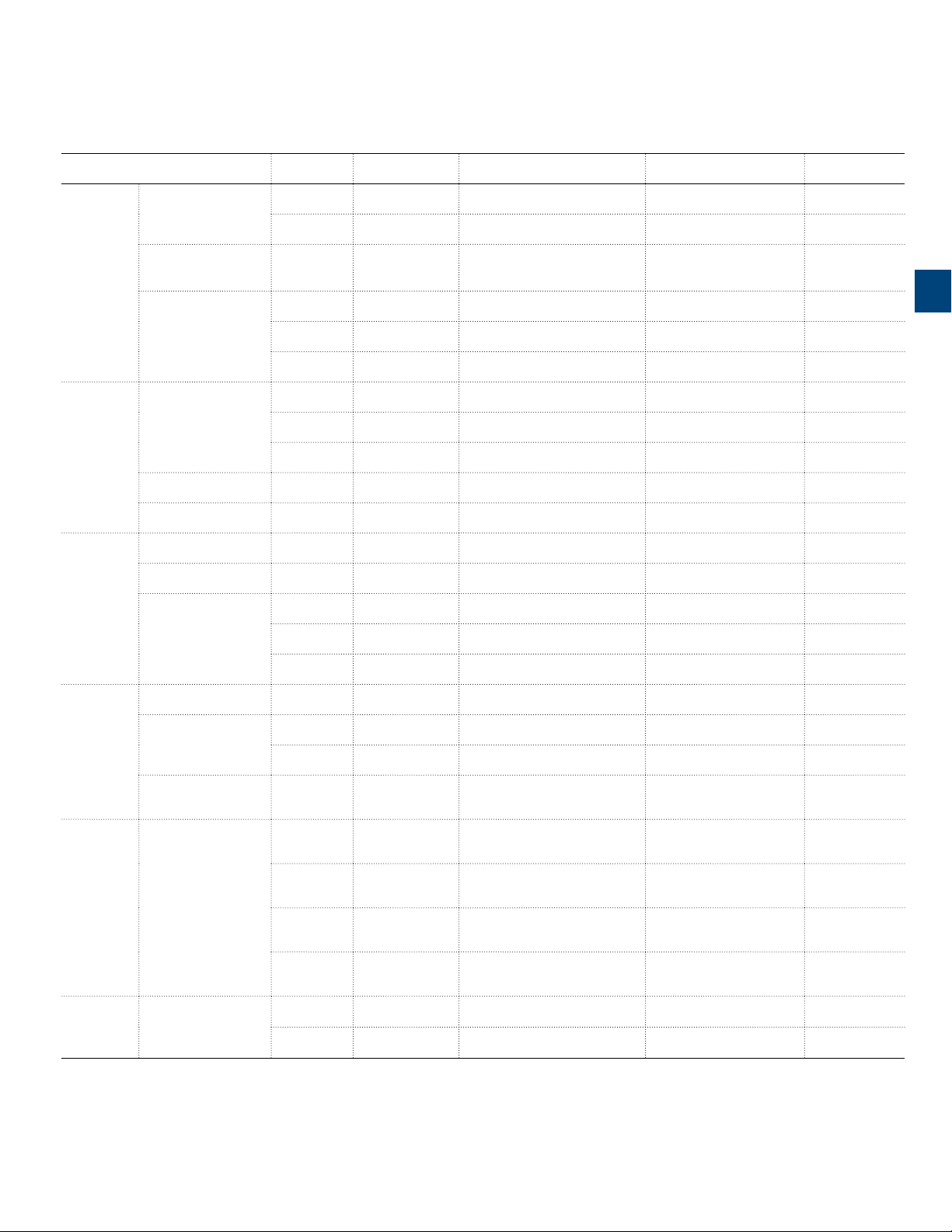

Mechanical accessories

Terminals

Terminal covers

Phase barriers

Flange handle operating mechanism MKC - Cable operated flange handles

Rotary handle operating mechanism

Front for operating lever mechanism FLD - Front for locks

Locks on circuit breaker

Mechanical interlock

F - Front terminals

EF - Extended front terminals

ES - Extended spread terminals

FCCu - Front for copper cables

FCCuAl - Front for copper/aluminum cables

FB - For flexible busbars

MC - Multi cable for copper cable

R - Rear oriented

EF - Extended front for the fixed part

HR/VR - Horizontal rear / Vertical rear for fixed part

R for RC - Rear for residual current release

LTC - Low terminal cover

HTC - High terminal cover

PB - 25mm/0.98in

PB - 100mm/3.94in

PB - 200mm/7.87in

RHD - Direct rotary handle

RHE - Extended rotary handle

RHS - Side rotary handle (right and left sides)

LH - Long "pistol" rotary handle (for RHE or RHS)

RHL - Rotary handle/front lever lock, open

RHL - Rotary handle/front lever lock, open/closed

PLL - Padlock device, removable

PLL - Padlock device, open

PLL - Padlock device, open/closed

KLC - Key lock, open

KLC - Key lock, open/closed

MIR - Mechanical interlock (HR and VR)

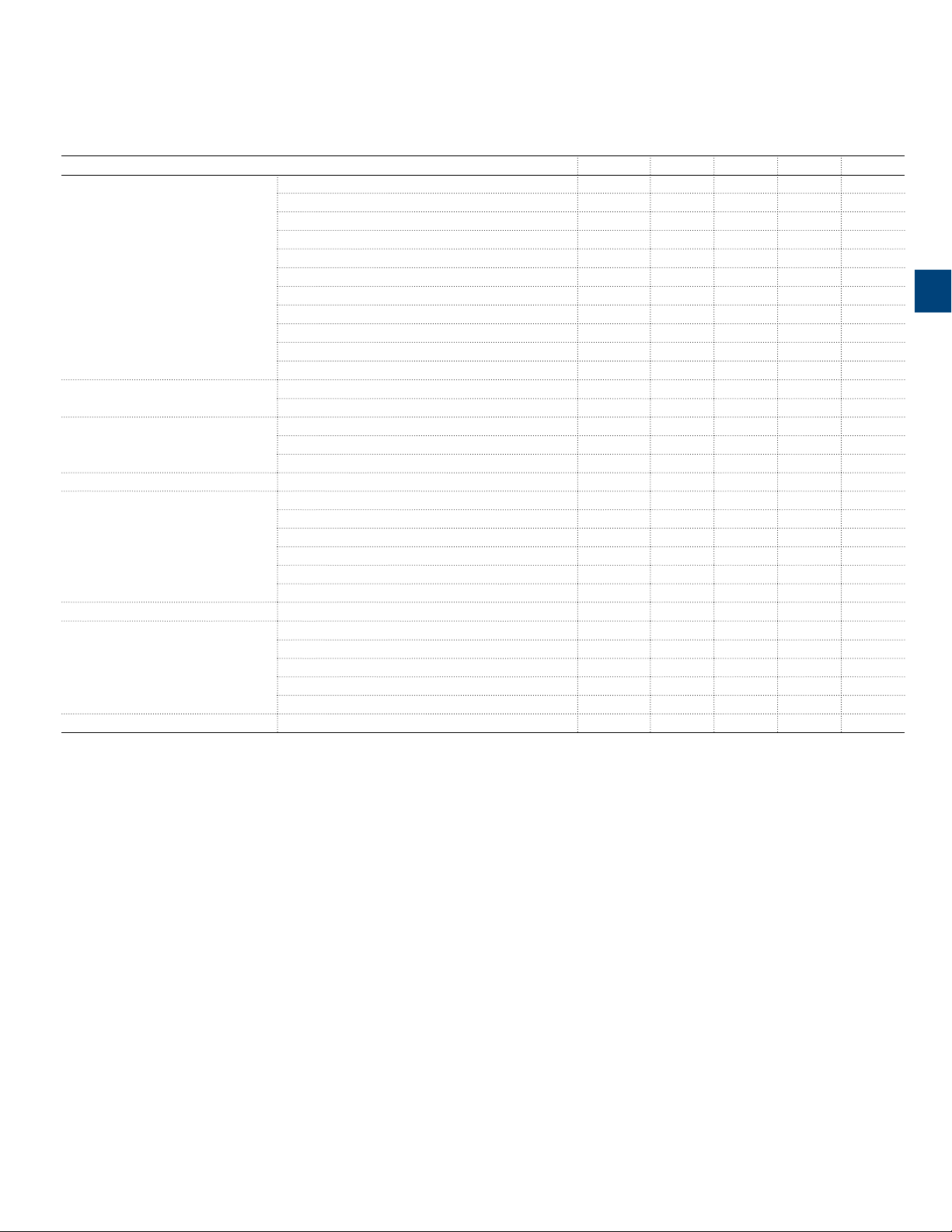

UL Listed XT1 XT2 XT3 XT4

n n n n n

n n n n n

n n n n n

n n n n n

n

–

n n n n n

–

n n n n n

–

–

–

n n n n n

n n n n n

n n n n n

n n n n n

n n n n n

n n n n n

n n n n n

n n n n n

n n n n n

n n n n n

n n n n n

n

n n

n n n n n

n n n n n

n n n n n

n n n n n

n n n n n

– –

n n n n

n n n n

n n n n

n

n n n n

–

–

n

–

n n

n

–

n

–

n

–

3

Connection terminals

Connection terminals allow the circuit breaker to be connected to the system in the way best

