AAF International Type W RotoClone User Manual

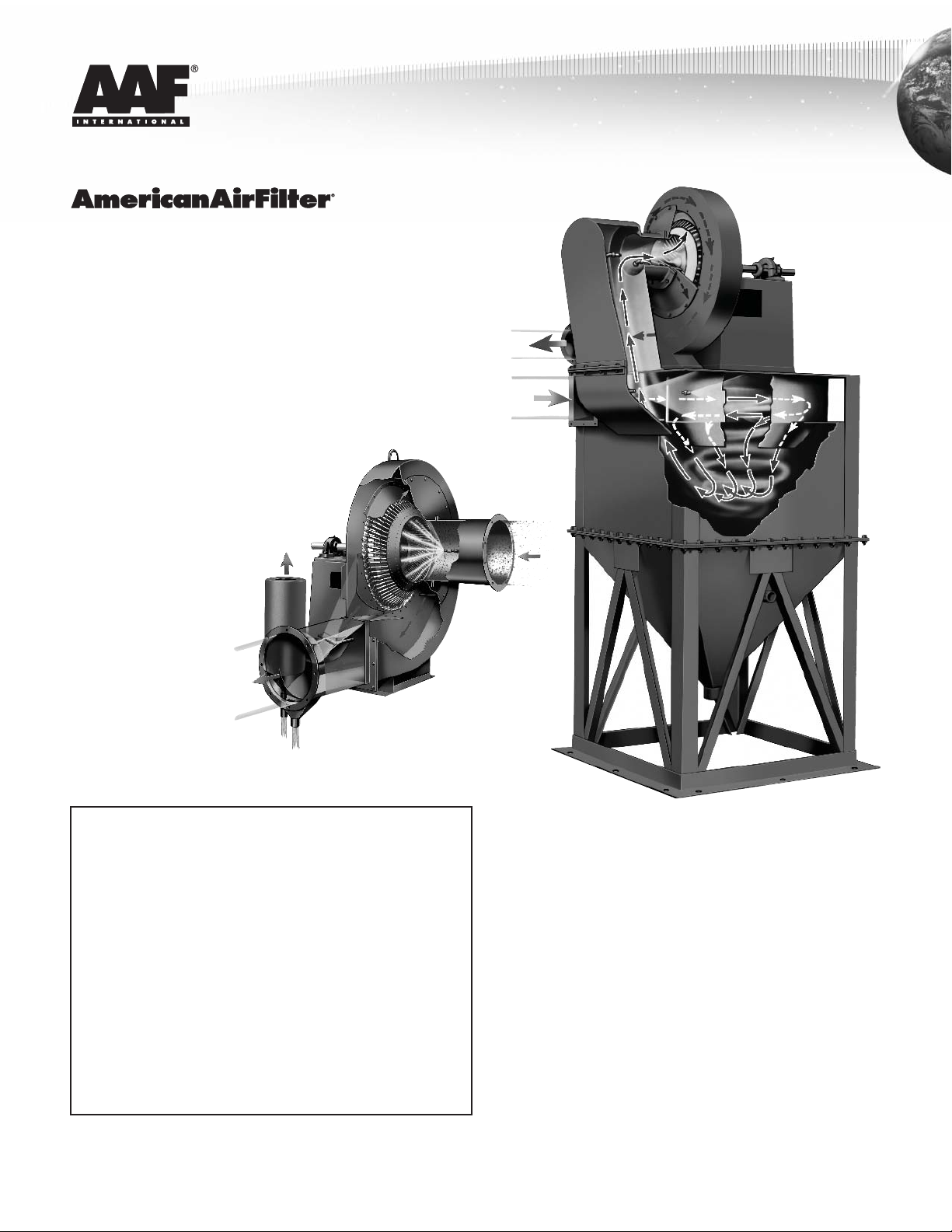

Type W RotoClone

®

Wet Centrifugal Collector

Installation, Operation,

and Maintenance Instructions

Better Air is Our Business

®

IMPORTANT:

Read this manual before installing or operating the equipment.

This manual should remain with the equipment for reference

regarding operation, maintenance and repair/parts. Write down

the information from the nameplate on the W RotoClone and

copy it to the front of this IOM for future reference.

