AAF International Millennium User Manual

Better Air is Our Business

®

Millennium

®

Pulse-Jet Fabric Dust Collectors

I

nstallation, Operation, and Maintenance Instructions

Table of Contents

1.0 Introduction

1.1 About This Document

1.2 Shipping and Receiving

1.3 Assembly

1.4 The Millennium - A Description

2.0 General Description

3.0 Installation Instructions

3.1 Space Requirements

3.2 Foundations and Anchoring

3.3 General Erection Procedure

3.4 Ductwork

3.5 Ladder and Handrail Assembly

3.6 Electrical Controls and Wiring

3.7 Compressed Air Connections

3.8 Bag, Cage and Venturi Assembly, and Pulse Pipe Installation

3.9 Roof Doors

3.10 Gauge Installation

3.11 Explosion Vent Installation

3.12 Hopper Discharge Device

4.0 Initial Startup Instructions

4.1 Preparation For Start Up

4.2 Timer Control

4.3 Pressure Demand Control

5.0 Principles of Operation

6.0 Maintenance

6.1 Daily

6.2 Monthly

6.3 Six Months

7.0 Troubleshooting

7.1 High Pressure Drop Reading

7.2 Visible Discharge

7.3 Insufficient Hood Control

7.4 Fabric Bag Problems

8.0 Spare Parts

9.0 Equipment Characteristics, Operating Weights,

and Shipping Weights

1.0 Introduction

1.1 About This Document

This document contains the information necessary to properly

receive, assemble, install, operate, and maintain the Millennium

dust collector. The purchaser, installer, and operator of the

Millennium MUST read this document in its entirety prior to

receipt and operation of the equipment.

CAUTION: These instructions are specific to the Millennium dust

collector. All ancillary tasks including, but not limited to, electrical and

mechanical work, equipment handling and safety procedures must be

performed in accordance with industry accepted practice and all

relevant local and federal codes.

1.2 Shipping and Receiving

The Millennium modules are packaged for domestic transit and

shipped FOB factory.

Obtain the original purchase order, the product drawing that was

submitted for the order, and a copy of the Bill of Lading along with

any other shipping papers. Upon receipt of the Millennium, these

documents should be used to ensure the correct modules/assemblies

have been received.

Complete the following steps upon receipt of the Millennium:

• Inspect the shipment and all associated documentation. Notify

the carrier immediately if there is any damage to the shipment,

or a discrepancy in the shipping papers.

• Confirm that the equipment received agrees with the

shipping documents.

• Confirm that the shipping documents agree with the Purchase

Order (P.O.). Refer to the product drawing submitted for the order,

as necessary.

• Confirm that the document package, consisting of a copy of the

IOM, the handrail, ladder, leg and brace installation drawings,

and the electrical connection diagram, has been received with

the shipment.

• If it is determined that modules/assemblies or any other equipment

specified on the P.O. has not been delivered, and is not accounted

for in the shipping documentation, contact AAF International

immediately at 800.477.1214.

The shipment will consist of assembled modules and some

loose parts for attachment at the jobsite, and will include the

following components:

1. Fully assembled plenum, housing and hopper modules.

2. Support structures including leg and bracing assemblies. See

drawings included with shipment for the proper number of parts.

3. Compressed air manifold connection kits for multiple modules.

4. One pulse control assembly for each unit.

5. Filter bags and cages. These filter elements may be shipped and

received separate from the other listed components.

6. Safety hand rails for standard plenum style units.

7. Safety ladder and cage assembly

8. Hardware kit

9. Caulk

1. Assemble Leg & Brace structure.

2. Seal with caulk and bolt together each adjoining module

(if multiple modules have been supplied).

3. Raise each module/assembly, and then attach and anchor to the

support legs and bracing structure.

4. Install the safety ladder.

5. Install the safety railing.

6. Install compressed air manifold interconnection kit(s) (if multiple

modules have been supplied).

7. Install compressed air manifold customer supplied

condensate drain(s).

