AAF International Type N RotoClone User Manual

Type N RotoClone

®

Hydro-static Precipitator Model B Arrangement C

Design 2 or 3, Size 1

1

⁄2 thru 6

Design 4 or 5, Size 8 thru 28

Installation, Operating and Maintenance Instructions

Better Air is Our Business

®

The Type N RotoClone is a complete dust control unit. Designed

to perform its various functions automatically, the RotoClone

requires very little maintenance. Like any other mechanical

equipment, however, it should have regular attention and be

operated according to instructions to insure long life and

trouble-free service.

Design 2 and 4 have the exhauster on the clean air side of the

Type N RotoClone. In the Design 3 and 5, the exhauster is on the

dirty air side and discharges into the Type N RotoClone.

It is recommended that the back page of this manual be filled

in with specific design details for future reference. These

include: design number, sludge ejector control device, operating

line, type of water level control and wiring diagram that applies

to this Type N RotoClone.

Operating Principle

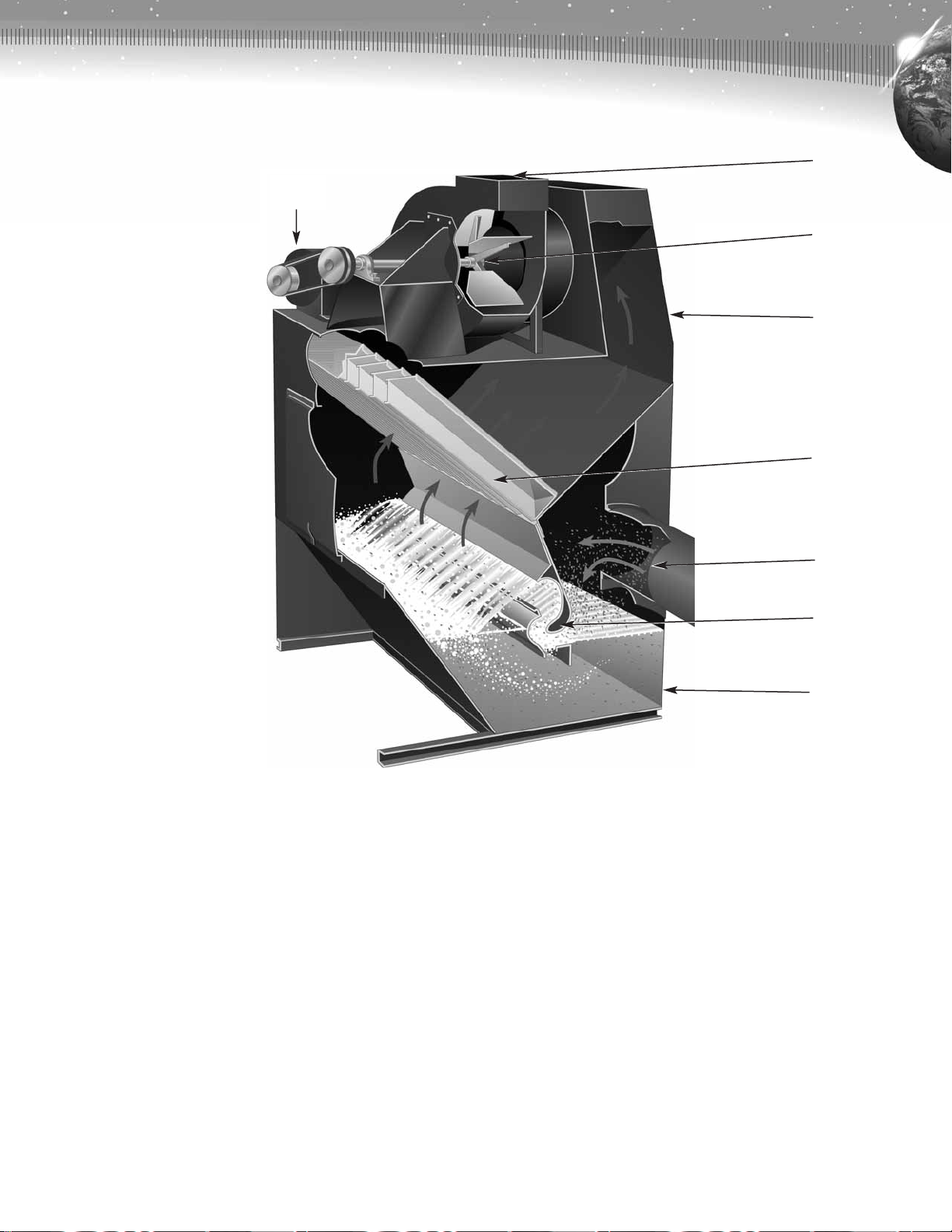

The Type N RotoClone cleans the air by the combined action of

centrifugal force and a thorough intermixing of water and dust-laden

air. The dust is separated from the air by means of a water curtain,

created by the flow of air through a partially submerged stationary

impeller (see Figure 1). Air flowing through the impeller at a high

velocity conveys water with it in a very turbulent sheet. Additional

water is introduced at the narrowest portion of the impeller opening

through a specially designed slot at the bottom. Since there is a

certain pressure drop through the impeller, the water flows upward

through the slot in an attempt to reach the water level on the clean air

side. The water flow upward through the slot creates increased

interaction between the dust and water, thus, increased collection

efficiency. Since the water flows upward in an attempt to reach the

level on the clean air side of the impeller, the impeller opening can be

decreased (resulting in higher pressure drop and collection efficiency)

by raising the water level in the unit. This is accomplished by means

of an exclusive and patented variable water level control box. The

centrifugal force exerted by rapid changes in direction of flow causes

the dust particles to penetrate the water film and become permanently

trapped. (Figure 1).

Table of Contents

Operating Principle

Installation Instructions

A. Foundations

B. RotoClone Erection

C. Lubrication

D. Duct Connections

E. Water Supply Connection

F. Drain Connection

G. Fan Drain

H. Electrical Connections

I. Water Level Control Options

J. Flow Control Valve

K. Sludge Container

Water Level Control Box Arrangements

Operating Instructions

A. To Fill RotoClone

B. To Start RotoClone

C. To Stop RotoClone

Maintenance Instructions

A. Routine Maintenance

B. Correction of Poor RotoClone Operation

Type N RotoClone Performance Curves