Retain all drawings and documents that came with the RotoClone

(in the “Instructions Envelope”) and keep with the IOM in a readily

accessible location.

If you are an installer and not the owner of this equipment, all

of these documents should be submitted to the end user, upon

completion of the installation.

Table of Contents

1.0 Description

2.0 Installation

2.1 Foundations

2.2 RotoClone Erection (Arrangement A & D)

2.3 Duct Connections (Arrangement A & D)

2.4 Water Connections (Arrangement A & D)

2.5 Average Water Requirements

2.6 Wiring & Controls

2.7 Spray Nozzles

2.8 Sludge Connection (Arrangement A & D)

2.9 Drain Connection (Arrangement A & D)

2.10 Emergency Overflow (Arrangement D)

2.11 Bearings

2.12 Drive

2.13 Placing RotoClone in Service

3.0 Operation

4.0 Maintenance

4.1 Lubrication

4.2 Nozzles and Strainer

4.3 RotoClone Inlet (Arrangement A)

4.4 Precleaner Inlet (Arrangement D)

4.5 RotoClone Impeller

4.6 Drains

4.7 Emergency Overflow (Arrangement D)

4.8 Shaft Seal

4.9 Replacement of Shaft, Impeller or Water Cone

5.0 Troubleshooting

5.1 Water Entrainment

5.2 Dust Entrainment

6.0 Weights & Water usage Tables

7.0 Storage Instructions

8.0 Parts List

9.0 Supplements for Optional Features

9.1 Food Quality W RotoClones

9.2 Range Hood and FM Controls

9.3 Auxiliary Impeller Flushing

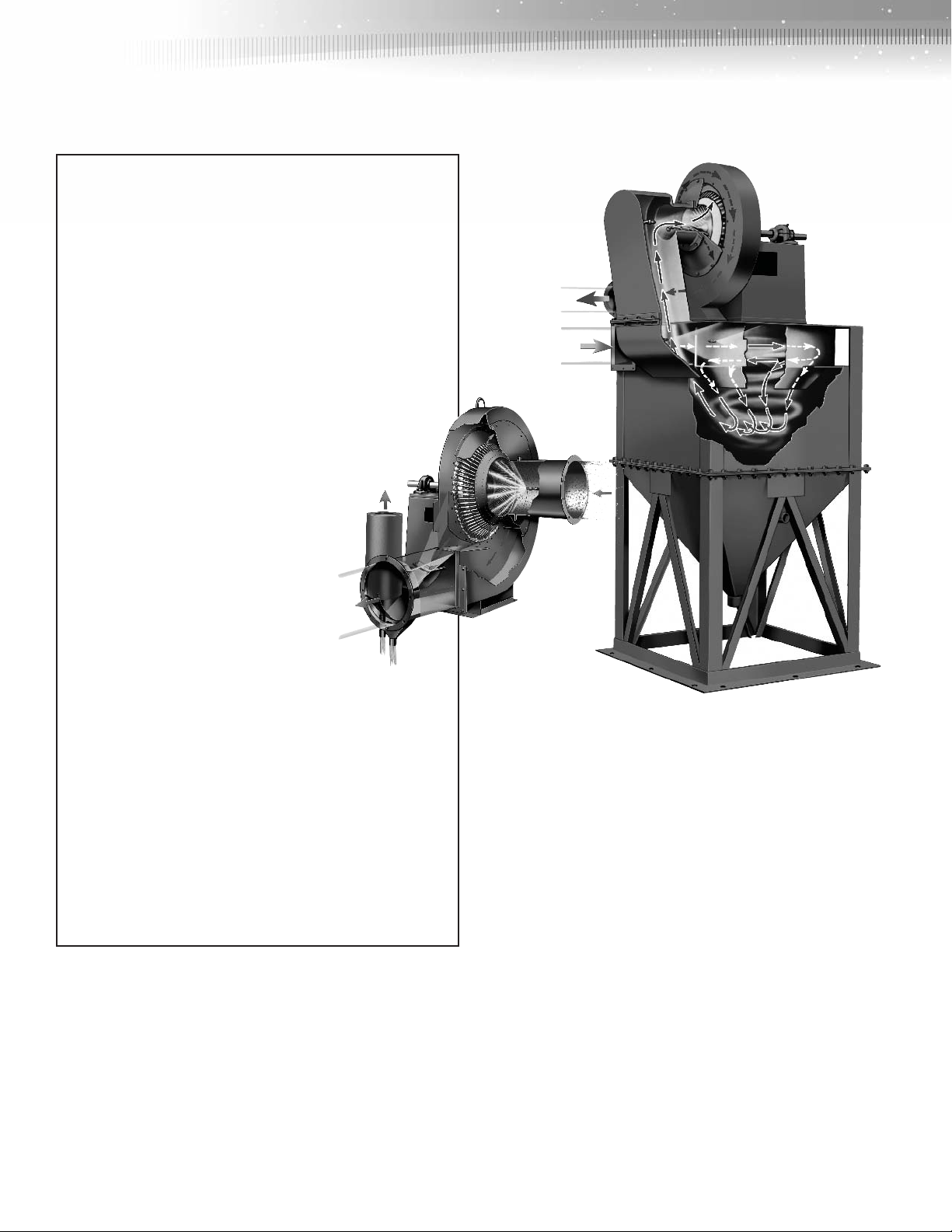

1.0 Description

The Type W RotoClone is a complete dust control unit. It combines

exhauster and dust collector in a single compact unit, and continuously

discharges the collected material in a slurry form.

The Type W RotoClone has been designed to perform its various

functions automatically and requires very little maintenance. Like

any other mechanical equipment, however, it should have regular

attention and be operated according to instructions to ensure long

life and trouble-free service.

2

2.0 Installation

The following instructions should be read carefully before installing

the RotoClone.

2.1 Foundations

Foundations must be true, level, and rigid enough to prevent vibration

and support the weight of the RotoClone. (See Section 6, Table 2 for

net weights of RotoClone.)

