AAF International DynaPure User Manual

DynaPure

®

Oil Mist Collector

Installation, Operation, and Maintenance Instructions

Better Air is Our Business

®

Table of Contents

1.0 Description

2.0 Unpacking

3.0 Drain

4.0 Operation

5.0 Installation

5.1 General

5.2 Prefilter

5.3 Final Filter

6.0 Maintenance

6.1 General

6.2 Throwaway Liner Replacement

6.3 Cleaning Procedure - Size A-1

6.4 Cleaning Procedure - Sizes AS-100 and Larger

6.5 Motor Replacement - Size A-1

6.6 Motor Replacement - Sizes AS-100 through AS-1000

6.7 Prefilter Pad Replacement

7.0 DynaPure Parts List

1.0 Description

The DynaPure®filter is designed to remove particles of mist from

contaminated air and discharge clean air to the atmosphere. The filter

draws in contaminated air and removes the mist by the spinning

action of the drum and filter elements. The collected particles are

discharged as a liquid through the drain, and the cleaned air is

exhausted through the outlet.

2.0 Unpacking

Inspect the shipping carton carefully for damage. If the carton is

intact, open it and check the unit for damage. Remove the unit from

the carton. Notify your shipping agent if there was any damage

during shipment.

3.0 Drain

Sizes larger than A-1 are equipped with a 1" NPT drain connection

which may be piped directly to the oil sump, allowing filtered oil to

drain into the sump and be reused. If the mist generated contains

undesirable elements, it may be collected in any suitable container.

Drain should not be trapped, reduced in size, or have an elbow

connection at the drain connection.

4.0 Operation

It is recommended that the unit be run continuously during the hours

of plant operation as intermittent cycling may cause unnecessary

loading of the motor, reducing its service life.

The DynaPure should continue to be operated at least twenty

(20) minutes after the machine being exhausted is shut off. This

will allow time for the unit to purge itself of oil.

5.0 Installation

5.1 General

Model A-1 must be installed vertically using the threaded inlet opening

for mounting. The A-1 drains back through the inlet, eliminating

separate drain piping or inlet ducting. On sizes larger than A-1, the

base is pre-drilled for mounting. Units should be as close as possible

to the point of mist generation. Try to keep the length of hose to a

minimum, preferably less than eight feet. Cut the proper length of

hose required to connect the inlet of the filter to the outlet of the

pickup duct or hood. Avoid excessive sagging which would form a

trap. Clamp the hose to the filter and pickup duct or hood, making

sure there are no air leaks.

CAUTION

ROTATION MUST BE CLOCKWISE WHEN LOOKING INTO INLET.

2

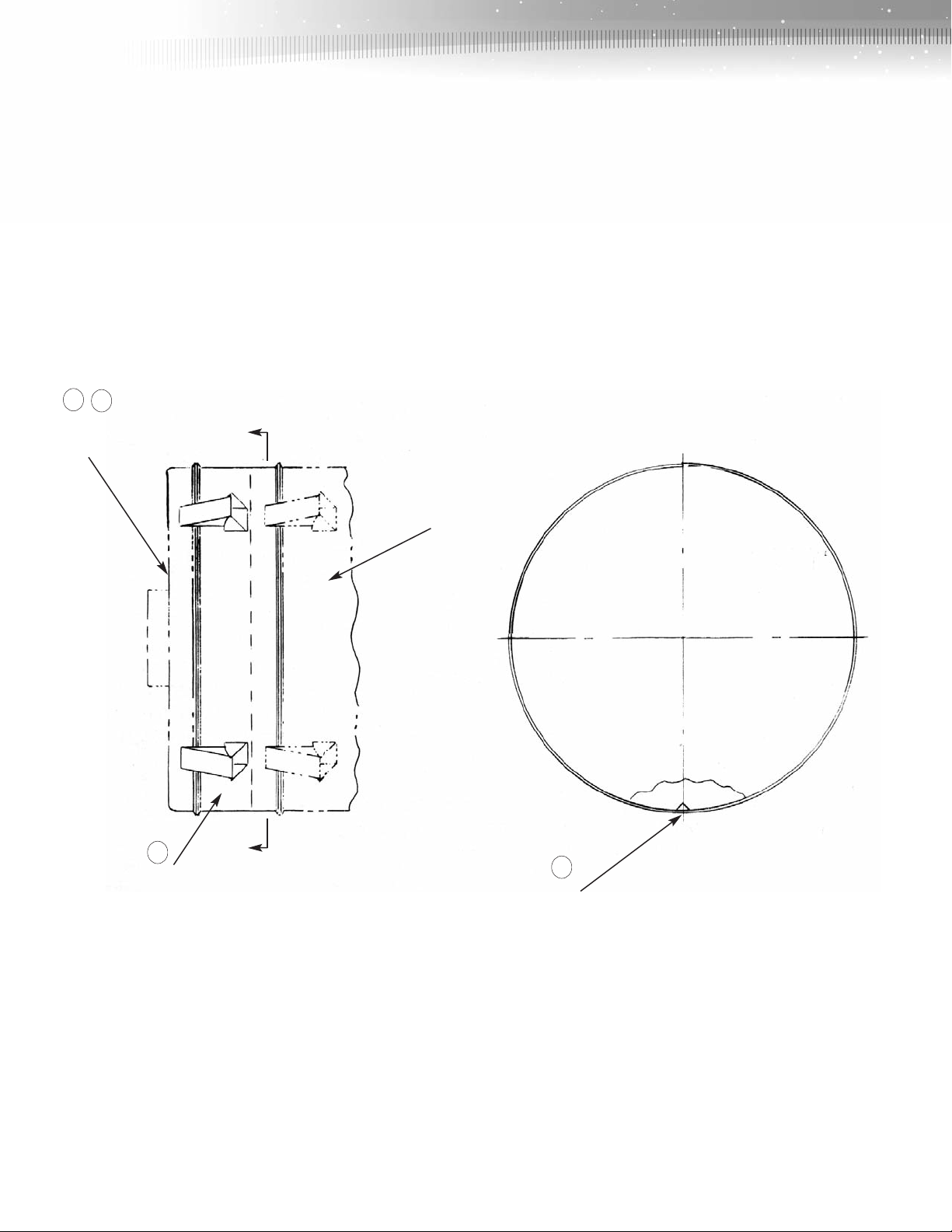

5.2 Prefilter

The optional prefilter is shipped separately to avoid shipping damage.