suited to the installation requirements. By and large, they consist of front terminals for connecting

cables or busbar directly from the front of the circuit breaker.

Where possible, the terminals have laser markings on the surface to indicate the tightening

torques for the correct isolation of cables and bars.

Fixed version

Standard SACE Tmax XT circuit breakers for UL and CSA are supplied with front terminals (F).

However, they can be fitted with the following types of terminal as accessories thanks to the

special kits:

n

extended front (EF);

n

extended spread front (ES);

n

front for copper/aluminum cables (FCCuAI), for XT3 and XT4 sizes;

n

front for copper cables (FCCu);

n

multicable for copper cable (MC);

n

for flexible busbar (FB);

n

rear oriented (R)1).

For XT1 and XT3 sizes, the use of non-insulated busbar with Ue ≤ 480V involves the mandatory

assembly of terminal-covers HTC.

1)

IEC only

US Technical Catalog | SACE Tmax XT UL/CSA 3/5

Accessories

Mechanical accessories

Plug-in and withdrawable versions

The fixed part of plug-in and withdrawable version circuit-breakers is normally supplied with

extended front terminals (EF) or horizontal/vertical rear terminals (HR/VR).

Horizontal/vertical rear terminals (HR/VR) are factory-mounted in the horizontal position. If

needed, the terminals can easily be field-rotated to the vertical position.

A fixed part with front terminals (EF) can be converted into a fixed part with rear terminals

3

(HR/VR) by ordering the appropriate terminal kit. The fixed parts can also be fitted with some

of the same types of terminal available on the fixed circuit breaker after an adapter has been

installed on the terminal zone of the fixed part itself. Consequently, the following types of

connection terminals are also acceptable for use with the fixed part:

n

extended spread front (ES);

n

for copper cables (FCCu);

n

multi-cable (MC).

n

for copper and aluminum cables (FCCuAl);

n

for flexibar (FB).

The adapter mimics the terminal zone of the fixed circuit breaker. This means that fixed parts can

also be equipped with the same terminal covers and phase separators as those used for fixed

circuit breakers.

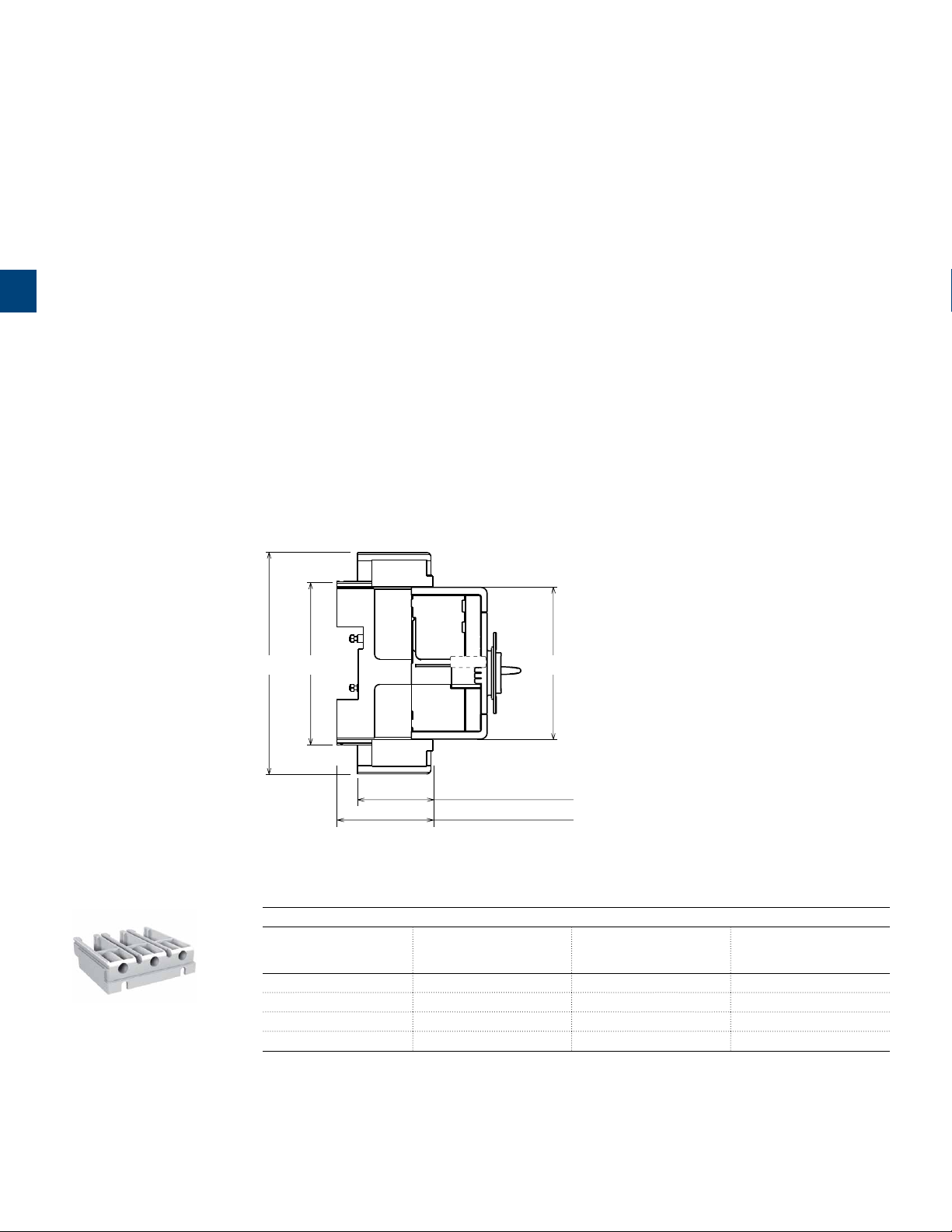

Fixed part adapter

H3H

Fixed part adapter

Circuit breakers H1

XT1 146/5.75 134/5.28 181/7.13

XT2 153/6.02 134/5.28 188/7.40

XT3 166/6.54 154/6.06 225/8.86

XT4 182/7.17 164/1.46 228/8.98

1

Installing at 50mm/1.97in

Installing at 70mm/2.76in

fixed part

[mm/in]

H

2

H2

circuit breaker

[mm/in]

H3 fixed part

with two adapters

[mm/in]

3/6 SACE Tmax XT UL/CSA | US Technical Catalog

Front terminals - F

D

W

CB. Vers. Busbar dimensions

(1)

[mm/in]

Cable terminals

[mm/in]

Tightening

[Nm/lb-in]

W min W max H Ø D min D max W Ø Cable or busbar

H Terminal covers

[mm/in]

H Phase separators

[mm/in]