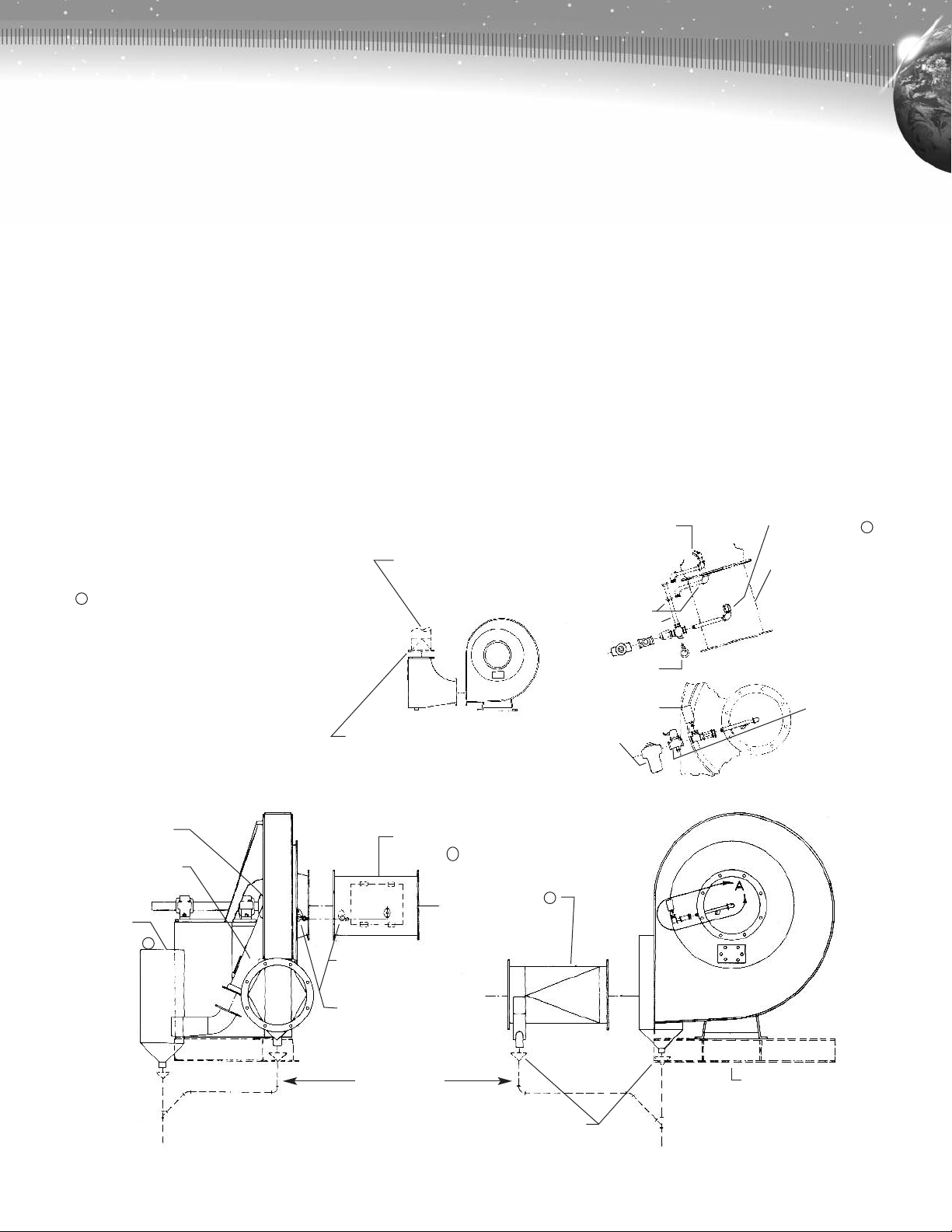

2.2 RotoClone Erection (Arrangement A)

Refer to Installation Diagram - Figure 1. Assembly of the RotoClone

should proceed in the following manner sealing all joints using

gaskets and bolts included with shipment. Some RotoClones,

size 16 and smaller, have inlet, outlet, and expansion chamber

welded to housing in lieu of flanged and bolted connections.

1. Bolt RotoClone outlet connection to RotoClone outlet. Be sure

that the bottom of the outlet piece is even with the bottom of the

RotoClone outlet and that no gasket material is protruding inside

as this will cause water carryover.

2. Bolt RotoClone on foundation. If vibration isolators are used,

a sub-base must be used to support the exhauster with the

isolators located at each corner of the sub-base. Connecting

ductwork requires flexible connections when vibration isolators

are used.

3. Bolt RotoClone inlet connection to RotoClone inlet.

(Note: Eliminate elbows and other inlet obstructions if at all

possible. Sharp elbows at the fan inlet or other disturbances

will seriously reduce the air volume and can affect the RotoClone’s

dust collection efficiency. A minimum of 4-5 inlet diameters of

straight duct prior to the RotoClone is recommended to evenly

distribute airflow.)

4. Bolt expansion chamber to water outlet.

Discharge stack supplied by others.

Extend vertically above roof line.

Joints must be made water-tight.

Supply gasket at RotoClone connection.

90˚ Elbow Assembly Shown

Auxiliary Spray Nozzle

Location for

sizes 8 - 14

*

Pressure Gage

*

Inlet Spray Nozzle

*

Inlet Connection Assembly

Pressure Switch

*

Strainer

*

Solenoid Valve

(if supplied)

*

View A

These parts and necessary connecting

bolts are shipped separately on sizes

24 and larger or for units with special

interior coatings. On standard units

sizes 16 and smaller, these pieces

may be welded to housing.

These parts are shipped separately.

