Better Air is Our Business®

Communications Module

Real-time Reactivity Monitor

Installation, Operation, and

Maintenance Instructions

Read and Save These Instructions!

NOTE: 1. Read and understand all operating instructions before

using the SAAFShield Communications Module.

2. Save this manual for future reference.

This instruction manual provides important information on the

installation and operation of the AAF International SAAFShield

Communications Module. These instructions must be carefully

followed in order to operate the unit safely and correctly. If there are

any questions regarding the use or care of this unit, please contact

AAF at 888.AAF.2003 or by email at SAAFShield@aantl.com

for assistance.

Table of Contents

1.0 Principles of Operation

2.0 Components and Hardware

3.0 Placement of SAAFShield

4.0 Connecting to SAAFShield Detecting Unit

5.0 Connecting to 4-20 mA Output

6.0 Menu System

7.0 Programming Instructions

8.0 Data Input and Output

9.0 Local Readout

10.0 Troubleshooting

11.0 SAAFShield Parts List

1.0 Principles of Operation

The SAAFShield Communications Module in combination with the

Detecting Unit is part of the system that allows users to monitor

atmospheric corrosion in real time. This monitoring can be used to

display and trend corrosion data over time allowing users to

evaluate operational procedures, environmental factors, or other items

that occur at specic times and their impact on producing a corrosive

environment.The SAAFShield system utilizes Quartz Crystal

Microbalance (QCM) technology to measure metal corrosion due to

reactions with the environment.