2/0.08 50/1.97 60/2.36 25/0.98 100/3.94 200/7.87

/Terminal

XT1 F 13/0.512 16/0.630 7.5/0.295 6.5/0.256 3.5/0.138 5/0.197 16/0.630 6.5/0.256 M6 6/53.1 – R – S R R

XT2 F 13/0.512 20/0.787 7.5/0.295 6.5/0.256 2.5/0.098 5/0.197 20/0.787 6.5/0.256 M6 6/53.1 – R – S R R

XT3 F 17/0.669 25/0.984 9.5/0.374 8.5/0.335 5/0.197 8/0.315 24/0.945 8.5/0.335 M8 8/70.8 – – R S R R

XT4 F 17/0.669 25/0.984 10/0.394 8.5/0.335 5/0.197 8/0.315 25/0.984 8.5/0.335 M8 8/70.8 – – R S R R

(1)

UL Listed

F terminal with cable lug F terminal with busbarFront terminal - F

3

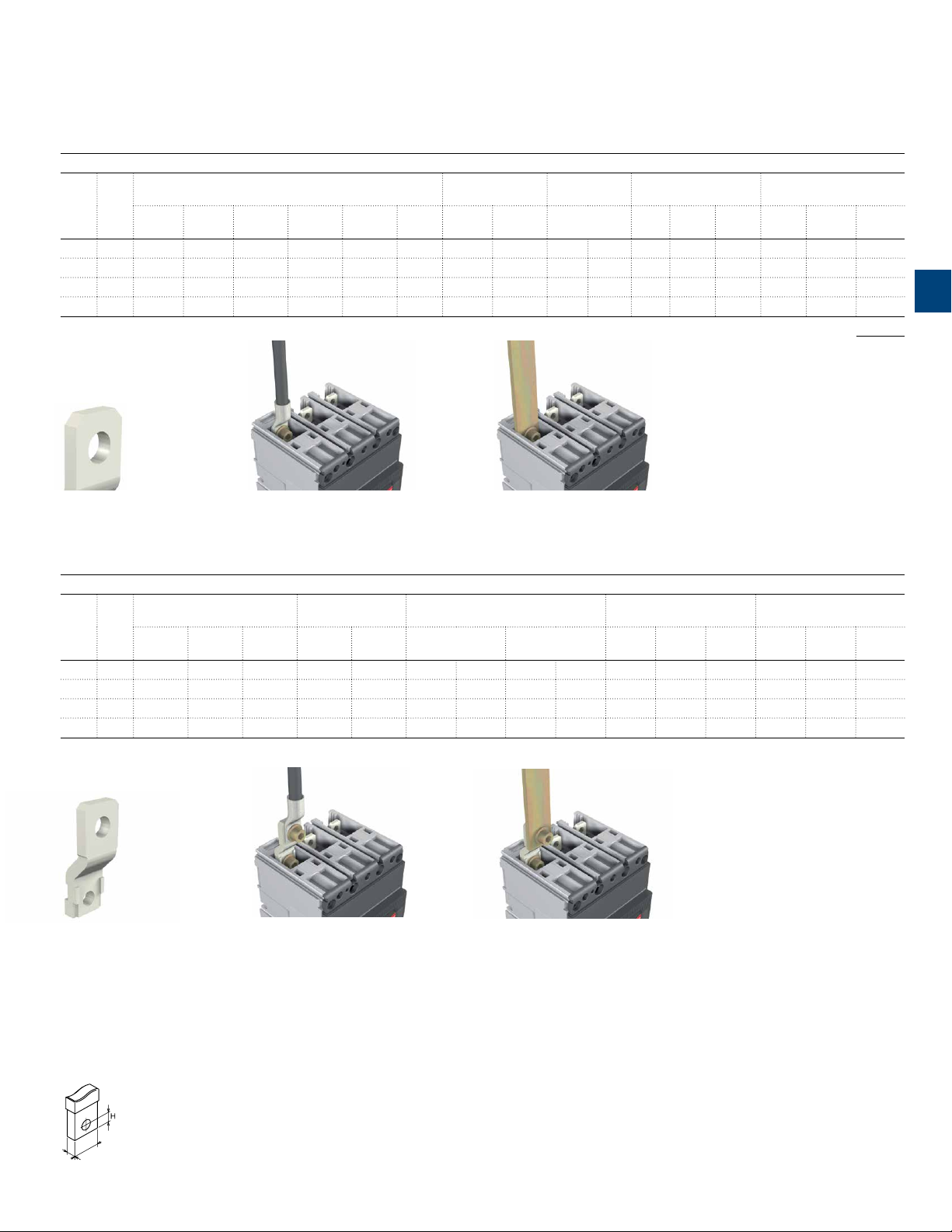

Front extended terminals - EF

CB Vers. Busbar dimensions

[mm/in]

W D Ø W Ø Terminal

(1)

Cable terminals

[mm/in]

Tightening

[Nm/lb-in]

/CB

Cable or busbar

/Terminal

H Terminal covers

[mm/in]

H Phase separators

[mm/in]

2/0.08 50/1.97 60/2.36 25/0.98 100/3.94 200/7.87

XT1 F 20/0.787 4/0.157 8.5/0.335 20/0.787 8.5/0.335 M6 6/53.1 M8 9/79.7 – R – – S R

XT2 F 20/0.787 4/0.157 8.5/0.335 20/0.787 8.5/0.335 M6 6/53.1 M8 9/79.7 – S – – S R

XT3 F 20/0.787 6/0.236 10/0.394 20/0.787 10/0.394 M8 8/70.8 M10 18/159.3 – – R – S R

XT4 F 20/0.787 10/0.394 10/0.394 20/0.787 10/0.394 M8 8/70.8 M10 18/159.3 – – S – S R

(1)

UL Listed

Front extended terminal - EF EF terminal with cable lug EF terminal with busbar

W Width F Fixed

H Hole height P Plug-in

D Depth W Withdrawable

Ø Diameter

S Standard

R On Request

US Technical Catalog | SACE Tmax XT UL/CSA 3/7

D

W

Accessories

Mechanical accessories

Front extended spread terminals - ES

CB Vers. Busbar dimensions MAX

[mm/in]

W D Ø W Ø Terminal

(1)

Cable terminals

[mm/in]

Tightening

[Nm/lb-in]

/CB

Cable or busbar

/Terminal

H Terminal covers

[mm/in]

H Phase separators

[mm/in]

2/0.08 50/1.97 60/2.36 25/0.98 100/3.94 200/7.87

XT1 F-P 25/0.984 4/0.157 8.5/0.335 25/0.984 8.5/0.335 M6 6/53.1 M8 9/79.7 – – – – – S

XT2 F-P-W 30/1.181 4/0.157 10.5/0.413 30/1.181 10.5/0.413 M6 6/53.1 M10 18/159.3 – – – – – S

XT3 F-P 30/1.181 4/0.157 10.5/0.413 30/1.181 10.5/0.413 M8 8/70.8 M10 18/159.3 – – – – – S

3

XT4 F-P-W 30/1.181 10/0.394 10.5/0.413 30/1.181 10.5/0.413 M8 8/70.8 M10 18/159.3 – – – – – S

(1)

UL Listed

Front extended spread terminal

- ES

ES terminal with cable

lug

ES terminal with busbar

Terminals for copper cables - FCCu

CB Type of

Vers. Cable Inner dimensions

terminal

AWG/kcmil mm

(3)

XT1

internal F-P 1x14…1/0 1x2.5…70 12x12/0.472x0.472 7/61.95 16/0.629 – R – S

(4)

XT1

internal F-P 1x14…1/0 1x1.5…70 9,5x16/0.37x0.63 7/61.95 16/0.629 – R – S

XT2 internal F-P-W 1x14…1/0 1x2.5…95 14x14/0.551x0.551

XT3 internal F-P 1x10…250 1x6…185 18x18/0.709x0.709 14/123.91 20/0.787 – – R S

XT4 internal F-P 1x10…250 1x6…185 18x18/0.709x0.709 14/123.91 16/0.787 – – R S

(2)

[mm/in]

2

[Nm/lb-in]

Cable or busbar/Terminal 2/0.08 50/1.97 60/2.36 25/0.98 100/3.94 200/7.87

2

<50mm

(1/10 AWG): 7/61.95

2

≥50mm

(1/10 AWG): 8,5/75.23

Tightening

L cable

stripping

H Terminal covers

[mm/in]

[mm/in]

14/0.551 – R – S

H Phase separators

[mm/in]

(1)

R R

(1)

R R

(1)

R R

(1)

R R

(1)

R R

XT4 internal F-P 1x14-1/0 1x2.5...50 1x2.5...50 – – – – – – – –

(1)

Phase separators are supplied as standard with the basic version of the circuit breaker;

(2)

UL Listed;

(3)

MCCB only application;

(4)

MCCB/MCP application.