8. Connect compressed air supply to the compressed air manifold.

9. Mount and wire the pulse control.

10.Attach inlet and outlet air ducts.

11.Install the filter elements.

12.Install optional components.

Detailed instructions regarding each of these operations are provided

in subsequent sections of this manual.

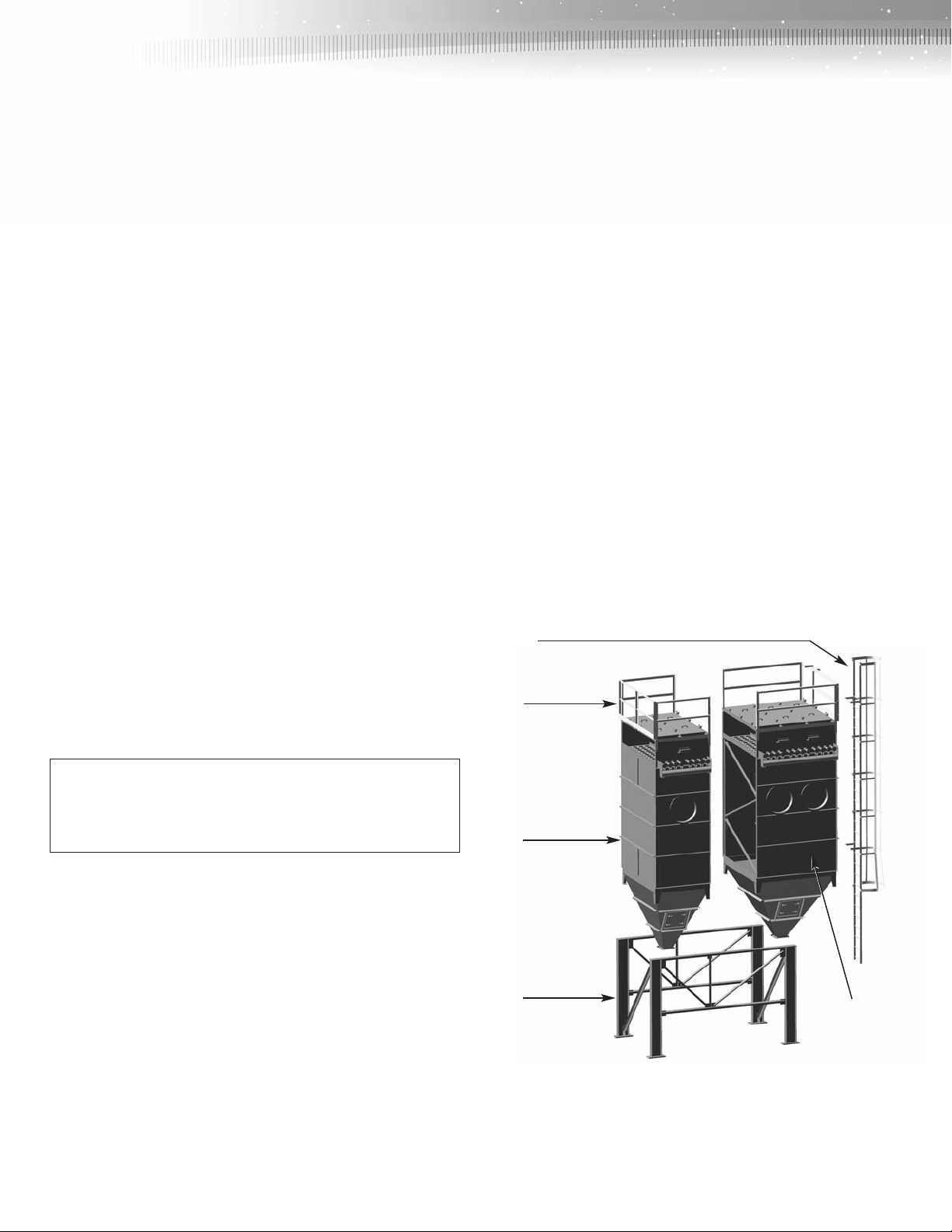

Access

Ladder

Safety

Railing

NOTE: Anchor bolts for bolting the equipment to the foundations and

hardware for connecting the inlet and outlet ducts are not included

with the Millennium and must be supplied by others.

