AAF International Front Access Housings User Manual

Better Air is Our Business

¤

SAAF Front Access Housings

with SAAF Cassette Gas Phase Chemical Filters

Installation, Operation and Maintenance Instructions

Table of Contents

1.0 Introduction

1.1 About this document

1.2 Packaging and shipping, receiving and inspection,

handling, and storage

1.3 Product descriptions

1.4 Product model designations

1.5 Product drawings

1.6 Assembly — general comments

1.7 Related system equipment

2.0 Principles of Operation

3.0 Installation Instructions

3.1 Space requirements

3.2 Foundations and anchoring

3.3 Typical Front Access Housing (FAH) details

3.4 General filter bank erection procedure

3.5 Preparation for filter installation

3.6 Gas phase chemical filter installation

3.7 Prefilter installation

3.8 Pressure gauge

3.9 After-filters

5.4 Removal and replacement of particulate and gas phase

chemical filters

5.5 Disposal of used filters

5.6 Gaskets

5.7 General system maintenance

6.0 Troubleshooting

6.1 High pressure drop reading across the filter system

6.2 Visible discharge of particulate

6.3 Odors and smells

7.0 Spare Parts List

8.0 Equipment Characteristics, Operating Weights, and

Shipping Weights

1.0 Introduction

1.1 About this Document

This document contains the information necessary to properly receive,

assemble, install, operate, and maintain the AAF Front Access

Housing (FAH) filter bank and filters. The purchaser, installer, and

operator of the filter system MUST read and comply with this

document in its entirety prior to installation of the equipment and its

operation. Failure to comply with the requirements of this manual may

void the product warranty.

4.0 Start-up Instructions

5.0 Maintenance

5.1 Prefilter

5.2 After-filter

5.3 Gas phase filter monitoring

CAUTION

These instructions are specific to the AAF Front Access Housing

(FAH) filter bank and filters. All ancillary tasks including, but not

limited to, electrical and mechanical work, equipment handling, and

safety procedures must be performed in accordance with industry

accepted practice and all relevant local, state, and federal

government codes, laws, and policies.

1.2 Packaging and Shipping, Receiving and Inspection, Handling

and Storage

1.2.1 Packaging and Shipping: Unless otherwise defined in the

purchase order and agreed by AAF, the FAH and filters are

packaged for domestic transit and shipped FOB the AAF factory.

The method of shipment will be as specified in the customers

purchase order to AAF.

1.2.2 Receiving and Inspection: Obtain a copy of the purchase

order, the product drawing that was submitted by AAF in

association with the order, and a copy of the bill of lading, along

with any other shipping papers. Upon receipt of the equipment, or

any part thereof, these documents shall be used to ensure that the

correct product has been received.

For maximum protection, complete the following steps upon receipt

of the FAH filter bank and filters:

— Inspect the shipment and all associated documentation. Notify

the carrier immediately if there is any visible damage to the

packaging or the equipment, or a discrepancy in the shipping

papers and, if necessary, file an immediate claim with the carrier

against such damage or discrepancy.

— Confirm that the equipment received agrees with the contents

of the shipping papers.

— Confirm that the shipping documents agree with the purchase

order. Refer to the product drawing submitted for the order as

necessary.

— If it is determined that any equipment ordered on the purchase

order has not been delivered and is not accounted for in the

shipping papers contact AAF international immediately by calling

1-800-477-1214. Reference the AAF control number which will

be listed on the shipping papers.

Each shipment may include:

— Individually packaged Front Access Housings.

— Packaged particulate filters.

— Packaged gas phase chemical filter cassettes.

Note that the housings and the particulate and gas phase filters

may ship from different locations and be received at different times.

At all times the equipment shall be protected from exposure to weather.

The equipment shall be stored in a clean, dry, temperature controlled

environment. All items shall be stored on pallets so that they are

elevated above grade. The Front Access Housings and particulate and

gas phase filters shall not be stacked more than three (3) cartons high

to prevent crushing. Only FAH shall be stacked on FAH, particulate

filters on particulate filters, and gas phase filters on gas phase filters.

The gas phase filters ship inside a carton enclosed in transparent

protective plastic. Under no circumstances shall the filters be removed

from this plastic protection until immediately prior to installation.

