Abarth 500C, 595, 500 User Manual

Fiat & ABARTH

tricks

by GREG SCHMIDT

FIAT and ABARTH TRICKS

by Greg Schmidt

Copyright 1984 Greg Schmidt

Revised 5th

produced by Greg Schmidt with thanks to: Adrienne, Trudi, June, and Roy for production support; to Maurice Dhoore for "investigation"; to Chris Butler for the cover page; and Doc Sekito for "Good vibrations".

Revised second printing October 1984 with updated pages reformated and printed on a daisywheel printer by Kennerley C. Ashley, D.D.S and bis Radio Shack Model Four computer.

Enthusiasts will also want a copy of ABARTH by Pat Braden and Greg .Schmidt, 160 pages, with 220 illustrations, Osprey Publishing Ltd., England 1983. ABARTH is distributed in the USA by Classic Motorbooks (see above & use order #F770A). ABARTH was reviewed in the September 184 issue of Road & Track Magazine on page 28. Note that about 80% of engine rebuilding, conversions & part numbers are contained in ABARTH.

From time to time, new/revised materials are produced for this book. If you would like updated pages forwarded to you, please send a pest card with your name, address, and the number of the book that you have (noted in red on page 1) to: FlAT and ABARTH TRlCKS 1512 E. 5th Street #94 Ontario, Calif. 91764 USA

(There is no charge for this service)

1

FIAT & ABARTH Tricks

l hope the information contained in this book will prove valuable to you. New material, corrections and comments are always welcome. Questions and new materials will be accepted when accompanied by a self-addressed and stamped return envelope. "MORE ABARTH TRICKS" may be forthcoming (see page 82).

With the Sporting intent,

PURPOSE

The purpose of this book is to provide a comprehensible source of technical information for owners and enthusiasts of Fiat-Abarth and other make sport cars which were derived from the Fiat 600 and Fiat 850. Special emphasis is placed on returning more of these vehicles to every day use and maintaining them with reasonable efficiency and a minimum of misspent time or frustration. So it. is hoped that a few owners who have heretofore Dot had the opportunity and pleasure of experiencing their neat little cars in action (or on a regular basis) will be provided with enough "first-hand experienced" information (which with time might otherwise have been lost) and provided the incentive to restore them to original or updated "drivers car" condition. Because, when these cars work right they can be as entertaining as any production sports car yet offered to the driving public. And that full song high-reving engine and cat-like agility (from a vehicle of such humble specifications yet) is usually more than enough to quickly remind the owner that this is "his kind of automotive plaything"..!

The best use of F.I.A.T. and ABARTH

For conveyance and protection, it is recommended that the pages of this booklet be put in a hard cover loose-leaf binder. For heavy workshop use, clear plastic sleeve page covers can be used to protect those pages removed as reference for the job at hand. Both ABARTH (see bottom of facing page) and FlAT and ABARTH TRlCKS are designed to complement each other. You should have both so they can be used hand -ln -hand. Best results will be obtained by first reading (or rereading) chapters: 3, 6, 7, 11, 12, 13, and skimming the appendix of ABARTH. Then read all of FlAT and ABARTH TRlCKS.

Make reference notations in the margins of_ABARTH about the loctions of updated, new and related information in FlAT and ABARTH TRICKS. Lastly, l suggest that you Dot loan this book to anyone, as even with the best of intentions, one-of-a-kind publications like this one are frequently Dot returned to the lender. Protect your copy and encourage your friend to purchase his own copy by giving him the ordering information on the facing page. That way I can continue to make FlAT and ABARTH TRICKS and ABARTH available to those who really enjoy these purposeful, efficient, and fulfilling conveyance devices.

2

ILLUSTRATIONS-- |

starting on page 84 |

Figure 1: Fiat and Abarth Pushrod-engine Pistons...................................................................... |

84 |

Figure 2: Timing Gear and Ignition Timing Marks ........................................................................ |

84 |

Figure 3: 600/750 Oil Filter Assembly ............................................................................................ |

84 |

Figure 4: 600/750 Distributor and Abarth Tachometer Drive ... 85 Figure 5: 850/0TI000 Weber 30 DIC

Carburetor |

......................................................................................................................................... |

|

86 |

Figure 6: Induction Systems and Hardware.................................................................................. |

87 |

||

Figure 7:Cooling ..........................................................System Parts |

88 |

||

Figure 8:Exhaust ....................Systems and 850/0T1000 Mounting |

88 |

||

Figure 9: |

Clutches |

89 |

|

Figure 10: 600/750 .............................................................Clutch Actuation and Cable Support |

89 |

||

Figure Il: 600/750 ......................................................Mounts and Engine Compartment Panels |

90 |

||

Figure 12: 850/0TlOOO .......................................................................Mounts and Modifications |

90 |

||

Figure 13: Drive ............................................................................................-Train Movement Bar |

90 |

||

Figure 14: 600/750 ...............................................................Transaxle, Axles and Gear Change |

91 |

||

Figure 15: 850/0T1000 ...................................................................Gear Change and Drive axels |

