Page 1

3

Carbon Monoxide Monitor and

Retrofit Carbon Monoxide Monitor

Kit W -2808/37027

User Instructions

(Keep these instructions for reference)

Page 2

Page 3

i

English

TABLE OF CONTENTS

GENERAL SAFETY INFORMATION 2

– Intended Use 2

– List of Warnings and Cautions within these User Instructions 2

USE INSTRUCTIONS AND LIMITATIONS 3

– Use For 3

– Do Not Use For 3

– General Description 3

SPECIFICATIONS 6

PRODUCTS,ACCESSORIES AND P AR TS 7

– 3MTMCarbon Monoxide Monitor 7

– 3MTMRetrofit Carbon Monoxide Monitor Kit W-2808/37027 7

– 3MTMAccessories and Parts 7

ASSEMBLY 8

SET UP PROCEDURES AND PERFORMANCE CHECK 10

– Monitor Calibration Frequency 10

OPERATING INSTRUCTIONS 11

– Normal Operation 11

– Calibration 12

REPLACEMENT PART INSTRUCTIONS 13

– Batteries 13

– 3M

TM

Carbon Monoxide Sensor 529-05-22 13

TROUBLESHOO TING 15

IMPORTANT NOTICE 17

– W arranty 17

– Remedy 17

FOR MORE INFORMATION 18

Page 4

2

GENERAL SAFETY INFORMATION

Intended Use

The 3MTMCarbon Monoxide (CO) Monitor and the 3MTMRetrofit Carbon Monoxide (CO)

Monitor Kit are designed to provide continuous, direct read CO monitoring for compressed

air used with supplied air respirators.

List of Warnings and Cautions within these User Instructions

• These products are designed for carbon monoxide monitoring. Misuse may result in

sickness or death. For proper use, see supervisor or User Instructions, or call 3M in U.S.A.,

1-800-243-4630. In Canada, call Technical Service at 1-800-267-4414.

• The impedance of any connected load device at the REM ALARM (remote alarm) jack must

be greater or equal to 12 ohms, when operating from internal batteries or AC adapter. Failure

to do so may damage the carbon monoxide monitor and result in sickness or death.

• The intrinsic safety of the carbon monoxide monitor is voided when remote alarm is used.

• The intrinsic safety of the carbon monoxide monitor is voided when the 110-120 volt AC

adapter is used.

• Your employer must provide breathing air that meets at least the requirements of the

specification for Grade D breathing air, as described in the Compressed Gas Association

Commodity Specification G-7.1-1997 in the United States. In Canada refer to CSA standard

Z180.1, for the quality of the compressed breathing air. Failure to do so may result in

sickness or death.

• Use of equipment described in these User Instructions must be in accordance with applicable

health and safety standards, or pursuant to the recommendations of an industrial hygienist.

• Each person using this equipment must read and understand the information in these User

Instructions. Use of this equipment by untrained or unqualified persons, or use that is not

in accordance with these User Instructions, may adversely affect product performance and

result in sickness or death.

W WARNING

CAUTION:

• Observe proper polarity when inserting batteries. Polarity is marked on the inside of the drawers.

• The sensor in the carbon monoxide monitor contains a small amount of sulfuric acid. Always

wash hands thoroughly after handling sensor cell. Sulfuric acid is poisonous and can cause

severe burns. Do not allow acid to contact skin or eyes. If eyes are exposed to acid, flush

thoroughly and seek immediate medical attention.

Page 5

3

English

USE INSTRUCTIONS AND LIMITATIONS

Important

Before use, each person using this equipment must read and understand these User Instructions.

Keep these instructions for reference.

Use For

Monitoring for carbon monoxide level in compressed air intended for respiratory protection systems.

Do Not Use For

Monitoring other compressed gas streams.

General Description

These User Instructions apply to the 3MTMCO Monitor mounted inside some of the 3MTMPortable

Compressed Air Filter and Regulator Panels and the 3M

TM

Retrofit CO Monitor Kit W-2808/37027.

The retrofit kit includes the 3M CO monitor and accessories to attach the CO monitor to a

3

/

8

-inch

port on a filter and regulator panel that does not currently have CO monitoring capability, such as

the 3M

TM

Compressed Air Filter and Regulator Panel W-2806/07006.