FCCu terminal FCCu terminal with cable FCCu terminal with busbar

W Width F Fixed

H Hole heigth P Plug-in

D Depth W Withdrawable

3/8 SACE Tmax XT UL/CSA | US Technical Catalog

Ø Diameter

S Standard

R On Request

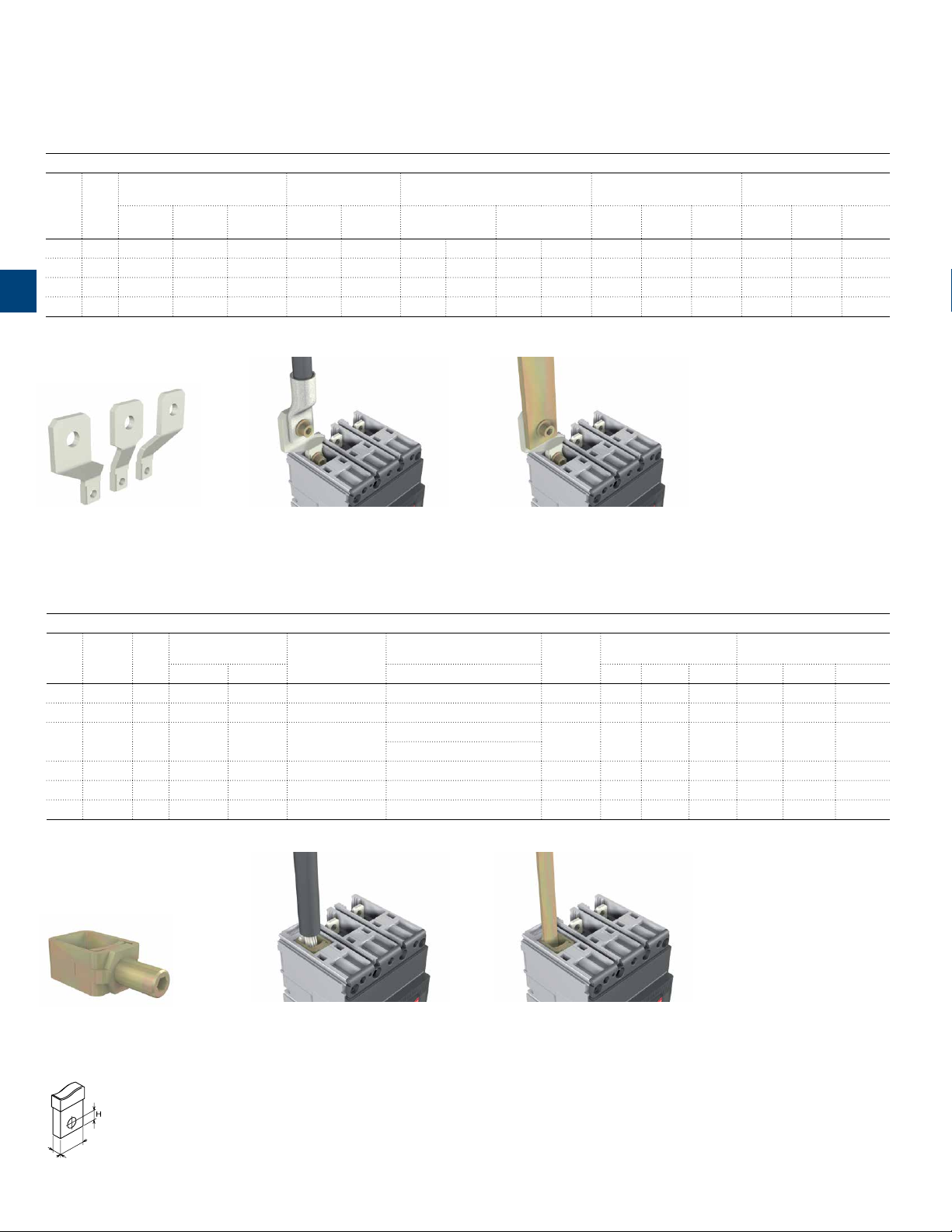

Terminals for copper cables - FCCuAl

D

W

CB Type of

Vers. Cable Tightening

terminal

AWG/kcmil mm

XT2 internal F-P 1x14…1/0 1x2.5…50 2.5/22.12 M6 ≤ 8mm2 (8 AWG):4.5/39.82

(1)

L

2

Terminal/CB Cable or busbar/Terminal 2/0.08 50/1.97 60/2.36 25/0.98 100/3.94 200/7.87

[Nm/lb-in]

cable

stripping

[mm/in]

15,5/0.61

> 8mm2 (8 AWG) 5.7/50.44

XT3 internal F-P 1x14…1/0 1x2.5…50 9/79.7 slot 5.6/50 15,5/0.61

internal F-P 1x4…300 1x25…150 9/79.7 M6 22.6/200 20/0.787

XT4 internal F-P 1x14…1/0 1x2.5…50 9/79.7 slot 5.6/50 15,5/0.61

internal F-P 1x4…300 1x25…150 9/79.7 M6 22.6/200 20/0.787

XT4 internal F-P 1x250...350 1x127...177 not app M6 25/221 24

XT4 X internal F-P 1x14...1/0 1x2.5...50 9/79.7 M6 <8mm

2

(8 AWG): 2.3/20.35

16

≥8mm2 (8 AWG): 5.6/49.56

(1)

UL Listed

H Terminal covers

[mm/in]

– – –

– – –

– – –

– – –

– – –

– – –

– – –

H Phase separators

[mm/in]

S R R

S R R

S R R

S R R

S R R

S R R

S R R

3

Internal FCCuAl terminal for

copper/aluminum cables

Internal FCCuAl terminal for

copper and aluminum cable

with take-up of auxiliary

voltage

FCCuAl internal terminal

with cable

Terminals for flexible busbars - FB

CB Type of

terminal

Vers. Busbar dimensions

MIN [mm/in]

Busbar dimensions

MAX [mm]

Tightening

[Nm/lb-in]

W D Nr W D Nr Cable or busbar/Terminal

H Terminal covers

[mm/in]

2/0.08 50/1.97 60/2.36 25/0.98 100/3.94 200/7.87

XT1 internal F-P 10/0.394 0,8/0.031 2/0.078 10/0.394 0,8/0.031 9/0.354 7/61.95 – R – S

XT2 internal F-P-W 10/0.394 0,8/0.031 2/0.078 10/0.394 0,8/0.031 9/0.354 7/61.95 – R – S

XT3 internal F-P 16/0.629 0,8/0.031 2/0.078 16/0.629 0,8/0.031 10/0.394 14/123.91 – – R S

XT4 internal F-P-W 16/0.629 0,8/0.031 2/0.078 16/0.629 0,8/0.031 10/0.394 14/123.91 – – R S

(1)

Phase separators supplied as standard with basic version circuit breaker

Terminal for flexible busbars (FB) FB terminal with flexible

busbars

H Separators

[mm/in]

(1)

R R

(1)

R R

(1)

R R

(1)

R R

W Width F Fixed

H Hole heigth P Plug-in

D Depth W Withdrawable

Ø Diameter

S Standard

R On Request

US Technical Catalog | SACE Tmax XT UL/CSA 3/9

Accessories

D

W

Mechanical accessories

Multi-cable terminals - MC Cu

CB Type of

terminal

XT1 external F-P 6x14…2 6x2.5…35 6/53.1 7/61.95 10, 20, 30 / 0.394, 0.787, 1.181 – S – – – –

XT2 external F-P-W 6x14…2 6x2.5…35 6/53.1 7/61.95 10, 20, 30 / 0.394, 0.787, 1.181 – S – – – –

XT3 external F-P 6x12…2 6x2.5…35 8/70.8 7/61.95 15, 30 / 0.591, 1.181 – – S – – –