Install as follows:

1. Unlatch and remove the cover of the DynaPure.

2. Install the prefilter housing on the front of the DynaPure where the

cover has been and latch in place. Locate notch in interior

baffle at bottom center to allow for drainage path.*

3. Reinstall the cover (to the prefilter housing) and latch in place.

1

Cover

(Ref.)

Optional

Prefilter

DynaPure

Filter (Ref.)

Figure 2. Prefilter Installation

Section A-A

3

2 *

2

Notch

A

A

3

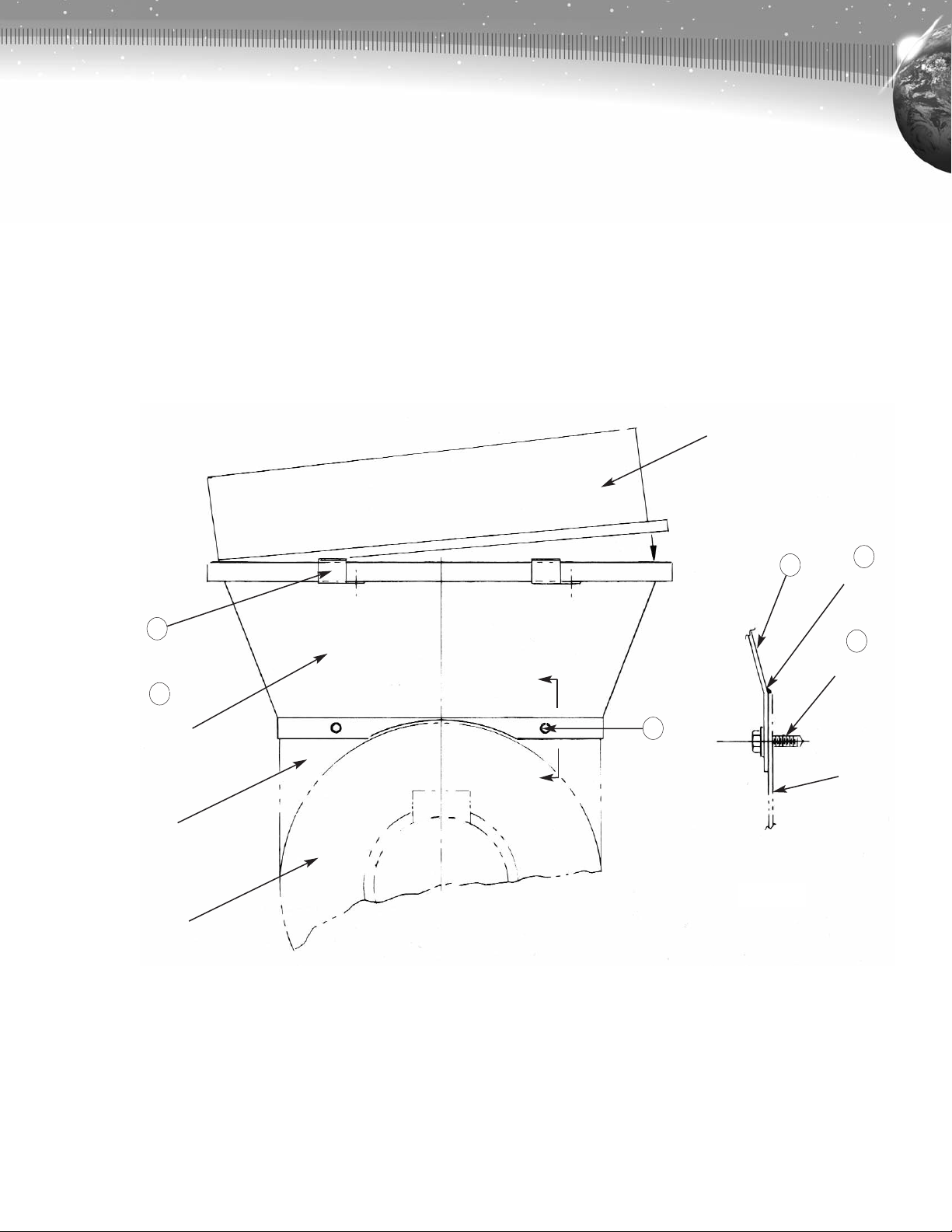

5.3 Final Filter

The optional final filter is shipped separately to avoid shipping

damage. Install as follows:

1. Slip the final filter housing over the DynaPure outlet until the top

edge of the outlet is approximately even with the break in the

sides of the final filter housing.

2. Fasten with the self-drilling screws provided.

3. Seal the joint on the inside with the caulk provided.

4. Set the final filter cartridge in the top of the housing and

latch in place.

1

Final Filter

Cartridge

Outlet

DynaPure

Outlet

Figure 3. Final Filter Installation

Section A-A

3

2

DynaPure

Self Drill

Screw

Caulk

1

2

4

Final Filter

Housing

A

A

Loading...

Loading...