AAF International SAH User Manual

SAAF Side Access Housings (SAH)

with SAAF Cassette Gas-phase Chemical Filters

Installation, Operation, and Maintenance Instructions

Better Air is Our Business

®

1.0 Introduction

1.1 About this Document

This document contains the information necessary to properly receive,

assemble, install, operate, and maintain the AAF Side Access

Housing (SAH) filter system and filters. The purchaser, installer, and

operator of the filter system MUST read and comply with this

document in its entirety prior to installation of the equipment and its

operation. Failure to comply with the requirements of this manual may

void the product warranty.

CAUTION

These instructions are specific to the AAF Side Access Housing

(SAH) filter system and filters. All ancillary tasks including, but not

limited to, electrical and mechanical work, equipment handling, and

safety procedures must be performed in accordance with industry

accepted practice and all relevant local, state, and federal

government codes, laws, and policies.

Table of Contents

1.0 Introduction

1.1 About this document

1.2 Packaging and shipping, receiving and inspection,

handling, and storage

1.3 Product descriptions

1.4 Product model designations

1.5 Product drawings

1.6 Assembly – general comments

1.7 Related system equipment

2.0 Principles of Operation

3.0 Installation Instructions

3.1 Space requirements

3.2 Foundations and anchoring

3.3 Typical Side Access Housing (SAH) details

3.4 General filter system installation procedure

3.5 Preparation for filter installation

3.6 Pre-filter Installation

3.7 Gas-phase chemical filter installation

3.8 After-filter installation

3.9 High-efficiency filter installation

3.10 Latch SAH doors

3.11 Pressure gauge

3.12 Fans

4.0 Start-up Instructions

5.0 Maintenance

5.1 Prefilter

5.2 After-filter

5.3 High-efficiency final filters

5.4 Gas-phase filter monitoring

5.5 Removal and replacement of particulate and gas-phase

chemical filters

5.6 Disposal of used filters

5.7 Gas-phase chemical filter cassette face sealing gaskets

5.8 After-filter and high-efficiency particulate filter sealing gaskets

5.9 Access door sealing gaskets

5.10 General system maintenance

6.0 Troubleshooting

6.1 High pressure drop reading across the filter system

6.2 Visible discharge of particulate

6.3 Odors and smells

7.0 Spare Parts List

8.0 Equipment Characteristics, Operating Weights, and

Shipping Weights

9.0 Technical Guidelines

9.1 Fan selection and sizing

1.2 Packaging and Shipping, Receiving and Inspection, Handling

and Storage

1.2.1 Packaging and Shipping: Unless otherwise defined in the

purchase order and agreed by AAF, the SAH filter housing and

filters are packaged for domestic transit and shipped FOB the AAF

factory. The method of shipment will be as specified in the

customer’s purchase order to AAF.

1.2.2 Receiving and Inspection: Obtain a copy of the purchase

order, the product drawing that was submitted by AAF in

association with the order, and a copy of the bill of lading, along

with any other shipping papers. Upon receipt of the equipment, or

any part thereof, these documents shall be used to ensure that the

correct product has been received.

For maximum protection, complete the following steps upon receipt

of the AAF Side Access Housing (SAH) and filters:

– Inspect the shipment and all associated documentation. Notify

the carrier immediately if there is any visible damage to the

packaging or the equipment, or a discrepancy in the shipping

papers and, if necessary, file an immediate claim with the carrier

against such damage or discrepancy.

– Confirm that the equipment received agrees with the contents

of the shipping papers.

– Confirm that the shipping documents agree with the purchase

order. Refer to the product drawing submitted for the order as

necessary.

– If it is determined that any equipment ordered on the purchase

order has not been delivered and is not accounted for in the

shipping papers contact AAF International immediately by calling

1-800-477-1214. Reference the AAF control number, which will

be listed on the shipping papers.

Each shipment may include:

– One or more individually packaged Side Access Housings (SAH).

– Packaged particulate filters.

– Packaged gas-phase chemical filter cassettes.

Note that the Side Access Housing (SAH) and the particulate and

gas-phase filters may ship from different locations and be received

at different times.