The 3M carbon monoxide monitor is designed to provide continuous, direct read CO monitoring

for compressed air used with supplied air respirators. An internal microprocessor controls the

indication and alarm functions in response to the signals of an electrochemical CO sensor. It

continuously monitors a compressed air sample introduced to its sensor at an approximate rate

of 1.0 standard cubic foot per hour (scfh) and gives an alarm when the CO in the sample reaches

a preset level (10 ppm in USA; 5 ppm in Canada).

The CO monitor is a battery powered unit utilizing two 9 volt alkaline batteries. It is designed to

be intrinsically safe when used on battery power. The CO monitor is CSA certified intrinsically

safe for Class I, Div. I, Groups A,B,C, and D Hazardous Locations when utilizing two 9 volt

alkaline batteries to power the monitor.

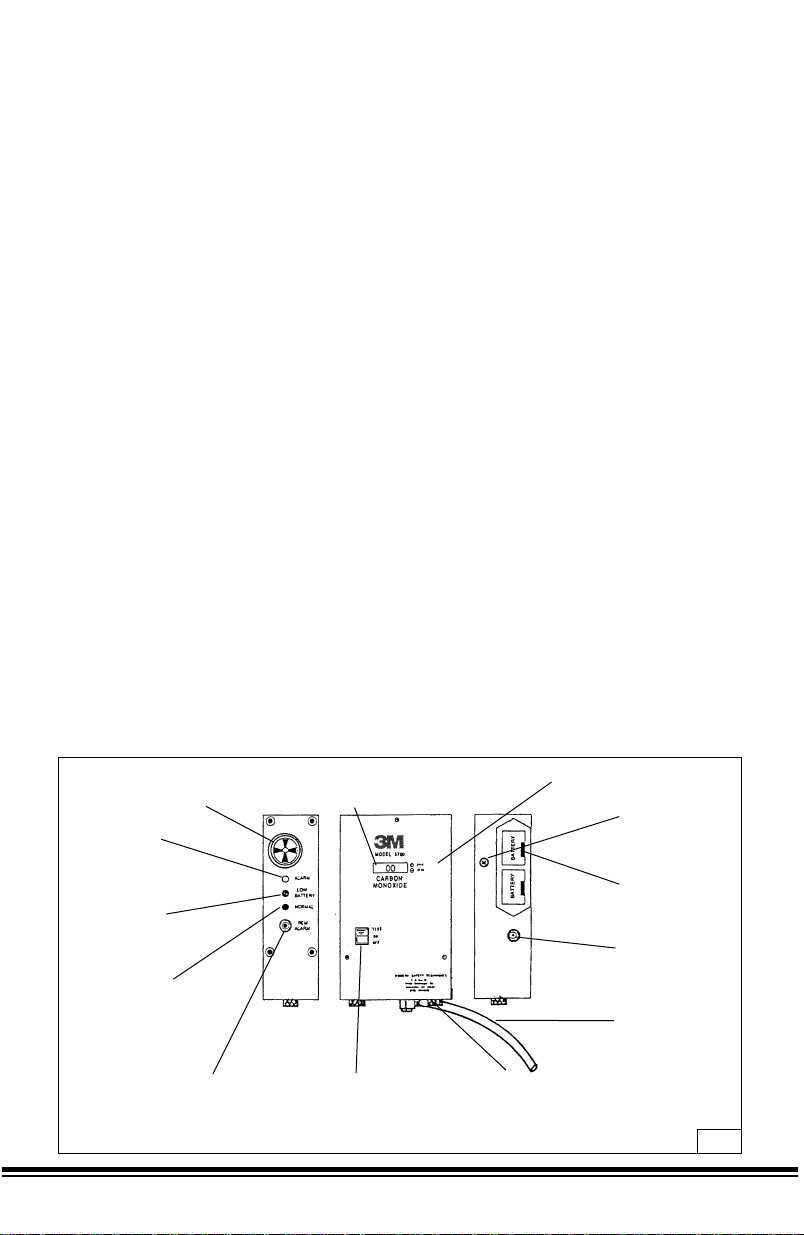

The components of the monitor are assembled into a black powder-coated aluminum housing

6˝ H x 4˝ W x 2˝ D overall. A hose barb, with plastic sample tube attached for introducing the

sample gas, extends from the bottom. Available at the front face are the OFF/ON/TEST switch,

the display (LCD), SPAN and ZERO adjustments.