92 |

||

Figure 16: 600/750 ........................................................................................................Handbrake |

|

92 |

|

Figure 17: Drum .......................................................................Brakes and Automatic Adjusters |

93 |

||

Figure 18: Hydraulic ............................................................................................Brake Cylinders |

93 |

||

Figure 19: 850/0T1000 .......................................................................Spider Covered Headlights |

93 |

||

Figure 20: Suspension and Steering(a. Fiat b. Special Abarth). 94 |

|

||

Figure 21: l27/Al12 ...........................................................................................Conversion engine |

96 |

||

Figure 22: Abarth ...............................................................................................750 DORC Engine |

97 |

||

Figure 23: Berlina ...........................................................................Corsa TC and TCR Hardware |

98 |

||

Figure 24: Fiat .....................................................................................-Abarth Trim and Emblems |

99 |

||

Figure 25: Currently ..........................................................................Available Abarth products |

100 |

||

Note: Part numbers net found in these illustrations are located in “Abarth” parts interchange, or drawings in chapters 12 & 13.

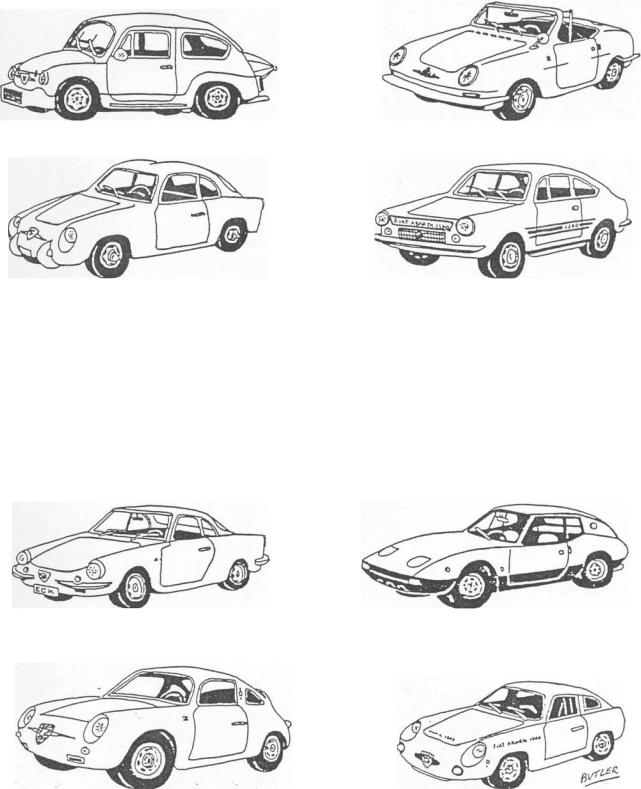

Cover page: |

|

|

Berlina Corsa TC |

OT1000 Spider |

|

750 |

Double Bubble |

1300/124OT |

850 |

Scorpione |

Scorpione 1300 SS |

750 |

Record Monza |

1000" Bialbero |

3

CONTENTS

Chapter 1: OLD BUSINESS FROM "ABARTH" |

|

" |

, |

|

Missing Photos and Flat-Abarth Desirability ...................................................................... |

|

4 |

||

Corrected Copy ..................................................................................................................... |

|

|

5 |

|

Corrections and Supplements to Technical Chapters 7 ........................... |

Fiat-Abarth Bialbero Engine Details 12 |

|||

Chapter 2: POWER UNIT REMOVAL AND REPLACEMENT |

|

|

||

Power Unit Removal |

13 |

|

|

|

Installation Procedures and Checks 18 |

|

|

||

Starting, Adjustments and Break-in .................................................................................. |

|

26 |

||

Chapter 3: MAINTENANCE AND REPAIR |

|

|

|

|

Maintenance Checklist........................................................................................................ |

|

|

32 |

|

Tune-Ups |

.............................................................................................................................. |

|

|

33 |

V-Belt Adjustment ............................................................................................................... |

|

|

35 |

|

oil |

Filter.................................................................... |

|

_.............................................. |

36 |

Oil Changes and Leaks |

........................................................................... |

|

37 |

|

Head Gasket and Cooling System ..................................................................................... |

|

40 |

||

Head Retorque and Valve Adjustment .............................................................................. |

|

41 |

||

Timing Chain and Gears..................................................................................................... |

|

|

41 |

|

Clutch Replacement............................................................................................................ |

|

|

42 |

|

Distributor, Generator and Starter..................................................................................... |

|

42 |

||

Carburation and Fuel System............................................................................................. |

|

43 |

||

Exhaust System................................................................................................................... |

|

|

46 |

|

Cables and Controls ........................................................................................................... |

|

|

46 |

|

Drive Axles........................................................................................................................... |

|

|

49 |

|

Transaxle and Gearlube...................................................................................................... |

|

|

52 |

|

Brake System, Adjustent and Handbrake |

|

53 |

||

Wheels |

and Tires.......................................................................................................... |

|

|

55 |

Suspension and Steering ................................................................................................... |