Optional components such as hopper discharge devices, gauges and

other ancillary equipment may also be included in the shipment.

Consult the P.O. and shipping documents to confirm.

1.3 Assembly

The Millennium has been designed specifically to minimize the

amount of jobsite assembly required. Consult with an experienced

rigger for an accurate estimate of the time and equipment that will be

required. All jobsite assembly will be limited to bolting components

together. NO WELDING WILL BE REQUIRED. Following is an outline

of the assembly required for a standard Millennium. See Figure 1 for

details of the Millennium:

2

96 Bag

Module

Legs &

Bracing

Figure 1. Millennium Components

NOTE: The modules will normally be bolted together prior to

attaching the legs, handrailing, and ladder.

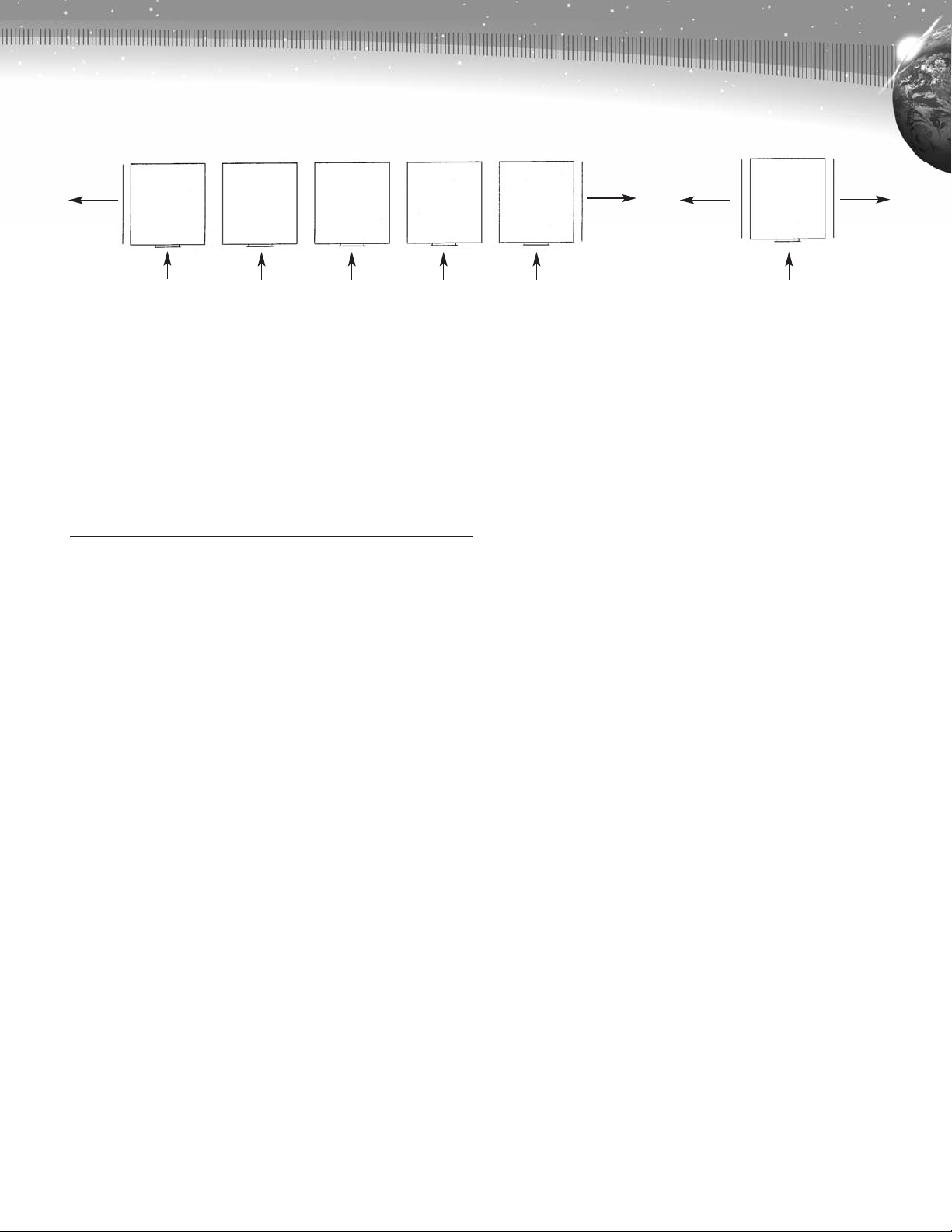

144 Bag

Module

Std.

Outlet

Alt.

Outlet

A

B

B B C D

Std.

Outlet

Alt.

Outlet

Figure 2

Inlets Inlet

1.4 The Millennium - A Description

The standard Millennium collector comes in 14 basic sizes. The size

variations are composed of combinations of either 96 bag or 144 bag

modules, with one to five modules per unit. The Millennium will use

514" diameter bags in a 7" x 7" spacing pattern. Bag lengths of 8, 10,

12, and 14 ft. are available.

Standard module combinations are listed below. The 96 bag modules

are indicated as “96” and the 144 bag modules as “144”. The letter

designation refers to the diagram shown above in Figure 2.

Size Module Arrangement

96 D96

144 D144

192 A96 + C96

240 A96 + C144

288 A144 + C144

336 A96 + B96 + C144

384 A96 + B144 + C144

432 A144 + B144 + C144

480 A96 + B96 + B144 + C144

528 A96 + B144 + B144 + C144

576 A144 + B144 + B144 + C144

624 A96 + B96 + B144 + B144 + C144

672 A96 + B144 + B144 + B144 + C144

720 A144 + B144 + B144 + B144 + C144

There is no limit to the size collector that can be supplied.

However, any arrangements exceeding the combinations listed

