Page 1

Application examples

C578

Electronic

Safety relays

7

Application

The overtravel distance tester C 578 is intended for checking the overtravel of

linearly operating hydraulic, pneumatic and spindle presses in accordance with

VBG 7n5.2 §11.

Functions and connections

The overtravel distance tester C 578 has four safety outputs, three NO contacts

and one NC contact. Two LEDs indicate the functions.

The C 578 tests the overtravel distance in connection with a position switch

every time the control voltage is switched on. The permissible overtravel distance

corresponds to dimension ʼsʼ of the cam that is used

to operate the position switch. Obtain dimension ʼsʼ from the press manufacturer

in accordance with ZH 1/456 (published by the German central offi ce for

accident prevention and labour safety, Cologne).

Terminal marking

Supply A1 L/+

voltage A2 N/-

Outputs 13, 14 Safety output 1 (tool down)

23, 24 n/o contact (tool up)

33, 34 n/o contact (overtravel distance

OK)

41, 42 n/c contact (hydraulic pump ON)

Inputs Y11,12, 13, 14 Feedback loop (K4)

Y21, 22 Position switch (S4)

Y31, 32, 33, 34 Top dead centre switch (S3)

Operation

Sequence of operations after the press has been switched on:

1. Switch on the hydraulic pump with S5, move plunger to top dead

centre, if necessary by means of S6.

2. Operate S1, S2 on the two-hand control console until the position

switch for test-cam (S4) opens.

3. Stop operating S1, S2.

4. Operate S1, S2 again: Indicator light H1 lights up if the overtravel

distance is OK.

5. Stop operating S1, S2: The plunger returns to top dead centre.

6. If overtravel distance is OK, all outputs remain active until the

control voltage is switched OFF.

LEDs Operation

POWER Release

Overtravel distance OK.

Overtravel distance incorrect or test not yet

performed

Fault

If the cam overtravels position switch S4, indicator light H1 does not light up.

The hazardous part of the machine can be moved up to top dead centre only by

means of S6.

The press can no longer be used for production. When this happens, notify the

maintenance staff that the press needs attention.

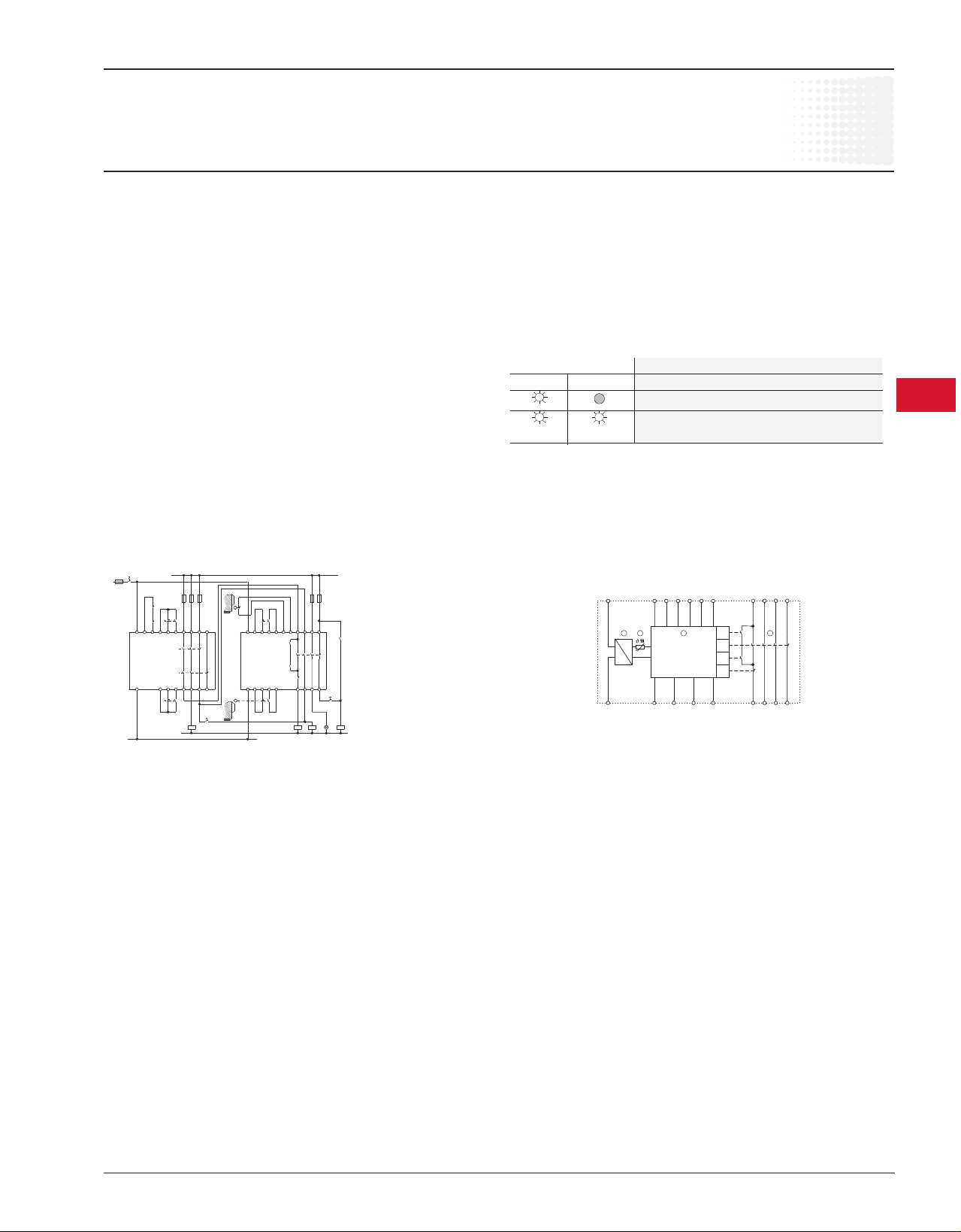

External circuit Internal circuit

S0

+

L/

L/+

K3

K4

Y22Y21Y12Y11

C575 C578

A2

N/-

S1

Y23

S2

N/-

13 23A131 41

14 24Y33 32 42Y32Y31

K4

S4

K4

13 23 33 41

Y22A1 Y14Y13Y12Y11 Y21

S3

S6

14 24 34 42

K2K3 H1

C 575 two hand control unit,

S0 Main switch,

S1, S2 keys at two hand

control console,

S3 Position switch for top

dead centre,

K1

S4 Position switch for test

cam

S5 Hydraulic pump "ON",

S6 Tool "up" (manual mode),

K1 Contactor for hydr. pump,

S5

K2 Tool "up",

K3, K4 Tool "down",

H1 Indicator light

K1

A1

A2

Y11 Y12 13 23 4133

Y13 Y14 Y21

Y22

2

1

3

J

Y31 Y32 Y33 Y34

7

4

14 24 4234

Low Voltage Products & Systems 7.47

AC 1000 - 11/03

Loading...

Loading...