|

|

55 |

|

Battery and Cables.............................................................................................................. |

|

|

56 |

|

Electrical System, Gauges, and Lights ............................................................................. |

|

57 |

||

Chapter 4:"DRIVERS CAR" CONVERSIONS AND IMPROVMENTS |

|

|

||

Late Model European Engine Conversions....................................................................... |

|

59 |

||

High Fuel Economy Preparations...................................................................................... |

|

62 |

||

124 Engine Conversion for the 850.................................................................................... |

|

63 |

||

Front Radiators.................................................................................................................... |

|

|

66 |

|

Diaphrgam Clutch Conversion and Cab1e Support ... 66 |

|

|

||

Mounts Strengthening ........................................................................................................ |

|

|

67 |

|

Drive Train Movement Bar.................................................................................................. |

|

|

68 |

|

Shifter Modification |

.'.................................. |

_........................................... |

68 |

|

6000 Transaxle Conversion................................................................................................ |

|

|

68 |

|

Brake System Improvements ............................................................................................. |

|

68 |

||

Suspension Set-Up and Improvements............................................................................. |

|

69 |

||

Battery Conversion ............................................................................................................. |

|

|

70 |

|

Chapter 5: BODY, TRIM AND REPLICA CARS |

|

|

|

|

Body, Trim and Accessories Notes ................................................................................... |

|

71 |

||

Berlina Corsa Replicas ....................................................................................................... |

|

|

74 |

|

Berlinetta Bertone, OT1600/2000. . . . . . . . . . . . . .. |

77 |

|

|

|

Chapter 6: COMPETITION EVENTS AND PREPARATION

Individualized Specifies,..................................................................., Carburetor Jetting 79

High Performance Engine Lubrication System ................................................................ |

80 |

|

Chapter 7: PARTS, SERVICE WORK AND A LITTLE EXTRA _ |

|

|

Availability of Parts & Service............................................................................................ |

81 |

|

"Getting Mead", "Your short Pump" . .'. .............................................................................. |

83 |

|

Machine Works, future. Booklet.127 Water Pump............................................................. |

82 |

|

Appendix : Specifications |

|

|

Yearly Changes, Gearing Jetting, Engine Specs Misc ..... |

101 |

|

New Materials as ol 1/1/85, 3/85, 7/85 |

|

|

How About Trying a Complete Drive-Line Conversion? 106 |

|

|

Ashley Clutch Linkage Fix for 850/OTIOOO .................................................................... |

107 |

|

Drawings : Pedal Linkage, 750 Muffler strap ...... |

108 |

|

Fuel Recommendations) Windshield Repair, ..................................................................109 |

||

Abarth Scorpione vs OTAS Grand. Prix........................................................................... |

110 |

|

4

CHAPTER 1: OLD BUISINESS FROM "ABARTH"

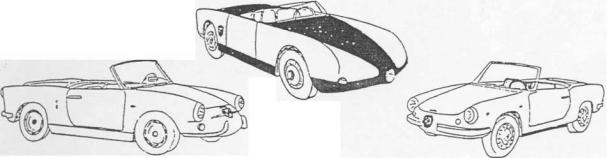

MISSING PHOTO

We were unable to locate representative photos of: the Spider sinle headlight Fiat-Abarth 210A which was the first specialbodied 600-based Abarth (See page 50 of "ABARTH"), the "ugly ducking" Allanano 750 Spider in street configuration (pages 55-56), and the handsome Allanano 850 Spider "Riviera" which was an Allemano coupe with the roof chopped off (pages 56, 58) . Below are drawings of these models. Photos and information on the or 2000 coupe (850 coupe body and 2000cc Abarth twin cam with modified chassis similar to the or 1600 Sedan) should have appeared on page 84 of "ABARTH" and can be found on page 77 of this booklet.

"The Duck" |

210A |

Riviera |

|

Why Are FIAT-ABARTH Cars Desirable? |

|

What is an everyday road-going "sports car?" Perhaps a vehicle that possesses everything the sporting driver could wish for. Like: responsive performance from the engine, suspension, steering, and brakes plus lightweight, aerodynamic good looks, reasonable driver confort and a certain "aggressive emotional flavor". Along with these forms of efficiency, l am going to add fuel economy, ease of maintenance and repair, and simplicity of design for a given purpose. Brute power (and attendant bulk) may have its place for racing or "weekend fun" but as everyday sporting transportation it leans heavily into the areas of ego gratification and over-use/abuse of resources necessary for the desired result. A true sports car qets the most it can from what it needs. Fiat-Abarths embody aIl of these qualities. Add to all this the fact that these cars are for the most part quite inexpensive to purchase (as classic sports cars go no,.; days), and there is not a lot more an enthusiast could ask for in sporting transportation....

ln the case of the Fiat and Abarth sports cars, which this booklet is about, the only real issues that might be considered "flaws in the mold" would be: (1) noise and vibration levels for extended highway use, (2) relatively short-lived and fragile power unit components and accessories, and (3) poor braking efficiency on early 600-based cars. ln the first case, other than using a quieter muffler, more sound insulation and higher final drive gearing, there is not much that can be done about it. The second is rea1ly net an issue (especially if you are a mechanical hobbyist) in that hardly a car in existence bas an engine or related hardware easier to remove and simpler to rework. And on the third point ; it is a small matter to convert to the front disk brakes from a later model Fiat.