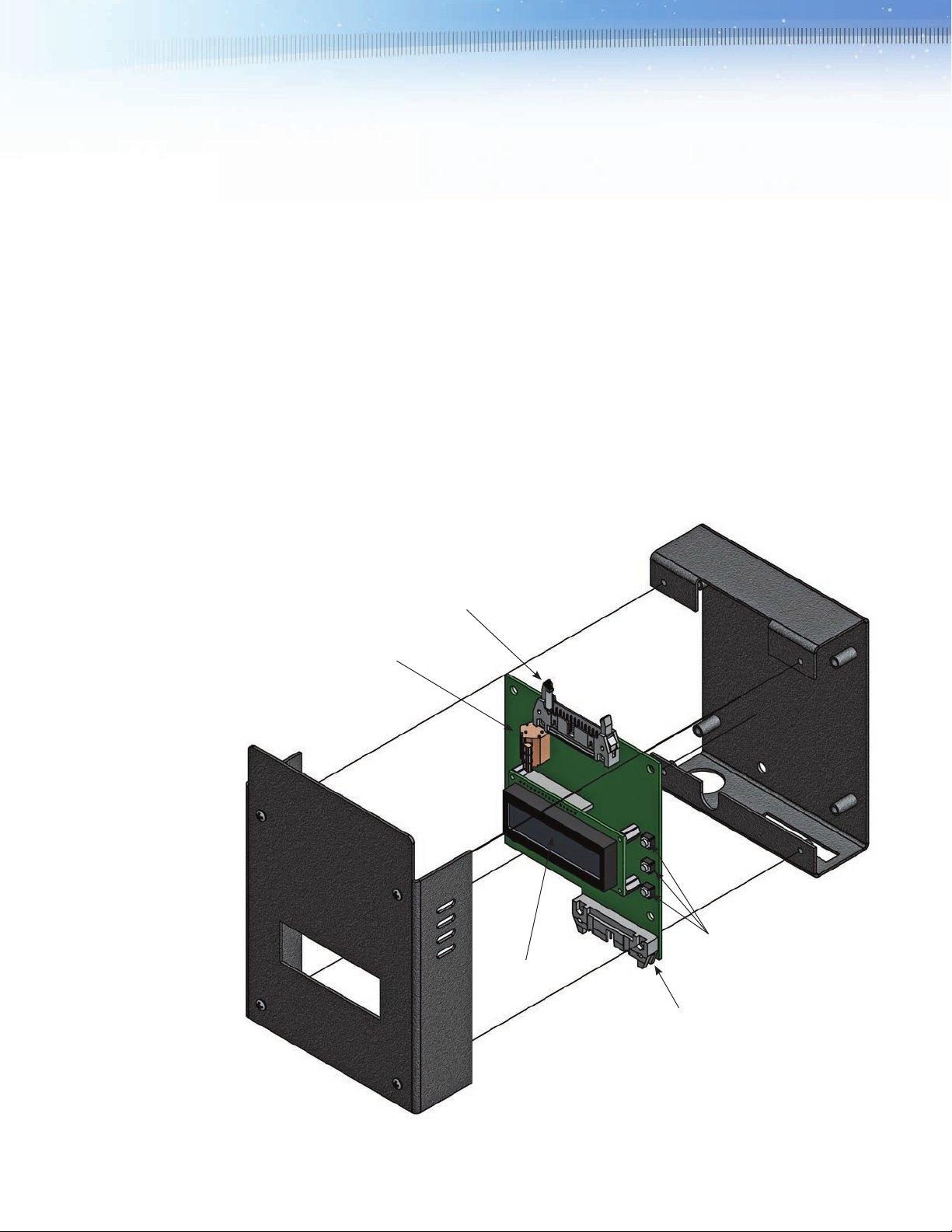

Ribbon Connector

to SAAFShield® DU

2.0 Components and Hardware

• Graphic LCD

• Integrated temperature sensor and humidity sensor

• 18-30 VDC power input

• Real time G-class and S-class monitoring

• Built in real time clock and calendar chip

• 4-20 mA output for Programmable Logic Controller (PLC) interfacing

• 3-inch ribbon cable

The SAAFShield Communications Module and its main components

are shown in Figure 1.

Further details on packaging and physical specications can be found

in the specication.

The Communications Module portion of the SAAFShield device is used

to read, compute, and transmit corrosion, temperature and relative

humidity data.

Connector for Power

and 4-20 mA Output

LCD Screen

Ribbon Connector

to SAAFShield

®

Menu Bottons (Up, Down, OK)

RU

Figure 1. Major components of the SAAFShield® Communications Module.