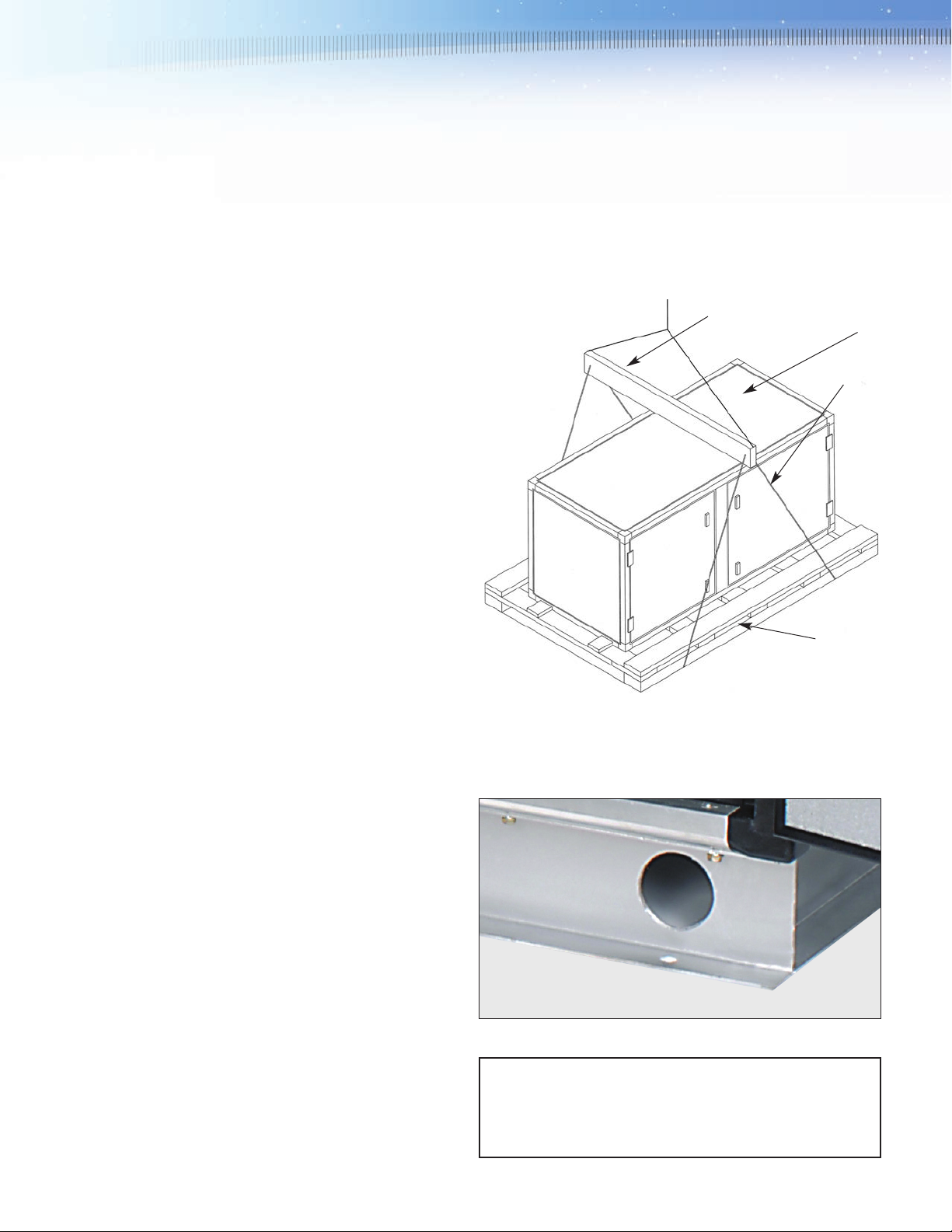

1.2.3 Handling and Storage: Following receipt, inspection, and

acceptance of the equipment, and prior to installation, the Side

Access Housing (SAH) and the particulate and gas-phase filters shall

be handled with great care. The Side Access Housing (SAH) ships

mounted on a pallet for protection during shipping and handling. It is

recommended that it remain on its pallet until it has been moved to

its final installation location. Only personnel experienced in rigging

and handling large equipment shall be employed for this task. Small

SAH’s may be moved using a forklift. A suggestion for rigging larger

equipment is shown in Figure 1. Rig the housing using straps or a

sling. Fasten the strapping under the skid on which the SAH ships.

To prevent damage to the exterior surface of the SAH use spreader

bars at all times. Position the spreader bars to keep the cables from

rubbing against any part of the housing. Before hoisting make sure

that the load is properly balanced.