Parts List for Sludge Ejectors Type W-2 and Type L2

2

Entrained moisture in the cleaned air is removed by specially

designed, wide-space chevron eliminators made in removable

sections for Size 11⁄2 through 6 and curved entrainment baffles for

Sizes 8 and larger.

The water in the reservoir is continually reused, and since the water

curtain is produced by the air flow, no pumps or nozzles are required.

The water level is maintained by the overflow weir in the control box

as long as a small amount of fresh water is supplied through the

make-up water connection or by electrical controls that automatically

add water, as required, to compensate for evaporation and water lost

as the collected dust is removed from the unit.

Sludge Ejector

The sludge hopper is designed with steep sides to prevent material

buildup on the hopper walls. The ejector is constructed for heavy duty

service and long life. The chains and sprockets are constructed of

wear resistant materials and the chain speed is slow enough to permit

sufficient dewatering of sludge.

There are two types of ejector designs. Sizes 11⁄2 thru 12 have the

“W” ejector system. Sizes 16 thru 48 use the “L” ejector system.

Figures 9 and 10 show the designs and designate the appropriate

replacement parts by part number.

The sludge ejector is operated continuously for most applications.

It is driven by a flange-mounted, fractional horsepower motor.

An optional accessory that can be obtained is an automatic sludge

ejector timer control. This timer allows the sludge ejector to operate

for two hours after the RotoClone shuts down. Thus, materials

with slow settling rates can be removed from the unit after

RotoClone operation.

Size

1

1

⁄2

21⁄2

4

6

8

12

16

20

24

28

32

36

40

44

48

Maximum

Operating

Wt. Lbs.

(Note 1)

6,300

6,400

9,500

11,400

13,200

16,500

28,500

33,600

40,300

46,000

51,100

56,300

64,500

70,200

76,100

Normal

Operating

Wt. Lbs.

(Note 2)

4,800

4,900

7,100

8,700

10,500

13,200

21,600

25,300

30,500

34,800

38,500

42,400

49,200

53,500

58,000

Water

Capacity

Gallons

300

300

470

540

530

650

1,370

1,650

1,950

2,220

2,500

2,775

3,050

3,330

3,610

RotoClone

Only

2,000

2,000

2,700

3,600

5,300

6,500

8,000

9,400

11,000

12,400

13,700

14,800

19,300

21,300

23,400

Exhauster

Only

300

400

500

600

800

1,300

2,200

2,200

3,300

4,000

4,000

4,500

4,500

4,500

4,500

Installation Instructions

Read the following instructions completely and carefully.

A.Foundations

Foundations must be true, level and rigid enough to prevent vibration

and to support the weight of the RotoClone with its maximum dust

and water load given below.

Erecting Weights

B.RotoClone Erection

1. Set RotoClone on foundation and adjust base until unit is level.

Place spirit level on the leveling strips welded on two or more sides

of the hopper. Use care in leveling both directions as the operation

of the RotoClone depends on the accuracy of the leveling function.