*

*

Shaft Seal

Water Outlet

*

Expansion

Chamber

Side Elevation

Front Elevation

Inlet Connection

Assembly

Location for

sizes 8 - 14

To auxiliary spray nozzle

*

Piping by others

Outlet Connection

Assembly

*

Open Drain Funnel

Foundation by others

Figure 1 — Installation Diagram

3

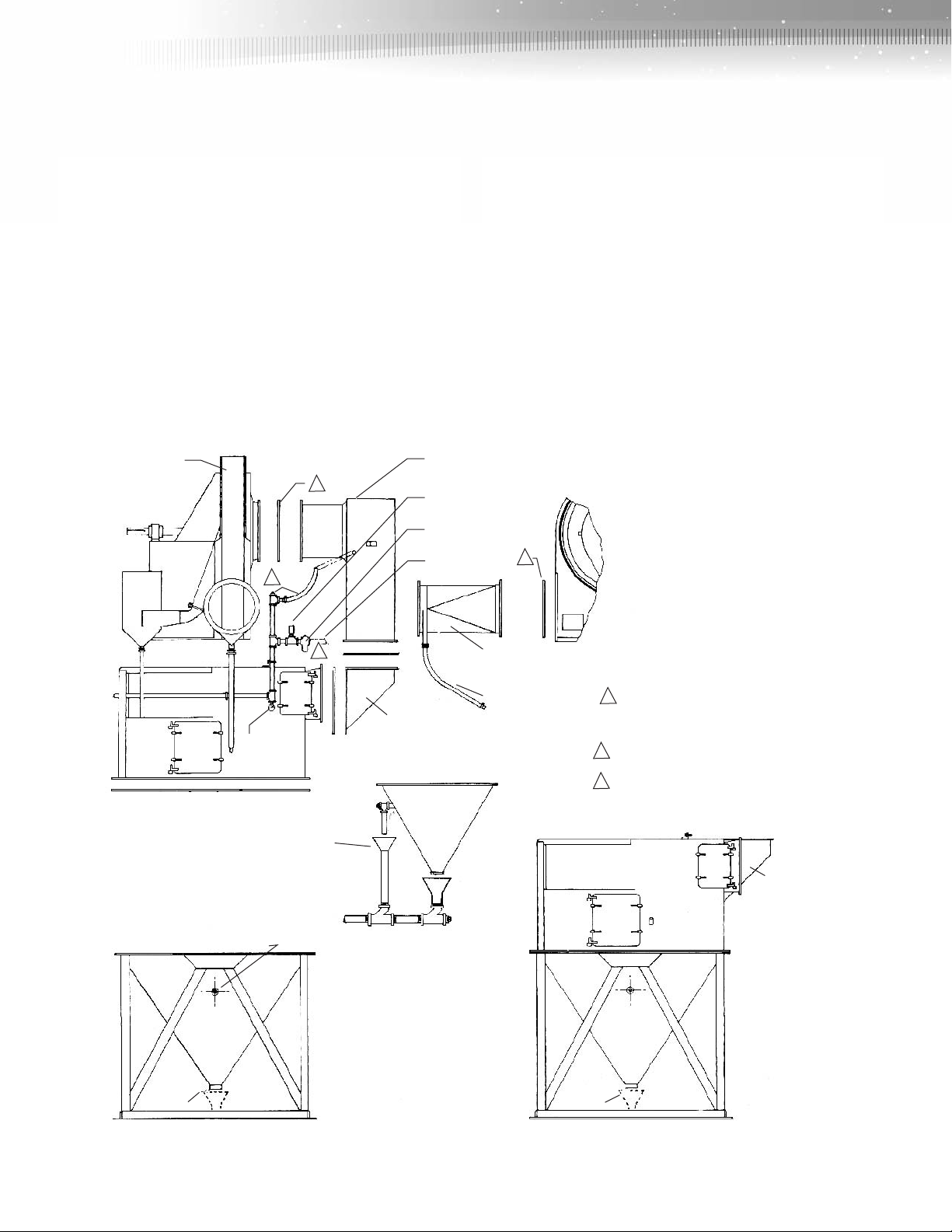

RotoClone Erection (Arrangement D)

Refer to Arrangement D Erection Diagram - Figure 2. Assembly

should proceed in the following manner, using gaskets and bolts

included with shipment for each joint. Some RotoClones, sizes 16 and

smaller, may have inlet, outlet, and expansion chamber welded to

housing in lieu of flanged and bolted connections.

1. Place hopper section on foundation and anchor.

2. Bolt precleaner section to hopper top. (Note: On RotoClones

sizes 8 through 20, the hopper and precleaner sections

are normally shipped assembled.)

3. Bolt RotoClone outlet connection to RotoClone outlet. Be sure

that the bottom of the outlet piece is even with the bottom of the

RotoClone outlet and that no gasket material is protruding inside

as this will cause water carryover.