2

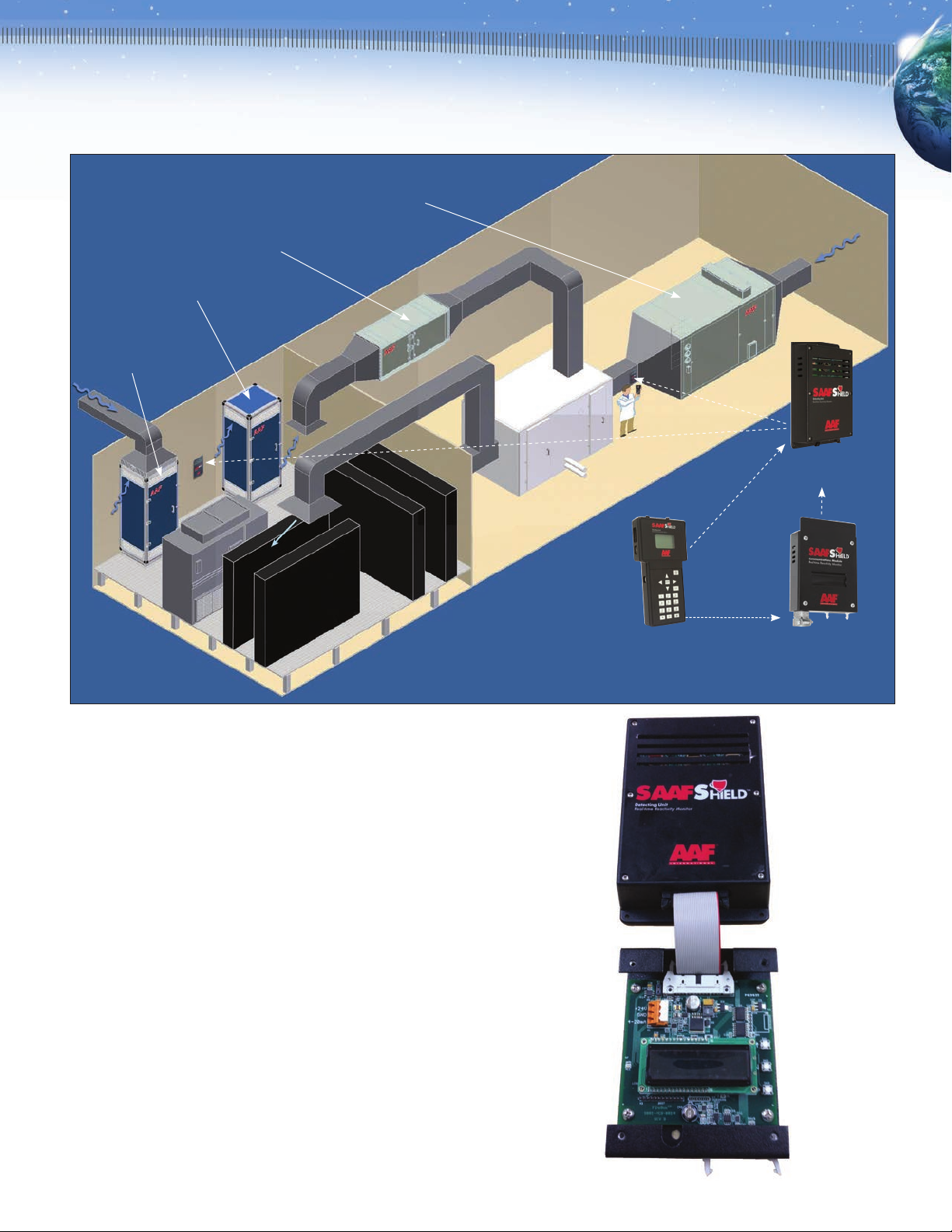

SAAF™

Recirculation Unit

SAAF™

Pressurization and

Recirculation Unit

SAAF™ Deep

Bed Scrubber

SAAF™ Side

Access Housing

SAAFShield® Detecting Unit

Computer Room Air

Conditioning Unit

(CRAC)

Figure 2. Typical placement for SAAFShield units.

3.0 Placement of SAAFShield Monitors

When determining the reactivity of a room or space within a building,

the SAAFShield should be placed in a location representative of the air

that contacts the electronics or materials being protected. If the

protected items are spread out within the space, then an approach,

similar to a thermostat should be used. If the protected items are

concentrated in one area inside the space, then a location as close as

possible to them is preferred.

When determining the condition downstream of a gas-phase lter or

scrubber to evaluate media performance and life, the SAAFShield

should be placed after the nal particulate lter. This will protect it from

the majority of particulates and allow it to monitor the condition of the

outlet air. When the rate of corrosion begins increasing beyond what is

normal, it is time to change the media or lter.

4.0 Connecting to SAAFShield Detecting Unit

The SAAFShield Detecting Unit and Communications Module come

equipped with 26-pin ribbon cable connectors. To connect the CM to

the DU, rst remove the CM cover and locate the ribbon cable connector at the top of the CM circuit board. (Figure 3)

Figure 3.

SAAFShield

Reading Unit

(for periodic data

®

SAAFShield®

Communications Module

(for continuous

data transmission)

3

5.0 Connecting to 4-20 mA Output

The unit connects to the host control/monitoring system via a standard

“3-wire” analog loop.

There are three terminals for this connection labeled as follows:

• +24V Positive 24 VDC

• GND 24 VDC common

• 4-20mA Signal to the analog input of the host system.

The 24 VDC power for the unit must be connected to the same source

as the host control/monitoring system, and in particular the 24 VDC

common (GND) must be the same as is used for reference by the

analog input module in the host control/monitoring system. (Figure 4)

6.0 Menu System

The SAAFShield Communications Module has three push buttons

to the right of the LCD display (Figure 5). Press any button to enter

the menu.

4-20 mA

Connector

Figure 4.

Detecting Unit Connector

Reading Unit Connector

Figure 5.