5

"ABARTH" CORRECTIONS ( Sure, we made mistakes) Listed by page and location, corrected copy underlined

page

##

26 Right column middle first paragraph: described in detail in Chapter 11.

27 Middle of left column : a modern Fiat 127 cam can be used in the 850 block to change engine rotation for use in 600-00.500 Abarth conversions ( see Chapter 13).

27 Second paragraph: complete cylinder head with side draft Weber two barrel carburetor, or 850 style downdraft Weber and special valves and springs for the standard head, olus high-performance camshaft and _exhaust_ Systems.

27 Last paragraph : As to 127 aftermarket engine parts appropriate to Fiat 850 and Abarth OT1000. there is only a set of heavy-duty valve springs (There is a cog-belt camshaft drive conversion kit suitable for 600/850 based motors but it is different from a 127 kit) . The high performance 127 camshafts, while good for 850/903 conversion engines going into a 600-based car, are of no use in an 850-based car unless you have the direct drive camshaft gears to overcome reverse rotation. Likewise, the special 127 combination valve cover and intake manifold with 32/32 Weber barrel carburetor may be unusable as delivered because the float bowl will sit sideways in 600 and 850 based cars (also at a 5 degree angle in the 850based cars). ln addition, the ail filler cap is on the opposite end of the valve cover which makes adding oil difficult.

48 The last paragraph in the left column was insert here by mistake (it also appears in the right column). The following text should have been in its place: The Fiat 600 handling and heatinq sins proved negligible for the stock car, but critical for the Abarth-modified cars. The tendencies to roll over or over-heat were magnified when the available power was increased. They were characteristics of the Fiat 600 which Abarth never completely conquered. In view of the unqualified success of his cars as racers, he obviously solved then well enough to suit his purposes. One other design limitation that nagged Abarth was the marginal brakes of the 600. This was finally dealt with by fitting disk brakes up front on the street cars and

disk all around on the racinq oriented machinery. |

|

|

||||

50 |

Middle of the left column: Outer springs were - available in 34, 43 or 50 |

kg. |

||||

|

strengths(measured at 1.25" |

compressed. length) or inner sprinqs of 29 kg. could be used with |

||||

the standard 24 kg. 600/750 outer spring giving a total spring pressure of 53 kg. |

|

|||||

53 |

Photo |

caption |

and "Spider. Zagato" |

paragraph: The Zagato brothers cut off the roof and |

||

redesigned the rear body sections of their coupes to create two Fiat-Abarth spiders. The upper photo shows a 56 “topless Double Bubble”, and below it a '58 "topless Record Monza”. Both models used pushrod engines (no rear-engine DOHC spider street cars were made).

58 Photo caption: Perhaps the most pleasantly proportioned, available, 600-based road-going Abarth and certainly the most conformable tourer, the Allemano-bodied Scorpione Coupe came with an 850 cc., or on rare occasions, the one liter pushrod engine.

59 First paragraph: Brakes were improved by increasing the wheel cylinder diameter and replacing_the hinged brake shoes with self-centering type.

60 Bottom of the third paragraph: The engine-driven fan (not the rear radiator) was removed on this model, and a short water pump was used

60 Replace the last sentence before "850 Sports Prototype" with: This car has the non-covered headlights and non-removable rear body/motor mount panel and no starter motor access panel. Front disk brakes were fitted, but nearly all other details remained identical to the original Record Monza 750 twin cam model.

63 Middle of the last paragraph: The cars which came before were simply unknown and most which came after were either too mundane (warmed over Fiat look-alikes) or too exotic and expensive.

6

pp.72 The third and fourth sentences should read: The 817cc U.S. smog exempt version of the 850 engine that Fiat Obtained by decreasing the cy1inder bore by one millemeter (to 64mn) in 1968 to 1971 sedan models was used along with a 32mm one-barrel Weber and special : intake manifold, exhaust system, cam and finned alloy five quart sump by Giannini .

pp. 106 #8 should read: 17mm heads on high-tensile steel cylinder head bolts marked _ABARTH & C" (Fiat 600 has 13mm bolt heads & Fiat 850 bas 14 or 17 mm heads on semi-hardened iron bolts which are labeled “Fiat”)

pp. 107-110 regarding the current value of the various Fiat-Abarth models : The prices listed are now quite low especially with the recent upsurge in classic car collecting & racing. Also, when "Abarth" was being written (1981-2), my experience had been more with the "low dollar fixer" type of car & this was reflected in my value estimates along with the fact that "being in the business" allowed me to meet many. enthusiasts & hear of the base deals. Keep in mind though chat a nice complete & running car can Cake as much time & money to restore to original as “rough basket-case” because a "nice" car will still require stripping totally to make it 100%. The only Car worth a lot of money is one that's nearly perfect....