above will require intermediate support legs and additional outlets

in order to maintain acceptable airflow velocities. See contract

drawings for details.

The modular design will permit an existing Millennium system to

be expanded with no significant disruption to the operating unit(s).

Housings, hoppers, plenums, and tube sheets are made of 10 ga.

carbon steel. Modules are available for -20" and -30" w.g. plenum

pressure, and for temperatures of 180, 270, and 400 degrees

Fahrenheit. Consult the P.O. and submittal documents to verify

which version you have.

Support legs are designed for 130 mph wind or Universal Building

Code seismic zone 4 loading, and are available for hopper clearances

of 4, 6, 8, and 10 ft. Up to five modules may be bolted together

and supported by one set of 4 legs. Standard design is for 4 ft.

hopper clearance.

The standard Millennium is supplied with a pyramid style hopper.

A trough style hopper is available as an option. Pyramid hoppers

have a minimum side slope of 60 degrees and a flanged outlet of

12" x 12" with a drilling that matches an optional Rotary Lock. The

trough hoppers have a 10" wide opening with drilled flanges for

conveyor mounting. Both types of hoppers have quick release lift-off

access doors.

The outlet plenum can be either open to roof top access or

walk-in style. Outlets may be located at either end of the plenum,

and have a 2'-1" x 8'-4" opening with a standard drilling as shown

on the drawings.

2.0 General Description

The Millennium is a modular, continuous, automatic, self-cleaning,

fabric pulse-jet dust collector. The standard module is an open top

design. Flanges inside the roof top doors prevent water from leaking

into the housing. The access doors are lift-off type. Each size 96

module has two doors; while the size 144 module has three doors.

The walk-in plenum design will have one 20” x 60” access door

opening at one end of the unit, opposite the air discharge opening.