4. Bolt RotoClone to precleaner top. (Note: On RotoClones sizes

8 and 10, RotoClone is shipped assembled to precleaner

and hopper.)

5. Bolt precleaner outlet connection to precleaner section.

(Note: On RotoClones sizes 8 through 16, the precleaner

outlet connection and precleaner are shipped assembled.)

6. Bolt RotoClone inlet connection to RotoClone inlet and

precleaner outlet connection.

7. Connect hose from water drain in RotoClone outlet connection

to nipple provided in hopper using fittings provided.

Figure 2 — Arrangement D Erection Diagram

RotoClone

Open Drain

Funnel

Precleaner

Pressure

Gage

Precleaner

Outlet Connection

Water Drain

RotoClone

Outlet Connection

RotoClone Inlet Connection

Pressure Switch

Strainer

Water Supply

Recommended drain

and overflow piping

furnished by others.

Hopper and precleaner

separated for shipment

as shown for RotoClone

size No. 24 and larger.

Emergency Overflow

Hopper

Drain

1

1

2

1

2

Trap Hose

Precleaner

Hopper

Drain

Hopper and precleaner

shipped as one unit

for RotoClones thru

size No. 20.

Precleaner Outlet

Connection

Notes: All gaskets are Minnesota Mining Co. sealer #EC-1055.

Piping hose and clamps shipped separately.