7

Corrections & Supplemental. Materials for "Abarth" Technical Chapters

pp. 109 Fiat-Abarth 1300/124 OT item #3. : Reclined to 3/4 upright front radiator ; mounted & shrouded on left side of original spare tire well with Abarth grille & electric fan etc...

pp. 109 regarding engine number on cylinder block: 1300/12h number is located on right sida of block near fuel pump.

PP. 109 info regarding Fiat-Abarth Scorpione 1300 S/SS : with pop-up head lights and a 1300cc pushrod version of the Fiat 124 engine. Top of pp.

110 : Was modified by Lombardi to fit the Fiat 850 chassis. The true Scorpione SS has special suspension and 4-wheel disc brakes (the Scorpione S and the 1300/124 previously listed has 850-type......

pp.l07, 113, 120, 122 aIl these pages mention a non existsant Chapter 14. You probably realized wo meant to say chapter 13 On pp.135 at end of first paragraph we meant to say: refer to chapter 12 (pp 120).

pp 113 regardin, those "Larger engines for Early Abarths”, GOOD NEWS : Maurice Dhoore in Belgium has investigated for me the possibilities of using currently produced readily available fiat 127/Autobianchi A112 engines of tram 903 to 1050cc in early Abarths.

These engines are closely related to the Fiat 850 but rotate in the desired clockwise direction. There are some outer accessories that need to be replaced or modified ("see pp. 59-61 of this booklet), but the engine itself would Ot require disassembly or internal modification as with the conversion outlined in chapter 13 of "Abarth”. Of particular interest is the Autobianchi A.112 Abarth 1050cc engine which produces around 70 horsepower (compared to about 42 hp for Abarth 750)

pp. 113 right column 5th line should read : cylinder boring and an oversize head gasket are required for sizes over about 67mm.

pp. 114:special 9.8 to 1 pistons (altered piston pin height with full floating pin design) and rings (thin width)

pp. 114 add to bottom of page : Special Abarth Muffler - with chrome tipped twin large diameter outlet pipes -

p. 116 add to the list of “Updating for Daily Use”

x« Available battery » conversion

xDrive-line movement bar

xClutch cable locator/center support strengthening bracket

x850/OT 1000 diaphram clutch conversion

x850/OT1000 stvle cooling system thermostat conversion

pp. 118 just above “Condition of the Crankshaft”, should have appeared the paragraph in the middle of the right column of page 133 ( Henceforth. When referring ... etc) which is also applicable for this booklet too.

Then the following additional information : Engine rebuilding and assembly procedures are easier to accomplish if you mount front (flywheel end) of cylinder bIock to an engine stand that allows motor to be rotated to varying positions (especially to flip_ block over and back during piston insertion and rod-cap installation). Take care_ when mounting block to leave enough room for front crankshaft seal-housing installation.

Pp 118 and of first paragraph under “condition of the Crankshaft” : Note also that oversize Abarth bearings do not come in standard U.S. sizes (.010", .020" etc)" So double check Abarth bearings before crankshaft grinding. Finally as a general rule, most Abarth 850, 1000 and OT1000 engines use special Abarth large main bearings while nearly all pushrod motors use standard Fiat rod bearings.

pp. 119 under "The Cylinder Block" at end of first paragraph : Fiat no-longer supplies late 903 center main bearings with oil delivery hale and grooves. Therefore using Fiat bearings will negate the desirable pressurized center main bearing; so bearings made by other suppliers (like A.E.) should be used in this situation.

Note also that bearings for pressurized center mains can be used on aIl other 850 engines even though oil holes will ho of no functional value.

8

While on the subject of 903 cylinder blocks (identified by 4 boIt water pump mounting flange) note that they are about 5mm taller than 843/OT1000 blocks to compensate for increased crankshaft stroke and longer connecting rods (which allow s same pistons

to be used in both 843 and 903 motors). ln addition 903 cylinder head thickness is different and pushrod and distributordrive shaft lengths are longer than 843 /OT1000 pieces. Note also that 843's can be made into “903's by substituting 903 crank with 843 rods special made pistons. 817's can be bored out 1mm (or larger if desired) to make an 843 as well.

pp. 119 and 120 regarding align-honing block main-bearing 8addles and connecting rod. big-ends : ln this process, a very small amount of metal is ground away from mating surface of bearing cap and block or rod saddle resulting in a smaller diameter hole which is then honed or bored-out to original size specifications after cap is torqued in place.

pp. 119 just before lest paragraph in left column : After good “dry” measurements are obtained remove crankshaft and lubricate bearings/thrust washers before refitting and torquing main caps. Now “flip” crank over using only your fingers on the counterweights. If it won't "spin" freely at least one-haIf turn, something is wrong. Loosen one main cap at a time to Iocate a "tight” bearing and determine the problem. pp. 119 regarding crankshaft and end-play at bottom of left column : Proper procedure for measuring is 1. insert large screwdriver tip at one side of center main-cap and lever crankshaft away from center bearing. 2. Measure clearance at one of the end main-bearings (between main-cap end machined edge of crank journal). 3. Move screwdriver to other side of center main and lever crank in opposite direction. Take second measurement at same end main-bearing as before. 4. subtract smaller figure from larger. End-play should be .010" maximum.