3

XT4 external F-P 6x12…2 6x2.5…35 8/70.8 7/61.95 15, 30 / 0.591, 1.181 – – S – – –

Installation on loas side only

(1)

UL Listed

Vers. Cable Tightening

(1)

AWG/kcmil mm

2

[Nm/lb-in]

Terminal

/CB

Multi-cable terminals with cablesMulti-cable terminals (MC)

Cable or busbar

/Terminal

L

cable stripping

[mm/in]

H Terminal covers

[mm/in]

2/0.08 50/1.97 60/2.36 25/0.98 100/3.94 200/7.87

H Phase separators

[mm/in]

Rear horizontal terminals - R

CB Vers. Busbar dimensions MAX

[mm]

W H D Ø Terminal/CB Cable or busbar/terminal 2/0.08 50/1.97 60/2.36 25/0.98 100/3.94 200/7.87

XT1 F 15/0.590 7.5/0.295 5/0.196 6.5/0.255 M5

XT2 F 20/0.787 9/0.354 4/0.157 8.5/0.335 M6

XT3 F 20/0.787 9/0.354 6/0.236 8.5/0.335 M8 8/70.8 M8 8/70.8 S – – – – –

XT4 F 20/0.787 9/0.354 6/0.236 8.5/0.335 M8 8/70.8 M8 8/70.8 S – – – – –

Rear horizontal terminals (R) R terminal with horizontal busbar R terminal with vertical busbar

W Width F Fixed

H Hole heigth P Plug-in

D Depth W Withdrawable

Ø Diameter

S Standard

R On Request

Tightening

[Nm/lb-in]

5/44.2

6/53.1

M6

M8

6/53.1

8/70.8

H Terminal covers

[mm]

S – – – – –

S – – – – –

H Separators

[mm]

3/10 SACE Tmax XT UL/CSA | US Technical Catalog

Extended front terminals for fixed part - EF

D

W

CB Vers. Busbar dimensions

[mm/in]

W D Ø W Ø Terminal/

(1)

Cable terminals

[mm/in]

Tightening

[Nm/lb-in]

CB

Cable or busbar

/Terminal

Phase separators

[mm/in]

100/3.94 200/7.87

XT1 P 20/0.787 5/0.197 8.5/0.335 21/0.827 6.5/0.256 M6 6/53.1 M6 9/79.7 S R

XT2 P-W 20/0.787 5/0.197 8.5/0.335 21/0.827 6.5/0.256 M6 6/53.1 M6 9/79.7 S R

XT3 P 25/0.984 8/0.315 8.5/0.335 30/1.181 8.5/0.335 M6 8/70.8 M8 18/159.3 S R

XT4 P-W 25/0.984 8/0.315 8.5/0.335 30/1.181 8.5/0.335 M6 8/70.8 M8 18/159.3 S R

(1)

UL Listed

EF terminals for fixed part

Rear flat horizontal terminals for fixed part - HR

CB Vers. Busbar dimensions

[mm/in]

W D Ø W Ø Terminal/

Cable terminals

[mm/in]

Tightening

[Nm/lb-in]

CB

Cable or busbar

/Terminal

Rear Separators

[mm/in]

90/3.543

XT1 P 20/0.787 4 8.5/0.335 20/0.787 8.5/0.335 6/53.1 9/79.7 R

XT2 P-W 20/0.787 4 8.5/0.335 20/0.787 8.5/0.335 6/53.1 9/79.7 R

XT3 P 25/0.984 6 8.5/0.335 25/0.984 8.5/0.335 8/70.8 9/79.7 R

XT4 P-W 25/0.984 10 8.5/0.335 25/0.984 8.5/0.335 8/70.8 9/79.7 R

3

HR terminals for fixed part

Rear flat vertical terminals for fixed part - VR

CB Vers. Busbar dimensions

[mm/in]

W D Ø W Ø Terminal/

Cable terminals

[mm/in]

Tightening

[Nm/lb-in]

CB

Cable or busbar

/Terminal

XT1 P 20/0.787 4 8.5/0.335 20/0.787 8.5/0.335 6/53.1 9/79.7 R

XT2 P-W 20/0.787 4 8.5/0.335 20/0.787 8.5/0.335 6/53.1 9/79.7 R

XT3 P 25/0.984 6 8.5/0.335 25/0.984 8.5/0.335 8/70.8 9/79.7 R

XT4 P-W 25/0.984 10 8.5/0.335 25/0.984 8.5/0.335 8/70.8 9/79.7 R

VR terminals for fixed part

W Width F Fixed

H Hole heigth P Plug-in

D Depth W Withdrawable

Ø Diameter

S Standard

R On Request

US Technical Catalog | SACE Tmax XT UL/CSA 3/11

Rear Separators

[mm/in]

90/3.543

Accessories

Mechanical accessories

Terminal covers and phase barriers

Terminal covers are applied to the circuit breaker to prevent accidental contact with live parts,

thereby providing protection against direct contacts. The high terminal covers are pre-punched

for knock-outs on the front to facilitate installing busbars and/or cables and ensuring correct

insulation.

The phase barrier partitions increase the insulation characteristics between the phases on a level

3

Terminal covers

Phase barriers

with the connections. They are mounted from the front, even when the circuit breaker has already

been installed, by inserting them into the corresponding slots.

The table lists the various terminal covers and phase barriers available for each SACE Tmax

XT circuit breaker. The terminal covers/phase barriers that are able to ensure adequate circuit

breaker installation and correct insulation are listed in the “Connection terminals” section of this

chapter, alongside each terminal.

HTC - High terminal covers [mm/in] 50/1.97 50/1.97 60/2.36 60/2.36

LTC - Low terminal covers

Phase barrier - low [mm/in] 25/0.98 25/0.98 25/0.98 25/0.98

Phase barrier - medium [mm/in] 100/3.94 100/3.94 100/3.94 100/3.94

Phase barrier - high [mm/in] 200/7.87 200/7.87 200/7.87 200/7.87

Rear phase barrier for FP

(1)

IEC rear terminals only

XT1 XT2 XT3 XT4

(1)

