AAF International Type LVN RotoClone User Manual

Type N RotoClone

®

Hydrostatic Precipitator - Model LV

Installation, Operation and Maintenance Instructions

Better Air is Our Business

®

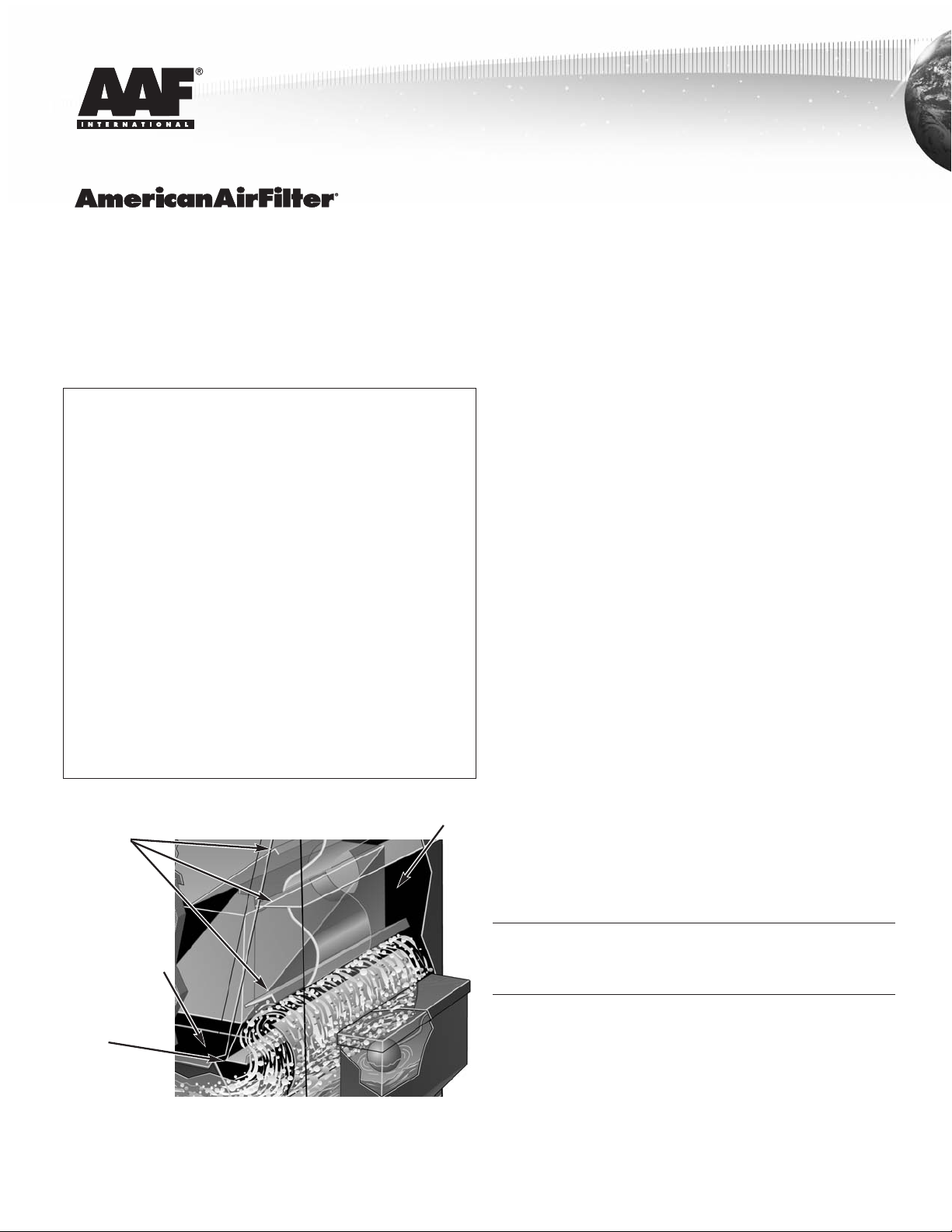

Figure 1

Cross section of Type N RotoClone Impeller.

Size

500

1,000

1,500

2,000

Maximum

Operating

Wt. Lbs.

(Note 1)

1,670

1,700

2,360

2,400

Normal

Operating

Wt. Lbs.

(Note 2)

1,570

1,600

2,160

2,200

Water

Capacity

Gallons

61

61

102

102

Erecting

Weight

(Lbs.)

1,045

1,075

1,320

1,360

Note 1: Weight based on maximum sludge capacity with a sludge

weight of 80 pounds per cubic foot.

Note 2: Weight based on weight of water 62.4 pounds per cubic foot.

1.0 Description

1.1 General Information

The Type N RotoClone is a complete dust control unit. Designed

to perform its various functions automatically, the RotoClone requires

very little maintenance. Like any other mechanical equipment,

however, it should have regular attention and be operated according

to instructions to insure long life and trouble-free service.