pp. 119 right column 2nd paragraph 2nd sentence, (600/750 camshaft bearings are not pressed into block but held by locator bolts like the rear cam bearings).

pp. 119 middle of right column : After boring/honing cylinder, do not use solvent to clean them. Use water and detergent and then clean, oiled rags.

pp. 120 under “Pistons and connecting Rods”, after first sentence : when rebuilding, .6mm (about .024") "over" your bore-diameter is usually a good safe piston size to order as it leaves room to bore again but is normally sufficient to remove grooves in cylinders caused by broken piston rings. Remember that size stated on piston box and stamped on piston crown is not piston diameter but rather the appropriate finished bore diameter.

pp. 120 figure-A should have looked more like figure-1 of this booklet (pp.84)

pp. 120 bottom of left column end top of right column OT/1000 piston pins are "full floating” and not press fit into connecting-rod as stated.

pp.120 right. Column starting at 13th line clown should read: Most original pistons have at least a slightly stepped topexcept 600, 600D, and OTl000 (sec figure-1 of this booklet) making it obvious which direction pistons must face when taking note of combustion chamber shape in cylinder head.

Note: piston or rod weights should not vary more than 1 gram.

9

pp 121 the end of first paragraph : If you find that piston and rod assemblies are quite difficult to install in block because piston ring installation chamber at too of cylinder bore is not exaggerated enough, use a self round-file to accomplish the desired effect your self (rather than returning to machine shop again.) Be sure to stuff rags in cylinder bores to catch motel dust. Light tapping with a hammer handle on piston crown ( and some patience) is aIl that should be required to insert piston in bore. Incidentally, if you should ever hear a definite “snap” when installing a piston, always remove ring compressor and purchase a new ring to replace the one you just broke... As a precaution, crankshaft should be turned so that rod journal for cylinder you ere working on is in the down position. This helps avoid contact between connecting rod and freshly machined crank journal during installation. Use cheap and simple flat-cast- iron piston rings. Exotic design or alloys may break or fail to seat thus spoiling Your engine job. Ring end-gap should be . 0081” to .012”.

pp.121 right column, at end of 1 st paragraph : Keep in mind that using a high performance reground cam sometimes necessitates machining off material (maybe .045" or so) from the undersides of rocker arm stands to cancel side-effects (geometry and adjustment problem). Also note that Abarth racing cams with rear rollerbearing can be installed in any block.

pp.124 the end of 1st paragraph: (600 20mm/..80"and 850 25”/1” pump gears). 600D/850 style pumps require oil-delivery tube blanking-plate to be fitted over hole in pump cover-lid/pickup when used in a 600/750 motor.

pp.124 under : "Timing Chain and Gears” see additional timing gear installation and alignment details on pp. 41 and figure 2 of this booklet.

pp.128 first paragraph: same style keepers : springs, & locator/retainer CupS

pp. 128 Second paragraph see new info pp. 6 of. this booklet regarding pp.106 #8 of "Abarth" for information about Fiat 600 and Abarth 750/OT1000headbolts. Note that 850/903 bolts are 9mm fine tread, 750/OT1000 are 100mm course thread and 600/600D use smaller 8mm bolts. Also it should be mentioned, that Fiat made special offset “crows foot” wrenches in both 14mm and 17mm sizes, thus negating the need for one oddsize (14mm) bolt head to fitted behind thermostat housing on 903 engines. Finally, when Abarth bolts are fitted with two washers, the thin brass one goes against the cylinder head surface and thick hardened steel type between bolt head and brass washer. Don' t use oil on head-bolt threads or washers as torque values will be effected.

pp.128 right column, middle of paragraph just before “The distributor should read (especially the left front cover).

Figure 7 will side in identifying and dealing with cooling system parts as described on pp 130, pp.132#11, and pp.155-136 of “ABARTH” as well as its parts interchange (pp.149,) and new materials in this booklet. pp.131 #8 1 Note that cylinder head locator dowels are only fitted to 850/903/OT1000 engines.

pp.132 first two paragraphs Note that valve adjustment, distributor installation and timing adjustment procedures are explained in detail on pp:29 #3 and 42 of this booklet. Also note that about two three healthy squirts of motor oil from a lever-operated oil can is sufficient to aid piston ring lubrication with tight new engines.

pp.132 #10 regarding installation and adjustment of carburettor linkage : On 850/OT1000 models and conversion engines, grease linkage pivot pin on top of valve cover and install pivot arm (with cable attaching-sleeve or stud fitted), spacer/retainer washer, and clip or cotter. Fit return spring to arm and valve cover bracket. Grease linkage pivot ball on carburettor and snap on plastic socket with threaded rod and (loose) jam nut fitted. Adjust length of treated rod so that when inserted in arm hole, stop "foot" on valve cover 1/8” from touching pivot arm. Install rod retainer clip. Rock plastic socket back and forth on linkage baIl and hold in position at center of travel while tightening jam nut (8mm open-end wrench). Original 600/750 engines have similar but non-adjustable throttle control linkage (see figure F pp. 138 for parts identification).