The left side contains the indicating lights, the alarm buzzer, and the remote alarm jack.

Accessible on the right side are the two battery drawers and the auxiliary power jack. (Fig. 1)

Buzzer - Provides continuous tone

during high “CO” alarm; a pulsing tone

during certain malfunction conditions.

Display - LCD type refreshed

every 0.8 seconds; the red LED

light faintly blinks at same time.

Span & zero potentiometers

used in calibrating.

Screw sealed

access hole to

alarm level

potentiometer.

“Transistor”

type battery

holders

Auxiliary “power

source” jack

Air sample tube

Remove knurl thumbscrews for

access to “CO” sensor. Bottom pla te

sensor/sample tube assembly. Can be

moved approx. 2-3˝ before sensor wire

connections limit travel.

On/Off/Test switch-three

position type. Alternate

on-off position with

momentary “test”

position.

Remote alarm jack; for

plugging remote alarm

devices or relays to be

energized when monitor

goes into alarm.

Green normal LED

light; comes on steady

when monitor on &

goes off in alarm

conditions.

Yellow low battery

LED light; comes on

when 9 volt battery

voltage falls below

about 7.0 volts.

Red alarm, LED light;

blinks faintly during

normal operations

& on steady during

high “CO” alarm

conditions.

Fig. 1

Page 6

4

The impedance of any connected load device at the REM ALARM (remote alarm) jack must be

greater or equal to 12 ohms, when operating from internal batteries or AC adapter. Failure to do

so may damage the carbon monoxide monitor and result in sickness or death.

W WARNING

Front Panel On/Off/Test Switch

This switch is a three-position type with alternate ON and OFF positions, and a momentary

TEST position. Switch is located at the lower left side.

Display

Display is a centrally located LCD type and is refreshed every 0.8 seconds; the red ALARM

light faintly blinks at the same time.

Span and Zero Adjustments

Located to the right of the display are two miniature multi-turn slotted-shaft potentiometers,

accessible through holes in the panel with a small screwdriver.

Left Side

The next five items are aligned toward the rear from the center of the left side panel and from

top to bottom are:

Buzzer

Buzzer is at the top of the side panel. It provides a continuous tone during high CO alarm,

a pulsing tone during certain malfunction conditions.

Alarm Light

Red ALARM light blinks faintly during normal operation and is on steadily during the high CO

alarm condition.

Low Battery Light

Yellow LOW BATTERY light comes on when battery voltage falls to where the instrument

will not function properly (about 7 volts DC). Batteries should be replaced at this time.

Normal Light

The green NORMAL light acts as a pilot light and glows when the instrument is turned on.

At the same time the red ALARM light flickers faintly at intervals of about one second.

Remote Alarm (REM ALARM)

A miniature size phone jack is provided for plugging in a remote alarm device so that the alarm

sound can be repeated at a distance from the instrument. The outer shell of the jack is grounded to

the case, and is negative. This jack will be energized at voltage about 8.5 volts DC when operating

from “fresh” internal batteries or about 8.9 volts DC when operating from AC adapter whenever

instrument is in alarm condition.

Page 7

5

English

Bottom

A rectangular opening in the bottom allows clearance for the sensor that is mounted to the upper

face of the bottom plate. The bottom plate is held in place by two knurled thumbscrews. The

sample inlet fitting and tubing extends from the outer face of the bottom plate.

Right Side

These items are aligned toward the rear of the right side panel.

There are two battery compartment drawers near the top. They contain the two 9 volt alkaline

batteries, connected in parallel, which power the instrument.

Auxiliary Power Jack

A 2.5 mm pin jack is located near the bottom for operating the instrument from the AC adapter.

The AC adapter will power the instrument as long as power is supplied to it. The outer shell of

the jack is grounded to the case and is negative.