A channel base is offered as an option with the SAH. Check to see if

this has been included. The channel base includes web openings for

the insertion of pipes for hoisting the equipment. See below for details.

! WARNING: The housing top will not support the weight of the

unit. Any attempt to support the housing from the top may result

in serious equipment damage and severe personal injury. Do not

walk on the top of the unit or use the top for storage of materials.

2

Figure 1

Optional channel base.

SAH

Straps

or sling

Shipping skid

Spreader bar

(multiple spreader bars

may be needed, depending

on size of unit)

3

The components shall be retained and stored in their protective packaging

until immediately prior to installation. Care shall be taken to ensure that the

packages are not dropped or subjected to any impact loads.

At all times the equipment shall be protected from exposure to weather.

The equipment shall be stored in a clean, dry, temperature-controlled

environment. All items shall be stored on pallets so that they are

elevated above grade. Side Access Housings (SAH) shall not be

stacked. Particulate and gas-phase filters, shall not be stacked more

than three (3) cartons high to prevent crushing. Only particulate filters

shall be stacked on particulate filters, and gas-phase filters on gas-phase

filters. The gas-phase filters ship inside a carton enclosed in transparent

protective plastic. Under no circumstances shall the filters be removed

from this plastic protection until immediately prior to installation.

Filter products shall not be stored in areas where they may become

contaminated by chemicals, either acids or alkali’s, in liquid, vapor or

gaseous form.

Side Access Housing, Model SAH-202-2P-MD-2P-6F, with

tracking to accommodate four (4) MD cassettes. Optional channel

base is included.

1.3 Product Descriptions

1.3.1 Side Access Housing (SAH): Each (SAH) will be received

individually mounted on a shipping pallet and wrapped in plastic for

protection during shipping. Depending on the size and complexity

of the SAH it may ship in sections on multiple pallets. Refer to the

product drawings submitted on the order for details. The SAH can

be supplied in three styles, Type MD, Type HD or Type CG,

depending on the style of SAAF Cassette gas-phase chemical filter

that it is intended to accommodate (see 1.3.2 for details). Different

internal support tracks and track spacings will be provided

depending on the type of cassette to be used.

Any particular filter system will normally be assembled using only

one type of cassette, Type MD, Type HD, or Type CG. Cassettes will

almost never be mixed in a single-filter system. Different types of

cassettes are not interchangeable within any particular filter bank.

1.3.2 Gas-phase Chemical Filter Cassettes: Gas-phase filter

cassettes are shipped in cartons and plastic bags. The carton shown

below contains a single 6" high x 24" wide x 18" deep Type MD

cassette which is supplied as two (2) 6" high x 12" wide x 18" deep

half cassettes.

Typical Side Access Housing, Model

SAH-202-2P-(MD)(HD)(CG)-2P-6F.

Optional channel base is included.

1.4 Product Model Designations

The SAH model is designated as follows:

SAH - 202 – 2P – MD– F – MD – 2P – 6F

Supports a 6" deep particulate final filter, if required

Supports a 2" deep particulate after-filter, if required

Second gas-phase chemical filter bank, if required, supports Type MD cassettes

Fan

First gas-phase chemical filter bank, supports Type MD cassettes

Supports a 2" deep particulate pre-filter, if required

Is nominally 2' high x 2' wide

Side Access Housing

4

6" high x 24" wide x 18" deep Type MD cassette ships in two halves.

1.3.2 continued

12" high x 24" wide x 12" deep Type HD cassette ships in two halves.

24" high x 12" wide x 12" deep Type CG cassette ships in one piece.

The three (3) types of gas-phase chemical filter cassettes that can be

supplied are as follows:

1.3.3 Particulate filters:

Prefilters and after-filters - Particulate prefilters and after-filters

will typically be AAF PerfectPleat®pleated filters. Depending on the

size of the Side Access Housing (SAH) ordered 24" high x 24" wide

x 2" deep full size filters, 24" high x 12" wide x 2" deep or 12" high

x 24" wide x 2" deep half-size filters may be supplied. PerfectPleat

2" deep filters are packaged 12 to a carton.