10

pp.134 end of #3 should read: Maybe noisy for a street car.

pp.134 middle of right column regarding distributor/oil pump shaft length headaches : lts possible to cure shaft length problems without disassembly of engine if motor has been put together with the wrong shaft length. If shaft is too long for your block, you can fit brass spacer washers between head and distributor housing. If your engine should ever "jump" distributor timing when you bit a pronounced clip or bump in the road, you knew shaft length is too short. Machining the base of distributor housing or making a “splined adapter” from an old distributor shaft-end end drive-shaft-end brazed together) to fit between drive shaft and distributor shaft can help take care of this Iittle inequity,

pp.135 first sentence of "Cooling System" has two comma's missing : three-boIt water pump , fan , and shroud.

pp.136 10th line clown misspelling : or utilize a small filler/ header tank.

pp.136 second paragraph 7th line: will require a 1" section of the 600/750 hose . pp.136 regarding thermostat housing and fittings for conversion engines:

see figure 7 of this booklet.

pp.137 “Exhaust System” : See figure 8, pp, 108 drawinng, & pp. 46 of this booklet for more details. pp. 139 after third sentence in 2nd paragraph: see figure 5 of this booklet .

pp.141 right column should be all-one-paragraph.

pp.142 right column end of 1st paragraph : see pp 22. of this booklet for cable-adjustment and adaptersleeve info .

pp.142 right column 2nd paragraph, end of first sentence add: (note that 850 disk is a slightly larger outside diameter but will usually clear inside of 600/750 pressure pIate mounting flange.)

pp 142 1st paragraph of "Clutch" : see pp 66 and figure 9 of this booklet for diaphragm clutch conversion .

"ABARTH" Interchangeable Parts Lists : Corrections & Updates |

|

|

|

||

"ABARTH" |

|

|

|

|

|

Page |

Part Description |

Columns |

|

Correction/Update |

|

146 |

.. Carburetor Base Gasket .................................. |

600 Notes |

|

for Weber 26 IM |

|

146 |

.. Engine Gasket Set........................................... |

Fiat 600........................... |

|

907945 |

$5.80 |

148 .. |

Tappet-std........................................................ |

Fiat 850........................... |

|

SAME(8req) |

|

*149 .. |

Thermostat ....................................................... |

A750/F600 ...................... |

|

4045626 |

$16.30 |

149 .. |

Thermostat....................................................... |

OT1000/F850.................. |

4154313 |

$3.30 |

|

149 .. |

Fan & Pu11ey Key........................................... |

750&600 Notes... |

delete-NLA |

|

|

149 .. |

Hub for Plastic Fans ....................................... |

600 Notes ... |

late 600D same as 850 |

|

|

149 .. |

Fan Cooling Shroud........................................ |

750&600 Notes .. |

delete information |

||

151 .. Input/Clutch-Pilot Shaft .. 750&600 Notes..late type(early NLA) |

|

|

|||

151 .. |

3rd Gear............................................................ |

A750/F600 ...................... |

|

NLA(old# 875487) |

|

151 .. |

seal for Inner Boot .......................................... |

750&600 Notes..600D seal-40001150 |

|||

*152 .. |

Axle Shaft ........................................................... |

A750/F600 ....................... |

|

early 23mm axle-NLA |

|

*152 .. |

Axle Shaft ......................................................... |

A750/F600 ... |

24.34m axle-4009303 |

|

|

*152 .. |

Axle Shaft ......................................................... |

750&600 Notes.. 600D axle-4061138 |

|

||

*152 .. |

Sp1ined Ax1e-Attaehing Sleeve..A.750/F600........................................... |

|

|

for 23mm-878272 |

|

*152 .. Sp1ined Ax1e-Attaehing Sleeve..A750/F600.. for 24.34mm-4095427 |

|

||||

152 .. |

Snap Ring to Retain Axle .. 750&600 Notes..for 24.34:mn axle only |

|

|||

152 .. |

Tie Rod Ends ................................................... |

750&600 Notes..early type(late NLA) |

|||

152 .. |

King Pin Set ............................................................. |

750/600/OT1000/850..1900637 |

$16.60 |

||

|

|

|

|

11 |

*152 .. |

Leaf Spring (Lower)Bushing..A750/F600.............................................. |

4007967 |

$3.50 |

|

152 .. |

Leaf Spring (Lower)Bushi_g..0T1000/F850 ......................................... |

4140008 |

$6.20 |

|

152 .. |

Inner Front Bearing Seal |

...OT1000/F850............................................. |

SAME(2req.) |

|

*153 .. |

Collapsible Bearing Spacer..A750/F600 ............................................... |