[mm/in] 2/0.08 2/0.08 2/0.08 2/0.08

[mm/in] 90/3.54 90/3.54 90/3.54 90/3.54

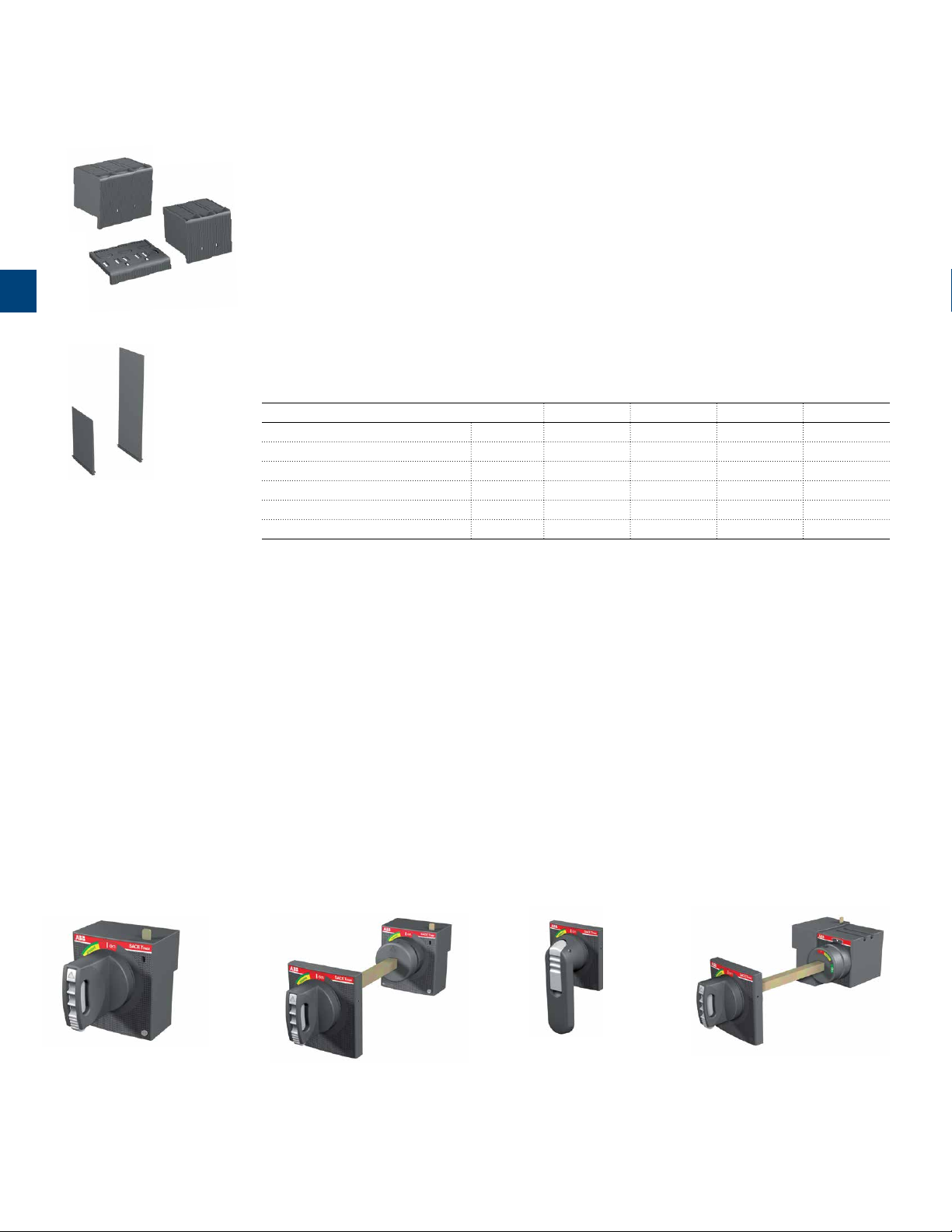

Rotary handle operating mechanism

This device allows the circuit breaker to be operated by means of a rotary handle, which makes

the circuit breaker easier to open and close.

Different types of handle are available:

n

direct (RHD): installed directly on the front of the circuit breaker. Allows it to be operated from

the front;

n

extended (RHE): installed on the panel door. Allows the circuit breaker to be operated by

means of a rod which acts on a base installed on the front of the circuit breaker;

n

side, for lateral left (RHS-L) and lateral right (RHS-R). Allows operation from the side by means

of a shaft which acts on the base installed on the front of the circuit breaker.

A long handle grip (LH) which can be combined with the extended handle (RHE) and with the side

Direct rotary handle (RHD) Extended rotary handle (RHE) (LH) Long handle (RHS) Side rotary handle

3/12 SACE Tmax XT UL/CSA | US Technical Catalog

All rotary handles are available in two versions:

n

standard: grey color;

n

emergency: red on a yellow background. Suitable for operating machine tools.

Rotary handles can be ordered:

n

by specifying one single sales code (for RHD, RHE, RHS L/R);

n

by indicating the following three devices (only for RHE):

– rotary handle on compartment door with normal standard handgrip (RHE_H, RHE_H LH)

or emergency handgrip (RHE_H_EM, RHE_H_EM LH);

– 60.5mm/2.38" and 170.5mm/6.71" rod (RHE_S). The minimum and maximum distances

between the fixing plate and the door are 60.5mm/2.38" and 170.5mm/6.71";

– base to fix to the circuit base (RHE_B).

Using the rotary handle is an alternative to the motor operator and to all accessories of the front type.

The rotary handles can be locked by means of a vast range of key locks and padlocks (consult

the “Locks” section of this chapter).

The direct and extended rotary operating mechanisms allow early contacts to be used on

closing in order to supply the undervoltage release in advance of the circuit breaker's closing

(consult the “Early auxiliary contacts” section of this chapter).

IP54 Protection

3

IP54 protection

Front for operating lever mechanism

A device that can be applied onto the transmitted rotary and lateral handle allowing IP54 degree of

protection

(G.1.11)

to be achieved.

Front for operating lever mechanism

This device can be installed on the front of the circuit breaker, allowing it to be locked with key

locks and padlocks.

The front for operating lever mechanism can only be installed on XT2 and XT4 three-pole and

four-pole circuit breakers. It can be fitted with a vast range of key locks and padlocks (see the

"Locks" section of this chapter).

US Technical Catalog | SACE Tmax XT UL/CSA 3/13

Accessories

Mechanical accessories

Locks

Padlocks or key locks prevent the circuit breaker from being closed and/or opened. They can be fitted:

n

n

Key lock

3

Fixed padlock in open position

n

n

n

n

All locks that hold the circuit breaker in the open position ensure circuit isolation in accordance with the

IEC 60947-2 Standard. In the closed position, the locks do not prevent the mechanism from releasing

after a fault or remote control.

directly on the front of the circuit breaker;

on the rotary handle operating mechanism;

on the front for lever operating mechanism;

on the motor;

to the fixed and withdrawable part, to prevent the moving part from being inserted;

on the front of the thermal magnetic trip unit, to prevent the thermal part adjustor from being tam-

pered with.

Fixed padlock in open/

closed position

Removable padlock

in open position

Key lock/padlock for

withdrawable fixed part

Circuit breaker with

removable padlock in open

position

RHD with key lock RHE with key lock FLD with key lock

Circuit breaker with fixed

padlock in open position

Circuit breaker with fixed

padlock in open/close

position

MOD with key lock MOE with key lock Withdrawable fixed part

3/14 SACE Tmax XT UL/CSA | US Technical Catalog

with key lock/padlock

Type of lock Circuit-

breaker

Circuitbreaker

PLL

Fixed padlock device

XT1…XT4 Optional OPEN / CLOSED padlocks max 3 padlocks Ø

XT1…XT4 Optional OPEN padlocks max 3 padlocks Ø

PLL

XT1, XT3 Optional OPEN padlocks max 3 padlocks Ø

Removable

padlock device

KLC

Key lock

(5)

XT1…XT4 Optional OPEN Ronis Same key

XT1…XT4 Optional OPEN Ronis

XT1…XT4 Optional OPEN Ronis

Rotary handle

(RHD/RHE/

RHE-LH/

RHS)

RHL

Key lock

(1)

XT1…XT4 Optional OPEN Ronis

XT1…XT4 Optional OPEN Ronis

XT1…XT4 Optional OPEN / CLOSED Ronis

Padlock device XT1…XT4 Standard OPEN padlocks max 3 padlocks Ø

(4)

XT1…XT4 Standard DOOR LOCKED WHEN

Frontal for

Door lock

Padlock device XT2, XT4 Standard OPEN padlocks max 3 padlocks Ø

operating

lever

(FLD)

Door lock XT2, XT4 Standard DOOR LOCKED WHEN

RHL

Key lock

(1)

XT2, XT4 Optional OPEN Ronis

XT2, XT4 Optional OPEN Ronis

XT2, XT4 Optional OPEN / CLOSED Ronis

Motor

Padlock device XT1…XT4 Standard OPEN padlocks max 3 padlocks Ø

(MOD, MOE,

MOE-E)

Key lock on motor

XT1…XT4 Optional OPEN Ronis

MOL-D

Fixed part of

withdrawable

MOL-S

Key lock against

manual operation

(2)

MOL-M

KLF-FP

Key lock / padlock

XT1…XT4 Optional OPEN Ronis

XT1…XT4 Optional MANUAL Ronis

XT2, XT4 Optional Key WITHDRAWN / INSERTED

for fixed part of

withdrawable device

XT2, XT4 Optional Key WITHDRAWN / INSERTED

XT2, XT4 Optional Key WITHDRAWN / INSERTED

XT2, XT4 Optional Key WITHDRAWN / INSERTED

Trip unit Lock of thermal

regulation

(3)

XT1, XT3 Optional

XT2, XT4 Standard

Optional/

Standard supply

Position of

circuit breaker lock

Type

of lock

7mm stem (not supplied)

7mm stem (not supplied)

7mm stem (not supplied)

(A, B, C, D type)

Different key

Same key

Same key

Different key

Different key

6mm stem (not supplied)

CIRCUIT BREAKER CLOSED

– –

6mm stem (not supplied)

CIRCUIT BREAKER CLOSED

– –

Same key

Different key

Different key

8mm stem (not supplied)

Different keys

Same keys

key

Ronis key Different +

Padlock WITHDRAWN

padlocks max 3 padlocks Ø

6mm stem (not supplied)

Ronis key Same + padlocks

Padlock WITHDRAWN

max 3 padlocks Ø 6mm

stem (not supplied)

Giussani key Different +

Padlock WITHDRAWN

padlocks max 3 padlocks Ø

6mm stem (not supplied)

Giussani key Same +

Padlock WITHDRAWN

padlocks max 3 padlocks Ø

6mm stem (not supplied)

– – –

– – –

Removability

of key

–

–

–

OPEN

OPEN

OPEN / CLOSED

OPEN

OPEN

OPEN / CLOSED

–

–

OPEN

OPEN

OPEN / CLOSED

–

OPEN

OPEN

WITH LOCK

INSERTED

–

–

–

–

3

(1)

On the transmitted rotary handle (RHE), the lock is mounted on the base. The key lock is not available on the lateral handle (RHS).