Up Button Down Button OK Button

1. The Communications Module will not enter the menu system if

data is being transmitted. Transmitting notice will be shown on

the LCD display.

2. Press any of the three buttons to enter the menu system. If the

unit is not transmitting data, you will enter the menu system

immediately. If the unit is transmitting data, you will enter the

menu system once the transmitting procedure is complete.

3. When the Communications Module is in the menu, the selected

eld will blink.

4. Use the UP and DOWN buttons to increase /decrease the setting

of that eld.

5. Use the OK button to select the value and scroll to the next eld.

6. If Exit (EXT) eld is reached using the OK button, press either

UP or DOWN to exit from menu system back into main mode.

7. After setting the time and date, it is recommended to initialize the

sensors. Once you leave the time/ date setup menu, the device

will ask if the sensors should be initialized. Press the UP button to

initialize the sensors or press DOWN to exit the menu system.

Note: The Communications Module will conduct the next data

transmission when the scheduled time comes though the LCD

display will NOT change to show this transmission. The red LED

on the left of the LCD display will blink at a faster rate when the

transmission is taking place.

7.0 Programming Instructions

When programming your building management software to receive

the 4-20 mA signal from the SAAFShield CM, you can utilize three

different languages: structured text, ladder logic, and function block

diagram. Please refer to AAF document SAAFShield Appendix

GPF-3-118, “Detailed Programming Instructions for SAAFShield

Communications Module.”

4

8.0 Data Input and Output

The SAAFShield Detecting Unit control logic interface block interprets

the 4-20 mA signal originating in the SAAFShield Communications

Module and produces a set of data consisting of each piece of data

collected by the SAAFShield detecting unit. The block also has some

failure detection capabilities. If a failure is detected the Fail bit is set

and a fail code is populated.

Block Diagram

FAL

In

Qui

SAAFShield

Communications

Rst

Module

Inputs

Parameter Name Type Description

In DINT Physical IO Tag

Qui Boolean Signal Quality

Rst Boolean Initialize output to starting values

Details

Parameter Name Type Description

FAL Boolean True if QUI is False

CumCu DINT Cumulative Copper reading in angstroms

CumAg DINT Cumulative Silver reading in angstroms

IncCu DINT Incremental Copper reading in angstroms

IncAg DINT Incremental Silver reading in angstroms

RH Real Relative Humidity reading

Temp Real Temperature reading

Error Real Error Code

Notes:

The range and unit of measure for all metal readings is 0 – 4000 angstroms.

• Relative Humidity is measured 0 – 100%.

• Temperature is measured -50 – 150º C

Pulse Codes

Variable Number Pulse Level Length

of Pulses (raw value) of Time

Start Signal 1 6.28 mA or 16486 3 seconds

Inter-data Pulse 2 8.58 mA or 22486 1 second each

Data Transfer 1 N/A 5 seconds

CumCu

CumAg

IncCu

IncAg

RH

Temp

Error

Cycle

Every 15 minutes the SAAFShield Communications Module sends data

to the analog input (SigIn). It sends the start signal for 3 seconds, waits

2 seconds, and then begins data transmission. Each measurement

is transmitted for 5 seconds. There is a two second wait followed by

two inter-data pulses. Then the next measurement sequence is

transmitted. The chart below (Figure 6) shows an example sequence.

Note that all data transmitted is set high. When the Communications

Module has sent all pieces of data, it waits for 15 minutes before

beginning the cycle.

Figure 6.

Steps

1. Send one 6.28 mA pulses of 3 seconds.

2. Wait 2 seconds.

3. Transmit Cumulative copper data in the range of 4-20mA

for 5 seconds.

4. Wait 2 seconds.

5. Send two 8.58 mA pulses of 1 second each with inter-pulse

pause of 1 second (set loop to 4mA during pause)

6. Wait 2 seconds.

7. Transmit Cumulative silver data in the range of 4-20mA

for 5 seconds.

8. Wait 2 seconds.

9. Send two 8.58 mA pulses of 1 second each with inter-pulse

pause of 1 second (set loop to 4mA during pause)

10. Wait 2 seconds.

11. Transmit incremental copper measurement in the range of 4-20mA

for 5 seconds.