Filter products shall not be stored in areas where they may become

contaminated by chemicals, either acids or alkalis, in liquid, vapor, or

gaseous form.

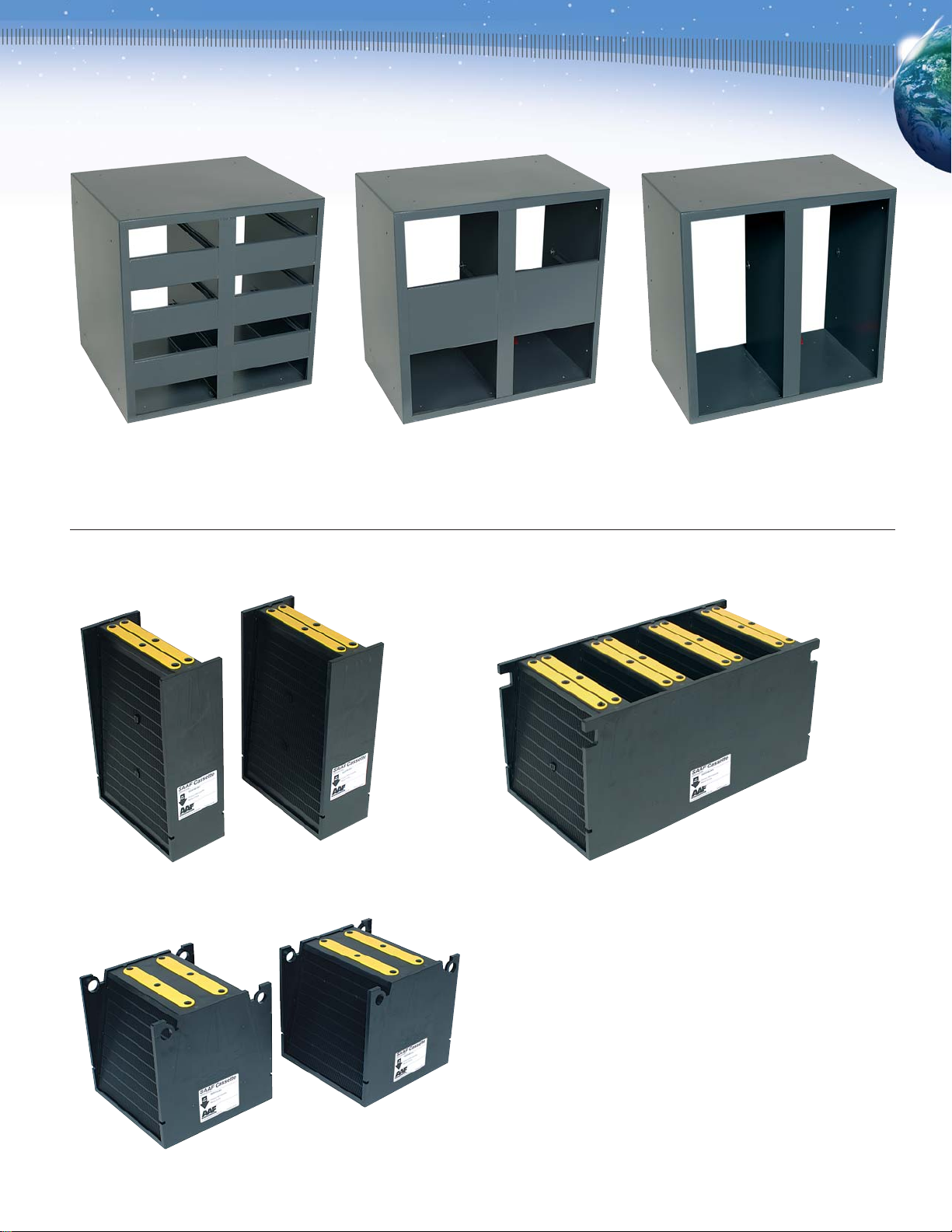

1.3 Product Descriptions

1.3.1 Front Access Housing (FAH): Each FAH will be received

individually in a carton. Depending on the quantity supplied, these

cartons may be palletized and banded together. The FAH is supplied

in three styles: Type MD, Type HD, or Type CG (as shown at top of

page 3) and will be the full size 2 high x 2wide housings shown, or

depending on the size of the filter bank required, may include half

size housings. Half size housings are available in half height (1 high

x 2wide) or half width (2high x 1wide) sizes, except for the Type

CG which is only provided in the half width size. Half size housings

hold half the number of gas phase cassettes as full size housings

and use half size particulate filters.