1.2 Operating Principle

The Model LV RotoClone collector cleans the air by the combined

action of centrifugal force and a violent inter-mixing of water and dustladen air. The dust is separated from the gas stream by means of a

water curtain created by the high velocity flow of air through a

stationary impeller (see Figure 1). This high velocity flow carries water

with it in a heavy turbulent sheet. The centrifugal force exerted by the

rapid changes in direction of air flow causes the dust particles to

penetrate the water droplets and become permanently trapped within

them (Figure 1).

The dust-laden water droplets are then removed from the air stream

by the water eliminator. The dust settles in the bottom of the collector

and the water is reused. Since the water curtain is produced by the

airflow, no pumps or nozzles are required.

2.0 Installation Instructions

Read the following instructions completely and carefully.

2.1 Foundations

Foundations must be true, level and rigid enough to prevent vibration

and to support the weight of the RotoClone with its maximum dust

and water load given below.

Mist

Eliminator

Baffles

Dirty Air Side

Clean Air Side

Entering

Edge

Table of Contents

1.0 Description

1.1 General Information

1.2 Operating Principle

2.0 Installation Instructions

2.1 Foundations

2.2 Lubrication

2.3 Duct Connection

2.4 Water Supply Connection

2.5 Drain Connection

2.6 Electrical Connections

2.7 Water Level Control

3.0 Operating Instructions

3.1 To Fill RotoClone

3.2 To Start RotoClone

3.3 To Stop RotoClone

4.0 Maintenance Instructions

4.1 Removal of

Collected Material

4.2 Routine Maintenance

5.0 Troubleshooting

5.1 Correction of Poor

RotoClone Operation

6.0 LVN Bench Attachment

6.1 Description

6.2 Installation Instructions

6.3 Operating Instructions

6.4 Maintenance

Instructions

6.5 Troubleshooting

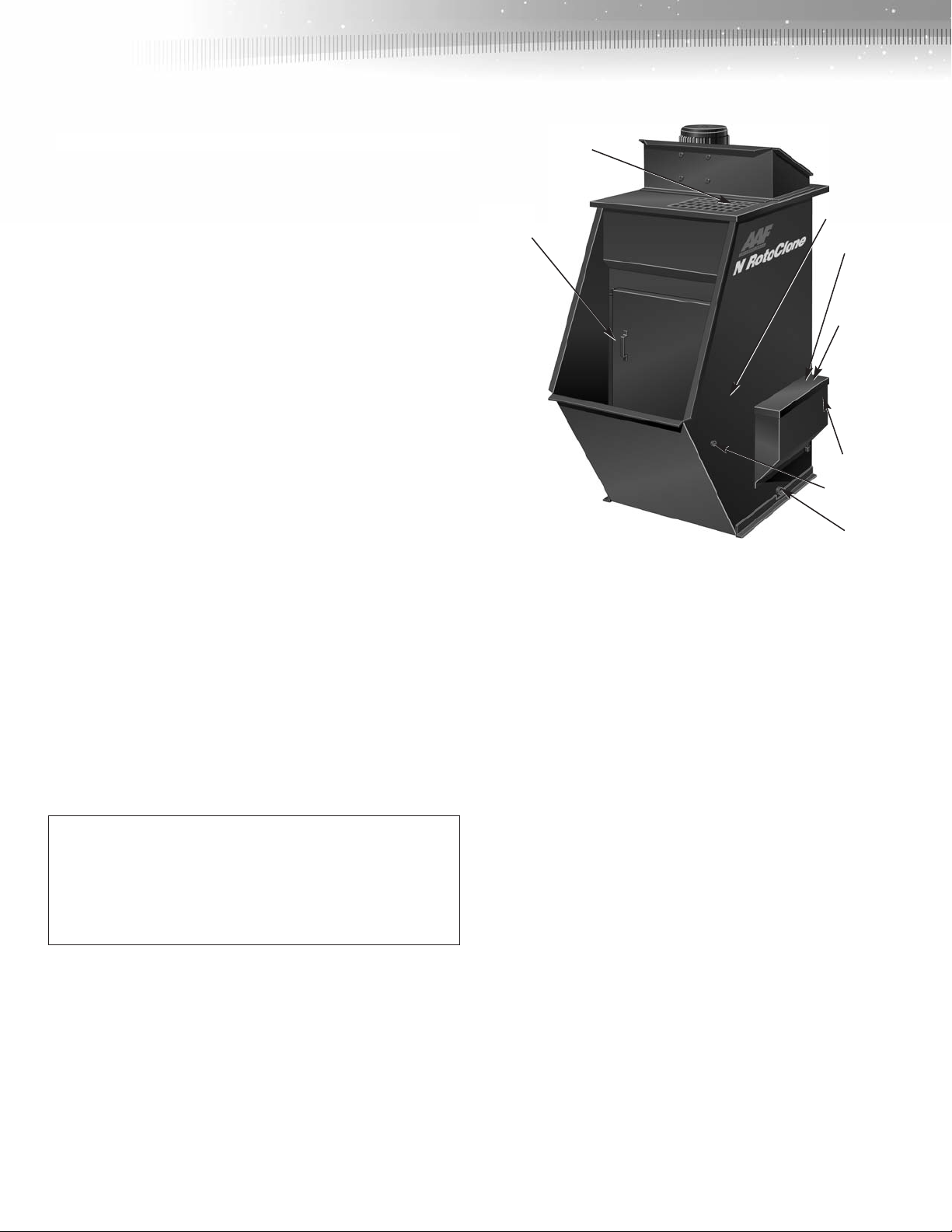

Figure 2

Typical Type N

RotoClone Model LV.