High efficiency filters – High efficiency filters will typically be AAF

M-Pak pleated filters. Depending on the size of the Side Access

Housing (SAH) ordered 24" high x 24" wide x 6" deep full size

filters, 24" high x 12" wide x 6" deep or 12" high x 24" wide x 6"

deep half size filters may be supplied. M-Pak filters are packaged 2

to a carton.

Note that other optional or special filter arrangements may be

supplied depending on the requirements of the project. Check the

purchase order and the AAF submittal drawing(s) for details.

5

1.5 Product Drawings:

Details of some standard SAH filter systems are shown on the

following AAF drawings:

SAH Module AAF Drawing Number

SAH-XXX-MD 114D-3025681

SAH-XXX-MD-MD 114D-3025657

SAH-XXX-2P-MD-MD-6F 114D-3025608

SAH-XXX-2P-MD-MD-MD-6F 114D-3025632

SAH-XXX-HD 114D-3025756

SAH-XXX-HD-HD 114D-3025772

SAH-XXX-2P-HD-HD-6F 114D-3025798

SAH-XXX-2P-HD-HD-HD-6F 114D-3025814

SAH-201-2P-CG 114D-3027513

SAH-XXX-CG 114D-3025848

SAH-XXX-CG-CG 114D-3025830

SAH-XXX-2P-CG-CG-6F 114D-3025822

Copies of the appropriate drawings will have been supplied as part

of the AAF submittals in response to the purchase order. Obtain and

review the drawing(s) before proceeding with the installation of the

filter system. The SAH filter system drawings include the following

details for filter system sizes 102 (1' high x 2' wide) through 810

(8' high x 10' wide):

– Overall filter system dimensions

– Shipping weights

– Operating weights

– Sizes and quantities of the particulate and gas-phase filters required

– Details of the gas-phase chemical media supplied

– Details of the particulate filters supplied

– System design airflow

– Pressure losses across the filter system at nominal airflow

design velocities

– Product details

1.6 Assembly - General Comments

As indicated previously, the individual components that will comprise

the filter system will ship separately and will be required to be installed

on site. The AAF Side Access Housing (SAH) is a self-contained

product and, consequently, a minimum amount of assembly is

required. Refer to section 3.0, Installation Instructions, of this manual

for further detailed instructions. Consult with an experienced installer

to obtain an accurate estimate of the time, personnel and equipment

resources, and tools that will be required to complete the assembly

and installation of the filter system. Site assembly will be limited to

Many combinations and permutations of housings and filter banks

can be supplied depending on the application and the requirements.

Typical Side Access Housing (SAH) model numbers are shown in

Table 1 where -XXX- represents the size of the Side Access Housing.

Housing sizes are designated as shown in the examples in Table 2.

This list by no means exhausts the possibilities and the system

provided may be different from those shown here. Consult the

AAF drawing that was supplied on the purchase order in question.

Table 1: Typical SAH Model Numbers

With gas-phase chemical filters but With gas-phase chemical filters With gas-phase chemical filters,

without particulate filters and particulate filters particulate filters, and fans.

SAH-XXX-MD SAH-XXX-2P-MD-2P-6F SAH-XXX-2P-MD-F-2P-6F

SAH-XXX-MD-MD SAH-XXX-2P-MD-MD-2P-6F SAH-XXX-2P-MD-F-MD-2P-6F

SAH-XXX-MD-MD-MD SAH-XXX-2P-MD-MD-MD-2P-6F SAH-XXX-2P-MD-MD-F-MD-2P-6F

SAH-XXX-HD SAH-XXX-2P-HD-2P-6F SAH-XXX-2P-HD-F-2P-6F

SAH-XXX-HD-HD SAH-XXX-2P-HD-HD-2P-6F SAH-XXX-2P-HD-F-HD-2P-6F

SAH-XXX-HD-HD-HD SAH-XXX-2P-HD-HD-HD-2P-6F SAH-XXX-2P-HD-HD-F-HD-2P-6F

SAH-XXX-CG SAH-XXX-2P-CG-2P-6F SAH-XXX-2P-CG-F-2P-6F

SAH-XXX-CG-CG SAH-XXX-2P-CG-CG-2P-6F SAH-XXX-2P-CG-F-CG-2P-6F

Table 2: Examples of Typical SAH Size Designations

Size designation Nominal height (ft.) Nominal Width (ft.)