(2)

Only for MOE and MOE-E.

(3)

Applied to the cover of the circuit breakers on a level with the regulator of the thermal element of thermal magnetic release TMD to prevent it from being tampered with.

(4)

This function can be totally inhibited by the customer when the handle is assembled by means of a simple operation that can be reversed if needed.

Moreover, if the door lock function is not disabled by the customer during the assembly phase, the door lock can be temporarily deactivated with a tool in exceptional cases,

so that the door can be opened without opening the circuit breaker .

(5)

Incompatible with electrical accessories mounted in the third pole.

US Technical Catalog | SACE Tmax XT UL/CSA 3/15

Accessories

Mechanical accessories

Rear mechanical interlock

Support designed for rear installation of two circuit breakers that, through connections, prevents

the two installed breakers from closing simultaneously.

The circuit breakers in the Tmax XT family are interlocked two-by-two (IO-OI-OO) by means of a

chassis and special plates. Interlocked circuit breakers can be of a fixed, plug-in or withdrawable

version. Both circuit breakers and molded case switch disconnectors in the three-pole and four-

3

Interlock

pole versions can be interlocked.

Acceptable combinations are:

XT1

XT2

XT3

XT4

The following equipment must be ordered to make the rear interlock:

n

a vertical or horizontal chassis;

n

a plate for each circuit breaker to be interlocked.

XT1 XT2 XT3 XT4

n n n n

n n n

n n

n n n

Bracket for fixing on DIN rail

+

Interlock - Chassis Two Plates Interlock

=

Bracket for fixing on DIN rail

Support designed to be installed on the back of the circuit breakers to simplify assembly on

standardized DIN EN 50022 rail.

The following can be installed on DIN EN 50022 rail:

n

all Tmax XT circuit breakers in the fixed three-pole or four-pole versions;

n

XT1, XT3 circuit breakers equipped with RC Sel 200; RC Inst, RC Sel for XT1 and XT3 residual

current releases.

3/16 SACE Tmax XT UL/CSA | US Technical Catalog

XT1-XT3

with standard flange

Flanges

A flange is a plastic plate that acts as an interface between the circuit breaker and the hole in

the panel door. All the Tmax XT series flanges are newly designed and do not require screws for

installation. Flanges are applied:

n

around the front part of the fixed/plug-in circuit breaker;

n

around the operating lever for all fixed/plug-in/circuit breakers;

n

around the MOD or MOE motor operator;

n

around the front for FLD locks;

n

around the direct rotary handle operating mechanism;

n

around the extended rotary handle operating mechanism;

n

around the RC Inst, RC Sel for XT1 and XT3, RC Sel for TX2 and TX4 residual current release.

3

XT2-XT4

with standard flange

XT1-XT4

with operating lever

flange

Rotary handle

with flange

MOE

with flange

MOD

align flush left

under MOD

US Technical Catalog | SACE Tmax XT UL/CSA 3/17

Accessories

Electrical accessories

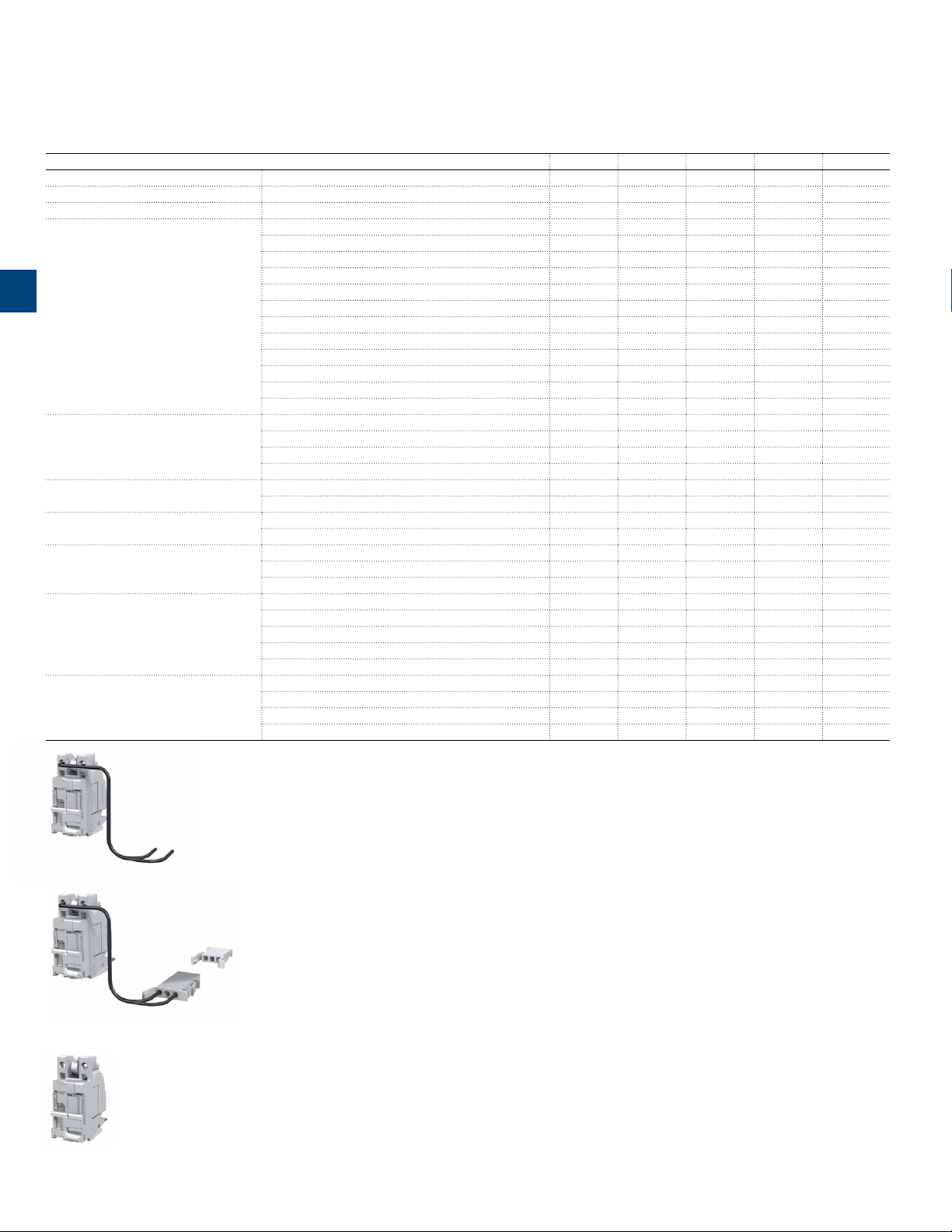

Tmax XT UL/CSA electrical accessories UL Listed XT1 XT2 XT3 XT4

Shunt opening release SOR / SOR-C (uncabled and cabled)

Undervoltage release UVR / UVR-C (uncabled and cabled)