2

control. The regulator should be set at 5 psi. A solenoid valve is

also provided. It is to be interlocked with the fan motor starter. The

solenoid valve prevents overfilling during shut down. Controls also

include a low water level switch and timer.

C.Level probe control (Model A) – Includes an electronic level

controller, level probe, solenoid valve and timer/relay to shut the unit

down when water level in the RotoClone is too low. The water level

controller and timer/relay are housed in a NEMA 4 control box,

shipped separately. The water level controller actuates the solenoid

valve when water level does not touch the electronic probe for more

than 2 minutes (the time delay minimizes solenoid “chatter”), and

allows the solenoid to close when water level again touches the

probe. If water does not reach its proper level in the preset time

(usually 3 minutes), the timer/relay shuts down the system.

3.0 Operating Instructions

3.1. To Fill RotoClone

A. Close drain valve or insert drain plug (on older units without drain

valve), and open any manual valves in the supply piping.

B. Fill the RotoClone with water to approximately 1

1

2" to 2 "

below the operating level on the level indicating tube. The unit

will be marked with a horizontal line indicating “Air (Fan) On”

water level. For units with the electronic probe, water level should

be 1

1

2" to 2 " below the probe tip.

3.2 To Start RotoClone

A. Check that the water level is approximately 2" below the

operating level on the level indicating tube.

B. Make sure sludge removal door is in place.

C. Press “start” button for exhauster motor.

D. Adjust water level to the correct operating level as shown on the

level indicating tube, or until it just touches the electronic probe.

Clean Air Discharge

Sludge

Removal

Door

Water

Inlet

Water

Level

Control

Box

Piping

Fill Valve

Overflow

Drain

Set RotoClone on foundation and adjust base until unit is level.

Use care in leveling in both directions as functioning of RotoClone

depends on accuracy of this operation.

Note: This level can be checked by filling the unit with water until the level reaches the

entering edge (Figure 1) of the impeller. This entering edge should be level with the

water along its entire length with maximum variation of1 16" plus or minus. (See Item

1.2, Operating Principles)

2.2 Lubrication

All motor bearings are packed with grease before leaving the factory.

Do not add more grease during installation. Some motors have

lubrication plugs. They should be removed and replaced with grease

fittings. Lubricate every six months under dusty operating conditions,

and every 12 months under reasonably clean conditions.

2.3 Duct Connections

The inlet duct must be supported from the floor, wall or ceiling, not

from the RotoClone. Four (4) to five (5) inlet diameters of straight

duct, prior to the RotoClone, should be allowed to “balance out”

uneven air/dust flow from elbows branch entries or other disturbances

in front of the RotoClone.

2.4 Water Supply Connection

Units are supplied with a 1" (FPT) quick fill valve and

1

4" (FPT)

solenoid valve for automatic water makeup. Connect supply piping

to both.

2.5 Drain Connection

A 2" (FPT) drain valve is supplied at the bottom of the hopper. Drain

piping, should be attached here and to the 1" (FPT) overflow coupling

on the side of the sludge chute.

2.6 Electrical Connections

The normal electrical connections for the RotoClone are to the

exhauster motor, water level control - solenoid valve, electronic probe

(Model A control), the electrical control box (shipped loose), and the

owner’s motor starter (the motor starter, S/S push buttons, control

transformer and disconnect are not normally supplied by AAF

International). Each connection is to be made in accordance with the

appropriate wiring schematic in the RotoClone instruction packet and

prevailing electrical codes.

CAUTION:

1. Insure that motor voltage matches line voltage, and wiring is per

diagram on motor.

2. After connecting the motor leads, insure that the motor rotates in

a clockwise direction as viewed from the top of the unit.

2.7 Water Level Control

Supply water makeup for the RotoClone is required because of water

losses due to evaporation and sludge removal. There are three types

of water level control available on the Type N RotoClone Model LV.

A. Manual control—Water is added through the sludge removal

chute. Water level is controlled to the mark found on the level

indicating tube.

B. Float valve control—A float valve is mounted within a control box

located on the side of the RotoClone. The float valve must be

adjusted to control the water level to the mark on the level

indicating tube. A pressure regulator is provided to improve level

Installation Instructions continued

Loading...

Loading...