12. Wait 2 seconds.

13. Send two 8.58 mA pulses of 1 second each with inter-pulse

pause of 1 second (set loop to 4mA during pause)

14. Wait 2 seconds.

15. Transmit incremental silver measurement in the range of 4-20mA

for 5 seconds.

16. Wait 2 seconds.

17. Send two 8.58 mA pulses of 1 second each with inter-pulse

pause of 1 second (set loop to 4mA during pause)

18. Wait 2 seconds.

5

19. Transmit Relative Humidity measurement in the range of 4-20mA

for 5 seconds.

20. Wait 2 seconds.

21. Send two 8.58 mA pulses of 1 second each with inter-pulse

pause of 1 second (set loop to 4mA during pause)

22. Wait 2 seconds.

23. Transmit Temperature measurement in the range of 4-20mA

for 5 seconds.

24. Wait 2 seconds.

25. Send two 8.58 mA pulses of 1 second each with inter-pulse

pause of 1 second (set loop to 4mA during pause)

26. Wait 2 seconds.

27. Transmit the fault data for 5 seconds.

6 to 8 mA: Power supply out of tolerance

8 to 10 mA: Copper out of range

10 to 12 mA: Silver out of range

12 to 14 mA: Gold out of range

14 to 16 mA: Self diagnostic failed, replace board

16 to 18 mA: Invalid time/date

18 to 20 mA: Other errors

9.0 Local Readout

The LCD on the front of the Communications Module has six (6)

screens.

3. Copper Corrosion Classication for the past 24 hours and the past

30 days

4. Silver Corrosion Classication for the past 24 hours and the past

30 days

1. The standard the device is currently congured to. The

Communications Module standard is set by the factory to the

standard of your choice. The choices in the standards are:

- Legacy Corrosion Control (ISA 71.04-1985)

- RoHS Corrosion Control (ASHRAE TC 9.9)

- or Museum & Archive

**Display charts of each standard, those on last page of SAAFShield brochure

GPF-1-140.

2. Temperature (ºC) and Relative Humidity (%)

6

5. Summary of the Environment’s Classication. This will report the

harshest of the classications for the standard used

6. Transmitting

10.0 Troubleshooting

Error Codes

When a detectable failure occurs, the fail bit is set and the failure code

is populated. The failure codes have the following meaning:

11.0 SAAFShield Parts List

It is recommended that the following spare parts be stored at the

installation site for replacement purposes. Consult with your AAF

representative to determine actual quantities required.

Code Number Meaning

0-5 mA No failure

6-8 mA Power Supply out of Tolerance

8-10 mA Copper out of Range

10-12 mA Silver out of Range

12-14 mA Gold out of Range

14-16 mA Self diagnostic, failed replace board

16-18 mA Invalid time/date

18-20 mA Other errors

Description Part Number

Detecting Unit (DU) 392-803-101

Silver Sensor 392-803-010

Gold Sensor 392-803-011

Copper Sensor 392-803-012

Reading Unit (RU) 392-803-001

Connection Cable (DU-RU) 392-803-003

12V Adaptor 392-803-000

Communications Module (CM)

- congured for Legacy 392-803-510

- congured for RoHS 392-803-520

- congured for Museum 392-803-530

Connection Cable (DU-CM) 392-803-004

To order replacement parts call: 1-800-AAF-2003.

7

Communications Module Real-time Reactivity Monitor

NOTES:

GPF-3-118 NOV ‘13

AAF International Building

9920 Corporate Campus Dr., Suite 2200

Louisville, Kentucky 40223-5000

Customer Service 888.223.2003

Fax 888.223.6500

www.aantl.com

AAF has a policy of continuous product research and

improvement and reserves the right to change

design and specications without notice.

ISO Certied Firm

The USGBC Member logo and LEED® are trademarks owned by

the U.S. Green Building Council and are used by permission.

© 2013 AAF International

Loading...

Loading...