Handrails and ladders are supplied with both plenum types. An

optional air and solenoid valve service platform is available. The

access ladder is selected to accommodate both bag length and

hopper clearance. On a standard roof top access unit, using a 12 ft.

bag with a 10 ft. hopper clearance, or a 14 ft. bag with either an 8 or

10 ft. hopper clearance, the access ladder is supplied in two sections

with an intermediate platform, to comply with OSHA regulations.

The cleaning cycle is controlled by a solid-state timer located in a

NEMA 4 enclosure. The timer control can be field adjusted for proper

operation. (See Bulletin E-97)

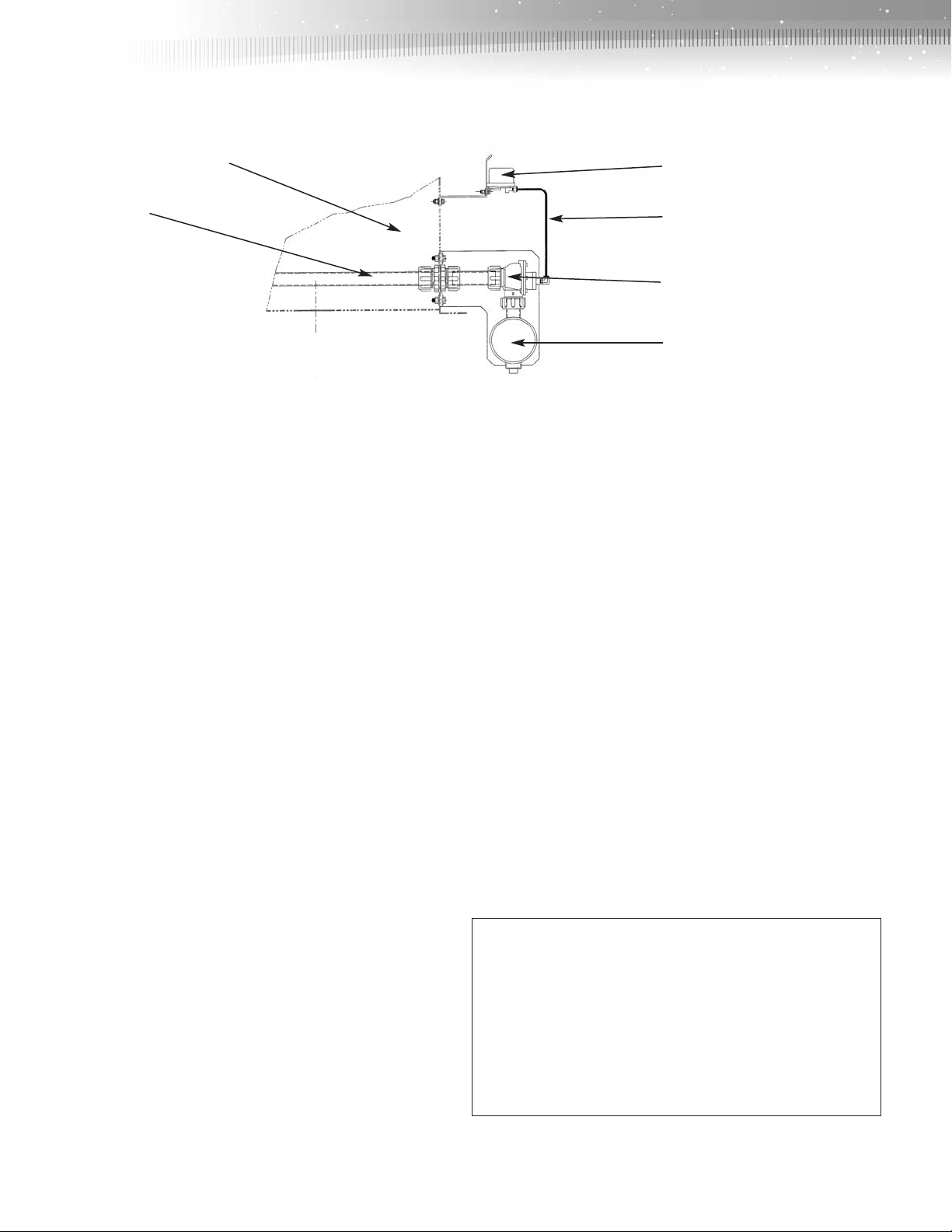

All modules are constructed with a 6" diameter surge tank

(compressed air manifold) which is fitted with 112" diaphragm pulse

valves. Pulse valves are connected to solenoid pilot valves with

plastic tubing on standard units, and with metal tubing on high

temperature units. See figure 3 for details of the compressed air surge

3

Clean Air

Plenum

Solenoid

Valve

Pulse Pipe

Figure 3

tank/pulse pipe assembly. Each pulse valve serves twelve bags.

1

Pulse pipes are 1

2", schedule 40 pipe and have a quick

disconnect coupling and a pinned end.

Standard collectors are primed and finish painted on the exterior with

high solids alkyd enamel. Interior surfaces have a prime coat. High

temperature collectors have one coat of zinc rich primer. Special paint

coatings are available as an option.

Some of the more common optional features available with the

Millennium include pressure demand cleaning, explosion vents, inlet

adapter plates, an arrangement to permit installation of up to 4"

thickness insulation at the destination job site, walk-in plenum, trough

hopper, high temperature features, and various ancillary components.

Consult the P.O. and submittal documents for what is included with

the specific order.

3.0 Installation Instructions

Consult the product drawing that was submitted for this order

before proceeding.

3.1 Space Requirements

A minimum of 24" clear space must be allowed on all sides of the

collector that do not include the access ladder or ductwork. The side

where the access ladder is located requires a minimum clear space of

46". For Walk-in Plenum units a minimum of 48” must be allowed on

the manifold side. More space may be required where inlet or outlet

ductwork and the explosion vent is located. For standard plenum top

access units, be sure to allow adequate height for removal of bags

and cages.

3.2 Foundations and Anchoring