Note: This level can be checked by filling the unit with water until the level reaches

the entering edge (Figure 1) of the impeller. This entering edge should be level with

the water along its entire length with maximum variation of 1⁄8 " plus or minus. (See

Operating Instructions, Item A-2).

2. For Sizes 11⁄2 thru 6, chevron mist eliminator bundles are shipped

loose for installation at the jobsite. Refer to drawing 1400415 for

Installation Instructions. For Sizes 8 thru 48, the entrainment baffles

are fixed in place as an integral part of the unit and it is not

necessary to make any adjustments (Figure 3).

Table 1—RotoClone weights

Note 1: Weight based on maximum sludge capacity with a sludge

weight of 100 pounds per cubic foot.

Note 2: Weight based on weight of water, 62.4 pounds per

cubic foot.

Clean Air

Side

Intermediate

Sheet

Dirty Air Side

Entering

Edge

Figure 1. Cross section of Type N RotoClone®Impeller.

3

Motor &

Drive

Figure 2. Cutaway section of typical Type N RotoClone Design 2 and 3 size 11⁄2 thru 6.

Clean Air

Discharge

Exhauster

Clean Air

Transition

Water

Eliminators

Dirty Air Inlet

Impellers

Hopper

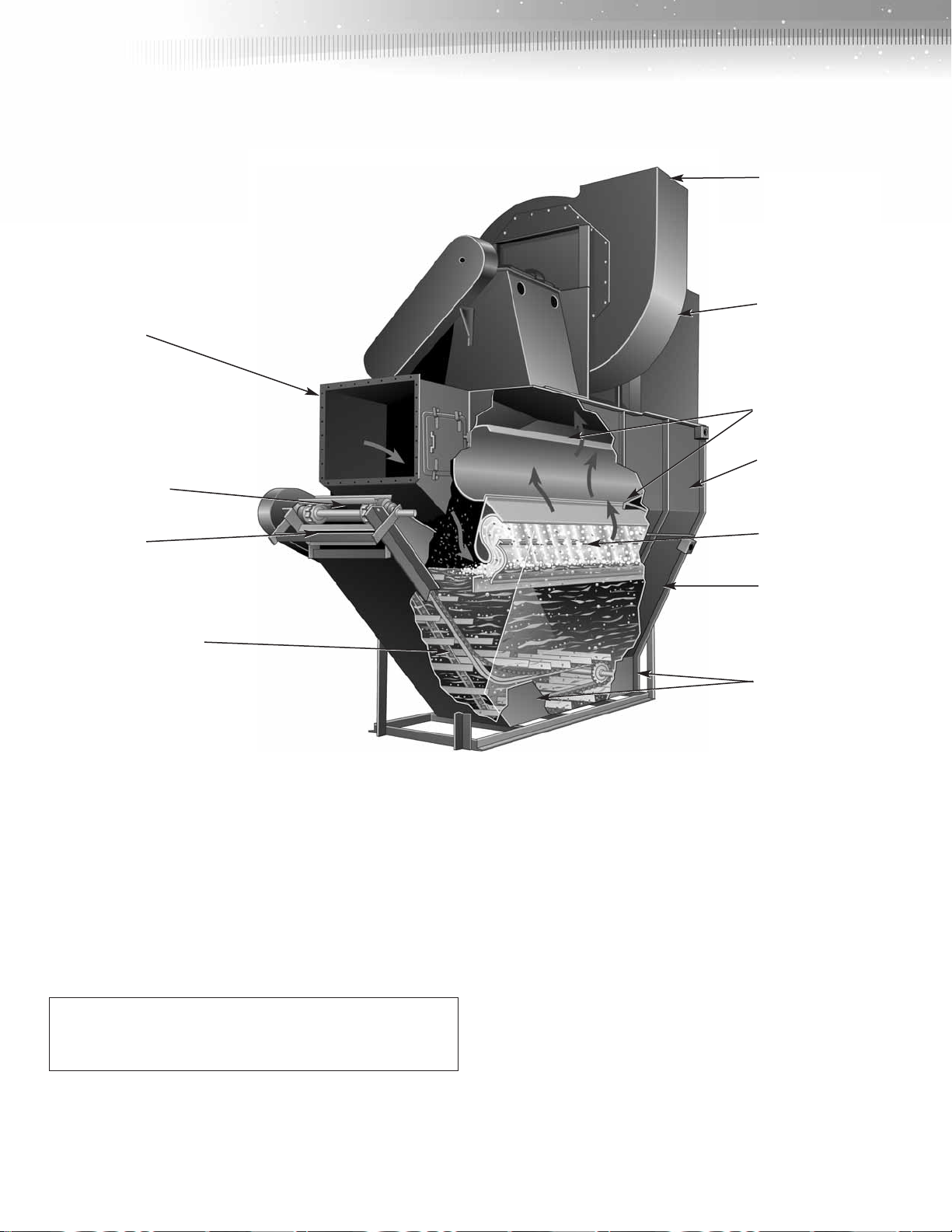

3. For RotoClone Sizes 11⁄2 thru 6 which are not shipped with

exhausters or for all RotoClone Sizes 8 and larger, three-inch

sealing tape is furnished. This tape seals the 5⁄8 inch nominal gap

between the clean air transition and the exhauster inlet.

4. RotoClones, Sizes 8 thru 48 are shipped disassembled in major

subassemblies; RotoClone, clean air transition, motor, drive, and

exhauster. Necessary gasket material for the flange between the

RotoClone and transition section and the three-inch sealing tape

noted above are packed in a box with bolts.

5. If necessary, Sizes 16 thru 48 can be shipped with the collecting

section and hopper section disconnected.

Field assembly of collecting section and hopper section will require

the following:

a. Install gaskets on top of hopper external flange.

b. Set collecting section in place so its bolting flange matches

hopper flange. Lower carefully, watching for interference between

intermediate sheets (lower section of curved entrainment baffles)

and impellers. Walls of interior center section, formed by the two

intermediate sheets must be inside impeller bolting surface

(Figures 1 and 3).

c. Bolt outside flanges of collecting section and hopper section.