Any particular filter bank will be assembled using only one type of

housing (Type MD, Type HD or Type CG). Housing types will never

be mixed in a single filter bank.

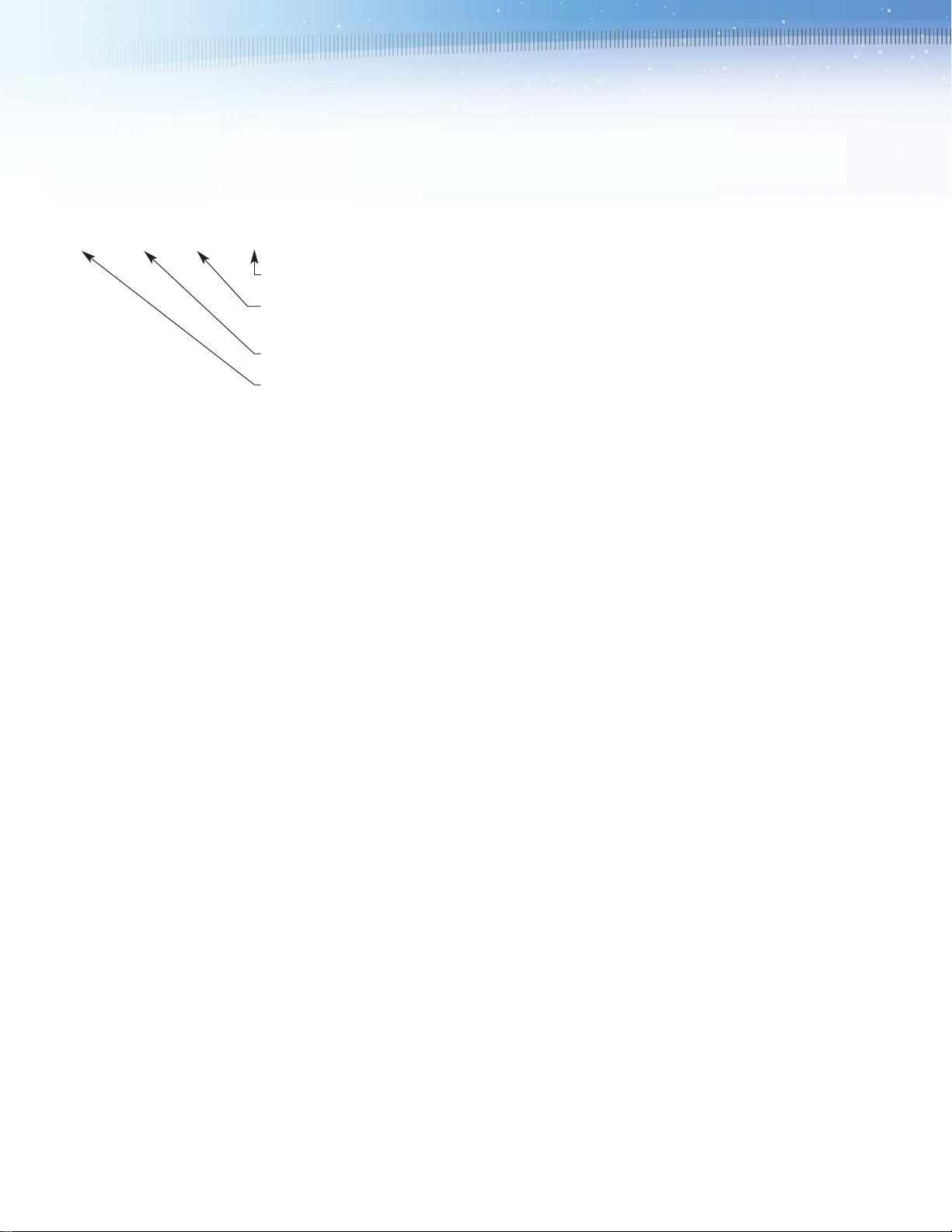

1.3.2 Gas Phase Chemical Filter Cassettes: Gas phase filter

cassettes are shipped in cartons and plastic bags. The carton

shown contains a single 6 high x 24 wide x 18 deep Type MD

cassette which is supplied as two (2) 6 high x 12 wide x 18 deep

half cassettes.