The foundation must be designed to be adequate to support the

collector’s operating weight (see Section 9), seismic, wind and snow

loads (if any), collected dust, and any optional equipment, in

accordance with appropriate codes. Secure all anchor bolts to ensure

that the collector is firmly attached to the foundation. Base plates on

columns may require grouting after leveling. Multiple module units,

operating at elevated temperatures, may require expansion provisions

in the structural supports (see erection drawings for details).

Air Hose

Diaphragm Pulse Valve

Compressed Air Surge Tank

3.3 General Erection Procedure

1. Spreader bars must be used at all times when handling the

Millennium to prevent any possibility of damage. These shall be

connected to the lifting lugs provided on the Millennium for this

purpose. Only personnel experienced in rigging and handling

heavy equipment shall be employed to erect the Millennium.

Refer to proper drawings for specific lifting instructions for

module configuration.

2. All modules shall be separately positioned on the structure and

adjacent to one another in the order in which they will be joined

together. (See Section 1.4)

3. All joints between one of the end modules and adjacent modules

shall be prepared for connection to one another. This applies to all

perimeter and internal connecting flanges. Ensure the following:

• All flanges are flat and planar. Correct any bending, warping, or

denting that may have occurred when the modules were being

transported or handled.

• All flanges are clean and free from debris, contamination and

discontinuities of any kind, such as weld or paint splatter, mud,

rust, oil, or grease.

• All bolt holes are correctly aligned.

4. Caulk all connecting surfaces using the caulking compound

supplied. On standard units, this is a butyl caulk. Silicone caulk is

supplied on units rated to 400°F. See Figure 4 for the method of

applying caulk to a housing flange.

CAUTION: Particular caution must be exercised when sealing the

internal connection between the tube sheets in adjacent modules.

The tube sheet is the horizontal plate through which the filters are

inserted and which forms the barrier between the clean and dirty air

sides of the collector. The flange of the tube sheet between modules

is provided with a double row of bolt holes. Each row of holes shall

be caulked as shown in Figure 4. It is only necessary to apply caulk

to one face of each joint. Apply the caulk liberally to ensure an

effective seal.

4

Loading...

Loading...