Page 8

6

SPECIFICATIONS

Sensor – Electrochemical/CO specific

Readout – Direct read LCD

Range – 0-199 ppm

Alarm – 85 dBA at 10 ppm CO (5 ppm Canada)

Sensor Life – Approximately 30 months

Sensor Replacement – User allowed to replace sensor

Intrinsic Safety – Class I, Div I, Group A, B, C, D (when operated

on battery power)

Power – 9 volt DC alkaline batteries (2 each)

Aux. Alarm Output – Maximum output current draw is 300 milliampere

Aux. Power Sources – 120 volt AC - 7.5 volt DC adapter

Operating Temperature Range – 0-110º F (17-43º C) (ambient temperature)

• The impedance of any connected load device at the REM ALARM (Remote Alarm) jack

must be greater or equal to 12 ohms, when operating from internal batteries or AC adapter.

Failure to do so may damage the carbon monoxide monitor and result in sickness or death.

• The intrinsic safety of the carbon monoxide monitor is voided when remote alarm is used.

• The intrinsic safety of the carbon monoxide monitor is voided when the 110-120 volt AC

adapter is used.

W WARNING

Page 9

7

English

PRODUCTS,ACCESSORIES AND PAR TS

3MTMCarbon Monoxide Monitor

The 3M CO monitor is factory mounted inside some of the 3MTMPortable Compressed Air Filter

and Regulator Panels. Consult the User Instructions for your 3M

TM

Portable Compressed Air

Filter and Regulator Panel.

3MTMRetrofit Carbon Monoxide Monitor Kit W-2808/37027*

The 3M retrofit kit allows the 3M CO monitor to be used with filter and regulator panels that do not

currently have CO monitoring capability, such as the 3M compressed air filter and regulator panel

W-2806/07006*. The 3M retrofit CO monitor kit is comprised of a 3M CO monitor, mounting

bracket, flow meter, and hardware connections to attach the monitor to an available

3

/

8

-inch port

on a filter and regulator panel.

* 37027 is an automotive product number for W-2808.

* 07006 is an automotive product number for W-2806.

3MTMAccessories and Parts

3M

TM

Adapter, 110-120 Volt AC (for CO Monitor)

This accessory will supply operating power to the instrument as long as it is plugged into an active

115 volt AC outlet, whether or not batteries are installed. The adapter will convert the 115 volt AC

to 7.5 volt DC, 650 mA.

1. Plug the adapter into an active, fused (1 amp) 115 volt 50/60 Hz outlet.

Note: To prevent unnecessary electrical interference, the outlet should be on a dedicated circuit

free of any intermittent heavy electrical loads, such as pumps, compressors or heaters.

2. Plug adapter cord connector into socket on the lower right-hand side of the monitor.

3. Adapter will power the instrument as long as the 115 volt AC source remains active.

4. Since the adapter voltage is slightly higher than that of the internal batteries, the adapter

will supply the power. Blocking diodes protect the internal interface.

529-04-49 Calibration Kit, Small

529-04-48 Calibration Kit, Large

529-04-50 Adapter, 110-120 Volt

529-05-18 Zero Gas Cylinder, 0.6

cubic feet of gas

(replacement Zero gas

for small kit, 529-04-49 )

529-05-19 Span Gas Cylinder, 0.6

cubic feet of gas

(replacement Span gas

for small kit, 529-05-49)

529-05-17 Zero Gas Cylinder, 3.6

cubic feet of gas

(replacement Zero gas

for large kit, 529-04-48 )

529-05-16 Span Gas Cylinder, 3.6

cubic feet of gas

(replacement Span gas

for large kit, 529-04-48)

529-05-20 Remote Alarm Audible,

119 dBA

529-05-21 Remote Alarm, Strobe

Light, 150,000 CP

(Requires 529-04-50)

529-05-23 Y-Plug Adapter

529-05-22 Carbon Monoxide Sensor

The intrinsic safety of the carbon monoxide monitor is voided when the 110-120 volt AC

adapter is used.

W WARNING

Page 10

8

ASSEMBLY

The following instructions apply only if you are using the 3MTMRetrofit CO Monitor Kit

W-2808/37027. (Fig. 2 and 3)

1. Secure the mounting bracket to a surface close to the filter and regulator panel with #8 x

1

/

2

˝

self tapping screws.

2. Secure the monitor to the mounting bracket with #6-32 x

1

/

2

˝ screws and #6 lock washers.

Screw holes are located on the left side of the monitor.

3. The CO monitor is supplied with a 2-foot sample tube attached to the hose barb located on the

monitor’s bottom plate.