d. Bolt impellers to intermediate sheets. Before tightening, entering

edge (Figure 1) of impellers must be in a straight line. Impellers

were installed in the hopper section and aligned at the

factory. Each impeller section is matched-drilled with holes in

intermediate sheet. Pull these bolts tight and check alignment

before tightening remainder of bolts through slotted holes in

impellers and drilled holes in intermediate sheets.

4

Figure 3. Cutaway section of typical Type N RotoClone

with Design “L2” Ejector and Design 4 and 5.

Sizes 16 through 48.

Fan Outlet

Clean Air Transition

Entrainment Baffles

Collecting Section

Impeller

Hopper

Lower Ejector

Shafts Mounted

Internally

RotoClone Inlet

Upper Ejector Shaft

Paddle Scraper

Design “L” Sludge Ejector

C.Lubrication

1. All bearings on the sludge ejector are ball bearings packed with

grease before leaving the factory. Do not add grease during

installation. See Maintenance Instructions, A-4 for greasing

instructions and schedules.

2. Gear reducer on sludge ejector drive was filled with oil before

shipment. Check for proper oil level. See Maintenance

Instructions, A-4.

NOTE: To prevent loss of oil while units are in transport, the

reducers are shipped with a brass pin in vent or filler plug. This

pin must be removed before the reducer is operated.

D.Duct Connections

In order to prevent surging within the RotoClone, four to five duct

diameters length of straight run prior to the inlet will provide uniform

distribution at the inlet. If an elbow is required due to space limitations,

turning vanes must be used in the elbow to evenly distribute the air

and prevent surging.

Inlet and exhaust duct must be supported from floor, wall or ceiling;

not from RotoClone or exhauster. Depending on the application and

local conditions, the discharge from the exhauster may be returned to

the workroom or discharged to the atmosphere. It may be desirable

to have both outside and inside discharges fitted with a selective

damper. This will save heat during the winter with recirculation and aid

ventilation by discharging outside during the summer months. Where

discharge duct is required, it should extend above adjacent roof lines

and should discharge vertically upward. As long as there is a drain in

the fan housing, a raincap or weather hood need not be used. Crosssection of the discharge duct should not be less than the exhauster

outlet area.