Time-delay device for undervoltage release UVD –

Cabled auxiliary contacts, 1m

Q: signaling contact open/closed

SY: trip position signaling contact

3

S51: signaling contact due to trip unit

tripping or interaction

Uncabled auxiliary contacts

Auxiliary position contacts

Early auxiliary contacts in the rotary handle

Motor operators

Residual current devices

Ekip electronic trip unit accessories

1 Q 1 SY 24V DC

3 Q 1 SY 24V DC

1 S51 24V DC

1 Q 1 SY 250V AC/DC

2 Q 2 SY 1 S51 250V AC/DC

3 Q 2 SY 250V AC/DC

3 Q 1 SY 250V AC/DC

1 S51 250V AC/DC

3 Q on left 250V AC/DC

2 Q 1 SY 250V AC/DC

1 Q 1 SY 400V AC

2 Q 400V AC

24V DC

S51 24V DC

250V AC/DC

S51 250V AC/DC

AUP - Inserted (24V and 250V)

AUP - Withdrawn (24V and 250V)

AUE - 2 contacts closed

AUE - 2 contacts open

MOD

MOE

MOE-E – –

RC Inst –

RC Sel 200 –

RC Sel for XT1 XT3 –

RC Sel for XT2 XT4 – –

RC B Type

Ekip Display

Ekip LED Meter

Ekip Com

HMI030 interface on the front of the switchboard

n n n n n

n n n n n

n n n n

n n n n n

n

n

n n n n n

n

n

n

n

n n n n n

n n n n n

n

n

n n n n n

n

n n n n n

n

n n n n n

n

n n n n n

n n n n n

n n

n

n

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

n

n

n

– –

–

–

–

–

n n n

n

n

n

n n n

n

n

n

n

n

n

–

n

n

–

– – –

–

n

n

n

n

n

–

–

–

–

–

–

–

–

–

n

–

–

n

n

–

n

–

–

–

–

n

n

n

n

n

n

n

n

n

–

n

n

–

–

n

–

n

n

n

n

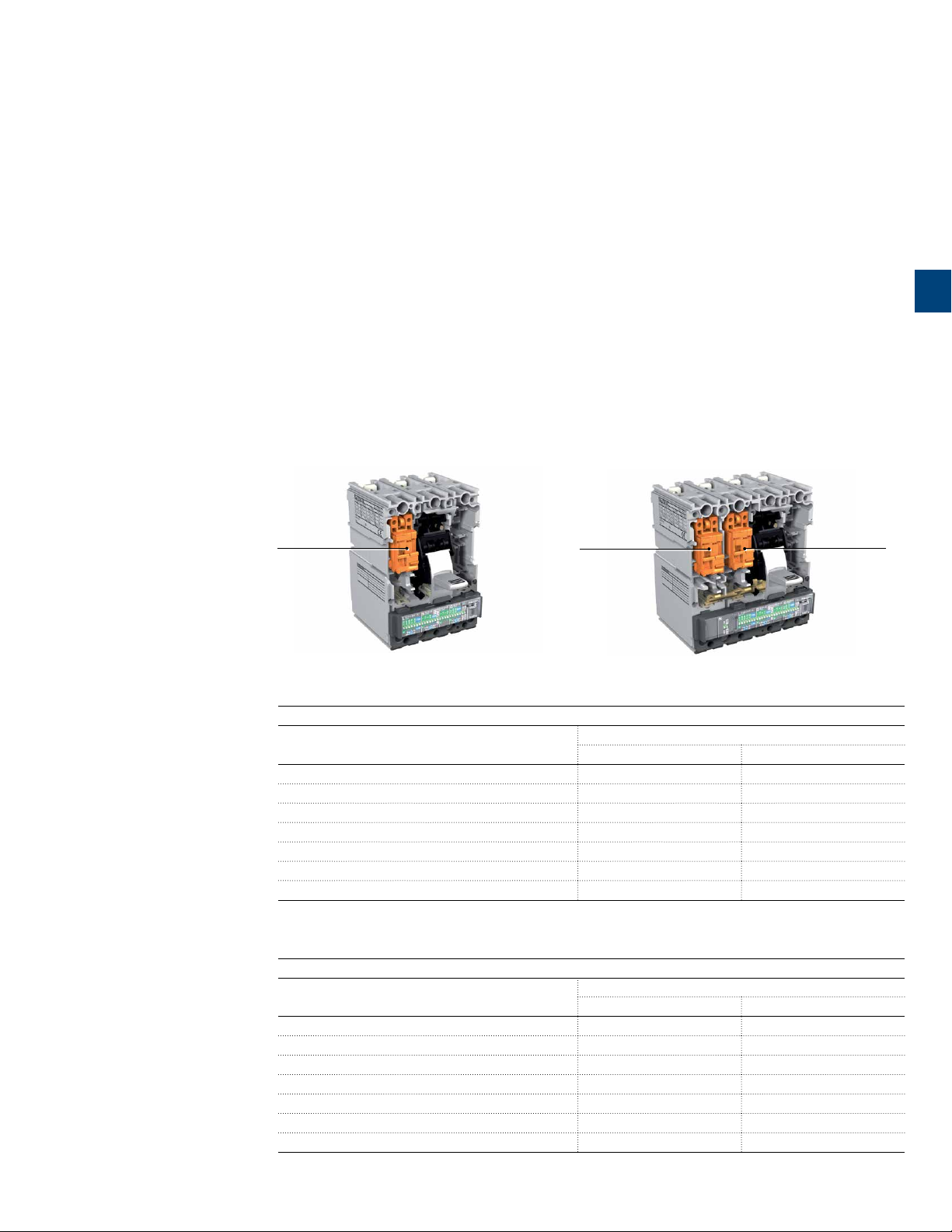

Service releases

Shunt opening release (SOR). Allows the circuit breaker to be opened by means of a nonpermanent electrical control. Release operation is ensured for voltages between 70% and 110%

Cabled SOR - UVR

Cabled SOR - UVR

for withdrawable circuit breaker

Uncabled SOR - UVR

3/18 SACE Tmax XT UL/CSA | US Technical Catalog

of the rated power supply voltage Un, in both alternating and direct current. The SOR is equipped

with a built-in limit contact to shut off the power supply in the open position with the relay tripped.

A remote controlled emergency opening command can be created by connecting an opening

button to the SOR.

Undervoltage release (UVR). Allows the circuit breaker to open when the release is subjected

to either a power failure or a voltage drop. Opening is ensured when the voltage is between 70%

and 35% of the rated power supply Un. After tripping, the circuit breaker can be closed again

if the voltage exceeds 85% of Un. When the undervoltage release is not energized, neither the

circuit breaker nor the main contacts can be closed. A remote controlled emergency opening

command can be created by connecting an opening button to the UVR.

None of the service releases in the Tmax XT series requires screws for installation. They are

extremely easy to fit. Just use slight pressure to snap the release into the appropriate place. All

service releases are available in two versions:

n

cabled (AWG20 cable section - 0.5mm2):

– for fixed/plug-in circuit breakers with 1m long cables;

– for withdrawable circuit breakers with fixed part and moving part connector;

n

not cabled:

– for fixed/plug-in circuit breakers with cables from (1.5 mm

2

/14 AWG in section).

In circuit breakers:

n

three-pole: either one SOR or one UVR can be installed in the slot on the left of the operating

lever;

n

four-pole: two service releases can be installed at the same time by using the third and fourth

poles. If the circuit breaker is the withdrawable type, the connector for the fourth pole must be

ordered to be able to install an SOR or UVR in the fourth pole.

3

SOR

UVR

SOR Electrical specifications

Version Max power absorbed on inrush

12V DC 50

24-30V AC/DC 50 50

48-60V AC/DC 60 60

110...127V AC-110...125V DC 50 50

220...240V AC-220...250V DC 50 50

380-440V AC 55

480-525V AC 55

UVR Electrical specifications

Version Power absorbed during normal operation

24-30V AC/DC 1.5 1.5

48V AC/DC 1 1

60V AC/DC 1 1

110...127V AC-110...125V DC 2 2

220...240V AC-220...250V DC 2.5 2.5

380-440V AC 3

480-525V AC 4

SOR

UVR

AC [VA] DC [W]

AC [VA] DC [W]

SOR

UVR

US Technical Catalog | SACE Tmax XT UL/CSA 3/19

Loading...

Loading...