4. Use the supplied 90° st. elbow, 2

1

/

2

˝ pipe nipple, and

3

/

8

˝ x

1

/

8

˝ reducing bushing to connect

the bottom of the flow meter to an available port, just prior to the compressed hose

connections, on the filter and regulator panel. If you are installing the flow meter on the 3M

compressed air filter and regulator panel W-2806/07006, you will need to remove the plug

from the CO sampling port located above the quick disconnect outlets on the panel.

Note: If your panel is wall-mounted, you may have to remove the panel from the wall to attach

the flow meter.

6. Pull up the black tube lock collar at the top of the flow meter and insert the free end of the

plastic sample tube. Push down on the lock collar to secure the sample tube.

C

A

R

B

O

N

M

O

N

O

X

ID

E

T

E

S

T

O

N

O

F

F

1

12

11

10

9

8

7

6

5

4

3

2

13

Fig. 2

Page 11

English

9

Assembled 3MTMRetrofit Kit W-2808/37027 attached to 3MTMCompressed Air Filter and Regulator

Panel W-2806/07006 (sold separately).

Item Product Description Quantity

Number Number Required

1 --- CO monitor 1

2 --- #6-32 x

1

/

2

˝ screw 4

3 --- #6 lock washer 4

4 --- #8 x

1

/

2

˝ self tapping screw 4

5 --- Mounting bracket 1

6 --- 2-foot sample tube 1

7 --- Tube lock collar 1

8 --- Flow meter 1

9 --- 90º st. elbow 1

10 --- 2-

1

/

2

˝ pipe nipple 1

11 ---

3

/

8

˝ x

1

/

8

˝ reducing bushing 1

12 W-2808/37027 3M

TM

Retrofit CO Monitor Kit-includes items 1-11

13 W-2806/07006 3M

TM

Compressed Air Filter and Regulator Panel (Sold

Separately)

CARBON

MONOXIDE

SPAN

TEST

ON

OFF

ZERO

Fig. 3

Page 12

10

SET UP PROCEDURES AND PERFORMANCE CHECK

1. Turn instrument on and allow 5 minutes to stabilize. Verify that the yellow LOW BATTERY

light is off.

2. Push up and hold switch in the test position.

– The red ALARM light will come on verifying the CO alarm circuit operation.

– The yellow LOW BATTERY light will also come on, verifying the low battery detection circuit.

– Green NORMAL light will blink several times, then come on steady verifying continuity of

the detector circuits.

– The buzzer will sound and the REM ALARM jack will be energized.

– The display will show an upscale reading.

– Release the switch. Indicators will return to normal and display may first show a negative

indication (-XX), then return close to 00.

3. Remove the plastic sample tube from the black tube lock collar on top of the flow meter.

Introduce a sample of zero air to the sample tube (see User Instructions for the 3M

TM

Calibration Kit 529-04-48 or 529-04-49). The sample flow should be between 0.5 and 1.5 scfh.

4. Verify that the green NORMAL light is on, the red ALARM light is flickering about once a

second and the display is showing 00 (zero), (see Calibration and Adjustment section of this

User Instruction).

5. Remove the zero air sample and introduce a known sample of 50 to 150 ppm CO to the

sample inlet tube (see User Instructions for the 3M

TM

Calibration Kit 529-04-48 or 529-04-49).

The sample flow should be between 0.5 and 1.5 scfh.

6. Verify that the display readings rise upscale and the alarm light and buzzer operate (see

Calibration and Adjustment section of this User Instruction).

7. Remove the CO sample.

8. Reconnect the sample tube to the black tube lock collar on top of the flow meter.

9. After adjusting the regulator on the air purification panel to the proper setting for your

respiratory protection, adjust the flow meter knob so that the black floating ball is within the

green boxed area etched on the flow meter body. Counterclockwise rotation of flow meter’s

knob will increase sample airflow to the monitor.

10. Instrument is now ready for normal use. Turn OFF when not in use.

Monitor Calibration Frequency

The CO monitor should be calibrated prior to use and every two weeks for the first month. After

the first month, calibrate the monitor monthly if it is used on a continuous basis (daily or weekly).

If the monitor is used on a non-continuous basis the monitor should be calibrated prior to each use.