1

2

4

5

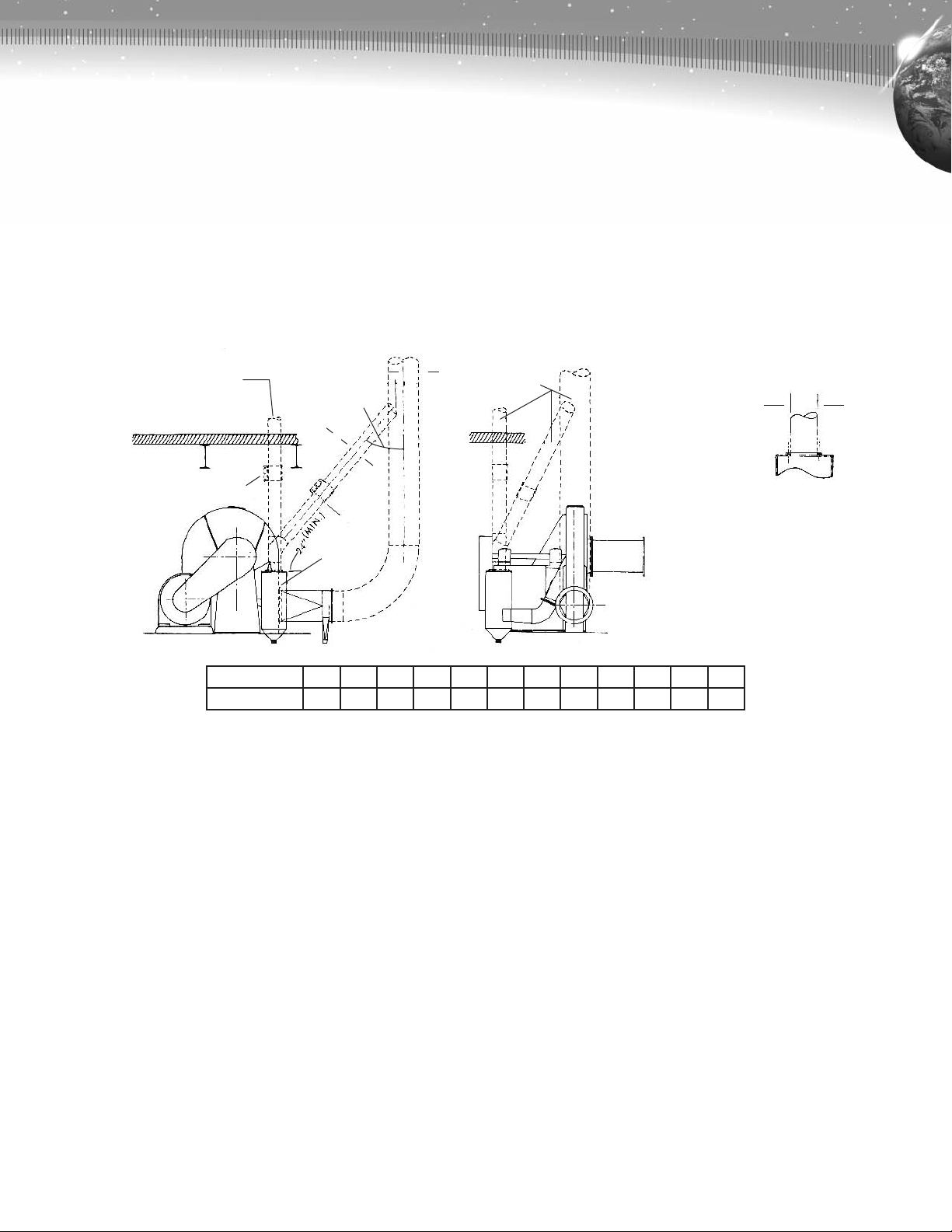

2.3 Duct Connections (Arrangement A)

Inlet and discharge ducts must be supported from floor, wall, or ceiling, and not by the RotoClone. The joint between the RotoClone inlet and

exhaust main must be water-tight. Inlet duct should slope downward with bottom of duct no lower than bottom of RotoClone inlet. There should

be at least four (4) duct diameters of straight run leading to the inlet of the RotoClone or performance may be impaired. Discharge duct should

extend above roof line and should discharge the air vertically upward. It should be of same diameter as the RotoClone inlet and seams must

be soldered or welded water-tight. A gasket (not furnished) should be placed between the outlet connection and the discharge duct to make

joint water-tight. A weather hood is not required. Expansion chamber should be vented per Figure 3, where recirculation of discharge air

is not permitted.

RotoClone Size 8 10 12 14 16 20 24 27 30 33 36 45

Vent Dia. "A" 3.5" 4" 5" 6" 7" 8" 10" 11" 12" 14" 15" 18"

Figure 3 — Expansion Chamber Venting Diagram

(Arrangement D)

Instructions same as Arrangement A except on Arrangement D, the

joint between Precleaner inlet and exhaust main must be water-tight.

2.4 Water Connections (Arrangement A)

RotoClone piping may be shipped loose to prevent damage during

shipping. Connect the two lines from the “cross” to the two

connections on the RotoClone inlet. The third outlet from the cross

connects to the pressure gauge supplied and the front leg should be

connected to the water supply line. Supply line should be 3/4” size for