1.2.3 Handling and Storage: Following receipt, inspection, and

acceptance of the equipment, and prior to assembly and installation,

the FAH and the particulate and gas phase filters shall be handled

with great care. The components shall be retained and stored in their

protective packaging until immediately prior to installation. Care shall

be taken to ensure that the packages are not dropped or subjected to

any impact loads.

2

Model FAH-202-2P-MD housing holds

four (4) MD cassettes.

Model FAH-202-2P-HD housing holds

two (2) HD cassettes.

The three (3) types of gas phase chemical filter cassettes that can be

supplied are as follows:

Model FAH-202-2P-CG housing holds

two (2) CG cassettes.

Leaving air face of the housings is shown.

6 high x 24 wide x 18 deep Type MD cassette ships in two halves.

12 high x 24 wide x 12 deep Type HD cassette ships in two halves.

24 high x 12 wide x 12 deep Type CG cassette ships in one piece.

1.3.3 Particulate filters: Particulate filters will typically be AAF

PerfectPleat¤pleated filters. Depending on the size of the filter

frame ordered 24 high x 24 wide x 2 deep full size filters, 24

high x 12 wide x 2 deep, or 12 high x 24 wide x 2 deep half size

filters may be supplied. PerfectPleat 2 deep filters are packaged

12 to a carton.

3

1.4 Product Model Designations

The FAH model is designated as follows:

FAH - 202 — 2P — MD

Supports Type MD cassettes

Supports a 2 deep particulate pre-filter,

if required.

Is nominally 2 high x 2wide

Front Access Housing

FAH model numbers available are:

Type MD Type HD Type CG

FAH-202-2P-MD FAH-202-2P-HD FAH-202-2P-CG

FAH-102-2P-MD FAH-102-2P-HD FAH-201-2P-CG

FAH-201-2P-MD FAH-201-2P-HD

The assembled filter bank model number is typically designated as follows:

FAH - 608 - 2P - MD

In this case the - 608 - indicates a filter bank that is nominally

6high x 8wide.

1.5 Product Drawings

Details of individual Front Access Housings are shown on the

following AAF drawings:

FAH AAF Drawing Number

FAH-202-2P-MD 114D-3026127

FAH-102-2P-MD 114D-3027273

FAH-201-2P-MD 114D-3027281

FAH-202-2P-HD 114D-3027869

FAH-102-2P-HD 114D-3027901

FAH-201-2P-HD 114D-3027877

FAH-202-2P-CG 114D-3027539

FAH-201-2P-CG 114D-3027513

Copies of the appropriate drawings will have been supplied as part of

the AAF submittals in response to the purchase order. Obtain and

review these drawings before proceeding with the assembly and

installation of the filter bank. The assembled filter bank drawings

include the following details for filter bank sizes 102 (1 high x 2 wide)

through 812 (8 high x 12wide):

— Overall filter bank dimensions

— Shipping weights

— Operating weights

— Sizes and quantities of Front Access Housings required

— Sizes and quantities of filters required

— Details of the gas phase chemical media supplied

— Details of the particulate filters supplied

— Pressure losses across the filter bank at nominal airflow design

velocities

— Installation and assembly details

1.6 Assembly — General Comments

As indicated previously, the individual components that will comprise

the filter bank will ship separately and will be required to be

assembled and installed on site. Refer to Section 3.0, Installation

Instructions, of this manual for further detailed instructions. Consult

with an experienced installer to obtain an accurate estimate of the

time, personnel, and equipment resources and tools that will be

required to complete the assembly and installation of the filter bank.