SAH-404- 4 4

SAH-608- 6 8

SAH-810- 8 10

6

moving and lifting individual components, screwing components

together, and caulking. The SAH weights and dimensions can be

found on the product submittal drawings. The gas-phase chemical

filters will typically have a maximum weight of approximately 40

pounds (20kg). Particulate filters will typically weigh less than the

gas-phase filters.

Completion of the following preparations and provision of the following

items will be the responsibility of the installer or others:

– Site preparation

– Connecting screws and hardware for attaching inlet and outlet ducts

– Provisions for anchoring and supporting the Side Access Housing,

including anchor bolts, angles, straps, hangers and cradles, etc.

– Caulk, as required

– Inlet and outlet ducts, or other sheet metal parts, as required

These items will not be supplied by AAF, unless noted specifically in

the AAF quotation and in the accepted customer purchase order.

NO WELDING WILL BE REQUIRED.

In general, assembly of the filter system will consist of the following:

– Preparation of the installation location

– Transportation of all components to the installation location

– Unpacking the Side Access Housing

– Installing the Side Access Housing

– Installing inlet and outlet ducts

– Unpacking and preparation of the gas-phase chemical filter cassettes

– Installing gas-phase chemical filter cassettes

– Unpacking particulate filters

– Installing particulate filters

– Cleaning the site

– Start-up and commissioning of the filter system

1.7 Related System Equipment: Ventilation systems will often

include other equipment including but not limited to:

– Fan(s), if not supplied as part of the SAH

– Dampers

– Weather louvers

– Air tempering equipment

– Analog instrumentation

– Electronic instrumentation and controls

Neither the interface of these items with the filter system supplied by

AAF, nor the installation, operation, and maintenance of these items is

covered in this manual. Whether these items are supplied by AAF or

by others, consult the documentation specific to these products for

appropriate instructions.

2.0 Principles of Operation

An understanding of the design and operating principles of the Side Access

Housing with Gas-phase Chemical Filters is useful for effective installation,

operation, and maintenance. The system is intended to remove gaseous

contaminants from intake, re-circulated, or discharged ventilation air.

Examples of such contaminants may be nuisance odors and smells that

may cause domestic and neighborhood discomfort and reduce workplace

productivity, or harmful gases that may cause damage to health, plant and

product in industrial applications. The heart of the system is the AAF SAAF

Cassette. This is a high impact plastic frame that supports various types of

dry, granular, chemical media between perforated screens that allow air to

move through the filter. The SAAF Cassette is designed to support the

chemical media in a V-bank configuration of media beds that maximizes

the media exposed to the airstream, reduces the airstream velocity

through the media bed, maximizes energy efficiency, and maximizes the

removal of contaminants and the life of the product. The method of

contaminant removal is through a combination of the physical property of

adsorption and the chemical process of oxidation. AAF offers a variety of

impregnated and un-impregnated dry granular media to handle a wide range

of contamination problems. For more information on AAF’s gas-phase air

cleaning products contact your AAF representative.

The AAF Side Access Housing is one of the various framing and support

systems designed to support the SAAF Cassette in the air stream and to

allow easy installation, operation and maintenance of the system.

3.0 Installation Instructions

Consult the product drawing(s) submitted on this order before proceeding.

3.1 Space Requirements: A minimum of 36"clear space must be

available at the access side of the Side Access Housing to perform routine

maintenance and it is recommended that 24" clear space be available at

the opposite side for access during installation. Additional space may be

required for inlet and outlet ductwork. On large Side Access Housings,

greater than 4' wide, access doors may be supplied on both sides. In this

case 36" clear space must be provided on both sides for access.

3.2 Foundations, Supports, and Anchoring: The foundation and/or

supports must be designed to be adequate to support the filter system

operating weight, and any seismic, live or other loads (if any), with a

sufficient factor of safety as determined to comply with the

requirements of all applicable governing codes, standards, and laws.

Ensure that the foundation or support surface is level and smooth

before proceeding. The filter system is designed for operation in indoor

or, with appropriate modifications to resist weather, outdoor locations.

The equipment is not specifically designed to resist and operate under

unusual dynamic loading situations such as high winds or earthquake

conditions. If the equipment is required to function in such

circumstances special precautions may be required to ensure that the

equipment will remain intact, anchored, and functioning. If this situation

applies consult with a qualified professional engineer before installing

the equipment.

Loading...

Loading...