RotoClones through size 14; 1” size for size 16 RotoClones and larger

and designed for supply line water pressures. Connect the water

supply line to strainer located near RotoClone inlet, using pipe at

least as large as the strainer connection. The Solenoid Valve, should

be installed between the strainer and cross, and should be wired

in parallel with the RotoClone motor per the wiring diagram supplied

with the unit. Solenoid valves should always be installed with the coil

in the top, vertical position. Finished piping should be per Figure 1.

It is recommended that a manual shut-off valve be installed in

the supply line, to be able to do maintenance on the solenoid valve.

The water connection must be capable of supplying the volume listed

in Section 6, Table 1 to the spray nozzles at 40 to 60 psi pressure.

(Arrangement D)

Instructions same as Arrangement A, strainer located near Precleaner

inlet. Refer to Figure 2 for Pressure Gage Installation.

A by-pass connection with manual valve per Figure 4 (both

Arrangement A and D) may be included to safeguard operation

of RotoClone in case of solenoid valve failure or for strainer

maintenance.

2.5 Average Water Requirements

See Section 6.0, Table 1 for average water required.

2.6 Wiring & Controls

Refer to the wiring diagram supplied with the unit for

recommended connections.

Where conditions indicate vent can be

run directly to atmosphere

Provide clamping band to permit

inspection of expansion chamber

Expansion

Chamber

A

45˚ Maximum

30˚ Preferred

1

/

2 A

Piping by

customer

1

/

2 A

A

Enlarged detail

vent connection to

expansion chamber

Loading...

Loading...