Note: If monitor's alarm is energized, always check calibration to be sure monitor is not

malfunctioning and/or out of calibration producing a false alarm/reading.

Page 13

English

11

OPERATING INSTRUCTIONS

The following instructions are intended to serve as a guideline for the use of the 3MTMCarbon

Monoxide Monitor. It is not to be considered all-inclusive, nor is it intended to replace the policy

and procedures for each facility.

If you have any doubts about the applicability of the equipment to your job situation, consult an

industrial hygienist or call 3M's Occupational Health and Environmental Safety Division Technical

Service Department 1-800-243-4630. In Canada, call Technical Service at 1-800-267-4414.

Normal Operation

– The monitor will analyze the compressed air and show CO content on the display, in parts per

million (ppm).

– The green NORMAL light will glow continuously and the red ALARM light will flicker about

every second.

– When the CO concentration reaches the alarm point (10 ppm for USA, 5 ppm for Canada) the

red ALARM light will come on steady, the green NORMAL light will go off, the buzzer will

sound a steady tone, and the REM ALARM jack will be energized.

– When the CO concentration drops below the alarm setting, the indicators will automatically

return to normal.

• Your employer must provide breathing air that meets at least the requirements of the

specification for Grade D breathing air, as described in the Compressed Gas Association

Commodity Specification G-7.1-1997 in the United States. In Canada refer to CSA

standard Z180.1, for the quality of the compressed breathing air. Failure to do so may

result in sickness or death.

• Use of equipment described in these User Instructions must be in accordance with

applicable health and safety standards, or pursuant to the recommendations of an

industrial hygienist.

• Each person using this equipment must read and understand the information in these

User Instructions before use. Use of this equipment by untrained or unqualified persons,

or use that is not in accordance with these User Instructions, may adversely affect product

performance and result in sickness or death.

W WARNING

Page 14

12

Calibration

Calibrate the monitor in the temperature range in which it will be used. After each adjustment

in the following steps, allow time for the changes to stabilize. Recheck all adjustments. Turn

monitor on and allow at least 5 minutes warm-up before calibration and adjustments are made.

Zero Adjustment

Remove sample tube from the black tube lock collar on top of the flow meter. Introduce a sample

of zero air to the sample tube (see User Instructions for the 3M

TM

Calibration Kit 529-04-48 or

529-04-49). The sample flow should be between 0.5 and 1.5 scfh.

Verify that the green NORMAL light is on, the red ALARM light is flickering about once a second

and the display is showing “00”. If the display is showing other than “00”, adjust the ZERO

potentiometer (next to the display) so that the reading is “00”. Clockwise adjustment increases

reading. Notice that the display jumps from 00 to +02 or to –02 (monitor does not display –01 or

+01). Try to set the potentiometer midway between the two extremes. Remove the zero air sample.

Span Adjustment

Introduce a known sample of 50 to 150 ppm CO to the sample tube (see User Instructions for the

3M

TM

Calibration Kit 529-04-48 or 529-04-49). The sample flow should be between 0.5 to 1.5 scfh.

Verify that the green NORMAL light is off, the red ALARM light is on full bright and the

stabilized reading, after approximately one minute, is equal to the known concentration of CO.

If the display is showing a difference, adjust the SPAN potentiometer (next to the display) to

obtain proper value. Turn clockwise to increase reading. If the span adjustment cannot be made

as indicated, the sensor needs to be replaced; make sure this is not happening due to an empty

span gas cylinder. See Replacement Part section of this User Instruction.

Remove the known sample of CO and reconnect the sample tube to the black tube lock

collar on top of the flow meter. The instrument is now properly adjusted for use.

Page 15

English

13

REPLACEMENT PART INSTRUCTIONS

Batteries

Check batteries each time instrument is turned on by noting that the green NORMAL light is on

and the yellow LOW BATTERY light is off. If the yellow light is on, the batteries need replacing.

Two 9 volt alkaline batteries will power the monitor continuously for approximately 30-35 hours.

Batteries are contained in drawers on the right-hand side.

To replace the batteries:

Pull the small slot in the drawer face toward the front of the monitor to unlatch the drawer and pull

the drawer out of the housing.