986842 |

$1.55 |

|

153 .. |

Wheel Cy1inderFront .................................. |

750&600 Notes..600D-4394465 $18.20 |

||

153 .. Wheel CylinderFront.0T1000/850 Notes.850 Sedan-4379471 |

$11.00 |

|

||

155 .. |

Fuse Box......................................................... |

F600 ............................... |

SAME |

|

155 .. |

Wiper Rheostst ....................................... |

OTIOOo/850 Notes .. |

67-72 Spyder |

|

156 Revised Spark Plug Recommendation Chart:

Brand Name |

Abarth 750 |

Fiat 600/600D |

Abarth OT/OTS |

Fiat 850 Sport |

Fiat 127 |

|

Pushrod |

|

1000,1300/124 |

A112Abarth |

A112 |

Champion |

L-5, L-4J |

L-7J |

N-6Y |

N-7Y |

N-9Y |

NGK |

B-7HS |

B-6HS |

BP -8ES |

BP-7ES |

BP-6ES |

Lodge |

2HN |

HN |

3HLNY |

25HUIT |

HLNY |

Bosch |

W225T1 |

W175T1 |

W260T30 |

W200T30 |

W175T30 |

Marelli |

CW-7N |

CW-6N |

CW-8LP |

CW-78LP |

CW-7LP |

Abarth |

AB200 |

AB175 |

AB260LY |

AB230LY |

AB200LY |

158 .. Fiat 600 Front Grille with Emblem .. 889868 $4.55, Upper & Lower Grille Whiskers .. 884321(4req.) $2..90, Center Wiskers .. NLA(2req.) 158 .. Fiat 600D Hubcap. .411722?(4req#) $12.90 159 .. Motorsport Imports .. Note: 600/850 & 127 cog-belt kits differ.

. Denotes a major error :in. "ABARTH" Interchangeable Parts List.

New Listings for "ABARTH" Parts Interchange

|

|

Page # Part Description |

A750/F600 |

OT1000/F850 |

Notes |

|

||||

147 .. |

Connecting Rod... |

88822(4req.) $7.25 |

425683 |

$13.5 |

843 |

|

|

|||

|

|

|

|

|

427731 |

$23.5 |

903 |

|

|

|

147 |

.. Conn Rod Bolt........................................... |

884067(8req) $.30 .... |

|

4187674 $1.45 |

||||||

147 .. |

Rod Bolt Nut........................................... |

12566220(8req) $.55 . . ----------------- |

............. |

|

|

|||||

148 .. Replacement Pistons. 66-5765 Borgo-600D.. 66-6210 Borgo-817cc |

|

|

|

|

||||||

|

|

(62mm ... |

oversize) ... |

(64mm + oversize) |

|

|

|

|

|

|

148 .. |

Exhaust Valve ................................. |

4064702(4req) 54.15-600D(23.5mm) may fit 750 |

||||||||

148 .. |

Valve Spring.............................................................. |

|

898327(8req) $1.20..use A12/127 Abarth |

|||||||

|

|

|

|

|

to OTI000(16req) |

|

|

|

||

148 .. |

Valve SpringOuter.................................................................................... |

|

|

|

|

4208869(8req) $2.15 |

||||

148 .. |

Valve Spr_Inner.. ...........................................................................4183703(8req) $.95 |

|||||||||

148 .. |

Rocker Arm ........................................................... |

|

991327( 4req) $5.90. .4189130(.4req) $4.30 |

|||||||

|

|

|

|

99l328(4req) $3.65..4189131(4req) $4.30 |

||||||

148 .. |

Push Rod..................................................................... |

|

880904(8req) $2.00..4130697 |

$7.00 843 |

||||||

|

|

|

|

|

4109429 |

$2.10..903 |

|

|

|

|

149 .. |

Fan Shroud Clamp Ring................................................................................. |

|

|

|

|

4109842 |

$1.65 ..... |

|||

149 .. |

T .Stat. Housing Lid/Water Outlet ............................................. |

|

4100580 $9.05 . to mid 68 |

|||||||

|

|

|

|

4187098 $6.55 |

.. 69-73 |

|

|

|

||

150 .. |

Intake Manifold _. NLA( use... aftermarket) ... |

4226436. $28.00 |

|

|

|

|

|

|||

150 .. |

Flywheel Ring Gear NLA(use.. 4113558 fly- .. |

4109024 |

$15.55 |

|

|

|

|

|

||

|

wheel complete $86.75) |

|

|

151 |

.. Speedometer Cable ... see.pp.91. of FAT................................................ |

4136084 |

$9.40 |

155 .. |

Combination Light/Wiper Switches(3-inch)..4204126 |

$13.00-coupe |

|

155 .. |

Heater Fan Switch ... ................................................................................. |

4294181 |

$2.75 |

160 Vandervell, Clevite, AE, Repco, & Glacier are good alternate sources .to try for Fiat engine bearings. - 160 other Abarth clubs are located in : England, Germany, France, Sweden, Japan.

159-160 ADS & PES are out of the Fiat business and most of the other

listed sources no longer supply much for the early cars. See pp. 81-82 of this booklet for good new sources....

Loading...

Loading...