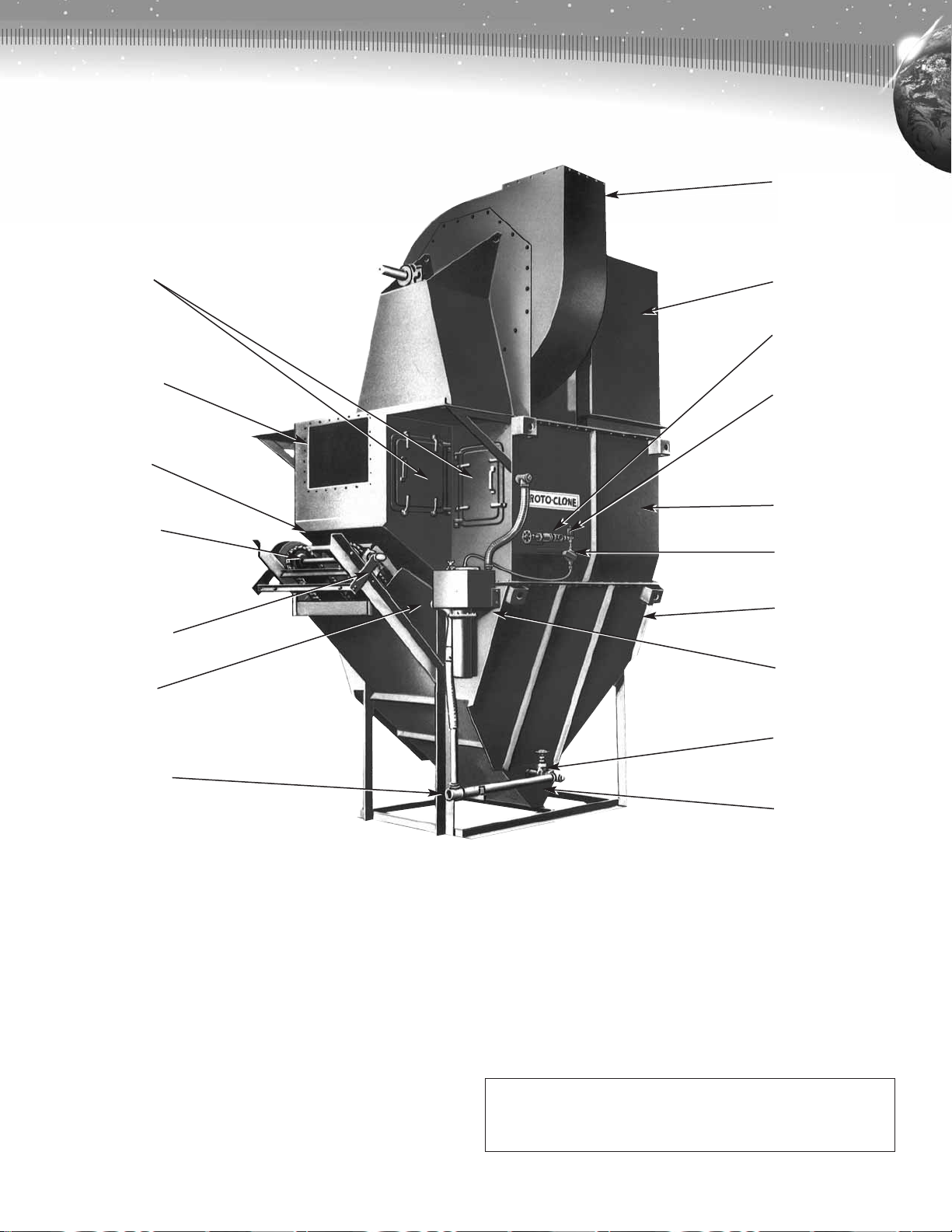

E. Water Supply Connection

Connect a 1" line for Size 1

1

⁄2 thru 6 or a 2" line for Sizes 8 and larger

at point shown on Figure 4.

5

Figure 4. Typical Type N RotoClone with Design “W2” Ejector.

Sizes 1

1

⁄2 through 12.

F. Drain Connection

Connect a 2" drain line for Sizes 11⁄2 thru 12 or a 4" drain line for

Sizes 16 and larger at point shown on Figure 4.

G.Fan Drain

When fans are mounted on the RotoClone, a drain pipe from the fan

drain should be installed back down through the top of the RotoClone

(a hole is supplied in the top of the RotoClone). An “oversized washer”

should be slipped over the drain pipe and caulked to the RotoClone

roof to close off the annulus formed by the drain pipe and hole in the

roof of the RotoClone.

H.Electrical Connections

Electrical components of the RotoClone are the exhauster motor,

sludge ejector motor, motor starters, solenoid valve, and flow switch.

Each connection is to be made in accordance with the appropriate

wiring schematic enclosed with the RotoClone instruction packet.

1. Exhauster motor—The motor nameplate will show the connection

hookup of the motor leads.

CAUTION: After connecting motor leads, insure that the exhauster

rotates in the proper direction as indicated by the arrow on

exhauster housing.

Fan Outlet

Clean Air Transition

Fill Valve

Water Supply

Connection

Collecting Section

Leveling Strip

Hopper Section

Water Level

Control Box

RotoClone

Drain Valve

Lower Ejector

Shaft Mounted

Internally

Access Doors

RotoClone Inlet

Design “W”

Sludge Ejector

Paddle Scraper

Take Up Bearings

Standing Level

Overflow Drain

Drain Connection

Loading...

Loading...