Pry battery out of drawer with fingers and replace with a fresh 9 volt alkaline battery, providing for

proper polarity by placing minus (-) terminal uppermost in holder. Place bottom of fresh battery

against spring and press into place.

CAUTION:

Observe proper polarity when inserting batteries. Polarity is marked on the inside of the drawers.

Push drawer back into housing until it latches in place. Drawers inserted incorrectly will not latch.

Repeat above steps for the second battery. (It is possible to operate with only one battery, but

operating hours will be greatly reduced).

3MTMCarbon Monoxide Sensor 529-05-22

To replace sensor: (Fig. 4)

Remove the two knurled thumbscrews at bottom.

Pull the bottom plate off the housing as far as the wiring will allow.

Remove the 2 screws holding the wire connectors’circuit board/sensor cell in flow block.

An o-ring is located under the sensor at the bottom of the flow block cavity – DO NOT LOSE.

Pull the wire connectors’ circuit board from the sensors’ pins carefully so as not to damage the

circuit board.

Discard old sensor cell. It contains a small amount of sulfuric acid. Dispose of sensor according

to local regulations.

CAUTION:

The sensor in the carbon monoxide monitor contains a small amount of sulfuric acid. Always wash

hands thoroughly after handling sensor cell. Sulfuric acid is poisonous and can cause severe burns.

Do not allow acid to contact skin or eyes. If eyes are exposed to acid, flush thoroughly and seek

immediate medical attention.

The wire connectors’ circuit board relates to the 3 pins on the sensor as shown in figure 4. The

fourth pin is used as a guide pin to install circuit board to sensor. Carefully press circuit board

evenly on sensors’4 pins. New sensors have a shorting wire/spring between the sensing and

reference pins, remove and discard.

Page 16

14

Wire Color Detector Terminal

Black CNTR

Blue REF

Red SENSING

Be sure flow block cavity and o-ring are dry

and clean of oils, dirt etc. The o-ring must be

positioned evenly in the bottom of the flow

block cavity. Push the sensor into block against

o-ring and evenly tighten the 2 screws that hold

the circuit board/sensor to flow block. Tighten

screws lightly to assure good seal with o-ring.

Do not overtighten screws or damage to circuit

board/sensor may occur.

Replace the bottom plate and secure it

with thumbscrews.

Make sure the inlet sample swivel elbow

is firmly tightened.

Allow at least one hour for stabilization,

then calibrate as in Calibration and Adjustment

section of this User Instruction.

Fig. 4

Circuit board/

sensor to flow

block mounting

screws.

Wire connectors’

circuit board

“CO” sensor cell

O-ring

Flow block

Page 17

English

15

CO monitor’s LED red and

green lights blink on/off

along with the alarm buzzer

and display shows 'SC'

The sensor has internal failure

Poor connection between

sensor pins and circuit

board connections

Turn monitor off and after

a few seconds turn monitor

back on. Try to calibrate the

monitor. If the monitor will

not calibrate, replace the sensor.

Unplug-Plug circuit board

from sensor pins to make

better contact connection.

Try to calibrate monitor.

If monitor will not calibrate

or ‘SC’appears again,

replace sensor.

TROUBLESHOO TING

Low battery

As the battery voltage declines toward the end of its life, the following indications occur:

a) At 7.0 volts, the amber LOW BATTERY light will come on. Battery replacement is

recommended at this point, but continued operation is still possible.

b) At 6.4 volts, the buzzer will beep at intervals of about 7 seconds.

c) At 5.8 volts, the buzzer will beep at 1-second intervals and the display will go to --.

This malfunction indication will continue until the battery is completely dead.

CO monitor display will not

move from zero ‘00’when

the sensor is exposed to a

known sample of CO

SPAN adjustment may

be set to zero

Span gas cylinder empty

The sensor has lost sensitivity

Circuit malfunction

Recalibrate the monitor

Replace the cylinder

Replace the sensor

Repair is needed

The CO monitor cannot

be calibrated

The span gas and/or zero

gas bottle(s) may be empty

The sensor has lost sensitivity

Replace the empty span

and/or zero gas bottle(s)

Replace the sensor

Problem Potential Cause Corrective Action

The span adjustment cannot

be made when the span gas is

applied (i.e. the reading will

not reach the span gas value)