Site assembly will be limited to moving and lifting individual

components with a maximum weight of approximately 55 pounds (25

kg), riveting or screwing components together, and caulking.

Completion of the following preparations and provision of the following

items will be the responsibility of the installer or others:

— Site preparation

— Stainless steel rivets, as required

— Caulk, as required

— Sheet metal, or other duct, as required

— Sheet metal perimeter blank-off panels, as required

These items will not be supplied by AAF unless noted specifically in

the AAF quotation and in the accepted customer purchase order.

Details of the assembled filter banks are shown on the following

AAF drawings:

FAH Filter Bank AAF Drawing Number

FAH-XXX-2P-MD 114D-3027919

FAH-XXX-2P-HD 114D-3028271

FAH-XXX-2P-CG 114D-3027919

4

NO WELDING WILL BE REQUIRED.

In general, assembly of the filter bank will consist of the following:

— Preparation of the installation location

— Transportation of all components to the installation location

— Unpacking the Front Access Housings

— Assembling and installing the Front Access Housings

— Sealing the filter bank perimeter to prevent by-pass of unfiltered air

— Unpacking gas phase chemical filter cassettes

— Installing gas phase chemical filter cassettes

— Unpacking particulate filters

— Installing particulate filters

— Cleaning the site

— Start-up and commission of the filter system

1.7 Related System Equipment

Ventilation systems will often include other equipment including but

not limited to:

— Fan(s)

— Dampers

— Weather louvers

— Air tempering equipment

— Other filter banks

— Instrumentation

— Electronic instrumentation and controls

— Ductwork

Neither the interface of these items with the filter system supplied by

AAF, nor the installation, operation and maintenance of these items is

covered in this manual.

Whether these items are supplied by AAF or by others, consult the

documentation specific to these products for appropriate instructions.

2.0 Principles of Operation

An understanding of the design and operating principle of the Front

Access Housings with Gas Phase Chemical Filters is useful for

effective installation, operation and maintenance. The system is

intended to remove gaseous contaminants from intake, re-circulated,

or discharged ventilation air. Examples of such contaminants may be

nuisance odors and smells that may cause domestic and

neighborhood discomfort and reduce workplace productivity, or harmful

gases that may cause damage to health, plant and product in industrial

applications. The heart of the system is the AAF SAAF Cassette. This

is a high impact plastic frame that supports various types of dry,

granular, chemical media between perforated screens that allow air to

move through the filter. The SAAF Cassette is designed to support the

chemical media in a V-bank configuration of media beds that maximizes

the media exposed to the air stream, reduces the air stream velocity

through the media bed, maximizes energy efficiency, and maximizes the

removal of contaminants and the life of the product. The method of

contaminant removal is through a combination of the physical property of

adsorption and the chemical process of oxidation. AAF offers a variety of

impregnated and un-impregnated dry granular media to handle a wide

range of contamination problems. For more information on AAFs gas

phase air cleaning products contact your AAF representative.

The AAF Front Access Housing (FAH) is one of the various framing

and support systems designed to support the SAAF Cassette in the

air stream and to allow easy installation, operation and maintenance

of the system.

3.0 Installation Instuctions

Consult the product drawing(s) submitted on this order before

proceeding.

3.1 Space Requirements: Aminimum of 24 clear space must be

available at the rear, or downstream side, of the filter bank and 36

clear space at the front, or upstream side, of the filter bank for access

to perform routine maintenance. Additional space may be required for

inlet and outlet ductwork.

3.2 Foundations and Anchoring: The foundation must be designed to

be adequate to support the filter bank operating weight, and any

seismic, live or other loads (if any), with a sufficient factor of safety as

determined to comply with the requirements of all applicable governing

codes, standards, and laws. Ensure that the foundation surface is level

and smooth before proceeding. The filter frame is designed for

operation in indoor locations without any unusual loading condition,

other than the static loading from the filters and the pressure loss

across the filter bank. For this reason, the lower housings are not

intended to be anchored to the foundation. If anchors are used the

installer shall ensure that the anchor heads do not interfere with the

installation of the lowest tier of gas phase filter cassettes. If the frame

bank is required to withstand unusual or dynamic loads, then special

anchoring arrangements featuring removable supports may be required.

5