The span gas bottle may

be empty

The sensor has lost sensitivity

Replace the empty span

gas bottle

Replace the sensor

With zero gas flowing

through the monitor after

approximately one-minute

display reads minus one

(-1) to the far left

Zero potentiometer may be

turned counter

clockwise all

the way

The sensor has lost sensitivity

Adjust the zero potentiometer

c

lockwise until zero

‘00’ reached

Replace the sensor

Page 18

16

With span gas flowing

through the monitor after

approximately one-minute

display reads one (1) to the

far left

Span potentiometer may be

turned c

lockwise all the way

The sensor has lost sensitivity

Adjust the zero potentiometer

counter

clockwise to 199 and

then turn down to value of

span gas

Replace the sensor

When calibrating the CO

monitor you cannot move

display off zero '00' with

zero potentiometer

Monitor may have been

adjusted ‘00’ using the

span potentiometer

Turn the span potentiometer

screw several full revolutions

c

lockwise until the display

reads the value of the span

gas then start the calibration

procedure over again

Display goes below 0 (i.e.

display indicates a –02,

-1, SC)

Zero misadjust

Sensor has internal failure

Circuit malfunction

Recalibrate the monitor

Replace the sensor

Repair is needed

Problem Potential Cause Corrective Action

Monitor display

numbers wander and

alarm periodically

Monitor is powered by the

110-120 volt AC adapter and

walkie-talkies are being used

near the monitor

Large voltage spikes are

present in the AC circuit

Ambient temperatures exceed

110º F (43º C)

Do not use walkie-talkies

in the area

Isolate by using dedicated line

Decrease ambient temperature

Page 19

English

17

IMPORTANT NOTICE

W arranty

3M warrants its Carbon Monoxide Monitor for a period of one (1) year and its Carbon Monoxide

Sensor for a period of two (2) years from the original shipping date, to be free from defects in

material and workmanship in normal service and under normal conditions. This warranty is void if

the Carbon Monoxide Monitor or Carbon Monoxide Sensor has been damaged by accident, misuse,

neglect, improper service, or other causes not arising out of defects in material or workmanship.

This warranty does not include replaceable items, such as filter elements, which are considered part

of a regular maintenance program. Any implied warranties arising out of the sale of 3M’s Carbon

Monoxide Monitor and its Carbon Monoxide Sensor, including but not limited to the implied

warranties of merchantability and fitness for a particular purpose, are limited in duration to the

above one (1) and two (2) year periods respectively. 3M shall not be liable for loss of use of

any of its products or incidental or consequential costs, expenses, or damages incurred by the

purchaser or any other user.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER

WARRANTIES EXPRESS, IMPLIED, OR STATUTORY, INCLUDING WARRANTY OF

MERCHANTABILITY.

Remedy

Should the Carbon Monoxide Monitor or the Carbon Monoxide Sensor fail in normal service

under normal conditions through no fault of the purchaser or any other user during the warranty

period, return the Carbon Monoxide Monitor or Carbon Monoxide Sensor to a 3M authorized

warranty repair service center. No charges will be made for repair or replacement. Each

repaired unit is warranted for sixty (60) days or the remaining portion of the original equipment’s

warranty, whichever is longer. THE FOREGOING CONSTITUTES THE SOLE AND

EXCLUSIVE REMEDY AND IS IN LIEU OF ANY AND ALL OTHER REMEDIES

WHICH MAY BE AVAILABLE.

This warranty becomes void immediately should any repair of or alterations to the warranted

equipment be made without authorization by 3M.

Page 20

© 3M 2003

38-9018-0147-2

3

3M Occupational Health and

Environmental Safety Division

3M Center, Building 235-2W-70

P.O. Box 33010

St. Paul, MN 55133-3010

3M Occupational Health and

Environmental Safety Division

3M Canada Company

P.O. Box 5757

London, Ontario N6A 4T1

FOR MORE INFORMATION

In United States, contact:

Internet: www.3M.com/occsafety

Technical Assistance: 1-800-243-4630

For other 3M products:

1-800-3M-HELPS or 1-651-737-6501

In Canada, contact:

Internet: www.3M.com/CA/occsafety

Technical Assistance: 1-800-267-4414

For other 3M products:

1-800-364-3577

Loading...

Loading...